GE P2S975BEM1BB, P2S975BEM2BB, P2S975BEM3BB, P2S975BEM4BB, P2S975CEM1CC Installation Guide

...Page 1

I Ilnstallation I Self-CleaningDualFuelI

nstructions Slide-In Range P2S975

Questions? Call 800.GE.CARES (800.432.2737) or Visit our Website at: ge.com

In Canada, call 1.800.361.3400 or Visit our Website at: www.geappliances.ca I

IN THE COMMONWEALTH OF

MASSACHUSETTS:

• This product must be installed by a

licensed plumber or gas fitter.

• When using ball-type gas shut-off valves,

they shall be the T-handle type.

• A flexible gas connector, when used, must

not exceed 3 feet.

BEFORE YOU BEGIN

Read these instructions completely

and carefully.

• IMPORTANT - Savethese

instructions for local inspector's use.

• IMPORTANT - Observeall

governing codes and ordinances.

• Note to Installer - Be sure to leave these

instructions with the Consumer.

• Note to Consumer - Keep these

instructions for future reference.

• Product failure due to improper installation

is not covered under the Warranty.

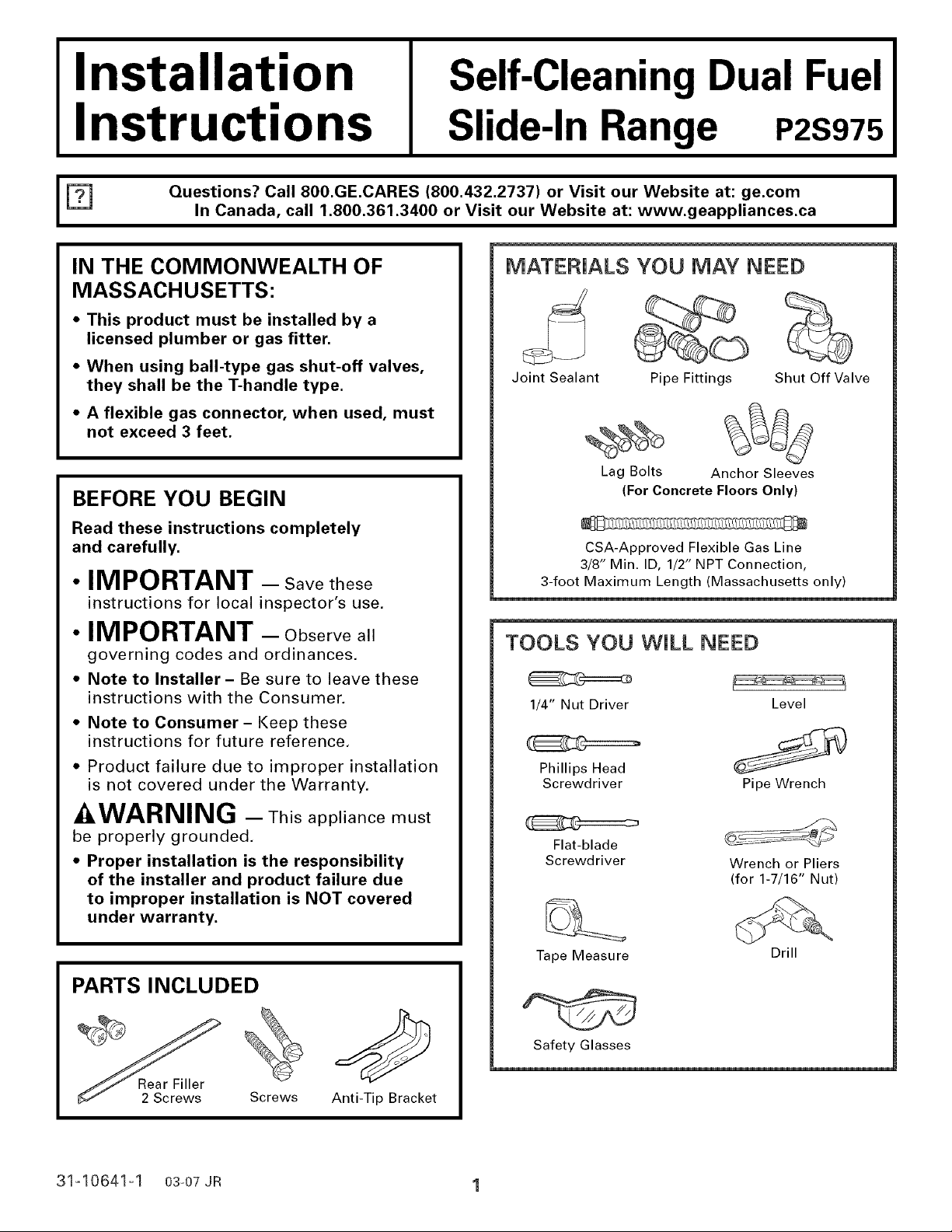

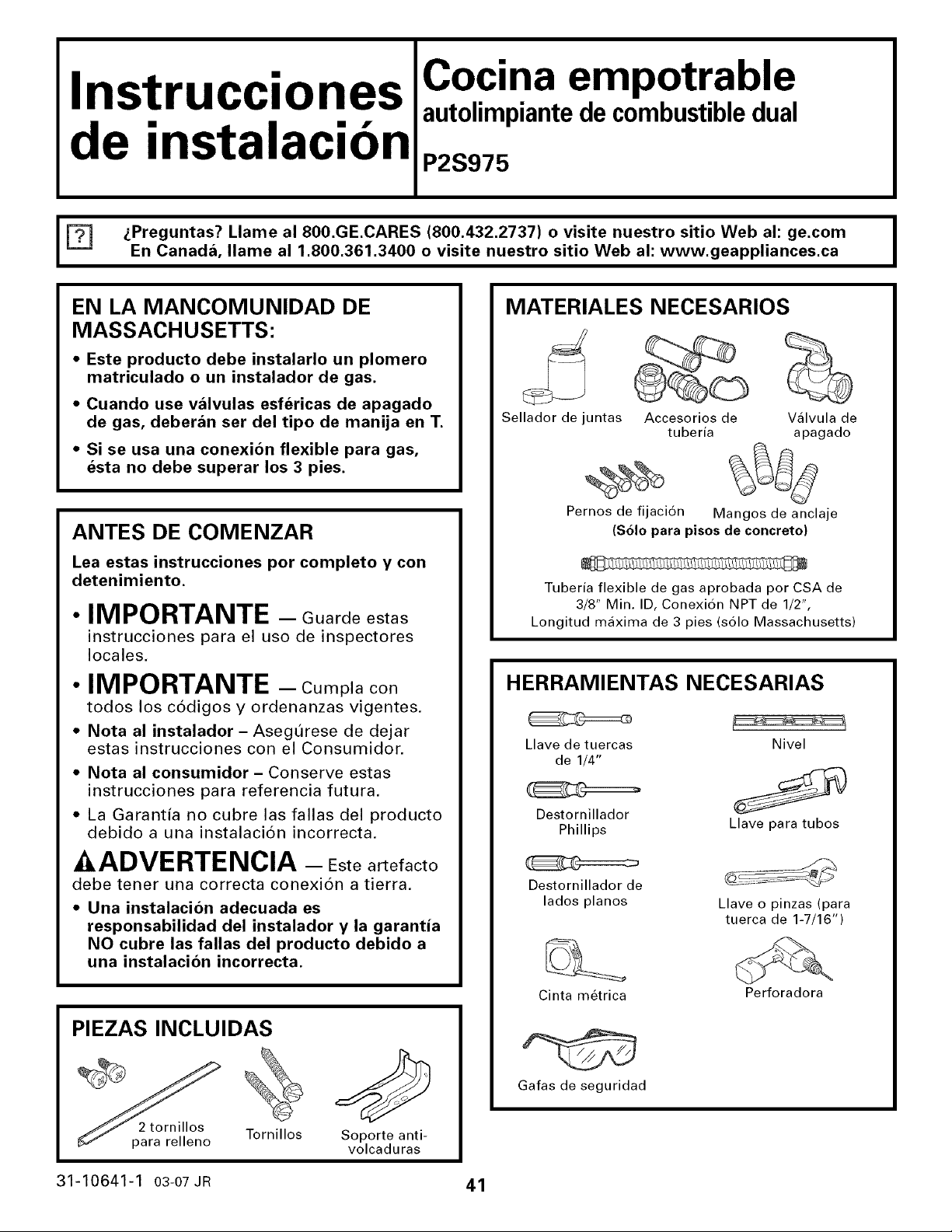

MATERIALS YOU MAY NEED

Joint Sealant Pipe Fittings Shut Off Valve

Lag Bolts Anchor Sleeves

(For Concrete Floors Only)

CSA-Approved Flexible Gas Line

3/8" Min. ID, 1/2" NPT Connection,

3-foot Maximum Length (Massachusetts only)

TOOLS YOU WiLL NEED

1/4" Nut Driver Level

Phillips Head

Screwdriver Pipe Wrench

AWARNING - This appliance must

be properly grounded.

• Proper installation is the responsibility

of the installer and product failure due

to improper installation is NOT covered

under warranty.

PARTS INCLUDED

Screws

31=10641=1 03-07 JR 1

Anti-Tip Bracket

Flat-blade

Screwdriver Wrench or Pliers

(for 1-7/16" Nut)

Tape Measure Drill

Safety Glasses

Page 2

JnstaJJation instructions

IMPORTANT SAFETY INSTRUCTIONS

FOR YOUR SAFETY:

• Do not try to light any appliance. Do not

touch any eJectricaJ switch; do not use any

phone in your buiJding.

• JmmediateJy caJJ your gas suppJier from a

neighbor's phone. Follow the gas suppJier's

instructions.

• if you cannot reach your gas suppJier,

caJJ the fire department.

This range has been design certified by

UNDERWRITERS LABORATORIES for use in

the United States and Canada. You'll find

safety precautions in your Owner's Manual.

Read them carefully.

• Installation of this range must conform with

local codes or in the absence of local codes

with the National Fuel Gas Code, ANSI

Z223.1-Latest edition.

Be sure your range is installed properly by

a qualified installer or service technician.

To eliminate reaching over surface burners,

cabinet storage above burner should be

avoided.

• Do not install the unit near an outside door

or where a draft may affect its use,

installation and service must be performed

by a quaJified instaJJer, service agency or

the gas suppJier.

Page 3

mnstaliation mnstructions

FOR YOUR SAFETY:

WARNING - For personal safety,

remove house fuse or open circuit breaker

before beginning installation. Failure to do so

could result in serious injury or even death,

All rough-in and spacing dimensions must be

met for safe use of your range. Electricity to

the range can be disconnected at the outlet

without moving the range if the outlet is in

the preferred location (remove lower drawer).

To reduce the risk of burns or fire when

reaching over hot surface elements, cabinet

storage space above the cooktop should be

avoided. If cabinet storage space is to be

provided above the cooktop, the risk can

be reduced by installing a range hood that

protrudes at least 5" beyond the front of the

cabinets. Cabinets installed above a cooktop

must be no deeper than 13".

Be sure your appliance is properly installed

and grounded by a qualified technician.

ANTI-TIP DEVICE

AWARNING - Toreducetherisk

of tipping, the appliance must be secured by

properly installed Anti-Tip bracket packed

with this appliance.

If the Anti-Tip device supplied with the range

does not fit this application, use the universal

Anti-Tip device WB2X7909. Skip Steps 4, 19

and 21.

To check if the bracket is installed and

engaged properly, carefully tip the range

forward. The anti-tip bracket should engage

and prevent the range from tipping over.

-&WARNING -

• All ranges can tip

• Injury to persons could result

• Install Anti-Tip bracket packed

with range

• See Installation Instructions

If you pull the range out and away from the

wall for any reason, make sure the Anti-Tip

bracket is engaged when the range is pushed

back against the wall.

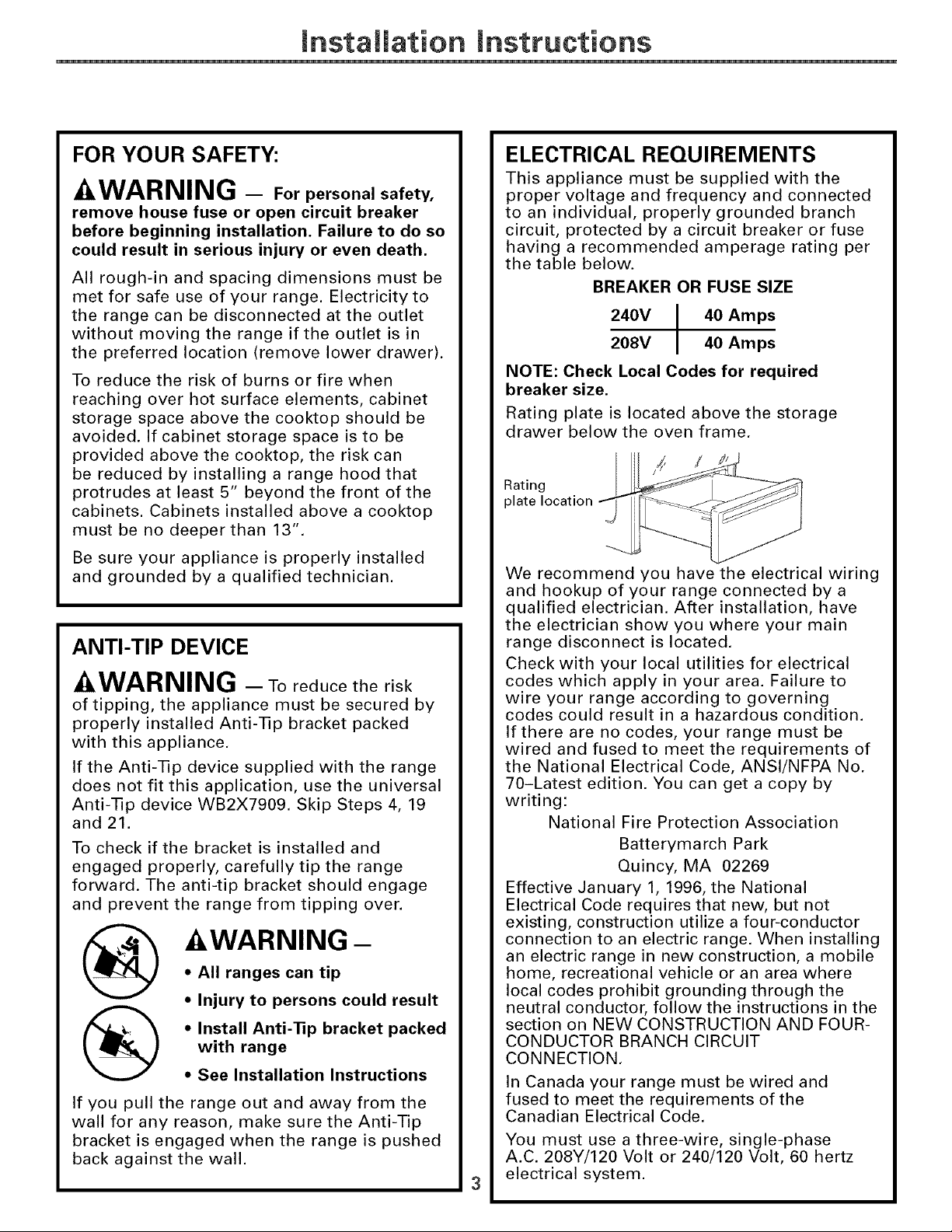

ELECTRICAL REQUIREMENTS

This appliance must be supplied with the

proper voltage and frequency and connected

to an individual, properly grounded branch

circuit, protected by a circuit breaker or fuse

having a recommended amperage rating per

the table below.

BREAKER OR FUSE SIZE

240V I 40 Amps

208V I 40 Amps

NOTE: Check Local Codes for required

breaker size,

Rating plate is located above the storage

drawer below the oven frame.

Rating

plate location

We recommend you have the electrical wiring

and hookup of your range connected by a

qualified electrician. After installation, have

the electrician show you where your main

range disconnect is located.

Check with your local utilities for electrical

codes which apply in your area. Failure to

wire your range according to governing

codes could result in a hazardous condition.

If there are no codes, your range must be

wired and fused to meet the requirements of

the National Electrical Code, ANSI/NFPA No.

70-Latest edition. You can get a copy by

writing:

National Fire Protection Association

Batterymarch Park

Quincy, MA 02269

Effective January 1, 1996, the National

Electrical Code requires that new, but not

existing, construction utilize a four-conductor

connection to an electric range. When installing

an electric range in new construction, a mobile

home, recreational vehicle or an area where

local codes prohibit grounding through the

neutral conductor, follow the instructions in the

section on NEW CONSTRUCTION AND FOUR-

CONDUCTOR BRANCH CIRCUIT

CONNECTION.

In Canada your range must be wired and

fused to meet the requirements of the

Canadian Electrical Code.

You must use a three-wire, single-phase

A.C. 208Y/120 Volt or 240/120 Volt, 60 hertz

electrical system.

Page 4

mnstaliation mnstructions

PRE-INSTALLATION CHECKLIST

[] iNSPECT iNSTALLATiON

Refer to akernate construction section for

the following non=standard installations.

[] Counter opening extends to the wall:

Maintop Filler (supplied with the

range.} (See page 17 for Installation

Instructions) or

Backguard (Kit JXS32XX or JXS37XX).

[] Counter height greater than 36-3/4":

Lower Trim Slideqn (Kit JXS56XX).

[] One side is not enctosed by a cabinet:

Bodyside (Kit JXS77XX).

[] rostand mnstaliation:

To provide an optimum installation, the

top surface of the countertop must be

tevel and flat die or) the same phne)

around the 3 sides that are adjacent to

range cooktop. Proper adjustments to

make the top fiat should be made or

gaps between the countertop and

range cooktop may occur. Forcing the

cooktop to fit may cause excessive

gaps.

To obtain Kits:

a. Visit GE Web Site (See page 1)

b. Call GE Answer Center (See page 1)

c. Contact Dealer

_-I MOVE RANGE INDOORS IN

FRONT OF CABINET OPENING

Do not use hand trucks when moving the

unpackaged range.

[] PROTECT THE KITCHEN

FLOOR

Flatten and place a piece of the shipping

carton in front of the installation location to

protect the flooring.

[_] CAREFULLY, TILT RANGE TO

ACCESS RANGE LEVELING

LEGS

Use an adjustable wrench to screw leveling

legs out so that support flanges clear top of

countertop.

4

Page 5

Installation Instructions

[] REMOVE THE DOOR IF

NECESSARY

Door removal is not a requirement for

installation of the product, but is an added

convenience, To remove the door:

[] UNLOCK HINGES

Push both hinge locks down toward the

door frame, to the unlocked position.

This may require a flat blade screwdriver.

Hinge

unlocked

Hinge

slot

_arm

[] POSITION DOOR

Place hands on both sides of the door, and

close the oven door to the removal position.

This is half way between the broil stop and

fully closed.

position

REMOVE THE DOOR IF

NECESSARY (cont.)

[] LIFT OFF DOOR

Lift door up and out until the hinge arms

clear the slots.

DO NOT LIFT THE DOOR BY THE HANDLE.

NOTE: The oven door is very heavy. Be sure

you have a firm grip before lifting the oven

door off the hinges. Use caution once the

door is removed. Do not lay the door on its

handle. This could cause dents or scratches.

iJ

Hinge clears slot

REMOVE PACKING

MATERIALS

Also remove labels on door, plastic on trim

and panel and all tape around the range.

[] REMOVE STORAGE DRAWER

[] Pull the drawer out until it stops.

[] Lift the front of the drawer until the

stops clear the guides.

Rail

Stop

[] Pull forward and remove the drawer.

_Guide

Page 6

Installation Instructions

PRE-INSTALLATION CHECKLIST (CONT.)

[] PRE-INSTALLATION CUTOUT

AND REQUIRED CLEARANCES

If cabinets are placed less than 30" above the

range, see Alternate Construction, Step 25D,

on page 18.

