Page 1

Reference Manual

05-2818A01, REV. C

AUGUST 2009

MDS P-60/P-60 HL

Packaged Radio System

Including Reference Material for Legacy

MDS P-50 Packaged Models

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 2

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 3

MDS 05-2818A01, Rev. C MDS P-60/P-60 HL Reference Manual i

TABLE OF CONTENTS

1.0 Introduction..................................................................................7

1.1 About This Manual ...........................................................................7

1.2 Equipment Description .....................................................................8

1.3 Accessories ....................................................................................11

2.0 MDS P-60 Installation................................................................12

2.1 Unpacking and Inspection .... ..........................................................12

2.2 Installation Considerations .............................................................12

2.3 Mounting the Enclosure .................................................................12

2.4 MDS P-60 Cable Connections .......................................................17

2.5 Audio and Keyline Connections—Analog Interface/Utility

Board (P/N 03-2110A01) ......... .... ... ................................................19

2.6 Data Connections—Digital Interface/

Utility Board (P/N 03-2472Axx) ......................................................23

2.7 Final MDS P-60 Installation Tasks .................................................25

3.0 MDS P-50 installation................................................................ 26

3.1 Unpacking and Inspection .... ..........................................................26

3.2 Installation Considerations .............................................................26

3.3 Mounting the Enclosure .................................................................26

3.4 MDS P-50 Cable Connections .......................................................31

3.5 Analog Interface/Utility Board Connections (P/N 03-1105A21) ......32

3.6 Digital Interface/Utility Board Connections

(P/N 03-1467A21) ..........................................................................36

3.7 Final MDS P-50 Installation Tasks .................................................38

4.0 P-60/P-50 Operation.................................................................. 39

4.1 Introduction ....................................................................................39

4.2 Initial Power-Up ..............................................................................39

4.3 Interface/Utility Board Features and Indicators ..............................42

5.0 Servicing Data ........................................................................... 47

5.1 Introduction ....................................................................................47

5.2 Preventive Maintenance .................................................................47

5.3 Fuse Replacement .........................................................................47

5.4 Backup Battery ...............................................................................48

5.5 System Troubleshooting ................................................................50

5.6 List of Replaceable Assemblies .....................................................51

5.7 Packaged System Adjustments—MDS P-60 .................................52

5.8 Service Drawings and Reference Data—

MDS P-60 ......................................................................................55

5.9 Packaged System Adjustments—MDS P-50 .................................64

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 4

ii MDS P-60/P-60 HL Reference Manual MDS 05-2818A01, Rev. C

5.10 Order Wire Levels (Analog Interface/Utility Board

P/N 03-1 105A21)........................................................................... 65

5.11 Service Drawings and Reference Data—

MDS P-50 ......................................................................................66

Copyright Notice

This Installation and Operation Guide and all software described herein

are protected by Copyright: 2009 GE MDS, LLC. All rights reserved.

GE MDS reserves its right to correct any errors and omissions.

Operational Safety Notices

The radio equipment described in this guide emits radio frequency

energy. Although the power level is low, the concentrated energy from

a directional antenna may pose a health hazard. Do not allow people to

come in close proximity to the front of the antenna when the transmitter

is operating.

This manual is intended to guide a professional installer to install,

operate and perform basic system maintenance on the described radio.

ISO 9001 Registration

GE MDS’ adherence to this internationally accepted quality system

standard provides one of the strongest assurances of product and service

quality available.

GE MDS Quality Policy Statement

We, the employees of GE MDS, are committed to achieving total customer satisfaction in everything we do.

Total Customer Satisfaction in:

• Conception, design, manufacture and marketing of our products.

• Services and support we provide to our internal and external

customers.

Total Customer Satisfaction Achieved Through:

• Processes that are well documented and minimize variations.

• Partnering with suppliers who are committed to providing quality and

service.

• Measuring our performance against customer expectations and

industry leaders.

• Commitment to continuous improvement and employee involvement.

RF Exposure

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 5

MDS 05-2818A01, Rev. C MDS P-60/P-60 HL Reference Manual iii

Notice

While every reasonable effort has been made to ensure the accuracy of

this manual, product improvements may result in minor differences

between the manual and the product shipped to you. If you have additional questions or need an exact specification for a product, please contact our Customer Service Team using the information at the back of this

guide. In addition, manual updates can often be found on the GE MDS

Web site at www.gemds.com.

Environmental Information

The manufacture of this equipment has required the extraction and use

of natural resources. Improper disposal may contaminate the environment and present a health risk due to hazardous substances contained

within. To avoid dissemination of these substances into our environment, and to limit the demand on natural resources, we encourage you

to use the appropriate recycling systems for disposal. These systems will

reuse or recycle most of the materials found in this equipment in a sound

way. Please contact GE MDS or your supplier for more information on

the proper disposal of this equipment.

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 6

iv MDS P-60/P-60 HL Reference Manual MDS 05-2818A01, Rev. C

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 7

MDS 05-2818A01, Rev. C MDS P-60/P-60 HL Reference Manual 7

1.0 INTRODUCTION

1.1 About This Manual

This manual explains how to install and operate GE MDS packaged radio systems. It is a companion to the transceiver instruction manual that is shipped

with our packaged system units. After installation, we suggest that you keep

this manual with the transceiver manual for future reference.

This manual is arranged into five chapters:

• Chapter 1—Introduction

Tells how the manual is organized and describes the features and differences of the various packaged systems. You are in this section now.

• Chapter 2—MDS P-60 Installation

Provides the steps to mount the MDS P-60 and make the cable connec-

tions.

• Chapter 3—MDS P-50 Installation

Provides the steps to mount the MDS P-50 and make the cable connec-

tions.

• Chapter 4—Operation

Contains instructions for placing the units into normal service and

describes how to connect plug-in accessories such as a diagnostic terminal and order wire handset.

• Chapter 5—Servicing Data

Presents adjustment procedures, assembly drawings and a list of

replaceable assemblies for the packaged systems. Also includes a section on preventive maintenance and a troubleshooting chart to help

resolve system difficulties.

NOTE: Keep in mind that this manual is a system-level guide for the pack-

aged radio sys tems. Radio model numbers, and information about

specific radios , are not included in this manual un less there is an

exception to installation or operation. For specific radio information,

refer to the transceiver manual shipped with your unit.

GE MDS radios are designated by a model number, which indicates the radio’s

operating frequency, type (licensed or spread spectrum), and packaging. The

model number of an unpackaged, licensed 200 MHz radio is shown below as

an example.

Example:

Radios shipped as part of a P-60 or P-50 packaged radio system will have a

model number ending in -60 or -50.

Chassis configuration (10=no chassis)

7=Licensed narrow-band radio, 8=Unlicensed spread spectrum radio

Frequency band (usually) (for example, 2=200 MHz)

2 7 1 0

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 8

8 MDS P-60/P-60 HL Reference Manual MDS 05-2818A01, Rev. C

1.2 Equipment Description

GE MDS packaged systems include a radio transceiver, power supply (with

battery backup for AC-powered models) and Interface/Utility Board normally

mounted inside a weather resistant, padlockable enclosure. The only connections required are for primary power, antenna, and interface connection to the

customer-supplied equipment. All of these wiring connections are made within

the housing, leaving no connections exposed to weather.

The one-box design makes packaged systems well suited for outdoor

mounting, and for use in areas with limited space. Packaged systems are normally installed in wall-mount or pole-mount configurations, but an optional

plate is available for mounting the system in a 19 inch rack.

NOTE: Due to restricte d ventilation, the P-60 enclosure is not suitable for

applications employing a continuously-keyed radio, such as a master

station or repeater. Overhe ating may occur in these si tuations,

causing component failures in transceivers.

