Page 1

GE Consumer & Industrial

XXR

Q

H

O

T

VE

R

Y

H

O

T

LEFT

SIDE

RIGHT

SIDE

NO

T

SO

H

O

T

XBEW

Y

W

ARM

XQM

A

H

O

T

XX

R

Q

H

O

T

VE

R

Y

H

OT

NO

T

SO

H

O

T

XBEW

Y

W

ARM

XQM

A

H

O

T

LEFT

SIDE

RIGHT

SIDE

REALL

Y

H

O

T

Technical Service Guide

April 2008

Profi le and Monogram

30- and 36-in.

Induction Cooktop

31-9164

PHP900

PHP960

ZHU30

ZHU36

GE Appliances

General Electric Company

Louisville, Kentucky 40225

Page 2

IMPORTANT SAFETY NOTICE

!

The information in this service guide is intended for use by

individuals possessing adequate backgrounds of electrical,

electronic, and mechanical experience. Any attempt to repair a

major ap pli ance may result in personal injury and property

damage. The man u fac tur er or seller cannot be responsible for the

in ter pre ta tion of this in for ma tion, nor can it assume any liability in

connection with its use.

WARNING

To avoid personal injury, disconnect power before servicing

this prod uct. If electrical power is required for diagnosis or test

purposes, disconnect the power immediately after performing the

necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used to

complete a path to ground are removed for service, they must be

returned to their original position and properly fastened.

GE Consumer & Industrial

Technical Service Guide

Copyright © 2008

All rights reserved. This service guide may not be reproduced in whole or in part

in any form without written permission from the General Electric Company.

– 2 –

Page 3

Table of Contents

Appearance Defects ........................................................................................................................................................21

Component Locator Views ...........................................................................................................................................17

Control Features ................................................................................................................................................................ 8

Cooktop Components ..................................................................................................................................................... 21

Cooktop Removal From Countertop ........................................................................................................................21

Diagnostics and Service Information ......................................................................................................................31

Elements ...............................................................................................................................................................................22

Fans .........................................................................................................................................................................................30

Filter Board ..........................................................................................................................................................................29

Generator Boards .............................................................................................................................................................28

Glass Maintop ..................................................................................................................................................................... 22

Heat Shield ........................................................................................................................................................................... 26

Installation ........................................................................................................................................................................... 7

Introduction ......................................................................................................................................................................... 4

Introduction to Induction Cooking ............................................................................................................................ 6

LINbus Connectors ........................................................................................................................................................... 27

Nomenclature .................................................................................................................................................................... 5

Operation Overview .........................................................................................................................................................16

Schematics and Wiring Diagrams ............................................................................................................................33

Thermal Cut-out ................................................................................................................................................................28

Touch Board ........................................................................................................................................................................23

Warranty .............................................................................................................................................................................. 35

– 3 –

Page 4

Introduction

Introducing GE Profi le and GE induction cooktops―

offering fast, effi cient cooking.

Induction cooktops provide unmatched cooking performance and

fl exibility. Induction technology heats only the pan and its contents and

offers energy effi ciency by reducing wasted heat when compared to

radiant and gas cooktops.

The new Monogram and Profi le, 30- and 36-in. Induction Cooktops have

the following new features:

Innovative technology• ―delivers the responsiveness of a gas cooktop.

Superior performance• ―Induction technology heats only the pan and

its contents, providing an incredibly fast boil time.

Remarkable versatility• ―This induction cooktop offers the choice of 19 different power levels, including

a 3700-watt, 11" element for large cookware ( the highest wattage induction element in the industry*),

warming capability, and a low-heat simmer setting for delicate sauces.

Cooler cooktop surface• ―Since there is not a traditional thermal heating element, the induction cooktop

stays cooler than conventional radiant cooktops.

Below cooktop venting• ―that dissipates heat, permitting less depth to the burner box.

Easy cleanability• ―Cooktop cleaning is easier since spills and splatters do not burn on the cooktop.

Distinguished appearance• ―Sleek cooktop fi ts fl ush with the countertop, and is surrounded completely

in full-frame stainless steel trim. This cooktop can be installed above a GE® or GE Profi le™ wall oven.**

The four-burner models feature 1 ten-inch, 3700 W element, 2 seven-inch, 2500 W elements, and 1 six-inch

1800 W element. And with the 36-in. models, you get the addition of 1 eight-inch, 3200 W element.

*Among leading manufacturer brands

**Not to be installed over wall ovens with Trivection® technology

– 4 –

Page 5

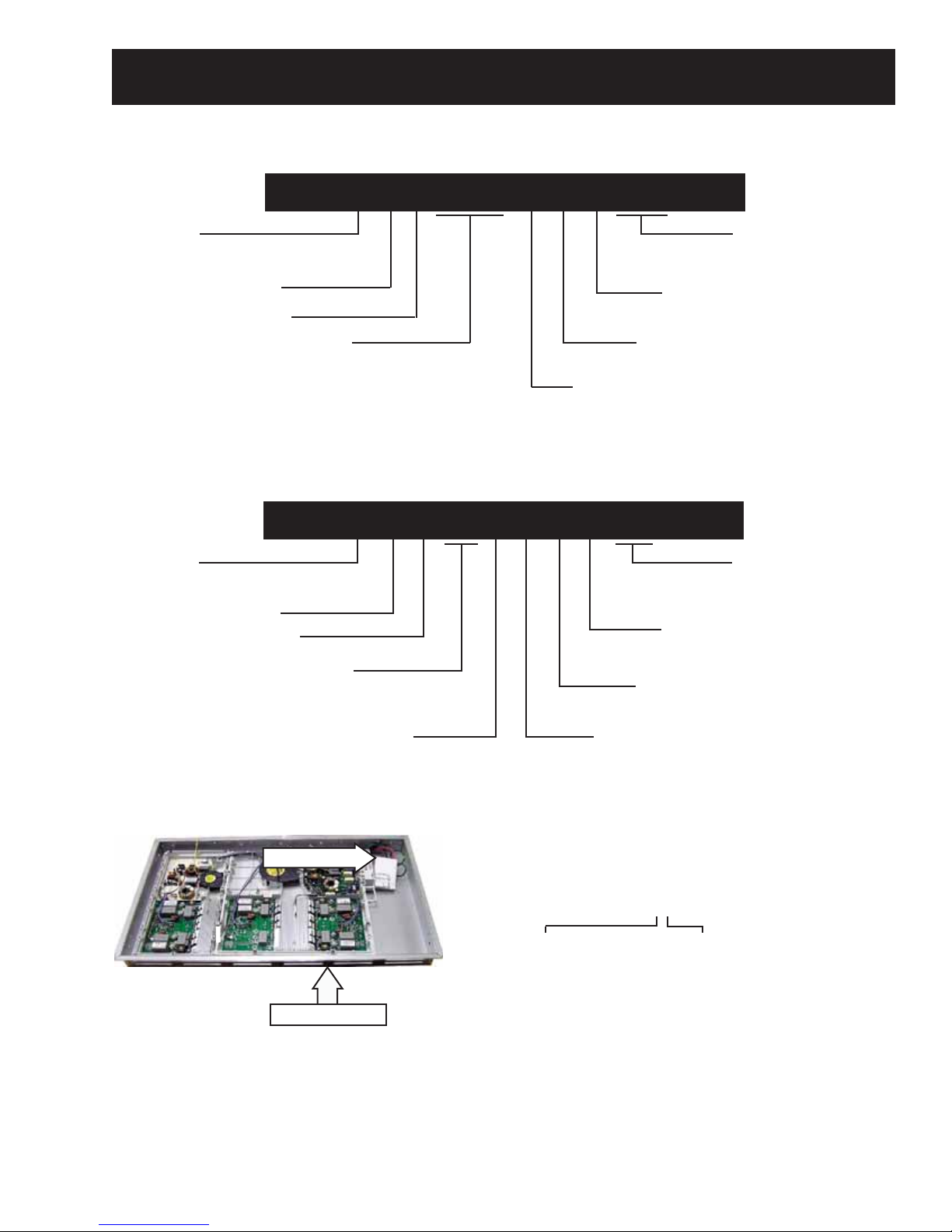

Profi le Model Number

Nomenclature

P H P 9 0 0 D 1 M B B

Brand

P = Profi le

H = Induction

P = Cooktop

Feature Pack

900 = 30-in. Width

960 = 36-in. Width

Monogram Model Number

Brand

Z = Monogram

H = Induction

U = Cooktop

Feature Pack

30 = 30-in. Width

36 = 36-in. Width

D = Color

S = Stainless

Z H U 30 R B M 1 B B

Control Type

R = Digital

Color Code

BB = Black on Black

SS = Stainless Steel

Model Year

M = 2007

Engineering Digit

1 = 1st Version

Color Code

BB = Black on Black

SS = Stainless Steel

Engineering Digit

1 = 1st Version

Model Year

M = 2007

B = Black

S = Stainless

PHP960 Model shown

Mini-Manual

Nomenclature

The nomenclature plate is located under the

cooktop.

The mini-manual is located inside the

burner box and is accessed by removing the

electrical cover on the bottom of the cooktop.

– 5 –

Serial Number

The fi rst two numbers of the serial number

identify the month and year of manufacture.

Example: AR123456S = January, 2008

A - JAN 2008 - R

D - FEB 2007 - M

F - MAR 2006 - L

G - APR 2005 - H

H - MAY 2004 - G

L - JUN 2003 - F

M - JUL 2002 - D

R - AUG 2001 - A

S - SEP 2000 - Z

T - OCT 1999 - V

V - NOV 1998 - T

Z - DEC 1997 - S

The letter des ig nat ing

the year re peats every

12 years.

