Page 1

Page 2

-.

Readthis book carefully.

His intendedto help you operate and

maintain your new oven properly

Keep it handy for arxwmr$ to your

questions.

If you don’t understand something or

need more help, write (include your

phonenumber):

ConsumerAffairs

RCA

Appliance pa~

Louisville,KY 40225

Write down the model and

serial numbers.

You’llfind them on a label on the front

of the oven behind the oven or broiler

door.

Write these numbers into the space

below. Alsowrite the numbersintothe

spaceon thewarranty cardthat came

with your oven before you send the

card in.

Hyou received

a damagedoven...

Immediately contact the dealer (or

builder)that sold youthe oven.

Savetime and money.

Beforeyou request

service...

Check the Problem Solver. It lists

causes of minor operating problems

that you can correct yourself.

,.

ModelNumber

serial Number

Usethese numbers in any correspon-

denceor service calls concerning your

oven.

2

Page 3

#- =%

I

~~

#sm.

-USE=

Hyx! W“mMgas:

OperIwindows

1.

2 Don’ttouch electrical switches.

Donotstoreor usegasolineor other

flammable vapors and liquids in the

vicinitycdthisor any otherappliance.

3. Extinguish any open fkme.

4. Immediatelycallyour gassupplier

A

—.

b

/

IJ?

TheadjustmentsintheInstallationSectionmust be

madebeforeyoutry to useyourown.

lfyou are using Gas(bottled

gas)allM? adjustmentsinthe installationSection

mustbe madebeforeuse.

Hyowoven isnotproperlyadjusted,flamesmaybe

toohigh,ortheown mayusetoomuchfuel,release

toxicfumesor cookpoorly.

3

GNcmN3

Page 4

LK3T’

~/8°drill bit

1.

Electricor hand drill

2.

3*

Flat bladed screwdriver

4.

No. ~or No. 2 Phillips screwdriver

Pencil

5.

Rulerand straight edge

6.

Hand saw or saber saw

7.

pipe wrench

8.

5/8” wrench and 1/2” wrench or adjustable wrench

9.

3/16“ hexsocket driver

10.

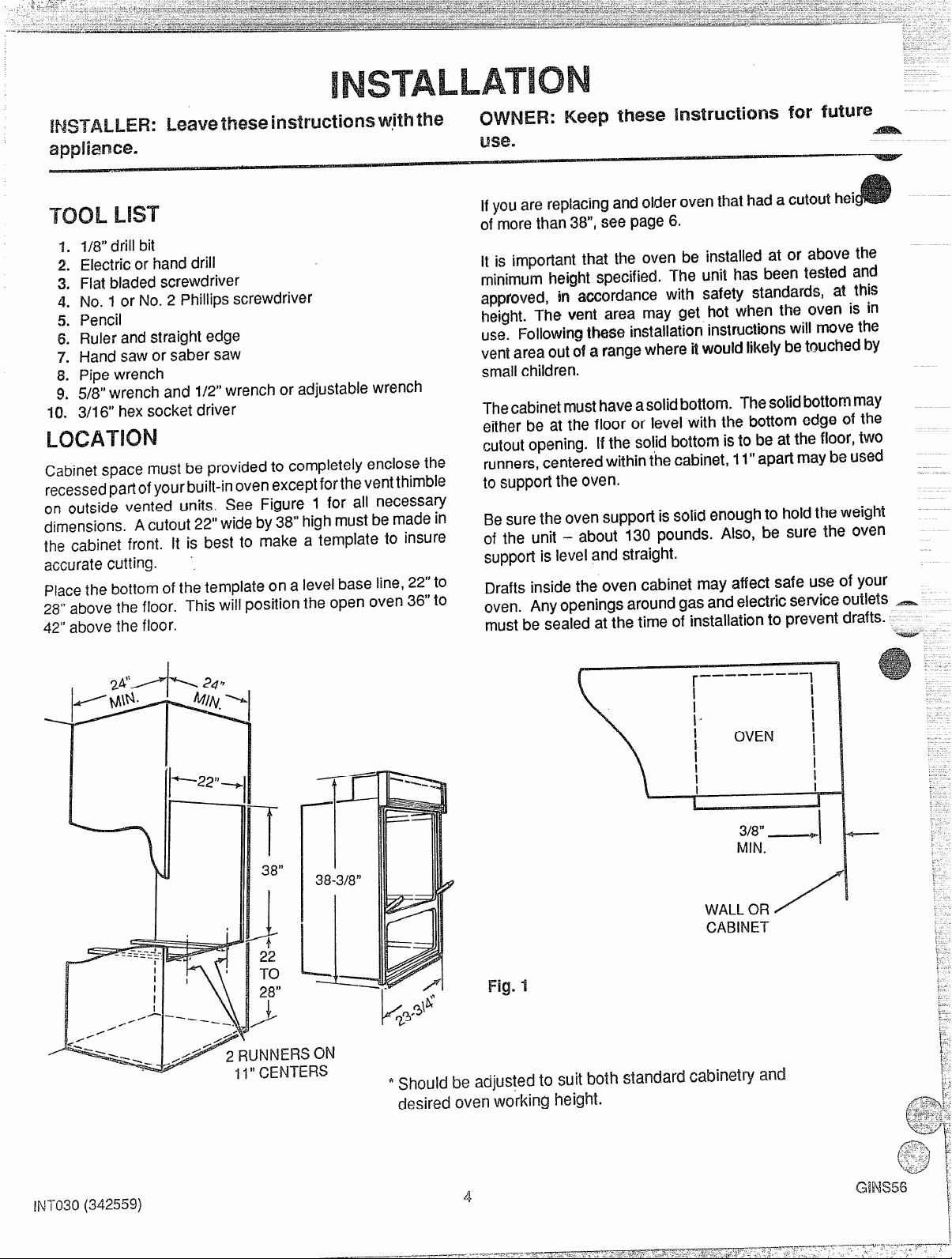

Cabinetspace must be providedto completely enclosethe

recessedpartofyourbuilt-inovenexceptfortheventthimble

on outside vented units. See Figure 1 for all necessary

dimensions. A cutout 22’’wide by 38” highmustbe madein

the cabinet front. It is best to make a template to insure

accuratecutting.

Placethe bottom of the template on a level base line,22”to

28” above the floor. This will position the open oven 36” to

42” abovethe floor.

Ifyou are replacingand older oventhat hada cutout hei

of morethan 38”, see page 6.

II is important that the oven be installed at or above the

minimum height specified. The unii has been tested and

approved, in accordance with safety standard% at this

height. The vent area may get hot when the oven is in

use. Followingthese installation instruc~bnswill movethe

ventarea out of a rangewhere itwould likely betouched by

smallchildren.

Thecabinet mustha~ea~~~idbo~om. ThesoiidbottQm~maY

either be at the floor or level with the bottom edge of Ihe

cutoutopenir~g.Hthe solid bottom is to be at the floor, two

runners,centeredwithin the cabinet, 11”apart maybe used

to support the oven.

Besurethe oven supportis solid enoughto holdthe weight

of the unit –

about 130 pounds. Also, be sure the oven

support is ieveland straight.

Drafts inside the oven cabinet may affect safe use of your

oven. Any openings aroundgas and electricsewice outlets —

must be sealed at the time of installation to prevent drafts.

-ww–

,/--

/“

INT030(342559)

3/8” —*

MiN.

WALLOR

I

/“”

CABINET

i

I

I

I

‘ -----

-.

~\ti’

@“

l=’

2 FHJNNERSON

I -f“ CENTERS

* Should be adjusted to suit both standard cabinet~ and

desired oven working height.

