Page 1

GE

Measurement & Control Moisture

Moisture Target™ Series 6

Hygrometer

User’s Manual

910-291 Rev. E

August 2014

Page 2

Page 3

GE

Measurement & Control

Moisture Target™ Series 6

Hygrometer

User’s Manual

910-291 Rev. E

August 2014

www.ge-mcs.com

©2014 General Electric Company. All rights reserved.

Technical content subject to change without notice.

Page 4

[no content intended for this page]

ii

Page 5

Preface

Information Paragraphs

• Note paragraphs provide information that provides a deeper understanding of

the situation, but is not essential to the proper completion of the instructions.

• Important paragraphs provide information that emphasizes instructions that

are essential to proper setup of the equipment. Failure to follow these

instructions carefully may cause unreliable performance.

• Caution! paragraphs provide information that alerts the operator to a hazardous

situation that can cause damage to property or equipment.

• Warning! paragraphs provide information that alerts the operator to a

hazardous situation that can cause injury to personnel. Cautionary information

is also included, when applicable.

Safety Issues

WARNING! It is the responsibility of the user to make sure all local, county,

state and national codes, regulations, rules and laws related to

safety and safe operating conditions are met for each

installation.

Auxiliary Equipment

Local Safety Standards

The user must make sure that he operates all auxiliary equipment in accordance

with local codes, standards, regulations, or laws applicable to safety.

Working Area

WARNING! Auxiliary equipment may have both manual and automatic

modes of operation. As equipment can move suddenly and

without warning, do not enter the work cell of this equipment

during automatic operation, and do not enter the work

envelope of this equipment during manual operation. If you do,

serious injury can result.

WARNING! Make sure that power to the auxiliary equipment is turned OFF

and locked out before you perform maintenance procedures on

the equipment.

Moisture Target Series 6 Hygrometer User’s Manual iii

Page 6

Preface

Qualification of Personnel

Make sure that all personnel have manufacturer-approved training applicable to the

auxiliary equipment.

Personal Safety Equipment

Make sure that operators and maintenance personnel have all safety equipment

applicable to the auxiliary equipment. Examples include safety glasses, protective

headgear, safety shoes, etc.

Unauthorized Operation

Make sure that unauthorized personnel cannot gain access to the operation of the

equipment.

Environmental Compliance

Waste Electrical and Electronic Equipment (WEEE) Directive

GE Measurement & Control is an active participant in Europe’s Waste Electrical

and Electronic Equipment (WEEE) take-back initiative, directive

2002/96/EC.

The equipment that you bought has required the extraction and use of natural

resources for its production. It may contain hazardous substances that could impact

health and the environment.

In order to avoid the dissemination of those substances in our environment and to

diminish the pressure on the natural resources, we encourage you to use the

appropriate take-back systems. Those systems will reuse or recycle most of the

materials of your end life equipment in a sound way.

The crossed-out wheeled bin symbol invites you to use those systems.

If you need more information on the collection, reuse and recycling systems, please

contact your local or regional waste administration.

Visit http://www.ge-mcs.com/en/about-us/environmental-health-and-

safety/1741-weee-req.html for take-back instructions and more information

about this initiative.

iv Moisture Target Series 6 Hygrometer User’s Manual

Page 7

Contents

Chapter 1. Features and Capabilities

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.2 Electronics Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.3 Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Chapter 2. Installation

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.2 Selecting the Recorder Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.3 Mounting the Electronics Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.3.1 Basic Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.3.2 Adapter Plate Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.4 Mounting the Sample System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.5 Installing the Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.6 Wiring the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.6.1 Connecting a Standard Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.6.2 Connecting a VeriDri Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.6.3 Connecting the Recorder Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.6.4 Connecting the Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.6.5 Installing the AC Power Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.6.6 Installing the DC Power Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Moisture Target Series 6 Hygrometer User’s Manual v

Page 8

Contents

Chapter 3. Operation and Programming

3.1 Using the MTS6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.1.1 Starting Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.1.2 Accessing the Menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.1.3 Entering Numeric Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.2 Setting Up the Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.2.1 Selecting Primary Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.2.2 Setting Decimal Places . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.2.3 Contrast. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.3 Setting Up the Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.3.1 Entering the Output Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.3.2 Selecting Output Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.3.3 Selecting an Output Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.3.4 Changing the Upper Output Span. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.3.5 Changing the Lower Output Span. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.3.6 Testing the Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.3.7 Trimming the Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.4 Setting Up Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.4.1 Selecting an Alarm Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.4.2 Selecting Alarm Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.4.3 Selecting Alarm Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.4.4 Selecting an Alarm Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.4.5 How the Alarm Types Work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3.4.6 Changing the Upper Alarm Span. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

3.4.7 Changing the Lower Alarm Span. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

3.4.8 Testing the Alarm Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

3.5 Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

3.5.1 Checking the Data Log Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

3.5.2 Log Settings Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3.5.3 Managing Log Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

3.5.4 Ejecting the SD Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

3.5.5 Viewing Data Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

3.6 Setting Other Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

3.6.1 Entering the Passcode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

3.6.2 Setting the Fault Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

3.6.3 Setting Autocal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

3.6.4 Setting Calibration Data 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

vi Moisture Target Series 6 Hygrometer User’s Manual

Page 9

Contents

3.6.5 Setting Calibration Data 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

3.6.6 Reading and Setting the Calibration References . . . . . . . . . . . . . . . . . 65

3.6.7 Entering the M Series Probe Serial Number . . . . . . . . . . . . . . . . . . . . . . 67

3.6.8 Setting the Volume Mixing Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

3.6.9 Resetting the Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

3.6.10 Selecting the Probe Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

3.6.11 Setting a Constant DP °C Offset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

3.7 Viewing System Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

3.7.1 Checking the ID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

3.7.2 Checking the Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

3.7.3 Checking the Software Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

3.7.4 Checking the Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

3.7.5 Checking the Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

3.8 Locking the Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Chapter 4. Service and Maintenance

4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

4.2 Common Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

4.3 Replacing/Recalibrating Moisture Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

4.4 Cleaning the MTS6 Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Chapter 5. Specifications

5.1 Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

5.2 Moisture Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Appendix A. Outline and Installation Drawings

Appendix B. Menu Maps

Appendix C. Reading the MicroSD Card

C.1 Removing the Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

C.2 Accessing the Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

C.3 Setting Up the Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Appendix D. The Non-Enclosure MTS6 Package

Moisture Target Series 6 Hygrometer User’s Manual vii

Page 10

Contents

viii Moisture Target Series 6 Hygrometer User’s Manual

Page 11

Chapter 1. Features and Capabilities

Chapter 1. Features and Capabilities

1.1 Introduction

The Moisture Target Series 6 (MTS6) is a microprocessor-based,

single-channel hygrometer that measures moisture content in gases. It is

intended for Original Equipment Manufacturer (

suitable for a wide range of process conditions that require real-time

moisture measurement.

The MTS6 accepts any calibration range provided with GE probes (see

Chapter 5, Specifications for more information). It comes equipped with

two standard alarm relays, one fault alarm relay, and a single analog output.

It also has onboard data logging capability using an micro SD card.

1.2 Electronics Unit

The MTS6 displays measurement data on a liquid crystal display (LCD). You

can program your unit and enter probe information using the keys on the

front panel (see Figure 1). The MTS6 accepts line voltages of a universal

power supply from 100 to 240 VAC, or 24 VDC, depending on what is

ordered.

OEM) applications, and is

Figure 1: Front Panel

Moisture Target Series 6 Hygrometer User’s Manual 1

Page 12

Chapter 1. Features and Capabilities

1.3 Probes

The moisture probe is the part of the system that comes in direct contact

with the process. The MTS6 uses any GE M Series (see Figure 2) or a

VeriDri probe (see Figure 3) to measure dew point temperature in °C or °F.

The sensor assembly is secured to the probe mount and is protected with a

sintered stainless steel shield (see Figure 2).

Note: Other types of shields are available upon request.

Figure 2: M Series Probe

Figure 3: VeriDri Probe

2 Moisture Target Series 6 Hygrometer User’s Manual

Page 13

Chapter 2. Installation

Chapter 2. Installation

2.1 Introduction

Installing the MTS6 includes the following steps:

• selecting the recorder output

• mounting the electronics unit

• mounting the sample system

• installing the probe into the sample system

• wiring the input power

• wiring the probe and alarm connections

WARNING! To ensure safe operation, the MTS6 must be panel

mounted and operated as described in this manual. Also,

be sure to follow all applicable local safety codes and

regulations for installing electrical equipment.

