Page 1

ÄKTA

™

Monitor UV-900

User Manual

GE Healthcare

Page 2

Page 3

Important user information

All users must read this entire manual to fully under-

stand the safe use of Monitor UV-900.

WARNING !

The WARNING! sign hig hlights instructions

that must be followed to avoid personal

injury. It is important not to proceed until

all stated conditions are met and clearly

understood.

CAUTION!

The Caution! sign highlights instructions that must be

followed to avoid damage to the product or other equip-

ment. It is important not to proceed until all sta ted con-

ditions are met and clearly understood.

Note

The Note sign is used to indicate information important

for trouble-free and optimal use of the product.

CE Certifying

This product meets the requir e ment s of app licable CE-

directives. A copy of the corresponding Declaration of

Conformity is available on request.

The CE symbol and corre spon ding dec lara tion of con for-

mity, is valid for the instrument when it is:

– used as a stand-alone unit, or

– connected to other CE-marked GE Healthcare

instruments, or

– connected to other products recommended or

described in this manual, and

– used in the same state as it was delivered from GE

Healthcare except for alterations described in this

manual.

Recycling

This symbol indicates that the waste of

electrical and electronic equipment must

not be disposed as unsorted municipal

waste and must be collected separately.

Please contact an au thorized r epr ese nta-

tive of the manufacturer for information

concerning the decommissioning of equip-

ment.

WARNING!

This is a Class A pruduct. In a domestic environment this

product may cause radio interference in whi ch ca se the

user may be required to make adequate measures

Monitor UV-900 User Manual 18-1120-05 Edition AF

Page 4

Page 5

Monitor UV-900 User Manual 18-1120-05 Edition AF

V

Contents

1 Introduction

1.1 General ................................................................................................7

1.2 Safety ...................................................................................................8

2 Installation

2.1 Unpacking ..........................................................................................9

2.2 General precautions .....................................................................9

2.3 Installing the flow cell ................................................................10

2.3.1 Fixing the flow cell.................................................................... 10

2.3.2 Connecting the optical fibers...............................................11

2.4 Connecting electrical signal cables .................................... 12

2.4.1 Connecting to recorder (if used)..........................................12

2.5 Connecting to communication link .....................................12

2.6 Connecting to supply voltage ...............................................13

2.7 Connecting the tubing .............................................................. 13

2.8 Mounting the cell holder cover .............................................14

3Operation

3.1 On/off ................................................................................................15

3.2 Menu selection and settings ..................................................15

3.2.1 Menu selection ...........................................................................15

3.2.2 Return to main menu .............................................................. 16

3.2.3 Select value..................................................................................16

3.3 Main menu overview .................................................................17

3.4 Setting lamp on/off .....................................................................17

3.5 Reading absorbance values ...................................................18

3.6 Setting wavelength .....................................................................18

3.7 Autozero .......................................................................................... 19

3.8 Storage and shut-down ...........................................................19

3.9 Using an external chart recorder ........................................20

3.9.1 Setting range and zero...........................................................20

3.9.2 Event mark...................................................................................20

3.10 Filtering noise ................................................................................21

3.11 UV cell calibration .......................................................................22

3.12 Changing flow cell .......................................................................24

3.13 Restart after power failure ...................................................... 24

4 Maintenance

4.1 Periodic maintenance ...............................................................25

Page 6

Contents

VI

Monitor UV-900 User Manual 18-1120-05 Edition AF

4.2 Cleaning-in-place .........................................................................25

4.3 Checking the instrument ..........................................................26

4.3.1 Lamp intensity ............................................................................26

4.3.2 Lamp on–time .............................................................................26

4.3.3 Flip time..........................................................................................26

4.3.4 UV flow cell ...................................................................................26

4.4 Cleaning the flow cell and optical fiber connectors ....27

4.4.1 Cleaning the flow cell...............................................................27

4.4.2 Cleaning the optical fiber connectors...............................27

4.4.3 Instrument housing...................................................................27

4.5 ..................................................................Cleaning the system 27

4.6 Recycling ..........................................................................................28

5 Trouble-shooting

5.1 General .............................................................................................29

5.2 Faults and actions .......................................................................29

5.3 Error messages .............................................................................30

Reference information

A Description ........................................................................................................31

A.1

Instrument

............................................................................................................31

A.2

Flow cell

.................................................................................................................32

A.3

Monitor principle

................................................................................................32

B Menus .................................................................................................................. 34

B.1

Check menu

.......................... ..... ..... ..... ..... ..... ..... ..... ..... ..... .... ..... ..... ..... ..... ..... .....34

B.2

Setup menu

..........................................................................................................36

B.3

Setting and using the alarm timer

.............................................................37

B.4

Service displays

..................................................................................................37

B.5

Menu overview

...................................................................................................38

C Technical specifications .............................................................................39

D Accessories and spare parts ....................................................................42

Short instructions on side 39

About this manual

This manual comprises two parts; a practical part

(sections 1–5) and a reference part (sections A-D).

Sections 1–5 contain the necessary information for operating the

instrument.

Page 7

Introduction 1

Monitor UV-900 User Manual 18-1120-05 Edition AF

7

1 Introduction

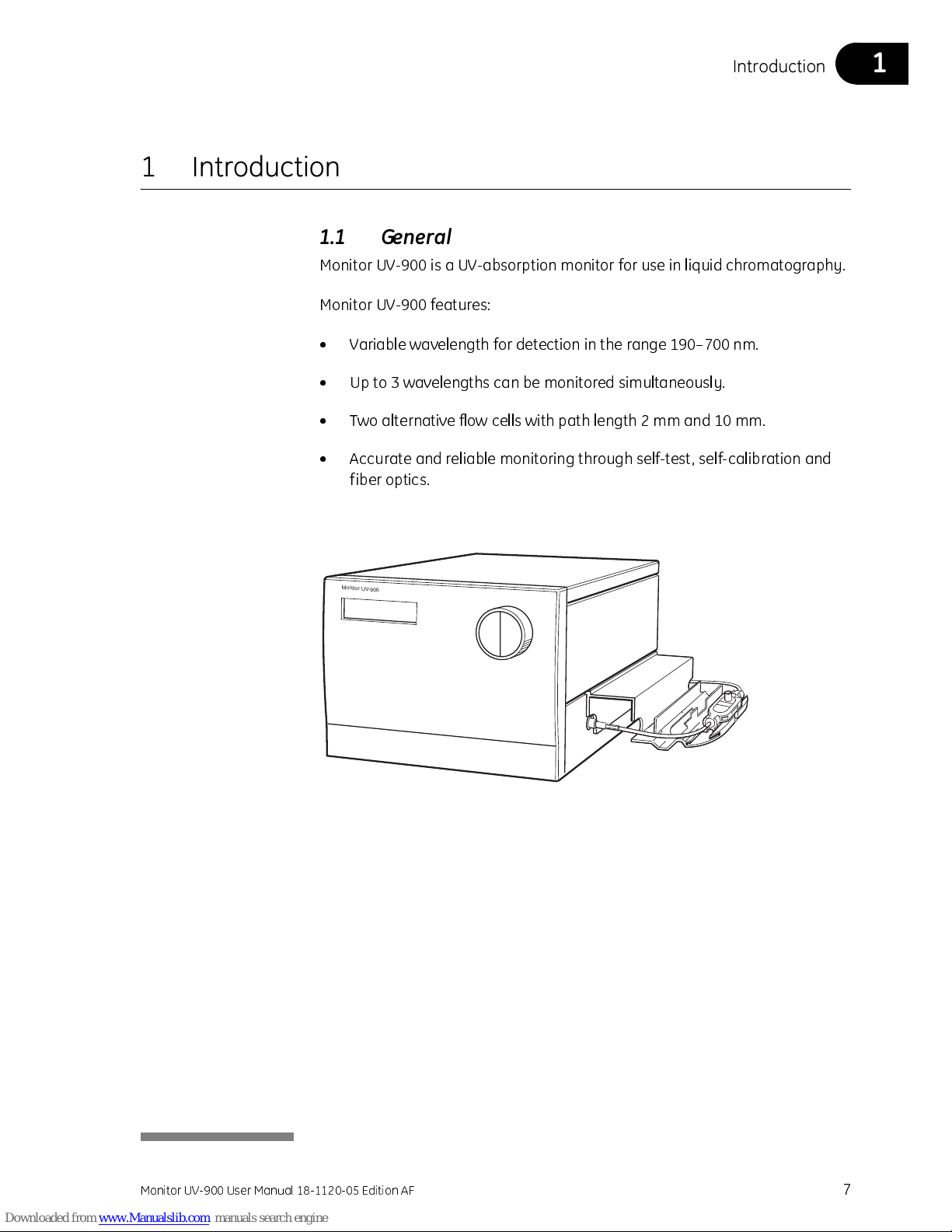

1.1 General

Monitor UV-900 is a UV-absorption monitor for use in liquid chromatography.

Monitor UV-900 features:

• Variable wavelength for detection in the range 190–700 nm.

• Up to 3 wavelengths can be monitored simultaneously.

• Two alternative flow cells with path length 2 mm and 10 mm.

• Accurate and reliable monitoring through self-test, self-calibration and

fiber optics.

M

on

ito

r U

V

-9

00

Page 8

1 Introduction

8

Monitor UV-900 User Manual 18-1120-05 Edition AF

1.2 Safety

• The instrument is designed for indoor use only.

• Do not use in a dusty atmosphere or close to spraying water.

IMPORTANT!

Monitor UV-900 is intended for laboratory use only, not for

clinical or in vitro use, or for diagnostic purposes.

WARNING!

When using hazardous chemicals, all suitable protective

measures, such as protective glasses, must be taken.

WARNING

! The instruments must not be opened by the user. They contain

high voltage circuits which can give a lethal electric shock.

WARNING

! The system must be connected to a grounded mains socket.

WARNING

! Always disconnect the power supply before attempting to

replace any item on the instrument.

WARNING!

The instrument uses high intensity ultra-violet light. Do not

disconnect the optical fibers while the monitor is running.

CAUTION!

