Page 1

....,

.”- —..—— ..—

.——.~

.—

--,:

.. ...—-..—.--—.—---..—-..—.——.

Appliance Registration

Broiling

Burner Ignition

Care and Cleaning

ChCk

Features

Installation

IXnmerAdjustments

Electrical and Gas Supply

Location

LOP.Adjustments

Light Bulb Replacement

10

4-7

9

7

5

4

6

Model and SeriaI Number

Oven Cooking

Problem Solver

Recipes

Repair Service

Safety Instructions

Thermostat Adjustment

10,11

18,19

13,14

2

8

19

Back Cover

,-----

.....

,<

Page 2

Rethbocar

mo

If isintendedto help you operateand

maintain your new oven properly.

Keep it handy for answers to your

questions.

If youdon’t understandsomethingor

need more help, write (include your

phonenumber):

ConsumerAffairs

RC

AppliancePa*

Louisville,KY 40225

I y re

a daov

Immediately contact the dealer (or

builder)that soldyouthe oven.

S t a

Bey re

ser

Check the Problem Soh@r. It lists

causesof minor operating problems

that youcan correctyourself.

Wrdot moa

senwm

You’llfindthemon alabelonthefront

of Iheovenbehindthe ovenor broiler

door.

Write these numbers into the space

below.Alsowritethe numbersintothe

spaceon the warrantycardthatcame

with your oven before you send the

card in.

ModelNumber

SerialNumber

Usethese numbers in anycorrespondenceorservicecallsconcerningyour

oven.

Page 3

/

Se

yo

re

-—-.——..—.. ——.—..

—.—

\

FOR

Hy smg

qxWi

1.

Dotoeleswi

2

Extia o fl

3

4

Immec y g su

D n s o u g o o

flv a l i t

vio t o a o a

S

/

L

L

T adjui t InsSe! b

mabey t t u y o

[fa us!lJPeG (b

gaa L adji t Ins

mub m beu

I

t hio t o m u t m f

tofuo c po

o i n pradf m

3

GNOT03

Page 4

.-...—.-

.

.——.———-

-.

fNSTN-f&R: Leavethese instructions with theapp!lance

-I-Us-r

1.1/8”drill bil

2. Eleclric or hand drill

q Flatbladedscrewdriver

v.

4. No. 1or No. 2 Phillips screwdriver

5. Pipe Wrench

6. Pencil

7. Ruleror slraight edge

8. Hand or sabersaw

9. 5/8” wrenchand 1/2” wrenchor adjustablewrench

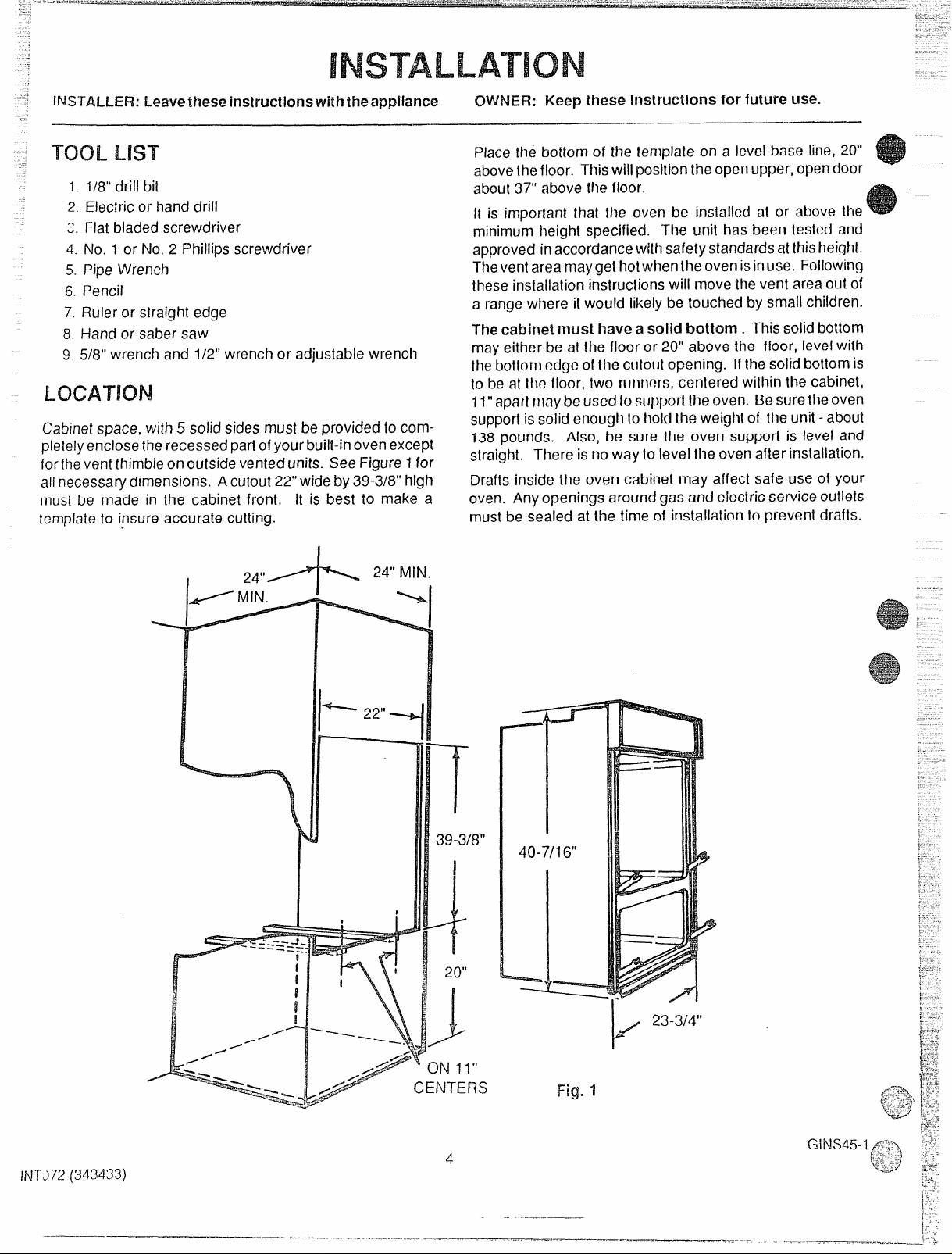

Cabinetspace,with 5 solidsides must beprovidedto com-

pletelyenclosethe recessedpartofyourbuilt-inovenexcept

forfhe ventthimbleonoutsidevenfedunits. See Figure1for

allnecessarydimensions. A cutout22”wideby39-3/8”high

must be made in the cabinet front. It is best to make a

templaieto insure accurate cutting.

