Page 1

GE Marine

Clean, lean marine

GE’s L250 EPA Tier 3 inline diesel engine

GE imagination at work

Page 2

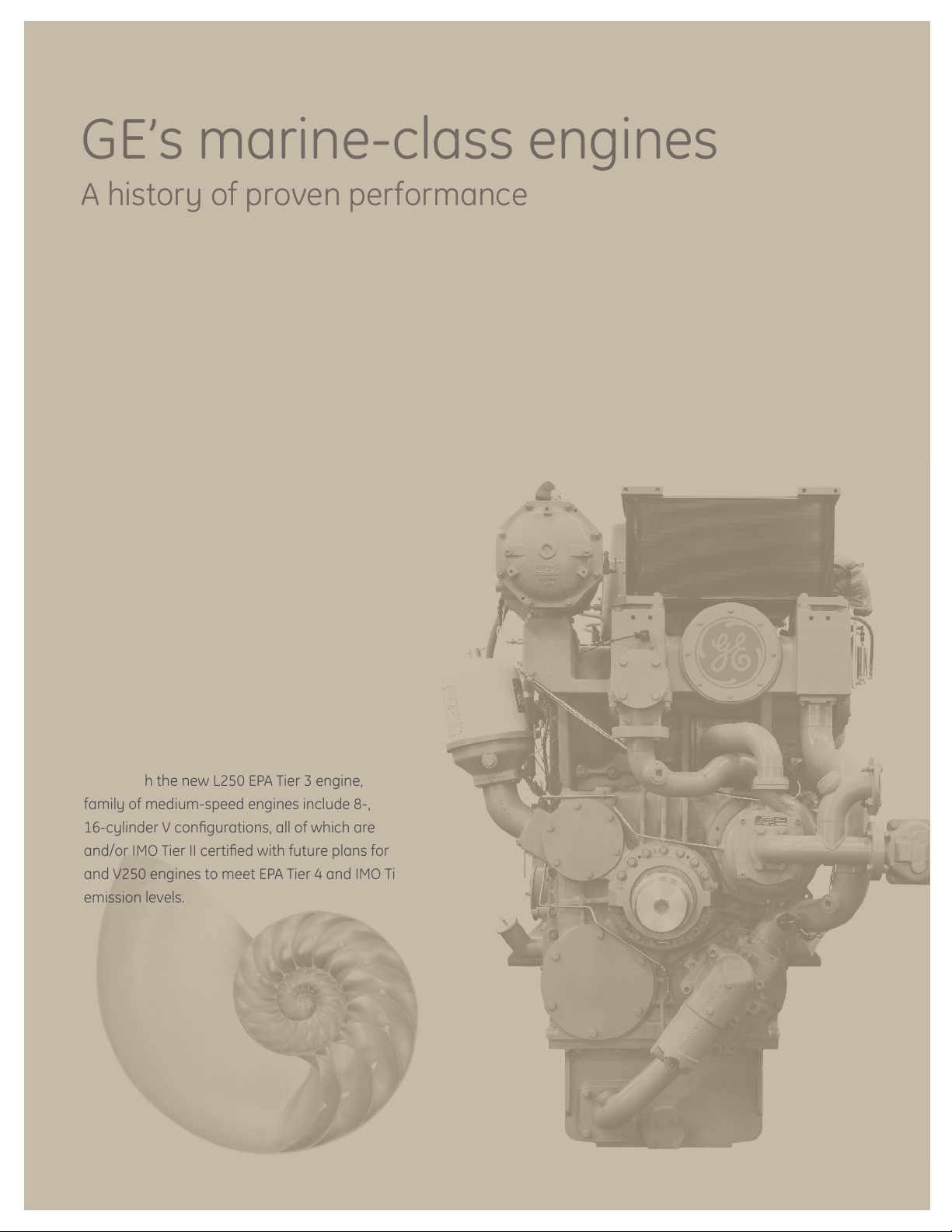

GE’s marine-class engines

A history of proven performance

GE Transportation has been serving the transportation

industry for more than a century. For nearly 50

years, we have designed and built high-performance

diesel engines and have become one of the largest

manufacturers of medium-speed engines in the world.