The flow cell must not be used at pressures above 2 MP a (20 bar,

290 psi). At higher pressures the flow cell may break.

WARNING!

When using hazardous chemicals, take all suitable protective

measures, such as wearing protective glasses and gloves resistant to the

chemicals used. Follow local regulations and instructions for sa fe operati on

and maintenance of the system.

WARNING!

There must always be a sample loop connected to ports 2 and 6

of the injection valve. This is to prev ent liquid spraying out of the ports when

switching the valve. This is especially dangerous if hazardous chemicals are

used.

WARNING!

This is a Class A product. In domestic environment this product

may cause radio interference in which the user may be required to take

adequate measures.

Page 9

Installation 2

Monitor UV-900 User Manual 18-1120-05 Edition AF

9

2 Installation

2.1 Unpacking

Unpack the instrument and check the items against the supplied packing list.

Inspect the items for obvious damage which may have occurred during

transportation.

• The system should be installed on a stable laboratory bench providing a

suitable working area.

• To maintain correct ventilation, the system requires an appropriate

amount of free space. Do not block the ventilation inlets or outlets on the

system!

It is recommended that all packing materials should be retained if onward

transport of the instrument is expected.

2.2 General precautions

The instrument should not be installed in a corrosive atmosphere or in an

atmosphere where deposits are liable to form on the optical surfaces.

The instrument should be located in a place of low temperature variations,

away from heat sources, draughts and direct sunlight.

The instrument may be operated at normal ambient temperatures in the range

+4 to +40 °C.

The instrument should be installed on a stable laboratory bench or in

ÄKTA™

explorer or ÄKTApurifier. To ensure correct ventilation a free space of

0.1 m is required behind and in front of the instrument. Place the instrument

directly on the bench. Do not use any soft material under the instrument, to

ensure that the ventilation inlet in the front is not blocked.

CAUTION! The following information should be read car efully to ensur e that

the instrument is installed correctly.

Monitor UV

-900

Page 10

2 Installation

10

Monitor UV-900 User Manual 18-1120-05 Edition AF

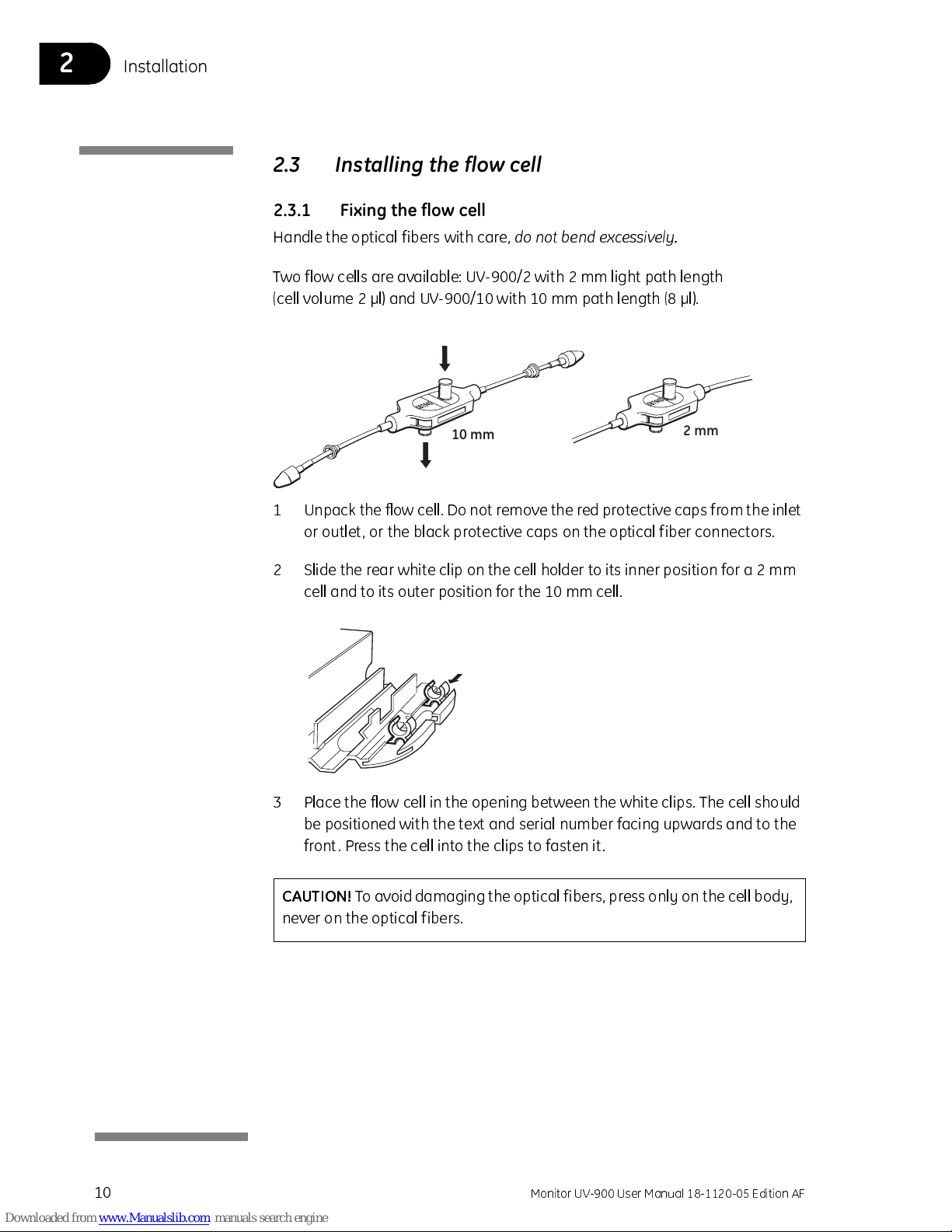

2.3 Installing the flow cell

2.3.1 Fixing the flow cell

Handle the optical fibers with care,

do not bend excessively.

Two flow cells are available: UV-900/2 with 2 mm light path length

(cell volume 2 µl) and UV-900/10 with 10 mm path length (8 µl).

1 Unpack the flow cell. Do not remove the r ed pr otective caps f r om the inle t

or outlet, or the black protective caps on the optical fiber connectors.

2 Slide the rear white clip on the cell holder to its inner position for a 2 mm

cell and to its outer position for the 10 mm cell.

3 Place the flow cell in the opening between the white clips. The cell should

be positioned with the text and serial number facing upwards and to the

front. Press the cell into the clips to fasten it.

10 mm

2 mm

CAUTION!

To avoid damaging the optical fibers, press only on the cell body,

never on the optical fibers.

Page 11

Installation 2

Monitor UV-900 User Manual 18-1120-05 Edition AF

11

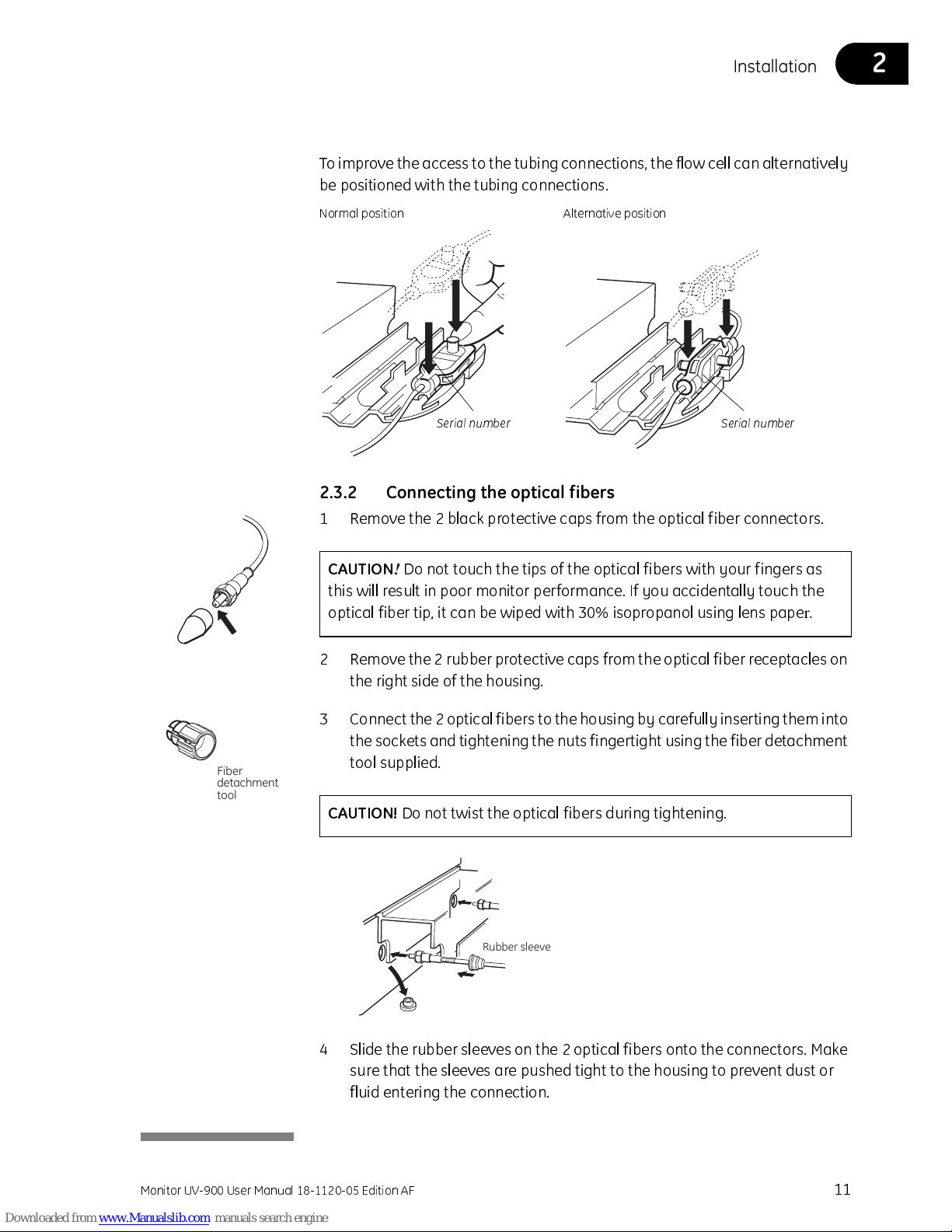

To improve t he access to the tubing connections, the flow cell can alternatively

be positioned with the tubing connections.

