GE Profile JGP656 Series, Profile JGP6560 Series, Monogram ZGU365 Series, Monogram ZGU3650 Series Technical Service Manual

Page 1

g

GE Consumer Home Services Training

TECHNICAL SERVICE GUIDE

Monogram/Profile

Gas Cooktop

MODEL SERIES:

JGP656

JGP6560

ZGU365

ZGU3650

PUB # 31--9056 08/00

Page 2

!

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by

individuals possessing adequate backgrounds of electrical,

electronic, and mechanical experience. Any attempt to repair a

major appliance may result in personal injury and property

damage. The manufacturer or seller cannot be responsible for the

interpretation of this information, nor can it assume any liability in

connection with its use.

WARNING

If the information in this manual is not followed exactly, a fire or

explosion may result causing property damage, personal injury or

death. If you smell gas:

- Do not try to light any appliance.

- Do not touch any electrical switch; do not use any phone in

the building.

- Immediately call the gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

- If you cannot reach the gas supplier, call the fire department.

CAUTION

To avoid personal injury, disconnect power before servicing this product. If electrical power is required for diagnosis or test purposes,

disconnect the power immediately after performing the necessary

checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used to

complete a path to ground are removed for service, they must be

returned to their original position and properly fastened.

GE Consumer Home Services Training

Technical Service Guide

Copyright © 2000

All rights reserved. This service guide may not be reproduced in whole or in part

in any form without written permission from the General Electric Company.

Page 3

Table of Contents

Table of Contents

Cooktop Features and Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Downdraft Vent Features and Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Care and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Cabinet Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Downdraft Vent Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cooktop Installationx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Conversion to LP (Propane) Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Removal and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Schematics and Strip Circuitsx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Parts Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Warranty Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

– 1 –

Page 4

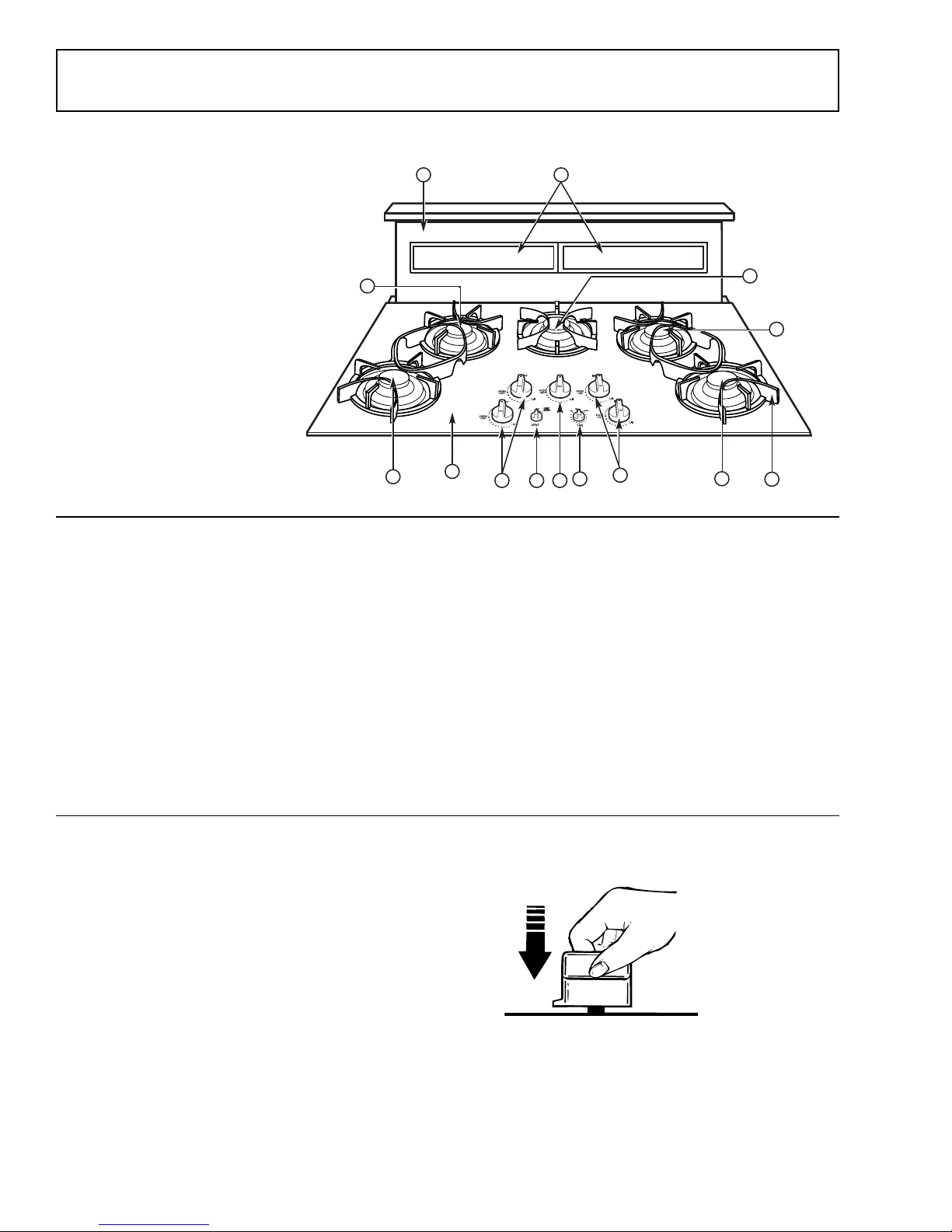

Cooktop Features and Controls

Throughout this manual, features and appearances may vary from the customer’s model.

Feature Index

1. Vent*

2. Vent Filters*

3. Spillproof Burners (2 or 3)

4. Simmer Spillproof Burner

3

5. High-Power Spillproof Burner

6. Fan Speed Control*

7. Vent Control*

8. Surface Unit Controls

9. Glass Cooktop Surface

10. Cast-Iron Burner Grates

*Downdraft models only

3

Using Electric Ignition

The surface burners are lighted by electric

ignition, eliminating the need for standing pilot

lights with constantly burning flames.

All the igniters make clicking sounds and

spark even when only a single burner is being

turned on. Do not touch any of the burners

when the igniters are clicking.

1 2

3

8

6

7988

5

In case of a power outage, the surface burners

on the cooktop can be lit with a match. Hold a

lighted match to the burner, then turn the knob to

the HIGH position. Use extreme caution when

lighting burners this way.

Surface burners in use when an electrical power

failure occurs will continue to operate normally.

4

10

GEA00260

The burners on this cooktop automatically

relight if the flame goes out. All burner igniters

spark while a burner is relighting.

Lighting a Burner

Push the control knob in and turn it

counterclockwise to the desired position from

HIGH to LO.

After the burner ignites, turn the knob in

either direction to adjust the flame size.

To turn a burner off, turn the knob clockwise,

as far as it will go, to the OFF position.

The right rear burner is best for smaller pans

and cooking operations that require carefully

controlled simmering conditions. The center

and two left burners are best for general

Check to be sure the burner you

turned on is the one you want to use.

GEA00261

– 2 –

Page 5

cooking. The front right burner is the high-power

burner for larger pans and fast boiling.

WARNING: Be sure the burners and grates are

cool before you place your hand, a pot holder,

cleaning cloths, or other materials on them.

Caution: Do not operate a burner for an

extended period of time without cookware on the

grate. The finish on the grate may chip without

cookware to absorb the heat.

Selecting Flame Size

Watch the flame, not the knob, as you reduce

the heat.

The flame size on a gas burner should match

the cookware you are using.

For safe handling of cookware, never let the

flame extend up the sides of the cookware.

Any flame larger than the bottom of the

cookware is wasted and only serves to heat the

handle.

GEA00262

Selecting Cookware

Aluminum: Medium-weight cookware is

recommended because it heats quickly and

evenly. Most foods brown evenly in an aluminum

skillet. Use saucepans with tight-fitting lids for

cooking with minimum amounts of water.

Cast Iron: If heated slowly, most skillets will give

satisfactory results.

Enamelware: Under some conditions, the

enamel of some cookware may melt. Follow

cookware manufacturer’s recommendations for

cooking methods.

Glass: There are two types of glass cookware:

those for oven use only and those for surface

cooking (saucepans, coffee pots, and teapots).

Glass conducts heat very slowly.

Heatproof Glass - Ceramic: This can be used

for either surface or oven cooking. It conducts

heat very slowly and cools very slowly. Check

the cookware manufacturer’s directions to be

sure it can be used on gas cooktops.

Stainless Steel: This metal alone has poor

heating properties, and is usually combined with

copper, aluminum, or other metals for improved

heat distribution. Combination metal skillets

generally work satisfactorily if they are used at

medium heat as the manufacturer recommends.

– 3 –

Page 6

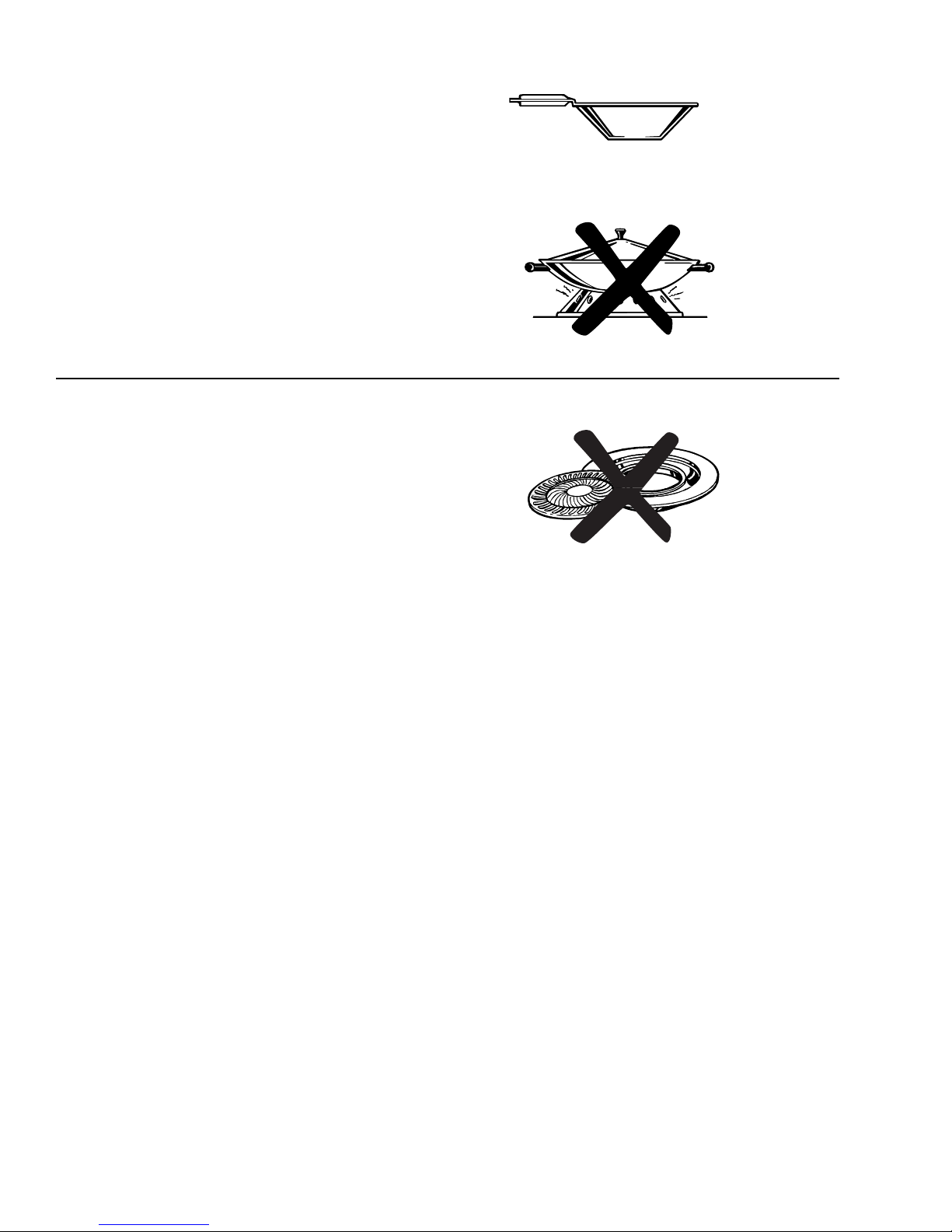

Using Woks

WARNING: Do not use woks that have

support rings. Use of these types of woks, with

or without the ring in place, can be dangerous.

Placing the ring over the burner grate may cause

the burner to work improperly, resulting in carbon

monoxide levels above allowable current

standards. This could be dangerous to the

customer’s health. Do not try to use such woks

without the ring. Serious burns may result if the

wok is tipped over.