I

Page 5

Checkwithyourlocal utilitiesforelectricai codeswhichapplyinyour

area. if there are no kxal codes, the Nafional Electrical Code,

~a- ANS1/NFPANo.70-1987mustbefollowecf.Youcangetacopyby

—.— .,.——

““-“

.-...s-

National Fire ProtectionAssociation

5attetymarch Park

C?uincy,IvIA

An adequateelectrical supply and outlet mustbe usedto operate

the electrical parts of your oven, The oven cord has three prong

plugand mustbe usedwith a properlygroundedthree holeoutlet

with a standard 120volt, 60cycleAC householdcurrent.

Instalitheelec!ricaloutlet belowtheovenon the rightside. Itshould

be easily reached through cabinet doors below the oven, See

Figure5.

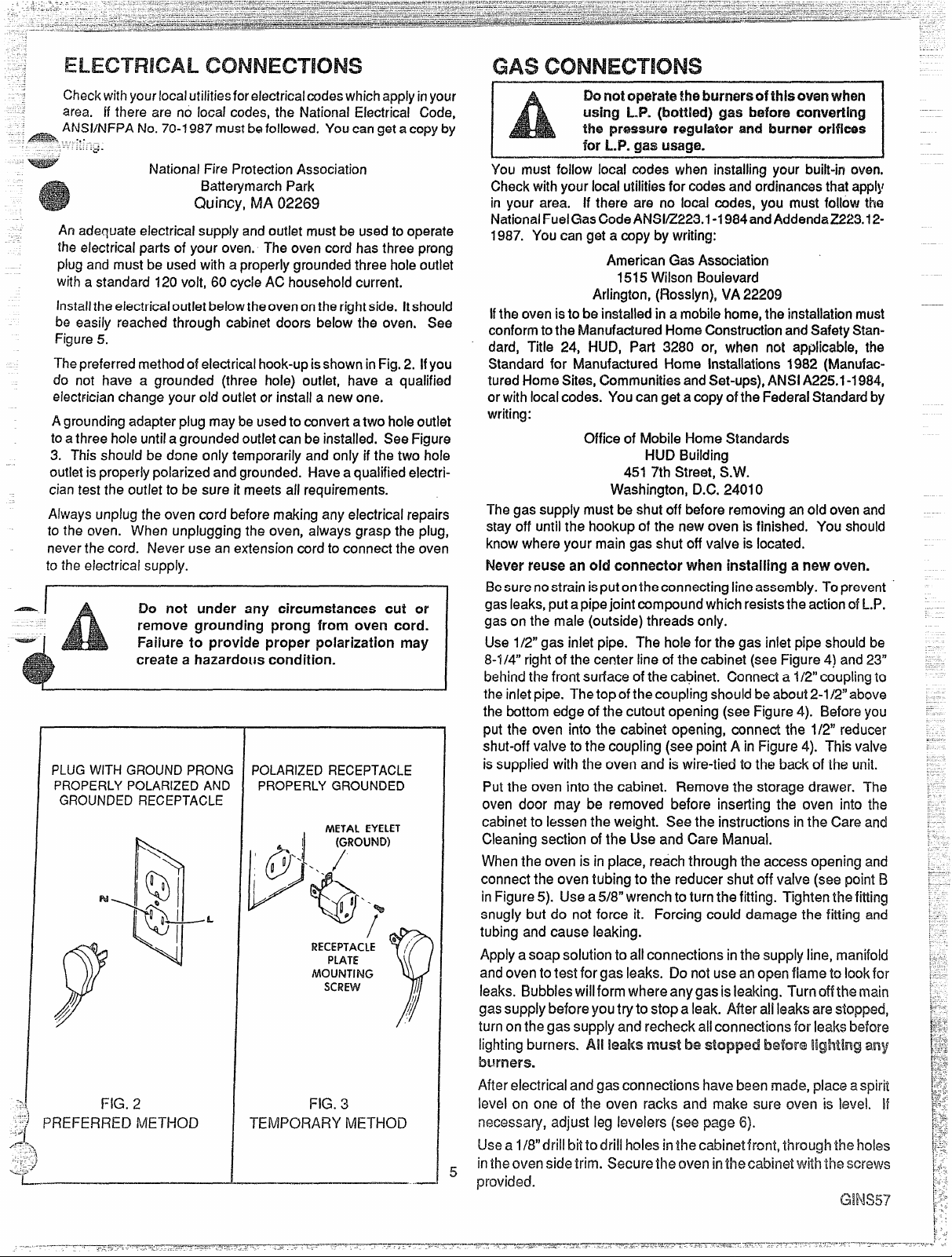

Thepreferredmethodof electricalhook-upisshowninFig.2. Ifyou

do not have a grounded (three hole) outlet, have a qualifi~d

eiect~icianchange your old outlet or install a newone,

Agroundingadapter plug maybe usedto convertatwo holeoutlet

to athree hole until a grounded outletcan beinstalled. SeeFigure

3. This should be done only temporarily and only if the two hole

outletis properly polarized andgrounded. Haveaqualifiedelectrician test the outlet to be sure it meets all requirements.

Always unplug the oven cord before makingany electrical repairs

to the oven. When unplugging the oven, always grasp the plug,

neverthe cord. Never use an extension cord to connect the oven

to the electrical supply.

PLUGWITHGROUNDPRONG

PROPERLYPOLARIZEDAND

GROUNDEDRECEPTACLE

FIG. 2

PREFERREDMETHOD

02269

POLARIZEDRECEPTACLE

PROPERLYGROUNDED

METALEYELET

(GROUND)

@ ,

0 0“ ‘..

a

P@

11,~“%7

PLATE

SCREW

/

v

RECEPTACLE‘ /

MOUNTING

FIG. 3

TEMPORARYMETHOD

\

L

!.%3

notoperatethe bwmwsofthlscwm when

wing fW. @ottkdJ gas imfom mnvmting

the prwmm rfaguiakwand burner orifices

for L.P. gas usage.

You must foilow kmai codes when installing your built-in oven.

Checkwith your local utilitiesfor codes and ordinances that appiy

in your area.

NationalFuelGas CodeANSi/Z225.l -1W?4andAddendaZ223.12-

1987. YOUcan get a capy bywriting:

Ifthe oven isto ba installed in amobilehome,the installationmust

conformtothe l’vianufactur~dHomeConstruction andSafetyStandard, Title 24, HUD, Part 3280 or, when not applicable, the

Standard for Manufactured Home installations 19$2 (Manufactured HomeSites, CommunitiesandSet-ups),ANSi A225.I -1984,

orwith localcodes. Youcan getacopyof the FederalStandardby

writing:

Thegas supply mustbe shut off before removingan old ovenand

stay off until the hookupof the new oven is finished. You should

knowwhere your main gas shut off valve is located.

iVeverreuse an oid connector when installinga new oven.

Besure nostrain isputonthe connectingiineassembly. Toprevent

gasleaks,put apipejoint compoundwhichresiststhe actionofLP.

gas on the male (outside) threads only.

