Page 1

Installation & Operation Guide

Supporting Phase 1 Units

MDS 05-4819A01, Rev. 08

MAY 2010

MDS LCT 450

Tri-Mode Data Transceiver

Page 2

OPERATIONAL & SAFETY NOTICES

Concentrated energy from a directional antenna may pose a health

hazard to humans. Do not allow people to come closer to the antenna

than the distances listed in the table below when the transmitter is

operating. More information on RF exposure can be found online at

the following website:

www.fcc.gov/oet/info/documents/bulletins

.

Above data based on a 30-watt RF output level with a 100% duty cycle.

FCC Part 15 Notice

The transceiver is approved under Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause undesired operation. Any unauthorized modification or changes to this device without the express approval of

Microwave Data Systems may void the user’s authority to operate this device. Furthermore,

this device is intended to be used only when installed in accordance with the instructions outlined in this manual. Failure to comply with these instructions may void the user’s authority to

operate this device.

Antenna Gain vs. Recommended Safety Distance

Device complies with Power Density requirements at 20 cm separation: No

Required separation distance for 5 dBi antenna (in meters): 1.6

Required separation distance for 10 dBi antenna (in meters): 2.8

Required separation distance for 16.5 dBi antenna (in meters): 6.0

RF Exposure

Page 3

05-4819A01, Rev. 08 LCT 450 Installation/Operation Guide

1

INTRODUCTION

This guide presents installation and operating instructions for the

MDS LCT 450 Series wireless transceiver.

The transceiver (Figure 1) is designed to operate in Railroad Distributed Power applications. It is software-configurable to provide flexible operation in a variety of applications using one hardware

platform. It employs microprocessor control and Digital Signal Processing (DSP) technology to provide robust communications even

under adverse conditions.

Figure 1. Data Transceiver

NOTE:

Some features may not be available on all units, based on the

options purchased and the applicable regulatory constraints

for the region in which the radio will operate.

Front Panel Connectors

Figure 2 and Figure 3 show the interface connectors and indicators on

the transceiver’s front and rear panels. These items are referenced in

the installation steps given later in this guide.

Page 4

2 LCT 450 Installation/Operation Guide 05-4819A01, Rev. 08

Invisible place holder

Figure 2. Antenna & DC Power Connectors

Invisible place holder

Figure 3. Data Interface Connectors & LED Status Panel

DC Power Input

13.6 Vdc +/-15%

Antenna Connector

(UHF)

Power Connector:

Tyco/AMP Electronics 172129-1

LED Indicator Panel

P1 Control Interface Connect

(DB-25)

PWR

DCD

TXD

RXD

P2 Programming & Diagnostic

(DB-9)

Page 5

05-4819A01, Rev. 08 LCT 450 Installation/Operation Guide

3

INSTALLATION

There are three main requirements for installing the transceiver as follows:

• Adequate and stable primary power

• An efficient and properly installed antenna system

• Correct data connections between the transceiver and the data

equipment.

Figure 4 shows a typical station arrangement. This is followed by

step-by-step procedures for installing the transceiver and making front

and rear panel connections.

Figure 4. Typical Station Arrangement

INTEGRATED PROCESSING

MODULE (IPM)

ANTENNA

SYSTEM

LOW-LOSS

COAXIAL CABLE

(50 Ohm)

RADIO

TRANSCEIVER

PL-259 UHF

CONNECTOR

DB-25M

CONNECTOR

Antenna Connector

DC POWER CABLE

Negative Ground

13.6 Vdc +/-15%

Page 6

4 LCT 450 Installation/Operation Guide 05-4819A01, Rev. 08

Installation Steps

Below are the basic steps for installing the transceiver. Refer to

Figure 4 as necessary when making cable connections.

1.

