Page 1

GE Oil & Gas

GE Data Classification: Public

Masoneilan*

SVI* II ESD

Smart Valve Interface with SIL3

Emergency Shutdown PST Controller

Installation and Maintenance Manual

Page 2

About this Guide

This instruction manual covers the following instruments and approved software:

Through SVI II ESD -6

with Firmware version 3.1.2 or greater

with ValVue* ESD version 1.0 or greater

with Handheld HART

®

Communicator with DD published for SVI II ESD

Masoneilan* Device Type 203 or 0xCB

with PRM PLUG-IN ValVue ESD version 1.0 or greater

The information contained in this manual, in whole or part, shall not be transcribed or copied without GE’s written permission.

In no case does this manual guarantee the merchantability of the positioner or the software or its adaptability to a specific

client needs.

Please report any errors or questions about the information in this manual to your local supplier or visit www.geoilandgas.com/valves.

U. S. Patent No. 6,957,127, Additional Patents Pending

DISCLAIMER

THESE INSTRUCTIONS PROVIDE THE CUSTOMER/OPERATOR WITH IMPORTANT PROJECT-SPECIFIC REFERENCE INFORMATION IN ADDITION TO THE CUSTOMER/OPERATOR’S NORMAL OPERATION AND MAINTENANCE PROCEDURES. SINCE

OPERATION AND MAINTENANCE PHILOSOPHIES VARY, GE (GENERAL ELECTRIC COMPANY AND ITS SUBSIDIARIES AND

AFFILIATES) DOES NOT ATTEMPT TO DICTATE SPECIFIC PROCEDURES, BUT TO PROVIDE BASIC LIMITATIONS AND

REQUIREMENTS CREATED BY THE TYPE OF EQUIPMENT PROVIDED.

THESE INSTRUCTIONS ASSUME THAT OPERATORS ALREADY HAVE A GENERAL UNDERSTANDING OF THE REQUIREMENTS

FOR SAFE OPERATION OF MECHANICAL AND ELECTRICAL EQUIPMENT IN POTENTIALLY HAZARDOUS ENVIRONMENTS.

THEREFORE, THESE INSTRUCTIONS SHOULD BE INTERPRETED AND APPLIED IN CONJUNCTION WITH THE SAFETY RULES

AND REGULATIONS APPLICABLE AT THE SITE AND THE PARTICULAR REQUIREMENTS FOR OPERATION OF OTHER EQUIPMENT AT THE SITE.

THESE INSTRUCTIONS DO NOT PURPORT TO COVER ALL DETAILS OR VARIATIONS IN EQUIPMENT NOR TO PROVIDE FOR

EVERY POSSIBLE CONTINGENCY TO BE MET IN CONNECTION WITH INSTALLATION, OPERATION OR MAINTENANCE.

SHOULD FURTHER INFORMATION BE DESIRED OR SHOULD PARTICULAR PROBLEMS ARISE WHICH ARE NOT COVERED

SUFFICIENTLY FOR THE CUSTOMER/OPERATOR'S PURPOSES THE MATTER SHOULD BE REFERRED TO GE.

THE RIGHTS, OBLIGATIONS AND LIABILITIES OF GE AND THE CUSTOMER/OPERATOR ARE STRICTLY LIMITED TO THOSE

EXPRESSLY PROVIDED IN THE CONTRACT RELATING TO THE SUPPLY OF THE EQUIPMENT. NO ADDITIONAL REPRESENTATIONS OR WARRANTIES BY GE REGARDING THE EQUIPMENT OR ITS USE ARE GIVEN OR IMPLIED BY THE ISSUE OF THESE

INSTRUCTIONS.

THESE INSTRUCTIONS ARE FURNISHED TO THE CUSTOMER/OPERATOR SOLELY TO ASSIST IN THE INSTALLATION, TESTING, OPERATION, AND/OR MAINTENANCE OF THE EQUIPMENT DESCRIBED. THIS DOCUMENT SHALL NOT BE REPRODUCED IN WHOLE OR IN PART TO ANY THIRD PARTY WITHOUT THE WRITTEN APPROVAL OF GE.

Copyright

All information contained herein is believed to be accurate at the time of publication and is subject to change

without notice.

Copyright 2016 by General Electric Company. All rights reserved. PN 011523-561 Rev. F

Page 3

Document Changes

Version/Date Changes

B/4-2011 Removed non-installation software-related issues (See help). Rearranged book. Updated installation.

Amended Switches description.

Registration section updated to GE logo software.

C/3-2013 Removed references to double-acting.

D/9-2013 Changed the Simplified Switch diagram in Output Switches section and added a cross reference to it

in the install section. Added Cautions about Position Low and Upper Limits.

Added text about the 4-20 retransmit galvanic isolation.

E/2-2014 Updated load description for optional switches.

F/4-2016 Updated the Installation section and the Fault Matrix.

Modified connection drawings for intrinsically safe in Appendices B and C.

Made changes to Wiring Guidelines for Position retransmit.

© 2016 General Electric Company. All rights reserved.

Masoneilan Products SVI II ESD Installation and Maintenance Manual =| 3

Page 4

This page intentionally left blank.

