Page 1

GE

Power Conversion

MV Induction Motors

For industrial pump, fan, compressor

and other industrial applications.

NEMA Frames 5800-8000

500-7500 HP

IEC Frames 400-PV900

400-5600 kW

Page 2

Experience Matters

For over 100 years, GE has produced countless medium voltage induction

machines for the petrochemical, power generation, mining and minerals, water

and wastewater industries. These motors are commonly used for centrifugal

compressors, blowers, boiler feed pumps, crushers and grinders, multi-stage high

pressure pumps such as water injection or pipeline applications.

Standards

GE motors are designed for, but are not limited

to these critical industry standards:

NEMA MG1

IEC 60034-1

ANSI C50.41

IEEE 112

API 541 & 547

Applicable ISO, AFBMA, ANSI, ASME, and ASTM requirements

Quality

Our world-class testing facility has the capability of meeting a wide range of NEMA,

IEC and API motor requirements. GE is dedicated to manufacturing excellence.

Our facilities are ISO 9001 Certified with over 20 years of Six Sigma process

enhancements and best practice implementations. Our commitment is to deliver

the highest quality design to fit your system requirements with service to exceed

your expectations.

Page 3

Superior Design

Meets or exceeds API 541

requirements for Petroleum

& Chemical Applications

GE provides machines that are fully compliant to API 541

standards, globally recognized among the most stringent.

You can be assured that you are getting a well-designed and

reliable product, optimized for your specific application.

Inverter Duty

The insulation system meets the requirements of NEMA MG-1,

part 31. If required, a shaft grounding device is installed to

reduce shaft voltage. Both bearings are insulated and the

drive end bearing is grounded. Our cage induction motors are

certified for use with the GE MV4, MV6 and MV7000 range of

variable frequency drives.