2.3.2 Connecting the optical fibers

1 Remove the 2 black protective caps from the optical fiber connectors.

2 Remove the 2 rubber protective caps from the optical fiber receptacles on

the right side of the housing.

3 Connect the 2 optical fibers to the housing by carefully inserting them into

the sockets and tightening the nut s fingertight using the fiber detachment

tool supplied.

4 Slide the rubber sleeves on the 2 optical fibers onto the connectors. Make

sure that the sleeves are pushed tight to the housing to prevent dust or

fluid entering the connection.

Serial number

Normal position

Serial number

Alternative position

CAUTION! Do not touch the tips of the optical fibers with your fingers as

this will result in poor monitor performance. If you accidentally touch the

optical fiber tip, it can be wiped with 30% isopropanol using lens pape

r.

Fiber

detachmen

t

tool

CAUTION! Do not twist the optical fibers during tightening.

Rubber sleeve

Page 12

2 Installation

12

Monitor UV-900 User Manual 18-1120-05 Edition AF

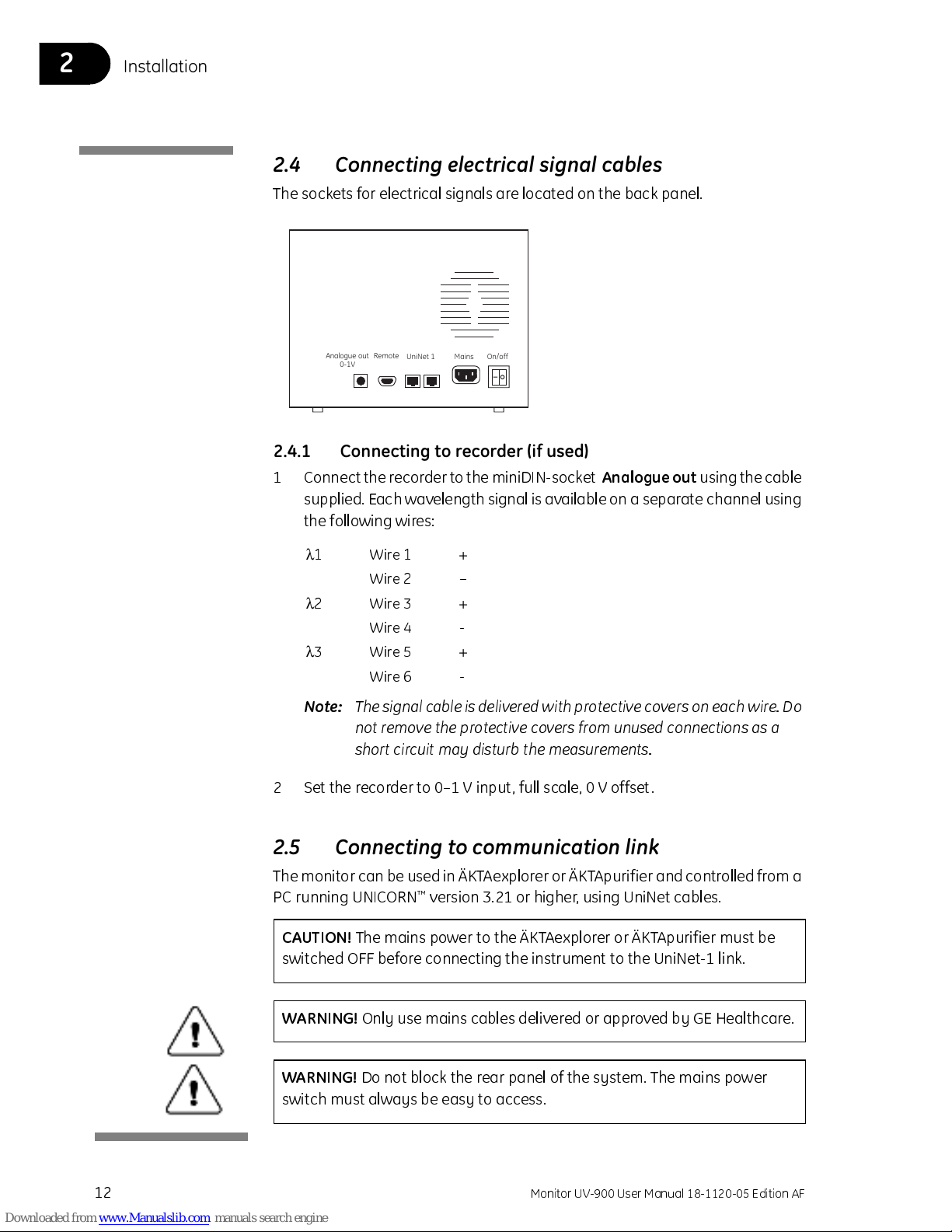

2.4 Connecting electrical signal cables

The sockets for electrical signals are located on the back panel.

2.4.1 Connecting to recorder (if used)

1 Connect the recorder to the miniDIN-socket

Analogue out using the cable

supplied. Each wavelength signal is available on a separate channel using

the following wires:

Note:

The signal cable is delivered with protective covers on each wir e. Do

not remove the protective covers from unused connections as a

short circuit may disturb the measurements.

2 Set the recorder to 0–1 V input, full scale, 0 V offset.

2.5 Connecting to communication link

The monitor can be used in ÄKTAexplorer or ÄKT Apurifier and controlled from a

PC running UNICORN™ version 3.21 or higher, using UniNet cables.

Analogue out

0-1V

Remote

UniNet 1 Mains On/off

λ

1 Wire 1 +

Wire 2 –

λ

2 Wire 3 +

Wire 4 -

λ

3 Wire 5 +

Wire 6 -

CAUTION!

The mains power to the ÄKTAexplorer or ÄKTApurifier must be

switched OFF before connecting the instrument to the UniNet-1 link.

WARNING!

Only use mains cables delivered or approved by GE Healthcare.

WARNING!

Do not block the rear panel of the system. The mains power

switch must always be easy to access.

Page 13

Installation 2

Monitor UV-900 User Manual 18-1120-05 Edition AF

13

Connect two UniNet cables to the UniNet-1 connectors. The inst rument can be

connected in series anywhere in the chain between the PC and the termination

plug. The UniNet-1 link connects, in series, the PC with Pump P-905,

Monitor pH/C-900 and Monitor UV-900. The termination plug is connected to

the last instrument in the chain.

2.6 Connecting to supply voltage

1 Make sure the on/off switch is in the OFF position (O).

2 Connect a mains cable between the instrument and a grounded mains

socket. The instrument is delivered with both European and US type mains

cables, as standard. Any voltage 100–240 V AC, 50–60 Hz, can be used.

The instrument contains no user replaceable fuse.

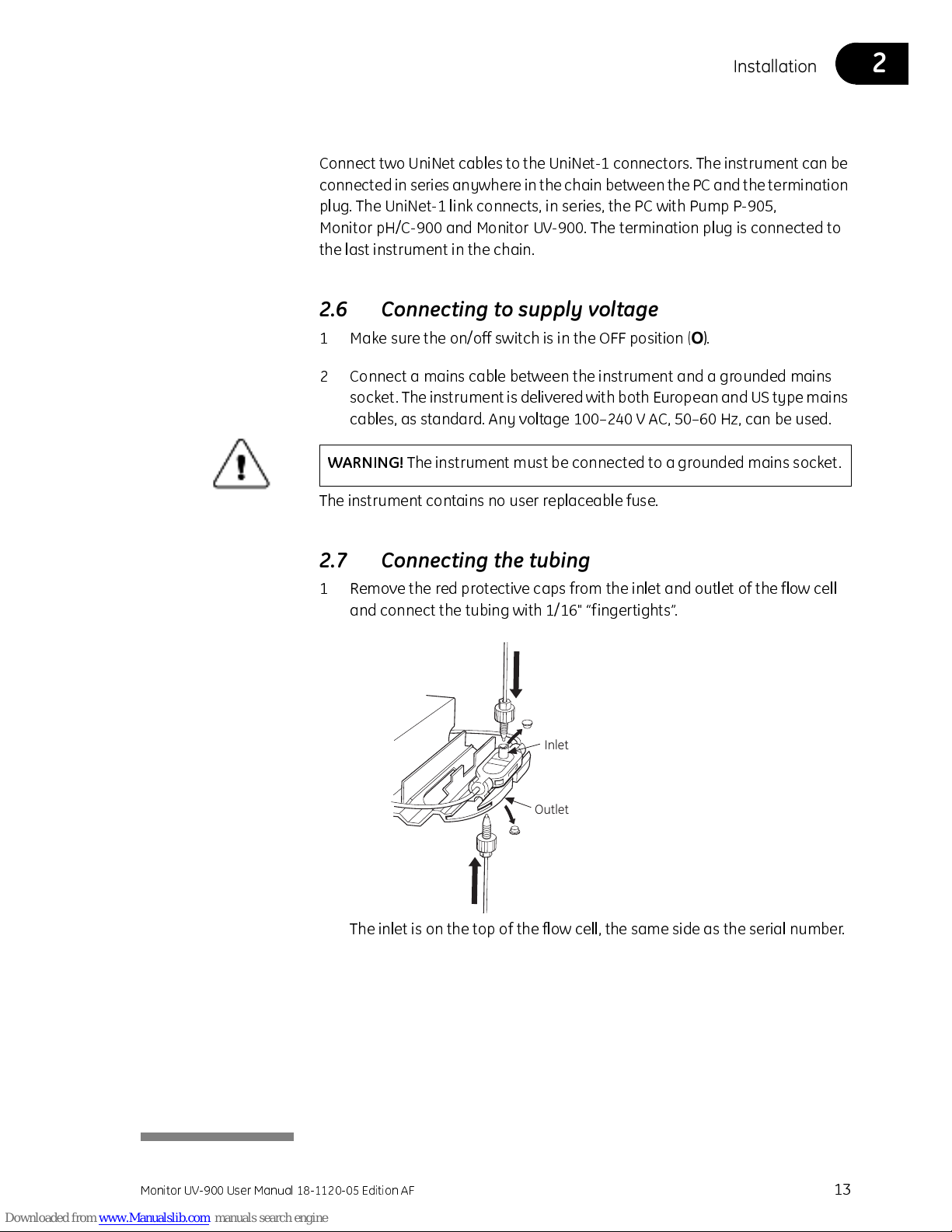

2.7 Connecting the tubing

1 Remove the red protective caps from the inlet and outlet of the flow cell

and connect the tubing with 1/16" “fingertights”.