Note: For the non-enclosure MTS6 package, please refer to Appendix D for

mounting and installation.

Moisture Target Series 6 Hygrometer User’s Manual 3

Page 14

Chapter 2. Installation

2.2 Selecting the Recorder Output

Note: By default, the recorder is set to the current output.

Note: The customer will provide their own cable for connecting the

recorder. Acceptable cables range from 16 to 26AWG.

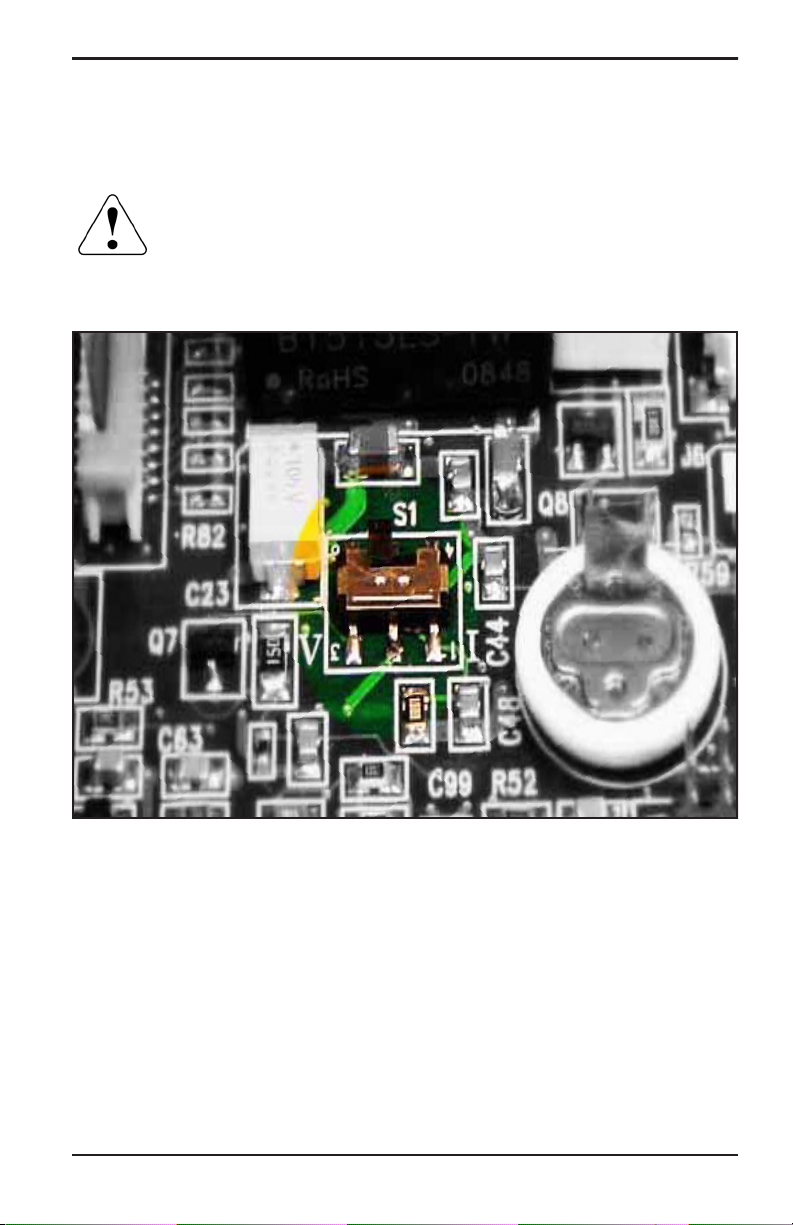

The MTS6 has one isolated analog recorder output. The recorder output

provides either a current or voltage signal, which is set by switch S1 on the

main PC board.

Complete these steps to check or reset switch

WARNING! Never connect line voltage or any other power input to

S1 (see Figure 8 on page 7).

the recorder output terminals.

1. Make sure the MTS6 is turned off and unplugged.

WARNING! The MTS must be isolated or disconnected from all voltage

sources before changing the recorder output.

2. Remove the screw at the top of the back panel (see Figure 4).

Figure 4: Back Panel

4 Moisture Target Series 6 Hygrometer User’s Manual

Page 15

Chapter 2. Installation

2.2 Selecting the Recorder Output (cont.)

3. Lift the back edge of the cover (see Figure 5), slide the cover back (see

Figure 6), and lift it from the enclosure (see Figure 7 on page 6).

Figure 5: Lifting the Back Edge of the Cover

Figure 6: Sliding the Cover Back

Moisture Target Series 6 Hygrometer User’s Manual 5

Page 16

Chapter 2. Installation

2.2 Selecting the Recorder Output (cont.)

Figure 7: Lifting the Cover

6 Moisture Target Series 6 Hygrometer User’s Manual

Page 17

Chapter 2. Installation

2.2 Selecting the Recorder Output (cont.)

4. Locate switch S1 (see Figure 8, highlighted area).

CAUTION! Use proper ESD grounding prior to changing the

switch.

5. Set switch S1 to the desired position: V for voltage or I for current.

Figure 8: Switch S1 on the Main PC Board

6. After setting the switch, replace the cover and reinsert the rear

enclosure screw.

Moisture Target Series 6 Hygrometer User’s Manual 7

Page 18

Chapter 2. Installation

2.3 Mounting the Electronics Unit

The MTS6 unit can be installed in a panel up to 0.25 in. (6 mm) thick. See

Appendix A, Outline and Installation Drawings, for the required panel

cutout dimensions.

IMPORTANT: For NEMA 4 and IP66 installation, the MTS6 must be mounted

in a rigid, flat panel using the panel gasket and both mounting

brackets provided.

2.3.1 Basic Mounting

To mount the MTS6 in a panel with a basic 94 mm (3.69”) x 46 mm (1.81”)

opening, refer to the following figures and complete the following steps:

1. Remove the side panel mount label prior to installation.

Figure 9: Removing Side Panel Mount Label

8 Moisture Target Series 6 Hygrometer User’s Manual

Page 19

Chapter 2. Installation

2.3.1 Basic Mounting (cont.)

2. Slide the small gasket along the MTS6 and place it around the back of

the display (see Figure 10).

Figure 10: Installing the Gasket Behind the Display

3. Slide the MTS6 into the panel cutout (see Figure 11).

Figure 11: Sliding the MTS6 into the Panel Cutout

Moisture Target Series 6 Hygrometer User’s Manual 9

Page 20

Chapter 2. Installation

2.3.1 Basic Mounting (cont.)

4. Behind the panel, insert the mounting brackets into the side holes

provided (see Figure 12).

Figure 12: Installing the Mounting Brackets

5. Hold the chassis and lock each mounting bracket in place by sliding it

toward the rear of the MTS6 (see Figure 13).

Figure 13: Locking the Mounting Brackets in Place

10 Moisture Target Series 6 Hygrometer User’s Manual

Page 21

Chapter 2. Installation

2.3.1 Basic Mounting (cont.)

6. Use a screwdriver to extend the bracket screws to the back of the panel

and secure the MTS6 in the panel cutout (see Figure 14).

Figure 14: Securing the MTS6 to the Panel

7. Using a feeler gauge behind the gasket, check the compression, and

tighten the bracket screws until the gap is 0.028” ±0.002” (see

Figure 15).

