GE Monogram ZDP30_ _H, Monogram ZDP36_ _ _H, Monogram ZDP48_ _ _H, Monogram ZGU36_ _ _H, Monogram ZGU48_ _ _H Technical Service Manual

Page 1

GE Consumer & Industrial

TECHNICAL SERVICE GUIDE

Monogram Dual Fuel Pro Ranges

And

Monogram Gas Cooktops

MODEL SERIES:

ZDP30_ _H

ZDP36_ _ _H

ZDP48_ _ _H

ZGU36_ _ _H

ZGU48_ _ _H

PUB # 31-9119 3/04

Page 2

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by

individuals possessing adequate backgrounds of electrical,

electronic, and mechanical experience. Any attempt to repair a

major appliance may result in personal injury and property

damage. The manufacturer or seller cannot be responsible for the

interpretation of this information, nor can it assume any liability in

connection with its use.

WARNING

If the information in this manual is not followed exactly, a fire or

explosion may result causing property damage, personal injury or

death. If you smell gas:

- Do not try to light any appliance.

- Do not touch any electrical switch; do not use any phone in

the building.

- Immediately call the gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

- If you cannot reach the gas supplier, call the fire department.

WARNING

To avoid personal injury, disconnect power before servicing this

product. If electrical power is required for diagnosis or test

purposes, disconnect the power immediately after performing the

necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used

to complete a path to ground are removed for service, they must

be returned to their original position and properly fastened.

All rights reserved. This service guide may not be reproduced in whole or in part

in any form without written permission from the General Electric Company .

GE Consumer & Industrial

Technical Service Guide

Copyright © 2004

– 2 –

Page 3

TABLE OF CONTENTS

Blower Thermal Cutout....................................................................................................16

Burner Alignment .............................................................................................................12

Burner Valve..................................................................................................................... 11

Check for Proper Ignition .................................................................................................12

Component Access ........................................................................................................... 8

Component Locator Views ................................................................................................6

Components ......................................................................................................................8

Convection Fan Assembly ...............................................................................................18

Door Assemblies ...............................................................................................................9

Flame Characteristics ..................................................................................................... 11

Grates ..............................................................................................................................12

Griddle Leveling ...............................................................................................................15

Griddle Removal ..............................................................................................................14

Griddle Thermostat Adjustment .......................................................................................15

Grill Burner/Griddle Burner Ignition Systems (On Some Models) ....................................1 3

Grill or Griddle Air Adjustment ..........................................................................................15

Grill or Griddle Igniter Removal ........................................................................................16

Grill Removal ...................................................................................................................14

Ignition and Re-ignition.....................................................................................................12

Introduction ........................................................................................................................4

Lock Motor Assembly.......................................................................................................19

Nomenclature ....................................................................................................................5

Orifice Conversion Kits....................................................................................................11

Oven Blower Motor (30-in. Range Models) ......................................................................20

Oven Blower Motor (36-in. and 48-in. Range Models) .....................................................19

Oven Door .........................................................................................................................8

Oven Light Bulbs .............................................................................................................1 0

Oven Select Switches .....................................................................................................17

Oven Thermostat............................................................................................................. 17

Oven Thermostat Calibration...........................................................................................16

Relays, Convection Pulser T imers and Main Power Connection.....................................1 7

Schematics and Wiring Diagrams................................................................................... 21

Simmer Orifice Burner Replacement .............................................................................. 11

Sparking....................................................................................................................... ....12

Spark Module ...................................................................................................................13

Surface Burner ................................................................................................................10

Surface Burner Adjustments............................................................................................11

Warranty ..........................................................................................................................30

– 3 –

Page 4

Introduction

The Monogram Ranges are available in 30-in.

36-in. and 48-in. configurations. The 36-in. can

have 6 burners, no grill or griddle or 4 burners

with grill or griddle. The 30-in. and 36-in. models

have a 27-in. self-cleaning oven and the 48-in.

model has an additional 12-in. standard clean

oven.

The gas cooktop-only models are available in

36-in. and 48-in. configurations with the same

grill and griddle combinations as the cooktop on

the 36-in. and 48-in. range models.

All models are available in either natural gas or

LP gas and must be ordered appropriately from

the dealer at the time of purchase.

