Page 1

Installation & Operation Guide

Invisible place holder

05-4801A01, Rev. A

NOVEMBER 2007

LINK

PWR

LINK

COM1

ETH

DI-1

DI-2

DO-1

DO-2

COM2

WeXP

COM1

Wireless Communication Transceivers

for Analog & Digital I/O Signals

MDS NETio-TBTM Series

Base

Module

Expansion

Module

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 2

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 3

05-4801A01, Rev. A MDS NETio-TB Installation & Operation Guide i

Table of Contents

1 INTR

ODUCING THE MDS NETio SYSTEM................. 1

1.1 ABOUT THIS MANUAL...................................................................................................... 3

1.1.1 Conventions Used ...................................................................................................................3

1.2 PRODUCT DESCRIPTION................................................................................................ 3

1.3 HOW IT WORKS................................................................................................................ 5

1.3.1 I/O Operating Modes ...............................................................................................................5

1.3.2 Configuration Levels ................................................................................................................6

1.3.3 Module Profiles ........................................................................................................................6

1.4 CONNECTOR OVERVIEW................................................................................................ 7

1.5 DIN RAIL MOUNTING & REMOVAL................................................................................. 9

1.6 ACCESSORIES ...............................................................................................................10

2 CONFIGURING WIRELESS SYSTEM

PARAMETERS.......................................................... 13

2.1 INTRODUCTION ............................................................................................................. 15

2.2 INITIAL SETUP................................................................................................................ 15

2.2.1 NETio Backplane Communication .........................................................................................16

2.2.2 Measure & Connect DC Power ..............................................................................................16

2.3 SET BASIC CONFIGURATION OF THE NETio BASE MODULE ................................... 17

2.3.1 Starting Information Screen ...................................................................................................18

2.3.2 Main Menu .............................................................................................................................20

2.3.3 Wireless Configuration Menu ................................................................................................20

2.3.4 TransNET Configuration ........................................................................................................21

2.3.5 WeXP Configuration Menu ....................................................................................................22

2.3.6 Wireless Expansion Module Configuration ............................................................................23

2.4 ASSIGNING MODULE IDs .............................................................................................. 24

2.4.1 ID Conflict List Menu .............................................................................................................26

2.4.2 Conflict (Resolution) Menu ....................................................................................................27

2.4.3 Configuring WeXP Wireless Expansion Modules .................................................................. 27

2.4.4 I/O Module Configuration Menu .............................................................................................28

2.4.5 Module Menu .........................................................................................................................29

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 4

ii MDS NETio-TB Installation & Operation Guide 05-4801A01, Rev. A

2.5 CHECK for NORMAL OPERATION ................................................................................. 29

3 I/O POINT CONFIGURATION .................................... 31

3.1 I/O POINT CONFIGURATION ......................................................................................... 33

3.2 I/O NETWORK MENU ..................................................................................................... 33

3.2.1 I/O Module Configuration Menu .............................................................................................34

3.2.2 Discrete Input Menu ..............................................................................................................35

3.2.3 Analog Input Menu ................................................................................................................ 36

3.2.4 Discrete Output Menu ............................................................................................................37

3.2.5 Analog Output Menu .............................................................................................................38

3.3 CONFIGURING NETio OUTPUTS for PROTOCOL CONTROL...................................... 39

3.4 MAPPING INPUTS TO OUTPUTS FOR SIGNAL EXTENSION & REGENERATION ..... 39

3.4.1 Setting the Source Field for Mapping ....................................................................................40

3.5 FAILSAFE SETTINGS ..................................................................................................... 42

3.5.1 Configuring Failsafe Settings .................................................................................................42

3.5.2 Configuring Failsafe Timeout—Base Modules ...................................................................... 43

3.5.3 Configuring Failsafe Timeouts over WeXP ............................................................................43

3.6 I/O UPDATE REFRESH RATES ...................................................................................... 44

4 WIRING & TERMINATIONS ....................................... 45

4.1 I/O & POWER CONNECTIONS....................................................................................... 47

4.1.1 Module Dimensions ...............................................................................................................47

4.1.2 I/O Configurations .................................................................................................................47

4.2 I/O POINTS WIRING & TERMINATION ........................................................................... 48

4.2.1 Analog Input Wiring (Current Signals) ...................................................................................48

4.2.2 Analog Output Wiring (Current Signals) ................................................................................49

4.2.3 Analog Input Wiring (Voltage Signals) ...................................................................................49

4.2.4 Discrete Points Wiring ...........................................................................................................50

4.2.5 Module Wiring Diagrams .......................................................................................................50

5 CONFIGURING THE SERIAL PORTS ....................... 59

5.1 Configuring the NETio Serial Port.................................................................................... 61

5.2 Configuring COM2 Payload Port...................................................................................... 62

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 5

05-4801A01, Rev. A MDS NETio-TB Installation & Operation Guide iii

6 PROTOCOLS .............................................................. 65

6.1 CONFIGURING MODBUS OPERATION ......................................................................... 67

7 MAINTENANCE & SUPPORT FUNCTIONS ............ 69

7.1 INTRODUCTION ............................................................................................................. 70

7.2 NETio TransNET RADIO MAINTENANCE & SUPPORT................................................. 70

7.2.1 Performance, Statistics, RSSI Information ............................................................................70

7.2.2 Maintenance/Tools/Date and Time ........................................................................................71

7.3 WeXP & NETio MODULE MAINTENANCE ..................................................................... 72

7.3.1 View/Set Expansion Module WeXP RF Power ......................................................................72

7.3.2 Changing Base Module WeXP RF Output Power ..................................................................73

7.3.3 Changing WeXP RF Channel ................................................................................................74

7.3.4 WeXP RSSI and Backplane Communication Statistics ......................................................... 74

7.4 DEVICE, MODULE and I/O POINT DESCRIPTIONS ..................................................... 75

7.4.1 Changing the NETio Device Name ........................................................................................75

7.4.2 Changing NETio Module and I/O Point Names .....................................................................76

7.5 TECHNICAL SPECIFICATIONS ...................................................................................... 76

General .......................................................................................................................................76

NETio Base Module .................................................................................................................... 77

NETio Expansion Module Models...............................................................................................77

Analog Input................................................................................................................................77

Digital Inputs ...............................................................................................................................77

Analog Outputs ...........................................................................................................................78

Digital Outputs ............................................................................................................................78

900 MHz Model Radio Specifications .........................................................................................78

2.4 GHz Model Radio Specifications ..........................................................................................78

WeXP Radio Specifications - 802.15.4 ....................................................................................... 78

Mechanical..................................................................................................................................79

Agency Approvals ....................................................................................................................... 79

7.6 dBm-WATTS-VOLTS CONVERSION CHART ................................................................. 80

Copyright Notice

This publication is protected by U.S.A. copyright law. Copyright 2007, GE MDS, LLC. All rights

reserved.

ISO 9001 Registration

GE MDS adheres to the internationally-accepted ISO 9001 quality system standard.

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 6

iv MDS NETio-TB Installation & Operation Guide 05-4801A01, Rev. A

Related Materials on the Internet

Data sheets, frequently asked questions, application notes, information on firmware upgrades, and

other valuable information can be found on the GE MDS Web site at www.GEmds.com.

About GE MDS

Over two decades ago, GE MDS began building radios for business-critical applications. Since

then, we’ve installed more than 500,000 radios in over 110 countries. To succeed, we overcame

impassable terrain, brutal operating conditions and disparate, complex network configurations. We

also became experts in wireless communication standards and system applications worldwide. The

result of our efforts is that today, thousands of utilities around the world rely on GE MDS-based

wireless networks to manage their most critical assets.

OPERATIONAL & SAFETY NOTICES

FCC Transmitter Identifications

An MDS NETio Base Module can contain two internal FCC-approved transmitters:

• FCC ID: E5MDS-EL806 “MDS OEM TransNET 900MHz FHSS transceiver”

IC ID: 3738A-MDSEL806

• FCC ID: OUR-XBEEPRO “2.4 GHz Zigbee module”

IC ID: 4214A-XBEEPRO

NETio Expansion Modules equipped with wireless expansion services (WeXP) contain one FCC-approved transmitter:

• FCC ID: OUR-XBEEPRO “2.4 GHz Zigbee module”

IC ID: 4214A-XBEEPRO

CSA

/US

Notice

This product is available for use in Class I, Division 2, Groups A, B, C & D Hazardous Locations.

Such locations are defined in Article 500 of the National Fire Protection Association (NFPA) publication NFPA 70, otherwise known as the National Electrical Code.

The transceiver has been recognized for use by the Canadian Standards Association (CSA). The

certification for the transceiver is as a Recognized Component in hazardous locations, in accordance with the CSA Certification STD C22.2 No. 213-M1987.