Example:

T - 1974

T - 1986

T - 1998

Page 6

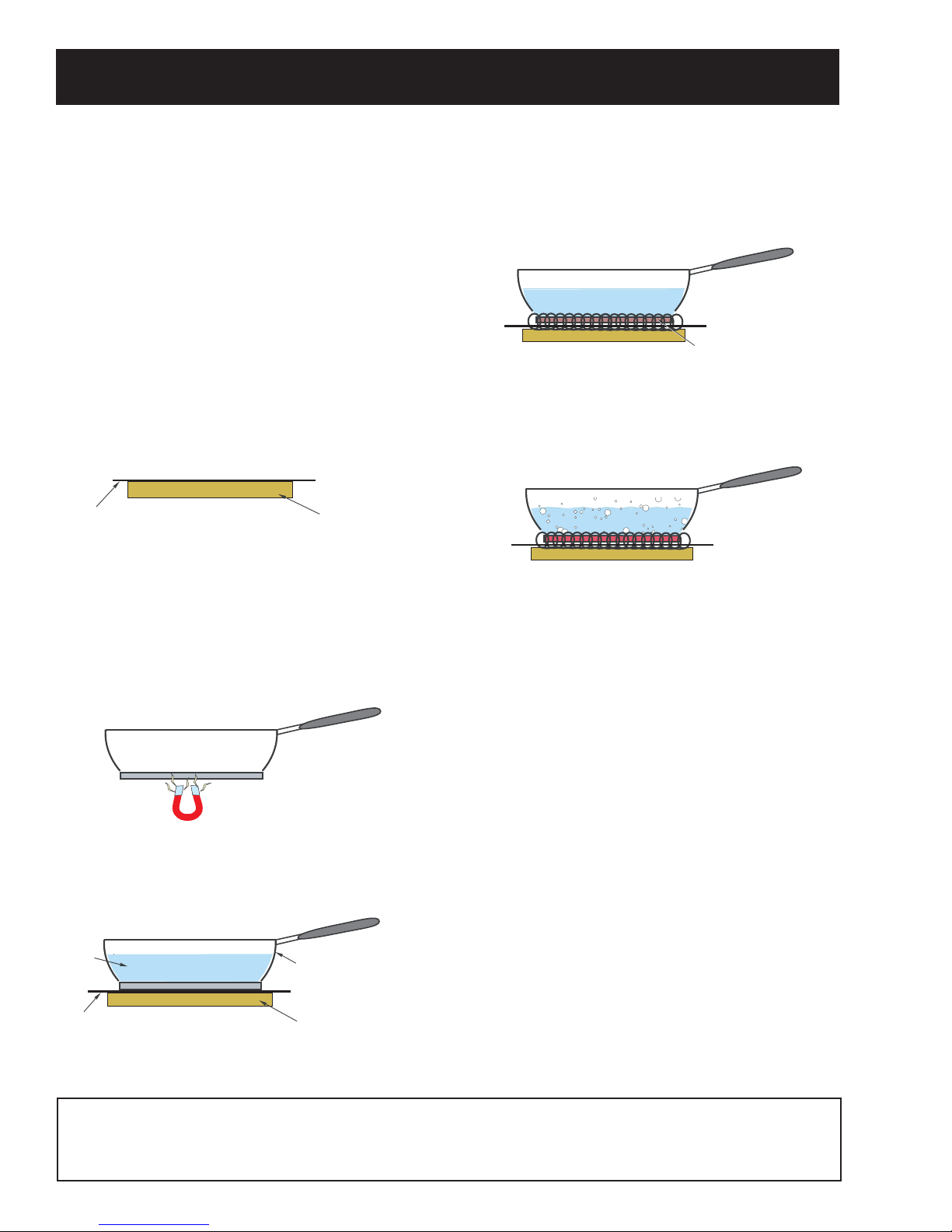

Introduction to Induction Cooking

How Induction Cooking Works

Induction cooking uses high frequency (20-50 K hz)

magnetic energy to heat a ferrous metal pan when

it is placed over the induction coil. The induction

fi elds have no affect on non magnetic surfaces

such as paper, plastic, or non ferrous metals like

aluminum, or copper. Thermal sensors under the

glass surface communicate with microprocessor

controls for pan sensing and turn-down.

Part one: Coil produces electromagnetic energy

The fi rst component needed is an induction coil or

element. The induction coil generates the magnetic

fi eld needed for induction cooking.

Glass Cooktop Surface

Induction Coil

Part two: Pan uses the energy to produce heat

The second component is the ferromagnetic cooking

pan with a bottom constructed of material that will

attract a magnet. If a magnet will not stick to the

bottom of the pan, it can not be used for induction

cooking.

created by the induction coil is applied to only the

bottom of the pan.

Induction Fields

The contents of the pan are therefore heated more

quickly than they would be if heated by a gas

fl ame or a traditional radient heating element.

By heating only the bottom of the pan, the

surrounding surface remains cooler than with

traditional cooktops.

Features:

Testing Bottom of Pan with Magnet

Easy cleanability• ―Cooktop cleaning is easier

since spills and splatters do not burn on the

cooktop, which is about 500°F vs 1200°F for

radiant.

Control and responsiveness equal to gas• ―

This induction cooktop give you instant control

When the proper type of pan is placed over an

of the amount of heat added to the cookware.

energized induction coil, a fi eld of magnetic waves

will cause the bottom of the pan to heat.

Fast and Powerful• ―providing an incredibly

fast boil time. 3700 w, 8.5 min. to boil vs 12 to

14 min. for radiant and 14 to 16 min. for gas

Water

Glass Cooktop Surface

Pan with Bottom of

Magnetic Material

Induction Coil

(18k BTU).

Effi cient performance• ―Induction technology

heats only the pan and its contents, not the

kitchen. Effi ciency ratings are: Induction 83%,

Radiant 72%, and gas 38%.

Induction cooking is very effi cient. The energy

Note: There are no health risks associated with the use of this cooktop. The RF fi eld from an induction

element dies away to almost nothing at a distance of about one foot (30 centimeters). You will not receive

even trivial radiation from an induction cooktop unless you spend a long time well within one foot of an

operating element.

– 6 –

Page 7

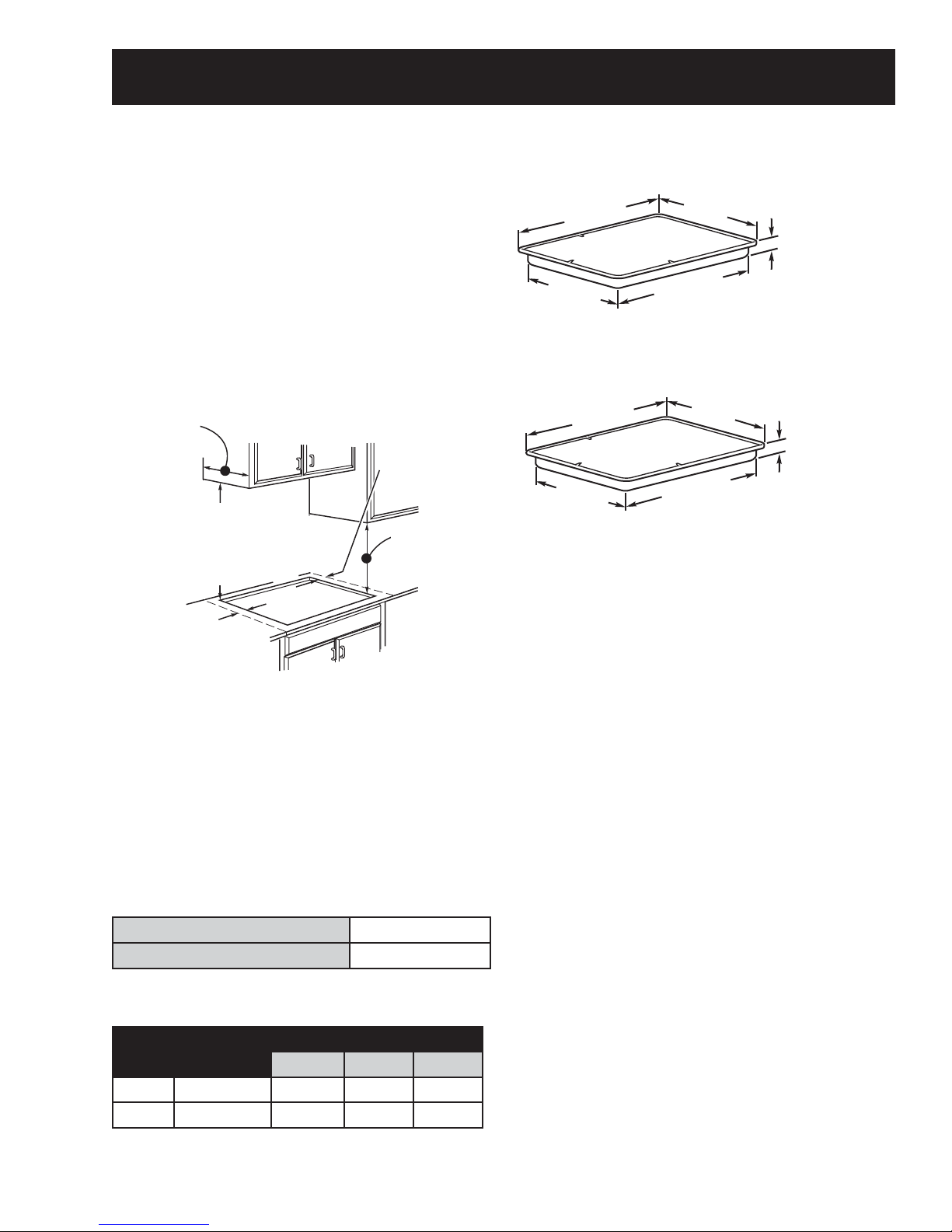

Installation

r

WARNING: Before beginning the installation,

switch power off at the service panel and lock the

service disconnecting means. When the service

disconnecting means cannot be locked, securely

fasten a warning tag to the service panel.

