Page 1

..

.—

——.. .-

~

ApplianceRegistration

Burner Ignition 11

Care and Cleaning 14,15

Cooktop cooking 11

Features

10

Installation 4-7

Adjustments

ElectricalConnections

Gas Comections 5,6

Location

Modeland Serial Number 2

ProblemSolver 16

Recipes 12,13

RepairSemice 17

SafetyInstructions 8,9

Wamrlty

Back Cover

u

2

7

5

..

4

. .

%.

Page 2

?-k?lpLls

.—

Readthis book carefully.

His intendedto help youoperateand

maintainyour new counterunit properly Keepithandy for answersto your

questions.

if youdon’t understandsomethingor

need more help, write (include your

phonenumber):

ConsumerAffairs

RCA

AppliancePark

Louisville,KY 40225

Writedown the model and

serialnumbers.

You’llfindthemon alabelintheburner

box,underthe lift-up cooktop.

Writethese numbers inlo the space

below. Alsowritethenumbersintothe

space on th6 warrantycardthatcame

wjthyourcounterunitbeforeyousend

the card in.

youreceived

damagedcounterunit..

Immediately contact the dealer (or

builder)that sold youthe range.

Savetimeandmoney.

Beforeyou request

serVlce...

Check the Problem Solver, It lists

causes of minor operating problems

that you can correctyourself.

ModelNumber

SerialNumber

Use these numbersin anycorrespon-

dence~rservkecallsconcerningyour

counter unit.

Page 3

/

Y

Ifyou smellgas:

1.Openvvimbm.

2. Don’ttouch electricalswitches.

DOnotstoreor usegasolineorother

flammablevapors and liquidsinthe

vicinityofthisoranyotherappliance.

3. Extinguishanyopen flame.

4. knmediatdy callyourgassupplier

\ A

r

M? Burner

.-

Theadjustments inthe Installation Section rm.Jstbe

made before you try to use your range.

Hfyouare using Gas (bottled

gas) all L.f? adjustments inthe Installation Section

must be made before use.

Hyour appliance is not properly adjusted, flames

maybetoo high,orthe appliancemayusetoo much

fuel, release toxic fumes or cook poorly.

Page 4

me

LJs’r

Leavethese with

il’a!epWMw?’rmm’wmmsforfuture

use.