U.S. Installations: Professional installation required. The radio equipment described in

this guide emits radio frequency energy. Although the power level is low, the concentrated

energy from a directional antenna may pose a health hazard. For 900 MHz units, do not

allow people to come closer than 23 cm (9 inches) to the antenna. For 2.4 GHz units, do

not allow people to come closer than 5 cm (2 inches) to the antenna. These distances apply

whether the transmitter is operated in indoor or outdoor environments.

For units with the optional wireless expansion service (WeXP) installed, a minimum separation distance of 23cm (9.05") must be maintained between the two antennas (Link and

WeXP) when mounted in their final locations.

More information on RF exposure is available on the Internet at

www.fcc.gov/oet/info/documents/bulletins .

RF Exposure

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 7

05-4801A01, Rev. A MDS NETio-TB Installation & Operation Guide v

CSA/

US

Conditions of Approval:

The transceiver is not acceptable as a stand-alone unit for use in the hazardous locations described

above. It must either be mounted within another piece of equipment which is certified for hazardous locations, or installed within guidelines, or conditions of approval, as set forth by the

approving agencies. The conditions of approval are as follows:

1. The transceiver must be mounted in a separate enclosure suitable for the intended application.

2. The antenna feedline, DC power cable and interface cable must be routed through conduit in

accordance with the National Electrical Code.

3. Installation, operation and maintenance of the transceiver should be in accordance with the

transceiver's installation manual, and the National Electrical Code.

4. Tampering or replacement with non-factory components may adversely affect the safe use of

the transceiver in hazardous locations, and may void the approval.

5. When installed in a Class I, Div. 2, Groups A, B, C or D hazardous location, observe the following:

WARNING — EXPLOSION HAZARD—

Do not disconnect equipment unless power has

been switched off or the area is known to be non-hazardous.

Refer to Articles 500 through 502 of the National Electrical Code (NFPA 70) for further information on hazardous locations and approved Division 2 wiring methods.

FCC Part 15 Notice

The transceiver complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation. This device is

specifically designed to be used under Section 15.247 of the FCC Rules and Regulations. Any

unauthorized modification or changes to this device without the express approval of Microwave

Data Systems may void the user’s authority to operate this device. Furthermore, this device is

intended to be used only when installed in accordance with the instructions outlined in this manual.

Failure to comply with these instructions may also void the user’s authority to operate this device.

Manual Revision and Accuracy

While every reasonable effort has been made to ensure the accuracy of this manual, product

improvements may result in minor differences between the manual and the product shipped to you.

If you have additional questions or need an exact specification for a product, please contact our

Customer Service Team using the information at the back of this guide. In addition, manual

updates can often be found on the GE MDS Web site at www.GEmds.com.

Environmental Information

The equipment that you purchased has required the extraction and use of natural resources for its

production. Improper disposal may contaminate the environment and present a health risk due to

hazardous substances contained within. To avoid dissemination of these substances into our environment, and to diminish the demand on natural resources, we encourage you to use the appropriate

recycling systems for disposal. These systems will reuse or recycle most of the materials found in

this equipment in a sound way. Please contact GE MDS or your supplier for more information on

the proper disposal of this equipment.

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 8

vi MDS NETio-TB Installation & Operation Guide 05-4801A01, Rev. A

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 9

05-4801A01, Rev. A MDS NETio-TB Installation & Operation Guide 1

1

INTRODUCING THE

MDS NETio SYSTEM

1 Chapter Counter Reset Paragraph

1.1 ABOUT THIS MANUAL ........................................................... 3

1.1.1 Conventions Used .................................................................... 3

1.2 PRODUCT DESCRIPTION ..................................................... 3

1.3 HOW IT WORKS ..................................................................... 5

1.3.1 I/O Operating Modes ................................................................ 5

1.3.2 Configuration Levels ................................................................. 6

1.3.3 Module Profiles ........................................................................ 6

1.4 CONNECTOR OVERVIEW...................................................... 7

1.5 DIN RAIL MOUNTING & REMOVAL ...................................... 9

1.6 ACCESSORIES....................................................................... 11

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 10

2 MDS NETio-TB Installation & Operation Guide 05-4801A01, Rev. A

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 11

05-4801A01, Rev. A MDS NETio-TB Installation & Operation Guide 3

1.1 ABOUT THIS MANUAL

This guide provides installation and operating instructions for MDS

NETio Series products. It is arranged into the following chapters:

• Chapter 1—Introducing the MDS NETio System (Page 3)

• Chapter 2—Configuring Wireless System Parameters (Page 13)

• Chapter 3—I/O Point Configuration (Page 31)

• Chapter 4—Wiring and Terminations (Page 45)

• Chapter 5—Serial or IP/Ethernet Configuration (Page 59)

• Chapter 6—Maintenance & Support Functions (Page 69)

1.1.1 Conventions Used

Quick Start Steps—

How to Use Them...

You will find

Quick Start Step

headings presented in the left-hand margins of Chapters 2 and 3. These headings indicate essential steps for getting the NETio system up and running. If you only need to perform basic

setup and configuration, look for these headings and follow the instructions given. The steps should be performed in sequence.

Additional detail is provided for each menu screen to assist those

needing more information.

Menu Navigation—

Finding the Menu

You Need...

To help show the path to a menu selection, navigation strings are used

in several places in this manual. For example, suppose you wished to

access the I/O Module Configuration Menu. The navigation string

shown in the text would appear as follows:

Main Menu>I/O Network>I/O Module Configuration

By following this order of menus, you will quickly reach the I/O Module

Configuration Menu.

1.2 PRODUCT DESCRIPTION

MDS NETio is an integrated, scalable family of wireless communication products for analog and discrete I/O signals. It supports three primary functions that can be implemented separately or concurrently:

• I/O Signal Extension —This function allows acquiring, transmitting and regenerating I/O signals between control and monitoring devices such as PLCs or RTUs.

•

Protocol Node —Allows direct addressing of I/O using a com-

mercial protocol such as MODBUS. Consult the factory for a

complete list of the protocols supported in the NETio Protocol

Library.

•

Payload Communication —Accommodates the serial connec-

tion of a separate PLC, RTU or other peripheral device for wireless connectivity to host devices or systems.

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 12

4 MDS NETio-TB Installation & Operation Guide 05-4801A01, Rev. A

Invisible place holder

Figure 1-1. MDS NETio-TB Unit

(Consisting of a Base Module & Optional Expansion Module)

Basic NETio

Architecture

A NETio Unit consists of a Base Module and, if needed, one or more I/O

Expansion Modules to achieve the I/O capacity required at a given location.

The Base and Expansion Modules communicate with each other over an

internal power and communication bus. Optionally, Expansion Modules

can be wirelessly distributed up to 3,000 feet (914 meters) away from

the Base Module if equipped with the WeXP option. WeXP is a completely separate 2.4 GHz 802.15.4 wireless network designed for

