Page 1

GE

Digital Solutions

Pressure Automated Calibration Equipment

User manual - K0470 Revision A

PACE Indicators

© 2010 General Electric Company. All Rights Reserved. Specifications are subject to change

without notice. GE is a registered trademark of General Electric Company. Other company or

product names mentioned in this document may be trademarks or registered trademarks of their

respective companies, which are not affiliated with GE.

Page 2

PACE Pressure Indicators User Manual

Introduction

This manual contains Installation and operating instructions for PACE Pressure Indicators.

Safety

The manufacturer has designed this equipment to be safe when operated using the

procedures detailed in this manual. Do not use this equipment for any other purpose than

that stated, the protection provided by the equipment may be impaired.

This publication contains operating and safety instructions that must be followed to make

sure of safe operation and to maintain the equipment in a safe condition. The safety

instructions are either warnings or cautions issued to protect the user and the equipment

from injury or damage.

Use qualified * technicians and good engineering practice for all procedures in this

publication.

Pressure

Do not apply pressures greater than the maximum working pressure to the equipment.

Toxic Materials

There are no known toxic materials used in construction of this equipment.

Maintenance

The equipment must be maintained using the procedures in this publication. Further

manufacturer’s procedures should be done by an authorized service agents or the

manufacturer’s service departments.

Technical Advice

For technical advice contact the manufacturer.

* A qualified technician must have the necessary technical knowledge, documentation,

special test equipment and tools to carry out the required work on this equipment.

[EN] English i K0470 Revision A

Page 3

General Specification

Display LCD: Colour display with touch-screen

Operating temperature 10°C to 50°C (50° to 122°F)

Storage temperature -20°C to 70°C (-4° to 158°F)

Ingress protection IP20 (EN60529)

Operating humidity 5% to 95% RH (non-condensing)

Vibration MIL-PRF-28800 Type 2 class 5 style E/F

Operating altitude Maximum 2000 metres (6560ft)

EMC EN 61326

Electrical safety EN 61010-1, UL61010-1, CSA 22.2, No. 61010-1 and IEC61010-1

Power adaptor Input range: 100 - 240VAC, 50 to 60Hz, 660mA. Installation category II

Pressure safety

Pressure Equipment Directive - class: sound engineering practice (SEP)

for group 2 fluids.

Pollution degree 2

Operating Environment Indoor use only. Do NOT use in potentially explosive environments

Abbreviations

The following abbreviations are used in this manual; abbreviations are the same in the singular and plural.

a Absolute min Minute or minimum

a.c Alternating current mm millimetre

ALT Altitude mV millivolts

ASCII American Standard Code for Information Interchange MWP Maximum working pressure

BSP British pipe thread No Number

CAS Calibrated airspeed NPT National Pipe Thread

CSK Countersunk PACE

d.c. Direct current Para. Paragraph

DPI Digital Pressure Instrument PDCR Pressure transducer

etc. And so on PED Pressure equipment directive

e.g. For example psi Pounds per square inch

Fig. Figure PTX Pressure transmitter

ft Foot ROC Rate of climb (vertical speed)

g Gauge RS232 Serial communications standard

GPIB General purpose interface bus Rt CAS Rate of Calibrated airspeed

Hg Mercury Rt MACH Rate of MACH

Hz Hertz Rx Receive data

IAS Indicated airspeed SCPI

IDOS Intelligent digital output sensor (GE product) SDS Sales data sheet

Pressure automated calibration

equipment

Standard commands for

programmable instruments

K0470 Revision A ii [EN] English

Page 4

PACE Pressure Indicators User Manual

i.e. That is SELV

IEEE 488

in Inch UUT Unit under test

kg kilogram V Volts

kts knots +ve Positive

m Metre -ve Negative

mA milliampere °C Degrees Celsius

max Maximum °F Degrees Fahrenheit

mbar Millibar

Institute of Electrical and Electronic Engineers standard

488 (for programmable devices with a digital interface)

Tx Transmit data

Separated (or Safety) extra low

voltage

Related publications

K0467 User Guide and Safety Instructions

K0469 PACE Heritage Communications Manual

K0450 PACE Series Calibration Manual

K0472 PACE Series SCPI Manual

[EN] English iii K0470 Revision A

Page 5

Symbols

This equipment meets the requirements of all relevant European safety directives.

The equipment carries the CE mark.

This symbol, on the equipment, indicates that the user should read the user manual.

This symbol, on the equipment, indicates a warning and that the user should refer to

the user manual.

Ce symbole, sur l’instrument, indique que l’utilisateur doit consulter le manuel d’utilisation. Ce symbole, dans le manuel, indique une situation dangereuse.

This symbol warns the user of the danger of electric shock.

Ce symbole alerte l’utilisateur sur le danger de choc électrique.

Do not dispose of this product as household waste. Use an approved organisation

that collects and/or recycles waste electrical and electronic equipment. For more

information, contact one of these:

- Our customer service department: www.gemeasurement.com

- Your local government office.

WARNINGS

TURN OFF THE SOURCE PRESSURE(S) AND CAREFULLY VENT THE PRESSURE LINES BEFORE

DISCONNECTING OR CONNECTING THE PRESSURE LINES. PROCEED WITH CARE.

ONLY USE EQUIPMENT WITH THE CORRECT PRESSURE RATING.

BEFORE APPLYING PRESSURE, EXAMINE ALL FITTINGS AND EQUIPMENT FOR DAMAGE.

REPLACE ALL DAMAGED FITTINGS AND EQUIPMENT. DO NOT USE ANY DAMAGED

FITTINGS AND EQUIPMENT.

DO NOT EXCEED THE MAXIMUM WORKING PRESSURE OF THE INSTRUMENT.

THIS EQUIPMENT IS NOT RATED FOR OXYGEN USE.

K0470 Revision A iv [EN] English

Page 6

PACE Pressure Indicators User Manual

THE GROUND LEAD OF THE INSTRUMENT MUST BE CONNECTED TO THE AC SUPPLY

PROTECTIVE SAFETY GROUND.

ISOLATE THE POWER SUPPLY BEFORE MAKING ANY ELECTRICAL CONNECTIONS TO THE

REAR PANEL.

Pressure units and conversion factors

Pressure units Factor (hPa) Pressure units Factor (hPa)

mbar 1.0

bar 1000.0

cmH

mH

O @ 20°C

2

O @ 20°C

2

0.978903642

97.8903642

Pa (N/m2)

hPa 1.0

kPa 10.0 torr 1.333223684

MPa 10000.0 atm 1013.25

mmHg @ 0°C 1.333223874 psi 68.94757293

cmHg @ 0°C 13.33223874

mHg @ 0°C 1333.223874

inHg @ 0°C 33.86388640341

mmH

cmH2O @ 4°C

mH

O @ 4°C

2

O @ 4°C

2

0.01

0.0980665

0.980665

98.0665

2

kg/m

kg/cm

lb/ft

inH

inH

inH2O @ 60°F

ftH2O @ 4°C

ftH2O @ 20°C

2

2

O @ 4°C

2

O @ 20°C

2

0.0980665

980.665

0.4788025898

2.4908891

2.486413

2.487641558

29.8906692

29.836983

mmH

Unit Conversion

O @ 20°C

2

0.097890364

Convert FROM pressure VALUE 1 in pressure UNITS 1 TO pressure VALUE 2 in pressure UNITS

2, calculate as follows:

[EN] English v K0470 Revision A

ftH2O @ 60°F

29.8516987

VALUE 2 = VALUE 1 x FACTOR 1

FACTOR 2

Page 7

CONTENTS

Section Title Page

1 Description 1-1

1.1 Introduction 1-1

2 Installation 2-1

2.1 Packaging 2-1

2.2 Packaging for Storage and Transportation 2-1

2.3 Preparation for Use 2-1

2.4 Connecting the Instrument 2-2

2.5 Mounting kits 2-8

2.6 Electrical connections 2-10

3 OPERATION 3-1

3.1 Preparation 3-1

3.2 Power-up Sequence 3-1

3.3 Measure Mode 3-2

3.4 Operation and Example Procedures 3-8

3.5 Global Set-up Selections 3-11

3.6 Supervisor Set-up 3-12

3.7 Instrument Status 3-13

4 MAINTENANCE 4-1

4.1 Introduction 4-1

4.2 Visual inspection 4-1

4.3 Cleaning 4-1

K0470 Revision A vi [EN] English

Page 8

PACE Pressure Indicators User Manual

4.4 Test 4-1

4.5 Calibration 4-1

5 TESTING AND FAULT FINDING 5-1

5.1 Introduction 5-1

5.2 Standard Serviceability Test 5-1

5.3 Ethernet testing 5-1

5.4 Fault Finding 5-4

5.5 Approved Service Agents 5-4

6 REFERENCE AND SPECIFICATION 6-1

6.1 Installation notes 6-1

6.2 Reference port 6-2

6.3 Icons 6-3

6.4 Measure Set-up 6-6

6.5 Status 6-7

6.6 Global Set-up 6-8

6.7 Supervisor Set-up 6-9

6.8 Calibration 6-27

6.9 Specification 6-27

6.10 Options 6-28

6.11 Installation and Ancillary Equipment 6-31

6.12 Return Goods/Material Procedure 6-31

6-13 Packaging Procedure 6-31

[EN] English vii K0470 Revision A

Page 9

Intentionally blank

K0470 Revision A viii [EN] English

Page 10

PACE Pressure Indicators User Manual

1Description

1.1 Introduction

The PACE Pressure Indicator measures both pneumatic and hydraulic pressures and

displays, on a colour touch-screen, the measured pressure and instrument status. The

touch-screen enables selections and settings in measuring modes. The instrument can be

operated remotely through communication interfaces.

Figure 1-1 PACE1000 General view

The rear of the instrument houses all the electrical and pressure input connections. The

electrical connections provide a power supply, serial and parallel communication interfaces,

pressure ports and option ports.