Figure 15: Checking the Gasket Compression

Moisture Target Series 6 Hygrometer User’s Manual 11

Page 22

Chapter 2. Installation

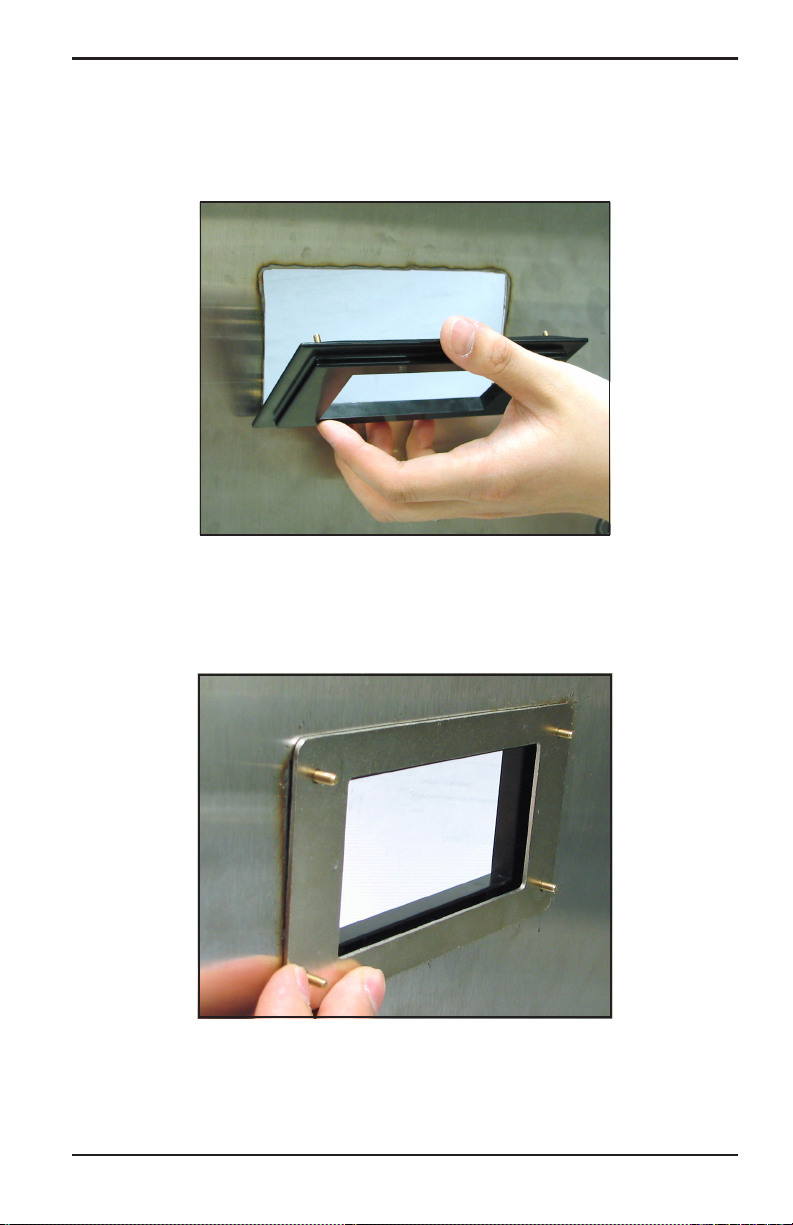

2.3.2 Adapter Plate Mounting

Some customers may need to retrofit an MTS6 into a cut-out sized for GE’s

previous OEM panel-mount hygrometers: MTS5, MTS4 or PanaDry

models. The previous generations were of a larger size requiring a 5.40”

(137.2 mm) W x 2.65” (67.3 mm) H cut-out. The MTS6 is smaller, requiring

a 3.69” (94 mm) W x 1.81” (46 mm) H cut-out. For those customers who

need to retrofit the larger panel cut-out sizes, GE offers an optional adapter

plate. See Appendix A, Outline and Installation Drawings, for the required

panel cutout.

1. Fit the larger gasket around the adapter plate (see Figure 16).

Figure 16: Installing the Adapter Plate Gasket

12 Moisture Target Series 6 Hygrometer User’s Manual

Page 23

Chapter 2. Installation

2.3.2 Adapter Plate Mounting (cont.)

2. Fit the adapter plate into the panel cutout (see Figure 17).

Figure 17: Inserting the Adapter Plate

3. Behind the panel, place the metal backing plate over the four adapter

plate mounting screws (see Figure 18).

Figure 18: Applying the Backing Plate

Moisture Target Series 6 Hygrometer User’s Manual 13

Page 24

Chapter 2. Installation

2.3.2 Adapter Plate Mounting (cont.)

4. Apply nuts to the four screws and secure the assembly to the panel (see

Figure 19 and Figure 20). Use a feeler gauge behind the gasket, check

the compression, and tighten the nuts until the gap is 0.032” ±0.002”.

Figure 19: Securing the Assembly to the Panel

Figure 20: Plate Assembly Mounting Complete

14 Moisture Target Series 6 Hygrometer User’s Manual

Page 25

Chapter 2. Installation

2.3.2 Adapter Plate Mounting (cont.)

Now mount the MTS6 using steps 1-6 in Basic Mounting on page 8.

Re-verify the adapter plate gap after the MTS6 is mounted to the adapter

plate. The installation should appear similar to Figure 21 and Figure 22.

Figure 21: MTS6 Installation with Adapter Plate - Rear

Figure 22: MTS6 Installation with Adapter Plate - Front

Moisture Target Series 6 Hygrometer User’s Manual 15

Page 26

Chapter 2. Installation

2.4 Mounting the Sample System

Figure 23: Typical Sample System

16 Moisture Target Series 6 Hygrometer User’s Manual

Page 27

Chapter 2. Installation

2.4 Mounting the Sample System (cont.)

The sample system is normally fastened to a flat metal plate that has four

mounting holes. Upon request, GE can also provide the sample system in an

enclosure.

Complete the following steps to mount the sample system:

1. Fasten the sample system plate or enclosure to a vertical wall or panel

with a bolt in each of the four corners.

2. Connect the sample system inlet to the process and the outlet to the

return, using appropriate stainless steel fittings and tubing.

CAUTION! Do not start the process flow through the system

until the probe has been properly installed (see the

following section).

2.5 Installing the Probe

GE probes are usually installed in a sample system to protect the probe from

any damaging elements in the process. The probe is mounted in a

cylindrical container called the

your sample system.

sample cell, which is included as part of

Standard M2 probes and VeriDri probes are mounted into the sample system

or process line with 3/4-16 straight threads that are sealed with an o-ring.

Other fittings are available for special applications.

CAUTION! If the probe is to be mounted directly in the

process line, without a sample system, consult GE for proper

installation instructions and precautions.

Refer to Figure 24 on page 18, and complete these steps to install the probe

into the sample cell:

1. Insert the probe into the sample cell and thread the probe into the

sample cell fitting. Make sure you do not to cross the threads.

2. Tighten the probe securely.

Moisture Target Series 6 Hygrometer User’s Manual 17

Page 28

Chapter 2. Installation

2.5 Installing the Probe (cont.)

3. Identify the sample cell inlet port as the connection that is perpendicular

to the installed probe.

CAUTION! For maximum protection of the aluminum oxide

sensor, the probe shield should always be left in place.

Figure 24: Probe/Sample Cell Assembly

2.6 Wiring the System

Wiring the MTS6 system includes the following steps:

• connecting the probe

• connecting the recorder output

• connecting the alarms

• installing the power cable

WARNING! To ensure safe operation, the MTS6 must be installed and

operated as described in this manual. Also, be sure to

follow all applicable local safety codes and regulations for

installing electrical equipment.

18 Moisture Target Series 6 Hygrometer User’s Manual

Page 29

2.6 Wiring the System (cont.)

The CAUTION! symbol is a reminder that MTS6 components can

be damaged if electrical connections are not correctly made.

Figure 25: MTS6 Rear Panel Connections - AC Version

Chapter 2. Installation

Figure 26: MTS6 Rear Panel Connections - DC Version

Moisture Target Series 6 Hygrometer User’s Manual 19

Page 30

Chapter 2. Installation

2.6 Wiring the System (cont.)

Figure 27: MTS6 Wiring Diagram

20 Moisture Target Series 6 Hygrometer User’s Manual

Page 31

Chapter 2. Installation

2.6.1 Connecting a Standard Probe

The probe must be connected to the MTS6 with a continuous run of GE

two-wire shielded cable. When connecting the probe, protect the cable from

excessive strain (bending, pulling, etc.) and avoid subjecting the cable to

temperatures above 65°C (149°F) or below –50°C (–58°F).

Note: Standard factory-assembled cables are available from GE in lengths

up to 600 meters (2000 feet).

Figure 28: Two-Wire, Shielded, M Series Probe Cable

To connect the probe cable, refer to Figure 25 on page 19 and Figure 29 and

Figure 30 on page 22, and complete the following steps:

1. Insert the end of probe cable with the bayonet-type connector onto the

probe and twist the shell clockwise until it snaps into a locked position

(approximately 1/8 turn).

IMPORTANT: Ensure that the power is off before proceeding.

2. Connect the end of the probe cable with the three leads to the lower

terminal block (pins 16, 17 and 18) on the back of the MTS6.