Note: The complete installation instructions are

inclosed with the Use and Care Manual. Carefully

read and follow these instructions.

The following minimum clearance dimensions must

be maintained.

13″ MAX. Depth of uprotected

overhead cabinets

30″ MIN.

Clearance from

countertop to

unprotected

overhead surface

2″ MIN. Clearance

from cutout to side

wall on the left of

the unit

2″ MIN. Clearance

from cutout to

side wall on the

right of the unit

15″ MIN. Height

from countertop to

nearest cabinet on

either side of unit

If a 30-in. clearance between the cooking surface

and overhead combustible materials or metal

cabinets cannot be maintained, a minimum

clearance of 24-in. is required and the underside of

the cabinets above the cooktop must be protected

with not less than 1/4-in. insulating millboard

covered with sheet metal not less than 0.0122-in.

thick.

Grounding Specifi cations

Models PHP900 and ZHU30

29-3/4″

(29-7/8″ SS)

Cooktop

19-3/8″

21-3/8″

(21-1/2″ SS) at center

28-1/4″

4-5/8“ at front

baffle

3-1/4” at rear ai

intake

Models PHP960 and ZHU36

(36-1/8″ SS) at center

36″

Cooktop

18-7/8″

20-7/8″

(21″ SS) at center

33-5/8″

4-5/8“ at front

baffle

3-1/4” at rear air

intake

Power Supply

The cooktop must be connected to a supply circuit

of the proper voltage and frequency as specifi ed

on the rating plate. Wire size must conform to the

National Electrical Code or the prevailing local code.

The rating plate is located on the bottom of the

burner box.

Wiring

Built-in power leads are UL-approved for connection

to larger gauge household wiring. The insulation of

these leads is rated at temperatures much higher

than the temperature rating of household wiring.

The current-carrying capacity of a conductor is

governed by the temperature rating of the insulation

around the wire rather than the wire gauge alone.

Ground Path Resistance

Insulation Resistance

.

Overcurrent Protection

Maximum Kilowatt Rating

Size NEC Rating

30-in. 40 Amp 8.3 9.4 9.6

36-in. 50 Amp 10.4 11.8 12.0

The branch circuit load for one counter-mounted

cooktop is the rating on the nomenclature plate.

208V 236V 240V

0.10Ω Max.

205KΩ Min.

WARNING: Improper connection of aluminum house

wiring to these copper leads can result in a serious

problem. Use only connectors designed for joining

copper to aluminum and follow the manufacturer's

recommended procedure closely.

Ceramic Glass Cooktop

If the glass is damaged, it may be replaced as a

separate part. The touch board and electronics are

separate parts.

– 7 –

Page 8

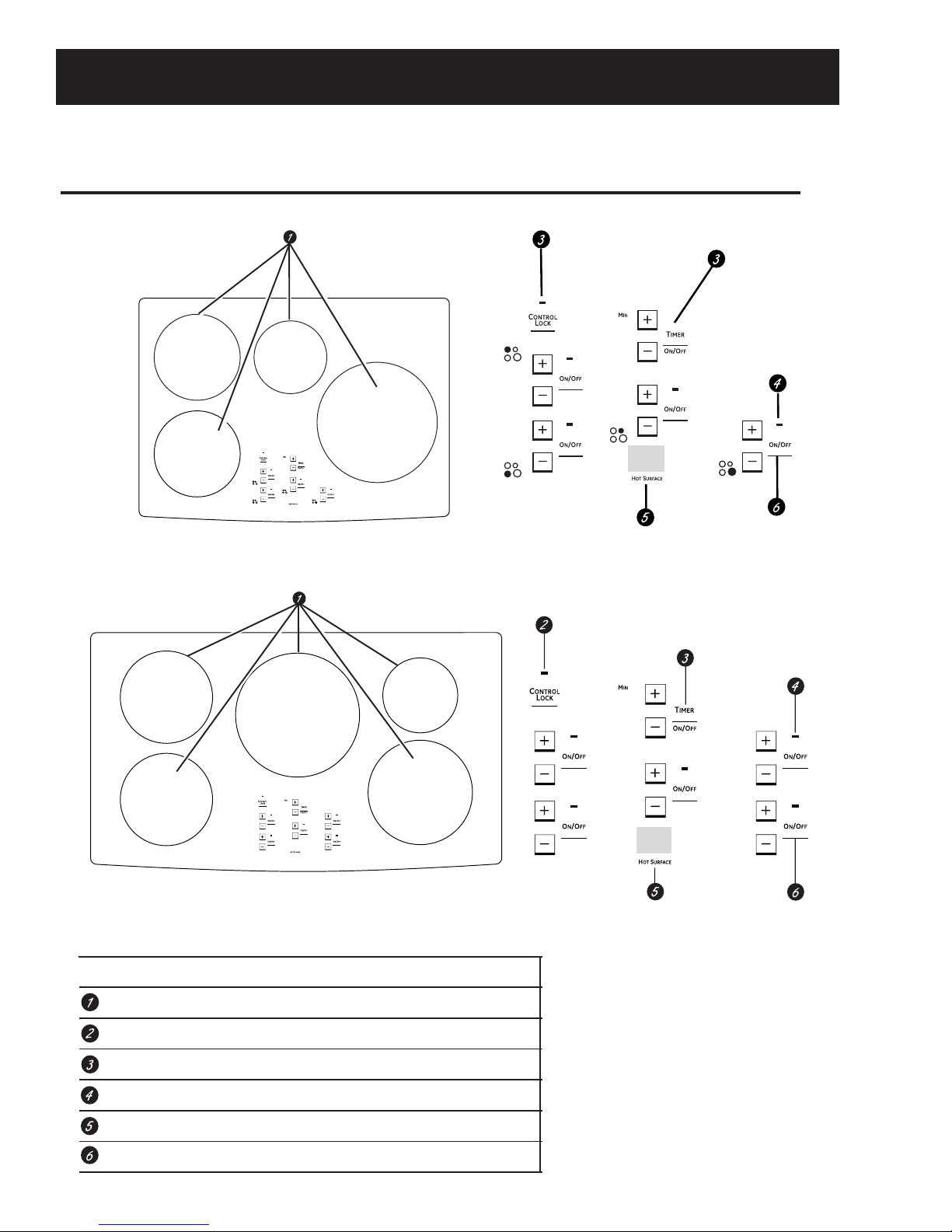

Control Features

Features of your cooktop.

Throughout this manual, features and appearance may vary from your model.

PHP900 30″ Cooktops

PHP960 36″ Cooktops

NOTE: 30” models have cooking element location

indicators next to each control.