We recommend using only a flat-bottomed wok,

available at local retail stores.

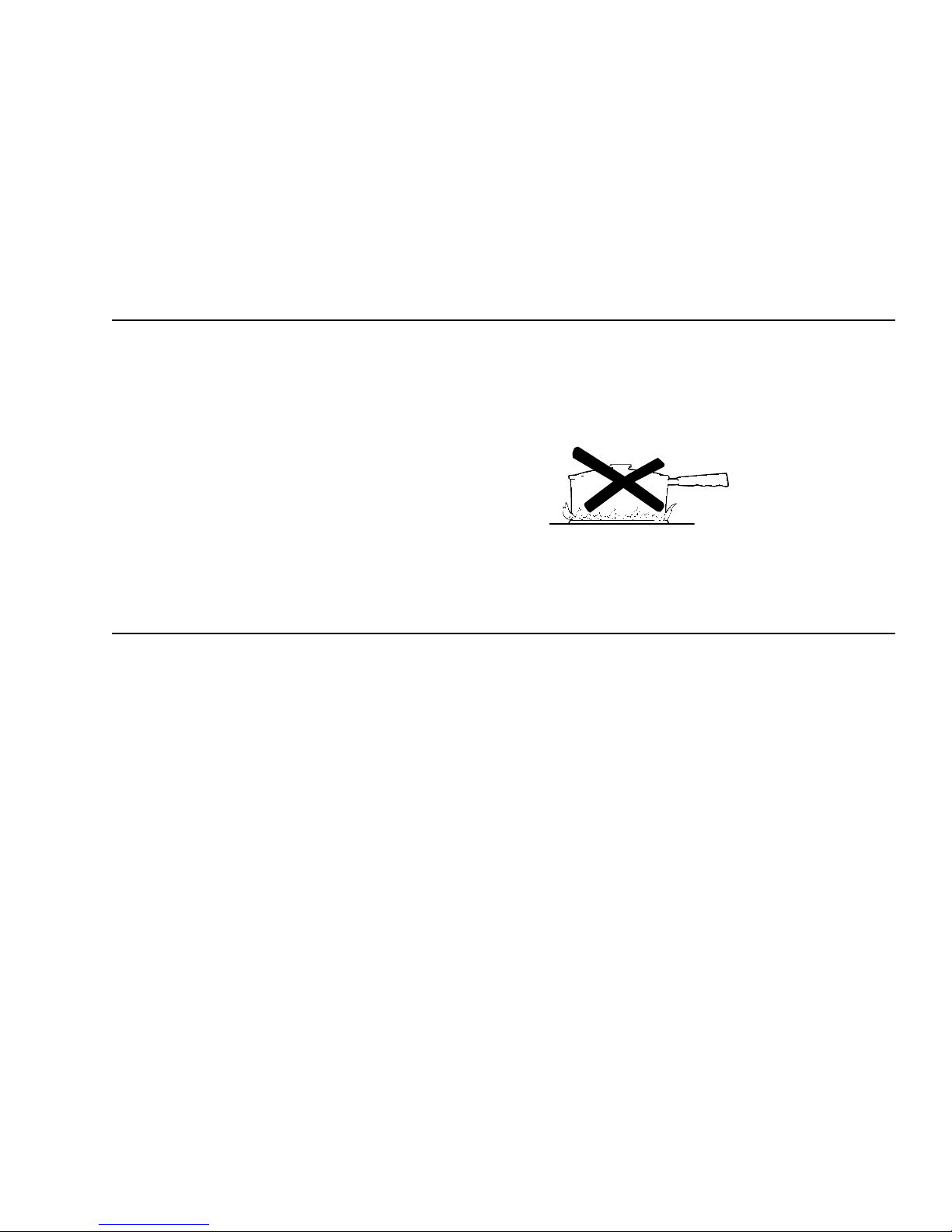

Using Stovetop Grills

WARNING: Do not use stovetop grills on your

sealed gas burners. Using the stovetop grill on

the sealed gas burner will cause incomplete

combustion and can result in exposure to carbon

monoxide levels above allowable current

standards. This can be hazardous to the

customer’s health.

Recommended

Not recommended

GEA00263

GEA00264

– 4 –

Page 7

Downdraft Vent Features and Controls

GEA00265

Throughout this manual, features and appearances may vary from the customer’s model.

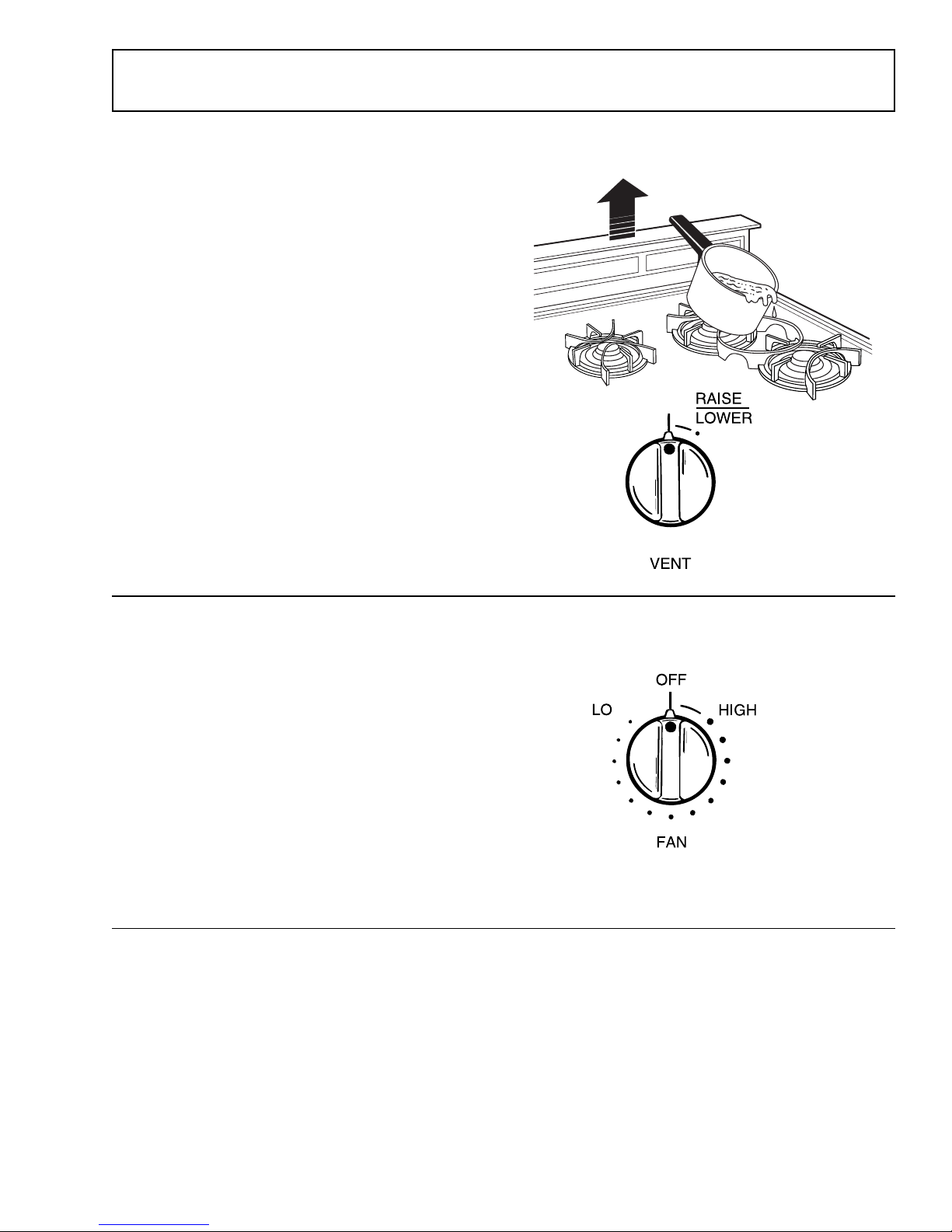

Raising or Lowering the Vent

WARNING: Be careful when raising or lowering the

vent. Be sure pots, pot handles, and other objects

are clear of the vent cover and cannot be struck or

tipped by the vent being raised. Keep hands and

fingers away from all vent parts.

Note: The vent fan will only operate in the fully

extended position.

To raise the vent, turn the VENT knob to the

RAISE/LOWER position. The vent will rise to the

fully extended position. There is no intermediate

position.

To lower the vent, turn the VENT knob again to

the RAISE/LOWER position. The vent will then

descend.

GEA00267

Operating the Vent System

Turn the FAN knob to the HIGH position to turn it

on. If you continue turning the FAN knob, you can

select a fan speed between HIGH and LO.

The FAN knob does not have to be turned to OFF

before the vent is lowered. The fan will

automatically turn off when the VENT LOWER

position is selected.

If the fan was not turned OFF when the vent was

lowered, it will automatically come on at the

previously selected speed when the vent is fully

raised.

GEA00266

– 5 –

Page 8

Care and Cleaning

Proper care and cleaning are important for efficient and

satisfactory service.

WARNING: Before cleaning, be sure all burners are

OFF and disconnect electrical power to the cooktop at

the fuse box, circuit breaker panel, or cooktop power

plug, located inside the cabinets beneath the cooktop.

Cleaning Glass Cooktop

WARNING: Do not cook on, or clean, a broken or

cracked cooktop. Cleaning solutions and spillovers

penetrating the cooktop can create a risk of electric

shock.

Caution: Do not use abrasive materials such as metal

pads, cleansing powder,or scouring pads—they may

scratch the surface. Do not use harsh chemicals such as

bleach or chemical oven cleaners.

GEA00251

GEA00252

To keep the cooktop looking its best, wipe up any spills

as they occur. This will keep them from burning on and

becoming more difficult to remove. As soon as the

cooktop is cool, wash the glass surface with a cloth

moistened with warm, soapy water. Rinse the surface

with clean water, and dry it with a soft cloth. You can use

any liquid household detergent.

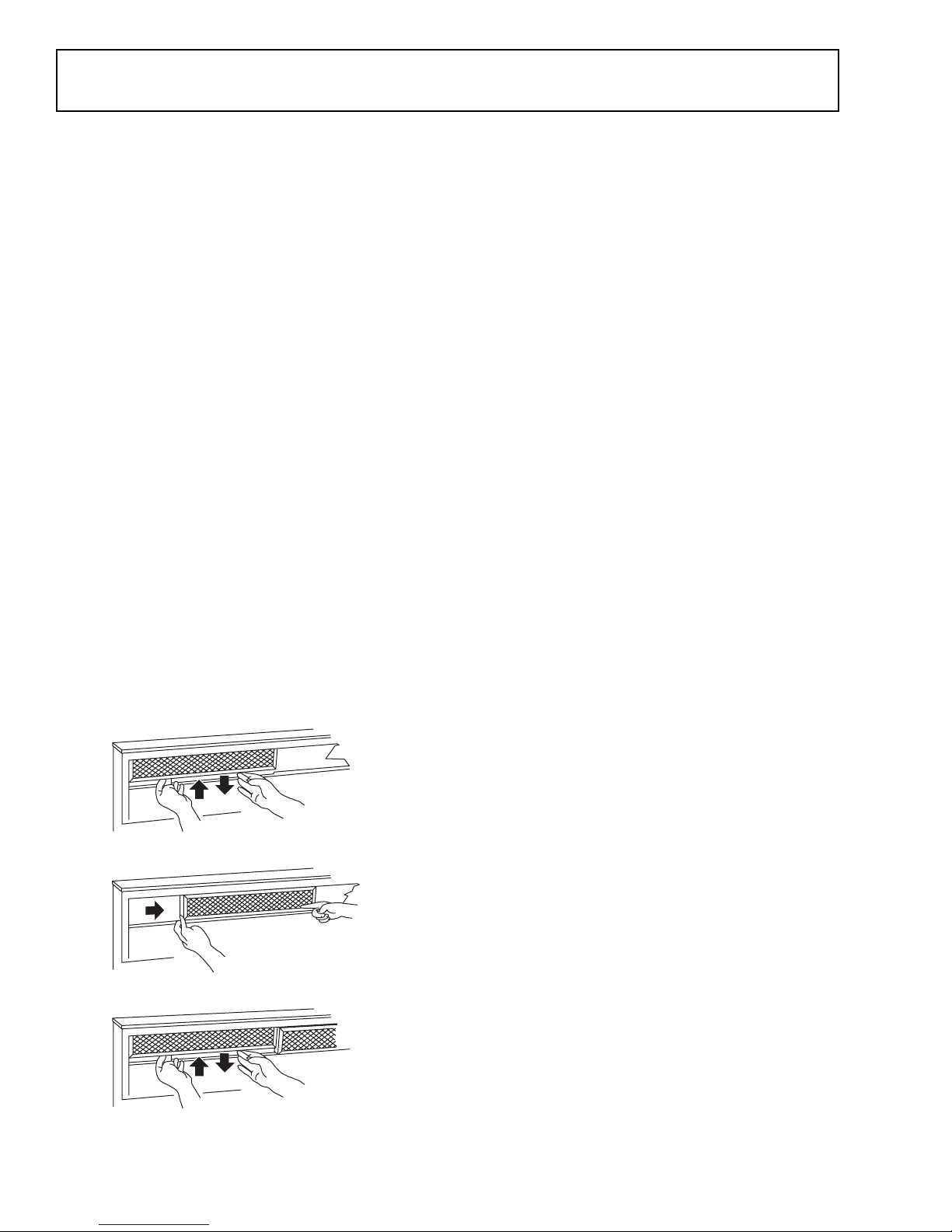

Cleaning Grease Filters

The efficiency of the downdraft depends on a clean filter.