The inlet is on the top of the flow cell, the same side as the serial number.

WARNING!

The instrument must be connected to a grounded mains socket.

Inlet

Outlet

Page 14

Installation 2

Monitor UV-900 User Manual 18-1120-05 Edition AF

14

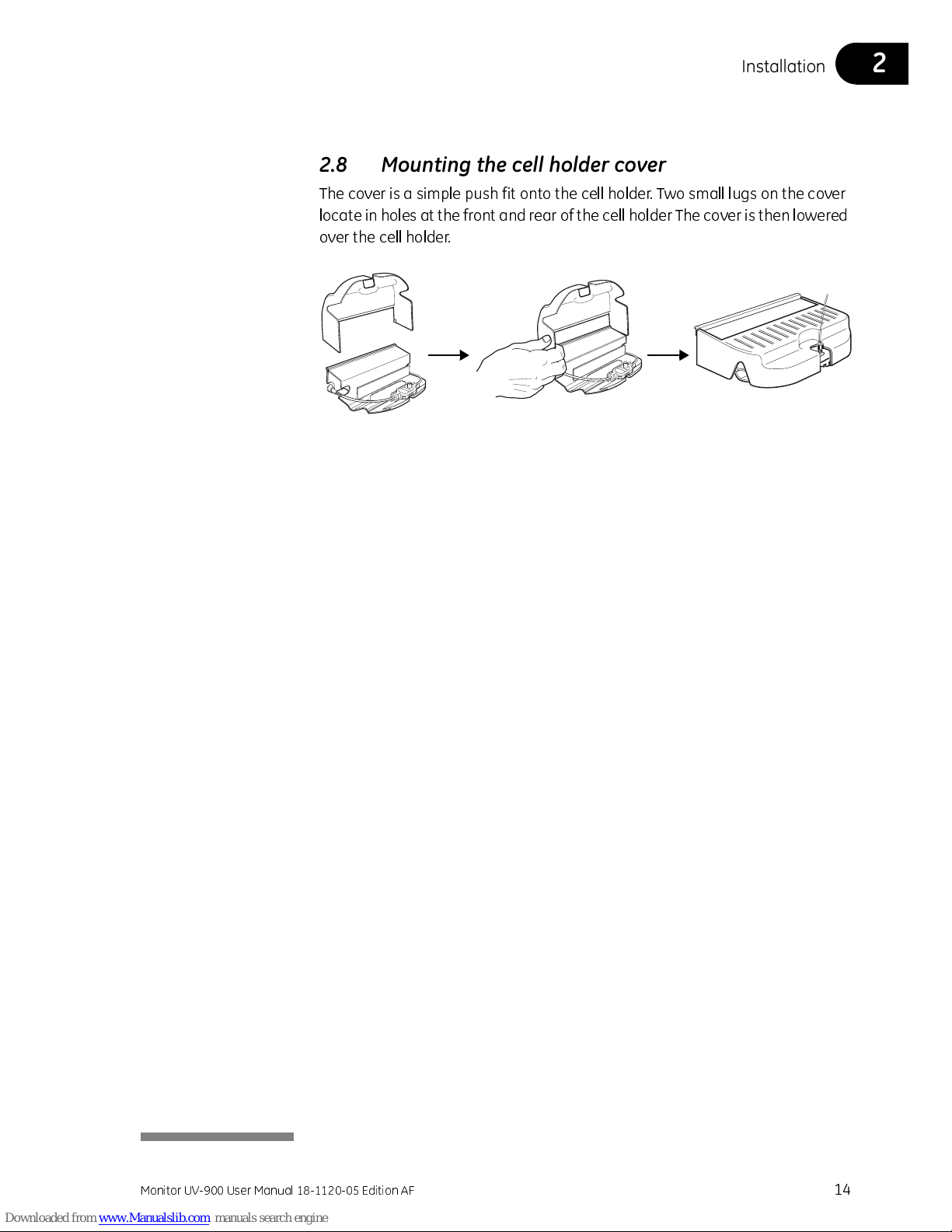

2.8 Mounting the cell holder cover

The cover is a simple push fit onto the cell holder. Two small lugs on the cover

locate in holes at the front and rear of the cell holder The cover is then lowered

over the cell holder.

Page 15

Operation 3

Monitor UV-900 User Manual 18-1120-05 Edition AF

15

3 Operation

3.1 On/off

1 Switch on the instrument at the mains switch on the rear panel.

2 The instrument performs a self-test and then starts calibration.

3 If the instrument has a calibrated cell path length set that differs from the

nominal length, a warning message appears on the monitor display.

Another message, displaying the calibrated cell length, also appears. The

display toggles between these messages.

4 To go to the

Main operating menu

, press

OK

or wait for about 45 seconds

to return automatically.

5 If no such warning messages appear , th e display automatically shows the

Main operating menu

after approximately 1 minute. The instrument is

ready to use.

All parameters are factory set to default values.

3.2 Menu selection and settings

3.2.1 Menu selection

A specific menu is selected by turning the front selection dial clockwise or

counter clockwise. When the required menu is visible the menu or selection is

accepted by pressing the OK button.

Selftest

Please wait...

Calibrating

Please wait...

Please Check UV Cell!

Press OK/Esc to cont.

Real UV Cell Length

(?,??mm, SN??????

λ1(215) 1.123 AU

λ2(254) 0.02345 AU

Menu selection

OK

button

ESC

button

Select submenu Return one menu level

Page 16

3 Operation

16

Monitor UV-900 User Manual 18-1120-05 Edition AF

If a menu has sub levels, the sub menu is displayed by pressing the

OK

button. Pressing the

ESC

button moves back one menu level.

3.2.2 Return to main menu

Pressing

ESC repeatedly, always returns to the

main menu 2 which is the main

operating menu. Press ESC

once more to return to

main menu 1

, the mode

changing menu.

3.2.3 Select value

A cursor below a text or numerical value shows what is a ffected by t he dial. T o

increase the value turn the dial clockwise. To decrease the value turn the dial

counter clockwise.

When setting numerical values, the cursor moves up to the next digit if the dial

is turned quickly in one direction, to simplify entering large values. The cursor

moves back one place to the right every two seconds if the dial is not turned.

The text or numerical value displayed is accepted by pressing the OK

button.

To cancel, press the

ESC

button.

Sub menu 3.3.1

Sub menu 3.3.2

Main menu 1

Main menu 2

Main menu 3

Main menu 4

Main menu 5

Sub menu 3.1

Sub menu 3.2

Sub menu 3.3

Sub menu 3.1.1

ESC

OK

ESC

OK

ESC

OK

Main menus Sub menus Sub menus

Main menu 1

Main menu 2

ESC

ESC ESC ESC

ESC

Parameter

Current value

New value to be set

Set Wavelength

(280 nm) 250.0

Page 17

Operation 3

Monitor UV-900 User Manual 18-1120-05 Edition AF

17

3.3 Main menu overview

Mode changing menu (mode menu)

.The menu is accessed from all positions by

pressing the

ESC

button repeatedly.

Main operating menu 1

. Wavelength display showing first two wavelengths

and, if the instrument is in Run mode, their absorbance.

Main operating menu 2

. Wavelength display showing the thir d wavelength and,

if the instrument is in Run mode, the absorbance.

Autozero the instrument.

Produce event mark.

Set the wavelengths for the measurements.

Set the recorder output

.

Filtering noise.

Flow cell path length calibration.

Check internal operating values.

See section

B.1 Check menu.

Setup language, unit number etc.

See section

B.2 Setup menu.

Set different timer options.

See section

B.3 Setting and using the alarm timer.

3.4 Setting lamp on/off

The lamp should be switched off when no measurement is made to conserve

the lamp operating time. The lamp is switched on when a run is started. No

warm-up time is required.

1 Select the mode changing menu.

2 Switch the lamp on (

Run

) or off (

End

) by pressing OK. Its current status is

shown in the upper left of the display.

When controlled from UNICORN, the lamp is switched on automatically when

the flow is started and off when the run is ended.

Run

Press OK to End

λ1(215) 1.123 AU

λ2(254) 0.02345 AU

λ3(280) 1.123 AU

Autozero

Eventmark

Set Wavelength

(215, 254, 280 nm)

Set Analogue Out

(2.000AUFS, 10%)

Set Averaging Time

(2,56s)

Set UV Cell Length

(--.-- mm, SN ------)

Check

Setup

Alarm/Timer 00:22:24

Current status

Run

Press OK to End

Page 18

3 Operation

18

Monitor UV-900 User Manual 18-1120-05 Edition AF

3.5 Reading absorbance values

The main operating menu shows the absorbance values for up to 3 active

wavelengths. The menu is reached from any other menu by pressing the

ESC

button repeatedly. The display for the third wavelength is reached by turning

the dial clockwise.

As an alternative all 3 wavel engths can be shown in a single display, but limited

to 3 decimals. This alternative is reached by turning the dial clockwise.

3.6 Setting wavelength

The instrument can measure up to 3 wavelengths simultaneously and

wavelength changes can be set at any time.

1 Select main menu Set Wavelength

, press OK.

2 Select sub menu

Set Wavelength λ1

, press OK.

3 Set the value, press OK.

4 The next wavelength λ2 is now shown. Set the value or turn the

wavelength off, by turning the dial counter clockwise until the value passes

through 190 nm. If only one wavel ength is to be used, λ2 and

λ3

should be

set to off. Press OK.