Moisture Target Series 6 Hygrometer User’s Manual 21

Page 32

Chapter 2. Installation

2.6.1 Connecting a Standard Probe (cont.)

Figure 29: M Series Probe Cable Connections

IMPORTANT: To maintain good contact at the terminal block and to avoid

damaging the pins on the wiring connector, pull the connector

straight off (not at an angle) the terminal block. Then, make

the cable connections while the connector is off the unit.

Finally, after the wiring is complete, push the connector

straight onto the terminal block (not at an angle).

Figure 30: Bottom Connector Removed

22 Moisture Target Series 6 Hygrometer User’s Manual

Page 33

Chapter 2. Installation

2.6.1 Connecting a Standard Probe (cont.)

Figure 31: Making Probe Cable Connections to the Connector

Figure 32: Reinserting the Connector into the Terminal Block

Moisture Target Series 6 Hygrometer User’s Manual 23

Page 34

Chapter 2. Installation

2.6.2 Connecting a VeriDri Probe

Use the following steps to wire the VeriDri to the MTS6.

Figure 33: Four-Wire, VeriDri Probe Cable

1. Insert the end of probe cable with the connector onto the probe and

twist the connector head clockwise until it is secure.

IMPORTANT: Ensure that the power is off before proceeding.

24 Moisture Target Series 6 Hygrometer User’s Manual

Page 35

Chapter 2. Installation

2.6.2 Connecting a VeriDri Probe (cont.)

2. Using the flying leads at the end of the VeriDri cable, connect the probe

to the lower terminal block (pins 10, 11, 12 and 13) on the back of the

MTS6 (see Table 1 and Figure 35 and Figure 36 on page 26).

Table 1: VeriDri Wiring Connections

Wire Color Pin Number Designation

Brown 10 RTN

Black 11 COM –

White 12 COM +

Blue 13 +15V

IMPORTANT: To maintain good contact at the terminal block and to avoid

damaging the pins on the wiring connector, pull the connector

straight off (not at an angle) the terminal block. Then, make

the cable connections while the connector is off the unit.

Finally, after the wiring is complete, push the connector

straight onto the terminal block (not at an angle).

Figure 34: Bottom Connector Removed

Moisture Target Series 6 Hygrometer User’s Manual 25

Page 36

Chapter 2. Installation

2.6.2 Connecting a VeriDri Probe (cont.)

Figure 35: Wiring the Cable to the Connector

Figure 36: Reinserting the Connector into the Terminal Block

Note: When there is a No Link error for the VeriDri, check the wiring to

ensure proper connections and make sure there is no short between

the +15V and RTN.

26 Moisture Target Series 6 Hygrometer User’s Manual

Page 37

Chapter 2. Installation

2.6.3 Connecting the Recorder Outputs

IMPORTANT: Ensure that the power is off before proceeding.

Connect your recorder to the lower terminal block on the back of the MTS6

(pins 14 and 15), as shown in Figure 25 and Figure 26 on page 19.

IMPORTANT: To maintain good contact at each terminal block and to avoid

damaging the pins on the connector, pull the connector

straight off (not at an angle), make cable connections while the

connector is away from the unit, and push the connector

straight on (not at an angle) when the wiring is complete.

2.6.4 Connecting the Relays

Note: The customer will provide their own cable for connecting the alarm

relays. Acceptable cables range from 16 to 26AWG.

The MTS6 has one fault alarm relay and two high/low alarm relays. Each

alarm relay is a single-pole, double-throw contact set that contains the

following contacts:

• Normally Open (NO)

• Common (C)

• Normally Closed (NC)

Table 2: Pin Designations for Relay Contacts

Fault Alarm A Alarm B

Normally Open 1 4 7

Common 2 5 8

Normally Closed 3 6 9

Moisture Target Series 6 Hygrometer User’s Manual 27

Page 38

Chapter 2. Installation

2.6.4a Connecting the High/Low Alarms (A and B)

IMPORTANT: Ensure that the power is off before proceeding.

Each of these alarms can be set to trip on either a high or low condition. For

a high alarm, the alarm will trip if the input exceeds the setpoint. For a low

alarm, the alarm will trip if the input drops below the setpoint. Make

connections to the Alarm A and Alarm B upper terminal block on the back

of the MTS6, as shown in Figure 25 and Figure 26 on page 19.

IMPORTANT: To maintain good contact at each terminal block and to avoid

damaging the pins on the connector, pull the connector

straight off (not at an angle), make cable connections while the

connector is away from the unit, and push the connector

straight on (not at an angle) when the wiring is complete.

Figure 37: Removing the Upper Connector

28 Moisture Target Series 6 Hygrometer User’s Manual

Page 39

Chapter 2. Installation

2.6.4b Connecting the Fault Alarm

If enabled, the fault alarm trips when one or more of the following faults

occurs:

• power failure

• range error (configurable)

• watchdog function system reset

Note: The watchdog function is a supervisory circuit that automatically

resets the unit whenever a system error occurs.

The fault alarm may operate in fail-safe mode and uses pins 2 and 3 to

provide a “normally closed” contact. When the MTS6 is operating in a

non-fault state, the fault alarm relay is energized to open the contact

between pins 2 and 3. When a fault occurs, the fault alarm relay is

de-energized to close the contact between pins 2 and 3.

Note: The contact between pins 1 (normally open) and 2 works in the

opposite way. The alarm is energized to close the contact during

ordinary operation and the alarm is de-energized to open the contact

when there is a fault.

IMPORTANT: Ensure that the power is off before proceeding.

To wire the fault alarm, make connections to the upper terminal block on

the back of the MTS6, as shown in Figure 25 and Figure 26 on page 19.

IMPORTANT: To maintain good contact at each terminal block and to avoid

damaging the pins on the connector, pull the connector

straight off (not at an angle), make cable connections while the

connector is away from the unit, and push the connector

straight on (not at an angle) when the wiring is complete.

Moisture Target Series 6 Hygrometer User’s Manual 29

Page 40

Chapter 2. Installation

2.6.5 Installing the AC Power Cable

To install the AC power cable, included with the MTS6, simply plug the

female connector end of the cable into the male connector on the rear panel

of the MTS6 (see Figure 25 on page 19, Figure 38 and Figure 39).

Figure 38: Inserting the AC Power Cable

Figure 39: The AC Power Cable Installed

30 Moisture Target Series 6 Hygrometer User’s Manual

Page 41

Chapter 2. Installation

2.6.6 Installing the DC Power Cable

The DC power cable (with 14 to 26 AWG wires) is supplied by the

customer. Use the following instructions to connect the cable to the MTS6.

Figure 40: MTS6 Rear Panel Connections - DC Version

1. Remove the DC Connector from the rear panel (see Figure 41).

Figure 41: Removing the DC Connector

Moisture Target Series 6 Hygrometer User’s Manual 31

Page 42

Chapter 2. Installation

2.6.6 Installing the DC Power Cable (cont.)

2. Strip each conductor of the DC power cable by approximately 3/8”.

3. Insert each wire into the appropriate slot (+, – and chassis) and tighten

each screw to secure them in place.

IMPORTANT: Ensure that the chassis ground connection is properly

grounded.

4. Reinsert the DC connector into the rear panel (see Figure 42).

[no content intended for this page]

Figure 42: Reinserting the DC Connector

32 Moisture Target Series 6 Hygrometer User’s Manual

Page 43

Chapter 3. Operation and Programming

Chapter 3. Operation and Programming

3.1 Using the MTS6

3.1.1 Starting Up

After proper installation, the MTS6 Transmitter can be set up to

accommodate the user’s requirements. Typically, the user may need to

configure the analog outputs, trim the analog outputs, and program logging.

Refer to a Menu Map, Figure 49 on page 94 when using an M Series probe,

or Figure 50 on page 95 when using a VeriDri probe, and complete the

following steps. Upon startup, the MTS6 proceeds through several displays

until a screen similar to the following appears:

After startup, the screen will need to be

unlocked. To unlock the screen, press

Cancel, Enter, Cancel.

Note: In most instances; use the Enter key to save an entry and/or move

ahead to the following screen; use the Cancel key to reject an entry

and/or return to the previous screen.

Moisture Target Series 6 Hygrometer User’s Manual 33

Page 44

Chapter 3. Operation and Programming

3.1.2 Accessing the Menus

After successfully unlocking the keypad, press Cancel . The MTS6 will

display the Main Menu (see Figure 43). Use the arrow keys to select the

menu item desired. Refer to Menu Map, Figure 49 on page 94.