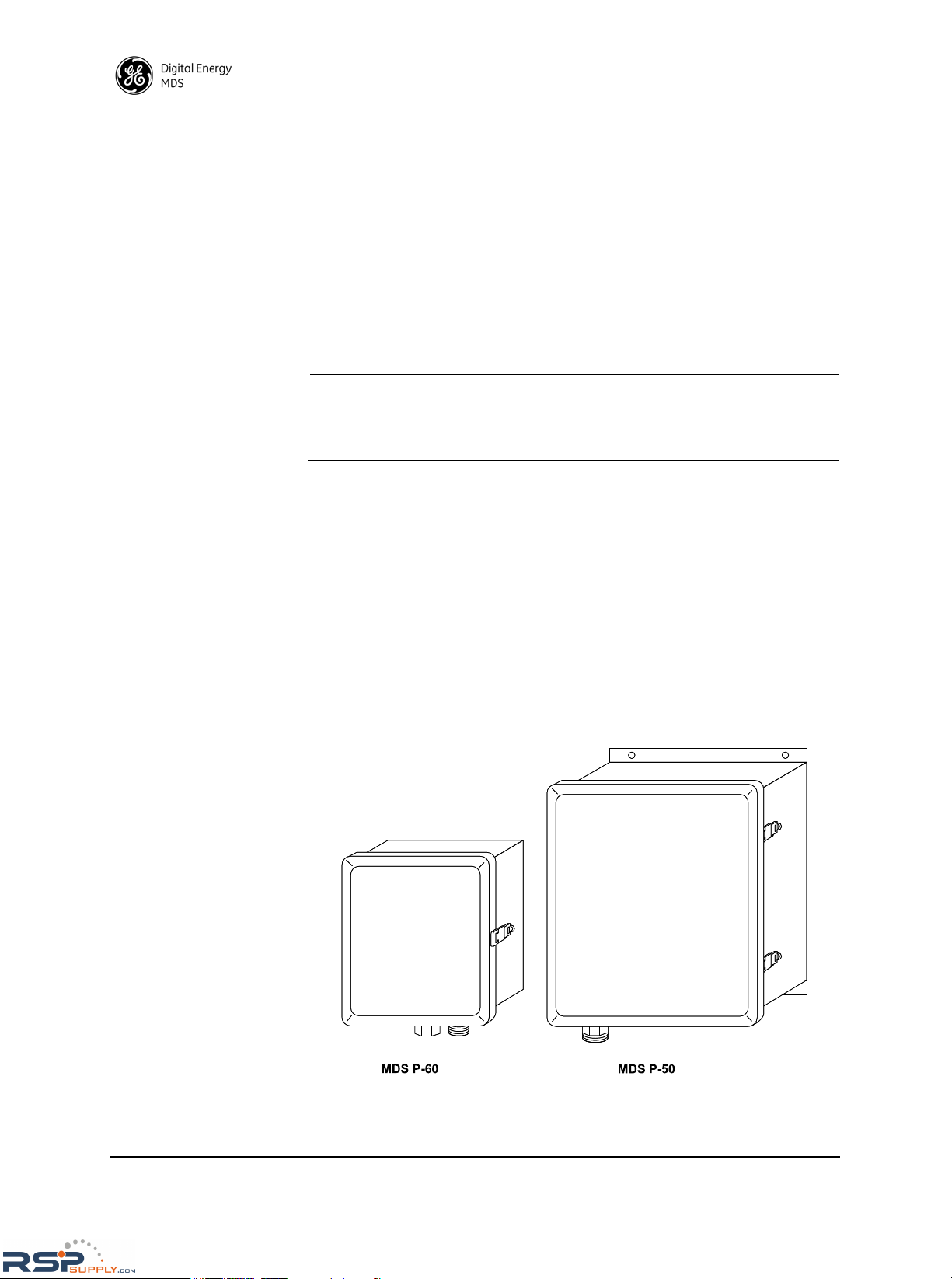

Enclosure Types

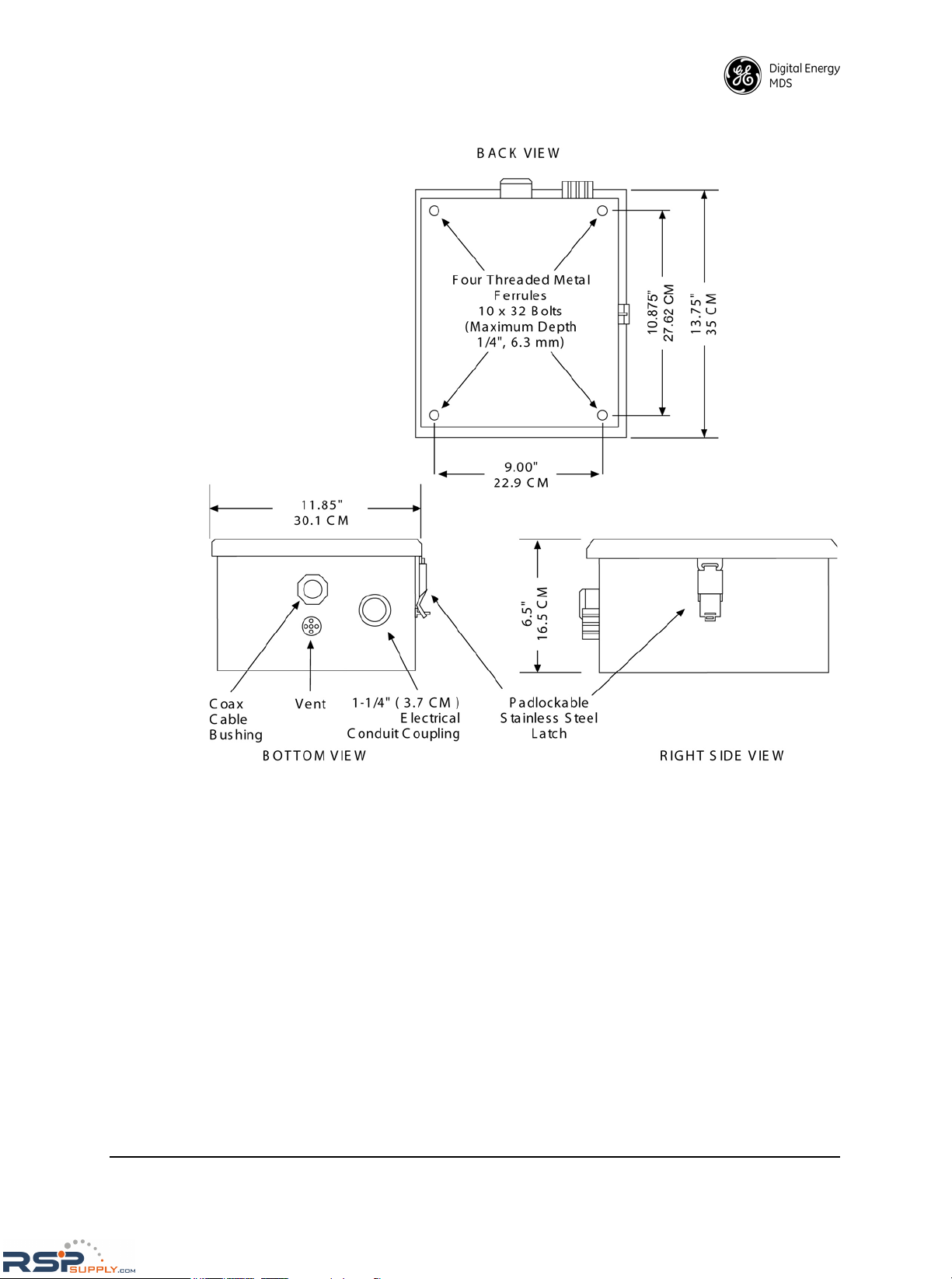

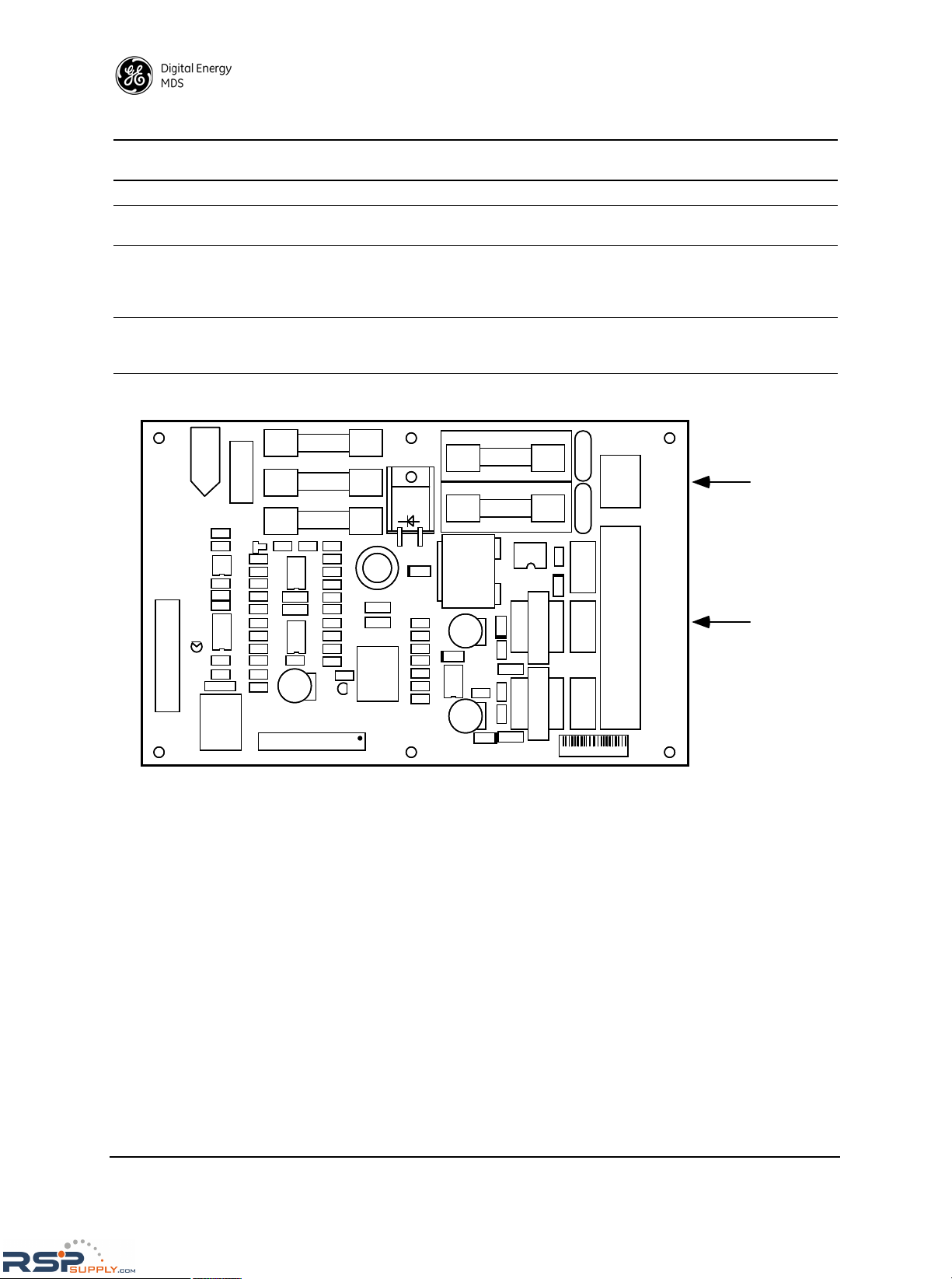

Figure 1 shows the two cabinet styles commonly used in the packaged system

family. Each is a gray fiberglass NEMA-approved enclosure.

•The MDS P-60 is a compact model measuring 13.75 inches high x

11.85 inches wide x 6.5 inches deep (35cm x 30.1cm x 16.5cm). This

model has less space inside for mounting of customer equipment, but is

ideal for use in locations where space is limited.

•The MDS P-50 is a discontinued model that is typically contained in a

large enclosure measuring 19.5 inches high x 17.5 inches wide x 9.5

inches deep (49.5cm x 44.5cm x 24.1cm). Extra space in the cabinet

may be used to mount customer-supplied equipment, if desired.

Invisible place holder

Figure 1. GE MDS Packaged Radio Systems

Shown with covers closed

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 9

MDS 05-2818A01, Rev. C MDS P-60/P-60 HL Reference Manual 9

WARNING! P-60 units installed in a hazardous environment (P-60 HL)

require special installation procedur es in addition to the instructions

provided in this manual. Refer to and comply with P-60 HL Packaged

Radio - Hazardous Locations Installation Procedure (P000530) when

installing these units.

MDS P-60 Units Equipped with MDS iNET or TransNET

Transceivers

The P-60 can be equipped with various transceiver types. Depending on order

requirements, the enclosure might contain one of MDS’ newer generation

transceivers, such as an MDS iNET or MDS TransNET Series. These units are

housed in blue, die-cast aluminum enclosures and are mounted with brackets

that attach to the bottom of the radio and extend out the sides.

In addition to the standard TransNET radio, there is also a board-only version

of this product that can be installed in a P-60. While electrically and operationally similar to the standard (metal-enclosed) TransNET, it does not have a full

enclosure. It is fitted with a non-metallic cover through which four mounting

screws are inserted to secure it to the P-60 plate.

These new generation transceivers are described below:

• The MDS iNET is a license-free IP/Ethernet transceiver measuring

1.50" high x 6.00" wide x 4.00" deep (3.8 x 15.2 x 10.2 cm). (Note:

Only three screws are used to mount MDS iNET models to the P-60

plate.)