36-in. Range Shown with Center Grill

48-in. Range Shown with Grill, Griddle, and 12-in. Oven

– 4 –

Page 5

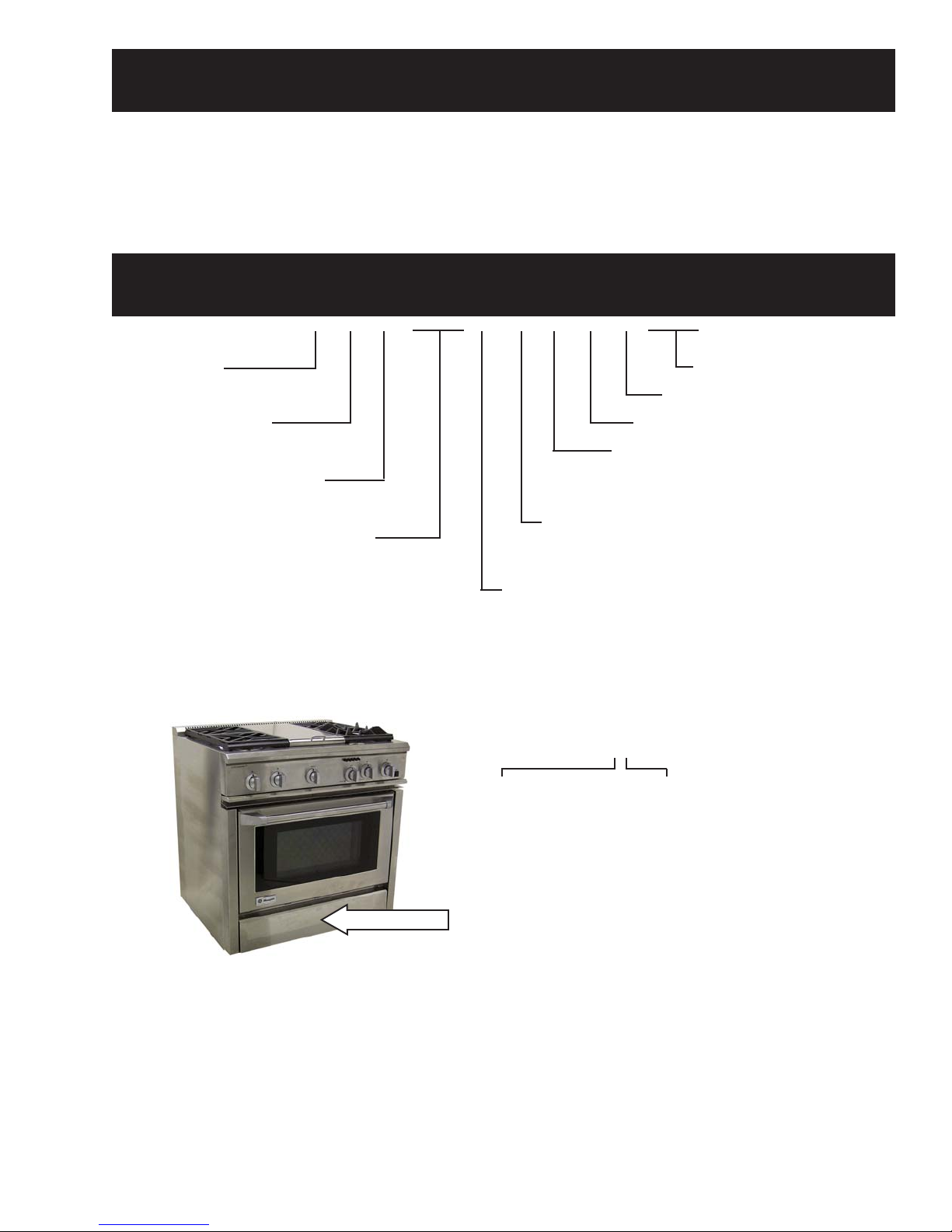

Model Number

Nomenclature

Z D P 4 8 N 4 G H 1 S S

Monogram

D = Dual Fuel

G = Gas

P = Self Clean

U= Cooktop

Width

Mini-manual

The mini-manual is located behind the bottom

cover.

Nomenclature information is located on the

back of the range.

St ainless Steel

Eng. Digit

Model Y ear

G = Grill and Griddle

R = Grill Only

D = Griddle Only

4 = Surface Burners

6 = Surface Burners

N = Natural Gas

L = LP Gas

Serial Number

The first two numbers of the serial number

identify the month and year of manufacture.

Example: AG123456S = January, 2004

A - JAN 2005 - H

D - FEB 2004 - G

F - MAR 2003 - F

G - APR 2002 - D

H - MA Y 2001 - A

L - JUN 2000 - Z

M - JUL 1999 - V

R - AUG 1998 - T

S - SEP 1997 - S

T - OCT 1996 - R

V - NOV 1995 - M

Z - DEC 1994 - L

The letter designating

the year repeats every

12 years.

Example:

T - 1974

T - 1986

T - 1998

– 5 –

Page 6

36-in. Range Models

Component Locator Views

4

1 2

9

5

7

6

3

8

1 - Spark Module

2 - Oven Select Switches

3 - Oven Control

4 - Door Lock High Limit

5 - Gas Shut-Off Valve

6 - Relays

7 - Clean Timer

8 - Terminal Block

9 - Transformer

– 6 –

Page 7

48-in. Range Models

2

9

5

6

1

7

8

2

3

4

1 - Spark Module

2 - Oven Select Switches

3 - Oven Control

4 - Door Lock High Limit

5 - Gas Shut-Off Valve

6 - Relays

7 - Clean Timer and Proof Timer

8 - Terminal Block

9 - Transformer

– 7 –

Page 8

Components

Component Access

All 36-in. and 48-in. Models

1. Remove the manifold/valve panel:

a. Remove the knobs from the control

valves.

b. Remove the 4 Torx screws located at

each corner of the manifold/valve panel.

c. Carefully pull off the panel. (Do not

scratch the panel.)

2. Remove the landing ledge:

a. Slide the right-side drip tray out (models

with a grill or griddle).

b. Remove the 4 Phillips head screws

holding the landing ledge in place, and lift

the ledge off.

30-in. Range Models

1. Remove the manifold/valve panel. (See 36-in.

and 48-in. Models.)

2. Remove the landing ledge:

a. Remove the 4 Phillips head screws

holding the landing ledge in place, and lift

the ledge off.