The first wavelength λ1

can never be set to off.

5 Repeat step 4 in the menu Set Wavelength λ3

.

6 Press

ESC

to return to the main operating menu.

In UNICORN, the wavelengths are set with the instruction

Wavelength in

System Control:Manual:Alarm&Mon

.

λ1(215) 1.123 AU

λ2(254) 0.02345 AU

λ3(280) 1.123 AU

or

215nm 254nm 280nm

1.123 0.023 0.123

Set Wavelength

(215, 254, 280 nm)

Set Wavelength λ1

(215, 254, 280 nm)

Set Wavelength λ1

(215nm) 234

Set Wavelength λ2

(254nm)

Page 19

Operation 3

Monitor UV-900 User Manual 18-1120-05 Edition AF

19

3.7 Autozero

The autozero function sets the detected absorbance to zero when the OK

button is pressed. All three wavelengths are autozeroed. Autozero is

recommended after wavelength changes in a method and before the sample

is injected.

1 Select main menu

Autozero

, press OK. The normal absorbance value

display is then shown.

In UNICORN, Autozero is set with the instruction

AutoZeroUV in

System

Control:Manual:Alarm&Mon

.

3.8 Storage and shut-down

Overnight:

The flow cell can be left filled with buffer.

Weekend and long term storage:

Flush the flow cell with distilled water and

then fill it with 20% ethanol.

The flow cell can also be stored dry by flushing as above with distilled water

and then blowing a compressed inert gas such as nitrogen (N2) through the cell.

Replace the red protective caps. Never use compressed air as th is may contain

droplets of oil.

Autozero

CAUTION!

Do not allow solutions which contain dissolved salts, proteins or

other solid solutions to dry out in the flow cell. Do not allow particles to

enter the flow cell as damage to the flow cell may occur.

Page 20

3 Operation

20

Monitor UV-900 User Manual 18-1120-05 Edition AF

3.9 Using an external chart recorder

3.9.1 Setting range and zero

The external chart recorder output fr om the instrument is always 0–1 V, but the

absorbance value for full scale defle ction and the Zero Absorbance lev el on the

recorder can be set.

1 Select main menu

Set Analogue Out

, press OK.

2 Set the range value in the sub menu

Set Range

and press OK. The range is

the full scale absorbance range for the chart recorder (1 V). Only fixed

steps between 5.0 AU and 0.01 AU can be set and the value is the same for

all 3 wavelengths.

3 Select menu

Set Zero Level

, press OK.

4 Set the value and press OK. This value determines where the zero

absorbance level should be in relation to full scale on the recorder.

The instrument has an automatic overrange

function. If during a peak the monitor signal

reaches the full scale value, the signal will drop

instantly to 0 V and give an accurate display of

the peak starting from this position.

3.9.2 Event mark

Event marks can be set, for example when the

sample is injected, and displayed as spikes on all

three channels of the chart recorder. The spikes are

10% of the full scale of the chart recorder which

corresponds to 0.1 V.

1 Select main menu

Event mark, press OK.

Set Analogue Out

(2.000AUFS, 10%)

Set Range

(2.000AUFS) <0.1>

Set Zero Level

(10% of FS) 20

Range

AU

Overrange

Measured absorbance

level (A U)

Signal to

recorder (V)

0 V

1 V

Page 21

Operation 3

Monitor UV-900 User Manual 18-1120-05 Edition AF

21

3.10 Filtering noise

To filter the noise in the UV-signal, a moving average filter is used. The

averaging time is the time interval used for calculating the moving average of

the absorbance signal. A long averaging time will smooth out noise efficiently,

but it will also distort the peaks. Peaks narrower than the minimum peak width

value may be distorted. Because of this the averaging time should be as short

as possible, see the table be low. On delivery the averaging time is set to 2.56 s.

1 Select menu

Set Averaging Time

, press OK.

2 Set the value, press OK. Use the fixed

values

between 5.12 and 0.08 s.

When monitoring more than one wavelength, the recommended

averaging time is a minimum of 1.28 s.

In UNICORN the averaging ti me is set with the i nstruction

AveragingTime

in System Control:Manual:Alarm&Mon

.

Set Averaging Time

(2.56s) <2.56>

Averaging time (s) Time constant (s)

(approximate)

Min. peak width

at half height (s)

5.12 2.0 32

2.56 1.0 16

1.28 0.5 8.0

0.64 0.2 3.2

0.32 0.1 1.6

0.16 0.05 0.8

0.08 0.03 0.5

Page 22

3 Operation

22

Monitor UV-900 User Manual 18-1120-05 Edition AF

3.11 UV cell calibration

The path length in the UV flow cell might differ from the nominal lengt h (1, 2 , 5

respective 10 mm) which interferes the calculation of the protein concentration

in the eluate. To achieve normalized absorbance, the path length in the UV flow

cell must be calibrated.

It is recommended to calibrate a new UV flow cell before use. An old flow cell

can be calibrated whenever you think that a calibration is required.

Equipment required

To perform the calibration you need test solutions, syringes and accessories for

desired cell length:

• UV-900 1 mm Calibr. kit, no. 18-6324-01

• UV-900 2 mm Calibr. kit, no. 18-6324-02

• UV-900 5 mm Calibr. kit, no. 18-6324-04

• UV-900 10 mm Calibr. kit, no. 18-6324-05

To calculate the real cell length use the supplied Excel-file:

• UV-900 Cell Calibr. Excel-file, no. 18-6324-06

Removing an old calibration setting

If the instrument already has a calibrated cell length set that differs from the

nominal length, a warning message appears on the UV monitor display at

start-up. Anothe r message, displaying the calibrated cell length, also appe ars.

The display toggles between these messages. The display automatically

returns to the main operating menu after about 45 seconds, or if pressing OK.

1 To remove an old calibration value, press

Esc

while the display toggles

between the two messages. The

Set UV Cell Length

menu appears.

Press OK.

2 At the

Set Calibr. Length

menu, set the cell length to 0. Press OK.

Preparing the calibration

1 Remove any old calibration value by setting the cell length to 0 (see above).

2 Unpack the UV Test kit.

3 Make sure that the Flow restrictor is connected in the flow path after the

UV flow cell.

4 Mount the Union Luer female/ 1/16" male, included in the test kit, in the

upper inlet of the UV flow cell.

Please Check UV Cell!

Press OK/Esc to cont.

Real UV Cell Length

(?,??mm, SN??????

Set UV Cell Length

(--,--mm, SN------)

Set Calibr. Length

(--,--mm) --.--

Union

Page 23

Operation 3

Monitor UV-900 User Manual 18-1120-05 Edition AF

23

5 Open the UV-900 Cell Calibr. Excel-file on the computer.

6 The solution bottles are marked with the concentration value and the

reference absorbance value for each solution.

Enter the concentration of the solutions in increasing order in the column

UV Test kit Concentration (mg/l)

.

Enter the absorbance value in increasing order in the column

UV Test kit Absorbance (AU/cm)

.

Performing the absorbance measurements

For each of the four test solutions, the absorbance will be measured and

automatically compared to its reference value.

1 Switch on the UV lamp, see

3.4 Setting lamp on/off

.

2 Select a main menu on the monitor display that shows wavelength

254 nm.

3 Fill one of the supplied syringes with 1.5–2 ml of the 0 AU/cm solution.

Make sure that there is no air in the syringe!

4 Fit the syringe in the Union Luer connector and inject the solution. Do NOT

remove the syringe.

5 Wait until the monitored absorbance value is stable.

6 Perform an

Autozero

operation. See section

3.7 Autozero

.

WARNING!

When using hazardous chemicals, take all suitable protective

measures, such as wearing protective glasses and gloves resistant to the

chemicals used. Follow local regulations and instructions for safe operation

and maintenance of the system.

WARNING!

Sulfuric acid included in the test soluitons is injurious to health.

Avoid spillage and use eye protection.

Page 24

3 Operation

24

Monitor UV-900 User Manual 18-1120-05 Edition AF

7 Remove the syringe.

8 Inject the other four test solutions in increa sing concentration or der. Use a

new syringe for each solution.

Note:

Air trapped in the UV cell causes inaccurate measur ements. To avoid

introducing air into the cell, gently fill the Luer union up to the edge

using test solution from the syringe that is next. Then insert the

syringe into the Luer union.

9 After each injection, wait for a stable absorbance value and enter the

measured values in the column

UV -900 Absorbance (AU) in the UV-900

Cell Calibr . Excel-file.

10 When all absorbance values have been entered, the real cell length is

shown next to the

Real cell length square.

Note:

The regressions coefficient should be larger than 0.999.

If not, one or several measured values are faulty.

Entering the new real length

1 Select menu

Set UV Cell Length

in the UV monitor. Press OK.

The Set

Calibr. Length menu appears. Press OK.

2 Enter the

Real cell length value (from the Excel-file) and press OK.

3The

Set UV Cell Type

menu appears. Check the cell type value.

If the value is corre ct, turn the selection dial clockwise to go to next menu.

If the value has to be changed, press OK to change it.

4 At the

Set Cell Serial No.

menu press OK.

5 Enter the serial number of the cell (see the label on the flow cell). Press OK.

3.12 Changing flow cell

The flow cell can be changed when required, for example from 2 mm to 10 mm

when the sensitivity of the measur ement must change due to a small amount

of sample being applied, or from a 10 mm to 2 mm when a lower sensitivity is

desired, due to output signal limitation.

See section

2.3 Installing the flow cell

.

3.13 Restart after power failure

If the power supply to the instrument is interrupted, the instrument

automatically restarts itself and displays the main operating window. All set

values are retained in the instrument but the instrument starts with the lamp

switched-off.

Set UV Cell Length

(--,--mm, SN------)

Set Calibr. Length

(--,--mm) --.--

Set UV Cell Type

(2 mm)

Set Cell Serial No.

(SN ------) ------

Page 25

Maintenance 4

Monitor UV-900 User Manual 18-1120-05 Edition AF

25

4 Maintenance

4.1 Periodic maintenance

4.2 Cleaning-in-place

Pump a cleaning or sanitizing agent through the flow cell. The standard

recommendation is to pump 1 M NaOH at 1 ml/min for 30 minutes and then

wash out with buffer.