• The MDS TransNET is a license-free serial data transceiver measuring

1.40" high x 5.30" wide x 3.50" deep (3.8 x 15.2 x 10.2 cm).

• The MDS TransNET 900 Board-Only transceiver is operationally similar to the standard TransNET, but includes a non-metallic cover, and

measures 1.40" high x 5.30" wide x 3.50" deep (3.8 x 15.2 x 10.2 cm).

Figure 2. MDS iNET and TransNET Transceivers

Primary Power

Packaged systems can be equipped for a variety of AC or DC power supply

requirements. In addition, a 12 volt backup battery is provided as standard

equipment in AC-powered models. The battery provides at least four hours of

operation in the event of a primary power failure. (Depending on the transmit

duty cycle and how often the radio is polled, the battery may last much longer.)

The backup battery is float charged by the power supply during normal system

operation.

MDS TransNET

Transceiver

MDS TransNET

Board-Only Transceiver

MDS iNET IP/Ethernet

Transceiver

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 10

10 MDS P-60/P-60 HL Reference Manual MDS 05-2818A01, Rev. C

Programming and Diagnostics

Transceiver programming and diagnostics are performed by connecting an

MDS Hand-Held Terminal (HHT) or PC running MDS software. With MDS

P-60

models, an HHT can be plugged directly into the packaged system’s Inter-

face/Utility Board. This eliminates the need for unplugging the data cable from

the transceiver’s

INTERFACE connector. Instructions for connecting a diag-

nostic terminal are given in Section 4.0 P-60/P-50 Operation on Page 39.

Packaged System Specifications*

* Specifications are subject to change without notice. For radio specifications, refer

to the associated transceiver instruction manual.

Enclosure Dimensions:

(excluding hardware)

MDS P-60:

13.75 inches H x 11.85 inches W x 6.5 inches D

(35 x 30.1 x 16.5 cm)

MDS P-50:

19.5 inches H x 17.5 inches W x 9.5 inches D

(49.5 x 44.5 x 24.1 cm)

Approximate Weight:

(with backup battery)

MDS P-60:

21 lb. (9.53 kg)

MDS P-50:

33 lb. (15 kg)

Enclosure Impact Resistance: Tested to 6.78 Joule (5 ft./lb.)

Transceiver types used in packaged systems: MDS x710 Series, MDS x810 Series, MDS

2300/4300/9300 Series, MDS iNET, MDS

TransNET, Mercury, and others

Temperature Range: Full performance: –30°C to +60°C

(Reduced battery life at cold temperatures)

Humidity: 95% at + 40°C Non-Condensing

Primary Power Options: 12, 24, 48, 120 Vdc

120–220 Vac

Typical Supply Current:

(Excluding battery-charging current)

Transmit: 1.8 A @ 5 watts

1.0 A @ 1 watt

Receive: 80 mA maximum

Standby (transceiver in “sleep” mode): <15 mA

Backup Power Provision:

(Standard on AC-powered models.)

12 volt battery

4.6 Ah for P-60 series, 5 Ah for P-50 series

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 11

MDS 05-2818A01, Rev. C MDS P-60/P-60 HL Reference Manual 11

1.3 Accessories

GE MDS publishes an Accessories Selection Guide which lists a complete

array of additional items available for use with this product. Please contact

your factory representative or visit www.GEmds.com to obtain a copy of this

guide.

Table 1. P-60 Accessories

GE MDS Part Number Description

12-1307A01 Order Wire Handset

02-1501A01 Hand-Held Terminal (Kit P/N 03-1501A01)

82-1982A02 Mounting plate for 19 inch rack; 10.5 inches

high (mounts internal chassis)

Table 2. P-50 Accessories

GE MDS Part Number Description

82-1743A01 Pole-Mount Adapters (two required)

12-1307A01 Order Wire Handset

02-1501A01 Hand-Held Terminal (Kit P/N 03-1501A01)

02-1556A01 Mounting kit for 19 inch rack; 15.75 inches high

(mounts internal chassis)

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 12

12 MDS P-60/P-60 HL Reference Manual MDS 05-2818A01, Rev. C

2.0 MDS P-60 INSTALLATION

NOTE: Due to restricte d ventilation, the P-60 enclosure is not suitable for

applications using a continuously transmitting radio.

2.1 Unpacking and Inspection

After opening the shipping container, check the contents against the packing

list secured to the outside of the box. We recommend saving all shipping materials in case the unit needs to be shipped in the future.

The factory test data sheet is normally packed with the equipment. Check this

sheet to ensure that the packaged radio system has been configured to meet

your requirements. Specific items to check include: primary power voltage,

transmit and receive frequencies, modem speed (if applicable), FM deviation,

and transmitter RF power output. If there are discrepancies, contact GE MDS’

Customer Support at +1 (585) 242-9600 for assistance.

2.2 Installation Considerations

A short time spent planning the installation can help prevent performance

problems later on. Select a location that provides a stable mounting surface,

and also allows for convenient routing of the antenna, power and data cabling.

All of these cables (but especially the antenna feedline) need to be kept as short

as possible to minimize losses. Refer to the transceiver manual for a feedline

loss chart.

Packaged systems are normally mounted in either a wall-mount or pole-mount

configuration. If possible, install the unit in a location that can be easily

reached while standing on the ground. This allows convenient access for test

and servicing of the radio system.

If the unit must be installed in a location that is not easily accessible, it may be

desirable to first operate the packaged system on a test bench to verify proper

operation with customer-supplied equipment and to set any programmable

parameters before installation. However, installation tasks such as antenna

aiming and SWR checks should be done with the unit placed in its final operating position.

NOTE: The use of stainless steel mounting hardware is recommended for

outdoor installations.

2.3 Mounting the Enclosure

There are two basic mounting arrangements for the MDS P-60—pole mount or

wall mount. Methods for mounting the unit in both of these configurations

follow. When planning the installation, refer to Figure 3 on Page 13, which

shows the mounting dimensions of the MDS P-60 packaged system.

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 13

MDS 05-2818A01, Rev. C MDS P-60/P-60 HL Reference Manual 13

Invisible place holder

Figure 3. MDS P-60 Mounting Dimensions

Wall Mounting Instructions

The steps below describe mounting of the MDS P-60 unit to a wall or other flat

surface. Ordinary lag screws (with flat washers) can be used for mounting to a

wooden surface. If it is to be mounted to a drywall, masonry or other

non-wooden surface, suitable fasteners will be required that can support the

weight of the unit.

To wall mount the unit, follow these instructions:

1. Attach the four keyhole mounting clips (provided) to the back of the

enclosure with 10-32 screws, as shown in Figure 4 on Page 14. The

screws must be no longer than 3/8" (9.5 mm). Longer screws will

damage the enclosure.

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 14

14 MDS P-60/P-60 HL Reference Manual MDS 05-2818A01, Rev. C

2. Hold the packaged unit up to the wall in the desired mounting position.

Have an assistant mark the four mounting holes with a pencil or marker.

(The marks should be placed in the center of the wide portion of the

mounting clips.)

3. Prepare the mounting surface for the fasteners to be used. (If using lag

screws, a small pilot hole at each mark will allow easier starting of the

screw.)

4. Insert the screws part way into the wall, leaving enough space to slide the

enclosure mounting clips onto the screws. Hang the packaged system

enclosure onto the four screws and tighten the screws securely. Do not

over-tighten.

Figure 4 shows a typical wall mount installation.

Figure 4. Typical Wall Mounted Installation (MDS P-60)

TO PRIMARY

POWER

(CONDUIT)

13.38"

34 cm

9.0"

22.86 cm

COAXIAL CABLE

TO ANTENNA

TO DATA

EQUIPMENT

(RTU)

ATTACHED TO BACK

OF MDS xx60

A

ENCLOSURE WITH

10-32 SCREW

(SEE TEXT)

FLAT

WASHER

MOUNTING

CLIP

MOUNTING CLIP DETAIL

(4 REQD)

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 15

MDS 05-2818A01, Rev. C MDS P-60/P-60 HL Reference Manual 15

Pole Mounting Instructions

Standard pole mounting requires the use of two pole-mount adapters (P/N

82-1743A01). These brackets must first be bolted to the MDS P-60 enclosure.

The complete assembly can then be mounted to a wooden utility pole with two

lag screws or with two long bolts that extend through the pole. (Threaded rod

can also be used for through-the-pole mounting.) In either case, it is important

to use flat washers with the attaching hardware (fasteners are not supplied).

To pole mount the unit, follow these instructions:

1. Attach the two pole-mount adapter brackets to the MDS P-60

enclosure with four 10-32 screws, as shown in

Figure 5. The screws

must be no longer than 3/8" (9.5 mm). Longer screws will damage

the enclosure.

2. With the help of an assistant, position the MDS P-60 enclosure on the pole

at the desired mounting point.

3. Install the attaching hardware (with flat washers) in the center hole of the

two brackets.

4. Tighten the fasteners securely, but do not over-tighten.

Figure 5 shows a typical pole-mount installation with lag screws.

Invisible place holder

Figure 5. Typical Pole-Mounted Installation (MDS P-60)

TO PRIMARY POWER

(CONDUIT)

COAXIAL CABLE

TO ANTENNA

LAG SCREW

FLAT WASHER

(2 REQD)

TO DATA

EQUIPMENT

(RTU)

POLE MOUNT

BRACKET

82-1743A01

(2 REQD)

BRACKET ATTACHED

TO ENCLOSURE

WITH 10-32 SCREWS

(SEE TEXT)

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 16

16 MDS P-60/P-60 HL Reference Manual MDS 05-2818A01, Rev. C

Other pole-mount hardware is available for the MDS P-60, including a

mounting bracket with a sun shield (for use in excessively hot climates), a

tower mounting bracket, and other arrangements to meet special needs. Contact GE MDS for more information.

Rack Mount Alternative

In addition to wall and pole mounting, the packaged system can also be

mounted in a 19 inch equipment rack for indoor installations. Figure 6 shows

a typical rack mount installation using brackets fabricated from steel or aluminum. Figure 7 on Page 17 details the mounting plate configuration.

The electrical installation procedures given in this section apply fully to rack

mounted units. The physical mounting instructions, however, will differ,

depending on the type of rack cabinet to be used. Contact GE MDS if additional assistance is required.

Invisible place holder

Figure 6. Typical Rack Mount Installation (MDS P-60)

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 17

MDS 05-2818A01, Rev. C MDS P-60/P-60 HL Reference Manual 17

2.4 MDS P-60 Cable Connections

This section describes the connection of external cabling to the MDS P-60

packaged system. Included are steps for connecting DC power, the station

antenna, and data equipment (RTU) cabling. Figure 7 shows an overall view of

the connection points for all external cabling. Subsequent illustrations will

show more detailed views of wiring connections as required.

