Page 1

Monogram.

Use & Care Guide and

Installation Instructions

for ZDIB50

ZDIW50

Automatic Icemaker

Monogram.

General Electric Company

Louisville, KY 40225

TM

Monogram.

Automatic Icemaker

Pub. No. 49-6857

Part No. 162D7745P002

12-95 CG

TM

Page 2

Introduction

Your new Monogram icemaker makes an eloquent

statement of style, convenience and kitchen planning

flexibility. Whether you chose it for its purity of

design, practical features or assiduous attention to

detail—or for all of these reasons—you’ll find that

your Monogram icemaker’s superior blend of form

and function will delight you for years to come.

Contents

Appliance Registration.................3

Care and Cleaning ..................7–10

Changing the Light Bulb......10

Condenser ..............................7

Filtering & Treating Water...10

Icemaker System....................8

Inside Parts of the Icemaker...9

Outside Surfaces ....................7

Consumer Services .....................20

Controls ........................................6

Features.........................................6

Installation Instructions ........16–18

Electrical Requirements.......16

Free Standing Installation....16

Grounding Instructions........16

Model and Serial Number

Location.............................3, 6

The Monogram icemaker was designed to provide

the flexibility to blend in with your kitchen cabinetry.

The information on the following pages will help

you operate and maintain your icemaker properly.

For a listing of dealers—or if you have other

questions—please call the GE Answer Center

(800.626.2000).

Operating Instructions ..............5, 6

Preparation............................11–15

Changing the Bin

Door Panel ........................12

Changing the Lower

Access Panel.....................13

Leveling ...............................11

Location ...............................11

Custom Door

and Access Panels.............14

Thermostat Calibrations.......11

Unpacking the Icemaker ......11

Vacation and Moving...........15

Problem Solver ...........................19

Safety Instructions........................4

Warranty .....................................21

®

Questions?

Call GE Answer Center

800.626.2000

2

Page 3

HELP US HELP YOU…

Read this guide carefully. Write down the model and serial numbers.

It is intended to help you operate and maintain your

new icemaker properly.

Keep it handy for answers to your questions.

If you don’t understand something or need

more help, call:

GE Answer Center

800.626.2000

24 hours a day, 7 days a week

®

If you received a damaged icemaker…

Immediately contact the dealer (or builder) that sold

you the icemaker.

Save time and money .

Before you request service…

Check the Problem Solver. It lists minor operating

problems that you can correct yourself.

IF YOU NEED SER VICE

You’ll see them on a plate on the left side of the ice bin.

These numbers are also on the Consumer

Product Ownership Registration Card that came

with your icemaker.

Before sending in the registration card, please write

these numbers here:

Model Number

Serial Number

Use these model and serial numbers in any correspondence

or service calls concerning your icemaker.

To obtain service, see the Consumer Services page in

the back of this guide.

We’re proud of our service and want you to be

pleased. If for some reason you are not happy with the

service you receive, here are three steps to follow for

further help.

FIRST, contact the people who serviced your

appliance. Explain why you are not pleased. In most

cases this will solve the problem.

NEXT, if you are still not pleased, write all the

details—including your phone number—to:

Manager, Consumer Relations

GE Appliances

Appliance Park

Louisville, KY 40225

FINALLY, if your problem is still not resolved, write:

Major Appliance Consumer Action Program

20 North Wacker Drive

Chicago, IL 60606

3

Page 4

IMPOR TANT SAFETY INSTRUCTIONS

Read All Instructions Before Using This Appliance.

WARNING—To reduce the risk of fire,

electrical shock, or injury when using

your icemaker, follow basic precautions

including the following:

• Never allow children to operate, play with, or

crawl inside the icemaker.

• Never clean icemaker parts with flammable

fluids. The fumes can create a fire hazard or

explosion.

• For your safety: Do not store or use gasoline

or other flammable vapors and liquids in the

vicinity of this or any other appliance. The

fumes can create a fire hazard or explosion.

• Be sure your icemaker is properly installed and

grounded by a qualified technician in

accordance with the Installation Instructions.

• Do not attempt to repair or replace any part of

your icemaker unless it is specifically

recommended in this guide. All other servicing

should be referred to a qualified technician.

• It is your responsibility to be sure your

icemaker:

— has been installed where it is protected from

the elements.

— is located so that the front is not blocked to

restrict incoming or discharge air flow.

— is properly leveled.

— is located in a well ventilated area with

temperatures above 55°F. (13°C.) and below

110°F. (43°C.). Best results are obtained at

temperatures between 70°F. (21°C.) and

90°F. (32°C.).

— is properly connected to a water supply

and drain.

— is connected only to the proper kind of outlet,

with the correct electric supply and grounding.

A 120 volt, 60 Hz., 15 amp fused electrical

supply is required. NOTE: Time delay fuse or

circuit breaker is recommended.

— is not used by anyone unable to operate

it properly.

— is used only to do what icemakers are

designed to do.

— is properly maintained.

SAVE THESE

INSTRUCTIONS

4

Page 5

OPERATING YOUR ICEMAKER

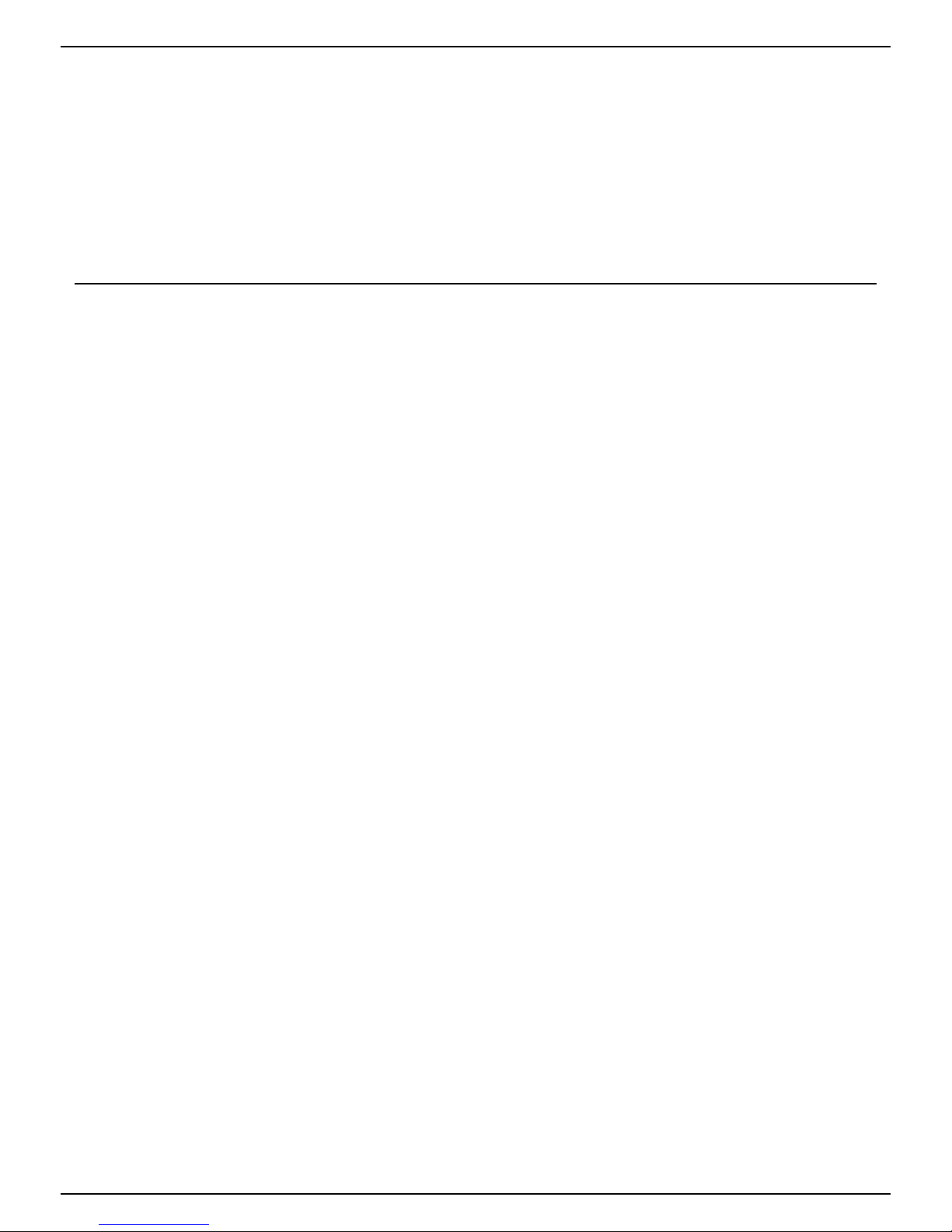

How the Icemaker W orks

1. Water is constantly circulated over a freezing plate.

As the water freezes into ice, the minerals in the

water are rejected. This produces a sheet of ice with

a low mineral content.

NOTE: The icemaker is designed to make clear ice

from the majority of water sources on a daily basis.

If your results are unsatisfactory, water may need to

be filtered or treated. See Filtering and Treating

Water in the Care and Cleaning section.

2. When the desired thickness is reached, the ice sheet

is released and slides onto a cutter grid. The grid

divides the sheet into individual cubes.

3. The water containing the rejected minerals is

drained after each freezing cycle.

4. Fresh water enters the machine for the next

icemaking cycle.

5. Cubes fall into the storage bin. When the bin is full,

the icemaker shuts off automatically and restarts

when more ice is needed.

Notes About This Icemaker

• Water enters only during the defrost cycle. Therefore

the first cycle will be completed without water in the

system.

• As the room and water temperatures vary, so will

the amount of ice produced. This means that higher

operating temperatures will result in reduced ice

production.

• The icemaker will shut off when ice in the storage

bin touches the bin thermostat well and will

automatically cycle to keep the bin full.

• The storage bin is not refrigerated and some meltage

will occur. This, too, varies with the room temperature.

• The icemaker needs good air circulation to

perform efficiently. Keep the front grille and

the condenser clean.

• The water system, including the filter screen in the

water inlet solenoid valve, needs to be cleaned

periodically for good circulation. Instructions are

located on the inner door panel.

(continued next page)

5

Page 6

OPERATING YOUR ICEMAKER

Setting the Controls

1. Select ice thickness. The icemaker has been preset

to produce ice approximately 1/2″ (13 mm) thick,

while operating in a room temperature of 70°F.

(21°C.).

Operation in different room temperatures may

require readjusting the control toward either the

“THICK” or “THIN” setting.

Best operation will be obtained with ice 1/2″

(13 mm) to 5/8″ (16 mm) thick.

If operating in a warm room (above 90°F. [32°C.])

DO NOT set the control to maximum thickness or

the icemaker may malfunction.