short-range communication. Actual range depends on the quality of the

2.4 GHz transmission path.

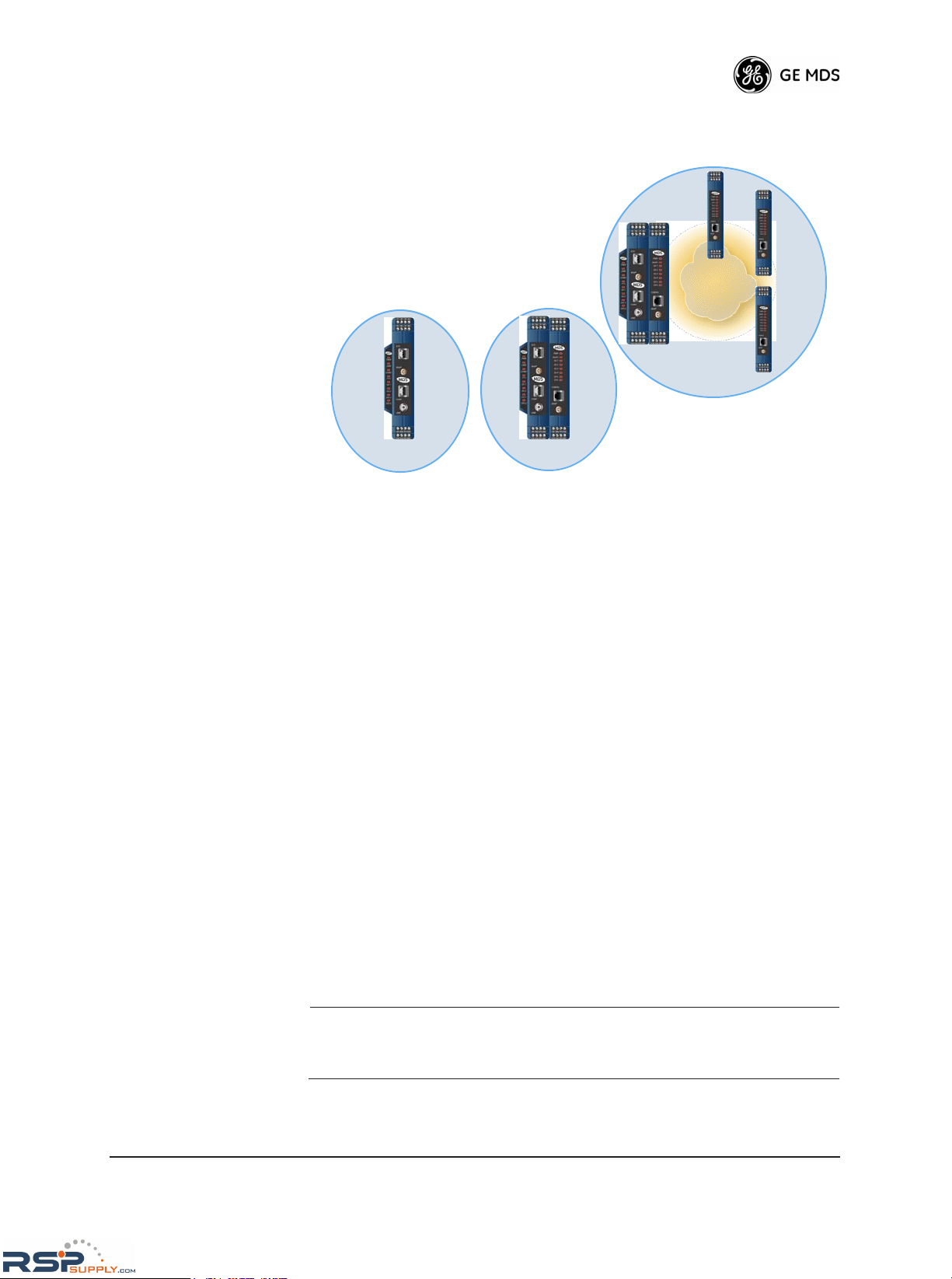

Figure 1-2 illustrates the “NETio Unit” concept in three different

arrangements; Base Module alone, Base Module connected with an

Expansion Module, and Expansion Modules linked to the Base via

WeXP.

PLC or RTU devices can optionally be connected at the Base Module’s

serial port (

COM2

) for payload communication to host devices or sys-

tems. (Note—This does not apply with WeXP.)

Base Module

Expansion Module

(Optional)

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 13

05-4801A01, Rev. A MDS NETio-TB Installation & Operation Guide 5

Invisible place holder

Figure 1-2. NETio “Unit Concept”

1.3 HOW IT WORKS

NETio reads analog and discrete input signals and generates analog and

discrete output signals. In this guide, any analog or discrete signal is

generically referred to as a “Point.”

1.3.1 I/O Operating Modes

“Signal Extender”

Mode

NETio-TB supports two operating modes. The first is called Signal

Extender

mode. In this mode, an analog or discrete input point read by

a NETio module at one location is transmitted to one or more NETio

modules at other locations via WeXP and regenerated as an output.

“Protocol Node”

Mode

The second operating mode is called Protocol Node . In this mode, the

desired protocol can be selected from the NETio Protocol Library. The

NETio Unit becomes “protocol aware” and you can monitor inputs and

generate outputs using the selected protocol.

Both modes can operate simultaneously. The only restriction is that

NETio does not allow an output point to be generated by both protocol

and signal extender modes. You must specify one or the other when configuring an output point.

NOTE:

NETio only supports one protocol for I/O while running in

Protocol Node mode. Other protocols can be used however, for

externally-attached devices.

WEXP

Up to

3,000 Feet/

914 meters

NETio Unit Concept

• A NETio Unit

• Always has a NETio Base Module

• Optionally has one or more expansion

modules to meet users I/O count

• Expansion Modules can

either connect physically to

Base Module or via WeXP.

• Is always a remote to a Master Radio or

Access Point

NETio Unit NETio Unit

NETio Unit

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 14

6 MDS NETio-TB Installation & Operation Guide 05-4801A01, Rev. A

1.3.2 Configuration Levels

There are several configuration levels associated with a NETio Unit

depending upon the functionality that needs to be implemented.

• NETio TransNET-class Radio Parameters

• WeXP 2.4 GHz Parameters (As needed, if WeXP is used)

• WeXP Network Address—Base Module and Wireless

Expansion Modules.

• NETio Module Activation (Required)

• Unit ID—Base Module ID

• Module ID—Expansion Module ID (if used)

• I/O Points (Required)

• I/O Point parameters such as signal type and range

• Signal Extender Functions (As needed)

• Protocol Node Functions (As needed)

• Optional Payload Communication (As needed)

• Support for an external RTU or PLC connected to NETio

serial communication port.

These Configuration Levels are further discussed in Chapters 2 and 3.

1.3.3 Module Profiles

NETio Base Module The NETio Base Module operates in the license-free 902–928 MHz

Industrial, Scientific, and Medical (ISM) band. It has the following I/O

capacity:

• 1 Analog Input (AI) @ 4–20 mA, 0-5 V, 0-10 V

• 1 Analog Output (AO) @ 4–20 mA

• 2 Discrete Inputs (DI) @ 5–36 Vdc

• 2 Discrete Outputs (DO) 36 Vdc rated at 2 A continuous load.

Invisible place holder

Figure 1-3. NETio-TB Base Module with WeXP Functionality

COM1

PWR

LINK

COM1

ETH

DI-1

DI-2

DO-1

DO-2

LINK

WeXP

COM2

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 15

05-4801A01, Rev. A MDS NETio-TB Installation & Operation Guide 7

Invisible place holder

NETio-XM

Expansion Module

Multiple NETio-XM Expansion modules can optionally attach to the

Base Module if a higher I/O count is needed. No additional power or

interconnection wiring is required for Expansion Modules that are physically attached to the Base Module. Expansion Modules can also be

equipped with WeXP 2.4 GHz functionality, which allows them to be

installed up to 3,000 feet (914 meters) from a Base Module. There are

six Expansion Module configurations summarized in Table 1-1. Expansion Modules are available with or without WeXP capability.

1.4 CONNECTOR OVERVIEW

Figure 1-4 shows all of the interface connectors and LEDs present on a

NETio-TB Base Module. Figure 1-5 shows this information for a

NETio-XM Expansion Module. A review of these items will assist you

in making the connections described later in this section.

Table 1-1. Expansion Module Configurations

(Shown with the WeXP Option present. Note that a Type 5 Module is not available.)

Type 1

NIOXM-1W

Type 2

NIOXM-2W

Type 3

NIOXM-3W

Type 4

NIOXM-4W

Type 6

NIOXM-6W

Type 7

NIOXM-7W

• 1 Analog

Input (0–5 V,

0–10 V,

4–20 mA)

• 1 Analog

Output

(4–20 Ma)

• 2 Discrete

Inputs

• 2 Discrete

Outputs

• 6 Discrete

Inputs

• 6 Discrete

Outputs

• 2 Analog

Inputs

(0–5 V, 0–10

V, 4–20 mA)

• 4 Discrete

Inputs

• 2 Analog

Inputs—

non-isolated

(0–5 V)

• 2 Analog

Outputs—

non-isolated

(0–5 V)

• 2 Discrete

Inputs

• 2 Discrete

Outputs

• 2 Analog

Inputs—

(4–20 mA)

isolated

• 1 Discrete

Inputs

• 3 Discrete

Outputs

PWR

WeXP

DI-1

DI-2

DO-1

DO-2

WeXP

CONFIG

PWR

WeXP

DI-1

DI-2

DI-3

DI-4

DI-5

DI-6

WeXP

CONFIG

WeXP

CONFIG

PWR

WeXP

DO-1

DO-2

DO-3

DO-4

DO-5

DO-6

PWR

WeXP

DI-1

DI-2

DI-3

DI-4

WeXP

CONFIG

PWR

WeXP

DI-1

DI-2

DO-1

DO-2

WeXP

CONFIG

PWR

WeXP

DI-1

D0-1

DO-2

DO-3

WeXP

CONFIG

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 16

8 MDS NETio-TB Installation & Operation Guide 05-4801A01, Rev. A

Invisible place holder

Figure 1-4. NETio-TB Base Module Interface Connectors & LEDs

Figure 1-5 shows the interface connectors for a typical NETio Expan-

sion Module. The number and function of LEDs, as well as the presence

of the WeXP antenna connector and the 24 Vdc power output, is dependent on the model.

Invisible place holder

Figure 1-5. Expansion Module Interface Connectors & LEDs

(Typical Model Shown)

Together, the NETio Base and Expansion modules offer deployment

alternatives that are uniquely scalable to a user’s I/O count, distance and

location requirements.

COM1

PWR

LINK

COM1

ETH

DI-1

DI-2

DO-1

DO-2

LINK

WeXP

COM2

PRIMARY POWER

◆ 13.8 Vdc @ 350 mA

(6–30 Vdc)

◆ Negative Ground

◆ 1 + / 2 –

24 VDC POWER OUTPUT

◆ 24.0 Vdc @ 40 mA

◆ Isolated from Ground

◆ Pins 3 (+) & 4 (–)

COM1

◆DCE Console/Terminal

◆ 19,200 bps/8N1 (Default)

◆No Handshaking

◆ RS/EIA-232

MDS entraNET RF CONNECTOR

◆ 50Ω TNC connector

◆ +30 dBm/1W Output (Max.)