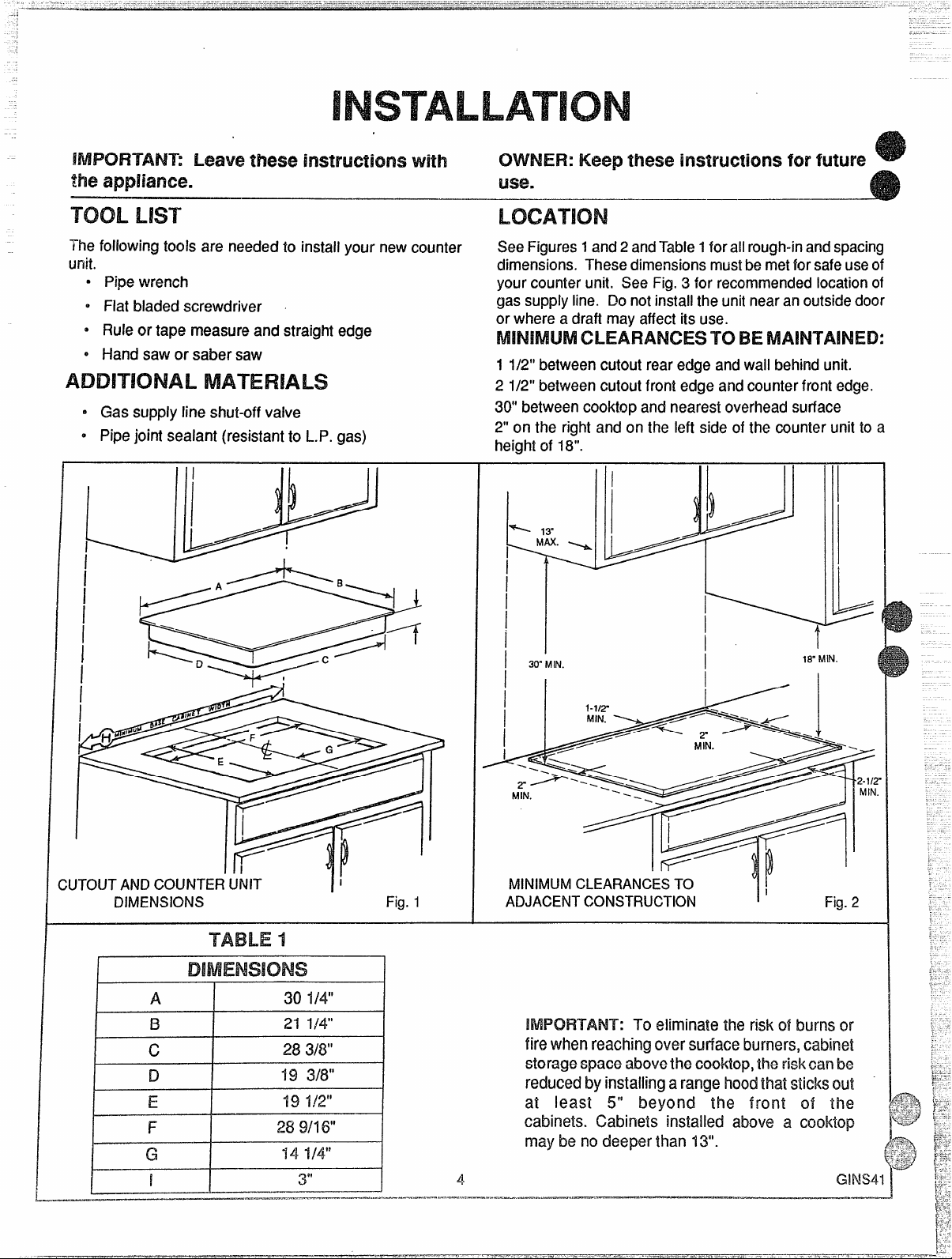

Thefollowing fools are neededto installyour new counter

unit.

● Pipewrench

e Flat Maded screwdriver

o Ruleor tape measureand straight edge

o Hand saw or saber saw

o Gas supply line shut-off valve

o Pipe joint sealant (resistantto L.P.gas)

I

I

I

SeeFigures1and2andTable1for allrough-inandspacing

dimensions. Thesedimensionsmustbemetforsafeuseof

yourcounterunit. See Fig,3 for recommendedlocationof

gassupplyline. Donot installthe unitnearanoutsidedoor

or where a draft may affect its use.

BE

1 1/2” betweencutout rear edge andwallbehindunit.

2 1/2”betweencutoutfront edge andcounterfrontedge.

3(Y’betweencooktopandnearestoverheadsurlace

2“ on the right and on the left side of the counterunitto a

heightof 18”.

I

30” MIN.

[

!

I

18”MN.

(

LJTOUTANDCOUNTERUNIT

DIMENSIONS

I

G

A

I

I

I

c

E

F

1

. . .. ... .. .... ... .... . ......... ..... ............ .... . .. . . .

I

I B

1

ID I

/

~~———~

——.—

1

301/4”

21 1/4”

28 3/8”

19 3/8”

19 1/2”

28!3/16“

14 1/4”

i

I

Fig.1

MINIMUMCLEARANCESTO

ADJACENTCONSTRUCTION Fig.2

‘1

I

1

I

To eliminate the risk of burns or

I

I

1

.4

fire when reaching over surfaceburners,cabinet

storagespaceabovethe cooktop,the riskcan be

reducedbyinstallingarange hoodthat sticks.out

at least 5“ beyond the front of Ihe

cabinets. Cabinets installed above a cooktop

may be no deeper than 13”.

GN’W41

.—-

Page 5

---dequatecounterspacemustbe providedfor the unit. The

- reashouldbe easyto reachandbelightedwithnaturallight

ringthe day.

Seethefirstpagefor cutoutdimensions. Markthe cutouton

thecounter, Usea handor saber sawto makethecut.

-n-E

ml

If you are installingIhe counter unit in a mobilehomeyou

must foliow the MANUFACTUREDHOME CONSTRUCTIONANDSAFETYSTANDARD,TITLE24CFR,Part3280

(formerlythe FederalStandardfor Mobile HomeConstruc-

tionandSafety,Title

notapply,youmustfollowtheSTANDARDFORMANUFACTUREDHOMEINSTALLATIONS1982(ManufacturedHome

Sites, Communities and Set-ups), ANSI A225.1-1984 or

loc@codes. Youcanget acopyofthestandardsbywriting.

Office of MobileHomeStandards

Callyour Eiectric Company and ask which codes apply in

ur area. If there are no codes, you must follow the

ATIONALELECTRICALCODE,ANS1/NFPANO.70-1987.

ou can get a copy of the code by writing:

