Page 1

GE Appliances & Lighting

Technical Service Guide

March 2010

Monogram

Under-the-Counter

Icemaker

ZDIS150WWW

31-9196

ZDIS150WSS

ZDIS150WBB

GE Appliances

General Electric Company

Louisville, Kentucky 40225

Page 2

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by

individuals possessing adequate backgrounds of air conditioning

and heat pump experience. Any attempt to repair an air conditioning

or heat pump system may result in personal injury and property

damage. The man u fac tur er or seller cannot be responsible for the

in ter pre ta tion of this in for ma tion, nor can it assume any liability in

connection with its use.

WARNING

To avoid personal injury, disconnect power before servicing air conditioning

or heat pu mp sy stem s. If e lectrical powe r is r equ ire d fo r dia gnosi s or tes t

purposes, disconnect the power immediately after performing the

necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used to

complete a path to ground are removed for service, they must be

returned to their original position and properly fastened.

All rights reserved. This service guide may not be reproduced in whole or in part

in any form without written permission from the General Electric Company.

GE Appliances & Lighting

Technical Service Guide

Copyright © 2010

– 2 –

Page 3

Table of Contents

Bin Light Bulb .....................................................................................................................................................................18

Bin Thermistor ....................................................................................................................................................................19

Care and Cleaning ......................................................................................................................................................... 13

Component Locator ........................................................................................................................................................16

Components ........................................................................................................................................................................18

Component Testing..........................................................................................................................................................32

Compressor .........................................................................................................................................................................27

Condenser ............................................................................................................................................................................29

Condenser Fan Motor .....................................................................................................................................................24

Control Board Diagnostics ............................................................................................................................................35

Control Features ................................................................................................................................................................12

Cutter Grid ............................................................................................................................................................................19

Door and Gasket ...............................................................................................................................................................18

Electronic Control Housing Components ..............................................................................................................21

Evaporator ...........................................................................................................................................................................29

Evaporator Thermistor ...................................................................................................................................................20

Features and Benefi ts ..................................................................................................................................................... 5

Hot Gas Solenoid...............................................................................................................................................................26

Hot Gas Valve .....................................................................................................................................................................27

Measured Fill Water Valve ............................................................................................................................................ 26

Nomenclature ....................................................................................................................................................................4

Reservoir Drain Pump .....................................................................................................................................................24

Schematics and Strip Circuits .....................................................................................................................................42

Sealed System ...................................................................................................................................................................27

Service Test Mode (Diagnostic Mode) ................................................................................................................... 40

Specifi cations .....................................................................................................................................................................5

Theory of Operation ........................................................................................................................................................6

Troubleshooting ................................................................................................................................................................37

Warranty .............................................................................................................................................................................. 44

Water Distributor ..............................................................................................................................................................20

Water Level Sensor ..........................................................................................................................................................23

Water Recirculation Pump ........................................................................................................................................... 22

– 3 –

Page 4

Model Number

Nomenclature

Z D I S 150 W S S

Monogram

Ice Machine

Built-In

Stainless Capacity - 50 lbs

Nomenclature Tag

The nomenclature tag is located on the right

side of the ice bin. This tag contains important

information such as:

• Model/serial number

• Refrigerant charge

• Voltage rating

SS - Stainless Steel

BB - Black

WW - White

Model Year - 2009

Serial Number

The fi rst two characters of the serial number

identify the month and year of manufacture.

Example: AT123456S = January, 2010

A - JAN 2010 - T

D - FEB 2009 - S

F - MAR 2008 - R

G - APR 2007 - M

H - MAY 2006 - L

L - JUN 2005 - H

M - JUL 2004 - G

R - AUG 2003 - F

S - SEP 2002 - D

T - OCT 2001 - A

V - NOV 2000 - Z

Z - DEC 1999 - V

The letter des ig nat ing

the year re peats every

12 years.

Example:

T - 1986

T - 1998

T - 2010

Note: The Mini-Manual is located behind the

front cover panel. It is folded and tucked into

one of the loops of the condenser coil.

– 4 –

Page 5

Specifi cations

AC Power Supply . . . . . . . . . . . . . . . . . . . 97 to 127 VAC (rated 115 VAC), 60 Hz

Amperage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.5 Amps (max)

Minimum Circuit Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 Amps

Ice Shape . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3/4 in. x 3/4 in. Square

Ice Thickness @ Normal Setting (Approximate) . . . . . . . . . . . . . . 0.32 in. (8.1 mm)

Ice Thickness @ Thin Setting (Approximate) . . . . . . . . . . . . . . . . . 0.28 in. (7.1 mm)

Ice Thickness @ Thick Setting (Approximate) . . . . . . . . . . . . . . . . .0.3915 In. (9.9 mm)

15 In. Storage Capacity (Approximate). . . . . . . . . . . . . . . . . . . . 25 lbs (11.3 kg)

Exterior Dimensions (W x D x H). . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 or 18 in. x 24 in. x 34 in.

(381 or 457.2 x 609.6 x 863.6 mm)

Exterior Finish . . . . . . . . . . . . . . . . . . . . . . . . . . Stainless Steel or Painted Steel

Net Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 in. = 94 lbs (42.6 kg)

Cube Thickness Control . . . . . . . . . Water Level Sensor & Control Board Setting

Harvest Control . . . . . . . . . . . . . . . . . . . . . . . . . . . Thermistor under Evaporator

Bin Ice Level Control . . . . . . . . . . . . . . . . . . . . . . . . . . Thermistor on Side of Bin

Refrigerant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . R134a

Ambient Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55 to 100°F

Water Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 to 120 psig

Water Consumption (Dependent on Water Pressure) 6 to 10 gallons per 4 hours

Features and Benefi ts

Daily Ice Production at Ambient Temperatures

Ambient Temperature

70°F (21°C) 46 lbs (21 kg)

80°F (27°C) 47 lbs (21 kg)

90°F (32°C) 40 lbs (18 kg)

100°F (38°C) 40 lbs (18 kg)

110°F (43°C) 38 lbs (17 kg)

Water Temperature

60°F (15°C)

Hidden Electronic Controls allow for a fully •

integrated look.

Clean Sensor with LED Indicator•

Lighted Bin with Ice Scoop•

Reversible Door•

Daily Ice Production up to 50 lbs•

Water Level Sensor•

Electronic, LED Controls•

Drop-Down Door•

Clean Light•

Automatic Shut-Off•

– 5 –

Page 6

Theory of Operation

Operating Systems

There are 3 operating systems in the icemaker:

Electrical System•

Refrigeration System•

Water System•

Electrical System

The icemaker’s electrical system provides power for

the refrigeration and water systems and controls

the operation of each component.

– 6 –

(Continued next page)

Page 7

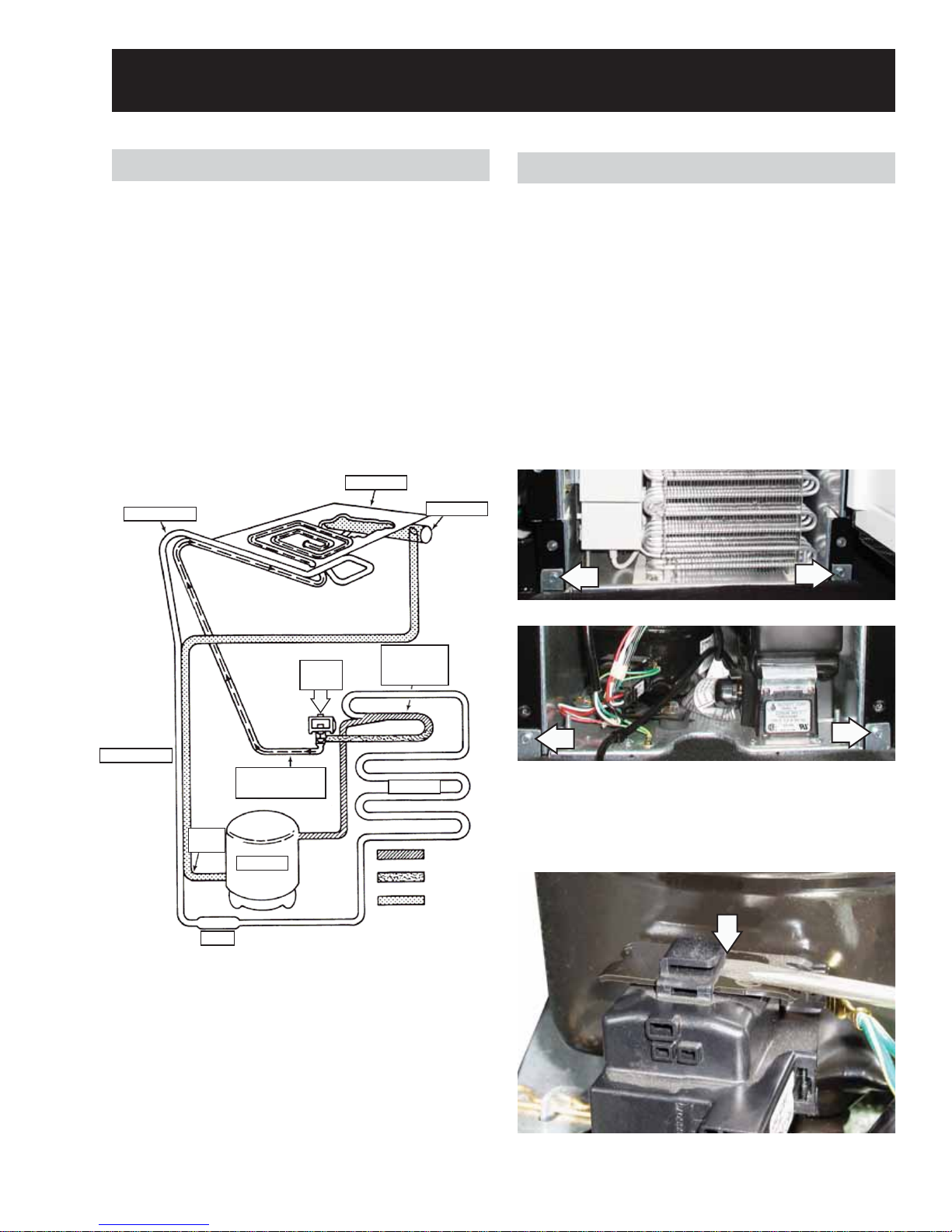

Refrigeration System

The refrigeration system is very similar to the

system used in other refrigeration appliances. The

refrigerant used in this unit is R134a.

There are 2 very important additions to the

refrigeration system in this Icemaker: the hot gas

valve and the condenser accumulator tube.

The 1. hot gas valve allows high pressure

refrigerant gas to bypass the condenser and

fl ow through the condenser accumulator tube.

Hot gas pushes liquid refrigerant through 2.

the condenser accumulator tube into

the evaporator, helping to evenly heat the

evaporator plate so that the ice slab releases

quickly and evenly.

Evaporator

Capillary Tube

Heat Exchanger

Hot Gas

Valve

Path of warm liquid refriger-

ant pushed by high-pres-

sure refrigerant gas

Accumulator

Condenser

Accumulating

Tube

Condenser

Suction

Tube

Drier

Compressor

– 7 –

High-Pressure

Refrigerant Gas

Warm Liquid

Refrigerant

Low-Pressure

Refrigerant Gas

(Continued next page)

Page 8

Water System

The water system provides:

Fresh water for ice production•

Water recirculation as ice is produced•

Water removal after ice is produced•

The water system circulates water on the

evaporator to freeze into ice during the freeze cycle.

During the harvest cycle, it drains away minerals

and contaminates. During the clean cycle, cleaning

Water System Component Locations

Evaporator

solution is circulated to clean the system of minerals

and contaminates.

The hardness of the water supplied to the icemaker

will affect the quality of the ice that is produced. It

may also affect the operation of the water system.

A water softener, or poly-phosphate feeder, will not

cure all of the problems associated with hard water,

but they can be used to reduce scale buildup in the

icemaker.

Water Distributor

Water Return Tube

Water Valve Outlet Tube

Measured Fill

Water Inlet Valve

From Water Supply

Manual Drain

Drain Overfl ow

– 8 –

Water Level Sensor

Water Recirculation Pump

Reservoir Pan

Reservoir Drain Pan

Bin Drain

(Continued next page)

Page 9

Operational Modes

There are 4 main operational modes for the

icemaker:

Ice-making cycle (Freeze Mode) 1.

Harvest2.

Clean3.

Service (Diagnostics)4.

Ice-Making Cycle (Freeze Mode)

There are 3 possible “Off” cycles for the icemaker.

They occur when:

The bin is full of ice and the ON LED is 1.

illuminated (Idle Mode).

The OFF control pad has been held for 3 sec. 2.

(The ON LED will go out.)

The power is interrupted by overfi ll. (Model ZPK1 3.

only with internal drain pump.)