2. To start the normal icemaking cycle, turn the Cycle

Control Knob to “ON.”

3. To stop icemaker operation, turn Cycle Control

Knob to “OFF.”

The “CLEAN” setting is used whenever solutions are

circulated through the icemaker for cleaning. Only the

water pump operates at this setting. See Cleaning the

Icemaker System in the Care and Cleaning section for

specific instructions.

(continued)

THIN

THIN

NORMAL

ICE

NORMAL

ICE

THICK

THICK

OFF

OFF

ON

CLEAN

CYCLE

ON

CLEAN

CYCLE

FEATURES OF YOUR ICEMAKER

Model and Serial

Number Plate

(not shown)

Ice Retainer

Baffle

Lower

Access

Panel

Ice Thickness

Knob

ON

NORMAL

CLEAN

OFF

THICK

THIN

CYCLE

ICE

Cycle Control

Knob

Bin Light

Ice Bin

Ice Scoop

6

Page 7

CARE AND CLEANING

Periodically inspect and clean the icemaker to keep it

operating at peak efficiency and to prevent premature

failure of system components.

Both the icemaking system and the air-cooled

condenser need to be cleaned regularly.

The minerals rejected from the circulating water

during the freezing cycle will eventually form a hard

scaly deposit in the water system which prevents a

rapid release of the ice from the freezing plate.

Clean the ice and water system periodically to remove

mineral scale build-up. Frequency of cleaning

depends on water hardness. With hard water (15 to 20

grains/gal.), cleaning may be required as frequently as

every six months.

A dirty or clogged condenser:

• prevents proper air flow.

• reduces icemaking capacity.

• causes higher than recommended operating

temperatures which may lead to component failure.

Cleaning Outside Surfaces

Wash the outside enamel surfaces and gaskets with warm water and mild

soap or detergent. Rinse and dry. Regular use of a good household

appliance cleaner and wax will help protect the finish.

Do not use abrasive cleaners on enamel surfaces as they may scratch

the finish.

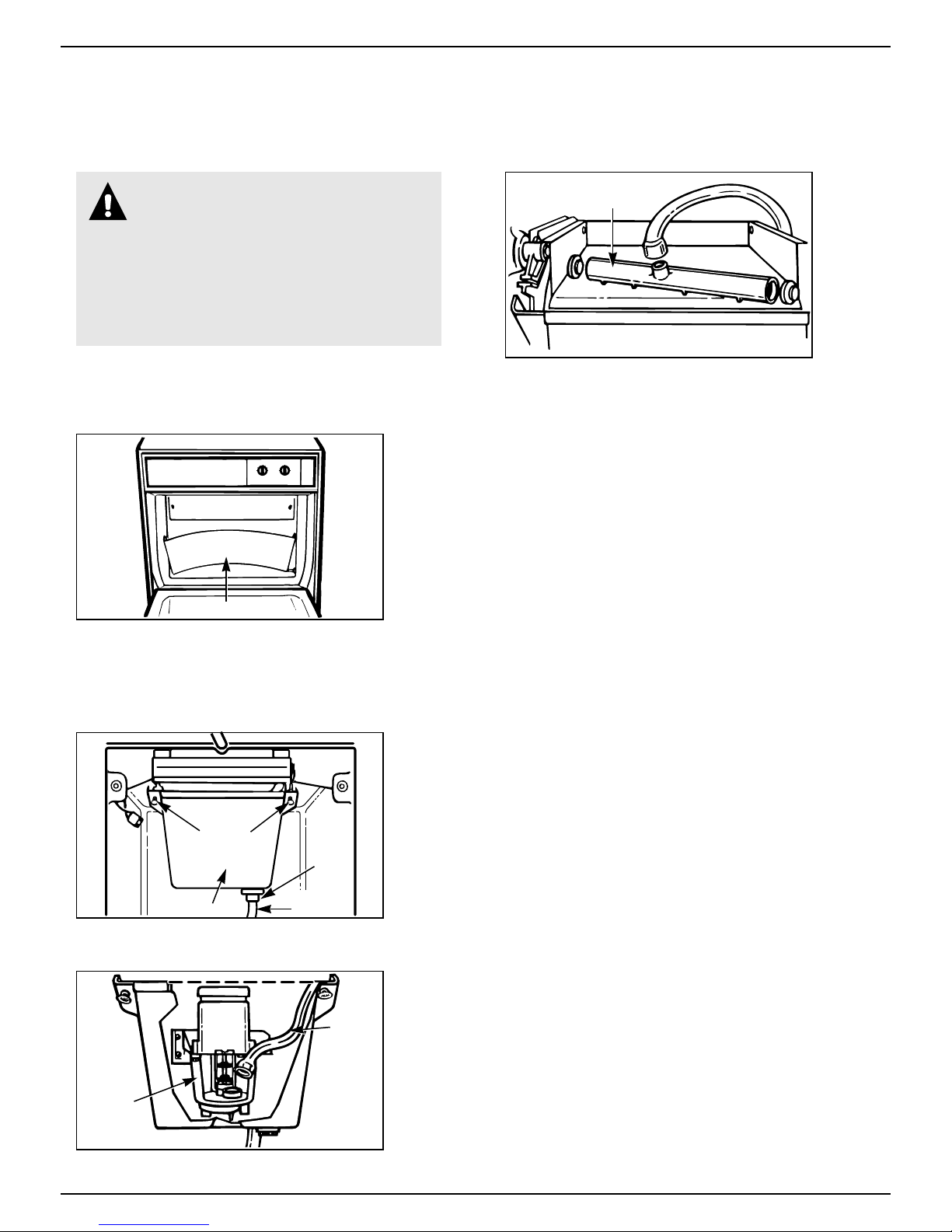

Cleaning the Condenser

WARNING:

• Be sure the icemaker is OFF and

disconnected from the main power

supply. The icemaker could suddenly start if

not disconnected. Condenser fan rotation,

sharp condenser fins and hot tubing could

cause personal injury .

• Condenser fins can bend easily. Use care

when vacuuming the condenser to keep from

bending the fins.

1. Disconnect the electrical power supply to the

icemaker and turn the Cycle Control Knob to “OFF.”

2. Remove the screw from the top of the lower access

panel and the two screws from the grille area of the

lower access panel.

3. Pull forward at the bottom, then down to remove

the panel.

4. Remove dirt and lint from the condenser fins and

the icemaker compartment with a brush attachment

attached to a vacuum cleaner.

5. Replace the lower access panel and screws. The

top of the access panel needs to be secured under

the two metal tabs before replacing the screws.

6. Plug icemaker in and turn the Cycle Control Knob

to “ON.”

Lower

Access

Panel

Grill

Area

Screw

Screws

(continued next page)

7

Page 8

CARE AND CLEANING

Cleaning the Icemaker System

WARNING: Most ice machine cleaners

are citric or phosphoric acid which can

cause irritation even after dilution. In

case of contact with eyes, flush eyes thoroughly

with fresh water and contact a physician

immediately. In case of contact with skin, rinse

well with water. If swallowed, give large

amounts of water and contact a physician

immediately. Do not induce vomiting. KEEP

OUT OF REACH OF CHILDREN.

(continued)

THIN

NORMAL

ICE

THICK

OFF

ON

CLEAN

CYCLE

1. Turn the Cycle Control Knob to “OFF.”

NORMAL

Electrical

Harness

Screws (long)

ON

THIN

OFF

THICK

CLEAN

ICE

CYCLE

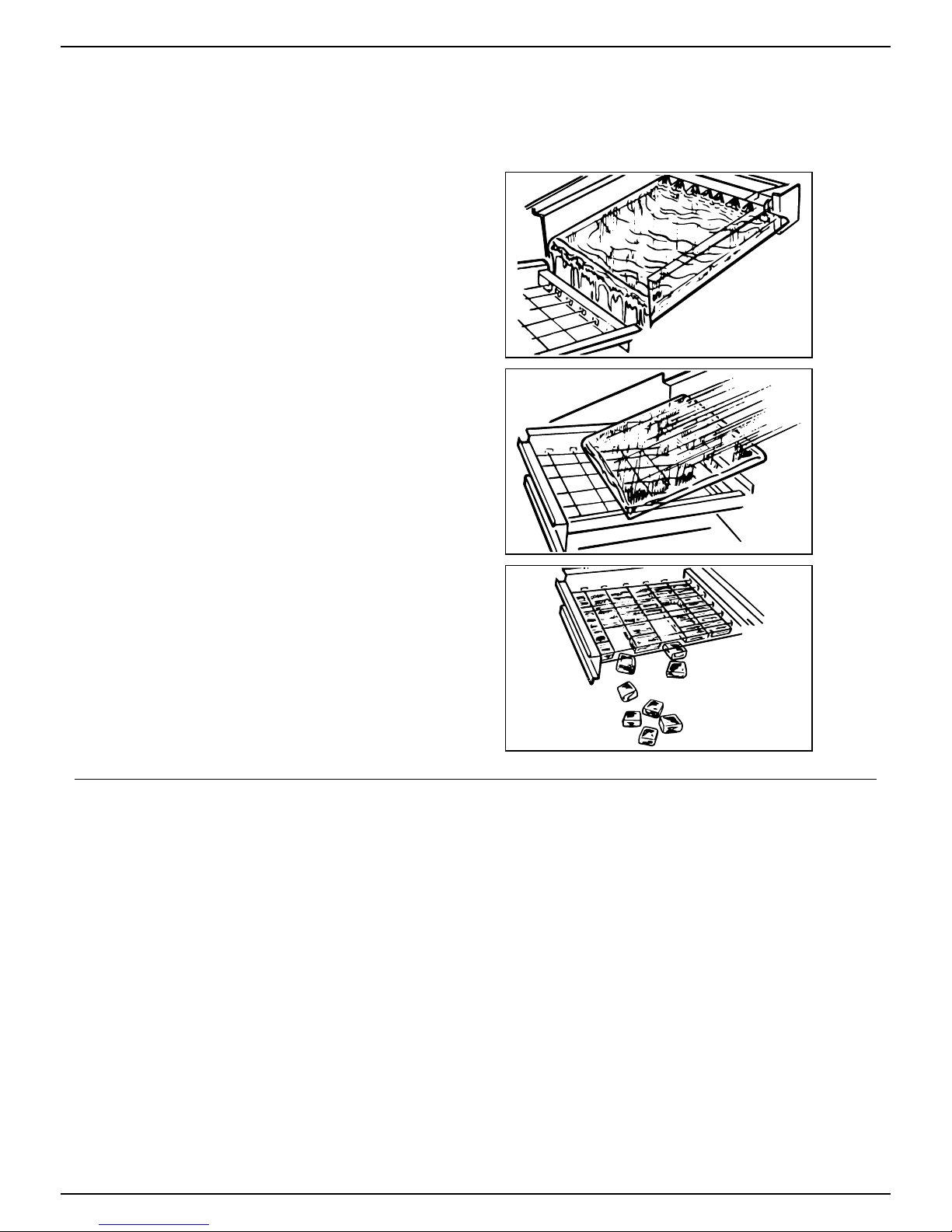

2. Remove the two screws and slide the ice cutter grid

forward, out of the two slots near the water pan.