WARNING!

Always disconnect the power supply before attempting to

replace any item on the system during maintenance.

WARNING!

Only spare parts that are approved or supplied by GE

Healthcare may be used for maintaining or servicing the system.

Interval Action (see procedures below)

Every 3 month Check the instrument

Every 6 month

or more often if required

Clean the flow cell and optical fiber connectors

WARNING!

Remove liquid or dirt from the system surface using a cloth and,

if necessary, a mild cleaning agent.

WARNING!

When using hazardous chemicals, take all suitable protective

measures, such as wearing protective glasses and gloves resistant to the

chemicals used. Follow local regulations and instructions for safe operation

and maintenance of the system.

WARNING!

When using hazardous chemicals, make sure that the entire

system has been flushed thoroughly with bacteriostatic solution, e.g. NaOH,

and distilled water before service and maintenance.

WARNING!

NaOH is injurious to health. Avoid spillage.

Page 26

Maintenance 4

Monitor UV-900 User Manual 18-1120-05 Edition AF

26

4.3 Checking the instrument

4.3.1 Lamp intensity

1 Select menu

Check

, press OK.

2 Select menu

Check Lamp Intensity

.

If the lamp intensity is < 20%, contact GE Healthcare for lamp replacement or

change of internal optical fiber.

4.3.2 Lamp on–time

1 Select menu

Check

, press OK.

2 Select menu

Check Lamp Run Time

.

If the lamp ontime is > 4000 hours, contact GE Healthcare for lamp

replacement.

4.3.3 Flip time

The flip time is the time the monochromator stepper motor has been in

operation.

1 Select menu Check

, press OK.

2 Select menu

Check Flip Time

.

If the flip time is > 2000 hours, contact GE Healthcare for maintenance.

4.3.4 UV flow cell

This menu shows the set path length and the serial number of the UV flow cell.

1 Select menu Check

and press OK.

2 Select menu

UV Flow Cell

.

Check Lamp Intensity

210nm 85% 300nm 95%

Check Lamp Run Time

200h

Check Flip Time

50h

UV Flow Cell

(--,--mm, SN -----)

Page 27

Maintenance 4

Monitor UV-900 User Manual 18-1120-05 Edition AF

27

4.4 Cleaning the flow cell and optical fiber connectors

A clean flow cell and optical connectors are essential for ensuring the correct

operation of the UV-monitor.

4.4.1 Cleaning the flow cell

1 Connect a syringe to the inlet of the flow cell and squirt distilled water

through the cell in small amounts. Then fill the syringe with a 10% surface

active detergent solution like

Decon 90, Deconex 11, RBS 25

or equivalent,

and squirt five times.

2 After five squirts, leave the detergent solution in the flow cell for at least

20 minutes.

3 Pump the remaining detergent solution through the flow cell.

4 Rinse the syringe and flush the cell with distilled water (10 ml).

4.4.2 Cleaning the optical fiber connectors

Wipe with 30% isopropanol on lens paper.

4.4.3 Instrument housing

4.5 Cleaning the system

• Wipe the surface regularly with a damp cloth. Do not allow spilt liquid to

dry on the instrument.

• Remove dirt from the surface using a cloth and a mild cleaning agent.

• Let the system dry completely before using it.

Wipe the instrument housing regularly with a damp cloth. Let the instrument

dry completely before use.

CAUTION!

Do not allow solutions containing dissolved salts, proteins or

other solid solutes to dry out in the cell. Do not allow particles to enter the

flow cell as damage to the flow cell may occur.

WARNING!

When using hazardous chemicals, make sure that the entire

system has been flushed thoroughly with bacteriostatic solution, e.g. NaOH,

and distilled water before service and maintenance.

Page 28

4 Maintenance

28

Monitor UV-900 User Manual 18-1120-05 Edition AF

4.6 Recycling

This symbol indicates that the waste of electrical and electronic equipment

must not be disposed as unsorted municipal waste and must be collected

separately. Please contact an authorized representative of the manufacturer

for information concerning the decommissioning of equipment

Page 29

Trouble-shooting 5

Monitor UV-900 User Manual 18-1120-05 Edition AF

29

5 Trouble-shooting

5.1 General

When contacting GE Healthcare for support, state the program version of the

instrument, which is shown for 2 seconds after the self-test, during switch-on,

or in the menu

Check Service Mode

, see

page 35

.

5.2 Faults and actions

If the suggested actions do not correct the fault, call GE Healthcare.

Monitor UV-900

V1.06

WARNING!

The instruments must not be opened by the user. They contain

high voltage circuits which can give a lethal electric shock.

Fault Possible cause Corrective action

No text on the front display

No power to the monitor Check that the mains cable is connected

and the power switch is in ON-position I

Noisy UV-signal, signal drift

or instability

The buffer may be impure Check if the signal is still noisy with water

There may be air in the flow cell Check that the flow restrictor gives a back

pressure of 0.2 MPa in ÄKTAexplorer, and

3-5 MPa in ÄKTApurifier

If there is a lot of air in the water, degas

the buffer continuously (we recommend

helium sparging)

Check the connections of the UV cell

optical fibers

Clean the UV cell, see section 4.4

Ghost peaks

Air in the eluents Degas if necessary (we recommend

helium sparging)

Dirt or residues in the flow path

from previous runs

Clean the system in accordance

with ÄKTAexplorer or

ÄKTApurifier System Manual

Residues in the column from

previous runs

Clean the column in accordance with the

column instructions

Bad mixing of the eluents Check that the mixer is functioning

correctly and that the correct chamber

volume is being used

Error in external chart

recorder

The recorder not properly set up Check the chart recorder in accordance

with its manual

Monitor UV-900 not properly set upTest the recorder function by selecting

recorder test according to section

Check

Analogue Out on page 35

Page 30

5 Trouble-shooting

30

Monitor UV-900 User Manual 18-1120-05 Edition AF

5.3 Error messages

If the suggested actions do not correct the fault, call GE Healthcare.

Message Action

Sample fiber failure

There may be too high absorption in the UV cell.

1. Check the liquid.

2. Ensure that there are no air bubbles in the system.

3. Check the connections of the UV cell optical fibers.

4. Clean the UV cell, see section

Cleaning the flow cell and

optical fiber connectors

.

Not calibrated

Calibration failed

Recalibrate by switching the instrument off and then back to

on, or choose

Recalibrate

in the

Check

menu

Change lamp

Call GE Healthcare for Xe-lamp exchange

Mode fiber failure

Reference fiber failure

Lamp module failure

Low light intensity

Block filter is defect

Call GE Healthcare

High intensity

in Reference fiber

Recalibrate by switching the instrument off and on

High intensity

in Sample fiber

1. Disconnect the optical fiber connectors.

2. Recalibrate by switching the instrument off and on.

ERROR Number 10

ERROR Number 16

ERROR key(OK)

ERROR key(Esc)

ERROR key(OK+Esc)

ERROR 100

ERROR 109-113

ERROR 120-121

1. Switch off the instrument.

2. Check all connections.

3. Switch on the instrument.

ERROR 106-108

ERROR 118

1. Switch off the instrument.

2. Check all UniNet connections.

3. Switch on the instrument.

Page 31

Reference information A

Monitor UV-900 User Manual 18-1120-05 Edition AF

31

Reference information

A Description

A.1 Instrument

The Monitor UV-900 is a UV-absorption monitor with v ariabl e w av elen gth. The

instrument contains no internal user replaceable items.

Connect any auxiliary equipment to the 9-pole D–Sub female REMOTE

connector (5 V TTL signals only).

Connector/switch Function

Analogue out 0–1 V Recorder output, 3 channels 0–1 V

Remote Digital signal inputs, lamp on/off, autozero, event mark

UniNet 1 Computer network

Mains Supply voltage, grounded

On/off Instrument on/off switch

M

onitor U

V

-900

Analogue out

0-1V

Remote

UniNet 1 Mains On/off

12345

6789

Pin Signal Function

Active status = low or closed terminal to pin 5 (0V)

1 Remote on/off Active = lamp on, inactive = lamp off

2 Autozero From inactive to active > 100 ms = Autozero

3 Event mark From inactive to active > 100 ms = Event mark

4–

50 V

6–9 –

Page 32

A Reference information

32

Monitor UV-900 User Manual 18-1120-05 Edition AF

A.2 Flow cell

The optical path length of the flow cell is 2 mm and 10 mm. The flow cell is made

of quartz with a titanium housing.

The unique design of the flow cell prev ents the formation of distinct interfaces

between eluent components with different refractive indices and eliminates

the negative influence these would cause. The precision of monitoring is

enhanced by the construction of the flow cell, which ensures total reflectance

of light. This maintains a high intensity of light to the detector. The long path

length combined with a small cell volume increases sensitivity.

A.3 Monitor principle

A Xenon flash lamp gives a high intensity, continuous spectrum throughout the

range 160–2000 nm. The light enters a monochromator which includes a

condensing system, blocking filter, entrance slit and a concave aberration-

corrected holographic grating. Monochromatic light from the grating is

directed to an optical fibre. The grating is turned by a stepping motor for

wavelength selection between 190–700 nm, in steps of 1 nm. Up to 3

wavelengths can be monitored simultaneously.

For wavelengths between 360 –700 nm, a blocking filter is moved into the light

path to filter out unwanted light, of a half wavelength from the second order

spectrum, before entering the monochromator.

The light from the monochromator to the flow cell and from the cell to the

detector electronics is guided by optical fibres which focus its full intensity on

the liquid flow path, maximising the sensitivity of the monitoring. Before

entering the flow cell, the monochromatic light is split in a beam splitter, with

50% of the light passing through the sample fibre (S) and the flow cell, and 50%

being directed through the reference fibre (R). Two photodiodes with identical

characteristics monitor the intensities of the measuring and reference beams.

Page 33

Reference information A

Monitor UV-900 User Manual 18-1120-05 Edition AF

33

The long path length and small volume of the flow cell ensure very high

sensitivities and high signal-to-noise ratios. The detection system is also very

stable and because the optical unit is located away from the lamp and

electronics, noise and drift caused by temperature variations is avoided.