Frequency of cleaning depends on the type of cooking

you do. Grease filters should be cleaned at least once a

month. Never operate the downdraft without the filters in

place.

To remove: Lift up and pull the bottom out. Remove the

left filter first, then slide the right filter to the left and

remove it.

To clean: Soak, then agitate in a hot detergent solution.

Light brushing may be used. Rinse, shake, and remove

moisture before replacing. Filters may be cleaned by

placing them in a dishwasher, although some slight color

fading may occur after several washings.

GEA00253

With careful handling, the filter will last for years. If

replacement becomes necessary, order the part from

your dealer.

– 6 –

Page 9

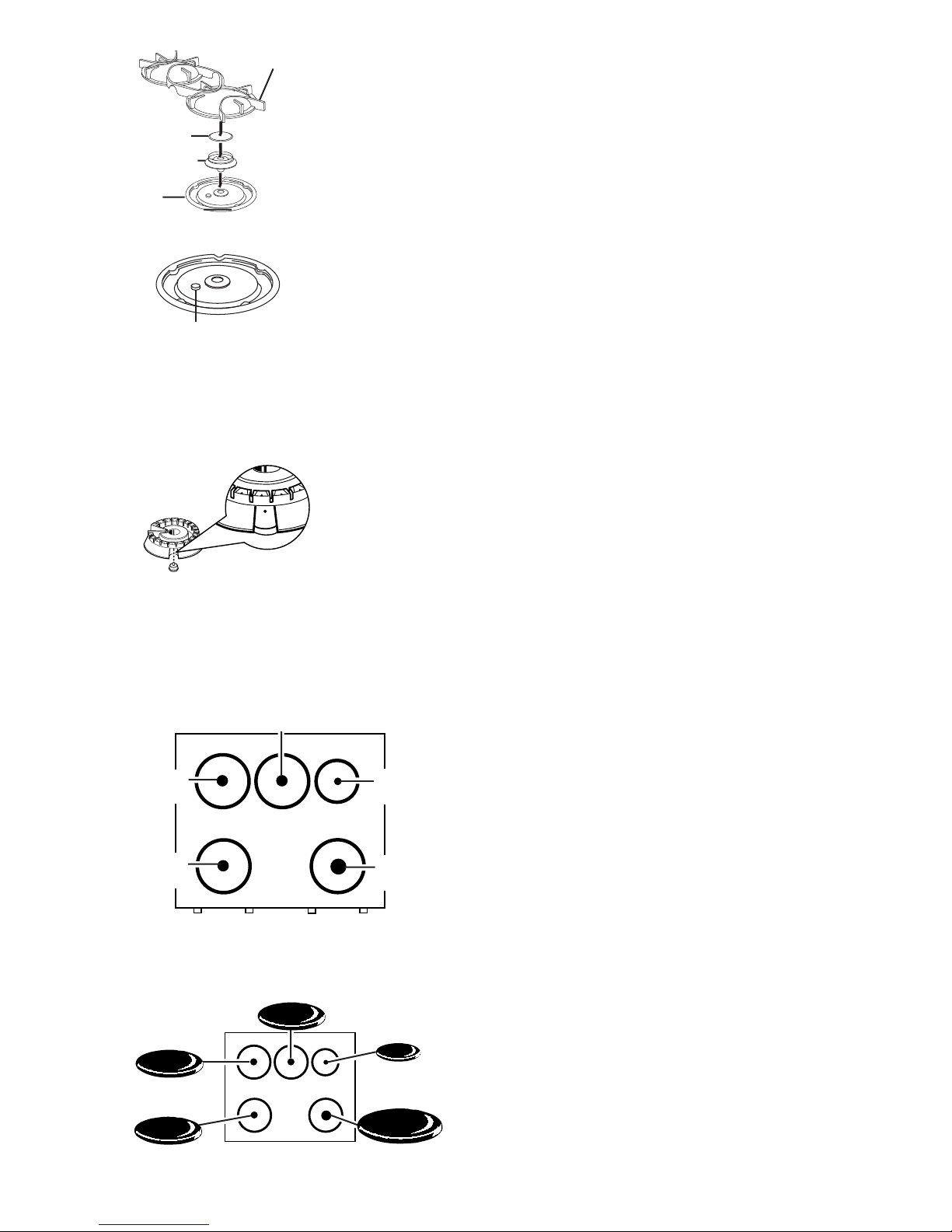

Burner Cap

Burner Head

Burner

Bowl

Burner Grate

GEA00268

Cleaning Control Knobs

To remove a control knob for cleaning, pull it straight

up. Wash the control knobs in soap and water but do not

soak. Avoid getting water into the control knob’s stem

holes.

Cleaning Sealed Burner Assemblies

The electrode of the

spark igniter is

exposed when

the burner head is

Electrode

LITE, all the burners spark. Do not attempt to

disassemble or clean around any burner while

another burner is on. An electric shock may

result, which could cause you to knock over

hot cookware.

Use a sewing needle or twist-tie to

unclog the small hole in the burner

head. After cleaning, make sure the

slot in the burner head is positioned

over the electrode.

Medium Head

(183D5612)

removed. When one

burner is turned to

GEA00270

GEA00269

WARNING: Do not operate the burner without all burner

parts in place.

• Turn all controls OFF before removing burner parts.

The burner grates, caps, and burner heads can be lifted

off, making them easy to clean.

Cleaning Burner Heads

Note: Before removing the burner heads and caps,

remember their sizes and locations. Replace them in the

same locations after cleaning.

For proper ignition, make sure the small hole in the

section that fits over the electrode is kept open. A

sewing needle or wire twist-tie works well to unclog it.

The slits in the burner heads of your cooktop must be

kept clean at all times for an even, unhampered flame.

You should clean the surface burners routinely,

especially after bad spillovers, which could clog these

openings. To remove burned-on food, soak the burner

heads in a solution of mild liquid detergent and hot water

for 20 to 30 minutes. For more stubborn soil, use a

toothbrush.

Medium Head

(183D5612)

Medium Head

(183D5612)

Front of Cooktop

Medium

Cap

Medium

Cap

Medium

Cap

Front of Cooktop

Small Head

(183D5613)

Large Head

(183D5614)

GEA00271

Small

Cap

Large

Cap

GEA00272

Before putting the burner head back, shake out excess

water and then dry it thoroughly by setting it in a warm

oven for 30 minutes. Replace the burner heads and

caps. Make sure the heads and caps are replaced in the

correct locations. There are 2 or 3 medium, 1 large, and

1 small head and cap.

Cleaning Burner Caps

Lift off when cool. Wash burner caps in hot, soapy water

and rinse with clean water. You may scour with a plastic

scouring pad to remove burned-on food particles. Dry

them in a warm oven or with a cloth — don’t reassemble

them wet.

Make sure that caps are replaced on the correct size

burner. There are 2 or 3 medium, one large, and one

small head and cap.

– 7 –

Page 10

GEA00237

Cleaning Burner Grates

Cast-iron burner grates should be washed regularly and,

of course, after spillovers. Wash them in hot, soapy

water and rinse with clean water. Dry the grates with a

cloth—don’t put them back on the cooktop wet. When

replacing the grates, be sure they’re positioned securely

over the burners.

To get rid of burned-on food, place the grates in a

covered container or plastic bag. Add 1/4 cup ammonia

and let them soak for 30 minutes. Wash, rinse well, and

dry.

To prevent rusting, apply a light coat of cooking oil on

the bottom of the grates.

Caution: Do not operate a burner for an extended

period of time without cookware on the grate. The finish

on the grate may chip without cookware to absorb the

heat.

Note: Although they’re durable, the grates will gradually

lose their shine, regardless of the best care you can give

them. This is due to their continual exposure to high

temperatures.

Cleaning Stainless Steel Surfaces

Caution: Do not use a steel wool pad on stainless steel;

it will scratch the surface.

Some models have stainless steel surfaces. Clean with

hot, soapy water. Rinse and dry. If food soil remains, try

a general kitchen cleaner such as Fantastik

Green®, or Formula 409®.

For hard-to-clean soil, use a standard stainless steel

cleaner, such as Bon-Ami

®

or Cameo®. Soils can be

soaked for several hours with wet towels. Apply cleaner

with a damp sponge, rinse thoroughly, and dry. Always

scrub lightly in the direction of the grain.

After cleaning, use a stainless steel polish such as

Stainless Steel Magic

®

, Revere Copper and Stainless

Steel Cleaner®, or Wenol All Purpose Metal Polish®.

Follow the product instructions for cleaning the stainless

steel surface.

®

, Simple

– 8 –

Page 11

Installation Requirements

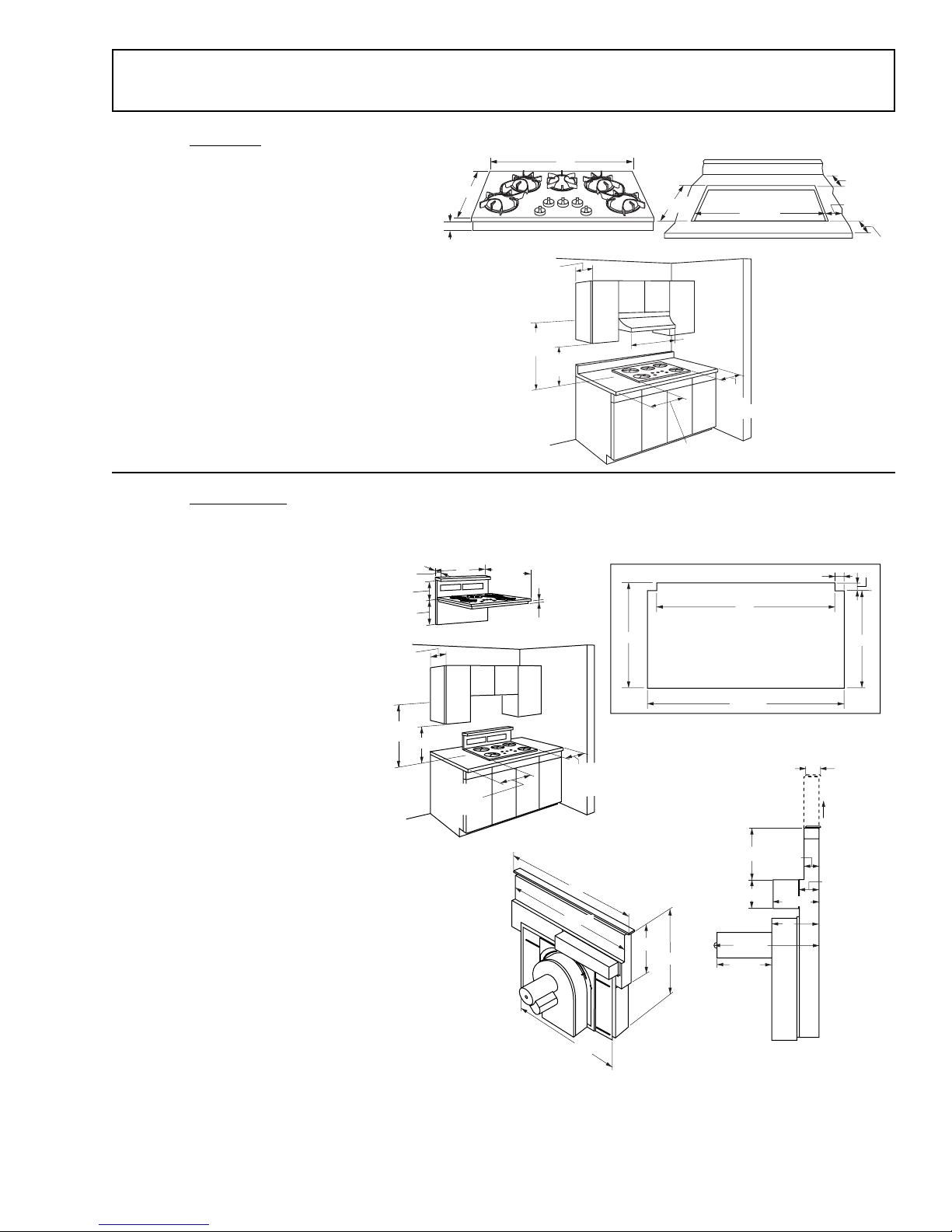

36" Gas Updraft Cooktop - Models ZGU3650 and JGP6560

These gas updraft cooktops are only 3"

deep and can be installed over cabinet

drawers.