Press Enter to select the highlighted item. Many menu items will

display another menu. Use Cancel to return to the previous menu page.

Pressing Cancel from the Main Menu will return the screen to the

Measurement Display.

Note: Menu items displayed with an ellipsis (shown as a series of three dots

after the menu item) will bring up more choices, while those without

take immediate action.

Figure 43: Main Menu

34 Moisture Target Series 6 Hygrometer User’s Manual

Page 45

Chapter 3. Operation and Programming

3.1.3 Entering Numeric Values

Since the MTS6 has no numeric keypad, numeric values are entered using a

“combination lock” style of entry:

Use the left and right arrow keys to select the digit to change. The

digit selected will be indicated with a .

Use the up and down arrow keys to increment or decrement the

digit.

Note: If incrementing or decrementing a digit would cause the numeric

value to exceed its allowable range (maximum/minimum value), the

digit will not change.

Press Enter to save the new value and return, or Cancel to return,

leaving the original value intact.

Figure 44: Numeric Entry

Moisture Target Series 6 Hygrometer User’s Manual 35

Page 46

Chapter 3. Operation and Programming

3.2 Setting Up the Display

When the screen is unlocked, touch the

Cancel key and the Main Menu appears

with several options. To set up the display,

select Display... and press Enter . The

following screen appears:

3.2.1 Selecting Primary Units

To select units for the primary display, select

Unit Select and press Enter . The

following screen appears:

Use the arrow keys to select the desired

units and press Enter . The screen

returns to the Display Menu.

Note: If the VeriDri probe is being used, FH

replaces MH.

Note: If the ppmv software version was purchased, PPMv, mg/m

3

and kg/m

will be available.

3

, g/m3,

36 Moisture Target Series 6 Hygrometer User’s Manual

Page 47

Chapter 3. Operation and Programming

3.2.2 Setting Decimal Places

To set the decimal places for unit values,

from the Display Menu use the arrow keys

to select Decimal and press Enter . The

following screen appears.

The decimal places setting determines the number of digits displayed for

the value to the

right of the decimal symbol (“.”), if possible.

Use the arrow keys to change the number of

decimal places and press Enter , or press

Cancel if no changes are necessary. The

screen returns to the Display Menu.

3.2.3 Contrast

To modify the display contrast, from the

Display Menu use the arrow keys to select

Contrast and press Enter . The

following screen appears.

Use the Right/Left arrow keys to

increase/decrease display contrast. Press

Enter to save the changes, or press

Cancel to return to the previous setup.

The screen returns to the Display Menu.

Moisture Target Series 6 Hygrometer User’s Manual 37

Page 48

Chapter 3. Operation and Programming

3.3 Setting Up the Output

3.3.1 Entering the Output Menu

To set up the output, from the Main Menu

choose Output... and press Enter . The

following screen appears.

3.3.2 Selecting Output Units

From the Output Menu, select Units and

press Enter . The following screen

appears.

Use the arrow keys to select the unit type

and press Enter . The screen returns to

the Output Menu:

Note: If the VeriDri probe is being used, FH

replaces MH.

Note: If the ppmv software version was purchased, PPMv, mg/m

3

and kg/m

38 Moisture Target Series 6 Hygrometer User’s Manual

will be available.

3

, g/m3,

Page 49

Chapter 3. Operation and Programming

3.3.3 Selecting an Output Type

Note: Before changing the output type, refer to Section 2.2 Selecting the

Recorder Output on page 4 to make sure that Switch S1 is at the

correct setting (V for voltage or I for current).

To change the output type, from the Output

Menu select Type and press Enter . A

screen similar to the following appears:

Use the arrow keys to select a new output

type. Press Enter to save (or Cancel

to keep the previous value), and return to the

Output Menu.

3.3.4 Changing the Upper Output Span

To adjust the upper output span, from the

Output Menu select Upper and press

Enter . A screen similar to the following

appears.

Use the left and right arrow keys to select

each digit to be changed and the up and

down arrow keys to increase or decrease its

value. Press Enter to save (or Cancel

to keep the previous value), and return to

Output Menu.

Moisture Target Series 6 Hygrometer User’s Manual 39

Page 50

Chapter 3. Operation and Programming

3.3.5 Changing the Lower Output Span

To adjust the lower output span, from the

Output Menu select Lower and press

Enter . A screen similar to the following

appears.

Use the left and right arrow keys to select

each digit to be changed and the up and

down arrow keys to increase or decrease its

value. Press Enter to save (or Cancel

to keep the previous value), and return to

Output Menu.

3.3.6 Testing the Output

The Test Menu causes the MTS6 to generate a 0- or 4-20mA output, or a

0-2V output, at the percent of scale selected. For example, in 4-20mA

operation, 0% = 4mA, 50% = 12mA, 100% = 20mA. This allows the proper

function of recording or SCADA equipment to be verified. In 0-20

operation, 0% = 0mA, 50% = 10mA, 100% = 20mA

To test system output, from the Output

Menu select Test and press Enter . The

MTS6 will proceed to check the settings, and

a screen similar to the following will appear.

Use the left and right arrow keys to select

each digit to be changed, and the up and

down arrow keys to increase or decrease its

value. Press Enter to save (or Cancel

to keep the previous value), and return to the

Output Menu.

Check your output wiring. If the reading on your SCADA or DCS is off

slightly, then you may use the Trim feature to trim the output zero or span.

40 Moisture Target Series 6 Hygrometer User’s Manual

Page 51

Chapter 3. Operation and Programming

3.3.7 Trimming the Outputs

The Trim Menu enables the operator to compensate for differences in

measurement of the 0/4-20 mA or 0-2V outputs by connected recorders or

SCADA equipment. To trim the output:

Select Trim from the Output Menu and press

Enter . The following screen appears.

When performing a Trim operation, the

MTS6 unit requires you to first reset the trim.

To reset the trim output, select Reset Trim

and press Enter . The following screen

appears.

Use the left or right arrow keys to select YES

and press Enter . This cancels any

previous trim values, and returns the MTS6

to its factory adjustment. The display returns

to the previous screen.

To trim the zero value, select Trim Zero and

press Enter . A screen similar to the

following appears.

This will cause the MTS6 to output 4.000 mA or 0.4 V on the output being

trimmed. The output value should then be read using the connected

recorder, SCADA equipment, or DVM. Enter the value read from the

connected equipment as the Zero Trim value, as follows:

Note: Since you cannot trim 0 mA or 0 V for negative offsets, trim for the

lower end of the scale is at the 4 mA or 0.4 V output level.

Moisture Target Series 6 Hygrometer User’s Manual 41

Page 52

Chapter 3. Operation and Programming

3.3.7 Trimming the Outputs (cont.)

Use the left and right arrow keys to select

each digit to be changed, and the up and

down arrow keys to increase or decrease its

value. Press Enter to save (or Cancel

to keep the previous value).

The Output Trim menu returns with Trim

Span highlighted. To change the span value,

press Enter . A screen similar to the

following appears.

This will cause the MTS6 to output 20.000 mA on the output being trimmed.

The output value should then be read using the connected recorder, SCADA

equipment, or DVM. Enter the value read from the connected equipment as

the Span Trim value.

Use the left and right arrow keys to select

each digit to be changed, and the up and

down arrow keys to increase or decrease its

value. Press Enter to save (or Cancel

to keep the previous value).

Trimming is complete. Accuracy can be verified using the Test Menu,

above.

Example: Trim is reset, then Trim Zero is selected. The SCADA input

reports 3.977 mA.

The operator enters “3.977” as the Zero Trim value.

Trim Span is selected. The SCADA input reports 19.985 mA.

The operator enters “19.985” as the Span Trim value.

MTS6 will adjust the output accordingly to true the output as read by the

customer recorder, SCADA or DVM.

Using the Test Menu, the operator verifies that a test value of 0% now reads

4.000 mA at the SCADA equipment, and a test value of 100% now reads

20.000 mA.

42 Moisture Target Series 6 Hygrometer User’s Manual

Page 53

Chapter 3. Operation and Programming

3.4 Setting Up Alarms

Note: The MTS6 is equipped with two programmable high/low alarm relays

and one fault alarm.

3.4.1 Selecting an Alarm Output

To set up alarm outputs, on the Main Menu

choose Alarm and press Enter . From the

Alarm Menu choose Select and press

Enter . A screen similar to the following

appears.

Use the arrow keys to select the output

(A or B) to be set up and press Enter .