Electrical System: Line voltage is supplied to

the electrical control switches and the primary

side of the step-down dual transformer. The dual

transformer reduces 120 VAC to 8.75 VAC for the

cutter grid and the bin light, and 12 VAC for the

drain and recirculating pumps.

The electronic control board directs 12 VAC to the

water recirculating and reservoir drain pumps, and

120 VAC to the hot gas solenoid, condenser fan

motor, and compressor.

During the later stages of the freeze mode, an ice

slab forms on the evaporator freezing plate. This

ice slab causes some of the refrigerant passing

through the evaporator to not evaporate into a

gas, but remain a liquid. This liquid refrigerant

settles in the accumulator. The refrigerant vapor is

sucked off through the suction tube at the top of the

accumulator.

This accumulated liquid refrigerant will eventually

be directed to the evaporator to quickly warm the

evaporator plate during the harvest mode.

Caution: It is very important that the accumulator

is not tilted out of a horizontal position. If moved, it

could cause compressor failure.

Water System: The water recirculation pump

moves the water from the reservoir pan up to the

distributor. The water fl ows out over the evaporator

freezing plate. Water that does not freeze on the

evaporator plate runs off the front edge. It falls back

into the reservoir, where it is recirculated back to the

water distributor.

As the ice slab forms, the minerals in the water are

on the surface of the ice. The water fl owing over

the top of the ice slab washes these minerals back

into the water reservoir pan. The water continues to

recirculate until the water level in the reservoir drops

below a level determined by the water level sensor.

At this point, the control terminates the freeze mode

and initiates the harvest mode.

The measured fi ll water inlet valve will always

have 120 VAC on the black and white wires and

14 VDC on the orange/white and black/red wires.

An evaporator thermistor supplies temperature

information to the electronic control to determine

when to terminate the harvest cycle. A water level

sensor initiates the next harvest.

Refrigeration System: The hot gas refrigerant,

under high pressure, is forced through the

condenser, where it changes into a liquid and

fl ows through the drier and capillary tube into the

evaporator. Under low pressure in the evaporator,

the liquid refrigerant absorbs heat from the

water fl owing over the evaporator and the liquid

refrigerant changes to gas. As a low-pressure gas,

the refrigerant fl ows back through the suction line of

the heat exchanger to the compressor.

During the freeze mode, some of the hot gas that is

in the condenser accumulating tube condenses to a

liquid and remains in the accumulating tube.

– 9 –

(Continued next page)

Page 10

Harvest Mode

Electrical System: When the water level in the

reservoir drops below the water level sensor, it

signals the electronic control to terminate power to

the condenser fan, and then the water recirculating

pump. The reservoir drain pump is activated (on for

20 sec., off 20 sec., back on for 20 sec.), to fully drain

the reservoir. Power is then supplied to the hot gas

valve and a fi ll request is sent to the measured fi ll

water inlet valve. The fi ll valve fi lls to the requested

volume while the hot gas valve is energized for

the balance of the harvest mode. If the evaporator

thermistor is unplugged, the evaporator defaults to

a timed 4-minute harvest.

If the water level sensor is disconnected or open, the

control defaults to 25 minutes of freeze time. The

cleaning indicator LED feature will not function if the

water level sensor is disconnected.

Refrigeration System: The hot gas valve opens,

allowing high-pressure refrigerant gas to bypass

the condenser, and fl ow through the condenser

accumulating tube. The hot gas pushes the

liquid refrigerant that has accumulated in the

accumulator tube up into the evaporator. The hot

liquid refrigerant evenly heats the evaporator plate

so that the ice slab releases quickly and evenly.

Water System: The reservoir drain pump is

activated (on for 20 sec., off 20 sec., back on for 20

sec.) to fully drain the reservoir. When fully drained,

the electronic control board sends a signal to the

water valve. The signal tells the measured fi ll water

inlet valve how much water is to be fi lled, allowing

water to fl ow into the water reservoir pan. The water

fi ll volume is determined by the ice thickness setting.

Thin Ice uses 32oz (954cc), Normal Ice uses 37oz

(1106cc) and Thick Ice uses 42.5oz (1258cc).

Note: Two minute maximum fi ll. The cycling

between freeze and harvest continues until the ice

bin is full. The electronic control board operates the

various components and systems in the icemaker

for each of the freeze and harvest modes.

Clean Mode (CLEAN LED on Amber, then Red)

The CLEAN LED turns from green to amber, then to

red. The CLEAN LED will turn from green to amber

after 50 hung slabs* or 3500 freeze cycles. The

CLEAN LED will then turn to red after 70 hung slabs*

or 4000 freeze cycles.

With the CLEAN LED on red and steady, the unit

must be cleaned to turn it off. When the clean cycle

is complete (approximately 70 minutes), the CLEAN

LED will be green and the OFF LED will be red.

The ice slab, when released, slides off of the

evaporator plate onto the cutter grid.

As a result of the hot gas fl ow and the ice sliding off

the evaporator plate, the evaporator temperature

begins to rise. When the evaporator thermistor

reaches the set temperature (52°F), the unit switches

to the Freeze Mode.

Select and hold the OFF pad for 3 seconds to turn

the unit off. Then press the ON pad to turn the unit

on. Customer instructions for Clean Cycle are on the

inside of the door.

*Hung Slab: If the time between the start of a freeze cycle

and the start of the harvest cycle is less than fi ve minutes, the

control will count a hung slab.

– 10 –

(Continued next page)

Page 11

Electrical System: The electronic control board

operates the various components and systems

during the clean mode. The clean mode may only

be selected while the icemaker is turned off (OFF

button held 3 sec.) at the user interface.

When the clean mode begins, the clean light fl ashes

1 sec. on then 1 sec. off. The circulation pump,

compressor, and hot gas valve are energized for

40 min.

The measured fi ll water inlet valve is energized

for 3 minutes, and then the recirculation pump is

energized for 3 minutes. This process is repeated 5

times for a total of 30 minutes.

The electrical control board turns all components

off. The CLEAN LED remains on with reservoir full.

Refrigeration System: The compressor and hot

gas valve operate to heat the evaporator. The

evaporator thermistor will cycle the compressor off

at 125°F and on at 95°F.

Water System: When the icemaker is in the CLEAN

mode, the water recirculating pump circulates

the cleaning solution that has been added to the

reservoir up to the water distributor, across the

evaporator, and back into the reservoir, where it is

recirculated.

Note: Do not continue with the diagnosis of the ice

maker if a fuse is blown, a circuit breaker is tripped,

or if there is less than a 120-Volt power supply at

the wall outlet. All units that have failed during the

fi rst few days of use should be checked for loose

connections or miswiring.

– 11 –

Page 12

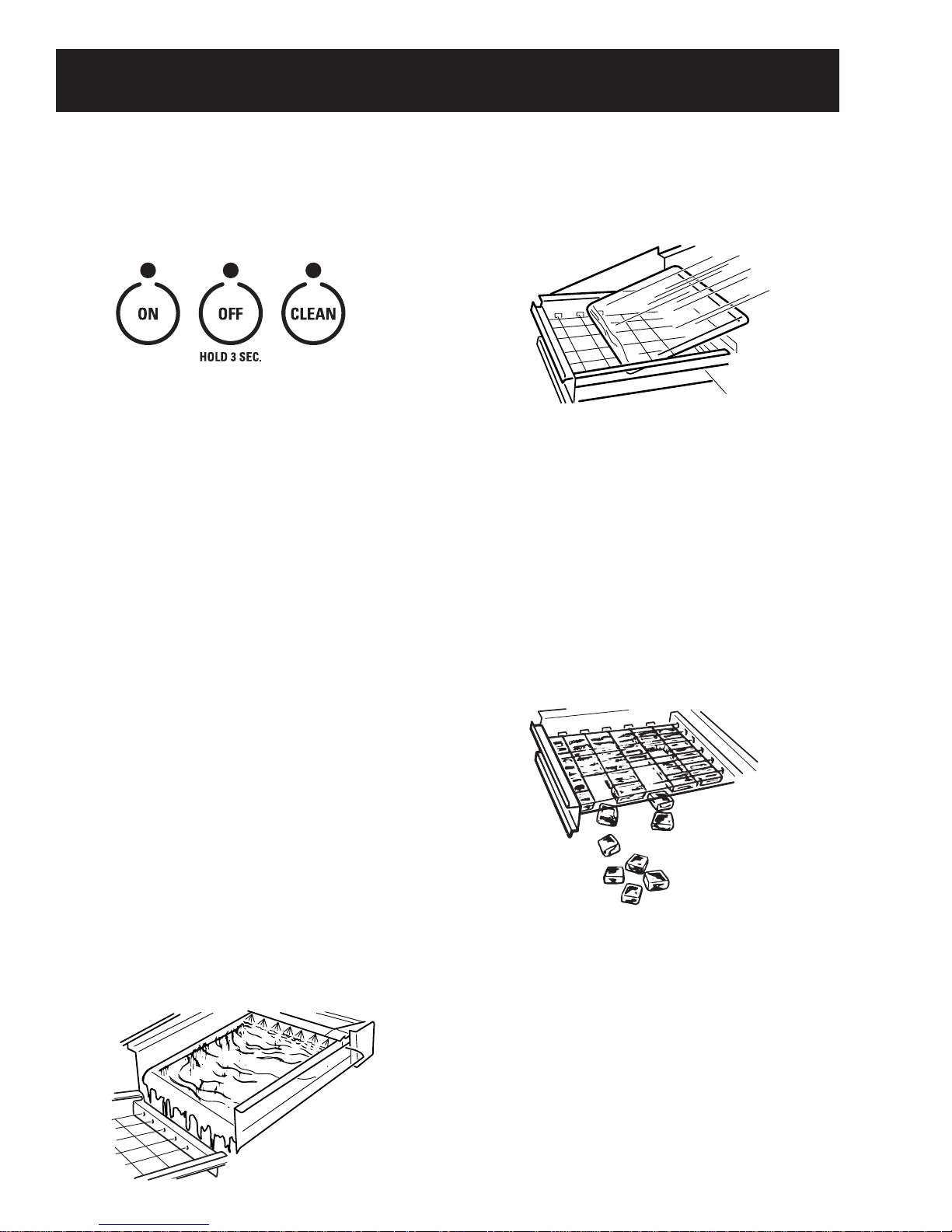

Control Features

User Controls

To start the normal ice making cycle, select 1. ON.

To stop icemaker operation, press and hold 2. OFF.

Note: The CLEAN setting is used whenever solutions

are circulated through the icemaker for cleaning.

How the Icemaker Works

When you fi rst start your icemaker, the water

reservoir will fi ll and the system will rinse itself

before starting to make ice. The rinsing process

takes about 5 min.

Under normal operating conditions, the icemaker

will cycle on and off as needed. The ice level sensor

located in the ice storage bin will monitor the ice

levels.

Notes:

When the desired thickness is reached, the ice 2.

sheet is released and slides onto a cutter grid.

The grid divides the sheet into individual cubes.

The water containing the rejected minerals is 3.

drained after each freezing cycle.

Fresh water enters the machine for the next ice-4.

making cycle.

Cubes fall into the storage bin. When the bin 5.

is full, the icemaker shuts off automatically

and restarts when more ice is needed. The ice

bin is not refrigerated and some melting will

occur. The amount of melting varies with room

temperature.

If the water supply to the icemaker is turned off, •

be sure to set the icemaker control to OFF. Drain

the water reservoir and leave the icemaker door

open to allow it to dry completely.

The icemaker is designed to make clear ice from •

the majority of water sources on a daily basis. If

your results are unsatisfactory, your water may

need to be fi ltered or treated.

Making Ice

Water is constantly circulated over a freezing 1.

plate. As the water freezes into ice, the minerals

in the water are rejected. This produces a clear

sheet of ice with a low mineral content.

Note: As the room and water temperatures vary,

so will the amount of ice produced and stored. This

means that higher operating temperatures result in

reduced ice production.

– 12 –

(Continued next page)

Page 13

Care and Cleaning

Caring for the Icemaker

The CLEAN light signal will illuminate yellow when

the electronic control senses that the need for

cleaning is approaching. At this time you need to

purchase

nickel-safe ice machine cleaner

by

Nu-Calgon, available at most appliance repair shops

or through GE Parts and Accessories. Order part

number WX08X42870. In the U.S.A., call 1-800-626-

2002 or visit Monogram.com. In Canada call 1-800-

561-3344. The CLEAN light will eventually turn

red which means the icemaker must be cleaned,

otherwise ice production will decrease signifi cantly

or stop altogether.

IMPORTANT: For best results, use the entire contents

of the bottle to clean the unit. (See Icemaker System.)

The air-cooled condenser needs to be cleaned

regularly for effi cient ice production and energy

conservation.(See Cleaning the Condenser.)

Exterior surfaces

Door handles and trim―Clean with a cloth

dampened with soapy water. Dry with a soft cloth.

Keep the outside clean. Wipe with a clean cloth

lightly dampened with mild liquid dish detergent.