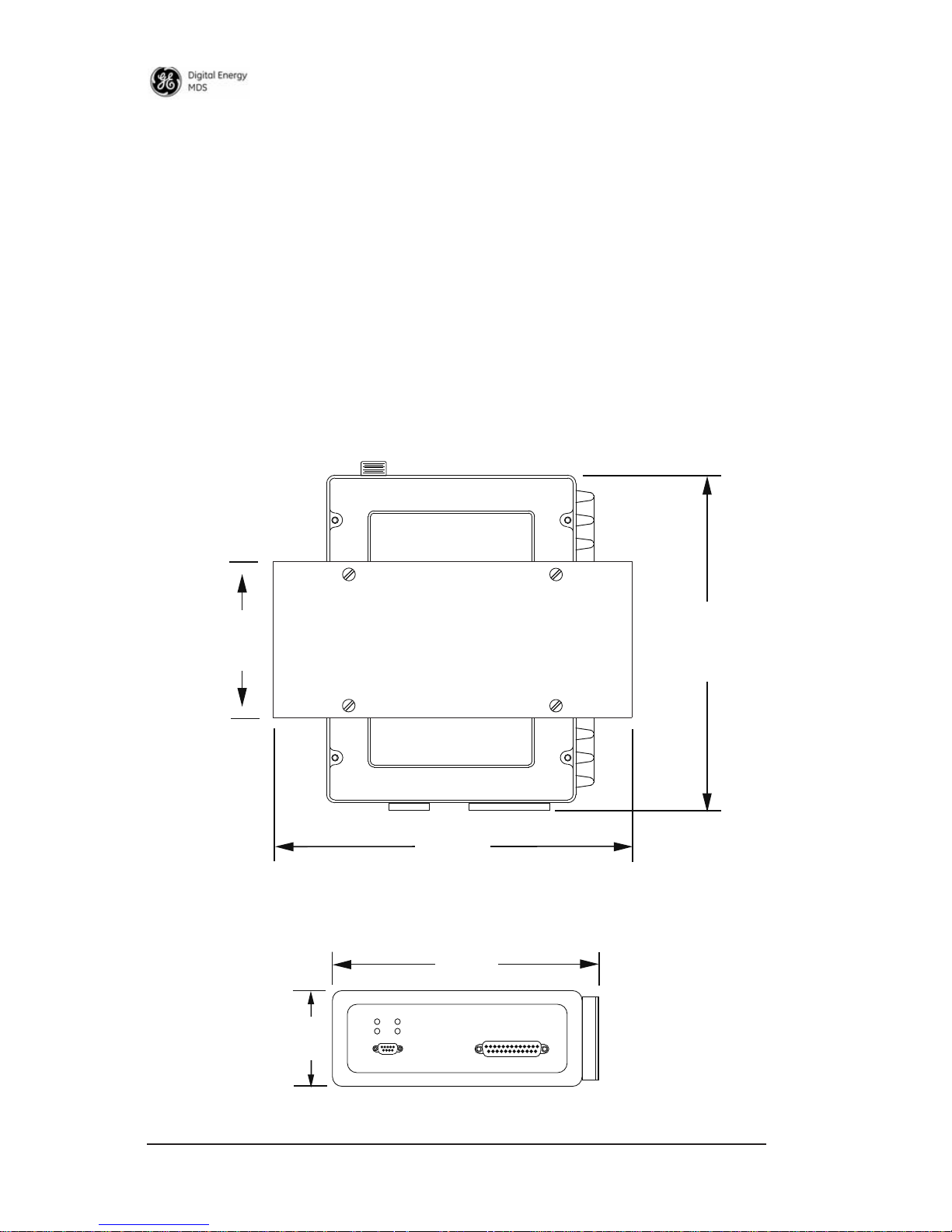

Mount the transceiver to a stable surface using the U-shaped

bracket provided. Begin by attaching the radio’s mounting bracket

to the bottom of the transceiver case (if not already attached) using

the four 6-32 x 1/4 inch (6 mm) screws supplied. Figure 5 shows

the transceiver mounting dimensions with bracket attached.

NOTE:

To prevent moisture from entering the radio, do not mount the

case with the cable connectors pointing up. Also, dress all

cables to prevent moisture from running along the cables and

into the radio.

Invisible place holder

Figure 5. Transceiver Mounting Bracket Dimensions

6.86"

3.25"

83 mm

2.0"

51 mm

5.63"

143 mm

174.24 mm

177.80 mm

7.00"

U-Shaped Bracket

(Part No. 821753A14)

Page 7

05-4819A01, Rev. 08 LCT 450 Installation/Operation Guide

5

Using screws longer than 1/4 inch (6 mm) to attach the

bracket to the radio may damage the internal PC board.

Use only the supplied screws.

2.

Install the antenna and feedline for the station. The antenna

used with the transceiver must be designed to operate in the

radio’s frequency band, and be mounted in a location that provides a clear path to the other associated station(s). Use low loss

coaxial feedline and keep the cable as short as possible.

3.

Connect the data equipment to the

DATA INTERFACE

connector. Check P1 CONTROL INTERFACE on Page 24 for pin wiring

details.

NOTE:

The radio’s

P2

port is used for entering configuration

commands and reprogramming the radio’s firmware.

4.

Connect primary power to the transceiver. Power applied must

be 13.6 Vdc (+/- 15%) and capable of providing at least 8

Amperes of continuous current. A power connector with is provided with each unit (see Figure 4).

The transceiver is designed for use with negative-ground systems only. The power supply should be

equipped with overload protection (NEC Class 2 rating),

to protect against a short circuit between its output terminals and the radio’s power connector.

This completes the installation of the transceiver.

SOFTWARE COMMANDS

Table 1 lists software commands commonly used during configuration

of the transceiver. In many cases, no changes or settings will be

required, as the radio is typically supplied ready for operation from the

factory. These commands are provided in the event future changes are

needed, or to facilitate troubleshooting of the unit.