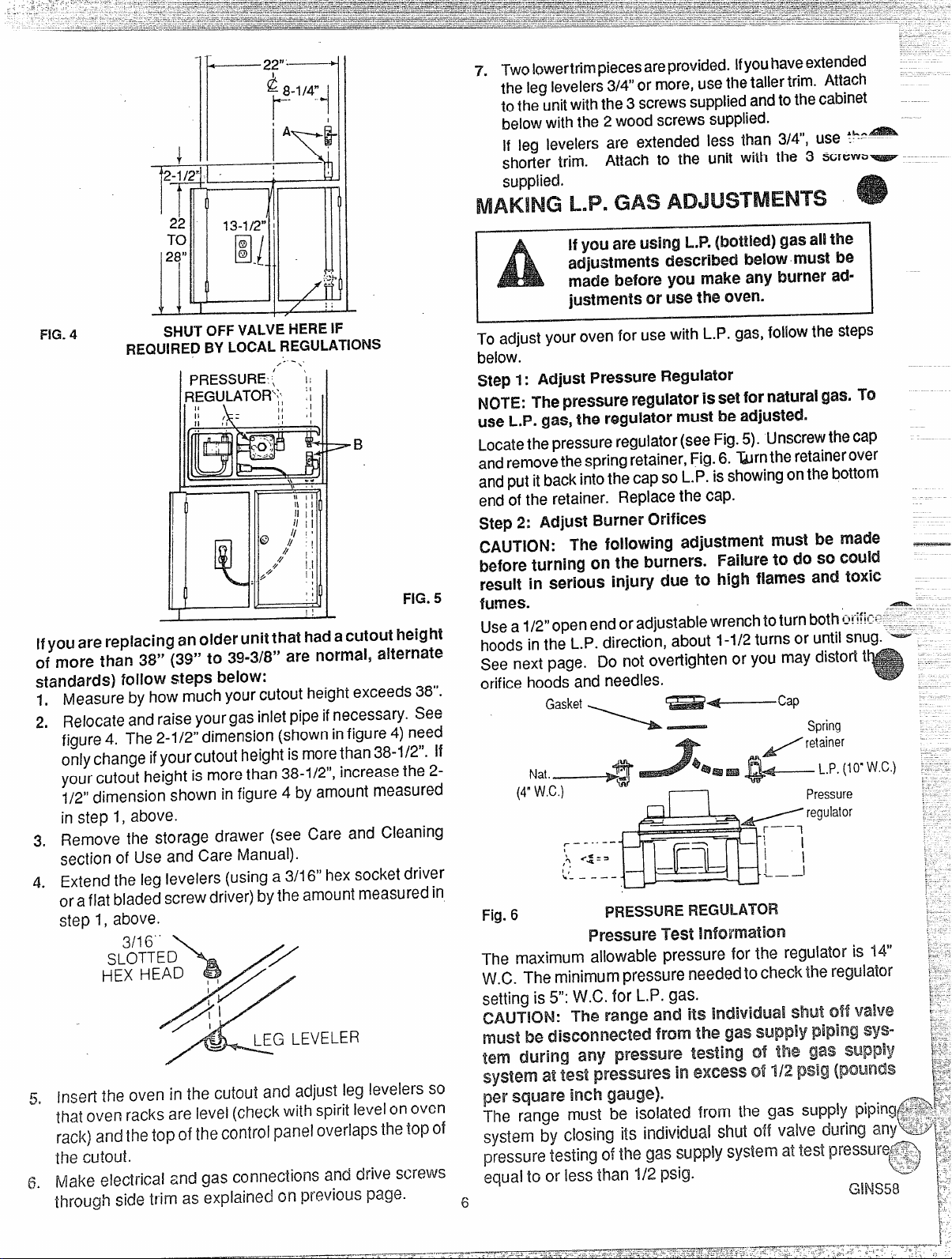

Use 1/2”gas inlet pipe. The hole for the gas inlet pipe should be

8-1/4” right of the center iine of the cabinet (see Figure 4) and .23”

behindthe front surfac.eof the cabinet. Connect a l/2’’ couplingto

the inletpipe. Thetopof thecoupling shouldbeabout2-1/2’’above

the bottom edgeof the cutout opening (see Figure 4). Beforeyou

put the oven into the cabinet opening, connect the

shut-offvalvetothecoupling(seepointA inFigure4).

is supplied with the oven and is wire-tied to the back of the unit.

Put the oven into the cabinet. Remove the storage drawer. The

oven door may be removed before inserting the oven into the

cabinetto lessen the weight. Seethe instructions in the Care and

Cleaning section of the Use and Care Manual.

Whenthe oven is inplace, reach through the access opwiing and

connect the oven tubing to the reducer shut off valve (see point B

inFigure5). Use a5/8”wrench toturn the fitting. Tighten the fitting

snugly but do not force it. Forcing could damage the fitting and

tubing and cause leaking.

Applyasoap solution to all connections inthe supplyline, manifold

andoven to test for gas leaks. Do not use an open flame to !ookfcx

leaks. Bubbleswill form whereanygasisleaking. Turnoffthemain

gassupplybefore youtryto stopa leak. Mterali Ieaksare stopped,

turn on the gassupply and recheck allconnections for leaksbefore

lighting burners.

!oWmm3.

After electrical and gas connections havebeen made, p!acwaspirit

level cm one of the oven racks and make sure oven is level. If

necessary, adjust leg levelers (see page 6).

Usea 1/8”drill bitto drill hcdesin the cabinet frcmt,through the holes

intheoven sidetrim. %curethe oven inthecabirwt with the screvvs

5

provided.

If there are no local codes, you must foilow the

American Gas Association

1515Wilson Boulevard

Arlington, (Flossiyn),VA22209

Office of Mobile HomeStandards

HUD Building

451 7th Street, S.W.

Washington, D.C.24010

1/2”reducer

This valve

Ni leaks must be before any

GNX?7

Page 6

2-1/,

*Gregu’a

7. Twolowertrimpieces arePr@Jided”lfyouhave@~tended

the leg levelers 3/4” or more,usethetal!ertrim. Attach

to the unitwith the 3 screwssuppliedandto thecabinet

belowwith the 2 wood screws supplied.

It leg levelers are extended less Iban 3/4”, use tkc-

Shorter trim.

supplied.

Attach to the unit With the ~ SGJEW~- .

h-

22

-1-o

2?”

L

F!(3.4

Hyou are repiacing an older unit that had a cutout height

of more than WY’ (39” to 39-3/8” are normal, aHernat@

standaf’d~) Wow steps below:

1,

Measure by how much your cutout height exceeds 38”.

2. Relocateand raiseyourgas inlet pipe if necessary. See

figure 4. The 2-1/2” dimension (shown in figure 4) need

only change ifyourcutout height is morethan 38-1/2”. If

your cutout height is morethan 38-1/2”, increase the 2-

1/2” dimension shown in figure 4 by amount measured

SHUTOFFVALVEHEREIF

RECWIREDBY LOCALREGULAT~Q~~

instep 1,above.

3. Removethe storagedrawer (see Care and Cleaning

sectionof UseandCareManual).

4. Extend the leg levelers (using a 3/16” hex socketdriver

or a fIat bladed screw

driver)bytheamountmeasuredin

step1, above.

3/16””

SLOTTED

HEX HEAD ; ,

h

&

/

/

I

II

I

/

LEG

LEVELER

.

B

FIG. 5

IL.!%

To adjust your oven for use with L.P. gas, follow the steps

below.

Step ~: Adjust Pressure F?egulaUJr

NOTEI:The pressure regulator issetfornat~ra~ gas. To

use L.P.

Locatethe pressureregulator(~ee Fig.5). UnscreWthecaP

and

andput it backinto the cap soL.P. is showingonthe bottom

end of the retainer. Replacethe cap.

Step 2:

CXWW3N:

before t~rnhlg on lhe burners. Failure tO dQSOc~u~~

result in serious injury due to high fkimes and toxic

fumes.