48-in. Range Model Shown

Landing Ledge

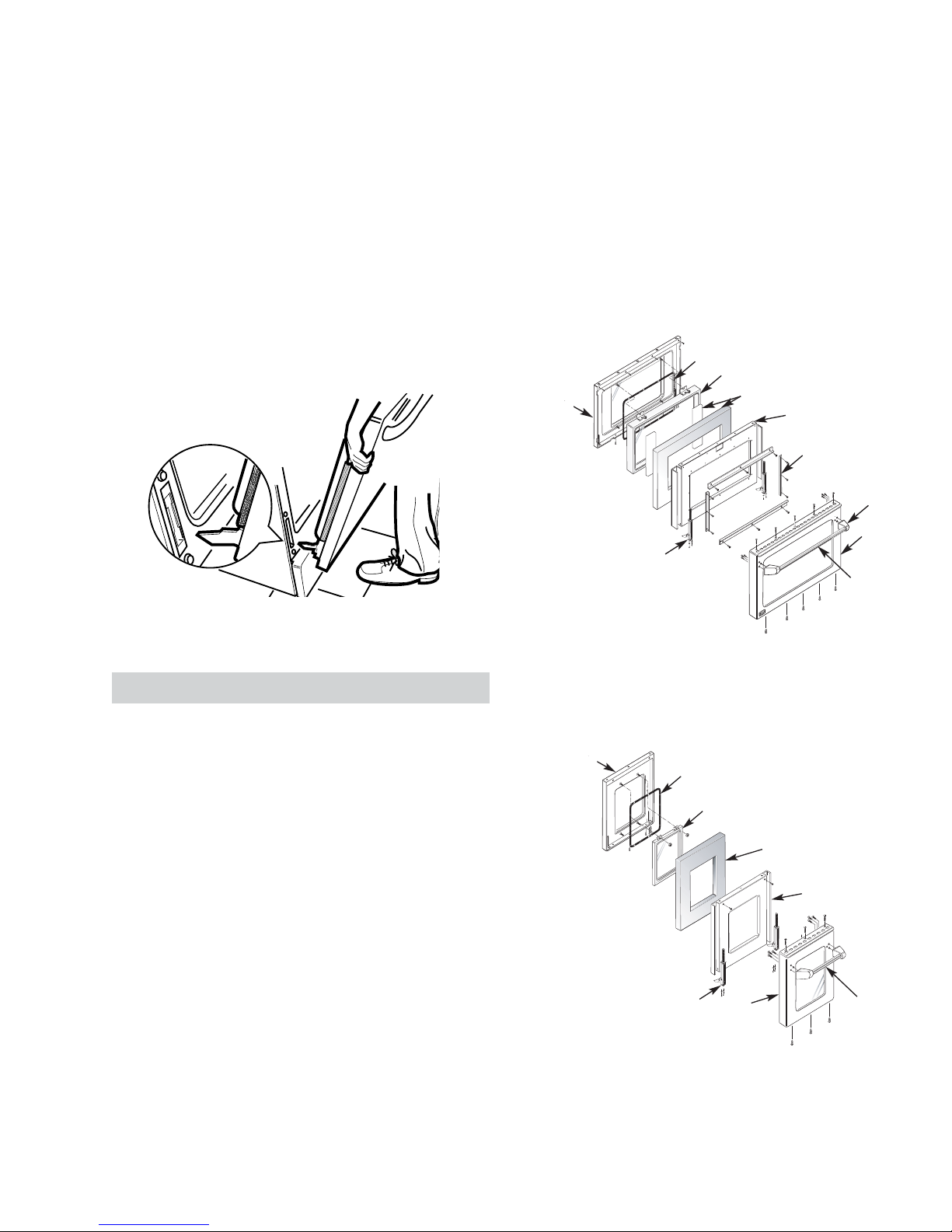

Oven Door

To remove the door:

1. Fully open the door .

2. Each hinge has a hinge lock. Close the hinge

latches down against the door frame.

3. Firmly grasp the door at the top sides.

4. Close the door to the near-vertical position.

5. Lift the door up and pull straight out.

Hinge Lock

– 8 –

Pull the hinge locks

down to u

nlock.

Page 9

To install the door:

Door Gasket

1. Firmly grasp the door at the top sides. This is

critical.

2. Approach the range with the door angled in a

vertical position.

3. Guide the hinges into the slots.

4. Push the door in firmly while opening.

5. Once in position, open the door completely .

Push the hinge locks back in and toward the

front frame.

Note: If the door cannot be fully opened, the

hinge is not properly seated.

The gasket is attached to the front frame around

the outer edge of the oven liner. A series of spring

clips mounts the gasket to the front frame. The

ends are tucked into the front frame at the bottom

of the oven liner, leaving approximately 15 inches

of opening across the bottom for air intake on selfclean models. The gasket stops just above the

hinges on the standard oven.

27-in. Oven

Window Gasket

Window Pack

Door Liner

Hinge

Insulation

Insulation

Retainer

Compression

Brackets

ndle

Ha

End Cap

Door

Skin

Handle

Door Assemblies

12-in. Oven Door (48-in. Range Model Only)

The oven door consists of outer and inner

assemblies. The outer assembly consists of the

outer panel and glass along with the handle and

spacers. The inner assembly consists of the

window pack, insulation guard, inner door panel

and hinges.

27-in. Oven Door (30-in., 36-in. and 48-in.

Range Models)

The oven door consists of an outer and inner

assembly. The outer assembly consists of an

outer panel and glass along with the handle and

spacers. The inner assembly is made up of the

window pack, insulation guard, inner door panel,

hinges and window pack gasket.

