Page 1

g

DOC. ID: DXSE0012

MANUFACTURING PROCEDURES

GE Medical Systems

TITLE: DEXA PM Work Instructions

LUNAR

REVISION: G

DATE: 2/28/02

WRITTEN BY: Jeff Franz

APPROVED ON CO: L10173

PURPOSE

This procedure describes the steps necessary to do a Planned Maintenance Check on

a DEXA scanning system at a customer's site, and to assure that the system is

operating within GE-LUNAR's specifications and in compliance with applicable Federal

and State regulations.

APPLICATION

This procedure applies to all employees performing Planned Maintenance or Site

Certification of DPX Series or PRODIGY, and DPX-NT scanning systems.

SAFETY PRECAUTIONS

When power is applied this equipment generates ionizing radiation. Take precautions

that no part of your body passes through the x-ray beam when the equipment is

energized.

ASSOCIATED MATERIALS

DXAP0008 DPX-Series Installation Test Procedures

DXAP2007 Prodigy Hacksaw Test

DXAP3002 DPX-NT Installation Test Procedures

DXQC0022 Aluminum Spine Phantom Scan Procedure

DXQC2022 enCORE software Aluminum Spine Phantom Scan Procedure

DXSE0036 OINK Daughter board and Limit Switch Field Replacement Instructions

DXSE0038 DEXA PM Quality record

DEFINITIONS

DPX Series scanners are all non- Prodigy, non- DPX-NT/MD+ scanners.

enCORE based systems are all PRODIGY and DPX-NT/MD+ scanners.

PRODIGY I systems are defined as PRODIGY systems with system numbers 11999

and lower.

DPX-NT (A) systems are defined as DPX NT systems with system numbers 71999 and

lower.

QUALITY SYSTEM DOCUMENT Page 1 of 10

It is the responsibility of the user to verify this document originated from the controlled master and is the active revision prior to use.

This document contains confidential or proprietary information of GE Lunar. Neither the document nor the information therein is to be reproduced, distributed,

used or disclosed, either in whole or in part, except as specifically authorized by GE Lunar.

Page 2

GE Medical Systems

LUNAR

DOC ID: DXSE0012

REV: G DATE: 2/28/02 CO: L10173

PROCEDURE

A. QA HISTORY AND ERRORLOG.

1. Perform a Quality Assurance test to insure the system is operating.

a. Verify that all tests on the QA are passing.

2. DPX Series scanners:

The QA values needed may be found by viewing the QA database (F4

Database options – F2 QA History) and / or in the Daily QA printouts in the

Customer’s QA binder.

a. Verify that the Detector has not lost significant resolution by checking that

the high and low energy air counts have not decreased by more than 10%

from the date of installation or the date of the last tube head or detector

change).

b. Verify that the air ratio has not changed by more than .02. from the date of

installation or last tube head or detector change (calculate from earliest

QA or lookup on QA printouts).

3. Systems with enCORE software

a. Copy the QA.mdb file to a diskette (Tools / Send Configuration / Select

Error Log and QA Database, make sure compress Files is selected and

select Span Multiple Disks if necessary).

b. Select the appropriate drive (3 ½ floppy A: ) insert disk into drive and click

OK.

c. Label with system number and PM, the file may be mailed to Service

Engineering or email file to lunar.support@med.ge.com

NOTE: This is only to gather statistical in formation on enCORE ba sed

systems performance, there will be no follow up regarding these QA histories.

4. Analysis of the QA History file

a. DPX Series

i. Verify % Spillover is between 6.3 and 9.5

ii. Check the Air Ratio – it cannot deviate more than .02 since the last

detector / tube change

iii. Check the low air counts – a change greater than 10% since the

date of last detector change indicates a failing detector

iv. Check the Large standard Mass – should not deviate more than

2%

QUALITY SYSTEM DOCUMENT Page 2 of 10

It is the responsibility of the user to verify this document originated from the controlled master and is the active revision prior to use.

This document contains confidential or proprietary information of GE Lunar. Neither the document nor the information therein is to be reproduced, distributed,

used or disclosed, either in whole or in part, except as specifically authorized by GE Lunar.

Page 3

GE Medical Systems

LUNAR

DOC ID: DXSE0012

v. If any of the above parameters are failing, call GE-Lunar Customer

Support for help diagnosing the system.