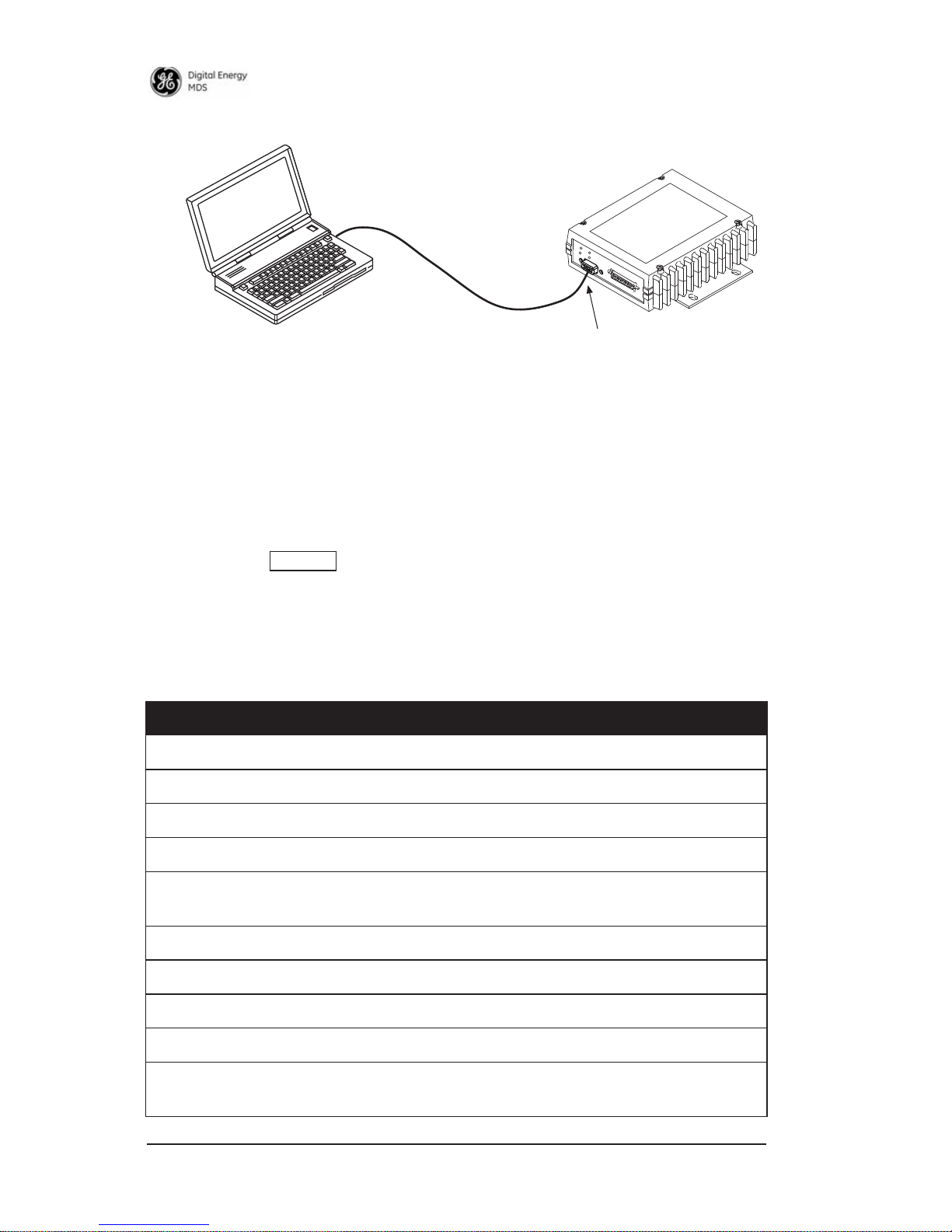

These commands require a PC to be connected to the transceiver as

explained in the following steps:

1. Connect a PC to the transceiver’s

P2

connector as shown in

Figure 6. If desired, a connecting cable may be assembled using

the information shown on Page 26.

CAUTION

POSSIBLE

EQUIPMENT

DAMAGE

CAUTION

POSSIBLE

EQUIPMENT

DAMAGE

Page 8

6 LCT 450 Installation/Operation Guide 05-4819A01, Rev. 08

Invisible place holder

Figure 6. PC Configuration Setup

2. Launch a terminal communications program, such as HyperTerminal (included with most Windows

TM

systems). Data parameters

are 8 data bits, no parity, and 1 stop bit (8N1). Data rate is determined by autobaud, but 1115200 bps is the preferred speed.

3. Press the key a few times (at half-second intervals) to

obtain the ready “>” prompt on the screen. Commands may now

be entered from the keyboard.