CNNNER:Keep these instructions for future use.

Placethe bottom of the template on a level base line, 20”

abovethefloor. Thiswillpositionthe openupper,opendoor

aboul37” above the floor.

His importan! thal the oven be installed at or above the

minimu’mheight specified, The unit has been tested and

approvedinaccordancevdthsafetystandardsat thisheight.

Theventareamaygethotwhenthe ovenisinuse, Following

theseinstallation instructionswill movethevent areaout of

a rangewhere it would likelybe touched by smallchildren.

Thecabinet must have asolid bottom. Thissolidbottom

mayeither be at the floor or 20” above the floor, levelwith

thebotlornedgeofthe cuto[ltopening. If the solidbottom is

to be at thf?floor, two rllntwrs, centered within the cabinet,

11”apfitt IIIaybeusedtosupporttheoven. fl? suretile oven

supportis solid enoughtoholdtheweight of the unit -about

138pounds.

straight. There isnowayto levelthe ovenafter installation.

Drafts inside the oven cabinet may affect safe use of your

oven. Anyopenings aroundgas andelectricserviceoutlets

mustbe sealed at the time of installation to preventdrafts.

Also, be sure the oven support is level and

~ 24”MIN.

c

EfW

11“

‘ERS

23-3/4”

k

Fig. 1

IN1J72(343433)

.—————-

4

-.

Page 5

Checkwith yourioca!utilitiesfor electricalcodesthat apply

your area. Uthere are no local

lecMcaicode,

You

canget a copyby writing:

An adequate electrical supplyand outlet must be used to

operatethe electricalpartsofycwroven. Theovencordhas

a three prong plug and must be used with a properly

groundedthree hole outlet ina standard120volt, 60 cycle

AC household current. Never use an extension cord to

connectthe oven to the electricalsupply.

installthe electricaloutlet belowthe oven on the rightside.

Itshouldbe easily reachedthroughcabinet

AN!3VNFPANo.70-1987mustbefollowed.

National Fire ProtectionAssociation

13atteryrnarchPark

CMincy,MA 02269

codes,the National

doorsbelowthe

oven.SeeFigure5.

Thepreferedmethodof electricalhook-upisshowninFig.2.

If you do not have a grounded (three hole) outlet, have a

qualified electrician change

youroldoutletor installa new

one.

Agroundingadapterplugmaybe usedtoconverfatvvohole

outlet to a three hole outlet until a grounded outlet can be

installed. SeeFigure

ily andoniy if the Mo hole outlet is properly polarized and

arouncied. Have a cwalifiedelectrician test the outlet to be

meetsallrequirements.

re it

3. Thisshouldbedoneonlytemporal-

Alwaysunplugtheovencordbeforemakinganyelectrical

irs to the oven. When unplugging the oven, always

sp the plug, never

Do n under any Wcwnstancesc or

removegroundingfprcmg

Failure to provide proper polarization

thecord.

f csvencord.

may causeshock and fire hazard.

PLUGWITHGROUNDPRONG

PROPERLYPOLARIZEDAND

GROUNDEDRECEPTACLE

POIARIIZEDRECEPTACLE

PROPERLYGROUNDED

METALEYELET

o

VQ

g‘ ‘ .../

(GROUND)

RECEPTACLE

FUTE

MOUNTING

“< SCREW

141

KM

n c the+bwmm o MS oven

when using i (imttkd) gas before

the preswm$ tmcl

burngasusage.1)’Mg$l

f!arne$

Swkms injury.

You must follow local codes when installing your built-in

oven. Check with your local utilities

nanceswhichapplyin

you mustfollow the NationalFuel GasCodeANSl/Z223.11984and Addenda Z223.12-1987. You can get a copyby

writing:

Arlington (Rosslyn),VA 22209

Iftheovenisto be installedina mobilehome,the installation

mustconformto the Manufactured Home Constructionand

SafetyStandard,Title 24CFR,pad 3280 (formerlythe

eralStandardfor

Title24,HUD,Part280)or,whennotapplicable,theStandardfor ManufacturedHomeInstallations1982(Manufac-

turedHomeSites,CommunitiesandSet-ups),ANSI

1984, or with local codes.

standardsby writing.

Officeof MobileHomeStandards

Thegassupplymustbeshutoffbeforeremovingan’olcloven

andstayoffuntilthehookupofthenewovenisfinished.You

shouldknowwhereyourmaingasshutoffvalveislocated.

Neverreuseanoldconnectorwhen installinga,newoven.

Be

sure nostrain isputonthe connectinglineassembly.To

preventgasleaks,putapipejointcompound,whichresists

theactionofL.P.gas,onthe male(outside)threadsonly.

Usel/2’’gasinletpipe.Theholeforthegasinletpipeshould

be8-1/4’’totherightofthecenterlineofthecabinet.Connect

a 1/2” couplingto the inletpipe. Thetop of the ccmp!ing

shouldbeabout2-1/2”abovethebottomedgecdtheCMCM

opening(seeFigure4). Beforeyou putthe ovenintothe

cabinetopening,connectthe 1/2”reducershut-oftvalveto

thecoupling(seepointA infigure

withtheovenandiswire-tiedtothe backof theunit.

Puttheovenintothecabinet,NOTE: Theovenandbroiler

door’sshouldberemovedbeforeinsertingMeovenintothe

cabinettolessentheweight.Seethe

andusesectionoftheuseandcaremanual

doom.

md toxic n (xu.ikfGWS4?

for codesandordi-

yourarea, Ifthere arenoIocaicodes,

American GasAssociation

1515Wilson Boulevard

Fed-

Mobile Home Construction andSafety,

AA225.1-

You can get a copy of the

HUDBuilding

4517thStreet,S.W.