Wall coverings, counters and cabinets around

range must withstand heat (up to 194°F)

generated by the range.

r-_ STANDARD iNSTALLATiON

Jf the construction of your cabinet cannot

provide a 1/4" fiat area at the back of the

countertop opening, consider changing the

countertop to accommodate this dimension.

See AJternate Construction section.

NOTE: A 1ol/2" minimum cJearance must

be maintained between the rear edge of the

cooktop and the rear waJJ above the cooktop.

9/16"

min.

flat

......

1/4" min. T

flat /

23-3/16" 25"

typically typically

I<_ 29-15/16"-30-1/16" _1

smooth cut

9/16"

_ min.

L!'at

6

Page 7

mnstaliation mnstructions

GAS CONNECTIONS

[] MAKING THE CONNECTIONS

15_

[]

Install a manual shut-off valve in the gas

supply line in an easily accessible location.

[]

Know how and where to shut off the gas

supply to the range.

[]

Shut off gas supply before removing an

old range. Leave it off until hookup of

new range is finished.

[]

Because solid pipe restricts moving the

range, we recommend use of a C.S.A.

certified flexible metal appliance

connector.

WARNING: Never reuse old

flexible connectors. The use of old flexible

connectors can cause gas leaks and personal

injury. Always use new flexible connectors

when installing a gas appliance.

GaSCr e,r to

[T_ MAKING THE CONNECTIONS

{cont.}

[] tnstall 1/2" flare union adaptor to the 1/2"

NPT elbow on pressure regulator.

[] Connect flexible appliance connector to

flare union.

[] Move range into approximate position

and connect flexible connector to gas

suppiy line with proper flare union

adaptor.

Shut-off valve Flexible gas line

T Pressure

7" Max. regulator

_L

90° street

Gas elbow

supply

line

[] To prevent gas leaks, put a pipe joint

sealant or Teflon #_'tape on all male

threads. NOTE: Make sure sealant or tape

is compatible with Natural and LP gases.

[] When you are finished making

connections, be sure that all range knobs

are turned to OFF before you open the

main gas supply vatve.

Pressure

regulator as

f?r nge

NOTE: When

screwing on the flare

union adaptor, hold

the gas inlet firmly

with a wrench.

WARNING: Do not use a flame

to check for gas leaks. Use liquid leak detector

at all joints and connections to check for leaks

in the system.

Page 8

Installation Instructions

ELECTRICAL CONNECTIONS

The range is shipped with a 4-

wire power cord. If your outlet

looks like the one shown, skip to

step 19 and proceed.

NEMA 14-50R

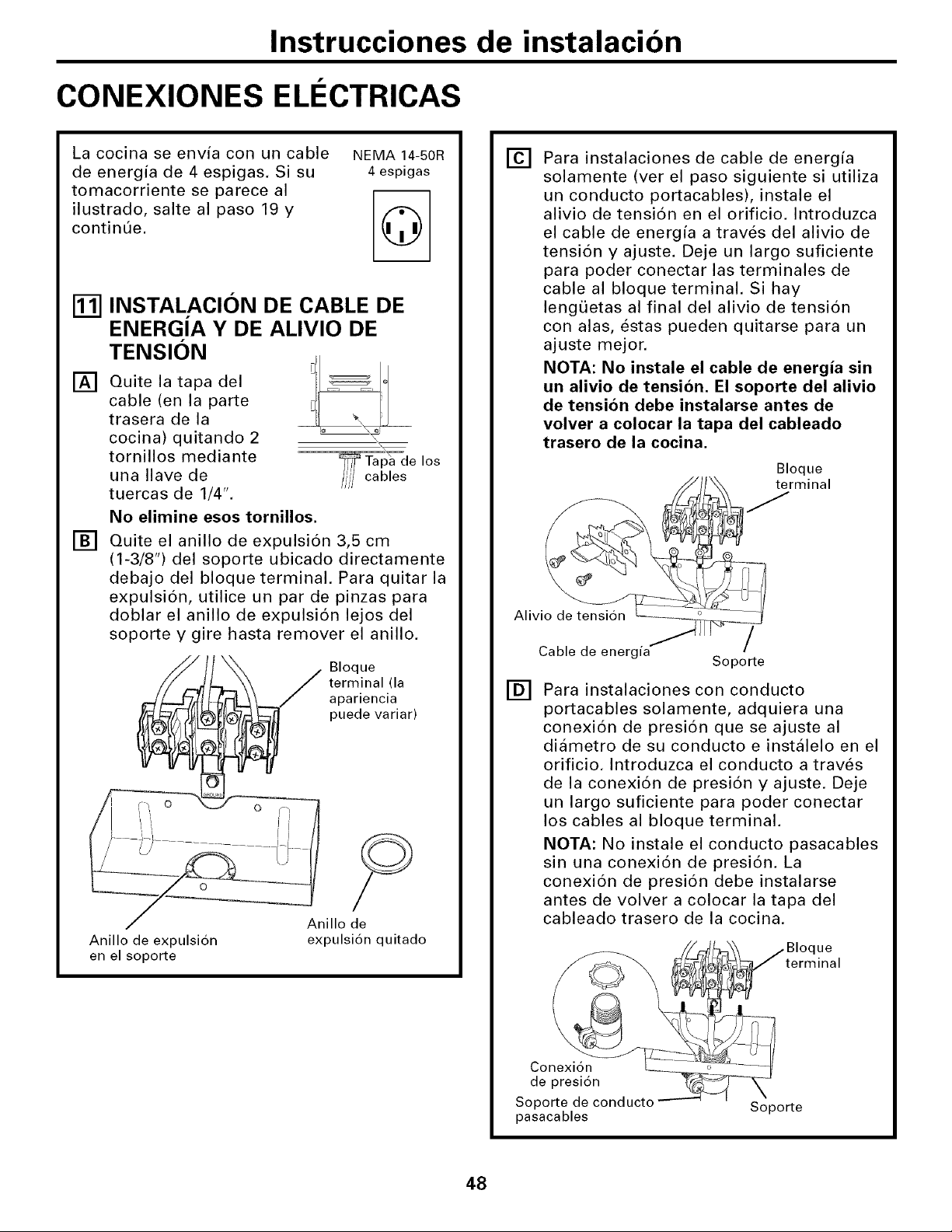

[] POWER CORD AND STRAIN

RELIEF INSTALLATION

Remove the wire

[]

cover (on the back

of the range) by

removing 2

screws, using a

1/4" nut driver.

Do not discard

these screws,

Remove the knockout ring (1-3/8")

[]

located on bracket directly below the

terminal block. To remove the knockout,

use a pair of pliers to bend the knockout

ring away from the bracket and twist

until ring is removed.

Terminal block

(appearance

may vary)

4-wi re

[]

For power cord installations only (see the

next step if using conduit), assemble the

strain relief in the hole. Insert the power

cord through the strain relief and tighten.

Allow enough slack to easily attach the

cord terminals to the terminal block. If

tabs are present at the end of the winged

strain relief, they can be removed for

better fit.

NOTE: Do not install the power cord

without a strain relief. The strain relief

bracket should be installed before

reinstalling the rear range wiring cover.

Terminal

block

Strain relief

Power cord

[]

For conduit installations only, purchase

a squeeze connector matching the

diameter of your conduit and assemble

it in the hole. Insert the conduit through

the squeeze connector and tighten. Allow

enough slack to easily attach the wires to

the terminal block.

NOTE: Do not install the conduit without

a squeeze connector. The squeeze

connector should be installed before

reinstalling the rear range wiring cover.

/

Bracket

Knockout ring

in bracket

Knockout

ring removed

block

Squeeze

connector

Conduit

Bracket

8

Page 9

mnstaliation mnstructions

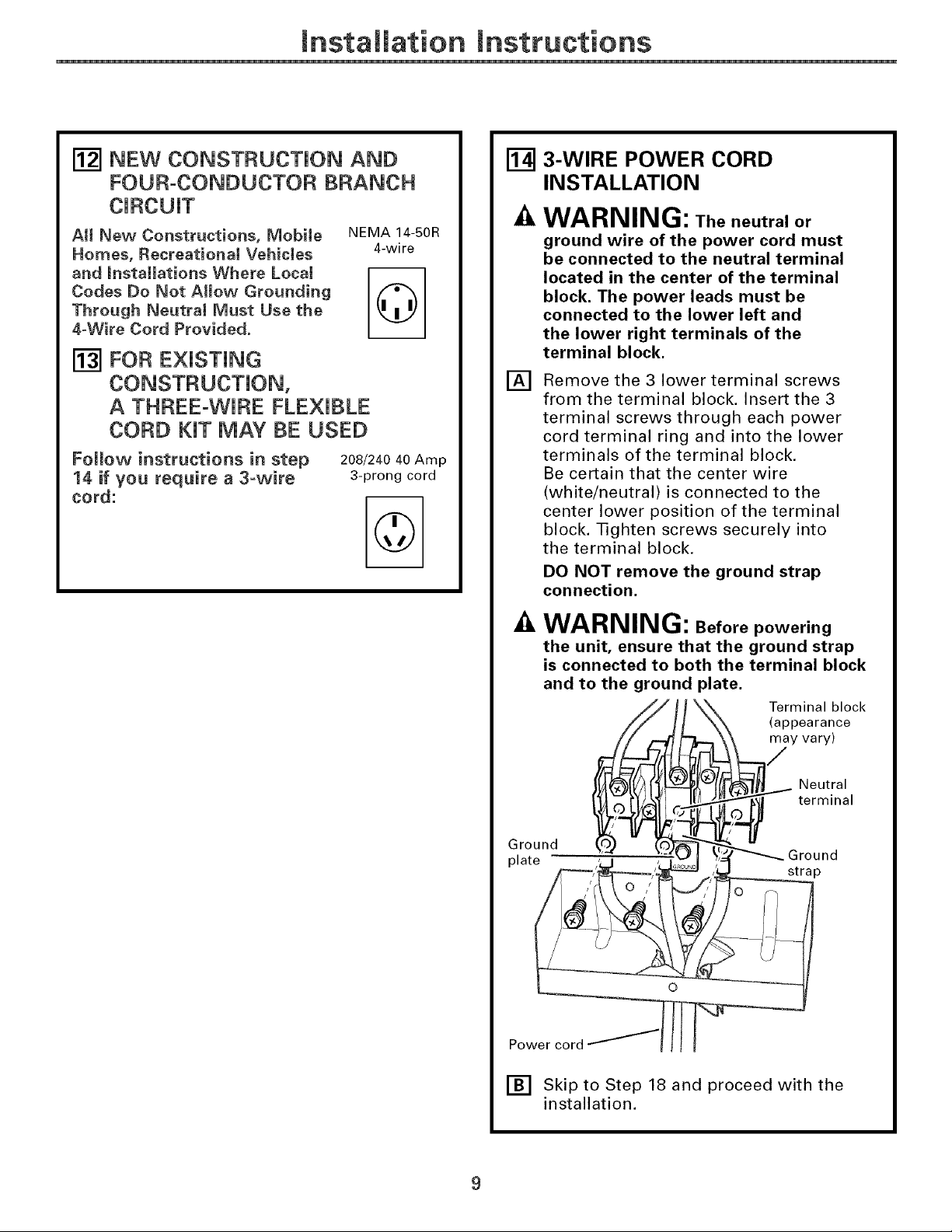

Fi_ NEW CONSTRUCTION AND

FOUR-CONDUCTOR BRANCH

All New Constructions, Mobile

Homes, Recreationam VehicJes

and mnstaHations Where Local

Codes Do Not AHow Grounding

Through Neutral Must Use the

4-Wire Cord Provided.

NEMA 14-50R

4-wi re

r_] FOR EXISTING

A THREE-WiRE FLEXIBLE

CORD KiT MAY BE USED

Follow instructions in stop

14 if you require a 3-wire

cord:

208/240 40 Amp

3-prong cord

3-WIRE POWER CORD

INSTALLATION

WARNING: The neutral or

ground wire of the power cord must

be connected to the neutral terminal

located in the center of the terminal

block. The power leads must be

connected to the lower left and

the lower right terminals of the

terminal block.

Remove the 3 lower terminal screws

[]

from the terminal block. Insert the 3

terminal screws through each power

cord terminal ring and into the lower

terminals of the terminal block.

Be certain that the center wire

(white/neutral) is connected to the

center lower position of the terminal

block. Tighten screws securely into

the terminal block.

DO NOT remove the ground strap

connection.

WARNING: Before powering

the unit, ensure that the ground strap

is connected to both the terminal block

and to the ground plate.

Terminal block

(appearance

O_,_ y vary)

Ground

plate

Power cord

'_ Ground

tNe_iralal

strap

[] Skip to Step 18 and proceed with the

installation.

Page 10

Installation Instructions

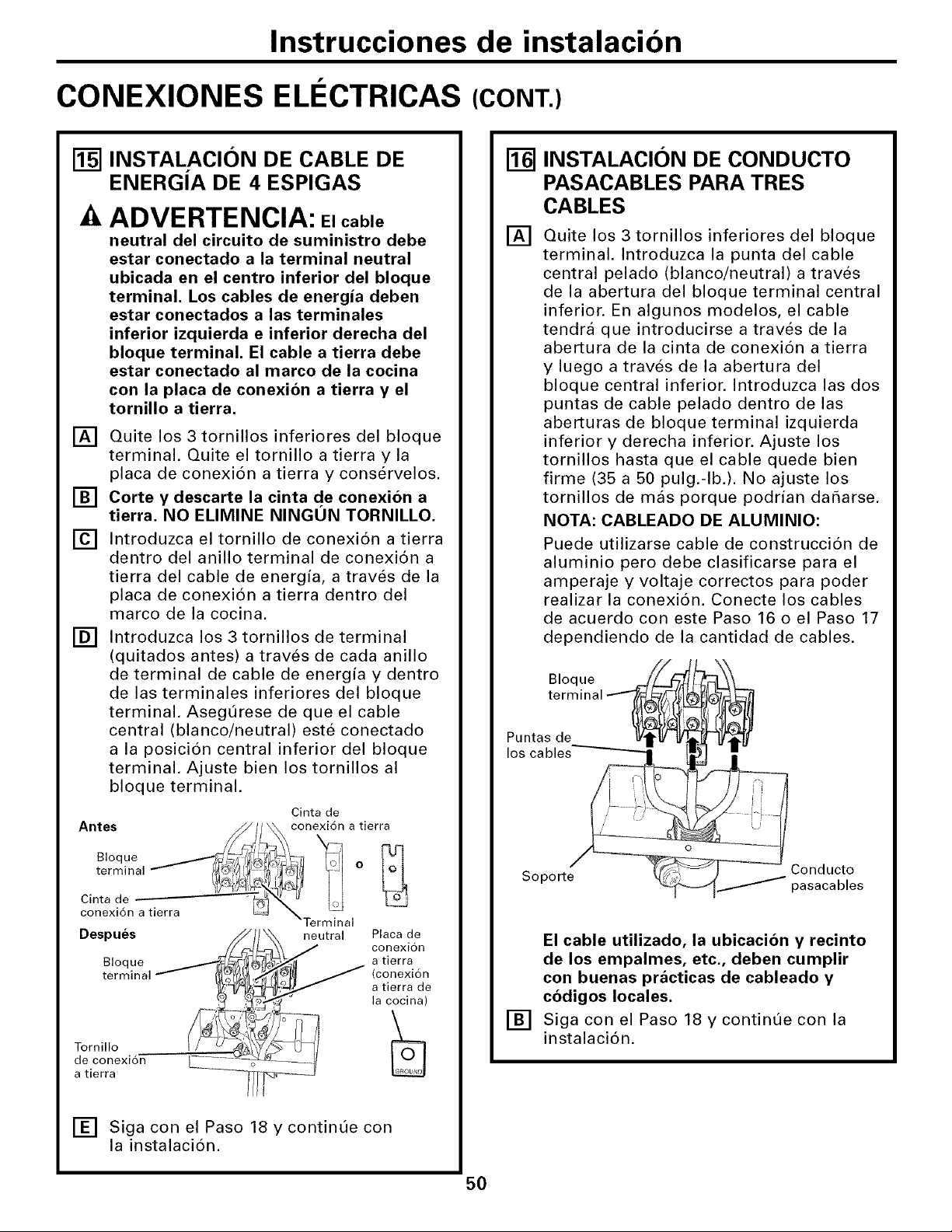

ELECTRICAL CONNECTIONS (CONT.)

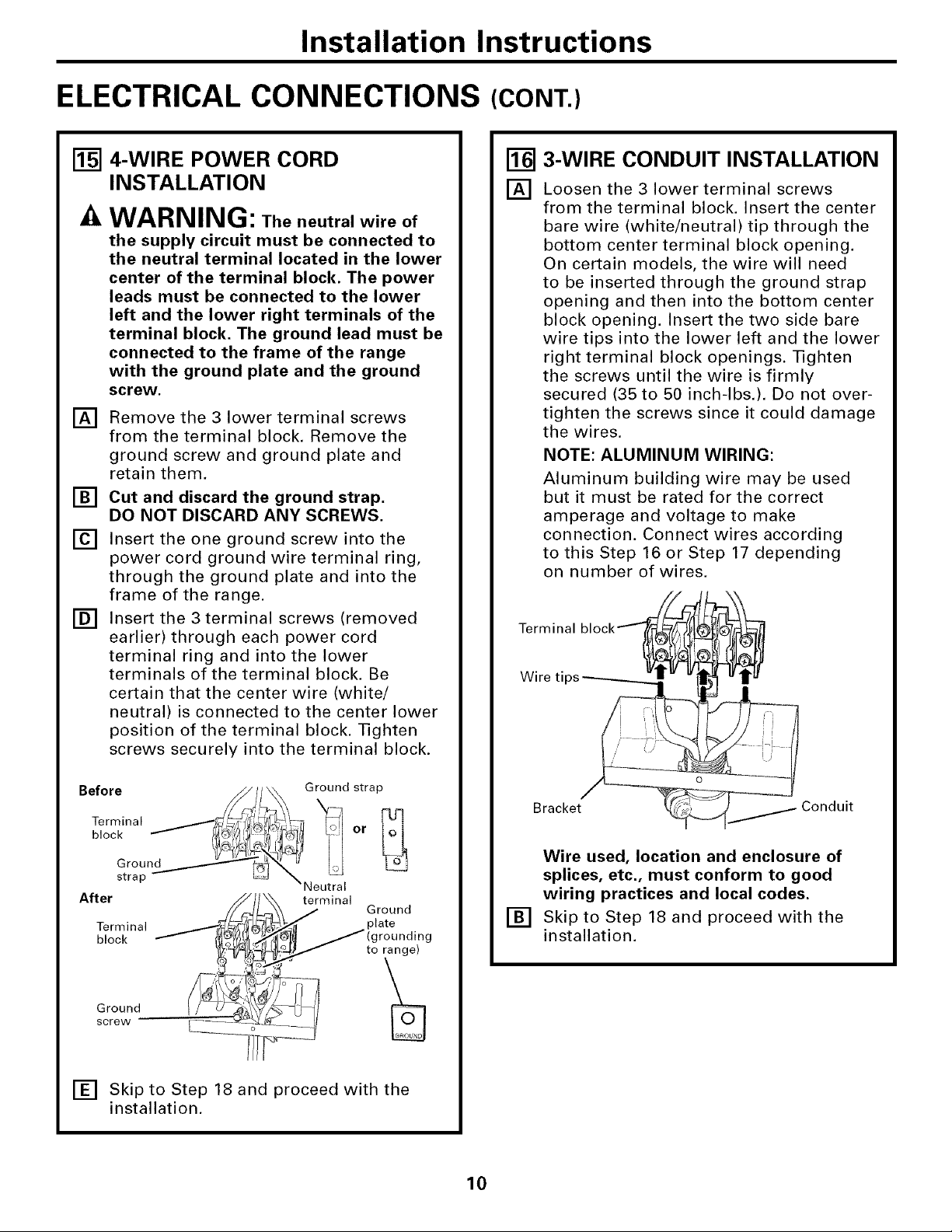

4-WIRE POWER CORD

[]

INSTALLATION

WARNING: The neutral wire of

the supply circuit must be connected to

the neutral terminal located in the lower

center of the terminal block. The power

leads must be connected to the lower

left and the lower right terminals of the

terminal block. The ground lead must be

connected to the frame of the range

with the ground plate and the ground

screw.

