Page 1

1

I

ApplianceRegistration

Broiling

BurnerIgnition

CareandCleaning

ElectronicOvenControl

Clock

UpperOven/TimerControls

Features

Installation

BurnerAdjustment

GasandElectricalSupply 5

L.F.GasAdjustments

Location

LightBulbReplacement

Modeland SerialNumber

(

OvenCooking 11.12

ProblemSolver

Recipes

RepairService

SafetyInstructions

Warranty,

BackCover

16-18

10

;.>7

1

b

4-7

18

19

14,15

20

2

13

9

9

.,

7

6

4

2

8

-

Page 2

Readthis book C%mMJny.

[t i intendedt help you operate and

maintain your new oven properly.

K&3p it handy for answers to your

‘questions.

if you c!o’n’tunderstand something or

need more help, write (include your

phone number):

Consumer Affairs

RCA

Appliance Park

Louisville, KY 40225

Write down the modeland

serial numbers.

You’ll find them orIa labelorIthe front

of the ovenbehind the ovenor broiler

door.

Write these numbers into the space

below. Alsowritethe numbersintothe

spaceon the warranty cardthat came

with your oven before you send the

card in.

Ifyou rfxxived

a

immediately contact the dealer (or

builder)that soldyou the oven.

Ovens.”

Saw time and money.

Beforeyou request

service...

Check the Problem Solver. M iists

causes of minor operating problems

that you can correctyourself.

ModelNumber

SerialNumber

Usethese numbers in anycorrespondenceorservice callsconcerning your

oven.

.,

2

Page 3

/-

yo

.

IfyoL4smell gas:

1.Open windows.

2. Don’t touch electrical switches.

3 Extinguishany open flame.

4. Immediatelycallyour gassupplier

<

M?

Dorid store or usegasoline orother

flammable vapors and liquids in the

vicinityofthisoranyotherappliance.

/

The adjustments inthe Installation Section mwst b

mabefy t t u

Hyou areWmMJ Gas (bottled

gas) all LJ? adjustments inthe Installation Section

must be made

Hyow own isnot properly adjusted, flames maybe

too high,orthe oven may usetoo much fuel, release

toxic fumes or cook poorly.

befus

ov

Page 4

the WM?.

.

—

TOOL iLKiin-

1/8” drill bit

1.

Electric or hand drill

2.

Flat bladed screwdriver

3.

No.

4.

5.

6.

7.

8.

9.

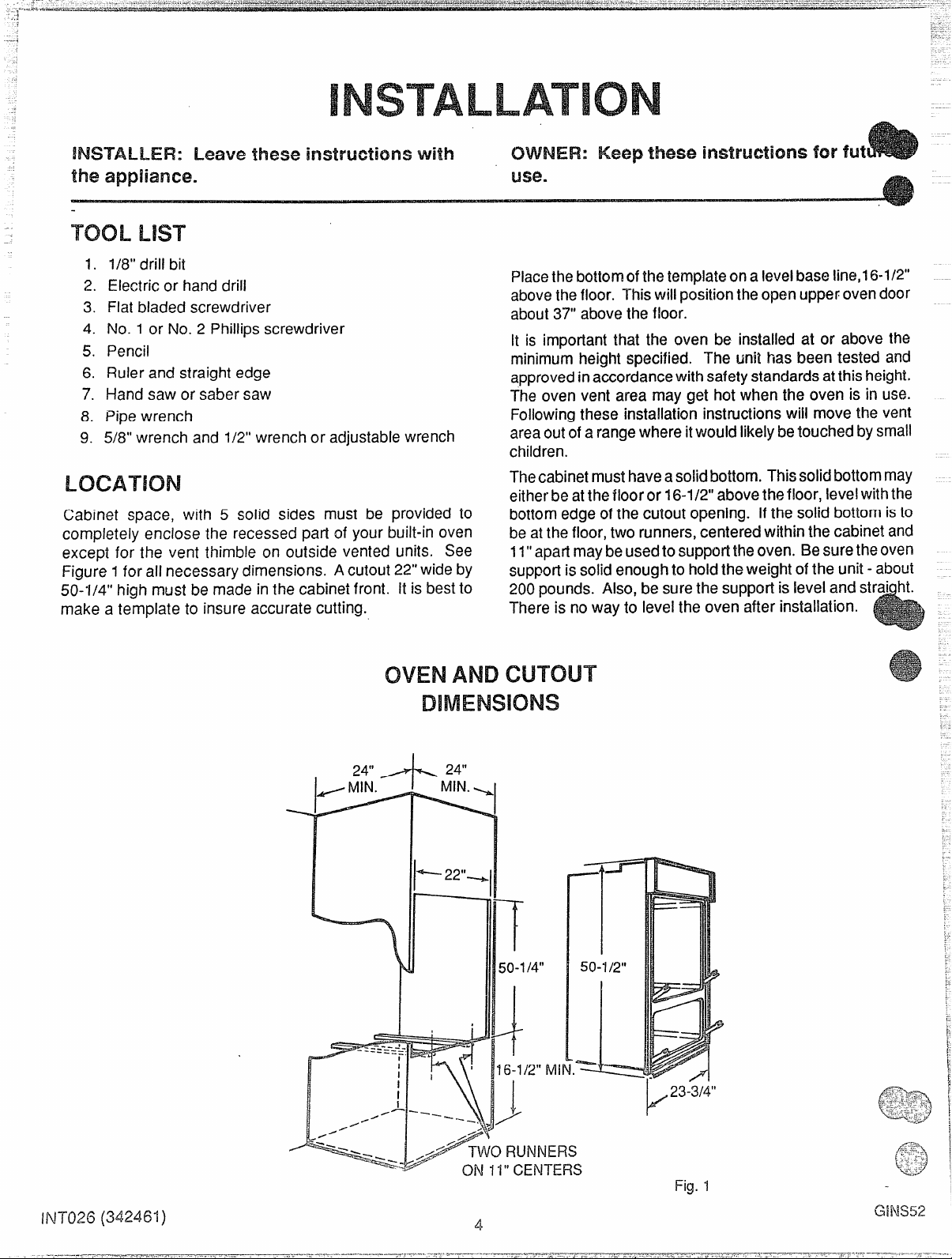

Cabinet space, with 5 solid sides must be provided to

completely enclose the recessed part of your built-in oven

except for the vent thimble on outside vented units. See

Figure ~for all necessary dimensions. A cutout 22’’wide by

50-1/4” high must be made in the cabinet front. His best to

make a template to insure accurate cutting.

