Page 1

Appliance Registration

Broiling

Care and Cleaning

Cooktop cooking

Electronic Range Control

clock

Oven/Timer Controls

Self-Clean Cycle Controls

Features

Installation

Electrical Supply

9

9

Lweling

Location

Stability Bracket

Light Bulb Replacement

Model and Serial Number

Oven Cooking

Oven Vent

Problem Solver

Recipes

Repair Service

Safety Instructions

Therxnostat Adjustment

4

4

14

8

Your Range

/.

.

‘-A-

--fv_L/$p,j-

Page 2

Help us

help you...

Read this book carefully.

It is intended to help you operate and

maintain your new range properlj

Keep i? handy for answers to your

questions. .

If you don’t understand something or

need more help, write (include your

phone number):

Consumer Affairs

RCA

Appliance PaA

Louisville, KY 40225

Write down the model and

serial numbers.

You’ll find them on a label on the front

of the range behind the lower storage

drawer panel.

Write these numbers into the space

below. Also write the numbers into the

space on the warranty card that came

with your range before you send the

card in.

If you received

a damaged range...

Immediately contact the dealer (or

builder) that sold you the range.

Save time and money.

Before you request

service ..

Check the Problem solver. It lists

causes bf minor operating problems

that you can correct yourself.

Model Number

Serial Number

Use these numbers in any correspon-

dence or service calls concerning your

ranae.

4

i+

i

CNOTO1

Page 3

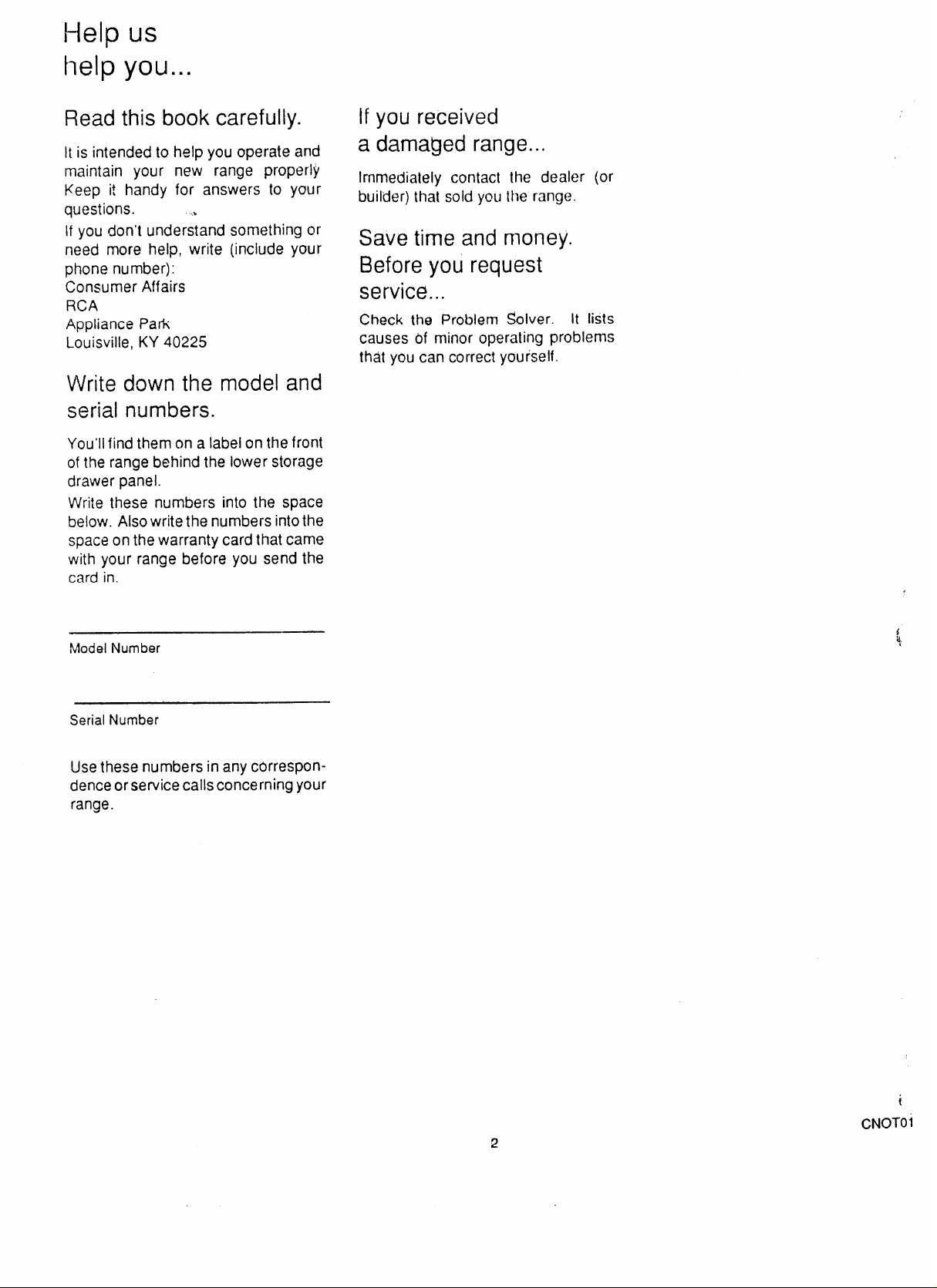

WARNING

A

s ALL RANGES CAN TIP

● INJURY COULD RESULT

● INSTALL ANTI-TIP BRACKET

PACKED WITH RANGE

● SEE iNSTRUCTIONS

STABILITY BRACKET INSTALLATION INSTRUCTIONS

FOR BRACKET KIT

NO. 342473

TOOLS NEEDED: Phillips head screwdriver

1-3/8” or adjustable wrench

Bracket attaches to floor or wall to hold either right or left rear

leg leveler. If fastening to floor, be sure that screws do not

penetrate electrical wiring or plumbing. If this cannot be

determined, use shorter screws that will not penetrate through

flooring.

If the bracket came with your range, it is shipped attached to

the lower range back. Remove and discard the shipping

screw that holds the bracket and then follow instructions

)elow.

1.2.Decide whether the bracket will be installed on the right or

left side of range location.

if the bracket side of the range is adjacent to a cabinet,

place the 5racket aga!nst ba;k 4wa!land cabinet as shown

in figurel.

If there is no adjacent cabinet, determine where the

adjacent cabinet

location of range side panel

or final

\

outside edge of bracket to be

flush with left or right side

location of the range side (painted outside pane!) will

be. Place the bracket with its outside edge at this location

and against back wall. See figure 1.

Determine whether you will anchor the bracket to the floor

3.

or wall. Fasten the bracket securely with the screws

provided. Screws are self-drilling in wood, plywood,

particle and chip board, and most metal framing. If

attaching to masonry you can buy suitable screws and

anchors at hardware stores. Use a masonry drill to drill

the required holes.

4.

Using the wrench, back out the four leg levelers at least

two turns. See your installation guide for more leveling

information before positioning range.

Slide the range into place. Be sure rear leg leveler fully

5.

engages slot in bracket. If range cannot be moved back

far enough for rear leg leveler to enter bracket, move

bracket forward as required and attach to floor in new

location.