Remove the 3 lower terminal screws

[]

from the terminal block. Remove the

ground screw and ground plate and

retain them.

[]

Cut and discard the ground strap.

DO NOT DISCARD ANY SCREWS.

[]

Insert the one ground screw into the

power cord ground wire terminal ring,

through the ground plate and into the

frame of the range.

Insert the 3 terminal screws (removed

[]

earlier) through each power cord

terminal ring and into the lower

terminals of the terminal block. Be

certain that the center wire (white/

neutral) is connected to the center lower

position of the terminal block. Tighten

screws securely into the terminal block.

3-WIRE CONDUIT INSTALLATION

Loosen the 3 lower terminal screws

[]

from the terminal block. Insert the center

bare wire (white/neutral) tip through the

bottom center terminal block opening.

On certain models, the wire will need

to be inserted through the ground strap

opening and then into the bottom center

block opening. Insert the two side bare

wire tips into the lower left and the lower

right terminal block openings. Tighten

the screws until the wire is firmly

secured (35 to 50 inch-lbs.). Do not over-

tighten the screws since it could damage

the wires.

NOTE: ALUMINUM WIRING:

Aluminum building wire may be used

but it must be rated for the correct

amperage and voltage to make

connection. Connect wires according

to this Step 16 or Step 17 depending

on number of wires,

Terminal

Wire til

strap

After ////_\ terminal

Term na tgroand ng

block _','_,"_L _-'"_ to range)

Ground

screw - __

[] Skip to Step 18 and proceed with the

installation.

_._,_ _ L_. plate

//_./___ / Ground

--J' ,2_J ,;'_

Bracket

Wire used, location and enclosure of

splices, etc., must conform to good

wiring practices and local codes.

[] Skip to Step 18 and proceed with the

installation.

10

Page 11

mnstaliation mnstructions

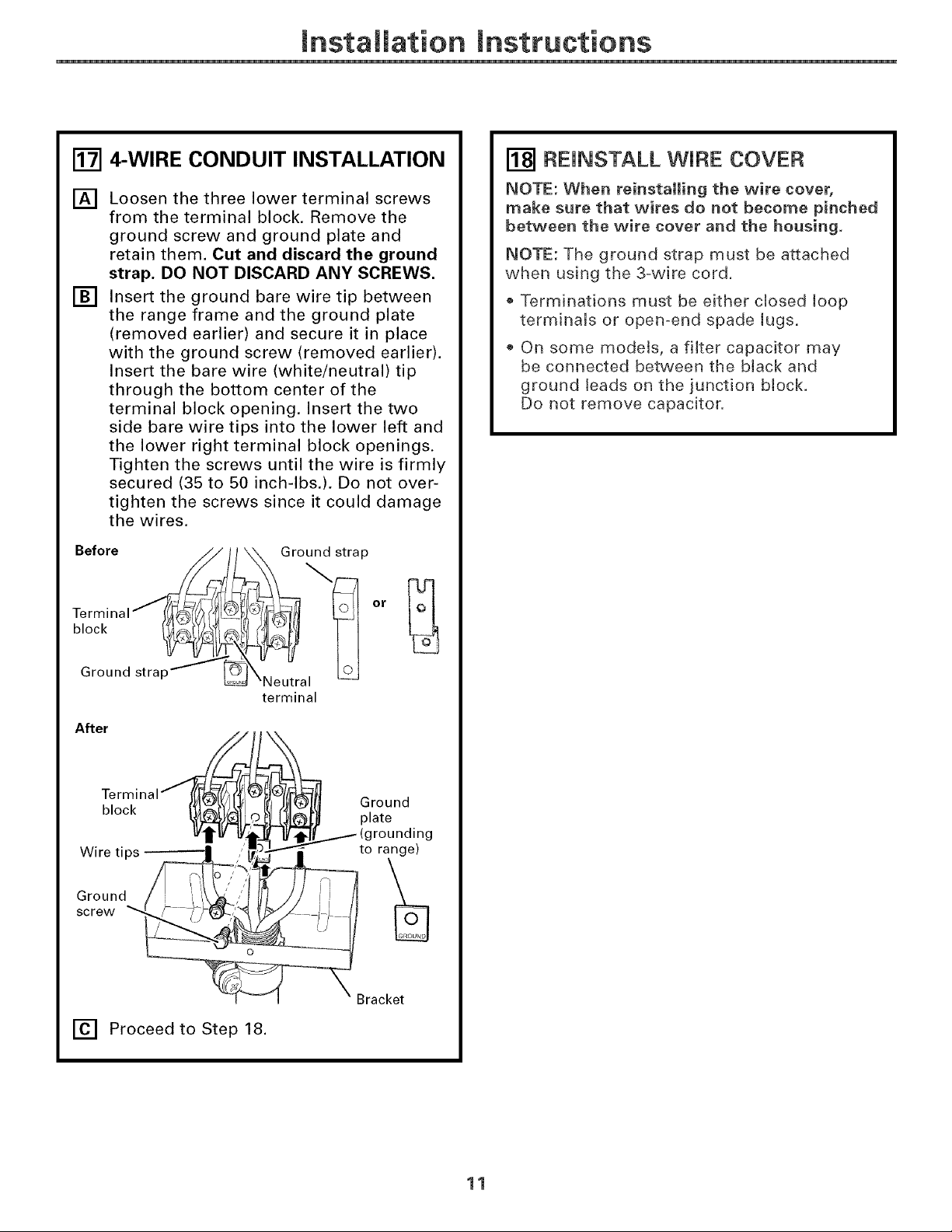

I'_ 4-WIRE CONDUIT INSTALLATION

Loosen the three lower terminal screws

[]

from the terminal block. Remove the

ground screw and ground plate and

retain them. Cut and discard the ground

strap. DO NOT DISCARD ANY SCREWS.

Insert the ground bare wire tip between

[]

the range frame and the ground plate

(removed earlier) and secure it in place

with the ground screw (removed earlier).

Insert the bare wire (white/neutral) tip

through the bottom center of the

terminal block opening. Insert the two

side bare wire tips into the lower left and

the lower right terminal block openings.

Tighten the screws until the wire is firmly

secured (35 to 50 inch-lbs.). Do not over-

tighten the screws since it could damage

the wires,

Before /

Terminal

I

or

[_] REINSTALL WiRE COVER

NOTE: When reinstalling the wire cover,

make sure that wires do not become pinched

between the wire cover and the housing.

NOTE: The ground strap must be attached

when using the 3wire cord.

- Terminations must be either closed toop

terminals or open=end spade tugs.

On some models, a filter capacitor may

be connected between the black and

ground leads on the junction block.

Do not remove capacitor.

block _

Ground strap /

After

Terminal _® _ .

block /'_'Xt_ _ IL_ PIraluna

iVy-IV __ _1 ! t_J_...--.-_" (grounding

Wire tips _ ,'_._-'_ to range)

\Neutral

terminal

Grour, , '/ill

_ Bracket

[] Proceed to Step 18.

\

11

Page 12

mnstaliation mnstructions

INSTALL THE RANGE

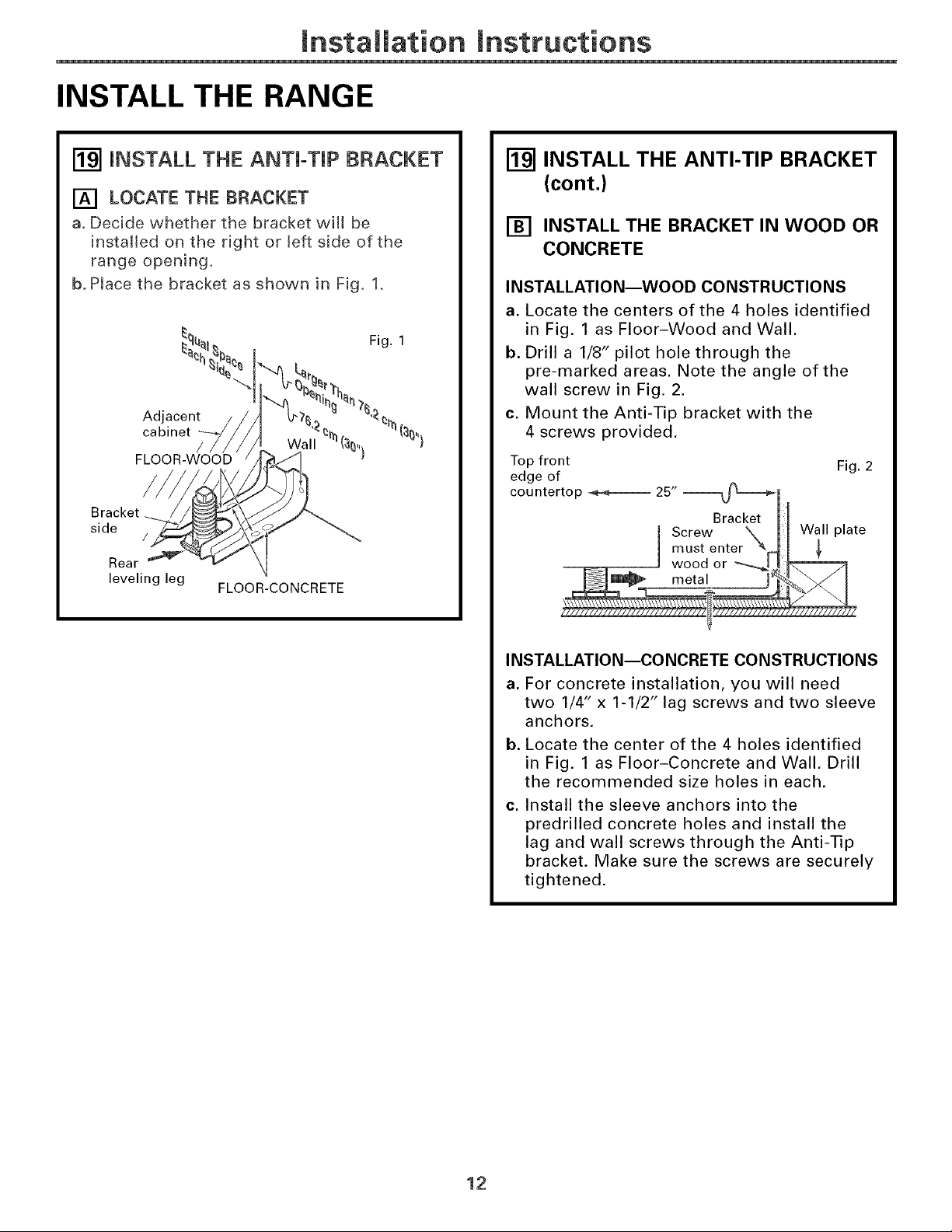

[] iNSTALL THE ANTi-TiP BRACKET

[] LOCATE THE BRACKET

a. Decide whether the bracket will be

installed on the right or teft side of the

range opening.

b. Place the bracket as shown in Fig. 1.

Fig. 1

Bracket

side

/

Rear

leveling leg

FLOOR-CONCRETE

r_ INSTALL THE ANTI-TIP BRACKET

(cont.)

[] INSTALL THE BRACKET IN WOOD OR

CONCRETE

INSTALLATION--WOOD CONSTRUCTIONS

a. Locate the centers of the 4 holes identified

in Fig. 1 as Floor-Wood and Wall.

b. Drill a 1/8" pilot hole through the

pre-marked areas. Note the angle of the

wall screw in Fig. 2.

c. Mount the Anti-Tip bracket with the

4 screws provided,

Top front Fig. 2

edge of

countertop 25" _'_i__[

I Screw \|l Wall plate

Bracket m'l

must enter _r_l

wood or -_t _!_

INSTALLATION--CONCRETE CONSTRUCTIONS

a. For concrete installation, you will need

two 1/4" x 1-1/2" lag screws and two sleeve

anchors.

b. Locate the center of the 4 holes identified

in Fig. 1 as Floor-Concrete and Wall, Drill

the recommended size holes in each,

Install the sleeve anchors into the

C,

predrilled concrete holes and install the

lag and wall screws through the Anti-Tip

bracket. Make sure the screws are securely

tightened.

12

Page 13

Installation Instructions

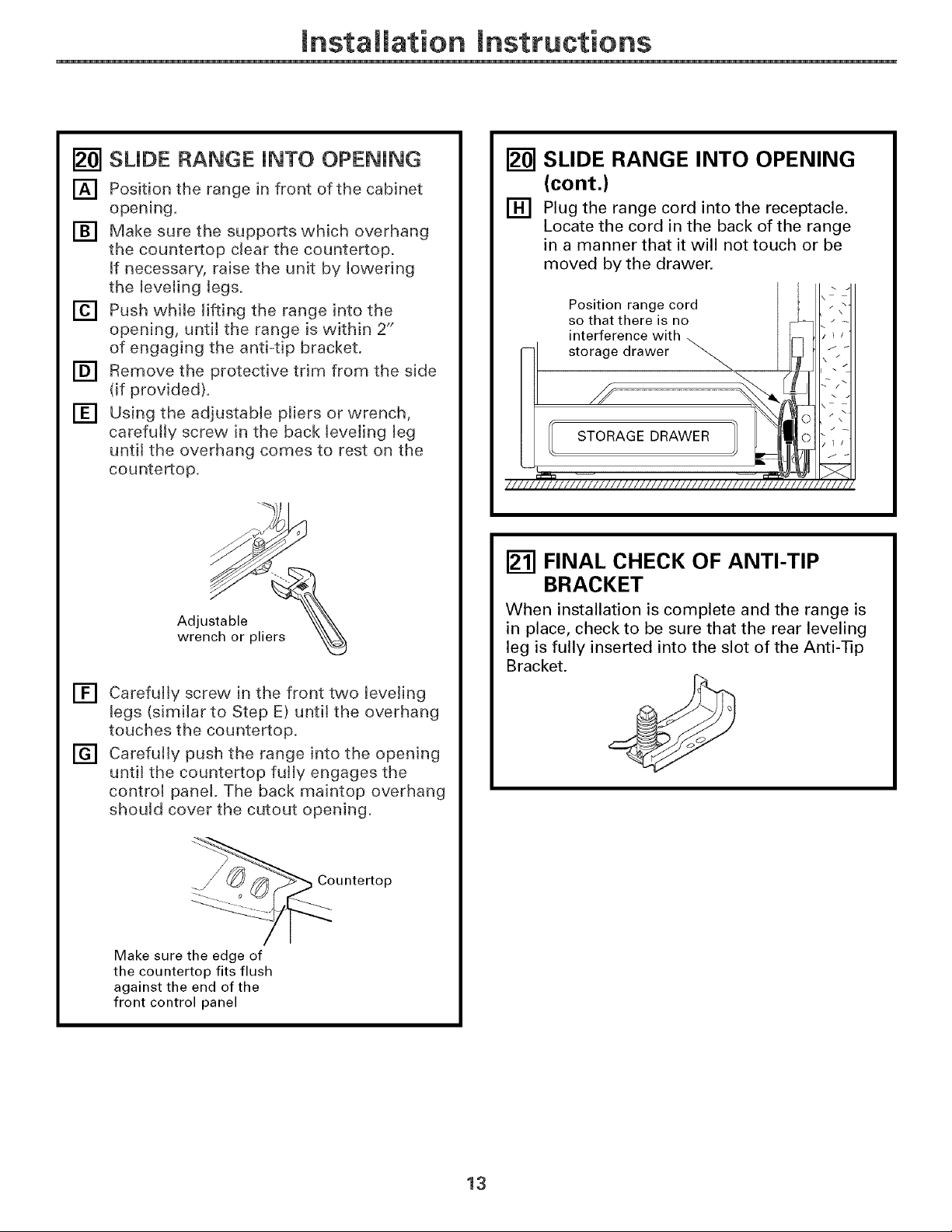

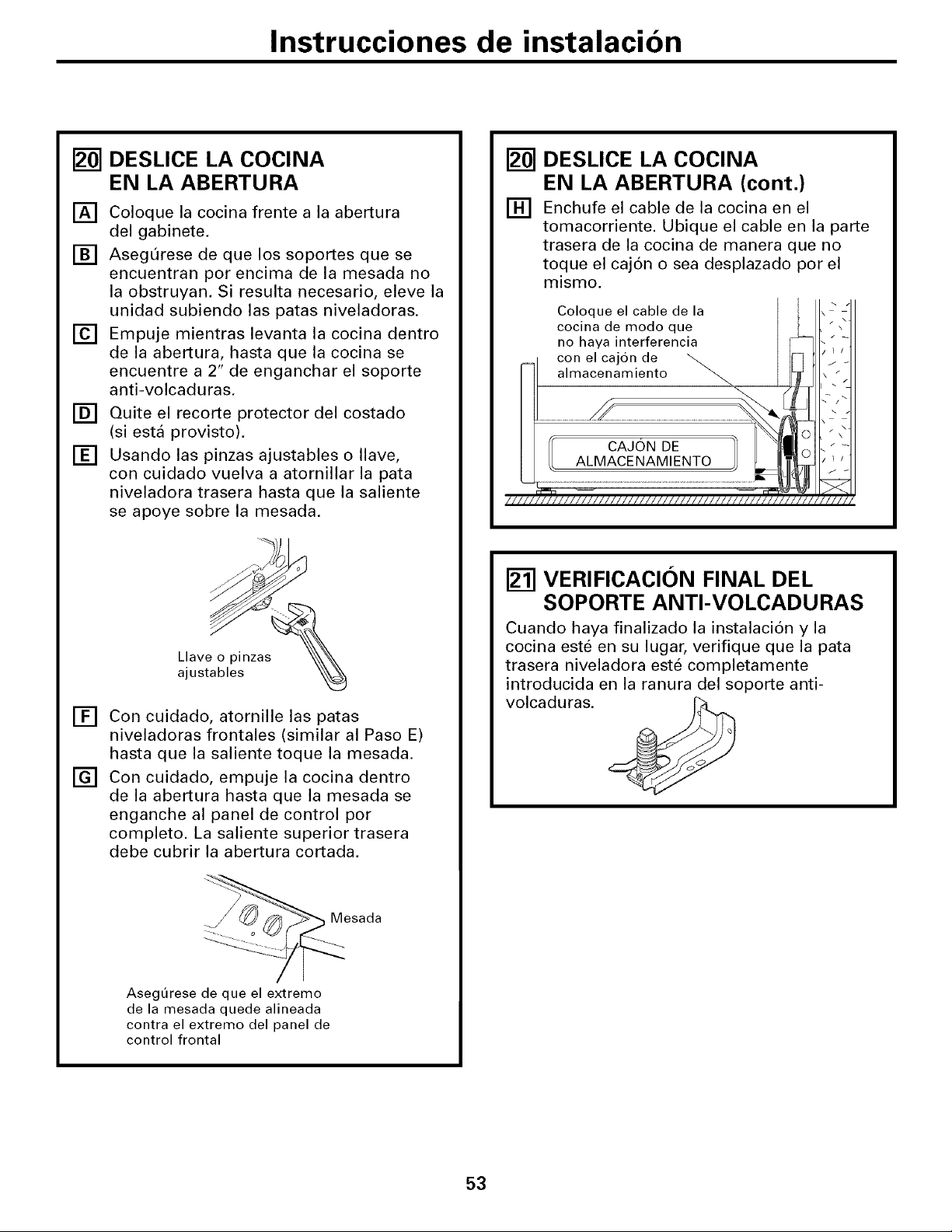

SLIDE RANGE INTO OPENING

[]

[]

Position the range in front of the cabinet

opening.

[] Make sure the supports which overhang

the countertop dear the countertop.

If necessary, raise the unit by lowering

the leveling legs.

[] Push while lifting the range into the

opening, until the range is within 2"

of engaging the anti-tip bracket.