At calibration the instrument automatically finds 2 persistent lines in the

spectrum of Xenon. The wavelengt hs of these known lines are used to calibrate

the stepper motor that turns the grating.

Detectors

and electronics

Flash lamp 100 Hz

Monochromator

Beam

splitter

S

R

Con-

densor

Block

filter

Flow cell

Page 34

B Reference information

34

Monitor UV-900 User Manual 18-1120-05 Edition AF

B Menus

B.1 Check menu

Checking autozero level

The instrument internal absorbance value for autozero can be checked to test

the consistency in buffers.

1 Select main menu

Check

, press OK. The autozero absorbance value for

wavelength 1 is shown.

2 Turn the selection dial clockwise to display wavelengths 2 and 3.

Lamp intensity, Lamp Ontime, Fliptime, UV Flow cell

See

Chapter 4 Maintenance.

Checking the wavelength

If there is any doubt that the instrument is showing the correct values, the

wavelength calibration can be checked.

1 Select main menu

Check

, press OK.

2 Select sub menu

Check Wavelength

, press OK. The check starts and after

approx. 20 seconds the message Wavelength OK

or

Wavelength not OK

is shown together with the deviation values. If not OK, recalibration can be

selected.

If a deviation in wavelength occurs repeatedly when checked, contact

Amersham Biosciences.

Recalibrate

If the instrument is left switched on for a long period (> 10 days), it may be

necessary to recalibrate it. This calibration is identical to that done when the

instrument is switched on.

1 Select main menu

Check

, press OK.

2 Select sub menu

Recalibrate, press OK. The recalibration starts and af ter

approx. 60 seconds the message

Recalibration finished is shown.

Check Autozero

AZ1 (215) 0.23456 AU

AZ2 (254) 0.23775 AU

AZ3 (280) 0.12326 AU

Checking Wavelength

Please wait...

Wavelengths OK

230+0 459+0 542+0 OK

Checking Wavelength

Please wait...

or

Wavelengths not OK

230-4 459+3 542+4 OK

Wavelengths not OK

Recalibrate? OK

Recalibrating

Please wait...

Recalibration

finished OK

Page 35

Reference information B

Monitor UV-900 User Manual 18-1120-05 Edition AF

35

Check Analogue Out

The function of the connected chart recorder can be tested.

1 Select main menu

Check

, press OK.

2 Select sub menu

Check Analogue Out

, press OK.

3 Start the test by selecting on, press OK. The

test will ramp the signal on each channe l up

to 1 V and then decrease the signal in 10%

steps back to 0 V. The test is run

continuously. Compare the diagram of the

chart recorder with the figure.

4 Stop the test by pressing OK or

ESC

.

Check Service Mode

Service information relevant to the instrument can be checked. Information

may not be available in all menus.

1 Select main menu Check

, turn the selection dial clockwise for next display.

2 Select sub menu

Check Service Mode

by pressing OK.

3 The service telephone number is displayed. Turn the selection dial

clockwise to view the next display.

4 The service contract number is displayed. Turn the selection dial clockwise

to view the next display.

5 The instrument serial number is displayed. Turn the selection dial

clockwise to view the next display.

6 The instrument name and software version are displayed. Turn the

selection dial clockwise to view the next display.

7 The date of the last service is displayed. Turn the selection dial clockwise

to view the next display.

8 Press OK to test the instrument buzzer.

Press

Esc to return to the

Check Service Mode

menu.

Check Analogue Out

(off) on

1 V

Signal to recorder

0 V

Check Service Mode

Telephone Service

012345678901

Contract Number

012345678901

Serial Number

01234567 YM 012345

Monitor UV-900

V1.06

Date of Maintenance

?

Buzzer Test.

Page 36

B Reference information

36

Monitor UV-900 User Manual 18-1120-05 Edition AF

B.2 Setup menu

Setup language

Sets the language used in the display.

1 Select main menu

Setup

, press OK.

2 Select sub menu

Setup Language, press OK.

3 Select the desired language.

GB

= British English

D

= German

F

= French

E

= Spanish

I = Italian

Setup unit number

The unit number is the identification the UV monitor has on the UniNet-bus. It

should correspond to the number set in UNICORN for the UV monitor. The

number should be set to 0 if one UV monitor is used. If more than one UV

monitor is used, they must all have different identification numbers.

1 Select main menu

Setup

, press OK.

2 Select sub menu

Setup Unit Numbe

r,

press OK.

3 Select unit number (0–25).

Setup display angle

The display angle can be set to compensate for different viewing heights.

1 Select main menu

Setup, press OK.

2 Select sub menu

Set Display Angle, press OK.

3 Select viewing angle (-> \ Up, -> | Mid or -> / Down).

Setup Language

(GB) GB D F E I

Setup Unit Number

(0)

Setup Display Angle

( ->I ) ->\ ->I ->/

Page 37

Reference information B

Monitor UV-900 User Manual 18-1120-05 Edition AF

37

B.3 Setting and using the alarm timer

You can set the alarm function to either a fixed alarm time or using a count-

down timer. The UV monitor can be started or stopped automatically, or an

alarm can sound, at the set time. It is not possible to set both an alarm time and

a count-down timer. Current values are shown in parentheses.

1 Select main menu

Alarm/Timer

, press OK.

2 Set the action to t ake place. Pr ess

OK to select action.

Buzzer will generate

an audible alarm for 15 s and a message. Run will start the pump at the

set flow rate,

End will stop the pump, each generating one beep and a

message.

3 Use the sub menu

Set Alarm

if you want to set an alarm at a fixed time.

Press OK to enter the time value in the form

HH.MM.SS

, pressing the OK

button after entering each time unit.

4 If you want to set a count-down timer , turn the dial to select sub menu Set

Timer

. Press OK to enter the countdown value in the form

HH.MM.SS

,

pressing the OK button after entering each time unit.

5 Press

ESC

button to return to the

Alarm/Timer

menu which now shows the

set alarm time or count-down time as

BzzHH:MM:SS

.

6 When the alarm time is due or the count-down timer reaches 00:00:0 0, an

alert display is shown and the instrument beeps, until the OK button is

pressed.

The alarm timer is based on the internal instrument clock which can be set in

the Set Clock

menu placed after the Alarm/Timer

menu. The clock will be reset

when power is turned

OFF

.

An already set alarm/timer function can be reset by pressing OK in the menu

Alarm/Timer off?

B.4 Service displays

The instrument has service displays for use by authorised service personnel. If

the service display

Enter Access Code: is accidentally selected, press the

ESC

button to exit to the normal operation display.

Alarm/Timer 12:30:52

Alarm/ Timer Action

(Bzz) Buzzer Run End

Set Alarm 12:32:22

(0) 00.00.00

Set Timer

(0) 00.00.00

Alarm/Timer 12:30:52

(Bzz 12:33:00)

Bzz12:41:29 12:41:49

! ! Alarm time ! !

Set Clock

00

:32:22 (00:36:53)

Alarm/Timer off?

(Bzz 05:33:00)

Enter Access Code!

Page 38

B Reference information

38

Monitor UV-900 User Manual 18-1120-05 Edition AF

B.5 Menu overview

Run

Press OK to End

Alarm/Timer 00:22.24

Set Averaging Time

(2.56s)

Set Analogue Out

(2.000AUFS, 10%)

Autozero

Set Range

(2.000AUFS)

Set zero Level

(10% of FS)

Check Autozero

AZ1 214nm 0.0356AU

AZ2 254nm 0.0356AU

AZ3 280nm 0.3876AU

Check Lamp Intensity

210 nm 85% 300 nm 95%

Check Lamp Run Time

40h

Check Flip Time

87h

Setup language

(GB) GB D F E I

Setup Unit Number

(0)

Setup Display Angle

( ->I ) ->\ ->I ->/

Alarm/Timer off?

Set Wavelength λ1

(215nm)

Set Wavelength λ2

(254nm)

Set Wavelength λ3

(280nm)

λ1(280) 1.123 AU

λ2(254) 0.02345 AU

Set Wavelength

(215, 254, 280 nm)

Set Wavelength λ1

(215nm) 214

Set Wavelength λ2

(215nm) 260

Set Range

(2.000AUFS) <0.01>

Set zero Level

(10% of FS) 20

Set Averaging Time

(2.56s) <2.56>

Check

Setup

Checking Wavelength

Please wait...

Wavelengths OK

230+0 459+0 542+0 OK

Wavelengths not OK

Recalibrate? OK

Recalibrating

Please wait...

Recalibration finished

OK

Check Analogue Out

(off) on

Setup Unit Number

(0)

Eventmark

λ3(215) 0.00000 AU

280nm 254nm 215nm

0.000 0.000 0.000

Set Clock

(00:36:53) 00.00.00

Set Timer

(0) 00.00.00

Set Alarm 12:32:21

(0) 00.00.00

A l a rm / T i m e r a c t io n

(Bzz) Buzzer Run End

Set Calibr. Length

(--.--mm)

Set UV Cell Type

(2 mm)

Set Cell Serial No.

(SN------)

Set Calibr. Length

(--.--mm) --.--

Set UV Cell Type

(2 mm) 2

UV Flow Cell

(--,--mm, SN -----)

Check Wavelength

Recalibrate

Check Analogue Out

Check Service Mode

Set UV Cell Length

(--.--mm, SN ------)

Set Cell Serial No.