The instrument can be used as follows:

• Free-standing instrument positioned on a horizontal surface.

• Rack-mounted in a standard 19 inch rack using the rack-mount option kit.

• Panel mount using the panel-mount option kit.

[EN] English 1 - 1 K0470 Revision A

Page 11

1 Description

Options available for the PACE1000 refer to the data sheet.

Information and notes on applications (Ref: Reference and Specification, Section 6) or

www.gemeasurement.com

K0470 Revision A 1 - 2 [EN] English

Page 12

PACE Pressure Indicators User Manual

2 Installation

2.1 Packaging

Check the contents of the PACE1000 packaging with the list that follows:

Packaging List - PACE1000

i) PACE1000 Pressure Indicator.

ii) Adaptor, power supply (GE part number 191-370).

iii) User guide and safety instructions, and CD containing the full documentation suite.

iv) Calibration certificate.

2.2 Packaging for Storage or Transportation

To store or return the instrument for calibration/repair do the procedures that follow:

1. Pack the instrument (Ref: Reference and Specification, Section 6.13).

2. Return the instrument for calibration/repair complete the return goods procedure (Ref:

Reference and Specification, Section 6.12).

2.3 Preparation for Use

The instrument can be used as a:

• Free-standing instrument positioned on a horizontal surface.

• Panel-mounted using the panel-mount option kit (Ref: Section 2.5).

• Rack-mounted in a standard 19 inch rack using the rack-mount option kit (Ref: Section

2.5).

For free-standing instruments, the feet on the front of the base can be used elevate the instrument

to a better viewing angle.

Note: Allow a free flow of air around the instrument, especially at high ambient temperatures.

[EN] English 2 - 1 K0470 Revision A

Page 13

2 Installation

ISO 228 G1/8 ISO 228 G1/8

bonded seal bonded seal

Recommended method Alternative method below 100 bar

2.4 Connecting the Instrument

WARNINGS

TURN OFF THE SOURCE PRESSURE(S) AND CAREFULLY VENT THE PRESSURE LINES BEFORE

DISCONNECTING OR CONNECTING THE PRESSURE LINES. PROCEED WITH CARE.

ONLY USE EQUIPMENT WITH THE CORRECT PRESSURE RATING.

BEFORE APPLYING PRESSURE, EXAMINE ALL FITTINGS AND EQUIPMENT FOR DAMAGE.

REPLACE ALL DAMAGED FITTINGS AND EQUIPMENT. DO NOT USE ANY DAMAGED

FITTINGS AND EQUIPMENT.

DO NOT EXCEED THE MAXIMUM WORKING PRESSURE OF THE INSTRUMENT.

THIS EQUIPMENT IS NOT RATED FOR OXYGEN USE.

Pneumatic Pressure (Figure 2-1)

1. Refer to the Data sheet for the correct pressure mediums to be used.

2. Connect the Unit Under Test (UUT) to the required connection port.

Note: For instruments with NPT connections, use applicable bonded sealing as shown in figure

below.

Figure 2-1, Sealing Pneumatic Connections

K0470 Revision A 2 - 2 [EN] English

Page 14

PACE Pressure Indicators User Manual

Parallel threads must be used.

Female thread type is parallel thread to

ISO228/1 (DIN ISO228/1, JIS B0202)

G1/8

Tapered threads NOT allowed.

PACE pressure port

PACE rear

panel

9

8

PACE rear

panel

PACE pressure port

Pneumatic connections

WARNING

PARALLEL THREADS MUST BE USED. FEMALE THREAD TYPE IS PARALLEL THREAD TO

ISO228/1 (DIN ISO228/1, JIS B0202) G1/8.

TAPERED THREADS NOT ALLOWED.

For examples of adaptors (Ref: page 2 - 4).

Input Pressure (Figure 2)

Note: For instruments with NPT connections, use applicable bonded sealing as shown in figure

[EN] English 2 - 3 K0470 Revision A

Connection

Input ISO228/1 G 1/8 parallel threads (DIN ISO228/1, JIS B0202)

Reference ISO228/1 G 1/8 parallel threads (DIN ISO228/1, JIS B0202)

1. Make sure the user systems can be isolated and vented.

2. Connect the Unit Under Test (UUT) to the output connection port.

below.

Page 15

2 Installation

2) Bonded seal

1) Connector

2

1

Figure 2-2, Pneumatic Connections

Installation

The instrument connects to the Unit Under Test.

Input Pressure and Equipment

The pressure should not exceed 1.25 x full-scale or MWP stated on the rear panel of the

instrument.

To protect the instrument from over-pressure a suitable protection device (such as a relief valve or

bursting disc) must be fitted to prevent over pressurization.

Pneumatic Connection

WARNING

PRESSURE RANGES > 210

BAR (3000 PSI) ARE ONLY RATED FOR HYDRAULIC USE.

CAUTIONS

Do not exceed the maximum pressures stated in the appropriate Component Manual for

the unit under test.

Reduce pressure at a controlled rate when venting to atmosphere.

Carefully de-pressurize all pipes to atmospheric pressure before disconnecting and

connecting to the unit under test.

Connections

1. Switch off the power supply before connecting or disconnecting the instrument.

2. Use the appropriate sealing method for all pressure connections.

Note: For instruments with NPT connections, use applicable bonded sealing as shown in figure

below.

K0470 Revision A 2 - 4 [EN] English

Page 16

PACE Pressure Indicators User Manual

ISO 228 G1/8 ISO 228 G1/8

bonded seal bonded seal

Recommended method Alternative method below 100 bar

IO-SNUBBER-1

IO-ADAPT-9/16AUTOC

ISO 228 Male to 9/16 Autoclave

IO-DIFFUSER-1

IO-ADAPT-G1/4

ISO 228 Male to G1/4 Female

IO-ADAPT-1/8NPT

ISO 228 Male to 1/8 NPT Female

IO-ADAPT-1/4NPT

ISO 228 Male to 1/4 NPT Female

IO-ADAPT-7/16UNF

ISO 228 Male to 7/16 UNF Female

IO-ADAPT-AN4

ISO 228 Male to AN4 37° Male

IO-ADAPT-AN6

ISO 228 Male to AN6 37° Male

IO-ADAPT-BARB

ISO 228 Male to 1/4 Hose

Method of connection

Adaptors

Refer to the data sheet for the range of adaptors.

[EN] English 2 - 5 K0470 Revision A

Page 17

2 Installation

Hydraulic Pressure

WARNINGS

HYDRAULIC LIQUID IS DANGEROUS. OBSERVE RELEVANT HEALTH AND SAFETY

PRECAUTIONS. USE APPROPRIATE PROTECTIVE BARRIERS AND EYE PROTECTION.

BEFORE APPLYING PRESSURE, EXAMINE ALL FITTINGS AND EQUIPMENT FOR DAMAGE AND

ENSURE THAT ALL EQUIPMENT IS TO THE CORRECT PRESSURE RATING.

DO NOT EXCEED THE MAXIMUM WORKING PRESSURE OF THE INSTRUMENT.

PURGE ALL AIR FROM THE HYDRAULIC LIQUID.

PRESSURE RANGES > 210

BAR (3000 PSI) ARE ONLY RATED FOR HYDRAULIC USE.

DO NOT USE A SENSOR FOR GAS THAT HAS BEEN USED WITH HYDRAULIC LIQUID.

CAUTIONS

Do not exceed the maximum pressures stated in the appropriate component manual for

the unit under test.

Reduce pressure at a controlled rate when venting to atmosphere.

Carefully de-pressurize all pipes to atmospheric pressure before disconnecting and

connecting to the unit under test.

Observe absolute cleanliness when using the instrument.

Severe damage can be caused if equipment connected to this instrument is

contaminated.

Connect only clean equipment to the instrument.

To avoid any contamination, an external filter is recommended.

K0470 Revision A 2 - 6 [EN] English

Page 18

PACE Pressure Indicators User Manual

ISO 228 G1/8 ISO 228 G1/8

bonded seal bonded seal

Recommended method Alternative method below 100 bar

Installation

The instrument connects to the Unit Under Test.

Input Pressure and Equipment

1. The pressure should not exceed 1.25 x full-scale or MWP stated on the rear panel of

the instrument.

2. To protect the instrument from over-pressure a suitable protection device (such as a

relief valve or bursting disc) must be fitted to limit the pressure to below the MWP.

Note: For instruments with NPT connections, use applicable bonded sealing as shown in figure

below.

Figure 2-3, Sealing Hydraulic Connections

Hydraulic connections

Connection

Input ISO228/1 G 1/8 parallel threads (DIN ISO228/1, JIS B0202)

Reference ISO228/1 G 1/8 parallel threads (DIN ISO228/1, JIS B0202)

Note: Pressure connections greater than 210 bar are 9/16” 18UNF Male Autoclave.

1. Switch off the power supply before connecting or disconnecting the instrument.

2. Use the applicable sealing method for all pressure connections.

3. Isolate the hydraulic pressures and de-pressurise the pipes before connecting or

disconnecting the instrument.

Pressure input (Figure 2)

1. Make sure the user systems can be isolated and vented.

2. Use the applicable sealing method for all pressure connections.

3. The hydraulic liquid must be clean, refer to specification given in the Data sheet.

4. Connect the Unit Under Test (UUT) to the appropriate connection port.

[EN] English 2 - 7 K0470 Revision A

5. Fill and bleed the UUT and connecting pipes.

Page 19

2 Installation

2.5 Mounting kits

Rack-mount option (Figure 2-5)

There must be enough space at the rear of the instrument for all the cables and pipes. The length

of the cables and pipes must allow for the removal and installation of the instrument. The cooling

air of the instrument must not be obstructed. Allow a free flow of air through the equipment rack

and around the instrument, especially at high ambient temperatures.

Procedure

1. Locate instrument in rack mount assembly

2. Secure with the four M3 x 6 screws , (maximum length M3 x 8).

3. Support the instrument and connect the cables and pipes.

4. Refer to the electrical connections below before fitting the instrument into the

equipment rack.