1 or No. 2 Phillips screwdriver

Pencil

Ruler and straight edge

Hand saw or saber saw

Pipe wrench

5/8” wrench and 1/2” wrench or adjustable wrench

Placethebotlornof thetemplateona levelbase line,16-1/2°

abovethe floor. Thiswill positionthe open upper ovendoor

about37” abovethe floor.

It is important that the oven be installed at or above the

minimum height specified. The uni2has been tested and

approvedinaccordancewith safetystandardsatthis height.

The oven vent area may get hot when the oven is in use.

Following these installation instructions wiil move the vent

areaout of a rangewhere itwould likelybetouched bysmall

children.

Thecabinetmusthaveasolidbottom. Thissolictbottommay

eitherbe atthe floor or 16-1/2”abovethefloor, levelwiththe

bot!om edge of the cutout opening. If the solid bottom isto

beat the floor, two runners,centered within the cabinet and

11“apartmaybeusedto supporttheoven. Besuretheoven

support is solid enoughto holdthe weight of the unit - about

200pounds. Also, be surethe supportis level and stra~ht.

There is no way to levelthe oven after installation.

I (

23-3/4”

k

Fig.1

~

G

Page 5

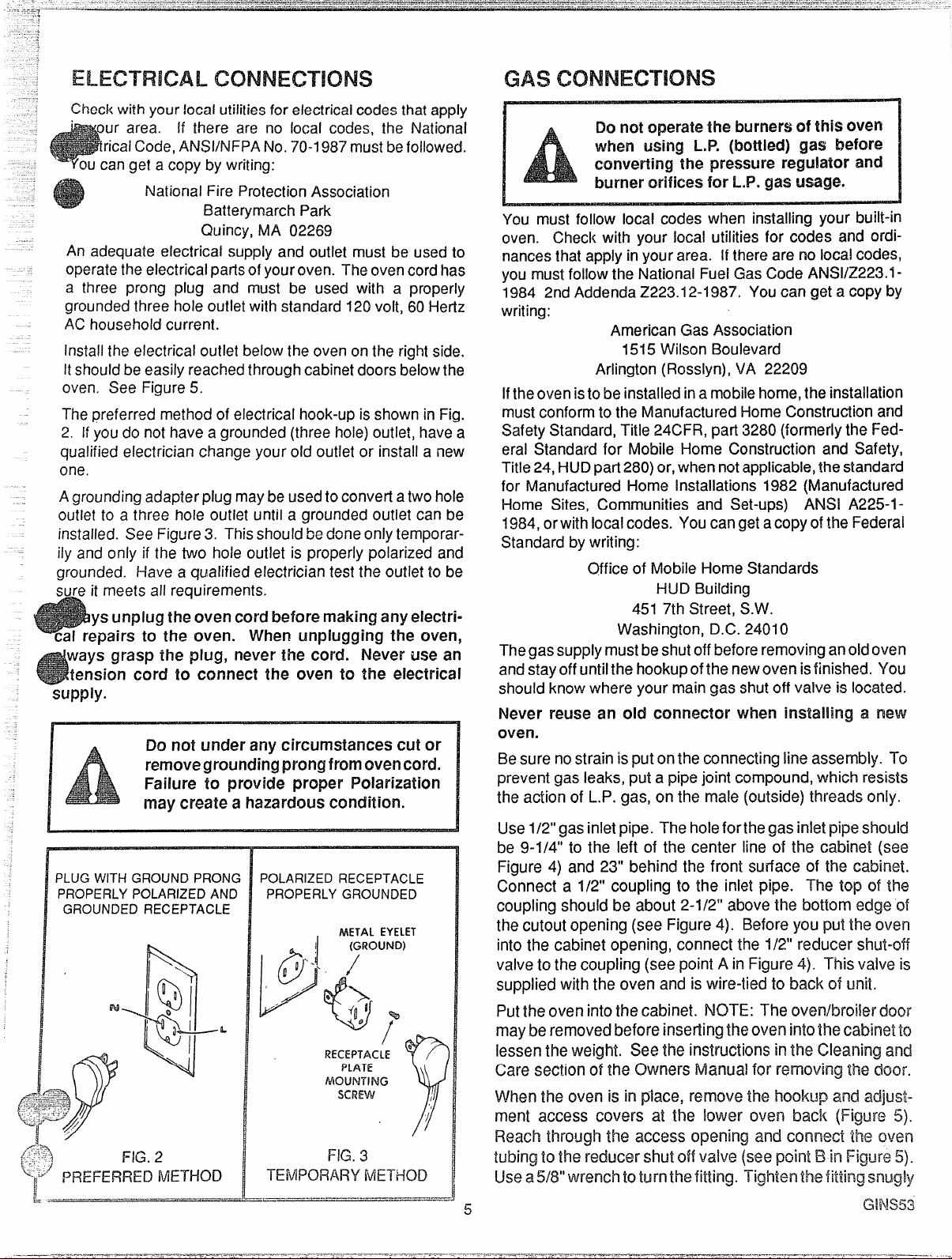

Checkwith your local utilitiesfor electricalcodes that apply

.7

If there are no local codes, the National

e,ANS1/NFPANo.70-! 987mustbefollowed,

copy by writing:

National Fire ProtectionAssociation

Batterymarch Park

Quincy, MA 02269

An adequate electrical supply and outlet must be usedto

operatethe electricalpartsof your oven. Theovencordhas

a three prong plug and must be used with a properly

groundedthree hole outlet with standard 120volt, 60Hertz

AC household current.

Installthe electrical outlet belowthe ovenon the rightside.

Itshouldbe easily reachedthrough cabinetdoors belowthe

oven. See Figure 5.

The preferred method of electrical hook-up is shown in Fig.

2. Ifyou do not have agrounded (three hole)outlet, havea

qualified electrician change your old outlet or install a new

one.