bracket

Fig. 1

wall plate

screw must enter wood or metal

-x

Fig. 2

ATTACHMENT TO WALL

CINS06

Page 4

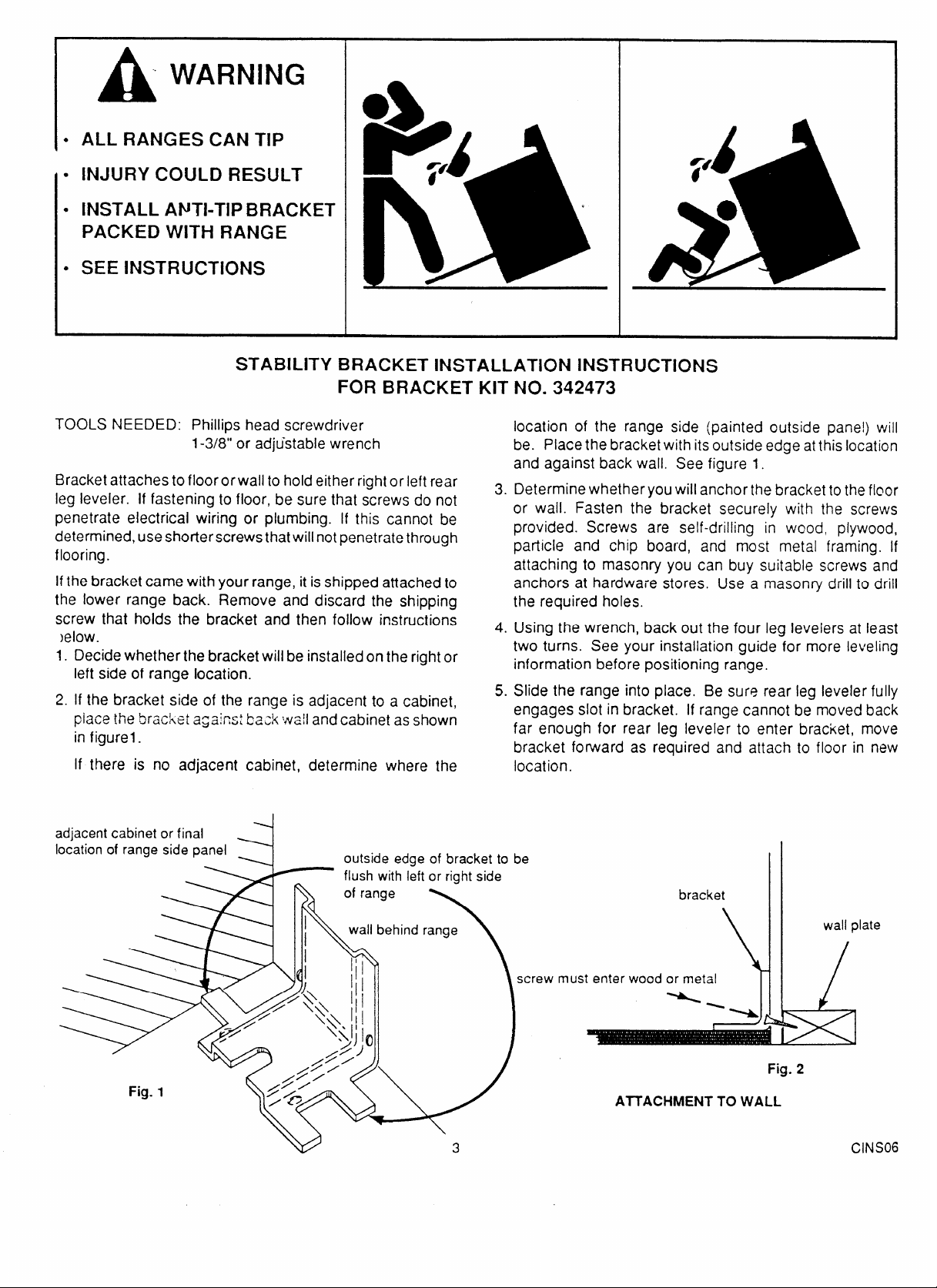

INSTALLATION

IMPORTANT: Save these instructions for the local electrical inspector’s use.

IIUUIUL

#

18” MIN

1~1

=====11

MINIMUMDIMENSIONSBETWEEN

Fig. 1

9

See Figures 1 and 2 for all rough-in and spacing

dimensions. These dimensions must be met for safe use

of your range. The location ofthe electrical outlet maybe

changed as needed, but electricity to the range can be

disconnected at the outlet without moving the range if the

outlet isinthe suggested location (remove lowerdrawer).

9

To eliminate the risk of bums or fire when reaching over

hot surface elements, cabinet storage space above the

cooktop should be avoided. Ifcabinet storage space is to

,*LN,~—’

1 - I$;N t

I=

COOKTOPANDWALLS

ABOVE COOKTOP

I

1

I

I

I

\\ I

0-

UGGESTEDELECTRICAL

-1

Fig. 2

be provided above the cooktop, the risk can be reduced

by installing a range hood that sticksout at least 5“ beyond

the front of the cabinets. Cabinets installed above

cooktop may be no deeper than 13“.

●

The range may be placed with O“clearance (flush) at W

back wall and side walls of the range if the front edges of

the range side panels stick out beyond the cabinet fronts

at least 1/4”. See Figure 2.

ROUGHED-INDIMENSIONS

. . . .

..

J i

1

I

\

OUTLET AREA

I

I &4 1/2”

2 1/4”

I

a

PREPARATION

1. Remove alltape and packaging. Be sure to remove clear

plastic film that covers some chrome parts (around glass

oven doors, side trim) and any tape or packaging from

inside the oven.

2. Take the accessory pack out of the oven.

3. Check to be sure that no range parts have come loose

during shipping.

4. Remove the shipping wire from each of the four cooktop

elements (coil cooktop element models only).

5. For proper cooking and baking the range must be leveled:

a. Install the oven racks (see use and care section for

instructions).

b. Use a 1-3/8” open end wrench or an adjustable wrench

to equally back out the four leg levelers two or three

turns each.

c. Put a spirit level or a glass measuring cup partially

filled with water, on one of the oven racks.

d. Use the wrench to adjust the leg levelers.

EINS06-3

Page 5

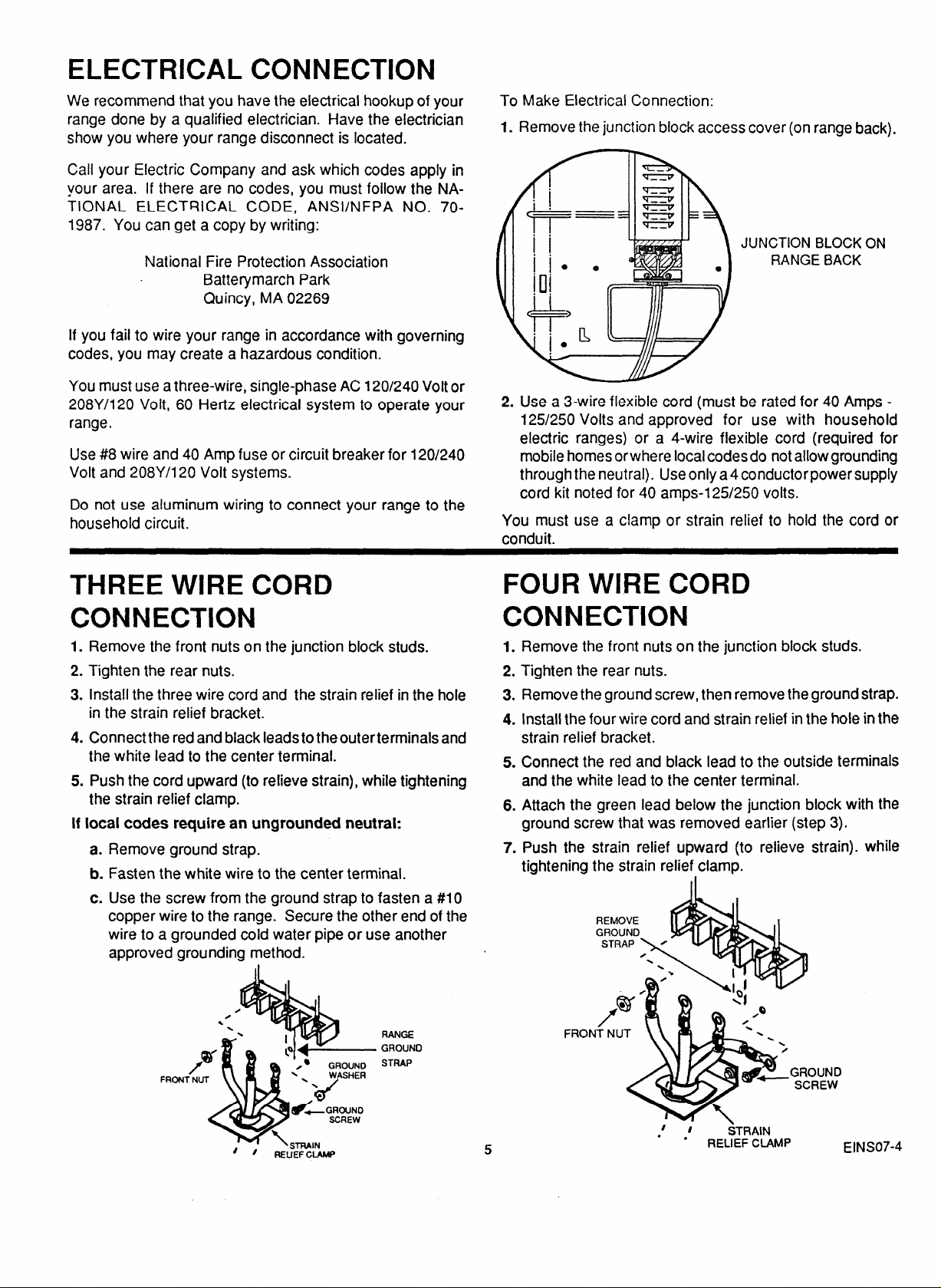

ELECTRICAL CONNECTION

We recommend that you have the electrical hookup of your

range done by a qualified electrician. Have the electrician

show you where your range disconnect is located.

Call your Electric Company and ask which codes apply in

your area. If there are no codes, you must follow the NATIONAL ELECTRICAL CODE, ANS1/NFPA NO. 70-

1987. You can get a copy by writing:

National Fire Protection Association

Battery march Park

Quincy, MA 02269

If you fail to wire your range in accordance with governing

codes, you may create a hazardous condition.

To Make Electrical Connection:

1. Remove the junction block access cover (on range back).

JUNCTION

BLOCK

RANGE BACK

ON

You must use a three-wire, single-phase AC 120/240 Volt or

2t)8Y/120 Volt, 60 Hertz electrical system to operate your

range.