◆ –30 dBm Input (Max.)

WeXP RF CONNECTOR

◆ Wireless Expansion

◆ Antenna

◆ 2.4 GHz (IEEE 802.15.4)

9–12

13–16

TERMINATIONS

LED PANEL

◆PWR —Primary Power

◆MDS entraNET Radio Link

◆COM1 —COM Port Activity

◆ETH —ETHERNET Port Activity

◆DI-1 —Digital Input 1 Active

◆DI-2 —Digital Input 2 Active

◆DO-1 —Digital Output 1 Active

◆DO-2 —Digital Output 2 Active

1–4

5–8

TERMINATIONS

+

–

–

+

COM2

◆DCE Console/Terminal

◆ 19,200 bps/8N1 (Default)

◆No Handshaking

◆ RS/EIA-232

WeXP RF CONNECTOR

◆ Wireless Expansion

◆ Antenna

◆ 2.4 GHz

◆ (IEEE 802.15.4)

CONFIGURATION

◆DCE Console/Terminal

◆ 19,200 bps/8N1 (Default)

◆No Handshaking

◆ RS/EIA-232

1–4

5–8

TERMINATIONS

9–12

13–16

TERMINATIONS

LED PANEL

◆Power

◆ WeXP

◆Digital Input or Output Active

+

–

–

+

PWR

WeXP

DI-1

DI-2

DI-3

DI-4

WeXP

CONFIG

PRIMARY POWER

◆ 13.8 Vdc @ 350 mA

(6–30 Vdc)

◆ Negative Ground

◆ 1 + / 2 –

24 VDC POWER OUTPUT

◆ 24.0 Vdc @ 40 mA

◆ Isolated from Ground

◆ Pins 3 (+) and 4 (–)

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 17

05-4801A01, Rev. A MDS NETio-TB Installation & Operation Guide 9

The NETio Base Module can be purchased with two different levels of

service:

NETio Protocol Node—Supports access to the protocol library

for direct protocol addressability.

NETio Complete—Adds concurrent payload communication

for an attached RTU, PLC or other peripheral device, and signal

extension via WeXP to protocol capabilities. Serial connections

are supported. WeXP is also included for short-range linkage to

Wireless Expansion Modules installed up to 3,000 feet (914

meters) away.

Key Operating

Features

• Ability to read analog inputs and discrete inputs

• Ability to generate analog outputs and discrete outputs

• Protocol-addressable analog and discrete points via a serial connection

• Analog and discrete signal regeneration between devices via

WeXP

• NETio Wireless Expansion capability—WeXP

• Serial communication for an external RTU or PLC

Rugged Packaging MDS NETio modules are housed in compact and rugged high-impact

cases that need only be protected from direct exposure to the weather.

The modules are supplied with 35 mm DIN-rail brackets for quick and

easy installation.

Robust Radio

Operation

The transceivers are designed for frequency-hopping spread-spectrum

operation in the license-free 900 MHz or 2.4 GHz band. They can provide reliable long distance communications over line-of-sight signal

paths. They employ digital signal processing (DSP) techniques for high

performance operation, even in the presence of weak signals or interference.

Multiple Services Users with a mixture of equipment requiring serial data interfaces can

employ a combination of both NETio modules and MDS TransNET

Remotes communicating with a common MDS TransNET Master

Radio.

1.5 DIN RAIL MOUNTING & REMOVAL

NETio Base and Expansion Modules are designed for direct mounting

to a 35 mm DIN rail without the need for tools. To mount a module,

simply hook the bracket over the top portion of the DIN rail, and then

push the bottom of the radio in until it locks in place. Figure 1-6 shows

the NETio being attached to a DIN rail.

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 18

10 MDS NETio-TB Installation & Operation Guide 05-4801A01, Rev. A

Invisible place holder

Figure 1-6. Mounting NETio Equipment to DIN Rail

(Hook unit over top of rail, and push in at bottom)

Removal from the DIN rail requires only a flat-blade screwdriver or

other tool to pull down on the spring-loaded tab at the bottom of the

radio’s mounting bracket (see Figure 1-7). With the tab held down,

swing the bottom of the radio away from the rail, then lift the unit up

slightly to fully release it from the mount.

Invisible place holder

Figure 1-7. Removal of NETio Equipment from DIN Rail

(Pull down on tab and swing bottom of unit away from rail)

1.6 ACCESSORIES

MDS NETio equipment may be used with one or more of the accesso-

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 19

05-4801A01, Rev. A MDS NETio-TB Installation & Operation Guide 11

ries listed in Table 1-1. Contact the factory for ordering details.

Table 1-1. Accessories

Accessory Description MDS Part No.

AC Power

Adapter Kit

A small power supply designed for continuous

service. UL approved. Input: 120/220; Output:

13.8 Vdc @ 2.5 A

01-3682A02

OmniDirectional

Antennas

Rugged antennas well suited for use at Access

Point installations. Consult with your factory

Sales Representative for details

Contact factory

Yagi Antenna

(Directional)

Rugged antennas well suited for use at Remote

installations. Consult with your factory Sales

Representative for details.

Contact factory

TNC Male-to-N

Female Adapter

One-piece RF adaptor plug. 97-1677A161

TNC Male-to-N

Female Adapter

Cable

Short length of coaxial cable used to connect

the module’s TNC antenna connector to a Type

N connector commonly used on large diameter

coaxial cables.

97-1677A159

(3 ft./1m)

97-1677A160

(6 ft./1.8m)

RJ-12 to DB-9

Female Adapter

Allows access to CONFIG port on Expansion

Modules. Used if your configuration device is

equipped with DB-9 connectors instead of

RJ-12.

73-2434A02

RJ-45 to DB-9

Female Adapter

Allows access to COM1 on Base Modules.

Used if your configuration device is equipped

with DB-9 connectors instead of RJ-45.

73-2434A12

RJ-45 to RJ-45

Straight-thru

Cable (CAT5)

Cable assembly used to connect an external

device to the transceiver. Both ends of the

cable are wired identically.

(Cable length ≈ 3 ft./1M)

97-1870A20

EIA-232

Shielded Data

Cable

Shielded cable terminated with a DB-9 male

connector on one end, and a DB-9 female on

the other end, 6 ft./1.8 m long.

97-1971A03

Fuse Small, board-mounted fuse used to protect

against over-current conditions.

29-1784A03

Coaxial Cable

Assembly

SMA Male to N Male 50 Ohm RG-142B Coax

Assy. 12 in./30.48 cm

97-2036A23

Coaxial Cable

Assembly

SMA Male to N Male 50 OHM RG142B Coax

Assy. 24 in./61 cm

97-2036A24

Coaxial Cable

Assembly

SMA Male to N Male 50 OHM RG142B Coax

Assy. 36 in./.91 m

97-2036A25

Coaxial Cable

Assembly

SMA Female to SMA Right Angle Coax

Adapter

97-2036A26

Whip Antenna 2.4 GHz Antenna with SMA Male Connector 97-4278A10

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 20

12 MDS NETio-TB Installation & Operation Guide 05-4801A01, Rev. A

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 21

05-4801A01, Rev. A MDS NETio-TB Installation & Operation Guide 13

2

CONFIGURING WIRELESS

SYSTEM PARAMETERS

2 Chapter Counter Reset Paragraph

2.1 INTRODUCTION 17

2.2 INITIAL SETUP 17

2.2.1 NETio Backplane Communication 18

2.2.2 Measure & Connect DC Power 18

2.3 SET BASIC CONFIGURATION OF THE NETio BASE MODULE

19

2.3.1 Starting Information Screen 20

2.3.2 Main Menu 22

2.3.3 Wireless Configuration Menu 22

2.3.4 TransNET Configuration 23

2.3.5 WeXP Configuration Menu 24

2.3.6 Wireless Expansion Module Configuration 25

2.4 ASSIGNING MODULE IDs 26

2.4.1 ID Conflict List Menu 28

2.4.2 Conflict (Resolution) Menu 29

2.4.3 Configuring WeXP Wireless Expansion Modules 29

2.4.4 I/O Module Configuration Menu 30

2.4.5 Module Menu 31

2.5 CHECK for NORMAL OPERATION 31

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 22

14 MDS NETio-TB Installation & Operation Guide 05-4801A01, Rev. A

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 23

05-4801A01, Rev. A MDS NETio-TB Installation & Operation Guide 15

2.1 INTRODUCTION

Prior to installation, it is recommended that the equipment be set up in a

benchtop environment to become familiar with its operation and features. This also allows tests of various network designs and configurations prior to installation. A benchtop test can be performed with any

number of modules.

This section describes the hardware setup and software configuration of

NETio. Quick Start steps are provided to assist installers who only wish

to perform basic setup and configuration tasks. Additional detail is provided for each step, for those wishing to obtain more background. information.