Dry with a clean, soft cloth. Do not wipe the

icemaker with a soiled dish cloth or wet towel. These

may leave a residue that can damage the fi nish.

Do not use scouring pads, powdered cleaners,

bleach or cleaners containing bleach because these

products can scratch and damage the fi nish.

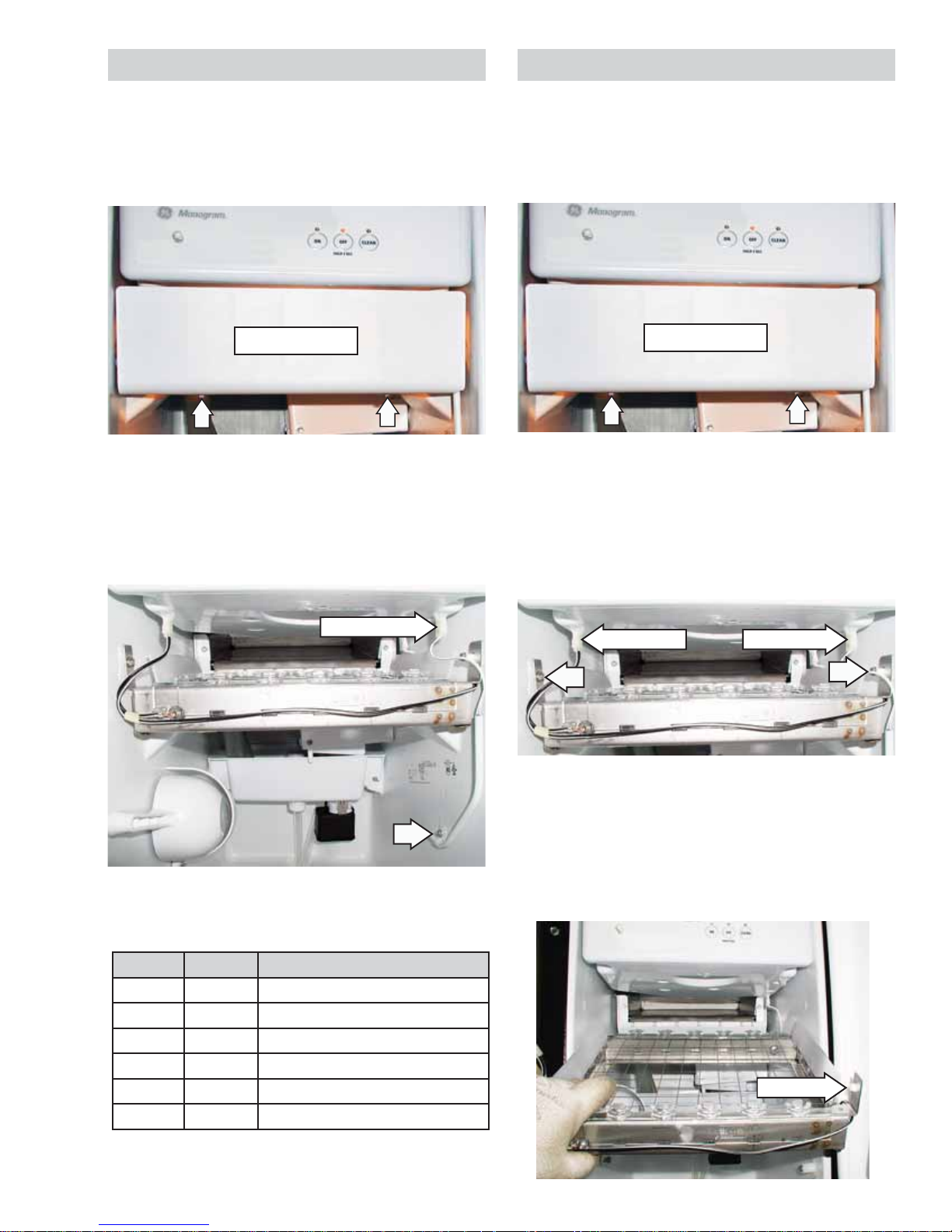

Press and hold the 1. OFF button for 3 seconds.

Wait 5 to 10 minutes for the ice to fall into the 2.

storage bin. Remove all ice from the storage bin.

Unscrew the drain cap from the bottom of the 3.

water reservoir located inside the storage bin as

shown. Allow the water to drain completely.

Drain cap

Water reservoir

Replace the drain cap.4.

For best results, use the entire 16 oz. bottle of 5.

nickel-safe ice machine cleaner

. Follow all

safety precautions on the bottle. Pour one bottle

of solution into the water reservoir. Fill the bottle

twice with tap water and pour it into the water

reservoir.

Press and hold the CLEAN button for 3 sec. The 6.

CLEAN light will begin to blink, indicating that

the cleaning cycle is in process. The cleaning

time is approximately 70 min.

Stainless steel―Regularly clean and polish the

stainless steel door panels and handles (on some

models) with a commercially available stainless

steel cleaner such as Stainless Steel Magic™

to preserve and protect the fi ne fi nish. Stainless

Steel Magic is available through GE Parts and

Accessories, 800.626.2002, or monogram.com.

Order part number WX10X15. Do not use appliance

wax or polish on the stainless steel.

Icemaker System

Note: To remove stubborn buildup, pour a small

amount of cleaning solution on a non-scratching,

blue Scotch-Brite™ pad. Using only front-to-back

motions, clean the top of the plate, the sidewalls,

and the front edge of the evaporator. The frontto-back motion is important to avoid scratches

that could keep the ice slab from sliding off the

evaporator plate.

– 13 –

When the indicator light becomes solid and 7.

remains lit, the cleaning cycle is complete.

During the cleaning cycle, the system will both

clean and rinse itself.

After the cleaning cycle is complete, remove 8.

the drain cap from the water reservoir to see

if any cleaning solution, green in color, is left in

the water reservoir. If cleaning solution drains

from the water reservoir, you should run the

clean cycle again adding only tap water to

the reservoir. Be sure to replace the drain cap

before running the cycle again. If the cap is not

securely tightened, water can leak, causing thin

ice or no ice.

(Continued next page)

Page 14

Note: Severe scale buildup may require repeated

cleaning with a fresh quantity of cleaning solution.

Press the 9. ON button for 3 sec. to resume ice

production.

Cleaning the Condenser

For best performance, brush or vacuum lint and dirt

from the condenser at least once a year. A dirty or

clogged condenser:

Uses more energy.•

Reverse-Osmosis System

IMPORTANT: The performance of the icemaker may

be affected when connected to a reverse-osmosis

system. An RO system may also reduce water

pressure and affect the fi ll cycle, which is dependent

on time and fl ow. The reduced water pressure may

cause the reservoir not to fi ll and fl ush properly

during the ice-making cycle. The pressure of the

water supply coming out of a reverse-osmosis

system going to the measured fi ll water inlet valve

of the icemaker needs to be between 30 and 120 psi.

Prevents proper airfl ow.•

Reduces ice-making capacity.•

Causes higher-than-recommended operating •

temperatures, which may lead to component

failure.

Unplug the icemaker or disconnect power.1.

Remove the 2 screws in the lower access panel 2.

and the 2 screws from the base grille area of the

front panel support. Pull forward to remove the

lower access panel.

Pull the bottom forward and then pull down to 3.

remove the lower access panel.

If a reverse-osmosis water fi ltration system is

connected to your cold water supply, the water

pressure to the reverse-osmosis system needs

to be a minimum of 40 psi. The reverse-osmosis

system must provide 1 gal. of water per hour to the

icemaker for proper icemaker operation.

Note: Do not use copper tubing when the icemaker

is connected to a reverse-osmosis water system.

Remove dirt and lint from the condenser 4.

fi ns and the unit compartment with a brush

attachment attached to a vacuum cleaner.

Replace the lower access panel using the 4 5.

screws.

Plug in the icemaker or reconnect power.6.

– 14 –

Page 15

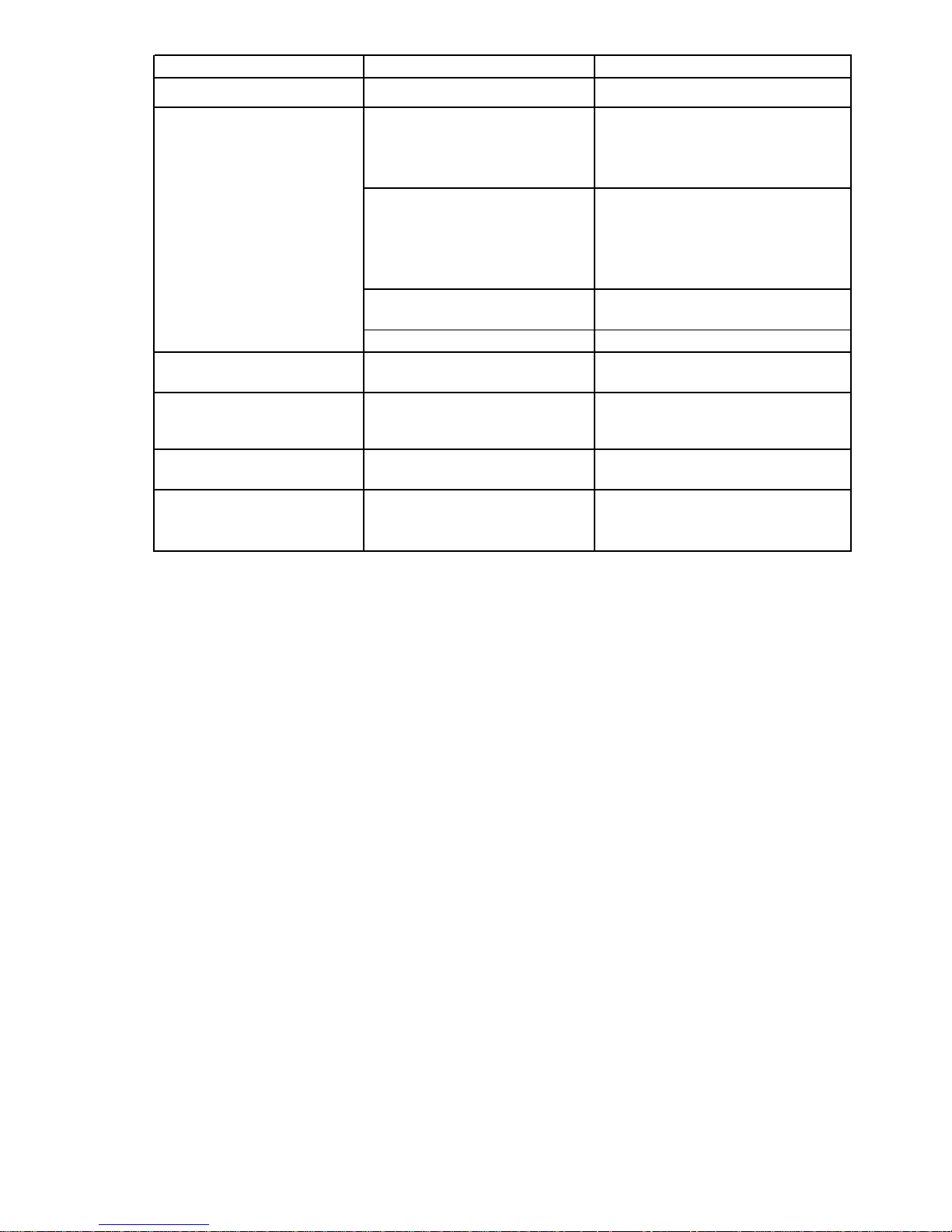

Problem Solving Chart

PROBLEM POSSIBLE CAUSE

CLEAN INDICATOR

LIGHT ON CONTROL

PANEL IS YELLOW

CLEAN INDICATOR

LIGHT ON CONTROL

PANEL IS RED

ICEMAKER DOES

NOT OPERATE

ICE CUBES

HAVE ODOR/TASTE

ICEMAKER IS ON,

BUT DOESN’T

PRODUCE ICE

ICEMAKER IS ON,

BUT PRODUCES

LITTLE OR NO ICE

ICEMAKER PUMPS

CONTINUOUSLY,

BUT PRODUCES

NO ICE

ICE IS THIN, SOFT

OR CLUMPED

ICEMAKER SOUNDS

• It will soon be time to clean the icemaker. You will need WX08X42870 Nickel Safe

Ice Machine Cleaner to clean the icemaker.

See Care and Cleaning–Care for your Icemaker.

• It is time to clean the icemaker. See Care and Cleaning–Icemaker System section.

• Power cord is not plugged into a live outlet.

• The control is set at OFF.

• The fuse is blown/circuit breaker is tripped. Replace fuse or reset the breaker.

• ZPK1 Auxiliary Kit fault.

• Drain line kinked or blocked.

• High mineral content in the water supply. Water may need to be filtered or treated.

• Food items stored in ice bin. Do not store any foods in the ice bin.