Washington,D.C.24010

4 Thisva!veis

Fig..2

Prcm-mdMmmd

WherIthe ovenis inplace,removethe andadjt.M-

mentaccesscoversatfheIowerovenback 5)0

I

Hg.3

throughtheaccessopeningandconnecttheoven !0

5

Page 6

tl~ereducershut-off vaive[see point B in figure 5). Use a

‘

L-

.

;..

~~,

~-,

5/8”wrench10turnthe fit(ing. Tightenthefitting snuglybut

donotforceit, Forcingthefitting coulddamageitandti5ing

andcauseleaking,

Applya soapysolutionto ailconnectionsirrthe supplyline,

manifoldandoventotestforgas leaks. f30not useanopen

flame to look for leaks. Bubbleswill formwhereanygasis

leaking. Turnoff the maingassupplybeforeyoutrytostop

aleak. Afterallleaksarestopped,turnonthegassupplyand

recheckall connectionsfor leaksbeforelightingburners,

Afterelectricalandgas connectionshavebeenmade,usea

1/8”drillbittodrili holesinthecabinetfront,throughtheholes

in the oven trim. Secure ihe oven in the cabinet with the

screwsprovided.

IL----=---+-H

I GAS

r

below.

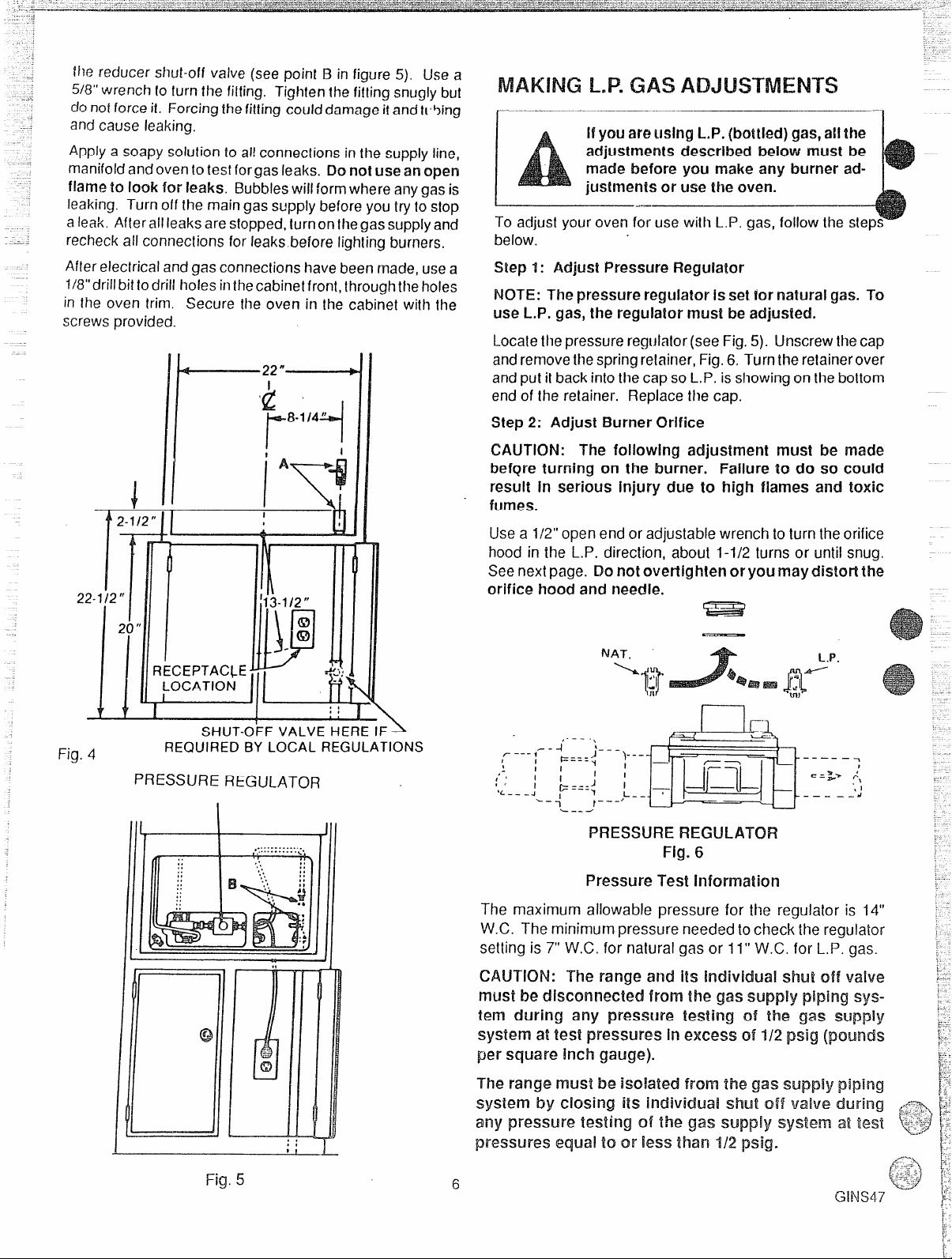

Step 1: Adjust PressureRegulator

hlOT~: Thepressure regulatorissetfornatura

use L.P. gas, the regulator must be adjusted.

Locatethe pressureregulator(seeFig.5). IJnscrewthecap

andremovethespringre!ainer,Fig.6. Turntheretainerover

andput ifbackintothecapsoL,P. isshowingon the bottom

endof the retainer. Replacethe cap.

Step2: Adjust Burner Orifice

CAUTION: The following adjustment must be made

bef~re turning on the burner. Failure to do so could

result in serious Injury due to high flames aild toxic

fu

gas. To

I

22-112“

Fig. 4

II

20

II

SHUT-OFFVALVEHEREIF>

REQUIREDBY LOCALREGULATIONS

PRESSURE REGULATOR

Usea 1/2”openend or adjustablewrenchto turntheorifice

hood in the L.P. direction, about 1-1/2 turns or urlil snug.

Seenextpage. Donot overtlghtenoryoumaydistortthe

orifice hoodand needle.

E=E!z?