Page 5

Contents

1. Safety Information ...................................................................................................................................................................... 17

Introduction ................................................................................................................................................................................. 17

Terms and Abbreviations....................................................................................................................................................... 17

Acronyms.............................................................................................................................................................................. 18

Safety Symbols........................................................................................................................................................................... 19

Related Literature ..................................................................................................................................................................... 19

Reference Standards............................................................................................................................................................... 20

SVI II ESD Device Description ............................................................................................................................................... 20

Designing an SIF Using an SVI II ESD ............................................................................................................................... 21

Safety Function.................................................................................................................................................................. 21

Environmental Limits....................................................................................................................................................... 21

Design Verification ........................................................................................................................................................... 22

SIL Capability....................................................................................................................................................................... 22

Connecting the SVI II ESD to the SIS Logic Solver.............................................................................................. 23

General Requirements.................................................................................................................................................... 24

Installation.................................................................................................................................................................................... 25

SVI II ESD Installation Configurations ...................................................................................................................... 25

Physical Location and Placement Guidelines...................................................................................................... 25

Pneumatic Connections................................................................................................................................................. 25

Electrical Connections .................................................................................................................................................... 25

Operation, Setup, Commissioning..................................................................................................................................... 25

Maintenance................................................................................................................................................................................ 25

Diagnostics................................................................................................................................................................................... 25

PST............................................................................................................................................................................................ 25

SVI II ESD Product Safety ....................................................................................................................................................... 27

2. Introduction .................................................................................................................................................................................... 29

ValVue ESD Overview .............................................................................................................................................................. 29

ValVue ESD Software............................................................................................................................................................... 30

ValVue ESD Trial Version................................................................................................................................................ 30

System Requirements..................................................................................................................................................... 31

Available Models................................................................................................................................................................ 32

About This Manual.................................................................................................................................................................... 32

© 2016 General Electric Company. All rights reserved.

Masoneilan SVI II ESD Installation and Maintenance Manual =

| 5

Page 6

3. Software Installation and Setup ........................................................................................................................................... 33

Install ValVue ESD and PRM Plug-In.................................................................................................................................. 33

Installing ValVue ESD Software...................................................................................................................................33

Installing the Yokogawa® PRM Plug-In ..................................................................................................................37

Registering ValVue ESD...........................................................................................................................................................49

Entering Software Keys ..................................................................................................................................................53

4. Installation and Setup ................................................................................................................................................................ 55

Overview ........................................................................................................................................................................................55

SVI II ESD Dimensions and Weights.......................................................................................................................... 56

Pre-Installation Issues .............................................................................................................................................................57

Storage................................................................................................................................................................................... 57

Unpacking.............................................................................................................................................................................57

Installation ....................................................................................................................................................................................57

Physical Location and Placement Guidelines ......................................................................................................58

Mounting the SVI II ESD on Rotary Valves.............................................................................................................. 61

Travel Sensor Alignment ................................................................................................................................................63

Mounting the SVI II ESD with NAMUR Kits..............................................................................................................64

Mounting the SVI II ESD on Reciprocating Valves .............................................................................................. 66

Checking the Magnet ......................................................................................................................................................69

Using ValVue ESD to Check Magnet Position .......................................................................................................69

Checking Actuator, Linkages, or Rotary Adapter ...............................................................................................70

Connecting the Tubing and Air Supply.................................................................................................................... 71

Checking the Air Supply..................................................................................................................................................73

Wiring the SVI II ESD......................................................................................................................................................... 73

Powering Up the SVI II ESD ........................................................................................................................................... 78

Making Connections to the Terminal Board .........................................................................................................83

SVI II ESD Maintenance ...........................................................................................................................................................84

Repair and Replacement ............................................................................................................................................... 84

Factory Notification..........................................................................................................................................................84

Display Cover Removal and Installation................................................................................................................. 85

5. Configuration and Calibration ............................................................................................................................................... 87

Overview.......................................................................................................................................................................................87

SVI II ESD Setup........................................................................................................................................................................... 87

Configuration...............................................................................................................................................................................88

Configuration with Pushbutton Display ..........................................................................................................................88

Calibration with Pushbutton Display................................................................................................................................91

Calibration using Auto Tune.........................................................................................................................................92

Correct for Over Travel.................................................................................................................................................... 92

Adjust Input Signal Range .............................................................................................................................................93

Configuring with ValVue ESD ...............................................................................................................................................94

Starting ValVue ESD/ESDVue .......................................................................................................................................94

Check-out with a HART® Handheld Communicator ................................................................................................ 95

6 | =GE Oil & Gas

© 2016 General Electric Company. All rights reserved.

Page 7

6. Using the Digital Interfaces ..................................................................................................................................................... 97

Overview........................................................................................................................................................................................97

Local Display and Pushbuttons .................................................................................................................................. 97

HART® Handheld Communicator ............................................................................................................................. 97

ValVue ESD ........................................................................................................................................................................... 98

Pushbuttons and Local Display .......................................................................................................................................... 98

Accessing Pushbuttons ............................................................................................................................................... 100

Pushbutton Locks and Configuration-Lock Jumper...................................................................................... 100

Display Menus.......................................................................................................................................................................... 102

NORMAL Operating Mode and MANUAL Mode Menus................................................................................. 102

Configure Menu............................................................................................................................................................... 103

Calibration Menu ............................................................................................................................................................ 105

PST Configuration Menu ............................................................................................................................................. 106

VIEW DATA Menu............................................................................................................................................................ 107

PST CONF (VIEW DATA) Menu ................................................................................................................................... 109

VIEW ERR............................................................................................................................................................................ 110

Clear Error.................................................................................................................................................................................. 111

FAILSAFE Mode................................................................................................................................................................ 111

Handheld Communicator................................................................................................................................................... 112

ValVue ESD ................................................................................................................................................................................ 113

7. Partial Stroke Testing .............................................................................................................................................................. 115

Overview..................................................................................................................................................................................... 115

Partial Stroke Test Diagnostics ........................................................................................................................................ 116

PST Configuration................................................................................................................................................................... 116

PST Configuration with Display Menu................................................................................................................... 116

PST Setup with ValVue ESD................................................................................................................................................ 118

PST Data from ESDVue ................................................................................................................................................ 118

8. Operation and Maintenance ............................................................................................................................................... 121

Operational Overview........................................................................................................................................................... 121

SVI II ESD Applications and Designated Safety Function Activation...................................................... 122

Additional Features ....................................................................................................................................................... 123

Physical and Operational Description .......................................................................................................................... 124

SVI II ESD Components......................................................................................................................................................... 125

Electronics Module ........................................................................................................................................................ 125

Output Switches.............................................................................................................................................................. 127

Pneumatic Module......................................................................................................................................................... 130

Optional Display and Pushbuttons ........................................................................................................................ 131

SVI II ESD Maintenance........................................................................................................................................................ 131

Repair and Replacement............................................................................................................................................ 131

Factory Notification....................................................................................................................................................... 132

Display Cover Removal and Installation.............................................................................................................. 132

Upgrading Firmware............................................................................................................................................................. 134

Tools Required ................................................................................................................................................................. 134

Installing Firmware Upgrade.................................................................................................................................... 134

© 2016 General Electric Company. All rights reserved.