5. Temporarily locate the two spigots* to each side of the equipment rack.

6. Locate and slide the instrument into the rack.

7. Locate the instrument on the spigots*.

K0470 Revision A 2 - 8 [EN] English

Figure 2-5 Rack-mounting

.

Page 20

PACE Pressure Indicators User Manual

8 Secure the instrument in the equipment rack with two of the screws and washers

(supplied).

9. Remove the two spigots* and replace with the remaining two screws and washers

(supplied).

Panel-mount option (Figure 2-6)

There must be enough space at the rear of the instrument for all the cables and pipes.

The length of the cables and pipes must allow for the removal and fitment of the instrument.

The cooling air of the instrument must not be obstructed.

Allow a free flow of air through the equipment rack and around the instrument, especially at high

ambient temperatures.

Procedure

1. Remove the four screws

2. Locate the instrument in panel mount assembly.

3. Secure with the four screws

4. Support the instrument and connect the cables and pipes.

5. Refer to the electrical connections below before fitting the instrument into the panel.

6. Secure the instrument in the panel with four screws and washers

[EN] English 2 - 9 K0470 Revision A

Figure 2-6 Panel-mounting

from the instrument.

.

.

Page 21

2 Installation

2.6 Electrical connections

WARNINGS

THE GROUND LEAD OF THE INSTRUMENT MUST BE CONNECTED TO THE AC SUPPLY

PROTECTIVE SAFETY GROUND.

ISOLATE THE POWER SUPPLY BEFORE MAKING ANY ELECTRICAL CONNECTIONS TO THE

REAR PANEL.

CAUTIONS

Use the power adaptor supplied with the instrument (GE part no. 191-370). Using other

power adaptors may cause over-heating, this can result in a fire.

Do not let the power adaptor come into contact with any moisture or liquids.

Connecting (Figure 2-7)

1. Before use, make sure the SELV power adaptor supplied with the

instrument is used (GE part number 191-370).

2. Install an accessible power isolator to use as the disconnecting device

in the power adaptor supply circuit.

3. The power adaptor input power supply range: 100 - 240VAC, 50 to 60Hz

660mA, Installation Category II.

Note: The power adaptor must be supplied by a fused or overload-protected power

supply.

4. Connect the power adaptor to the instrument.

5. Switch the power supply on.

6. Check that the front panel display shows the power-up sequence (Ref:

section 3.2).

Note:. After the power-up sequence, the instrument shows the default display on the

touch screen. The touch screen divides into a number of mimic keys.

Requirements for rack-mounted and panel-mounted instruments

1. Install an accessible power isolator to use as the disconnecting device in the power

adaptor supply circuit.

2. Set the power supply isolator to OFF.

3. Connect the power adaptor before sliding the instrument into the rack.

4. Set the power supply isolator to ON.

5. Check that the front panel display shows the power-up sequence (Ref: section 3.2).

K0470 Revision A 2 - 10 [EN] English

Page 22

PACE Pressure Indicators User Manual

2

4

5

6

7

22V to 26V

ANALOGUE 1

CONSULT HANDBOOK

1

Communication Connections

Connect the applicable connectors into the rear panel communications ports and, if appropriate,

secure with the captive screws.

Note: The RS232 and IEEE 488 interfaces are both enabled at power-up. Set the required parameters

in Supervisor Setup/communications menu, see Section 3.6.

Figure 2-7, Communication Connectors

1

Power supply adaptor 2 RS232 4 IEEE488

5

USB B 6 USB A 7 Ethernet

RS232 Interface

When using the RS232 interface, a cable must be connected directly from the instrument to a

suitable port on the computer in a ‘point to point’ link.

The pin connections for the 9-pin D-type, RS232 connector and the relationship between the

instrument and the RS232 control signals, together with device interconnection interface is shown

in Table 2-1. The instrument is configured as Data Circuit Terminating Equipment (DCE).

[EN] English 2 - 11 K0470 Revision A

Page 23

2 Installation

Instrument Control Line Computer/Printer

Instrument

Function

RxD (I/P) 3 TxD 3 2

TxD (O/P) 2 RxD 2 3

GND 5 GND 5 7

CTS (I/P) 7 RTS 7 4

RTS (O/P) 8 CTS 8 5

Pulled

high

internally

Not

connected

Pulled

high

internally

Equipment

chassis

Connector

9-way

D-type

Pin No.

1

4 DTR 4 20

6

Connector

shell

Signal

Direction

Cable Screen - 1

RS232

Terminology

RLSD

(DCD)

DSR

DCE Ready

Connector Type

9-way

D-type

Pin No.

18

66

25-way

D-type

Pin No.

Table 2-1, RS232 Connections

Handshaking connections

Software handshaking use: TXD, RXD and GND.

Hardware handshaking use: TXD, RXD, GND, CTS, RTS and DTR.

K0470 Revision A 2 - 12 [EN] English

Page 24

PACE Pressure Indicators User Manual

2

3

IEEE 488 Interface

The interface complies with IEEE 488 standard.

The IEEE 488 parallel interface connects a computer/controller to one or more PACE1000

instruments and other instruments.

Up to 30 instruments can be connected through a high-speed data bus to the computer/controller.

Note: The length of each IEEE 488 cable must be less than 3 metres to comply with the EMC

requirements (Ref: Data sheet).

Single Unit Installation (Figure 2-8)

1. Connect an IEEE 488 connector/cable assembly to the rear panel of the instrument.

2. Connect the other end of the connector/cable assembly to the IEEE 488 connector on

the controller/computer.

3. Change the IEEE 488 communication parameters (Ref: Supervisor set-up, Section 6.7).

Multiple Unit Installation (Figure 2-8)

To install multiple units use stacking plugs to link

the first instrument and second instrument as

follows:

1 Connector to rear panel of first

instrument (Ref Illustration).

2 Connector from controller/computer

(Ref Illustration).

3 Connector to rear panel of second

instrument (Ref Illustration).

4. Connect the IEEE 488 connector on

the controller/computer and the other

connector into the next instrument.

5. Repeat this procedure for all the instruments in the system.

6. Use the Supervisor set-up (communications) menu on each instrument to set-up the

required communication parameters (Ref: Section 3.8).

1

[EN] English 2 - 13 K0470 Revision A

Page 25

2 Installation

IEEE 488

ADDRESS 1

ADDRESS 2

ADDRESS N

(30 maximum)

6

7

8

DAV (DATA VALID)

NRFD (NOT READY FOR DATA)

NDAC (NO DATA ACCEPTED)

5

9

101117

EOI (END OF IDENTIFY)

IFC (INTERFACE CLEAR)

SRQ (SERVICE REQUEST)

ATN (ATTENTION)

REN (REMOTE ENABLE)

1

2

3

4

13

DIO1

DIO2

DIO3

DIO4

DIO5

14

15

16

DIO6

DIO7

DIO8

1819202122

GND (6)

GND (7)

GND (8)

GND (9)

GND (10)

23

24

GND (11)

GND

DATA /

STATUS

BAR

0V (GND)

12 CHASSIS/FRAMECHASSIS/FRAME

K0470 Revision A 2 - 14 [EN] English

Figure 2-8 - IEEE 488 Connection

Page 26

PACE Pressure Indicators User Manual

Do not touch the display screen during power-up

3Operation

This section contains quick reference charts detailing all the available functions and the set-up

menu.

3.1 Preparation

Make sure the electrical cables and pneumatic pipes comply with the installation requirements

(Ref: Section 2).

Before use do the following:

1. If necessary, do the maintenance task (Ref: Section 4).

2. For bench-top, single instrument operation do the following:

a. Connect the instrument to the electrical supply.

b. Inspect the pneumatic hoses for damage, ingress of dirt and moisture.

3. Before use, the instrument should be tested.

4. Review and become familiar with the procedure before starting a process on a

component or system.

3.2 Power-up sequence

The following sequences of operation shows the instrument display.

Note: The following sequence is an example, the values and selections displayed depend on the

range(s) and options enabled in the instrument.

1. Set the power supply to ON.

2. The display shows the power-up sequence.

3. The instrument carries out a self-test.

a. If the test finds a fault, the display

shows an error (Ref: Fault Finding and

Testing, Section 5).

4. If the self-test is successful the system

enables the touch screen and changes to

measure mode.

5. The touch screen shows the measured

pressure in the parameters selected in set-up.