Usea

hoods in the L.P. direction, about 1-1/2turns or until snug.-”—

See next page. Do not overtighten or you may distofl t

orifice hoods and needles.

gas, the regulator must be adjustedm

rernovethe springretainer, Fig.6. T+urntheretainer@Jer

MjuSt Burner OrificeS

The fdowing adjustment must be made

~/2JJOpenendoradjustabie vurenc!l totumbothc~fil:=:-. ‘-- .-

~- ------

n I l-m II

~—+ I-IL–-I

AFzm.

s, Inserttheoven inthe cutoutand adjustleglevelersso

thatovenracksareIevei(checkwithspiritlevelonoven

rack)andthetopofthecontrolpaneloverlapsthetopof

Ihe cutout.

6. Makeelectricaland gas connectionsanddrivescrevvs

throughsidetrim as explainedon previOUSpage.

&qualto or less tban 1/2 psig.

Page 7

:

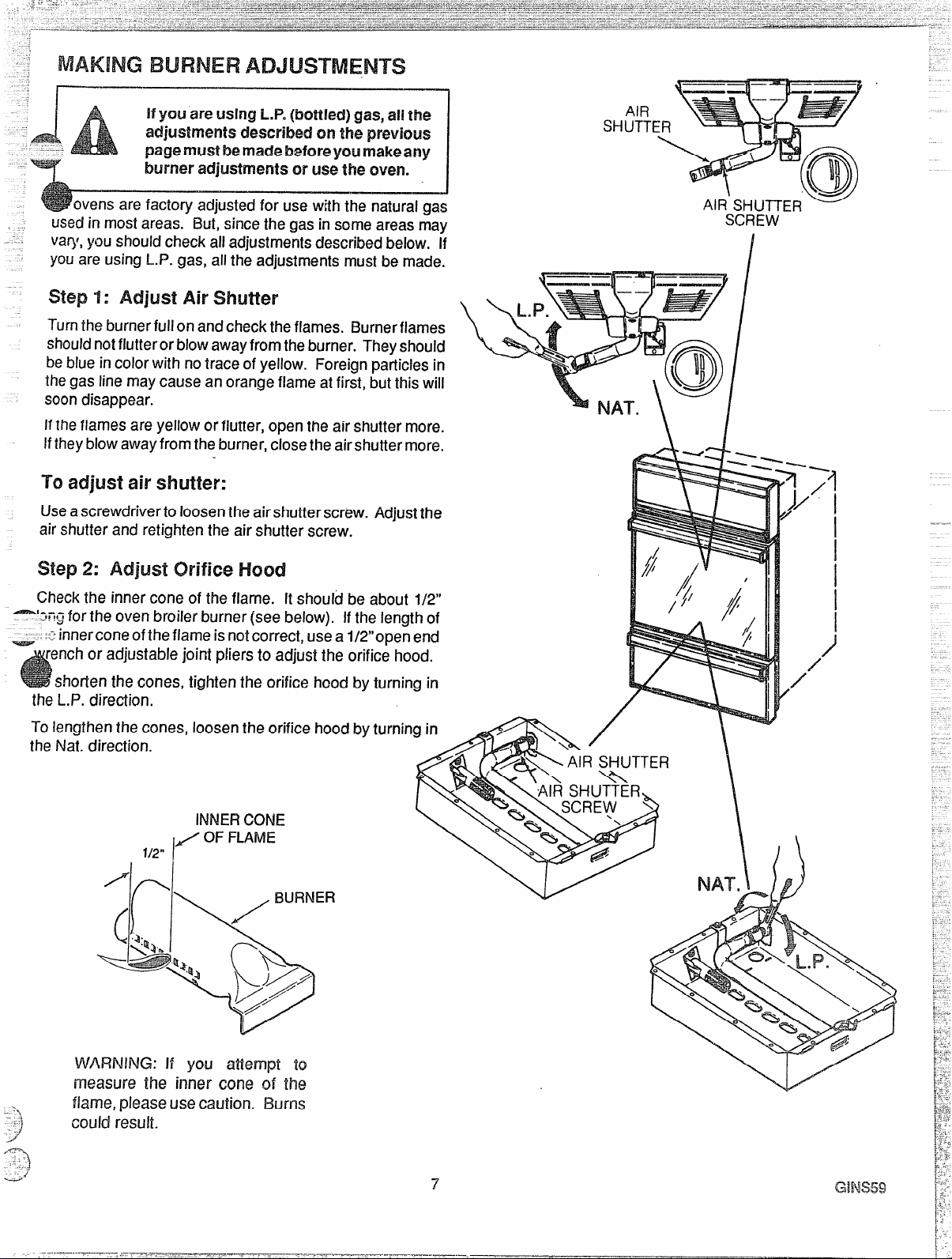

Ail?

SHUTT

used

in mostareas. But, sincethe gas in some areas may

va~~,y~u ShOUIdcheck alladjustmentsdescribedbelow. if

youare using t_.P.gas, allthe adjustments must bemade.

~~e~ 1:

Turntheburnerfuilon and checktheflames. Eh.wnerflames

shouldnotf!utterorb!ow awayfromthe burner. Theyshould

blue incolorwith notrace of yellow. Foreignparticles in

be

thegas finemaycause an orange flame at first, but thiswill

soondisappear.

If the flames areyellow or flutter, open the air shutter more.

they blow awayfrom the burner,closethe airshuttermore.

If

TO i3~Jus~

Use ascrewdriverto loosenthe airshutterscrew. Adjustthe

airshutter and retighten the air shutter screw.

air shutter:

Air Shutter

Step2: orifice Hood

Checkthe inner cone of the flame. It should be about 1/2”

-’~=tgforthe oven broiler burner(see below). Ifthe iength of

=-. =::innercone of the flame is notcorrect,usea 1/2’’open end

renchor adjustable joint pliers to adjust the orifice hood.

SCREW

shorten the cones, tighten the orifice hood by turning in

the L.P. direction.

To lengthen the cones, loosen the orifice hood

the Nat. direction.

INNERCONE

/OF

1/2”

FLAME

/

H

(. \~’BuRNER

WARNING: !f yOL! atkWIPt to

measure the inner cone of the

--.

.-y

-:

,.3’

./’

#<4.

-3

“/-

flame, please use caution. Bums

could result.

by

7

G!NS59

Page 8

Keep this book for later use.

us~fl(g:~~$~

.--2>

%&_..#

I&3sure

edy

your oven is installed and gmunciecl pmp-

13ya qualified technician.

keep the oven area clear and free from

thifigsthat willburn, gasolineandotherflammable

vapors and liquids.

change oven rack positions while oven is

cool.

ARer broiling,alwaystakethe broiler panoutofthe

ovenandcleanit. Leftovergrease inthebroilerpan

can catch on fire next time you usethe pan.

Always

from Me oven.

use dry pot holders when removing pans

MoM or damp potholders can

cause steam burns.

Always usecarewhen opening ovendoor. Lethot

air and steam out before moving food.

follow cleaning instructions in this book.

Teachchildren nottoplaywithovencontrolsorany

other part of the oven.

Never try to repairor replaceany part ofthe ovem

unlessinstructionsaregiveninthisbook.

All Oiii&l-

work should be done by a skilledtechnician.

Never heatunopenedfood containers, Pressu

build up may make container burst and cause

injury.

INeverleave jars or cans of fat or drippings near

theoven. Neverletgrease build upon yourovem

You can keep grease fires from starting if you

clean up grease and spills after each oven use.

Never use aluminum foil to line oven bottoms.

Improper use of foil could start a fire and cause

incomplete combustion.

Never block the flow pf combustion and ventila-

tion air through oven vents.

Never try to move a pan of hot fat, especially a

deep fat fryer. Wait until the fat has cooled.

Never leave children alone br unattended where

an oven is in use.

Never use your oven for warming or heating a -

room. Such use can be dangerous and could —- -

damage oven parts.