National Fire ProtectionAssociation

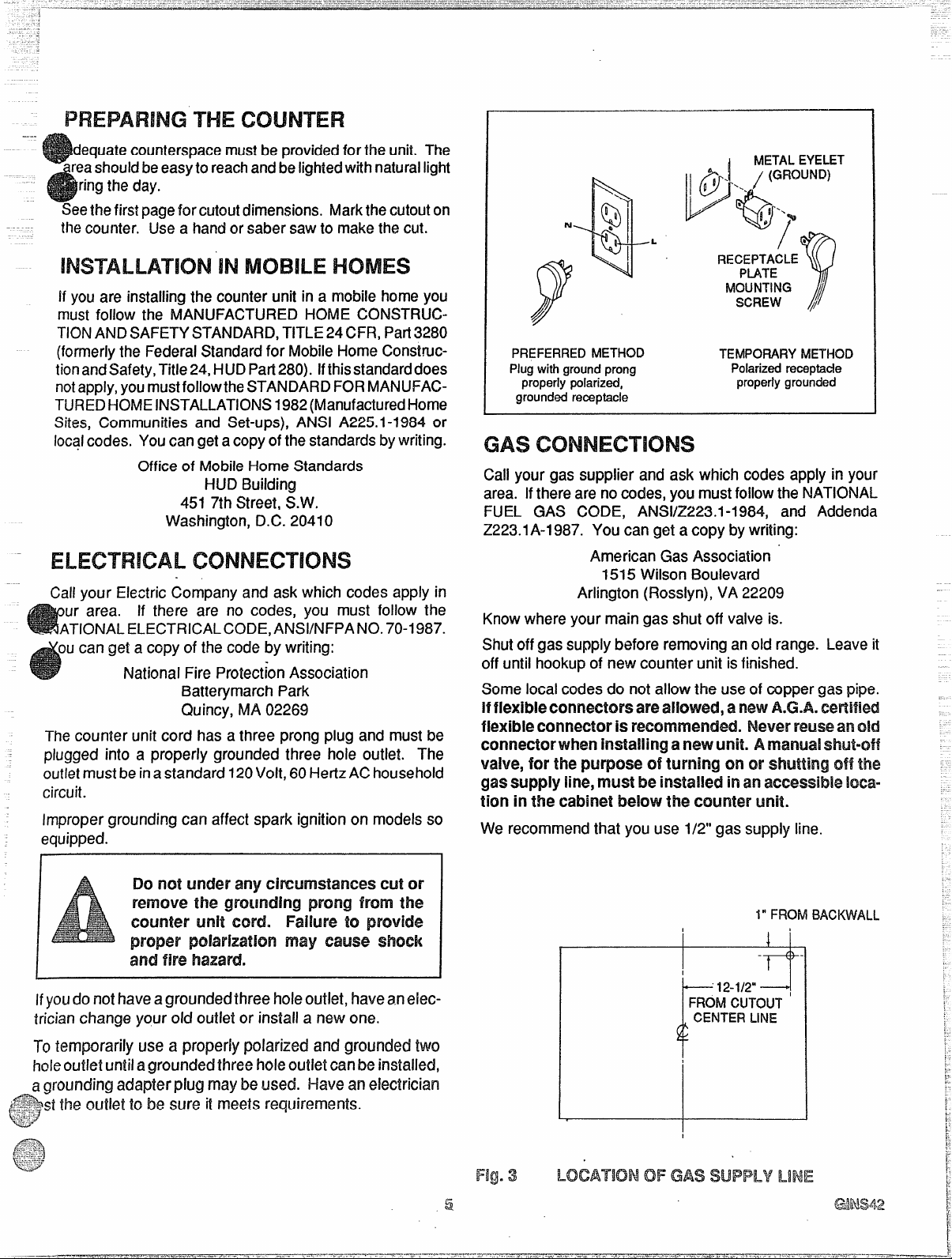

The counter unit cord has a three prong plug and must be

plugged into a properly grounded three hole outlet. The

outletmustbeinastandard120Volt, 60HertzAC household

circuit.

Impropergrounding can affect spark ignition on modelsso

equipped.

24, HUDPar1280).Ifthisstandarddoes

HUD Building

451 7th Street, S.W.

Washington, D.C.

. .

Batterymarch Park

Quincy, MA 02269

20410

i

METALEYELET

(y.../’G~ouND’

/’

V’$!!jj

PREFERREDMETHOD

Plug

withgraundprong

properlypolarized,

groundedreceptacle

Call your gas supplier and ask which codes apply in your

area. Ifthere are nocodes,you mustfoilowthe NATIONAL

FUEL GAS CODE, ANSi/Z223.l-1984, and Addenda

Z223.lA-1987. You can get a copy bywriting:

American Gas Association “

1515 Wilson Boulevard

Arlington (Rosslyn),VA 22209

Knowwhereyour main gas shut off valve is.

Shutoffgassupplybefore removing anoldrange. Leaveit

off until hookupof new counter unit isfinished.

Some local codes do not allow the useof copper gas pipe.

Hfiexibieccmectcm are alicmfed,a newMM.

fiexiblecmnectm is reccmmmled. Never

mnnectorwhen installing anewunit.

waive,W the purpose of turning cmor off the

gassuppiy iine,must be installed inan lcwa-

tion in the cabinet below the counter unit.

We recommend that you use 1/2” gas supply line.

