Page 1

GE

g

READ THOROUGHLY BEFORE INSTALLING

Lighting Solutions

WARNING

Risk of electric shock

• Turn power off before servicing

– see instructions

THE OPERATING TEMPERATURE “T-CODE”

LISTED FOR THIS LUMINAIRE IS BASED ON THE

FOLLOWING BULB SIZES. USE OF OTHER THAN

THESE MAY RESULT IN A HIGHER OPERATING

TEMPERATURE AND COULD RESULT IN A HAZARDOUS CONDITION.

LAMP TYPE WATTAGE BULB SIZE

HIGH PRESSURE SODIUM 70,100,150 ED 23 1/2

HIGH PRESSURE SODIUM 250, 400 ED 18

METAL HALIDE/MERCURY 175, 250 ED 28

METAL HALIDE/MERCURY 400 ED 37

AVERTISSEMENT: COUPER L’ALIMENTATION

AVANT L’INSTALLTION OU L’ENTRETIEN.

GENERAL

A complete luminaire consists of a ballast housing,

optical assembly, and a cover/mounting.

CAUTION: When installing luminaire in

hazardous locations check operating temperature

limits prior to installation to insure it conforms to

the environmental temperature restrictions and

NEC classifications.

MOUNTING INSTALLATION

CAUTION

Unit will fall if not installed properly

• Follow installation instructions

GEH-5847

INSTRUCTIONS

Mini•Gard Luminaire

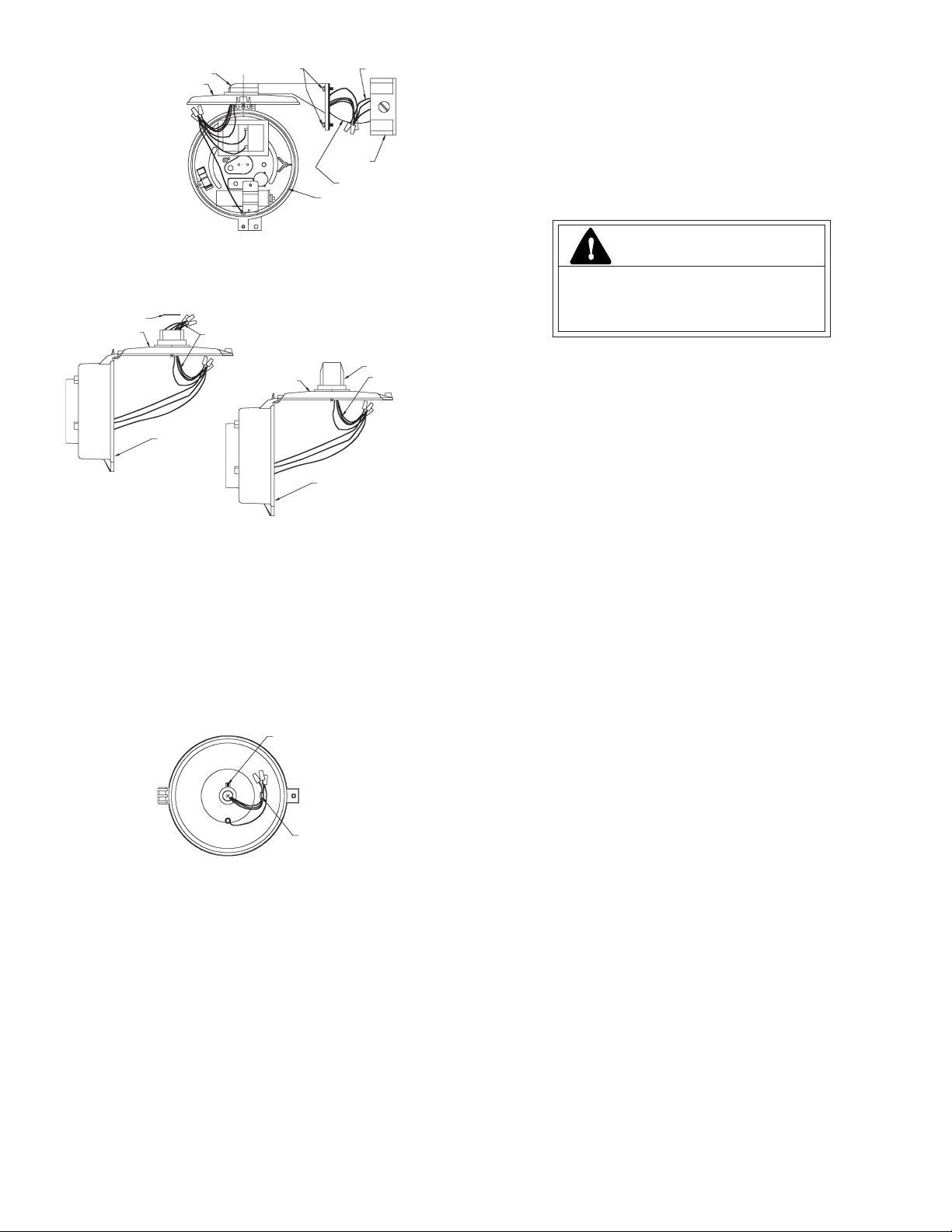

Flexible Cover (See Figures 2 and 3)

Loosen four(4) bolts holding mounting hub to cover.