..

.-

~

Never wear loose fitting or hanging clothes whe

using your oven.

Such clothes could catch fir

and cause serious injury.

Never use a towel or other bulky cloth as a pot

holder. Such cloths could catch

Never’ store things in an own.

fire on a burner.

Never use wateron a grease tire—-itwill CM’Ny

spread the flames.

OVEN FIRE

1. CIcxx?oven Ckmr and turn off.

2. if ‘fire fcxmtirws,thnwv soda cmthe

fireoruseadry foamor type

D(?nottrytomove m?pan.

TheCaliforniaSafeDrinkingWaterandToxicEnforcement andsoot, caused primarilybythe incompletecombustionof

Actrequiresthe Governorof Californiato publish a listof

substancesknowntothestatetocause cancer andrequires

businessestowarncustomersof potentialexposure10such

substances.Gasappliancescancauseminorexposureto

threeof thesesubstances,namelybenzene,forrnakiehyck?

naturalgasorL.P.fuels.Properlyadjustedranges,indicated

by abluishratherthan ayellowflame,will minimizeinccmplete combustion.Exposureb Uwse subskmcescan be :

minimizedfur!herby venlhg with anopen~~~~~~or

aventilationfanor hood.

8

GSAFCM-I

-..

T

-=>&

@’2?l,

.~-.---.:-

)

~.,-----

>-7

.,.

(d

Page 9

and serial number of your

—

is found orI a tag,

oven

—

behindthe u~perovendoor,

‘lopy the numbers into the

ace on page 2 of this

manual. ----

The model

—

I

2

?

1 / II

1. Oven l_ightSwitch

2.

Oven Vent (area may get hot during oven

x

II e

I Ii R F?6?rYlm/

we; DO NOT b!ock vent)

HecWmic Oven Gontrol

Q<

Oven

4

5

61

7. Removable Oven E30tlom

. . . .. ... .abie Oven Doorwith

9. Removable Sforage Drawer

0. Door Gasket

Broil Burner

Light

Oven

Broil pan and (Zirid

Window

w

1

c

.

F

\\

u--i ~m?%dl-

I

\Y/-- II

I

- --=-..$-..

.--— ------

H

I

*

7“%

(“3)

It 1

Whenyou turn the Oven Controlon, the glow bar igniter

belowtheovenbottoni beginsto heat. Whenthe igniteris

hotenough,inabout1minute,thegasf!owsintothe burner

andis ignited.

Theigniterglowsbrightorangewhenhot. Itcyclesonandoff

withthethermostatandwillglowwhenevertheburnerison.

.s-

.=-,

., -.

----

1A

4 14kk!li

.. . -,:

DLmng a

be lit ‘and ycw SMwbl MMtryto‘do so.

I

Whentheoven ken, heatedairrncwesfhroughawmt below

thecontrolpanel. This hotair maymakecontrolpanelarea

hot.

Thevent is necessaryfor properair circulationinthe oven

andgoodbakingresults. DOI

may CaLlse fm’.$!’e,fireor %0theRangQ=

1

I

Page 10

1

(3--

YNKXL

OVEN CANCEL- BUTIWN - Cancels everything

1.

except the clock andtimer. Pushthis button to

turn the oven off orto clear everything if you’ve

made a mistake in programming.

COOK TIME - Push before setting length of

9.

cook time for automatic oven operations.

CLEAN - Pushto use self-clean cycle.

10.

DISPLAY UW31CATORS- Light upto tell you

2.

is being shown in the TIME DISPL/4Y

what

WlfNDOW.

WVl~

3.

DISPLAY WHWXIW- Shows the time of

dayorthetimesyousetforthetimeror auto-

matic oven operation.

OVEN TEMPERATURE AND BROIL DISPLAY

4.

WINDOW - Shows the oven temperature or broil

settingyou haveselected.

FUNCTION

5.

whether oven is baking,broilingor self-cleaning.

SETKNOB- Turnto settimesandtempera-

6.

INDICATORS - Light up to show

turesafterpushingafunctionbutton.

7-13 B!.rr’nxw

BAKE- Pushbeforesettingbaketemperature.

7.

8.

E3FKNL-

Push before selecting BROIL setting.

STOP TME - Push before selecting the

11.

when you want the oven to turn off for aAI-fiiik _‘.

oven operations.

CLOCK uPush before setting clock or to bring

12.

time of day into the TIME DISPLAY WINDOW.

TIMER - Push before setting amount of time.

13.

TO

time :e---

10

Page 11

TURNTO

-.—m .-. ...—..”-......——.— ——..———.— ————.—.. .————————— —-—

SEET1...I3WTH

OF COOK

TlfvlfE

TiJRhi T(3

SET TH’vIP

TIJR~ TO

SET OVEfd

CANCEL~

TIMER

b

The red display will show the oventemperature as

it rises (in 5° steps).

A tone will sound when the oven is ready.

CLOCK ::: CLEAN ;:: BROIL BAKE

PUSH ~

0

I

OFF

TURN TO SET ~

\

TURN TO ~

J

CANCELI-

“MERCLWKTIME

3

●

.~

‘Top CLEAN;::

I 1 I

BROILBAKE

.4

(i)@@

PUSH

Whencooktime hasended,atone willsoundandthe oven

will turn off.

IT) THE

f -’l

PUSH

TURN TO

SET NVIOUNT ~

OF TIME

PUSH

0

:ANCEIANCEL

TIMER CLOCK ;;:; c1

The ERC will calculate when to turn the oven off.

When the stop time is reached, a tone willsound and the

oven wil~turn off.

1. Attenlion Tonewill sound if oven has only beenpartially

programmed. Forexampie, if you have selected acook

time but notemperature, you will hear theAttention Tone

wlil you select a temperature or pmh CANCEL.

FunctionErrorTonewillsound ifthereisaproblemwith

2,

oneofIhe rangefunctions.

the CANCEL button. If the tone starts again, call for

service.

:.,:

“ Youmay recall any set function by pushing the button of that

.--m,

7L-~’unction.

..=.-

~AN COOK

~,M~ BROIL BAKE

I I

/

PUSH

1

u

Cancel the tone by pushing

1

I

n

~ PUSH

u

I

( I ) PUSH

Atone will sound when time is up.

NOTE:

the oven.

Ifyou prefer that your range not have a tone whenever you

push a button, you can eliminate tones by pushing and

holding the

to act!vate tones again.

The timer is a rerninderonly and wi!l not operate

CANCELbutton until you hear a beep. Repeat

(~ ) PUSHA~D HOLD

~ 3 SECONDS TO CANCEL

IFOR

Cooktimes programmed for automatic oven operations start

counting downwhen ihe ovenfirst comes on, notwheri it has

reachedthe settemperatures. Ittakest(l !055 minutesto

reachthesettemperature,thusadditionalcocktimemaybe

necessary.

11

CCI-L042

Page 12

Always follow recipe carefully.

b?t the oven ~reheat h3NN@l~y before ‘:-;---

cooking baked products. $411(IW10-1’5reinWs preheattime.

Avoid opening the door too often to check

the food during baking as heat will be lost.

Thismay resultin poor bakingresults.

Cakes, cookies, muffins, and quick bread

should be baked in shiny pans — to reflect

the heat —

gokkm

becausethey shouldhavea light

crust. ‘feast breads and pie crusts

shotikl be baked in glassor dull (non-shiny

pans)

— to absorbthe heat —

becausethey

shouldhavea brown,crispcrust.

Measure

Use

ingredientsproperly.

properpan placement.