Masoneilan SVI II ESD Installation and Maintenance Manual =| 7

Page 8

9. Troubleshooting ......................................................................................................................................................................... 135

Overview ..................................................................................................................................................................................... 135

Internal Diagnostics............................................................................................................................................................... 135

FAILSAFE Mode ............................................................................................................................................................... 136

Accessing Diagnostic Information.................................................................................................................................. 136

Error Messages on LCD........................................................................................................................................................ 137

Positioner Fault Messages ......................................................................................................................................... 137

Return to Normal Operation...................................................................................................................................... 137

VIEW ERR Diagnostics Messages ............................................................................................................................ 138

Fault Matrix................................................................................................................................................................................ 139

Troubleshooting with ESDVue .......................................................................................................................................... 153

Appendix A. Specifications and References .......................................................................................................................155

Physical and Operational Specifications ..................................................................................................................... 155

Models and Applications ..................................................................................................................................................... 161

Hazardous Area Certifications ................................................................................................................................. 161

SVI II ESD Models............................................................................................................................................................. 164

Appendix B. Installing an SVI II ESD in a Natural Gas Environment ......................................................................... 165

Remote Actuator Vent Gas Connection ....................................................................................................................... 167

Remote Gas Piping......................................................................................................................................................... 167

Single Acting Installation............................................................................................................................................. 167

Appendix C. HART® Wiring Configurations ........................................................................................................................169

Overview ..................................................................................................................................................................................... 169

System Connections.............................................................................................................................................................. 169

HART® Wiring Guidelines ................................................................................................................................................... 171

SVI II ESD Setups ............................................................................................................................................................. 172

Grounding Practices...................................................................................................................................................... 174

Compliance Voltage in Single Drop Current Mode ......................................................................................... 175

Wire Size and Conduit .................................................................................................................................................. 176

HART® Physical Layer Compliance of the Control System................................................................................. 177

Impedance Constraints ............................................................................................................................................... 177

Noise Constraints ........................................................................................................................................................... 177

Cabling and Interconnection Requirements...................................................................................................... 178

Capacitance vs. Length of Cable for HART®..................................................................................................... 178

HART® Filter Required for Certain Control System Output Circuits ....................................................... 178

Split Range Applications...................................................................................................................................................... 179

Setting Loop Addresses for Split Range Systems............................................................................................ 179

Multiple Output Circuit Control System................................................................................................................ 181

Isolators .............................................................................................................................................................................. 182

Supplemental Power Supply ..................................................................................................................................... 184

Verify Wiring and Connections................................................................................................................................. 184

Required Practices for Explosion Proof Installations ............................................................................................. 186

Clarification of Terminology ...................................................................................................................................... 186

Recommended Practice for Severe or Humid Environments.................................................................... 186

8 | =GE Oil & Gas

© 2016 General Electric Company. All rights reserved.

Page 9

HART® DCV Setup.................................................................................................................................................................. 187

HART® Module Positions............................................................................................................................................ 187

Field Wiring ....................................................................................................................................................................... 187

Appendix D. HART® Communications with Intrinsic Safety ........................................................................................ 189

Overview..................................................................................................................................................................................... 189

HART® Barrier Compliance ............................................................................................................................................... 190

Output Channel Isolation.................................................................................................................................................... 191

HART® Filter Requirements............................................................................................................................................... 191

Modem and Computer Use in Intrinsically Safe Circuits...................................................................................... 193

MACTek® Intrinsically Safe modem, Model 010005...................................................................................... 193

MACTek® Warning ....................................................................................................................................................... 193

Use of Hand-held Communicators In Intrinsically Safe Circuits .............................................................. 193

Appendix E. Air to Open and Air to Close Actuators ........................................................................................................ 195

Actuator Action........................................................................................................................................................................ 195

Appendix F. Air Supply Requirements .................................................................................................................................... 199

Appendix G. Adjusting Speed of Response .......................................................................................................................... 201

Appendix H. Glossary ..................................................................................................................................................................... 203

© 2016 General Electric Company. All rights reserved.

Masoneilan SVI II ESD Installation and Maintenance Manual =| 9

Page 10

This page intentionally left blank.

Page 11

List of Figures

1 SVI II ESD................................................................................................................................................................................ 29

2 ValVue ESD CD Browser ................................................................................................................................................. 33

3 Software Choice.................................................................................................................................................................34

4 Install Shield Wizard......................................................................................................................................................... 34

5 License Agreement...........................................................................................................................................................35

6 Choose Destination Location.......................................................................................................................................35

7 Ready to Install................................................................................................................................................................... 36

8 ValVue ESD CD Browser ................................................................................................................................................. 37

9 Software Choice.................................................................................................................................................................38

10 PRM Plug-In Main Screen............................................................................................................................................... 38

11 PRM Central Server License Agreement................................................................................................................. 39

12 PRM Central Server Destination Folder...................................................................................................................39

13 PRM Central Server Database Directory Destination Folder......................................................................... 40

14 Ready to Install...................................................................................................................................................................41

15 PRM Central Server Dialog ............................................................................................................................................ 41

16 PRM Central Server Dialog II......................................................................................................................................... 41