3. Unplug the electrical harness.

CAUTION: Any ice on the grid should be

melted under running warm water. Attempting

to pick the ice slab off the grid may stretch and

damage the grid wires.

4. Remove all ice from the storage bin and the

freezing plate.

Screws

Drain

Plug

Water Pan

5. Drain the water pan by removing the drain plug

and then replace the plug.

6. Pour 1/2 gallon (1.9 L) of hot tap water into the

water pan* and turn the Cycle Control Knob to

“CLEAN.” This warms up the system to make the

cleaning solution more effective. Let circulate for

five minutes. While tap water is circulating,

prepare the cleaning solution. Mix: 6 oz. (170 g)

powdered citric or phosphoric acid into 1/2 gallon

(1.9 L) hot water. (Citric and phosphoric acid

crystals are available or can be ordered from many

pharmacies or scientific supply houses.)

Commercial ice machine cleaners (liquid) are also

available from your dealer or refrigeration parts

supply stores. Mix according to instructions on

label (total quantity 1/2 gallon [1.9 L]).

7. Turn the Cycle Control Knob to “OFF” and drain

the water pan. (See step 5.)

8. Turn the Cycle Control Knob to “CLEAN”

and slowly pour the hot cleaning solution into

the water pan.* (If the solution foams while

pouring, wait until the foaming stops.) Then add

the balance of the solution.

Allow the solution to circulate until the scale has

dissolved (15 to 20 minutes). Severe scale buildup may require repeated cleaning with a fresh

quantity of cleaning solution.

To clean scale off the side flanges of the freezing

plate, use rubber gloves and scrub with a nonabrasive plastic scrubbing pad or nylon brush

dipped in cleaning solution.

9. Keep rubber gloves on to drain the cleaning

solution. Turn the Cycle Control Knob to “OFF”

and drain the water pan. (See step 5.)

10. Replace the plug and add 1/2 gallon (1.9 L) of

fresh water.* Set Cycle Control Knob on

“CLEAN,” circulate five minutes and drain.

Repeat rinsing process.

*For easier pouring of water and cleaning solution,

use a 1- or 2-cup container.

8

Page 9

Cleaning the Inside Parts of the Icemaker

WARNING:

• Do not operate the icemaker with the

lower access panel or control panel

removed. Electrical shock or personal injury

could result.

• Do not wash plastic parts in dishwasher.

They cannot withstand temperatures above

145°F. (63°C.).

1. Turn the Cycle Control Knob to “OFF” and

disconnect the electrical power supply to the

machine. Open the storage bin door and remove

any ice that is in the bin.

NORMAL

ON

THIN

OFF

THICK

CLEAN

ICE

CYCLE

Ice Retainer Baffle

2. Remove the ice retainer baffle by flexing it and

then slide it off the studs.

3. Remove the ice cutter grid by unscrewing the two

screws, sliding the grid forward and unplugging

the electrical wire harness.

Screws

Drain

Plug

Water Pan

Insert into

drain

4. Remove the water pan by unscrewing and

removing the two screws and washers.

Water Distributor

6. Remove the water distributor from the freezing

plate. It is held in place by rubber end caps.

Remove the inlet hose and clean all water

distributor holes and the small orifice in the inlet

side of the distributor. When replacing the

distributor, make sure the end caps are located in

the evaporator flange detents and that the water

distributor holes face down.

7. Wash the interior components (ice retainer baffle,

cutter grid, water pan, inlet hose and water

distributor) and the storage bin, door gasket and

ice scoop with mild soap or detergent and warm

water. Rinse in clean water. These components

should also be cleaned in a solution of 1 oz.

(29.6 ml) of chlorine bleach in 1 gallon (3.8 L)

warm water. Rinse again thoroughly in clean water.

8. Replace the interior components: water

distributor, inlet hose and water pan.

9. Check the following:

• The hose from the water valve is in the water pan.

• The rubber drain plug is in the water pan.

• The water distributor is seated and the holes are

facing down.

• The hose is reconnected to the pump and the

water distributor.

• The hose from the water pan is inserted into the

storage bin drain opening.

10. Reconnect the electrical harness, slide the cutter

grid into place and tighten the screws. Replace

the ice retainer baffle.

11. Turn Cycle Control Knob to “ON.”

Water

Pump

5. Remove the hose from the water pump.

(continued next page)

Hose

9

Page 10

CARE AND CLEANING

Filtering and Treating Water

(continued)

In most areas it will be beneficial to filter or treat the

water being supplied to the icemaker. It can improve

the reliability of the icemaker, reduce water system

maintenance and produce the best quality of ice.

The installation of a polyphosphate feeder will

generally reduce scale build-up and the icemaker will

require less frequent cleaning.

Changing the Light Bulb

WARNING: Before removing the light

bulb, either unplug the icemaker or

disconnect the electricity leading to

the icemaker at the main power supply.

Shock and injury can occur if electricity

remains connected.

The icemaker has a light bulb in the top of the storage

bin. To replace it, open the bin door and follow these

instructions:

1. Disconnect the icemaker from the power supply.

2. Remove the two screws and slide the ice cutter grid

forward, out of the two slots near the water pan. Set

the ice cutter grid on the bin door.

3. Press the front of the light shield in while pulling

down to remove it from the light bracket.

4. Remove the bulb. Replace it with a 15-watt bayonet

base type bulb.

5. Replace the light shield, ice cutter grid and two

screws.

6. Reconnect the power supply.

Municipal water systems are generally treated with

chlorine to maintain a safe drinkable water supply.

Activated carbon filters will sufficiently remove the

residual chlorine from the water to reduce surface

staining of stainless steel materials in the icemaker.

For more information on filtering and treating the

water, see the dealer from whom you purchased

your icemaker.

NORMAL

ON

THIN

OFF

THICK

CLEAN

ICE

CYCLE

Light

Switch

Screws

Light

Bracket

Light

Shield

10

Page 11

Unpacking the Icemaker

PREPARATION

1. Lay the carton on rear face and break open the

bottom flap.

2. Set the carton

upright with all

four flaps outward.

3. Lift carton up and

off icemaker.

Open Bottom

Flaps

4. Remove all tape and

packaging material from

the outside and inside of

the cabinet.

5. Remove the front grille; take

out the screws securing the

grille at the bottom and lift it

free of the cabinet.

6. Turn the fan by hand to make certain it moves freely.

Location Leveling

THIS ICEMAKER MUST BE INSTALLED IN AN

AREA PROTECTED FROM THE ELEMENTS,

SUCH AS WIND, RAIN, WATER SPRAY OR DRIP.

1. Place the icemaker so the front side will be

completely unobstructed to provide proper air flow.

2. The area should be well ventilated with temperature

above 55°F. (13°C.) and below 110°F. (43°C.). Best

results are obtained between 70°F. (21°C.) and

90°F. (32°C.).

3. Provision for electricity, water and drain

connections should be determined.

4. The icemaker may be closed in on the top and three

sides, but the front MUST BE unobstructed for air

circulation and proper operation. Installation should

be such that the cabinet can be moved forward for

servicing, if necessary.

1. After placing the icemaker into position, check to

make certain the icemaker is level side to side and

front to back.

2. Accurate leveling is essential for proper operation.

3. The icemaker should be shimmed so that it is solid

as well as level. The shims should be of hard

permanent type material such as masonite.

4. Compliance with National Sanitation Foundation

standards requires that this type of product be

sealed to the floor at the bottom rail in order to

prevent contamination from spills or the entrance

of vermin. Therefore, we recommend that when

installing the icemaker you seal it to the floor in

accordance with those standards. A silicone-type

sealer is recommended.

Remove

Interior

Packing

Thermostat Calibrations

If the icemaker is installed above two thousand feet of altitude, the bin and

evaporator thermostats must be adjusted to a warmer setting. Disconnect

electricity, remove thermostat and follow the directions for turning the

altitude adjustment screw as shown in the label on each thermostat.

(continued next page)

11

Page 12

PREPARA TION

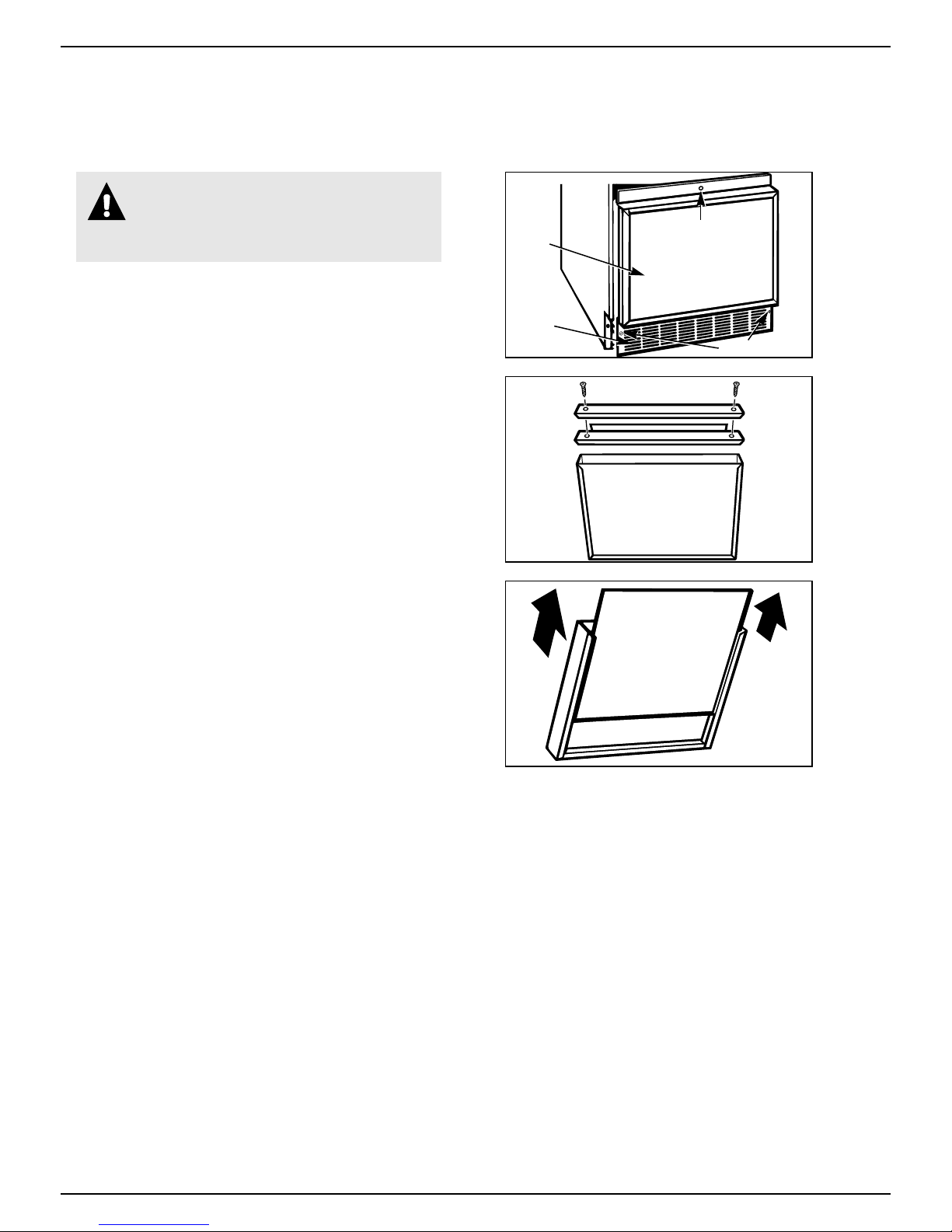

Changing the Bin Door Panel

You can easily change the color of the front panel on

the storage bin door. Two colors are available: black

and white.