Placepanson the oven rackswith 1%- 2“ of

air space onall sides of qch pan. Avoid

overcrowdingthe oven,

Panstoo close to each other, to oven WMS

or to the oven bottom i510ck the free movement of air.

unevenbrowningand

.<-.=

/

.-w

&i*

.’

knproper air movement causes

cooking,

>>. .

---

.:Q

---..—-*=—

4 cake layers

Oven temperatures should be reduced 25

degrees below recommended temperatures -ifyou use dark pans or oven proofglass. ~

‘Theremay be some odor when the oven is

first used. This is caused by the heating of

new parts and insulation.

Do not cover the oven bottom or an entire -. -

oven rack with foii. The foil can Mock nor-

mal heat flow, cause

damagethe oven interior.

cookhwjfaih-m~,~~d :-:

.

Q ~OS~ ~~~ingshIould be done cm the SEXXN?d

shelf p3si%ion from the fmtkwn.

several items, use two shelves placed cmthe

second and fourth rack positicwls from the

bottom of -theoven. stagger pans so that no

pan is directly above another, ERN<eangei

food cakes 0!7 the first shelf ‘fI”om

Me of the oven.

’12

;-.

Page 13

CM a grcmw fire. Seethe

-..

sectiontansafety.

CANCEL ~

—

~

“MER CLWK TIME

$Wsh When

~

o

Finished

-.

Ivfostfoocfscanbe broilecfatthe HI BroilSetting. Select the

!&l Broil setting to avoid excessive browning or’drying of

foodsthat should be cooked to the well-done stage (such

as thickpork chops or poultry).

Broilingiscooking by directheatfrom the broil burner.

Tender cuts of meat or marinated meat should be selected for broiling. For best results steaks and chops

should be at least 3/4” thick.

After placing food on the broilerpan, putthe panon an

oven rack in the proper rack position. The recommended rack position and cooking time can be found

in the chart at right.

Thecloser the food IStothe broil burner, the faster the

meatbrowns on theoutside,yet stays redto pink inthe

center. Moving the meatfarther awayfrom the burner

letsthe meatcooktothecenterwhile browningoutside.

Side one should be cooked 1–2 minutes longer than

side two.

Yomoven dcmrshmkf be while

broiling.

v

Use only the broiler pan and grid that came with your

range for broiling. They are designed for proper

drainage of fat and liquids and help prevent spatter,

smoke or fire.

Do not preheat when broiling. Preheating may cause

the thermostat to cycle the broil burneroff and on. For

evenbroiling onboth sides, startthe food on acoldpan.

Whenbroiling frozen meat, useone rackposition lower

than recommended and up to 1 1/2 times the sug-

t

‘Tw CLEAN

;::

>

BROIL BAKE

1 Push

c1

gestedbroilingtime.

Trimtheouterlayeroffatfromsteaksandchops. Slit

thefattyedgesto keepthe meatfromcurling.

Formaximumjuiciness,saltthe first sidejust before

turningthe meat. Salt the second side just before

serving.

Brushchickenand fish with butterseveraltimes as

they

broil. When broiling fish, grease the grid to keep

it from sticking and broil with skin side down. !$is not

necessary to Iurn fish.

Newer leave a soiled br~i!er pan In the range,

~rea~e inthe pan may smoke nEXttime the

Ovenis used.

Donot

with foil. Poor of hotfat

may &alMe a IWoiier fire.

Mafire

Wx3,Wow sodaonthefire.

m not put water an the fire.

Food F%@tion (minutes)

I

Steak - 1“ Thick

Flare 4

Medium

Well Done

Ground Beef Patties

Medium

Well Done 3

Lamb Chops – t“ Thick

Pork Chops - 1“ Thick

Pork Shoulder Steaks

l-lamSlice - 1“ Thick

Fish (Fillets)

chicken (Halves) 1 40-60

‘frankfurters

Zacon

Open-face Sandwiches .2

This chart k a generalguide. The siz~,

perahwe.

13

I

stark, dose the cweridoor

lffirecmtin-

Rack Total

4 = Highest

1 = Lowest

3

3

3

3

3

3

3

3

3

3 !5-7

I

Time

10-12

14-16

20–22 I

11–13

13–15

16-20

20-25

15-20

14--16

10--15

1o–t 5

6--10

‘GiEmuxi

I

Pm5

Page 14

3/4 wp margarine,softened

7cup sugar

2 eggs

1CUP

sour cream

2cups all-purpose flour

7teaspoonbaking powder

7teaspoonsoda

1/2 teaspoonsalt

1teaspoonnutmeg

3/4 cup light brown sugar

1/2cup chopped pecans

1teaspooncinnamon

Cream

salt and nutmeg. Add to batter and mix well. Pour batter into greasedand

margarineandsugaruntillightandfluffy. Add eggs andsour cream; mix well. Combine flour, bakingpowder, soda,

floured 13” x 9“ x 2“ baking pan.

Combine brown sugar, pecans and cinnamon; mix weii. Sprinkie one haif of this mixture over cake batter; swiri mixture

through batter.Sprinkie remaining one haif mixture evenlyover cake batter.

Cover and chiil overnight. Uncover and bake in preheated 350°F oven for 35to 45 minutes or untii cake tests done with

toothpick.

2-10 oz.pkg. frozen chopped broccoli

1cup mayonnaise

1cup sharp cheddar cheese,grated

2 eg&, beatenslightly

1can cream of mushroom SOUp

2 tablespoons chopped onion

1cup cheesecracker crumbs

-

P~eheatoven to 375°F. Cook broccoii according to package directions; drain.

Mix with other ingredients. Pour into greased two (2) quart casseroie.SprinKie

v

with cheese cracker crumbs. Bake at 375°F for 20-25minutes.

A delicious quick-to+nake hearty stew that wiii feed a crowd or feed the famiiy. Refrigerate or freeze the remainder for

another day.

1-70 oz.

can barbecue beef

?- ?0oz. can barbecue pork

1-24 oz. can Brunswick stew

7-5 oz. can boneless chicken

A

7-12 oz. can vacuum packed corn niblets

7-16 oz. can baby !ima beans, drained

2-1602. cans stewed tomatoes

j - IGI/zoz. can sliced okra, drained

Drain okra and iirna beans. Addto allother ingredients in.4 quart

pan. i-led on medium to serving temperature.

Page 15

1/2cup margarine

1

3/4 cup chopped green pepper

a 1/3cup chopped onion

3 eggs, well beaten

v 17oz.can cream style corn

7oz. can who!e kernel com with liquid

Ilzoz. p)fgcornmuffin ‘ix

1cup cheddar cheese,shredded

350° F. Sautd green peppers and onion in margarine; combine

—.

Preheatoven to

with remaining ingredients except cheese, Pour into greasedtwo (2) quart casserole; sprinkie with cheeseand bake 45-55minutes in 350°F oven. Let stand 5

minutes before serving.

CcwteSy:Illinois CooperativeExtensionHomemakers

2-1 oz.squares semi-sweet chocolate

1stick margarine

1cup sugar

1/4 cup flour

2 eggs

1tsp. vanilla

Dash salt

1/2 cup chopped pecans

Frozen 9“ pie shell

.4%

::

..-

G

Preheat oven to 350°F. Melt chocolate and margarine. Add other

.s3Em+.

—-

1-20 oz. can apple pie filling

1/2 cup sugar

1-9 oz. box white cake mix (1 layer size)

1stick margarine, melted

1/2 cup chopped pecans

Preheat oven to 350° F. Place in layers in greased 9“ or 10” square baking dish:

apples, sugar, dry cake mix. Pour melted margarine over top of cake mix. Bake

at 350° F for 35 minutes. Sprinkle with pecans. Continue baking 15 minutes.