GE Marine, a division of GE Transportation, is one of the

world’s leading manufacturers of marine products that

help tackle the most important challenges facing the

marine industry today through integrated solutions,

breakthrough technologies and process innovations.

You can rely on GE’s experience, innovation and

proven performance to help you succeed. We’ve

invested millions to ensure our engines comply with

the latest emission standards through technological

advancements that will exceed your expectations. The

L250 engine series is just one example of our dedication

to a sustainable environment and supporting our

customers with GE’s ecient, reliable and economic

diesel engines. Where applicable, the L250 engines

meet EPA Tier 3 emission standards without the need for

exhaust after treatment.

With more than 15,000 engines operating worldwide in

some of the most challenging industrial environments,

GE’s medium-speed engines are dependable, long-

lasting, durable and ecient. From tugboats in Turkey

and shing vessels in Peru to oshore construction

vessels in Norway and ferries in Texas, GE’s marine

engines are supported by an extensive global parts,

distribution and service network.

Along with the new L250 EPA Tier 3 engine, GE’s

family of medium-speed engines include 8-, 12- and

16-cylinder V congurations, all of which are EPA Tier 2

and/or IMO Tier II certied with future plans for our L250

and V250 engines to meet EPA Tier 4 and IMO Tier III

emission levels.

Page 3

The new

L250 EPA Tier 3 inline diesel engine

GE’s new L250 inline diesel engine oers a streamlined

design that is fuel-ecient and delivers continuous power

from 1,518 to 1,999 kW. The L250 is specically engineered

for marine applications with its accessories mounted on

the engine for maintenance ease and oers a full-power

PTO option.

The L250 is marine-class compliant and meets U.S. EPA

Tier 3 emission requirements (certied to EPA Tier 2

during 2013) — a proactive approach to fuel savings and

emissions reduction natural to GE. Depending on the

application and duty cycle, the L250 oers an average 12%

fuel savings when compared to the V228 engine.

The engine, available in 6- and 8-cylinder models, also

oers ease of re-power as its narrow inline footprint takes

in mind marine engine room constraints where space is at

a premium. The narrower frame uses a similar footprint as

competitive engines for minimum design change.

GE designed the L250 engine based on the successful

V250 engine platform using the Six Sigma Quality

design process. Together, with exible installation and

maintenance options, proven parts performance and

support from GE’s worldwide distribution network, the

L250 oers customers reliability and limited downtime.

6

FUEL-EFFICIENT

6

EPA TIER 3 EMISSIONS-COMPLIANT

6

COMPACT POWER

6

NARROW FOOTPRINT

6

EASY TO MAINTAIN

Page 4

Sturdy

L250 components — Marine class. Inline design.

mainframe

The L250’s

mainframe is

a rugged one-

piece iron casting

which provides excellent

vibration-dampening characteristics and

long-term stability to minimize line bore

distortion. Further strength and rigidity

are added by bolting main bearing caps

both vertically and horizontally. The lube

oil gallery and passages are cast or drilled

into the frame to provide lubrication to

all vital engine areas with no pipe or hose

connections within the frame, to help

eliminate leaks or loss of lubrication.

Turbocharger

The L250 uses a new, high-eciency,

radial ow and water-cooled turbocharger

to achieve EPA Tier 3 emissions without

sacricing engine performance. Depending

on duty cycle and application, response

time and fuel eciency have improved

over the L250 Tier 2 engines and fuel

consumption improved 5% to 6% at

85% of MCR.

Crankshaft and engine drive train

The crankshaft is press-forged, highquality alloy steel. Oil passages drilled

in the crankshaft allow oil delivery to

connecting rod bearings and pistons. A

ywheel with ring gear for the starting

motor is bolted directly to the crankshaft

ange.

One-piece liners

The sti, one-piece,

mid-stop liner has an

integral external water

jacket that removes

the possibility of water

leaks. An anti-polishing

ring provides a durable

running surface, improving lube oil

consumption and liner life. The top onethird of the liner is cooled.

Power assemblies

The L250’s power assemblies

are designed to meet the

high-pressure demands of

the engine while adhering to

strict reliability requirements

and an easy-to-maintain

assembly concept. Unitized

cylinder assembly enables

quick change-outs and

increased engine uptime.