~

s“,%

o

a

RECEPTACLE

MOUNTING

TEMPORARYMETHOD

/

PLATE

/

SCREW //

Polarizedreceptacle

properlygrounded

Y

notfumier any chfwnskmxix cut w

Do

remove the prong

Cxx.mkw’

p’qxw mayWwse SMlci(

I

ifyoudo not haveagroundecfthreeholeoutlet, haveamelec-

changeyouroldoutletorinstalianew one.

trician

Totwnporarilyuseaproperlypolarizedandgroundedbvo

and WJehazard.

unitCOrdo Failure toprovide

fromthe

holeoutletuntilagroundedthreeholeoutletcanbeinstaiied,

agrounding adapter plug may beused. Haveanelectrician

$&@stthfj o~t~~fto ~~ ~Uret meets requirements.

.,;—.-.----

+&

~?

1“FROMBACKVVALL

I

12-1/2”+

FROMCUTOUT

t-

CENTERLINE

f

{

I

Page 6

@m-at.)

Apressureregulatorissuppliedandmustbe installedinthe

gas supplylineunderthe unit. Installtheregulatorinthegas

supplyline between the shut off valve andtheunitmn-

riectkm(seeFigure5). Thetopof thereguiatorshouldface

towardthecabinetfrontandbeeasilyaccessiblethroughthe

cabinetdoors.

NOTE: the pressureregulatork setfornaturalgas. To

useL.P.gas,the regulatormustbe converted.

To convert for L.P. gas, unscrewthe cap and removethe

springretainer(see Figure4). Turnthespringretainerover

andput backintothe regulator. L.P.shouldbevisibleonthe

springretainer. Replacethe cap.

NAT. —

PRESSUREREGULATOR

t-

19-1/2”CUTOUT~

I

L.P,

i

II

Use a pipe wrench to make connections. Do not put any

strainon the connectinglineassembly.

Anyopeningsaroundgasandelectricoutletsmustbesealed

at the time of installation. When you are finished makin

connections,be sure that control knobsareturnedto OFF

beforeyouopen the maingas supplyvalve.

TO CHECK FOR LEAKS:

Apply a soapsolutionto all gas connections. Bubbleswill

formwhere andgas is leaking.

DO NOT use and open flameto lookfor leaks.

Turnoff main gas supply beforeyoutry to stop a leak.

Turnmaingas supplybackonandrecheckconnectionsafter

stoppinganyleaks.

Be sure all leaks are stopped before lighting pilots (some

models)or burners.

PRESSURETEST INFOFWIATION

Themaximumailowabletest pressureforthe regulatoris14“

W.C. Theminimumpressure neededtocheckthe regu!ator

setting is 7“ W.C. for naturalgas or 11”W.C.for L.P. gas.

CAUTION: The counter unit and its incfividuai shutoff

valvemustbe disconnectedfromthegassupplypiping

system during any pressure testing of the gas supply

system attest pressures in excess of 1/2 psig (pounds

per square inch gauge).

The counter unit must be isolatedfromthe gas supply

piping system by closing its individual shut otf wNv

duringanypressuretesting ofthe gassuppiysystem

test pressuresequal to or less than 1/2 psig.

3“ MIN.

SHUTOFF VALVE~

I

“1

I

1

I

I

I

Page 7

ift the cooktop (grasp at front) and remove the shipping

—

.+--\-

..——-. ————

—.————

crewfrom eachof thefoursurfaceburnerassemblies(see

ig. 7). Thescrewscan bediscarded.

M? GAS

CAUTION: the following adjustments must be

rnadebeforetwmingonthe burner.Failuretodoso

couki result in serious injury. Besure pressure

regulator has been converted as described an

previouspage.

Removethecontrol knobsandthecontrolpanel. Use

a 1/2” open end wrenchto turn the orifice hoodinthe

!-p. cfirecticm. See Figure 8. Turn the orifice hood

about 1 1/2turnsor until snug. Do notovertightenor

you may distortthe orificehoodandneedle.

The unit has been factory adjusted for use with the most

commontypeofnaturalgas. The gasusedinsomepartsof

the country may be different. In order to assuresafe and

energy efficient operation, check adjustments described

below. If you are using L.P. gas, the orifice hoods and

pressureregulator must beconvertedas describedabove,

before making any burner adjustments.

urnallburnersfullon andcheckthe flames. Elurnerfiames

shouldnotf!utterorblow away from the burner. Theyshould

eblue incolorwith no traceof yellow. Foreignparticlesin

egas line may cause an orangeflame atfirst, but this will

soondisappear.

Tomakeadjustments, removethe controlknobs andpanel.

Use pliers to adjust the air shutter. Be sureto keepthe gap

inthe air shutter facing straight up. Be very mrefui notto

bendthe air shutter when using piiers to make adjust-

ments.