6. The instrument is now ready for use.

[EN] English 3 - 1 K0470 Revision A

Page 27

3 Operation

1

2

3

4

5

6

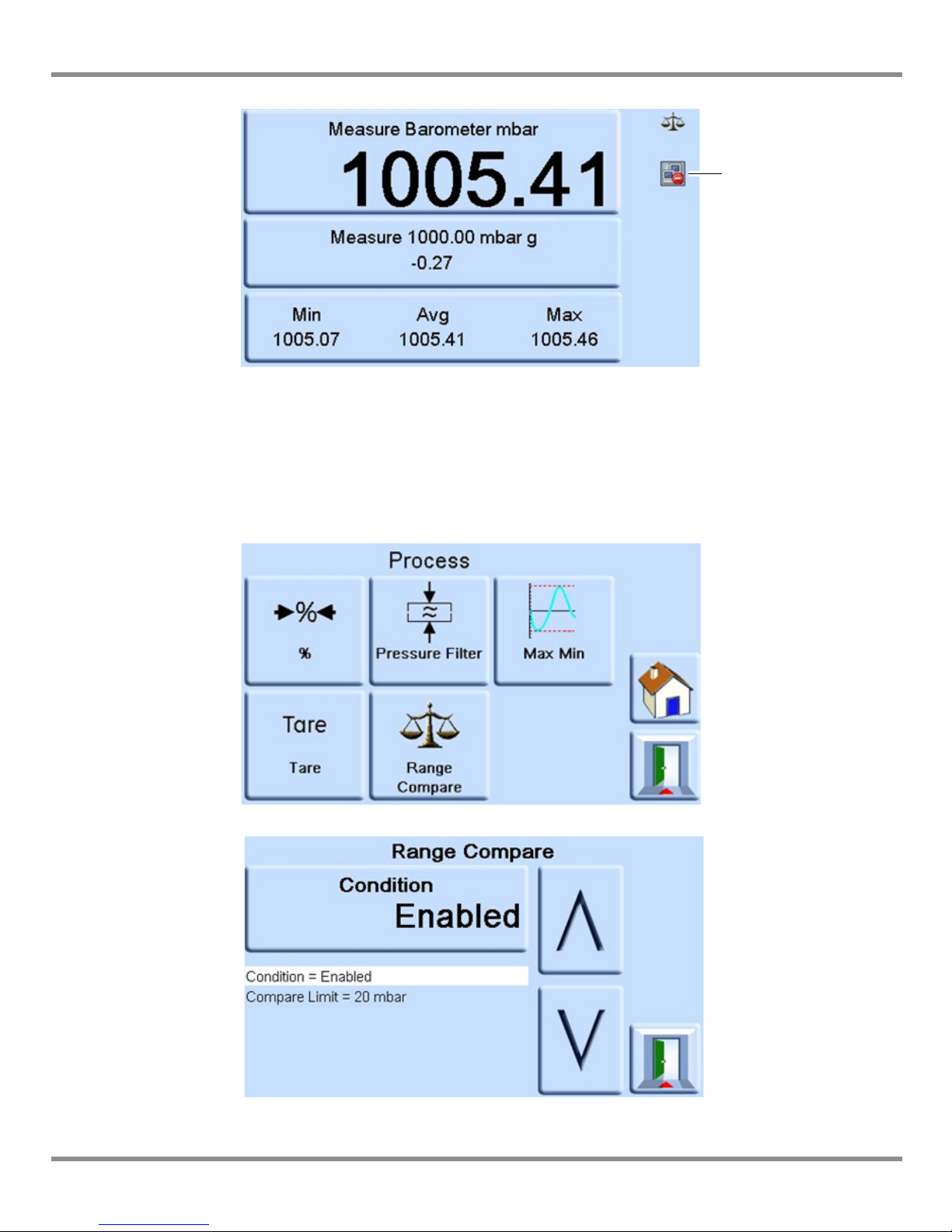

3.3 Measure mode

Touch screen areas

1 Pressure reading 2 Functions enabled 3 Zero key (vent system before starting zero sequence)

4 Function area 5 Status area 6 Current pressure range

Display Icons

Tare enabled Filter pressure reading

Percentage Ethernet not connected

Reference level difference

(gas head correction)

Ethernet connected

K0470 Revision A 3 - 2 [EN] English

Page 28

PACE Pressure Indicators User Manual

1

Function area Min/Avg/Max is performed on the reading selected for display in the top

screen.

The Ethernet LAN Status indication (1) shows the following:

• Colour red - not connected

• Colour green - connected

[EN] English 3 - 3 K0470 Revision A

Page 29

3 Operation

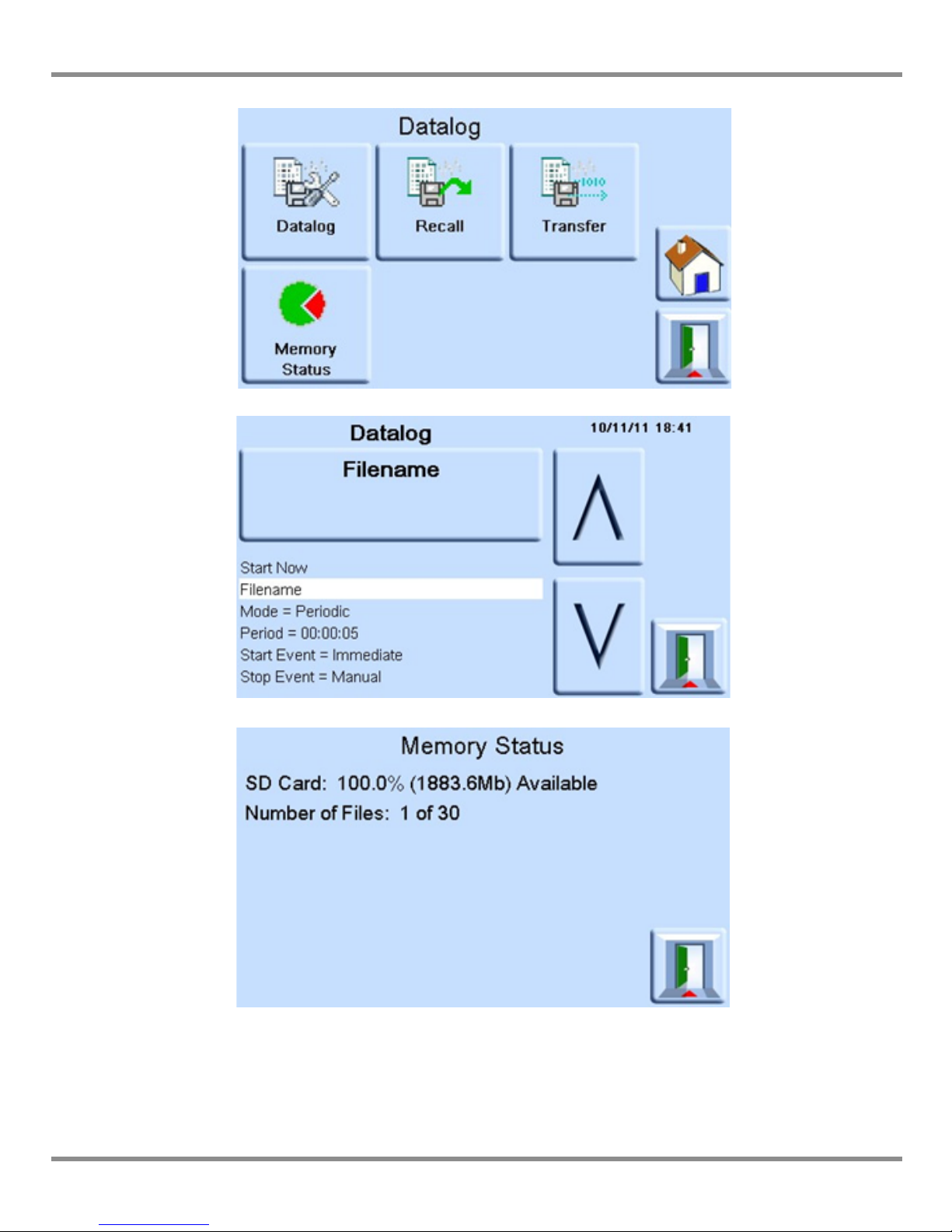

1

Data Logging

The “Datalog” icon (1) is present when a memory card is fitted:

K0470 Revision A 3 - 4 [EN] English

Page 30

PACE Pressure Indicators User Manual

[EN] English 3 - 5 K0470 Revision A

Page 31

3 Operation

K0470 Revision A 3 - 6 [EN] English

Page 32

PACE Pressure Indicators User Manual

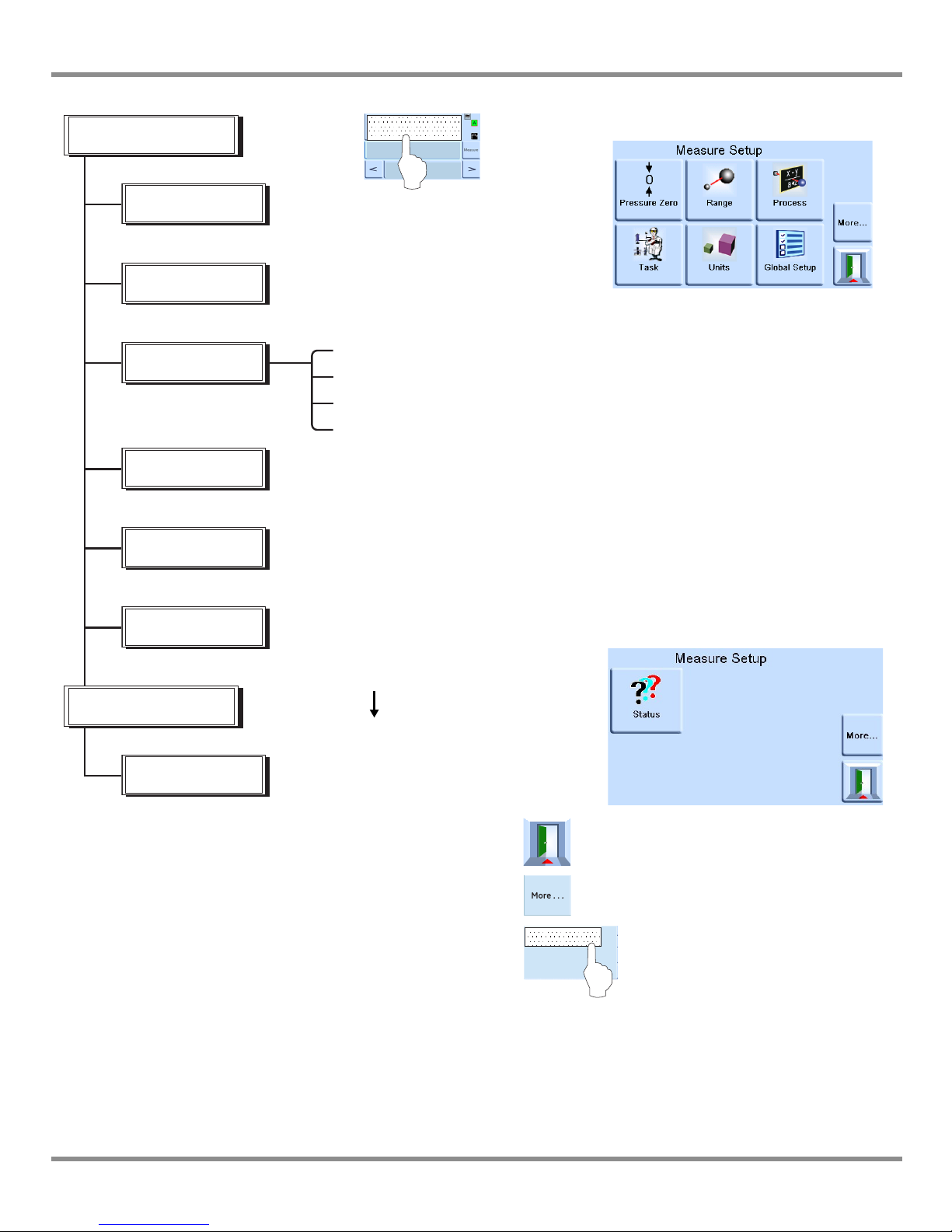

current pressure reading to zero,

offset stored for current range.

allows selection of available pressure

ranges. Ê

-

-

select from list of available pressure

measurement units.