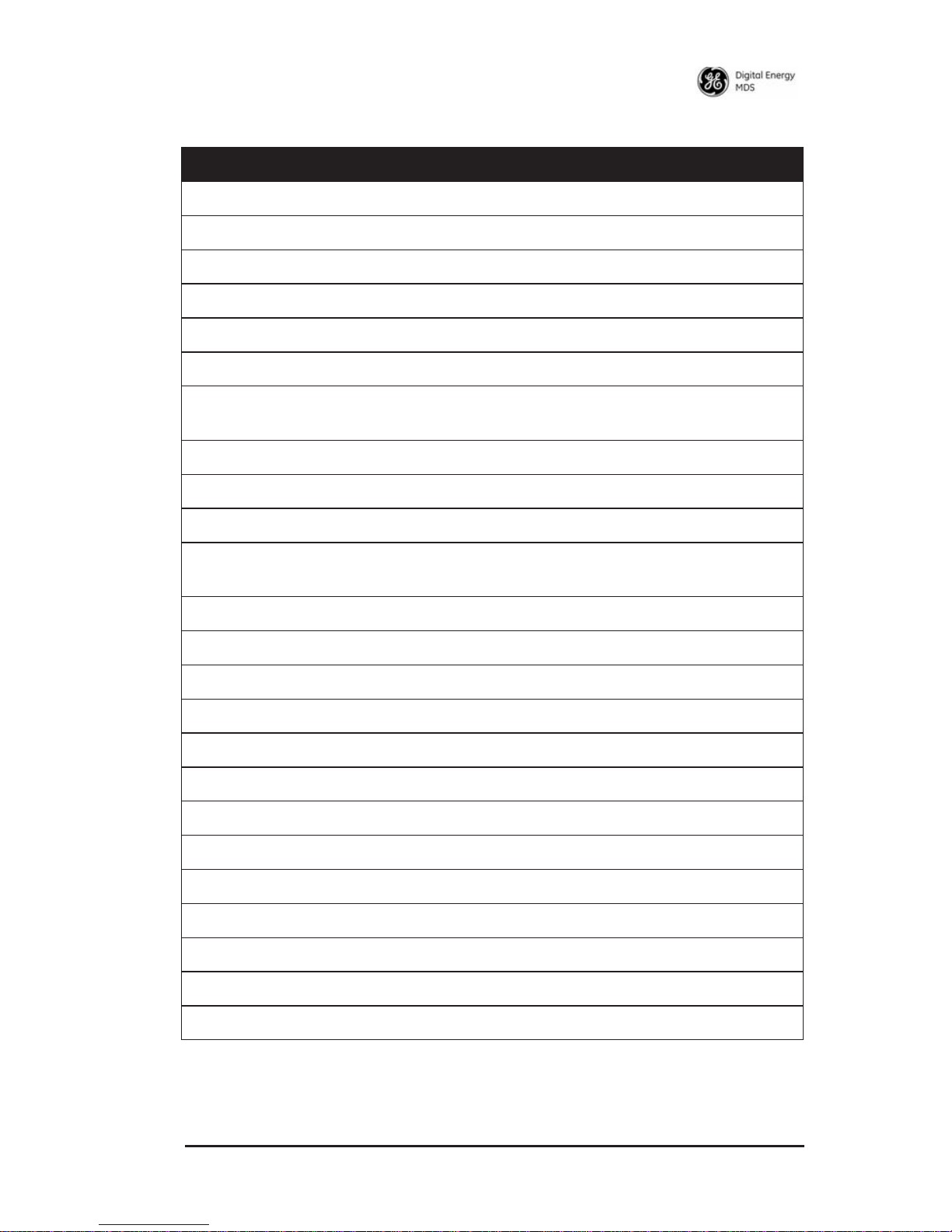

Table 1. Command Summary

Command Name

Function

ALARM

Alarm Summary

AMASK

Alarm Mask

AUDIO

Audio Monitor/Orderwire Status

BOOT

Reboot Radio

CHAN

Channel commands (RX/TX frequency, RF

power, bandwidth)

CKEY

Key TX Continuously (Digital Only)

DATAKEY

Key on Data Activity

DUMP

Read Current Unit Profile

EMP

Modem TX Audio Pre-Emphasis

FSET

Receive or Transmit frequency mini/max

value

PC Running Terminal Session

Transceiver

To DB-9

Management Port

ENTER

Page 9

05-4819A01, Rev. 08 LCT 450 Installation/Operation Guide

7

HELP

User Help

HREV

Display Hardware Revision

INIT

Initialize EEPROM Defaults

MODE

Radio Mode

MODEL

Model Number Information

MTYPE

Modem Family Type

OPT, OPTION,

OPTIONS

Display Authorized Options

OWM

Owner’s Message

OWN

Owner’s Name

PROG

Program

PWRL, PWRM, PWRH,

PWRRXH

Power Lo (5W), Medium (20W), Hi (25),

Extra-High (30W)

PTT

Push-to-Talk Delay

REF

Reference Frequency

RSSI

Received Signal Strength Indicator

RXTOT

Loss of RX Data Alarm Time

SER

Radio’s Serial Number

SHOW

Show Power Settings

SPECTRUM

Internal Spectrum Analyzer

SQUELCH

Squelch Operation

SREV

Software/Firmware Revision Level

STAT

Alarm Status

TEMP

Internal Temperature

TOT

TX Timeout-Timer

VERSION

Firmware Version

Table 1. Command Summary

(Cont’d)

Command Name

Function

Page 10

8 LCT 450 Installation/Operation Guide 05-4819A01, Rev. 08

DETAILED USER COMMANDS

The commands in this section may be used in two ways. First, you can

type only the command name to view the currently programmed data.

Secondly, you can set or change the existing data by typing the command, followed by a space, and then the desired entry. In the list

below, allowable programming variables, if any, are shown in brackets

following the command name.

ALARM

Alarm Summary

The

ALARM

command displays a summary of the radio's current operating condition. An eight-digit code will be presented which can be

decoded as described in “Major Alarms vs. Minor Alarms”.

AMASK [0000 0000-FFFF FFFF]

Alarm Mask

The

AMASK

command displays or sets which events cause an alarm

output signal to be active. Normally, the mask is

FFFF FFFF

, meaning

that any of the 32 possible events will activate the alarm output signal.

Entering the

AMASK

command alone displays the current setting of

alarm events in hexadecimal format. Entering the

AMASK

command

followed by an eight-digit hexadecimal number reprograms the specified events to trigger an alarm. The eight-digit hexadecimal number

used as the command parameter specifies 0 to 32 events that can

trigger the external alarm output. The hex value for the mask corresponds to the hex value for the

STAT

command. Each bit that is a '1'

identifies an alarm condition that can trigger the external output. For

more information on configuring the alarm response, contact GE

MDS.

ASENSE [HI/LO]

Alarm Sense

The

ASENSE

command sets or displays the sense of the alarm output

at Pin 6 of the COM2 port. Entering the

ASENSE

command alone

shows whether the alarm output is active high or low. Entering the

ASENSE

command followed by

HI

or

LO

resets the alarm output to

active high or low.

Page 11

05-4819A01, Rev. 08 LCT 450 Installation/Operation Guide

9

AUDIO [ON/OFF]

Audio Monitor/Orderwire Status

Used to set or display Audio Monitor/Orderwire functionality (on or

off)

BOOT [1, 2, OTHER]

Reboot Radio

Used to reboot to selected image or current image if no image specified.

CHAN [0-8, ALL]

[RXFREQ xxx.xxxx]

(MHz)

[TXFREQ xxx.xxxx]

(MHz)

[PWR [5, 20, 25, 30]

(Watts)

[BW [12.5, 25]

(kHz)

Channel Mods...

If only the first argument is given, then it displays the channel(s)

parameters. If a third (or greater) argument is given, then that channel

with have its parameters changed.

CKEY [ON/OFF] -

Digital Only

Key TX Continuously

The

CKEY

command enables or disables the continuously keyed func-

tion of the radio. When

CKEY

is set to ON, the radio is continuously

keyed and the Timeout Timer is disabled.

CTS [0-255]

Clear-to-Send Time

The CTS (clear-to-send) command selects or displays the timer value

associated with the CTS line response. The command parameter

ranges from

0 to 255 milliseconds.

For DCE operation, the timer specifies how long to wait after the RTS

line goes high, before the radio asserts CTS and the DTE can transmit

the data. A CTS value of zero keys the radio and asserts the CTS line

immediately after the RTS line goes high.

Page 12

10 LCT 450 Installation/Operation Guide 05-4819A01, Rev. 08

For CTS Key operation (see DEVICE command), the timer specifies

how long to wait after asserting the CTS, before sending data out the

DATA INTERFACE port. A timer value of zero means that data will be

sent out the data port without imposing a key-up delay. (Other delays

may be present based on selected radio operating parameters.)