2.2 INITIAL SETUP

The following steps explain how to make connections to NETio, power

it up, and set basic configuration.

Quick Start

Step #1:

Review power and module interconnection discussion below, then

proceed to Section 2.3.

Figure 2-1 is a drawing of a benchtop arrangement for configuration and

staging of NETio equipment. The NETio modules may also be installed

on DIN rails if desired (see “ DIN RAIL MOUNTING & REMOVAL” on

Page 9).

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 24

16 MDS NETio-TB Installation & Operation Guide 05-4801A01, Rev. A

Invisible place holder

Figure 2-1. Typical Benchtop Arrangement

2.2.1 NETio Backplane Communication

When a NETio Unit consists of a Base Module and Expansion Modules,

as shown in Figure 2-1, all Expansion Modules should be connected to

the Base Module using the Backplane/power connector on the side of

the modules. The configuration process is easiest if all modules are

attached together via their Backplane/power connector.

2.2.2 Measure & Connect DC Power

Input power applied to NETio must be within 6–30 volts DC and be

capable of continuously providing a minimum of 11 Watts. (Typical

current consumption is: 220 mA @13.8 Vdc for NETio Base Modules.

Each module has screw terminations for power and I/O signals. Terminations 1 and 2 are for power as shown in Figure 2-2. Strip the wire

leads to 6 mm (0.25"). Be sure to observe proper polarity with the positive lead (+) on the left and negative on the right.

PC Running Terminal Session

(19,2000 bps, 8N1)

Base Module

COM1 Port

ETH

COM1

PWR

LINK

COM1

ETH

DI-1

DI-2

DO-1

DO-2

LINK

ETH

WeXP

PC Running Terminal Program

(19,2000 bps, 8N1)

OR:

* As an alternative, WeXP-equipped Expansion Modules

may be configured over the air via 2.4 GHz link after

they have been configured with their WeXP Network

Address (See Section 2.3.7).

Base Module

COM1 Port

ETH

COM1

PWR

LINK

COM1

ETH

DI-1

DI-2

DO-1

DO-2

LINK

ETH

WeXP

PWR

WeXP

DI-1

DI-2

DI-3

DI-4

WeXP

CONFIG

PWR

WeXP

DI-1

DI-2

DI-3

DI-4

WeXP

CONFIG

PWR

WeXP

DI-1

DI-2

DI-3

DI-4

WeXP

CONFIG

PWR

WeXP

DI-1

DI-2

DI-3

DI-4

WeXP

CONFIG

Exp. Module

Exp. Module

Exp. Module

Exp. Module

Exp. Module

(With WeXP)*

PWR

WeXP

DI-1

DI-2

DI-3

DI-4

WeXP

CONFIG

Base ModuleBase Module

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 25

05-4801A01, Rev. A MDS NETio-TB Installation & Operation Guide 17

NOTE: When multiple modules are connected via the Back-

plane/power connector, all modules are powered via the Base

Module only. Do not connect power to each of the Expansion

Modules.

NOTE: It will take about 15-30 seconds for the NETio modules to be

ready for operation after power is connected.

Invisible place holder

Figure 2-2. DC Power Input for NETio Modules

The modules must be used only with negative-ground

systems. Make sure the polarity of the power source

is correct. The module is protected from reverse

polarity by an internal diode and on-board fuse.

2.3 SET BASIC CONFIGURATION OF

THE NETio BASE MODULE

The following instructions give a summary of the basic settings for a

NETio Base Module.

Quick Start

Step #2:

Start a HyperTerminal session to COM1 on the Base Module, and log

into NETio. Proceed to Section 2.3.1.

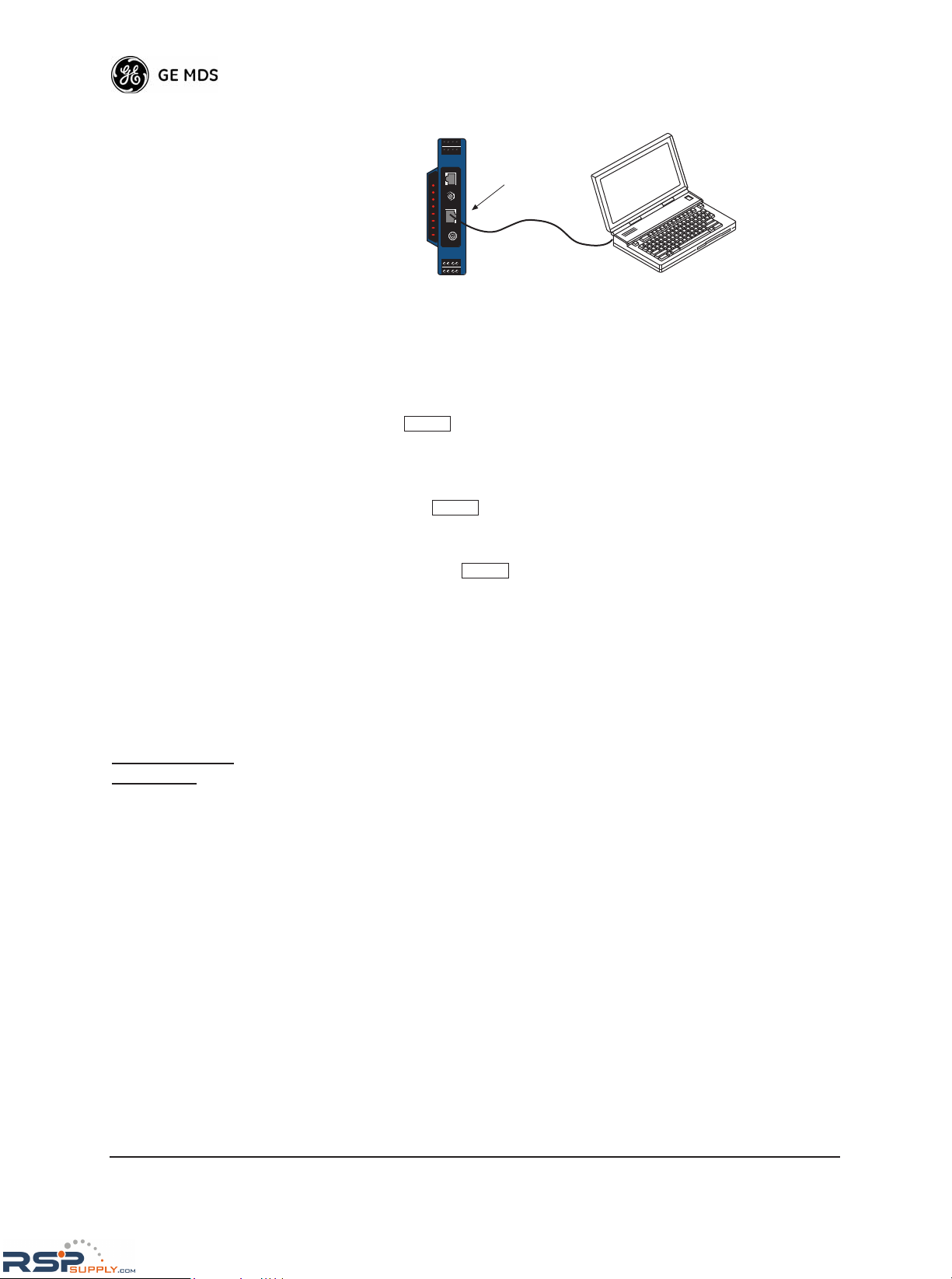

Console Terminal

Connection

The NETio Base Module is configured using a PC running Hyper Terminal or a console terminal (see Figure 2-3). Connect a PC to the NETio

Base Module’s

COM1 port and establish a HyperTerminal session using

the following parameters: 19200 bps, 8 bits, no parity, one stop bit

(8N1), flow control disabled, VT100 emulation.

The COM1 port uses an RJ-45 connector. A DB-9 to RJ-45 adaptor with

cable is supplied with each NETio Base Module.

NOTE: The exact parameters given above must be used for console

terminal communication. Improper settings are a common

cause of difficulty.

+

–

PRIMARY POWER

• Nominal 13.8 Vdc @ 350 mA

(Range: 6–30 Vdc)

• Negative Ground Only

• Terminal 1 is Positive (+)

• Terminal 2 is Negative (–)

CAUTION

POSSIBLE

EQUIPMENT

DAMAGE

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 26

18 MDS NETio-TB Installation & Operation Guide 05-4801A01, Rev. A

Invisible place holder

Figure 2-3. Local NETio Configuration Setup

With a PC connection made, log into the Base Module as follows:

1. Press the key to receive the

Login prompt. The COM1 LED

flashes to indicate data communications.

2. At the

Login prompt, enter the username (admin is the default user-

name). Press .

3. At the Password prompt, enter the password. (admin is the default

password). Press . Upon successful log-in, the Starting Information Screen appears.