~ SHIPPINGSCREW

I

Ifthe flames are yellow or flutter, open the airshuttermore.

If the flames blow away from the burner, close the shutter

more.

Checkthe irmercone of theflame. Hshouldbe about 11/16”

long. Ifthe Iengthofthe innerconeoftheflame isnotcorrect,

usea l/2’’open endwrenchoradjustablejointpliersto adjust

the orifice hood.

Toshorlenthe cones,tighten theorificehoodbyturning inthe

L.P.direction.

Tolengthen the cones, loosenthe orifice hoodbyturning in

Nat.direction.

the

+ llH6- ~

Fig.9

7

INNERCONE

OFFLAME

G!NS44

Page 8

.

1

I

Teachchildrennot to playwithcontrol

knobsoranyotherpartofthecounterunit.

Neverleavechildrenaloneorunattended

whereacounterunit is in use.

I

Alwayskeepthe counterunitareaclear

andfreefromthingsthatwillburn.

Neverstorethingsnearcooktopelements/

burners.Thesethingsmaycatchfireand

plasticitemscouldmelt.

CAUTION!Neverstorethingschildren

mightwantaboveacounterunit.

Neier letanyoneclimb,sitorstandonthe

counterunit.Theymightbecomeseverely

burned.

Neveruseyourcounterunitforwarmingor

heatinga room. Suchusecouldbedangerousanddamagecounterunitparts.

Neverleaveanovendooropenwhenyou

arenotwatchingtherange.

Neverletchildrensitorstandonanopen

ovendoor.

Neverlet pot handlesstickoutoverthe

frontofthecounterunit.Turnhandlesin

sothattheycannotbebumpedinto. Keep

thehandlesawayfromother

ments/

burners.

cooktopele-

r

Never wear loose clothing when using

your counter unit.

catchfire.

Such clothing could

Neveruseatowelorotherbulkyclothasa

potholder.Suchclothscouldcatchfireon

an~lement/burner.

8

NW&wleavecooktop@lQmQnts/burnersunwatchedat highheatsettings.l%iloveif.%~$:

causesmokingandgreasyspikwerscouk.’~’

catchfirQ.

<3

Page 9

o

❑ illif!lm

ep this book for lateruse.

13esureycwrcounterunitisinstaikdandgrounckxl

properlyby a qua!ifkxftechnician.

keepthe counter unit areaclear andfree

from things that will burn, gasoline and other

flammablevapors and liquids.

Only some kindsofglass orceramicpans can be

usedforcooktopcooking. 13esurethatthepanyou

use will not break when heated on the cooktop

burners.

Always use dry pot holderswhen removing pans

fromthe cooktop. Moistor damp potholderscan

causesteam burns.

Always follow cleaning instructions in this book.

Never try to repair or replace any part of the

counter unit unless instructionsare given in this

book. All other work should be done by a skilled

technician.

Never heatunopened food containers. Pressure

build up may make container burst and cause

injury.

Never leavejars or cans offat or drippingson or

nearthecounterunit. NeverIetgreasebuildupon

yourcounter unit. Youcankeepgreasefiresfrom

startingifyoucleanup greaseandspillsaftereach

counter unituse.

Never use aluminum foil to line drip bowls. improper use of foil could start a fire and cause

incompletecombustion.

Never blockthe flowofcombustionandventilation

air to cooktop burners.

Never try to move a pan of hot fat, especially a

deep fat fryer. Wait untilthe fat has cooled.

Fh%d

and Wlderstandthis Now!

youeverneedit, youWWnothave time

forreading.

it

Neverusewater m a grease

fire—

spreadmefkmws.

The CaliforniaSafeDrinkingWaterandToxicEnforcement

ACIrequires the

substancesknowntothe

~z

+f:pusirwsses towarncustomersofpotentialexposuretosuch

.-.

L

‘“substances.(MS appliancescancauseminorexposureto

mree ofthesesubstances,namelybenzene,formaldehyde

&

GovernorofCaliforniato publisha listof

statetocausecancerandrequires

Wiill only

Never pick up a

d.Turn otfthe burner.

2.SBmYther

the firewith a !&Ml lid,

Sxxh

or Vwmla dry or

type

andsoot,causedprimarilybytheincomplete

naturalgasorL.P.fuels. Properlyadjustedranges,indicated

abluishratherthanayellowflame,will minimize incxxm-

by

plete combustion.Exposureb these substancescanbe

minimizedfurlherbyventingwithanopenwindoworusing

aventilationkm or hood.

combustionof

9

C%3AF%8

Page 10

.

Porcelain enameled Burner Grate

1.

Removable Cooktop Burner

2.

Cooktop Controls

3.

I

4

(!)

4. Lift-Up Cooktop

5. Removable Chrome Drip Bowls

.“.

;

, . .