Use #8 wire and 40 Amp fuse or circuit breaker for 120/240

Volt and 208Y/120 Volt systems.

Do not use aluminum wiring to connect your range to the

household circuit.

THREE WIRE CORD

CONNECTION

1.

Remove the front nuts on the junction block studs.

2.

Tighten the rear nuts.

Install the three wire cord and the strain relief in the hole

3.

in the strain relief bracket.

4.

Connect the red and black Ieadstotheouter terminals and

the white lead to the center terminal.

5.

Push the cord upward (to re!ieve strain), while tightening

the strain relief clamp.

If local codes require an ungrounded neutral:

Remove ground strap.

a.

Fasten the white wire to the center terminal.

b.

Use the screw from the ground strap to fasten a #1O

c.

copper wire to the range. Secure the other end of the

wire to a grounded cold water pipe or use another

approved grounding method.

2.

Use a 3-wire flexible cord (must be rated for 40 Amps 125/250 Volts and approved for use with household

electric ranges) or a 4-wire flexible cord (required for

mobile homes or where local codes do not allow grounding

through the neutral). Use only a4 conductor power supply

cord kit noted for 40 amps-125/250 volts.

You must use a clamp or strain relief to hold the cord or

conduit.

FOUR WIRE CORD

CONNECTION

1. Remove the front nuts on the junction block studs.

2. Tighten the rear nuts.

3. Remove the ground screw, then remove the ground strap.

4. Install the four wire cord and strain relief in the hole in the

strain relief bracket.

5. Connect the red and black lead to the outside terminals

and the white lead to the center terminal.

6. Attach the green lead below the junction block with the

ground scr~w that was removed earlier (step 3).

7. Push the strain relief upward (to relieve strain). while

tightening the strain relief clamp.

REMOVE

GROUND

STRAP \“ - WI

/

,

f i

‘~ GROUND

/- -

\

STRAIN

?EUEF CXA&lP

SCREW

RANGE

GROUND

STRAP

t

e

t #-

● ☛

/

%

%#L—

K

iiTRAIN

RELIEFCLAMP

GROUND

SCREW

EINS07-4

Page 6

HVIPC)RTANT VWTRUC7’IONS

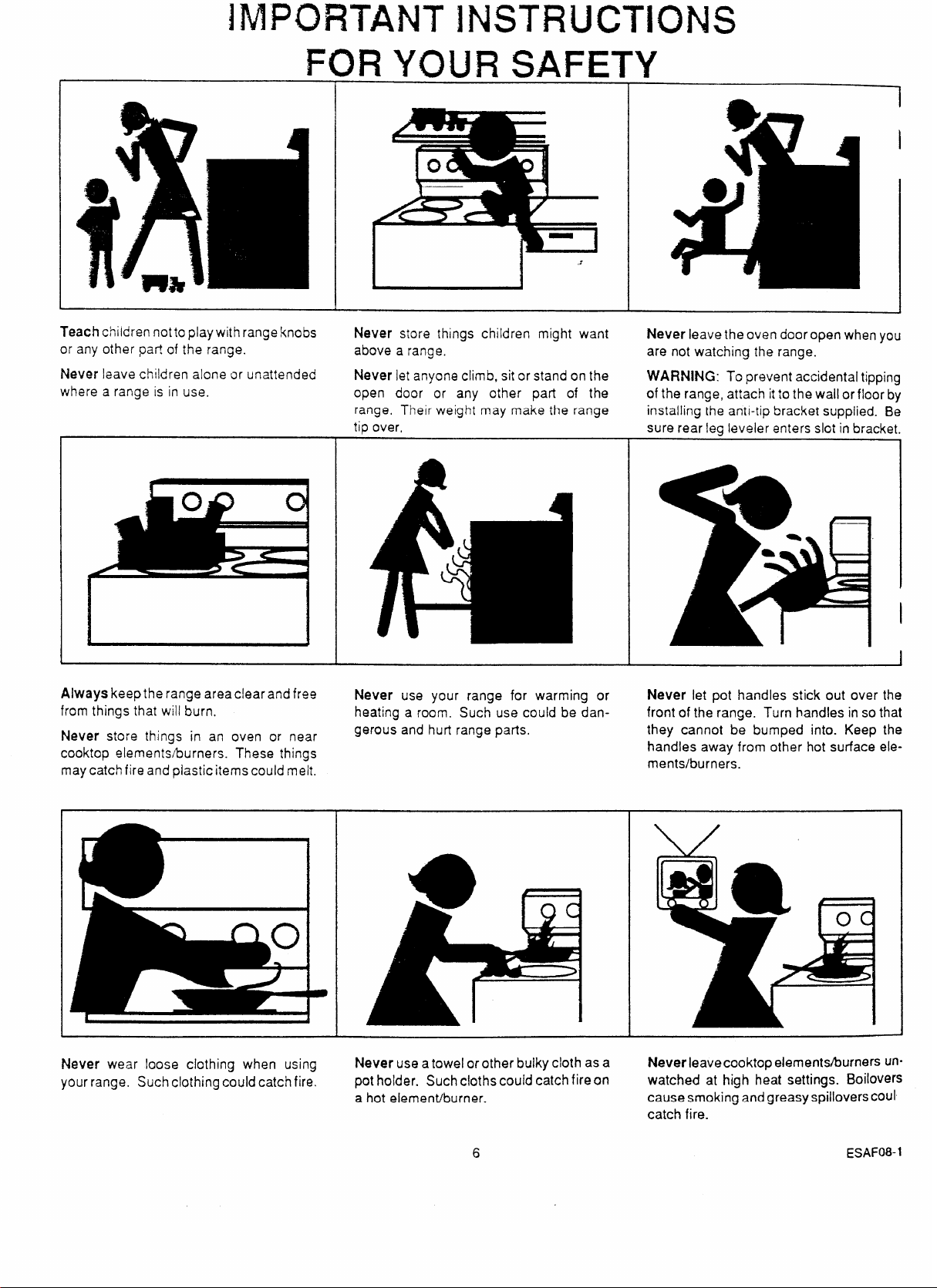

Teach children notto play with range knobs

or

any other pa-! of the range.

Never leave

where a range is in use.

children alone or unattended

FOR

Never store things children might want

above a range,

Never

open

range. Their weight may make the range

ti~ over,

YOUR SAFETY

let anyone climb, sit or stand on the

door or any other part of the

I

I

Never Ieavetheoven door open when you

are not watching the range.

WARNING: To prevent accidental tipping

of the range, attach it to the wall or floor by

installing the anti-tip bracket supplied. Be

sure rear !eg leveler enters slot in bracket.

I

Always keep the range area c!earand fres

from things that will burn.

store things in an oven or near

Never

cooktop elements/burners.

may catch fire and plastic items could melt.

Never wear loose clothinq when usinq

your range. Such clothing c;uld catchfir~

These things

Never use your range for warming or

heating a room. Such use could be dan-

gerous and hurt range parts.

Never use a

pot holder.

a hot element/burner.

towel or other buiky cloth as a

Such cloths could catch fireon

I

J

Never let pot handles stick out over the

front of the range. Turn handles in so that

they cannot be bumped into. Keep the

handles away from other hot surface elements/burners.

Never leave cooktop element shurners un”

watched at high heat settings. Boilovers

cause smoking and greasy spillovers COUI

catch fire.

6

ESAF08-1

Page 7

DO■ ==

DON’T...

Keep this book for later use.

le sure your range is installed

properly.

Choose pots acd pans with flat bottoms, large

enough to cover the entire cooktop element.

will cut down the risk of setting pot holders or

clothing on fire with an uncovered element and

waste less energy.

and grounded

This

Always use care when touching cooktop ele-

ments, areas near cooktop elements, oven heat-

ing elements or inside the oven. tieating ele-

ments could be hot enough to burn you even if they

are dark in color.

door may also become hot during range use.

Only some kinds of glass or ceramic pans can be

used for cooktop cooking. Be

you use will not

elements.

The oven vent duct and oven

sure that the pan

break when heated on the cooktop

Always change oven rack positions while oven is

cool.

Mter broiling, always take the broiler pan out of the

ange and clean it. Leftover grease in

pan can catch on fire next time you use the pan.

the broiler

Always use dry pot holders when removing pans

from the oven orcooktop. Moist or damp potholders can cause steam burns.

Always use care when opening oven door. Let

hot air and steam out before moving food.

Never tryto repair or replace any part of the range

unless instructions are given in this book. All other

work should be done by a skilled technician.

Never heat unopened food containers. Pressure

build up may make container burst and cause

injury.

Never leave jars or cans of fat or drippings on or

near the range. Never let grease build

range. You can keep grease fires from statiing if

you clean up grease and spills after each range

use.

upon your

Never use aluminum foil to line drip bowls or oven

bottoms. Improper use of foil could start a fire.

Never block free airflow through the oven vent.

Never try to move a pan of hot fat, especially a

deep fat

fryer. Wait until the fat has cooled.