• Packaging materials were not removed. Make sure that all packaging materials

were removed at the time of installation.

• Ice storage bin needs cleaning.

• Scale has built up in the icemaker. If there is white scale buildup in the icemaker’s

water or freezing system, you should clean the icemaker.

See Care and Cleaning—Icemaker System.

• The control is set at OFF.

• Water supply is turned off or not connected.

• Condenser is dirty. Dirt or lint may be blocking the airflow through the condenser.

See Care and Cleaning—Condenser.

• Scale has built up in the icemaker. If there is white scale buildup in the icemaker’s

water or freezing system, you should clean the icemaker.

See Care and Cleaning—Icemaker System.

• Check for a kink in the drain hose from the ZPK1 Drain Pump Kit to the house drain.

• Water supply has been interrupted.

• Have a plumber check for a clogged water valve.

• Room temperature is colder than normal. Room temperature must be above

55˚F (13˚C). Otherwise, bin thermostat may sense cold room temperature

and shut off even though the bin is not full of ice. Also, unit may not restart once

it does shut off.

• Condenser is dirty. Dirt or lint may be blocking the airflow through the condenser.

See Care and Cleaning—Condenser.

• Scale has built up in the icemaker. If there is white scale buildup in the icemaker’s

water or freezing system, you should clean the icemaker.

See Care and Cleaning—Icemaker System.

• Water is leaking from the water reservoir because the drain cap is not secure.

Make sure the drain cap is securely tightened. Refer to illustration in

Care and Cleaning—Icemaker System section.

• Room temperature is too hot. Room temperatures of more than 90˚F (32˚C)

will reduce ice production.

•

The ice sheet is trapped on the cutter grid. Shut off the icemaker for at least one

hour to allow the ice sheet to melt. Turn the icemaker back on. The icemaker will

reset itself and start a new cycle after flushing water through the system. NOTE:

Follow the directions in the Care and Cleaning—Icemaker System section to clean

with the Nickel Safe Ice Machine Cleaner.

• High mineral content in the water supply. Water may need to be filtered or treated.

• Scale has built up in the icemaker. Clean your icemaker.

See Care and Cleaning—Icemaker System section.

• The ice bin is not refrigerated, so ice not regularly used will melt and form clumps.

Break the clumps with the ice scoop provided.

• After an ice-making cycle, you may hear ice cubes dropping into the storage bin.

• Water is circulated by a pump through the icemaker during the entire ice making

-

cycle. Water is added once per ice-making cycle.

• The compressor may cause a clicking or chirping sound when attempting

to restart.

• The flow of refrigerant through the refrigerating system may make a gurgling

sound like boiling water.

• A “whooshing” sound may indicate the water supply is not connected properly,

the water supply is turned off or the drain cap is loose.

– 15 –

(Continued next page)

Page 16

Evaporator*

Cutter Grid

Compressor

Dual Transformer

Component Locator

Electronic

Light Switch

Control Board

Push-button

Switch

Bin Thermistor

Water Level

Sensor

Water Recirculation

Pump

Reservoir

Drain Pump

Condenser Fan Motor

Hot Gas Valve & Solenoid

(Behind Condenser)

Measured F1 Water Valve

* The evaporator thermistor is located on

tubing below the evaporator.

Condenser

Condenser Accumulator Tube

– 16 –

(Continued next page)

Page 17

Water System Component Locations

Evaporator

Water Distributor

Water Return Tube

Water Valve Outlet Tube

Measured Fill

Water Inlet Valve

From Water Supply

Manual Drain

Drain Overfl ow

Water Level Sensor

Water Recirculation Pump

Reservoir Pan

Reservoir Drain Pan

Bin Drain

– 17 –

Page 18

Components

Door and Gasket

Note: If unit has a handle attached to the top of the

door it must be removed to access the hinge screw.

To remove the door, remove the large screw from

the top of the icemaker door, pull the door open, and

lift the door off the bottom hinge.

Bin Light Bulb

Remove two 1/4-in. hex-head screws from the

bottom of the cutter grid cover and pull the cover

from the ice machine.

Reach in and above the cutter grid to the depression

in the bottom of the control assembly. Grasp the

bulb and pull straight down.

Cutter Grid Cover

Note: Be sure to check the new gasket for a proper

seal after it is installed.

To remove the door gasket, open the icemaker door

and pull the gasket out of the door track.

The bulb is a #917 auto type (12V) and can be

purchased locally.

– 18 –

Page 19

Bin Thermistor

Cutter Grid

To remove the bin thermistor:

Remove two 1/4-in. hex-head screws from the

bottom of the cutter grid cover and pull the cover

from the ice machine.

Cutter Grid Cover

Disconnect the thermistor plug from the bottom of

the control panel.

Remove the hex-head screw and clamp securing

the thermistor to the side wall and remove

thermistor.

To remove the cutter grid:

Remove two 1/4-in. hex-head screws from the 1.

bottom of the cutter grid cover and pull the

cover from the ice machine.

Cutter Grid Cover

Disconnect the cutter grid and bin thermistor 2.

connectors from the bottom of the control

housing.

Remove the 2 hex-head screws from both sides 3.

of the cutter grid, (Note that the longer screw

and white spacer are on the right side.)

Thermistor Plug

The bin thermistor should read 12.49 KΩ at room

temperature.

°F °C Thermistor Resistance

0 -18 81,715 - 99,874 Ω

10 -12 59,422 - 72,627 Ω

32 0 30,266 - 36,992 Ω

50 10 18,219 - 22,267 Ω

70 21 10,280 - 12,564 Ω

90 32 6,387 - 7,807 Ω

Disconnect

Disconnect

Note: Take care not to scratch the icemaker liner.

Slide the cutter grid forward and out of the unit 4.

and place it on a protected work surface.

Remove the spacer from the right cutter grid 5.

bracket tab.

Spacer

– 19 –

(Continued next page)

Page 20

Unsnap the 2 ice guides, if necessary, from 6.

the cutter grid tabs. (There should be a slight

outward tilt after the guides are installed.)

Evaporator Thermistor

To remove the evaporator thermistor:

Remove the cutter grid. (See 1.

Cutter Grid.)

Disconnect the evaporator thermistor from the 2.

bottom of the control housing.

Ice Guide

Ice Guide

Remove the 2 hex-head screws from the water 3.

trough and pull the trough from the unit.

Disconnect

Bend the metal tabs outward, if necessary.7.

Reach behind the accumulator, and unclip the 4.

evaporator thermistor.

When installing, snap the thermistor onto the 5.

evaporator tubing behind the accumulator.

Water Distributor

Remove the cutter grid from the unit. See (1. Cutter

Grid.)

Pull out on the left and right water distributor 2.

retainers, and remove the tabs from the slots in

the evaporator.

Pull the distributor forward and remove the 3.

water hose.

Water Hose

– 20 –

Page 21

Electronic Control Housing Components

Note: The control housing components consist of:

Electronic control board•

Dual transformer•

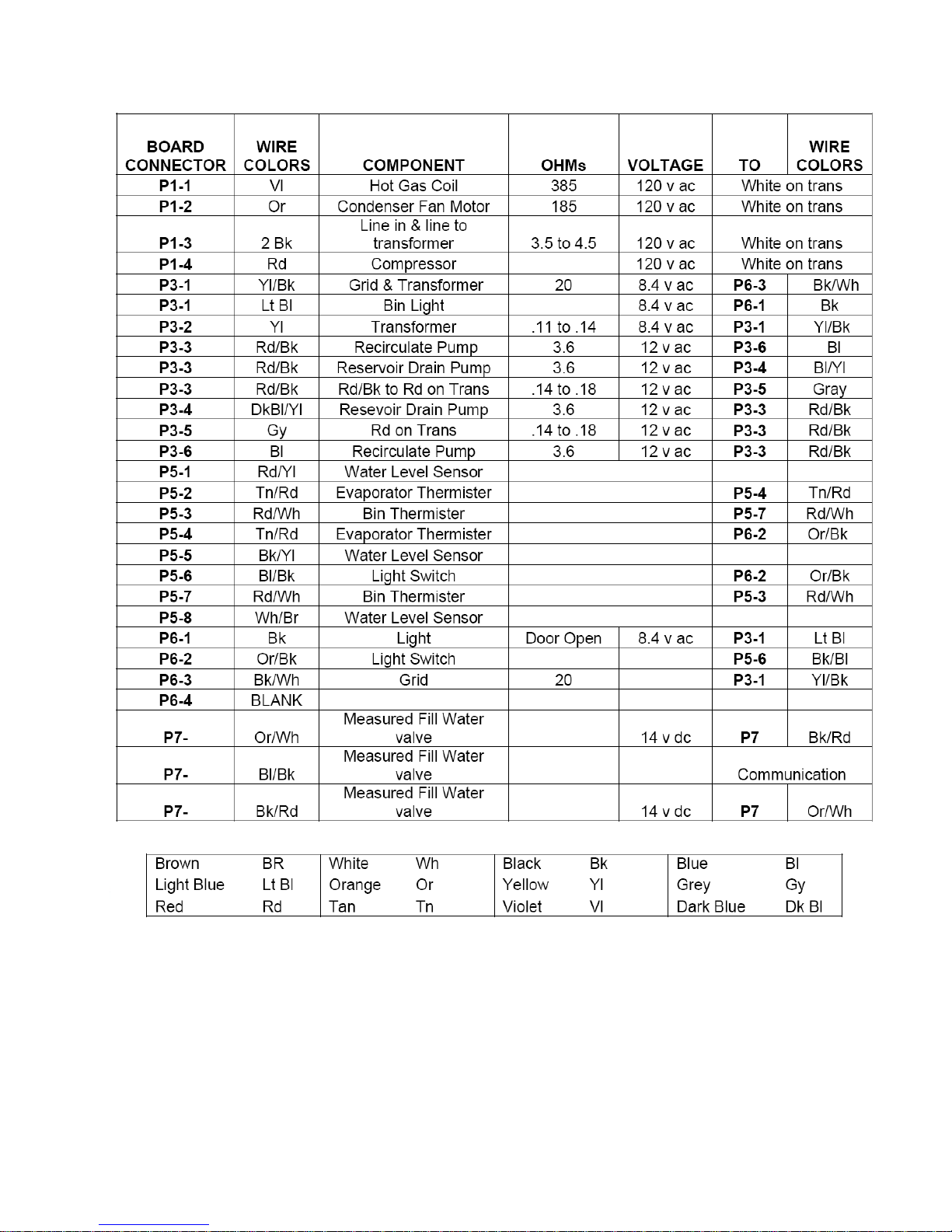

To Remove the Dual Transformer

Disconnect the 6-pin wire connector from the 1.

harness.

Remove the 2 mounting screws from the 2.

transformer bracket.

Light switch•

Push-button switch assembly•

Remove the cutter grid cover and the cutter 1.

grid. (See

Cutter Grid.)

Disconnect the 2 thermistor connectors. (See 2.

Thermistor and Evaporator Thermistor.)

Remove the 4 hex-head screws from the control 3.

housing and lower the housing to access the

components.

Disconnect the green ground wire from its 3.

terminal.

Bin

Transformer

2nd screw on opposite side

To Remove the Light Switch/Push-Button

Assembly

Note: If the switch assembly or light switch is

replaced, the replacement part and decorative

overlay must be ordered using the model number of

the icemaker. The service replacement switch is not

supplied with a decorative overlay

To Remove the Electronic Control Board

Disconnect the 6 harness connectors from the 1.

board terminals.

Remove the 2 mounting screws and remove the 2.

electronic control board.

Peel off the decorative overlay from the front of 1.

the control housing.

– 21 –

(Continued next page)

Page 22

Disconnect the Molex plug from switch 2.

assembly.

Press the back of switch assembly and push the 3.

switch assembly out of the housing.