Feature Index (Features and appearances may vary.) Explained on page

Cooking Elements 10

Control Lock 13

Kitchen Timer 12

ON Indicator Light (one for each element) 10

Hot Surface Indicator Light Area 12

Cooking Element ON/OFF Control 10

– 8 –

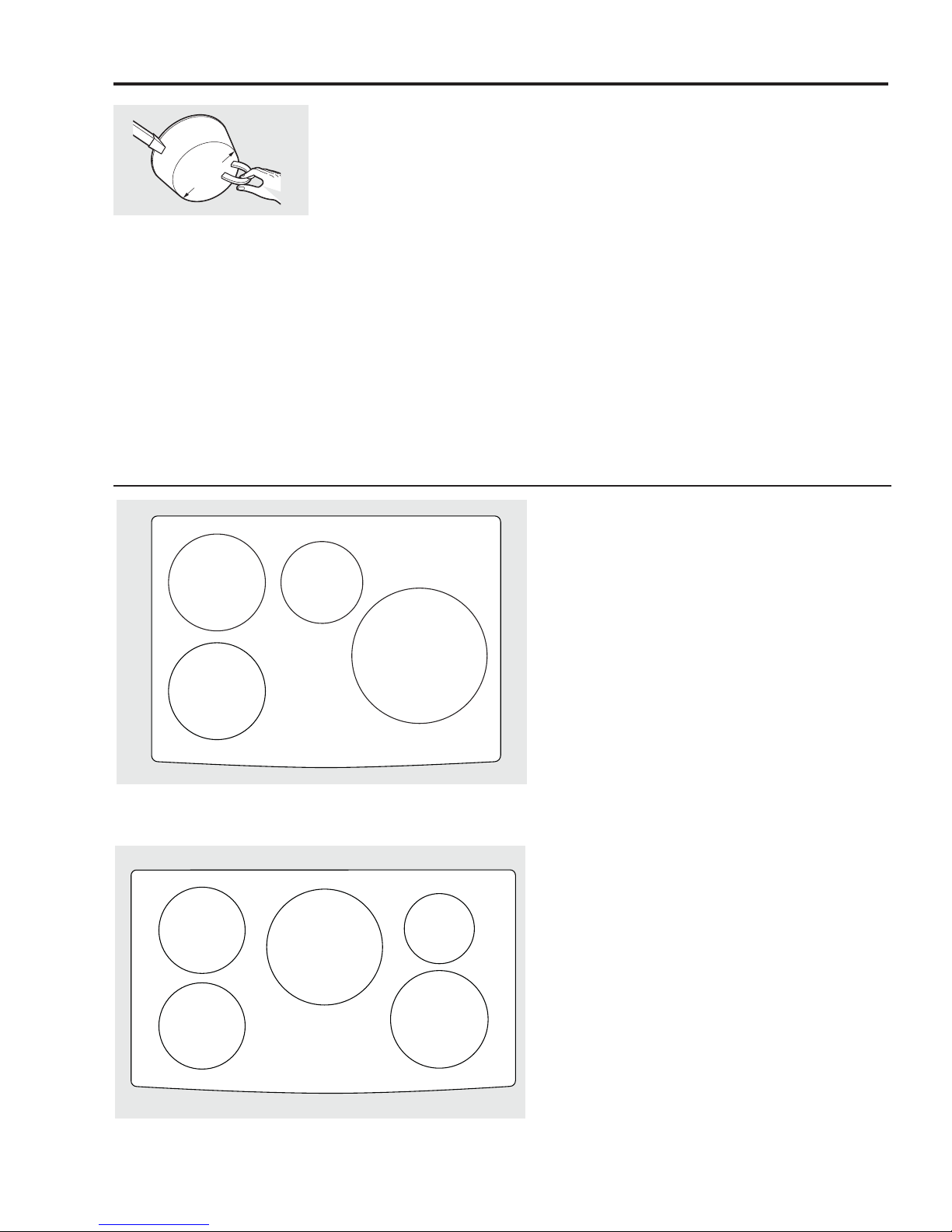

Page 9

How induction cooking works. ge.com

Min. Size

Use the minimum size pan for

the element. The pan material is

correct if a magnet sticks to the

bottom.

5-3/4” Min. Dia.

Pan Size

5-3/4” Min. Dia.

Pan Size

The elements beneath the cooking

surface produce a magnetic field that

causes the electrons in the ferrous

metal pan to vibrate and produce

heat.

The cooking surface itself does not

heat. Heat is produced in the cooking

pan, and cannot be generated until a

pan is placed on the cooking surface.

When the element is activated, the pan

begins to heat immediately and in turn

heats the contents of the pan.

4-3/4” Min. Dia.

Pan Size

7” Min. Dia.

Pan Size

Magnetic induction cooking requires

the use of cookware made of ferrous

metals—metals to which magnets will

stick, such as iron or steel.

Use pans that fit the element size.

The pan must be large enough for the

safety sensor to activate an element.

The cooktop will not start if a very

small steel or iron utensil (less than

the minimum size across the bottom) is

placed on the cooking surface when

the unit is turned on—items such as

steel spatulas, cooking spoons, knives

and other small utensils.

Using the correct size cookware

Each cooking element requires a MINIMUM pan

size. If the pan is properly centered, and of the

correct material, but is too small for the cooking

element, the element cannot be activated. The

display will flash “F” along with the power level

selected.

Cookware larger than the element ring may be

used; however, heat will only occur above the

element.

30” Wide Cooktop. Use the minimum size pan shown for each cooking

element.

5-3/4” Min. Dia.

Pan Size

5-3/4” Min. Dia.

Pan Size

36” Wide Cooktop. Use the minimum size pan shown for each cooking

element.

7” Min. Dia.

Pan Size

4-3/4” Min.

Dia. Pan Size

7” Min. Dia.

Pan Size

For best results, the cookware must make FULL

contact with the glass surface.

Do not allow the bottom of the pan or cookware to

touch the surrounding metal cooktop trim or to

overlap the cooktop controls.

For best performance, match the pan size to the

element size. Using a smaller pot on a larger burner

will generate less power at any given setting.

– 9 –

Page 10

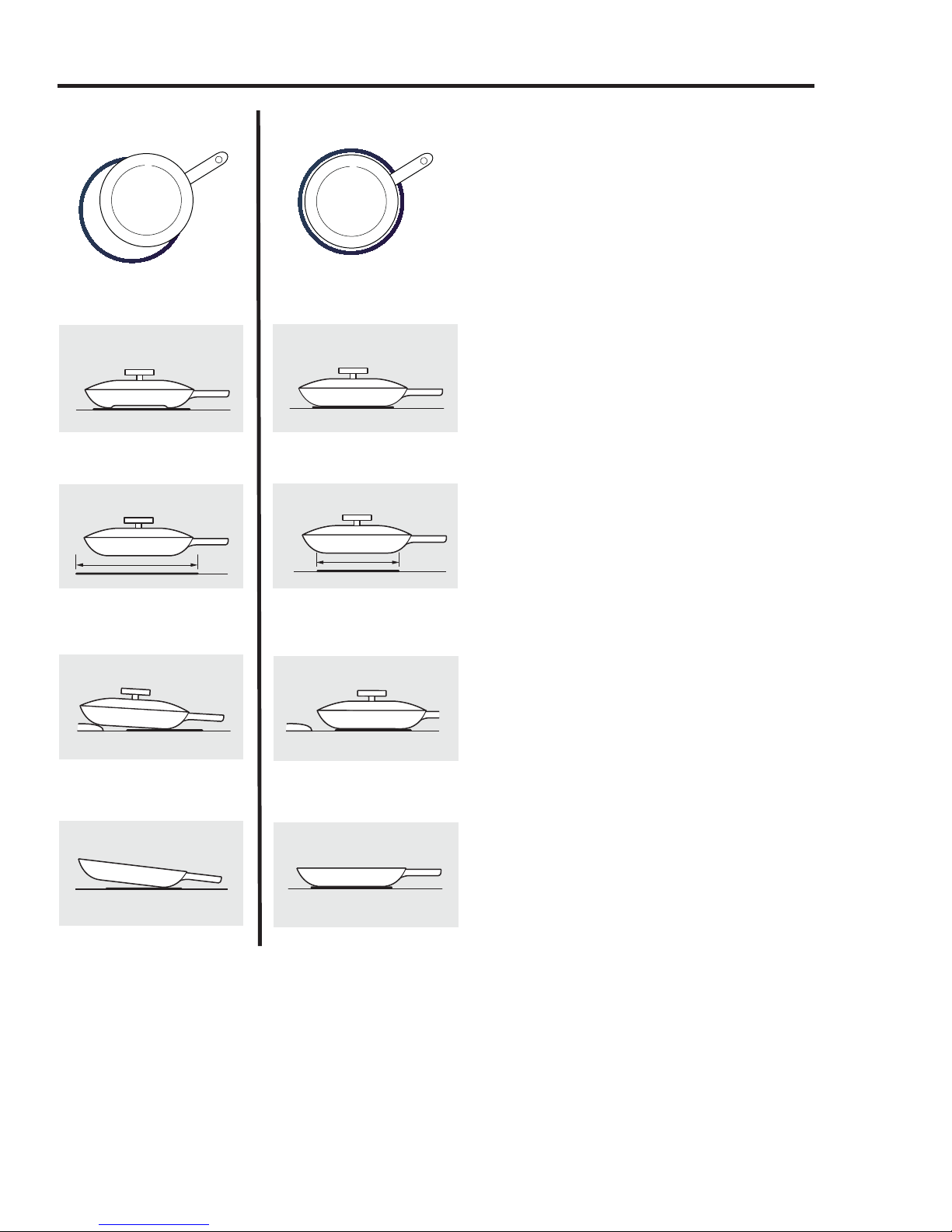

Choosing the correct cookware to use.

INCORRECT

Cookware not centered on cooking

element surface.

Curved or warped pan bottoms

or sides.

CORRECT

Cookware centered correctly

on cooking element surface.

Flat pan bottom.

Cookware recommendations

Cookware must fully contact the surface of the

cooking element.

Use flat-bottomed pans sized to fit the cooking

element and also to the amount of food being

prepared.

CAUTION:

■ The cooking elements may appear to be cool while

turned ON and after they have been turned OFF.

The glass surface may be HOT from residual heat

transferred from the cookware and burns may occur.

■ DO NOT TOUCH HOT COOKWARE or PANS directly

with hands. Always use mitts or pot holders to

protect hands from burns.

■ DO NOT SLIDE cookware across the cooktop

surface. Doing so may permanently damage the

appearance of the ceramic cooktop.

Pan does not meet the minimum

size required for the cooking

element used.

Pan bottom rests on cooktop trim

or does not rest completely on the

cooktop surface.

Heavy handle tilts pan.

Pan size meets or exceeds the

recommended minimum size

for the cooking element used.

Pan bottom rests completely on the

cooktop surface.

Pan is properly balanced.