[] Remove the protective trim from the side

(if provided).

[] Using the adjustable pliers or wrench,

carefully screw in the back leveling leg

until the overhang comes to rest on the

countertop.

SLIDE RANGE INTO OPENING

(cont.)

[] Plug the range cord into the receptacle.

Locate the cord in the back of the range

in a manner that it will not touch or be

moved by the drawer.

Position range cord

so that there is no

interference with .

F] storage drawer _..

//

\

tl/

\

/I/

/////

\ /

. \

j

\

\

[] Carefully screw in the front two leveling

legs (similar to Step E) until the overhang

touches the countertop.

[] Carefully push the range into the opening

until the countertop fully engages the

control pane[. The back maintop overhang

should cover the cutout opening.

Counte_op

Make sure the edge of

the countertop fits flush

against the end of the

front control panel

I_1 FINAL CHECK OF ANTI-TIP

BRACKET

When installation is complete and the range is

in place, check to be sure that the rear leveling

leg is fully inserted into the slot of the Anti-Tip

Bracket.

13

Page 14

Installation Instructions

INSTALL THE RANGE (CONT.)

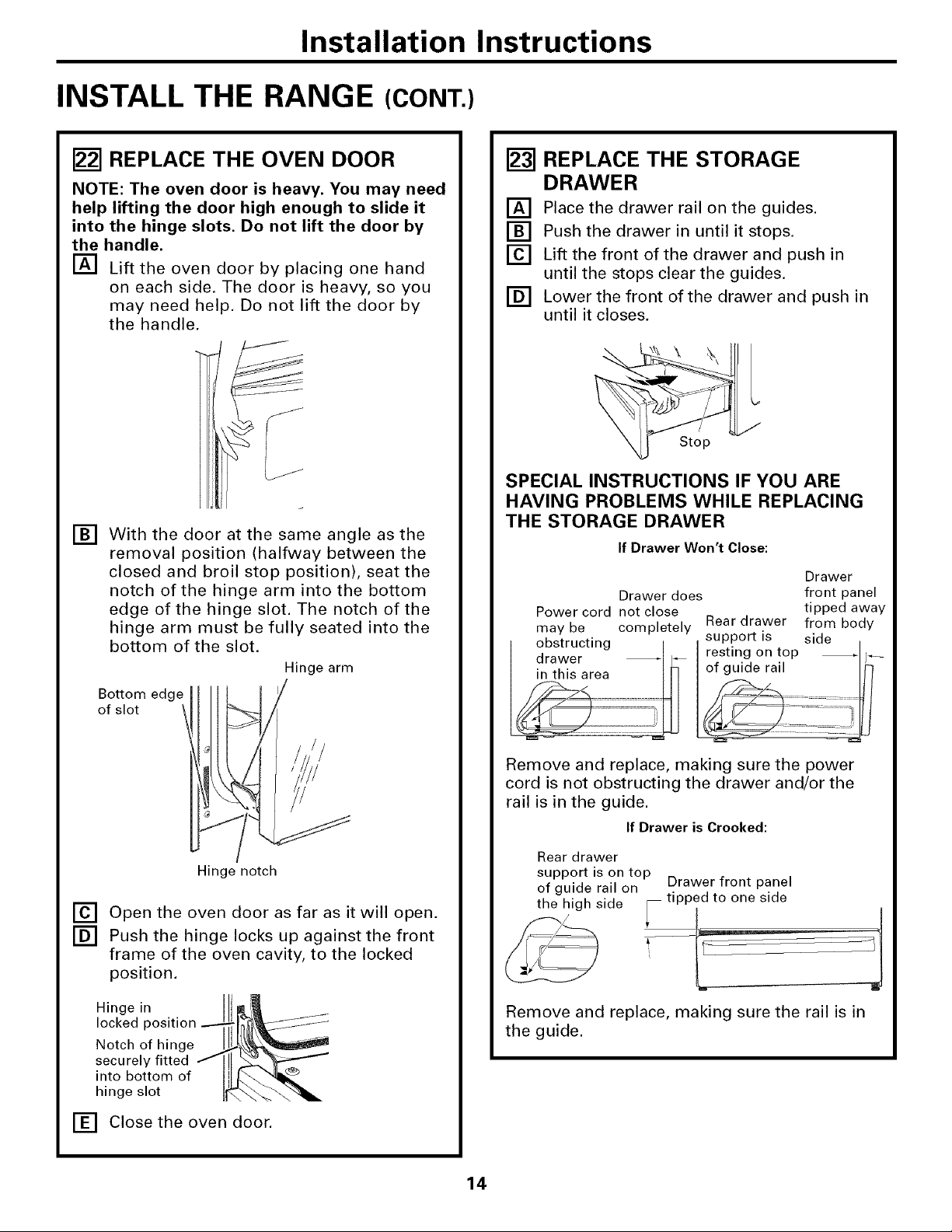

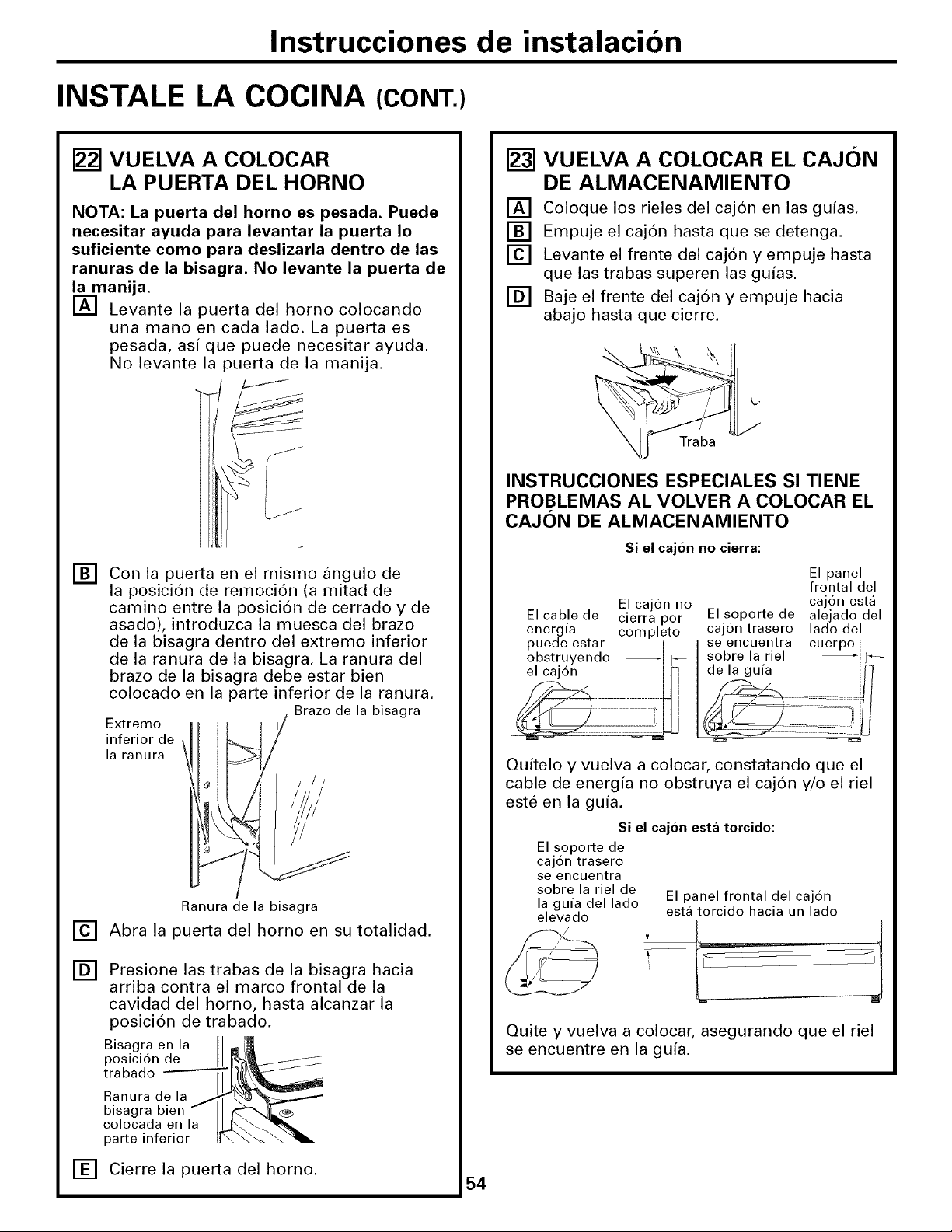

_-_ REPLACE THE OVEN DOOR

NOTE: The oven door is heavy. You may need

help lifting the door high enough to slide it

into the hinge slots. Do not lift the door by

the handle.

[] Lift the oven door by placing one hand

on each side. The door is heavy, so you

may need help. Do not lift the door by

the handle.

With the door at the same angle as the

[]

removal position (halfway between the

closed and broil stop position), seat the

notch of the hinge arm into the bottom

edge of the hinge slot. The notch of the

hinge arm must be fully seated into the

bottom of the slot.

Hinge arm

Bottom edge

of slot

[] REPLACE THE STORAGE

DRAWER

[] Place the drawer rail on the guides.

[] Push the drawer in until it stops.

[] Lift the front of the drawer and push in

until the stops clear the guides.

[] Lower the front of the drawer and push in

until it closes.

Stop

SPECIAL INSTRUCTIONS IF YOU ARE

HAVING PROBLEMS WHILE REPLACING

THE STORAGE DRAWER

If Drawer Won't Close:

Drawer

Drawer does front panel

Power cord not close tipped away

may be completely Rear drawer from body

i _b:tru:ti_ q l_ S:is_iP_ite°iati_ P side I f_

Hinge notch

[] Open the oven door as far as it will open.

[] Push the hinge locks up against the front

frame of the oven cavity, to the locked

position.

Hinge in

locked position

Notch of hinge

secu rely fitted

into bottom of

hinge slot

[] Close the oven door.

Remove and replace, making sure the power

cord is not obstructing the drawer and/or the

rail is in the guide.

If Drawer is Crooked:

Rear drawer

support is on top

of guide rail on Drawer front panel

the high side tipped to one side

J

Remove and replace, making sure the rail is in

the guide.

14

Page 15

Installation Instructions

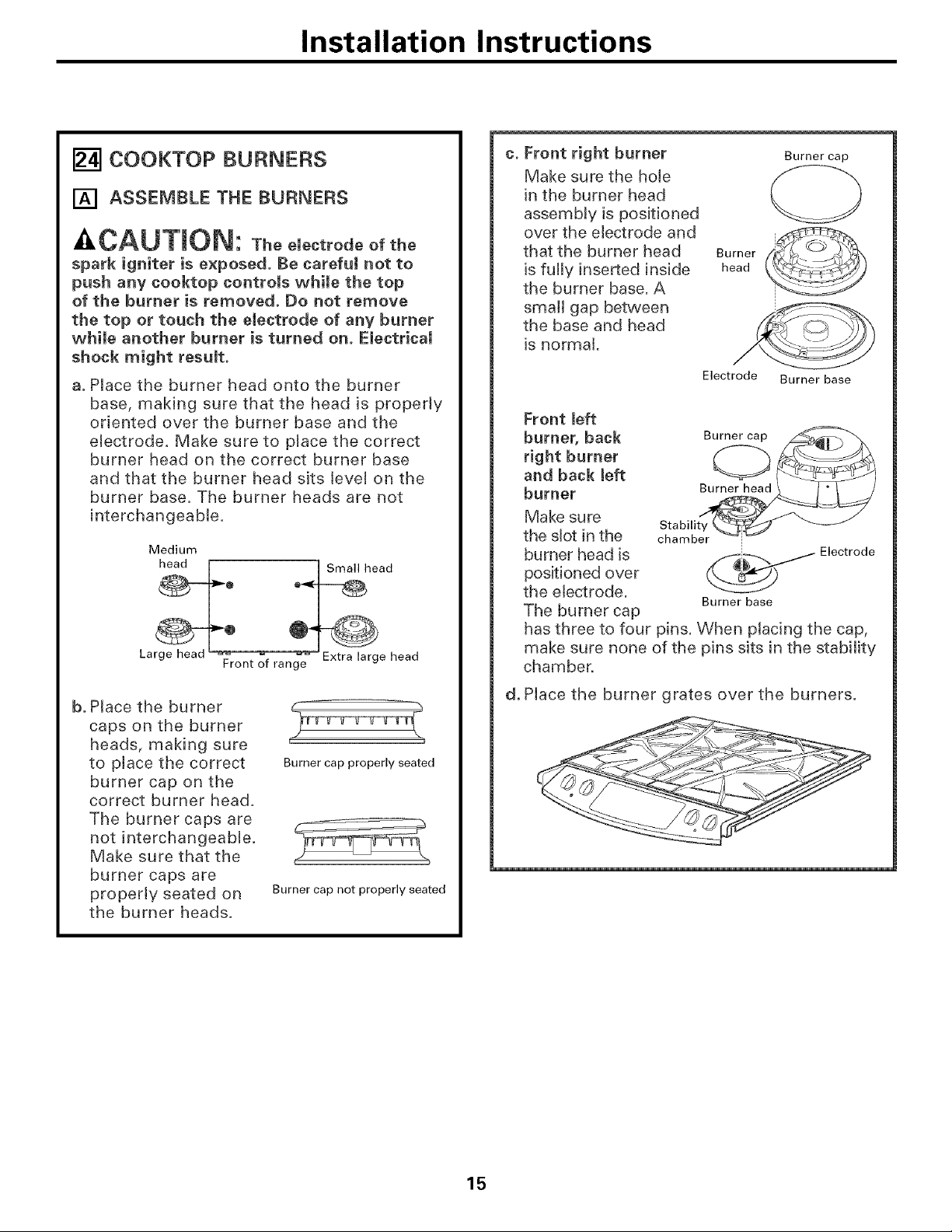

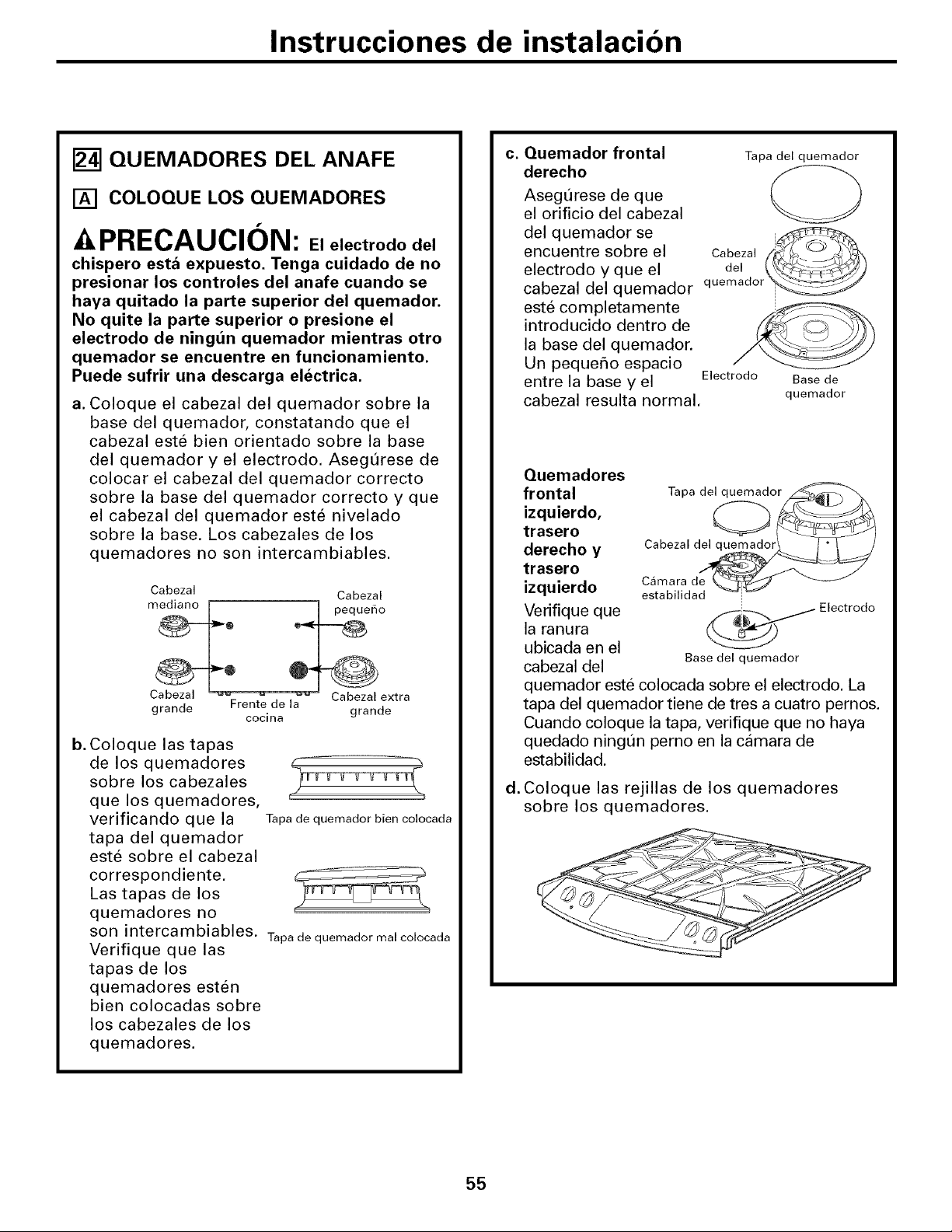

[] COOKTOP BURNERS

[] ASSEMBLE THE BURNERS

CAUTION: Theemectrodeofthe

spark igniter is exposed. Be carefuJ not to

push any cooktop controJs whiJe the top

of the burner is removed. Do not remove

the top or touch the eJectrode of any burner

while another burner is turned on. ElectricaJ

shock might resuJt.

a. Place the burner head onto the burner

base, making sure that the head is properly

oriented over the burner base and the

electrode. Make sure to place the correct

burner head on the correct burner base

and that the burner head sits level on the

burner base. The burner heads are not

interchangeable.

Medium

Large head _ Extra large head

c. Front right burner Burner cap

Make sure the hole

in the burner head

assembly is positioned

over the electrode and

that the burner head Burner

iSfully inserted inside head

the burner base. A

small gap between

the base and head

is normal.

Electrode

Front left

burner, back

right burner

and back left

burner

Make sure

the slot in the

burner head is

positioned over

the electrode.

The burner cap

has three to four pins. When placing the cap,

make sure none of the pins sits in the stability

chamber.

Burner base

Burner base

b. Place the burner

caps on the burner

heads, making sure

to place the correct

burner cap on the

correct burner head.

The burner caps are

not interchangeable.

Make sure that the

burner caps are

properly seated on

the burner heads.

d. Place the burner grates over the burners.

Burner cap properly seated

Burner cap not properly seated

15

Page 16

Installation Instructions

INSTALL THE RANGE (CONT.)