CTSHOLD [0-60000]

Clear-to-Send Hold Time

Used in DEVICE CTS KEY mode, this command sets the amount of time

in milliseconds that CTS remains present after transmission of the last

character out the RXD pin of the

DATA port. This “hold time” can be

used to prevent squelch tail data corruption when communicating with

other radios.

The CTSHOLD setting can range from 0 to 60000 ms (i.e., 60 seconds).

The default value is

0, which means that CTS will drop immediately

after the last character is transmitted. If the command is entered when

the radio is in

DEVICE DCE mode, the response CTSHOLD N/A is dis-

played.

DATAKEY [ON/OFF]

Key on Data Activity

The

DATAKEY command enables or disables the ability of the radio to

key the transmitter as data is received at the

DATA INTERFACE con-

nector. Asserting RTS keys the radio regardless of this command setting.

If

DATAKEY is set to ON, the radio will key when a full data-character

is received at the transceiver's

DATA INTERFACE connector. If

DATAKEY is set to OFF, the radio needs to be keyed by asserting RTS.

DEVICE [DCE, CTS KEY]

Data Device Mode

The

DEVICE command controls or displays the device behavior of the

radio. The command parameter is either

DCE or CTS KEY.

Page 13

05-4819A01, Rev. 08 LCT 450 Installation/Operation Guide 11

In DCE mode (the default setting), CTS will go high following RTS,

subject to the CTS programmable delay time. If the

DATAKEY com-

mand is set to

ON, keying can be stimulated by the input of characters

at the data port. Hardware flow control is implemented by signaling

the CTS line if data arrives faster than it can be buffered and transmitted.

In CTS KEY mode, the radio is assumed to be controlling another radio.

It will still key based on the RTS line, but the CTS line is used as a keyline control for the other radio. CTS is asserted immediately following

the receipt of RF data, but data will not be sent out the

DATA INTER-

FAC E port until after the CTS programmable delay time has expired.

(This gives the other radio time to key.)

DUMP

Read Current Unit Profile

This command causes all of the programmed settings to be displayed.

EMP [ON/OFF]

Modem TX Audio Pre-Emphasis

This command displays or sets the TX pre-emphasis and RX

De-Emphasis when the radio is operating with the analog mode and

the radio's modem is turned off (

MODEM NONE). It should be set to

match the other radios in the system. The use of pre and de-emphasis

can help reduce the detrimental influence of high frequency audio

noise.

FSET

Receive or transmit frequency min/max value

HELP

User Help

Show available commands.

HREV

Display hardware revision

Page 14

12 LCT 450 Installation/Operation Guide 05-4819A01, Rev. 08

INIT

Initialize EEPROM Defaults

The INIT command is used to re-initialize the radio's operating parameters to the factory defaults. This may be helpful when trying to

resolve configuration problems that may have resulted from the entry

of one or more improper command settings. If you are unsure of which

command setting may have caused the problem, this command allows

you to get back to a known working state. The following changes to

the radio are made when

INIT is entered:

•

CTS is set to 0

• DATAKEY is set to ON

• DEVICE is set to DCE

• PTT is set to 0

• SCD is set to 0

• TOT is set to 30 seconds and set to ON

• PWR is set to +37 dBm (5 watts)

All other commands remain as previously set.

MODE [NORMAL, TEST]

Radio Mode

This command puts the radio into a

TEST or NORMAL mode. In the test

mode, it disables the radio from looking at the hardware channel select

lines and automatically selects Channel 0.

MODEL, MODEL1, MODEL2

Model Number Information

MTYPE [SD | X710_AE | X710_B | LOOPBACK]

Modem Family Type

OPT, OPTION, OPTIONS

Display Authorized Options

Page 15

05-4819A01, Rev. 08 LCT 450 Installation/Operation Guide 13

OWM [XXX...]

Owner's Message

This is a command to display or program an owner's message. To program the owner's message, type

OWM then the message, followed by

an ENTER keypress.

To display the owner's message, type

OWM, followed by an ENTER

keypress. The owner's message appears on the display.

OWN [XXX...]

Owner's Name

This is a command to display or program an owner's name. To program the owner's name, type

OWN then the name, followed by

ENTER.

To display the owner's name, type

OWN then ENTER. The owner's

name appears on the display.

PROG

Program

The

PROG command used for serial reprogramming - spoof entry into

the bootloader.

PROGRAM

Program

The

PROGRAM command spoofing MDS x710 bootloader program

command to start serial reprogramming. Erases and programs inactive

image via serial port with xon/xoff flow control. Returns when complete. If successful active image is switched. Only valid after program

or prog command at

LOADER> prompt. Used for serial reprogram-

ming.

PWRL [0-30], PWRM [0-30], PWRH [0-30],

PWRXH [0-30]

Sets Power Level

This command sets the power level value for this name. This name is

used for the power calibration command (CPWR). PWRL defaults to

5 watts, PWRM defaults to 20, PWRH is 25 and PWRXH is 30 watts.

Page 16

14 LCT 450 Installation/Operation Guide 05-4819A01, Rev. 08

PTT [0-255]

Push-to-Talk Delay

This command sets or displays the key-up delay in milliseconds. This

timer specifies how long to wait after the radio receives a key signal,

before actually keying the radio.

REF [xxxxx]

Reference Frequency

RSSI

Received Signal Strength Indicator

This command continuously displays the radio's Received Signal

Strength Indication (RSSI) in dBm units, until you press the Enter key.

Incoming signal strengths from -50 dBm to -120 dBm can be read.

NOTE: The RSSI samples the incoming signal for one to two seconds

before providing an average reading to the connected PC.

RTU [ON/OFF/0-80] Digital Only

RTU Emulator

This command enables or disables the radio's internal RTU simulator,

which runs with proprietary factory polling programs such as

poll.exe

and

rsim.exe. The internal RTU simulator is available whenever a

radio has diagnostics enabled. This command also sets the RTU

address that the radio will respond to.

