GE MVAD007MV2AA, MVAD009MV2AA, MVAD012MV2AA, MVAD018MV2AA, MVAD024MV2AA Installation Instructions Manual

Page 1

Installation Instructions

Plenum, Slim Duct Models

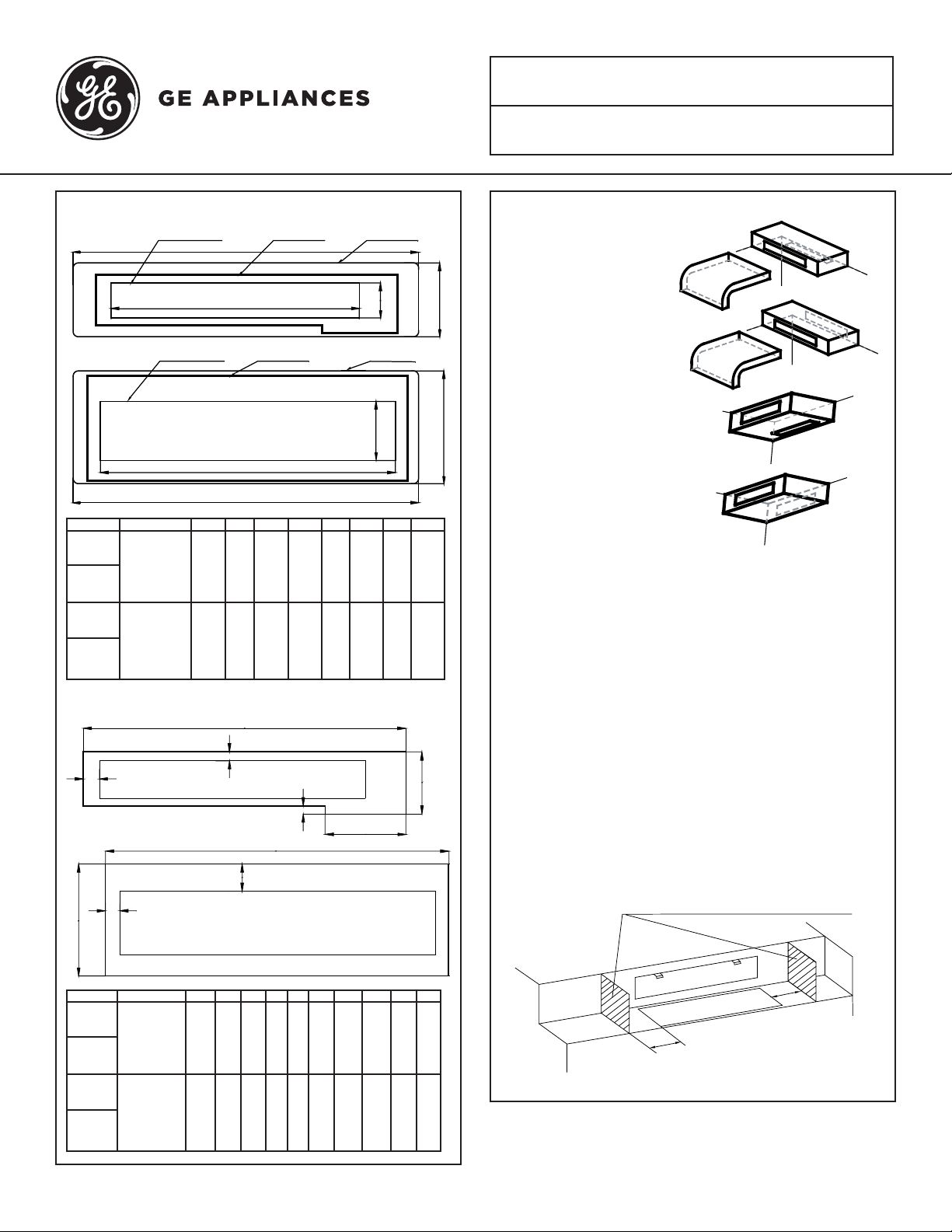

1. Dimensions

Ceiling opening

A

F

H

C

7-1/2

35

(190)

(890)

7-1/2

47-5/8

(190)

(1210)

11-1/2

(291)

11-1/2

(291)

3-1/2

(90)

3-1/2

(90)

25-1/4

(640)6 (152)