19-3/4"

36"

18-5/16"

34-7/16"

2-5/16"

8-13/16"

These models are shipped for natural gas

operation. They can be converted to liquid

propane use. (Order ZXLP56 conversion kit.)

3"

13"

Max.

Use these gas updraft cooktops with any 36”

or wider exhaust hood, if desired. No special

ventilation is required.

30"

Min.

18"

Min.

36" Gas Downdraft Cooktop - Models ZGU365 and JGP656

These downdraft systems with a blower,

a motor, and ductwork will occupy

18"Min.

8" Min. to

Wall When

Installed

36"

22-1/4"

2"

8" Min. to

Wall When

Installed

36"

33-3/4"

the cabinet below the cooktop.

Drawers cannot be installed

below this cooktop.

These models are shipped for

natural gas operation. They can

be converted to liquid propane.

(Order ZXLP56 conversion kit.)

These gas downdraft cooktops

are equipped with a vent system

which can be retracted when

not in use.

Note: JXBA56WW (white) or

JXBA56BB (black) blower/motor

assembly is required for both models.

Be sure to order the color that

matches the cooktop.

Accessories (see

Accessories

)

8-3/4"

15"

13"

Max.

30"

Min.

2"

21"

14-3/4"

36" Min.

8" Min. to Wall

27"

8"

Min.

to Wall

Back of Countertop

5/16"

34"

34-5/8"

Front of Countertop

7-1/2"

2-1/4"

3-1/4"

6-3/8"

7"

12-3/8"

5-3/8"

2-1/4"

GEA00274

2"

19"

2"

8-1/2" Lift

3-1/4"

• JXRB57 optional accessory for indoor

remote location of blower/motor assembly.

Use kit when the blower and motor

assembly will be located outside of or below

the cabinet floor.

• JXBC57 optional outdoor cover accessory

may be ordered for installation of blower and

motor assembly on outside wall.

26"

GEA00276

– 9 –

Page 12

Before You Begin

Important Safety Instructions

Read these instructions completely and carefully.

Note: Save instructions for local inspector’s use.

• Observe all governing codes and ordinances.

• This appliance must be properly grounded.

Tools and Materials You will Need:

• Saw

• Large, flat-blade screwdriver

• Duct tape (downdraft only)

• Measuring tape or scale

• Carpenter’s square

• Pipe wrench

• Manual gas line shutoff valve

• Pipe joint sealant that resists action of LP gas

• Duct work to suit the situation (downdraft only)

• Wood screws (downdraft only)

For Flexible Connection Where

Local Codes Permit:

• Flexible metal tubing (same 3/4-in. or 1/2-in.

I.D. as gas supply line)

• Flare union adapter for connection to supply

line (3/4-in. NPT x 3/4-in. I.D. or 1/2-in. NPT x

1/2-in. I.D.)

• Flare union adapter for connection to regulator

(1/2-in. NPT x 3/4-in. I.D. or 1/2-in. I.D.)

For Rigid Connection:

• Pipe fittings as required

These cooktops have been design-certified by the

American Gas Association. As with any appliance

using gas and generating heat, there are certain

safety precautions that must be followed.

The cooktop must be electrically grounded in

accordance with local codes, or in their absence,

with National Electrical Code ANSI/NFPA No. 70 –

Latest Edition.

Installation of cooktop must conform with local

codes, or in their absence, with National Fuel Gas

Code ANSI Z223.1 – Latest Edition.

Disconnect the electrical supply before servicing.

Wall coverings, countertops, and cabinets should

be able to withstand 200 °F heat generated by the

cooktop.

Avoid placing cabinets above the cooktop.

If cabinets are placed above the cooktop, use

cabinets no more than 13 in. deep.

If cabinets are placed above the cooktop, allow a

minimum clearance of 30 in. between the cooking

surface and the bottom(s) of unprotected

cabinet(s).

If a 30-in. clearance between cooking surface and

overhead combustible material or metal cabinets

cannot be maintained, protect the underside of

cabinets above cooktop with insulating millboard

at least 1/4-in. or gypsum board at least 3/16-in.

thick, covered with 28 gauge sheet steel or 0.020

in. thick copper.

Clearance between the cooking surface and

protected cabinets must never be less than 24 in.

Exception:

or cooking appliance over the cooktop shall

conform to the installation instructions packed with

the appliance.

Installation of a listed microwave oven

Vertical distance from the plane of the cooking

surface to the bottom of adjacent overhead

cabinets extending closer than 1 in. to the plane of

the cooktop sides must not be less than 18 in.

Adjacent cabinets should be at least 8 in. from the

side of the cooktop.

– 10 –

Page 13

Cabinet Preparation

Cut Opening for Updraft Cooktop

8-13/16" Min.

to Side Wall

8-13/16"

Min.

Cutout

To Side

Wall

18-5/16"

4-7/16"

Min.

2-1/4"

Min. From

Front of

Countertop

Caution: Wall coverings, countertops, and

cabinets should be able to withstand 200°F heat

generated by the cooktop.

Measure carefully when cutting the countertop.

Make sure the sides of the opening are parallel,

and the rear and front cuts are exactly

perpendicular to the sides.

The gas updraft cooktop is designed to fit in a

36 in. or larger base cabinet. The countertop

cutout for the cooktop must:

• Be 34-7/16 in. wide.

• Be 18-5/16 in. deep.

• Allow at least 4-7/16 in. clearance between the

back of the cutout and the wall.

34-7/16"

GEA00295

• Allow at least 8-13/16 in. clearance from the

right and left sides of the cutout to the adjacent

wall.

• Allow at least 2-1/4 in. clearance between the

front of the cutout and front edge of the

countertop.

The cooktop requires a 3 in. free space below the

countertop. If installing the cooktop above a

cabinet with drawers, it may be necessary to use a

shorter length drawer to allow clearance for the

gas connection. In some cases, two 3/8-in. I.D. 45°

elbows and a pipe nipple may be added between

the regulator and the cooktop to move the

regulator further back in order to avoid

interference with the drawer.

– 11 –

Page 14

Cut Opening for Downdraft Cooktop

1-1/4"

min.

21"

8-3/4"

15"

2"

2-1/4"

min. to

front edge

36"

34"

22-1/4"

2"

19"

34-5/8"

8-13/16"

min. to

side walls

2"

5/16"

GEA00277

Caution: Wall coverings, countertops, and

cabinets should be able to withstand 200°F heat

generated by the cooktop.

Cut out the opening as shown in plan view

diagram (page 9). Measure carefully when cutting

the countertop. Make sure the sides of the

opening are parallel, and the front and rear cuts

are exactly perpendicular to the sides.

The front of the opening must clear the front

support rail on the cabinet, and the rear of the

opening must clear the rear support of the

cabinet.

Measure carefully when cutting the countertop.

Make sure the sides of the opening are parallel,

and the rear and front cuts are exactly

perpendicular to the sides.

The gas downdraft cooktop is designed to fit in a

36-in. or larger base cabinet.

The Countertop Cutout for the Cooktop must be:

• 34-5/8 in. at the front of the counter and 34 in.

at the back.

• 19 in. front to back of notch.

• 21 in. front to back of cutout.

The Notches at the Back of the Cutout are:

• 2 in. forward and 5/16 in. to the inside.

Follow the Illustration Shown:

• Allow at least 1-1/4 in. clearance between the

back of the cutout and the wall.

• Allow at least 8-13/16 in. clearance from the

right and left sides of the cutout to the

adjacent wall.

• Allow at least 2-1/4 in. clearance between the

front of the cutout and the front edge of the

countertop.

– 12 –

Page 15

Power Supply Locations

Gas Supply

Electrical Supply

WARNING: For personel safety, appliance must

be properly grounded.

These cooktops feature pilotless electric ignition

for energy savings and reliability. They operate on

a 120-volt, 60-Hz power supply. A separate circuit,

protected by a 15-amp time delay fuse or circuit

breaker, is required. A properly grounded

three-prong receptacle must be located within

reach of the cooktop’s 4-ft power cord.

The appliance power cord is equipped with a

three-prong (grounding) plug which mates with a

standard three-prong grounding wall receptacle to

minimize the possibility of electric shock hazard.

The customer should have the wall receptacle and

circuit checked by a qualified electrician to make

sure the receptacle is properly grounded and has

correct polarity.

Note: Where a standard two-prong wall receptacle

is encountered, it is the customer’s responsibility

and obligation to have it replaced with a properly

grounded three-prong wall receptacle.

Do not, under any circumstances, cut or remove

the third (ground) prong from the power cord.

Do not use an extension cord.

These cooktops are designed to operate on

natural gas at 4 in. of water column pressure, or

on LP gas at 10 in. of water column pressure.

Cooktops are shipped from the factory set for

natural gas. To use the cooktop with LP gas,

conversion adjustments must be made. (Order

JXLP56 Conversion Kit.)

The pressure regulator must be connected in

series with the cooktop manifold and must remain

in series with the supply line, regardless of the

type of gas being used.

For proper operation, maximum inlet pressure to

the regulator must be no more than 10 in. water

column pressure for natural gas and 14 in. water

column pressure for LP gas.

When checking the regulator, the inlet pressure

must be at least 1 in. greater than the regulator’s

output setting. If the regulator is set for 4 in. of

water column pressure, the inlet pressure must be

at least 5 in. If the regulator is set for 10 in. of

water column pressure, inlet pressure must be at

least 11 in.

Note: Purchase new flexible line. Do not use old,

previously used flexible line.

For ease of installation, and if local codes permit,

the gas supply line into the cooktop should be

1/2-in. or 3/4-in. ID flexible metal appliance

connector, 3 to 5 feet long.

2" Min. Below

Bottom of Counter

5/8"

Forward

of Back

of Cutout

1-5/8"

From Right

of Cutout

GEA00275

Make the gas connection through the rear wall, or

on the cabinet floor at the rear, as illustrated.

Downdraft CooktopUpdraft Cooktop

Do Not Locate Gas or Electrical

Connections Within Shaded Area

34"

29-1/2"

Electrical

Outlet

12" Above

Cabinet Floor

GEA00241

Gas Location

4"

14"

– 13 –

Page 16

Loosen screws to adjust

blower left to right

Downdraft Vent Installation

Venting Options

The downdraft vent is shipped with the discharge outlet

pointing straight down. The outlet can be changed to leftor right-side discharge.

Side-to-Side Adjustments

The blower mounting plate can be adjusted 3-1/2 in. to

the left or right. This will help to align vent discharge to

house ductwork.

Nut location inside the

blower discharge

30 rotation left or right

Discharge down (as supplied)

30° Rotation

For even more flexibility, the entire blower can be rotated

up to 30° left or 30° right.

Discharge Direction

Note: A left or right 90° direction adjustment should be

performed before dropping into countertop opening.

The blower assembly may be removed and turned 90°

for a left- or right-side discharge (see illustration).

1. Flatten the shipping box to use as a pad.

2. Lay the vent on its back onto the pad.

3. Remove 4 nuts holding the blower to the mounting

plate (see illustration). One nut is just inside the

blower discharge.

4. Remove and turn the blower 90° to the right or left.

5. Reinstall 4 nuts.

Cut Holes for Ductwork

Discharge right

Discharge left

GEA00238

1. Temporarily place the vent into the countertop

opening.

2. Push the vent all the way to the back of the opening.

3. If you are transitioning to 6 in. round, place the

transition piece over the discharge outlet.

a. Mark the location and remove the assembly.

b. Cut holes and install the ductwork connections.

Note: For installation of the blower and motor below the

floor, order Kit JXRB57. See

Accessories

.

• For installation of the blower and motor outdoors,

order Kit JXBC57. See

Accessories

.

– 14 –

Page 17

Duct Fittings

Table of Equivalent Lengths

Note: Any home ventilation system, such as

a cooktop with a downdraft exhaust

mechanism, may interrupt the proper flow of

combustion air and exhaust required by

fireplaces, gas furnaces, gas water heaters,

and other naturally vented systems. To

minimize the chance of interruption of such

naturally vented systems, follow the heating

equipment manufacturer’s guidelines and

safety standards such as those published by

NFPA and ASHRAE.