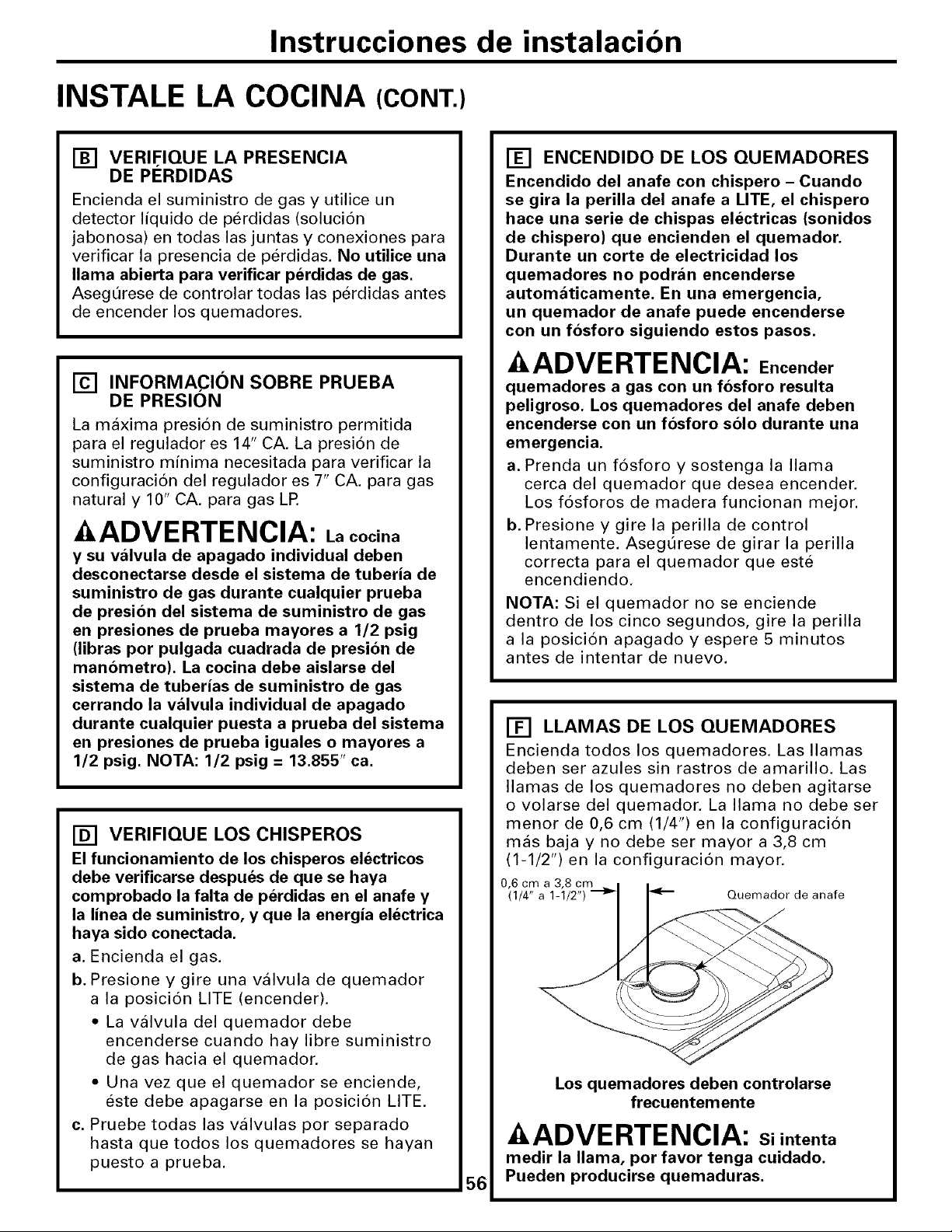

[] CHECK FOR LEAKS

Turn the gas supply on and use a liquid

leak detector (soap solution) at all joints and

connections to check for leaks. Do not use an

open flame to look for leaks. Be sure all leaks

are stopped before lighting burners.

[] PRESSURE TEST INFORMATION

The maximum allowable supply pressure

for the regulator is 14" W.C. The minimum

supply pressure needed to check the regulator

setting is 7" W.C. for natural gas and 10" W.C.

for LP gas.

-4,WARNING: The range and its

individual shut-off valve must be disconnected

from the gas supply piping system during any

pressure testing of the gas supply system at

test pressures of more than 1/2 psig (pounds

per square inch gauge). The range must be

isolated from the gas supply piping system

by closing its individual shut-off valve during

any pressure testing of the gas supply system

at test pressures equal to or greater than

1/2 psig. NOTE: 1/2 psig = 13.855" w.c.

[] CHECK THE IGNITERS

Operation of the electric igniters should be

checked after the cooktop and supply line

have been carefully checked for leaks and the

cooktop has been connected to the electrical

power.

a. Turn on gas.

b. Push and turn a burner valve to the LITE

position.

• The burner valve should light when gas

is available to the burner.

• Once the burner lights, it should be

turned out of the LITE position.

c. Try each valve separately until all burners

have been checked.

[] BURNER IGNITION

Cooktop Spark Ignition--When you turn

the cooktop knob to LITE, the spark igniter

makes a series of electric sparks (ticking

sounds) which light the burner. During a

power failure the burners will not light

automatically. In an emergency, a cooktop

burner may be lit with a match by following

the steps below.

WARNING: Lighting gas burners

with a match is dangerous. You should match

light the cooktop burners only in an

emergency.

a. Light a match and hold the flame near the

burner you want to light. Wooden matches

work best.

b. Push in and turn the control knob slowly.

Be sure you are turning the correct knob

for the burner you are lighting.

NOTE: If the burner does not light within

five seconds, turn the knob off and wait

5 minutes before trying again.

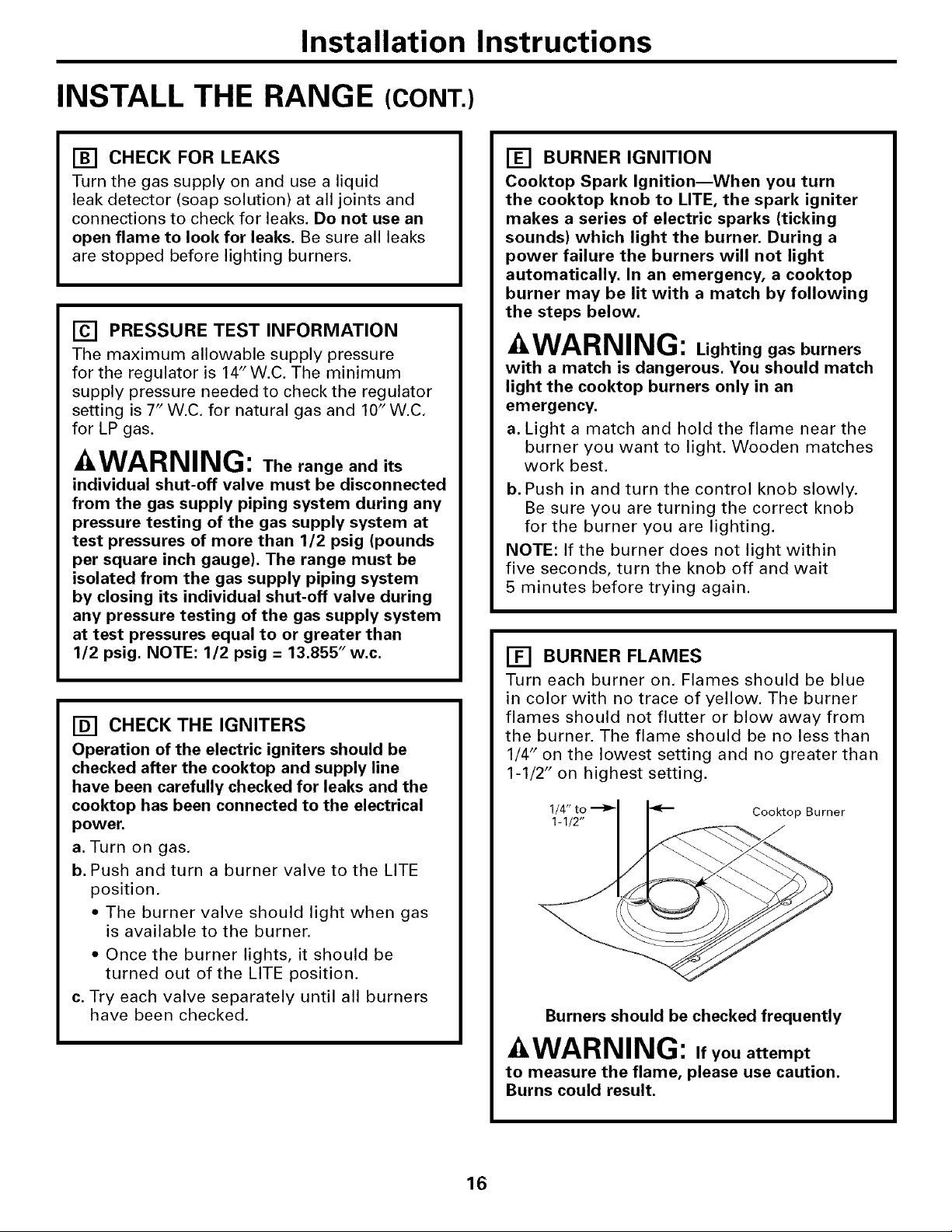

[] BURNER FLAMES

Turn each burner on. Flames should be blue

in color with no trace of yellow. The burner

flames should not flutter or blow away from

the burner. The flame should be no less than

1/4" on the lowest setting and no greater than

1-1/2" on highest setting.

Cooktop Burner

Burners should be checked frequently

WARNING: .you attempt

to measure the flame, please use caution.

Burns could result.

16

Page 17

Installation Instructions

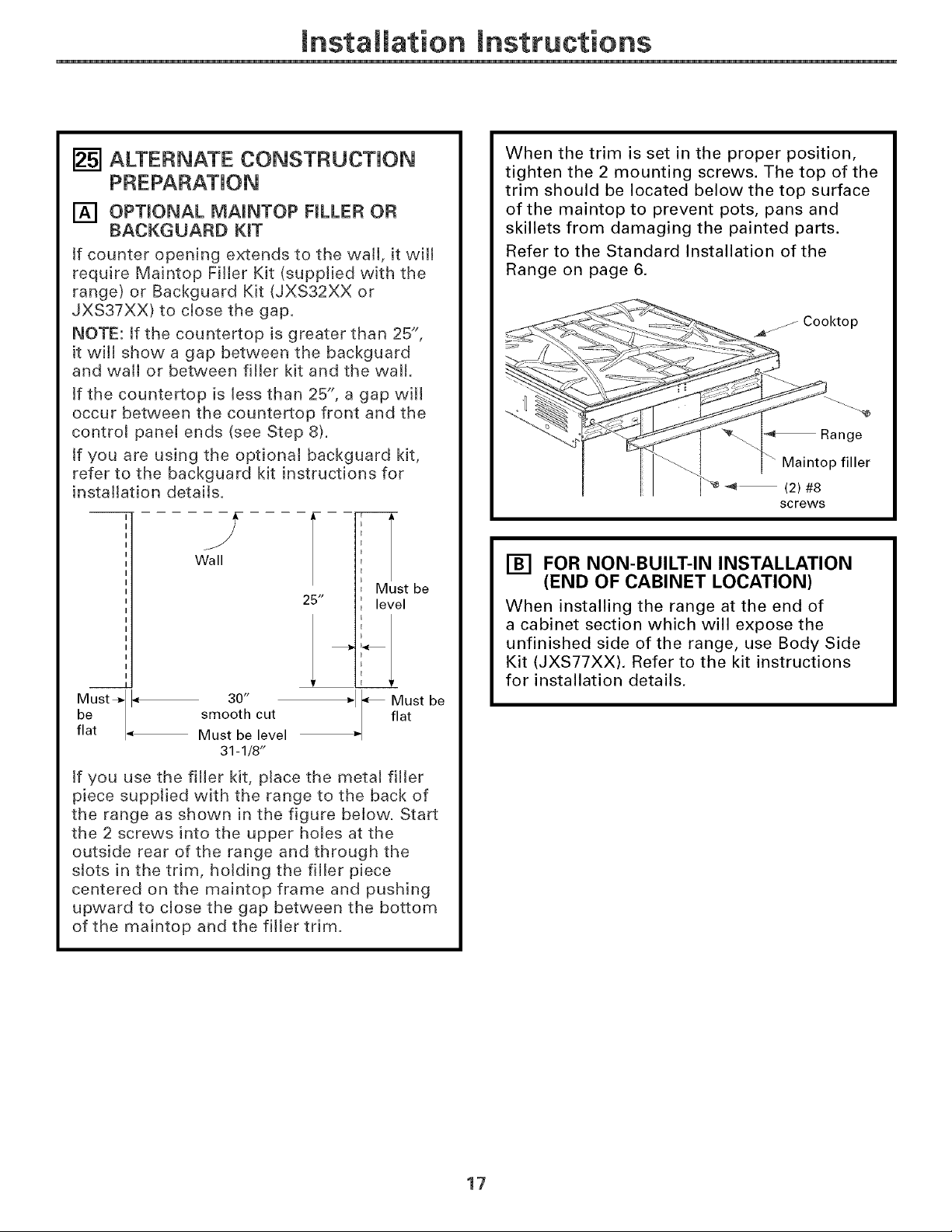

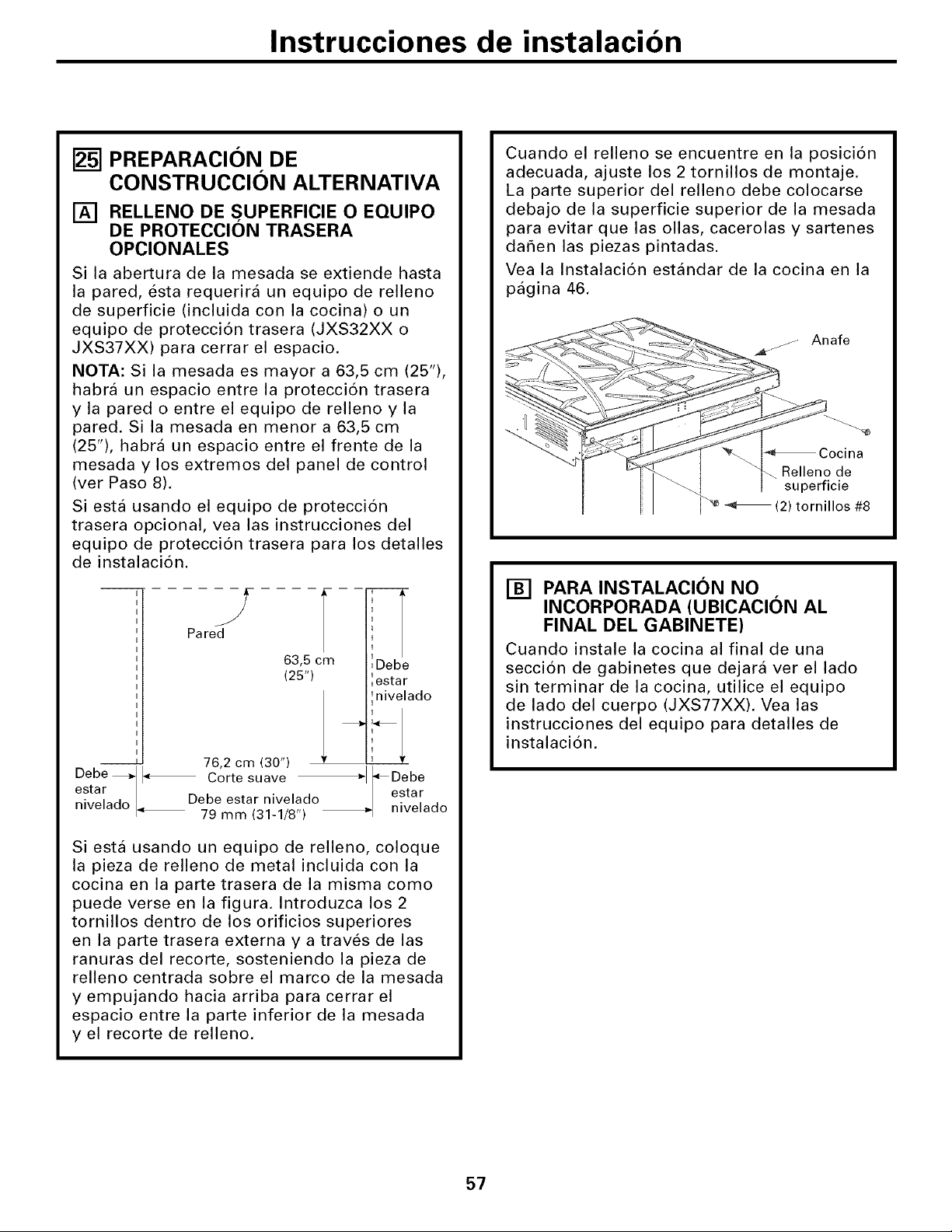

[] ALTERNATE CONSTRUCTION

[] OPTIONAL MAINTOP FILLER OR

BACKGUARD KiT

tf counter opening extends to the wall, it will

require Maintop FHler Kit (supplied with the

range} or Backguard Kit (JXS32XX or

JXS37XX) to dose the gap.

NOTE: tf the countertop is greater than 25",

it will show a gap between the backguard

and wall or between filler kit and the walt.

tf the countertop is less than 25", a gap wilt

occur between the countertop front and the

control panel ends (see Step 8).

tf you are using the optional backguard kit,

refer to the backguard kit instructions for

installation details.

f

Wall

25"

Must be

level

When the trim is set in the proper position,

tighten the 2 mounting screws. The top of the

trim should be located below the top surface

of the maintop to prevent pots, pans and

skillets from damaging the painted parts.

Refer to the Standard Installation of the

Range on page 6.

J

Cooktop

%

_¢-,_ _ _ Range

p filler

I\'_ _-- (2) #8

screws

[] FOR NON-BUILT-IN INSTALLATION

(END OF CABINET LOCATION)

When installing the range at the end of

a cabinet section which will expose the

unfinished side of the range, use Body Side

Kit (JXS77XX). Refer to the kit instructions

for installation details.

llaMUSt_'1._ 30" _ Must be

bet smooth cut flat

tf you use the filler kit, place the metal filler

piece supplied with the range to the back of

the range as shown in the figure below. Start

the 2 screws into the upper holes at the

outside rear of the range and through the

slots in the trim, holding the filler piece

centered on the maintop frame and pushing

upward to close the gap between the bottom

of the maintop and the filler trim.

Must be level

31-1/8"

17

Page 18

Installation Instructions

INSTALL THE RANGE (CONT.)

[] ALTERNATE CONSTRUCTION

PREPARATION (cont.)

[] ISLAND INSTALLATION

Attach the Anti-Tip bracket per instructions

in Step 19, making sure that the rear of the

bracket is 25" from the front of the

countertop.

Be aware that the screws provided are long

and may penetrate through the back of the

island cabinets. In this event, use shorter

screws (not provided) or the screws provided

should be used in the floor (see Step 19B for

Wood/Concrete Floor Installation).

Do not use Backguard Kit JXS32XX or

JXS37XX.

[] CABINETS OVER THE RANGE LESS

THAN 30"

If a 30" clearance between cooking surface

and overhead combustible material or metal

cabinets cannot be maintained, protect the

underside of the cabinets above the cooktop

with not less than 1/4" insulating millboard

covered with sheet metal not less than

0.0122" thick.

OPERATION CHECKLIST

= Double check to make sure everything in

this guide has been completed. Rechecking

steps will ensure safe use of the cooktop.

• Make sure all controls are left in the OFF

position.

• Make sure the flow of combustion

and ventilation air to the cooktop is

unobstructed.

• The serial plate for your Range is located

under the oven door above the storage

area. In addition to the model and serial

numbers, it tells you the ratings of the

burners and the type of fuel and pressure

the cooktop was adjusted for when it left

the factory.

• When ordering parts, always include the

serial number and model number to ensure

proper replacement parts.

• Recheck Steps: Double check to make

sure everything in this guide has been

completed. Rechecking steps will ensure

safe use of the Range,

Please see L.P. conversion instructions

supplied with this range when L.P. Gas

is used.

NOTE: Instructions are mounted on

regulator bracket.