12-in. Oven (48-in. Range Models Only)

Door Liner

Window Gasket

Door Hinge

Window Pack

Door

Skin

Insulation

nsulation

I

Retainer

Handle

– 9 –

Page 10

r

Oven Light Bulbs

Surface Burner

Socket

Receptacle

Bulb

Tab

Glass cover

Caution: Before replacing the oven light bulb,

disconnect the electrical power to the range at the

main fuse or circuit breaker panel.

Note: Allow light cover and bulb to cool

completely.

Replace with a new 130V halogen bulb, not to

exceed 35 watts.

To remove and replace the oven light bulb:

1. Turn the glass cover counterclockwise

1

/4 turn

until the tabs of the glass cover clear the

grooves of the socket.

2. Using gloves or a dry cloth, remove the bulb

by pulling it straight out.

3. Using gloves or a dry cloth, remove the new

bulb from its packaging. Do not touch the

bulb with bare fingers.

4. Push the bulb straight into the receptacle all

the way . Place the tabs of the glass cover into

the grooves of the socket. Turn the glass

cover clockwise

1

/4 turn to engage.

To remove the surface burner:

1. Lift off the burner cap and burner head.

2. Remove the burner ring locking nut using a

1

/16-in. socket wrench, crescent wrench or

1

channel-lock pliers.

3. Lift off the burner ring. Do not remove the

burner base.

To replace the surface burner:

1. Align the locator pins on the burner ring into

the labeled hole in the burnerbase. Seat in

place and push toward the electrode to set

gap properly .

2. Replace the burner ring locking nut. Tighten

the nut three times to remove small

imperfections in the parts. This will ensure the

nut remains tight over life:

1

• Hand tighten nut, tighten

/4 turn with

wrench or pliers, then loosen.

• Hand tighten nut a second time, tighten

1

/4 turn with wrench or pliers, then loosen.

1

• Hand tighten nut and final tighten

/4 turn

with wrench or pliers.

3. Align the locator pin in the burner head into the

hole in the burner ring. Seat in place.

4. Replace the burner caps.

Burner Cap

Burner Head

(Brass)

Locator Pins

Burner Ring

(Aluminum)

Locator Pin

Pin Slot

Burner Base

Burner Ring

Locking Nut

With Chamfe

Side View

Electrode

5. For improved lighting inside the oven, clean

the glass cover frequently using a wet cloth.

This should be done when the oven is

completely cool.

6. Reconnect electrical power to the oven.

Note: Locator Pin Fits

Into Burner Base Pin Slot

– 10 –

Page 11

Main Flame

Simmer Flame

ORIFICE/JET SIZES

ORIFICE (mm) RATE (BTU/HR)

BURNER GAS MAIN SIMMER Valve HI LO SIM

D BURNER NG 1.85 0.57 mm 0.57 17k 2700 1300 185 P

D BURNER LP 1.18 0.34 mm 0.34 15k 2500 1200 118 E

GRILL/GRIDDLE NG 1.93 ––––– 0.94 18k 6000 –––– 48 –––

GRILL/GRIDDLE LP 1.32 ––––– 0.47 18k 6000 –––– 55 –––

MAIN ORIFICE CODE

SIMMER ORIFICE CODE

ORIFICE/JET SIZES

Sea Level 3000 ft. 6000 ft.

BURNER GAS MAIN Orifice (mm)

D BURNER NG 1.85 1.78 1.61

D BURNER LP 1.18 1.09 1.07

GRILL/GRIDDLE NG 1.93 1.85 1.70

GRILL/GRIDDLE LP 1.32 1.32 1.18

HIGH ALTITUDE CONVERSION

Recommended Orifice Size for High Altitude Installation

Burner Valve

Flame Characteristics

The burner valves are attached to the manifold by

two screws and contains an orifice which sets

the flow rate for the simmer flame. This valve

does not have a low flame adjustment, it is

controlled by the orifice size.

Simmer Orifice Burner Replacement

The simmer burner orifice requires a 4mm socket

to remove it. If necessary a 4mm socket is

available under part # WX05x10006.

Burner flames should be blue and stable with no

yellow tips. (Yellow tipping may be normal for LP

gas.) The flame should not have excessive noise

or lifting of the flame from the burner . If any of

these conditions exist, check the burner ports for

blockage.

Orifice Conversion Kits

Burner orifice conversion kits are available for:

• Converting burner orifices from LP to Natural

Gas and from Natural Gas to LP

Surface Burner Adjustment s

Standard adjustments to the air shutter and gas

metering orifices are not possible on sealed

burners.

If burner flames appear to be abnormal, check the

following:

• Check gas pressure available to the burners.

The required operating pressure is 5" W.C.P.

Natural Gas or 10" W.C.P. L.P. (Propane) Gas.

• Check for drafts entering the burner box from

behind the cooktop.

• Check for blockage or partial blockage of the

orifice. Inspect the orifice to be sure it has

been drilled on center and is free of debris or

burrs.

• Check the burner alignment per

Alignment.

• If the cause of the problem cannot be found,

installing an orifice with smaller diameter

openings may solve the problem. In high

altitude (above 6000 ft.) installation, the

orifices will usually have to be downsized.

Burner

• Installation at high altitudes

Natural/LP Conversion Kit - Order part number

WB49X10132

LP/Natural Conversion Kit - Order part number

WB49X10133

High Altitude Conversion Kit – Order p art number

WB49X10130

– 11 –

Page 12

Grates

Ignition and Re-ignition

To repair damaged feet on range cooktop grates,

order the repair kit, part # WB2X11095.