Serve warm.

ingredients to melted mixture. Pour into unbaked pie shell and

bake 35-40 minutes or until pie appears set. Serve warm with ice

cream or whipped cream.

apprcmimateiy 2 tablespoons cook-

or /3”or 9“ square baking pan. F%3ce

Tilt pan to coat bottom evenly. Mix

into+hot gK?asE?dpan, Ehke 20-25

Page 16

A

-._...--i-e

1. Remove ‘thebroil pan and grid, oven racks,all utensils

and any foil that may be inthe oven. Do nottry to clean

utensils or any other objects in the oven during a selfclean cycle. Itoven racks are left in the range during a

cleancycle,theywiildarken, Iosetheirlwsterand become

hardtoslide. Ifyouchooseto Ieavethe racksintheoven,

youcanpo!ishthe edgesof the racks with steelwooland

apply asmall amount of vegetable oilto the rackedges

afterthe self-cleancycle.Thiswill makethe rackseasier

to slide.

2.

Soil onthe ovenfront frame, under the front edgeofthe

cooktop (doesnot apply to built-inovens), thedoor liner

outside the door seal and the front edge of the oven

cavity (about 1“into the oven) will not becleanedduring

a clean cycle (see illustration). Clean these areas by

hand before starting a clean cycle.

Use hot water with a soap-filled steel wool pad, then

rinse well.

Wipeup heavyspilloverson the ovenbottom. Too much

3.

soil may cause smoking during the clean cycle.

Cleanthe door seal by using aclean sponge to soakthe

4.

soiled area with hydrogen peroxide. Repeated soaking

maybe neededdependingontheamountofsoil.Frequent

cleaning will help prevent excessive soilbuild-up. Donot

rubthe door seal. The fiberglass material ofthe sealhas

an extremely low resistance to abrasion. An intact and

well fitting ovendoor seal isessential for energyefficient

ovenoperation and goodbaking results. Ifyou noticethe

seal becoming worn, frayed or damaged in any way or

if it has become

displaced on the door, you should

replacetheseal.

--

,, --..

FRCW+$TFRAME

~

I

1

1

I

i-l

.

I

A

After a clean cycle, you may notice some white ash in the ~ .

oven. Just wipe it up with a damp cloth.

If white spots remain, remove them with a soap-filled steel ~” ‘

WOOIpad. Be sure to rinse thoroughly with a vinegar an

water mixture. These deposits areusually asalt residuethat

cannot be removed by the clean cycle.

if the oven

need to be repeated.

isnotCleanafter one clean ~Y~le,the V~~e maY ~DJŠ-.

.-

16

esclul

I

Page 17

-.

--

A

.+-

1 PUSH

c1

Thedoor locks automatically after the controls are set.

Theself-clean cycle lasts 3-1/2 hours.

Whentheovenreaches Iockingtemperature the wordLOCK

will be shown in the ERC display.

You can push STOP TIME BUTTON to find out when the

cycle will end. Push CLEAN BUTTON to return to count

~down.

TURN.COUNTER

CLOCK WISE

TURN ~-

Q

1/2

1 Pus+

Y

Thenfollow instructions under WHEN A CLEAN CYCLE IS

FINISHED.

!S

WAITUNTIL 1

LOCKGOES OUT

(20-30 minutes)

7

o

SET

Afferaclean cycle,the oven doorcannotbeunlockedunless

the word LOCK is off in the ERC display and the oven has

cooled. If you cannot open the door immediately after the

-17

Cxxx.w

Page 18

On the following pages, all rimova~le pafl~

Warmwater, amilddetergent anda softclot

as Fantastic@,ca

m also be used. DO nol use metai scourin9 pads,exceptwhere recommended”

—

cmyour range are shown.

hare~afeto

USeon allcleanable aprtsof yourfan9e. All Pu~P~~ecleaners’

Referto those pageswhen cleanin9your range.

d

PART

Control panel

Glassoven door/window

Self-cleaningoven finish

Ovendoor gasket

racks

Oven

CLHMNG

MATEFl!A~~

Detergent,warmwater,softcloth

Glass cleaner and papertowels

Detergent, warm water and scouring pad orsoap

Hydrogenperoxide

filledsteelwool pad

I

Detergent,warmWatE!r,scouringpad

or soap-filled steel wool pad

Donot

Removestubborn soilwith paste of bakingsoda and

water.

oughly.

use abrasivecleaners.

DO not use abrasive cleaners. Rinse tb~r-

-—

Rinse well after cleaning. Cleaning inside the oven

need only be done as an optional touchup between

self-cleancycles. Seethe self-cleaning oven section

in this manual for more information.

Soak with hydrogen peroxide} using a

sponge. Frequent soaking helps prevent soil bui!d-

up. Do not rub. See se!f-cleanin9 section fOr more

I information.

Remove from oven to clean”

Rinsethoroughly.

1-

I

——

—-

-- ‘-

Page 19

--

meoven $(XM’can i%?KwYN3vedforfc$eanhge

To remove:

“A#ss%h

.-~=#SS%hOpenthe door@ the broil stop position (see illustration).

.

Graspthedoor ateachsideam.fliftup andoff thehinges.

E: When the door Is removed and Mnge arms areat

slop position, do not bump or try to move the hinge

arms. The hinges could snapback causing an lnjw-yto

thehandsor damageto the porcelain onthefrontof the

range. Cover the hinges with towelhqj or ernp{ytowel

rollswhile working in the oven area.

To replace:

1. f-foldthe dooroverthe hingeswilh the slots atthe bottom

edgeof thedoor lined upwith the hinges.Thehingearms

must still be in Ihe stop position.

2. Slidethe cfoorcfownontothe hingesasfar asitwill go and

close the door.

Be careful not to scratchthe oven finish when ilnstal!ing

or removing oven racks.

TOinstall:

Set the raised back edge of the rack on a pair of rack

1.

.-

-- guides.

<-- Push the rack in until you reach the bump in the rack

.

uide,then lift the front oftherack a bit and push the rack

Ithe way in.

To remove:

Pull the oven rack out, then up,

1.

THE OW3+J

Do not touch oven bulb when hot, with wet IwKfs, or

vidpeown light area with wet clolh.

~-

GLASS –

Electrical pm.fvermust be shut

a Ibf’o!wm

bulb.

offMyou have to .repkice

I. Remove the three screwsand liftoff the glassretainer,

glass cover and gasket.

Replace thebulb with a 40 watt appliance bulb.

2.

Replace the gasket, glass cover and glass

3.

~{e~ainer. Tightenscrewssecurely.

-“,!,,

3

19

B.r

GLASS

COVER

SC%!N

)

w

ENMW-21

Page 20

The oven bottom may be removed for cleaning heavy

spilloversor to reachthe oven burner.

careful not to scratch the oven finish when removing

Be

or replacing the oven bottom.

70 remove:

1. Slide

the tab at the centerfmnt to the left.

2. Lift the oven bottom up and out.

To replace:

1. Sliptheoven bottom intOthe oven sothetabsintheoven

bottom fit into the slots in the oven back.

2. Lowerthe front of the oven bottom into place and slide

the tab at the front right to lock the oven bottom into

place.

‘- ‘-

--

--

This drawer provides space for keepingcookwareand

bakeware.

be kept

Hastics and flammable material should not

in this drawer.

Donotoverloadthe storagedrawer. Ifthe contentsofthe

draweraretooheavy,thedrawermay

opened. Toopen the drawer,grasp the centerof the handle

and pull straight out.

To remove: pull drawer straight out and Iiff over the guide

stops.