The internal RTU can be used for testing system payload data or

pseudo bit error rate testing. It can be helpful in isolating a problem to

either the external RTU or the radio.

RXTOT [NONE, 1-255]

Loss of RX Data Alarm Time

The

RXTOT command selects or displays the receive time-out timer

value in minutes. This timer triggers an alarm (Event 12) if data is not

detected within the specified time.

Entering the

RXTOT command without a parameter displays the timer

value in minutes. Entering the

RXTOT command with a parameter

ranging from

0 to 255 resets the timer in minutes. Entering the RXTOT

command with the parameter

NONE disables the timer.

Page 17

05-4819A01, Rev. 08 LCT 450 Installation/Operation Guide 15

SCD [0-255]

Soft-Carrier Dekey

This command displays or changes the soft-carrier dekey delay in milliseconds.

This timer specifies how long to wait after the removal of the keying

signal before actually releasing the transmitter. A value of 0 milliseconds will unkey the transmitter immediately after the removal of the

keying signal.

SER

Radio's Serial Number

This command displays the radio's serial number as recorded at the

factory.

SHOW [DC, PORT, PWR]

Show Power Settings

The

SHOW command displays different types of information based on

the command variables. The different parameters are:

•

DC-Display DC input/output voltages

•

PWR-Display RF power output

SPECTRUM [xxx.xx]

Internal Spectrum Analyzer

Activates the built-in spectrum analyzer tool (see Figure 8) that can be

displayed on a connected PC. This tool is helpful in diagnosing interference problems on or near your channel frequency.

Access the spectrum analyzer by entering spectrum at the command

prompt. A display appears showing detected signals on your current

channel.

Optionally, you can specify a frequency at the command prompt to

view the surrounding spectrum of that frequency. To do this, enter

spectrum xxx.xx, where xxx.xx is the frequency in MHz.

Page 18

16 LCT 450 Installation/Operation Guide 05-4819A01, Rev. 08

A typical spectrum analyzer display is shown in Figure 8. The display

creates a received signal strength indication (RSSI) vs. frequency plot

for the frequency and surrounding signals. By analyzing the display,

you can determine the presence of other signals near the transceiver's

operating frequency. This information can be helpful in troubleshooting interference problems.

SQUELCH [AUTO, BYPASSED]

Squelch Operation

Set or display analog squelch bypass.

SREV

Software/Firmware Revision Level

This command displays the software revision level of the transceiver

firmware.

STAT

Alarm Status

This command displays the current alarm status of the transceiver.

If no alarms exist, the message

NO ALARMS PRESENT appears.

If an alarm does exist, a two-digit code (

00-31) is displayed and the

alarm is identified as “Major” or “Minor.” A brief description of the

alarm code is also given.

TEMP

Internal Temperature

This command displays the internal temperature of the transceiver in

degrees Celsius.

TOT [1-255, ON, OFF]

TX Timeout-Timer

This command sets or displays the transmitter Time-out Timer value

(1-255 seconds), as well as the timer status (

ON or OFF). If the timer is

on, and the radio remains keyed for a longer duration than the

TOT

value, the transmitter is automatically unkeyed.

Page 19

05-4819A01, Rev. 08 LCT 450 Installation/Operation Guide 17

When this happens, the radio must be commanded back to an unkeyed

state before a new keying command is accepted. The default timer

value is

30 seconds.

VERSION

Firmware Version

Displays package version information for each firmware image.

RADIO TESTS & TEST MODE COMMANDS

The following are checks and settings that can be performed by a technician to ensure optimal performance of the radio. For most tests, it

will be necessary to connect a PC to the radio as described in SOFT-

WARE COMMANDS on Page 5.

Antenna System SWR Check

SWR is a parameter related to the ratio between forward transmitter power and the reflected power from the antenna system.

As a general guideline, reflected power should not exceed 10%

of the forward power (≈ 2:1 SWR). A high SWR may result in

decreased performance, and should be corrected.

The transceiver’s

TXD/RXD LEDs will light when the SWR is too

high. Actual SWR can be measured by connecting a reflected

power meter, such as a Bird Model 43

™

directional wattmeter

with the proper element installed, between the transceiver and

the antenna system. Use the

KEY/DEKEY commands described

below to control the transmitter during these tests. Test transmissions should be kept as brief as possible.

If the results are normal, record them for comparison during

future routine preventative maintenance. Abnormal readings

indicate a possible trouble with the antenna or the transmission

line that will need to be corrected. Look for cable damage, poor

connections, or improper positioning of the antenna (such as

having the antenna whip too close to a metal surface).

Page 20

18 LCT 450 Installation/Operation Guide 05-4819A01, Rev. 08

Over-Temperature Check

If the transmitter is approaching an out-of-tolerance temperature condition, an error code is issued (see Table 3) and the

PWR lamp will

flash. Further operation may be inhibited. Over-temperature conditions should be investigated and resolved before further use of the

radio.

To read the actual internal temperature of the radio (in degrees Celsius), the

TEMP command may be issued from a PC. Excessive temper-

atures may be caused by inadequate ventilation of the transceiver case,

or operating the unit beyond its rated duty cycle (see “SPECIFICA-

TIONS” on Page 26).

Test Mode Commands

The following commands may be used by a technician to test the radio

or to make advanced setting changes during installation and maintenance activities.

BW [xxxxx]

Channel Bandwidth

This command displays the current bandwidth or sets the modem

bandwidth for channel 0. This command also sets the appropriate deviation for this bandwidth.

CHAN [0-8, ALL]

[RXFREQ xxx.xxxx] (MHz)

[TXFREQ xxx.xxxx] (MHz)

[PWR [5, 20, 25, 30] (Watts)

[BW [12.5, 25] (kHz)

Channel Mods...