– 10 –

(Continued next page)

Page 11

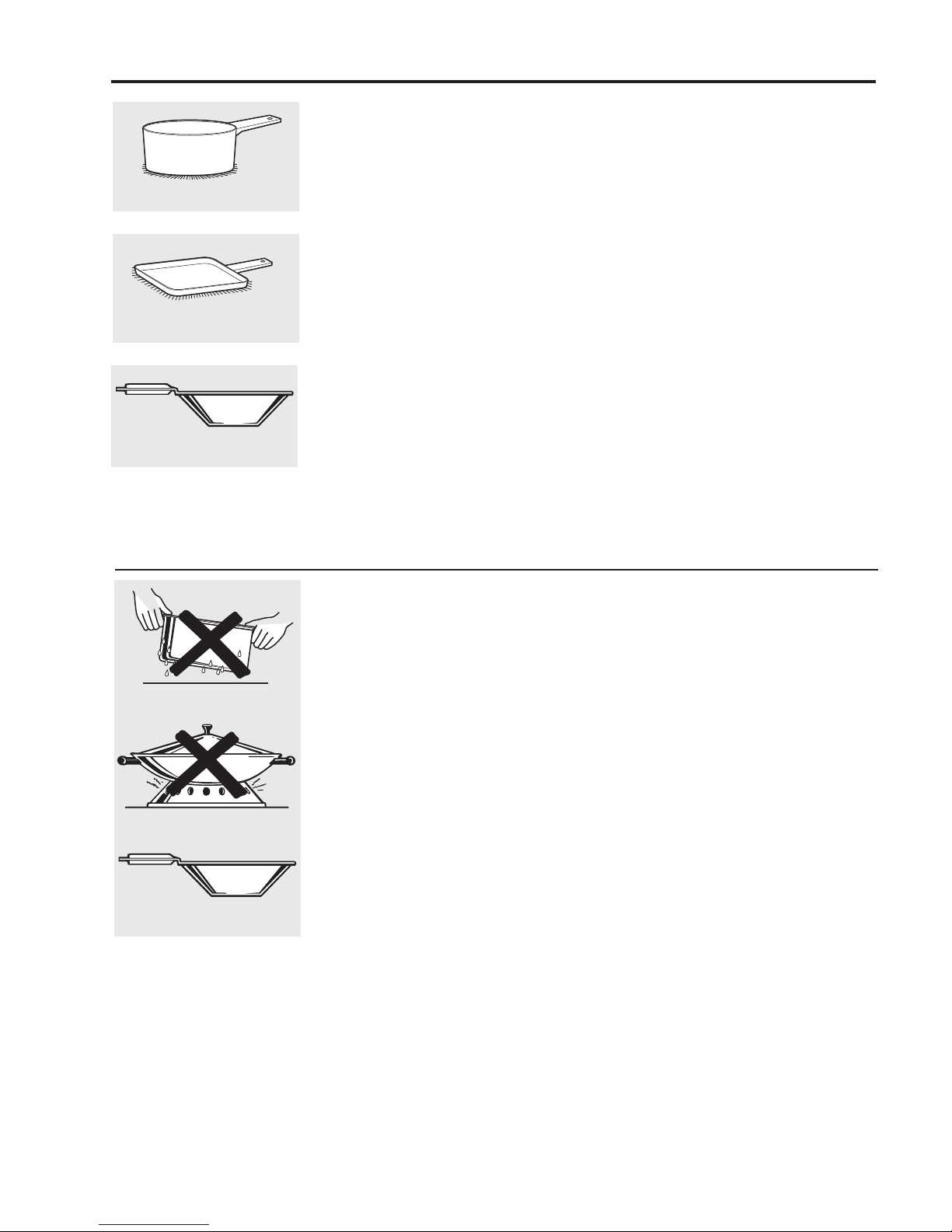

Use flat-bottomed pans.

Use a griddle.

Use a flat-bottomed wok.

Suitable Cookware

Use quality cookware with heavier

bottoms for better heat distribution

and even cooking results. Choose

cookware made of magnetic stainless

steel, enamel coated cast iron,

enameled steel and combinations

of these materials.

Some cookware is specifically

identified by the manufacturer for use

with induction cooktops. Use a magnet

to test if the cookware will work.

Flat-bottomed pans give best results.

Pans with rims or slight ridges can be

used.

Round pans give best results. Pans

with warped or curved bottoms will

not heat evenly.

For wok cooking, use a flat-bottomed

wok. Do not use a wok with a support

ring.

Cookware “noise”

Slight sounds may be produced by

different types of cookware. Heavier

pans such as enameled cast iron

produce less noise than a lighter

weight multi-ply stainless steel pan.

The size of the pan, and the amount

of contents, can also contribute to

the sound level.

When using adjacent elements that are

set at certain power level settings,

magnetic fields may interact and

produce a low whistle or intermitted

"hum". These noises can be reduced or

eliminated by lowering or raising the

power level settings of one or both of

the elements. Pans that completely

cover the element ring will produce less

noise.

A low “humming” noise is normal

particularly on high settings.

Do not place wet pans

on the glass cooktop.

Do not use woks with support

rings on the glass cooktop.

Use flat-bottomed woks

on the glass cooktop.

For Best Results

■ Do not place wet pans or lids on the

cooking surface or induction rings.

■ Do not place wet fingers on the glass

cooktop. Wipe up spills on the controls

with dry hands.

■ Do not use woks with support rings. This

type of wok will not heat on an induction

element.

■ Use only a flat-bottomed wok, available

from many cookware manufacturers.

The bottom of the wok should match the

diameter of the induction ring to insure

proper contact.

■ Some special cooking procedures

require specific cookware such as

pressure cookers, deep-fat fryers, etc.

Cookware with flat bottoms that match

the size of the surface element being

used will produce the best results.

– 11 –

Page 12

Setting the controls.

Using the Touch Control.

Touch the pad lightly with the flat part

of your fingertip. Touch the center of the

pad to ensure the cooktop response.

Operating the Cooking Elements

A "beep" sound can be heard with each

touch to any pad.

1/2

The power level with a fraction

indicates the additional half-step

setting.

Each of the cooking elements have

separate ON/OFF pads and LED display.

Be sure to use cookware that meets the

minimum pan size requirements.

To turn on a cooking element:

Place a pan with food onto the

induction element. The pan size

should match the indicator ring.

Touch the ON/OFF pad. “5” will flash

in the display.

Touch the (+) or (-) pad to select power

level and to activate the induction

element. A sound will beep. The (+) or

(-) pad must be pressed within 10

seconds to activate the element.

NOTE: You can also touch and hold the

pad to scroll quickly to the desired setting.

Power Level Settings

The cooktop offers 19 power levels,

including a Boost setting. Power levels

range from “L” to 9 in precise half-step

increments. For example: 1, 1-1/2, 2,

2-1/2 and up to power level 9.

Power Level “L”, the lowest setting, is

recommended for “Keep Warm.”

The induction circuit detects the pan and

allows the element to be activated. Both

the element ON indicator light and the

cooktop HOT SURFACE light will illuminate.

If no power level is selected within 10

seconds, the zone will be deactivated.

To turn the control to OFF, touch the

ON/OFF pad. The induction element will be

turned off and the display will be blank.

With an element control ON:

If a pan is removed or moved to off-center

from the cooking ring, the control will flash

“F” along with the power setting. After 30

seconds, the element will be deactivated

and displays will turn off.

If the pan is placed back on the zone

within 30 seconds, the flashing will stop

and cooking will resume.

The power level increases one-half level

with each touch.

Power level 9 is the highest normal

power setting.

Flashing “F” in the Display

If a pan is removed or moved off-center

from the cooking ring during the

cooking process, the control will flash

“F” along with the power setting. The

flashing "F" indicates that the pan is no

longer detected. After 30 seconds, the

element will be deactivated and the

display will turn off.

If the pan is returned to the surface

element within 30 seconds, the flashing

“F” will disappear and cooking will

resume.

(Continued next page)

– 12 –

Page 13

“H” indicates that the Boost power

level has been selected for rapid

cooking and boiling.

Boost Setting

Boost is the highest power level, designed

for large quantity rapid cooking and

boiling. Boost will operate for a maximum

of 10 minutes. After 10 minutes, it will

automatically revert to power level 9.

Boost may be repeated after the initial

10 minute cycle.

CAUTION: Do not leave a pot unattended

while in the Boost Mode.

To start the Boost power setting:

Place a pan matching the size of the

induction element over the selected

indicator ring.

Touch the ON/OFF pad. “5” will flash

in the display.

Touch and hold the (+) pad until the

display reads “H.”

Power Sharing

Four burner cooktops are divided into two separate

heating zones. The right and left side cooking zones

are powered by separate and independent induction

generators. One generator controls 2 elements, or two

cooking zones within a heating section share the power

of one generator.

NOTE: If the pan is removed, the display

will flash “F” alternating to “H”. After 30

seconds, the elements will turn off

automatically.

Sounds you may hear:

You may hear a slight “buzz” sound when

cooking with the Boost or high mode. This

is normal. The sound depends on the type

of pot being used. Some pots will “buzz”

louder depending on the material. A “buzz”

sound may be heard if the pan contents

are cold. As the pan heats, the sound will

decrease. If the power level is reduced, the

sound level will go down.

4 burner cooktops with right and left side (2) induction generators.

5 burner cooktops with right, left and center (3) induction generators.

Five burner cooktops are divided into 3 zones. The

right and left side have separate cooking zones and the

large center element is another separate cooking zone.

Power Sharing is activated when both elements in the

same cooking zone are activated and one element is

set for Boost (H). The element that is not set for Boost

will change to a lower power level. This is called

Power Sharing. When Boost operation is complete

(10 minutes), the other element may be reset to any

power level. Both elements can operate simultaneously

at normal power level settings of “L” to 9.

IMPORTANT NOTE FOR FOUR BURNER MODELS:

The elements on the right side share one generator.

Both elements can operate at any non-Boost (level L

to 9) power level at the same time. If the large front

element is set for "H" or Boost, the smaller element

at the right rear will be deactivated or turned off

automatically. The smaller right rear element can be

activated and set for any power level after the Boost

operation of the larger element is completed (10

minutes).

– 13 –

(Continued next page)

Page 14

Using the "L" Low Setting

Place a pan with food onto the

induction element. The pan size

should match the indicator ring.