17 PRM Central Server Dialog III ....................................................................................................................................... 42

18 Database Directory Reminder.....................................................................................................................................42

19 ValVue ESD CD Browser ................................................................................................................................................. 43

20 Software Choice................................................................................................................................................................. 44

21 PRM Plug-In Main Screen............................................................................................................................................... 44

22 Install Shield PRM Plug-In .............................................................................................................................................. 45

23 PRM Plug-In License Agreement................................................................................................................................ 45

24 PRM Plug-In Destination Folder.................................................................................................................................. 46

25 Choose Folder .....................................................................................................................................................................46

26 PRM Plug-In Client Database Location Destination Folder............................................................................ 47

27 Choose Folder .....................................................................................................................................................................47

28 Ready to Install................................................................................................................................................................... 48

29 Owner and Product Key Registration Window....................................................................................................49

30 Applying Owner and Product Key Information ................................................................................................... 50

31 Software and Mux Key Window .................................................................................................................................50

32 Launching Registration Window................................................................................................................................51

33 Registration Window .......................................................................................................................................................51

© 2016 General Electric Company. All rights reserved.

Masoneilan SVI II ESD Installation and Maintenance Manual =

| 11

Page 12

34 Save Registration Information.....................................................................................................................................52

35 Registration File Saved Dialog.....................................................................................................................................52

36 Registration Email Sent Dialog ....................................................................................................................................53

37 Entering Software Key.....................................................................................................................................................53

38 Entering Mux Unlock Key ...............................................................................................................................................54

39 Successful Registration Message...............................................................................................................................54

40 SVI II ESD Exploded View ................................................................................................................................................55

41 SVI II ESD Dimensions ......................................................................................................................................................56

42 Camflex with Mounting Bracket (Side View)..........................................................................................................61

43 Namur 20/30 mm Mounting Kit..................................................................................................................................64

44 Namur 50 mm Mounting Kit.........................................................................................................................................65

45 Magnet Holder for Reciprocating Valves................................................................................................................66

46 Reciprocating Valve Mounting Bracket...................................................................................................................66

47 Reciprocating Linkage.....................................................................................................................................................67

48 Lever for Model 87/88 Multispring Actuator .........................................................................................................68

49 ValVue ESD for Checking Magnet Position ............................................................................................................70

50 Air Ports on Single Acting PST Controller ................................................................................................................72

51 Analog Safety Demand (ASD) Configuration.........................................................................................................75

52 Discrete Safety Demand (DSD) Configuration ......................................................................................................75

53 Analog with Discrete Safety Demand (A/DSD) Configuration.......................................................................76

54 Connections to ASD Electronics Module (via Terminal Board)......................................................................81

55 Connections to DSD Electronics Module (via Terminal Board) .....................................................................82

56 Connections to A/DSD Electronics Module (via Terminal Board).................................................................82

57 SVI II ESD Pneumatic and Display Covers ..............................................................................................................85

58 Configuration Pushbutton Guide................................................................................................................................90

59 ValVue ESD Icon .................................................................................................................................................................94

60 SVI II ESD HART® Communicator Connections...................................................................................................95

61 SVI II ESD Display................................................................................................................................................................98

62 NORMAL Operation and MANUAL Menu Structures.......................................................................................102

63 CONFIGure Menu ............................................................................................................................................................103

64 CALIBration Menu...........................................................................................................................................................105

65 PST CONFiguration Menu............................................................................................................................................106

66 VIEW DATA Menu ............................................................................................................................................................108

67 PST CONFiguration (VIEW DATA) Menu.................................................................................................................110

68 View Err Menu...................................................................................................................................................................110

69 FAILSAFE Menu ................................................................................................................................................................112

70 PST Configuration Pushbutton Menu ....................................................................................................................117

71 PST Diagnostic Graph Example................................................................................................................................118

72 PST Benefits.......................................................................................................................................................................119

73 Block Diagram with I/P Converter and Pressure Sensor.............................................................................. 124

74 Simplified Switch Installation Drawing: Correct Configuration .................................................................128

75 Simplified Switch Installation Drawing: Configuration Not Allowed .......................................................128

76 Pneumatic Module with Single Acting Relay......................................................................................................130

77 SVI II ESD Pneumatic and Display Covers ...........................................................................................................132

78 SVI II ESD Model Numbering...................................................................................................

...................................164

81 General Purpose and Explosion Proof Installation..........................................................................................173

12 | =GE Oil & Gas

© 2016 General Electric Company. All rights reserved.

Page 13

82 Intrinsically Safe Installation ..................................................................................................................................... 174

83 Selecting Set Options - Tools Menu on Connected Devices Screen ....................................................... 180

84 Selecting Set Options - Right Click on Connected Devices Screen ......................................................... 180

85 ValVue ESD Setup Options for Multidrop............................................................................................................. 181

86 Split Range with Isolator ............................................................................................................................................. 183

87 Split Range with Supplemental Power Supply - Non-Hazardous............................................................ 185

88 HART® Device in DCV Application.......................................................................................................................... 187

89 Intrinsically Safe Installation with Zener Barrier and HART® Filter......................................................... 190

90 Intrinsically Safe Installation with Galvanic Isolator ...................................................................................... 192

91 ATO and ATC Action with Linear Positioner Characteristics....................................................................... 196

92 ATO and ATC Action in Percentage of Positioner Characteristics............................................................ 197

© 2016 General Electric Company. All rights reserved.

Masoneilan SVI II ESD Installation and Maintenance Manual =| 13

Page 14

This page intentionally left blank.