18

Page 19

19

Page 20

2O

Printed in the United States

Page 21

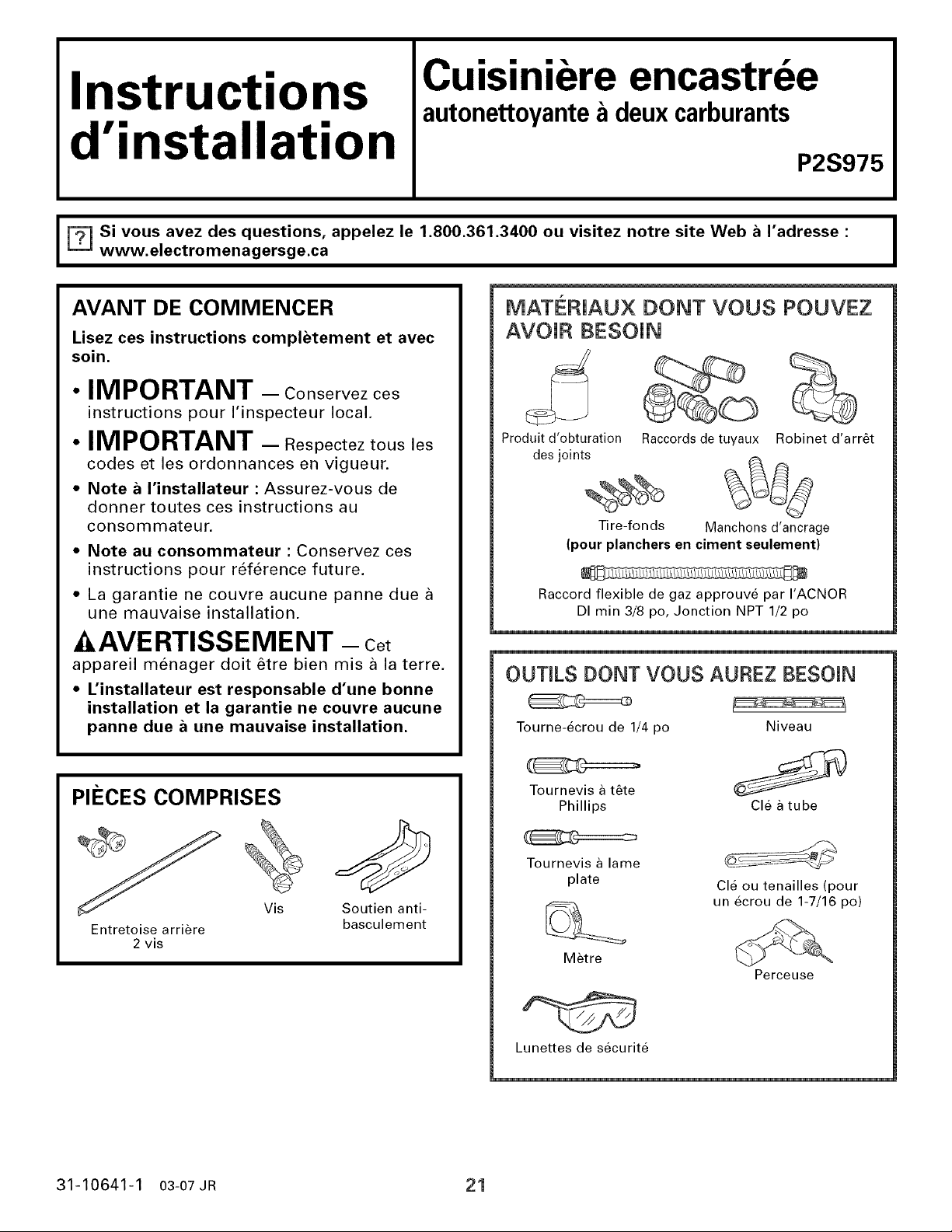

Instructions

d'installation

Cuisiniere encastr

autonettoyante a deux carburants

P2S975

I_ i vous avez des questions, appelez le 1.800.361.3400 ou visitez notre site Web a I'adresse :

www.electromenagersge.ca

AVANT DE COMMENCER

Lisez ces instructions completement et avec

soin.

MATERJAUX DONT VOUS POUVEZ

AVOJR BESOJN

• IMPORTANT - Conservezces

instructions pour I'inspecteur local.

• IMPORTANT - Respectez tousles

codes et les ordonnances en vigueur.

• Note a I'installateur : Assurez-vous de

donner toutes ces instructions au

consommateur.

• Note au consommateur : Conservez ces

instructions pour reference future.

• La garantie ne couvre aucune panne due

une mauvaise installation.

Produit d'obturation

desjoints

(pour planchers en ciment seulement)

Raccord flexible de gaz approuve par I'ACNOR

DI min 3/8 po, Jonction NPT 1/2 po

Raccordsdetuyaux Robinet d'arr6t

Tire-fonds Manchons d'ancrage

_kAVERTISSE ME NT - Cet

appareil menager doit 6tre bien mis a la terre,

• L'installateur est responsable d'une bonne

installation et la garantie ne couvre aucune

panne due a une mauvaise installation.

OUTmLSDONT VOUS AUREZ BESOtN

Tourne-ecrou de 1/4 po

Niveau

I

PIECES COMPRISES

Vis

Soutien anti-

Entretoise arriere

2 vis

31-10641-1 03-07 JR 21

basculement

Tournevis a t6te

Phillips Cle a tube

Tournevis a lame

plate

Metre

Lunettes de securite

Cle ou tenailles (pour

un ecrou de 1-7/16 po)

Perceuse

Page 22

Instructions d'instamlation

CONSEILS DE SI CURITE IMPORTANTS

POUR VOTRE SECURJTE :

AAVERTISSEIVIENT -

Si vous ne suivez pas exactement lee

reneeignements contenue dane ce manuem,

voue pouvez occaeionner un incendie, une

e×pmosion ou une fuite de gaz qui peut causer

dee dommagee mat_,riele, dee bteeeuree

corporetlee ou la mort.

Ne conaervez ou n'uaez ]amaia d'eaaenee

ou d'autre liquide ou vapeur inflammable

pro×imite de eet appareil ou de tout autre

appareH menager!

QUE FAJRE SJ VOUS

SENTEZ LE GAZ :

e N'essayez jamais d'ai[umer un appareii

menager. Ne touchez aucun commutateur

eiectrique; n'utilisez aucun tet6phone dans

votre b&t[ment.

Appelez imm6diatement votre fournisseur

de gaz en utiiisant te tet6phone d'un vo[sin.

Suivez tes instructions du fournisseur de gaz.

e Si vous n'arrivez pas a communiquer avec

votre fournisseur de gaz, appelez tes

pompiers.

L'installation et le service doivent 6tre faits

par un instalhteur qualifie, une agence de

service ou votre fournisseur de gaz.

La conception de cette cuisiniere a

ete certifiee par les UNDERWRITERS

LABORATORIES du Canada. Vous trouverez

des precautions de securite dans votre

Manuel du proprietaire. Lisez-les avec soin.

• L'installation de cette cuisiniere doit

se conformer aux codes Iocaux ou, en

I'absence de codes Iocaux, au National Fuel

Gas Code, ANSI Z223.1--Derniere edition.

• Assurez-vous que votre cuisiniere soit bien

installee par un installateur qualifie ou un

technicien du service.

• Pour eviter de vous pencher sur les

brQleurs de surface, vous devez eviter de

placer au-dessus des brQleurs une armoire

de rangement.

• N'installez jamais votre appareil pres d'une

porte dormant sur I'exterieur ou dans tout

endroit ou un courant d'air peut g_ner son

usage.

AVERTISSEMENT- Pour

votre securite personnelle, enlevez le fusible

de votre maison ou debranchez le disjoncteur

de courant avant de commencer votre

installation. Si vous ne le faites pas, vous

pouvez occasionner des blessures serieuses

ou m_me la mort.

Vous devez respecter toutes les dimensions

d'espacement libre pour utiliser votre

cuisiniere en toute securite. Vous pouvez

debrancher I'electricite de votre cuisiniere

la prise sans bouger la cuisiniere si la prise

se trouve dans sa position preferee (enlevez

le tiroir du bas).

Pour reduire le risque de brQlures ou

d'incendie quand vous vous penchez sur

des elements de surface chauds, vous devez

eviter de placer une armoire de rangement

au-dessus de la table de cuisson. Si vous

devez placer une armoire de rangement au-

dessus de la table de cuisson, vous pouvez

reduire ce risque en installant une hotte de

ventilation qui avance au moins de 12,7 cm

(5 po) par rapport a I'avant de I'armoire. Les

armoires installees au-dessus d'une table de

cuisson ne peuvent depasser 33 cm (13 po)

de largeur.

Assurez-vous que votre appareil soit bien

installe et mis a la terre par un technicien

qualifie.

22

Page 23

mnstructions d'instamiation

MI CANISME ANTI-BASCULANT

AVERTISSEMENT - Pourreduire

le risque de basculement, vous devez fixer

votre appareil en installant bien le support

anti-basculement livre avec votre appareil.

Si le mecanisme anti-basculant fourni avec la

cuisiniere ne convient pas a cette application,

utilisez le mecanisme anti-basculement

universel WB2X7909. Sautez les etapes 4,

19 et 21.

Pour verifier si ce support est bien installe

et engage, faites doucement basculer la

cuisiniere vers I'avant. Le support anti-

basculement doit s'engager et emp_cher la

cuisiniere de basculer.

-&AVERTISSEMENT-

• Toutes les cuisinieres peuvent

basculer

• Cela peut occasionner des

blessures corporelles

• Installez le support anti-

basculant livre avec votre

cuisiniere

• Consultez les instructions

d'installation

Si vous tirez la cuisiniere pour I'ecarter du

mur pour quelque raison que ce soit, assurez-

vous que le support anti-basculement

s'engage quand vous repoussez la cuisiniere

contre lemur.

EXIGENCES ELECTRIQUES

Cet appareil menager doit 6tre livre avec le

bon voltage et la bonne frequence et branche

son propre circuit de derivation bien mis

la terre, protege par un disjoncteur ou un

fusible ayant I'amperage recommande dans

le tableau ci-dessous.

TAILLE DE DISJONCTEUR OU DE FUSIBLE

240V 40 Am ps

208V 40 Amps

RENIARQUE : Verifiez les codes Iocaux pour

trouver la taille de disjoncteur requise.

La plaque signaletique est situee au dessus

du tiroir de rangement sous le chassis de

la cuisiniere.

Emplacement

de la plaque

signaletique

Nous vous recommandons de faire brancher

le c_blage electrique et la fiche de votre

cuisiniere par un electricien qualifi& Apres

I'installation, demandez a I'electricien de vous

montrer I'emplacement de votre coupe-circuit

principal.

Demandez a votre entreprise de services

publics les codes electriques en vigueur

dans votre region. En ne c_blant pas votre

cuisiniere conformement aux codes en

vigueur, vous provoquez une situation

dangereuse. En I'absence de codes, vous

devez c_bler et isoler votre cuisiniere

conformement aux exigences du Canadian

Electrical Code.

Vous devez utiliser un systeme electrique

uniphase, a trois fils A.C. 208Y/120 volts ou

240/120 volts, 60 Hertz.

23

Page 24

Instructions d'installation

LISTE DE VITRIFICATION AVANT L'INSTALLATION

[] INSPECTEZ L'EMPLACEMENT

OU VOUS ALLEZ INSTALLER

Consultez la section d'autre construction

pour les installations suivantes qui ne sont

pas normales.

[] L'ouverture du comptoir se poursuit

jusqu'au mur :

Trousse de remplissage (fournie avec

la cuisiniere) (consultez les installations

d'instruction a la page 37) ou

Dosseret (trousse JXS32XX ou

JXS37XX).

[] La hauteur du compteur est plus

grande que 93,4 cm (36-3/4 po):

Garniture du bas a glisser (trousse

JXS56XX).

[] Un c6te n'est pas enferme dans une

armoire :

C6te d'appareil (trousse JXS77XX).

[] Installation dans un ilot :

Pour obtenir une bonne installation, la

surface du haut du comptoir doit 8tre

horizontale et plate (au mSme niveau)

des trois c6tes qui sont adjacents a la

table de cuisson de la cuisiniere. Vous

devez bien ajuster la surface du haut

afin de bien I'aplatir, autrement il se

produira des ecarts entre le comptoir et

la table de cuisson de votre cuisiniere.

En poussant la table de cuisson pour

aller dans le comptoir, vous pouvez

occasionner des ecarts excessifs.

Pour obtenir les trousses :

a. Visitez le site Web GE (voir page 21)

b. Appelez le centre de reponse GE

(voir page 21)

c. Appelez le vendeur

_-I AMENEZ LA CUISINIERE A

L'INTI_RIEUR EN FACE DE

L'OUVERTURE DE L'ARMOIRE

N'utilisez pas de chariot a main pour

transporter la cuisiniere sans emballage.

[] PROTI_GEZ LE PLANCHER DE

LA CUISINE

Aplatissez et placez un morceau de carton

d'emballage devant I'emplacement ou vous

allez installer votre cuisiniere pour proteger

le plancher.

_-I FAITES BASCULER AVEC SOIN

LA CUISINII=RE POUR AVOIR

ACCES AUX PIEDS

D'INCLINAISON DE LA

CUlSINIERE

Utilisez une cle ajustable pour visser les

pieds d'inclinaison afin de mettre a niveau

le soutien avec le haut du comptoir.

24

Page 25

mnstructions d'instamiation

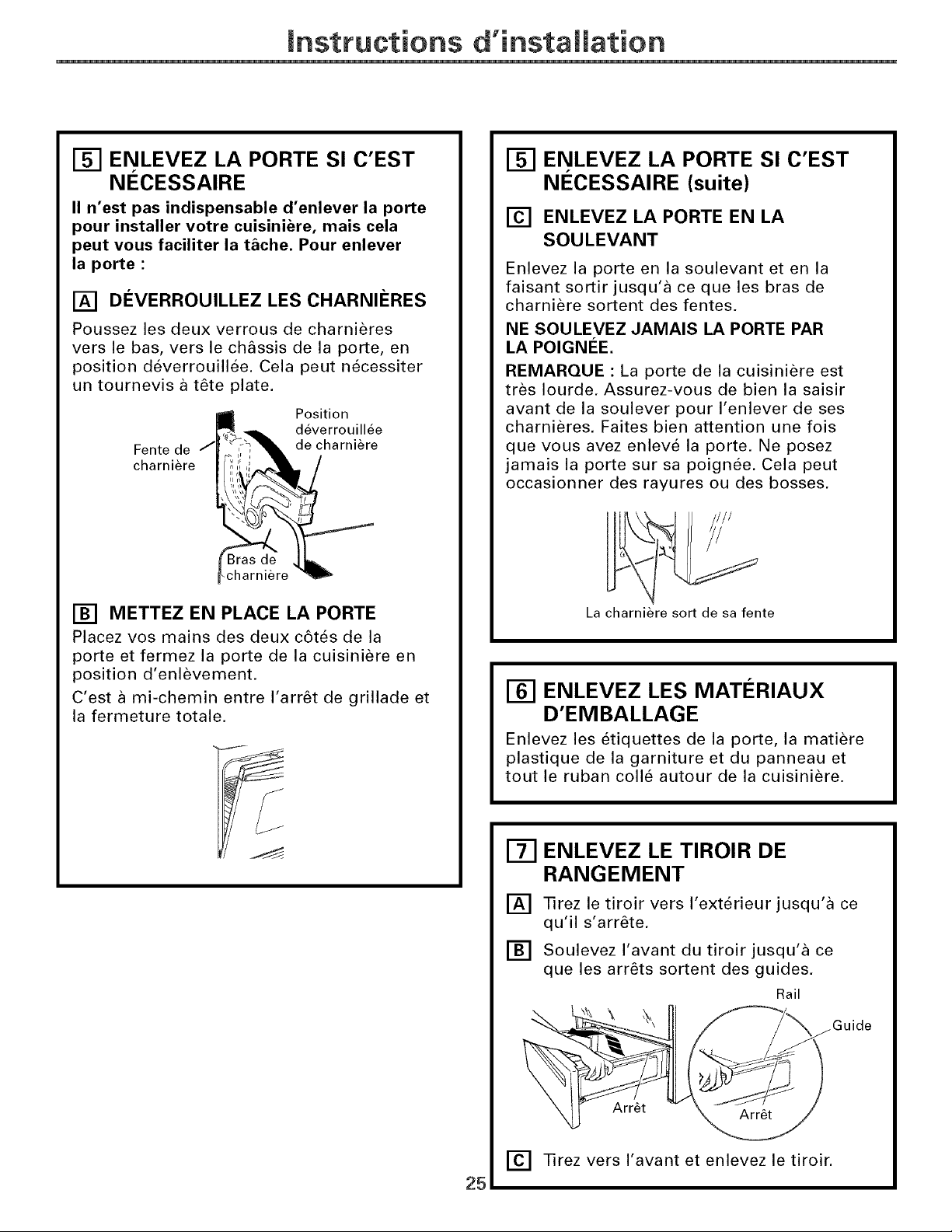

I-_ ENLEVEZ LA PORTE Sl C'EST

NI_CESSAIRE

II n'est pas indispensable d'enlever la porte

pour installer votre cuisiniere, mais cela

peut vous faciliter la t&che. Pour enlever

la porte :

[] DI_VERROUILLEZ LES CHARNIERES

Poussez les deux verrous de charnieres

vers le bas, vers le chassis de la porte, en

position deverrouill6e. Cela peut necessiter

un tournevis a t6te plate.

Position

deverrouillee

Fente de

charniere

,charniere

[] METTEZ EN PLACE LA PORTE

Placez vos mains des deux c6t6s de la

porte et fermez la porte de la cuisiniere en

position d'enlevement.

C'est a mi-chemin entre I'arr6t de grillade et

la fermeture totale.

de charniere

[-_ ENLEVEZ LA PORTE Sl C'EST

NI_CESSAIRE (suite)

[] ENLEVEZ LA PORTE EN LA

SOULEVANT

Enlevez la porte en la soulevant et en la

faisant sortir jusqu'a ce que les bras de

charniere sortent des fentes.

NE SOULEVEZ JAMAIS LA PORTE PAR

LA POIGNI_E.

REMARQUE : La porte de la cuisiniere est

tres Iourde. Assurez-vous de bien la saisir

avant de la soulever pour I'enlever de ses

charnieres. Faites bien attention une fois

que vous avez enleve la porte. Ne posez

jamais la porte sur sa poignee. Cela peut

occasionner des rayures ou des bosses.

La charniere sort de sa fente

[_ ENLEVEZ LES IVIATI_RIAUX

D'EMBALLAGE

Enlevez les etiquettes de la porte, la matiere

plastique de la garniture et du panneau et

tout le ruban colle autour de la cuisiniere.

[-_ ENLEVEZ LE TIROIR DE

RANGEMENT

[] Tirez le tiroir vers I'exterieur jusqu'a ce

qu'il s'arr6te.

[] Soulevez I'avant du tiroir jusqu'a ce

que les arr6ts sortent des guides.

Arr6t

[] Tirez vers I'avant et enlevez le tiroir.

25

Rail

Guide

Page 26

Instructions d'installation

LISTE DE VITRIFICATION AVANT L'INSTALLATION (SUITE)

I-_ DI_COUPE AVANT [.'INSTALLATION

ET DI_GAGEMENTREQUIS

Si les armoires sont placees a moins de

76,2 cm (30 po) au-dessus de la cuisiniere,

consultez la section d'autre construction,

etape 25D, a la page 38.

Les rev6tements de mur, les comptoirs et

les armoires autour de la cuisiniere doivent

supporter la chaleur (pouvant atteindre 194°F

[90°C]) produite par la cuisiniere.

Profondeur totale

70 cm (27-1/2")-_j

79,4 cm (31-1/4")

7,3 cm

Depuis la surface

avant du comptoir

r-_ iNSTALLATiON NORMALE

Si Ja construction de votre armoire ne peut

fournir une surface plate de 6 mm (1/4 po}

t'ardere de J'ouverture du comptoir, envisagez

changer te comptoir pour obtenir cette

dimension. ConsuJtez ta section d'autre

construction.

REMARQUE : Vous devez conserver un espace

tibre minimum de 1-1/2 po entre t'ar6te arriere

de Ja surface de cuisson et le mur arriere au-

dessus de ta surface de cuisson.