Burner Alignment

Burner alignment is very important for proper

operation. Make sure the locator pin on the burner

ring is properly aligned with the hole on the burner

base. Each brass burner head is marked with a

clock face. Replace the burner head with the

arrow pointing to the rear of the cooktop (12

o’clock position).

The ignition systems consists of 3 major

components.

• Transformer

• Sp ark Module

• Electrodes and Associated Wiring

Features of the cooktop determine whether the

ignition system uses a 4 or 5 wire spark module.

The spark modules are rated at 240v and have an

internal transformer. The internal transformer

serves two functions.

• An isolation device to prevent random

sparking in reverse polarity situations.

• To increase the input voltage from 120v to

240v .

During the ignition process all the electrodes will

spark simultaneously when any burner is

selected. Once the ignition process is complete,

the flame ionizes the surrounding air which

completes the sensing circuit and satisfies the

module that a flame is present.

Check For Proper Ignition

All the igniters make clicking sounds and spark

even when only a single burner is being turned

on. Do not touch any of the burners when the

igniters are clicking.

1. Push in one control knob and turn 90° to LITE

position.

2. The igniter will spark and the burner will light;

the igniter will cease sparking when the

burner is lit.

3. The first test may require some time while air

is flushed out of the gas line.

4. Turn knob to OFF.

5. Repeat the procedure for each burner .

Sparking

• Input voltage should be 240 V AC and the

ground line should be properly connected to

the range chassis. Volt age should be

measured on one leg of the power supply.

• Make sure electrical circuit is properly

polarized.

• If the igniter electrodes continue to spark after

the burners are lit, check that each burner

component is assembled and seated properly

by observing uniform gaps between each

layer. Disassemble and reassemble as

required.

• If water spills onto the electrode, the burner

will not reignite. The wet electrode will conduct

spark energy to ground, preventing it from

sparking or sensing flame across the spark

gap. The burner will operate normally once the

electrode and wiring connections are dry.

– 12 –

Page 13

Spark Module

Spark Module

All 36-in. and 48-in. models have a single spark

module located behind the manifold/valve panel.

To remove the module:

1. Remove the manifold/valve panel (see

Component Access).

2. Remove the screws at the upper-right and

lower-left corners of the module.

3. Pull the module up and out.

36-in. Model Shown

30-in. Range Models

Grill Burner/Griddle Burner Ignition

Systems (On Some Models)

The grill burner and griddle burner are ignited by

Norton style glowbar ignition systems. The ignition

circuit consists of the grill switch (grill burner

only), griddle thermostat (griddle burner only), the

igniter and the thermal/safety valve (gas valve).

The components are wired in series for each

cooking function.

Note: The igniter resistance decreases as the

igniter surface temperature increases. The safety

valve operates by current, not by voltage.

From a cold start, the igniter needs 30–60

seconds, with voltage applied, to reduce its

electrical resistance enough to provide a

minimum of 3.2 - 3.6 amps of current flow in the

series circuit. This is the required current flow

needed for the safety valve to open and supply

gas to the burner.

The glowbar should provide a steady current flow

of 3.2 to 3.6 amps flowing in the circuit. At that

point, the igniter temperature is between 1800°F

and 2500°F . The igniter will remain energized at all

times during burner operation. If the igniter glows

red but does not draw at least 3.2 - 3.6 amps, the

fault is usually with the igniter, not the valve.

30-in. range models have a single spark module

located in the center of the burner box.

To remove the module:

1. Remove the burner grates.

2. Lift off the center trim from the burner

maintop.

3. Remove the 2 screws at the front and rear of

the air duct cover , and remove the cover.

4. Remove the 2 screws securing the spark

module to the range.

– 13 –

Page 14

Grill Removal

Griddle Removal

To remove the grill burner assembly:

1. Remove the grill cover, grill grates and grill

radiant.

2. Lift off the front trim from the front of the grill.

3. Remove the 2 Phillips head screws at the

front of the grill box that secure the grill box to

the cooktop.

4. Carefully lift up the grill box enough to access

the wire nut connecting the igniter to the

neutral, and unscrew the nut. Unplug the wire

going to the valve.

5. Lift the grill up and off the cooktop.

Grill Cover

To remove the griddle assembly:

1. Remove the griddle cover .

2. Lift off the front trim from the front of the

griddle.

3. Remove the 2 Phillips head screws at the

front of the griddle that secure the griddle to

the cooktop.

4. Remove the rear cover from the rear of the

griddle.

5. Remove the center shipping screw and

washer, if they have not already been

removed.

Note: Do not remove the 2 outer leveling screws.

6. Lift the griddle assembly out of the opening

and pull out the thermostat capillary from

beneath the plate.

Burner

Grill Box

Grill Grates

Grill Radiant

Igniter

Front

Trim

Rear

Cover

Griddle

Plate

Assembl

y

Griddle Baffle

Leveling

s

Screw

Griddle

Cover

Front

T

rim

Igniter

Burner

– 14 –

Page 15

Griddle Leveling

Grill or Griddle Air Adjustment

The 2 screws at the rear of the griddle plate

assembly are leveling screws. They can be

turned to level the griddle or to provide a forward

slope to help grease and oils to drain away from

the food being cooked.

Griddle Thermostat Adjustment

To adjust the griddle thermostat:

1. Pull the griddle control knob off.

2. On the back of the knob, loosen both screws,

but do not completely remove.

3. With the back of the knob facing you, hold the

outer edge of the knob with one hand and turn

the back of the knob with the other hand.