37-3/4

(960)6 (152)

Supply

PAD0890SA

Return

PAD0890RA

Supply

PAD1210SA

Return

PAD1210RA

Supply air outlet

Model A B C D E F G H

AD07SL2VH*

AD09SL2VH*

AD12SL2VH*

MVAD007MV2AA

MVAD009MV2AA

MVAD012MV2AA

AD18SL2VH*

MVAD018MV2AA

MVAD024MV2AA

35

(890)

47-5/8

(1210)

2. Rough Opening Dimensions:

A

E

Plenum opening

E

Plenum opening Return air inlet Ceiling opening

G

29-7/8

(760)

42-1/2

(1080)

3. Typical Configurations

Supply and return down

B

Supply down, return rear

D

Supply side, return down

Supply side, return rear

NOTES:

Maintain 36” (915 mm) between supply outlet and return inlet for floor and ceiling locations.

If the supply outlet and the return inlet are on a common wall, one must be 36” (915 mm) higher than the

other.

All duct longitude and latitude joints must be sealed.

Duct insulation values should meet local code requirements.

F

H

Supply

PAD0890SA

Return

PAD0890RA

Supply

PAD1210SA

Return

PAD1210RA

D

C

G

I

J

Model A B C D E F G H I J

AD07SL2VH*

AD09SL2VH*

AD12SL2VH*

MVAD007MV2AA

MVAD009MV2AA

MVAD012MV2AA

AD18SL2VH*

MVAD018MV2AA

MVAD024MV2AA

30-1/2

(776)

43-1/8

(1096)

5-7/8

(150)

5-7/8

(150)

7-5/8

(194)

7-5/8

(194)

3/4

(20)

3/4

(20)

7/8

(21)

7/8

(21)

1-5/8

(40)

1-5/8

(40)

32-1/4

(820)

44-7/8

(1140)

10-1/4

(260)

10-1/4

(260)

2-3/8

(60)

2-3/8

(60)

B

1-1/4

(31)

1-1/4

(31)

The cabinet of the Slim Duct unit must be insulated if

installed in a non-conditioned space.

4. Set the Blocking in the Ceiling to Protect the Indoor Unit

The inside of two sides of the celing must

be sealed.