—

1

I

I

:

I

J

=-

-1

-l’”-- “’L--

~.. ,{

:

----- =

\-

I —

I

I

,-–_t

PRESSUREREGLJLATOFt

~--- ,- -

1

:

1’‘

,/

% _ - -

I

Fig.6

Pressure Test Iilformatkm

The maximum allowable pressure for the regulator is 14” ‘

W.C. The minimumpressure needed tocheckthe regulator ~

....

setting is 7“W.C. for natural gas or 11” VV.C.for L.F’.gas. :

CAUTION: The range and its individual shut OffVahR ...

must be dkmnmcted from the gas supply piping systern during any pressure testing of the gas supply ~

system a! test pressures In excess of 1/2 psig (pounds $

per square inch gauge).

Fig. 5

—L

T

6

Page 7

f

~..

, ,-

If you are usingi-.P. (bottied) gas, fhe

adjustmentsdescribedon the previous

pagemust bemade 13eforeyoumakeany

burner adjustmentsor usethe oven.

-J

ernoveIheovenbottomasshowninthecareandcleaning

secto thusancaman

Remoth

Ailrangesarefactoryadjustedforusewiththemostcommon

[ype of natural gas.

countrymaybedifferent. Inorderto assuresafeandenergy

efficient operation of this appliance, you should check ail

adjustmentsdescribedbelow and onthe nextpage. if you

areusing L.P. gas, aii the adjustments must be made.

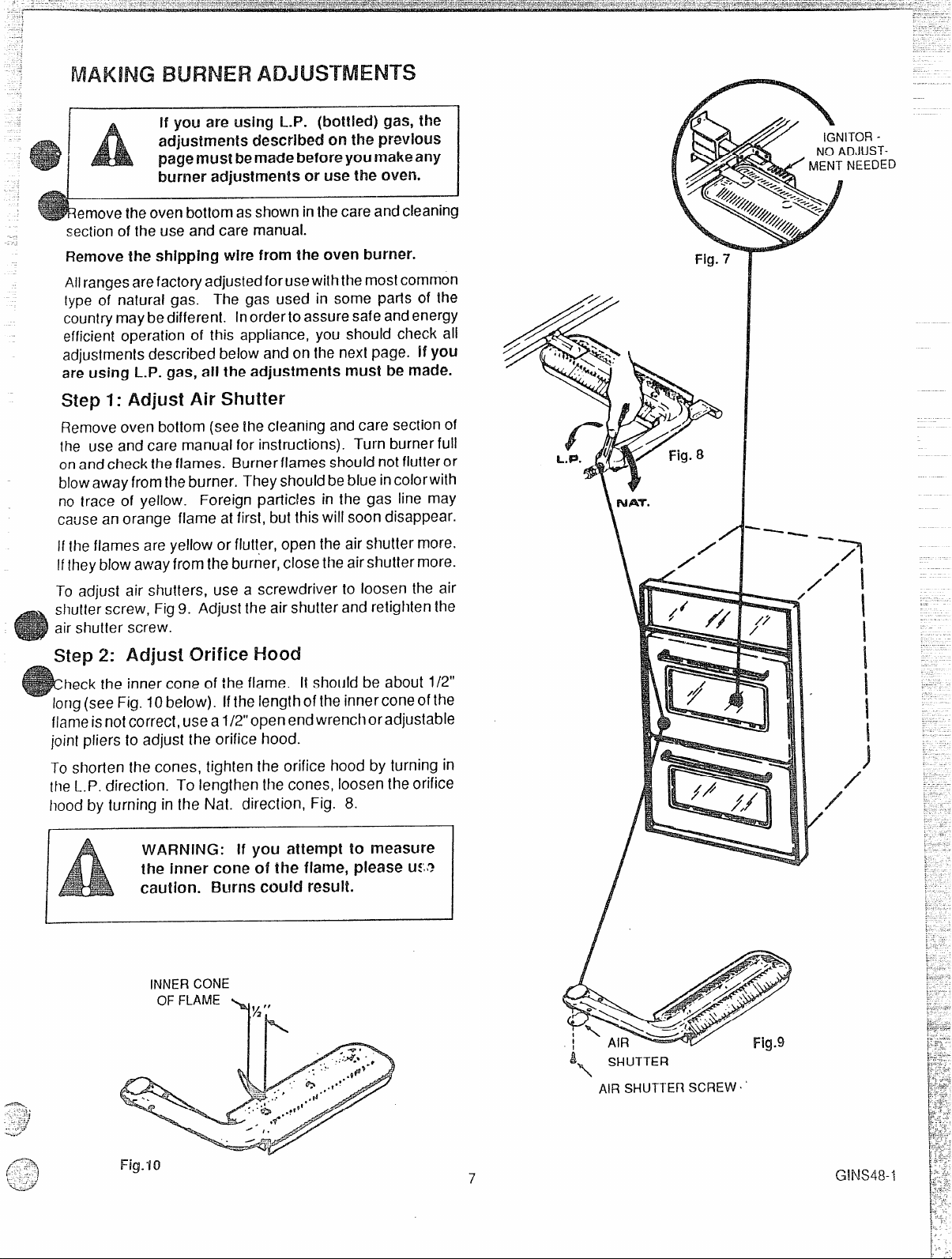

step 1: Adjust Air shutter

Removeoven bottom (seeIhecleaning andcare sectionof

the use andcare manual

onandchecktheflames. Burnerflames shouidnot flutteror

blowawayfromtheburner. Theyshouldbeblueincolorwith

no trace of yellow.

causeanorange flame at first,but thiswill soondisappear.

Ifthe flames are yellow or flutter, open the air shuttermore.

If/hey blowawayfrom the burner,closetheairshuttermore.

To adjust air shutters, use a screwdriver to loosen the air

shutterscrew, Fig9. Adjust theair shutterand retightenthe

air shutter screw.

shipping wirefrom the oven burner.

The gas used in some parts of the

f instrucTurn burnerfull

Foreign particles in the gas line may

N

\

TOFIDJUSTNEEDED

Step 2: Adjust Orifice Hood

.

heckthe inner cone of the flame. It should be about 1/2”

long(see Fig. 10below). Ifthe Iengthofthe innerconeofthe

flameisnotcorrect,usea1/2”openendwrenchoradjustable

joint pliers to adjust the orifice hood.

To shorten the cones, tighten the orifice hood by turning in

theL.P. direction. To lengthen thecones, loosenthe orifice

hoodby turning in the fUa-t.direction, Fig. 8.