The display returns to the Alarm Menu.

3.4.2 Selecting Alarm Status

To select the alarm status, from the Alarm

Menu select Status and press Enter . The

following screen appears:

Use the arrow keys to select OFF or ON and

press Enter . The display returns to the

Alarm Menu.

Moisture Target Series 6 Hygrometer User’s Manual 43

Page 54

Chapter 3. Operation and Programming

3.4.3 Selecting Alarm Units

To select alarm units, from the Alarm Menu

select Units and press Enter .

Use the arrow keys to select a unit. Press

Enter to save (or Cancel to keep the

previous value), and return to the Alarm

Menu.

Note: If the VeriDri probe is being used, FH

replaces MH.

Note: If the ppmv software version was purchased, PPMv, mg/m

3

and kg/m

will be available.

3.4.4 Selecting an Alarm Type

3

, g/m3,

To change the alarm type, from the Alarm

Menu select Type and press Enter . A

screen similar to the following appears:

Use the arrow keys to select an alarm type.

Press Enter to save (or Cancel to

keep the previous value), and return to the

Alarm Menu.

44 Moisture Target Series 6 Hygrometer User’s Manual

Page 55

Chapter 3. Operation and Programming

3.4.4 Selecting an Alarm Type (cont.)

• SetPoint: Alarm activates when parameter exceeds upper limit, and

deactivates when parameter is less than lower limit.

• Inner Band: Alarm activates when parameter is between upper and

lower limits.

• Outer Band: Alarm activates when parameter is outside upper and

lower limits.

3.4.5 How the Alarm Types Work

Figure 45: Example of Alarm Types

Moisture Target Series 6 Hygrometer User’s Manual 45

Page 56

Chapter 3. Operation and Programming

3.4.6 Changing the Upper Alarm Span

To adjust the upper alarm span, from the

Alarm Menu select Upper and press

Enter . A screen similar to the following

appears.

Use the left and right arrow keys to select

each digit to be changed and the up and

down arrow keys to increase or decrease its

value. Press Enter to save (or Cancel

to keep the previous value), and return to the

Alarm Menu.

3.4.7 Changing the Lower Alarm Span

To adjust the lower alarm span, from the

Alarm Menu select Lower and press

Enter . A screen similar to the following

appears.

Use the left and right arrow keys to select

each digit to be changed and the up and

down arrow keys to increase or decrease its

value. Press Enter to save (or Cancel

to keep the previous value), and return to the

Alarm Menu.

46 Moisture Target Series 6 Hygrometer User’s Manual

Page 57

Chapter 3. Operation and Programming

3.4.8 Testing the Alarm Relays

To test the alarm relay, and devices

connected to it, from the Alarm Menu select

Test and press Enter . A screen similar to

the following appears.

Use the left and right arrow keys to select

Reset or Trip and press Enter . If Reset

was selected, the message Alarm is RESET

appears. If Trip was selected, the message

Alarm is Tripped appears. Press Cancel

to return to the Alarm Menu.

3.5 Logging

3.5.1 Checking the Data Log Status

To check the data log status, from the

Logging Menu select Status and press

Enter . A screen similar to the following

appears.

The current data log status is displayed.

After about 10 seconds, the screen returns to

the Logging Menu.

Moisture Target Series 6 Hygrometer User’s Manual 47

Page 58

Chapter 3. Operation and Programming

3.5.2 Log Settings Menu

Note: To access the Settings... option under the Logging Menu, the log file

must be stopped (see Starting/Stopping Log Files on page 51.

3.5.2a Setting Log Units

From the Logging Menu select Settings...

and press Enter . The following screen

appears.

To set units to log, from the Set Log Params

menu, select Units and press Enter . The

following screen appears.

Use the arrow keys to select the unit to log,

and press Enter . The following screen

appears.

To change the unit setting, select Modify and

press Enter . The following screen

appears.

48 Moisture Target Series 6 Hygrometer User’s Manual

Page 59

Chapter 3. Operation and Programming

3.5.2a Setting Log Units (cont.)

Use the arrow keys to select the unit to be

represented by #1 and press Enter . The

screen returns to the Units to Log menu.

Note: If the VeriDri probe is being used, FH

replaces MH.

Note: If the ppmv software version was purchased, PPMv, mg/m

3

and kg/m

will be available.

3

, g/m3,

To remove a unit, from the Units to Log menu, select Remove and press

Enter . Select the unit to be removed, press Enter , and the unit is

deleted. Press Cancel to return to the Set Log Params menu.

3.5.2b Setting the Log Interval

To set the log interval, from the Set Log

Params menu, select Interval and press

Enter . The following screen appears.

Use the left and right arrow keys to select

each digit to be changed and the up and

down arrow keys to increase or decrease its

value. Press Enter to save (or Cancel

to keep the previous value), and return to the

Set Log Params menu.

Moisture Target Series 6 Hygrometer User’s Manual 49

Page 60

Chapter 3. Operation and Programming

3.5.2c Setting a Field Separator

To designate a mark to separate the log

fields, from the Set Log Params menu select

FieldSep and press Enter . The following

screen appears.

Use the arrow keys to select the mark used to

separate the log fields and press Enter .

The screen returns to the Set Log Params

menu.

3.5.2d Setting Log Status Flags

Note: The flags used to identify the log status are as follows:

Range Err No Comm Bad Message No Data Read Err

Over Range No Link Auto Cal No Cal ADC Failure

Under Range Bad CRC No Refs Write Err Cal Error

To turn log status flags on or off, from the

Set Log Params menu select Flags and press

Enter . The following screen appears.

Use the arrow keys to select OFF or ON and

press Enter . The screen returns to the

Set Log Params menu.

Press Cancel to return to the Logging

Menu.

50 Moisture Target Series 6 Hygrometer User’s Manual

Page 61

Chapter 3. Operation and Programming

3.5.3 Managing Log Files

To manage the log file status, from the

Logging Menu select Manage and press

Enter . If no log has been created, the

following screen appears.

3.5.3a Creating a New Log

Note: In order for the new log option to be available, there can be no log

running or paused. If there is any previous log running/paused, it will

need to be closed. Once closed, the closed log file cannot be resumed.

To create a new log, from the Manage Log

Files menu select New Log and press

Enter . A screen similar to the following

appears.

A file name is assigned by the MTS6 to the

new log. This name corresponds to the date

and time the log is started. A log started on

May 1 at 4:37 pm will be named 05011637.

After about 10 seconds, the screen returns to

the Manage Log Files menu.

Note: When a new log is created, the Manage Log Files menu changes to

the following screen.

Moisture Target Series 6 Hygrometer User’s Manual 51

Page 62

Chapter 3. Operation and Programming

3.5.3b Pausing a Log

When a new log is created, it can be paused

or closed. To pause the log, from the

Manage Log Files menu select Pause/Close

and press Enter . The following screen

appears.

Select Pause and press Enter . the screen

returns to the Manage Log Files menu.

Note: When a log is paused, the Manage

Log Files menu changes to the following

screen.

3.5.3c Resuming a Log

A paused log can be resumed or closed. To

resume the log function, from the Manage

Log Files menu select Resume/Close and

press Enter . The following screen

appears.

Select Resume and press Enter . the

screen returns to the Manage Log Files

menu.

Note: When a log is resumed, the Manage

Log Files menu displays the Pause/Close

option again.

Note: If a log is running and it reboots due to a power failure, it will always

return to the previous state prior to the power failure. If it was

running, it will continue to run. If it was paused, it will stay paused

and can be resumed.

52 Moisture Target Series 6 Hygrometer User’s Manual

Page 63

3.5.3d Viewing the Log Directory

To view the existing log names, select

Directory and press Enter . A screen

similar to the following appears.

When a listing is highlighted, the date, time

and size of each log appears at the bottom of

the screen. Use the arrow keys to move from

one listing to another. To return to the

Manage Log Files menu, press Cancel .

Chapter 3. Operation and Programming

Moisture Target Series 6 Hygrometer User’s Manual 53

Page 64

Chapter 3. Operation and Programming

3.5.3e Deleting Log Files

To erase an existing log file(s), from the

Manage Log Files menu, select Erase Log

and press Enter . The File Listing screen

appears.

Using the arrow keys, move to the listing to

be deleted, and press Enter . The

following screen appears.

Using the arrow keys, select YES to erase the

listing, or NO to save the listing. Press

Enter and the screen returns to File

Listing. If YES was selected, the particular

number is gone. If NO was selected, the

number is still present.