1. To aid in diagnosis, email the QA.MDB file to

lunar.sppport@med.ge.com

5. Review the error log(s).

b. DPX Series systems print from DOS prompt

i. C:\> ERRDUMP –L –N >PRN

1. See DPX Series CSB Vol 9 for DPX Series Error Log

Interpretation

c. enCORE based systems Tools\ Error Log – add to instructions

d. Verify that there are no hardware subsystem failures (X-ray, Detector,

Mechanical)

e. Contact Lunar Service Department if any unexplained or unusual errors

are discovered in the error log.

i. Error Log may be faxed to 608-826-7107 to aid in interpretation.

REV: G DATE: 2/28/02 CO: L10173

f. Delete error log for DPX Series (C:\LUNAR> del err_320.bin or C:\LUNAR

del errlog.bin).

g. Start a new error log for enCORE-based systems by clicking on Initialize

Log.

B. HOST PC MAINTENANCE

1. Clean the Printer according to the manufacturer’s instructions

a. For Hewlett Packard Printers go to www.hp.com and search the support

pages for the customer’s printer model.

2. DPX series systems:

a. From a DOS prompt

i. Delete contents of C:\SCRATCH and C:\PRNTMNGR directories.

ii. Delete all *.CHK files in C:\ directory.

3. Software updates

a. DPX Series systems: all DPX-IQ densitometers may be updated to

version 4.7e software free of charge.

b. All other (non-IQ) DPX Series Densitometers should be running version

3.65 or 4.7e (if upgraded to IQ software)

c. If the customer is running a version lower than 4.7e, or 3.65 ask them if

they are interested in this free update, they may get by contacting the GELunar Apps line (USA) or you may order it from GE-Lunar at

lunar.support@med.ge.com

or at 866-225-4771.

QUALITY SYSTEM DOCUMENT Page 3 of 10

It is the responsibility of the user to verify this document originated from the controlled master and is the active revision prior to use.

This document contains confidential or proprietary information of GE Lunar. Neither the document nor the information therein is to be reproduced, distributed,

used or disclosed, either in whole or in part, except as specifically authorized by GE Lunar.

Page 4

GE Medical Systems

LUNAR

DOC ID: DXSE0012

d. enCORE based systems:

i. Contract and W a rranty customers are entitled to free software

updates (all software versions <6.0 are updates, > 6.0 is

considered an upgrade and all customers must purchase it)

ii. Billable customers may purchase software updates by contacting

GE-Lunar at 866-225-4771.

C. SCAN TABLE MAINTENANCE

1. Remove the scanner tabletop.

a. Power down the scan table.

b. DPX Series tables – unlock the end panel doors and remove the tabletop

screws.

i. DPX-IQ

ii. Non DPX-IQ

c. DPX-NT – unlock the end panels and remove the tabletop screws.

REV: G DATE: 2/28/02 CO: L10173

i.

d. PRODIGY – lift up the table pad and remove the 4 counter sunk 1/8” hex

head screws in the 4 corners of the tabletop.

2. Clean the scanner interior

a. Clean the electronics pan of dust and dirt.

b. Wipe the dust and dirt off of the rear longitudinal rail and the transverse

rail.

3. Inspect mechanical parts and cables for wear and breakage.

a. Check all cables on the cable trough for wear

b. Check the v-wheels on the rear longitudinal carriage for appropriate

tension Insert V-wheel instructions.

4. X-Ray Generator

a. Power up the scan table.

b. Ramp the scanner to the appropriate kV / mA and read the test points on

the appropriate board as indicated in the X-Ray Settings table on

DXSE0038.

i. DPX Series

1. Load the version specific diagnostic software from the Tools

disk – from a DOS prompt type: A:/diags/diagnos load

c:/lunar

2. Enter the diagnostic software – from a C:\LUNAR prompt

type: diags

3. Choose option 5 Static Counter

QUALITY SYSTEM DOCUMENT Page 4 of 10

It is the responsibility of the user to verify this document originated from the controlled master and is the active revision prior to use.

This document contains confidential or proprietary information of GE Lunar. Neither the document nor the information therein is to be reproduced, distributed,

used or disclosed, either in whole or in part, except as specifically authorized by GE Lunar.