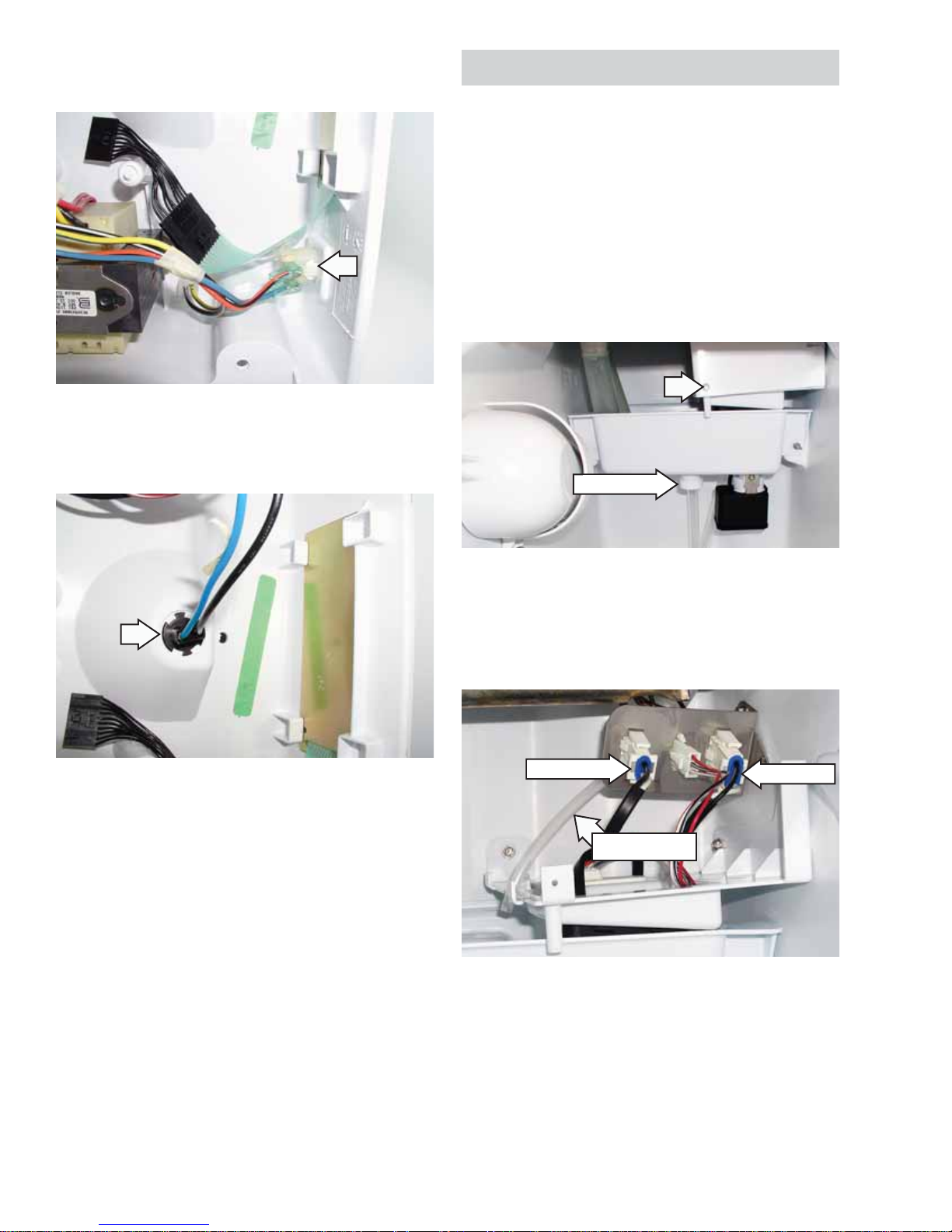

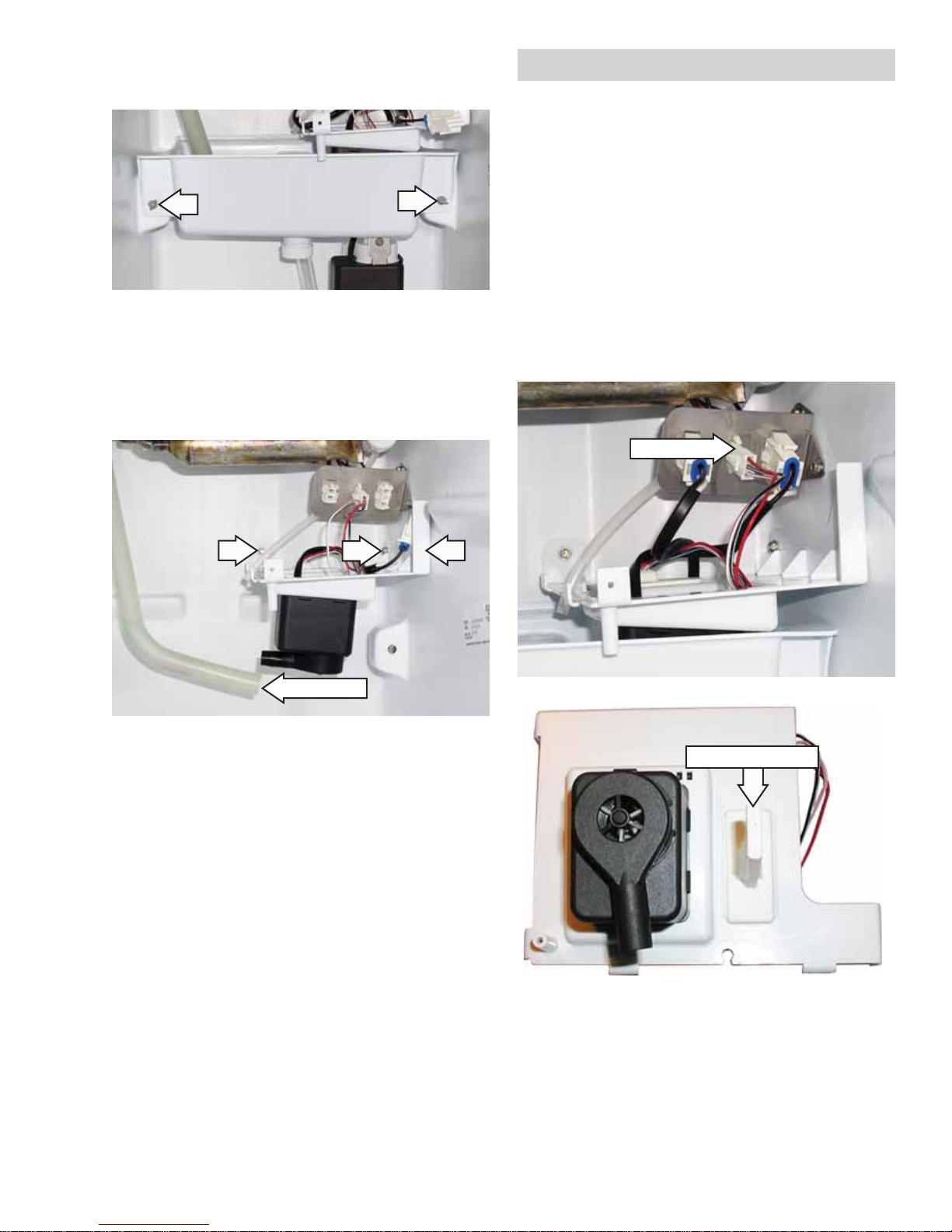

Water Recirculation Pump

Remove the ice from the storage bin prior to

removing the recirculation pump.

Note: Pump operates on 12 VAC and has a

resistance of 3.8Ω.

To remove the water recirculation pump:

Unscrew the drain cap from the reservoir, drain 1.

the water, and replace the cap tightly.

Remove the hex-head screw from the water 2.

recirculation pump shield and remove the shield.

Drain Cap

Disconnect the water fi ll tube from the pump 3.

mounting bracket.

Disconnect the wire recirculation and drain 4.

pump connectors from the harness block.

Disconnect

Water Fill Tube

Disconnect

– 22 –

(Continued next page)

Page 23

Remove the 2 thumbscrews from the reservoir 5.

and remove the reservoir from the icemaker.

Remove the recirculation pump outlet tube.6.

Remove 3 hex-head screws from the pump 7.

mounting bracket and remove the pump/water

level sensor assembly.

Water Level Sensor

Remove the ice from the storage bin prior to

removing the recirculation pump.

To remove the water level sensor:

Remove the hex-head screw from the water 1.

recirculation pump shield and remove the shield.

(See

Water Recirculation Pump.)

Disconnect the water level sensor electrical 2.

connection.

Remove the retaining clips, if present.3.

Pull the sensor up and out of the bracket.4.

Disconnect

Outlet Tube

Water Level Sensor

– 23 –

Page 24

Reservoir Drain Pump

Condenser Fan Motor

Remove the ice from the storage bin prior to

removing the recirculation pump.

Note: Pump operates on 12VAC and has a

resistance of 3.8Ω.

To remove the reservoir drain pump:

Unscrew the drain cap from the reservoir, drain 1.

the water, and replace the cap tightly.

Remove the recirculating pump cover hex-head 2.

screw.

Drain Cap

To remove the condenser fan motor:

Disconnect the water and drain lines from 1.

the icemaker and remove the unit from its

installation.

Remove the 4 hex-head screws from the front 2.

panel and remove the panel.

Disconnect the reservoir drain pump electrical 3.

connection.

Remove the pump-retaining Phillips-head screw 4.

and bracket.

Rotate the pump 1/4 turn and pull it down and 5.

out of the reservoir.

Disconnect

Remove the two 5/16-in. screws from the front 3.

of the cabinet.

Remove 2 hex-head screws from the measured 4.

fi ll water valve bracket.

Allow the valve to drop down out of the way.5.

Measured Fill Water Valve

– 24 –

(Continued next page)

Page 25

From the back of the unit, remove the 4 hex-6.

head screws from the unit compartment cover

and remove the cover.

Tilt the front of the cabinet back until you can 9.

access the 2 side screws on the condenser fan

motor shroud, and secure the cabinet so that it

cannot tip forward or backward.

Disconnect the wire connector from the 10.

condenser fan motor.

Remove the 4 screws (2 bottom and 2 side) 11.

from the condenser fan motor shroud. Slide the

shroud assembly back towards the compressor,

and then lift and remove the assembly from the

unit.

Disconnect

Remove the two 5/16” screws from the rear of 7.

the cabinet.

Note: If the unit you are servicing is not equipped

with an internal drain pump, skip the next step.

Disconnect the inlet tube and the vent tube from 8.

the internal drain pump.

Vent Tube

Inlet Tube

Remove condenser fan motor blade by pulling 12.

the fan blade straight off the shaft.

Note: Make sure when reinstalling the fan blade

that the blade is seated completely on the motor

shaft.

Remove the 2 hex-head screws from the 13.

condenser fan motor and remove the motor

from the shroud.

– 25 –

Page 26

Measured Fill Water Valve

Hot Gas Solenoid

To remove the measured fi ll water valve:

Turn the water supply off to the icemaker.1.

Remove the 4 hex-head screws from the front 2.

panel and remove the panel.

Remove the 2 hex-head screws from the 3.

measured fi ll water valve bracket.

To remove the hot gas solenoid:

Tip the cabinet back and securely prop it up to 1.

access the hot gas valve solenoid.

Disconnect the 2-wire connector from the 2.

solenoid terminals.

Measured Fill Water Valve

Note: Place a pan or towel under the valve to catch

the water.

Disconnect the water inlet and outlets tubing 3.

from the quick-disconnect fi ttings on the

measured fi ll water valve.

Disconnect the 2 electrical connectors from the 4.

valve.

Outlet Tube

Inlet Tube

Disconnect

Remove the 7-mm hex-head screw from the 3.

solenoid and lift the solenoid off the hot gas

valve.

Disconnect

– 26 –

Page 27

Sealed System

Hot Gas Valve

To remove the hot gas valve:

Remove the solenoid from the hot gas valve. 1.

(See

Hot Gas Solenoid.)

Access the sealed system and discharge the 2.

refrigerant into an approved recovery system.

Unbraze the hot gas valve from the tubing.3.

Caution: When installing the new hot gas valve,

use a generous amount of thermal heat trap paste

between the valve and tubing joints to protect the

valve when brazing.