Surface plate

Arriere

Avant

91,4 cm (36")

6 mm (1/4")

Plancher

Suivez les instructions

emballees avec I'autre 76 2 cm

appareil menager _ (76"_ r_il/n __

24,1 cm (9,5") i'_ _

min depuis -----

i__x__li _-r-_---_

Pour une bonne _ 2 cm (30") min

installation, ces depuis la table de

surfaces doivent cuisson jusqu'au

6tre plates et bas de I'armoire

horizontales 58,9 superieure

90,8 cm

(35=3/4 ") a 92,7 prise, la prise

cm (36=1/2 ") electrique et le

depuis le

plancher

jusqu'au

comptoir

cm (3")

7,6 J "_"_

38,1 cm

76 cm (29=15/16 ") min

76,5 cm (30=1/16 ") max

Endroit acceptable

pour la conduite de

gaz et la prise

.......... _-- min de

_33_m (13") verticale

max de depuis le bas

profondeur des armoires

_--- _ adjacentes

63,5 cm (25") Profondeur de

comptoir (normal)

comptoir jusqu'en

saillante pour liberer

electrique

panneau de contr61e

45,7 cm (18")

T distance

superieures

3,2 cm (1-1/4")

min depuis le

haut du tiroir

Rabotez Par6te

79,1 cm (31=1/8 ")

d'epaisseur de

14 mm

(9/16")

Plat min_

....... ]

...... Mur _

6 mm (1/4") 63,5 cm

Plat min. (25'9

Typ quement

58,9 cm (23-3/16") 14 mm

| (9/16")

i

i

i

_ Plat min.

76 cm a 76,4 cm

(29-15/16"-30-1/16")

Coupe douce

26

Page 27

Instructions d'installation

BRANCHEMENT DU GAZ

BRANCHEMENT

, 1,7,,,

38,1

30,5 cm_

[] Installez le robinet d'arr_t manuel dans la

conduite d'alimentation de gaz dans un

emplacement facile d'acces.

[] Trouvez comment couper I'alimentation

de gaz a la cuisiniere, et ou se trouve le

robinet d'alimentation.

[] Coupez I'alimentation de gaz avant

d'enlever une vieille cuisiniere. Laissez-la

coupee jusqu'a la fin du branchement de

la nouvelle cuisiniere.

[] Comme les conduites rigides limitent le

deplacement de la cuisiniere, nous vous

recommandons I'utilisation d'un raccord

flexible en metal certifie par I'ACNOR.

AVERTISSEMENT: N'utilisez

jamais un vieux raccord flexible. L'utilisation

d'un vieux raccord flexible peut occasionner

des fuites de gaz et des blessures corporelles.

Utilisez toujours un raccord flexible neuf pour

installer un appareil menager a gaz.

Approvisionnement de

au brQleur de haut

[_] BRANCHEMENT (suite}

[] tnstaJJez J'adaptateur evas6 de 13 mm

(1/2 po) au coude NPT de 13 mm (1,/2 po)

sur le regulateur de pression.

[] Branchez te raccord flexible d'appareil

menager a t'adapteur.

[] Mettez la cuisiniere dans son

emplacement approximatif et branchez

te raccord flexible a la conduite

d'approvisionnement de gaz avec

te bon adaptateur 6vas&

Robinet d'arr6t Raccord flexible

T f_-X Regul.ateur de

Max ,, _A-_"__\ presslon

Conduite / provenance _. _ [

dapprovisionnement delarue _--J

de gaz 90 °

[] Pour empScher les fuites de gaz, mettez

un agent d'etanch6it6 pour joint de tuyau

ou un ruban Teflon ¢)sur tous tes fitetages

mSles. REMARQUE : Assurez=vous que

t'agent d'etanch6it6 ou te ruban soient

compatible avec le gaz naturel et te gaz

de petrole tiquefi&

[] Quand vous avez termine de faire les

branchements, assurez vous que tous les

boutons de la cuisiniere soient en position

OFF (arr6t) avant d'ouvrir te robinet

d'approvisionnement de gaz principal.

_ 6gulateur de

REMARQUE : pour visser sur

le regulateur de pression,

tenez fermement I'entree de

gaz avec une cle anglaise.

pression vue

de devant la

--J cuisiniere

AVERTISSEMENT: N'utilisez

jamais une flamme pour verifier s'il y a une

fuite de gaz. Utilisez un deteeteur de fuite

liquide au niveau de tousles ioints et les

raeeords pour verifier les fuites darts le

systeme.

27

Page 28

mnstructions d'instamiation

BRANCHEMENT DE L'I LECTRICITI

La cuisiniere est envoyee avec

un cordon d'alimentation

4 ills. Si votre prise ressemble

celle indiquee, passez

I'etape 19 et continuez.

INSTALLATION DU CORDON

[]

NEMA 14-50R

4-fils

D'ALIMENTATION ET DE LA

BRIDE DE CORDON

[] Enlevez le

couvercle des ills

(situe derriere la

cuisiniere) en

devissant les

2 vis, a I'aide d'un _=

tourne-ecrou de Hi/ des fils

1/4 po.

Ne jetez pas ces vis.

[] Enlevez la rondelle defon£able (1-3/8 po)

situee darts le soutien directement au-

dessous de la bofte de connexion. Pour

enlever la rondelle defon£able, utilisez

des tenailles pour la plier afin de I'oter

du soutien et tordez-la jusqu'a ce que

vous I'ayez enlevee.

Rondelle defonq, able

dans le soutien

Couvercle

Bofte de

connexion

(son aspect

peut varier)

Rondelle

defonq, a hie

enlevee

Pour seulement les installations avec

[]

cordon d'alimentation (suivez I'etape

suivante si vous utilisez un conduit),

assemblez la bride de cordon dans le

trou, inserez le cordon d'alimentation

dans la bride de cordon et serrez.

Laissez suffisamment de jeu pour

joindre facilement les rondelles de

borne du cordon aux bornes de la

bofte de connexion. Si la bride de

cordon est ailee et il y a des taquets

ses extremites, vous pouvez les enlever

pour obtenir une meilleure installation.

REMARQUE : N'installez jamais le

cordon d'alimentation sans bride de

cordon. Vous devez installer le support

de la bride de cordon avant de remettre

le couvercle des fils a I'arriere de la

cuisiniere.

Bri__-

d'alimentation Soutien

Pour seulement les installations avec

[]

conduit, achetez un raccord a pression

qui corresponde au diametre de votre

conduit et assemblez-le dans le trou.

Inserez le conduit dans le raccord

pression et serrez-le. Laissez

suffisamment de jeu pour joindre

facilement les ills a la bofte de connexion.

REMARQUE : N'installez jamais le

conduit sans raccord a pression. Vous

devez installer le raccord a pression

avant de remettre le couvercle des ills

I'arriere de la cuisiniere.

Bofte de

nnexion

de

connexion

28

Raccord

pression

Conduit

Soutien

Page 29

mnstructions d'instamiation

r_] NOUVELLE CONSTRUCTION

ET CiRCUiT DE DC:RJVATJON A

QUATRE CONDUCTEURS

Toutes lee nouvelles

constructions, lee maisons 4-fils

mobiles, lee v@hicules reereatife

et lee installations oQ lee codes

loeaux ne permettent pas la raise

la terre par l'intermediaire du

neutre doivent utiliser le cordon

4 file fourni

NEMA 14-50R

IOl

r_] POUR UNE CONSTRUCTmON

EXmSTANTE,VOUS POUVEZ

UTmUSERUN CORDON FLEXIBLE

A TROIS FILS

Suivez lee instructions

de m'etape 14 si vous avez

besoin d'un cordon a 3 file •

208/240 40 Amp

Cordon triphase

r_-z-4]INSTALLATION AVEC CORDON

D'ALIMENTATION A 3 FILS

AVERTISSEMENT :vous

devez brancher le fil neutre ou de mise

la terre du cordon d'alimentation a la

borne neutre situee au centre de la boite

de connexion. Vous devez brancher lee

ills de courant aux bornes situees en bas

gauche et a droite de la boite de

connexion.

[] Enlevez lee trois vie des bornes du bas

de la bofte de connexion. Inserez lee

3 vie des bornes dane lee rondelles

de borne du cordon d'alimentation et

dane lee bornes du bas de la bofte de

connexion. Assurez-vous que le fil du

centre (blanc/neutre) soit branche en bas

au centre de la bofte de connexion. Serrez

fort lee vie dane la bofte de connexion.

N'ENLEVEZ JAMAIS la connexion a la

tresse de masse.

AVERTISSEMENT •Avant

de mettre le courant a votre appareil,

assurez-vous que la tresse de masse soit

branchee a la borne de connexion et a la

borne neutre.

Boite de

connexion

(son aspect

_/_ut varier)

l___. _ Borne

Plaque

de mise

la terre

Cordon

d'alimentation

[] Passez a I'etape 18 et continuez votre

installation.

_ neutre

_ '_"---_.. Tresse de

29

masse

Page 30

Instructions d'installation

BRANCHEMENT DE L'I LECTRICITI (SUITE)

[] INSTALLATION AVEC CORDON

D'ALIMENTATION A 4 FILS

-&AVERTISSEMENT :vous

devez brancher le fil neutre du circuit

d'alimentation electrique a la borne

neutre situee en has au centre de la

boite de connexion. Vous devez

brancher les fils de courant aux bornes

situees en bas a gauche et a droite

de la boite de connexion. Vous devez

brancher le fil de mise a la terre au

ch&ssis de la cuisiniere avec la plaque

de mise a la terre et la vis de mise

la terre.

[] Enlevez les trois vis des bornes du bas

de la boite de connexion. Enlevez la vis

de mise a la terre et la plaque de mise

la terre et mettez-les de c6t&

[] Coupez et jetez la tresse de masse. NE

JETEZ AUCUNE VIS.

[] Inserez la vis de mise a la terre dans

la rondelle de borne du fil de mise a la

terre du cordon d'alimentation, puis

inserez-la dans la plaque de mise a la

terre et darts le chassis de la cuisiniere.

[] Inserez les 3 vis de borne (enlevees

plus t6t) dans les rondelles de borne

du cordon d'alimentation et dans les

bornes du bas de la bofte de connexion.

Assurez-vous que le fil du centre

(blanc/neutre) soit branche en bas au

centre de la bofte de connexion. Serrez

fort les vis darts la bofte de connexion.

INSTALLATION AVEC CONDUIT

A 3 FILS

Desserrez les 3 vis des bornes situees

[]

en bas de la bofte de connexion.

Inserez le bout du fil denude du centre

(blanc/neutre) dans I'ouverture situee en

bas au centre de la bofte de connexion.

Sur certains modeles, vous devez faire

passer le fil par I'ouverture de la tresse

de masse, puis par I'ouverture situee en

bas au centre de la boite de connexion.

Inserez les deux bouts de ills denudes

de c6te dans les ouvertures situees en

bas a gauche eta droite de la boite de

connexion. Serrez les vis jusqu'a ce que

le fil tienne bien (35 a 50 po./Ibs.). Ne

serrez pas trop fort la vis, car vous

risquez d'endommager les ills.

NOTE : RL D'ALUMINlUM :

Vous pouvez utiliser du fil d'aluminium

de construction, mais pour pouvoir le

brancher, vous devez utiliser du fil

d'aluminium du bon amperage et

voltage. Branchez les ills en suivant les

etapes 16 ou 17, selon le hombre de ills.

Boite de

connexion

Bout

du fil

[] Passez a I'etape 18 et continuez votre

installation.

3O

Patte

de fixation

Les fils utilises, I'emplacement et

I'isolement des epissures, etc. doivent

se conformer aux bonnes pratiques

d'installation des fils et aux codes

Iocaux.

Passez a I'etape 18 et continuez votre

[]

installation.

Page 31

instructions d'installation

r_] INSTALLATION AVEC CONDUIT

A 4 RLS

Desserrez les 3 vis des bornes situ6es en

[]

bas de ta bofte de connexion. Enlevez ta

vis de mise a la terre et Ja plaque de

mise a ta terre et mettez-les de c6t&

Coupez et jetez Ja tresse de masse.

NE JETEZ AUCUNE VlS.

tns@ez le bout du fil denud6 entre te

[]

chassis de ta cuisiniere et ta plaque de

mise a la terre (enievee plus t6t) et

fixez le avec ta vis de mise a ta terre

(enlevee plus t6t). lnserez le bout du fil

denud6 (blanc/neutre) dans Vouverture

situee en bas au centre de ta boTte de

connexion, lnserez les deux bouts de fits

denud6s de c6te darts les ouvertures

situees en bas a gauche et a droite de la

boke de connexion. Serrez les vis jusqu'a

ce que le fii tienne bien (35 a 50 po./tbs.).

Ne serrez pas trop fort ta vis, car vous

risquez d'endommager tes fits.

[_] REMETTEZ EN PLACE LE

COUVERCLE DE FILS

NOTE : Quand vous remettez en place le

couvercle de ills, assurez-vous de ne pas

pincer les ills entre le couvercle et le boitier

des fils.

NOTE : Vous devez fixer le collier de mise

la terre quand vous utilisez le cordon a 3 ills.

• Les extremites doivent _tre des bornes

en boucle ou des bornes embrochables

ouvertes.

• Sur certains modeles, vous pouvez

brancher un condensateur de filtrage entre

les ills de connexion noirs et de mise a la

terre dans le bloc de connexion. N'enlevez

pas le condensateur.

\

connexion

Tresse de masse

- . /"_'_LF_(_h Plaque de

Boite ae- II,J_=_l(/,_H _"__l_ ,_r_tJ • •

connexion (f,l_Y)_'_!-&/¢_1_l_1 mlse a la .

Bouts IVll'll/ tit,it_ _ I111.1_..-_ la terre a la

de fil ---------t ,'_,_ A-_-'_- cu s n ere)

Vis de ,'l

miseala I : ,__-J_t.LJ : 11 k___

terre _ I / /-?(r&/'_il_Y l .--i I1 I

"- tl_,_lJ.,,O_i_J_ terre (riqlse a

_Patte de

I \Tr_sse de masse

.... \Borne _ ou

neutre

O "_'

I -- I "fixation

[] Passez a t'etape 18.

31

Page 32

Instructions d'installation

INSTALLATION DE LA CUISINII RE

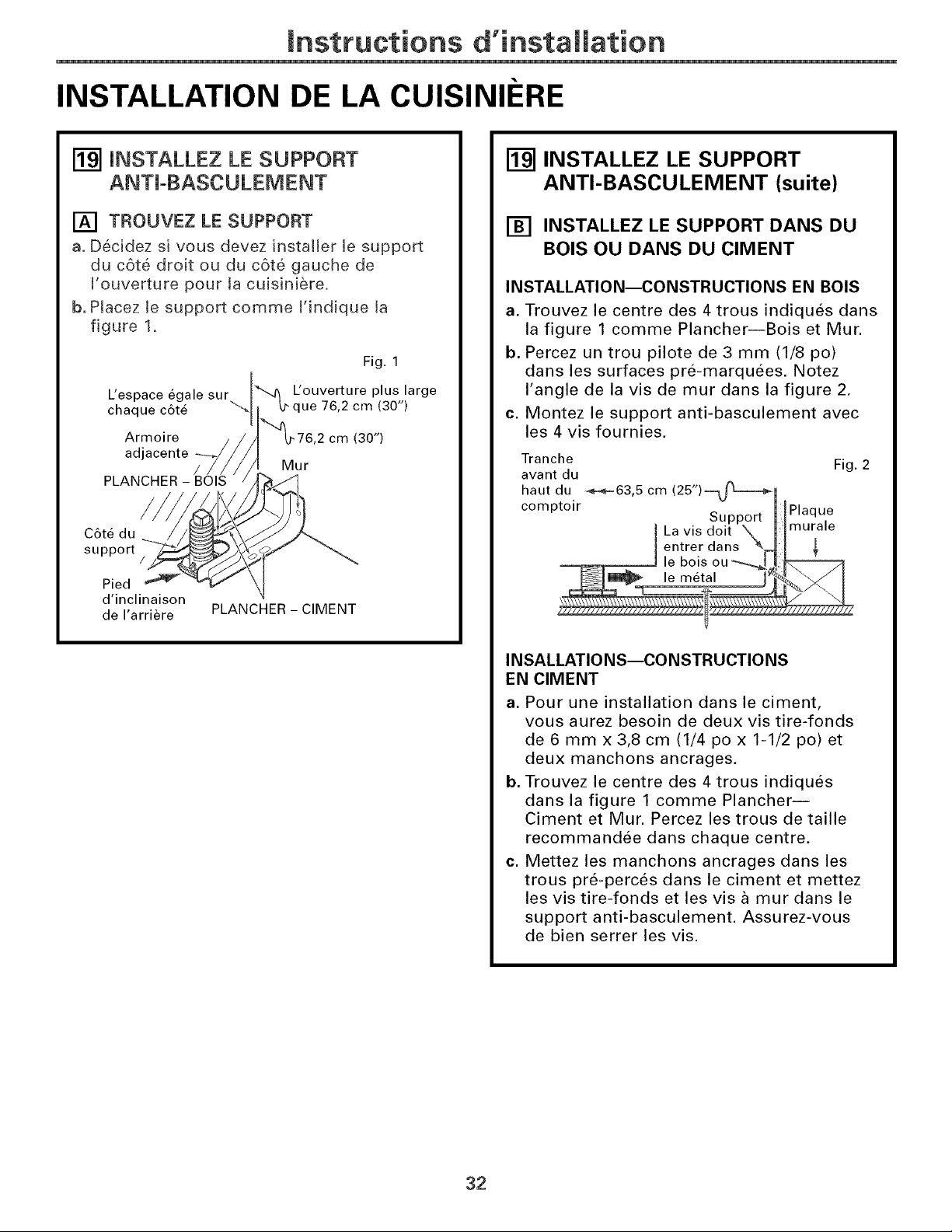

[] JNSTALLEZ LE SUPPORT

ANTJ-BASCULEMENT

[] TROUVEZ LE SUPPORT

a. D6cidez si vous devez installer te support

du c6te droit ou du c6te gauche de

t'ouverture pour ta cuisini6re.

b. Placez le support comme tqndique ta

figure 1.

Fig. 1

L'espace egale sur

chaque c6te

Armoire

adjacente

PLANCHER - BOIS ,

d'inclinaison

de I'arriere

/

PLANCHER - CIMENT

L'ouverture plus large

ue 76,2 cm (30")

2 cm (30")

Mur

INSTALLEZ LE SUPPORT

ANTI-BASCULEMENT (suite)

[] INSTALLEZ LE SUPPORT DANS DU

BOIS OU DANS DU ClMENT

INSTALLATION--CONSTRUCTIONS EN BOIS

a. Trouvez le centre des 4 trous indiques dans

la figure 1 comme Plancher--Bois et Mur.

b. Percez un trou pilote de 3 mm (1/8 po)

dans les surfaces pre-marquees. Notez

I'angle de la vis de mur dans la figure 2,

c. Montez le support anti-basculement avec

les 4 vis fournies,

Tranche Fig.

avant du

haut du _-63,5 cm (25")-_----_

comptoir £ ...... I IPlaque

I La vis do_['"_" llmurale

entrer dans _Jl Jf

,eboiso.

INSALLATIONS--CONSTRUCTIONS

EN ClMENT

a. Pour une installation dans le ciment,

vous aurez besoin de deux vis tire-fonds

de 6 mm x 3,8 cm (1/4 pox 1-1/2 po) et

deux manchons ancrages.

b. Trouvez le centre des 4 trous indiques

dans la figure 1 comme Plancher--

Ciment et Mur. Percez les trous de taille

recommandee dans chaque centre.

c. Mettez les manchons ancrages dans les

trous pre-perces dans le ciment et mettez

les vis tire-fonds et les visa mur dans le

support anti-basculement. Assurez-vous

de bien serrer les vis.

32

Page 33

instructions d'installation

FAJTES GUSSER LA CUJSJNJF:RE

[]

DANS L'OUVERTURE

PJacez la cuisiniere en face de Fouverture

[]

de l'armoire.

Assurez-vous que le support qui

[]

surplombe le comptoir libere le comptoir.

Si necessaire, soulevez l'appareil en

descendant tes pieds d'inclinaison.

Poussez tout en soutevant Ja cuisiniere

[]

dans t'ouverture, jusqu'a ce que la

cuisiniere se trouve a 5,1 cm (2 po)

d'entrer dans te soutien anti-basculant.