TOreplace: lift over the guide stops and slide drawer into

place.

slipoff the trackwhen

20

Page 21

Savethe and mmey-—ClWckthis list before yw cdl W service.

t

FTKH3LEWI

Pcxsumx CJuwE

Dcm’-r

(XWLFORSE3!WKXUNTIL

Ycw C%!ECX

o Ovenburners do not work. .

I

“ Foods do not bake properly

)

Gas supply not connected or

not turned on. If using L.P.

gas, tank may be empty

Appliance

grounded or polarized. This

can affect spark ignition(on

models so equipped).

Controls not set correctly

Burnersnot adjusted properly

Oven not preheated long

not properly

enough

Improperrackor

pan place-

ment

Ovenven?blockedorcovered

Improper use Offoil

Improper temperature setting

for utensil used

Recipe not followed

Improper thermostat calibra-

tion

Using improper cookware

o Ch~ckthe reducershut-offvaive andthe

gassupplyshut-off valve to be surethey

are open (see installation section).

If using L.P, gas; is there any gas in the

L.P. tank?

o Checkinstallation sectioninthis manual.

o Check operating instructions in this

manual.

~ See the installation ,seciion in this man-

= Be sureto preheat.

10 minutes below 350 degrees

!5 minutes above 350 degrees

IDMaintainuniformair spacearoundpans

andutensils; seeoven

Besure oven vent is not blocked

~

~ Foil use not recommended,

s Reducetemperature 25degreesforglass

or dull/darkened pans.

~ Is recipe tested and reliable?

o Checkoventemperature adjustment pro:

cedures (next page).

o See oven cooking section.

cooking section.

23

Page 22

* Foodsdo not broil

properly.

s Improperrackposition

Oven preheated

~

“ Improper utensil used

o Improper broilingtime

CALLiFc)iRSERVKX

I

“ ~:X&broii pan placement; see Broiling

.

0 Do not preheatwhen broiling.

~ Use broiler pan and grid suppliedwith range.

s Check broiling chart.

You

4

o Oven smokes.

o Ovenlightorwork

lightdoesnot

(ifequipped).

~ Ovendoesnotclean

or poor cleaning

results (Self-clean

models only).

o Ovendoorwill not

unlock (Self-clean

modelsonly).

I

* Tonedoesnotsound

o Heavily soiled or

stained chrome

cooktop cannot be

satisfactorilycleaned

work

o Dirtyoven

* Broilerpanfullofgreaseleftin

oven

o Light switch in off position

● Light bulb or fluorescent light

starter burned out

o Controlsnotsetproperly

o (lean cycleinterruptedtoo

soon

s Oventoodirty

E Cleancyclenotcomplete

o Tone has been eliminated by

pushing and holding CANCEL

button

D Spillswerenotwipedup

promptly

~ Checkfor heavy spilkwer.

o Clean pan and grid after each use.

Checkswitch setting.

~

o Check or repiace light bulb orfluorescent

light start~r; see use and care instructions.

o Check self-clean instructions.

o Heavily soiled ovens require a 3 1/2 hr.clean

cycle.

M Heavy spillovers should be removedbefore

setting clean cycle.

o Oven must cool below locktemperature

(20 to 30 minutes after clean cycle is

complete).

o Push and hold CANCEL button to activate

tone.

e

See theinstructions, under Cleaning Tips, ~

forcleaningchrome cooktops.with oven

cleaner. This procedure requires extreme

caution. Read instructions carefully.

.

Thetemperaturein yournewovenhasbeensetcorrectly

at thefactory, so be sureto followthe recipetemperatures

andtimesthefirstfew timesyoubakeinyournewoven,

Ifyouthinkthe ovenshouldbe hotter or cooler,youcan

adjustityourself. Todecidehow muchtochangethe

temperature,setthe oventemperature25°F higheror

lowerthanthetem~eratureinyour recipe,thenbake. The

r;sulls of this‘lest; shouldgiveyou an ideaof howmuch

the temperatureshouldbechanged.

~0

Pushthe BAKEbutton.

Selecta temperaturebetween500°Fand

550°Fwith Me

SETknob.

Quicklv(withintwoseconds,beforetheBAKEFunction

3.

energi;es)pushandholdthb BAKEbutton.

The display will change to theamountofdegrees

differencebetweentheoriginalfactorytemperature

settingandthe currenttemperaturesetting.if theoven

hastheoriginalfactorysetting,thedisplaywill read00.

Thetemperaturecanbe adjustedupto 35°F hotteror

4.

cooler(in5°F steps), by turning the SETknob. A

minussign(-) beforethe numbermeansthattheoven

will becoolerby displayedamountof

When You have made the desired adjustment, push

5.

degrees.

theC~~OCKbuttontogo backto thetimeof daydisplay

or useyourovenas

you would normally.

Note:Theself-cleantemper’atwewillnotbectmngedby

theacljustmen~sdescribedabove.

22

/44>,

$’$’$!

Page 23

Aim%

-waw-

To obtain setvice, see yourwarranty

on the back pageof this book.

We’re proud of our service and want

youto be-pleased. Ifforsome reason

youarenot happywiththeserviceyou

receive,herearethree Stepsto follow

for fu~her help.

FIRST, .conlactthe peoplewho servicedyour appliance. Explainwhyyou

are not pleased. In mostcases, this

‘will solve the problem.

NEXT,ifyouarestill notpleased,write

ail the details-including your phone

number-to:

Manager, Consumer Relations

RC14

Appliance Park

Louisville, Kentucky40225

FINALLY, if your problem is still not

resolved,write:

Major Appliance

Consumer Action Panei

20 North Wacker Drive

Chicago, Illinois 60606

\

I

f

.

-.

,,,

..

,,

23 CxN3w-i

Page 24

Save proofof original purchasedate such as your salesslip or cancelledcheckto establishwarrantyperiod.

—

!s

FULL

Forone yearfrom the date of

original purchase,we will provide,

free of charge,parts and service

labor inyour home to repairor

replace

fails becauseof a manufacturing

defect.

This warranty is extendedto the

original purchaser and any succeed-

ing owner for products purchasedfor

ordinary home use inthe 48 main-

land states, Hawaii andWashington,

D.C. In Alaska the warranty isthe

same exceptthat it is LIMITED

because you must payto ship the

product to the service shopor for the

service technician’s travel costs to

your home.

I!SNOT e

you how to usethe product.

about operating the product,

please contact your dealer or our

below.

contact your dealer or installer. You

quate electrical, plumbing and other

connecting facilities.

anypafl of theran~~ that

Service trips to your home to teach

!Readyour Use and Care material.

If you tpen have any q8.MXiQfl~

Consumer Affair$

officeataddress

I

E Improper installation.

Ifyouhave an installation problem,

are responsible for providing ade-

We at RCAstriveto providethe high-

est quaiity productsand service.

Therefore,we havedesignatedGE

CONSUMERSERVICE, a leader in

the service inclustfy,to fulfill your

serviceneeds. Should your appliance

need service,during thewarranty

periodor beyond, lookin the White or

Yellow pagesof yourtelephone

directow for GE CONSUMERSEIW-

iCE or an ALJTH~RizE~ RCAAPPLl-

ANCE SERVICER.

o

Replacement of housefuses or

resettingof circuit breakers.

*

Failureof the product if it is used

for other than its intended purpose of

used commercially.

e

Damageto product caused by

accident,fire, floods or acts of God.

WARRANTOR IS NOT RESPON-

SIBLE FOR CONSEQUENTIAL

DAMAGES.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

other rights which vary from state to state.

consult your local or state consumer affairs office or your state’s Attorney General.

This warranty givesyou specific legal rights, and you may also have

To know what your legal rights are in your state,

Loading...

Loading...