Invisible place holder

Figure 7. MDS P-60 Cable Connection Points

Primary Power—TB2

The power input terminations for the MDS P-60 are provided on the Inter-

face/Utility Board connector TB2 via screw terminals (see Figure 8 on

Page 19). Note that TB2 is used for input power regardless of whether the unit

is configured for AC or DC operation. Primary power wiring should be routed

via conduit to the hole on the bottom right of the enclosure. This hole is fitted

with a standard 1-1/4" (3.37 cm) conduit coupling.

CAUTION:

The MDS P-60 is available for operation on a wide variety

of AC or DC supply voltages. Be sure to check the label near TB2 and

make sure that the supply voltage you are using matches that specified

on the label before applying power. Use of an incorrect supply voltage

can permanently damage the radio, power supply, or both.

DC Operation

Connector TB2 is used for primary power input on DC-powered models. Pin 1

is the negative (–) connection. Pin 3 is the positive (+) connection.

BACK-UP BATTERY

CONNECTION (J4)

PRIMARY POWER

CONNECTION (TB2)

DATA EQUIPMENT

CONNECTION (TB1)

ANTENNA

CONNECTION

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 18

18 MDS P-60/P-60 HL Reference Manual MDS 05-2818A01, Rev. C

The MDS P-60 is normally wired by the factory for “floating” power connections. However, either of the primary power leads can be connected to TB2 Pin

2 (chassis ground), if desired, to configure the unit for positive or negative

ground.

AC Operation

Connector TB2 is used for primary power input on AC-powered models. Pins

1 and 3 are the AC line inputs. The AC Ground must be connected to Pin 2

(chassis ground).

AC power supplies are most commonly wired for 120 Vac, but can readily be

rewired for 230 Vac if desired. There is a chart on the side of the power supply;

unmount the power supply to view it.

Power Supply Bypass Plug

The MDS part number for the Power Supply Bypass plug (used on models

without a DC-DC converter) is 03-1304A01.

Accessory Power—With Analog Interface/Utility Board Installed

Interface terminal block TB1 Pin 12 can be used to provide up to 1 ampere for

13 Vdc negative ground accessories. TB1 Pin 11 is the negative connection.

Fuse F5 provides protection for this accessory power.

Backup Battery—Important information

Packaged systems supplied wired for AC operation have a backup battery

system installed as standard equipment. The battery is disconnected for shipping by unplugging its cable from the Interface/Utility Board. This prevents

accidental discharge of the battery and radio operation while the unit is in shipment or storage. Plug the battery cable into J4 to enable the backup power

option.

Antenna Connection

A type-N coaxial connector on the lower right side of the transceiver chassis

serves as the antenna connection to the packaged system. Route the antenna

coax through the weathertight bushing on the bottom of the enclosure and

attach it to the transceiver connector. This bushing is also commonly used to

pass the RTU interface through to the Interface/Utility Board. Do not tighten it

until all cabling has been installed.

The antenna connection is not made directly to MDS iNET and TransNET

transceivers, as with other MDS radios. A pigtail coaxial lead is provided (P/N

03-3576A01), that makes the antenna connection readily accessible, and converts it from a TNC connector to a Type-N connector. After connecting the

antenna feedline to the pigtail connector, the assembly should be well insulated

(for example, electrical tape or shrink tubing) to prevent contact with other circuitry inside the P-60 housing.

Refer to the transceiver manual for additional information on installing

antennas and feedlines.

NOTE: The following subs ection describes audio and keyline connections

to an MDS P-60 Analog Interface/Utility Board (P/N 03-2110A01).

Instructions for the Digital Interface/Utility Board are given in the

next major subsection.

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 19

MDS 05-2818A01, Rev. C MDS P-60/P-60 HL Reference Manual 19

2.5 Audio and Keyline Connections—Analog

Interface/Utility Board (P/N 03-2110A01)

The Analog Interface/Utility Board serves as the connection point for all audio

and keyline connections to the MDS P-60. Route the cabling to the Inter-

face/Utility Board through the weathertight bushing on the bottom of the

enclosure (also used for the antenna coaxial cable). Tighten the bushing after

installing the interface cable.

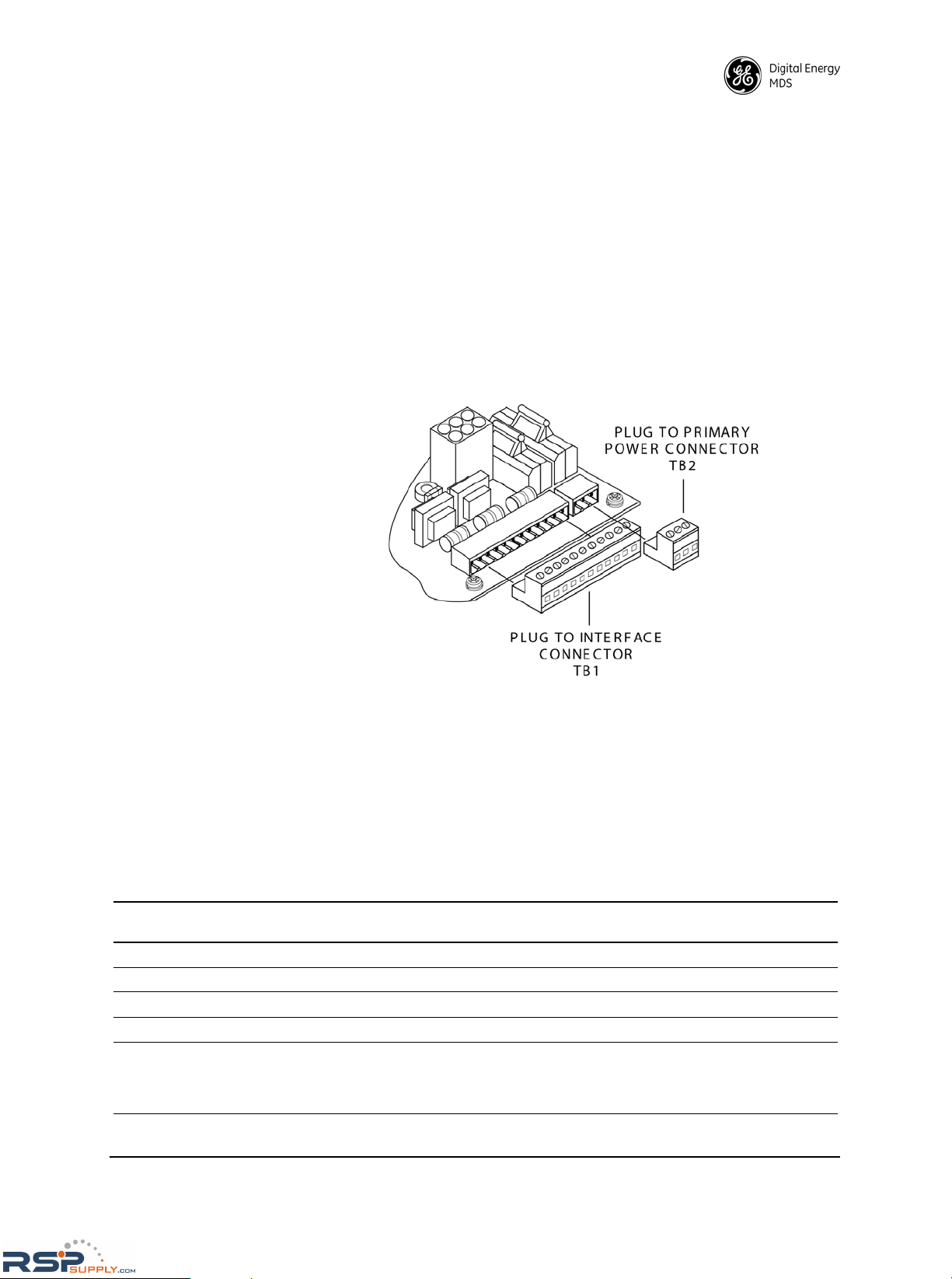

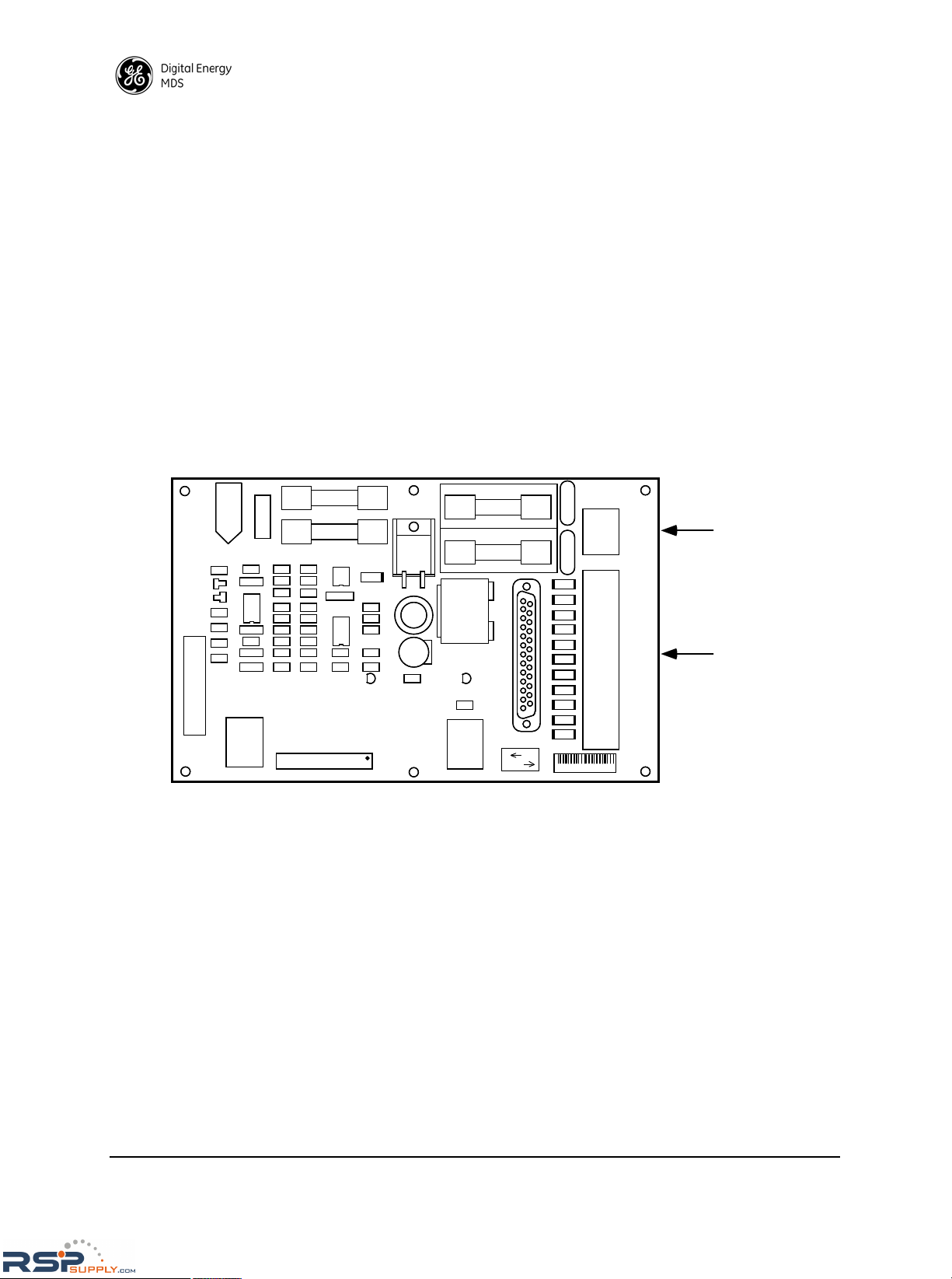

Interface/Utility Board connections are made through two compression-screw-type plug assemblies (see Figure 8). The plug assemblies are