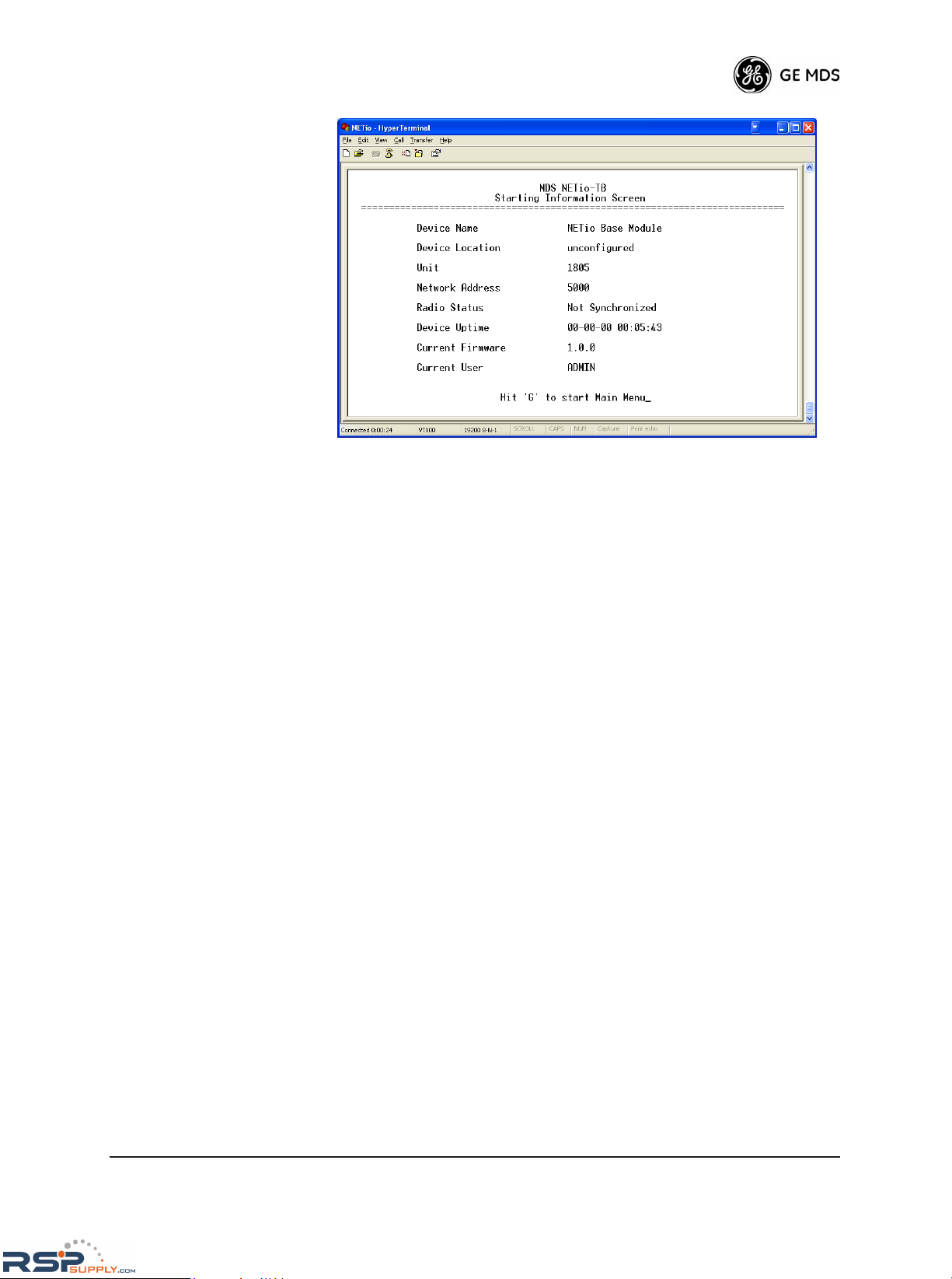

2.3.1 Starting Information Screen

Upon successful log-in the Starting Information Screen (Figure 2-4)

appears. This screen provides a read-only overview of the Base

Module’s current operating conditions.

Quick Start

Step #3:

Select G to go the Main Menu. Refer to Section 2.3.2, Main Menu

for detailed information.

PC Running Terminal Session

(19,2000 bps, 8N1)

Base Module

COM1 Port

ETH

COM1

PWR

LINK

COM1

ETH

DI-1

DI-2

DO-1

DO-2

LINK

ETH

WeXP

ENTER

ENTER

ENTER

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 27

05-4801A01, Rev. A MDS NETio-TB Installation & Operation Guide 19

Invisible place holder

Figure 2-4. Starting Information Screen—Local Console Session

• Device Name—User-defined name for the unit (40 characters

maximum).

•

Device Location—User-defined string commonly used to identify

the module’s location (40 characters maximum).

•

Unit—Shows the NETio Base Unit's unique Unit ID. This value

defaults to the last four digits of the NETio Base Module’s serial

number, but can be modified as desired.

•

Network Address—Shows the Network Address of the MDS

TransNET network to which this Unit belongs. The Network

Address is essential for association to an MDS TransNET Master Radio. All Units in a system must have the exact same Network Address.

•

Radio Status—Shows the module’s TransNET radio association

status as follows:

•

Associated—Unit is operating normally and associated (com-

municating) with the TransNET Master Radio.

•

Alarmed—A alarming event has been logged and not cleared.

Note: If an alarm is present when this screen is displayed, an

“

A)” will appear to the left of the Radio Status field. (The PWR

LED will also flash.) Pressing

A on your keyboard takes you

directly to the

Current Alarms screen.

• Device Uptime—Elapsed time since the transceiver was powered-up.

•

Current Firmware—Version of firmware that is currently active in

the Unit.

•

Current User—Privilege level at which you are logged in.

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 28

20 MDS NETio-TB Installation & Operation Guide 05-4801A01, Rev. A

2.3.2 Main Menu

The Main Menu is the gateway to all NETio features. A summary of

available selections is given below.

Quick Start

Step #4:

Select C to go to the Wireless Configuration Menu (Section 2.3.3).

Invisible place holder

Figure 2-5. Main Menu

• Starting Information—Select this item to return to the Startup

Screen.

•

Device—Provides Base Module device information and various

configurable parameters.

•

Wireless Configuration—Menu for NETio TransNET and

WeXP wireless configuration and data.

•

Com1 Configuration—Tools to configure the COM1 serial port.

• I/O Network—Used for configuring I/O points for the Base Module and Expansion Modules directly connected or associated

through the wireless expansion (WeXP) with this Base Module.

•

Maintenance/Tools—Tools for modifying firmware.

• Payload/Protocol Configuration—Tools to configure COM2 and

Protocol Addressability.

•

Statistics/Events—Shows a log of various operational parame-

ters and performance data.

2.3.3 Wireless Configuration Menu

The configuration tasks to be performed here depend on whether you

will use the NETio’s internal TransNET radio and/or whether you use

the WeXP radio.

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 29

05-4801A01, Rev. A MDS NETio-TB Installation & Operation Guide 21

Quick Start

Step #5:

To configure the TransNET radio parameters, select A to go the

NETio TransNET Configuration Menu (Section 2.3.4). Otherwise,

proceed to Section 2.3.5.

Invisible place holder

Figure 2-6. Wireless Configuration Menu

• TransNET Configuration—Select options for NETio

TransNET-class radio parameters.

•

WeXP Configuration—Select options for WeXP operation (if

equipped with this feature).

2.3.4 TransNET Configuration

The TransNET Configuration Menu allows access to all NETio TransNET radio-class parameters and provides a review of radio performance data. The NETio-TB uses the same command line configuration

for a TransNET radio as those of a standard TransNET. Refer to the

MDS TransNET manual (05-2708A01) for a complete list of commands. When finished entering commands, type

ESC or clos to close the

interface.

Quick Start

Step #6:

Complete TransNET radio configuration, then proceed to Section

2.3.5.

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 30

22 MDS NETio-TB Installation & Operation Guide 05-4801A01, Rev. A

Invisible place holder

Figure 2-7. TransNET Command Screen

2.3.5 WeXP Configuration Menu

To configure the WeXP parameters, return to the main Wireless Configuration Menu (Figure 2-6), and select

B to access the WeXP Configura-

tion menu.

NOTE: The Base Module is the master WeXP radio. All NETio Wire-

less Expansion Modules you wish to associate with this Base

Module must have the same unique WeXP Network Address.

The WeXP Configuration menu is where you set the unique WeXP Network Address in the Base Module. This address will also be configured

into each Wireless Expansion Module that you wish to associate with

this Base Module. The WeXP channel, power level and timeout limit

(for failsafe applications) may also be set here.

Quick Start

Step #7:

Select B and enter the WeXP Network Address. It is recommended

that the last 4 digits of the Base Module’s serial number be used for

this entry. Proceed to Section 2.3.6.

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 31

05-4801A01, Rev. A MDS NETio-TB Installation & Operation Guide 23

Invisible place holder

Figure 2-8. WeXP Configuration Menu

• Channel Number—The channel number can be set to any value

from 12 to 23.