The Low setting will keep hot, cooked food

at serving temperature. Always start with

hot food. Do not use to heat cold food.

CAUTION: Do not warm

food on the “L” power level

for more than two hours.

Touch the ON/OFF pad. “5” will flash

in the display.

Touch the (-) pad until the display

reads “L.” A sound will beep.

Do not use plastic wrap to cover food.

Plastic may melt onto the surface and be

very difficult to remove.

Use only cookware recommended for

this cooktop.

Using the Kitchen Timer

NOTE: Use the kitchen timer to measure

cooking time or as a reminder. The kitchen

timer does not control the cooking

elements.

Touch the Timer ON/OFF pad.

Touch the (+) or (-) pad to choose the

desired number of minutes. When the

(+) or (-) pad is held for several

seconds, the timer will increase or

decrease at a faster rate. The timer will

automatically start to count down the

minutes you have selected within 5

seconds of the last entry. The display

will show the minutes and a “

will flash.

.“

Placing uncooked or cold food on surface

element set for Low could result in foodborne illness.

For best results, all food set for Low should

be covered with a lid or aluminum foil.

Pastries or breads should be vented to

allow moisture to escape.

Always use pot holders or oven mitts when

removing food from the element set for

Low as cookware and plates will be hot.

The timer displays minutes remaining

until it reaches one minute. At one

minute, the timer will beep and start

counting down seconds.

With one minute remaining, the timer

will beep every 10 seconds. When all

time has counted down, the timer will

signal a long beep and the display will

become blank.

Touch the ON/OFF pad to turn the timer

off at any time. Touch (+) or (-) to add or

subtract to the set time.

Hot Surface Indicator Light

A HOT SURFACE indicator light (one for each

cooking element) will glow immediately

when any element is activated. The

indicator light(s) glow when the glass

surface is hot, and will remain on until the

surface has cooled to a temperature that is

safe to touch.

– 14 –

Page 15

Using the surface elements. ge.com

Error Alerts (Flashing “E”/”c” and “E” “o”)

Error alerts indicate a temporary problem

that may be corrected by the user.

Clear Keypad—If the display flashes “E”

alternating to “c”, the keypad is sensing

continuous activation of one or more

keypads. Clean or clear any obstructions

on the keypad area. Obstructions may be

water, food spills, a utensil or other objects.

To resume cooking, touch the ON/OFF pad,

then select the power level.

Over Temperature—If the display flashes

“E” alternating to “o”, the cooktop sensor

indicates that the induction element or

electronics have overheated.

Overheating of the element is caused by

placing an empty pan on the element and

selecting a high power level. The element

sensor detects very high temperatures

(above normal cooking temperatures),

turns off the power and displays the error.

A second potential cause of this error is

a lack of cooling air to the bottom of the

cooktop, which can cause overheating

of the electronics. If this situation occurs,

make sure the air inlet below the cooktop

is unobstructed.

Touch the ON/OFF pad and allow the

cooktop to cool for 30 to 45 minutes before

operation can begin again.

If either of these conditions persist,

call for service.

IMPORTANT: If the “E” flashes alone,

without alternating to a “c” or “o”, a

hardware error has occurred. Call for

service.

Control Lock

IMPORTANT: As a convenience, you can

lock the entire cooktop at any time when it

is not in use or before cleaning. Locking the

cooktop will prevent surface elements from

being turned on accidentally.

To lock the cooktop:

Touch and hold the CONTROL LOCK pad

for 5 seconds.

A two-beep signal will sound, and the

CONTROL LOCK light will glow, indicating

that the cooktop is locked.

If the cooktop is locked while a surface

element is in use, it will automatically

turn off.

The CONTROL LOCK does not affect the

timer. If Control Lock is set while the timer is

counting down, it will continue to operate.

To unlock the cooktop:

Touch and hold the CONTROL LOCK pad

again for 5 seconds. A two-beep signal will

sound, and the CONTROL LOCK light will

go out, indicating that the cooktop is

unlocked.

– 15 –

Page 16

Operation Overview

Normal Operation:

When activated by the touch board, a fi lter board

supplies 240 VAC to 1 or 2 generator boards along

with the LINbus (Logic) connections. Each generator

board operates 1 or 2 elements.

The 30-in cooktops have 1 fi lter board that supplies

voltage to 2 generator boards. The left generator

board operates the 2 left-side elements. The right

generator board operates the 2 right-side elements.

Filter Board

The 36-in. cooktops have 2 fi lter boards that supply

voltage to 3 generator boards. The left fi lter board

supplies voltage to the left generator board. The left

generator board operates the 2 left-side elements.

The right fi lter board supplies voltage to the center

and right generator boards. The center generator

board operates the center element and the right

generator board operates the 2 right-side elements.

Right Filter Board

Left Filter Board

Left

Generator

Board

Center

Generator

Board

Right

Generator

Board

Left

Generator

Board

Right

Generator

Board

Generator board maximum output is 3700W. When

using an element on high and a second element

sharing the same generator board is then operated,

the second element will receive priority. For

example, if the fi rst element was using 3700W when

the second element was turned on, power on the

fi rst element will be reduced to a lower setting.

7 "- 2500 W

7 "- 2500 W

7 "- 2500 W

7 "- 2500 W

Element Size and Wattage

30-in. Cooktop

6 "- 1800 W

11 "- 3700 W

36-in. Cooktop

6 "- 1800 W

11 "- 3700 W

8 "- 3200 W

– 16 –

Page 17

Component Locator Views

t

e

u

36-in. Models ZHU36 and PHP960

Glass

Elements

Insulation Left

Left

Generator

Module

Filter

Board

Left

Side

Generator

Board

Left

Generator

Module

Box

Fan Covers

Fan

Center

Generator

Board

Foam Seals

Wire Harness

Wiring

Cable

Harness

Kit

Electrical

Cover

Touch Board

Filter

Board

Conduit

Clamp

Insulation Right

Aluminum

Heat Shield

Righ

Gen

Mod

Right Side

Generator Board

Right Generator Module Box

Protective Tape

Burner Box

Hold-Down

Brackets with

Thumbscrews

Baffle

– 17 –

(Continued next page)

Page 18

30-in. Models ZHU30 and PHP900

Elements

Touch Board

Shield

Glass

Wiring Harness

Cable Kit

Left Side

Generator

Board

Fan

Fan Cover

Foam Seal

Wire Harness

Electrical

Cover

Filter Board

Right Side

Generator

Board

Generator Module

Generator Module Box

Protective Tape

Burner Box

Hold-Down

Brackets with

Thumbscrews

Conduit

Clamp

Baffle

– 18 –

Page 19

36-in. Models ZHU36 and PHP960

Aluminum

Heat Shield

Touch Board

Filter Board

Left Side Generator Board Center Generator Board

Left Side

Fan

Main Fan

Thermal

Cut-out

Filter Board

Thermal

Cut-out

Right Side Generator Board

– 19 –

(Continued next page)

Page 20

30-in. Models ZHU30 and PHP900

Aluminum

Heat Shield

Touch Board

Fan

Filter Board

Thermal

Cut-out

Right Side Generator Board

Left Side Generator Board

– 20 –

Page 21

Cooktop Components

WARNING: Before servicing the cooktop, power

must be removed from the cooktop by turning the

power off at the circuit breaker.

WARNING: Sharp edges may be exposed when

servicing. Use caution to avoid injury. Wear Kevlar

gloves or equivalent protection.

Note: When servicing the cooktop, care must be

taken not to scratch or damage the glass.

All components are accessible by removing the •

glass top.

If the display/touch board is damaged, it can •

be replaced as a unit by removing the glass top

and replacing the touch board. The touch board

is located by pins and springs/foam tape on the

back side of the board.

If the power or fi lter boards are damaged, they •

can be replaced by removing the glass top,

removing the elements, removing the touch

board, and removing the aluminum heat shield

and insulation. This will allow access to the

electronics assemblies, and the board can be

removed and replaced.

Cooktop Removal From Countertop

To remove the cooktop from the countertop:

Caution: The hold-down brackets, heat baffl e (if

installed), and screws on the bottom of the burner

box can damage the countertop surface. Use care

to protect the countertop appearance.

Open the cabinet door and remove each of the 1.

2 thumbscrews that secure the cooktop to the

bottom of the countertop.

Remove the outer hex-head screw from each 2.

hold-down bracket.

Loosen the inner hex-head screw from each 3.

hold-down bracket.

Cooktop Countertop

Cooktop

Bracket

Countertop

Appearance Defects

Scratches, marks, discoloration, stains, spots, etc.

can be caused by food, cookware, utensils, cleaning

solutions, or water. Before replacing the cooktop,

use the cooktop cleaning procedure outlined in the

Owner’s Manual.

Thumbscrew

Inner Screw

Outer Screw

– 21 –

(Continued next page)

Page 22

4. Turn the bracket inwards to avoid interference

when lifting the cooktop from the countertop.

Bottom of Cooktop

Note: In the following step a baffl e is not installed if

cooktop is installed over an oven.

Glass Maintop

The glass maintop must be removed for element,

sensor testing, and touch board replacement. The

glass maintop is attached to the burner box with

twelve 1/4-in hex-head screws (4 on the front, 4 on

the back, and 2 on each side). After removing the

screws, the glass maintop can then be lifted straight

up and placed on a towel or padded surface.

30-in. Model

Elements

5. Remove the two 1/4-in. hex-head screws and

the baffl e from the bottom of the cooktop.