Page 15

List of Tables

1 Proof Test Steps .................................................................................................................................................................26

2 ValVue Software Installation Sizes............................................................................................................................31

3 Software Requirements.................................................................................................................................................. 31

4 SVI II ESD Installation Steps ..........................................................................................................................................57

5 Travel Sensor Alignment................................................................................................................................................ 63

6 Reciprocating Valve Mounting Hole and Turnbuckle Length....................................................................... 68

7 Pneumatic Connections/Air Supply Requirements ........................................................................................... 71

8 SVI II ESD Models and Functionality .........................................................................................................................81

9 VIEWDATA Settings...........................................................................................................................................................89

10 Pushbutton Display Menus...........................................................................................................................................99

11 Pushbutton Lock Security Level............................................................................................................................... 100

12 SVI II ESD Fault Matrix .................................................................................................................................................. 139

13 Environmental Specifications................................................................................................................................... 155

14 Safety Rated Inputs....................................................................................................................................................... 156

15 Operational Specifications......................................................................................................................................... 156

16 Input Signal, Power, and Display Specifications .............................................................................................. 157

17 Construction Material Specifications .................................................................................................................... 157

18 System Connectivity...................................................................................................................................................... 158

19 Pneumatics Single Acting Standard Flow........................................................................................................... 158

20 Control Valve Mounting System .............................................................................................................................. 159

21 ESD and Diagnostic Capabilities ............................................................................................................................. 159

22 Device ID Information .................................................................................................................................................. 160

23 Burst Mode Data Return ............................................................................................................................................. 160

24 SVI II ESD Model Features........................................................................................................................................... 161

25 SVI II ESD Physical Attributes .................................................................................................................................... 161

27 CSA International Certifications............................................................................................................................... 162

28 FM Approvals.................................................................................................................................................................... 162

29 Temperature Class......................................................................................................................................................... 162

26 ATEX Approvals................................................................................................................................................................ 162

30 Immunity Performance................................................................................................................................................ 163

31 Radiation Performance ............................................................................................................................................... 163

32 Compliance Voltage for Single Channel Zener with 22 AWG Cable Installation .............................. 175

33 Compliance Voltage for Galvanic Isolator with 22 AWG Cable Installation ....................................... 175

© 2016 General Electric Company. All rights reserved.

Masoneilan SVI II ESD Installation and Maintenance Manual =

| 15

Page 16

34 Compliance Voltage for No Barrier with HART® Filter and Resistor and 18 AWG Cable .............176

35 Supplemental Voltage for Split Range..................................................................................................................184

16 | =GE Oil & Gas

© 2016 General Electric Company. All rights reserved.

Page 17

1. Safety Information

Introduction

This section provides information necessary to design, install, verify and maintain a Safety

Instrumented Function (SIF) utilizing a Masoneilan Smart Valve Interface, SVI II ESD. This manual

provides necessary requirements for meeting the IEC 61508 or IEC 61511 functional safety

standards.

Terms and Abbreviations

The following terms and abbreviations are related to safety functions of the SVI II ESD and are

used throughout this document.

Safety Freedom from unacceptable risk of harm.

Functional

Safety

Basic Safety The equipment must be designed and manufactured such that it protects

Safety

Assessment

Fail-Safe State State where the SVI II ESD is de-energized and has exhausted Actuator 1 in a sin-

Fail Safe Failure that causes the valve to go to the defined fail-safe state without a

Fail Dangerous Failure that does not respond to a demand from the process (i.e. being unable to

The ability of a system to carry out the actions necessary to achieve or to maintain a defined safe state for the equipment / machinery / plant / apparatus

under control of the system.

against risk of damage to persons by electrical shock and other hazards and

against resulting fire and explosion. The protection must be effective under all

conditions of the nominal operation and under single fault condition.

The investigation to arrive at a judgment - based on evidence - of the safety

achieved by safety-related systems.

gle acting configuration or has caused Actuator 1 to be at an equal or lower

pressure than Actuator 2 in a dual acting configuration.

demand from the process.

go to the defined fail-safe state).

© 2016 General Electric Company. All rights reserved.

Masoneilan SVI II ESD Installation and Maintenance Manual =

| 17

Page 18

Fail Dangerous

Undetected

Failure that is dangerous and that is not being diagnosed by automatic stroke testing.

Fail Dangerous Detected Failure that is dangerous but is detected by automatic stroke testing.

Fail Annunciation

Undetected

Fail Annunciation Detected Failure that does not cause a false trip or prevent the safety function

Fail No Effect Failure of a component that is part of the safety function but that has

Low Demand Mode Mode, where the frequency of demands for operation made on a

Acronyms

FMEDA Failure Modes, Effects and Diagnostic Analysis

HFT Hardware Fault Tolerance

MOC Management of Change. These are specific procedures often done

Failure that does not cause a false trip or prevent the safety function

but does cause loss of an automatic diagnostic and is not detected

by another diagnostic.

but does cause loss of an automatic diagnostic or false diagnostic

indication.

no effect on the safety function.

safety-related system is no greater than twice the proof test frequency.

The following acronyms are related to safety functions of the SVI II ESD and are used

throughout this document.

when performing any work activities in compliance with government

regulatory authorities.

PFDavg Average Probability of Failure on Demand

PST Partial Stroke Test, a test used to detect failure modes in the posi-

tioner, actuator, and valve assembly.

SFF Safe Failure Fraction, the fraction of the overall failure rate of a

device that results in either a safe fault or an diagnosed unsafe fault.

SIF Safety Instrumented Function, a set of equipment intended to reduce

the risk due to a specific hazard (a safety loop).

SIL Safety Integrity Level, discrete level (one out of a possible four) for

specifying the safety integrity requirements of the safety functions to

be allocated to the E/E/PE safety-related systems where Safety

Integrity Level 4 has the highest level of safety integrity and Safety

Integrity Level 1 has the lowest.

SIS Safety Instrumented System – Implementation of one or more Safety

Instrumented Functions. A SIS is composed of any combination of

sensor (s), logic solver (s), and final element (s).

18 | =GE Oil & Gas

© 2016 General Electric Company. All rights reserved.

Page 19

Safety Symbols

Conventions used in this manual are as follows:

Italicized letters are used when referencing a term used in the program display

window.