Agrounding adapter plug maybe usedtoconvert atwo hole

outlet to a three hole outlet until a grounded outlet can be

installed. See Figure 3. This should bedoneonly temporarily and only if the two hole outlet is properly polarized and

grounded. Have a qualified electrician test the outlet to be

sure it meets all requirements.

p unplug the oven cord before making any electri-

cal repairs to the oven.

When unplugging the oven,

waysgrasp the plug, never the cord. Never use an

tension cord to connect the oven to the electrical

supply.

Do not under any circumstances cut or

removegroundingprongfromovencord.

Failure to provide proper Polarization

may create a hazardous condition.

P W G P

P P

G R

I

Y

& ,——”—.-.—.-.,. .. . .

P R

P G

M E

/

R e

P

M

S

FIG.3

TEMPCWL4RYMEWKXI

.r-..uc

GAS

cm operatethe burners of this oven

when using LP. (bottled) gas before

converting the pressure regulator and

bur’rw?f’orifices for M. gas usage.

You must follow local codes when installing built-in

oven. Check with your local utilities for codes and ordinancesthat applyin your area. If there are no loca!codes,

you must follow the National Fuel Gas Code ANSl/Z223.11984 2nd Addenda Z223.t2-1987, You can get a copy by

writing:

American Gas Association

1515Wilson Boulevard

Arlington (Rosslyn),VA 22209

Iftheoven isto be installedinamobilehome,the installation

mustconform to the !vlanufacturedHomeConstruction and

Safety Standard, Titie 24CFR,parl 3280(formerlythe Federal Standard for Mobile Home Construction and Safety,

Title24,HUDpart280)or,when notapplicable,the standard

for Manufactured f-tome installations 1982 (Manufactured

Home Sites, Communities and Set-ups) AMY A225-l-

1984,orwith localcodes. You canget acopy of the Federal

Standard by writing:

Office of Mobile Home Standards

HUD Building

451 7th Street, S.W.

Washington, D.C. 24010

Thegas supply mustbeshutoff beforeremovinganoldoven

andstayoff until the hookup of the newoven isfinished. You

should know where your main gas shut off valve is located.

Never reuse an old connector when a new

oven.

Besure nostrain isput onthe connecting line assembly. To

prevent gas leaks, put a pipe joint compound, which resists

the action of L.P. gas, on the male (outside) threads only.

Usel/2’’ gas inlet pipe. The hok?forthe gas inlet pipe shoulci

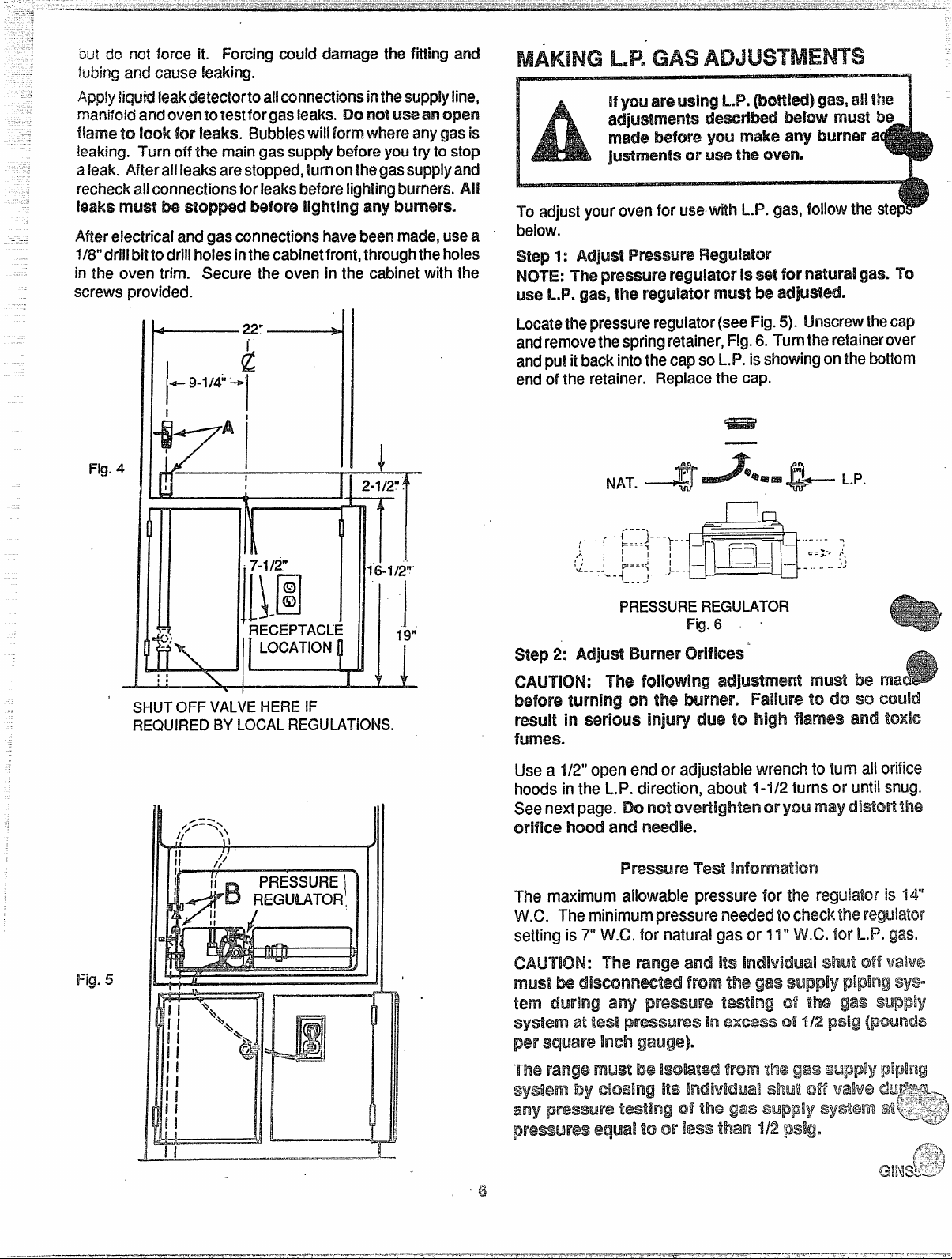

be 9-1/4” to the left of the center line of the cabinel (see

Figure 4) and 23” behind the front surface of the cabinet.