To change the panel:

1. Open the storage bin door. Remove the two screws

on the top of the door which hold the handle.

2. Loosen the screws in both of the side trim pieces.

3. Remove the handle and the handle insert.

4. Carefully slide the panel out. You will find the

reverse side is black. For units with black panels

showing, the reverse side will be white.

5. Choose the color you want to show and carefully

slide the panel back into the door.

NOTE: Be careful not to scratch the panel as it is

inserted.

6. Replace the handle insert and tighten the screws in

both side trim pieces. Replace the handle and screws.

NOTE: You can make a decorative wood front to

match existing cabinets. See the section on Custom

Door and Access Panels.

(continued)

Handle

Handle

Insert

12

Page 13

Changing the Lower Access Panel

WARNING: Do not operate the

icemaker with the lower access panel or

control panel removed. Electrical shock

or personal injury could result.

1. Remove the screw from the top of the lower access

panel and the two screws in the bottom grille area.

Pull forward at the bottom, then down to remove

the panel.

2. Remove the two screws from the top panel trim and

remove the top trim.

3. Carefully slide the panel out.

4. Choose the color you want to show and carefully

slide the panel back into the lower access panel.

NOTE: Be careful not to scratch the panel as it

is inserted.

5. Replace the top trim and screws. Replace the lower

access panel assembly and screws. The top of the

access panel needs to be secured under the two

metal tabs before replacing the screws.

NOTE: You can make a decorative wood front to

match existing cabinets. See the section on Custom

Door and Access Panels.

Lower

Access

Panel

Grill

Area

Screw

Screws

(continued next page)

13

Page 14

CUSTOM DOOR AND ACCESS PANELS

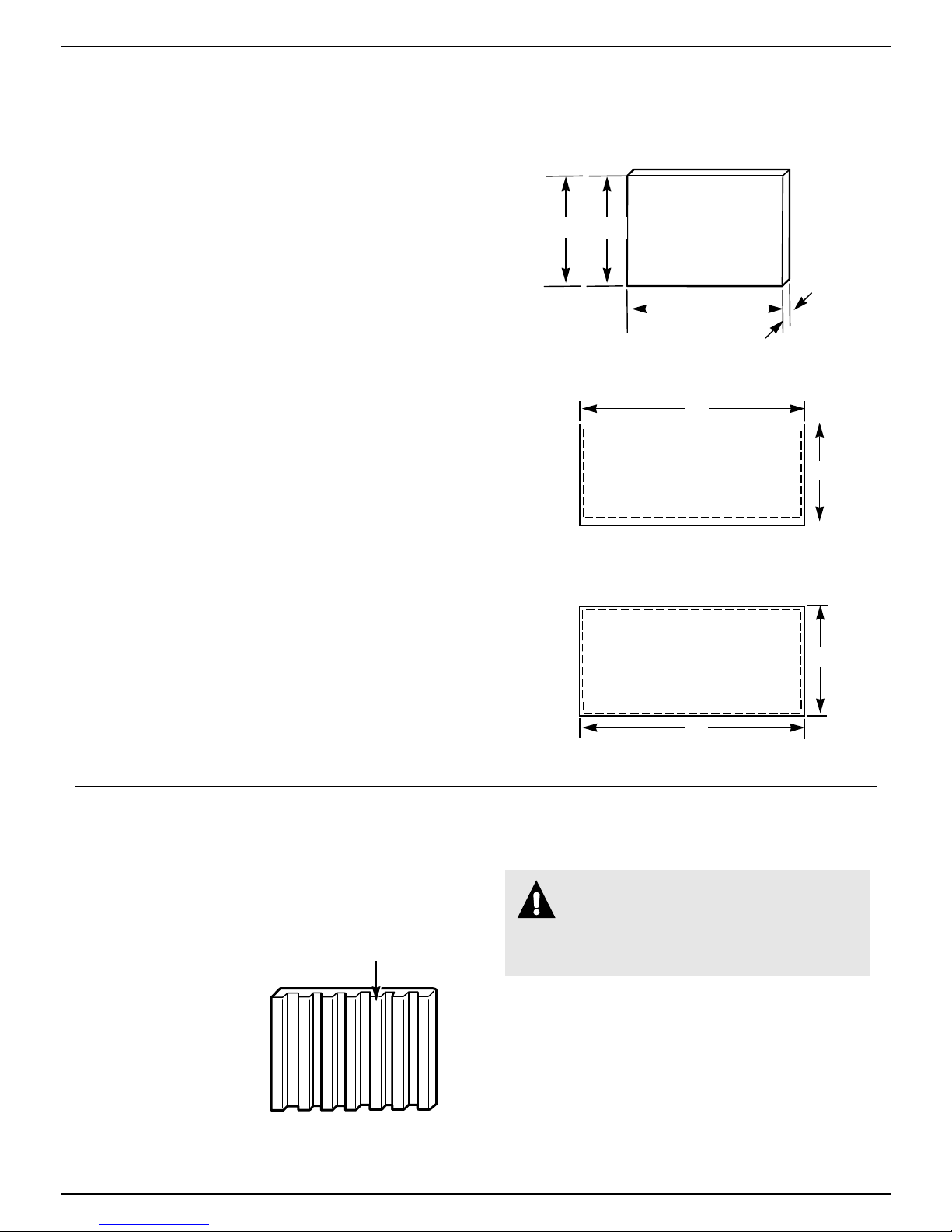

Custom Door and Access Panels—1/4″ Thick

Cut panels to the same size as the production

metal panel.

Door

Bin

111/4″

Lower

Panel

1115/16″

Wood Panel

Dimensions

1/4″

17″

Custom Door and Access Panels—3/4″ Thick

These door and access panels—both raised and flat

design—should be constructed in the same manner as

typical cabinet doors or drawers.

Storage bin door panel:

• Cut the panel 17″ wide x 11

1

/4″ high.

• Rout the top and both sides 5/16″ wide, 1/2″ deep

for a total thickness of 1/4″.

• Rout the bottom of the panel 1″ wide, 1/2″ deep for

a total thickness of 1/4″. This will allow the door to

open without binding against the lower panel. For a

custom appearance, consider tapering this 1″ rout.

Lower access panel:

• Cut the panel 17″ wide x 11

15

/16″ high.

• Rout all four sides 5/16″ wide and 1/2″ deep for a

total thickness of 1/4″.

Install Custom Door and Access Panels

To install the storage bin door panel:

1. Open the storage bin door.

2. Remove the two screws on top

of the door which hold the handle.

3. Remove the handle.

Remove all door

insulation ribs to

accept wood

panel thickness

4. Slide the metal panel out.

5. Break off the ribs on

the door insulation to

allow for the wood

thickness.

6. Slide the wood panel

into the door frame.

7. Replace the handle

and screws.

14

17″

Storage Bin Door Panel

Rout 1/2″ deep, 1″ wide across bottom

Rout 1/2″ deep, 5/16″ wide top and sides

Rout 1/2″ deep, 5/16″ wide on all sides

Lower Access Panel

17″

3/4″ Thick Panels

111/4″

1115/16″

To install the lower access panel:

WARNING: Make sure the icemaker is

disconnected from the main power supply

before removing the lower access panel.

Failure to do so could result in electric

shock or personal injury .

1. Remove the screw at the top of the lower access

panel assembly and the two screws at the bottom that

hold the lower access panel assembly to the icemaker.

2. Remove the two screws from the top panel trim.

3. Slide the metal panels and spacers out.

4. Slide the wood panel into the door frame.

5. Replace the top of the panel assembly.

NOTE: Make sure the galvanized panel is replaced

in back of the panel assembly.

Page 15

Vacation and Moving

WARNING: Make sure the icemaker is

disconnected from the main power supply

before removing the lower access panel.

Failure to do so could result in electric

shock or personal injury .

To shut down the icemaker:

1. Disconnect the electrical power supply to the

icemaker and turn the Cycle Control Knob to “OFF.”

2. Remove all ice from the storage bin.

3. Shut off the water supply.

4. Remove the screw from the top of the lower access

panel and the two screws from the grille area of the

lower access panel, then remove the panel. Pull

forward at the bottom, then down.

THIN

Lower

Access

Panel

Grille

Area

NORMAL

ICE

THICK

OFF

ON

CLEAN

CYCLE

Screw

Screws

5. Disconnect the inlet and outlet lines to the water

valve. Allow these lines to drain and then reconnect

to the valve.

6. Replace the lower access panel and screws. The

top of the access panel needs to be secured under

the two metal tabs before replacing the screws.

7. Remove water from the drain lines and drain

water pan.

8. Before using again, clean the icemaker and

storage bin.

NOTE: All components of the icemaker are

permanently lubricated at the factory. They should

not require any additional oiling throughout the

normal life of the machine.

Outlet

Inlet

Water

Pan

15

Page 16

FREE STANDING INST ALLATION

For the Installer

When this icemaker is installed free standing (not under a counter) we

strongly recommend that the bottom rear corners of the icemaker be

fastened to the floor to prevent accidental tipping.