Italics is used for emphasis on important items.

Fields where data is entered or user-entered data is italicized.

Actions performed on buttons, checkboxes, etc. appear bolded. For example: Click

Done.

NOTE Indicates important facts and conditions.

CAUTION Indicates a potentially hazardous situation, which if not avoided

may result in property damage or data loss.

WARNING Indicates a potentially hazardous situation, which if not avoided

Related Literature

Listed below are documents related to the SVI II ESD.

TUV Certificate No. SAS0016/07, Vers. 1.0

Hardware Document SVI II ESD Quick Start Guide, MN-SVI-ESD_QSG-GEA19520

Guidelines/

References

may result in death or serious injury.

SVI II ESD SIL 3 Partial Stroke Test Device, BW500-ESD

Safety Integrity Level Selection – Systematic Methods

Including Layer of Protection Analysis, ISBN 1-55617-777-1,

ISA

Control System Safety Evaluation and Reliability, 2nd Edition,

ISBN 1-55617-638-8, ISA

Safety Instrumented Systems Verification, Practical

Probabilistic Calculations, ISBN 1-55617-909-9, ISA

© 2016 General Electric Company. All rights reserved.

Masoneilan SVI II ESD Installation and Maintenance Manual =| 19

Page 20

Reference Standards

Listed below are Functional Safety reference standards related to the SVI II ESD:

IEC 61508: 2000 – Functional safety of electrical/electronic/programmable electronic

safety-related systems

ANSI/ISA 84.00.01-2004 (IEC 61511 Mod.) Functional Safety – Safety Instrumented

Systems for the Process Industry Sector

SVI II ESD Device Description

An ESD valve is a valve that operates to ensure that the process is brought to its safe state.

During normal operation, these ESD valves are typically energized to stay open (ATO). In case

of an unsafe situation, the ESD valve is de-energized by the Safety System. The SVI II ESD

device performs this shutdown function for Safety Instrumented Functions (SIF) that require

field devices to be certified for safety related applications according to IEC61508 as certified

by TUV for use up to SIL3 with an HFT of 0 in low demand applications. The built-in

microprocessor is used for valve diagnostics only. The microprocessor has no direct role in

performing the designated safety function therefore the SVI II ESD is considered a Type A

device.

The SVI II ESD is a valve controller which mounts on a pneumatically actuated valve assembly.

Its role is to position an emergency shutdown valve to 0% or 100% with a PFDavg in

accordance with IEC61508 for SIL3 application.

Because of its capability of monitoring data from its embedded sensors, the SVI II ESD is

capable of validating the health of its integral components. In addition, due to the ability of

partially stroking, the ESD valve while in normal operations (energized to stay open - ATO); it

becomes possible to validate the health of the valve and actuator assembly. Configurable

time based testing of the ESD valve reduces the PFDavg by detecting dangerous failures.

20 | =GE Oil & Gas

© 2016 General Electric Company. All rights reserved.

Page 21

Designing an SIF Using an SVI II ESD

The following must be taken into consideration when designing a SIF (Safety Instrumented

Function) using the SVI II ESD:

Safety Function

Environmental Limits

Design Verification

SIL Capability

Connecting the SVI II ESD to the SIS Logic-Solver

General Requirements

Safety Function

When de-energized, the SVI II ESD moves to its fail-safe position. For a single-acting PST

controller the safe state is when the port Actuator 1 is exhausted to a pressure less than 1

PSIG (0.069 bar, 6.9 kPa). The valve actuation must automatically move the valve to the safe

state when the digital valve controller falls in safe state.

The SVI II ESD is intended to be part of final element subsystem, as per IEC 61508, and the

achieved SIL level of the function must be verified by the function designer.

Environmental Limits

The designer of a SIF must check that the product is rated for use within the environmental

limits as stated in Table 13 on page 155.

Application Limits

Listed below are the application limits for the SVI II ESD installed in a SIF:

The application of the SVI II ESD is limited for SIF where the safe state is the

de-energized state (shutdown) of the valve. The PST Controller can be operated with

either one of two control signals: 4 - 20 mA or 0 - 24 VDC.

With a 4 - 20 mA control signal, normal operation is with a 20 mA current loop signal to

the PST controller. A shutdown command is issued by bringing the current to 5.6 mA or

lower.

With a 0 - 24 VDC control signal, normal operation is with a 24 VDC signal applied to

the PST controller. A shutdown command is issued by opening the loop or bringing the

control signal to 3 VDC or lower.

© 2016 General Electric Company. All rights reserved.

Masoneilan SVI II ESD Installation and Maintenance Manual =| 21

Page 22

Design Verification

The following describes the design verification criteria for the SIF and the SVI II ESD:

A detailed Failure Mode, Effects, and Diagnostics Analysis (FMEDA) report is available

from the factory. This report details all failure rates and failure modes as well as the

expected lifetime.

The achieved Safety Integrity Level (SIL) of an entire Safety Instrumented Function (SIF)

design must be verified by the designer by means of PFDavg calculation, considering

redundant architectures, proof test interval, proof test effectiveness, any automatic

diagnostics, average repair time and specific failure rates of all products included in

the SIF. Each subsystem must be checked to assure compliance with minimum

hardware fault tolerance (HFT) requirements. The exida exSILentia

recommended for this purpose as it contains accurate models for the SVI II ESD and

related failure rates.

When using an SVI II ESD in a redundant configuration, include a common cause factor

of 5% in safety integrity calculations.

The failure rate data listed in the FMEDA report is valid only for the useful life time of an

SVI II ESD. The failure rates sometimes increase after this time period. Reliability

calculations based upon the data listed in the FMEDA report for mission times beyond

the lifetime can yield results too optimistic, i.e. the calculated Safety Integrity Level will

not be achieved.