Never put removable heating elements in water.

Never use the cooktop without reflector pans or

drip bowls being in place. If these pans or bowls

are not there during cooking, wiring or other range

parts may be damaged (does not apply to ranges

with solid disk cooktop elements).

Never rub, move or damage the door gasket on

self-cleaning ranges. The gasket is essential

good seal. Only clean the gasket by soaking it

with hydrogen peroxide, as described in the selfclean section of the manual.

for a

Always follow cleaning instructions in this book.

Always remove the broiler pan and other utensils

from the oven before a self-clean cycle.

Never use water on a grease fire -it will only

spread the flames.

COOKTOP GREASE FIRE

Never pick up a flaming pan...lnstead:

1.Turn off the element.

2. Smother the fire with a tightly fitting pan

lid, baking soda or an extinguisher.

OVEN FIRE

1.Close oven door and turn controls off.

If fire continues, throw baking soda on the

2.

fire.

ESAF13-1

Page 8

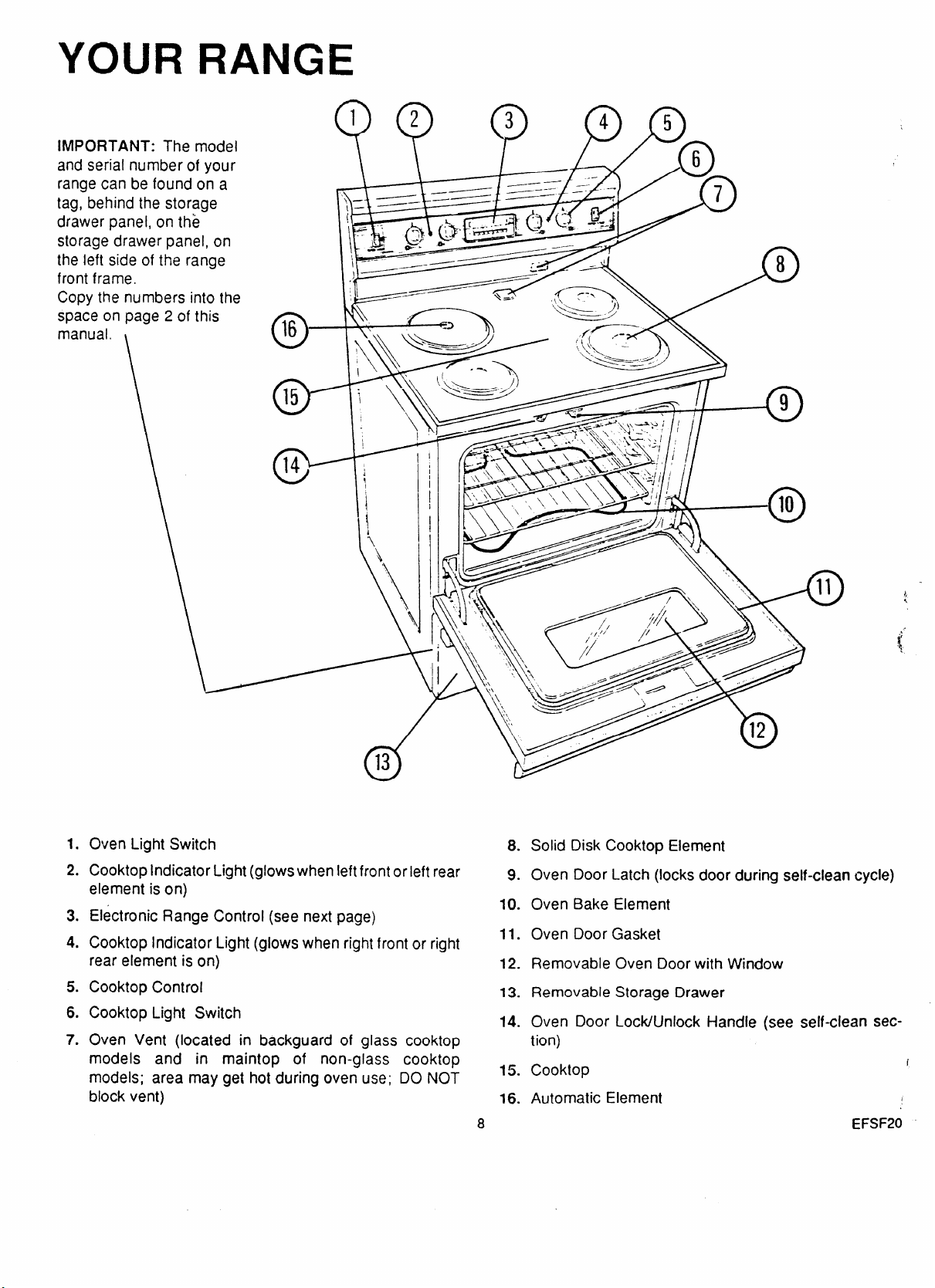

YOUR RANGE

IMPORTANT: The model

and serial number of your

range can be found on a

tag, behind the storage

drawer panel, on the

storage drawer panel, on

the left side of the range

front frame.

Copy the numbers into the

space on page 2 of this

manual.

\

w Pp’m

-r.

I

I

\

13

a

1.

Oven Light Switch

2.

Cooktop Indicator Light (glows when left front or left rear

element is on)

Electronic Range Control (see next page)

3.

4.

Cooktop indicator Light (glows when right front or right

rear element is on)

5.

Cooktop Control

6.

Cooktop Light Switch

7.

Oven Vent (located in backguard of glass cooktop

models and in maintop of non-glass cooktop

models; area may get hot during oven use; DO NOT

block vent)

‘(

8.

Solid Disk Cooktop Element

9.

Oven Door Latch (locks door during self-clean cycle)

10.

Oven Bake Element

11.

Oven Door Gasket

12.

Removable Oven Door with Window

13.

Removable Storage Drawer

14.

Oven Door LocidUnlock Handle (see self-clean section)

15.

Cooktop

16.

Automatic Element

8

EFSF20

(

1

Page 9

The Electronic Range Control

ERC)

1

0-

2

o

\

1.

OVEN CANCEL BUTTON - Cancels everything

except the clock and timer. Push this button to

turn the oven off or to clear everything if you’ve

made a mistake in programming.

5

P

COOK TIME - Push before setting length of

9.

cook time for automatic oven operations.

10.

CLEAN - Push to use self-clean cycle.

DISPLAY INDICATORS - Light up to tell you

2.

what is being shown in the TIME DISPLAY

WINDOW.

TIME DISPLAY WINDOW - Shows the time of

3.

day or the times you set for me timer or auto-

matic oven operation.

4.

OVEN TEMPERATURE AND BROIL DISPLAY

WINDOW - Shows the oven temperature or broil

setting you have selected.

FUNCTION INDICATORS - Light up to show

5.

whether oven is baking, broiling or self-cleaning.

SET KNOB - Turn to set times and tempera-

6.

tures after pushing a function button.

7–13 FUNCTION BUTTONS

BAKE - Push before setting bake temperature.

7.

BROIL - Push before seiecting BROiL setting.

8.

STOP TIME - Push before selecting the time

11.

when you want the oven to turn off for automatic

oven operations.

CLOCK - Push before setting clock or to bring

12.

time of day into the TIME DISPLAY WiNDOW.

TIMER - Push before setting amount of time.

13.

TO SET THE CLOCK

Turn to set ~

time of day

/

CANCEL

@f~

;f:

BI?OL

Q

>

J

BAKE

x

*

\

SET

\

CERC03-3

Page 10

Start Things

Cookingf

Cooktc)p Cooking

Before using the solid disk elements for

A

A

To properly cure the solid elements, heat each element at the

highest setting, without a pan on the element.

There will be some non-toxic smoke and odor and the rings

around the elements will change to a gold color. All this is

normal. Heat the elements for 3 to 5 minutes — until the

smoking stops.

Solid disk elements are made from a flat heavy casting ofthe

same type of material as cast ironskillets. Cast iron reaches

temperature gradually and evenly and holds the heat very

weli.

Cast iron must be kept dry to prevent rust. It is normal for

cast iron to lose its luster as it ages. See the Cleaning Tips

inthis manual for information on cleaning and restoring ap-

pearance of solid disk elements.

the first time, you must cure them to

harden the protective coating for long

life. If the elements are not cured properly, the coating can stick to your pan

and remove some of the finish on the

element. See instructions below.

Do not use decorative element covers on solid disk elements. These covers can trap moisture and promote rusting.

The red dot inthe center of some of the elements isforfactoty

identification only. It can be removed by scouring.

Some cooking processes will differ from those you may be

used to with coil elements. Cooking times for some foods

may change because solid disk elements will take longer to

heat up and cool down. Heat-up and cool-down times will

depend on initial temperature setting, quaiity of utensil and

amount of food being cooked.

Cooking performance Is directly related to the use of

proper pans.