Page 11

.-

—— . —- .-.-———

/--> “

I

C(X)KKW SPARKiGN#TIWW—Whenyouturnthecooktop

knob lo LITE, the spark igniters make a series of electric

sparks(ticking sounds) which lights the burner.

TO OPERATE COfWTWLS—The sign near each cooktop

controlknobshowswhich burner is turned on by that knob.

Light burners before placing utensil on it.

I. Push to turn knob left to LITE,

2. Afterthe burnerlights, tUrnknobtodesiredf lamesetting.

MWORTNW: Do not leave the knob on L!TE after the

burner lights, or life of the spark igniter maybe shortened.

As a safety precaution you should set

cm?rds so flame heats pm bottom only

does notMM pan skfes. Flames

and

Wting pan sides are unsafe and waste

1

If a cooidop burner fails to light within five seconds, turn the

knob to OFF and wait one minute before trying again. Kthe

JVrner still wiH not light, check the service section in this

#’$-~

$.:-’%z+J[~@l,

~;;,

heat.

start

Watchfoods when heating them quicklyon H1.

thefoodreachescooking temperature,turndowntheheat.to

the lowest setting that will keep it cooking

Duringapowerfailurethe burnerswill notlightautomatically.

In an emergency, a cooktop burner maybe lit with a match

by following the steps below.

Lighting gas

dangerous. The fhmes can burn you or

a build-up of gas can explode. You

should match light the ccmktopburners

only in an emergency.

1. Lighta match and ho!dthe flame nearthe bwmeryouwant

to light. Wooden matches work best.

2. Push in and turn the control knob slowly. Be sureyouare

turning the correct knob for the burner you are Iigh!ing.

NOTE: If the burner does not light within five seconck,

turn the knob off and wait one minute before trying again.

burners with a match k

As soonas

.$

-i

1}

Gi’vf”rcl7-1

Page 12

Ame

3!4 cup margarine,softened

cupsugar

1

2 eggs

1

cupsour cream

2cups all-purposeflour

1teaspoonbakingpowder

1teaspoonsoda

li2 teaspOOn

1teaspoon

3/4cup light brownsugar

1:2 cup choppedpecans

1teaspooncinnamon

Creammargarineand sugaruntil lightandfluffy. Add eggsandsourcream;

saltand nutmeg.Add to batter and mix well. Pourbatterinto greasedand floured 13”x 9“ x 2“ baking Pan.

Combine brown sugar, pecansand cinnamon; mix well. Sprinkleone half of this mixture overcake batter;swirl mixture

through batter.Sprinkle remainingone half mixtureevenlyovercakebatter.

Coverand chill overnight. Uncover and bake in preheated350°Fovenfor 35to 45minutesor until caketests done with

toothpick.

salt

nutmeg

mixwell.Combineflour, bakingpowder,soda,

2-10 oz.pkg. frozenchoppedbroccoli

1cup mayonnaise

1cupsharpcheddarcheese,grated

2 eggs,beatenslightly

1can cream of mushroomsoup

2 tablespoonschopped onion

1cup cheese crackercrumbs

Preheatoven to 375°F.Cook broccoli according to packagedirections; drain.

Mix with other ingredients.Pourinto greasedtwo (2)quart casserole.Sprinkle

with cheesecracker crumbs. Bakeat 375°Ffor 2G25 minutes.

Adelicious quick-to-make hearty stew that will feed a crowd or feed the family.

another day.

1-10 oz. can barbecue beef

I -10 oz. can barbecuepork

7-24 oz. can Brunswick stew

“ -5 oz. can boneless chicken/

I -12 oz. can vacuum packed corn niblets

I -76 OZ.can baby lima beans,drained

2-16 oz. cansstewed tomatoes

~41/2Oz, can sliced okra, drained

~-

Refrigerate or freeze the remainder for

Drainokra and lima beans.Add to all other ingredients in 4quart

:xm. Heat on medium to serving

temperature.

Page 13

1/2cup margarine

/4 cup chopped greenpepper

7/3cup chopped onion

eggs,wellbeaten

oz.cancreamstyle corn

17oz.can whole kernel com with liquid

8?/2oz.p~g. corn muffin ‘ix

1cup cheddar cheese,shredded

Preheatovento 350°F. saute greenpeppers

withremainingingredientsexceptcheese,Pour into greasedtwo (2)quart cas-

serole;sprinkle with cheeseand bake45-55minutes in 350°Foven.Letstand 5

minutes beforeserving.