removed by sliding the connectors away from the center of the PC board. There

is a pair of small clips on the plug that prevent the connectors from falling out

of the PCB mounted receptacles.

Invisible place holder

Figure 8. Plugs for Primary Power TB2

and Interface TB1 Connectors

Audio and Keyline—TB1

Connector TB1 on the Analog Interface/Utility Board is used for all audio and

keyline terminations. Table 3 lists the pin assignments for TB1. When making

connections, refer to Figure 9 on Page 20 for a detailed view of the Analog

Interface/Utility Board.

Table 3. Pin Connections (Analog Interface/Utility Board)

TB1

Pins

Connection Remarks

1 & 2 Transmit Audio 600 , balanced

3 Ground

4 & 5 Receive Audio 600 , balanced

6 Ground

7 & 8 Keyline connection for positive or

negative keying

This arrangement allows the radio to be keyed by a variety

of different methods that will accommodate most systems.

For more information, see “Keyline Options” discussion

below.

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 20

20 MDS P-60/P-60 HL Reference Manual MDS 05-2818A01, Rev. C

Invisible place holder

Figure 9. Analog Interface/Utility Board, P/N 03-2110A01

Keyline Options

Several methods may be used to key the transceiver, depending on the facilities

available at the installation site and the design of the customer-supplied data

equipment. (See Figure 10 on Page 22.) This section discusses three common

keying methods. Contact the factory if further assistance is required.

Positive or Negative Keying

One keyline option is to use a keyed 12 to 25 volt source or a fixed voltage

source and a series relay. The relay contacts can be included in either the positive or negative supply lead. (See Figure 10 on Page 22, examples 1 and 2.)

The use of an opto-isolator allows both keying supply leads to “float” above or

below ground, and tolerates line to ground transients up to 2500 volts. TB1 Pin

7 must be positive with respect to TB1 Pin 8. For keying supply voltages higher

than 25 volts, add a resistor in series with the connection to TB1 Pin 7 or TB1

Pin 8 to limit the keying current to 10 to 20 mA.

9 AC Alarm Normally 11 Vdc; drops to zero volts if an AC failure occurs.

10 Received Signal Strength

Indication (RSSI)

Approximately 0 to 5 Vdc through a 10K resistor.

8 & 11 Keyline connection when an

internal current source is used.

(Requires a jumper between Pins

7 and 12.)

This method uses the on-board 12 volt DC supply. For more

information, see “Keyline Options” discussion below.

12 +13 Vdc Accessory power (1 Amp maximum). Jumpered to Pin 7 for

keying with an internal current source. See description for

Pins 8 & 11 above.

Table 3. Pin Connections (Analog Interface/Utility Board) (Continued)

TB1

Pins

Connection Remarks

LINE 2/DC +

NEUTRAL

LINE 1/DC

+13V ACCY

GND

RSSI

AC ALARM

KEYLINE LO

KEYLINE HI

GND

RX AUDIO

RX AUDIO

GND

TX AUDIO

TX AUDIO

2

3

1

00-00000-00

POWER

CONNECTIONS

(TB2)

INTERFACE

CONNECTIONS

(TB1)

1

2

3

4

5

6

7

8

9

10

11

12

1

2

3

J5

J4

J7

F5

F4

F3

J3

J2

J6

J1

F1

F2

T2

T1

TB1

TB2

MOV1

MOV2

26

25

2

1

25

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 21

MDS 05-2818A01, Rev. C MDS P-60/P-60 HL Reference Manual 21

Internal Current Source Keying

Another keyline option is to use the on-board 12 volt DC supply. This is done

by adding a jumper from TB1 Pin 7 to Pin 12. TB1 Pins 8 and 11 should then

be connected to the keyline relay contacts. (See Figure 10 on Page 22, example

3.)

Manual Keying Button (for test purposes)

A red pushbutton switch, SW1, is provided on the Interface/Utility Board to

key the transmitter manually when desired. This is intended for use during initial setup and testing of the packaged system.

NOTE: The Transmit Test Key, SW1, on the Interface/Utility Board is

non-functional with MDS iNET or TransNET radios.

Additional Interface Connections

Two unique outputs are provided on TB1 for custom applications: AC power

failure alarm, and the transceiver’s Received Signal Strength Indication

(RSSI).

AC Alarm —Pin 9

H = AC Present—Approximately 11 Vdc through a 1 K

resistor

L = AC Failure—Ground through a 1 K resistor

Received Signal Strength Indicator (RSSI)—Pin 10

Same as transceiver’s RSSI output. It provides a DC voltage proportional to the

received signal strength. The range is approximately zero to five volts DC

through a 10K current limiting resistor. Refer to the transceiver manual for

additional RSSI information.

For MDS iNET and TransNET Radios

The Orderwire and Diagnostic connectors on the Interface/Utility Board are

not used when MDS iNET or TransNET radios are installed. Orderwire and

diagnostic connections must be made directly at the radio, using appropriately

wired connectors. Refer to the transceiver manual for pinout information.

The TransNET’s Sleep and Alarm lines are not carried onto the P-60 terminal

strip, J1/TB1. If these functions are required, make the connection directly at

the radio, using an appropriately wired connector.

Two interface cables are packed inside each P-60 when an MDS iNET or

TransNET radio is installed. The proper cable must be identified by the user

and installed between the radio’s DB-9 data connector and J2 on the Interface/Utility Board.

• The 03-2848A01 cable is for use with an iNET radio’s COM2 port.

• The 03-2876A01 cable is for use with either a TransNET radio, or an

iNET radio’s COM1 port.

P-60 units with an MDS iNET transceiver installed include an Ethernet Transient Protector that is mounted at the bottom of the enclosure. A heavy ground

wire (green) extends between the stud on the protector, and the P-60’s ground

point.

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 22

22 MDS P-60/P-60 HL Reference Manual MDS 05-2818A01, Rev. C

Invisible place holder

Figure 10. Keying Options, Analog Interface/Utility Board, P/N 03-2110A01

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 23

MDS 05-2818A01, Rev. C MDS P-60/P-60 HL Reference Manual 23

2.6 Data Connections—Digital Interface/

Utility Board (P/N 03-2472Axx)

The Digital Interface/Utility Board serves as the connection point for all data

connections to the MDS P-60. Route the cabling to the Interface/Utility Board

through the weathertight bushing on the bottom of the enclosure (also used for

the antenna coaxial cable). Tighten the bushing after installing the interface

cable.

Interface/Utility Board connections are made through two compression-screw-type plug assemblies. The plug assemblies are removed by sliding

the connectors away from the center of the PC board. There is a pair of small

clips on the plug that prevent the connectors from falling out of the PCB

mounted receptacles.

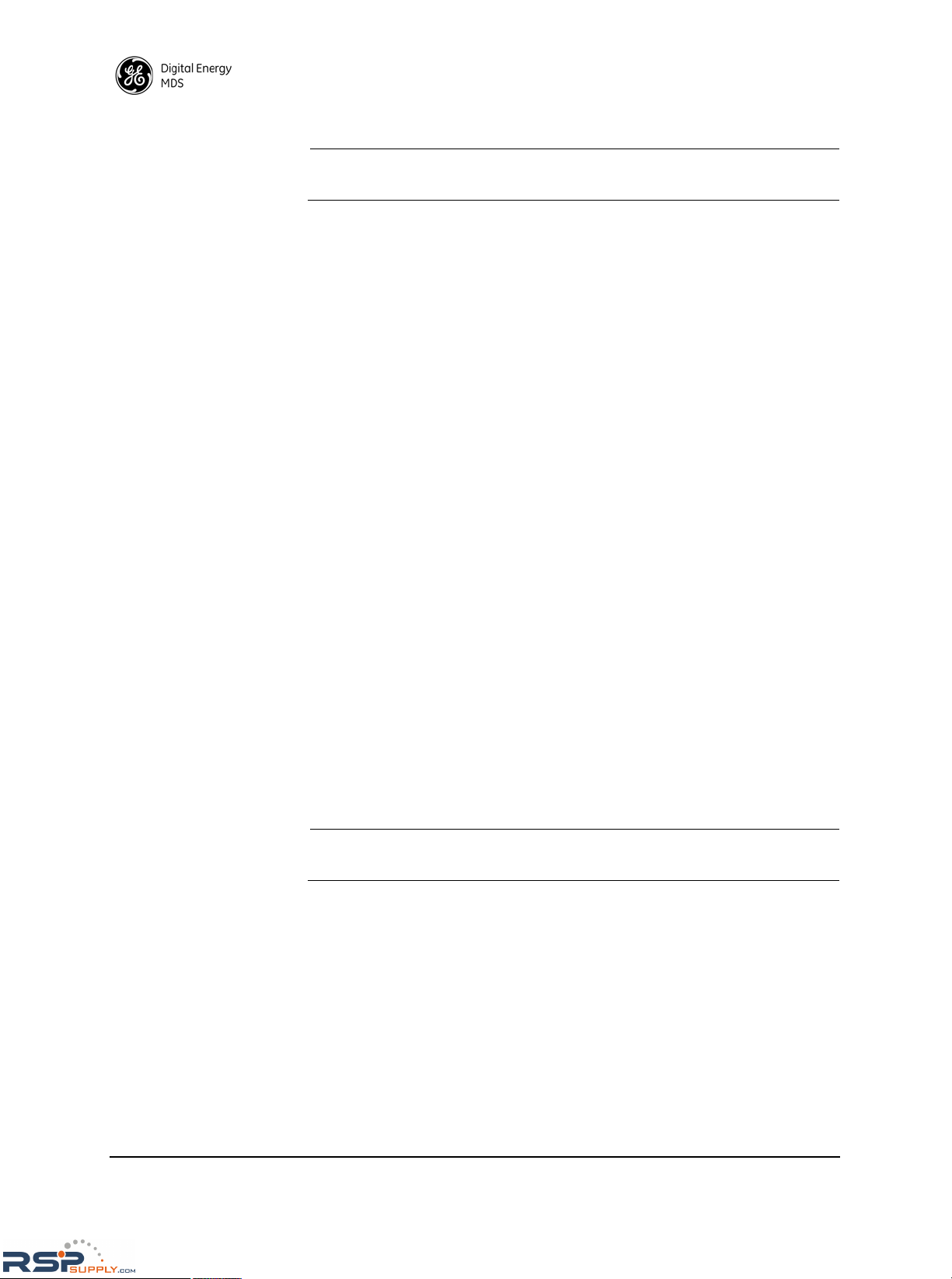

RS-232/EIA-232 Data Connections—TB1

Table 4 lists the functions of the RS-232/EIA-232 pins on TB1 of the Digital

Interface/Utility Board. When making connections, refer to Figure 11 on

Page 24 for a detailed view of the Digital Interface/Utility Board.