Each assembly is mounted

directly to the mainframe

and includes liner assembly,

cylinder head, intake and

exhaust valves, valve linkage

and a high-pressure fuel-injection

pump and nozzle. This design enables

excellent ow paths for combustion,

lower fuel consumption and reduced

emissions. Design improvements will

result in a signicant reduction in lube oil

consumption over L250 Tier 2 engines.

Page 5

Exhaust manifold

Pistons

Advanced EFI

The exhaust manifold provides

increased transient response and

better eciency under pulse and

constant pressure operation. It is

modularized with identical piping and

bellows sections for all of the cylinder

assemblies. The bellows sections

help lower the thermal and vibrationinduced stresses on the exhaust

system.

Intercooler and air-intake

manifold

The L250’s combustion air-intake

system includes one intercooler

mounted on the mainframe between

the turbo outlet and air manifold inlet.

This allows for lower fuel consumption,

emissions and exhaust temperatures.

For servicing, the intercooler can be

removed without dismantling other

engine components.

Our pistons are ruggedly designed to

accommodate the high-peak ring

pressure requirements of L250 engines.

The pin and skirt components are

also designed to yield better piston

lubrication and guidance as it travels

within the liner.

The design helps

minimize oil

consumption and

blow-by as well as

lengthen oil life.

Connecting rod assembly

The forged-steel connecting rods are

exceptionally strong and exhibit high

stiness, which is benecial during the

engine’s lifetime. Large bearing widths

with optimized oil grooves also help

improve oil-lm thickness and pressure,

allowing for optimum performance and

lower friction losses.

Designed for greater eciency at

varying speeds and loads, the L250’s

electronic fuel injection features

precise fuel control, increased

pressure capability and rened timing.

Optimization of the cam prole, injection

start, injection volumes and ows, and

control algorithms have produced a

relatively simple system, proven reliable

through extensive validation.

Camshafts

The camshafts on the L250 are made of

sectional carbon steel forgings joined

by dowel-bolted anges, a design that

simplies component removal and

replacement. Individual sections of the

camshaft, rather than the entire

camshaft, can be serviced or replaced.

Page 6

L250 EPA Tier 3 inline diesel engine specications

Engine data

Number of cylinders

Stroke cycle

Cylinder arrangement

Bore

Stroke

Compression ratio

Power output at 900 rpm

Maximum continuous rating*

Power output at 1,000 rpm

Maximum continuous rating*

Power output at 1,050 rpm

Maximum continuous rating*

Engine dimensions

Length

Width

Height including sump

Crankshaft center line to sump

Crankshaft center line to mounting feet

Exhaust diameter

Dry weight

6L250

6

4

inline

250 mm (9.84 in)

320 mm (12.60 in)

15.7

1,518 kw (2035 hp)

1,687 kw (2261 hp)

1,771 kw (2374 hp)

5,095 mm (200 in)

2,032 mm (80 in)

2,962 mm (116 in)

940 mm (37 in)

308 mm (12 in)

457 mm (18 in)

15,909 kg (35,000 lbs)

8L250

8

4

inline

250 mm (9.84 in)

320 mm (12.60 in)

15.7

1,998 kw (2679 hp)

N/A

N/A

5,985 mm (235 in)

2,032 mm (80 in)

2,962 mm (116 in)

940 mm (37 in)

308 mm (12 in)

457 mm (18 in)

19,090 kg (42,000 lbs)

*Maximum continuous rating (MCR):

Maximum speed and load conditions at which the engine is capable of operating continuously for an unlimited number of

hours per year; between the normal maintenance intervals stated by GE, under standard ambient conditions and with the

maintenance prescribed by GE having been carried out. Engine overload is limited for U.S. EPA Tier 3 (40 CFR Part 1042)

regulations.

Dimensions and weights are approximate and include all engine mounted accessories.

GE Marine

To learn more,

visit www.getransportation.com.

GE imagination at work

GE, the GE Monogram, imagination at work, ecomagination and all other

trademarks, and service marks, unless otherwise noted, are owned or

licensed by General Electric Company or its subsidiaries. All other brand

names, product names or trademarks belong to their respective holders.

Copyright © 2012. General Electric Company. All rights reserved.

Recycled Paper

20246-A

Loading...

Loading...