INSTALLA TION REQUIREMENTS

IMPORTANT…Please Read Carefully

For the Electrician—Electrical Requirements

A 115 Volt, 60 Hz, AC only, 15 Amp fused electrical supply is required

(time delay fuse or circuit breaker is recommended). It is recommended that

a separate circuit, serving only this appliance, be provided. DO NOT use an

extension cord.

ELECTRICAL GROUND IS REQUIRED ON THIS APPLIANCE.

Recommended Grounding Methods

DO NOT, UNDER ANY CIRCUMSTANCES,

REMOVE THE POWER SUPPLY CORD

GROUND PRONG.

For your personal safety, this appliance must be

properly grounded.

This appliance is equipped with a power supply cord

having a 3-prong grounding plug. To minimize

possible shock hazard, the cord must be plugged into

a mating 3-prong grounding type wall receptacle,

grounded in accordance with the National Electrical

Code and local codes and ordinances. If a mating wall

receptacle is not available, it is the personal

responsibility and obligation of the customer to have a

properly grounded 3-prong wall receptacle installed

by a qualified electrician.

3-Prong

Grounding Type

Wall Receptacle

3-Prong

Grounding

Plug

Power Supply

Cord

16

Page 17

INSTALLA TION INSTRUCTIONS

13

/32″

Back view

7

3/4″

1/4″ O.D.

water line

compression

fitting at

water valve

Figure 1

Right end view

7

/8″

23

Water inlet

solenoid valve

3

/4″

1

7

/2″

Bend field supplied water line to

connect to water valve fitting

3

34

21/2″

UTILITIES

OBSERVE LOCAL CODES

Each installation is unique but will require:

• A cold water inlet of 1/4″ O.D. soft copper

tubing and a shutoff valve.

• Either a gravity drain system or a sump pump

to lift the water to an existing drain.

• An electrical branch circuit of 115 volt, 60 Hz.

1 phase, with a 15 amp delayed action fuse or

circuit breaker.

FOR THE PLUMBER

Connect to water. (Observe local codes.)

• Use 1/4″ O.D. soft copper tubing for the cold

water supply.

Provide a convenient manual shutoff valve in the

•

water line.

• Position the tubing so it can enter the access

hole located in the right-hand rear of the

icemaker cabinet. The tubing should extend

beyond the cabinet front so when the icemaker

is pushed back in position it will reach the water

inlet location in the front. See Figure 1.

NOTE: Always purge the water line before

making the final connection to the inlet of the

water valve to prevent possible water valve

malfunction.

With the icemaker in its permanent location,

bend the tubing to meet the connection at

the water valve. The garden hose threaded

compression fitting is found in the parts bag.

This joint provides a convenient disconnect

for service. Be sure the tubing is clear of

compressor, to prevent rattle.

1

/2″

3/4″

17

7

/8″

4″ long 5/8″ I.D.

9″

rubber drain

tube—run to

open drain

11/4″ Min.

Hole for field

supplied water line

90°

Figure 2

341/2″

9″

Max.

center line

18″

4

1

/2″ to

90°

LEVELING

• After placing the icemaker into position, check

to make certain the icemaker is level side to side

and front to back.

• Accurate leveling is essential for proper

operation.

• The icemaker should be shimmed so that it is

solid as well as level. The shims should be of

hard permanent type material such as masonite.

• Compliance with National Sanitation

Foundation standards requires that this type of

product be sealed to the floor at the bottom rail

in order to prevent contamination from spills or

the entrance of vermin. Therefore, we

recommend that when installing the icemaker

you seal it to the floor in accordance with those

standards. A silicone-type sealer is recommended.

ALTERNATE METHOD

If a drain connection directly below the

drain tube outlet is not available, install a

UL-listed drain pump in the rear compartment

of the icemaker.

Drain pump specifications:

• UL-listed and have a UL-listed, 120VAC, 3-wire

grounded service cord

• Overall outside dimensions (maximum):

15″ wide x 6″ deep x 9

• Pump flow rate (minimum): 24.0 gph (0.4 gpm)

@ 12 feet lift

• Operating temperature range 55°F. to 110°F.

(13°C. to 43°C.)

1

/2″ high

(continued next page)

17

Page 18

INSTALLA TION INSTRUCTIONS

(continued)

DRAIN PUMP

• When the drain connection is below the level of

the icemaker, a drain pump may be used to lift the

water to an available drain. Use only an approved

drain pump kit ZDK50 from your dealer.

• Complete installation instructions are included

with the drain pump kit.

CHECK OPERATION

• Start the icemaker by turning the service

switch to “ON” and opening the line water valve.

• NOTE: Left is “OFF”—Middle is “ON”—Right

is “CLEAN.” In “CLEAN” position, only the

pump operates.

• Check the condenser fan to make sure it is

revolving.

• Water will not enter the pump pan until the

freezing plate gets cold and the icemaker goes

into a harvest cycle.

• Check for even water flow over the freezing

plate. The icemaker must be level for proper

operation.

• Check for desired cube thickness and after 24

hours adjust if necessary. Maximum ice yield will

be obtained with ice thickness at 1/2″ to 5/8″.

• Replace the grille.

18

Page 19

QUESTIONS?

USE THIS PROBLEM SOLVER

PROBLEM POSSIBLE CAUSE

ICEMAKER DOES • Cycle Control Knob must be in the “ON” position.

NOT RUN

ICEMAKER RUNS BUT • Cycle Control Knob must be in the “ON” position.

PRODUCES NO ICE

ICEMAKER RUNS • Room temperature may be extremely high, more that 90°F. (32°C.). In this case

BUT PRODUCES it is normal for ice production to be low.

VERY LITTLE ICE

• Check to see that the power cord is plugged in.

• Have you checked your home’s main fuses or circuit breaker box?

• Room temperature must be above 55°F. (13°C.). Otherwise, the bin thermostat

may sense the cold room temperature and shut off even though the bin is not

full of ice. Also, the icemaker may not restart once it does shut off.

• Check water supply to make sure it is open.

• If the icemaker is operated at an elevation of 2,000 feet or more above sea level,

both the bin thermostat and ice thickness thermostat need to be recalibrated.

See the Installation Instructions.

• Dirt or lint may be blocking the air flow through the finned condenser.

Condenser needs to be cleaned.

• Check to see if the icemaker has a scale build-up in water and freezing system.

Clean if necessary.

GRID IS NOT CUTTING • Check the grid harness plug to make sure the connection is secure.

ICE SHEETS

TASTE IN ICE CUBES • There may be an unusually high mineral content in the water supply. Water may

need to be filtered or treated.

• Do not store any foods in the ice bin.

• Packaging material not all removed.

If you need more help…call, toll free:

GE Answer Center

consumer information service

®

, 800.626.2000

19

Page 20

We’ll Be There

With the purchase of your new GE appliance, receive the assurance that if you ever need

information or assistance from GE, we’ll be there. All you have to do is call—toll-free!

GE Answer Center®

800.626.2000

Whatever your question about any GE major appliance, GE Answer Center®

information service is available to help. Your call—and your question— will be

answered promptly and courteously. And you can call any time. GE Answer

Center® service is open 24 hours a day, 7 days a week.

In-Home Repair Service

800-GE-CARES (800-432-2737)

A GE consumer service professional will provide expert repair service,

scheduled at a time that’s convenient for you. Many GE Consumer Service

company-operated locations offer you service today or tomorrow, or at your

convenience (7:00 a.m. to 7:00 p.m. weekdays, 9:00 a.m. to 2:00 p.m. Saturdays).

Our factory-trained technicians know your appliance inside and out—so most

repairs can be handled in just one visit.

For Customers With Special Needs…

800.626.2000

6’ 10"

Upon request, GE will provide

Braille controls for a variety of

GE appliances, and a brochure to

assist in planning a barrier-free

kitchen for persons with limited

1"

SCALE 1’

=

mobility. To obtain these items,

Consumers with impaired hearing or speech who have

access to a TDD or a conventional teletypewriter may

call 800-TDD-GEAC (800-833-4322) to request

information or service.

SINGLE CONTROL

FAUCET

8"

5"

1/8

3’

"

R SHALLOW DEPTH SINKS (6") WITH REAR DRAIN.

SINK SHOULD ALSO BE UNDERCOATED

SECTION A-A

2’ 6"

TBXTOLITE

ON WALL

6"

5"

1’ 0"

7"

FLUORESCENT

FIXTURE

THIS LIGHT CAN

BE INSTALLED

IN BOTTOM OF

WALL CABINETS

2’ 10"

free of charge, call 800.626.2000.

Service Contracts

800-626-2224

You can have the secure feeling that GE Consumer Service will still be there

after your warranty expires. Purchase a GE contract while your warranty is still

in effect and you’ll receive a substantial discount. With a multiple-year contract,

you’re assured of future service at today’s prices.

Parts and Accessories

800-626-2002

Individuals qualified to service their own appliances can

have parts or accessories sent directly to their home. The

GE parts system provides access to over 47,000 parts…and

all GE Genuine Renewal Parts are fully warranted. VISA,

MasterCard and Discover cards are accepted.

User maintenance instructions contained in this booklet

cover procedures intended to be performed by any user.

Other servicing generally should be referred to qualified

service personnel. Caution must be exercised, since

improper servicing may cause unsafe operation.

20

Page 21

YOUR GE ICEMAKER

WARRANTY

Staple sales slip or cancelled check

here. Proof of original purchase date

is needed to obtain service

under warranty.

WHA T IS COVERED

FULL ONE-YEAR WARRANTY

For one year from date of original

purchase, we will provide, free of

charge, parts and service labor in

your home to repair or replace

part of the icemaker

because of a manufacturing defect.

FULL FIVE-YEAR WARRANTY

For five years from date of original

purchase, we will provide, free of

charge, parts and service labor in

your home to repair or replace any

part of the sealed icemaking

system (the compressor,

condenser, evaporator and all

connecting tubing) that fails

because of a manufacturing defect.

that fails

any

******************************

This warranty is extended to

the original purchaser and any

succeeding owner for products

purchased for use in the 48

mainland states, Hawaii and

Washington, D.C. In Alaska the

warranty is the same except that it

is LIMITED because you must pay

to ship the product to the service

shop or for the service technician’s

travel costs to your home.

All warranty service will be

provided by our Factory Service

Centers or by our Authorized

Customer Care®servicers during

normal working hours.

Should your appliance need

service, during warranty period

or beyond, call 800-GE-CARES

(800-432-2737).

WHA T IS NOT COVERED

• Service trips to your home to

teach you how to use the

product.

Read your Use and Care material.

If you then have any questions

about operating the product please

contact your dealer or our

Consumer Affairs office at the

address below, or call, toll free:

GE Answer Center

800.626.2000

consumer information service

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion

may not apply to you. This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

To know what your legal rights are in your state, consult your local or state consumer affairs office or your state’s Attorney General.