Position adapter plate correctly to balance luminaire. Use

widest bolt spacing possible to secure plate to cover. Hang

ballast housing on cover by hinge. Proceed to Wiring.

MOUNTING HUB

COVER

BALLAST HOUSING

Figure 2 Figure 3

Ceiling Cover (See Figure 4)

Using the slotted tabs, mount cover to ceiling. Hang

ballast housing on cover by hinge. Proceed to Wiring.

COVER

.875

ADJUSTMENT

CUSTOMER LEADS

CUSTOMER LEADS

Bolt pattern

for lower

wattages

GROUND

SCREW

Bolt pattern

for higher

wattages

Pendant Cover (See Figure 1)

Thread cover onto conduit. Orient cover and seal

around conduit using approved NEC procedures. Tighten

set screw at mounting hub. Hang ballast housing on cover

by hinge. Proceed to Wiring.

COVER

Figure 1

These instructions do not purport to cover all details or variations in equipment nor to provide for every possible contingency to be met in connection with installation, operation or

maintenance. Should further information be desired or should particular problems arise which are not covered sufficiently for the purchaser’s purposes, the matter should be referred

to GE Lighting Solutions.

BALLAST HOUSING

CUSTOMER LEADS

Wallmount Cover (See Figure 5)

Mount wiring box provided and pull leads. Tether is

supplied to hold arm assembly while connecting supply

leads. Attach arm assembly to wiring box. Do not damage

gasket attached to arm assembly. Mounting screws should

be tightened in alternate sequence. Hang ballast housing

on cover by hinge. Proceed to Wiring.

BALLAST HOUSING

Figure 4

Page 2

MOUNTING ARM

COVER

MOUNTING

SCREWS

CUSTOMER LEADS

IF MULTIWATT:

Multiwatt ballasts are available in various combina-

tions of wattage. See wiring instructions on wiring

tag inside the luminaire.

WIRING

BOX

TETHER

Figure 5

BALLAST HOUSING

Straight Stanchion Cover (See Figure 6)

Attach mounting arm onto conduit. Hang ballast

housing on cover by hinge. Proceed to Wiring.

WIRING BOX DOOR

COVER

BALLAST

HOUSING

CUSTOMER LEADS

COVER

MOUNTING ARM

CUSTOMER LEADS

BALLAST HOUSING

Figure 6

Figure 7

Angle Stanchion Cover (See Figure 7)

Attach mounting arm onto conduit. Hang ballast

housing on cover by hinge. Proceed to Wiring.

B.WIRING:

Cut incoming supply conductors to six (6)

inches inside cover. Route conductors through lead

clip provided and make electrical connections,

including ground as shown on wiring label (See

Figure 8).

SET SCREW

BALLAST HOUSING INSTALLATION

Swing unit shut. Tighten ballast cover screw securely.

LAMP INSTALLATION

CAUTION

Risk of burn

• Allow lamp/fixture to cool before

handling

Use only lamps specified on nameplate. Observe

lamp manufacturer’s recommendations and restrictions on lamp operation, particularly ballast type,

burning position, etc.

Lamp Tightness – Medium Base Lamp: The lamp

should be tightened to a light firmness sufficient to depress

the center contact.

OPTICALS

CAUTION: GLOBE IS TEMPERED GLASS. DO NOT

SCRATCH OR CHIP.

Attach globe by threading firmly into bottom of ballast

housing.

Prismatic Refractor Assembly

Type V, R or L

Thread adapter firmly into ballast housing. To orient

asymmetrical glass, loosen clamping screws, turn glass and

retighten screws. To relamp, unscrew complete optical from

ballast housing.

Figure 8

LEAD CLIPS

Make all electrical connections in accordance with

the National Electrical Code and any applicable

local code requirements.

Verify that supply voltage is correct by comparing it

to nameplate.

When changing voltage on reconnectable units,

move only the lead with the insulated connector.

IF SINGLE VOLTAGE:

All single voltage ballasts are pre-wired such that

user need only connect the supply conductors.

IF MULTIVOLT: (120/208/240/277 volts)

Connect the ballast lead with the insulated terminal

to the desired voltage terminal as indicated on the

ballast terminal nameplate.