Page 5

GE Medical Systems

LUNAR

DOC ID: DXSE0012

ii. EnCORE based systems

1. Place the scanner in Service Mode

a. Options / User Options / check the check box for

Service – Enter Password (Smile sw ver 1.0 – 2.05 or

Award ver 2.10 +)

2. Go to Tools / Diagnostics / Scanner X-ray

3. Enter desired kV and ma – click on ramp

NOTE: Be sure to use your anti-static wrist strap when working on

or near circuit board assemblies. .

5. Wedge Test (Rollover Test – DPX Series Only)

a. Select the Static Counter from the initial menu. When the static counter

screen appears, use the arrow key to move the cursor to Operating

Voltage, and enter 76.0.

b. Move the cursor to Tube Current and enter the number 150.

REV: G DATE: 2/28/02 CO: L10173

c. Set the "Repeat" number to 20 and the "Printer" to ON.

i. If the AGS is operating properly, the low channel counts will be

approximately 600,000 to 800,000 counts, and there will be fewer

high channel counts in the range of approximately 400,000 to

700,000. Both counts will be stable to approximately +/- 3000

counts from one sample to the next.

d. Place the aluminum wedge test tool on the top of the collimator, with the

thin edge toward the collimator’s larger aperture, and the thick edge away

from the aperture. Insure that the aluminum wedge is NOT in the beam.

e. Press <Esc> and the shutter will open. Allow a 7 samples to appear on

the monitor, and then slowly move the Aluminum Wedge through the

radiation beam, starting with the thin edge of the wedge.

f. Move the wedge very slowly until the beam reaches an aluminum

thickness of approximately 2 mm.

g. In the results displayed on the monitor, note the sample number where

the high channel air counts begin to be reduced. At this point the counts in

both channels should be reduced for the following samples. In other

words: both the high and low channel counts must decrease

consistently as the wedge enters the beam.

h. If the low channel counts increase at any point instead of decreasing, the

AGS is not properly adjusted or the detector is failing.

i. This may cause "bone points" or white pixels in the image around

the outside of a patient's Total Body scan and or white streaks in

femur scans.

QUALITY SYSTEM DOCUMENT Page 5 of 10

It is the responsibility of the user to verify this document originated from the controlled master and is the active revision prior to use.

This document contains confidential or proprietary information of GE Lunar. Neither the document nor the information therein is to be reproduced, distributed,

used or disclosed, either in whole or in part, except as specifically authorized by GE Lunar.

Page 6

GE Medical Systems

LUNAR

DOC ID: DXSE0012

REV: G DATE: 2/28/02 CO: L10173

i. Run the AGS wedge test and verify that it passes attach results to PM

Check sheet.

6. Alignment verification / Mechanical / Cabling check

a. Run Air Matrix Scan

i. Remove the tabletop if it is on.

ii. In DIAGS select F4 QUA LITY ASSURANCE TESTS, select option

3 – PERFORM AIR MATRIX SCAN. Choose 1 - Perform A Scan.

Change the number of lines to the maximum value, also change

the number of steps to the maximum value.

iii. Note the filename here_____________________________. This

will have to be entered to analyze the data (filename format: XM

followed by the 4-digit system number followed by MO.01A.

Subsequent scans have extensions 01B, 01C, etc.) Then Press

Esc to continue.

iv. Remove the detec to r collimator (non-IQ / MD systems only) and

install the Air Matrix Piece (attenuation insert) or tape a 0.25 inch

piece of aluminum over the detector (over on top of the collimator)

to reduce the intensity of the beam.

v. Press Esc to begin the scan. The scan will take approx. 30

minutes to complete.

NOTE: If anything passes through the beam during this test, IT WILL FAIL.

vi. Analyze the Air Matrix scan in DIAGS by selecting option F4

QUALITY ASSURANCE TESTS then select option 4 ANALIZE AIR

MATRIX SCAN.

vii. Enter the Air Matrix file name when prompted and press the enter

key.

viii. All categories mu st pass, see table 1 for Air Matrix values.

Category Limit

Chi Squared 45

Skew +/- 0.07

Kurtosis +/- 0.07

Table 1: Failure Limits for the Air Matrix Test

ix. Print the overall values by answering Y (yes) when the software

prompts

x. Return the printout of the passing Air Matrix with the PM

Checksheet report (DXSE0038).