2180919

Part No. 162D7745P002

Pub. No. 49-6857

®

Manager—Consumer Affairs, GE Appliances, Louisville, KY 40225

• Improper installation.

If you have an installation problem,

contact your dealer or installer.

You are responsible for providing

adequate electrical, plumbing and

other connecting facilities.

• Replacement of house fuses or

resetting of circuit breakers.

• Use of a non-approved Drain

Pump Kit.

Warrantor: General Electric Company

If further help is needed concerning this warranty, write:

• Failure of the product if it is used

for other than its intended

purpose or used commercially.

• Damage to product caused

by accident, fire, floods or acts

of God.

• Loss of food due to spoilage.

WARRANTOR IS

RESPONSIBLE FOR

CONSEQUENTIAL DAMAGES.

NOT

ZDIB50, ZDIW50

Printed in the United States

21

Page 22

NOTES

22

Page 23

Monogram.

Manual del usuario e

instrucciones para

la instalación

para ZDIB50

ZDIW50

Máquina para hacer hielo

Monogram.

General Electric Company

Louisville, KY 40225

TM

Monogram.

Máquina para hacer hielo

Pub. No. 49-6857

Part No. 162D7745P002

TM

Page 24

Introducción

Su nueva máquina para hacer hielo Monogram es

una afirmación elocuente de estilo, comodidad y

flexibilidad en la planeación de su cocina. Ya sea

que la elija por la pureza de su diseño, por las

características físicas o por la constante atención al

detalle—o por todas estas razones—encontrará que

la conbinación de forma y función de su maquina para

hacer hielo Monogram es superior y dará una gran

satisfacción durante los años venideros.

Contenido

Cuidado y limpieza.................7–10

Cambio del bombillo ...........10

Componentes interiores de la

máquina para hacer hielo....9

Condensador ..........................7

Filtrado y tratamiento

del agua.............................10

Sistema para fabricar hielo ....8

Superficies exteriores.............7

Controles.......................................6

Características...............................6

Instrucciones de instalación..16–18

Instalación independiente ....16

Instrucciones para

la conexión a tierra............16

Requerimientos eléctricos....16

Instrucciones de operación .......5, 6

Instrucciones de seguridad............4

Localización de números de

serie y de modelos..............3, 6

La máquina para hacer hielo Monogram fue diseñada

para proporcionar la flexibilidad requerida para

adaptarse a los gabinetes de su cocina.

La información contenida en las siguientes páginas le

ayudará a operar y a mantener de manera apropiada su

máquina para hacer hielo.

Si requiere una lista de distribuidores, o si tiene otras

preguntas, por favor llamé a GE Answer Center

(800.626.2000).

Preparación ...........................11–15

Calibraciones del

termostato..........................11

Cómo cambiar el panel del

depósito de la puerta .........12

Cómo cambiar el panel

inferior de acceso..............13

Cómo desempacar la

máquina para hacer hielo ..11

Localización.........................11

Nivelación............................11

Puerta y paneles de

acceso a la medida ............14

Vacaciones y mudanzas .......15

Registro del aparato......................3

Servicios al consumidor..............20

Solución a los problemas............19

Garantía ......................................21

®

¿Preguntas?

Llamé a GE Answer Center

®

800.626.2000

2

Page 25

AYUDENOS A AYUDARLE…

Lea cuidadosamente este folleto. Anote el modelo y los números de serie.

Es nuestra intención ayudarle a operar y mantener

adecuadamente su nuevo máquina para hacer hielo.

Mantenga este folleto a la mano para responder a

sus preguntas.

Si no entendiera algo o necesitara asesoría, llame a:

GE Answer Center

800.626.2000

24 horas del día, 7 días a la semana

®

Si usted recibiera un máquina para

hacer hielo dañado…

Contacte inmediatamente al distribuidor (o al

fabricante) que le vendió la máquina para hacer hielo.

Ahorre tiempo y dinero.

Antes de solicitar el servicio…

Revise la sección de Solución de problemas de este

folleto. Allí se describen problemas de operación

menores que usted mismo puede corregir.

Los verá en la placa del lado izquierdo del depósito de

almacenamiento.

Estos números se encuentran también en la Tarjeta de

registro de propiedad del producto del consumidor que

se proporciona junto con su máquina para hacer hielo.

Antes de enviar esta tarjeta, por favor anote aquí los

siguientes números:

Número de modelo

Número de serie

Use estos números en toda correspondencia o llamada

de servicio referentes a su máquina para hacer hielo.

SI SE NECESITA SERVICIO

Para solicitar servicio, vea la página de Servicios al

consumidor al final de este folleto.

Estamos orgullosos de nuestro servicio y deseamos

quede satisfecho. Si por alguna razón usted no

quedara satisfecho con el servicio recibido, por favor

siga los tres pasos siguientes:

PRIMERO contacte a las personas que le dieron

servicio a su aparato. Explíqueles por qué no quedó

satisfecho. En la mayoría de los casos, ellos le

resolverán su problema.

A CONTINUACION, si usted siguiera insatisfecho

con el servicio, escriba todos los detalles (incluyendo

su número telefónico) a:

Manager, Consumer Relations

GE Appliances

Appliance Park

Louisville, KY 40225

FINALMENTE, si aún siguiera sin resolver el

problema, escribir a:

Major Appliance Consumer Action Program

20 North Wacker Drive

Chicago, IL 60606

3

Page 26

INSTRUCCIONES DE SEGURIDAD

Lea todas las instrucciones antes de usar este electrodoméstico.

ADVERTENCIA—Para reducir el riesgo

de incendio, choque eléctrico o lesiones

cuando esté usando su máquina para

hacer hielo, siga precauciones básicas

incluyendo las siguientes:

• Nunca permita que los niños operen, jueguen

con la máquina o se metan al interior de la

máquina.

• Nunca limpie las partes de la máquina para

hacer hielo con líquidos inflamables. Los

vapores pueden crear riesgos de incendio o

explosión.

• Por su seguridad: No almacene ni use gasolina

u otros vapores y líquidos cerca de este o de

otro aparato. Los vapores pueden crear riesgos

de incendio o explosión.

• Haga que un técnico de servicio calificado

instale y conecte a tierra la máquina para

hacer hielo de manera correcta de acuerdo

con las Instrucciones de instalación.

• No trate de reparar o reemplazar ninguna

parte de su máquina para hacer hielo a menos

que se recomiende específicamente en esta

guía. Todo otro servicio se debe remitir a

un técnico de servicio calificado.

• Es responsabilidad de usted asegurarse de que

su máquina para hacer hielo:

— se haya instalado donde esté protegida de los

elementos.

— se localice de modo que el frente no esté

obstruido de modo que no limite el flujo de

aire de entrada o de descarga.

— esté nivelada correctamente.

— esté localizada en un área bien ventilada con

temperaturas superiores a 55 °F. (13 °C.) y

menores que 110 °F. (43 °C.). Los mejores

resultados se obtienen a temperaturas entre

70 °F. (21 °C.) y 90 °F. (32 °C.).

— esté conectada de modo adecuado a una línea

de suministro de agua y a una de drenaje.

— esté conectada sólo al tipo correcto de toma de

corriente, con el suministro eléctrico correcto y

conexión a tierra correcta. Se requieren 120

voltios, 60 Hz y 15 amperes de suministro

eléctrico. NOTA: Se recomienda un fusible de

retardo o un interruptor de circuito.

— que no la use alguien que sea incapaz de

operarla de manera adecuada.

— se use sólo para el fin para el que están

diseñadas las máquinas para hacer hielo.

4

— se le dé el mantenimiento correcto.

GUARDE ESTAS

INSTRUCCIONES

Page 27

OPERACION DE SU MAQUINA PARA HACER HIELO

Cómo funciona la máquina para hacer hielo

1. El agua circula constantemente sobre una placa de

congelación. A medida que el agua se enfría para

llegar a congelarse, los minerales que contiene el

agua son expulsados. Esto produce una capa

delgada de hielo con bajo contenido de minerales.

NOTA: La máquina para hacer hielo está diseñada

para fabricar hielo transparente con la mayoría de

las fuentes de suministro de agua todos los días.

Si los resultados no son satisfactorios, el agua

puede necesitar filtrarse o tratarse. Consulte

Filtración y tratamiento del agua en la sección

Cuidado y limpieza.

2. Cuando se haya alcanzado el espesor deseado, la

placa de hielo se libera y se desliza hacia la rejilla

cortadora. Esta rejilla divide la placa de hielo en

cubos individuales.

3. El agua que contiene los minerales expulsados se

drena después de cada ciclo de congelación.

4. El agua fresca entra en la máquina para el siguiente

ciclo de congelación.

5. Los cubos caen en el depósito de almacenamiento.

Cuando el depósito está lleno, la máquina para

hacer hielo se apaga automáticamente y se vuelve a

encender cuando se necesita más hielo.

Notas acerca de esta máquina para hacer hielo

• El agua entra sólo durante el ciclo de

descongelamiento. Por lo tanto el primer ciclo se

acabará sin tener agua en el sistema.

• Como las temperaturas ambiente y del agua varían,

así también variará la cantidad de hielo producido.

Eso significa que las temperaturas de operación más

altas resultarán en producción de hielo reducida.

• La máquina para hacer hielo se apagará cuando el

hielo en el depósito de almacenamiento toca la

fuente del termostato del depósito y ciclará

automáticamente para mantener lleno el depósito.

• El depósito de almacenamiento no se refrigera y

algún derretimiento ocurrirá. Eso, también, varía con

la temperatura ambiente.

• La máquina para hacer hielo necesita buena

circulación de aire para funcionar eficazmente.

Mantenga limpios la rejilla frontal y el condensador.

• El sistema de agua, incluyendo el filtro dentro de la

válvula de solenoide de entrada de agua, se necesita

limpiar periódicamente para buena circulación. Las

instrucciones se encuentran en el panel de la puerta

interior.

(pase a la página siguiente)

5

Page 28

OPERACION DE SU MAQUINA PARA HACER HIELO

(pase)

Ajustando los controles

1. Elija el espesor de hielo que desee. La máquina

para hacer hielo ha sido ajustada en la fábrica para

producir hielo de aproximadamente 1/2″ (13 mm)

de espesor, siempre que esté operando a una

temperatura ambiente de 70 °F. (21 °C.).

La operación a una temperatura ambiente distinta

puede requerir un reajuste del control ya sea hacia

la posición “THICK” (grueso) o “THIN” (delgado).

La mejor operación se obtendrá con hielo de 1/2″

(13 mm) hasta 5/8″ (16 mm) de grueso.