4. To raise the griddle temperature, turn the back

of the knob clockwise. To lower the griddle

temperature, turn the back of the knob

counterclockwise.

1. For the grill, remove the grill cover, grates and

grill radiant. For the griddle, remove the

griddle assembly (see

Griddle Removal).

2. If adjusting the grill air shutter, remove the 2

Phillips head screws at the rear of the burner

and lift the burner out.

3. Loosen the screw on the burner air shutter

using a flat head screwdriver.

4. Using a flat head screwdriver, move the air

shutter in the appropriate direction. If the

flame is too yellow, indicating insuf ficient air,

adjust the shutter counterclockwise to

increase the airflow. If the flame is too low or

tends to lift away from the burner , indicating

too much air, turn the shutter clockwise to

reduce the airflow .

5. Test and adjust as needed for proper flame

characteristics.

5. After the adjustment is made, retighten

screws so they are snug, and replace knob.

H

O

T

Ð20û+20û

/

Ð10û

+10û

GRIDDLE

C

+12û

OVEN

Ð12û

O

L

D

+24û

Ð24û

– 15 –

Page 16

Grill or Griddle Igniter Removal

Oven Thermostat Calibration

1. For the grill, remove the grill cover, grates and

grill radiant. For the griddle, remove the

griddle assembly (see

Griddle Removal).

2. Remove the 2 Phillips head screws at the

rear of the burner and lift the burner out.

3. Remove the 2 flat head screws holding the

igniter to the support bracket on the burner .

4. Replace with new igniter and replace all parts.

Note: When aligned properly , the dimple on the

igniter bracket should fit into the notch on the

support bracket on the burner.

Igniter

The A VERAGE center oven temperature should

be 350° ±15°F for baking at the 350°F setting.

Customers may change the average center oven

temperature by ±24°F to satisfy their own

cooking needs.

To adjust the oven thermostat:

1. Pull the oven control knob off.

2. On the back of the knob, loosen both screws,

but do not completely remove.

3. With the back of the knob facing you, hold the

outer edge of the knob with one hand and turn

the back of the knob with the other hand.

4. To raise the oven temperature, turn the back

of the knob clockwise. To lower the oven

temperature, turn the back of the knob

counterclockwise.

5. After the adjustment is made, retighten

screws so they are snug, and replace knob.

Burner

GRILL OR GRIDDLE OHMMETER TEST

COMPONENT OHMS

IGNITER 45–400 OHMS COLD

VALVE 1.0 to 1.2

SWITCH 0 OHMS

L1

GRILL

SWITCH

C

NC

L1

GRILL

VALVE

GRIDDLE

OHMS

CLOSED

HEAT

LIGHT

IGNITER

H

O

T

Ð20û+20û

/

C

Ð10û

+10û

GRIDDLE

N

+12û

OVEN

Ð12û

O

L

D

+24û

Ð24û

Blower Thermal Cutout

The thermal cutout will turn on the blower in any

mode of operation when it detects a temperature

in the control area of approximately 210°F. The

blower will cycle off when temperatures cool

below 120°F .

N

GRIDDLE

SWITCH

NO

C

THERMOSTAT

VALVE

HEAT

LIGHT

IGNITER

– 16 –

Page 17

Oven Select Switches

r

Select switch operation can be checked with

ohmmeter and strip circuits that show what

contacts are closed in each mode of operation.

Relays, Convection Pulser Timers and

Main Power Connection

Electrical relays and timers are located in the

compartment below the oven.

27-in. Oven

32 30 28 26 24 22 20 18 16 14 12 10

31 29 27 19 17 11 9

12-in. Oven

61 59 57 55 53 51 49 47 45 43 41

58 56 48 46 46 42 40

Remove the 2 screws from the top corners of the

bottom panel and pull straight off.

48-in. Range Models

Convection Broil

Unit Pulsar

K2 Relay

K1 Relay

K4 Relay

K3 Rela

y

Terminal

Clean Lockout Relay

Proof Timer

Clean Time

Block

Oven Thermostat

The operation of the thermostat contacts can be

checked with an ohmmeter and strip circuits.

Contacts 1 and 2 are the cycling contacts, which

are controlled by the expansion and contraction of

the helium in the capillary. Contacts 7 and 8 will

always be in the CLOSED position, except when

in the CLEAN mode of operation. (See above

illustration.)

Convection Broil

Unit Pulsar

30-in. and 36-in. Range Models

Clean Timer

K3

Relay

y

K4 Rela

y

K1 Rela

Terminal Block

– 17 –

Page 18

Convection Fan Assembly

The convection fan assembly is located behind the large oven liner .

To remove the convection fan assembly:

1. Disconnect power and remove the oven door and racks.

2. Loosen the fan cover mounted by 4 screws and spacers. Lift the cover off the keyhole opening.

3. Remove the 4 screws securing the fan assembly to the mounting plate.

4. Carefully pull the fan assembly into the oven.

Note: Fan assembly is heavy.

5. Disconnect the wires to remove the assembly from the oven, and place the assembly on a flat

surface for repair.

36-in. and 48-in. Range Models

Convection

Fan

Cover

Mounting

Screws (4)

Convection

Fan

30-in. Range Models

Cover

Blade

Convection

Fan Cover

Spacer (4)

Convection

Fan Assembly

Mounting

Screws

5/22 Blade Mounting

Screws (Allen)

(4)

5/32 Blade

Mounting Screw

(Allen)

(2)

Oven Cavity

Back

Motor Cooling

Fan Blade

Convection Fan Motor

Mounting

Insulation

Assembly Mounting

Plate

Convection Fan

Wiring Compartment

Cover

Start/Run

Capacitor

Convection

Fan Motor

Plate

– 18 –

Page 19

LOCKING

UNLOCKING

Lock Motor Assembly

A

The lock motor assembly is located at the center

top of the oven front frame. The assembly

consists of the mounting plate, motor, micro

switches, cam and hook assembly.