Press the Cancel key to return to the Manage Log Files menu.

54 Moisture Target Series 6 Hygrometer User’s Manual

Page 65

Chapter 3. Operation and Programming

3.5.4 Ejecting the SD Card

Removing the MicroSD card requires two steps. First, the active files must

be closed. This step is referred to as ejecting the SD Card. The MicroSD

card can now be removed from the MTS6.

Note: Physically removing the MicroSD card from the MTS6 without

performing the eject routine below may result in data loss. This will

not result in damage to either the MicroSD card or to the MTS6.

To eject the SD card, from the Logging

Menu, select Eject Card and press Enter .

The following screen appears.

Use the arrow keys to select EJECT or

CANCEL and press Enter . The screen

returns to the Logging Menu.

Press Cancel to return to the Main Menu.

Note: If EJECT was selected, the MicroSD card may now be removed from

the MTS6. To remove and read the card see Reading the MicroSD

Card on page 97.

3.5.5 Viewing Data Logs

Any MicroSD card reader may be used to read the MicroSD card. The log

file is in text format, therefore, any word processing or spreadsheet program

may be used to read the data.

Refer to Appendix C for examples on how to work with log files.

Moisture Target Series 6 Hygrometer User’s Manual 55

Page 66

Chapter 3. Operation and Programming

3.6 Setting Other Information

To change other settings, from the Main

Menu select Settings... and press Enter .

The following screen appears.

3.6.1 Entering the Passcode

The Settings Menu is the only menu that requires a passcode. The passcode

is a four-digit number that enables only authorized users to enter setup data.

The MTS6 prompts you to enter the passcode when you enter the Settings

Menu. See page 79 for your default passcode.

3.6.2 Setting the Fault Alarm

To configure the fault alarm, from the

Settings Menu select Fault Alarm and press

Enter . The following screen appears.

Note: To access the Fault Alarm menu, the

User Passcode is required (see section 3.6.1

above).

Use the left and right arrow keys to select

each digit to be changed and the up and

down arrow keys to increase or decrease its

value. Once the passcode has been entered,

press Enter and the following screen

appears.

56 Moisture Target Series 6 Hygrometer User’s Manual

Page 67

Chapter 3. Operation and Programming

3.6.2a Setting Fault Alarm Status

To check the status of the fault alarm, from

the Fault Alarm menu, select Status and

press Enter . The following screen

appears.

To change the status of the fault alarm, select

OFF or ON and press Enter . The screen

returns to the Fault Alarm menu.

3.6.2b Setting the Fault Relay Type

Note: For more information on the meaning of relay types, see section

2.6.4b Connecting the Fault Alarm on page 29.

To check and/or change the fault relay type,

select Type and press Enter . The

following screen appears.

To change the type of fault relay, select the

other option and press Enter . The screen

returns to the Fault Alarm menu.

Moisture Target Series 6 Hygrometer User’s Manual 57

Page 68

Chapter 3. Operation and Programming

3.6.2c Setting Fault Alarm Options

To view the status other options select

Options and press Enter . The following

screen appears.

To change the status of the range error

alarm, select Yes or No and press Enter .

The screen returns to the Fault Alarm menu.

Press Cancel to return to the Settings

Menu.

3.6.2d Testing the Fault Alarm

To test the fault alarm, select Test and press

Enter . The following screen appears.

To reset the fault alarm, select Reset and

press Enter . To trip the fault alarm,

select Trip and press Enter . Press Cancel

twice to return to the Settings Menu.

58 Moisture Target Series 6 Hygrometer User’s Manual

Page 69

Chapter 3. Operation and Programming

3.6.3 Setting Autocal

Note: To enter the Autocal Settings menu, you must be using a standard

M Series probe. If a VeriDri probe is being used, AutoCal is not

necessary and will not be accessible.

To change the Autocal settings, from the

Settings Menu select AutoCal and press

Enter . The following screen appears.

To change the Autocal interval settings,

select Interval and press Enter . A screen

similar to the following appears.

Use the left and right arrow keys to select

each digit to be changed and the up and

down arrow keys to increase or decrease its

value. Press Enter to save (or Cancel

to keep the previous value), and return to the

AutoCal Settings menu.

To accept or reject AutoCal, select Cal Now

and press Enter . A screen similar to the

following appears.

To accept AutoCal, select Yes. To reject

AutoCal select No. Press Enter to

confirm your selection and return to the

AutoCal Settings menu.

Moisture Target Series 6 Hygrometer User’s Manual 59

Page 70

Chapter 3. Operation and Programming

3.6.4 Setting Calibration Data 1

Note: If you are using a standard M Series probe, the following steps will

apply. If you are using a VeriDri probe, see Setting Calibration Data 2

on page 63.

Note: To update calibration data, from the

Settings Menu select Cal Data and press

Enter . The following screen appears.

Note: To access the Cal Data menu, the User

Passcode is required (see section 3.6.1 on

page 56).

Use the left and right arrow keys to select

each digit to be changed and the up and

down arrow keys to increase or decrease its

value. Once the passcode has been entered,

press Enter and the following screen

appears.

If you are using a standard M Series probe,

the MH/DP Cal will be highlighted. Press

Enter . The following screen appears.

60 Moisture Target Series 6 Hygrometer User’s Manual

Page 71

Chapter 3. Operation and Programming

3.6.4a Selecting the Number of Points

To select the number of points, highlight

Select Num of Points and press Enter .

The following screen appears.

Use the left and right arrow keys to select

each digit to be changed and the up and

down arrow keys to increase or decrease its

value. Press Enter to save (or Cancel

to keep the previous value), and return to the

Edit MH/DP Cal menu.

3.6.4b Selecting the Calibration Point

To select the calibration point, highlight

Select Cal Point and press Enter . The

following screen appears.

Use the left and right arrow keys to select

each digit to be changed and the up and

down arrow keys to increase or decrease its

value. Press Enter to save (or Cancel

to keep the previous value), and return to the

Edit MH/DP Cal menu.

Moisture Target Series 6 Hygrometer User’s Manual 61

Page 72

Chapter 3. Operation and Programming

3.6.4c Setting the MH Calibration

To set up the MH calibration, highlight Edit

MH and press Enter . The following

screen appears.

Use the left and right arrow keys to select

each digit to be changed and the up and

down arrow keys to increase or decrease its

value. Press Enter to save (or Cancel

to keep the previous value), and return to the

Edit MH/DP Cal menu.

3.6.4d Setting the Dew Point Calibration

To set up the dew point calibration, highlight

Edit DP/°C and press Enter . The

following screen appears.

Use the left and right arrow keys to select

each digit to be changed and the up and

down arrow keys to increase or decrease its

value. Press Enter to save (or Cancel

to keep the previous value), and return to the

Edit MH/DP Cal menu.

Press Cancel to return to the Cal Data menu.

62 Moisture Target Series 6 Hygrometer User’s Manual

Page 73

Chapter 3. Operation and Programming

3.6.5 Setting Calibration Data 2

Note: If you are using a VeriDri probe, the following steps will apply. For a

standard M Series probe, see Setting Calibration Data 1 on page 60.

To view calibration data, from the Settings

Menu select Cal Data and press Enter .

The following screen appears.

Note: To access the Cal Data menu, the User

Passcode is required (see section 3.6.1 on

page 56).

Use the left and right arrow keys to select

each digit to be changed and the up and

down arrow keys to increase or decrease its

value. Once the passcode has been entered,

press Enter and the following screen

appears.

If you are using a VeriDri probe, the

FH/DPCal will be highlighted. Press

Enter . The following screen appears.

3.6.5a Selecting the Calibration Point

To select the calibration point, highlight

Select Cal Point and press Enter . The

following screen appears.

Use the left and right arrow keys to select

each digit to be changed and the up and

down arrow keys to increase or decrease its

value. Press Enter to save (or Cancel

to keep the previous value), and return to the

Edit MH/DP Cal menu.

Moisture Target Series 6 Hygrometer User’s Manual 63

Page 74

Chapter 3. Operation and Programming

3.6.5b Reading the FH Value

To view the FH value, highlight Read FH

Value and press Enter . The following

screen appears.

The FH value is for viewing only. When you

are ready, press Cancel to return to the

Read FH/DP Calibration menu.

3.6.5c Reading the DP Value

To view the DP value, highlight Read DP

Value and press Enter . The following

screen appears.