ACCESSORIES

External Reflector

Insert mounting screws. Orient reflector to proper

position and slip over mounting screws. Turn reflector and

tighten screws securely.

Globe Guard

Insert protective guard into ballast housing and turn

until retained by detent.

MAINTENANCE AND CLEANING

It will occasionally be necessary to clean optical assembly

in order to maintain light levels. Frequency of cleaning will

depend on dirt levels in user’s facility and minimum

acceptable light levels . Reflector should be cleaned with

any suitable, non-abrasive solution of water and soap or

detergent. Residual cleaning agent should be removed with

clean water rinsing. Glassware may be cleaned with any

conventional glass cleaner. If unit gets soiled on the inside,

it should be cleaned and any damaged gasket or filter

replaced.

Page 3

GE

g

À LIRE AVEC SOIN AVANT D’INSTALLER

Lighting Solutions

DANGER

Risque d'électrocution

• Mettre hors tension avant d'intervenir

– suivez les instructions

LA TEMPÉRATURE NOMINALE“T-CODE” LISTÉE POUR CE

LUMINAIRE EST BASÉE SUR LES TAILLES D’AMPOULES

SUIVANTES. SI VOUS EN UTILISIEZ DE DIFFÉRENTES, CELA

POURRAIT AMENER UNE TEMPÉRATURE DE

FONCTIONNEMENT PLUS ÉLEVÉE ET PROVOQUER UNE

SITUATION DANGEREUSE.

TYPE DE LAMPE PUISSANCE TAILLE

SODIUM HTR PRESSION 70,100,150 ED 23 1/2

SODIUM HTR PRESSION 250, 400 ED 18

HALOGÈNURE/MERCURE 175, 250 ED 28

HALOGÈNURE/MERCURE 400 ED 37

AVERTISSEMENT : COUPEZ L’ALIMENTATION

AVANT L’INSTALLATION OU L’ENTRETIEN.

PRÉSENTATION

Un luminaire complet comporte un logement de ballast, un

assemblage optique et un couvercle/support.

ATTENTION : Si vous installez ce luminaire dans des

endroits dangereux, vérifiez la température limite de

fonctionnement avant de l’installer pour vérifier qu’il

compatible avec les restrictions de température de

l’environnement et les normes NEC.

GEH-5847

INSTRUCTIONS

Luminaire Mini•Gard

Couvercle flexible (Voir schémas 2 et 3)

Desserrez quatre(4) boulons qui tiennent l'axe de montage sur le

couvercle. positionnez la plaque d'adaptation pour équilibrer le

luminaire. Utilisez l’écartement entre boulons le plus grand possible

pour fixer la plaque de couverture. Accrochez le caisson de ballast sur

AXE DE MONTAGE

COUVERCLE

CAISSON DE BALLAST

Schéma 2

RÉGLAGE 22,2

MM

FILS D'ARRIVÉE

Disposition

de boulons

pour faibles

puissances

VIS DE TERRE

Disposition

de boulons

pour fortes

puissances

Schéma 3

INSTALLATION/MONTAGE

le couvercle par la charnière. Câblez.

Couvercle de plafond (Voir schéma 4)

ATTENTION

En utilisant les pattes montez le couvercle au plafond. Accrochez le

Risque de chute en cas de mauvais

COUVERCLE

montage • Suivez les instructions

Couvercle pendant (Voir schéma 1)

Entrez le couvercle dans la conduite. Orientez-le et faites

l'étanchéité autour de la conduite en suivant les procédures

approuvées NEC. Serrez la vis de fixation de l'axe de montage.

Accrochez le caisson de ballast sur le couvercle par la charnière.

Câblez.

COUVERCLE

FILS D'ARRIVÉE

Shéma 4

caisson de ballast sur le couvercle par la charnière. Câblez.

Couvercle sur mur (Voir schéma 5)

Montez la boîte de câblage et tirez les fils. Une attache est fournie

Schéma 1

Ces instructions n'ont pas pour destination de couvrir tous les détails ou variantes de l'équipement, ni de répondre à toutes les éventualités que vous pourriez rencontrer pendant l'installation,

le fonctionnement ou l'entretien. Si vous souhaitez des informations complémentaires, ou si vous rencontrez un problème particulier qui ne soit pas adressé de votre point de vue d'acheteur,

le sujet doit être remonté jusqu'à la société GE Lighting Solutions

CAISSON DE

BALLAST

pour tenir l’assemblage de bras pendant le câblage. Ensuite fixez le

bras (sans abîmer le joint qui y est attaché). Les vis de montage

doivent être serrées en séquence alternative. Accrochez le

FILS D'ARRIVÉE

CAISSON DE BALLAST

Page 4

VIS DE

BRAS DE MONTAGE

COUVERCLE

FIXATION

Schéma 5

caisson de ballast sur le couvercle par la charnière. Câblez.