Evaporator

Capillary Tube

Accumulator

Compressor

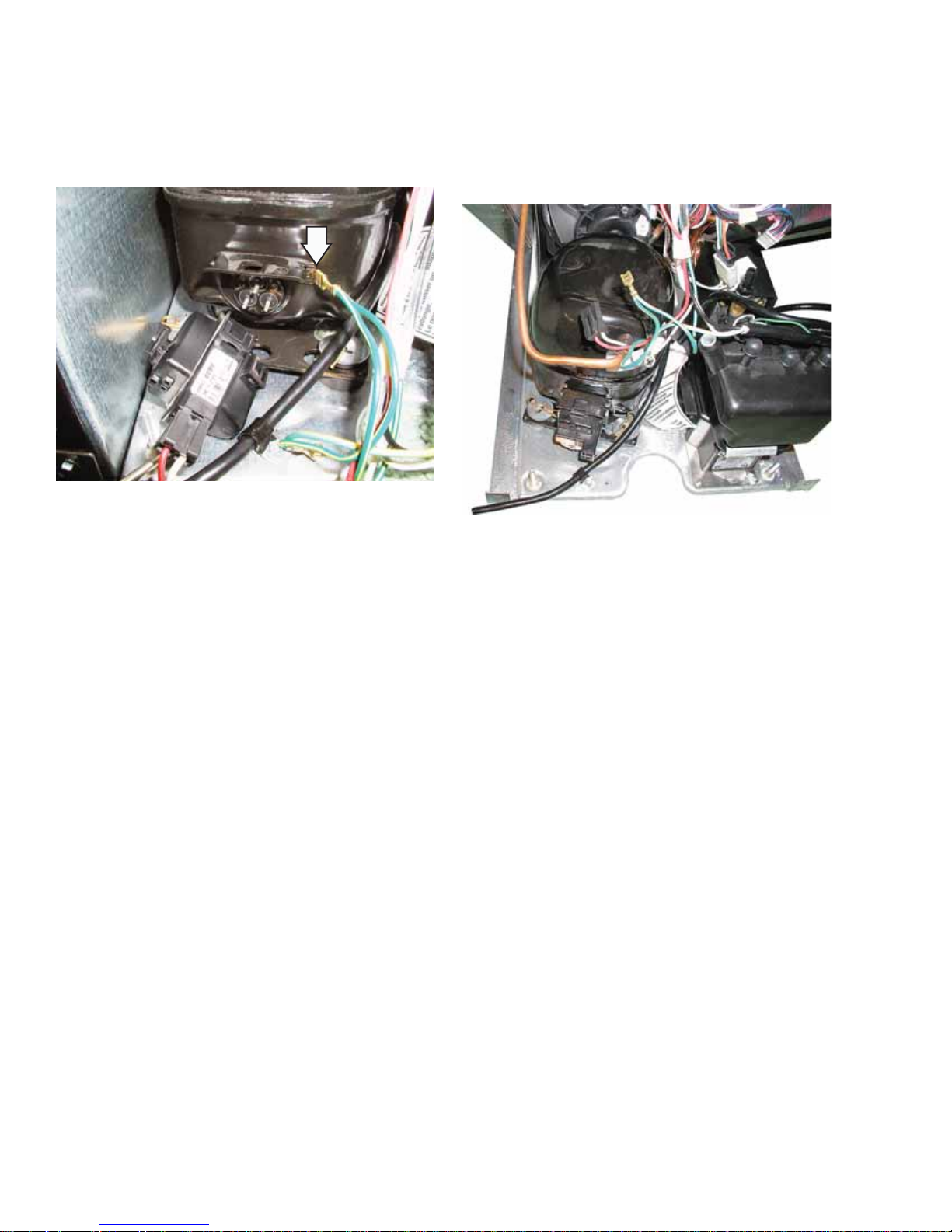

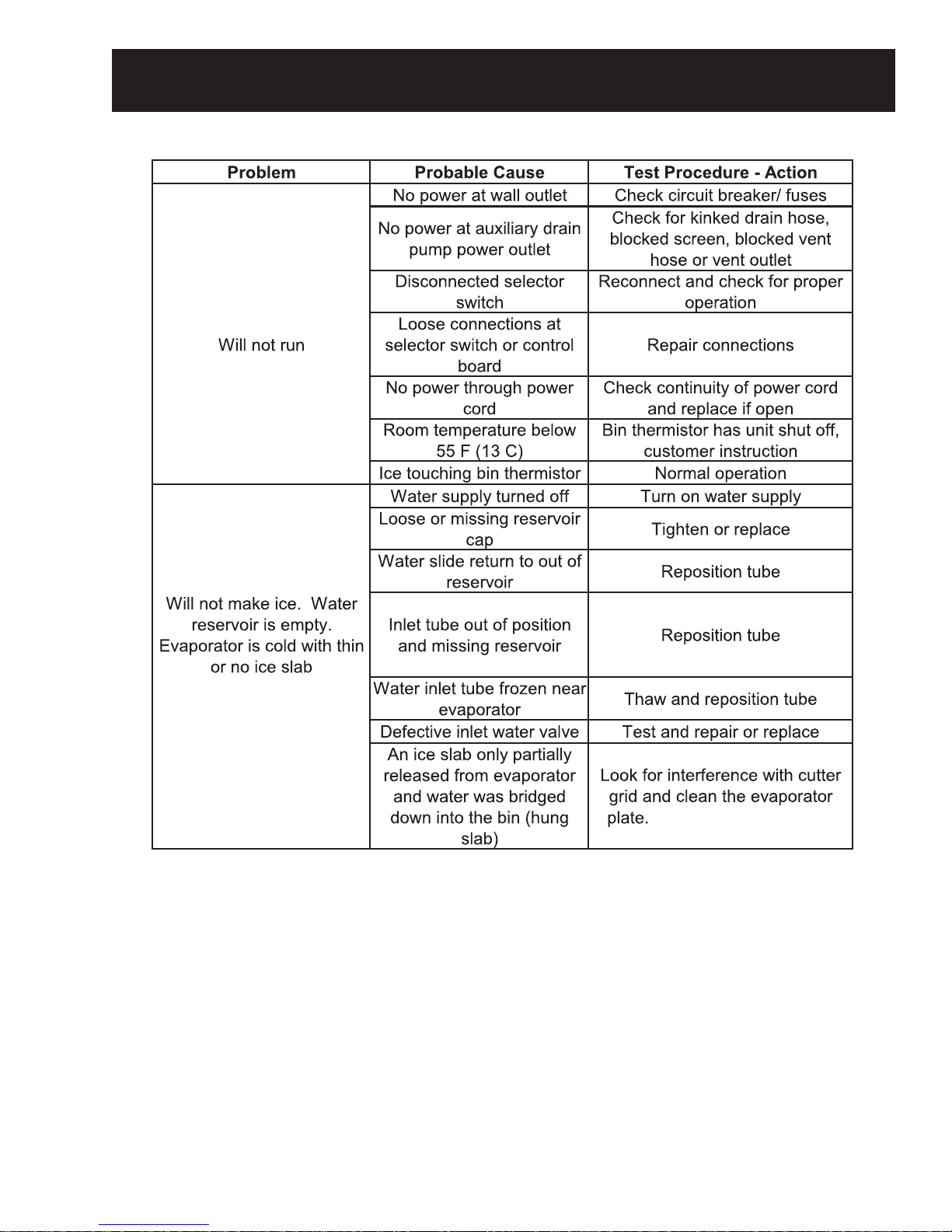

To remove the compressor:

Unplug icemaker or disconnect power.1.

Open the icemaker door.2.

Remove the ice from the storage bin.3.

Disconnect the water and drain lines from 4.

the icemaker and remove the unit from its

installation.

At the front and rear of the unit, remove 5.

the 4 hex-head screws from the unit outer

compartment cover and remove the cover.

Heat Exchanger

Suction

Tube

Drier

Hot Gas

Path of warm liquid

refrigerant pushed by high-

pressure refrigerant gas

Compressor

Valve

Condenser

Accumulating

Tube

Condenser

High-Pressure

Refrigerant Gas

Warm Liquid

Refrigerant

Low-Pressure

Refrigerant Gas

To remove the terminal cover, use a fl at blade 6.

screwdriver. Insert the screwdriver under the clip

to unsnap and remove it.

– 27 –

(Continued next page)

Page 28

Remove the wires from the ground terminal, 7.

the overload protector terminal, and the relay

terminal.

Pull the overload protector and relay from the 8.

compressor pins.

Pull the clips off the compressor mounting studs.15.

Lift the compressor off the 4 mounting studs 16.

and remove it from the unit.

Remove the 4 metal spacers and rubber 17.

isolators from the compressor stud locations.

Pull the 2 clips off the rear studs of the 9.

compressor.

Tip the front of the cabinet back and prop it up.10.

Access the sealed system and discharge the 11.

refrigerant into an approved recovery system.

Cut the suction and discharge lines from the 12.

compressor.

Caution: Do not use a torch to remove the drier

fi lter.

Cut the drier fi lter from the system. 13.

Unbraze the compressor suction and discharge 14.

joints from the tubing.

– 28 –

Page 29

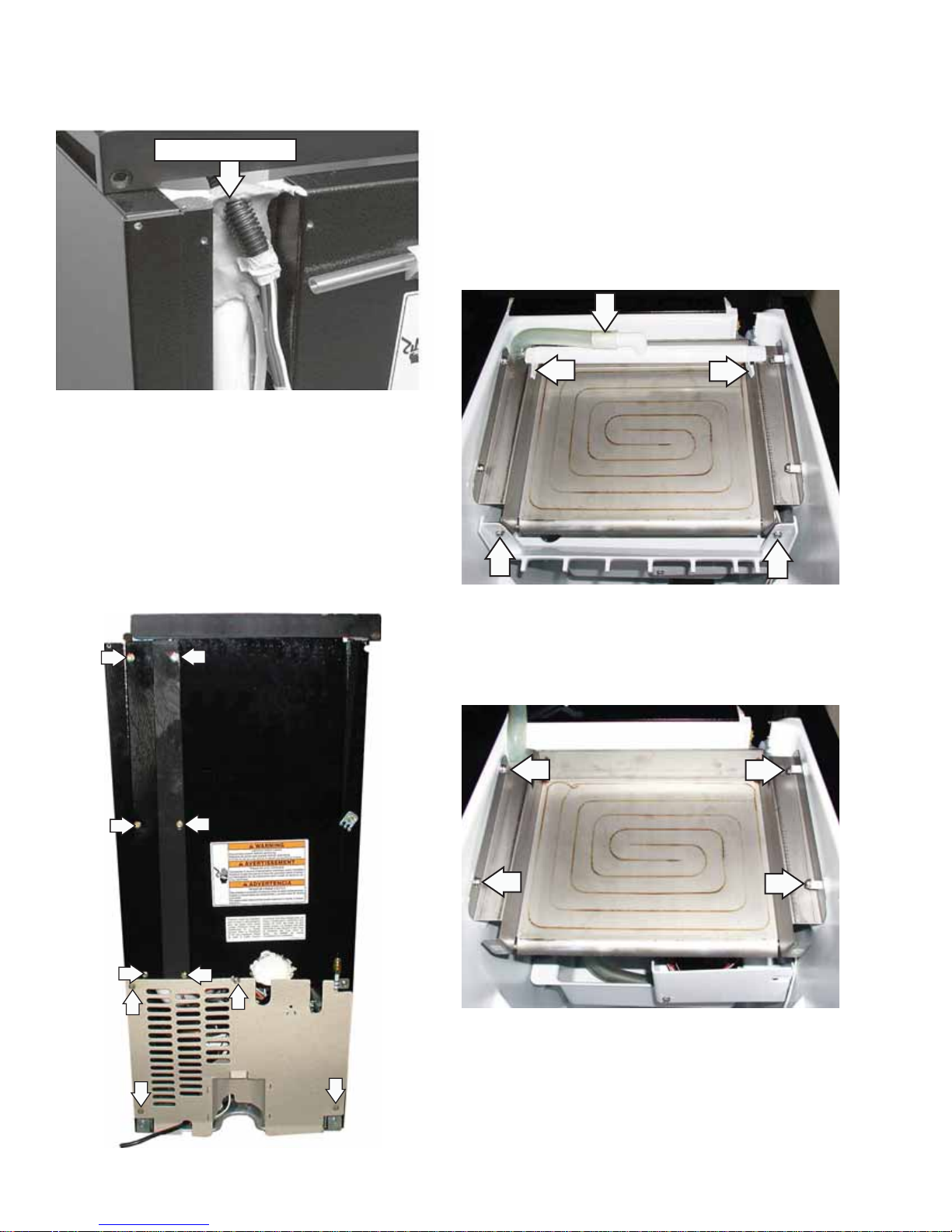

Condenser

Evaporator

To remove the condenser:

Unplug ice maker or disconnect power.1.

Tip the front of the cabinet back and prop it up.2.

Remove the 4 condenser fan motor screws from 3.

the fan motor shroud. Pull the motor assembly

back away from the condenser as far as

possible, but do not remove it.

Remove the 2 mounting screws from the 4.

condenser bracket fl anges.

To remove the condenser:

Unplug the ice maker or disconnect the power.1.

Note: If unit has handle attached to top of door it

must be removed to access hinge screw.

Remove the top door screw from the icemaker 2.

door, and pull the door off the bottom hinge.

Remove the ice from the storage bin.3.

Remove the cutter grid and the evaporator 4.

thermistor from the unit. (See

Cutter Grid and

Evaporator Thermistor.)

Disconnect the bin thermistor connector from 5.

the bottom of the control housing.

Remove the two 5/16-in. hex-head screws from 6.

the top hinge and remove the hinge.

Access the sealed system and discharge the 5.

refrigerant into an approved recovery system.

Unbraze the 2 condenser joints from the tubing.6.

Remove the 2 front and 2 rear screws from the 7.

cabinet top.

– 29 –

(Continued next page)

Page 30

Lift the cabinet top and position it forward on 8.

top of the unit, and then remove the permagum

from around the electrical throughput.

Remove Permagum

Note: In the photo above, the rear channel cover has

been removed for clarity.

From the rear of the unit, remove the 6 hex-9.

head screws from the channel cover and

remove the cover.

Lift the cabinet top off the unit and stand it on 11.

the fl oor near the rear of the unit.

Remove the hex-head screw from the water 12.

recirculation pump shield and remove the shield.

Pull out on the left and right water distributor 13.

retainers and remove the tabs from the slots in

the evaporator.