Connect a 1/2” coupling to the inlet pipe. The top of the

coupling should be about 2-1/2” above the bottom edge of

the cutout opening (see Figure 4). Before you put the oven

into the cabinet opening, connect the 1/2” reducer shut-off

valve to the coupling (see point A in Figure 4). This valve is

supplied with the oven and is wire-tied to

Putthe oven intothe cabinet. NOTE: The oven/broiler door

may be removed before inserting the oven

lessen the weight. See the kwtructkmsintheCleaningand

Care section of the Owners Manual for removing the door.

/

;

When the oven is in place, remove the hookup and adjustment access covers at the lower oven back (Figure 5).

Reach through the access opening and connect tlw oven

tubing to the reducer shutoff valve (see point Elin Figure 5).

Usea5/8’’wrenchtoturn the fitting.

5

backd unit.

intothe(x?Mwtto

Page 6

oui dc not force it. Forcing could damage the fitting and

t~~~ngand cause

liquid k?akdetectorto allconnectionsinthesupplyiine$

manifoldandoventotestfor gasleaks. DOnot

fkwnet~ look for leaks. Bubbleswi[lformwhere anygasis

leaking.

T o m gassupplybeforeyoutrytostop

kakin~.

aleak.Af%erallleaksarestopped,tl!rnonthegassupplyand

recheckallconnectionsforleaksbeforelightingburners.M

leaksmust be before any burners.

After

electrical and gasconnectionshavebeenmade,usea

l/13*’driHbittodrillholesinthe cabinetfront,

in the oven trim. Secure the oven in the cabinet with the

screws

LJ?

To adjustyourovenforusewithL.P. f

below.

Locatethepresmm reg.dator(seeFig.5). Unscrewthecap

andremovethespringretainer,Fig.6.Turntheretairwover

andputitbackintothecapsoL.P,isshowingonthebottom

endoftheretainer. Replacethecap.

I

1

A’

Fig.4

,

71

7-1/2W

:

1[).0

RECEPTACL

SHUTOFF VALVEHEREIF

RK?UIR13JBYLOCALREGULATIONS.

+

2-1/2?

TT

j

1

19;

L

1 I

,. --.,

-1

~ ..-..,- -

~==={---;-

,

I

I

,;

:/ ,

W

.4

I

I

B==={ ‘

&

_

4

PRESSUREREGIJLATOR

Fig.6 ~

step2: Adjust EwTiw CMifkx?s’

m?

befcm tw’nh’lgcmthe M!i’rwiF%ih.n todo

result inseriousrlriywy(we WI high imdiWn-4k

be ma

nmws.

Usea 1/2”openendor adjustablewrenchto turn allorifice

hoodsinthe L.P.direction,about1-1/2turnsor untilsnug.

Seenextpage.Do

orifice hood

and needle.

Fwess,nreTest

Fig.5

The maximumallowablep k

V

The r p n t r

s

,

o

W.G.for n g V

Page 7

,

1

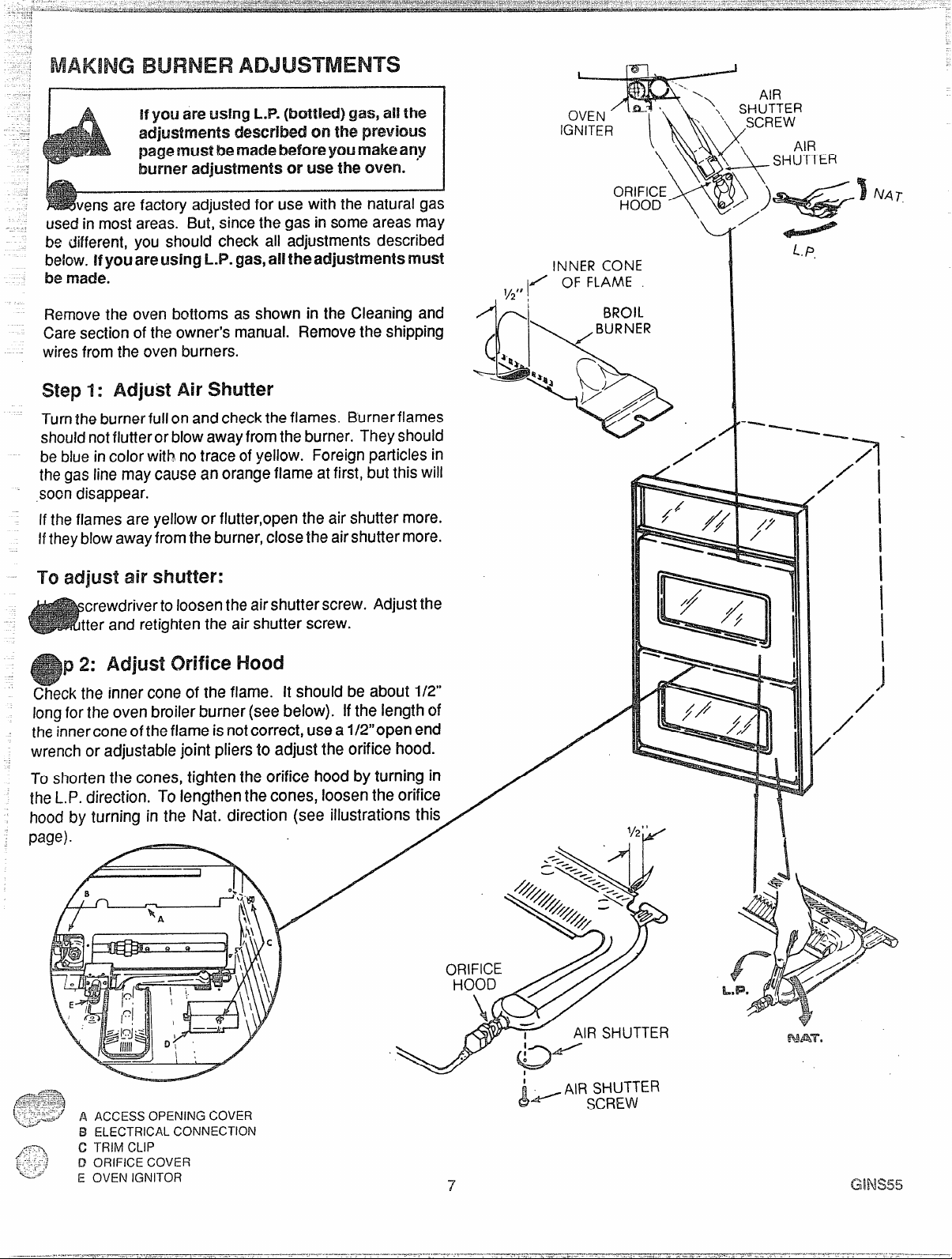

used But, since the gas in some areas may

be different, you should check all adjustments described

below.Ifyouareusing L.P.

be

made.