Use the chart at the right to compute the

maximum permissible lengths for duct runs

to outdoors.

Note: Do not exceed maximum permissible

equivalent lengths.

Flexible ducting

WARNING: Do not use flexible plastic

ducting.

If flexible metal ducting is used, all the

equivalent length values entered on the

worksheet for flexible ducting should be

doubled. The flexible metal duct should be

straight and smooth, and extended as much

as possible.

Vent installation should not exceed 150 feet

equivalent length.

Duct Pieces Length* Used Length

6" round, (per foot

straight length) feet

1

3

4

" x 10" (per foot

straight length) feet

6", 90

elbow

6", 45

elbow

1

3

4

" x 10"

90 elbow

1

3

4

" x 10"

45 elbow

1

3

4

" x 10"

90 flat elbow

6" round

1

4

" x 10"

to 3

transition

1

3

4

" x 10"

to 6" round

transition

6" round

1

to 3

4

" x 10"

transition

90 elbow

1

3

4

" x 10"

to 6" round

transition

90 elbow

Equivalent Number Equivalent

1 ft.

1 ft.

15 ft.

9 ft.

16 ft.

5 ft.

18 ft.

7 ft.

5 ft.

20 ft.

12 ft.

Total

– 15 –

6 " round wall

cap with damper

1

3

4

" x 10" wall

cap with damper

6" round

roof cap

6" round

roof vent

Total duct run should not exceed 150 ft.

21 ft.

27 ft.

20 ft.

24 ft.

GEA00240

Page 18

Install Downdraft Vent

1. Remove plastic ties on both ends at top of vent.

Optional Method —

Secure to Cabinet

Side With Top

Screw on Case

Or Use 2nd Screw

Secure the Lower Brackets

to Blower Housing

Plastic Ties

GEA00278

Preferred Method —

Secure the Upper

Brackets With Screws

Located on the Side of

Case and Attach to

Back Wall of Cabinet

GEA00242

2. Place downdraft vent into countertop cutout against

back side.

3. Secure downdraft to countertop with supplied

brackets (see illustration).

• Fasten brackets to top screws on front side of

vent and secure to cabinet side wall just below

countertop,

or

• Fasten one bracket to vent’s side and secure to

cabinet’s back wall.

4. Install two brackets on bottom of vent.

5. Attach brackets to slide screws on vent and to floor

using wood screws (not supplied).

6. When installing in a tile countertop surface, it may be

necessary to apply a locally approved caulking to

cover any gaps.

Install the Ductwork

Use minimum 26-gauge galvanized or 24-gauge

aluminum duct in 6-in. round or 3-1/4-in. x 10-in. size, or

a combination of both. PVC duct should be used if

installing under a poured concrete slab. Do not use

flexible plastic ducting.

Always use an appropriate roof or wall cap with damper.

Laundry type wall caps should never be used.

Air Flow

Duct Tape Over Seam

and Screw

Screw

GEA00205

Use the straightest duct run possible.

For satisfactory performance, the duct run should not

exceed 150 ft. or its equivalent length if bends or other

various fittings are used. Refer to

Lengths

for various duct configurations.

Table of Equivalent

Install ductwork so the piece of duct nearest the

downdraft unit slots into the next piece of duct. Secure

joints with self-tapping screws and apply duct tape

around joints to ensure airtight seal.

– 16 –

Page 19

Cooktop Installation

Regulator

Solid piping or flexible

connector

Pipe stub

Shut-off

valve

GEA00243

1/16"

3/8"

GEA00245

Install the Pressure Regulator

Note: Instead of using solid piping to connect to

the pressure regulator, an approved flexible metal

appliance connector may be used between shutoff valve and pressure regulator, if local codes

permit. Appropriate flare nuts and adapters are

required at each end of the flexible connector.

Install supplied pressure regulator and nipple in

gas line as close to cooktop’s inlet as possible.

Allowances for ventilation ducting may be

necessary. Make sure the regulator is installed in

the right direction.

Install manual shut-off valve in gas line in an easily

accessible location.

WARNING: Do not use a flame to check for gas

leaks.

Turn ON gas. Check for leaks using liquid leak

detector at all joints in system. (Pressure test

nipple is adjacent to gas inlet pipe on rear

right-hand side of cooktop’s bottom.)

Install the Cooktop

Note: If the cooktop is installed into a 36-in. base

cabinet, the pressure regulator must be installed

to the bottom of the cooktop before the cooktop is

placed into the cabinet.

1. Remove packaging from cooktop.

Note: When using test pressures greater than

1/2 psig to pressure-test the gas supply system of

a residence, disconnect cooktop and individual

shut-off valve from gas supply piping. When using

test pressures of 1/2 psig or less to test the gas

supply system, simply isolate cooktop from gas

supply system by closing individual shut-off valve.

Check edges all the way around to be sure all

cutout edges are concealed and there are no

gaps.

3. Carefully lift and remove cooktop.

2. To ensure a good fit, position cooktop over cut-

out opening and carefully lower into place.

GEA00244

4. Cut a 3/16-in. gasket strip in half. Peel off

backing and apply to underside of glass

cooktop edge, on each side at least 3/8 in.

from the back and as close to the edge as

possible without protruding.

– 17 –

Page 20

5. Apply the other gasket strip to underside of

glass at front of cooktop.

6. Remove remaining adhesive backing.

7. Position cooktop over opening, making sure

that power cord is dropped into cabinet.

Electrical Connections of Downdraft

8. Lower cooktop into cutout, pressing gently and

evenly to seat.

Note: If cooktop is installed in a 36-in. base

cabinet, mounting brackets cannot be used

because of interference with cabinet sides. In this

case, cooktop can be secured to cabinet with

angle brackets (not supplied).

Gasket

Countertop

GEA00246

GEA00247

1. Connect three-pin plastic plug from blower/

motor assembly to three-pin plastic socket on

underside of vent, next to conduit.

2. Slide metal cover over connection and secure

with screws.

Service

plate

Electrical

supply cord

6-pin plug

Metal

cover

Electrical

6-pin socket

Pressure

regulator

GEA00248

9. Remove one screw at bottom of cooktop body

on both sides and secure bracket with those

screws. Then secure brackets to cabinet sides.

10. Insert hold-down bracket into highest slots on

right and left sides of cooktop. Cooktop has

three slots; the highest available will depend

on thickness of countertop.

11. Secure brackets to underside of countertop

with screws provided.

3. Connect six-pin plastic plug from downdraft

assembly to six-pin plastic socket on

underside of cooktop, next to power cord.

4. Slide metal cover over connection and secure

with screws.

Connect Power

Plug power cord into properly grounded

receptacle.

– 18 –

Page 21

Assemble Burners and Check Ignition

Assemble burner as shown.

Burner Grate

Burner Cap

Burner Head

Install Filters, Check Operation

of Downdraft

1. To raise vent, turn VENT knob to RAISE/

LOWER. Hold knob until vent begins to rise.

Vent will automatically stop when it is fully

extended.

GEA00251

Burner Bowl

GEA00249

Place burner heads and caps on burners. Make

sure that heads and caps are placed on correct

size burner. There are 1 small, 2 (or 3) medium,

and 1 large head and cap.

Medium Head

(183D5612)

and Cap

Medium Head

(183D5612)

and Cap

Front of Cooktop

Small Head

(183D5613)

and Cap

Large Head

(183D5614)

and Cap

Make sure the slot in the burner

head is positioned over the

electrode.

GEA00250

Check for Proper Ignition

Note: First test may require some time, while air is

flushed out of gas line.

1. Push in one control knob and turn 90° to HIGH

position.

2. Tip filter into opening and pull straight down so

filter rests on slides.

GEA00252

3. Slide filter to right side.

GEA00253

4. Tip other filter into opening and pull straight

down.

5. To turn fan ON, turn FAN knob to HIGH.

Continue turning FAN knob to select a fan

speed between HIGH and LO.

Note: It is not necessary to turn fan OFF before

lowering vent. Fan will automatically turn OFF

when vent is lowered. When fan is not turned OFF

before lowering vent, it will automatically come ON

at previously selected speed when vent is fully

raised.

6. To lower vent, turn VENT knob to RAISE/

LOWER. Hold knob until vent begins to lower.

2. Igniter will spark and burner will light; igniter

will cease sparking when burner is lit.

3. Turn knob to OFF.

4. Repeat procedure for each burner.

– 19 –

Page 22

Conversion to LP (Propane) Gas

WARNING: If you are using LP (propane) gas, all

adjustments described in the following steps must

be made before attempting burner adjustments or

using cooktop.

• Use only approved pipe dope resistant to LP

gas.

Note: The cooktop leaves the factory set for use

with natural gas. If you convert to LP gas, keep

instructions and orifices to convert back to natural

gas.

Parts

The kit should contain the following:

• 1 Orifice—Large size—104-WB28K0093

• 3 Orifices—Medium size—(number to come)

• 1 Orifice—Small size—82-WB28K0094

• 1 Maxitrol LP adapter—WB01K055

• 1 Tie-on card/label for regulator

If you do not have all above-listed components,

contact the nearest GE Service and Parts Center.

Total input rating after conversion:

• Four-burner cooktop 35,000 Btu/hr.

• Five-burner cooktop 44,500 Btu/hr.

Tools Required:

• Adjustable wrench

• Nut driver: 9/32 in. or 7 mm

Convert the Surface Knobs

Valve

Shaft

GEA00254

1. Remove knobs from valve shafts.

2. Fully screw down brass low-flame adjustment

screws into valve bodies with clockwise

rotation.

3. Replace knobs and cams.

Convert the Surface Burners

Burner Grate

Burner Cap

Burner Head

Burner Bowl

GEA00255

Prepare Cooktop for Conversion

1. Turn OFF gas supply at shut-off valve.

2. Turn OFF electrical power to cooktop.

1. Remove grates and burner caps.

Note: Each orifice has a number and letter “L”

indicating LP gas.

• There will be one extra medium orifice spud and

burner head when converting a four-burner

cooktop.

GEA00256

2. Using a 9/32-in. or 7-mm nut driver, remove

and replace brass orifice spud inside each

– 20 –

Page 23

Five-Burner Cooktop Models

5 Burner Cooktop Models

Location BTUs Orifice Size Burner Head

LF, LR 9,500 .89Lmm (II) 183D5612

CTR 9,500 .89Lmm (II) 183D5612

RR 5,000 .63Lmm (I) 183D5613

RF 11,000 .99Lmm (III) 183D5614

Install orifices and position burner caps as shown

89

Medium

Four-Burner Cooktop Models

4 Burner Cooktop Models

Location BTUs Orifice Size Burner Head

LF, LR 9,500 .89Lmm (II) 183D5612

RR 5,000 .63Lmm (I) 183D5613

RF 11,000 .99Lmm (III) 183D5614

89

Medium

63

Small

89

Medium

89

Medium

Front

63

Small

99

Large

GEA00279

burner chimney as shown by number on the

above chart:

3. Place LP gas burner head onto chimney, as

indicated by number.

4. Place correct size burner caps onto burners,

then replace grates.

Convert the Pressure Regulator

WARNING: Do not remove pressure regulator

from cooktop.

89

Medium

Front

99

Large

GEA00280

3. Insert LP adapter into nut.

LP

GEA00258

NAT

LP

adapter

Nut

4. Reinsert assembly into regulator and attach tieon label to regulator using string provided.

1. Locate pressure regulator under rear of

cooktop.

2. Use an adjustable wrench to remove nut from

pressure regulator.

Gas flow into

range

LP

NAT

LP adapter

Nut

GEA00257

Check for Leaks

WARNING: Do not use a flame to check for leaks.

Check for leaks before attempting to light burners.

When all connections have been made, make sure

all cooktop controls are in the OFF position and

turn ON main gas supply valve. Use a liquid leak

detector at all joints and connections to check for

leaks in system.

Note: When using test pressures greater than 1/2

psig to pressure-test the gas supply system of a

residence, disconnect cooktop and individual shutoff valve from gas supply piping. When using test

pressures of 1/2 psig or less to test the gas supply

system, simply isolate cooktop from gas supply

system by closing individual shut-off valve.

– 21 –

Page 24

(A) Yellow flames

Call for service

(B) Yellow tips on outer

cones

Normal for LP gas

(C) Soft blue flames

Normal for natural gas

GEA00259

Check Quality of Flames

The combustion quality of burner flames needs to

be determined visually.

If burner flames look like (A), call for service.

Normal burner flames should look like (B) or (C),

depending on the type of gas used.

With LP gas, some yellow tipping on outer cones

is normal.

Final Steps

1. Fill in the date, plus the name and address of

the service organization performing the

conversion, in the spaces provided on the

conversion label.