®

tool is

SIL Capability

The SVI II ESD meets SIL 3 requirements as outlined below.

Systematic Integrity

The product has met manufacturer design process requirements of Safety Integrity Level (SIL)

3. These are intended to achieve sufficient integrity against systematic errors of design by the

manufacturer. A Safety Instrumented Function (SIF) designed with this product must not be

used at a SIL level higher than the statement without prior use justification by end user or

diverse redundant technology in the design.

Random Integrity

The SVI II ESD’s safety critical function is maintained by a Type A Device. Therefore based upon

the SFF > 90%, when the SVI II ESD is used as the sole component in a final element

subassembly, a design can meet SIL 3 @ HFT=0.

When the final element assembly consists of many components (SVI II ESD, quick exhaust

valve, actuator, isolation valve, etc.) the SIL must be verified for the entire assembly taking into

consideration failure rate of each component. This analysis must account for any hardware

fault tolerance and architecture constraints.

22 | =GE Oil & Gas

© 2016 General Electric Company. All rights reserved.

Page 23

Safety Parameters

For detailed failure rate information refer to the Failure Modes, Effects and Diagnostic Analysis

Report for the SVI II ESD available from the factory.

SIL Certification

This product guarantees to respond to commanded trip signal with a PFD in accordance to

IEC61508 SIL3

Capable of partially stroking the valve using one of the following initiation methods, that will

be IEC61508 SIL2 certified:

Built-In Scheduler within the SVI II ESD

Locally with an external pushbutton

Locally with built-in pushbutton

®

HART

command

Analog Input current threshold

Connecting the SVI II ESD to the SIS Logic Solver

When connecting the SVI II ESD to the SIS logic solver follow the guidelines below.

The SVI II ESD is connected to the safety rated logic solver which is actively performing

the safety function. Connections must be made as per the instructions supplied by the

safety rated logic solver.

The output rating of the I/O module has to meet or exceed the electrical specifications

of the SVI II ESD as referenced in ES-727 in the SVI II ESD Quick Start Guide,

MN-SVI-ESD_QSG-GEA19520.

© 2016 General Electric Company. All rights reserved.

Masoneilan SVI II ESD Installation and Maintenance Manual =| 23

Page 24

General Requirements

The following general requirements for the SVI II ESD must comply to the following:

The system response time shall be less than process safety time. The SVI II ESD

switches to its fail safe state in less than 100ms. Response time is actuator dependent.

The end user must add the SVI II ESD response time to actuator/valve response to

obtain overall response time.

All SIS components, including the SVI II ESD, must be operational before process

start-up. The internal diagnostic test monitoring SVI II ESD for faults has a one hour test

interval. This test does not partial stroke the valve.

In order to use the PST as an automatic diagnostic tool the PST shall be scheduled

(using ValVue ESD) to run at least once per month or ten times within the expected

hazard demand interval, whichever comes first. Detailed failure rate data is specified

in the FMEDA report available from the factory.

You must verify that the SVI II ESD is suitable for use in safety applications by

confirming that SVI II ESD’s nameplate is properly marked.

Personnel performing maintenance and testing on the SVI II ESD has to be qualified to

do so.

Results from the PST and proof tests shall be recorded and periodically reviewed.

The useful life of the SVI II ESD is discussed in the Failure Modes, Effects and Diagnostic

Analysis Report for the SVI II ESD.

24 | =GE Oil & Gas

© 2016 General Electric Company. All rights reserved.

Page 25

Installation

All installation related issues are outlined below.

SVI II ESD Installation Configurations

Refer to “SVI II ESD Configurations” on page 74

Physical Location and Placement Guidelines

Refer to “Physical Location and Placement Guidelines” on page 58

Pneumatic Connections

Refer to “Pneumatic Connections” on page 71 of this manual.

Electrical Connections

Refer to “Electrical Connection Guidelines” on page 73

Operation, Setup, Commissioning

Refer to “Configuration and Calibration” on page 87

Maintenance

Refer to “SVI II ESD Maintenance” on page 131.

Diagnostics

The SVI II ESD provides several types of diagnostic information:

Continuous device diagnostics

Internal diagnostics that run every hour and require no user configuration

Partial Stroke Testing (PST) diagnostics

PST

You can configure and run PST at any time. For more information on PST refer to “Partial

Stroke Testing” on page 115

© 2016 General Electric Company. All rights reserved.

Masoneilan SVI II ESD Installation and Maintenance Manual =| 25

Page 26

Proof Test

You can also manually run a proof test. The objective of proof testing is to detect failures

within an SVI II ESD and ESD valve that are not detected by any automatic diagnostic of the

system. Of main concern are undetected failures that prevent the safety instrumented

function from performing its intended function.

Proof testing frequency or proof test interval, has to be determined in reliability calculations

for the safety instrumented functions to which SVI II ESD is applied. The proof tests must be

performed more frequently or as frequently as specified in the calculation in order to maintain

the required safety integrity of the safety instrumented function.

The following proof test is recommended. Report any detected failures that compromise

functional safety to the factory.