If only the first argument is given, then it displays the channel(s)

parameters. If a third (or greater) argument is given, then that channel

with have its parameters changed.

Page 21

05-4819A01, Rev. 08 LCT 450 Installation/Operation Guide 19

DKEY

Unkey Transmitter

This command deactivates the transmitter after it has been keyed with

the

KEY command.

KEY

TX Key

This command activates the transmitter. See also the

DKEY command.

MODEM [xxxx]

Analog/Digital Modem Selection

This command selects the radio's modem characteristics. For digital

operation enter

MODEM xxxx, where xxxx equals the modem selection

of the radio (

9600 or 19200). For analog operation with an external

modem, enter

NONE for this parameter.

When the

MODEM command is set to NONE, the analog TX Input and

RX Audio outputs of the

DATA INTERFACE will be used to interface

with the connected external modem, and digital operation is disabled.

These levels must be set to complement the audio signal level requirements of the external modem. See “RXLEVEL [-20 to 0]” and

“TXLEVEL [-20 to 0, AUTO]” for details on setting these levels.

PWR [Watts]

NOTE: This function may not be available in all units, depending on

certification requirements for a particular country.

TX RF Power Output Level

This command displays the current power level in watts or sets the

desired RF forward output power setting for channel 0 of the radio.

The

PWR command parameter is specified in watts and its settings are

5, 20, 25, 30. The default setting is 5 watts. To read the actual (mea-

sured) power output of the radio, use the

SHOW PWR command.

RX [xxx.xxxx]

Receive Frequency

This command displays the current receive frequency or selects the

radio's receive frequency (in MHz) for channel 0. The frequency step

size is 6.25 kHz.

Page 22

20 LCT 450 Installation/Operation Guide 05-4819A01, Rev. 08

If the radio’s frequency has not been programmed at the factory, a

default frequency will be programmed in the radio near the center of

the frequency band.

SELCHAN [0-8]

Select Channel

This command causes the radio to go to another channel when the

radio is in

MODE TEST. It causes the radio to select appropriate RX and

TX frequencies, power level and bandwidth for that channel.

TX [xxx.xxxx]

TX Frequency

This command displays the radio's transmit frequency in MHz or

changes channel 0's transmit frequency. The frequency step size is

6.25 kHz.

If the frequency has not been programmed at the factory, a default frequency will be programmed in the radio near the center of the frequency band.

TROUBLESHOOTING

For proper operation, all radios in the network must meet these basic

requirements:

• Adequate and stable primary power

• Secure connections (RF, data and power)

• A clear transmission path between stations

• An efficient antenna system providing adequate received signal

strength.

• Proper programming of the transceiver’s operating parameters

• The correct interface between the transceiver and the connected

data equipment (correct cable wiring, proper data format, timing, etc.)

Page 23

05-4819A01, Rev. 08 LCT 450 Installation/Operation Guide 21

LED Indicators

The LED status indicators (Figure 7) are an important troubleshooting

aid and should be checked whenever a problem is suspected. Table 2

describes the function of each status LED on the front panel of the

radio.

Invisible place holder

Figure 7. LED Indicators

Additional LED indications—for trouble conditions:

TXD/RXD

lit: High Standing Wave Ratio (SWR). Check antenna

system.

PWR lamp flashing: Over temperature (Observe duty cycle, ensure

adequate ventilation)

Event Codes

When an alarm condition exists, the transceiver creates a code that can

be read on a connected terminal. These codes can be helpful in

resolving many system difficulties. Refer to Table 3 (Page 22) for a

definition of the event codes.

Table 2. LED Status Indicators

LED Name Description

PWR • Continuous—Power applied, no problems detected.

• Rapid flash (5 times-per-second)—Alarm indication.

TXD Unit is transmitting.

RXD Unit ready to receive data (not transmitting).

DCD Message is being received.

PWR

DCD

TXD

RXD

Page 24

22 LCT 450 Installation/Operation Guide 05-4819A01, Rev. 08

Checking for Alarms—STAT command

To check for alarms, connect a terminal to the radio’s P2 Programming

& Diagnostic port. See P2 PROGRAMMING & DIAGNOSTIC

INTERFACE on Page 26 for pinout information.

Enter

STAT on the connected terminal. If no alarms exist, the message

NO ALARMS PRESENT appears on the display.

If an alarm does exist, a two-digit alarm code (00–31) is displayed and

the event is identified as a Major or Minor Alarm. A brief description

of the alarm is also given.

Major Alarms vs. Minor Alarms

Major Alarms—report serious conditions that generally indicate a

hardware failure, or other abnormal condition that will prevent (or

seriously hamper) further operation of the transceiver. Major alarms

generally indicate the need for factory repair. Contact your factory

representative for assistance.

Minor Alarms—report conditions that, under most circumstances will

not prevent transceiver operation. This includes out-of-tolerance conditions, baud rate mismatches, etc. The cause of these alarms should

be investigated and corrected to prevent system failure.

Event Code Definitions

Table 3 contains a listing of event codes that may be reported by the

transceiver. The codes shown are a subset of a larger pool of codes

used for various GE MDS products. For this reason, the table does not

show a sequential listing of all code numbers. Only the codes applicable to this product are shown.

Table 3. Event Codes

Event

Code

Event

Class Description

01 Major Improper software detected for this radio model.

04 Major The RF synthesizer is reporting an out-of-lock

condition.

08 Major The system is reporting that it has not been

calibrated. Factory calibration is required for proper

radio operation.

Page 25

05-4819A01, Rev. 08 LCT 450 Installation/Operation Guide 23

Internal Spectrum Analyzer

The radio contains a built-in spectrum analyzer tool (Figure 8) that can

be displayed on a connected PC. The tool is helpful in diagnosing

interference problems on or near your channel frequency.