2. Remove the backing from the label and stick

the label in a convenient place on the

underside of the cooktop near the Rating

Plate. Make sure the area is clean and dry

before applying the label.

The conversion is now complete.

– 22 –

Page 25

Notes

– 23 –

Page 26

Hidden

Screws

Blower

Blower

Mounting

Plate

Accessories

Downdraft Vent Assembly —

JXBA56WW (White), JXBA56BB, (Black)

This unit contains motor and blower assembly for

downdraft applications and is required to complete

installation. Be sure to order the color that matches the

cooktop.

Blower Box

GEA00284

GEA00281

Indoor Remote Location Blower Mounting —

JXRB57 Kit

This kit provides for the installation of the blower and

motor outside of the cabinet, such as below the floor.

Use this kit for indoor remote installations only.

Note: A 3-1/4 in. x 10 in. transition to 6 in. round is

required.

Parts Supplied

Hanger Brackets

Package of screws

Cover Plate

Outlet Plate

GEA00282

– 24 –

Page 27

Cover

Outdoor Remote Location Blower Mounting —

JXRC57 Kit

The blower and motor assembly can be mounted on an

outside wall. This kit provides a means to mount the

blower outside with a protective cover.

Note: A 3-1/4 in. x 10 in. transition to 6 in. round is

required.

Parts Supplied

GEA00288

Package of screws

4 Hanger Brackets

Junction Box

Cover Plate

Outlet Plate

Base

Assembly

Outlet Pan

Damper

GEA00289

LP Gas Conversion Kit —

JXLP56

The kit contains LP conversion parts for both five- and

four-burner cooktop models. The kit contains 5 burner

heads, 5 brass orifices, 1 Maxitrol LP adapter, and 1

tie-on card/label for regulator.

– 25 –

Page 28

Removal and Replacement

Burner Cap

Burner Head

Burner Bowl

Burner Grate

GEA00249

Ignitor

Ignitor

Retainer

Retainer

Ring

Ring

Venturi

Venturi

Assembly

Assembly

3 Nuts

3 Nuts

and Washers

and Washers

WARNING: Disconnect electrical power to the

cooktop and turn OFF gas at the main valve before

performing any removal procedures.

Remove Venturi Assembly and Burner Bowl

1. Remove burner grate, burner cap, and burner head

from cooktop.

2. From below cooktop, remove 17 screws and bottom

pan.

3. From below cooktop, remove retainer ring and igniter

from burner bowl.

4. Remove 1/2-in. nut and gas line from venturi

assembly.

5. Remove three 7-mm nuts, 3 washers, and venturi

assembly from burner bowl.

6. Remove three 7-mm nuts, washers, felt washers, and

cooktop recess ring from burner bowl.

7. Remove burner bowl.

Cooktop

Cooktop

Recess Ring

Recess Ring

Manifold

Manifold

Gas Line

Gas Line

Fitting

Fitting

Gas Line

Gas Line

Fitting

Fitting

Screw

Screw

3 Nuts, Washers,

3 Nuts, Washers,

and Felt Washers

and Felt Washers

GEA00314

Screw

Screw

GEA00315

Remove Gas Valve Assembly

1. Remove 4 (or 5) gas control knobs.

2. From below cooktop, remove 17 screws and bottom

pan.

3. Remove 4 (or 5) gas line fittings.

4. Remove manifold gas line fitting from regulator.

Caution: When assembling the following, replace with

the exact screws to prevent glass breakage.

5. Remove 2 screws and manifold from cooktop.

6. Remove 1/4-in. screw and gas valve from manifold.

– 26 –

Page 29

Spark

Spark

Module

Module

Remove Fan and Vent Switches

Note: The fan and vent switches are removed similarly.

1. Remove the fan (or vent) switch knob.

2. From below cooktop, remove 17 screws and bottom

pan.

3. Remove the 5/8-in. nut and fiber washer from the

switch, and remove the switch.

4. Remove wire connections (and shield from vent

switch).

Caution: When assembling the vent switch, be sure to

replace the shield.

• When assembling the vent switch, be sure not to

overtighten the 5/8-in. nut. This could cause the glass

cooktop to break.

Remove Spark Module

1. From below cooktop, remove 17 screws and bottom

pan.

Valve

Shaft

Low Flame

Adjustment

Screw

Insulation

Insulation

GEA00316

GEA00313

2. Move the insulation covering the spark module.

3. Disconnect 8 wire connectors from spark module.

4. Push the module to the right and rotate the left end

toward the front to remove the module.

Caution: When assembling, be sure to replace the

insulation covering the spark module before replacing

the bottom pan.

Low-Flame (Simmer) Adjustment

The top burner valves have low-flame adjustment

screws in the center of the control shafts. A small, thinblade screwdriver (approx. 3/32-in. blade width) is

needed to engage the screw.

To adjust the low-flame setting, at least 2 other burners

must be lit. Light the burner being adjusted and turn the

knob to “LOW.” Remove the knob and insert the

screwdriver into the shaft of the control valve. Turn the

adjustment screw to obtain the desired flame size.

Test the flame’s stability by quickly turning the knob from

“HIGH” to “LOW.” If the flame goes out, increase the

flame size and test again.

– 27 –

Page 30

Schematics

Caution: Label all wires prior to disconnection when

servicing the controls. Wiring errors can cause

improper and dangerous operation. Verify proper

operation after servicing.

L

RED

R

TOP BURNER IGNITERS

R

BLACK

BLACK

RAISE/LOWER

SWITCH

R

BLACK

FAN ON/OFF

SPEED CONTROL SWITCH

RED

TOP BURNER IGNITION SWITCHES

WHITE

WHITE

WHITE

WHITE

WHITE

TOP/BOTTOM LIMITS

BLACK/WHITE

MICROSWITCH

FAN CUTOUT

PURPLE

MICROSWITCH

BLUE

BLACK/WHITE

L

WHITE

N

IGNITION

UNIT

RAISE/LOWER

MOTOR

FAN

MOTOR

THESE COMPONENTS MAY NOT

APPEAR ON ALL MODELS

WHITE

GREEN

WHITE

N

W

W

W

GEA00586

– 28 –

Page 31

Troubleshooting

melborPsesuaCelbissoPoDottahW

thgiltonodsrenruBretingitakrapsoN

rowolleyevahsrenruB

semalfdeppit-wolley

A.Yellow flames:

service.

renrubtawolfsagoN

Call for

B.Yellow tips on outer

cones:

Normal for LP gas.

eludoMkrapSecalpeR

noitisopNOnisibonkerusekaM

C.Soft blue flames:

for natural gas.

teltuoevilaotnideggulpsirewoplacirtceleerusekaM

noitisopNOnisievlavffo-tuhserusekaM

tneiciffussiylppusleuferusekam,GPLfI

Normal

GEA00273

– 29 –

Page 32

Model JGP656BB0BB

170 WB57K10004 GLASS-SORKEL-BLACK 1

Parts Lists

View Catalog Description Qty.

1 WB02X9857 SEAL-COOKTOP TO WORKTOP 2

1 31-20775 MINI-MANUAL (SNORKEL) 1

1 49-80011 MANUAL-USE & CARE 1

2 WB02X9857 SEAL GASKET 4

3 WB28K0145 ORIFICE-LP .78 LMM 2

3 WB28K10022 ORIFICE-NG 1.50MM 2

3 WB28K10029 ORIFICE-NG 1.07MM 1

3 WB28K10030 ORIFICE-NG 1.68MM 1

3 WB28K10031 ORIFICE-LP .63MM 1

3 WB28K10107 ORIFICE-LP .84MM 1

4 WB63K10022 CONTAINER BOX ASSEMBLY 1

8 WB21K10006 VALVE BURNER LFT RR 1

9 WB21K10007 VALVE BURNER RT RR 1

10 WB21K10005 VALVE BURNER RT FRONT 1

11 WB21K10008 VALVE BURNER LEFT FRONT 1

13 WB02K10036 BRACKET BURNER 4

14 WB01X1192 FLAT WASHER-M4 30

16 WB19K0026 PRESSURE REGULATOR 1

18 WB02K0024 COVER VALVE 4

21 WB01K0083 SCREW-MTG VALVE BURNER 5

30 WB34K10042 SHIELD SPARK MOD 1

31 WB35K10023 INSULATION-SPK MODULE 1

38 WB24K10001 BLOWER SPEED REGULATOR 1

40 WB24X0475 SWITCH 1

42 NOT STOCKED SHIELD-SWITCH 1

44 WB01X1382 HEX NUT 3/8" X 32 1

48 WB01X1383 FIBRE WASHER 10MM 2

50 WB02K10001 MOUNTING PLATE ELEC 1

51 WB06K0014 ADAPTOR 2

52 WB28K10106 INLET BLOCK 1

56 WB02X9838 POWER CORD CLAMP 1

58 WB18X0380 POWER SUPPLY CORD 1

60 NOT STOCKED SHIELD-TERMINAL BLOCK 1

62 NOT STOCKED TERMINAL BLOCK 1

64 WB01X1189 SCREW M4X8 21

66 WB18K10001 HARNESS-MAIN WIRING 1

66 WB18K10010 HV WIRE HARNESS 1

72 WB13K10007 ELECTRODE SPARK 5

74 WB01K10026 CLIP ELECTRODE 5

75 WB02K10037 GROUND PATH SHIELD 5

86 WB57K10051 GLASS COOKTOP (BLK) 1

88 WB02X9843 SEAL-DRIP PAN 5

91 WB02X9243 INSTALLATION HARDWARE PK 2

94 WB02K10044 RETENTION BRACKET 5

95 WB34K10043 CLAMPING PLATE 5

View Catalog Description Qty.

96 NOT STOCKED NUT M4 30

101 WB56X10010 COVER 36" 1

102 WB56X10004 PANEL GEAR MOTOR 1

103 WB07X10012 SLIDE 1

104 WB02X10303 PIVOT ARM 1

106 WB02X10306 ROLLER 1

108 WB02X10310 FILTER 2

109 WB02X10307 SEAL 1

110 WB13K10005 SPARK MODULE 5+0 1

112 WB31K10057 GRATE DOUBLE (BLK) 2

113 WB02X10308 BLOWER SUPPORT LEGS 8

114 WB28K10108 MANIFOLD PIPE 1

115 WB32K10018 DRIP PAN LFT FT & RR-BLK 2

115 WB32K10019 DRIP PAN RT RR-BLK 1

115 WB32K10023 DRIP PAN RT FT (BLK) 1

116 WB28K10102 SUPPLY TUBE-LEFT FRONT 1

118 WB28K10100 SUPPLY TUBE-LEFT REAR 1

122 WB28K10101 SUPPLY TUBE -RIGHT REAR 1

123 WB01X10004 U-BOLT 1

124 WB28K10099 TUBE SUPPLY-RIGHT FRONT 1

125 WB18K10011 HARNESS SWITCH 1

126 NOT STOCKED BASEPLATE 1

127 WB28K10105 SUPPLY TUBE MAIN 1

128 WB01K10025 SCREW-MTG SUPPLY TUBE 1

129 WB27X5599 CAPACITOR 1

133 WB01X10007 BUTTON SLIDE 4

135 WB01X10008 SCREW, PAN HEAD 2

138 WB07X1759 BEZEL-BLACK 5

140 WB03K10105 KNOB BURNER BLK 4

142 WB03K0104 DOWNDRAFT CTRL KNOB BLK 2

145 WB01K10005 NUT 6-32- MTG GLASS TRIM 4

146 WB34K10002 WIRE BOX 1

147 WB26X10005 GEAR MOTOR 1

148 WB38X5079 BLOWER 1

149 WB01X10006 HEYCO BUSHING 1

150 WB02X10309 SEAL 2

151 WB29K10009 CAP-BURNER SMALL (BLK) 1

152 WB29K10001 CAP-BURNER MED (BLK) 2

153 WB29K10006 CAP-BURNER LARGE (BLK) 2

155 WB16K10014 BURNER-SMALL 1

156 WB16K10005 BURNER-MED 2

157 WB16K10007 BURNER-LARGE 1

167 WB01X10003 SCREW BLACK 25

169 WB02X10301 FORMED BOX 1

– 30 –

Page 33

Model JGP656WB0WW

View Catalog Description Qty.