*DSR wired to +8 V in the transceiver.

†

Not applicable for x710 or x810 radios, which are asynchronous

NOTES

1. The radio is configured as DCE (Data Circuit-terminating Equipment)

as opposed to DTE (Data Terminal Equipment).

2. These lines are inputs: ETC, TXD and RTS.

3. These lines are outputs: TC, RC, RXD, CTS, DSR and DCD.

4. For asynchronous operation, make no connection to Pins 8, 9 or 10.

Table 4. Interface/Utility Board TB1 Connections

Pin Number and Function

1. Signal & Protective Ground (usually pin 1)

2. Transmit Data In (TXD)

3. Received Data Out (RXD)

4. Request-To-Send (RTS)

5. Clear-To-Send (CTS)

6. Data Set Ready (DSR)*

7. Data Carrier Detect (DCD)

8. Transmit Clock (TC) Synchronous Operation Only

†

9. Receive Clock (RC) Synchronous Operation Only

†

10. External Transmit Clock (ETC) Synchronous Operation

Only

†

11. Received Signal Strength (RSSI)

12. AC Alarm (AC Failure)

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 24

24 MDS P-60/P-60 HL Reference Manual MDS 05-2818A01, Rev. C

Additional Interface Connections

Two additional outputs are provided on TB1 for custom applications: AC

power failure alarm, and the transceiver’s Received Signal Strength Indication

(RSSI).

AC Alarm —Pin 12

H = AC Present—Approximately 11 Vdc through a 1 K

resistor

L = AC Failure—Ground through a 1 K resistor

Received Signal Strength Indicator (RSSI)—Pin 11

Same as transceiver’s RSSI output. It provides a DC voltage proportional to the

received signal strength. The range is approximately zero to five volts DC

through a 10K current limiting resistor. Refer to the transceiver manual for

additional RSSI information.

Invisible place holder

Figure 11. Digital Interface/Utility Board, P/N 03-2472Axx

00-00000-00

LINE 2/DC+

NEUTRAL

LINE 1/DC

AC ALARM

RSSI

ETC

RC

TC

DCD

DSR

CTS

RXD

TXD

GND

2

3

1

POWER

CONNECTIONS

(TB2)

INTERFACE

CONNECTIONS

(TB1)

RTS

1

2

3

4

5

6

7

8

9

12

10

11

1

2

3

J4

J7

F4

F3

F1

F2

J5

J1

J2

J6

J3

OUT

IN

SW2

26 25

21

2

TB1

TB2

MOV1 MOV2

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 25

MDS 05-2818A01, Rev. C MDS P-60/P-60 HL Reference Manual 25

2.7 Final MDS P-60 Installation Tasks

Perform the following steps to complete the installation of the MDS P-60 and

prepare the unit for normal operating service:

1. Dress and secure all external cabling in conformance with

applicable electrical codes.

2. Apply primary power to the unit and check for normal transceiver operation. (Checks for the radio are described in the transceiver manual.)

3. If necessary, refine the antenna heading for maximum RSSI. Refer to the

transceiver manual for additional RSSI information.

4. Close and latch the equipment cabinet. The cabinet latch may be padlocked if desired.

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 26

26 MDS P-60/P-60 HL Reference Manual MDS 05-2818A01, Rev. C

3.0 MDS P-50 INSTALLATION

NOTE: The MDS P-50 is a discontinued pro duct, an d is pro vided in th is

manual for historical reference only.

3.1 Unpacking and Inspection

After opening the shipping container, check the contents against the packing

list secured to the outside of the box. We recommend that all shipping materials

be saved in case you need to ship the unit in the future.

The factory test data sheet is normally packed with the equipment. Check this

sheet to ensure that the packaged radio system has been configured to meet

your requirements. Specific items to check include: primary power voltage,

transmit and receive frequencies, modem speed (if applicable), FM deviation,

and transmitter RF power output. If there are discrepancies, contact GE MDS

Customer Support at +1 (585) 242-9600 for assistance.

3.2 Installation Considerations

A short time spent planning the installation can help prevent performance

problems later on. Select a location that provides a stable mounting surface,

and also allows for convenient routing of the antenna, power and data cabling.

All of these cables (but especially the antenna feedline) need to be kept as short

as possible to minimize losses. Refer to the transceiver manual for further

information on selecting feedlines.

Packaged systems are normally mounted in either a wall-mount or pole-mount

configuration. If possible, install the unit in a location that can be easily

reached while standing on the ground. This allows convenient access for test

and servicing of the radio system.

If the unit must be installed in a location that is not easily accessible, it may be

desirable to first operate the packaged system on a test bench to verify proper

operation with customer-supplied equipment and to set any programmable

parameters before final installation. However, installation tasks such as

antenna aiming and SWR checks should be done with the unit in its permanent

operating position.

NOTE: The use of stainless steel mounting hardware is recommended for

outdoor installations.

3.3 Mounting the Enclosure

There are two basic mounting arrangements for the MDS P-50—wall mount or

pole mount. The steps below describe methods for mounting the unit in both of

these standard configurations. When planning the installation, refer to

Figure 12 on Page 27, which shows the mounting dimensions of the MDS P-50

packaged system.

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 27

MDS 05-2818A01, Rev. C MDS P-60/P-60 HL Reference Manual 27

Invisible place holder

Figure 12. MDS P-50 Mounting Dimensions

Wall Mounting Instructions

The steps below describe mounting of the MDS P-50 unit to a wall or other flat

surface. Ordinary lag screws (with flat washers) can be used if the unit is to be

mounted to a wooden surface. If it is to be mounted to a drywall, masonry or

other non-wooden surface, suitable fasteners will be required that can support

the weight of the unit.

To wall mount the unit, follow these instructions:

1. Hold the packaged unit up to the wall in the desired mounting

position. Have an assistant mark the four mounting holes with a

pencil or marker.

2. Prepare the mounting surface for the fasteners to be used. (If using lag

screws, a small pilot hole at each mark will allow easier starting of the

screw.)

3. Hold the packaged unit up to the wall again while an assistant installs the

four mounting screws. Make sure the screws are tightened securely, but do

not over-tighten.

Figure 13 on Page 28 shows a typical wall mount installation.

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 28

28 MDS P-60/P-60 HL Reference Manual MDS 05-2818A01, Rev. C

Invisible place holder

Figure 13. Typical Wall Mount Installation (MDS P-50)

Pole Mounting Instructions

Standard pole mounting requires the use of two pole-mount adapters (P/N

82-1743A01). These brackets must first be bolted to the MDS P-50 enclosure.

The complete assembly can then be mounted to a wooden utility pole with two

lag screws or with two long bolts that extend through the pole. (Threaded rod

can also be used for through-the-pole mounting.) In either case, it is important

to use flat washers with the attaching hardware (fasteners are not supplied).

To pole mount the unit, follow these instructions:

1. Attach the two pole mount adapter brackets to the MDS P-50

enclosure with suitable nut and bolt assemblies, as shown in

Figure 14 on Page 29.

2. With the help of an assistant, position the MDS P-50 enclosure on the pole

at the desired mounting point.

3. Install the attaching hardware (with flat washers) in the center hole of the

two brackets.

4. Tighten the fasteners securely, but do not over-tighten.

TO PRIMARY POWER

(CONDUIT)

COAXIAL CABLE

TO ANTENNA

LAG SCREW

FLAT WASHER

TO DATA EQUIPMENT (RTU)

(4 REQD)

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 29

MDS 05-2818A01, Rev. C MDS P-60/P-60 HL Reference Manual 29

Figure 14 shows a typical pole-mount installation using lag screws.

Invisible place holder

Figure 14. Typical Pole-Mounted Installation (MDS P-50)

Other pole-mount configurations are available for the MDS P-50, including a

mounting bracket with a sun shield (for use in excessively hot climates), a

tower mounting bracket, and other arrangements to meet special needs. Contact GE MDS for more information.

Rack Mount Alternative

In addition to wall and pole mounting, the internal chassis of the packaged

system can also be mounted in a standard 19 inch equipment rack for indoor

installations. The rack-mounted model is normally shipped without an enclosure and is supplied with hardware for mounting the chassis plate to the rack

cabinet. Figure 15 on Page 30 shows a typical rack mount installation, and

Figure 16 on Page 31 details the mounting plate configuration.

TO PRIMARY POWER

(CONDUIT)

COAXIAL CABLE

TO ANTENNA

LAG SCREW

FLAT WASHER

(2 REQD)

TO DATA

EQUIPMENT (RTU)

POLE MOUNT

BRACKET

82-1743A01

(2 REQD)

NUT & BOLT ASSEMBLY

(4 REQD)

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 30

30 MDS P-60/P-60 HL Reference Manual MDS 05-2818A01, Rev. C

The electrical installation procedures given in this section apply fully to rack

mounted units. The physical mounting instructions, however, will differ

depending on the type of rack cabinet to be used. Contact GE MDS if additional assistance is required.