The DP value is for viewing only. When you

are ready, press Cancel to return to the

Read FH/DP Calibration menu.

Press Cancel twice to return to the

Settings Menu.

64 Moisture Target Series 6 Hygrometer User’s Manual

Page 75

Chapter 3. Operation and Programming

3.6.6 Reading and Setting the Calibration References

Note: The following procedure applies only if an M Series probe is being

used. If a VeriDri probe is used, Cal Reference... is not accessible.

IMPORTANT: The MTS6 is factory programmed with high and low reference

MH values. These values are generated from a factory lab

calibration and should not be changed without first consulting

GE technical support. Changes to these values will alter the

accuracy of the unit measurements.

To update calibration data, from the Settings

Menu select Cal Data and press Enter .

The following screen appears.

Note: To access the Cal Data menu, the User

Passcode is required (see section 3.6.1 on

page 56).

Use the left and right arrow keys to select

each digit to be changed and the up and

down arrow keys to increase or decrease its

value. Once the passcode has been entered,

press Enter a screen similar to the

following appears.

To view and/or edit the calibration reference

settings, select Cal Reference and press

Enter . The following screen appears.

Moisture Target Series 6 Hygrometer User’s Manual 65

Page 76

Chapter 3. Operation and Programming

3.6.6a Setting the Calibration High Reference

To update high reference settings, from the

Edit Cal Refs menu select High Reference

and press Enter . A screen similar to the

following appears.

Use the left and right arrow keys to select

each digit to be changed and the up and

down arrow keys to increase or decrease its

value. Once the changes have been made,

press Enter . The screen returns to the

Edit Cal Refs menu.

3.6.6b Setting the Calibration Low Reference

To update low reference settings, from the

Edit Cal Refs menu select Low Reference

and press Enter . A screen similar to the

following appears.

Use the left and right arrow keys to select

each digit to be changed and the up and

down arrow keys to increase or decrease its

value. Once the changes have been made,

press Enter . The screen returns to the

Edit Cal Refs menu.

66 Moisture Target Series 6 Hygrometer User’s Manual

Page 77

Chapter 3. Operation and Programming

3.6.7 Entering the M Series Probe Serial Number

Note: The following procedure applies only if an M Series probe is being

used. If a VeriDri probe is used, Probe SN is not accessible.

To update the probe serial number, from the

Settings Menu select Cal Data and press

Enter . The following screen appears.

Note: To access the Cal Data menu, the User

Passcode is required (see section 3.6.1 on

page 56).

Use the left and right arrow keys to select

each digit to be changed and the up and

down arrow keys to increase or decrease its

value. Once the passcode has been entered,

press Enter a screen similar to the

following appears.

To view and/or edit the probe serial number,

select Probe SN and press Enter . The

following screen appears.

Use the left and right arrow keys to select

each digit to be changed and the up and

down arrow keys to increase or decrease its

value. Once the changes have been made,

press Enter . The screen returns to the

Cal Data menu.

Moisture Target Series 6 Hygrometer User’s Manual 67

Page 78

Chapter 3. Operation and Programming

3.6.8 Setting the Volume Mixing Ratio

Note: Setting the Volume Mixing Ratio is an optional feature, available

only if the ppmv software version was purchased.

Note: To set the volume mixing ratio, from

the Settings Menu select V/V Ratio and press

Enter . The following screen appears.

Note: To access the Cal Data menu, the User

Passcode is required (see section 3.6.1 on

page 56).

Use the left and right arrow keys to select

each digit to be changed and the up and

down arrow keys to increase or decrease its

value. Once the passcode has been entered,

press Enter and the following screen

appears.

3.6.8a Setting the Pressure Units

To set the pressure units, select Press. Units

and press Enter . The following screen

appears.

Use the left and right arrow keys to select

each digit to be changed and the up and

down arrow keys to increase or decrease its

value. Press Enter to save (or Cancel

to keep the previous value), and return to the

previous menu.

68 Moisture Target Series 6 Hygrometer User’s Manual

Page 79

Chapter 3. Operation and Programming

3.6.8b Setting the Pressure Value

To set the pressure value, select Press. Value

and press Enter . The following screen

appears.

Use the left and right arrow keys to select

each digit to be changed and the up and

down arrow keys to increase or decrease its

value. Press Enter to save (or Cancel

to keep the previous value), and return to the

previous menu.

3.6.8c Setting the k x PPMv Multiplier

To set the k x PPMv multiplier, select

k x PPMv and press Enter . The following

screen appears.

Use the left and right arrow keys to select

each digit to be changed and the up and

down arrow keys to increase or decrease its

value. Press Enter to save (or Cancel

to keep the previous value), and return to the

previous menu.

Moisture Target Series 6 Hygrometer User’s Manual 69

Page 80

Chapter 3. Operation and Programming

3.6.9 Resetting the Time

To reset the time, from the Settings Menu

select Clock and press Enter . The current

time appears on the following screen.

3.6.9a Setting the Hour

To change the hour, select Hour and press

Enter . The following screen appears.

Use the left and right arrow keys to select

each digit to be changed and the up and

down arrow keys to increase or decrease its

value. Press Enter to save (or Cancel

to keep the previous value), and return to the

previous menu.

70 Moisture Target Series 6 Hygrometer User’s Manual

Page 81

3.6.9b Setting the Minutes

3.6.9c Setting the Month

Chapter 3. Operation and Programming

To change the minutes, select Minutes and

press Enter . The following screen

appears.

Use the left and right arrow keys to select

each digit to be changed and the up and

down arrow keys to increase or decrease its

value. Press Enter to save (or Cancel

to keep the previous value), and return to the

previous menu.

To change the month, select Month and

press Enter . The following screen

appears.

Use the left and right arrow keys to select

each digit to be changed and the up and

down arrow keys to increase or decrease its

value. Press Enter to save (or Cancel

to keep the previous value), and return to the

previous menu.

Moisture Target Series 6 Hygrometer User’s Manual 71

Page 82

Chapter 3. Operation and Programming

3.6.9d Setting the Date

To change the date, select Date and press

Enter . The following screen appears.

Use left and right arrow keys to select the

digit to be changed. Use up and down arrow

keys to change the value. Press Enter to

save (or Cancel to keep the previous

value), and return to the previous menu.

3.6.9e Setting the Year

To reset the year, select Year and press

Enter . The following screen appears.

Use the left and right arrow keys to select

each digit to be changed. Use the up and

down arrow keys to change the value. When

finished, press Enter and return to the

previous menu, then press Cancel to

return to the Settings Menu.

Note: The Service menu is accessible only to service engineers and

requires the use of a Factory-Level passcode.

72 Moisture Target Series 6 Hygrometer User’s Manual

Page 83

Chapter 3. Operation and Programming

3.6.10 Selecting the Probe Type

Note: Use the following procedure to select the probe type.

IMPORTANT: Changing the probe setting will default the output and alarm

settings to DPC. Also, the default fault trip point values will be

set along with the default output range values.

From the Settings Menu select Probes and

press Enter . The following screen

appears.

Note: To access the Probes menu, the User

Passcode is required (see section 3.6.1 on

page 56).

Use the left and right arrow keys to select

each digit to be changed and the up and

down arrow keys to increase or decrease its

value. Once the passcode has been entered,

press Enter and the following screen

appears.

Use the left or right arrow key to select the

correct probe type and press Enter . The

MTS6 reboots in 5 seconds.

Moisture Target Series 6 Hygrometer User’s Manual 73

Page 84

Chapter 3. Operation and Programming

3.6.11 Setting a Constant DP °C Offset

This feature enables the customer to add a constant DP °C offset to their

reading. It allows for positive or negative offset limiting to +/- 50°C. It

works only within the calibrated range of the sensor. Alarms A & B are

based on the offset value, and likewise, they will work only within the

calibrated range of the sensor.

Note: Use the following procedure to set the DP °C Offset.

From the Settings Menu select DpC Offset

and press Enter . The following screen

appears.

Use the left and right arrow keys to select

each digit to be changed and the up and

down arrow keys to increase or decrease its

value. Press Enter to save (or Cancel

to keep the previous value), and return to the

previous menu.

74 Moisture Target Series 6 Hygrometer User’s Manual

Page 85

3.7 Viewing System Information

3.7.1 Checking the ID

To check identification information, from

the Main Menu, select About and press

Enter . The following screen appears.