Courtesy:Illinois Cooperative Extension Homemakers

and onionin margarine;combine

2-1 oz.squaressemi-sweet chocolate

1stick margarine

1cup sugar

1/4cup flour

2 eggs

1tsp. vanilla

Dashsalt

1/2 cup chopped pecans

Frozen 9“ pie shell

Preheat oven to 350°F. Melt chocolate and margarine. Add other

ingredients to melted mixture. Pour ir]to unbaked pie shell and

bake 35-40minutes or until pie appears set. Servewarm with ice

cream or whipped cream.

w

1-20 oz. can apple pie filling

1/2cup sugar

1-9 oz. box white cake mix (1 layer size)

1stick margarine, melted

1,’2cup chopped pecans

Preheatovento 350°F. Placein layers in greased 9“ or 10” square baking dish:

apples,sugar, dry cake mix. Pour melted margarine over top of cake mix. Bake

at 350°F for 35 minutes. Sprinkle with pecans. Continue baking 15 minutes.

Servewarm.

.—.-—-?

- ..

.....

approximately 2 tablespoons ccmkor 8“ or 9“ square baking pan. Place

Tilt pan to coat bottom evenly. Mix

“into hot greased pan. Bake 20-25

13

CRCP32-I

Page 14

Referakmtortextpagewhencleartingyourcounterunit.Warm

water,a

cleanableparts of your counter unit. All purposecleaners,

suchas Fantastik~, can also be used (excepton cooktop

burners; see below). Do not use metal scouring pads,

excep$where recommended.

mild detergent mcf a softclotharesafeto useonall

CLEANING MATEFWKS

Cooktopfinisheswill beeitherporcelainenamelorbrushe

chrome. Porcelainenamellooks like a paintedsurfac

13rushecfchromehasa metallicappearance.

I COntrO\panel and knobs

I

Porcelainenameledcooktop,

chrome drip bowls (some

models),areaundercooktop,

burnergrates

Cooktop burners

Brushed chrome cooktop

Detergent,warmwater,softcloth

Detergent, warm water,.plastic or

nylonscouringpad

Detergent, warm water, plastic or

nylonscouring pador boil in Dip-it@

solutionto removestubbornsoil

Detergent,warm water, soft clothor

achromecleaneror specialcooktop

cleaning creme

Donotuseabrasivecleaners. Knobspulioff

for easiercleaning.

Clean after each spillovei, Rub chrome

bowls (some models) gently with scouring

pad. Soak stubborn soil. Bowls can be

removedduringburnerusetokeepcleanand

to avoid discolorationcausedby excessive

heat.

Do not use all-purposecleaners, ammonia,

powder cleansers or oven cleaners. Such

productscanscratchordiscolortheburners.

Touse Dip-it@solution,removeburnersand

boilfor20 minutesin2 Tbsp. Dip-it@granules

per quart of water. Boil with burner head

down. Rinse thoroughly, drain and completely dry burners in a 200°F oven for 1/2

hour. After cleaning or a spiliover, Iighfthe

burners and make sure that no ports are

clogged (see nextpage).

Do not scour chrome tops. Stubborn stains

maybe removedbyusingEspreeMagwheel

Cleaner@ or Turtle Wax Polishing Com-

pound@.Toremovefingerprints on brushed

chrome, apply a little baby oil with a paper

towel. Flub in the direction of the brush

marks. Armor All Protestant@can also be

used (aftercleaning). 13esure to clean spills

of acidic foods quickly. Vinegar spills can

permanently stain chrome.

1

Ifcleaning methodsdescribed above

proveineffective,baked-onfoodresidueorstains

onchromecooktopscanberemovedbyusingpadtypeovencleaners.Useextreme

caution.Ovencleanersarecausticandwilldamagepaintedor aluminumsurfaces,

suchasrangesides,backguardorcontrolpanel.

Donotusespraytypeovencleaners.

Overspraywill damagenearbypaintedsurfacesand heatingelements.IJseseveral

layers of newspaper and masking tape to cover surfacessuchas the backguard,

:ontrolpanel,rangesides,countertops,etc.Applythepadtypeovencleanerevenlyto

theentiretopsurface.Theentiretopmustbecleanedtokeepthefinishconsistenti~

color.Useextremecautiontopreventtheovenclearlerfrom

coming incontact with any

othersurface. Let the cieanerremainonthetopfor20-30minutes.Rinsethetopwell

to

remove everytrace of oven cleaner.Drythe top andapp!yArmor AHProtestant@to

protect the finish.

14

Gcxwl 2

Page 15

Thecooktopcanbe raisedor removedsothe area under-

athcan be c\eaned.

o raise Cooktop:

emovethe burnergrates.

Graspthe cooktopat the front and lift up.

Somemodelshavea cooktopsupport.

FOR MODELS WITH SINGLE SUPPORT IN THE

CENTER—Raisethesupport(asshowninthe illustra-

tion) to holdtop whilecleaning.

Porcelainenamel can chip if dropped. Handle porcelain

enameledcooktopscarefully.

The cooktop burners on your range may be removed for

cleaning. Be sure all cooktop knobs are turned to OFF

andburnersarecool,thenremoveor raisethe cooktop.