FILS D'ARRIVÉE

BOÎTE

DE

CÂBLAGE

ATTACHE

CAISSON DE BALLAST

Couvercle sur poteau droit (Voir schéma 6)

Fixez le bras de montage sur la conduite. Accrochez le caisson

de ballast sur le couvercle par la charnière. Câblez.

PORTE DE BOÎTE DE

CÂBLAGE

COUVERCLE

Schéma 6

CAISSON DE

BALLAST

FILS D'ARRIVÉE

COUVERCLE

CAISSON DE

BALLAST

MOUNTING ARM

FILS D'ARRIVÉE

Schéma 7

Couvercle sur poteau coudé (Voir schéma 7)

Fixez le bras de montage sur la conduite. Accrochez le

caisson de ballast sur le couvercle par la charnière. Câblez.

CÂBLAGE

Coupez les conducteurs d'alimentation qui arrivent à 15 cm

(6") à l'intérieur du couvercle. Passez-les dans le serre-fils fourni

et réalisez les raccordements électriques, y compris la terre

comme indiqué sur l'étiquette de câblage (Voir schéma 8).

VIS DE

FIXATION

INSTALLATION DU LOGEMENT DE BALLAST

Basculez le luminaire en position fermée. Serrez solidement la

vis de couvercle de ballast.

ATTENTION

Risque de brûlure

Laissez le bloc d'ampoule refroidir

avant d'y toucher

INSTALLATION DE LA LAMPE

N’utilisez que le type de lampe spécifié sur la plaque

d’identification. Observez les recommandations et restrictions du

fabricant sur le fonctionnement de la lampe, en particulier pour le

type de ballast, la position d’utilisation, etc.

Serrage de lampe – culot moyen : La lampe doit être serrée

fermement sans forcer pour enfoncer le contact central de la

douille.

OPTIQUES

ATTENTION : LE GLOBE EST EN VERRE TREMPÉ, ÉVITEZ

LES RAYURES ET COUPS.

Globe en verre—Fixez le globe en le vissant fermement sur le

bas du caisson de ballast.

Assemblage de réflecteur

prismatique type V, R ou L

Vissez fermement le réflecteur sur le logement de ballast.

Pour orienter les verres asymétriques, desserrez les vis de

maintien, tournez le verre et resserrez. Pour changer de lampe

dévissez toute l’optique du caisson de ballast.

ACCESSOIRES

Réflecteurs externes

Insérez les vis de fixation. Orientez le réflecteur en bonne

position et enfilez-le sous les vis. Tournez le réflecteur puis serrez

bien les vis.

Protège globe

Inserez la protection dans le logement de ballast, tournez-la

pour qu’elle soit retenue par encliquetage.

Schéma 8

SERRE-FILS

Effectuez tous les raccordements en conformité avec les normes

nationales et les éventuels règlements locaux applicables.

Vérifiez que la tension secteur disponible est la bonne en

comparant avec l'indication de tension sur la plaque

d'identification.

En changeant la tension des unités reconfigurables, ne bougez

que le fil avec la cosse isolée.

MONO-TENSION :

Tous les ballasts sont précâblés et l'utilisateur n'a qu'à relier

les fils d'alimentation pour la tension prévue.

MULTI-TENSIONS : (120/208/240/277 volts)

Reliez le fil de ballast avec sa terminaison isolée sur la borne

de tension adéquate comme indiqué sur la plaque du ballast.

MULTI-PUISSANCES :

Les ballasts multi-puissances sont disponibles en diverses

combinaisons de wattages. Reportez-vous aux instructions de

câblage sur l'étiquette à l'intérieur du luminaire.

GE Lighting Solutions • 1-888-MY-GE-LED • www.gelightingsolutions.com

16943533----888

GE Lighting Solutions is a subsidiary of the General Electric Company. Evolve and other trademarks belong to GE Lighting Solutions. The GE brand and logo are trademarks of the General Electric Company.

© 2011 GE Lighting Solutions. Information provided is subject to change without notice. All values are design or typical values when measured under laboratory conditions.

g

ENTRETIEN

Il sera nécessaire à l'occasion de nettoyer l’ensemble optique

pour maintenir le niveau d'éclairage. La fréquence de ces

nettoyages dépend du niveau d'empoussièrage local et du seuil

minimum de luminosité acceptable pour l'utilisateur. Le réflecteur

doit être lavé avec une solution d'eau et de n'importe quel

détergent ménager doux et non abrasif, rincez à l'eau claire pour

enlever les résidus de nettoyant. Le vitrage peut être nettoyé

avec un produit pour vitres classique. Si le luminaire devenait sale

à l'intérieur, nettoyez-le et remplacez tout joint ou filtre détérioré.

35-201578-3N (1/01)

Loading...

Loading...