Removethe oven bottoms as shown in the Cleaning am!

Caresection of the

w f the oven burners.

step 1: Air Shutier

Turnthe burnerfull on and checkthe flames. Burnerflames

shouldnotfiutteror blow awayfrom the burner. Theyshould

bebJueincolor with notrace of yellow. Foreign particles in

the gas line may cause an orange flame atfirst, butthis will

,soondisappear.

Ifthe flames are yellow or flutter,open the air shutter more.

Htheyblow awayfrom the burner, close the airshutter more.

TO adjust air

crewdriverto loosenthe airshutterscrew. Adjust the

‘(

I

1

\

.

tter and retighten the airshutter screw.

2: Adjust orificemod

p

Checkthe inner coneof the flame. It should be about 1/2”

l forthe oven broiler burner (seebelow). Ifthe length of

!heinnercone ofthe flame isnotcorrect, use a l/2’’open end

wench or adjustable joint pliers to adjust the orifice hood.

I_oshorten the cones, tighten the orifice hood by turning in

heI-P. direction.

lood by turning in the Nat. direction (see illustrations this

o m Removethe shipping

ToIengthen the cones, loosen the orifice

gas,a!ltheadjmtmnts mm!

INNERCONE

1X FLAME

1/2”,

c

-+’ ,,4 ‘~

1!

a

L

.: .

\

/

L

L.P.

IN?OIL

B

LA) //y

I

I

I

I

1

I

)

/

/

/

1/2

“9’)”- “

A O C

E C

T C

O C

O I

OJJI(J

‘J

AIRSHUTTER

- AIR SHUTTER

L

d--- sc~~w

f?wwr.

Page 8

u

Keep this book for later use.

Besure

your oven is installedand grounded prop-

erly by a qualified technician.

keep the oven area clear and free from

things that will bum, gasoline and otherflammable

vapors and liquids.

Always change oven rack positions while oven is

coo!.

broiling,alwaystakethe broiler panoutofthe

ovenandclean it. Leftovergrease inthe broilerpan

can catch on fire next time you use the pan.

Ahnmysuse dry pot holders when removing pans

from the oven.

Moist or damp potholders can

cause steam burns.

Always usecare when opening oven door. Let hot

air and steam out before moving food.

Always follow cleaning instructions in this book.

Teach children notto playwith oven controls orany

other part of the oven.

I r or replaceany parl of the

unlessinstructionsaregiveninthis book.Al! d

work should be done by a ski!ledtechnician.

Never heat unopened foodcontainers. Pressu

build up may

m container burst and caus~

injury.

Never leave jars or cans of fat or drippings near

t ovNeMgrease buildup onycwroven.

You can keep grease fires from starting if you

clean up grease and spills after each oven use.

Never use aluminum foil to line oven bottoms.

Improper use of foil could start a fire and cause

incomplete combustion.

Never block the flow of combustion and ventila-

tion air through oven vents.

Never try to move a pan of hot fat, especially a

deep fat fryer. Wait until the fat has cooled.

Never leave children alone or unattended where

an oven k3in use.

Never use your oven for warming or heating a

room. Such use can be dangerous and c

damage oven parts.

Never wear loose fitting or hanging clotheswh

using your oven. Such clothes could catch f

and cause serious injury.

Never use a towel or other bulky cloth as a pot

holder. Such cloths could catch fire on a burner.

Never store things in an oven.

Neverfusewater cma grease f will cmly 1.close oven Ckmr and t u

Spu?ad m m

2. Hfire’ MMmNM?s, soda On the

f oruse adry chemical -kX3rn$29 t

!!30rid t W move‘me park

The California Safe Drinking Water and Toxic 1

Act requires the Governor of California to publish a list of

substances

businessestowarn custonwrsofpotentialexposuretosuch

substances.Gasappliancescan causeminorexposureto

threeof thesesubstances,namelybenzene,forrmakkhyde

knowntoMestatetoczwseCarxerandr

andsoot,causedprimarilybytheincompletecombustionof

naturalgasorL.P.fuels.

bya bluish

pkte combustion.Expc&m3to these substancescf$~~}3

minimizedfuriherby ventingwithan openwindoworN%+$9

a ventilationfanor hood.

r a y f!arne,willminimizeirKgn-

Properlyadjustedranges,indicated

‘“-’~

<:;;2’.

,,-Y;,j

;J

L_

8

Page 9

,

;

-

% =%2?-

-

.

,-A.

Themodel

and serial number @

yourfWl!m!sfCW’?dcma

tag, the upper

door, ‘on the left

f the front WM’lx?.

the numbers Into

space on page 2 of

manual.

1.

2.

3.

4.

5.

.

o Light s

LowerOven (Xntmi

Oven Vent (area may get

130tduringoven use: Do not

block vent)

Electronic Oven Co@rol

BroilPanandGrid

Ftemvabk?CWerIRacks

6.

(

7.

FWmvab!eOvenBottom

RemovableOvenDoor

8.

Lower Oven

9.

(9

and

/

Whenvou turn the upper or lower oven on, one of the glow

barign~terbeginsto %at. Whenth@igniter is hot enough, in

about1

minute,the glassflowsintotheburrterandisignited.

Theigniterglowsbrightorangewhen hot. Itcyclesonand

offwiththethermostatandwillglowwhenevertheburneris

on.

A Du~i~Q~PQ~~~f~~~~~~~~~~~f~~’~~~n~’ ‘

CIVEN

Whentheovenison,heatedairrnovesthroughavent under

thecontrolpanel. This hotairmaymakecontrolpanelarea

ho!.

See the following pages.