•

WeXP Network Address—Unique WeXP network identifier. We

recommend using last four digits of Base Module’s serial number.

•

WeXP Power Level—Use space bar to select the desired RF Output

power for WeXP radio (in dBm).

•

Expansion WeXP Ageout Time—Timeout period for WeXP com-

munication.

2.3.6 Wireless Expansion Module Configuration

NOTE: Review this entire section before proceeding to Section 2.4,

ASSIGNING MODULE IDs.

Each Wireless Expansion Module must be configured with the unique

WeXP Network Address used in the Base Module for wireless association (see Section 2.3.5). This can be accomplished in two ways:

Method 1—Attach all wireless expansion modules to the appropriate

Base Module via the Backplane/power connector. This provides access

to the Expansion Module(s) via the Base Module. Follow the remaining

instructions in this chapter for assigning module IDs. Beginning at Sec-

tion 2.4, you will assign the WeXP Address in Section 2.4.3.

Method 2—Connect a PC to the configuration port (RJ-11 modular) on

the front of the Expansion Module and establish a HyperTerminal session as described in Section 2.3. This provides a command line interface.

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 32

24 MDS NETio-TB Installation & Operation Guide 05-4801A01, Rev. A

Quick Start

Step #8:

Using the command line interface, enter the following and press the

Return key:

wexp netaddr<WeXP Network Address used in Base Module>

Repeat this step for all Wireless Expansion Modules that are to

associate with a particular Base Module. When finished, proceed to

Section 2.4.

2.4 ASSIGNING MODULE IDs

When power is applied to a NETio Base Module, an I/O Network is

automatically established for Expansion Modules. The I/O Network is

one Base Module (or a Base Module plus Expansion Modules) connected physically via the Power/Communication Bus and/or wirelessly

via WeXP. Note that only Wireless Expansion Modules whose WeXP

Network Address matches the address in the Base Module (see Section

2.3.5) will associate.

The NETio Base Module automatically resolves the quantity, type and

connection method for Expansion Modules upon power-up and assigns

temporary Module IDs until they are formally configured.

Set Module ID Formally “activate” the Expansion Modules in a NETio Unit by

assigning a permanent Module ID to each module.

NOTE: Activation is done through the I/O Network Menu configuration

screens. Upon power-up, all NETio Module(s) will appear first

in the Unconfigured/Conflicting Module menu. Once a Module ID

is assigned by the user, the Modules will appear on the I/O

Network Menu.

Figure 2-9 is an example of an operational network. If the menu displays

UNCONFIGURED/CONFLICTING MODULES, this means there are conflicts

that need to be resolved. If this menu option is not shown, then there are

no conflicts and you can proceed directly to Section 2.4.3. Selecting the

letter associated with a module takes you to its configuration screen.

Quick Start

Step #9:

Select K to proceed to the Unconfigured/Conflicting Modules Menu

(refer to Section 2.4.1), if shown. Otherwise, proceed to Section

2.4.3, Quick Start Step 12.

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 33

05-4801A01, Rev. A MDS NETio-TB Installation & Operation Guide 25

Invisible place holder

Figure 2-9. Example of I/O Network Menu

• Location—Module’s “name” or description as defined by the

user. This entry is optional.

•

ID #—The Module ID used by this module.

• Connection —The type of connection each Expansion Module

has to the associated Base Module, for example:

Base—This module is a Base Module.

Wired—Connected directly to the Base Module via the Back-

plane/power connector.

WeXP—Connected to the Base Module via the WeXP wire-

less network.

•

I/O Layout—The module’s I/O point (number and type) capacity.

The Unconfigured and Conflicting Modules Menu is very similar to the

Network Menu, but it lists only modules which are not configured or are

improperly configured.

NOTE: In most cases, newly-installed Expansion Modules will

initially appear on the Conflicting/Unconfigured Modules list.

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 34

26 MDS NETio-TB Installation & Operation Guide 05-4801A01, Rev. A

2.4.1 ID Conflict List Menu

The Conflict List Menu, Figure 2-10, is similar to the Network Menu,

but it lists only modules which have not been given a confirmed Module

ID. Each module must be “activated” through this menu. This menu displays all of the modules with conflicting Module IDs.

Quick Start

Step #10:

Select the letter associated with the Module in conflict to proceed to

the Conflict Menu (refer to Section 2.4.2).

NOTE: Modules on this list are functionally out-of-service until the

conflict is resolved by assigning each module a unique Module

ID.

Invisible place holder

Figure 2-10. ID Conflict Menu

Four informational fields are shown on this screen:

•

Location—Module’s “name” or description as defined by the

user. This entry is optional.

•

ID#—The temporary Module ID currently set for this module.

• Connection —The type of connection the Expansion Module has

to the Base Module. For example:

Wired—Connected directly to the Base via the Back-

plane/power connector.

WeXP—Connected to the Base Module via the WeXP wire-

less network.

•

I/O Layout—The module’s I/O point (number and type) capacity.

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 35

05-4801A01, Rev. A MDS NETio-TB Installation & Operation Guide 27

Selecting the letter corresponding to a conflicting module brings you to

the Conflict Menu, Figure 2-11, where the Module ID and Location

Field can be entered.

2.4.2 Conflict (Resolution) Menu

Each Module must be assigned a unique ID. Changing the Module

Name is optional. Once you have entered the ID, the module moves to

the I/O Network Menu.

Quick Start

Step #11:

Select B and enter a unique Module ID. Note that Module IDs must

be assigned to all modules in the Conflict List Menu. See Section

2.4.1. Once completed, refer to Section 2.4.3.

Figure 2-11. Conflict Menu

User-Alterable Parameters:

• Location—Configurable name for the module.

• Requested (Address) ID #—Unique Module ID number.

Read-Only Parameters:

• Serial #—Factory’s serial number of the module.

• Connection Type—The connection method for this Expansion to

the associated Base Module. Options are:

WeXP or Wired.

2.4.3 Configuring WeXP Wireless Expansion

Modules

Once all module ID conflicts have been resolved, all modules will

appear in the I/O Network Menu. You can change or modify the Module

ID at any time by selecting the letter associated with a particular module.

The only exception is the Base Module ID, which is fixed at

0 (zero).

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 36

28 MDS NETio-TB Installation & Operation Guide 05-4801A01, Rev. A

The final step is to set the WeXP Network Address in any Wireless

Expansion module that is part of this NETio Unit. Note that the WeXP

Network Address must match the value set in the Base Module in

Chapter 2.

Quick Start

Step #12:

If WeXP is used, configure the WeXP Network Address, if not

already configured in Section 2.3.6 Method 2. Otherwise, proceed to

Section 2.5 for final checkout.

NOTE: Wireless Expansion Modules show a “Connection” type of

“wired” if they are temporarily attached via the Backplane/power connector. They will display “WeXP” once

the WeXP Network Address is configured and the module

is unattached.

Select the letter for the Wireless Expansion Module that you wish to

configure. Proceed to Section 2.4.4.

Figure 2-12. Example of I/O Network Menu

2.4.4 I/O Module Configuration Menu

The I/O Module Configuration Menu (Figure 2-13) is where all NETio

Module parameters can be set or viewed, including I/O point parameters.

Quick Start

Step #13:

Select A and go to the Module Menu (proceed to Section 2.4.5)

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 37

05-4801A01, Rev. A MDS NETio-TB Installation & Operation Guide 29

Invisible place holder

Figure 2-13. I/O Module Configuration Menu

2.4.5 Module Menu

The Module Menu (Figure 2-14) is where general NETio module

parameters can be viewed or set.

Quick Start

Step #14:

Select B and enter the WeXP Network Address to match the

address entered in the Base Module (see Section 2.3.5 above). Next,

proceed to Section 2.5.

Invisible place holder

Figure 2-14. Module Menu

2.5 CHECK for NORMAL OPERATION

When all modules have been configured, you should be able to use all

modules in the I/O Network Menu. Note that you will only see Wireless

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 38

30 MDS NETio-TB Installation & Operation Guide 05-4801A01, Rev. A

Expansion Modules displayed with a connection type of WeXP if they

not attached via the Backplane/power connector.

Figure 2-15. Example of I/O Network Menu

Observe the Base Module LEDs on the faceplate for the proper indications. In a normally operating system, the following LED indications

should be seen:

•

PWR—Lit continuously

• LINK—Lit continuously (if associated with an TransNET AP)

• COM1—Blinks to indicate data communications with terminal

In a normally operating system, the following LED indications should

be seen within 30 seconds of start-up on the Wireless Expansion

Module:

•

PWR—Lit continuously

• WeXP—Lit continuously

If the previous steps have been successfully completed, the I/O point

configuration can be set. These steps are described in CHAPTER-3 I/O

POINT CONFIGURATION beginning on Page 31.