Invisible place holder

Figure 15. Typical Rack Mount Installation (MDS P-50)

POWER, DATA &

ANTENNA CABLING

PACKAGED SYSTEM

CHASSIS PLATE

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 31

MDS 05-2818A01, Rev. C MDS P-60/P-60 HL Reference Manual 31

3.4 MDS P-50 Cable Connections

This section describes the connection of external cabling to the MDS P-50

packaged system. Included are steps for connecting DC power, the station

antenna, and the customer-supplied equipment. Figure 16 shows an overall

view of the connection points for all external cabling. Subsequent illustrations

will show more detailed views of wiring connections as required.

Invisible place holder

Figure 16. MDS P-50 Cable Connection Points

Primary Power—J3

The power input terminations for the MDS P-50 are provided on the Inter-

face/Utility Board connector J3. Note that J3 is used for input power regardless

of whether the unit has been configured for AC or DC operation. Primary

power wiring should be routed via conduit to the rear hole on the bottom of the

enclosure. This hole is fitted with a standard 1-1/4" (3.37 cm) conduit coupling.

CAUTION:

The MDS P-50 is available for operation on a wide variety

of AC or DC supply volta ges. Be sure to check the label near J3 and

make sure that the supply voltage you are using matches that specified

on the label before applying power. The use of an incorrect supply voltage can permanently damage the radio, power supply, or both.

DC Input—J3

Connector J3 is used for primary power input on DC-powered models. Pin 1 is

the positive (+) connection. Pin 3 is the negative (–) connection.

The system can be configured for negative or positive chassis ground by connecting either the negative or positive supply lead to J3 Pin 2 (chassis ground

terminal). As an alternative, the DC supply leads can be left “floating” by

making no connection to J3 Pin 2.

AC Input—J3

Connector J3 is used for primary power input on AC-powered models. J3 Pins

1 and 3 are the AC line inputs. The AC Ground must be connected to J3 Pin 2

(chassis ground terminal).

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 32

32 MDS P-60/P-60 HL Reference Manual MDS 05-2818A01, Rev. C

AC power supplies are most commonly wired for 120 Vac, but can readily be

rewired for 230 Vac if desired. There is a chart on the side of the power supply;

unmount the power supply to view it.

Accessory DC Power Out—J8

Accessory Power connector J8 on the Interface/Utility Board can be used to

provide up to 2 amperes at 13 Vdc negative ground for accessories. Fuse F2

provides over-current protection for this power.

Pin 1 of J8 is connected to the +13 volt DC supply. Pin 2 is at DC ground.

Backup Battery—Important information

Packaged systems supplied wired for AC operation have a backup battery

system installed as standard equipment. The battery is disconnected for shipping by unplugging its cable from the Interface/Utility Board. This prevents

accidental discharge of the battery and radio operation while the unit is in shipment or storage. Plug the battery cable into J4 to enable the backup power

option.

Antenna Connection

A type-N coaxial connector on the lower right side of the transceiver chassis

serves as the antenna connection to the packaged system. Route the antenna

coax through the front hole (a weathertight bushing) on the bottom of the

enclosure and attach it to the transceiver connector. This bushing is also commonly used to pass the RTU interface cabling through to the Interface/Utility

Board. Do not tighten it until all cabling has been installed.

Refer to the transceiver manual for additional information on selecting and

installing antennas and feedlines.

NOTE: The following subs ection describes audio and keyline connections

to an MDS P-50 Analog Interface/Utility Board (P/N 03-1105A21).

Instructions for the Digital Interface/Utility Board are given in the

next major subsection.

3.5 Analog Interface/Utility Board Connections

(P/N 03-1105A21)

The Analog Interface/Utility Board serves as the connection point for all audio

and keyline connections to the MDS P-50. Route the cabling to the Inter-

face/Utility Board through the weathertight bushing on the bottom of the

enclosure (also used for the antenna coaxial cable). Tighten the bushing after

installing the interface cable.

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 33

MDS 05-2818A01, Rev. C MDS P-60/P-60 HL Reference Manual 33

Connector J1 on the Analog Interface Utility Board is used for all audio and

keyline terminations. Refer to Table 5 for a summary of J1 pin connections.

Figure 17 shows a detailed view of the Analog Interface/Utility Board.

Figure 17. Analog Interface/Utility Board Connections—MDS P-50

Table 5. J1 Pin Connections (Analog Interface/Utility Board)

J1

PINS

CONNECTION REMARKS

1 & 2 Transmit Audio 600 , balanced

3 No Connection

4 & 5 Receive Audio 600 , balanced

6 No Connection

7 & 8 Keyline connection for positive or negative

keying

This arrangement allows the radio to be keyed

by a variety of different methods that will

accommodate most systems.

See “Keyline

Options” on Page 34.

8 & 11 Keyline connection when an internal current

source is used. (Requires a jumper between

Pins 7 and 10.)

This method uses the on-board 12 volt DC

supply.

See “Keyline Options” on Page 34.

9 AC Failure Alarm Normally 11 Vdc; drops to zero volts if an AC

failure occurs.

10 +13 Vdc Accessory power (2 Amp maximum) jumpered

to Pin 7 for keying with an internal current

source. See description for Pins 8 & 11 above.

11 PCB ground connection Connects to ground on the Interface/Utility

Board.

12 Received Signal Strength Indication (RSSI) Approximately 0 to 5 Vdc through a 10K

resistor.

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 34

34 MDS P-60/P-60 HL Reference Manual MDS 05-2818A01, Rev. C

Keyline Options

Several methods may be used to key the transceiver, depending on the facilities

available at the installation site and the design of the customer-supplied data

equipment. (See Figure 18 on Page 35.) This section discusses three common

keying methods. Contact the factory if additional assistance is required.

Positive or Negative Keying

One keyline option is to use a keyed 12 to 25 volt source or a fixed voltage

source and series relay. The relay contacts can be included in either the positive

or negative supply lead (see Figure 18 on Page 35, examples 1 and 2). The use

of an opto-isolator allows both keying supply leads to “float” above or below

ground. J1 Pin 7 must be positive with respect to J1 Pin 8. For keying supply

voltages higher than 25 volts, add a resistor in series with the connection to J1

Pin 7 (or Pin 8) to limit the keying current to 10 to 20 mA.

Internal Current Source Keying

Another keyline option is to use the on-board 12 volt DC supply. This is done

by adding a jumper from J1 Pin 7 to Pin 10. J1 Pins 8 and 11 are then connected

to the keyline relay contacts (see Figure 18 on Page 35, example 3).

Manual Keying Button (for test purposes)

A red pushbutton, SW1, is provided on the Interface/Utility Board to key the

transmitter manually when desired. This is useful during initial setup and

testing of the packaged system.

Additional Interface Connections

Two additional outputs are provided on J1 for custom applications: AC power

failure alarm, and the transceiver’s Received Signal Strength Indication

(RSSI).

AC FAIL—Pin 9

H = AC Present—Approximately 11 Vdc through a 1 K

resistor

L = AC Failure—Ground through a 1 K resistor

RSSI—Pin 12

Same as transceiver’s RSSI output. Provides a DC voltage proportional to the received signal strength. Range is approximately

zero to five volts DC through a 10K current limiting resistor.

Refer to the transceiver manual for additional RSSI information.

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 35

MDS 05-2818A01, Rev. C MDS P-60/P-60 HL Reference Manual 35

Figure 18. Keying Options—Analog Interface/Utility Board, P/N 03-1105A21

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 36

36 MDS P-60/P-60 HL Reference Manual MDS 05-2818A01, Rev. C

3.6 Digital Interface/Utility Board Connections

(P/N 03-1467A21)

The Digital Interface/Utility Board serves as the connection point for all data

interface cabling to the MDS P-50. Route the cabling to the Interface/Utility

Board through the weathertight bushing on the bottom of the enclosure (also

used for the antenna coaxial cable). Tighten the bushing after installing the

interface cable.

Connector J1 on the Digital Interface/Utility Board is used for all data cabling

terminations. Refer to Table 6 for a summary of the required pin connections.

Figure 19 on Page 37 shows a detailed view of the Digital Interface/Utility

Board.

*DSR wired to +8 V in the transceiver.

†

Not applicable for x710 or x810 radios, which are asynchronous

NOTES

1. The radio is configured as DCE (Data Communications Equipment) as opposed to

DTE (Data Terminal Equipment).

2. These lines are inputs: ETC, TXD and RTS.

3. These lines are outputs: TC, RC, RXD, CTS, DSR and DCD.

4. For asynchronous operation, make no connection to Pins 8, 9 or 10.

Table 6. Interface/Utility Board J1 Connections

Pin Number & Description Pin Number & Description

1. Signal & Protective Ground 7. Data Carrier Detect (DCD)

2. Transmit Data In (TXD) 8. Transmit Clock (TC)

Synchronous Operation Only

†

3. Received Data Out (RXD) 9. Receive Clock (RC)

Synchronous Operation Only

†

4. Request-To-Send (RTS) 10. External Transmit Clock (ETC)

Synchronous Operation Only

†

5. Clear-To-Send (CTS) 11. Received Signal Strength

(RSSI)

6. Data Set Ready (DSR)* 12. AC Failure (Alarm)

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 37

MDS 05-2818A01, Rev. C MDS P-60/P-60 HL Reference Manual 37

Invisible place holder

Figure 19. Digital Interface/Utility Board Connections—MDS P-50

Additional Interface Connections

Two additional outputs are provided on J1 for custom applications: AC power

failure alarm, and the transceiver’s Received Signal Strength Indication

(RSSI).

AC FAIL—Pin 12

H = AC Present—Approximately 11 Vdc through a 1 K

resistor

L = AC Failure—Ground through a 1 K resistor

SGN-STRENGTH (RSSI)—Pin 11

Same as transceiver’s RSSI output. Provides a DC voltage proportional to the received signal strength. Range is approximately

zero to five volts DC through a 10K resistor. Refer to the transceiver manual for additional RSSI information.

+

–

BATTERY

PACK

RED

BLACK

FUSE

DIGITAL

INTERFACE

ASSEMBLY

SYSTEM

GROUNDSTUD

DATA

INTERFACE

PRIMARY

POWER

ANTENNA

TRANSMISSION LINE

POWER

SUPPLY

J7

J4

1

1

J8

1

F2

J2

1

J1

1

J6

J5+–

F1

MOV1 MOV2

J3

1

3

46

+

+

+

+

J10

+

J9

PRIMARY POWER

INPUT (AC or DC as

indicated on c hassis

label.)