Toi3ake:

1.Turn LowerOven

~ d t

2. WhenfinishedturnLowerOvenControlto OFF. The

lowerovencanbeusedwhilethe upperovenis on. You

cannotbroilinthe loweroven

9

GBlFc15

Page 10

Range

—-—.

TIME

Shows the time of day, the times you set for

maticovenoperationsor timer,oventempera-

ture

SET KIWX3- Turn to set times and temperatures.

2.

FUNCTION INDICATORS

3.

whether oven isbaking or broiling and whether you

are using the timer.

ALJTCNMATICOVEN INDICATORS-Show whether

4.

an automatic oven operation that will start later

(delay) iscurrently programmed and whether oven

or stop time is being shown.

OVEN TIME - Pushbefore setting length of time the

5.

oven will be on (for automatic oven operations).

TEMPERATURE DISPLAY WINDOW -

or broil settings you have selected.

- Light up to show

o

auto-

4

TIMER - Push

8.

BAKE - Push before settingtemperature.

C - C e e c

10.

t

you’ve made a mistake in programming.

EIRCNL- Pushbeforeselectingbroil setting.

It.

3

0

b s a t

oven off orto clear everything”

S

STOP TIME - Push before selecting the time

6.

want the oven to turn off

o

C -

7’.

of day into the

Push before setting clock or to bring time

l DISPLAY WINDOW.

C

B

a

C S O

T

\

10

r

PUSH

B

T

T

J

Page 11

-:.:

.............. ... . .. ......... .. . .

J

.

TO OR

2

d w I r

A t w s o r

OVEN OFF’

3 PUSH

n

)

ON OFT

[

/

i

— — —

n

T

Whencook e a s

wiil t

C

C S

l

O

w

n

L

. (

C

A

.

1

~

?

I

Y =’

;

——. —

C

T

W s r a s

o w t o

I

O

S

n

T

1 f

1

PUSH

(s”

—

w c

TOSET LENGTH

C

OR

Attention T s p

1.

p e s a

t t A

u y s a teCANCEL.

TURNTOSET

T

. . . .-

~\

PUSH

1

s HOLD

o“

3 S C

NOTE:T’tIetimer is a and will rm$operate

the oven.

You mayrecall f p b o

f

2. Funciion

o r f

s

E s t a p

~ b

& p

s a

Page 12

-------

~:..:,,,,..,..

,... .. ......

...,.

. ,..... . ..

“

;.;..

..:..::. . . .

... . ......

...

e

Alwaysfollow recipecarefully.

Measureingredientsproperly.

Use proper pan placement.

Let the oven preheat thoroughly before

Cookingbaked products.Allow

10-d5 mtin-

utespreheattime.

Avoidopening the door too often to check

the food during bakingas heat will be lost.

Thismay resultinpoorbakingresults.

Cakes, cookies, muffins,and quick breads

should be baked in shinypans— to reflect

the heat

— becausetheyshouldhavea light

golden crust. Yeast breads and pie crusts

shoul~ be bakedin glassor dull (non-shiny

pans)

— to absorbthe heat — be~au~etheY

shouldhavea brown,crispcrust.

@

Placepans on the ovenrackswith 1Vi- 2“ of

space cm all sides of each pan. Avoid

air

overcrowdingthe oven.

@

Pans too close to each other, to oven walls

or to the oven bottom block the free movement of air. Improper air movement causes

uneven browning and cooking.

2 cake hyers

Q

baking should be done on the second

shelf posRiOnfrom the bottom. When baking

several items, use two shelves placed on the

second and fourth rack positiOnSfrom the

bottom of the oven. stagger pans so that no

pan is directly above another. E3akf3angel

f(x)d cakes on the first shelf p(xithm from

the of the oven.

Oven temperatures should be reduced 25

degrees below recommendedtemperatures

if you usedark pansor ovenproofglass.

There may be some odor Whenthe oven is

first used. This is caused by the heating of

ne-wpartsand insulation.

@

Do not cover the oven bottom or an entire

oven rack with foil. The foil can block nor-

mal heat flow, cause cooking failures, and

damage the oven interior.

12

Page 13

WHEN

3

Most f b 1 S S

LO B s a e b

irq of foods that should be c the well done

s ( t porkc p

@ Broiling is cooking by direct heat from the broil

burner.Tendercutsof meator marinatedmeatshould

be selected for broiling. For best resuRssteaksand

chopsshouldbeat least%“thick.

@After placing food on the broiler pan, put the pan on

n oven rack in the proper rack position.The recom-

mended rackpositionand cookingtime can be found

inthe chartat right.

@The closer the food is to the broil burner, the faster

the meat brownson the outside, yet stays red to pink

in the center. Moving the meat farther away from the

burner letsthe meat cook to the center while browning outside. Side one should be

longerthan sidetwo.

* Your oven door be

@

rangefor broiling.They aredesignedfor proper

the broiler pan and gridthat came with your

1

TO

B 2

6

c m

while

d

and liquids andhelp preventspatter,smoke

or fire.

e DO ~of when broiling. Preheating

m

thermostat to cycle the broil burner off and on.