Disconnect the hose from the water distributor 14.

and remove the water distributor.

Remove the 4 hex-head screws from the unit 10.

compartment cover and remove that cover.

Remove the 4 Phillips-head screws from the 14.

evaporator, and then carefully lift the evaporator

just high enough to remove the 2 right spacers.

– 30 –

(Continued next page)

Page 31

Lift the evaporator and its connecting tubing 15.

high enough from the unit to access the tubing

underneath.

Access the sealed system and discharge the 16.

refrigerant into an approved recovery system.

Unbraze (or cut) the evaporator from the tubing 17.

at the following locations:

Suction line at the compressor•

Hot Gas

Joint Valve

Hot gas line at the hot gas valve•

Cut the capillary tube at the drier fi lter•

Suction Line

Drier Filter Capillary Tube

– 31 –

Page 32

Component Testing

Before testing any of the components, perform the

following checks:

Control failure can be the result of corrosion •

on connectors. Therefore, disconnecting and

reconnecting wires will be necessary throughout

test procedures.

All tests/checks should be made with a VOM or •

DVM having a sensitivity of 20,000 Ω per volt DC,

or greater.

Check all connections before replacing •

components. Look for broken or loose wires,

failed terminals, or wires not pressed into

connectors far enough.

Resistance checks must be made with power •

cord unplugged from outlet, and with wiring

harness or connectors disconnected.

Bin and Evaporator Thermistors

Note: For the most accurate measurement,

immerse the thermistor in ice water for 5 minutes

and then use the 32°F/0°C reading in the chart

below.

Water Recirculation Pump and

Reservoir Drain Pump

Leads are 3.6 Ω at 12 VAC.

Condenser Fan Motor

Run the service mode. Check for the proper operation

of the condenser fan motor, 185 Ω at 120 VAC.

Water Level Sensor

Run the service mode. Check for the proper

operation of the water level sensor. The Service LED

should stay on solid when the water level sensor is

immersed in water. When the water level sensor is

out of the water, the Service LED should blink.

Hot Gas Valve Solenoid

Leads are 365 Ω to 390 Ω at 120 VAC.

Measured Fill Water Valve

Run the service mode. The connector with black and

white wires should read 120 VAC. The orange/white

wire to the black/red wire should read 14 VDC.

Compressor, Overload Protector, and Relay

°F °C Thermistor Resistance

0 -18 81,715 - 99,874 Ω

10 -12 59,422 - 72,627 Ω

32 0 30,266 - 36,992 Ω

50 10 18,219 - 22,267 Ω

70 21 10,280 - 12,564 Ω

90 32 6,387 - 7,807 Ω

Cutter Grid

Leads are 4 Ω to 5 Ω at 8.4 VAC

Dual Transformer

Primary black and white leads are 3.5 • Ω to 4.5 Ω

at 120 VAC.

Secondary yellow and yellow leads are 0.11 • Ω

to 0.14 Ω at 8.4 VAC.

Secondary red and red leads are 0.14 • Ω to 0.18

Ω at 12 VAC.

To test the compressor windings:

Common (C) pin to the Start (S) pin should read •

8 to 11 Ω.

Common (C) pin to the Run (M) pin should read 2 •

to 3 Ω.

To test the relay:

Position the relay with the coil facing down.1.

Insert the tip on one of the ohmmeter test leads 2.

into the Run (M) pin socket, and touch the other

ohmmeter lead to the spade terminal. The meter

should indicate a closed circuit (0 Ω).

Move the tip of the ohmmeter test lead from 3.

the spade terminal into the Start (S) pin socket.

Leave the other ohmmeter lead at the Run (M)

location. The meter should indicate an open

circuit (infi nite).

Turn the relay over so that the coil faces up.4.

With the tip of the ohmmeter test leads at the 5.

Start (S) and Run (M) pin sockets, the meter

should indicate a closed circuit (0 Ω).

– 32 –

(Continued next page)

Page 33

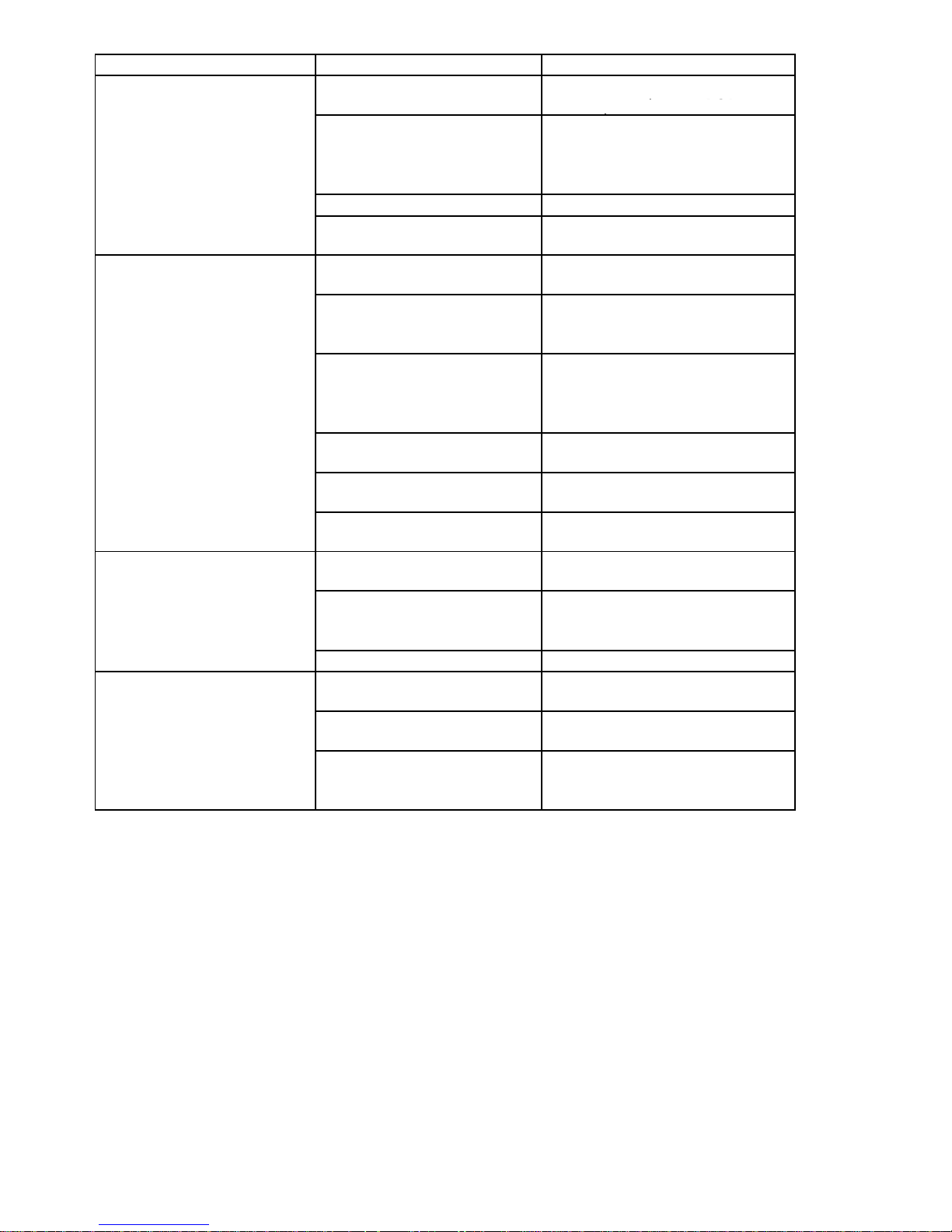

Board Connectors

See Page 40

See Page 32

See Page 32

See Page 32

See Page 40

See Page 32

See Page 40

– 33 –

(Continued next page)

Page 34

Component Connectors

See Page 32

See Page 32

See Page 40

See Page 40

See Page 40

– 34 –

Page 35

Control Board Diagnostics

Flush Mode: (Start-up Cycle) (6 minutes maximum)

The Flush Mode begins:

Every time the user plugs the icemaker in.•

The interface is changed from • OFF to ON.

When the icemaker is turned on after the •

completion of the CLEAN cycle, or

On auxiliary drain pump models only, power •

cycled off due to water touching the overfi ll

contact. This is often due to slow or blocked

drain, or a blocked vent hose.

When the power is applied or the icemaker is turned

ON at the user interface:

Water valve fi lls 45 oz. Maximum fi ll time is 2 •

minutes.

Recirculation pump runs for 1 minute.•

Reservoir drain pump is on for 20 sec., off for 20 •

sec., then on for 20 sec.

Water valve fi lls to the selected volume. •

Maximum fi ll time is 2 minutes.

Enter freeze mode•

Freeze Mode: (Ice-Making)

Note: If the water level drops below the sensor

before 5 minutes, the control counts a Hung Slab.

If the water level sensor is not detected, the control

sets a 25-minute freeze time.

Time in this mode is dependent on the water

level in the reservoir. There is no minimum time.

The maximum time is 25 minutes. Compressor,

condenser fan, and recirculation pump are all

energized.

Water continues to recirculate until the water level

in the reservoir drops below a level determined by

the water level sensor. At this point, the control

terminates the freeze mode and initiates the

Harvest Mode.

Harvest Mode

The time in this mode will be 2 to 17 minutes,

dependent on the condition of the evaporator

thermistor.

The compressor and hot gas valve is on for a

minimum of 1 minute.

Note: There is a 4-min. fi xed cycle time if the

evaporator thermistor is disconnected or open.

Harvest Mode: Bin Not Full

When the bin thermistor reads greater than 36°F:

Reservoir drain pump is on for 20 sec., off 20 •

sec., then back on for 20 sec.

Measured water fi ll is requested. Compressor •

and hot gas valve are on until: evaporator

thermistor reads greater than 52°F and more

than 1 minute, but less than 16 minutes have

passed; or after 4 minutes if the evaporator

thermistor is unplugged or open.

Harvest Mode: Bin Full

The time in this mode with the bin full will be a

minimum of 5 minutes. The mode continues as long

as the bin is full and the bin thermistor remains less

than 36°F.

Compressor and hot gas valve are on until the

evaporator thermistor is greater than 52°F and more

than 1 minute but less 16 minutes have passed;

or after 4 minutes if the evaporator thermistor is

unplugged or open.

Idle Mode:

Time in this mode is dependent on the temperature

at the bin thermistor.

Bin Not Full (Bin Thermistor Greater than 36°F)

The control sends a reservoir fi ll request and Freeze

Mode begins.

– 35 –

(Continued next page)

Page 36

Harvest Failure Mode:

If while in Harvest Mode, the evaporator thermistor

is less than 52°F and more than 16 minutes have

passed, Harvest Failure Mode will occur and the OFF

LED will fl ash 3 blinks. This mode will continue until

the failure is corrected.

OFF1. LED is fl ashing 3 blinks: Look for an

evaporator thermistor that has not reached

52°F. This may be due to an evaporator

thermistor being unplugged or open, a loose

or improperly positioned thermistor, a hot gas

failure, a sealed-system leak, or a restriction.

OFF2. LED is fl ashing 2 blinks: Look for a

disconnected or open bin thermistor.

Note: The bin thermistor is constantly checked

during the Flush Mode, the end of each Freeze

Mode, Harvest Modes, and Idle Mode.

Clean Mode:

Note: The customer instructions for clean cycle is on

the inside of door.

The Clean Mode may only be selected while the

icemaker is turned off (OFF pad held 3 sec.) at the

user interface.

Clean Mode is a 70-minute cycle:

When Clean Mode begins, The • CLEAN light

fl ashes 1 sec. on, 1 sec. off.

The circulation pump, compressor, and hot gas •

valve are energized for 40 minutes.

The water valve is energized for 3 minutes, and •

then the recirculation pump for 3 minutes. This

is repeated 5 times for total of 30 minutes.

All components off, • CLEAN LED remains on with

reservoir full.

Note: At the end of the Clean Mode, the icemaker

will stay off. CLEAN LED will be on green and OFF

LED on red. The reservoir is to be drained by the

consumer prior to restarting the icemaker. The

consumer must press OFF for 3 sec. before selecting

ON.

– 36 –

Page 37

Troubleshooting

,

oo

.

.

– 37 –

(Continued next page)

Page 38

Problem Probable Cause Test Procedure - Action

Will not make ice. Water

reservoir is empty. Evaporator

is cold with 3/4 inch thick or

-

larger ice slab.

Will not make ice. Water

reservoir is full. Evaporator is

cold with thin, partial, irregular

or no ice slab.

Will not make ice. Water

reservoir is full. Evaporator is

warm.

Poor ice production.