Note: In the following step, it will be necessary to

utilize 2 strips of wood or cardboard.

6. Push upward on the bottom of the burner box

approximately 4 in. and rotate slightly left or

right (to the best working advantage). Shim

under the burner box with protective wood or

cardboard as shown.

Each element consists of a coil and a sensor. The

resistance value of the coil is less than 1Ω at room

temperature. The resistance value of the sensor is

1000Ω at room temp (+or-10%). The sensor has a

positive coeffi cient. As the temperature increases,

the sensor's resistance increases. The sensor and

coil are replaced as a complete assembly.

To remove heating elements:

Remove the glass maintop. (See 1. Glass Maintop.)

Mark the alignment pins and guides for correct 2.

replacement.

Caution: To prevent damage to element insulation,

care should be taken when handling an element.

Note: If some insulation should separate from the

element, it can be placed back on the element in its

original position. Do not use any adhesives.

3. Lift an element off the pins and carefully place it

away from the wire entry.

+

O

N

/O

F

F

-

P

r

o

f

i

l

e

+

O

+

N

/O

F

F

O

N

/O

F

-

F

-

HOT

WA

R

MING ZO

1

2

IN

N

E

9

IN

+

6 IN

O

N

/

O

F

S

F

U

-

R

FA

C

E

C

O

N

T

R

O

L

LOC

+

K

O

N

/

O

F

F

-

Guide

Sensor

Element

Pin

(Continued next page)

– 22 –

Page 23

4. Lift and fold back the insulation from the wire

entry in the heat shield.

Note: On 11- and 8-in. elements, the choke must

be removed and transferred to the replacement

element. The choke must be attached at the same

location on the wires and secured with a plastic wire

tie.

Insulation

5. Note the routing of the element wires and

loosen the two slotted T-25 Torx screws holding

the element wires to the generator board.

Note

The element wire terminals are forked and can •

be removed without completely removing the

screws.

The individual wires from each element have no •

polarity and can be connected to either of the

screw posts for that specifi c element.

6. Use a fl atblade screwdriver to press the lock tab

inward, then lift the element sensor connector

from the generator board.

Choke

Plastic Wire Tie

Touch Board

The touch board employes a capacitive touch

system. When the glass keypad is touched, the

circuit is completed and the touch board responds

to the selection.

The touch board is positioned under the glass top.

Springs attached to the bottom of the touch board

and capacitance foam pads on top, provide precise

touch sensitivity between the touch board and the

cooktop glass.

To remove the touch board:

7. Extract the element wiring from the wire entry in

the heat shield.

Element Connection

Sensor Connection

Element Connection

Remove the glass maintop. (See 1. Glass Maintop.)

Note the location of the touch board wire 2.

harness, then disconnect the wire harness from

the touch board.

Note: To insure proper positioning when replacing

the touch board, be sure to engage pins in guides.

Pin

Capacitance Foam Pad

Guide

– 23 –

(Continued next page)

Page 24

Note: The bottom of the touch board is attached to

the heat shield with an adhesive foam cushion.

3. Raise the back of the touch board

approximately 1 inch. Using a putty knife at a

shallow angle, gently separate the foam spacer

from the heat shield.

Putty Knife

Note: If one or more functions do not work and no

apparent damage is present, the cause can be an

excessive fl at-bottom drop of the packaged unit

during shipping/handling. The force of the drop can

position the heat shield out of proper alignment to

the heat shield mounting tabs. This would cause

improper spacing between the underside of the

glass top and the capacitive switches on the

module, rendering the switches inoperative.

Result of Excessive Flat-bottom Drop

Heat Shield Tab

Note: Make sure all springs and capacitance foam

pads are in place for precise touch sensitivity

between the touch board and the cooktop glass.

Spring

Heat Shield

To correct a misaligned heat shield it is necessary to

remove the glass top. (See Glass Top.)

There are 10 tabs on 30-in. models and 14 tabs

on 36-in. models. All tabs are located along the

perimeter of the heat shield.

Tab Locations- 30-in. Model

– 24 –

(Continued next page)

Page 25

Tab Locations - 36-in. Model

In the following illustrations, the heat shield is out of

alignment due to an excessive fl at-bottom drop of

the cooktop. A large fl at blade screwdriver can be

inserted in the gap on the left-side of the tab.

It may be necessary to insert the screwdriver in the

right-side gap, push down on the screwdriver, and

raise the heat shield even with the tab.

Inspect all tab-to-heat shield alignment areas.

Repeat this alignment procedure on all tabs, if

necessary.

The heat shield can be aligned with the tab by

pushing down on the screwdriver and raising the

heat shield even with the tab.

Properly Aligned Heat Shield

– 25 –

Page 26

Heat Shield

To remove the heat shield:

Remove the elements. (See 1.

6. Remove the 20 Phillips-head screws from the

top of the heat shield. (On 30-in. models, remove

the 5 Phillips-head screws from the top of the

heat shield.)

Elements.)

Lift and remove the left and right insulation 2.

spacers.

Disconnect the touch board wire harness and 3.

remove the tape that holds the harness to the

heat shield.

Lift the insulation from the wire entry in the heat 4.

shield and tuck the touch board wire harness

under the heat shield.

36-in. model shown

Disconnect

Rail

36-in. model shown

7. Raise the rear of the heat shield approximately 3

inches and disconnect the 2 ground wires from

the bottom of the heat shield.

Rear view shown

Insulation Spacers

5. On 36-in. models, remove the fourteen 1/4-in.

hex-head screws, (5 on the front, 5 on the back,

and 2 on each side) from the outside of the

burner box. (On 30-in models, remove the 10

1/4-in. hex-head screws, (3 in the front, 3 in the

back, and 2 on each side) from the outside of

the burner box.)

36-in. model shown

8. Lift and remove the heat shield from the burner

box.

Note

The generator modules are not secured to •

the burner box. With the heat shield removed,

generator modules can be accidentally moved

out of position. To ensure proper alignment of

the modules to the heat shield, it may be helpful

to note and mark the position of the generator

modules.

If a generator module has shifted out of position, •

it may be helpful to drive one corner screw and

then shift the generator module as necessary to

align the other holes.

– 26 –

Page 27

LINbus Connectors

Caution: To prevent damage to LINbus (Local

Interconnect Networkbus) connections, properly

use (as shown below) a Molex 69008-1070 tool when

removing LINbus connectors.

Note: A Molex 69008-1070 tool will be provided with

any part that requires the LINbus connectors to be

removed.

Molex 69008-1070 Tool

Correct way: Use side-to-side motion to remove the

LINbus connector.

CORRECT

Note

LINbus is a communication network comprised •

of a LIN master and one or more LIN slaves. In

these cooktops, the fi lter board (right fi lter board

on 36-in. models), acts as the LIN master while

the generator boards and left fi lter board (on

36-in. models) are the LIN slaves.

Do not use front-to-back motion to remove LINbus

connector.

INCORRECT

All of these components receive a signal to •

perform a specifi c task, but only the appropriate

component will act on the message and

respond accordingly. The component which acts

on the specifi c task is based on programming.

Since the LINbus signal is a digital control signal,

special equipment, such as an oscilloscope, is

required to measure it.

Touch

Board

Generator

Board

Element

Filter

Board

Generator

Board

Element

– 27 –

Page 28

Generator Boards

To remove the generator boards:

Remove the heat shield. (See 1.

Note: The thermal cut-out on the right and left

generator boards on the 30-in. model and on the

center and right generator boards on the 36-in.

models are joined together with 2 metal clips. The

clips must be removed to replace either generator

board.

2. If applicable, use a small fl at blade screwdriver

to pry up and remove the 2 thermal cut-out

clips.

Clip

Heat Shield.)

6. Remove the two T-15 Torx screws that hold the

generator to the module base.

7. Lift the heat sink side and slide the generator

board away from the 2 tabs on the module

base.

Tab

Disconnect

Disconnect

Disconnect

Tab

Thermal

Cut-out

Clip

3. Mark the location of the black L1 and the blue L2

wires and disconnect both from the generator

board.

Note: When replacing the L1 and L2 wiring

connecting the fi lter board to the generator board,

connect that wiring in a matching confi guration. For

example, if the L1 output is connected to the bottom

terminal on the fi lter board, it must be connected to

the bottom terminal on the generator board.

Thermal Cut-out

The thermal cut-out is located between the fi ns of

each generator board heat sink and is connected

to the fi lter board with a wire harness. The location

of the thermal cut-out allows it to sense an overtemperature condition of the generator board.

The thermal cut-out has a resistance value of less

than 1 Ω and opens at approximately 250°F. An

open thermal cut-out will stop operation of the

cooktop. If the thermal cut-out is open, check for

proper operation of the fan and possible vent

obstructions.

Disconnect

4. Disconnect the LINbus connector. (See

Connectors.)

5. Note the position of the thermal cut-out and pull

it out of the heat sink fi ns.

LINbus

Thermal Cut-out

– 28 –

Page 29

Filter Board

To remove the main fi lter board:

5. Mark the location, then disconnect the black L1,

blue L2, and ground wire connections on the

fi lter board.

Remove the heat shield. (See 1.

Heat Shield.)

Lift the front of the module and mark the 2.

location of the black, red, and green wires and

the 2 jumper blades connected to the fi lter

board power terminals.

Using a T-20 Torx or a fl at blade screwdriver, 3.

remove the 4 screws, black and red wires, and

the 2 jumper blades.

Loosen the ground wire screw and remove 4.

the ground wire from the fi lter board power

terminal. Lower the module into the burner box.