T o access the assembly:

1. Open the oven door.

2. Remove the 2 Torx screws securing the

mounting plate to the front frame and pull the

assembly out.

Door lock motor operation:

1. When the oven controls are set for CLEAN,

power is applied to the K3 relay coil, which

will energize the lock motor.

2. The lock motor drives the cam that closes

the latch CLOSED switch. As the lock hook

engages, the motor position switch will open,

supplying power to the K1 relay , which turns

the clean timer on.

3. At the end of the clean cycle, when the select

switch is pushed to off or another mode of

operation, the K4 relay will energize the lock

motor to drive the cam to the unlock position.

L2

120V.

LOCK

K3

LIGHT

RELAY

96

NO

K3

5

LM

120V.

K4 RELAY

COIL

AB

LM

RELAY

74

T STAT

CLOSED

<

550˚F

K3 RELAY

COIL

82

NC

K4

AB

K3

RELAY

93

NO

L2

LATCH

"CLOSED"

SW

CNC

K3

RELAY

74

NO

LATCH

"OPEN"

SW

CNC

K4

RELAY

96

SEL

SW

31 32

RELAY

8

NO

SEL

SW

29 30

NO

LOCK

LIGHT

L1

L1

Oven Blower Motor (36-in. and 48-in. Range

Models)

The blower motor assemblies are located on the

back of the range above each oven.

The air switch on the blower motor completes the

circuit to the oven thermostat.

Motor

Lock

Blower

Thermostat

Mounting

Plate

Motor Position

Switch

Fan

Thermostat

ir Switch

Fan Assembly

Mounting Plate

Screws (4)

Motor Mounting

Screws (2)

Fan Mounting

Plate

To remove the blower assembly:

1. Remove the cooktop burner assemblies.

2. Remove the 4 screws securing the fan

mounting plate, and pull the plate with

attached blower motor forward.

3. Remove the blower motor from its mounting

plate by loosening the 2 screws on the plate

and sliding the blower to the right.

4. Install in reverse order .

– 19 –

Page 20

Oven Blower Motor (30-in. Range Models )

The blower motor assembly is located on the

back of the range above the oven. The air switch

on the blower motor completes the circuit to the

oven thermostat and hot wire relay.

To remove the blower assembly:

1. Lift off the burner cap.

2. Remove the left-side burner assembly and

disconnect the ignition wires.

3. Remove the screws at the front and back of

the air duct cover to reveal the spark module.

(See Spark Module .)

4. Lower the manifold/valve panel. (See

Component Access).

Reignition

Module

Screw

7. On the spark module, cut the wire tie securing

the module, and disconnect the spark module

from the wire harness by pulling straight off

the connector.

Spark Module

Connector

8. Lift the air duct out (with the wires still

connected to the spark module), and set it

aside.

5. Locate the bracket holding the oven

thermostat in place. Remove the 2 screws

securing the bracket, and pull the thermostat

out of the way to reveal the re-ignition module

bracket.

6. Remove the screw from the re-ignition module

bracket.

9. Locate the blower motor cover at the center

rear of the burner box. Remove the 2 screws

securing the blower motor cover , and lift the

blower motor up and into the burner box.

Screw

Blower

Motor Cover

Screw

– 20 –

Page 21

Schematics and Wiring Diagrams

WARNING: Disconnect electrical power before servicing.

Caution: Label all wires prior to disconnection. Wiring errors can cause improper and dangerous

operation. V erify operation after servicing.

Oven Circuits

L2

FAN

SEL

T STAT

SW

19 20

• During bake operation the broil unit is on 1/4 wattage while bake unit is

energized.

L2

K5 RELAY

COIL

AB

31

L2

SEL

SW

19 26

FAN

T STAT

87 21

BM

BAKE 27-in Oven

ON

LIGHT

T STAT T STAT

BAKE 12-in. Oven

N

ON

LIGHT

SELSWSEL

SW

T STAT T STAT

48 4950 51 8 7

BROIL 27-in Oven

N

240V.

240V.

HEAT

LIGHT

BAKE

UNIT

12.92A 12.92A

3100W

BROIL

1

UNIT

4.17A

2000W

HEAT

LIGHT

BAKE

UNIT

11.67A 11.67A

2800W

BROIL

1

UNIT

3.75A

1800W

BROIL

UNIT 2

2000W

BROIL

UNIT

1800W

SEL

SW

CUTOUT

10119

SEL

SW

4.17A

16 9

42

SEL

SW

CUTOUT

41

40

SEL

2

SW

3.75A

41 40

HIGH

TEMP

HIGH

TEMP

L1

L1

L1

L2

FAN

SEL

T STAT

SW

19 20

• The Convection Fan will turn on as soon as the CONV switch is pressed and

will remain on until the OFF switch is pressed or another mode of operation is

selected.

• Throughout the convection mode, anytime the bake unit cycles on, the broil unit

will be cycled at approximately a 50% rate at 120 volts.