—

VWARNifW: if you attempt to measure

the inner cone of the flame, please u:’,,?

caution. Burns could result.

INNCO

O FLA~,

,72

SHUTTER

‘

AIRSHUTTEffSCREW~‘

GINS48-I

Page 8

.

Hu

Kethbof lau

B suyoovi insa gropr

erb a qualtech

ket ova cla f f

thithwibugasa otfla

vapors and liquids.

Always change oven rack positions

who i

co

Afbroialtat brp o o t

ova cli Leftoi t bro

c cao finetiy u t p

Always u d p holw remp

frt ovMoo d potc

castbu

Always usewhopeo doL h

a a sto bemofo

Always focleinsti t bo

Teach chin t plw o cono a

otpao t ov

F&t t r o replace any part of the ove

uninsa g i t b A o

w s b d b a s t

N h unf coP

b u m m cob a c

in

N l j o c o f o d n

t o N l g b

Y c k g f f

c u g a s a e o u

N u alf t l o b

Imu o f c s a f a c

inco

N b t f o coa v

t a tho v

N t t m a p o h f e a

d f f W u t f h c

N l cha o u w

a o i i u

N u Your oven f w o h a

u y o

starting i y

r S u c b d a c

dao p

N w ! f o h c w u y o

S c c c f

a c sei

N u a t o o b c a a p

hoS c c c f o a b

N s t i a o

Rea

undethinfoN

Shoy evneH y w n h t

f rea

Neu

sprethflam

The California Safe Drinking Water and Toxic Enforcement

Act requires the Governor of California to publish a list of

substances knownto the state to cause cancer and requires

businessesto warn customers of potential exposure tosuch

substances. Gas appliances can cause minor exposure to

three of these substances, namely benzene, formaldehyde

watc a grefirwion

D n - t m t p

1 c o d a t O

2 Hf cob s o W

f ‘ u a d chf ‘ t

extinguisher.

and soot, caused by the incomplete combustion of natural

gas or L.P. fuels. Properly adjusted ranges, indicated by a

bluish rather than a yellow

combustion. Exposure to these

mized further by venting with

ventilation fan or hood.

8

f w r i

s c b r

a o ! o using ~-

~~AF(;j~

+_J

Page 9

M

PC)FITANT:

num@ yoov

serial

nb fouo atabeh

eovendoor,ontheleftside

.-

I&the rangefront frame.

copy the numbers into the

spaceon

ual.

Themodeland

pa2 o this man-

I

0

-.-....-.-y.-.

y --~..... . .

!w

11 ~

-...................

. . . . . . . . . . ..... ... .... ..7. .

. . . . . . . . .

1

.-—

I)J–.

-T

1. Oven Light Switch

2.

Oven Control

3. Electronic Clock arm’Timer

4.

Oven Light

<

6. RemovableOvenRacksandGuides

~~-) 7. Removable Oven Bottom

,

‘-----

—

.“...,.,-.:.-,-,.+&,

~c.~“-.,

9

——

—-

.

8.

9. RemovableBroilPanGuides

10.

11.

12. Broiler

“..9

RemovableOvenDoor

Broil Pan and (3icf

RemovableBroilerDoor

GBm4

Page 10

“ S t Then

1. Turnthe Clock/Timerknobinlhe clockwkedirection unt

the words “SETTIMER” aredisplayed.

2. Turn the Clock/Timer knob in either direction to

amountoftirne. Thetimerwil!automaticallystartcountin

down.

Note: To cancel timer,turn the Clock/Timerknob untilthe

display reads:OO

Whilethe timer isbeingused,the time of daywill beshown

in the display about every 10 seconds.

Thetimer is a reminderonly andwill notcontrol theoven.

‘c-.—

3’

CLOCK

TIMER

T Set thClo

1. TurntheclocWtimerknobinthecOuntercloCkwisedirection

untilthe words “SET TIME”are displayed.

2. Turn the Clock/Timer knob in either directionto set the

time of day. Clock is now set.

TOBakeor Broil:

1. Set the OVEfVCONTFIOLto desired temperature or to

f3ROlL. Whenbroiling, besureto setthe knoballtheway

to the stop in the BROIL section of the knob. See the

following pages for more information.

2

Whenfinished, turn OVEN CONTROLto OFF.

O

CC)NTROL

OvenIgnition

When you turn the Oven Control on, the glow bar igniter

belowoven bottom beginsto heat. Whenthe igniter is hot

enough,inabout 1 minute,the gasflows into

is ignited.

The igniter glowsbright orangewhen hot. Itcycles on and

offwith the thermostat and will glow wheneverthe burner.

theburnerand

o

Duringapower faikwethe b c

b l and y Shtx.kfn t RI d w

Oven V

Whenthe ovenison, heatedairmovesthrough aventunder

the control panel. This hot air may make the control panel

area hot.

The vent is necessary for proper air circulation in the oven

and good baking results. Do not block this vent. Doing so

may cause cooking failure, fire or damage to Me oven.

Page 11

.....-.i

~.,,.:,<.,.,,.,

..,.,:.:.:,...,...:.....:.,,-

...............

. .....

,:...,:.......

.,,;:::~.

,...::,

,-....:..

.. .

L t o preheat thoroughly before

cooking 13akeclproducts. Allow 10-15 minutes preheat time.

Avoid opening the door too of-ten tO check

t f d b a h w b l

T m r i p b r

Cacom a q b

shb b i s p — t r

t h

golden c Y b a p c

shb

p

shh a

@Alwforecipe carefully.

@

Meaingrpro

6

U prop plac

(3

Pipao t ovraw 1M- 2 o

— b t s h a l

baked i g o d (

—t a t h —

brown, crisp crust.

b t

a spo a sio e p Av

overct ov

.

Pans too close to each other, to oven walls

or to the oven bottom

ment of air. Improper air movement causes

uneven browning and

block the free move-

coo

O tems b r 2

deb ret

i y u d p o o p g

T m b s o w t o i

f u T i c b t h o

n p a in

D n c t o b o a e

o r w f T f

mal

.

h f c c f a

dat o in

2 cake layers

4 CA%?layers

Q Moibaking shot. ddbe done on the second

shelf

posfrt botW ba

seviteu t sheplo t

seca foraposf t

boto t ovStap s t n

.