[]

Enlevez ta garniture protectrice du c6te

(s'it yen a une).

/k Faide de la cJe anglaise ou des

[]

tenailles, vissez avec soin ta vis du pied

d'inclinaison de t'arriere jusqu'a ce que

te surplomb repose sur le comptoir.

Cle anglaise

ou tenailles

FAITES GLISSER LA CUISINII_RE

DANS L'OUVERTURE (suite)

[] Branchez le cordon de la cuisiniere dans le

receptacle. Placez le cordon a I'arriere de la

cuisiniere de maniere ace qu'il ne touche

pas le tiroir ou ne change pas de place

cause du tiroir.

Placez le cordon

de la cuisiniere de

maniere ace qu'il ne

///l__//////_////////toucheH_pas le tiroir__

\

/ I /

\ //

\

/11

/////

/ \

j

/ \

j _

\

[] VITRIFICATION FINALE DU

SUPPORT ANTI-BASCULEMENT

Quand I'installation est terminee et la cuisiniere

est en place, verifiez pour vous assurer que le

pied d'inclinaison arriere est bien entre dans la

fente du support anti-basculement.

[] Vissez avec soin tes deux pieds

dqnclinaison de devant (comme dans

t'etape E) jusqu'a ce que te surplomb

touche te comptoir.

[] Poussez avec soin la cuisiniere darts

t'ouverture jusqu'a ce que le comptoir

entre darts te panneau de contr6te. Le

surptomb de le table de cuisson arriere

doit couvrir t'ouverture.

, Comptoir

Assurez-vous que I'ar_te

du comptoir soit bien

alignee au panneau de

contr61e avant.

33

Page 34

Instructions d'installation

INSTALLATION DE LA CUISINII RE (SUITE)

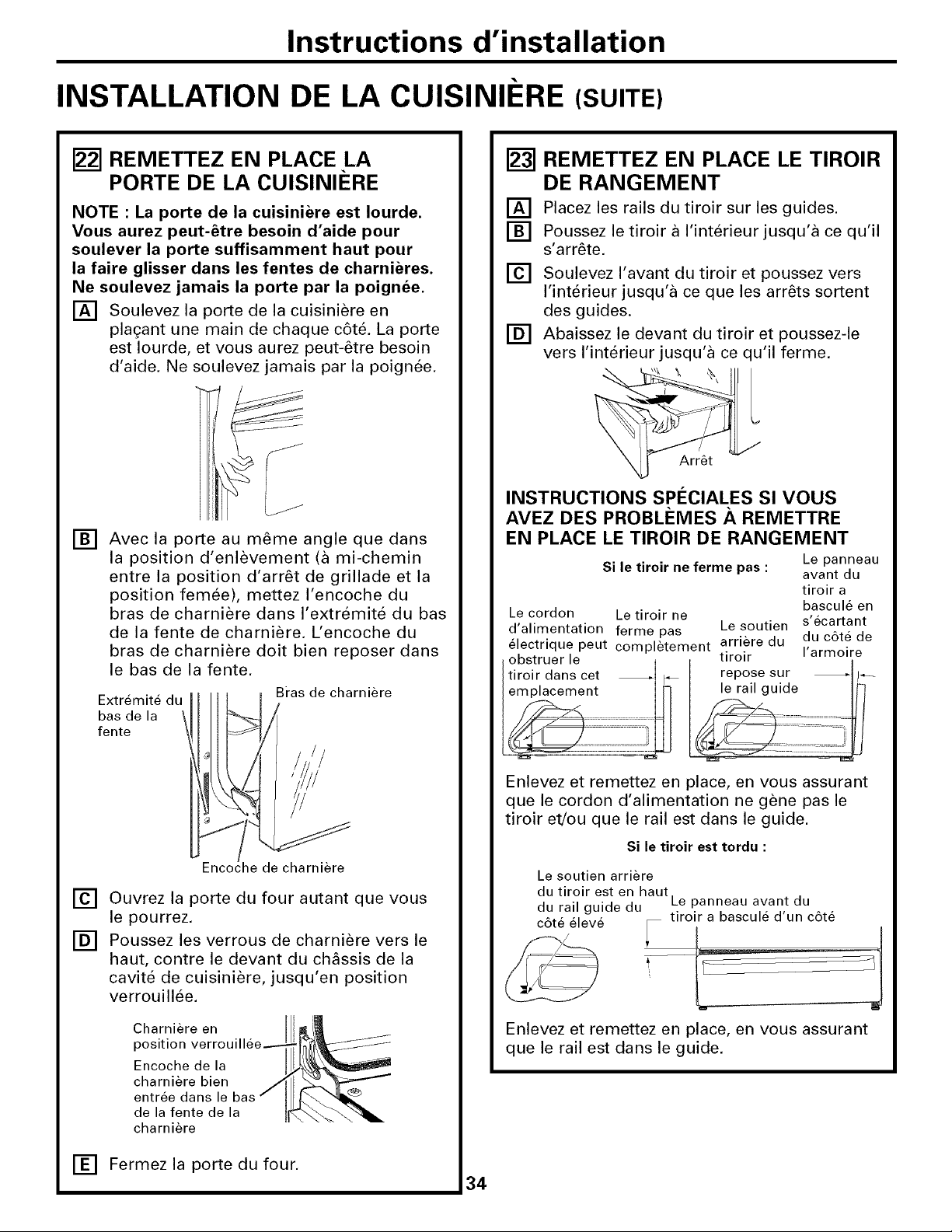

_-_ REMETTEZ EN PLACE LA

PORTE DE LA CUlSINII_RE

NOTE : La porte de la cuisiniere est Iourde.

Vous aurez peut-_tre besoin d'aide pour

soulever la porte suffisamment haut pour

la faire glisser dans les fentes de charnieres.

Ne soulevez jamais la porte par la poignee.

[] Soulevez la porte de la cuisiniere en

pla_:ant une main de chaque c6t& La porte

est Iourde, et vous aurez peut-6tre besoin

d'aide. Ne soulevez jamais par la poignee.

[]

Avec la porte au m_me angle que dans

la position d'enlevement (a mi-chemin

entre la position d'arr6t de grillade et la

position femee), mettez I'encoche du

bras de charniere dans I'extremite du bas

de la fente de charniere. L'encoche du

bras de charniere doit bien reposer dans

le bas de la fente.

Extremite du

bas de la

fente

Bras de charniere

REMETTEZ EN PLACE LE TIROIR

[]

DE RANGEMENT

Placez les rails du tiroir sur les guides.

[]

Poussez le tiroir a I'interieur jusqu'a ce qu'il

[]

s'arr_te.

[]

Soulevez I'avant du tiroir et poussez vers

I'interieur jusqu'a ce que les arr_ts sortent

des guides.

[] Abaissez le devant du tiroir et poussez-le

vers I'interieur jusqu'a ce qu'il ferme.

INSTRUCTIONS SPI_CIALES SI VOUS

AVEZ DES PROBLI_MES A REMETTRE

EN PLACE LE TIROIR DE RANGEMENT

Si le tiroir ne ferme pas :

Le cordon Le tiroir ne

d'alimentation ferme pas

electrique peut completement arriere du

obstruer le

tiroir dans cet _I _ repose sur _

I emplacement IN le rail guide I_

Le soutien

tiroir I'armoire

Le panneau

avant du

tiroir a

bascule en

s'ecartant

du c6te de

Enco_he de charniere

[]

Ouvrez la porte du four autant que vous

le pourrez.

Poussez les verrous de charniere vers le

[]

haut, contre le devant du chassis de la

cavite de cuisiniere, jusqu'en position

verrouillee.

Charniere en

position

Encoche de la

charniere bien

entree dans le bas

de la fente de la

charniere

[] Fermez la porte du four.

Enlevez et remettez en place, en vous assurant

que le cordon d'alimentation ne gene pas le

tiroir et/ou que le rail est dans le guide.

Si le tiroir est tordu :

Le soutien arriere

du tiroir est en haut

du rail guide du Le panneau avant du

c6te eleve tiroir a bascule d'un c6te

Enlevez et remettez en place, en vous assurant

que le rail est dans le guide.

34

Page 35

mnstructions d'instamiation

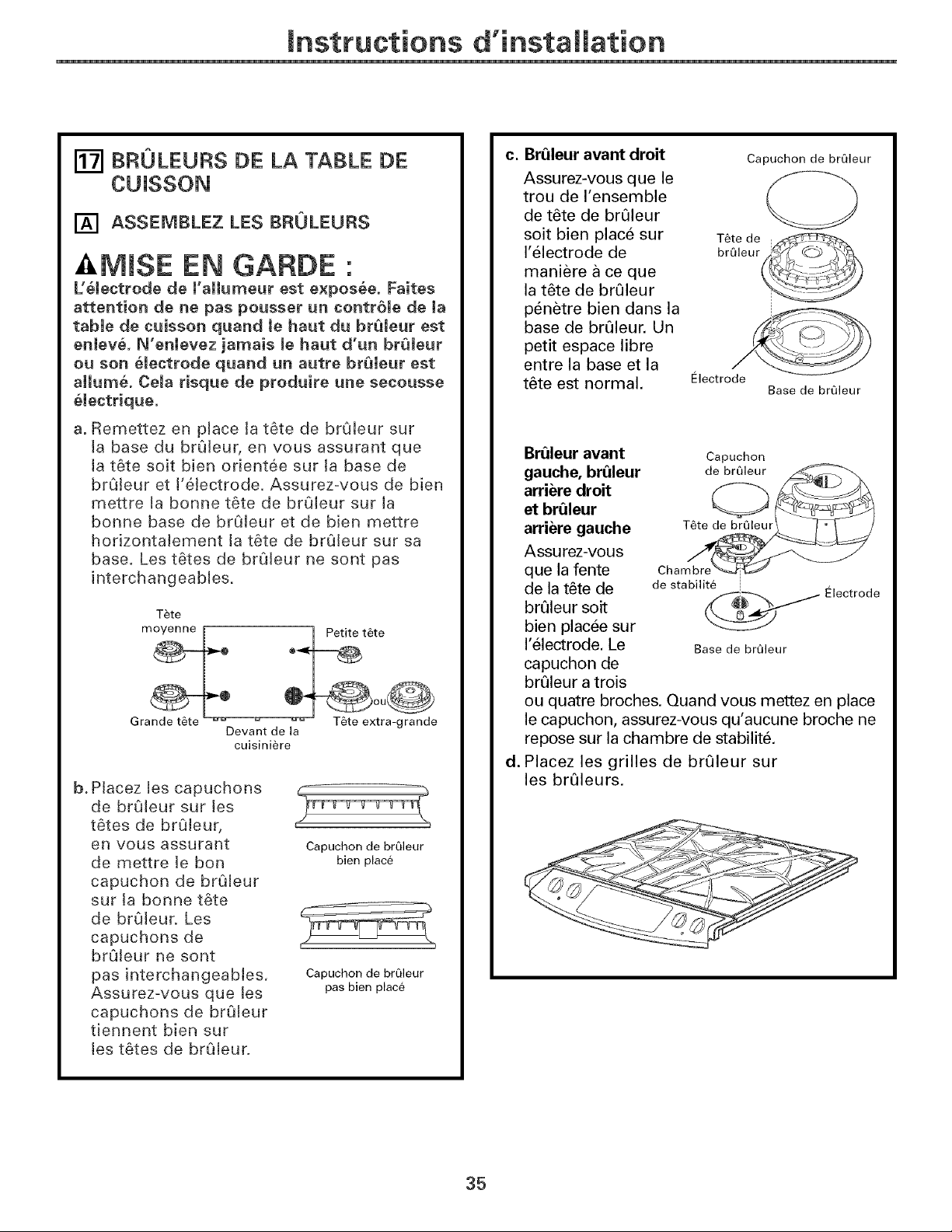

BROLEURS DE LA TABLE DE

[] ASSEMBLEZ LES BROLEURS

MmSE EN GARDE :

L'emectrode de m'allumeur est expoeee. Faitee

attention de ne pas poueser un contr61e de ma

tabte de cuieeon quand le haut du brhteur eet

enJeve. N'enlevez jamais le haut d'un brQJeur

ou son electrode quand un autre btQmeur est

allure& Ceia risque de produire une eecouese

eleetrique.

a. Remettez en pJace la t6te de brQleur sur

ta base du brQleur, en vous assurant que

ta t6te soit bien odentee sur la base de

brQleur et t'61ectrode. Assurez vous de bien

mettre ta bonne t6te de brQleur sur la

bonne base de brQleur et de bien mettre

horizontalement la t6te de brQleur sur sa

base. Les t6tes de brQteur ne sont pas

interchangeables.

T_te

Gra_x_em°genne ® Petite t_te

Devant de la

cuisiniere

b. Placez les capuchons

de brQleur sur tes

tStes de brQleur,

en VOUS assurant

de mettre te bon

capuchon de brOleur

sur ta bonne t6te

de brQJeur. Les

capuchons de

brQleur ne sont

pas interchangeables,

Assurez vous que tes

capuchons de brOteur

tiennent bien sur

tes t6tes de brQteur.

Capuchon de brOleur

bien place

Capuchon de brOleur

pas bien place

Brhleur avant droit

C. Capuchon de brOleur

Assurez-vous que le

trou de I'ensemble

de t_te de brQleur

soit bien place sur

I'electrode de

maniere ace que

T_te de i_ ._t_

brQleur _'_

la t_te de brhleur

penetre bien darts la

base de brhleur. Un

petit espace libre

entre la base et la

t_te est normal.

Brhleur avant

Electrode

Capuchon

Base de brQleur

gauche, brhleur

arriere droit

et brhleur

arriere gauche

Assurez-vous

Cha_ _/

que la fente

de la t_te de

de stabilite i Electrode

brhleur soit

bien placee sur

I'electrode. Le

Base de brQleur

capuchon de

brhleur a trois

ou quatre broches. Quand vous mettez en place

le capuchon, assurez-vous qu'aucune broche ne

repose sur la chambre de stabilit&

d,

Placez les grilles de brhleur sur

les brhleurs,

35

Page 36

Instructions d'installation

INSTALLATION DE LA CUISINII RE (SUITE)

[] VI_RIFIEZ QU'IL N'Y A PAS DE FUlTE

Allumez I'alimentation de gaz et utilisez un

detecteur de fuite liquide (solution savonneuse)

sur tous les joints et les connexions pour

verifier qu'il n'y a pas de fuite. N'utilisez jamais

une flamme vive pour chercher les fuites.

Assurez-vous d'arr_ter toutes les fuites avant

d'allumer les brQleurs.

[] INFORMATION D'ESSAI DE

PRESSlON

La pression d'alimentation maximum permise

pour le regulateur est 14 po W.C. La pression

d'alimentation minimum necessaire pour

verifier le regulateur est 7 po W.C. pour le gaz

naturel et 10 po W.C. pour le gaz de petrole

liquefi&

AVERTISSEMENT :vous

devez debrancher la cuisiniere et son robinet

d'arr_t du systeme de conduite d'alimentation

de gaz pendant tout essai de pression du

systeme d'alimentation de gaz de plus de

1/2 psig (livre par pouce au carte). Vous devez

isoler la cuisiniere du systeme de conduite

d'alimentation de gaz en fermant son robinet

d'arr_t pendant tout essai de pression du

systeme d'alimentation de gaz a des pressions

d'essai egales ou superieures a 1/2 psig.

REMARQUE : 1/2 psig = 13.855 po w.c.

[] VI_RIFIEZ LES ALLUMEURS

Vous devez verifier le fonctionnement des

allumeurs electriques apres avoir verifie

soigneusement I'absence de fuite et apres avoir

branche la table de cuisson a I'alimentation

electrique.

a. Ouvrez I'alimentation de gaz.

b. Poussez et tournez le robinet en position

LITE (allumer).

= Le robinet du brQleur doit s'allumer

quand il y a du gaz dans le brQleur.

• Une fois que le brQleur s'allume, il faut

I'enlever de la position LITE (allumer).

c. Essayez chaque robinet separement jusqu'a

avoir verifie tousles brQleurs.

[] ALLUMAGE DES BRULEURS

Ignition par etincelle de la table de cuisson--

Quand vous mettez le bouton de la table de

cuisson en position LITE (allumer), I'allumeur

etincelle fait une serie d'etincelles electriques

(sons de crepitement) qui allument le br_leur.

Pendant une panne de courant, les br_leurs

n'allumeront pas automatiquement. En cas

d'urgence, vous pouvez allumer un br_leur de

la table de cuisson a I'aide d'une allumette en

suivant les etapes suivantes :

AAVERTISSEMENT : II est

dangereux d'allumer les br_leurs a gaz avec une

allumette. Vous ne devez allumer un br_leur

avec une allumette qu'en cas d'urgence.

a. Allumez une allumette et tenez la flamme

pres du brQleur que vous voulez allumer. Les

allumettes en bois fonctionnent le mieux.

b. Poussez vers I'interieur et tournez

lentement le bouton de contr61e.

Assurez-vous de tourner le bon bouton

pour le brQleur que vous allumez.

REMARQUE : Si le brQleur ne s'allume pas

en cinq secondes, tournez le bouton en

position OFF (arr_t) et attendez cinq

minutes avant de recommencer.

[] FLAMMES DU BRULEUR

Allumez chaque brQleur. Les flammes doivent _tre

bleu sans trace de jaune. Les flammes du brQleur

ne doivent pas scintiller ou s'ecarter du brQleur. La

flamme ne peut pas _tre plus petite que 1/4 po en

reglage le plus bas et ne doit pas 6tre plus grande

que 1-1/2 po en reglage le plus haut.

0,6 ,_3,8 cm BrQleur de table

(1/4 ,_ 1-1/2 po) de cuisson

Vous devez verifier frequemment les br_leurs.

AVERTISSEMENT : sivous

essayez de mesurer la flamme, faites bien

attention, Vous pouvez vous br_ler,

36

Page 37

Instructions d'installation

[] PR[ PARATJON POUR UNE

AUTRE CONSTRUCTION

[] TROUSSE DE REMPLISSAGE DU

HAUT OU TROUSSE D'APPUI Eft[

OPTION

Si l'ouverture s'etend jusqu'au mur, elie

necessitera la trousse de remplissage du haut

(fournie avec la cuisiniere) ou la trousse de

dosseret (JXS32XX ou JXS37XX) pour

remplir ta fente.

NOTE : Si le comptoir est plus grand que

63,5 cm (25 po}, it y aura une fente entre te

dosseret et lemur ou entre ta trousse de

remplissage et temur.

Si le comptoir est infedeur a 63,5 cm (25 po),

it y aura une fente entre le devant du

comptoir et le extr6mites du panneau de

contr61e (voir l'etape 8).

Si vous utilisez la trousse de dosseret

en option, consultez tes instructions de la

trousse de dosseret pour obtenir tes detaits

de t'instattation.

Mur

63,5 cm (25")

Doit &tre

horizontal

Quand la garniture est posee dans la bonne

position, serrez les 2 vis de montage. Le haut

de la garniture doit se trouver au-dessous de

la surface le haut de la table de cuisson pour

emp_cher les casseroles, les poelles et les

ustensiles de cuisine d'endommager les

pieces peintes.

Consultez I'installation normale de la

cuisiniere page 26.

_ Table de

CUlSSOn

Cuisiniere

-_.Remplissage

du haut

(2) #8 Vis

[] POUR UNE INSTALLATION NON

ENCASTREE (EMPLACEMENT EN

EXTREMITE DE L'ARMOIRE)

Quand vous installez la cuisiniere

I'extremite d'une section d'armoire qui

expose le c6te non fini de la cuisiniere,

utilisez la trousse de c6te de cuisiniere

(JXS77XX). Consultez les instructions de la

trousse pour les details de I'installation.

Doit _- _ 76,2 cm (30") _'_ Doit 6tre

6tre I Coupe douce _ plat

plat I_ Doit 6tre horizontal

79,1 cm (31-1/8")

Si vous utilisez la trousse de remplissage,