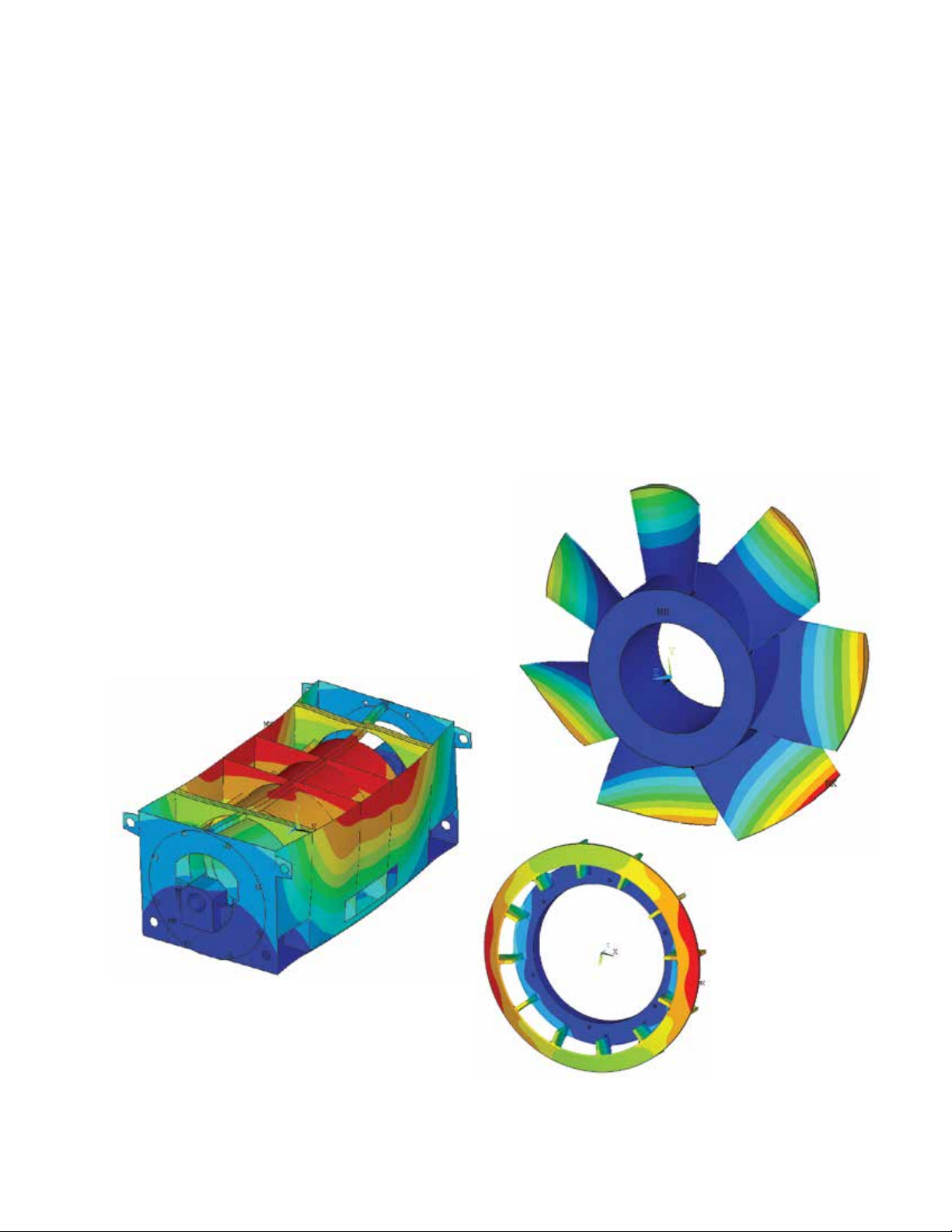

Reduction of Resonances

GE supplies both flexible and rigid rotor technology. All

machines 1800 rpm and below have rigid rotors as defined

by API. Use of the latest engineering simulation tools and

modern modal testing equipment makes it possible for GE

to assure shaft resonances do not impede operation of the

machine in the specified speed range.

Stator frames are designed using powerful

FEA tools. The design tools confirm safety

margins, and assure resonances are well

outside the operating region.

Improved ventilation

and cooling has been

achieved with a new

internal fan design.

Page 4

Built for Durability

Stator Construction

Laminations are precision punched from high quality, low loss

electrical sheet steel with a temperature stable insulating film.

The magnetic core consists of ring laminations compressed

and completely wound before the core package is inserted

into the frame.

The stator assembly

is configured for

increased air flow

which improves

heat transfer and

provides a more

compact design.

Insulation System

GE uses an epoxy solventless resin vacuum-pressure-im-

pregnation (VPI) process assuring long life. For line voltages

of 5000 Volts and above, a semi-conducting armor is applied

to the slot portion and beyond the core to provide corona

protection. The binding agent is GE’s third generation epoxy

resin, selected and tested to IEEE-1776. The coils receive a

protective armor of heavy glass tape for protection against

mechanical shock and abrasion. Custom Polyseal

winding insulation system that meets the requirements of

NEMA MG1 20.18..

It is available upon

request to operate in

severe environments

containing moisture,

oil, chemicals and

salt water.

®

is a sealed

Ground Wall

Insulation

Turn

Insulation

Strand

Insulation

Copper

Conductor

Rotor Construction

The magnetic circuit consists of punched thin steel disks

assembled to form a laminated core mounted on the shaft. The

laminations are coated with a temperature stable insulating

film to reduce magnetic losses yet maintain dimensional

stability in the face of severe thermal and mechanical stresses.

The rotor winding consists of a number of uninsulated metal

bars in the outer surface of the magnetic core parallel to the

shaft and short circuited by metal rings at both ends.

Copper bars are brazed

to their endrings, and

aluminum bars are

welded to their endrings.

Bearings

GE uses self-aligning spherical seat sleeve bearings per DIN

31693/4. Seal additions are also available to meet IP-56

requirements. Anti-friction bearings are available with

grease in a sealed housing to avoid contamination meeting

IP56 protection.

Self-aligning spherical seat sleeve bearings have features designed

to keep the oil in and the dirt out.

Page 5

Vertical

Wound Rotor

Accurate Frequency Response Design

System resonance can shorten the life of your equipment.

GE invested in the development and calibration of a new

Reed Critical Frequency (RCF) prediction tool. It arms our

engineers with the accurate data they need to create custom

designs for specific application challenges.