QUALITY SYSTEM DOCUMENT Page 6 of 10

It is the responsibility of the user to verify this document originated from the controlled master and is the active revision prior to use.

This document contains confidential or proprietary information of GE Lunar. Neither the document nor the information therein is to be reproduced, distributed,

used or disclosed, either in whole or in part, except as specifically authorized by GE Lunar.

Page 7

GE Medical Systems

LUNAR

xi. If any categories fail, check the deviation image for possible

xii. Run a Daily QA from the system software, or a Peak from the

xiii. Once an accepta ble Air Matrix scan is printed, delete the Air Matrix

b. Beam Wobble scan (Prodigy systems with software version 2.20 and

greater DXAP2011) or Alignment scan (Prodigy systems with software

versions lower than 2.20 and DPX-NT/MD+ systems- DXAP3001) as

appropriate and verify that it passes (attach the results).

7. Limit Switches

a. Verify Limit Switch distances (DPX series Diags – F1 Limit Switch

Diagnostics / 1 Limit to Limit Distance; enCORE systems - tools /

Diagnostics / scanner motion

DOC ID: DXSE0012

REV: G DATE: 2/28/02 CO: L10173

electronic or alignment problems, consult GE-Lunar OLC for

assistance.

diagnostic software, before trying the Air Matrix.

files (these files begin with "XM" or "XP" plus the System Number,

and they are generally the only files beginning with "X" in the

C:\LUNAR subdirectory).

b. DPX Series Only - Home the scanner

c. Mark the home position on the Home Jig

QUALITY SYSTEM DOCUMENT Page 7 of 10

It is the responsibility of the user to verify this document originated from the controlled master and is the active revision prior to use.

This document contains confidential or proprietary information of GE Lunar. Neither the document nor the information therein is to be reproduced, distributed,

used or disclosed, either in whole or in part, except as specifically authorized by GE Lunar.