1 WB02X9857 SEAL-COOKTOP TO WORKTOP 2

1 31-20775 MINI-MANUAL (SNORKEL) 1

1 49-80011 PM USE & CARE MANUAL 1

2 WB02X9857 SEAL GASKET 4

3 WB28K0145 ORIFICE LP .78 LMM 2

3 WB28K10022 ORIFICE-NG 1.50MM 2

3 WB28K10029 ORIFICE-NG 1.07MM 1

3 WB28K10030 ORIFICE-NG 1.68MM 1

3 WB28K10031 ORIFICE-LP .63MM 1

3 WB28K10107 ORIFICE SPUD LP .84MM 1

4 WB63K10022 CONTAINER BOX ASSEMBLY 1

8 WB21K10006 VALVE BURNER LFT RR 1

9 WB21K10007 VALVE BURNER RT RR 1

10 WB21K10005 VALVE BURNER RT FRONT 1

11 WB21K10008 VALVE BURNER LEFT FRONT 1

13 WB02K10036 BRACKET BURNER 4

14 WB01X1192 FLAT WASHER-M4 30

16 WB19K0026 PRESSURE REGULATOR 1

18 WB02K0108 COVER VALVE 5

21 WB01K0083 SCREW-MTG VALVE BURNER 5

30 WB34K10042 SHIELD SPARK MOD 1

31 WB35K10023 INSULATION-SPK MODULE 1

38 WB24K10001 BLOWER SPEED REGULATOR 1

40 WB24X0475 SWITCH 1

42 NOT STOCKED SHIELD-SWITCH 1

44 WB01X1382 HEX NUT 3/8" X 32 1

48 WB01X1383 FIBRE WASHER 10MM 2

50 WB02K10001 MOUNTING PLATE ELEC 1

51 WB06K0014 ADAPTOR 1

52 WB28K10106 INLET BLOCK 1

54 WB02X9836 GROUND POST ASSEMBLY 1

56 WB02X9838 POWER CORD CLAMP 1

58 WB18X0380 POWER SUPPLY CORD 1

60 NOT STOCKED SHIELD-TERMINAL BLOCK 1

62 NOT STOCKED TERMINAL BLOCK 1

64 WB01X1189 SCREW M4X8 21

66 WB18K10001 HARNESS-MAIN WIRING 1

66 WB18K10010 HV WIRE HARNESS 1

72 WB13K10007 ELECTRODE SPARK 5

74 WB01K10026 CLIP ELECTRODE 5

75 WB02K10037 GROUND PATH SHIELD 5

86 WB57K10052 GLASS COOKTOP-WH 1

88 WB02X9843 SEAL-DRIP PAN 5

91 WB02X9243 INSTALLATION HARDWARE PK 2

94 WB02K10044 RETENTION BRACKET 5

95 WB34K10043 CLAMPING PLATE 5

View Catalog Description Qty.

96 NOT STOCKED NUT M4 30

101 WB56X10010 COVER 36" 1

102 WB56X10004 PANEL GEAR MOTOR 1

103 WB07X10012 SLIDE 1

104 WB02X10303 PIVOT ARM 1

106 WB02X10306 ROLLER 1

108 WB02X10310 FILTER 2

109 WB02X10307 SEAL 1

110 WB13K10005 SPARK MODULE 5+0 1

112 WB31K10059 GRATE DOUBLE 2

113 WB02X10308 BLOWER SUPPORT LEGS 8

114 WB28K10108 MANIFOLD PIPE ASM 1

115 WB32K10021 PAN UNIT LEFT FRT & RR 2

115 WB32K10022 DRIP PAN RT REAR WH 1

115 WB32K10024 DRIP PAN RT FRONT WH 1

116 WB28K10102 SUPPLY TUBE-LEFT FRONT 1

118 WB28K10100 SUPPLY TUBE-LEFT REAR 1

122 WB28K10101 SUPPLY TUBE -RIGHT REAR 1

123 WB01X10004 U-BOLT 1

124 WB28K10099 SUPPLY TUBE-RIGHT FRONT 1

125 WB18K10011 HARNESS SWITCH 1

126 NOT STOCKED BASEPLATE 1

127 WB28K10105 SUPPLY TUBE MAIN 1

128 WB01K10025 SCREW-MTG SUPPLY TUBE 1

129 WB27X5599 CAPACITOR 1

133 WB01X10007 BUTTON SLIDE 4

135 WB01X10008 SCREW, PAN HEAD 2

138 WB07X1832 BEZEL-WHITE 5

140 WB03K10106 KNOB BURNER (GRAY) 4

142 WB03K0103 KNOB-DOWNDRAFT CTL GRAY 2

145 WB01K10005 NUT 6-32- MTG GLASS TRIM 4

146 WB34K10002 WIRE BOX 1

147 WB26X10005 GEAR MOTOR 1

148 WB38X5079 BLOWER 1

149 WB01X10006 HEYCO BUSHING 1

150 WB02X10309 SEAL 2

151 WB29K10002 CAP-BURNER SMALL (GRAY) 1

152 WB29K10004 CAP-BURNER MED (GRAY) 2

153 WB29K10007 CAP-BURNER LARGE (GRAY) 1

155 WB16K10014 BURNER-SMALL 1

156 WB16K10005 BURNER-MED 2

157 WB16K10007 BURNER-LARGE 1

167 WB01X10003 SCREW BLACK 25

169 WB02X10301 FORMED BOX 1

170 WB61K10002 GLASS-SNORKEL-WHITE 1

– 31 –

Page 34

Model ZGU3650BB0BG

View Catalog Description Qty.

75 WB02K10037 GROUND PATH SHIELD 5

86 WB57K10050 GLASS COOKTOP BLACK 1

88 WB02X9843 SEAL-DRIP PAN 5

91 WB02X9243 INSTALLATION HARDWARE PK 2

94 WB02K10044 RETENTION BRACKET 5

95 WB34K10043 CLAMPING PLATE 5

96 NOT STOCKED NUT M4 30

110 WB13K10005 SPARK MODULE 5+0 1

112 WB31K10057 GRATE DOUBLE (BLK) 2

113 WB31K10058 GRATE CENTER (BLK) 1

114 WB28K10104 MANIFOLD PIPE 1

115 WB32K10018 DRIP PAN LFT & CENTER BK 3

115 WB32K10019 DRIP PAN RT RR (BLK) 1

115 WB32K10023 DRIP PAN RT FT (BLK) 1

116 WB28K10102 SUPPLY TUBE-LEFT FRONT 1

118 WB28K10100 SUPPLY TUBE-LEFT REAR 1

120 WB28K10103 SUPPLY TUBE- CENTER 1

122 WB28K10101 SUPPLY TUBE -RIGHT REAR 1

124 WB28K10099 SUPPLY TUBE-RIGHT FRONT 1

125 WB18K10008 HARNESS SWITCH 1

126 NOT STOCKED BASEPLATE 1

127 WB28K10105 SUPPLY TUBE MAIN 1

128 WB01K10025 SCREW-MTG SUPPLY TUBE 1

138 WB07X1759 BEZEL-BLACK 5

140 WB03K10107 KNOB BURNER (BLK) 5

151 WB29K10009 CAP-BURNER SMALL (BLK) 1

152 WB29K10001 CAP-BURNER MED (BLK) 3

153 WB29K10006 CAP-BURNER LARGE (BLK) 1

155 WB16K10014 BURNER-SMALL 1

156 WB16K10005 BURNER-MED 3

157 WB16K10007 BURNER-LARGE 1

View Catalog Description Qty.

1 WB02X9857 SEAL-CKTOP TO WORKTOP 2

1 49-80012 MANUAL-USE & CARE 1

2 WB02X9857 SEAL GASKET 4

2 WB63K10022 CONTAINER BOX ASSEMBLY 1

3 WB28K10022 ORIFICE-NG 1.50MM 3

3 WB28K10029 ORIFICE-NG 1.07MM 1

3 WB28K10030 ORIFICE-NG 1.68MM 1

4 WB63K10022 CONTAINER BOX ASSEMBLY 1

8 WB21K10006 VALVE LFT RR & CENTER 2

9 WB21K10007 VALVE BURNER RIGHT REAR 1

10 WB21K10005 VALVE BURNER RT FRONT 1

11 WB21K10008 VALVE BURNER LEFT FRONT 1

13 WB02K10036 BRACKET BURNER 1

14 WB01X1192 FLAT WASHER-M4 30

16 WB19K0026 PRESSURE REGULATOR 1

18 WB02K0108 COVER VALVE 2

21 WB01K0083 SCREW-MTG VALVE BURNER 5

30 WB34K10042 SHIELD SPARK MOD 1

31 WB35K10023 SPARK MODULE INSULATION 1

50 WB02K10001 MOUNTING PLATE ELEC 1

51 WB06K0014 ADAPTOR 1

52 WB28K10106 INLET BLOCK 1

56 WB02X9838 POWER CORD CLAMP 1

58 WB18X0380 POWER SUPPLY CORD 1

60 NOT STOCKED SHIELD-TERMINAL BLOCK 1

62 NOT STOCKED TERMINAL BLOCK 1

64 WB01X1189 SCREW M4X8 21

66 WB18K10001 HARNESS-MAIN WIRING 1

66 WB18K10007 HARNESS HV 1

72 WB13K10007 ELECTRODE SPARK 5

74 WB01K10026 CLIP ELECTRODE 5

– 32 –

Page 35

Model ZGU3650WB0WG

157 WB16K10007 BURNER-LARGE 1

View Catalog Description Qty.

1 WB02X9857 SEAL-COOKTOP 2

1 49-80012 MANUAL-USE & CARE 1

2 WB02X9857 SEAL GASKET 4

3 WB28K10022 ORIFICE-NG 1.50MM 3

3 WB28K10029 ORIFICE-NG 1.07MM 1

3 WB28K10030 ORIFICE-NG 1.68MM 1

4 WB63K10022 CONTAINER BOX ASSEMBLY 1

8 WB21K10006 VALVE LFT RR & CENTER 2

9 WB21K10007 VALVE BURNER RIGHT REAR 1

10 WB21K10005 VALVE BURNER RIGHT FRONT 1

11 WB21K10008 VALVE BURNER LEFT FRONT 1

13 WB02K10036 BRACKET BURNER 1

14 WB01X1192 FLAT WASHER-M4 30

16 WB19K0026 PRESSURE REGULATOR 1

18 WB02K0108 COVER VALVE 1

21 WB01K0083 SCREW-MTG VALVE BURNER 5

30 WB34K10042 SHIELD SPARK MOD 1

31 WB35K10023 SPARK MODULE INSULATION 1

50 WB02K10001 MOUNTING PLATE ELEC 1

51 WB06K0014 ADAPTOR 1

52 WB28K10106 INLET BLOCK 1

56 WB02X9838 POWER CORD CLAMP 1

58 WB18X0380 POWER SUPPLY CORD 1

60 NOT STOCKED SHIELD-TERMINAL BLOCK 1

62 NOT STOCKED TERMINAL BLOCK 1

64 WB01X1189 SCREW M4X8 21

66 WB18K10001 HARNESS-MAIN WIRING 1

66 WB18K10007 HARNESS HV 1

72 WB13K10007 ELECTRODE SPARK 5

74 WB01K10026 CLIP ELECTRODE 5

75 WB02K10037 GROUND PATH SHIELD 5

View Catalog Description Qty.

86 WB61K10007 GLASS COOKTOP (WH) 1

88 WB02X9843 SEAL-DRIP PAN 5

91 WB02X9243 INSTALLATION HARDWARE PK 2

94 WB02K10044 RETENTION BRACKET 1

94 WB02X9846 RETENTION BRACKET 4

95 WB34K10043 CLAMPING PLATE 5

96 NOT STOCKED NUT M4 30

110 WB13K10005 SPARK MODULE 5+0 1

112 WB31K10059 GRATE DOUBLE (GRAY) 2

113 WB31K10060 GRATE CENTER (GRAY) 1

114 WB28K10104 MANIFOLD PIPE 1

115 WB32K10021 DRIP PAN LFT & CENTER WH 3

115 WB32K10022 DRIP PAN RT REAR WH 1

115 WB32K10024 DRIP PAN RT FRONT WH 1

116 WB28K10102 SUPPLY TUBE-LEFT FRONT 1

118 WB28K10100 SUPPLY TUBE-LEFT REAR 1

120 WB28K10103 SUPPLY TUBE- CENTER 1

122 WB28K10101 SUPPLY TUBE -RIGHT REAR 1

124 WB28K10099 SUPPLY TUBE-RIGHT FRONT 1

125 WB18K10008 HARNESS SWITCH 1

126 NOT STOCKED BASEPLATE 1

127 WB28K10105 SUPPLY TUBE MAIN 1

128 WB01K10025 SCREW-MTG SUPPLY TUBE 1

138 WB07X1832 BEZEL-WHITE 5

140 WB03K10108 KNOB TOP BURNER WH 5

151 WB29K10002 CAP-BURNER SMALL (GRAY) 1

152 WB29K10004 CAP-BURNER MED (GRAY) 3

153 WB29K10007 CAP-BURNER LARGE (GRAY) 1

155 WB16K10014 BURNER-SMALL 1

156 WB16K10005 BURNER-MED 3

– 33 –

Page 36

Model ZGU365DBB0BG

170 WB57K10004 GLASS-SORKEL-BLACK 1

View Catalog Description Qty.