-4/

~ ,-

‘&.

p i CtilabanoB an

..

“ fo

t boto t ov

..

cakes on the first shelf posf

.

11

.

.

can block nor-

Page 12

s F3rushchickenandfishwithbutterseveraltimesas‘they

—

.————. .——————.-——

broil.Whenbroili~fish,greasethegititOpWve~$t~iW

andbroilwith

fish.

skinsidedown. Mis notneces~awto turn

Broiling is cooking by direct heat from the broii

burner.Tender cuts of meator marinated meat should

be selected for broiling. For best results steaks and

chops should be at Jeast%“thick.

After placing food on the broiler pan, put the pan on

the rack in the lower broiling compartment. The

recommended rack position and cooking time can be

found in the chart at right.

The closer the food is to the broil burner, the faster

the meat browns on the outside, yet stays red to pink

in the center. Moving the meat farther away from the

burner lets the meat cook to the center while browning outside. Side one should be cooked 1 -2 minutes

I

‘onger than side two. ‘

40LMOVWIC&XXand !XOMWdoor sim.dcif be cxm)!eteiyckm?dwhile broiling.

Jseonly the broiler pan and grid that came with your

ange for broiling. They are designed for proper drain[geof fat and liquids and help prevent spatter, smoke

wfire.

10not pwheat when broiling. Preheating may cause

!3

Ie thermostat to cycle the broil burner off and on.

tl-

F

w even broiling on both sides, start the food on a

C(

id pan.

T

‘im the outer layer of fat from steaks and chops. Slit

th

e fatty edges to keep the meat from curling.

w maximum juiciness, salt the first side just before

Fc

ming the meat. Salt the second side just before

tul

se

wing.

* hive a sdk! Lwdk pan h

in the pan may smoke or burn the next time the oven

is used.

@Be sure you $Wmw

w? mn’ed ‘for

the Grease

w agreaseflSeethe w on s

m n

l%xwdrdniaged hot M maywwe a !m3iler

m

If a f $ dose h? aw?lmma! kmwer

dcms am!

throw bakingsoda cm the

water on the fire.

After placing food on the broiler pan, slide the pan into

the proper rack position in the lower broiling compartment. Be sure the sump (greasewe!!) inthepanisto the

frontof the range.

Steak- 1“ Thick

Rare

Medium

Well Done 2 20-22

Ground Beef patties

Medium

Well Done

Lamb Chops - 1“ T

Pork Chops - 1“ Thick 2

Pork Shoulder Steaks

Ham We - 1“ Thick

Fish (Fillets)

Chicken (Halves)

Frankfurters

I

b

Bacon

Open-face Sandwiches 2

This chart is a genera! guide. The size, weight, thick-

ness, and starting temperature cd the fcmd as weli as

your own personal preference will affect Me mxking

time. Times in the chart are based on the food being at

refrigerator temperature.

4XWWt e broiler grid with k

t controls o MWe

Fhck

I

Food

F@Mon Total

3 =

1 =Lowest

2

*

1

2

2

f IDor p

-

1

I

20-25

I

4

I

10-15

I

5-7

6 :,, ..

I

I

I

I

I

I

&q:

::~’~=$

7-’5~-;.

b

i-.<,,.

; -;

<

.

Page 13

A

R

4i

3/4cup margarine,softened

1Cupsugar

2eggs

7cup sour cream

2 cups all-purposeflour

1teaspoonbakingpowder

1teaspoonsoda

1/teaspoonsalt

1teaspoonnutmeg

3/4cup light brown sugar

1/2cup choppedpecans

1teaspooncinnamon

Creammargarineandsugaruntil light andfluffy. Add eggsand sour cream;mix well. Combineflour, baking powder,soda,

saltand nutmeg.Add to batter and mix well. Pour batter into greasedand floured 13” x 9“ x 2“ baking pan.

Combine brown sugar, pecansand cinnamon; mix well. Sprinkle one half of this mixture over cake batter; swirl mixture

through batter.Sprinkle remainingone half mixture evenlyovercakebatter.

Coverand chill overnight. Uncover and bakein preheated 350°F oven for 35to 45 minutes or until cake tests done with

toothpick.

2-oz.pkg. frozen choppedbroccoli

1cup mayonnaise

1cup sharp cheddar cheese,grated

2 eggs,beaten slightly

1can creamof mushroom soup

...

..”,.... ... .

A delicious quick-to-make hearty stew that will feed a crowd or

another day,

1-10 oz. can barbecue beef

1-10 oz. can barbecuepork

7-24 oz.can Brunswick stew

1-5 oz. can boneless chicken

1-oz. can vacuumpacked corn niblets

1--16 oz.can baby lima beans,drained

2-16 oz.cans stewed tomatoes

1- 14’/2oz. can sliced okra, drained

...

...-.

..”.5. .

n

~-~~.#alno~{raand li~a beans. Add to all other ingredients in 4 ~uati

‘pan. I-leat.on medium to serving temperature,

●“‘..

B

,..

‘

..

2 tablespoonschopped onion

1cup cheesecrackercrumbs

Preheat oven to 375”F. Cook broccoli according to packagedirections; drain,

Mix with other ingredients. Pour into greasedtwo (2) quart casserole.Sprinkle

with cheesecracker crumbs. Bakeat 375°Ffor 20-25minutes.

feed the family. Refrigerate or freezethe remainder for

13

C -

Page 14

1/cumarga

;

i

,

;

{

.

f

:

.

!

~

p-

~

:.

k

[j

3/4 cuchopped greenpepper

CUp chOppedonion

113

3 eggs, well beaten

cacreamstyle corn

17oz.

1 ozcawhokernel corn with liquid

8’; oz.pkg.

1cuchedcheeshre

Preheatoven to 350°F.Sautdgreen peppersand onion in margarine; combine

with remaining ingredients except cheese.Pour into greasedtwo (2) quart casserole;sprinkle with cheeseand bake 45-55minutes in 350°F oven. Letstand 5

minutes beforeserving,

CourfeIllinCooperaExtenHomem

comuffin m

2-1 o sqsemch

1stmar

1c su

1 c fl

2 eggs

tsva

1

Dashsalt

1/2cup chopped pecans

Frozen 9“ pie shell

Preheat oven to 350°F. Melt chocolate and margarine, Add other

ingredients to melted mixture. Pour into unbaked pie shell an

bake 35-40 minutes or until pie appears set. Serve warm with ic

cream or whipped cream.