Page 8

GE Medical Systems

LUNAR

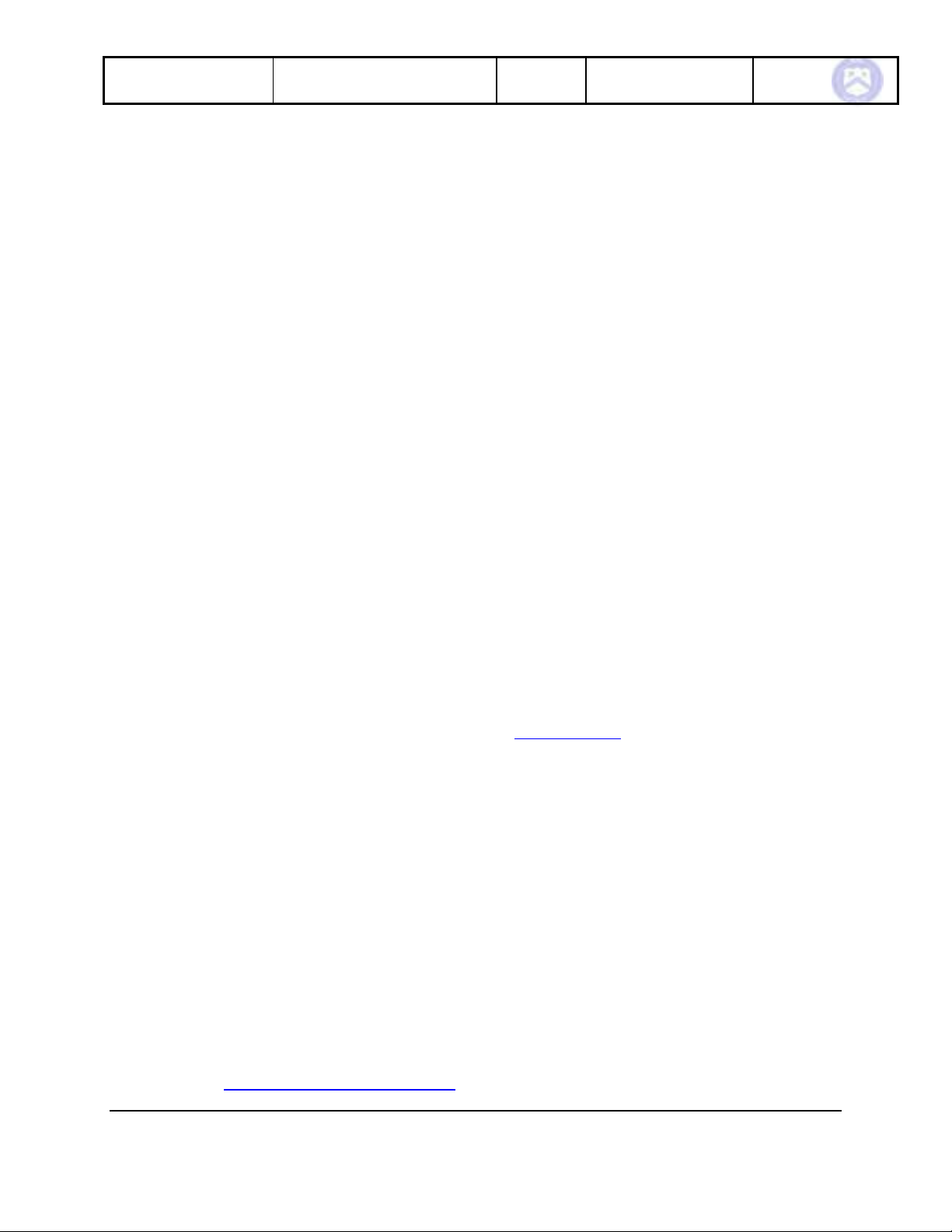

(4-3)

Transverse

Steps

DPXα

10920

–

10960

DOC ID: DXSE0012

DPXIQ /

MD180 or

DPXα

w/

4.1d or

greate

r host

1078010820

DPXL

1244

0 1248

0

DPXIQ /

MD240 or

DPXL

w/

4.1d or

greate

r host

1243012470

DPXSF

1092

0 –

1096

0

REV: G DATE: 2/28/02 CO: L10173

DPXSF w/

4.1d or

greate

r host

1078010820

PRODIGY

240cm

Table

12475

+/- 25

PRODIGY

180cm

Table

12475

+/- 25

DPXNT /

MD+

240c

m

Table

12450

+/- 20

DPXNT/MD+

180cm

Table

12450

+/- 20

(1-2)

Longitudina

l Steps

(3-4)

Transverse

Steps

(2-1)

Longitudina

l Steps

13360

–

13400

10920

–

10960

13360

–

13400

w/

3.63

host

1328013320

1078010820

1328013320

1988

0 1992

0

1244

0 –

1248

0

1988

0 –

1992

0

w/

3.63

host

1973019770

1243012470

1973019770

8. Replace the table top and screw down.

a. DPX Series Only – Insure Home position is correct by using the Home Jig

b. If necessary adjust limit switches

9. Daily QA Tests

4225

–

4265

1092

0 –

1096

0

4225

4265

w/

3.63

host

41954235

1078010820

41954235

19890

+/- 35

12475

+/- 25

19890

+/- 35

13790

+/- 35

12475

+/- 20

13790

+/- 35

19605

+/- 20

12450

+/-20

19605

+/- 20

13530

+/-20

12450

+/- 20

13530

+/- 20

a. DPX Series only – check the peak setting on the QA last run

i. If peak is not 500 +/- 25 units adjust the peak

1. The voltage to the detector is controlled by the adjustment of

the potentiometer on the SBC board labeled HV ADJ - R43.

2. The voltage at TP18 of the SBC is equal to the detector

voltage divided by 1000. If R43 is adjusted to decrease the

voltage at TP18 by 0.001, the peak will increase by 5 units.

3. The last peak value obtained during a Quality Assurance

scan is stored in the Quality Assurance History database file.

QUALITY SYSTEM DOCUMENT Page 8 of 10

It is the responsibility of the user to verify this document originated from the controlled master and is the active revision prior to use.

This document contains confidential or proprietary information of GE Lunar. Neither the document nor the information therein is to be reproduced, distributed,

used or disclosed, either in whole or in part, except as specifically authorized by GE Lunar.

Page 9

GE Medical Systems

LUNAR

DOC ID: DXSE0012

REV: G DATE: 2/28/02 CO: L10173

If the next peak value obtained differs from the last value

stored in the database by more than 50 units, the Quality

Assurance scan will fail. If the peak must be shifted by more

than 50 units to return it to 500 units +25, the peak must be

adjusted in steps of less than 50 units (40 unit steps are

recommended).