-

Absolute range selection available when

barometric option installed.

Ê

%

Filter pressure reading

Tare

Pressure zero

Range

Process

Task

Units

Global set-up

Status

Measure set-up

More

Next page of menu options. Loops

from last page to first page.

Stores settings and exits

set-up.

see 3.6:-

next page:-

Exit set-up.

Peak

Measure Menu Set-up

[EN] English 3 - 7 K0470 Revision A

Page 33

3 Operation

Selecting a task exits the menu and

changes the display to the task

selected.

Ê

Exit set-up.

Option refer to data sheet

Ê

Basic

Airfield

Task

Return to home.

3.4 Operation and Example Procedures

Introduction

Before operation, the instrument must be connected to the correct electrical and pneumatic/

hydraulic) supplies, (Ref: Installation,Section 2).

When the instrument is switched ON the display shows measured pressure mode and the task set

before the power-off.

Measure Mode

The instrument works as a precision pressure indicator and shows the pressure measured at the

output port.

Pressing Task enables pre-determined functions:

Task

The display shows the task screen (Ref: Illustration above).

When selected, e.g. Basic, the screen changes to show the selected task.

To measure pressure in the task proceed as follows:

1. Select the required units of pressure measurement from the measure set-up menu.

K0470 Revision A 3 - 8 [EN] English

Page 34

PACE Pressure Indicators User Manual

QNE QNH QFE

29.9212 inHg (1013.25 kPa)

Datum

Sea Level Reference Datum

(adjusted)

Runway

(on Earth’s surface)

Note: In the Airfield Task Q codes can be used. These units are standardised three letter codes and

are available in aeronautical units (feet and metres). The codes used are:

• QFE - Atmospheric pressure at sea level, corrected for temperature and adjusted to

airfield elevation. When set on the altimeter it reads height.

• QNE - Atmospheric pressure at Sea level in International Standard Atmosphere (ISA)

1013.25 mbar.

• QFF - Barometric pressure at a place, reduced to Mean Sea Level (MSL) using the

actual temperature at time of observation as mean temperature.

• QNH - Atmospheric pressure at Mean Sea Level (MSL) (may be local, measured

pressure or a Regional Forecast Pressure (RFP). When set on altimeter it reads

altitude.

[EN] English 3 - 9 K0470 Revision A

Page 35

3 Operation

Start

Test time

Leak test

Settings

Leak rate

/second

/minute

Leak testing option

This task, measures the leak rate over the measure dwell time.

At the start of the test, the instrument measures the test pressure of the user system. The

instrument then records the pressure change during measure dwell time.

On completion, the display shows the leak rate results with leak rate per second or per minute in

the current pressure units selected in measure set-up.

K0470 Revision A 3 - 10 [EN] English

Page 36

PACE Pressure Indicators User Manual

1

2

Supervisor set-up

Calibration

Global set-up

Save/recall user set-up

Save current user set-up

Recall current user set-up

Display

PIN - enter four digit code (4321)

- % brightness

- Timer (time-out) setting

Resolution - Measure display resolution

Back light

Audio volume - % of full volume

Satus area

Display Mode

Function area

Reading

Graph

3.5 Global Set-up Selections

Global set-up selections provide access to the instrument‘s settings for both measure and control

modes.

This set-up menu provides PIN-protected access to the supervisor set-up and calibration.

Pressing Global Set-up changes the touch-screen display to show available selections.

Supervisor Set-up, Calibration, Save/Recall User Set-up and Display.

1 Selections 2 Escape Key

[EN] English 3 - 11 K0470 Revision A

Page 37

3 Operation

enter four digit code

(0268)

-

-

Alarms

Communications

Restore last settings

Supervisor

More

next page:-

PIN

Pressing the escape key stores

settings and returns to global

set-up.

Enable/disable high pressure

Enable/disable low pressure

IEEE488

RS232

USB

Ethernet

Gas head correction

Enable/

disable

Head - in or m

Local gravity - m/s

2

Barometric - mbar

Reference port medium*

Test port medium*

Temperature (gas)

Humidity (gas)

*air or nitrogen

Lock

Lock/unlock individual tasks

Lock/unlock all tasks

Lock tasks

Change PIN

Enter new PIN

Re-enter new PIN

Enter new

supervisor PIN

User defined units

Enter the name of the defined units

Enter the equivalent value in Pascals

User defined units user unit 1

Instrument alias name

Language

Restore previous defaults Y/N?

Rate set-up

/second

/minute

Area of Use

Europe

North America

Japan

Asia

Rest of World

Additional selections for options enabled: Aeronautical etc.

3.6 Supervisor Set-up

K0470 Revision A 3 - 12 [EN] English

Page 38

PACE Pressure Indicators User Manual

Instrument

Software installed

Hardware build

Instrument Status

IEEE488*

Instrument Main Code

Instrument OS Build

Instrument Boot ROM

Analogue O/P Main Code

Analogue O/P Boot ROM

VFC Main Code

VFC Boot ROM

Additions to the

standard instrument

Pressing the escape key

stores settings and returns

to global set-up.

History

Calibration

Zero

Software

Hardware

Message

Communications

RS232*

* current settings, see 6.7

Current set-up

Support

Contact details

Ethernet (optional)

USB

Ethernet

More

next page:-

3.7 Instrument Status

The control set-up menu provides access to the status of the instrument:

[EN] English 3 - 13 K0470 Revision A

Page 39

3 Operation

Exit set-up.

Instrument Main Code

Software history

Analogue O/P Main Code

Instrument OS Build

Instrument Boot ROM

Analogue O/P Boot ROM

VFC Main Code

VFC Boot ROM

Example

Additional selections for options

enabled: Analgue etc.

Software

Software history, in the status menu, provides read only information on the current software in the

instrument.

K0470 Revision A 3 - 14 [EN] English

Page 40

PACE Pressure Indicators User Manual

4 Maintenance

4.1 Introduction

This section contains procedures for routine maintenance and the replacement of components

(Ref: Testing and Fault Finding, Section 5).

Table 4.1 - Maintenance Tasks

Task Period

Visual Inspection Before use

Test Before use

Cleaning Weekly*

Calibration 12 months †

* may change depends on usage (e.g., rack mounted, bench top) and environment (e.g., humidity, dust).

† may change depends on the required accuracy.

4.2 Visual Inspection

Inspect for obvious signs of damage and dirt on the following:

a. External of the instrument.

b. Power supply adaptor

c. Associated equipment.

Damaged parts must be replaced contact GE Service.

For cleaning (Ref: Cleaning Section 4.3).

4.3 Cleaning

CAUTION

Do not use solvents for cleaning.

Clean the front panel with a damp lint-free cloth and mild detergent.

4.4 Test

Do a standard serviceability test (Ref: Standard Serviceability Test, Section 5.2).

4.5 Calibration

The instrument should be returned to the manufacturer or calibration facility, (Ref: Section 6.14).

To find the date of the last calibration, press Measure set-up/Status/Calibration history.

[EN] English 4 - 1 K0470 Revision A

Page 41

4 Maintenance

Intentionally blank

K0470 Revision A 4 - 2 [EN] English

Page 42

PACE Pressure Indicators User Manual

5 Testing and Fault Finding

5.1 Introduction

This section details the standard serviceability test. Table 5.1 lists possible faults, and the

response.

The PACE1000 contains a self-test and diagnosis system that continuously monitors the

performance of the unit. At power-up, the system performs a self-test.

5.2 Standard Serviceability Test

The following procedure shows if the unit is serviceable and checks functions and facilities of

the PACE1000.

Procedure

CAUTION

Always release pressure before disconnecting pressure equipment from the outlet port.

1. Connect the instrument (Ref: Installation, Section 2) Connect a UUT.

2. After power-up, select measure set-up.

a. Select the required units of pressure measurement from the measure set-up

menu.

b. Apply a known pressure to one of the sensors. Make sure the instrument

pressure reading is within tolerance, stated in the specification (Ref: SDS).

c. Carefully release the applied pressure to atmospheric pressure.

d. Make sure the instrument pressure reading shows atmospheric or ambient

pressure.

e. Test complete.

After a successful serviceability test the instrument is ready for use.

5.3 Ethernet Testing

1. Connect PACE Ethernet port to a PC.

2. Check the PACE Ethernet LAN indication turns green after a few seconds.

3. Set the PACE Ethernet address to Auto IP.

4. Record the PACE auto IP address (The test screen below has auto IP address 3.115.21.237)

5. Open the PC command prompt screen.

6. Using the “ping” command, ping the PACE IP address (see screen capture below). The PACE

will reply if operating correctly.