1-ozcan apple pie filling

12 cup sugar

1-9 oz. box white cake mix (1 layer size)

1stick margarine, melted

I 2 cup chopped pecans

Preheatoven to 350°F. Placein layers in greased 9“ or 10” square baking dish:

apples, sugar, dry cake mix. Pour melted margarine over top of cake mix. Bake

at 350°F for 35 minutes, Sprinkle with pecans. Continue baking 15 minutes.

approximately 2 tablespoons cookor 8“ or 9“ square baking pan. Place,fi- ‘:

Tilt pan to coat bottom evenly. Mix ~j>’

‘into hot greased pan. Bake 20-25

\ )1

‘=--

,,-.,-.\

‘:.;j;;j

L

.-

t.

t

:

Page 15

o t following page, t rer

r oven are shown. Refer t i w

r range.

VVarrrlwater, a mild detergent and a soft cloth are

!

PMn’-

e p o

n cle; ming

CLEAN!NGMATERIALS

s t u o a clp o y r A

purpose cleaners, s a Fac a b

u D n u m s p e

where recommended.

REMARKS

Controlpanel andknobs

Glassovendoor/window(some

models)

Ovenfinishes:

Continuous-cleaning (some

models)

Standard porcelain enameled

ovens, porcelain enameled

(smooth) areas of continuous-

ieaningovens,broi\ercompart-

P

ment,broiler pan

Oven Racks (and guides on

somemodels)

Detergent,warmwater,softcloth

Glasscleanerand papertowels

See specialinstructionson previouspage.

Detergent,warmwater,scouring Rinsethoroughlyaftercleaning.Whenusing

pador soap filledsteelwool pad

or non-aerosol (brush-on)oven

cieaner cleaningfinish. Ovencleanerswill damage

Detergent,

scouringpad or soapfilled steel

wool pad

warm water and

Donotuseabrasivecleaners.Knobspulloff

for easiercleaning.

Removestubbornsoilwith paste of baking

sodaandwater. Donotuseabrasivecleaners. Rinse thoroughly.

ovencleaneroncontinuous-cleaningovens

besureto keepitawayfrom thecontinuous-

the continuous-cleaningfinish. C)venbottom can be removed for easier cleaning.

Removeoven bottom of continuous-cleaningovens if cleaningit with ovencleaner.

Removefromoventoclean Drythoroughly.

Page 16

l-f

OVF

f3carefulrmt?,oscratchtheoven

or removingoven racks.

T“oInsta!i:

PLJ[thepegsontheendofIl]e rackguideinlothe holes

in Ihe oven back.

2.

Lockthe front hookinthe slot inthe oven side.

Set the raised back edgeof the ovenrackson a pair

3.

of rackguidessothehooksatthe sidesofthe rackrun

underneaththe rackguides.

4

Pushthe rack in untilyou reach the bump in the rack,

then liftthe frontof theracka bit andpushthe rackall

Iheway in.

To remove:

1.

Pullthe oven rackout, then up.

2. Lift thefrontoftherackguideto unhookitfromtheoven

wall and pull out.

OVEN AND BROILER

DOORS

Removethe doors for easier cleaning.

To remove:

1. Open the door fully andraise the releasetab on each

door hinge (see fig. A).

Raisethe releasetabsasfarastheywillgo(seefig. B),

2.

then close the door to the point where it will hold a

parlially open position.

3. Grasp thedoor firmly at IIIUsides,pul! IIIGloweredge

awayfrom theoven andlift thedooroff thehinge arms

(see fig. C).

To replace:

1. Slip thehingearms intothe upper portion of theslotsin

the door.

2. Lowerthe door to the fully open position and push the

release labs down (seefig. A).

Cl’(s A

finishwheninstalling

./’

/“

L

RACKHOOK

RELEASE >.

,.,.% ~ >$;

//

~ig. A ill

/-’

\

\

‘..

\

-..

..+’::b ‘~ “’,.,.$

~i9’ ~

Ill

I

‘.

!)

/

.. .,

.

/

RACK

BUMP

Fig. B

I

./

Fig. D

./”.<

OVEN

Removethe oven bottom for easier cleaning.

~e careful not to scratch the oven finish when removing or

installingoven bottom.

To remove:

1. Remove the oven racks and guides (see above).

2. Lilt the front of the oven bottom enough to clear the

front frame, fhen pull out.

TCIreplace:

1. Slidethe oven botlom into the oven so that Ihe back

edge of the oven bottom resls on the ridge inthe back

oven wall.

‘) Lowerlhe frontof theoven bol!om intoplace behind!he

k.

FRONT FRAME

16

Page 17

T LIGHT(

D notfmnchhot oven btDo no! touch bulb Wwi w

hands.Never wipe cwn lightarwith w doll?.

evtouthelectrlimecolo t bu

when replacing it.

edricd powermustbeshutoffifyouhaveb rep!acea

brokbul

Replth

bulb with a 40 watt, appliance bulb. J\n

appliance bulb is smaller than a standard 40watt house-

hobuani mat withhiovtem

turanhaa mulonbuli

-.

17

Page 18

Savetime and money—CWck this list beforeyou call for service.

-—-—,,....

TOeliminateunnecessaryserviced!s, first,readaiithe instructionsinthismanuai carefully. Then,ifyouhaveaproblem,always check this tist of common problemsand possible solutions bef~re you call for Se!ViCe.

PROBLEM

● C)venburnd n wo

POSSIBLECAUSE

o Gas supply notconnected or

~ Check the reducershut-offvalve andthe

not turned on. If using L.F’.

gas, tank may be empty

o Appliance not properly

* Check installation section inthis manual.

grounded or polarized. This

can affect spark ignition.

= Foodsdo not bake properly

o Controls notset correctly

w Burnersnotadjustedproperly

Oven not preheated long

o Check operating instructions in this

o Seethe installationsectioninthis manual.

o Be sureto preheat.

enough

Improper rack or pan place-

D Maintain uniform air space around pans

ment

Ovenventblockedorcovered

Improper use of foil

Impropertemperature setting

● Be sure oven vent is not blocked

o Foil use not recommended.

o Reduce temperature 25degrees forg!a ”-- ~

for utensil used

Recipe not followed

o Is recipe tested and reliable?