4. A complete QA must be run

5. between each step to update the Quality Assurance History

database file.

6. If the software peak setting corresponds to where both the

high and low channel counts are at a maximum, (see fig.

6.3) follow the steps outlined below. The graph on the QA

will look similar to the one shown in fig 6.3 with the dashed

vertical line (where the software thinks the peak is) on the

graph at a point where both the high and low energy plots

are maximized (the dashed curved lines). If the graph on the

QA is unlike fig 6.3, go to part B of this procedure.

7. select "Peak / Set AMP Gain", then select "Perform Peak"

and [Esc] to run the peak. Observe the results generated by

the QA to determine if the software has selected the

Amplifier Setting where both high and low channel counts

are at a maximum. If not go to part B.

8. 3. If the peak requires adjustment, (is not within +/- 25 units

of 500) connect a voltage meter to the SBC at TP18 (see fig

6.2). Put the meter to the VDC scale and record the voltage

reading (e.g. 0.703VDC

9. Using the voltage recorded in step 3 and the peak value

recorded in step 2 determine the appropriate voltage

adjustment for R43.

10. To determine voltage adjustment:

a. If Peak >500: New

/5 * + Old

b. Peak <500 New

VTP18

Old

VTP18

VTP18 = (500 – Current Peak) / 5 * –

VTP18 = (Current Peak – 500)

c. Do not attempt to adjust the peak by more than 40

units as an adjustment without a complete passing

QA in the LUNAR software will cause a peak failure

on the QA. For Peak settings that are more than 50

units away from 500 multiple adjustments are

required.

QUALITY SYSTEM DOCUMENT Page 9 of 10

It is the responsibility of the user to verify this document originated from the controlled master and is the active revision prior to use.

This document contains confidential or proprietary information of GE Lunar. Neither the document nor the information therein is to be reproduced, distributed,

used or disclosed, either in whole or in part, except as specifically authorized by GE Lunar.

Page 10

GE Medical Systems

LUNAR

b. Run two Daily QA’s and verify that they all pass (attach passing QA’s).

c. Start an additional Quality Assurance test and verify the function of the

Emergency Stop button by using it to stop the system

DOC ID: DXSE0012

REV: G DATE: 2/28/02 CO: L10173

11. With your voltmeter attached to TP 18, adjust R43 (see fig

6.2) until your voltmeter reads what you determined in step

6.

12. From the main menu press F3 System Quality Assurance

and place the System Standard on the table silk-screen with

brass insert up and at head end of table. Press[Esc] and

allow the QA to run in its entirety and to print out. Verify that

QA passes.

13. If peak value is not within 25 units of 500, record peak value

from the QA that was just run and the current voltage at TP

18. Using these values repeat steps A. 3-8 until Peak is

within 25 units of 500 and a complete passing QA has been

run.

i. Verify that all four-indicator lamps are functioning.

10. Perform an AP Spine scan of the aluminum phantom (attach results) see

DXQC0022 (DPX Series) or DXQC2022 (enCORE based systems).

a. Verify that the scanner is not “Hacksawing” – the edges on the spine

phantom image should be straight – if they are not

i. Verify that the front and rear transverse pulleys are tight

ii. Check for transverse binding

iii. If the transverse belt is loose tighten it.

iv. Prodigy Scanners – Run the Hacksaw test (DXAP2007).

b. The L2-L4 result should be within the expected range for the individual

phantom.

c. % Fat result in (water based phantoms) should be within 4 to 5%.

d. Verify that the Patient Positioning Switches and the Patient Locator Laser

are functioning.

11. Run a final Daily QA

12. Re check the last session in the error log and make sure it is free of hardware

errors.

13. Make a copy of the DEXA PM Check sheet for the customer, discuss any service

concerns with the system and explain work performed.

GENERATED RECORDS

DXSE0038 DEXA PM Quality record

QUALITY SYSTEM DOCUMENT Page 10 of 10

It is the responsibility of the user to verify this document originated from the controlled master and is the active revision prior to use.

This document contains confidential or proprietary information of GE Lunar. Neither the document nor the information therein is to be reproduced, distributed,

used or disclosed, either in whole or in part, except as specifically authorized by GE Lunar.

Loading...

Loading...