[EN] English 5 - 1 K0470 Revision A

Page 43

5 Testing and Fault Finding

Ethernet open ports and their usage:

80/tcp PACE Web server (http)

111/tcp ONC RPC port mapper

372/tcp VXI-11 communication (Dynamically allocated)

443/tcp Web server (https)

5025/tcp PACE SCPI communication socket

111/udp ONC RPC port mapper

K0470 Revision A 5 - 2 [EN] English

Page 44

PACE Pressure Indicators User Manual

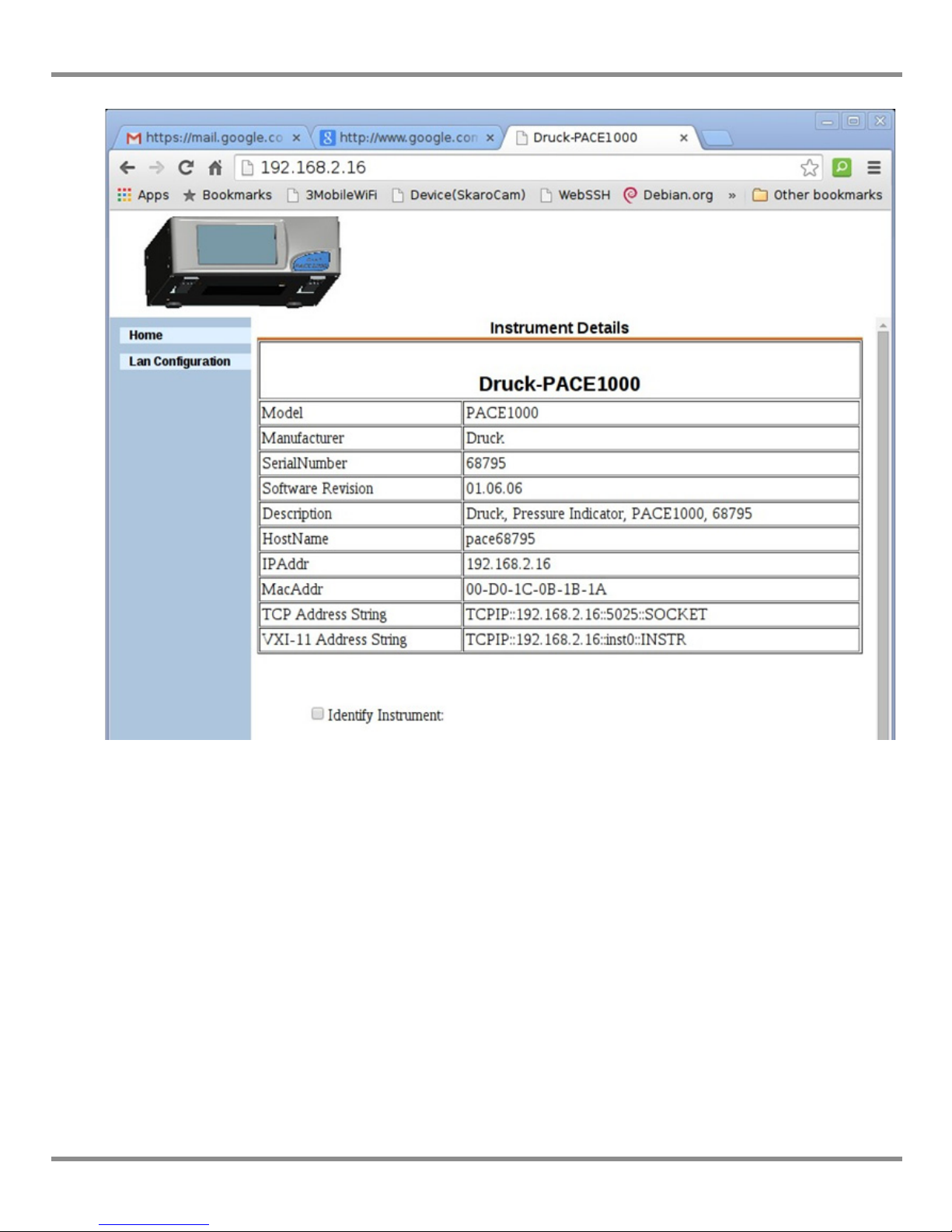

Ethernet testing using a web browser

[EN] English 5 - 3 K0470 Revision A

Page 45

5 Testing and Fault Finding

Ethernet testing using NI

http://www.ni.com/download/ni-daqmx-14.1/4953/en/

5.4 Fault Finding

Check the faults and responses (Ref: Table 5.1 Fault Diagnosis) before contacting

www.gemeasurement.com or a recommended Service Agent.

Fault Response

Power supply connected, display not lit. Check electrical power supply fuse or circuit breaker.

Display pressure reading in red Over-range, carefully de-pressurize.

Vent system pressure.

Instrument will not zero.

Check for blockage.

Contact approved service agent for repair.

Table 5.1 - Fault Diagnosis

5.5 Approved Service Agents

For the list of service centres logon to www.gemeasurement.com

K0470 Revision A 5 - 4 [EN] English

Page 46

PACE Pressure Indicators User Manual

6 Reference and Specification

6.1 Installation notes

The PACE1000 pressure indicator requires a set of connections with the exception of the

reference connection, this provides a reference to atmosphere for gauge sensors and

barometric sensors.

The gas density and type does not affect the accuracy of pressure measurement, assuming

that the UUT is at the same level (height) as the indicator or gas head correction is

accurately set.

-3

Values of air density (kg m

dioxide by volume.

) for air of relative humidity 50% and containing 0.04% carbon

Table 6-1 Air Density Values

Air

pressure

(kPa)

87

88

89

90

91

92

93

94

95

96

97

98

99

100

Air temperature (°C)

14 16 18 20 22 24 26

1.052 1.045 1.037 1.029 1.021 1.014 1,006

1.064 1.057 1.049 1.041 1.033 1.025 1.018

1.077 1.069 1.061 1.053 1.045 1.037 1.029

1.089 1.081 1.073 1.065 1.057 1.049 1.041

1.101 1.093 1.085 1.077 1.069 1.061 1.053

1.113 1.105 1.097 1.089 1.080 1.072 1.064

1.125 1.117 1.109 1.100 1.092 1.084 1.076

1.137 1.129 1.121 1.112 1.104 1.096 1.088

1.149 1.141 1.133 1.124 1.116 1.108 1.099

1.162 1.153 1.145 1.136 1.128 1.119 1.111

1.174 1.165 1.156 1.148 1.139 1.131 1.123

1.186 1.177 1.168 1.160 1.151 1.143 1.134

1.198 1.189 1.180 1.172 1.163 1.154 1.146

1.210 1.201 1.192 1.184 1.175 1.166 1.158

101

102

103

104

105

106

1.222 1.213 1.204 1.196 1.187 1.178 1.169

1.234 1.225 1.216 1.207 1.199 1.190 1.181

1.247 1.237 1.228 1.219 1.210 1.201 1.193

1.259 1.249 1.240 1.231 1.222 1.213 1.204

1.271 1.261 1.252 1.243 1.234 1.225 1.216

1.283 1.274 1.264 1.255 1.246 1.237 1.228

Note: 100 kPa = 1 bar

[EN] English 6 - 1 K0470 Revision A

Page 47

6 Reference and Specification

6.2 Reference Port

The reference port provides the negative pressure to the gauge sensor and to the barometric

reference (option). Gauge sensors use this port identified as “REF”. For gauge sensors

(without a barometric reference) small pressures can be applied (Ref: Specification, Section

6-7). All other pressure measurement requires the port to be opened to atmosphere. When in

gauge mode, the instrument shows and controls the pressure difference between the

reference port and the output port.

Note: This is not a true differential operation as there is no true differential calibration of the

sensor.

The transducer of the barometric reference option senses atmospheric pressure via the

reference port, when enabled the port MUST be open to atmosphere.

The reference connection should be actively used (differential connection option) for

precision low pressure measurement . The instrument measures pressure relative to the

pressure at the reference port.

An atmospheric pressure change causes the indicator to adjust the pressure and appears at

the pressure output as apparent instability. To keep a stable controlled pressure, the

reference port should be restricted. Using a reference port restrictor (snubber), short term

ambient pressure variations can be prevented from affecting indicator performance.

The indicator and UUT references should be connected together (using the optional

differential connection kit) to provide a common reference to atmosphere.

K0470 Revision A 6 - 2 [EN] English

Page 48

PACE Pressure Indicators User Manual

6.3 Icons

The following icons are used in the PACE series of instruments, not all icons are used in every PACE instrument.

Display Icons in Set-up Menus

Icon Function Icon Function Icon Function

Active Aero set-up Aeronautical

Airspeed range Alarm Altitude range

Area of use Asterisk Auto range

Audio volume Auto zero Backlight

Barometer Basic

Calibration Calibration history

Change supervisor

PIN

Control mode Copy

Correction SCM Correction sensor

Correction valve Current set-up Date & time

Delete

Communications Contrast

Diagnostic

analogue output

Burst pressure

control mode

Correction

analogue output

Correction source

sensor

Diagnostic

barometric option

Diagnostic general Diagnostic RS232

[EN] English 6 - 3 K0470 Revision A

Diagnostic control

sensor

Diagnostic

controller

Diagnostic source

sensor

Page 49

6 Reference and Specification

Icon Function Icon Function Icon Function

Diagnostic

vacuum sensor

Display Divider Error

Escape Ethernet

Ethernet

connected

Gas head pressure Gauge mode Global set-up

Go-to-ground Hardware build Home

Idle time-out IEEE488 Information

Diagnostic voltfree

Exclamation Fault history

Diagnostics

Ethernet not

connected

In limits Instrument

Instrument alias

name

Lock Lock tasks Logic output

Max-min Max peak Min peak

Nudge Passive mode Percentage

PIN Power-up Preset

Pressure Pressure filter Process

Language Leak test

Instrument

accuracy

K0470 Revision A 6 - 4 [EN] English

Page 50

PACE Pressure Indicators User Manual

Icon Function Icon Function Icon Function

Protective vent Question Range

Recall user set-up Reset use log Resolution

Re-try Roughing RS232

Restore to as

shipped settings

Save as shipped

Screen mode Screen saver SCM filter

SCM zero Select range

Set-point limits

Set date Set serial number Set time

Set-up zero Slew rate linear Slew rate max rate

Restore settings 2 Run

Save recall user

set-up settings

Set-point higher

limit

Save user set-up

Set-point disable/

enable

Set-point lower

limit

Software build

Status Status area Step (single)

Stop Supervisor set-up Switch test

Tare Support Task

[EN] English 6 - 5 K0470 Revision A

Software upgrade

history

Software upgrade

Page 51

6 Reference and Specification

Icon Function Icon Function Icon Function

Test program Test program copy

Timing Time out Timed zero

Units User defined units Use log

Use log history Vent Vent time out

Vent Yes/No Vent set-up Warning

Zero analogue

output

6.4 Measure Set-up

Pressure zero

Test program

delete

Zero history Zero

During use, the instrument pressure sensor can show small zero shifts caused by time and

temperature changes. Regular “zeroing” increases measuring precision.