In order to obtain top performance from your solid disk

elements your cookware must be

ofa heavy gauge material. Use atight-fitting lidwhenever

possible. An out-of-shape pan without a

cook with the same speed and evenness as a pan with a flat

bottom and

Heat cannot transfer properly from the element to the pan if

the pan bottom is only near the element. The pan and

element should actually touch each other across the entire

pan bottom.

a tight fitting lid.

flat on the bottom and be

lid cannot possibly

10

EMTC05-4

Page 11

Many pans have a slight depression in the center of the pan

bottom. Some cookware has circular ridges in the pan

bottom. Many older pans have become warped from overheating in the past. None of these pans will give top

performance on any type of electric cooking element be-

cause they do not make contact with the element across the

,ntire pan bottom.

COOKWARE TIPS

●

Pans must have flat bottoms and should have straight

sides and lightweight handles that do not tilt the pans.

●

Pans must cover the entire element to absorb the full heat

output. They should be the same size or slightly larger

(not more than 1” overhang) than the element.

9

Use tight fitting lids to shorten cooking time and allow food

to cook in a minimum amount of liquid.

●

Be sure that specialty pans such as woks, lobster pots,

pressure cookers, french fryers, griddles etc. meet the

same standards as other pans: flat bottom, balanced,

correct size and covered, if applicable. Use only flat

bottomed woks on solid disk elements.

●

Use canners that do not extend more than 1 inch beyond

the solid disk element. Be sure the canner has a flat

bottom. When canners do not meet these standards the

use of the high heat setting may cause the heat to become

excessive and may result in damage to the cooktop.

●

Place pans on the elements before controls are turned on

to conserve energy.

CAUTION

A

cooktop

and the heat retention characteristics of the cast iron

used for the elements, will cause the cooktop to get

hotter than you might be used to with open coil

elements and stay hot Iongerafter the elements have

been turned off.

Please use care when working around your cooktop

when any surface elements are on or when the cooktop

has not had time to cool after surface element use.

I

The cooktop could get hot enough to burn you,

especially during prolonged surface element use.

clamped securely to the cooktop to keep

spills from flowing in to the area below the

as happens with open coil elements. This,

— The solid disk elements are

SETTING COOKTOP CONTROLS

Be sure that the cooktop elements have been cured as

described on previous page, before first use.

The sign near each cooktop control knob shows which

element is turned on by that knob.

00 00 00 00

00 ● 0 00 00

Left Left Right

Rear Front

Rear

Right

Front

Pan Too Small

Warped Pan

CORRECT

Pan Bottom Flat / Pan Sits Level

Pan Covers Entire Element

INCORRECT

Warped Pan

Waqmd Pan

Heavy

Handle

Tilts Pan

To operate cooktop controls:

1. Push to turn. The control knobs for the regular cooktop

element turn in any direction. The knob for the automatic

element turns in the counterclockwise direction only.

2. Set on or between marks for desired heat.

The indicator light will glow when any cooktop element is on

8

7

5

REGULAR ELEMENT COOKTOP CONTROL

(shown here with settings numbered-to be used with chart on next page)

The elements have a built-in temperature protection device

which protects the element and your pan from excessive

(damaging) heat. If the element is left turned on without a

pan, or if a pan boils dry, the excess heat buildup will be

detected and power will be reduced to the element. If your

pans do not have a flat bottom and there is space between

the element and some parts of the pan bottom, this limiter

may detect excessive temperatures and automatically turn

the element down.

EMTC2&l

Page 12

THE AUTOMATIC ELEMENT

The automatic cooktop element (left rear) has a sensor in its

center. The sensor detects the temperature of the pan

bottom and compares itwith yourselected control setting. The

automatic element then supplies heat as needed. The auto-

matic element always begins with full power, no matter

where the cooktop control is set. When the temperature of

your selected setting has been reached, the element cycles

on and off to maintain that temperature, similar to your oven.

In order for the setlsorto work efficiently, you should keep it

clean and free moving.

When the correct setting has been selected, the pan does

not haveto be watched. The automatic element will not burn

food when the correct setting is selected. Food may dry out

The following chart is merely a guide to the suitable control

settings. Consider raising the setting for larger quantities,

uneven pan bottoms or uncovered pans, and for pan mate-

rialstilat are slow to conduct heat (such as cast iron). Lower

the setting forsmaller quantities and pan materials that heat

quickly (such as aluminum).

The regular element supplies heat at a constant power at

each setting. It heats whether the food needs more heat or

not. With the regular element the power is always on, unless

if left too long, but the sensor will

overheat beyond the selected setting.

Using the proper pan and lid, food will cook whether or nc

steam is visible. Cooking time does not depend on visitjt

steam. The automatic element cycles on and off as heat;-

needed. It is normal not to see activity, such as bubbling a,

steaming, during the time that the heat has cycled off.

If you feel that a heat setting should be changed, change it

gradually. Allow time for the element to adjust to the new

setting. Changing settings will be more satisfactory when

the increased setting is within one or two markings on the

control.

the control is turned off. After you start at a higher setting to

bring the food up to cooking temperature, turn the control

down to the lowest setting that will keep the food cooking.

The automatic element will always start with full power

(regardless of your control setting) and will continue to cycle

on and off, holding the temperature at the control setting you

have selected. It adds only the amount of heat necessary to

maintain the setting.

not let the food or the pan

See the illustration @fthe regular element control knob on the previous page. The marks for the knobs have been numbered

so that you can easily find the suggested setting (from chart) on your control knob. The automatic element control knob is

numbered on your range.

AUTOMATIC ‘

ELEMENT

SETTING

5-7

7-9

9-10

8-10

8-10

9-10

LO-3

3-4

LO-2

3-4

OPERATION

BOILING

Large Amounts

(over 1 quart)

Small Amounts

(under 1 quart)

BROWNING

FRYING

SIMMERING

MELTING Chocolate

FOOD

Macaroni Products

Vegetables 7-8

Meats 6-7

Bacon 6-7

Eggs

Meats

Potatoes

Vegetables

Gravies

6utter

REGULAR ELEMENT

SE”rTING TO START

9

4-6

6-7

7-8 7-8

2-3

4-6

1-2

6-7

SETTING TO FINISH

6-7 9-12

7-8

6-7

6-7

4-6

5-6

2-3

3-4

1-2

6-7

12

EMTC21

Page 13

TO BAKE OR ROAST

AUTOMATIC OVEN ON AND OFF

PUSH WHEN

3

FINISHED

9

e

[-

l!

I

CANCEL

\

,[. .–-. —

I

;

I

TIME > /~*:/~/ ~y ~

I

L__ ___ ___ ____________ .___>

I

“MER cLOcK TIME

I-h-m ;, ;

‘Top CLEAN

;::

The red display will show the oven

it rises (in 5° steps).

A tone will sound when the oven is

AUTOMATIC OVEN OFF

TURN TO SET

~:::l::v?

TURN TO *

SET TEMP

— —

PUSH 1

BROIL

“>

BAKE

I

c)

temperature as

ready.

TURN TO

SET LENGTH

OF COOK

TIME

?

\

SET

f

—--

I

,

—..

CANCEL

<–D~LAy

OVEN /- .,STOP :-/

TIME

L.–. _

TURN TO

SET TEMP

.—

j l-l J~rJ”_

● ~/ ~f BAKE !& 1

..~’

TURN TO SET OVEN

TURN OFF

TIME (TIME

OF DAY)

?

SET

I

I

CLEAN ;;;

‘lP*ER cLOcK TIME

J

\

‘Top

I

BROIL BAKE

1

I

J

(l-J@@

PUSH PUSH

When cook time has ended, atone will sound and the oven

will turn off.

TO USE THE TIMER

TURN TO

SET AMOUNT

OF TIME

PUSH

4

I I

BROIL 1 BAKE

/ 1

I

[

!

I

“MER cLOcK

,

! I

‘TopCLEAN ;::

TIME

The ERC will calcula~e when to turn the oven off.

When the stop time is reached, a tone will sound and the

oven will turn off.

INCOMPLETE OR INCORRECT

SETTINGS

1. Attention Tone will sound if oven has only been partially

programmed. For example, if you have selected a cook

time but no temperature, you will hear the Attention Tone

until you select a temperature or push CANCEL.

2. Function Error Tone will sound if there is a problem with

one of the range functions, Cancel the tone by pushing

the CANCEL button. If the tone starts again, call for

service.

RECALLING FUNCTIONS

You may recall any se{ function by pushing the button of that

Jnction.

1

d

:ANCEL

( 1 ) PUSH

TIMER

~

t

BROIL BAKE

(3)

PUSH AND HOLD

SET

J

W 3 SECONDS TO CANCEL

A tone will sound when time is up.

NOTE: Thetimerisa reminderonlyand will not operate

the oven.

CANCELLING TONES

If you prefer that your range not have a tone whenever you

push a button, you can eliminate tones by pushing and

holding the CANCEL button until you hear a beep. Repeat

to activate tones again.