If shippingscrewswere not removedfrom the burnerwhen

range was installed, do so now (see your Installation

ction for instructions).

remove burners:

Grasptheburnerheadandtiltittothe rightto releasethe

.

twotabs from the burner support(A in Fig.A).

2. Liftthe endof the burner assembly,then pull awayfrom

thefront of the rangeto free the air shutter from the gas

valve orifice (Fig. B). If they are clogged, use a wire or

needleto clear them.

See the Cleaning Chart

Be careful not to disturb the air shutter setting while

cleaning. If you need to readjust the air shutter, see the

InstallationSection.

TOreplace burners:

1,Slip the air shutter over the gas valve orifice (Fig. A).

2. Lowerthe burner assemblyand hookthe tab in the slots

inthe burner support (Fig. A).

3. Be sure both tabs are in theirslots,that theburnersits

levelandstraightandthattheflash

linefrom the igniter to the burner (Fig.B).

tube forms a straight

Burner

Ports

GasValve

‘tifice\/’

!

Fig. A

hmitor

AirShutter

Page 16

FWCN3LEM

$Cur?-mw

[

Cooktopknobswill notturn.

Cooktopburnerswill notlight.

Pushknobs into turn.

Gassupplynotconnectedor notturnedon.

Counterunit not propedygrounded orpokwized. This

can affect spark ignition. See installationsection.

No electricityto unit; check for trippedfuse or circuit

breaker. Be sure unit is pluggedin.

Soilcloggingholes in burnertop. Removeandclean.

Page 17

IFYoLINeed Service

To obtain service, see your warranty

on thebackpageof this book.

We’reproud of our service and want

youto bepleased. Iffor somereason

youarenothappywiththese?viceyou

receive,here arethree stepstofollow

for furlher help.

FIRST, contactthe people whoservicedyourappliance.-Ex~lainwhyyou

are notpleased. In most cases, this

will solvethe problem.

NEXT,ifyouarestill notpleased,write

the details-includingyour phone

all

number-to:

Manager,Consumer Relations

RCA

Appliance Park

Louisville,Kentucky 40225

LLY, if your problem is still not

MajorAppliance

ConsumerAction Panel

20 North Wacker Drive

Chicago,Illinois 60606

Page 18

YOUR

Saveproofof originalpurchasedatesuchas yoursalessliporcanceiledcheckto establishwarrantyperiod.

I

!s

FULL i3NE=YEARWVARIW!NTY

Forone yearfromthedateof

originalpurchase,wewill provide,

free of charge,partsand service

laborinyourhometo repairor

replaceany par?of the Ccwter

Unit thatfails becauseof a manu-

facturingdefect.Thiswarrantyisextendedto the

originalpurchaserand any succeed-

ingownerfor productspurchasedfor

ordinaryhomeuse in the 48 mainlandstates, HawaiiandWashington,

D.C. In Alaskathewarrantyisthe

sameexceptthat it is LIMITED

becauseyou mustpayto shipthe

producttothe serviceshopor for the

servicetechnician’stravel coststo

your home.

We at RCA striveto providethe hig

estqualityproductsand service.

Therefore,we havedesignatedGE

CONSUMERSERVICE,a leaderin

the serviceindustry,to fulfill your

serviceneeds. Shouldyourappliance

needservice,duringthe warranty

periodor beyond,look in the Whiteor

Yellowpagesof yourtelephone

directoryfor GECONSUMERSERVICEor an AUTHORIZEDRCAAPPLlANCE SERVICER.

Is NcrT

Some states do not allow the exclusionor limitation of incidentalor consequentialdamages, so the above

limitation or exclusion may not applyto you. This warranty givesyouspecific legalrights, and you may also have

other rights which vary from state to state. To know what your legal rights are in your state,

consult your local or state consumer affairs office or your state’s Attorney General.

Hfurther help is needed concerning this warranty, write:

● Servicetrips to your hometo teach

you how to usetheproduct.

Readyour Use and Cart?materiaL

If you then haveanyquestions

about operatingthe product,

please contactyour dealer or our

Consumer Affairs officeataddress

below.

“ Improperki’istallation.

If you havean installation problem,

contact your dealer or installer. You

are responsiblefor providingadequate electrical, plumbing and other

connecting facilities.

Warrantor: RCA Appliances

Manager—Consumer Affairs, FMX,

AppMKX2 Park, KY 40225

o Replacementof housefuses or

resettingof circuitbreakers.

s Failure of the productif it is used

for other than its intendedpurposeo

used commercially.

o Damageto product caused by

accident,fire, floods or acts of God.

WARRANTOR ISNOT RESPONSIBLE FOR CONSEQUENTIAL

DAMAGES.

4

! pafl~() MNLQ55w~zw-z

Pub. No, 79-4026

l--

)

Loading...

Loading...