Improper thermostat calibra-

tion

Using improper cookware

DON’T CALLFOR SERVICE UNTIL

Y(XJCHECK

gas supply shut-offvalve tobe surethey

areopen (see installationsection)

Ifusing L.P. gas; is there any gas in the

L.P.tank?

manual.

10 minutesbelow 350 degrees

15 minutesabove 350 degrees

and utensils; see oven cookingsection.

or dull/darkened pans.

d

A

$l!ll

Page 19

..

-Y

I

Foodsdo not broil

I

~ Oven smokes. c Dirtyoven

e !rnproperrack position

o Ovenpreheated

o Improperutensil used

o Improperbroilingtime

I

● Broilerpan full of grease left in

oven

s Check in broiling section.

o

D not preheatwhen broiling.

U broiler pan and grid supplied with

*

range.

o Checkbroiling chart in broilingsection.

o Checkfor heavyspillover.

o Cleanpan and grid after eachuse.

~ 13esure that sump (grease well) isto thefron

of the rangewhen broiling.

..

Lightswitch inoff position

D Ovenlight orwork light

does notwork (if

equipped).

= Continuous-Cleaning ~ Heavyspilioverswere not wipec

ovenfinish looks soiled up

(continuous-clean

modelsonly)

mperature in your newovenhas been set correctly at

thefactory,sobe sureto followthe recipetemperaturesand

times the first few times you bake in your newoven.

If you think the oven should be hotter or cooler, you can

adjust it yourself. To decide how muchto change the temperature,set the oventemp knob25°F higheror lowerthan

the temperature inyourrecipe,thenbake. Theresultsof this

‘lest” should give you an ideaof howmuchthetemperature

shouldbe changed.

o

c Lightbulb burnedout

I

l-cl ikrmkx

“ Checkswitch setting.

o Checkor replacelight bulb; see cleaning

and care instructions.

“ See continuous-cleaning oven information in

cleaning andcare sec!ion.

The continuous-cleaningovenfinish will not

keep your oven spotless, only presentably

clean.

4.

Holdthe knob handle (Aon illustration)while turningthe

knob skirt (B on illustration) in the desired direction. As

you turn, you should be able to hear clicks and feel

notchesorteeth. Eachclickor notch is 100. Youcanturn

upto 5 clicks or notches in either direction.

When you reachthe desired adjustment, retighten both

5.

screws.

B

D

B

P

I. Turn OVEN CONknt OFF and remove the

knob by pulling straight off.

.2.Lookat the back of the knob.The arrow pointing to the

center of the upper screw indicates the original factory

setting.T knob can be adjusted up to 5 Fhoo

5 cooi 1 incr

?. U a screwdriverto loosen thetwo screws about 1turn

each.

MACMCX30LER

(S

MovedToCh

19

MAKES

@crewMOW*TowardI-lo!tw)

O

Gsrml 8

Page 20

IfYbLJNeed Service

To obtain service, seeyour warranty

on the back pageof thisbook.

We’re proud of our serviceand want

youto be pleased. If for some reason

youare not happywiththeserviceyou

receive,herearethree stepsto follow

forfurther help.

FIRST, contactthe peoplewho servicedyour appliance. Explainwhyyou

are not pleased. In mostcases, this

will solvethe problem.

NEifyouarestill notpleased,write

all the details-including your phone

number-to:

Manager, Consumer Relations

RCA

Appliance Park

Louisville, Kentucky40225

FINALLY, if your problem is still not

resolved,write:

Major Appliance

Consumer Action Panel

20 North Wacker Drive

Chicago, Illinois 60606

.

Page 21

R

le

Save proofof originaipurchasedate suchas your salessliporcancelledcheckto establishwarrantyperiod.

—— —

FULLONE-YEARVVAFIF3ANTY

Foroneyearfrom the date of

originalpurchase,we willprovide,

free of charge,partsandservice

laborin your hometo repairor

repiaceanypiwf of the oven that

fails becauseof a manufacturing

defect.

Thiswarranty is extendedto the

originalpurchaserandanysucceedingownerfor productspurchasedfor

ordinaryhomeuse inthe 48 mainland states, HawaiiandWashington,

D.C. InAlaskathe warrantyisthe

same exceptthat it is LIMITED

becauseyou must payto ship the

productto the serviceshop or for the

servicetechnician’stravel costs to

your home.

INHAT I N Cx

● Servicetrips to yourhometo teach

you howto usethe product.

F?eadyour We and Care material.

If you then haveany questions o Failure of the product if it is

operatingthe product,

ab

please contact your dealer or

Consumer Affairs officeat address

below.

o Improperinstallation.

If you havean installationproblem, SIBLE FOR CONSEQUENTIAL

contact your dealer or installer. You

are responsiblefor providing ade-

quate electrical, plumbing and other

connecting facilities.

.

We at

est quality productsandservice.

Therefore,we havedesignated(3E

COS a leaderin

the serviceindustry,to fulfill your

serviceneeds. Shouldyourappliance

needservice,duringthe warranty

periodor beyond,look inthe Whiteor

Yellow pagesof yourtelephone

directoryfor GE CONSUMERSERVICEor an AUTHORIZEDRCAAPPLlANCE SERVICER.

o Replacementof housefuses or

resettingof circuitbreakers.

for other than its intendedpurposeor

o

used commercially.

E Damageto product caused by

accident,fire, floods or acts of God.

WARRANTOR IS NOT 13ESPON-

DAMAGES.

———

——

R striveto providethe high-

[

—.

u

(

Sostates do notallowtheexclusionorlimitationofincidentalorconsequentialdamages,sothe Aove

limitationor exclusionmaynotapply

othrigwhvafrstt stT k w y

conyoloo stconaffofo y stAtGe

Hfurther help is needed concerning this warranty, write:

t yoThwargiy spl ria y m a h

ria i y s

Warrantor: FKL4Appliances

Manager—Consumer Affairs, FICA,

Appliance Park, Louisville, KY 40225

Loading...

Loading...