PREHEATING FOR AUTOMATIC OVEN

OPERATIONS

Cookthes programmed for automatic oven operations start

counting down when the oven first comes on, not when it has

reached the set temperatures. It takes 10 tol 5 minutes to

reach the set temperature, thus additional cook time may be

necessary.

13

cCTL04-2

Page 14

..........

....

.... .. .. .

;,:’ .....

.,, . . .

.. . ... . . .. ...

.. . . .

.......

. ..

. .. . . . ... .

Let the oven preheat thoroughly before

cooking baked products. Allow 10-15 min-

utes preheat time.

m

Oven Cooking

●

Always follow recipe carefully.

●

Measure ingredients properly.

●

Use proper pan placement.

●

Place pans on the oven racks with 1% - 2“ of

air space on all sides of each pan.

overcrowding the oven.

Avoid

Avoid opening the door too often to check

the food during baking as heat will be lost

This may result in poor baking results.

Cakes, cookies, muffins, and quick breao.

should be baked in shiny pans — to reflect

the heat

golden crust. Yeast breads and pie crusts

should be baked in glass or dull (non-shiny

pans) — to absorb the heat — because they

should have a brown, crisp crust.

— because they should have a light

9

Pans too close to each other, to oven walls

or to the oven bottom block the

ment of air. Improper air movement causes

uneven browning and

cake layers

2

● Most baking should be done on the second

shelf position from the bottom. When baking

several items, use two shelves placed on the

second and fourth rack positions from the

bottom of the oven. Stagger pans so that no

pan is directly above another.

food cakes on the first shelf position from

the bottom of the oven.

cooking.

4 cake Iayera

free move-

Bake angel

Oven temperatures should be reduced 25

degrees below recommended temperature:

if you use dark pans or oven proof glass.

There may be some odor when the oven !.

first used. This is caused by the heating of

new parts and insulation.

Do not cover the c)ven bottom or an entire

oven rack with foil. The foil can block normal heat flow, cause cooking failures, and

damage the oven interior.

14

CoVcol

Page 15

Broiling

Turn to set

3 Push When

Finished

?

~’!

i\

;ANCEL

Most foods can be broiled at the HI Broil Setting. Select the

LO Broil setting to avoid excessive browning or drying of

foods that should be cooked to the well-done stage (such

as thick pork chops or poultry).

~“,~ “

;

‘

L.. ___ _______ -- -J

“MER cLOcK Tl!/lE

/

:1 “ l-l n:+ ,

It ●f It /6 ROILE !

CLEAN ;:EK

‘Top

BROILING TIPS

●

Your oven door should be open to the broil stop

position while broiling. If the door is closed, the

food will roast and not broil.

●

Use only the broiler pan and grid that came with your

range for broiling. They are designed for proper

drainage of fat and liquids and help prevent spatter,

smoke or fire.

8

Do not preheat when broiling. For even broiling on

both sides, start the food on a cold pan.

.

When broiling frozen meat, use one rack position lower

than recommended and

gested bt-oiling time.

●

Trim the outer layer of fat from steaks and chops. Slit

the fa:;~ ~@es to keep the meat from curiing.

●

For maximum juiciness, salt the first side just before

turning the meat. Salt the second side just before

serving.

●

Brush chicken and fish with butter several times as

they broil When broiling fish, grease the grid to keep it

from sticking and broil with skin side down. It is not

necessary to turn fish.

9

Never leave a soiled broiler pan in the range.

Grease in the pan may smoke or burn the next time the

oven is use.

●

Be sure you know the correct procedure for putting

out a grease fire. See the section on safety.

1A

h

I AA

1~

Do not cover the entire broiler grid

with foil. Poor drainage of hot fat

may cause a broiler fire.

If a fire starts, c!osetheoven door

and turn controls off. If fire continues, throw baking soda on the fire.

Do not put water on the fire.

up to 1 1/2 times the sug-

I

BROIL

\

?

2 HI orLC)

Broil

‘~

SET

BAKE

1 Push

t)

POSITIONING BROILER PAN

Broiling is cooking by direct heat from the broil element.

Tender cuts of meat or marinated meat should be selected

for broiling. For best results steaks should beat least 3/4”

thick.

After placing food on the broiler pan, put the pan on an oven

rack in the proper position. The recommended rack position and cooking time can be found in the chart below

The closer the food is to the broil element, the faster the

meat browns on the outside, yet stays red to pink in the

center. Moving the meat farther away from the element lets

the meat cook to the center while browning outside. Side

one should be cooked 1 -2 minutes longe~ than side two.

Rack

Position Total Time

Food 4 = Highest (minutes)

1 = Lowest

Steak -1” Thick

Rare

Medium

Well Done

Ground Beef Patties

Medium-1” Thick

Medium-1/2° Thick 4

——.—

Lamb Chops -1” Thick

Pork Chops – 1” Thick

.———.—.. ——. ..—..—

Pork Chops 1/2” Thick

Ham Slice - l/2’’Thick

-—

Fish (Fillets)

Chicken ( Pieces)

Frankfurters 3

———

Bacon

This chart is a genera{ guide. The size, weight, thickness,

and starting temperature of the food as well as your own

personaI preference will affect the cooking time. Times in

the chart are based on the food being at refrigerator temperature.

15

—

4 9-11

3

3

3

3

3

3

3

3

2

3

13-15

21-23

16-18

7-9

18-21

27-29

16-18

11-12

11-13

45-55

8-11

9-11

--1

Page 16

Favorite American Recipes

A Collection from Around the Country

LAZY-DAY COFFEE CAKE

3/4 cup margarine, softened

1 cup sugar

2 eggs

1 cup sour cream

2 cups all-purpose flour

1 teaspoon baking powder

1 teaspoon soda

7/2 teaspoon salt

1 teaspoon nutmeg

3/4 cup light brown sugar

1/2 cup chopped pecans

1 teaspoon cinnamon

Cream margarine and sugar until light and fluffy. Add eggs and sour cream; mix well. Combine flour, baking powder, soda,

salt and nutmeg. Add to batter and mix well. Pour batter into greased and floured 13” x 9“ x 2“ baking pan.

Combine brown sugar, pecans and cinnamon; mix well. Sprinkle one half of this mixture over cake batter; swid mixture

through batter. Sprinkle remaining one half mixture evenly over cake batter.

.,

,,.

“A

Cover and chill overnight. Uncover and bake in preheated 350° F oven for 35 to 45 minutes or until cake tests done with

toothpick.

BROCCOLI CASSEROLE

2-10 oz. pkg. frozen chopped broccoli

1 cup mayonnaise

7 cup sharp cheddar cheese, grated

2 eggs, beaten s/ight/y

1 can cream of mushroom soup

2 tablespoons chopped onion

7 cup cheese cracker crumbs

Preheat oven to 375° F. Cook broccoli according to package directions; drain.

Mix with other ingredients. Pour into greased two (2) quart casserole. Sprinkle

with cheese cracker crumbs. Bake at 375° F for 20-25 minutes.

SOUTHERN BRUNSWICK STEW

A delicious quick-to-make hearty stew that will feed a crowd or feed the family. Refrigerate or freeze the remainder for

another day.

1-10 oz. can barbecue beef

1-10 oz. can barbecue pork

1-24 oz. can Brunswick stew

1-5 oz. can boneless chicken

1-12 oz. can vacuum packed corn niblets

1-16 oz. can baby lima beans, drained

2-76 oz. cans stewed tomatoes

1- 14’/2oz. can sliced okra, drained

Drain okra and lima beans. Add to all other ingredients in 4 quart

pan, Heat on medium to serving temperature.

16

CRCPO1-1

Page 17

43

u

5

u

-.

(D

-.

“b

=

4

-.

-.

x

m

:

m

r

m

0

m

02

0

.,,

m

a

-f

w

m

a

o

1-

n

1-

m

c)

1

a

2

s=-’

Page 18

The Self-Clean Cycle

BEFORE A CLEAN CYCLE

1.2.Remove ttlebroilpan andgrid, oven racks, allutensilsand

any foil that maybe inlheoven. Do nottrytoclean utensils

or any other objects in the oven during a self-clean cycle.

Ifoven racks are left in the range during a clean cycle, they

will darken, Ioso their luster and become hard to slide. If

you choose to leave the racks in the oven, you can polish

the edges of the racks with steel wool and apply a small

amount of vegetable oil to the rack edges after the selfclean cycle. This will make the racks easier to slide.

Soil on the oven front frame, under the front edge of the

ccmktop, the door liner outside the door seal and the front

edge of the oven cavity (about 1” into the oven) will not be

cleaned during a clean cycle (see illustration below).

Clean these areas by hand before starting a clean cycle.

Use hot water with a soap-filled steel wool pad, then rinse

well.

FRONT FRAME

.—

I-—_ ---

-----

.

“ ““-”11

4. Clean the door seal by using a clean sponge to soak the

soiled area with hydrogen peroxide.

maybe needed depending on the amount of soil. Frequent

cleaning will help prevent excessive soil build up. DO nOt

rub the door seal. The fiberglass material of the seal h

an extremely low resistance to abrasion. An intact anb

well fitting oven door seal is essential for energy effici’

oven operation and good baking results. If you notice ~.

seal becoming worn, frayed or damaged in any way or if

it has become displaced on the door, YOUshould replace

the seal.