001

002

31-5000441 Rev. 0 09-19 GEA

Page 2

Installation Instructions

M

M

M

CN16CN15

CN14

SWING MOTOR-UP/DOWN

SWING MOTOR-UP/DOWN

SWING MOTOR-LEFT/RIGHT

INDOOR UNIT PCB

M

M

M

CN11-1

SWING MOTOR-UP/DOWN

SWING MOTOR-UP/DOWN

SWING MOTOR-LEFT/RIGHT

INDOOR UNIT PCB

CN11

CN35

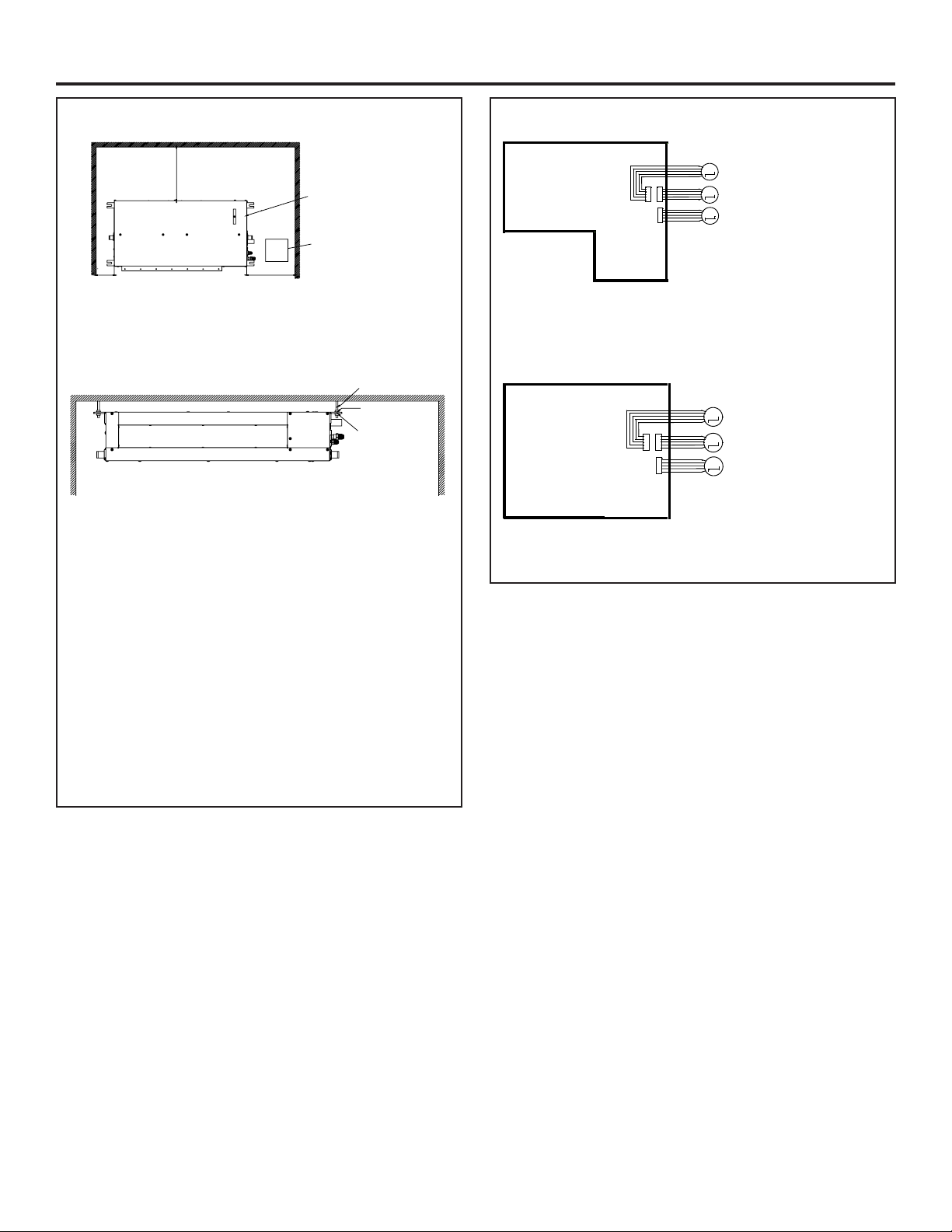

5. Minimum Clearances

0001>

39-3/8

electrical box

accessing opening

>100

If the unit location is not readily accessible, provide a 24”

X 24” (610 mm X 610 mm) service access panel per local

code.

Installation

A B

Install the unit level to the building structure, using 3/8”

threaded rods, washers, and nuts.

If a gravity drain is preferred, slope the cabinet 1/4”

toward the drain end.

4 qty. 3/8 hanging bolts

16 qty

3/8 nuts

8 qty

3/8 washer

7. Swing Motor Wiring, FlexFit Models

Connect up/down swing motors to CN15 and CN16.

The left/right swing motor goes to CN14.

8. Swing Motor Wiring, MRV-S Models

Connect up/down swing motors to CN11 and CN11-1.

The left/right swing motor goes to CN35

6. Connecting Plenum to Indoor Unit

A. Direct Connection

Use M4x3/8 sheet metal screws. Holes on the panel will

match the holes on the unit.

B. Connection to Ducts

Use the holes in the panel and the unit to attach the

ductwork. Use M4x3/8 screws. All ducts must be sealed

and insulated.

2

31-5000441 Rev. 0 09-19 GEA

Page 3

Instructions d’installation

Modèles à plénum, conduits étroits

1. Dimensions

Supply

PAD0890SA

Return

PAD0890RA

Supply

PAD1210SA

Return

PAD1210RA

Sortie d’air fourni

Ouverture du plafond

A

F

H

C

Modèle A B C D E F G H

AD07SL2VH*

AD09SL2VH*

AD12SL2VH*

MVAD007MV2AA

MVAD009MV2AA

MVAD012MV2AA

AD18SL2VH*

MVAD018MV2AA

MVAD024MV2AA

35

(890)

47-5/8

(1210)

7-1/2

(190)

7-1/2

(190)

35

(890)

47-5/8

(1210)

11-1/2

(291)

11-1/2

(291)

Ouverture du plénum

E

Ouverture du plénum Entrée d’air repris Ouverture du plafond

G

3-1/2

25-1/4

(90)

(640)6 (152)

3-1/2

37-3/4

(90)

(960)6 (152)

2. Dimensions d’ouvertures brutes:

A

E

B

D

29-7/8

(760)

42-1/2

(1080)

3. Configurations typiques

Air fourni et repris

dans le bas

Air fourni dans le bas,

air repris en arrière

Air fourni sur le côté,

air repris dans le bas

Air fourni sur le côté,

air repris en arrière

REMARQUES:

Gardez 36 po (915 mm) entre la sortie d’air fourni et

l’entrée d’air repris pour les emplacements de plancher

et de plafond.