Frame Design - Benefits

Large inspection windows on both ends of the frame ensure

easy maintenance and inspection access. The modular frame

design accommodates multiple cooling, bearing loading and

protection options without changing

the motor stator frame.

Rotor Design

Shaft FEA modeling (including Torsional, Radial and Axial

loads) help ensure rotor designs meet specifed application

requirements.

Bearing Design

API compliant options are available for the rolling

element and sleeve bearing

Energy Recovery System

GE wound rotor induction motors are designed to operate

with Slip Energy Recovery drives within a standard range of

80% to 110% of the rated speed. Every design is optimized

to suit each application and to provide maximum energy

savings, effective speed control, and high reliability.

Rotor Construction

The rotor has a three-phase insulated winding. Rotor winding

terminals are brought out through rotating slip rings and

stationery brushes. These terminals are used to connect

an external resistor in series with the rotor winding

in order to control the motor accelerating torque and

associated current.

Stator

Shaft

Rotor Lamination

Lower Endshield

Bearing

Upper Endshield

Chamber

(Enclosed or Open Types)

Frame

Brush Lifting Device

In a traditional application as the motor achieves nominal

speed, the starting resistor is shorted out through the brushes

between the slip rings. This shortens the life of the brushes

and adds extra wear in the motor. An optional solution from

GE, called a Brush Lifting Device, is an integrated mechanism,

which shorts the slip rings and lifts the brushes at nominal

speed to avoid this wear.

Page 6

Vertical MV Induction Motors

82004000 3000 8300 8300 8300 8300 8500 8500 8500

1000 750 8200 8200 8200 8200 8200 8200 8200 8200

1500 1100 8200 8200 8200 8200 8200 8200 8200 8200

2000 1500 8200 8200 8200 8200 8200 8200 8200 8200

2500 1900 8200 8200 8200 8200 8200 8200 8200 8200

3000 2200 8200 8200 8200 8300 8200 8200 8200 8300

3500 2600 8200 8300 8300 8300 8200 8300 8300 8400

4000 3000 8300 8300 8300 8400 8300 8300 8300 8400

4500 3400 8300 8400 8400 8400 8300 8400 8400 8400

5000 3700 8300 8400 8400 8300 8400 8400 8400

5500 4100 8400 8400 8400 8500 8400 8400 8400

6000 4500 8400 8500 8500 8500 8400 8400 8400

6500 4900 8400 8500 8500 8500 8400

7000 5200 8400 8500 8500 8500 8400

7500 5600 8500 8500 8500 8400

8000 6000 8500 8500 8500

9000 6700 8500

9500 7000 8500

10000 7500 8500

10500 7800 8500

ABABAB

500 400 8200 8200 8200 8200 8200 8200

600 450 8200 8200 8200 8200 8200 8200

700 500 8200 8200 8200 8200 8200 8200

800 600 8200 8200 8200 8200 8200 8200

900 650 8200 8200 8200 8200 8200 8200

1000 750 8200 8200 8200 8200 8200 8300

1250 950 8200 8200 8200 8200 8300 8300

1500 1100 8200 8200 8200 8200 8300 8300

1750 1300 8200 8200 8200

8300

8300 8300

2000 1500 8200 8200

8300

8300 8300 8400

2250 1700 8200 8300 8300 8300 8300 8400

2500 1850

8300

8300 8300 8300 8300 8400

3000 2250 8300 8300 8300 8400 8400 8400

3500 2600 8300 8300 8300 8400 8400 8400

4000 3000 8300 8400 8400 8400 8400 8400

A = WPI / WPII / TEWAC; IP23 / IP44W / IP54 / IP56

60Hz. shown, 50Hz. Available. These ratings are based on

4.1 kV. Enclosures for other voltages may be sized differently.

Contact your GE representative for more information.