For even broiling on both sides, start the food on a

cold

p

Q T t ~ i

the fatty edges to keep the meatfrom CWhI$J

A-F~_

,..g.e-=..-=---

~~~~~;=k juiciness, salt the first side just before

turning the meat.

,s-7) sw-!hg.

f- -.-l

!. -

. ,.*

of fat from steaksand ChOpS.S!it

Salt the stxxmd side just befme

E3rushchicken and fish with butter several times as

they broil.When broilingfish, greasethe grid to keep

itfrom stickingand broilwith skinsidedown. It isnot

necessaryto turnfish.

Neverleavea soiledbroiler pan in the range. Grease

in the pan may smokeor burnthe nexttime the oven

isused.

Be sureyou the correct for

QXNa greasefire.see the

Do nd txww the Mob grid foil.

drainaged hot fatmay txwse a Bw’$mw

PO(M’

me.

If a firestarts,dose oven door and turn

mnhds M. M conhues, throw baking

soda the me.Dcl notputwater the

me.

Rack

Fod

Position

4=

1=!LOwest

Steak - 1“ Thick

Rare

Medium

Well Done

Ground Beef Patties

Medium

Wel! Done

Lamb Chosm- 1“Thick ] 3

Pork Chops - 1“ Thick

Pork Shoulder Steaks

l-lamSlice - fl”Thick

Fish (Fillets)

Chicken (Halves)

Frankfurters

Sandwiches

This chart is a !2y37eralguide. The size, weight., tl7ick-

4

3

3

3

3

3

3

3

3

1

3

2

I

riess, and starti~g cd the food as well as

your own personal preference will affect the

time. Times in the chart are based on the food being at

Totai

I

1

10-12

14”16

20-22

11-13

13-15

16-20

20-25

15-20

14-16

10-15

40-60

10-15

6-10’

I

1

Time

I

1

Page 14

Ame

-

314cup margarine,softened

7cup sugar

2eggs

1cup sour cream

2 cups all-purpose flour

1teaspoonbaking powder

1teaspoonsoda

1/2teaspoonsalt

1teaspoonnutmeg

3/4 cup light brown sugar

1/2cup chopped pecans

1teaspooncinnamon

Creammargarine andsugaruntil light andfluffy. Add eggsand

saltand nutmeg. Add to batter and mix well. Pour batterinto gr

Combine brown sugar, pecans and cinnamon; mix well. Sprinkle one half of this mixture over cake batter;swirl mixture

through batter.Sprinkle remaining one half mixture evfmlyovercake batter.

c w C f b p s

‘ f x x b

Cover and chill overnight.

toothpick.

A delicious quick-to-make hearty stew that.will feed a crowd or feed the family. Refrigerate or freeze the remainder for

another day.

7-10 oz. can barbecue beef

7-70 oz. can barbecue pork

1-24 oz. can Brunswick stew

1-5 oz. can boneless chicken

1-12 oz. can vacuum packed corn niblets

7-76 oz. can baby lima beans, drained

2-16 oz. cans stewed tomatoes

; - J~I/~Oz.can sliced okra, drained

U and bake in preheated 350°F oven for 35 to 45 minutes or until caketests done with

2-10 oz. pkg. frozen chopped broccoli

1cup mayonnaise

Ycup sharp cheddar cheese,grated

2 eggs, beaten slightly

1can cream of mushroom soup

2 tablespoons chopped onion

1cup cheese cracker crumbs

Preheat oven to 375°F.Cook broccoli according to package directions; drain.

Mix with other ingredients. Pour into greased two (2) quart casserole.Sprinkle

with cheese cracker crumbs. Bakeat 375°F for 20-25minutes.

Elrainokra and lima beans. Add to all other ingredients in 4quart

@m.Heat on medium to serving temperature.

P

Page 15

1/2C mtwganm

CL@chopped gpwmpepper

cup chopped onion

3 eggs, well beaten

17oz. can cream style corn

17oz. can whole

muffin mix

7 cheddar chcmw?,shredded

Preheatoven to

350°F.$13uk?green peppers and onion in margarine; combine

with remaining ingredients except cheese. Pour into greased two (2) quart casserole; sprinkle with cheeseand bake45-55minutes in 350°F oven+.Letstand 5

minutes before serving.

(M@my:Illinois

Cooperative Extension Homemakers

squaresserni-sw@ chocolate

1stick margarine

1cup sugar

1/4cup flour

2 eggs

1tsp. vanilla

Dash salt

I%CUpchoppedpecans

Frozen 9“ pie shell

W oven to 350*F. Melt chocolate and margarine. Add othe~

ingredients to melted mixture. Pour into unbaked pie sheil and

bake 35-40 minutes or until pie appears set. Serve warm with ice

cream or whipped cream.

w

.

1-20 oz.

a pie filling

1/2 cup sugar

1-9 oz. box white cake mix (1 layer size)

1stick margarine, melted

1/2 cup chopped pecans

Preheat oven to 350°F. Place in layers in greased 9“ or 10” square baking dish:

apples, sugar, dry cake mix. Pour melted margarine over top of cake mix. Bake

at 350° F for 35 minutes. Sprinkle with pecans. Continue baking 15 minutes.

w

Serve

Page 16

..=

.-

..... .. ........ .......... .............

...

.-

Onthefollowing Pac&, the removable pals cm

your oven are shown. Referto those pages

when cleaning your range.

~ w a m d a c

PART

Control pane{ and knobs

Glassoven cfoor/wincfQw(some

models)

Oven finishes:

Continuous-cleaning (some

models)

Standard porcelain enameled

ovens, porcelain enameled

(smooth) areas of continuous-

cieaning ovens, broiler comPa~ment, broiler pan

CLEANINGMATEFtM-S

Detergent,warmwater,softcloth

Glasscleanerandpapertowels

See special instructionson previous Page”

Detergent,warmwater, scouring

pad or soapfilled steel WOOIpad

or non-aerosol (brush-on)o~en

cleaner

are safe to usecmall cleanable parts of your

range, /+[1purpose cleaners,such as F%rNastik@,can also be used. Do not use metal sw3uring pads, exceptwhere recommended.

Donotuse

foreasiercleaning.

Removestubbornsoilwithpasteof baking

sodaandwater. Donotuseabrasivecleaners. Rinsethoroughly.

Rinsethoroughly aftercleaning.Whenusing

ovencleaneroncontinuous-cleaningovens

besureto keep it awayfromthe continuOuscleaning finish. Oven cleanerswili damage

the continuous-cieanin9 finish. Oven bottom can be removed for easier cieaning.

Remove oven bottom of continuous-Giean-

ing ovens if cieaning it with oven cieaner.

abrasivecleaner~.Knobspul!off

--

O Racks (and guides on

some models)

Detergent, warm water and

scouring pad or soap tilled steel

wool pad