Process

Selects display processing features that change the reading, as follows:

%: Pressure can be displayed reading as a percentage of full-scale or as a percentage

of a specified span.

Filter: The displayed reading can be filtered by a custom low pass filter or the filter can

be disabled (default disabled). The indicator works at a speed independent of the

filter time constant.

Tare: A specific tare value can be selected or the current displayed pressure reading can

be “captured” as the tare value. The display shows the selected tare value in the

pressure window.

Peak: Maximum, minimum and average display of pressure readings.

Task

Selecting Task enables a set of pre-determined functions and software enabled optional

functions.

K0470 Revision A 6 - 6 [EN] English

Page 52

PACE Pressure Indicators User Manual

Units

Select the new units from the list of pressure measurement units. Special units can also be

defined (Ref: Global set-up,

Global set-up

Section 6.6, supervisor set-up).

Ref: Global set-up,

Set-up zero

Zero from top level screen (main range only).

If other ranges are fitted these can be zeroed by selecting the displayed reading.

Barometric Reference Option

The barometric reference option measures the barometric pressure at the reference port.

Depending on the sensors fitted, it also permits the indicator to operate in either pseudo-

gauge or pseudo-absolute mode by the addition of barometric pressure.

6.5 Status

The display shows the following:

a. Instrument status

Section 6.6.

•Model

• Serial number

• MAC address sensor(s)

• Range

• Last calibration date*

b. Software build - read only data.

c. Hardware build - read only data.

d. History - read only data

•Calibration

•Zero

• Software

• Hardware

• Message

• Ethernet connection

e. Communications, IEEE 488 and RS232 are fitted as standard. Additional communication

types are options - USB and Ethernet.

f. Current set-up - read only data.

g. Support

• List contact information for support and advice.

[EN] English 6 - 7 K0470 Revision A

Page 53

6 Reference and Specification

6.6 Global set-up

Supervisor set-up

PIN protected menu (Ref: Supervisor set-up, Section 6.7).

Calibration

PIN protected menu (Ref: Calibration set-up, Section 6.8).

Save/recall user set-up

Save user set-up.

Recall user set-up.

Display

a. Resolution

b. Backlight

c. Audio volume

d. Status area

e. Display Mode

•Reading (default)

• Graph

* The instrument date and time must have been set correctly.

K0470 Revision A 6 - 8 [EN] English

Page 54

PACE Pressure Indicators User Manual

6.7 Supervisor Set-up

The Supervisor menu provides facilities for programming settings. These are usually made

during installation as follows:

Important Note: A PIN protects the Supervisor menu against unauthorised use. Each

instrument on delivery contains the factory set PIN (0268). To continue

protecting the supervisor set-up menu the PIN should be changed as soon

as possible.

Alarms

An alarm can be set to trigger when the pressure exceeds the high alarm or falls below the

low alarm. A buzzer sounds when the alarm triggers and the alarm symbol (bell) appears on

the display.

Comms

Selects the communication port parameters and simultaneous operation of the RS232, IEEE

488 interface and Ethernet.

Note: PACE1000 Lab view drivers are available for download from:

http://sine.ni.com/apps/utf8/niid_web_display.download_page?p_id_guid=B6F9A6B06AEA01F1E0440021287E65E6

The user can select appropriate settings for communicating with the control computer (PC)

and the required command protocol.

Referring to the PACE SCPI communications user manual there are three commands that

can be used to retrieve pressure readings from the PACE100X:

:INST:SENS[x]:READ? Where x = 1 to 8 set in the comms range menu

:SENS:PRES?

:DISP[x]:WIND?

Returns the reading top main display window with display filtering

(2Hz update rate) applied

Where [x] = display (1=top main, 2=middle status area & 3= bottom

function area) window

To obtain fastest readings you must use the following SCPI command :INST:SENS[x]:Read?

This command returns two readings, a filtered reading and a raw reading (unfiltered

reading) from internal sensors, thus giving the user a choice of which reading to use which is

most suitable for their application.

e.g.

TX> :Inst:Sens2:Read?

RX> :INST:SENS2:READ "993.539148733033 993.543837356372"

Note: Raw reading returned from IDOS sensors is “0” as a raw readings cannot be obtained

from IDOS sensors.

Data throughput. Baud rates slower than 115k2 baud will slow the new data update rate

pro-rata. Even at a 115k2 baud rate the readings are slower than using IEEE. IDOS is a slower

sensor than internal sensors.

[EN] English 6 - 9 K0470 Revision A

Page 55

6 Reference and Specification

RS232

Located on the rear panel an external RS232 connection requires the following:

Connector 9-way ‘D’ female wired as per Table 2-1

Communications RS232 point-to-point only (daisy chain is not supported)

Baud Rate power-up default 9600, no parity & handshake = xon/xoff

Baud rates selectable ** 2400, 4800, 9600, 19k2, 38k4, 57k6 & 115k2

Parity None, Odd & Even

Flow control None, Hardware & xon/xoff

Protocols PACE SCPI

Heritage emulation DPI 142/150, DPI 141

Terminator CR or LF or CR/LF

** Selectable through the user interface.

RS232 Comms Range Setup

Note: The RS232 Comms Range values are set up by the user because of the hardware the

user desires to operate with the PACE 1000 equipment. This procedure only allows

supervisor to select these user pre-installed values. To initially define / change or

delete the RS232 Comms Range values, refer to (Ref: K0472 PACE SCPI Remote

Communications Manual).

K0470 Revision A 6 - 10 [EN] English

Page 56

PACE Pressure Indicators User Manual

1. On the main screen, touch any of the three horizontal touch areas on the screen.

2. On the MEASURE SETUP screen, select GLOBAL SETUP.

[EN] English 6 - 11 K0470 Revision A

Page 57

6 Reference and Specification

3. Select SUPERVISOR SETUP.

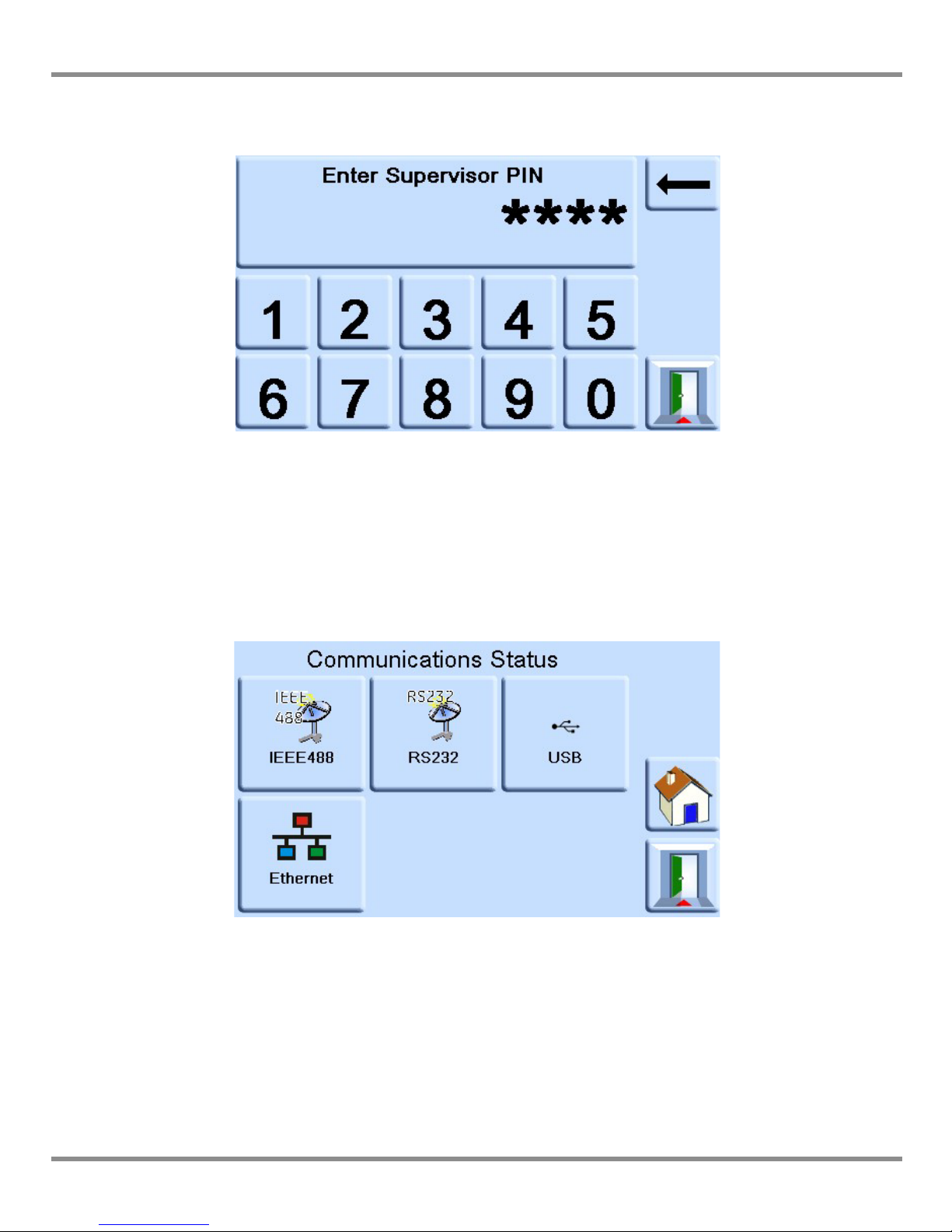

4. Enter the Supervisor PIN and press the top touch area. Use the back arrow in the top

right corner of the screen to delete any incorrect data entries.