+–

13 VDC

+

–

RS-232

INTERFACE

CONNECTOR

J1

25 26

2

CHASSIS

GROUND

+–

2345 678910 11 12

12345 678910

T

R

A

N

S

C

E

I

V

E

R

E

T

C

R

C

T

C

D

C

D

D

S

R

C

T

S

R

T

S

R

X

D

T

X

D

G

N

D

A

C

F

A

I

L

S

G

N

S

T

R

E

N

G

T

H

RESERVED FOR RS-422

(CONSULT FACTORY)

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 38

38 MDS P-60/P-60 HL Reference Manual MDS 05-2818A01, Rev. C

3.7 Final MDS P-50 Installation Tasks

Perform the following steps to complete the installation of the MDS P-50 and

prepare the unit for normal operating service:

1. Dress and secure all external cabling in conformance with

applicable electrical codes.

2. Apply primary power to the unit and check for normal transceiver operation. (Checks for the radio are described in the transceiver manual.)

3. Close and latch the equipment cabinet. The cabinet latches may be padlocked if desired.

4. If necessary, refine the antenna heading for maximum RSSI. (Refer to the

transceiver manual for additional RSSI information.)

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 39

MDS 05-2818A01, Rev. C MDS P-60/P-60 HL Reference Manual 39

4.0 P-60/P-50 OPERATION

4.1 Introduction

The packaged systems are designed for unattended field operation. The only

normal operator interaction is to apply power at the time of installation and

observe the unit for proper LED indications. This chapter discusses the steps

for initial power-up and also describes the connection of accessory equipment

to the packaged system. These instructions assume that the unit has been

installed in accordance with the installation procedures given earlier in this

manual.

4.2 Initial Power-Up

As soon as primary power is applied to the packaged system, the unit is ready

for operation. Follow these steps to begin operation:

1. Apply primary power to the packaged system.

2. Observe for normal operation. Typically, the radio will be transmitting

intermittently in response to polling signals from the master station. The

transceiver instruction manual describes other installation checks that can

be made to the radio and antenna system.

Battery Backup Operation—for AC-powered units

In AC-powered units, a 12 volt battery is provided as standard equipment. The

battery provides at least four hours of continued operation in the event of a primary power failure. (Depending on the transmit duty cycle and how often the

radio is polled, the battery may last much longer.) The battery is float charged

by the power supply during normal operation.

During battery backup operation, an

AC FAIL LED illuminates on the Inter-

face/Utility Board. (On DC-powered units, this LED will be lit continuously

under normal conditions.) A test procedure for the backup battery is given in

Backup Battery Testing on page 48.

NOTE: Packaged systems supplied wired for AC operation have a backup

battery system installed as stan dard eq uipment. The ba ttery is

disconnected for shipping by un plugging its cable from the Interface/Utility Board. This prevents accidental discharge of the battery

and radio operation while the unit is in shipment or storage. Plug the

battery cable into J4 to enable the backup power option.

Low Voltage Disconnect Assembly

A Low Voltage Disconnect Assembly (P/N 03-3077A01) is included in many

recently manufactured packaged radio systems. This section explains the operation of the assembly and provides schematic and component location information.

A field upgrade kit (P/N 03-3077A11) is also available to add the Low Voltage

Disconnect Assembly to older packaged radio units. Contact GE MDS for

additional information.

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 40

40 MDS P-60/P-60 HL Reference Manual MDS 05-2818A01, Rev. C

Functional Description

The Low Voltage Disconnect assembly is a small PC board mounted on the

chassis plate of GE MDS packaged model radio systems. It prevents battery

damage that may be caused by allowing a backup battery to drop below 10.2

volts while powering a transceiver, such as might occur during a lengthy power

outage. Component locations are shown in Figure 20, and Figure 21 provides

a schematic diagram.

When the battery voltage drops to 10.2 Volts (± 0.2V), the Low Voltage Disconnect Assembly automatically disconnects the battery from the transceiver.

This, of course, stops operation of the radio, but protects the battery from

potential damage. When AC power returns, the battery is automatically connected to the power supply (for charging) and normal radio operation resumes

immediately.

Invisible place holder

Figure 20. Low Voltage Disconnect Assembly, P/N 03-3077A01

Component Locations

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 41

MDS 05-2818A01, Rev. C MDS P-60/P-60 HL Reference Manual 41

Invisible place holder

Figure 21. Low Voltage Disconnect Assembly, P/N 03-3077A01

Schematic Diagram

Use of the Battery Reset Switch (SW1)

Normally, the operation of the Low Voltage Disconnect Assembly is fully

automatic. The only exception is when replacing a discharged battery with a

charged unit before AC power has returned. In this case, it is necessary to press

the

BAT. RESET switch on the assembly after installing the new battery. (See

Figure 22.) Use a pen or other pointed object to press the switch. This allows

the replacement battery to immediately supply power to the transceiver.

Invisible place holder

Figure 22. Low Voltage Disconnect Assembly

NOTE: For proper opera tion of the Low V oltage Disconnect assembly,

14.10 Vdc (±0.1 V) must be present at the battery connector on the

Interface/Utility Board (with the battery disconnected). This is the

standard factory setting.

U

MC33172

-

3

1

2

U

MC33172

-

6

7

5

U

MC33172

+

-

4

8

K1

+-

3

6

4

1

J1

1

2

3

E1+

E2

E1

GN

SW

0.1UF

C

10UF

C

1

121K

R

1

110K

R

10K

R

10K

R

100

R

1ME

R

MMBT3904L T1

Q

2

3

1

1N5231

CR

1

3

2

CR

1

3

2

CR

132

RESE

BATTER

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 42

42 MDS P-60/P-60 HL Reference Manual MDS 05-2818A01, Rev. C

Operational Test

To test for proper backup battery operation, proceed as follows:

1. Apply AC power to the packaged system and operate the radio in

the normal manner.

2. When the battery has charged, disconnect the AC power and verify that the

system continues to operate on battery power.

3. Re-apply AC power. This completes the checkout procedure.

4.3 Interface/Utility Board Features and Indicators

Most user interaction with the packaged system takes place at the Interface/Utility Board located in the lower left hand side of the enclosure.

Depending on the model of the unit, a variety of features are available on this

board that will assist you in monitoring and controlling the operation of the

system. Table 7 on page 42 contains a summary of the available features and

indicators on each packaged model.

Invisible place holder

Table 7. Interface/Utility Board Features & Indicators

Model

Configuration

Order

Wire

Jack

1

HHT Jack

LED

Indicator(s)

Test

Switch

1

Adjustments

2

MDS P-60

w/Analog

Interface/Utility

Board

J1

(Modular)

J3 (Modular) CR6—AC

power failure

indicator. (On

with battery

operation.)

CR10—

Transmitter

keyed

SW1—Red

button.

Used to

manually

key the

transceiver.

R9—TX audio

level

R10—RX audio

level

R28—Order wire

deviation

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 43

MDS 05-2818A01, Rev. C MDS P-60/P-60 HL Reference Manual 43

Connecting an Order Wire Handset

NOTE: Order wire (voice) operation over data frequencies is not permitted

in all countries. Check the regula tions before connecting an Order

Wire handset to your system.

The radio equipment installed in the packaged system is normally used for data

(non-voice) transmission. Occasionally, however, it may be desirable to establish a temporary voice link to personnel at the master station to coordinate

installation or maintenance activities. This is accomplished with an “Order

Wire” connection.

Many packaged system Interface/Utility Boards have a modular telephone-style jack that will accept an Order Wire handset (see Figure 23).

Table 7 on page 42 shows the appropriate jack number to use for each pack-

aged system model. Although many standard telephone handsets can be used

for Order Wire service, GE MDS offers a unit specifically intended for use

with its transceivers (P/N 12-1307A01). The Order Wire facility is not available on units equipped with an MDS 9000 Series Transceiver.

To use the Order Wire feature:

1. Plug the Order Wire handset into the modular jack on the

Interface/Utility Board. (See Table 7 on page 42 for the appropriate

jack number.)

2. Key the transmitter by speaking into the handset (VOX).

MDS P-60

w/Digital

Interface/Utility

Board

J1

(Modular)

J3 (Modular)

or

DB-25

connector

(SW2 used to

switch these

jacks in or out

of the circuit)

CR15—AC

power failure

indicator. (On

with battery

operation.)

CR12—

Transmitter

keyed

SW1—Red

button.

Used to

manually

key the

transceiver.

R13—Order

wire handset

1

MDS P-50

w/Analog

Interface/Utility

Board

J11

(Modular)

N/A

(HHT must be

connected

directly to

transceiver)

CR8—AC

power failure

indicator. (DC

power indicator

with battery

operation.)

SW1—Red

button.

Used to

manually

key the

transceiver.

R2—RX audio

level

R19—TX audio

level

MDS P-50

w/Digital

Interface/Utility

Board

J9

(Modular)

N/A

(HHT must be

connected

directly to

transceiver)

CR5—AC

power failure

indicator. (On

with battery

operation.)

CR4 Transmitter

keyed indicator

SW1—Red

button.

Used to

manually

key the

transceiver.

R19—Order

wire deviation

1

1. T hese features are not available on units equipped with an MDS 9000 Series Transceiver.

2. Control adjustment procedures are given in Chapter 5—Servicing Data.

Table 7. Interface/Utility Board Features & Indicators (Continued)

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 44

44 MDS P-60/P-60 HL Reference Manual MDS 05-2818A01, Rev. C

NOTE: Unintentional sound picked up by the Order Wire handset may key

the transmitter and interrupt the normal data flow through the transceiver. To prevent erratic operation of the system, remove the Order

Wire handset when the Order Wire is not in use.

Invisible place holder

Figure 23. Order Wire Handset Connected to Packaged System

(MDS P-60 shown; MDS P-50 similar)

Connecting a Hand-Held Terminal

A significant feature of GE MDS transceivers is the ability to accomplish many

radio programming and diagnostic tasks through software commands issued

from a Hand-Held Terminal (HHT). (See Figure 24 on Page 45.)

HHT control of the transceiver allows you to make several key measurements

and adjustments without the need for removing the transceiver cover, or having

to reconfigure internal switches or jumpers. The transceiver manual contains a

list of HHT commands for the specific radio installed in your system.

NOTE: When an HHT is connected, th e normal data communications

between t he Interface/Utility Board and the transceiver will be

disrupted. Disconnect the HHT to restore normal operation. Addi-

tionally, with MDS P-60 Digital Interface/Utility Boards, SW2 must

be returned to the OUT position when the HHT is disconnected.

ORDER WIRE

CONNECTION

(SEE TEXT)

HANDSET

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8466-MDS-P60-Compact-Enclosure-(One-Radio).aspx

Page 45

MDS 05-2818A01, Rev. C MDS P-60/P-60 HL Reference Manual 45

Invisible place holder

Figure 24. MDS Hand-Held Terminal

(Kit P/N 03-1501A01)

HHT Connection to an MDS P-60