Si la sortie d’air fourni et l’entrée d’air repris se trouvent

sur le même mur, l’un des deux doit être 36 po (915

mm) plus haut que l’autre.

Tous les joints de longitude et de latitude des conduits

doivent être scellés.

F

H

Supply

PAD0890SA

Return

PAD0890RA

Supply

PAD1210SA

Return

PAD1210RA

D

C

G

I

J

Modèle A B C D E F G H I J

AD07SL2VH*

AD09SL2VH*

AD12SL2VH*

MVAD007MV2AA

MVAD009MV2AA

MVAD012MV2AA

AD18SL2VH*

MVAD018MV2AA

MVAD024MV2AA

30-1/2

(776)

43-1/8

(1096)

5-7/8

(150)

5-7/8

(150)

7-5/8

(194)

7-5/8

(194)

3/4

(20)

3/4

(20)

7/8

(21)

7/8

(21)

1-5/8

(40)

1-5/8

(40)

32-1/4

(820)

44-7/8

(1140)

10-1/4

(260)

10-1/4

(260)

2-3/8

(60)

2-3/8

(60)

B

1-1/4

(31)

1-1/4

(31)

Les valeurs d’isolation des conduits doivent satisfaire

les exigences du code local.

L’enceinte du conduit étroit doit être isolée dans un

espace non conditionné.

4. Construire le blocage dans le plafond

pour protéger l’unité intérieure

L’intérieur des deux côtés du plafond

doit être scellé.

001

002

31-5000441 Rev. 0 09-19 GEA

Page 4

Instructions d’installation

M

M

M

CN16CN15

CN14

MOTEUR OSCILLANT - HAUT/BAS

MOTEUR OSCILLANT - HAUT/BAS

MOTEUR OSCILLANT - GAUCHE/DROITE

CARTE DE CIRCUIT

UNITÉ INTÉRIEURE

M

M

M

CN11-1

MOTEUR OSCILLANT - HAUT/BAS

MOTEUR OSCILLANT - HAUT/BAS

MOTEUR OSCILLANT - GAUCHE/DROITE

CARTE DE CIRCUIT

UNITÉ INTÉRIEURE

CN11

CN35

5. Dégagements minimaux

0001>

39-3/8

Boîte électrique

Orifice d’accès

>100

Si l’emplacement de l’unité n’est pas aisément accessible,

fournissez un panneau d’accès de service de 24 x 24 po

(610 mm x 610 mm) conforme au code local.

Installation

A B

Installez l’unité de niveau avec la structure du bâtiment,

à l’aide de tiges filetées 3/8 po et leurs rondelles et

écrous.

Si une évacuation par gravité est préférée, inclinez

l’enceinte de 1/4 po vers l’extrémité de l’évacuation.

Boulons de suspension 3/8 (4)

Écrou 3/8

(16)

Rondelle

3/8 (8)

7. Câblage du moteur oscillant,

modèles FlexFit

Connecter les moteurs haut/bas à CN15 et CN16. Le

moteur gauche/droite va à CN14.

8. Câblage du moteur oscillant,

modèles MRV-S

Connecter les moteurs haut/bas à CN11 et CN11-1. Le

moteur oscillant gauche/droite va à CN35.

6. Connexion du plénum à l’unité

intérieure

A. Connexion directe

Utilisez des vis à tôle M4 x 3/8. Les trous sur le pan-

neau vont correspondre à ceux de l’unité.

B. Connexion aux conduits

Utilisez les trous du panneau et de l’unité pour fixer les

conduits. Utilisez des vis M4 x 3/8. Tous les conduits

doivent être scellés et isolés.

2

31-5000441 Rev. 0 09-19 GEA

Loading...

Loading...