Slab will not release during

harvest due to scale buildup

Defective or disconnected hot

gas valve

Clean evaporator plate; See

procedure on 4-21

Test and repair or replace

Defective hot gas valve Test and repair or replace

Room temperature over 100 F

o

(38 C)

Seeping water valve

condenser is hot

Partial refrigerant leak or

restriction (u-shaped slab)

Blocked condenser or stalled

fan motor

Tube not attached to outlet of

recirculating pump

Defective recirculating pump

Partially blocked water

distributor

Compressor is not running

Blocked condenser or stalled

fan motor

o

Customer instruction

Replace water valve

Check for leak/restriction and

repair or replace defective

component

Clean condenser, repair or replace

motor

Re-attach tube

Repair or replace the pump motor

assembly

Clean distributor and evaporator

Test compressor, relay and

overload

Clean condenser, repair or replace

motor

Unit is in the start-up mode Wait 5 minutes and re-check

Room temperature below 55 F

o

(13 C)

Seeping water valve

condenser is hot

Slow or defective drain or drain

pump causing water to back up

into the bin

o

Bin thermistor has unit shut off,

customer instruction

Replace water valve

Repair or replace drain or drain

pump

– 38 –

(Continued next page)

Page 39

Problem Probable Cause Test Procedure - Action

Too much ice in bin Defective bin thermistor Replace

The slab dropping off the plate

Banging sound

and ice dropping from the cutter

grid into an empty bin are normal

The reservoir is empty. Look for a

partially released slab,

Noisy Grinding, cavitating sound

interference with cutter grid, etc.,

and clean the evaporator plate.

See procedure on

Grinding, cavitating sound

If the reservoir is full, replace the

from recirculation pump

Noisy drain pump Repair or replace

Ice freezing together in the

bin

Normal

This is normal with low customer

sounds

4-21

pump

usage

Cloudy, poor tasting ice Poor water quality

Off LED flashing 2 blinks

-

Open or disconnected bin

thermistor or thermistor wiring

Defective, loose, or mis-

Off LED flashing 3 blinks

positioned evaporator

thermistor

See chart on

4-2 & 4-3

Test thermistor and wiring harness

or reconnect

Test thermistor and wiring harness

or reconnect

– 39 –

Page 40

Service Test Mode (Diagnostic Mode)

Note: Drain the reservoir before entering service

diagnostics, press the ON pad.

test mode.

Note: If no pad is pressed within 5 sec., the product

Turn the icemaker 1. ON.

goes into the automatic diagnostic mode used at

the assembly plant. Each component is cycled

Within 10 sec. of power on, press and hold the 2.

for 5 sec.

ON and the CLEAN pads. (Release both pads

when all user interface LEDs begin to fl ash.)

Within 5 sec. of all LEDs fl ashing, press and 3.

release the OFF pad.

Service Test Mode Chart

After pressing the OFF pad to enter manual

diagnostics, all LEDs will illuminate for 5 sec. The

controls will then automatically move to the Bin

This begins manual diagnostics. The OFF pad is used

Thermistor test. Use the OFF pad to advance.

to advance through each step. To exit the manual

ORDER COMPONENT ON LED OFF LED CLEAN LED

1

Off pad to

advance

2

Off pad to

advance

3

Off pad to

advance

3

Continued

sensor check

4

Off pad to

advance

5

Off pad to

advance

6

Off pad to

advance

7

Off pad to

advance

8

Off pad to

advance

9

Off pad to

advance

Entry Into Test

Mode

Bin Thermistor On Solid OK

Evaporator

Thermistor

Water Valve 4

Minute Timeout

Clean Button

Press Will

Advance to Step 6

Water Level

Sensor

Recirculation

Pump

Reservoir Drain

Pump

Compressor and

Condenser Fan

Compressor and

Hot Gas Valve

Twice Ice Off Off On Solid – No Delay

Ice Thickness Off 2 Blinks – Thin

On On On

Off Off

2 Blinks Open

4 Blinks Short

Off Off On Solid OK

2 Blinks – Open

4 Blinks – Short

Off Blinking Reservoir Empty On

Off

(confirms sensor operation)

On On On

On Off Off

On Solid

While Cooling

On Solid

While Heating

Blinking When Evap.

Thermistor Reaches 4.5 °F;

Full Frost Pattern Should be

On Solid While Heating

Blinking When Evap.

Thermistor Reaches 52° F

4 Blinks – Normal

Press Clean Button to

Cycle Between Settings

On

Visible

6 Blinks – Thick

On Solid While Heating

Blinking – 10 Min. Delay

Between Cycles

Press

Clean Button to

Cycle Between Settings

On

On

Off

– 40 –

(Continued next page)

Page 41

Thermistor Error Displays (OFF LED 2 or 3 Blinks

During Normal Operation)

When the OFF LED blinks 2 or 3 times, an error is

indicated. These errors will occur at any time during

normal operation if a thermistor fails.

2 Blinks ― OFF LED is blinking twice in repeating

intervals. This signifi es a bin thermistor failure.

Check that the bin thermistor is plugged in to •

the control box.

Check that the bin thermistor is not open or •

shorted. Replace the thermistor if it is open or

shorted.

3 Blinks ― OFF LED is blinking three times in

repeating intervals. This signifi es a harvest failure.

Check that the evaporator thermistor is •

connected to the sealed-system tubing.

If the thermistor is plugged in, ensure that it is •

fully connected to the control box. (The icemaker

will operate on a timed cycle if the evaporator

thermistor is unplugged.)

Check the resistance of the thermistor. If the •

thermistor checks good, look for a hot gas

failure, a sealed system leak, or a restriction.

Models with Internal Drain Pumps (ZPK1)

The power cord on the internal drain pump is

connected to a 120 VAC wall outlet. The icemaker

is then connected to the 120 VAC outlet on the

drain pump. If the drain pump fails, or if the drain

becomes blocked, power is shut off to the 120 VAC

outlet on the drain pump.

When the unit is fi rst plugged in, the drain pump will

run for 20 sec. The power can be disconnected and

reconnected to verify that the pump is operating

properly.

Water from the icemaker reservoir, or melting ice

from the bin, drains down the bin drain tube into the

pump inlet, and then into the drain pump chamber.

As the water level rises, it bridges the Full contacts,

and the pump starts to run.

The pump discharges the water through the outlet

and the check valve. When the Full connection is

removed, the pump runs for an additional 12 sec. to

empty the tank.

If the water level in the drain pump continues to

rise, due to a slow or blocked drain or a blocked

vent hose, and touches the Overfi ll contact, power

will be turned off to the drain pump 120 VAC outlet,

causing the icemaker to turn off.

Pump Inlet

Overfi ll Contacts

Internal Drain Pump

Contacts sense continually

through the water

Full Contacts

Screen Washer

Vent Outlet

Pump Outlet &

Check Valve

White

Black

Green

Connector Hose (Contains

Screen Washer)

– 41 –

Page 42

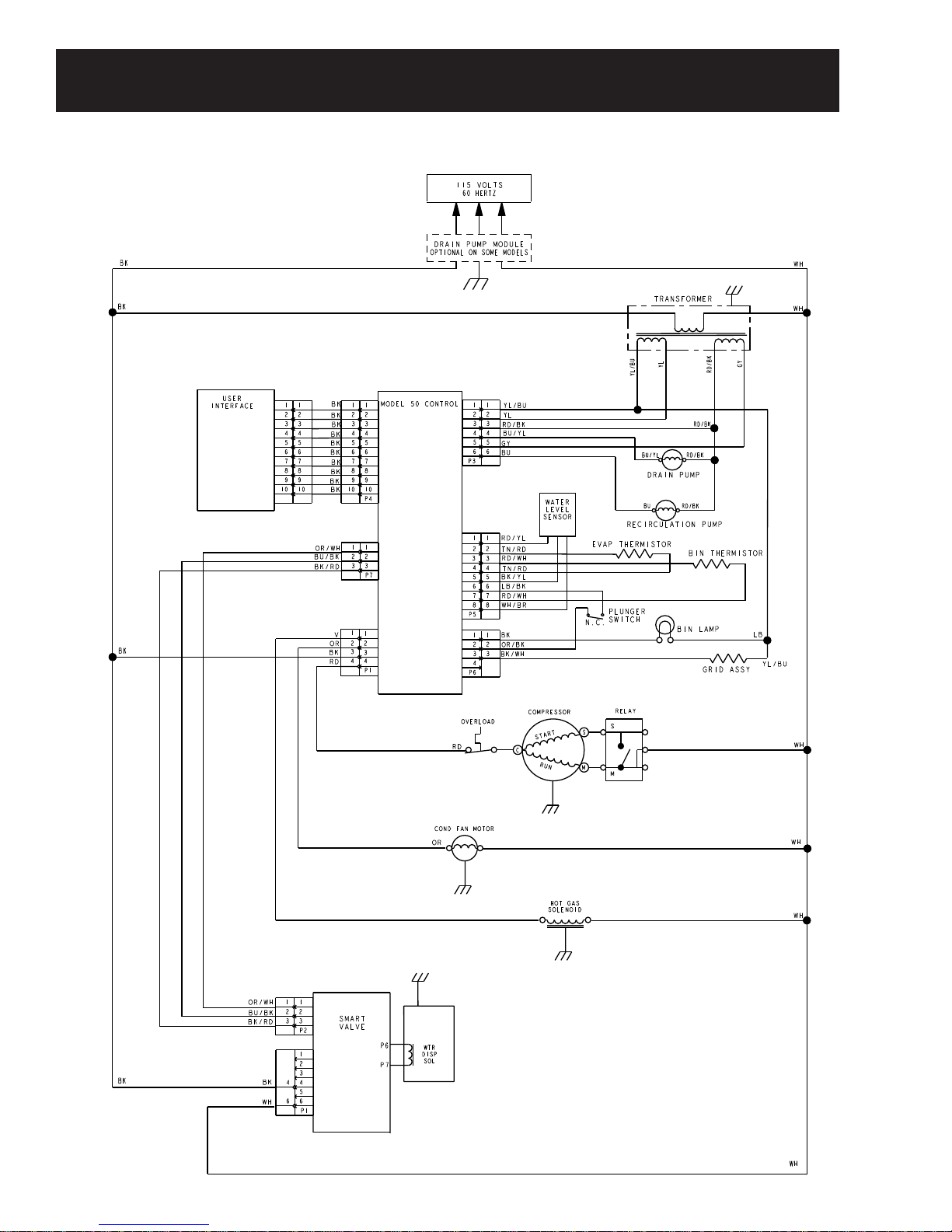

Schematics and Strip Circuits

Refer to the mini-manual attached to the unit.

– 42 –

(Continued next page)

Page 43

Clean Mode Strip Circuit

Bk

Electronic Control

Rd

Water Recirculation Pump

Rd/BkBu

Timing

Time = 20 Min

Wh

Transformer

Flush Mode Strip Circuit

Transformer

Bk

Wh

Bk

Bk

BK

Rd

Vi

Rd

Electronic Smart Valve

Electronic

Control

GY

Electronic Smart Valve

Bu

Bu/Yl

Hot Gas Solenoid

Overload

Water Valve

Water Recirculation Pump

Water Valve

Compressor

Reserve Drain Pump

Relay

Rd/Bk

Rd/Bk

Wh

Wh

Timing

Fill Reservoir

or

Wh

Time = 2 Min

Time = 1 Min

Time = 30 Sec

Fill Reservoir

Volume to Matching

Wh

Thickness Setting

Ice Making Mode Strip Circuit

Transformer

Bk

Wh

Harvest Mode Strip Circuit

Transformer

Bk

Wh

Rd

Bk

Bk

Electronic

Control

Rd

Bk

Bu/Yl

Vi

Rd

Electronic Smart Valve

Electronic

Control

GY

Reserve Drain Pump

Overload

Water Valve

Bu

Water Recirculation Pump

Or

Hot Gas Solinoid

Compressor

Condenser Fan

Relay

Rd/Bk

Wh

Wh

Wh

Timing

Time = 30 Sec

Fill Reservoir

Volume to Matching

Thickness Setting

Rd/Bk

Wh

Rd

– 43 –

Overload

Compressor

Wh

Relay

Page 44

Warranty

What Is Covered:

From the Date of the Original Purchase

Limited One-Year Warranty:

For one year from date of original purchase, we will provide, free of charge, parts and service labor in

your home to repair or replace any part of the icemaker that fails because of a manufacturing defect.

Limited Five-Year Warranty:

For fi ve years from date of original purchase, we will provide, free of charge, parts and service labor in

your home to repair or replace any part of the sealed icemaking system (the compressor, condenser,

evaporator and all connecting tubing) that fails because of a manufacturing defect.

This warranty is extended to the original purchaser and any succeeding owner for products purchased

for ordinary home use in the 48 mainland states, Hawaii, Washington, D.C. or Canada. If the product is

located in an area where service by a GE Authorized Servicer is not available, you may be responsible for

a trip charge or you may be required to bring the product to an Authorized GE Service location for service.

In Alaska the warranty is the same except that it is LIMITED because you must pay to ship the product to

the service shop or for the service technician’s travel costs to your home.

icemaker

icemaker.

– 44 –

Loading...

Loading...