L2

K1 RELAY

74

LATCH

SEL

"CLOSED"

SW

SW

CNO

27 28 1 2

FAN

SEL

T STAT

SW

19 22 6 9

K1 RELAY

82

CONVECTION BAKE

ON

LIGHT

T STAT T STAT

87 21

BM

K1 RELAY

COIL

AB

K1 RELAY

GRILL

GRIDDLE

12" OVEN

OVEN LIGHT

N

CLEAN

TIMER

240V.

4.17A

CLEAN

ON

LIGHT

T STAT

21

WILL NOT

OPERATE

WHEN SELECT

BUTTON IS SET

FOR CLEAN

HEAT

LIGHT

BAKE

UNIT

12.92A 12.92A

3100W

BROIL

BROIL

1

UNIT

UNIT

2000W

2000W

240V.

N

HEAT

LIGHT

8.3A 8.3A

SEL

SW

17 18

2

BROIL

UNIT

2000W

4.17A

8.3A

SEL

SW

10119

1

BROIL

UNIT 2

2000W

50%

PULSER

SEL

SW

14 9

12 9

8.3A

L1

HIGH

TEMP

CUTOUT

L1

HIGH

SEL

TEMP

SW

CUTOUT

ON

LIGHT

FAN

SEL

SW

56 57

T STAT

FAN

T STAT

SEL

SW

87 21

T STAT

BROIL 12-in. Oven

BM

N

SEL

SW

N

ON

LIGHT

SEL

SW

T STAT T STAT

48 4950 53 8 7 2 1

240V.

L2

SEL

SW

19 22

K5 RELAY

COIL

AB

31

HEAT

LIGHT

BROIL

UNIT

8.3A 8.3A

2000W

SEL

SW

8.3A

17 18

HEAT

LIGHT

BROIL

UNIT

7.5A 7.5A

1800W

SEL

SW

7.5A

46 47

HIGH

SEL

1

BROIL

UNIT

2

8.3A

2000W

1

BROIL

2

UNIT

7.5A

1800W

SW

12119

SEL

SW

434240

TEMP

CUTOUT

HIGH

TEMP

CUTOUT

L1

L2

SEL

SW

58 59 1 2

K5 RELAY

COIL

AB

FAN

T STAT

31

K2 RELAY

AB

N

PROOF 12-in. Oven Only

CLEAN

TIMER

COIL

ON

LIGHT

SEL

SW

NO

7450

55

L1

240V.

N

HEAT

LIGHT

BROIL

UNIT

1800W

BROIL

1

UNIT 2

3.75A

3.75A

1800W

SEL

SW

454240

HIGH

TEMP

CUTOUT

– 21 –

Page 22

36-in. Range Wiring Diagram

– 22 –

Page 23

36-in Range Schematic

– 23 –

Page 24

48-in. Range Wiring Diagram

– 24 –

Page 25

48-in Range Schematic

– 25 –

Page 26

30-in Range Schematic

– 26 –

Page 27

30-in. Range Wiring Diagram

– 27 –

Page 28

Gas Cooktop Wiring Diagram

– 28 –

Page 29

Gas Cooktop Wiring Schematic

– 29 –

Page 30

W arranty

MONOGRAM RANGE WARRANTY

Proof of original purchase date is needed to obtain service under warranty .

WHA T IS

COVERED

WHA T IS

NOT

COVERED

FULL ONE-YEAR WARRANTY

For one year from date of original purchase, we

will provide, free of charge, parts and service

labor in your home to repair or replace any part

of the range that fails because of a

manufacturing defect.

LIMITED FIVE-YEAR WARRANTY

For five years from the date of original purchase,

we will provide, free of charge, replacement gas

surface burners if they fail in normal household

use. (The grill, griddle and oven burners are not

included.) Y ou p ay for the service trip to your

home and all service labor charges.

• Service trips to your home to teach you how

to use the product.

• Discoloration of the griddle plate.

• Chipping of porcelain enamel grates.

This warranty is extended to the original

purchaser and any succeeding owner for products

purchased for ordinary home use in the 48

mainland states, Hawaii and Washington, D.C. In

Alaska the warranty is the same except that it is

LIMITED because you must pay to ship the

product to the service shop or for the service

technician’s travel costs to your home.

All warranty service will be provided by our

Factory Service Centers or by our authorized

Customer Care® servicers during normal working

hours.

Should your appliance need service, during

warranty period or beyond, in the U.S.A. call

800.444.1845. In Canada: 888.880.3030.

• Damage to the product caused by accident,

fire, floods or acts of God.

• Failure of the product if it is used for other

than its intended purpose or used

commercially.

• Replacement of house fuses or resetting of

circuit breakers.

• Incidental or consequential damage caused

by possible defects with this appliance.

• Damage after delivery.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitation or exclusion may not apply to you. This warranty gives you specific legal rights, and

you may also have other rights which vary from state to st ate. To know what your legal rights are in

your state, consult your local or state consumer af fairs office or your state’s Attorney General.

Warrantor: General Electric Company. If further help is needed concerning

Natural Gas Models

ZDP48N4G

ZDP48N6R

ZDP48N6D

ZDP36N6

ZDP36N4R

ZDP36N4D

ZDP30N4

• Improper installation, delivery or maintenance.

If you have an installation problem, contact

your dealer or installer . Y ou are responsible

for providing adequate electrical, gas,

exhausting and other connecting facilities as

described in the Installation Instructions

provided with the product.

Liquid Propane Models

ZDP48L4G

ZDP48L6R

ZDP48L6D

ZDP36L6

ZDP36L4R

ZDP36L4

DZDP30L4

– 30 –

Loading...

Loading...