Si su máquina opera en una habitación tibia (más

de 90 °F. [32 °C.]) NO coloque el control en el

espesor máximo ya que podría causar un mal

funcionamiento de la máquina para hacer hielo.

2. Para iniciar el ciclo normal de fabricación de hielo,

haga girar la perilla de Control de ciclo hasta la

posición “ON” (encendido).

3. Para detener la operación de la máquina para hacer

hielo, haga girar la perilla de Control de ciclo hasta

la posición “OFF” (apagado).

La posición de “CLEAN” (limpiar) se usa siempre

que hayan circulado impurezas a través de la

máquina para hacer hielo durante la limpieza de

ésta. Sólo la bomba de agua funciona en esta

posición de la perilla. Consulte Limpieza del sistema

de la máquina para hacer hielo en la sección Cuidado

y limpieza, si requiere de instrucciones específicas.

THIN

THIN

NORMAL

ICE

NORMAL

ICE

THICK

THICK

OFF

OFF

ON

CLEAN

CYCLE

ON

CLEAN

CYCLE

6

CARACTERISTICAS DE SU MAQUINA

PARA HACER HIELO

Control de espesor

del hielo

Placa con el

número de

serie y modelo

(no se muestra)

Placa

retenedora

del hielo

Panel

inferior de

acceso

ON

NORMAL

CLEAN

OFF

THICK

THIN

CYCLE

ICE

Perilla de

control de ciclo

Luz del depósito

Depósito para hielo

Cuchara para

hielo

Page 29

CUIDADO Y LIMPIEZA

Inspeccione y limpie periódicamente la máquina para

hacer hielo de modo que siga funcionando a su

máxima eficiencia y para prevenir una falla prematura

de los componentes del sistema.

Tanto el sistema de fabricación de hielo como el

condensador enfriado por aire necesitan ser limpiados

de manera regular.

Los minerales expulsados del agua circulante durante

el ciclo de congelación a la larga formarán un depósito

escamoso duro en el sistema de agua que evitará la

liberación rápida del hielo de la placa de congelación.

Limpieza de las superficies exteriores

Lave las superficies exteriores de esmalte y los empaques

con agua tibia y jabón o detergente suave. Enjuague y

seque. El uso regular de un buen limpiador doméstico

para aparatos y de cera ayudará a proteger el acabado.

Limpieza del condensador

ADVERTENCIA:

• Asegúrese de que la máquina para

hacer hielo esté en posición de “OFF”

(apagado) y desconectada del suministro

principal de energía eléctrica. La máquina

podría encenderse súbitamente si no está

desconectada. La rotación de las aspas del

condensador, las afiladas hojas del

condensador y las tuberías calientes podrían

causar lesiones permanentes en las personas.

• Las hojas del condensador pueden doblarse

con facilidad. Tenga cuidado cuando limpie

con aspiradora el condensador para evitar

que las hojas se doblen.

Limpie periódicamente el sistema de hielo y agua

para quitar las sales minerales escamosas que se

forman. La frecuencia con que se haga la limpieza

dependerá de la dureza del agua. Si el agua es dura

(15/20 granos/galón), la limpieza puede requerirse

con tanta frecuencia como lo sería cada seis meses.

Un condensador sucio o tapado:

• evita el flujo correcto de aire

• reduce la capacidad de fabricar hielo

• causa temperaturas de operación superiores a las

recomendadas que pueden llevar a una falla de los

componentes.

No use limpiadores abrasivos en superficies

esmaltadas ya que pueden rayar el acabado.

Panel

inferior de

acceso

Area de

la rejilla

Tornillo

Tornillos

1. Desconecte el suministro de corriente eléctrica que

alimenta la máquina para hacer hielo y ponga la

perilla de Control de ciclo en “OFF” (apagado).

2. Quite los dos tornillos del área de la rejilla en el

panel inferior de acceso.

3. Tire hacia adelante y hacia abajo para quitar el panel.

4. Quite la suciedad y la pelusa de las hojas del

condensador y del compartimiento de la unidad con

un accesorio para cepillar conectado a una aspiradora.

5. Vuelva a colocar el panel inferior de acceso y los

tornillos. La parte superior del panel de acceso

necesita asegurarse debajo de las dos lengüetas

de metal antes de volver a colocar los tornillos.

6. Conecte la máquina para hacer hielo y haga girar la

perilla de Control de ciclo hasta la posición de

“ON” (encendido).

(pase a la página siguiente)

7

Page 30

CUIDADO Y LIMPIEZA

(pase)

Limpieza del sistema de la máquina para hacer hielo

ADVERTENCIA: La mayoría de los

limpiadores para máquinas se hacen a

base de ácido cítrico o fosfórico y

pueden causar irritación incluso después de ser

diluidos. En el caso de contacto con los ojos,

enjuague los ojos meticulosamente con agua y

llame a un médico de inmediato. En caso de

contacto con la piel, enjuague bien con agua. Si

se ingiere, déle a la persona grandes cantidades

de agua y llame a un médico de inmediato. No

induzca el vómito. MANTENGASE FUERA

DEL ALCANCE DE LOS NIÑOS.

1. Coloque la perilla de Control de ciclo en posición

de “OFF” (apagado).

NORMAL

Colector del

cableado eléctrico

Tornillos (largos)

ON

THIN

OFF

THICK

CLEAN

ICE

CYCLE

2. Quite los dos tornillos y deslice la rejilla cortadora

de hielo hacia adelante, sacándola de las dos

ranuras cercanas a la bandeja para agua.

3. Desconecte el colector del cableado eléctrico.

PRECAUCION: Cualquier cantidad de hielo

que quede en la rejilla deberá derretirse bajo

agua tibia corriente. Si trata de quitar los

trozos de hielo de la rejilla puede estirar y

dañar los alambres de la rejilla.

4. Quite todo el hielo del depósito de hielo y de la

placa de congelación.

Tornillos

Tapón del

desagüe

Bandeja para agua

5. Drene la bandeja para agua quitando el tapón de

desagüe y luego vuelva a colocarlo.

8

6. Vierta 1/2 galón

(1.9 L) de agua

NORMAL

ON

caliente del grifo

en la bandeja para

THICK

OFF

CLEAN

agua* y haga girar

la perilla de Control

de ciclo hasta la

ICE

CYCLE

posición “CLEAN”

(limpiar). Esto calentará el sistema para hacer más

efectiva la acción de la solución limpiadora. Deje

que circule durante cinco minutos. Mientras el agua

del grifo está circulando, prepare la solución

limpiadora. Mezcle 6 onzas (170 g) de ácido cítrico

o fosfórico en polvo con 1/2 galón (1.9 L) de agua

caliente. (Los cristales de ácido cítrico y fosfórico

están disponibles o pueden ordenarse en muchas

farmacias y tiendas de materiales científicos.)

Los limpiadores comerciales para máquinas de

hacer hielo (líquidos) también los tiene su

distribuidor o las tiendas que venden partes para

refrigeración. Mezcle de acuerdo con las

instrucciones de las etiquetas (la cantidad total

debe ser de 1/2 galón [1.9 L]).

7. Haga girar la perilla de Control de ciclo hasta la

posición “OFF” (apagado) y desagüe la bandeja

de agua. (Vea el paso 5.)

8. Coloque la perilla de Control de ciclo en “CLEAN”

(limpiar) y vierta lentamente la solución limpiadora

caliente en la bandeja para agua.* (Si la solución

hace espuma mientras la está vertiendo, espere

hasta que deje de hacer espuma.) Luego añada lo

que queda de la solución.

Permita que la solución circule hasta que se hayan

disuelto los residuos acumulados (de 15 a 20

minutos). Una formación de residuos escamosos

muy grande puede requerir de una limpieza repetida

con una cantidad de solución limpiadora nueva.

Para limpiar las acumulaciones en las pestañas

laterales de la placa de congelación utilice

guantes de hule y talle con una fibra plástica no

abrasiva o con un cepillo de nylon empapado en

solución limpiadora.

9. No se quite los guantes de hule cuando drene la

solución limpiadora. Coloque la perilla de Control

de ciclo en “OFF” (apagado) y vacíe la bandeja

para agua. (Vea el paso 5.)

10. Vuelva a colocar el tapón y agregue 1/2 galón

(1.9 L) de agua limpia.* Haga girar la perilla de

Control de ciclo hasta la posición “CLEAN”

(limpiar), deje que circule durante 5 minutos y

luego drene. Repita el proceso de enjuague.

*Para facilitar el vertido del agua y de la solución

limpiadora use un recipiente con capacidad para 1 o

2 tazas.

Page 31

Limpieza de los componentes interiores

ADVERTENCIA:

• No opere la máquina para hacer hielo

si quitó el panel inferior de acceso o el

tablero de control. Puede sufrir un choque

eléctrico o lesiones en su persona.

• No lave las partes plásticas en la máquina

lavavajillas. Las partes no resisten

temperaturas superiores a 145 °F. (63 °C.).

1. Haga girar la perilla de Control de ciclo hasta

la posición de “OFF” (apagado) y desconecte

el suministro de corriente eléctrica que alimenta

la máquina. Abra la puerta del depósito de

almacenamiento y retire cualquier cantidad

de hielo que haya en el depósito.

2. Quite la placa

NORMAL

retenedora del hielo

doblándola un poco y

ON

THIN

OFF

THICK

ICE

CYCLE

luego sacándola de los

pernos prisioneros.

3. Quite la rejilla

cortadora de hielo

desatornillando los dos

tornillos, deslizando la

rejilla hacia adelante y

Placa retenedora

del hielo

desconectando el colector

del cableado eléctrico.

Tornillos (cortos)

Tapón

desagüe

Bandeja para agua

Inserte en el

desagüe

4. Retire la bandeja para agua desatornillando y

quitando los dos tornillos y las arandelas.

Manguera

Bomba

de agua

5. Quite la manguera de la bomba de agua.

Distribuidor de agua

6. Quite el distribuidor de agua de la placa de

congelación. Se mantiene en su sitio mediante topes

de hule. Quite la manguera de entrada y limpie todos

los agujeros de agua del distribuidor y el orificio

pequeño en el lado de entrada del distribuidor.

Cuando reemplace el distribuidor, asegúrese de

que los topes de hule se localicen en los reténes de

CLEAN

las pestañas del evaporador y de que los agujeros

del distribuidor de agua estén hacia abajo.

7. Lave los componentes interiores (placa retenedora de

hielo, rejilla cortadora, bandeja para agua, manguera

de entrada y distribuidor de agua) y el depósito de

almacenamiento, el empaque de la puerta y la

cuchara para hielo con jabón o detergente suave y

agua tibia. Enjuague con agua limpia. Estos

componentes también deben lavarse con una

solución de 1 onza (29.6 ml) de blanqueador de cloro

en un galón (3.8 L) de agua tibia. Enjuague de nuevo

perfectamente con agua limpia.