Removefrom ovento clean. Drythoroughiy.

Page 17

HOLES

.1

1-

ecarefulnot toscrakh the ovenfinish when insta$!ing

r removing oven racks.

“i-clmm!!:

.1. PM thepegsontheendofthe rackguideintotheholes

intheovenback.

Lockthe front hook in the slot inthe oven side.

2.

3.

Set the raised back edge of the oven rackson a pair

of rackguides sothe hooksatthe sides ofthe rackrun

underneaththe rackguides.

4.

Pushthe rack in until you reach the bump inthe rack,

Ihen lift the front ofthe racka bil and push the rackall

the way in.

r

To

,Pullthe oven rack out, then

2. Lift thefront ofthe rackguideto unhookitfromtheoven

pky

*

11

*/%””” “-‘ II

:

/

f

BUMP

/

the door.

2. Lowerthe doortothefullyopenpositionandpushthe

r tabs down (see fig. A).

Removetheovenbottomfor easier cleaning.

Becarefulnotto scratchthe ovenfinishwhen removing or

installing oven bottom,

remove:

-i-cl

1. F oven racks and guides (see above).

2. Lift the front of the oven bottom enough to clear the

front frame, then pull OUI.

To replace:

~ Slidethe oven bottominto the oven so thatthe back

*%*:1 .

.-----.=—~>-..—=

i----!=---.-,--2

.,,

,.-=-”-..d—>w-

~~+;-%

(

[~:% 2. LowerihefrOntof theov@nbo~omin?oPlacebehir]dthe

. .

edgeoftheovenbottomresisonthe

oven wall.

..

ridge inthe back

C ‘II

Fig.

I%(X=JTFRAME

//

\%’&.

-“/

l%. D I

1

.

I

Page 18

Do fnog wan bulb. notWdl bulbwith wet

hands. Newerwipemen light areawith wetcloth.

M& touch the electrically live metal collar on the bulb

when replacing it.

Replacethe bulb with a 40 watt, appliance bulb. An

appfiance b is’smailer than a standard 40 watt household bulb“andis made to withstand high oven tempera-

tures and havea much longer bulb life.

18

cHvmn-02

Page 19

%aw?m’ie t cmforW

0

e (Mm burnersdo notwork.

(Ms supplynotconnectedor

notturnedon. If usingM.

gas,tankmaybeempty

0

Appliance not properly

groundedor polarized. This

canaffectsparkignition.

e

Controls

9

Burnersnotadjustedproperly

notsetcorrectly

“ (Meckthe reducerstwt-offvalvearid~he

gassupplyshut-offvalvetoIX!surethey

areopen(seeinstallationsection)

IfusingL.P. gas; isthereanygas inthe

L.P. tank?

G Checkinstallationsectioninthisrn~nual.

e Check operatinginstructionsin this

manual.

o Foodsdo notbakeproperly

o F b p

~ O smokes

Oven not preheated long

enough

Improperrackor pan place-

ment

Ovenventblockedorcovered

Improperuseoffoil

Impropertemperaturesetting

forutensilused

Recipenotfollowed

Usingimpropercookware

o Improperrackplacement

o (Menpreheated

~ Improperutensilused

o Improperbroilingtime

~ Dirtyoven

Besureto preheat.

10minutesbelow350degrees

IS minutesabove350degrees

Maintain

unikmnairspace arotmdp

andutensils; seeovencookingsection.

Besureovenventis notMocked

Foilusenotrecommended. Reducetemperature25degreesforg~a$$

or dulVdarkenedpans.

!srecipetestedandreliable?

Seeovencookingsection.

Check broil

section.

Do not preheat

pan placement in broiling

whenbroiling.

Use broiler pan and grid suppliedwith

range.

Checkbroilingchartin broilingsection.

o (Meekfor heavyspiliover.

———

Broilerpanful[ofgreaseleflin

o

oven

~ clean panandgrid aftereachuse.

s Check witch setting.

Checkor replace twe w%w’@

Q

care

Page 20

H )’(3LI service

To obtain service, see your warranty

on the backpage of this book.

We’re proud of our service and want

youto be pleased. If for somereason

youarenot happywith the serviceyou

receive,here arethree stepsto follow

for further help.

FIRST, contact the people who serv-

icedyour appliance. Explainwhy you

arenotpleased. Inmost cases, this

will solvethe problem.

NEXT,ifyouarestill not pleased,write

ail the details-including your phone

number-to:

Manager, Consumer Relations

RCA

Appliance Park

Louisville, Kentucky 40225

F\NALLY, if your problem is still not

resolved,write:

Major Appliance

Consumer Action Panel

20 North VVacker12rive

Chicago,

~ 60606

20

Page 21

I

yoursalessliporcxmcekxicheckto

!!s FULL

f%!’

fxpurchase,we provide,

freeofcharge,partsandservice

laborinyourtmrrwto repairor

replace of theoventhat

failsbecauseofa manufacturing

defect.

Thiswarrantyisextendedtothe

originalpurchaserandanyswceed-

ingownerforproductspurchasedfor

ordinaryhomeuseinthe48 main-

landstates,HawaiiandWashington,

DC. InAlaskathewarrantyisthe

sameexceptthatitis LM!TE~

becauseyoumustpaytoshipthe

producttotheserviceshop or for the

servicetechnician’stravelcoststo

yourhome.

o Servicetripsto t

Ifyouthenhaveanyquestions

about theproduct,

pleasecontactyourdealerm our

I’xmlw.

~ improperinstallation.

Ifyouhavean installation

contact your dealer or instailer. You

.,

are responsiblefor providing adequate e9ectri6al,plumbing and other

connecting facilities.

me year km the date of

p

c

rna!m’idm

Affairsofficeataddress

problem,

WeatRCAstrivetoprovidethehighestquality

p s

Therefore,wehavedesignatedGE

CONSUMER

theserviceindustry,to

service needs. Should your appliance

need service,during the warranty

SEFWKX, aleaderin

Milt your

periodorbeyond,lookintheWhiteor

Yellowpages of

yourtelephone

directoryforGECONSUMERSEFWKX or anAUTHORIZEDRCA

ANCE SERVICER.

APPLl-

Q Replacementofhousefusesor

resettingof circuitbreakers.

~

Failureoftheproductif it isused

forotherthanitsintendedpurposeor

usedcommercially.

0 Damageto productcausedby

accident,fire,floodsor acfsofGod.

WARRANTOR K N(3T RESPCNSH3LEFOR CONSECWENTMd-

DAMAQES.

4

4

Somestatesdonotallowths exclusionorlimitationofincidentalor consequentialdamages,sothe above

limitationorexclusionmaynotapplyto you. Thiswarrantygivesyouspecificlegalrights,andyoumayalsoham

otherrightswhich fromstatetostate. Toknowwhatyourlegalrightsareinyour state,

consultyourlocalor stateconsumer

a o oryour state’sAttorneyGeneral.

Loading...

Loading...