Repealed soaking

AFTER A CLEAN CYCLE

After a clean cycle, you may notice some white ash in the

oven. Just wipe it up with a damp cloth.

If white spots remain, remove them with a soap-filled steel

WOOIpad. De sure to rinse ttloroughly with a vinegar and

waler mixture. These deposits are usually a salt residue that

cannot be removed by the clean cycle.

If the oven is not clean after one clean cycle, the cycle may

be repeated.

ill “ s

1’

-- ._

,,

I /’

Iz!r

1( ~y

—-.. ..—.-—._

~~==--

3. Wipe up heavy spillovers on the oven bottom. Too much

soil may cause smoking during the clean cycle.

-.-*.---—-

--.—

.—=-———--==—

-. .

L

I

r?

I

In

———.

‘X&l!)’!

-- .—

PORCELAIN ENAMELED

BOWLS (some models)

Some ranges have grey porcetain enameled cooktop element bowls. The bowls can be cleaned in the oven during the

self-clean cycfe. Place them on the oven racks.

Do not put the chrome trim rings in the oven. Doing so will

discolor and warp them.

18

ESCLOI-1

Page 19

TO SET SELF-CLEAN CYCLE

TO INTERRUPT A CLEAN

1. Slide door lock handle to the right. You may

need to slightly press

lock properly.

—1

.-

on the door to get it to

o

SE-r

1=

__lE!

2 PUSH

o

The self-clean cycle lasts 3-1/2 hours.

When the oven reaches locking temperature the

word LOCK will be shown in the ERC display.

You can push STOP TIME BUITON to find out

when the cycle will end. Push CLEAN BUTTON

to return to count down.

CYCLE

1 PUSH

?

:ANCEL

Then follow instructions under WHEN A CLEAN

CYCLE IS FINISHED

\

TIMER CLOCK :My

cl ‘-”

J

WHEN A CLEAN CYCLE IS

FINISHED

WAIT UNTIL 1

LOCK GOES OUT

(20-30 minutes)

Q,

2. Slide door lock handle to the left.

After a clean cycle the oven door cannot be

unlocked unless the word LOCK is off in the ERC

display and the oven has cooled.

NEVER force the door iock/unlock

handle. Forcing the

door lock mechanism.

m

“MER CLWK TIME

‘Top

CLEAN T,~

- BROIL BAKE

handle may damage the

?

Q

t

19

CSCL02-1

Page 20

Cleaning Tips

On the following pages, all removable parts on

shown.

r

I

Refer to those pages when cleaning your range.

PART

Control panel knobs

Solid Disk Elements

Detergent, warm water, soft cloth

Scouring powder, Scotch Brite Scour Pad@

CLEANING MATERIALS

your range are

warm,

water. a mild detergent and a soft clo!h are safe lo use on

all

cleanable parls of your rang~.

All purpose cleaners, such as

Fantastlk@, can also be used.

Do not use metal scouring

DO not use abrasive

easier cleaning.

Wipe with damp c]o!h after each use. Use the

mildest cleaning procedure that will dothejob. Rub

in the direction of the circular ridges. Rinse thoroughly and dry completely by heating element at a

medium setting. Cast iron will rust if not dried

completely. To restore appearance if elements

become dull, apply a small amount of salt-free

vegetable out with a paper towel (expect a Iittie

smoking at next use) or use ELCO or ELECTROL

solid element dressing (available at Sears).

pads, except where recommended.

—.——

REMARKS-

cleaners. Knobs pull off for

‘----------+

—.-—

Stainless steel trim rings and

automatic element sensor

Porcelain enameled cooktop

I

Brushed chrome cooktop

I

(some models)

I

I

Glass

I

Stainless steel scourer or baking soda

Detergent, warm water, plastic or nylon scouring pad

Detergent, warm water, soft cloth orachrome

cleaner or Sears Cooktop Cleaning Creme

Tousebaking soda, sprinkle ondampclothormake

paste with water. With normal element use, the trim

rings and

characteristic

performance. The original silver

stored by using a stainless steel scourer.

Clean after each spillover. Soak stubborn soil.

Do not scour chrome tops. Stubborn stains maybe

removed by using Espree tvlagwheel Cleaner@ or

Turtle Wax Polishing Compound~@. To

ger prints on brushed chrome, apply a little baby oil

with

brushed chrome, apply a little baby oil with a paper

towel. Rub in the direction of the brush

marks. Armor All Protestant T can also be used

(after cleaning). E3e sure to clean spills of acidic

foods quickly. Vinegar spills can permanently stain

chrome.

sensor change to a gold color. This is a

of stainless steel and does not affect

color can be re-

— —

remove fin-

a paper towel. Rub in the direction of the

If cleaning methods described above prove ineffective, baked-on food residue or stains on chrome

cooktops can be removed by using p@typeoven cleaners.

arecausticand will damage painted or aluminum surfaces,

Use extreme

such as range sides, backguard or control

caution. Oven cleaners

panes. Do not use spray type oven cleaners. Overspray will damage nearby painted surfaces and

heating elements. Use several layers of newspaper and masking tape to cover surfaces such as the

backguard, control panel,

disk elements), burner bowls, grates, etc. Apply the ~ type ovencleaner evenly to the entire top

range sides, countertops, etc.

Remove

cooktop elements (except solid

surface. The entire top must be cleaned to keep the finish consistent in color. Use extreme caution

to prevent the oven cleaner from coming in contact with any other surface, Let the cleaner remain

on the top for 20-30 minutes. Rinse the top well to remove every trace of oven cleaner. Dry the top

and apply Armor All Protestant@ to protect the finish.

Glasscleaner and paper towels

Remove stubborn soil with paste of baking soda

and water. Do not use abrasive cleaners. Rinse

thoroughly.

Oven interior

I

Oven door gasket

Detergent, warm water and/or soap filled

steel wool pad

Hydrogen peroxide

20

Clean inside the oven need only be done as an

optional touch -up between self -clean cycles. Rinse

oven interior thoroughly after cleaning.

Soak with hydrogen peroxide, using a ‘

sponge. Fequent soaking helps prevent soil build- I

up.

DO not rub. See self-clean section for more

information.

—————— ..—..—.

__–_-J

ECCH12

Page 21

REMWABLE OVEN RACKS

Be careful not to scratch the oven finish when installing

or removing oven racks.

To install:

1. Set the raised back edge of the rack on a pair of rack

guides.

J Push the rack in until you reach the bump in the rack

-.

guide, then lift the front of the rack and push the rack

all

the way in.

To remove:

1. Pull the oven rack out, then up.

REMOVABLE OVEN DOOR

To remove:

1. Open the door to the stop position (see illustration).

2. Grasp the door at each side and lift up and off the

hinges.

NOTE: When the door is removed and hinge arms are at

stop position, do not bump or try to move the hinge arms.

The hinges could snap back causing an injury to the

hands or damage to the porcelain on the front of the

range. Cover the hinges with toweling or empty towel

‘oIIs while working in the oven area.

To replace:

1. Hold the door over the hinges with the slots at the

bottom edge of the door !ir?ed up with the binges The

hinge arms must still be in the stop postion.

2. Slide the door down onto the hinges as far as it will go

and close the door.

REMOVABLE STORAGE DRAWER

This drawer gives you space for keeping cookware and

bakeware. Plastics and flammable material should not be

kept in this drawer.

Do not overload the storage drawer. If the drawer is too

heavy, it may slip off the track when opened. To open the

drawer, grasp the center of the handle and pull straight

out.

To remove: pull drawer straight out and lift over the guide

stops.

To replace: lift over the guide stops and slide drawer into

place.

STOP POSITION

!

/

~,

‘\- : .,,

v

‘NIV

/

/’

* //

.

/’,.

.

GUIDE STOP

h

\

‘%

L

;1

!1

Q.’

21

cMNT(ll-1

Page 22

REMOVABLE KNOBS

All control knobs may be removed for easy cleaning by

pulling the knob straight off the stem. Be sure that the knob

is in the OFF position before removal.

Hint: Slip a thin cloth (such as a handkerchief) or a piece of

string under and around the knob edge and pull up.

Caution: Read these instructions carefully before re-

placing the knobs. Replacing the knobs improperly will

damage the knc~s and the spring clips on the stems. If

this happens, the knovs will fit loosely.

To replace the knob:

1. The knob stem has a groove in each side. The groove on

one side has a spring clip. The other groove is clear (see

illustration).

2. Check the inside of the knob and find the molded rib.

3. Replace the knobby fitting the molded rib inside the knob

into the c!ear groove on the stem.

REPLACING THE OVEN LIGHT

MOLDED

RIB

I CLEAR

GROOVE IN STEM

Be sure that the light switch is in the off position.

Do not touch hot oven bulb. Do not touch bulb with wet

hands. Never wipe oven light area with wet cloth.