8. Vuelva a colocar los componentes interiores:

distribuidor de agua, manguera de entrada y

bandeja para agua.

9. Verifique lo siguiente:

• Que la manguera que viene de la válvula de agua

esté en la bandeja para agua.

• Que el tapón de hule para el desagüe esté en la

bandeja para agua.

• Que el distribuidor de agua esté bien colocado y

los agujeros den hacia abajo.

• Que la manguera haya sido conectada de nuevo

a la bomba y al distribuidor de agua.

• Que la manguera de la bandeja para agua se

inserta en el agujero de desagüe del depósito de

almacenamiento.

10. Vuelva a conectar el colector del cableado

eléctrico, deslice la rejilla cortadora en su lugar y

atornille con firmeza los tornillos. Vuelva a

colocar la placa retenedora del hielo.

11. Haga girar la perilla de Control de ciclo hasta la

posición de “ON” (encendido).

(pase a la página siguiente)

9

Page 32

CUIDADO Y LIMPIEZA

Filtrado y tratamiento del agua

(pase)

En la mayoría de las áreas sería beneficioso filtrar o

tratar el agua que alimenta la máquina para hacer

hielo. Esto puede mejorar la confiabilidad de la

máquina, reducir el mantenimiento del sistema de

agua y producir la mejor calidad de hielo.

La instalación de un alimentador de polifosfato por lo

general reducirá la formación de acumulaciones de

sales y la máquina para hacer hielo requerirá de

limpiezas menos frecuentes.

Cambio de la bombilla

ADVERTENCIA: Antes de quitar la

bombilla, desconecte la máquina para

hacer hielo o bien desconecte la

electricidad que alimenta a la máquina para

hacer hielo desde la fuente de energía

principal. Puede sufrir un choque eléctrico o

lesiones a su persona si la máquina sigue

conectada a la corriente eléctrica.

La máquina para hacer hielo tiene una bombilla en la

parte superior del depósito de almacenamiento. Para

reemplazarla, abra la puerta del depósito y siga estas

instrucciones:

1. Desconecte la máquina para hacer hielo de la

fuente de energía eléctrica.

2. Quite los dos tornillos y deslice la rejilla cortadora

hacia adelante, sacándola de las dos ranuras que se

encuentran cerca de la bandeja para agua. Coloque

la rejilla cortadora sobre la puerta del depósito.

3. Oprima el frente de la protección de la bombilla

mientras tira hacia abajo para quitarla de la

abrazadera que la sujeta.

4. Quite la bombilla. Reemplácela con una bombilla

de 15 watts con base de tipo bayoneta.

5. Vuelva a colocar la placa protectora, la rejilla

cortadora de hielo y los dos tornillos.

6. Vuelva a conectar el suministro eléctrico.

Los sistemas municipales de agua por lo general son

tratados con cloro para mantener un suministro de

agua potable libre de riesgos. Los filtros de carbón

activado por lo general serán suficientes para quitar el

cloro residual del agua y reducir las manchas en las

superficies de los materiales de acero inoxidable de la

máquina para hacer hielo.

Para mayor información sobre el filtrado y

tratamiento del agua, consulte con el distribuidor al

que le compró la máquina para hacer hielo.

NORMAL

ON

THIN

OFF

THICK

CLEAN

ICE

CYCLE

Interruptor

de luz

Tornillos

Abrazadera

de la

bombilla

Plaza

protectora

para la

bombilla

10

Page 33

PREPARACION

Cómo desempacar la máquina para hacer hielo

1. Coloque la caja sobre la parte inferior y abra las

tapas del fondo.

2. Coloque la caja

derecha con las

cuatro tapas abiertas

hacia afuera.

3. Levante la caja de

cartón hasta dejar

al descubierto la

máquina para

hacer hielo.

Abra las tapas

del fondo

4. Quite toda la cinta adhesiva

y los materiales de empaque

del exterior y del interior del

gabinete.

5. Quite la rejilla delantera, retire

los tornillos que aseguran la

rejilla con el fondo y levántela

sacándola del gabinete.

6. Haga girar el ventilador con la mano para

cerciorarse de que se mueve con libertad.

Localización Nivelación

ESTA MAQUINA PARA HACER HIELO DEBE

INSTALARSE EN UN AREA PROTEGIDA DE

LOS ELEMENTOS, POR EJEMPLO DEL VIENTO,

LA LLUVIA, EL ROCIO DE AGUA O GOTEO

DE AGUA.

1. Coloque la máquina para hacer hielo de modo que

el lado del frente esté completamente libre para

proporcionar un flujo de aire adecuado.

2. El área debe estar bien ventilada a una temperatura

superior a los 55 °F. (13 °C.) e inferior a 110 °F.

(43 °C.). Los mejores resultados se obtienen entre

70 °F. (21 °C.) y 90 °F. (32 °C.).

3. Deben determinarse las provisiones de electricidad,

agua y drenaje.

4. La máquina para hacer hielo puede cerrarse en la

parte superior y en tres lados, pero el frente DEBE

ESTAR libre de obstáculos para que haya

circulación de aire y una adecuada operación.

La instalación debe hacerse de tal modo que

el gabinete pueda moverse hacia adelante para

poder darle servicio en caso necesario.

1. Después de colocar la máquina para hacer hielo en

posición, revise para cerciorarse de que la máquina

para hacer hielo esté nivelada de lado a lado y del

frente hacia atrás.

2. Una nivelación precisa es esencial para una

operación adecuada.

3. La máquina para hacer hielo debe estar encuñada

para que quede sólida lo mismo que nivelada. Las

cuñas deben ser de un material duro y permanente

como el masonite (madera aglomerada).

4. Los estándares de la Fundación Nacional para la

Higiene determinan que este tipo de producto debe

quedar sellado al suelo en el riel inferior para así

evitar contaminación por derrames o la entrada de

sabandijas. Por lo tanto, recomendamos que cuando

instala la máquina para hacer hielo la asiente en el

suelo de acuerdo con esos estándares. Se

recomienda un sellador de tipo silicio.

Quite los

materiales

de empaque

del interior

Calibraciones del termostato

Si la máquina para hacer hielo se instala a más de dos mil pies (610 m), el

depósito y los evaporadores de los termostatos deben ajustarse para una

posición más tibia. Desconecte la electricidad, retire el termostato y siga las

instrucciones para hacer girar el tornillo de ajuste como se muestra en la

etiqueta en cada termostato.

(pase a la página siguiente)

11

Page 34

PREPARACION

(pase)

Cómo cambiar el panel de la puerta del depósito

Usted puede cambiar con facilidad el color del panel

delantero de la puerta del depósito de almacenamiento.

Hay dos colores disponibles: negro y blanco.

Para cambiar el panel:

1. Abra la puerta del depósito de almacenamiento.

Quite los dos tornillos que se encuentran en la parte

superior de la puerta y que sostienen la manija.

2. Afloje los tornillos en ambos lados de las

guarniciones.

3. Quite la manija y la inserción de la manija.

4. Deslice cuidadosamente el panel para sacarlo.

Encontrará que el reverso es negro. En las unidades

que muestren un panel negro hacia afuera, la cara

interior será blanca.

5. Elija el color que quiere mostrar y con cuidado

vuelva a deslizar el panel en la puerta.

NOTA: Tenga cuidado de no raspar el panel

mientras lo inserta.

6. Vuelva a colocar la inserción de la manija y apriete

los tornillos en ambos lados de las guarniciones.

Vuelva a colocar la manija y los tornillos.

NOTA: Usted puede hacer un panel frontal de

madera decorativa que se adapte a los gabinetes

existentes. Consulte la sección Puerta y paneles de

acceso a la medida.

Manija

Inserción

de la

manija

12

Page 35

Cómo cambiar el panel inferior de acceso

ADVERTENCIA: No opere la máquina

para hacer hielo si ha quitado el panel

inferior de acceso o el panel de control.

Puede sufrir un choque eléctrico o lesiones

personales.

Panel

inferior de

acceso

Tornillo

1. Quite el tornillo de la parte superior del panel

inferior de acceso y los dos tornillos que están en la

parte de abajo del área de la rejilla cortadora. Tire

hacia el frente en la parte de abajo, entonces tire

hacia abajo para quitar el panel.

2. Quite los dos tornillos de la guarda superior y quite

la guarda superior.

3. Deslice con cuidado el panel para quitarlo.

4. Elija el color que quiera mostrar y con cuidado

vuelva a poner en su lugar el panel inferior de

acceso. NOTA: Tenga cuidado de no rayar el

panel al insertarlo.

5. Vuelva a poner la guarda superior y los tornillos.

Vuelva a colocar el montaje del panel inferior de

acceso y los tornillos. La parte superior del panel

de acceso necesita asegurarse debajo de las dos

pestañas de metal antes de volver a colocar los

tornillos.

NOTA: Usted puede hacer un panel frontal de

madera decorativa que se adapte a los gabinetes

existentes. Consulte la sección Puerta y paneles de

acceso a la medida.

Area

de la

rejilla

Tornillos

(pase a la página siguiente)

13

Page 36

PUER TA Y PANELES DE ACCESO A LA MEDIDA

Puerta y paneles de acceso a la medida

de 1/4″ de espesor

Corte los paneles del mismo tamaño que el panel

de metal.

Puerta y paneles de acceso a la medida

de 3/4″ de espersor

La puerta y los paneles de acceso—ambos con diseños

en relieve y plano—se deberán armar de la misma

manera que el gabinete, las puertas o los cajones típicos.

Panel de la puerta del cajón de almacenamiento:

• Corte el panel a 17″ de ancho x 11

• Ranure la parte superior y ambos lados con una

anchura de 5/16″, y 1/2″ de profundidad para

obtener una anchura total de 1/4″.

• Ranure la parte inferior del panel con una anchura

de 1″, una profundidad de 1/2″ para obtener un

espesor total de 1/4″. Esto permitirá que la puerta se

abra sin golpearse contra el panel inferior. Si se

desea una apariencia personalizada, considere que

debe estrechar la ranura de 1″.

Panel de acceso inferior:

• Corte el panel a 17″ de ancho por 11

• Ranure los cuatro lados a una anchura de 5/16″ y una

profundidad de 1/2″ para tener un espesor total de 1/4″.

1

/4″ de alto.

15

/16″ de alto.

Depósito de

la puerta

111/4″

Panel

inferior

1115/16″

Panel de la puerta del

cajón de almacenamiento

Panel de acceso inferior

Paneles con grosor de 3/4″

Dimensiones del

panel de madera

17″

17″

17″

1/4″

111/4″

1115/16″

Ranure a una

profundidad