1 WB02X9857 SEAL-CKTOP TO WORKTOP 2

1 31-20775 MINI-MANUAL (SNORKEL) 1

1 49-80012 PM USE & CARE MANUAL 1

2 WB02X9857 SEAL GASKET 4

3 WB28K10022 ORIFICE-NG 1.50MM 3

3 WB28K10029 ORIFICE-NG 1.07MM 1

3 WB28K10030 ORIFICE-NG 1.68MM 1

4 WB63K10022 CONTAINER BOX ASSEMBLY 1

8 WB21K10006 VALVE LFT RR & CENTER 2

9 WB21K10007 VALVE BURNER RIGHT REAR 1

10 WB21K10005 VALVE BURNER RT FRONT 1

11 WB21K10008 VALVE BURNER LEFT FRONT 1

13 WB02K10036 BRACKET BURNER 1

14 WB01X1192 FLAT WASHER-M4 30

16 WB19K0026 PRESSURE REGULATOR 1

18 WB02K0024 COVER VALVE 5

21 WB01K0083 SCREW-MTG VALVE BURNER 5

30 WB34K10042 SHIELD SPARK MOD 1

31 WB35K10023 INSULATION-SPK MODULE 1

38 WB24K10001 BLOWER SPEED REGULATOR 1

40 WB24X0475 SWITCH 1

42 NOT STOCKED SHIELD-SWITCH 1

44 WB01X1382 HEX NUT 3/8" X 32 2

48 WB01X1383 FIBRE WASHER 10MM 2

50 WB02K10001 MOUNTING PLATE ELEC 1

51 WB06K0014 ADAPTOR 1

52 WB28K10106 INLET BLOCK 1

56 WB02X9838 POWER CORD CLAMP 1

58 WB18X0380 POWER SUPPLY CORD 1

60 NOT STOCKED SHIELD-TERMINAL BLOCK 1

62 NOT STOCKED TERMINAL BLOCK 1

64 WB01X1189 SCREW M4X8 21

66 WB18K10001 HARNESS-MAIN WIRING 1

66 WB18K10007 HARNESS HV 1

72 WB13K10007 ELECTRODE SPARK 5

74 WB01K10026 CLIP ELECTRODE 5

75 WB02K10037 GROUND PATH SHIELD 5

86 WB61K10008 GLASS COOKTOP (BLK) 1

88 WB02X9843 SEAL-DRIP PAN 5

91 WB02X9243 INSTALLATION HARDWARE PK 2

94 WB02K10044 RETENTION BRACKET 5

95 WB34K10043 CLAMPING PLATE 5

96 NOT STOCKED NUT M4 30

101 WB56X10010 COVER 36" 1

102 WB56X10004 PANEL GEAR MOTOR 1

103 WB07X10012 SLIDE 1

View Catalog Description Qty.

104 WB02X10303 PIVOT ARM 1

106 WB02X10306 ROLLER 1

108 WB02X10310 FILTER 2

109 WB02X10307 SEAL 1

110 WB13K10005 SPARK MODULE 5+0 1

112 WB31K10057 GRATE DOUBLE (BLK) 1

113 WB02X10308 BLOWER SUPPORT LEGS 8

113 WB31K10058 GRATE CENTER (BLK) 1

114 WB28K10104 MANIFOLD PIPE 1

115 WB32K10018 DRIP PAN LT & CENTER-BLK 3

115 WB32K10019 DRIP PAN RT RR (BLK) 1

115 WB32K10023 DRIP PAN RT FT (BLK) 1

116 WB28K10102 SUPPLY TUBE-LEFT FRONT 1

118 WB28K10100 SUPPLY TUBE-LEFT REAR 1

120 WB28K10103 SUPPLY TUBE- CENTER 1

122 WB28K10101 SUPPLY TUBE -RIGHT REAR 1

123 WB01X10004 U-BOLT 1

124 WB28K10099 SUPPLY TUBE-RIGHT FRONT 1

125 WB18K10008 HARNESS SWITCH 1

126 NOT STOCKED BASEPLATE 1

127 WB28K10105 SUPPLY TUBE MAIN 1

128 WB01K10025 SCREW-MTG SUPPLY TUBE 1

129 WB27X5599 CAPACITOR 1

133 WB01X10007 BUTTON SLIDE 4

135 WB01X10008 SCREW, PAN HEAD 2

138 WB07X1759 BEZEL-BLACK 5

140 WB03K10107 KNOB TOP BURNERS (BLK) 5

142 WB03K0109 KNOB-DOWNDRAFT CONTROL 2

145 WB01K10005 NUT 6-32- MTG GLASS TRIM 4

146 WB34K10002 WIRE BOX 11

147 WB26X10005 GEAR MOTOR 1

148 WB38X5079 BLOWER 1

149 WB01X10006 HEYCO BUSHING 1

150 WB02X10309 SEAL 2

151 WB29K10009 CAP-BURNER SMALL (BLK) 1

152 WB29K10001 CAP-BURNER MED (BLK) 3

153 WB29K10006 CAP-BURNER LARGE (BLK) 2

155 WB16K10014 BURNER-SMALL 1

156 WB16K10005 BURNER-MED 3

157 WB16K10007 BURNER-LARGE 2

167 WB01X10003 SCREW BLACK 25

169 WB02X10301 FORMED BOX 1

– 34 –

Page 37

Model ZGU365DWB0WG

170 WB61K10002 GLASS-SNORKEL-WHITE 1

View Catalog Description Qty.

1 WB02X9857 SEAL-COOKTOP TO WORKTOP 2

1 31-20775 MINI-MANUAL (SNORKEL) 1

1 49-80012 PM USE & CARE MANUAL 1

1 49-8832 MANUAL-INSTAL. INSTRUC. 1

2 WB02X9857 SEAL GASKET 4

3 WB28K10022 ORIFICE-NG 1.50MM 3

3 WB28K10029 ORIFICE-NG 1.07MM 2

3 WB28K10030 ORIFICE-NG 1.68MM 1

4 WB63K10022 CONTAINER BOX ASSEMBLY 1

8 WB21K10006 VALVE LFT RR & CENTER 2

9 WB21K10007 VALVE BURNER RIGHT REAR 1

10 WB21K10005 VALVE BURNER RIGHT FRONT 2

11 WB21K10008 VALVE BURNER LEFT FRONT 1

13 WB02K10036 BRACKET BURNER 1

14 WB01X1192 FLAT WASHER-M4 30

16 WB19K0026 PRESSURE REGULATOR 1

18 WB02K0024 COVER VALVE 5

21 WB01K0083 SCREW-MTG VALVE BURNER 5

30 WB34K10042 SHIELD SPARK MOD 1

31 WB35K10017 SPARK MODULE INSULATION 1

31 WB35K10023 INSULATION-SPK MODULE 1

38 WB24K10001 BLOWER SPEED REGULATOR 1

40 WB24X0475 SWITCH 1

42 NOT STOCKED SHIELD-SWITCH 1

44 WB01X1382 HEX NUT 3/8" X 32 2

48 WB01X1383 FIBRE WASHER 10MM 2

50 WB02K10001 MOUNTING PLATE ELEC 1

51 WB06K0014 ADAPTOR 1

52 WB28K10106 INLET BLOCK 1

56 WB02X9838 POWER CORD CLAMP 1

58 WB18X0380 POWER SUPPLY CORD 1

60 NOT STOCKED SHIELD-TERMINAL BLOCK 1

62 NOT STOCKED TERMINAL BLOCK 1

64 WB01X1189 SCREW M4X8 21

66 WB18K10001 HARNESS-MAIN WIRING 1

66 WB18K10007 HARNESS HV 1

72 WB13K10007 ELECTRODE SPARK 5

74 WB01K10026 CLIP ELECTRODE 5

75 WB02K10037 GROUND PATH SHIELD 5

86 WB61K10009 GLASS COOKTOP (WH) 1

88 WB02X9843 SEAL-DRIP PAN 5

91 WB02X9243 INSTALLATION HARDWARE PK 2

94 WB02K10044 RETENTION BRACKET 5

95 WB34K10043 CLAMPING PLATE 5

96 NOT STOCKED NUT M4 30

101 WB56X10010 COVER 36" 1

View Catalog Description Qty.

102 WB56X10004 PANEL GEAR MOTOR 1

103 WB07X10012 SLIDE 1

104 WB02X10303 PIVOT ARM 1

106 WB02X10306 ROLLER 1

108 WB02X10310 FILTER 2

109 WB02X10307 SEAL 1

110 WB13K10005 SPARK MODULE 5+0 1

112 WB31K10057 GRATE DOUBLE (BLK) 2

112 WB31K10059 GRATE DOUBLE (GRAY) 2

113 WB02X10308 BLOWER SUPPORT LEGS 8

114 WB28K10104 MANIFOLD PIPE 1

115 WB32K10021 DRIP PAN LFT & CENTER GR 2

115 WB32K10022 DRIP PAN RT REAR GRAY 1

115 WB32K10024 DRIP PAN RT FRONT GRAY 1

116 WB28K10102 SUPPLY TUBE-LEFT FRONT 1

118 WB28K10100 SUPPLY TUBE-LEFT REAR 1

120 WB28K10103 SUPPLY TUBE- CENTER 1

122 WB28K10101 SUPPLY TUBE -RIGHT REAR 1

123 WB01X10004 U-BOLT 1

124 WB28K10099 SUPPLY TUBE-RIGHT FRONT 1

125 WB18K10008 HARNESS SWITCH 1

126 NOT STOCKED BASEPLATE 1

127 WB28K10105 SUPPLY TUBE MAIN 1

128 WB01K10025 SCREW-MTG SUPPLY TUBE 1

129 WB27X5599 CAPACITOR 1

133 WB01X10007 BUTTON SLIDE 4

135 WB01X10008 SCREW, PAN HEAD 2

138 WB07X1759 BEZEL-BLACK 5

138 WB07X1832 BEZEL-WHITE 5

140 WB03K10108 KNOB TOP BURNER WH 5

142 WB03K0110 KNOB-DOWBDRAFT CTL 2

145 WB01K10005 NUT 6-32- MTG GLASS TRIM 4

146 WB34K10002 WIRE BOX 1

147 WB26X10005 GEAR MOTOR 1

148 WB38X5079 BLOWER 1

149 WB01X10006 HEYCO BUSHING 1

150 WB02X10309 SEAL 1

151 WB29K10002 CAP-BURNER SMALL (GRAY) 1

152 WB29K10004 CAP-BURNER MED (GRAY) 3

153 WB29K10006 CAP-BURNER LARGE (BLK) 1

153 WB29K10007 CAP-BURNER LARGE (GRAY) 1

155 WB16K10014 BURNER-SMALL 1

156 WB16K10005 BURNER-MED 3

157 WB16K10007 BURNER-LARGE 1

167 WB01X10003 SCREW BLACK 25

169 WB02X10301 FORMED BOX 1

– 35 –

Page 38

Warranty Information

Sales slip or cancelled check is required as proof of original purchase date to obtain

service under warranty.

All warranty service is provided by our Factory Service Centers or an authorized Customer

Care® technician. For service, call 800.GE.CARES.

For The Period Of:

One Year

From the date of the

original purchase

Five Years

From the date of the

original purchase

GE Will Replace:

Any part

ship. During this

charge

A replacement glass cooktop

discolor; or if the pattern wears off.

During this

for any labor or in-home service.

of the cooktop which fails due to a defect in materials or workman-

full one-year warranty

, all labor and in-home service to replace the defective part.

limited additional four-year warranty

What GE Will Not Cover:

• Service trips to your home to teach you

how to use the product.

• Improper installation.

• Failure of the product if it is abused, mis-

used, or used for other than the intended

purpose or used commercially.

• Damage to the glass cooktop caused by

use of cleaners other than the recommended cleaning creams.

, GE will also provide,

if it should: crack due to thermal shock;

, you will be responsible

• Damage to the glass cooktop caused by

hardened spills of sugary materials or

melted plastic that are not cleaned according to the directions in the Owner’s Manual.

• Damage to the product caused by accident,

fire, floods or acts of God.

• Incidental or consequential damage to

personal property caused by possible

defects with this applicance.

free of

• Replacement of house fuses or resetting of

circuit breakers.

This warranty is extended to the original purchaser and any succeeding owner for products purchased

for home use within the USA. In Alaska, the warranty excludes the cost of shipping or service calls to

your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

To know what your legal rights are, consult your local or state consumer affairs office or your state’s

Attorney General.

Warrantor: General Electric Company. Louisville, KY 40225

– 36 –

Page 39

– 37 –

Page 40

– 38 –

Loading...

Loading...