LINbus

Remove

Tab

6. Disconnect the thermal cut-out, touch board,

and fan motor wire harnesses.

7. On 36-in. models, disconnect the fi lter-to-fi lter

wire harness.

8. Disconnect the LINbus connectors. (See

Connectors.)

LINbus

9. Using a fl at blade screwdriver, carefully press in

the large 1 (30-in. model) or 2 (36-in model) tabs

away from the fi lter board. Lift the fi lter board

and pull the fi lter board away from the smaller

tab on the module base.

Remove

Jumper

Blade

Remove

Remove

Loosen

Jumper

Blade

Bottom of module shown

Tab

Note

Tab

LINbus

Touch Board

Wire Harness

Filter-to-Filter

Wire Harness

Arrows indicate disconnect locations

To remove the left side fi lter board on the 36-in. model, follow steps 1, and 5 through 9. The touch board •

wire harness is not connected to the left side fi lter board.

The left side fi lter utilizes a non-replaceable fuse. Never attempt to replace the fuse. If the fuse is found to •

be open, replace both left side fi lter and generator boards.

– 29 –

Page 30

Fans

The fan on the 30-in. model cools the left and right

generator board heat sinks.

The 36-in. model utilizes 2 fans. The main fan cools

the right and center generator board heat sinks. An

additional fan cools the left side generator board

heat sink.

Fans change speed based on heat. At low settings

the fan may not operate. As heat increases, the

fan will come on and increase in speed as heat

increases. When the highest power level (Boost)

is selected (indicated by H on the display), the fan

automatically comes on.

A single wire harness is connected to each fan

motor. All fans are operated by 12 VDC motors.

Caution: To prevent damage to fragile fan locking

tabs, test fan before removing it from the module.

Note: When testing these fans:

• You cannot test with an ohmmeter.

30-in. Model Fan and 36-in Model Main Fan

Disconnect

36-in. Model Left Side Fan

Disconnect

• Fan can be run for a short period of time using

a 9-volt battery. Connect the negative (-) battery

terminal to the black wire. Connect the positive (+)

battery terminal to the white wire.

The fan for the 30-in. model and the main fan on the

36-in. model are attached to the module base with 5

tabs. On the 36-in. model the left side generator fan

is attached to the module base with 3 locking tabs.

It is necessary to remove the heat shield to access

the fans. (See Heat Shield.)

– 30 –

Page 31

Diagnostics and Service Information

Failure Codes

The cooktop operates a self-diagnostic mode when power is applied. The touch board has error codes that

can be utilized by the service technician in order to quickly identify failed or improper operation of certain

cooktop components. To access failure codes, simultaneously press the TIMER ON/OFF and CONTROL LOCK

for approximately 10 seconds. Error codes will blink in the window of the corresponding element. The

pads

replacement of the failed component will clear the error code.

Whenever a failure code is encountered and before attempting to replace any components:

Turn off the power supply for 30 seconds, then reset it to see if this clears the failure code.1.

Verify proper voltage and orientation of the power supply wiring connections.2.

FAULT CAUSE CORRECTIVE ACTION

Er31

(36-in. models

only)

Er47 Bad communication in the ribbon

Er39 Internal electronic failure on

Er20 Internal electronic failure on

Er22 Internal electronic failure on

Ec Touch board is perceiving water

Eo Rate of temperature increase is

One fi lter board not confi gured to

work with the other fi lter board.

cable between touch board and

fi lter board.

touch board

touch board

touch board

or food on keypanel.

too fast or temperature at element is too high

Press and hold timer up key.

Press and release RF on/off key.

Press and release LF key.

Release timer up key.

Allow display to scroll horizontal bars and beep.

Replace fi lter board.

Visually check ribbon cable connection from touch

board to fi lter board.

Replace fi lter board.

Replace touch board.

Replace touch board.

Replace touch board.

Clean keypanel area. Replace touch board.

Check if an empty pan is being heated.

Check for obstruction in fan, wire connections to board.

Check fan vents for air blockage. Replace element.

(Continued next page)

– 31 –

Page 32

FAULT CAUSE CORRECTIVE ACTION

E5 Internal electronic failure on fi lter

board

E6 Internal electronic failure on gen-

erator board

E7 Unknown error in system Visually check for loose wires/connections. Replace

E9 Rate of temperature increase is

too fast or open sensor

Element not

Auto shut off activated Refer to Owner’s Manual―unit shuts down

hot enough/

element shuts

down

Foreign object on keypanel area

is activating touch board.

Pan not detected. Check pans for fl at bottom.

Pan not detected. Check pans with magnet for steel content.

Pan not detected. Check pan size vs element size.

Element turns off if pan is off

burner more than 30 seconds.

Element

changes

Internal temperature mainte-

nance

cooking level

Fan not running

Display fl ash-

es,

not heating

Fan doesn’t run at low heat set-

tings.

Pan not detected. Check pans for fl at bottom.

Pan not detected. Check pans with magnet for steel content.

Pan not detected. Check pan size vs element size.

Element not connected, open

connection.

Buzzing sound Elements may make a “buzz”

sound on boost and high.

Check AC coming to home >208 VAC.

Replace fi lter board.

Replace generator board.

generator module.

Visually check sensor connection to generator board.

Replace element.

Replace generator board.

after 18 hours.

Clear obstruction from keypanel.

Check if pan has been removed from element for more

than 30 seconds.

Refer to Owner’s Manual―element reduces from Boost

to 9 after 10 minutes.

Fan changes speeds based on heat.

Check connections on element wires.

Refer to Owner’s Manual― element may make an audible sound when on high.

– 32 –

Page 33

WARNING: To prevent electrical shock, disconnect power to the cooktop prior to servicing.

Model ZHU36 and PHP960

Aluminum Plate

Schematics and Wiring Diagrams

2 Wire

CAUTION: *A special tool

is required when removing

the connections (marked

with an *) from the circuit

boards. Damage to the

circuit boards or cables

may occur without

the special tool.

*

Caution: *A special tool is required

when removing the connections

(marked with an *) from the circuit

boards. (See LINbus Connectors.)

Damage to the circuit boards or wiring

harnesses may occur without utilizing

the special tool.

X3

Not used

X2

Not used

4 Wire

X1

– 33 –

*

*

*

WIRE COLORS

BARE U

BLACK B or BK

BLUE N or BU

BROWN C or BR

GRAY S or GY

GREEN G or GN

ORANGE O

RED R

VIOLET V

WHITE W

YELLOW Y

(Continued Next Page)

Page 34

Model ZHU30 and PHP900

Aluminum Plate

Ground

CAUTION: *A special tool

is required when removing

the connections (marked

with an *) from the circuit

boards. Damage to the

circuit boards or cables

may occur without

the special tool.

*

GND

L1

L2

Caution: *A special tool is required

when removing the connections

(marked with an *) from the circuit

boards. (See LINbus Connectors.)

Damage to the circuit boards or wiring

harnesses may occur without utilizing

the special tool.

– 34 –

Touch Board

Cable

WIRE COLORS

BARE U

BLACK B or BK

BLUE N or BU

BROWN C or BR

GRAY S or GY

GREEN G or GN

ORANGE O

RED R

VIOLET V

WHITE W

YELLOW Y

Page 35

Warranty

All warranty service provided by our Factory Service Centers,

or an authorized Customer Care

®

technician. To schedule

service, on-line, visit us at ge.com, or call 800.GE.CARES

(800.432.2737). (In Canada, call 1.800.561.3344.) Please have

Staple your receipt here.

Proof of the original purchase

date is needed to obtain service

under the warranty.

serial number and model number available when calling for

service.

For The Period Of: GE Will Provide:

One Year Any part of the cooktop which fails due to a defect in materials or workmanship. During this

From the date of the limited one-year warranty, GE will also provide, free of charge, all labor and in-home service

original purchase to replace the defective part.

What GE Will Not Cover:

■ Service trips to your home to teach you how to use

the product.

■ Improper installation, delivery or maintenance.

■ Failure of the product if it is abused, misused,

or used for other than the intended purpose or

used commercially.

■ Damage to the glass cooktop caused by use of

cleaners other than the recommended cleaning

creams and pads.

■ Replacement of house fuses or resetting of circuit

breakers.

■ Damage to the product caused by accident, fire, floods

or acts of God.

■ Incidental or consequential damage caused by possible

defects with this appliance.

■ Damage caused after delivery.

■ Product not accessible to provide required service.

■ Damage to the glass cooktop caused by hardened

spills of sugary materials or melted plastic that

are not cleaned according to the directions in

the Owner’s Manual.

EXCLUSION OF IMPLIED WARRANTIES—Your sole and exclusive remedy is product repair as provided in this Limited

Warranty. Any implied warranties, including the implied warranties of merchantability or fitness for a particular

purpose, are limited to one year or the shortest period allowed by law.

This warranty is extended to the original purchaser and any succeeding owner for products purchased for

home use within the USA. If the product is located in an area where service by a GE Authorized Servicer is not

available, you may be responsible for a trip charge or you may be required to bring the product to an Authorized

GE Service location for service. In Alaska, the warranty excludes the cost of shipping or service calls to your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty

gives you specific legal rights, and you may also have other rights which vary from state to state. To know

what your legal rights are, consult your local or state consumer affairs office or your state’s Attorney General.

Warrantor in the USA: General Electric Company. Louisville, KY 40225

Warrantor in Canada: Mabe Canada Inc., Burlington, Ontario

– 35 –

Loading...

Loading...