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 39

05-4801A01, Rev. A MDS NETio-TB Installation & Operation Guide 31

3

I/O POINT

CONFIGURATION

3 .............................................................................................. Chap-ter Counter Reset

3.1 I/O POINT CONFIGURATION35

3.2 I/O NETWORK MENU35

3.2.1 I/O Module Configuration Menu 36

3.2.2 Discrete Input Menu 37

3.2.3 Analog Input Menu 38

3.2.4 Discrete Output Menu 39

3.2.5 Analog Output Menu 40

3.3 CONFIGURING NETio OUTPUTS for PROTOCOL CONTROL41

3.4 MAPPING INPUTS TO OUTPUTS FOR SIGNAL EXTENSION

AND REGENERATION41

3.4.1 Setting the Source Field for Mapping 42

3.5 FAILSAFE SETTINGS44

3.5.1 Configuring Failsafe Settings 44

3.5.2 Configuring Failsafe Timeout—Base Modules 45

3.5.3 Configuring Failsafe Timeouts over WeXP 45

3.6 I/O UPDATE REFRESH RATES46

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 40

32 MDS NETio-TB Installation & Operation Guide 05-4801A01, Rev. A

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 41

05-4801A01, Rev. A MDS NETio-TB Installation & Operation Guide 33

3.1 I/O POINT CONFIGURATION

This section describes how to configure I/O points in a NETio Unit. This

process is required for each I/O signal connected to a NETio Unit. The

instructions here assume that you have established a PC connection with

the unit as described earlier in this manual.

This section also gives instructions for “mapping” an input to a particular output. This is required in cases where an input signal connected to

one NETio Module must be regenerated as an output from a different

NETio Module.

Each I/O point has a unique address that corresponds to where it is

located in a NETio Unit. You use this address when mapping one point

to another in a Signal Extender function, or when selecting the point in

a Protocol node.

A point address consists of three fields:

•

Module ID—The number assigned to the NETio module.

For Expansion Modules: The Module ID is set by the user (see

ASSIGNING MODULE IDs on Page 24).

•

Point Number—This number references the physical termina-

tion number of a particular I/O point on a NETio Module. It is

automatically assigned.

Each I/O point connected to a NETio Unit has an address with the

format shown below. Each field is separated by a comma:

<Module ID>,<Point Number>

3.2 I/O NETWORK MENU

The I/O Network menu shows the Base Module and any Expansion

Modules (if present) connected via the Backplane/power connector or

WeXP. If there are a large number of modules in the network, it will be

necessary to scroll down the screen to view all entries.

I/O points are configured by selecting the module that a signal is wired

to and then selecting a particular I/O point. When a wireless expansion

module is selected the WeXP LED blinks to indicate that it is being

accessed for configuration.

Quick Start

Step #15:

Select the letter associated with the module containing the I/O point

to be configured. Proceed to Section 3.2.1.

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 42

34 MDS NETio-TB Installation & Operation Guide 05-4801A01, Rev. A

Figure 3-1. Example of I/O Network Menu

3.2.1 I/O Module Configuration Menu

The I/O Module Configuration Menu is where all NETio Module-specific information can be viewed or changed.

Invisible place holder

Figure 3-2. I/O Module Configuration Menu

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 43

05-4801A01, Rev. A MDS NETio-TB Installation & Operation Guide 35

Quick Start

Step #16:

Select the letter associated with a specific I/O point to be configured

and proceed as follows:

If a Discrete Input is selected, proceed to Section 3.2.2.

If a Discrete Output

is selected, proceed to Section 3.2.4

If an Analog Input

is selected, proceed to Section 3.2.3

If an Analog Output

is selected, proceed to Section 3.2.5

3.2.2 Discrete Input Menu

This menu allows you to view and change the Point ID Tag for a discrete

input by selecting the letter A.

Figure 3-3. Discrete Input Menu

• Point ID Tag—Text to describe the use of this I/O point.

• Value—The current state of this point.

• Point Address— A composite of the Unit ID, Module ID and

Point (address) Number. The values are separated by commas.

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 44

36 MDS NETio-TB Installation & Operation Guide 05-4801A01, Rev. A

3.2.3 Analog Input Menu

This menu allows you to view and change the Input Range and/or the

Point ID Tag for an analog input.

Invisible place holder

This menu allows

you to review and revise many parameters for a analog point.

Figure 3-4. Analog Input Menu

User-Alterable Parameters:

• Point ID Tag—Text to describe the use of this I/O point.

• Range Mode—User-configured field that sets the type of

input. Options are determined by module type but can be

4-20 mA, 0-5 volts, or 0-10 volts.

Read-Only Parameters:

• Value—The present value in A/D counts for this point

address.

•

Point Address—Address used to identify this input point. For-

mat is: Unit ID, Module ID, Point Number

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 45

05-4801A01, Rev. A MDS NETio-TB Installation & Operation Guide 37

3.2.4 Discrete Output Menu

This menu allows you to view and change various parameters for a discrete output point.

Figure 3-5. Discrete Output Menu

User-Alterable Parameters:

• Point ID Tag—Text to describe the use of this I/O point.

• Source—The input point address to get this output's value

from. Format is: Module ID, Point Number (see Section

3.4).

•

Force Mode—A convenience field that allows the user to force

an output value. Press the spacebar to cycle through the available settings as follows:

Off—Force Mode disabled.

High (1)—Force Mode enabled and output is turned on.

Low (0)—Force Mode enabled and output is turned off.

• Failsafe Mode—The way this output should fail if communications is lost. Press the spacebar to cycle through the options

as follows:

On—On or logic 1.

Off—Off or logic 0.

Last—Hold last value

•

Failsafe Timeout—Amount of time (in ms) that the communi-

cation link with a Source Point must be lost before entering

Failsafe Mode.

Read-Only Parameters:

• Point Address—Address used to identify this input point. Format is: [

Module ID, Point Number]

• Value—The current state (logic high or logic low) of this

point.

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 46

38 MDS NETio-TB Installation & Operation Guide 05-4801A01, Rev. A

3.2.5 Analog Output Menu

This menu allows you to review and revise many parameters for a

analog output point.

Figure 3-6. Analog Output Menu

User-Alterable Parameters:

• Point ID Tag—Text to describe the use of this I/O point.

• Range Mode—User-configured field that sets the type of

input. Options are determined by module type but can be

4-20 mA, 0-5 volts, or 0-10 volts.

•

Source—The input point address to get this output's value

from. Format is: Module ID, Point Number (see Section

3.4).

•

Failsafe Mode—The way this output should fail if communica-

tions is lost. Press the spacebar to cycle through the options

as follows:

High—Highest possible output for range.

Low—Lowest possible output for range.

Last—Last value

Preset—User specified value.

• Preset Value—Preset value for Failsafe operation.

• Force Mode—A convenience field that allows the user to force

an output value. Press the spacebar to cycle through the available settings.

Off—Force Mode disabled.

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 47

05-4801A01, Rev. A MDS NETio-TB Installation & Operation Guide 39

High (1)—Force Mode enabled and output is turned on.

Low (0)—Force Mode enabled and output is turned off.

• Force Value—The value (in counts) to output when in Force

Mode.

•

Failsafe Timeout—Amount of time (in ms) that the communi-

cation link with a Source Point must be lost before entering

Failsafe Mode.

Read-Only Parameters:

• Point Address—Address used to identify this input point. Format is: Module ID, Point Number

•

Value—The present value in A/D counts for this point

address.

3.3 CONFIGURING NETio OUTPUTS

for PROTOCOL CONTROL

In order for a protocol to set control outputs for either analog or discrete

outputs connected to NETio Modules, the

Source variable for the partic-

ular output must be set to

Protocol. To do this, Select the letter for the

“Source” variable (shown in Figure 3-5 or Figure 3-6) to view the menu

shown in Figure 3-7. Enter

p to enable protocol control as the source for

the output.

Invisible place holder

Figure 3-7. I/O Mapping Wizard

3.4 MAPPING INPUTS TO OUTPUTS

FOR SIGNAL EXTENSION AND

REGENERATION

One of the primary uses of NETio is to regenerate Input signals connected to NETio modules at one location as outputs from NETio modules at a different location. This is accomplished by mapping.

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-8298-MDS-Net-IOE-7-Radio-Expansion-I/O-Radio-Module.aspx

Page 48

40 MDS NETio-TB Installation & Operation Guide 05-4801A01, Rev. A

Figure 3-8 shows a simplified representation of mapping. A 4-20 mA

analog input is connected to the NETio Wireless Expansion Module (on

the left) with a Module ID of 0. This input is mapped to a 4-20 mA

analog output connected to the NETio Expansion Module with a

Module ID of 1(on the right).

To configure the mapping, enter the address of the Analog Input (in this

example,

0, AI 1) in the Source field for the Analog Output (in this

example,

1, AO 1).

Invisible place holder

Figure 3-8. I/O Mapping Overview

I/O signals can be mapped between NETio Modules that share the same

WeXP Network Address and/or NETio-TB Base Module. The only limitation is than an input can only map to an output of the same type