Never touch the electrically live metal collar on the bulb

when replacing it.

Electrical power must be shut off if you have to replace

a broken bulb.

1.Remove the three screws and lift off the glass retainer,

glass cover and gasket.

2. Replace the bulb with a 40 watt appliance bulb.

3. Replace the gasket, glass

retainer. Tighten screws securely.

cover and glass

REPLACING COOKTOP LIGHT AND

STARTER

Do not touch the bulb when it is hot or with wet

hands. Never wipe light

power must be shut off if you have to replace

bulb.

To replace bulb:

1. Flip front of the hinged canopy up.

2. Remove bulb. Replace the bulb with one of the same

length and wattage.

3. Lower the canopy.

To replace starter:

1. Open canopy and remove bulb as explained above.

2. Grasp starter, turn it counterclockwise, about one quarter

turn and lift out. Replace with one of the same wattage.

3. Reposition bulb and lower the canopy.

area with a wet cloth. Electrical

a broken

BULB

~

R~~~~R+\

SOCK

/

J

BULB

COLLAR

\

GASKET

s

\ ,\

J

v

BULB

GLASS “

COVER

-. .... . .

22

EMNT18

Page 23

Problem Solver

Gave timeand money --Check this list before you call for service.

eliminate unnecessary service calls. first, read all the instructions in this manual carefully. Then, if you have a problem,

~,ways check this list of common problems and possible solutions before you call for service,

PROBLEM

● Range does not work;

totally inoperative.

● Oven does not heat;

cooktop elements OK

● Cooktop does not work;

oven OK

● Foods do not bake prop-

erly

I

● Oven temperature seems

inaccurate

POSSIBLE CAUSE

“ No power to range.

● Clock set incorrectly (on models

so equipped)

● Oven controls set incorrectly

● Door latch in incorrect position (self-

clean models only)

● Element(s) unplugged

● Improper operation of control

Oven not preheated long enough

Improper rack or pan placement

Oven vent blocked or covered

Improper use of foil

Improper temperature setting

for

utensil used

Recipe not followed

Range and oven rack not Ieve

● Using improper cookware

● Thermostat calibration

DON’T CALL FOR SERVICE

UNTIL YOU CHECK

● Check household circuit breaker or fuse.

● Check powercord to be sure it isplugged

in.

● Check clock instructions

● Check oven control instructions.

. Check self-clean instructions.

s Check element connections by remov-

ing and re-plugging element(s) firmly.

● Be sure knob is pushed in while turning

●

Be sure to pre-heat:

10 minutes below 350 degrees

15 minutes above 350 degrees

●

Maintain uniform air space around pans

and utensils; see cooking hints section.

●

Reflector

bowl must have hole in center

over oven vent.

●

Foil use

●

Reduce temperature 25 degrees for glass

not recommended

or dull/darkeced pans.

●

is recipe tested and reliable?

●

Check the installation section for leveling

instructions (models with leg levelers

only)

● See oven cooking section.

● See adjustments described on the

following page.

23

ESER13-I

Page 24

Before Calling for Service

PROBLEM

D Foods do not broil prop-

erly

● Oven smokes

c Oven or work light does

not work (if equipped)

“ Oven does not clean or

poor cleaning results

(Self clean models only)

● Oven door will not un-

lock (Self clean models

only)

● Tone does not sound

POSSIBLE CAUSE

s Improper rack position

● Oven preheated

“ improper utensil used

s Oven door closed during

broil

s Improper broiling time

● Dirty oven

● Broiler pan containing grease

left in oven

s Light switch in off position

● Light bulb or fluorescent light

starter burned out

● Controls not set properly

● Clean cycle interrupted too

soon

G Oven too dirly

s Clean cycle not complete

● Tone has been eliminated by

pushing and holding CANCEL

button

DON’T CALL FOR SERVICE

UNTIL YOU CHECK

● Check broil pan placement. See broilin~

section.

● Do not preheat when broiling.

● Use broiler pan and grid supplied with range.

● Open door to broil stop position; see remov-

able oven door section.

● Check broiling chart in broiling section.

● Check for heavy spiliover.

● Clean pan and grid after each use.

= Check switch setting; see operating instruc-

tions.

● Check or replace light bulb; see use and care

instructions.

● Check self clean instructions.

● Heavily soiled ovens require a 3 1/2 hour

clean cycle.

● Heavy spillovers should be removed before

settina clean cycle. Repeat clean cycle.

● Oven must cool below lock temperature 1

(approximately 30 minutes after clean cycle if

complete).

s Push and hold CANCEL button to activate

tone.

1

I

I

I

I

● t-teavilysoiled or stained

chrome cooktop cannot

● Spills were not wiped up

promptly

be satisfactorily cleaned

ADJUSTING OVEN TEMPERATURE

The temperature in your new range has been set correctly at

the factory, so be sure to follow the recipe temperatures and

times thefirst few times you bake in your new oven.

If you think the oven should be hotter or cooler, you can

adjust it yourself. To decide how much to change the temperature, set the oven temperature 25’F higher or lower than

the temperature in your recipe, then bake. The results of this

“test” should give you an idea of how much the temperature

should be changed.

To adjust temperature:

1. Push the BAKE button.

2. Select the temperature between 500°F and 550”F with

the SET knob.

Q See the instructions, under Cleaning Tips, for

cleaning chrome cooktops with oven

cleaner. This procedure requires extreme

caution. Read instructions carefully.

3.

Quickly (within two seconds, before the BAKE function

energizes) push and hold the BAKE button.

The display will change to the amount of degrees difference between the original factory temperature setting and

the current temperature setting. If the oven temperature

has the original factory setting, the display will read 00.

4.

The temperature can be adjusted Up to 35°F hotter or

35°F cooler (in 5°F steps), by turning the SET knob. A

minus sign (-) before the number means that the oven will

be cooler by displayed amount of degrees.

When you have made the desired adjustment, push thm

5.

CLOCK button to go back to the time of day display or~

your oven as you would normally.

Note: The self -clean temperature

will not be changed by...~

adjustments described above.

24

ESER04-5

Page 25

f You Need Service

To obtain service, set? your warranty

on the back page of this book.

We’re proud of our service and want

you to be pleased. If for some reason

you are not happy with the service you

receive, here are three steps to follow

for further help.

FIRST, contact the people who serviced your appliance. Explain why you

are not pleased. In most cases, this

will solve the problem.

NEXT, if you are still not pleased, write

all the details-including your phone

number-to:

Manager, Consumer Relations

RCA

Appliance Park

Louisville, Kentucky 40225

FINALLY, if your problem is still not

‘esolved, write:

Major Appliance

Consumer Action Panel

20 North Wacker Drive

Chicago, Illinois 60606

25

CSEROl

Page 26

YOUR RCA RANGE

WARRANTY

Save proof of original purchase date such as your sales slip or cancelled check to establish warranty period.

—.—c

quality products and service.

fulfill your

WHAT IS COVERED

FULL ONE-YEAR WARRANTY

For one year from the date of

original purchase, we will provide,

free of charge, parts and service

labor in your home to repair or

replace any part of the range that

fails because of a manufacturing

defect.

This warranty is extended to the

original purchaser and any succeed-

ing owner for products purchased for

ordinary home use in the 48 main-

land stales, Hawaii and Washington,

D.C.

In Alaska the warranty is the

same except that it is LIMITED

because you must pay to ship the

product to the service shop or for the

service technician’s travel costs to

your home.

— .—-—._________

We at RCA strive to provide the high-

est

Therefore, we have designated

CONSUMER SERVICE, a leader in

the service industry, to

service needs. Should your appliance

need service, during the warranty

period or beyond, look in the White or

Yellow pages of your telephone

directory for GE CONSUMER SERV-

ICE or an AUTHORIZED

ANCE SERVICER.

—.

GE

RCA APPLl-

I

I

WHAT IS NOT COVERED

Some

states do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you. This warranty gives you specific legal rights, and you may also have

other rights which vary from state to state. To know what your legal rights are in your state,

consult your local or state consumer affairs office or your state’s Attorney General.

If further help is needed concerning this warranty, write:

● Service trips to your home to teach

you how to use the product.

Read your Use and Care material.

If you then have any questions

about operating the product,

please contact your dealer or our

Consumer Affairs office at address

below.

● Improper installation.

If you have an installation problem,

contact your dealer or installer. You

are responsible for providing ade-

quate electrical, plumbing and other

connecting facilities.

Warrantor: RCA Appliances

Manager—Consumer Affairs, RCA,

Appliance Park, Louisville, KY 40225

c Replacement of house fuses or

resetting of circuit breakers.

● Failure of the product if it is used ‘

for other than its intended purpose or

used commercially.

● Damage to product caused by

accident, fire, floods or acts of God.

WARRANTOR IS

SIBLE FOR CONSEQUENTIAL

DAMAGES.

NOT RESPON-

—

.—

I

.-

I

L3B355GL (24

~

L3B360GL (2498)

Loading...

Loading...