Product Offering

HP kW A* B* ABABABABABAB AB

1800 RPM

8200 8200 8200 8200 8200 82002000 1500 8300 8300 8300 8300 8300 8300

8200 8200 8200 82002500 1900 8300 8300 8300 8300 8300 8300 8500

4500 3400 8300 8300 8300 8300 8500 8500

5000 3700 8300 8300 8300 8300 8500 8500 8500

5500 4100 8300 8300 8300 8500 8500 8500

6000 4500 8300 8300 8500

6500 4900 8300

7000 5200

7500 5600

8000 6000

8500 6300

8200 8200 82003000 2200 8300 8300 8300 8300 8300 8300 8500 8500

82003500 2600 8300 8300 8300 8300 8300 8300 8500 8500 8500 8500

Horizontal Wound Rotor MV Induction Motors

HP kW

8500 6300 8500 8500

ABABABAB

6 Poles

4 Poles

8200 8200 8200 8200 8200 8200 82001500 1100 8300 8300 8300 8300 8300

6600V

6 Poles

1200 RPM

8 Poles

6600V

8 Poles

8200 8200 8200 8200 8200 8200 8200 82001000 750 8300 8300

900 RPM

6 Poles

4000V

10 Poles

720 RPM

PV500

PV630

PV800

PV900

8 Poles

4000V

8200 8200 8200 8200500 370

12 Poles

600 RPM

14 Poles

514 RPM

Weather Protected (WPI) - IP23

500

560

630

710

16 Poles

450 RPM

(WPII) - IP24W and IP44W

18 Poles

400 RPM

Horizontal MV Induction Motors

HP kW

2 Poles 4 Poles 6 Poles

4500 3350

5000 3750 8400 8400 8400 8400 8400 8500

5500 4100 8400 8400 8400 8500 8500 8500

6000 4450 8400 8400 8400 8500 8500 8500

7000 5200 8400 8500 8500 8500 8500 8500

7500 5600 8500 8500 8500 8500 8500 8500

400

450

500

630

Ratings

* Enclosures

B = TEAAC; IP54 / IP56

Weather Protected (WPI) - IP23

(WPII) - IP24W and IP44W

Totally Enclosed Water-to-Air Cooled

(TEWAC) - IP54 or IP56

Totally Enclosed Air-to-Air Cooled

(TEAAC) - IP54 or IP56

Page 7

Business Centers

Global Expertise

Rotating Machine Factories

Converter Factories

Proven

Experience

Innovative

Technology

The GE

Advantage

Complete

Product

Offering

World-Class

Service

Few manufacturers can claim the depth and

breadth of experience that GE has in building

and delivering electrical and mechanical

solutions for customers.

GE offers a complete portfolio

of rotating machines.

GE has the global resources and capabilities

to maximize the performance and reliability

of your machines.

GE is constantly innovating product

technologies to meet and exceed

customer expectations.

Page 8

MAIN OFFICES

Australia, Botany

Tel: +61 (0) 2 8313 9980

Brazil, São Paulo

Tel: +55 11 3614 1930

Canada, Mississauga

Tel: + 1 905 858 5100

Chile, Santiago

Tel: + 56 2 271 92200

China, Shanghai

Tel: +86 21 6498 2600

France, Massy

Tel: +33 1 77 31 20 00

Germany, Berlin

Tel: +49 30 7622 0

India, Chennai

Tel: +91 44 4968 0000

Japan, Tokyo

Tel: +81 3 5544 3852

Russia, Moscow

Tel: +7 495 981 13 13

Singapore

Tel: +65 6332 0940

South Africa, Midrand

Tel: +2711237 0000

South Korea, Busan

Tel: +82 51 710 9015

UAE, Dubai

Tel: +971 44296161

UK, Rugby

Tel: +44 1788 563 563

USA, Pittsburgh

Tel: +1 412 967 0765

Additional Options

Monitoring/Protection/Accessories

Vibration displacement, velocity or acceleration

Temperature winding, cooling air, cooling water, bearing and bearing oil

Enclosure anti-condensation heaters, water leakage, differential pressure

Electrical current transformers, surge capacitors, surge arresters, partial discharge couplers

Mechanical soleplates, coupling guard supports, speed sensing

www.gepowerconversion.com

© 2014 General Electric Company. All rights reserved.

GEA31319 (7/2014)

Loading...

Loading...