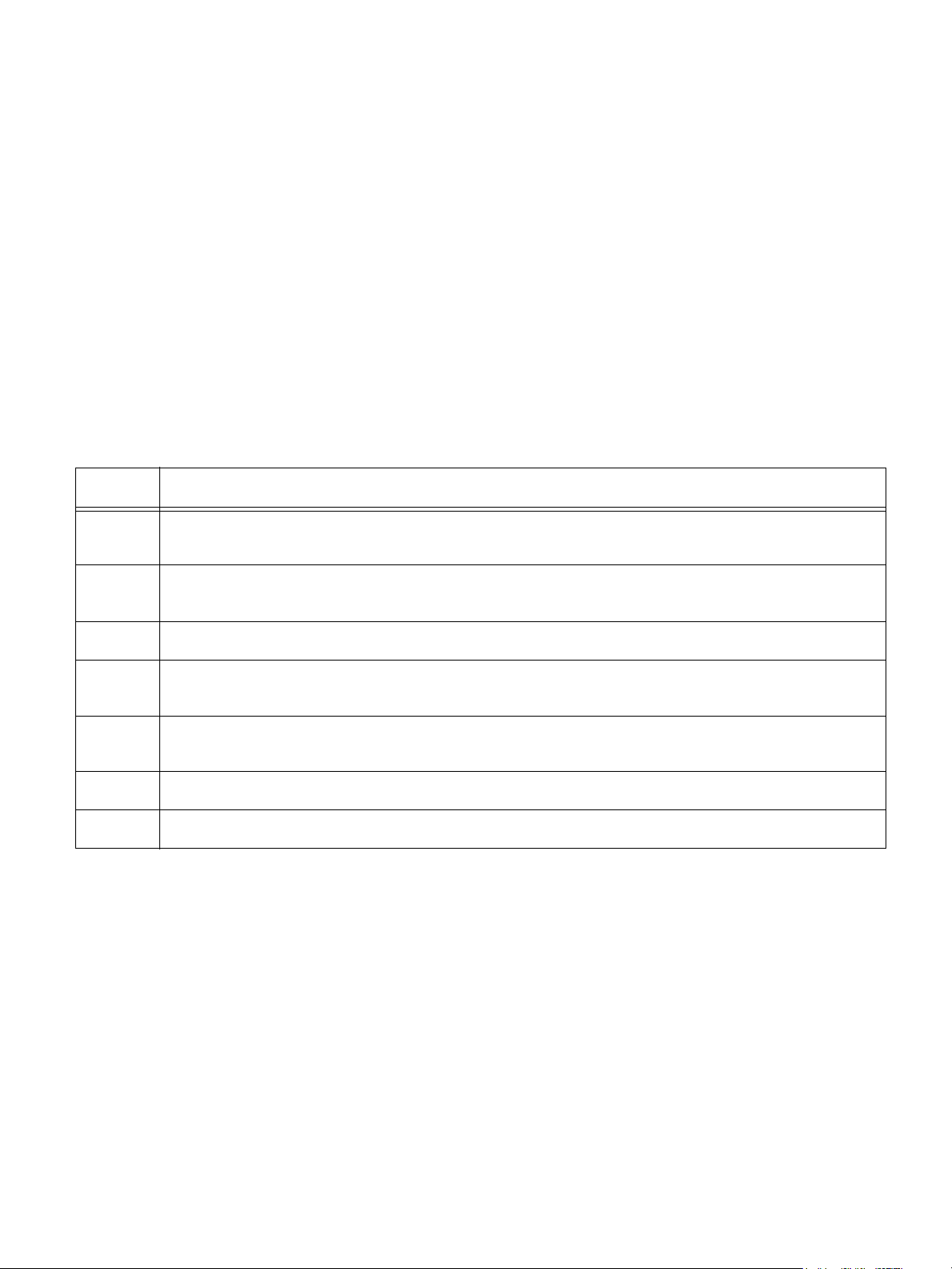

Table 1 Proof Test Steps

Step

1

2

3 Inspect the SVI II ESD for dirty or clogged ports and other physical damage

4

5

6 Record any failures in your company’s SIF inspection database. Restore the loop to full operation.

7 Remove bypass or otherwise restore normal operation

Read the SVI II ESD data record using a HART

faults before proceeding.

Bypass the valve, or isolate or take other appropriate action to avoid a false trip, following company Management of Change (MOC) procedures

De-energize the SVI II ESD and observe that the actuator and valve move. Energize the SVI II ESD after the

valve has moved to its full stroke length.

Inspect the SVI II ESD for dirt, corrosion or excessive moisture. Clean if necessary and take corrective

action to properly clean the air supply. It has to be done in order to avoid incipient failures due to dirty air.

Action

®

handheld device or ValVue ESD software. Solve any active

This test detects approximately 99% of possible DU failures in the SVI II ESD (Proof Test

Coverage).

The person (s) performing the proof test of an SVI II ESD must be trained in SIS operations,

including bypass procedures, maintenance and company Management of Change

procedures. No special tools are required.

26 | =GE Oil & Gas

© 2016 General Electric Company. All rights reserved.

Page 27

SVI II ESD Product Safety

The SVI II ESD is intended for use with industrial compressed air or sweet natural gas systems

only. Ensure that an adequate pressure relief provision is installed when the application of

system supply pressure may cause peripheral equipment malfunctioning. Installation must be

in accordance with local and national compressed air and instrumentation codes.

General installation, maintenance or replacement

Products must be installed in compliance with all local and national codes and

standards by qualified personnel using safe site work practices. Personal Protective

Equipment (PPE) must be used per safe site work practices.

Ensure proper use of fall protection when working at heights, per safe site work

practices. Use appropriate safety equipment and practices to prevent the dropping of

tools or equipment during installation.

Under normal operation, compressed supply gas is vented from the unit to the

surrounding area, and may require additional precautions or specialized installations.

Explosion/ flame proof installations

Products certified as explosion proof or flame proof equipment or for use in hazardous area

installations MUST BE:

Installed, put into service, used and maintained in compliance with national and local

regulations and in accordance with relevant standards recommendations for

potentially explosive atmospheres.

Used only in situations that comply with the certification conditions shown in this

document and after verification of their compatibility with the zone of intended use

and the permitted maximum ambient temperature

Installed, put into service and maintained by qualified and competent professionals

who have undergone suitable training for instrumentation used in areas with

potentially explosive atmospheres.

WARNING Before using these products with fluids/compressed gases other

than air or for non-industrial applications, consult the factory. This

product is not intended for use in life support systems.

WARNING Do not use damaged instruments.

© 2016 General Electric Company. All rights reserved.

Masoneilan SVI II ESD Installation and Maintenance Manual =| 27