(SN -------) ------

Set UV Cell Type

(2 mm)

Set Wavelength λ1

(215nm) 214

Set Wavelength λ2

(215nm) 260

Set Wavelength λ3

(215nm) 278

Page 39

Reference information C

Monitor UV-900 User Manual 18-1120-05 Edition AF

39

C Technical specifications

Operating data

Wavelength range

190–700 nm in steps of 1 nm,

3 wavelengths simultaneously

Bandwidth

4 nm

Wavelength accuracy

±2 nm

Wavelength reproducibility

±0.01 nm

Wavelength switch time

< 500 ms (one cycle from 214 nm to

254 nm and back to 214 nm)

Linearity

< 2% deviation up to 2 AU at 260 nm with

Uracil at pH 2

Noise (specified for 10 mm

flow cell)

1, 2

Single wavelength

short term (0.5–1 min)

long term (1–10 min)

Dual wavelengths

short term (0.5–1 min)

long term (1–10 min)

< 6x10-5 AU at 230 nm

< 6x10-5 AU at 230 nm

< 2x10-4 AU at 230 and 254 nm

< 2x10-4 AU at 230 and 254 nm

Drift

2)

< 2x10-4 AU/h at 254 nm

Environment

+4 to +40 °C

20–95% relative humidity

84–106 kPa (840-1060 mbar)

atmospheric pressure

1)

Measured with water at 1 ml/min, time constant 1 s.

2)

Typical values at room temperature after varm-up.

Flow cell

Max. flow rate

100 ml/min

Max. pressure

2 MPa (20 bar, 290 psi)

Backpressure

Max. 0.5 bar at 2 ml/min with water at

25 °C

Liquid temperature range

+4 to +40 °C

Optical path length

2 mm cell

10 mm cell

2 mm

10 mm

Cell volume

2 mm cell

10 mm cell

2 µl

8 µl

Degree of protection

IP 21

Wetted materials

PTFE (polytetrafluoroethylene)

PEEK (polyetheretherketone)

Titanium (palladium alloy)

Quartz (synthetic fused silica)

pH stability range

1–13, 1–14 (<1 days exposure)

Page 40

C Reference information

40

Monitor UV-900 User Manual 18-1120-05 Edition AF

Physical data

Chemical resistance

The wetted parts are resistant to organic

solvents and salt buffers commonly used

in chromatography of biomolecules,

except 100% Ethyl acetate, 100%

Hexane, and 100% Tetrahydrofuran (THF)

Tubing connections

UNF 10-32 "fingertights" for capillary

tubing with 1/16” outer diameter

Light source

Xenon flash lamp

Lamp lifetime

> 4000 hours

Control

Stand alone or from a computer running

UNICORN 3.21 or higher through

UniNet-1 connection

Power consumption

65 VA

Power requirement

100–240 V AC, 50–60 Hz

Analogue output

3 signals, 0–1 V full scale, overrange function

Digital inputs

5 V, 1 mA current sinking, lamp on/off,

autozero, event mark

Display

2 rows with 20 characters each

Dimensions (H xW xD)

200 x 260 x 370 mm

Weight

8.5 kg

Degree of protection

IP 20

Compliance with standards

The declaration of conformity is valid for the

instrument only if it is:

• used in laboratory locations

• used in the same state as it was delivered

from GE Healthcare except for

alterations described in the User Manual

• connected to other CE labelled

GE Healthcare modules or other products

as recommended.

Safety Standards

This product meets the requirement of the

Low Voltage Directive (LVD) 73/23/EEC

through the following harmonized standards:

• EN61010-1

• IEC 61010-1

• CAN/CSA-C22.2 No. 61010-1

• UL61010-1

Page 41

Reference information C

Monitor UV-900 User Manual 18-1120-05 Edition AF

41

EMC standards

This device meets the requirements of the

EMC Directive 89/336/EEC through the

following harmonized standards:

• EN 61326 (emission and immunity)

• EN 55011, GR 2, Class A (emission)

• This device complies with part 15 of the

FCC rules (emission). Operation is subject

to the following two conditions:

1 This device may not cause harmful

interference.

2 This device must accept any

interference received, including

interference that may cause

undesired operation.

Page 42

D Reference information

42

Monitor UV-900 User Manual 18-1120-05 Edition AF

D Accessories and spare parts

Item Quantity per pack Code no.

Monitor UV-900 complete but without

flow cells

1 18-1108-35

Flow cell UV-900/2 (2 mm) 1 18-1111-10

Flow cell UV-900/10 (10 mm) 1 18-1111-11

Signal cable 1 18-1110-64

Fibre detachment tool 1 18-1111-16

Teflon tubing, i.d. 1/8", o.d. 3/16" 3 m 18-1112-47

Tubing connector for 3/16" o.d. tubing 10 18-1112-49

Ferrule for 3/16" tubing 10 18-1112-48

Stop plug, 5/16" 5 18-1112-50

Stop plug, 1/16" 5 18-1112-52

Union Luer female/1/16" male 2 18-1112-51

Union 1/16" female/M6 male 6 18-1112-57

Union M6 female/1/16" male 8 18-1112-58

Union 1/16" male/ 1/16" male,

i.d. 0.25 mm

2 18-1120-92

Union 1/16" male/ 1/16" male,

i.d. 0.50 mm

2 18-1120-93

PEEK tubing, i.d. 0.15 mm, o.d. 1/16" 2 m 18-1156-59

PEEK tubing, i.d. 0.25 mm, o.d. 1/16" 2 m 18-1120-95

PEEK tubing, i.d. 0.50 mm, o.d. 1/16" 2 m 18-1113-68

PEEK tubing, i.d. 0.75 mm, o.d. 1/16" 2 m 18-1112-53

PEEK tubing, i.d. 1.0 mm, o.d. 1/16" 2 m 18-1115-83

Tefzel tubing, i.d. 0.25 mm, o.d. 1/16" 2 m 18-1121-36

Teflon tubing, i.d. 0.75 mm, o.d. 1/16" 2 m 18-1112-54

Fingertight connector 1/16" 10 18-1112-55

UV-900 1 mm Calibr. kit 1 18-6324-01

UV-900 2 mm Calibr. kit 1 18-6324-02

UV-900 5 mm Calibr. kit 1 18-6324-04

UV-900 10 mm Calibr. kit 1 18-6324-05

UV-900 Cell calibr. Excel-file 1 18-6324-06

Page 43

Monitor UV-900

User Manual 18-1120-05 Edition AF

43

Short instructions

The following short instructions are intended as a

guide for users who are fully familiar with the safety

precautions and operating instructions described in

this manual. The instructions assume that the unit is

installed according to the installation instructions.

1

Switch on the module

with the mains

switch on the rear panel.

2

Switch on the UV-lamp

by selecting

Run

.

3

Select wavelength

for one, two or three

wavelengths.

4

Autozero

the module by pressing OK.

5

The main operating menu

(RUN-menu)

is shown.

M

onitor U

V

-900

Select OK

ESC

Calibrating

Please wait...

End

Press OK to Run

Set Wavelength

(215, 254, 280 nm)

Set Wavelength λ1

(215nm)

Set Wavelength λ2

(254nm)

Set Wavelength λ3

(280nm)

Autozero

λ1(215) 1.123 AU

λ2(254) 0.02345 AU

λ3(280) 1.123 AU

Page 44

Page 45

Page 46

www.chromatography.

amershambiosciences.com

GE Healthcare Bio-Sciences AB

Björkgatan 30

751 84 Uppsala

Sweden

ÄKTA, ÄKTAdesign, UNICORN and DropDesign are trademarks of

GE Healthcare Ltd, a General Electric Company. GE, imagination at work and

GE monogram are trademarks of General Electric Company.

All goods and services are sold subject to the terms and conditions of sale of

the company within GE Healthcare which supplies them. GE Healthcare

reserves the right, subject to any regulatory and contractual approval, if

required, to make changes in specifications and features shown herein, or

discontinue the product described at any time without notice or obligation.

Contact your local GE Healthcare representative for the most current infor-

mation.

© 2005 General Electric Company – All rights reserved.

GE Healthcare AB

Björkgatan 30, 751 84 Uppsala, Sweden

GE Healthcare AB

Munzinger Strasse 9, D-79111 Freiburg, Germany

GE Healthcare AB

Amersham Place, Little Chalfont, Buckinghamhire, HP7 9NA, UK

GE Healthcare AB

800 Centennial Avenue, P.O. Box 1327, Piscataway, NJ 08855-1327, USA

GE Healthcare AB

Sanken Bldg. 3-25-1, Huakunincho, Shinjuku-ku, Tokyo 169-0073, Japan

Asia Paci.c Tel: +852 2811 8693 Fax: +852 2811 5251 • Australasia Tel: + 61 2 9899 0999 Fax: +61 2 9899 7511 • Austria Tel: 01/57606-1619 Fax: 01/57606-1627 • Belgium Tel: 0800 73 888

Fax: 03 272 1637 • Canada Tel: 800 463 5800 Fax: 800 567 1008 • Central, East, & South East Europe Tel: +43 1 982 3826 Fax: +43 1 985 8327 • Denmark Tel: 45 16 2400 Fax: 45 16 2424 •

Finland & Baltics Tel: +358-(0)9-512 39 40 Fax: +358 (0)9 512 39 439 • France Tel: 01 69 35 67 00 Fax: 01 69 41 96 77 • Germany Tel: 0761/4903-490 Fax: 0761/4903-405 • Italy T el: 02 27322 1

Fax: 02 27302 212 • Japan Tel: +81 3 5331 9336 Fax: +81 3 5331 9370 • Latin America Tel: +55 11 3933 7300 Fax: +55 11 3933 7304 • Middle East & Africa Tel: +30 210 9600 687

Fax: +30 210 9600 693 • Netherlands Tel: 0165 580 410 Fax: 0165 580 401 • Norway Tel: 815 65 555 Fax: 815 65 666 • Portugal Tel: 21 417 7035 Fax: 21 417 3184 • Russia & other C.I.S. & N.I.S

Tel: +7 (095) 232 0250, 956 1137 Fax: +7 (095)230 6377 • South East Asia Tel: 60 3 8024 2080 Fax: 60 3 8024 2090 • Spain Tel: 93 594 49 50 Fax: 93 594 49 55 • Sweden Tel: 018 612 1900

Fax: 018 612 1910 • Switzerland Tel: 0848 8028 12 Fax: 0848 8028 13 • UK Tel: 0800 616928 Fax: 0800 616927 • USA Tel: 800 526 3593 Fax: 877 29 5 81 02

E

l

a

n

d

e

r

s

T

o

f

t

e

r

s

2

0

0

5

imagination at work

User Manual 18-1120-05 AF

Loading...

Loading...