Access the spectrum analyzer by entering

spectrum at the command

prompt. A display appears showing detected signals on your current

channel.

Optionally, you can specify a frequency at the command prompt to

view the surrounding spectrum of that frequency. To do this, enter

spectrum xxx.xx, where xxx.xx is the frequency in MHz.

As shown in Figure 8, the display creates a received signal strength

indication (RSSI) vs. frequency plot for the frequency and surrounding signals. By analyzing the display, you can determine the

presence of other signals near the transceiver’s operating frequency.

This information can be helpful in troubleshooting interference problems.

12 Major Receiver time-out. No data received within the

specified receiver time-out time.

13 Minor A Transmitter timeout was detected. The radio

stayed keyed longer than the duration specified by

the TOT command.

17 Minor A data parity fault has been detected on the

PAYLOAD port. This usually indicates a parity

setting mismatch between the radio and the

customer equipment.

18 Minor A data framing error has been detected on the

PAYLOAD port. This may indicate a baud rate

mismatch between the radio and the customer

equipment.

26 Minor The DC input voltage is out-of-tolerance. If the

voltage is too far out of tolerance, operation may fail.

31 Minor The transceiver’s internal temperature is

approaching an out-of-tolerance condition. If the

temperature drifts outside of the recommended

operating range, system operation may fail.

Table 3. Event Codes (Cont’d)

Event

Code

Event

Class Description

Page 26

24 LCT 450 Installation/Operation Guide 05-4819A01, Rev. 08

Invisible place holder

Figure 8. Internal Spectrum Analyzer Display

P1 CONTROL INTERFACE

Table 4 lists the pin functions on the P1 Control Interface connector.

Table 4. P1 Control Interface Pin Descriptions (DB-25)

Pin No. Description

1 No connection (NC)

2 Audio Isolated Ground

3 No connection (NC)

4 Detected Audio

5 Channel Select 3 (see Note 1).

6 RXD+ (RS-485/422 digital). Output from radio.

7 PTT Keying signal (see Note 2)

8 RXD- (RS-485/422 digital) Output from radio.

9 No connection (NC)

10 No connection (NC)

Page 27

05-4819A01, Rev. 08 LCT 450 Installation/Operation Guide 25

Note 1:

Channel select decoding as follows: High = no connection; Low = Gnd. See

table below for radio channel selections.

Note 2:

Provide low impedance path to ground to key transmitter.

11 Audio Isolated Ground

12 No connection (NC)

13 No connection (NC)

14 Channel Select 2 (See Note 1)

15 No connection (NC)

16 RS-485/422 Isolated Ground

17 TX Audio input to radio

18 Channel Select Isolated Ground

19 Channel Select 0 (Note 1)

20 No connection (NC)

21 PTT Isolated Ground

22 No connection (NC)

23 Channel Select 1 (Note 1)

24 TXD+ (RS-485/422 digital). Input to radio.

25 TXD- (RS-485/422 digital) Input to radio.

Table 5. Channel Selection Table

Channel 3 Channel 2 Channel 1 Channel 0 Selected

High (future use) High High High 1

High (future use) High High Low 2

High (future use) High Low High 3

High (future use) High Low Low 4

High (future use) Low High High 5

High (future use) Low High Low 6

High (future use) Low Low High 7

High (future use) Low Low Low 8

Table 4. P1 Control Interface Pin Descriptions

Page 28

26 LCT 450 Installation/Operation Guide 05-4819A01, Rev. 08

P2 PROGRAMMING & DIAGNOSTIC

INTERFACE

Table 4 lists the pin functions on the DB-9 DIAGNOSTIC INTERFACE

connector.

SPECIFICATIONS

GENERAL

Frequency Range*: 450–512 MHz

Number of Channels: 8

RECEIVER

Maximum Usable Sensitivity: 0.35 uV for 12 dB SINAD

Bandwidth: 12.5 kHz

Maximum Applied Signal: +28 dBm

TRANSMITTER

RF Carrier Power: 5 Watts to 30 Watts

Duty Cycle: 25%

Output Impedance: 50 Ω

Channel Spacing: 12.5, 25 kHz

FCC Emission Designators:

6.25 kHz B/W: 4K00F1D, 4K00F2D,4K00F3D

Table 6. Diagnostic Interface Pin Descriptions (DB-9)

Pin No. Description

1 No connection (NC)

2 RX Data

3 TX Data

4 No connection (NC)

5 Signal Ground

6 No connection (NC)

7 No connection (NC)

8 No connection (NC)

9 No connection (NC)

Page 29

05-4819A01, Rev. 08 LCT 450 Installation/Operation Guide 27

12.5 kHz B/W: 9K30F1D, 9K30F2D, 9K30F3D

25.0 kHz B/W: 16K5F1D, 16K5F2D, 16K5F3D

DATA CHARACTERISTICS

(P1 Control Interface Connect)

Payload Signaling Type: CCITT V.23

Connector Types: DB-25 Female

Payload Data Rate: 1200 bps

DATA CHARACTERISTICS

(P2 Programming & Diagnostic Port)

Connector Type: DB-9F

Signaling Standard: RS-232

PRIMARY POWER

Voltage: 13.6 Vdc (+/- 15%)

Negative-Ground Systems Only

TX Supply Current: 8 Amperes (Typical) @ 30 Watts Output

RX Supply Current: Operational—125 mA, Nominal

Power Connection: 5-inch “pigtail” (14 AWG) with Tyco/AMP

connector (Part No. 172129-1)

Fuse: 8-Ampere, internal

Page 30

28 LCT 450 Installation/Operation Guide 05-4819A01, Rev. 08

Page 31

Installation Guide

Page 32

GE MDS, LLC

Rochester, NY 14620

General Business: +1 585 242-9600

FAX: +1 585 242-9620

Web: www.gemds.com

175 Science Parkway

Loading...

Loading...