K0470 Revision A 6 - 12 [EN] English

Page 58

PACE Pressure Indicators User Manual

5. On the SUPERVISOR screen, select COMMS.

6. On the COMMUNICATIONS screen, select COMMS RANGE SETUP.

7. On the COMMS RANGE SETUP, Use the Up and Down arrows to highlight the desired

Range (Ranges 1 to 10).

[EN] English 6 - 13 K0470 Revision A

Page 59

6 Reference and Specification

Comms range setup is used to re-align the SCPI index (x) to the correct pressure range.

Where Range is index (1)......etc.

8. Press the top touch area on the screen to change the range value.

9. Use the Up and down arrow to highlight the new Range value.

10. Press the top Measure on the screen to change the range value. The new range value

is set and the screen returns to the COMMS RANGE SETUP screen.

11. If necessary, repeat Steps 7 to 10 to set up other range values.

12. Press the Escape icon to go back to the COMMS RANGE SET UP screen.

13. When complete, press the Escape icon as necessary to return to the Measure screen.

IEEE

Located on the rear panel an external IEEE 488 connection requires:

Connector 24-way ‘D’ female wired as IEEE 488 standard

Communications IEEE488 GPIB

Default Address 16

Protocols PACE SCPI

Heritage emulation DPI 142/150, DPI 141

Ethernet

Located on the rear panel an external Ethernet connection requires the following:

Connector Ethernet RJ45

Protocol SCPI

Terminator CR/LF

Default Address Auto IP (0.0.0.0)

Host name PACExxxxxx (where xxxxxx = serial number)

Web Password 0268

Access control Open

Reset LAN Settings Selected in Supervisor set-up menu

Ethernet Firewall

A firewall protects the Ethernet connection. The firewall is always turned on. The following

ports are unfiltered to allow remote communication and control.

Port Description

80/tcp http (Web server)

111/tcp rpcbind (RPC for VXI)

111/udp rpcbind (RPC for VXI)

443/tcp https (Web server)

K0470 Revision A 6 - 14 [EN] English

Page 60

PACE Pressure Indicators User Manual

5025/tcp SCPI socket

*****/tcp VXI-11 communication (dynamic port allocated)

Ethernet Functionality

• PACE Ethernet supports both VXI-II and Sockets automatically.

• Socket port address 5025.

• Internet protocol IP4.

Ethernet Parameters Range Setup

1. Touch any of the three horizontal Measure touch pads on the home screen to open the

CONTROL SET UP screen.

2. On the MEASURE SETUP screen, select GLOBAL SETUP.

3. Select SUPERVISOR SET UP.

[EN] English 6 - 15 K0470 Revision A

Page 61

6 Reference and Specification

4. Enter the Supervisor PIN and press ENTER SUPERVISOR PIN. Use the back arrow in the

top right corner of the screen to delete any incorrect data entries.

Note: The factory set Supervisor PIN is 0268. If the Supervisor PIN has been locally changed,

make sure that the new PIN is kept in a safe place. If the new PIN is lost, it can only be

reset at a GE Service Centre.

5. Press COMMUNICATIONS STATUS to open the COMMUNICATIONS STATUS screen.

6. Select ETHERNET to open the ETHERNET PARAMETER screen.

K0470 Revision A 6 - 16 [EN] English

Page 62

PACE Pressure Indicators User Manual

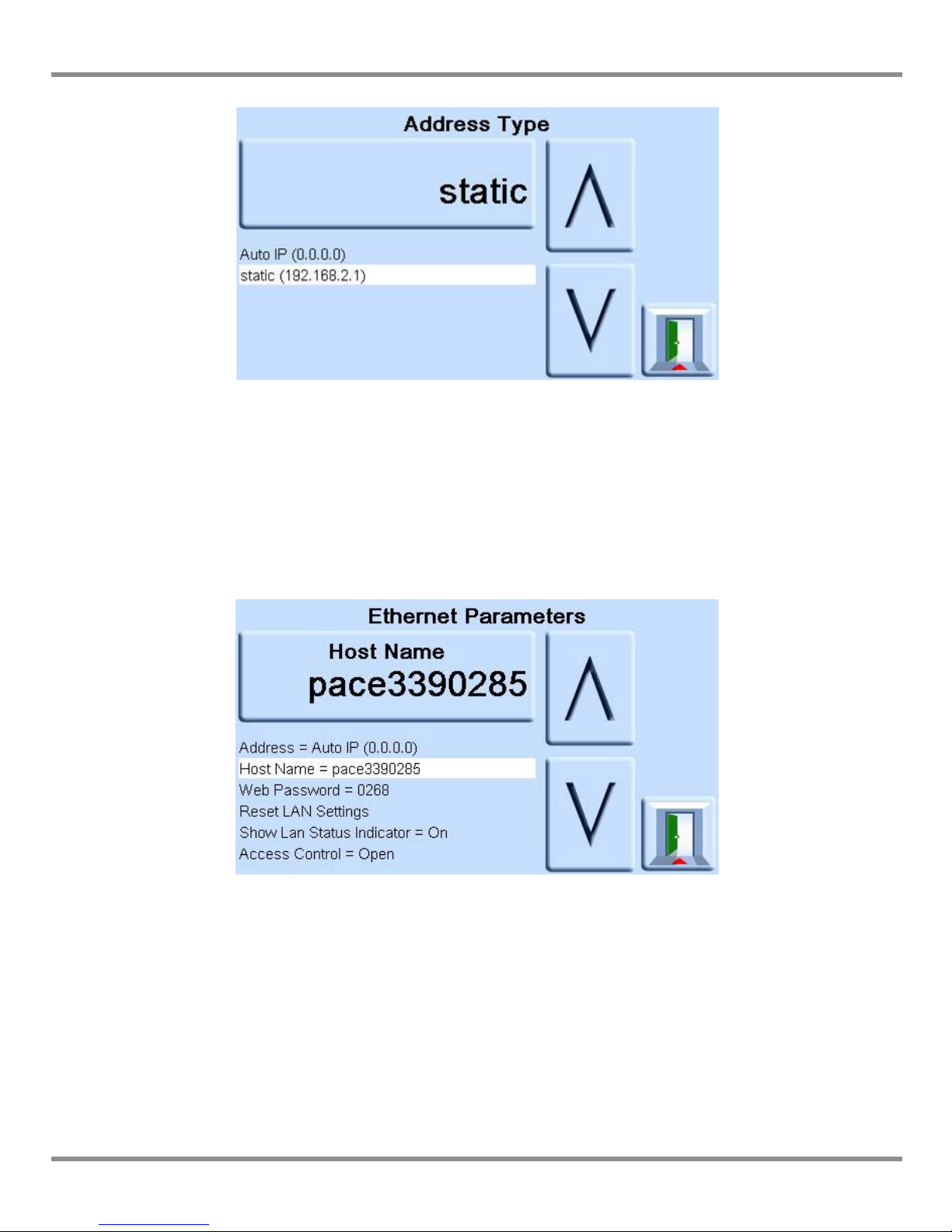

7. To change the ADDRESS parameter, complete the following:

a. On the ETHERNET PARAMETER screen, use the UP and DOWN arrows to

highlight the ADDRESS field.

b. Press the top touch pad on the screen to enter the ADDRESS TYPE screen.

c. Use the UP and Down arrows to highlight the desired address type (either

AUTO IP or STATIC).

[EN] English 6 - 17 K0470 Revision A

Page 63

6 Reference and Specification

d. Press the top touch pad on the screen to set the new address type. The

screen automatically returns to the ETHERNET PARAMETERS screen.

8. To change the host name, complete the following:

a. On the ETHERNET PARAMETER screen, use the UP and DOWN arrows on

the right of the screen to highlight the HOST NAME field.

b. Press the top touch pad on the screen to enter the HOST NAME screen.

c. Use the keyboard to input the new host name and then press the top

button on the screen to set the host name. The screen automatically

returns to the ETHERNET PARAMETERS screen.

K0470 Revision A 6 - 18 [EN] English

Page 64

PACE Pressure Indicators User Manual

9. To change the web password, complete the following:

a. On the ETHERNET PARAMETER screen, use the UP and DOWN arrows on

the right of the screen to highlight the WEB PASWORD field.

b. Press the top touch pad on the screen to enter the WEB PASSWORD

screen. The keyboard screen opens.

[EN] English 6 - 19 K0470 Revision A

Page 65

6 Reference and Specification

.

c. Use the keyboard to input the new web password and then press the top

touch area on the screen to set the new password. The screen

automatically returns to the ETHERNET PARAMETERS screen.

10. To reset the LAN settings, complete the following:

a. On the ETHERNET PARAMETER screen, use the UP and DOWN arrows on

the right of the screen to highlight the RESET LAN SETTINGS field.

b. Press the RESET THE LAN SETTINGS touch pad on the top touch pad of the

screen.

c. The RESET LAN SETTINGS sub-screen asking for confirmation of the reset.

Press YES to confirm reset of the LAN settings.

11. To turn the LAN status indicator on or off, complete the following:

a. On the ETHERNET PARAMETER screen, use the UP and DOWN arrows on

the right of the screen to highlight the SHOW LAN STATUS field.

K0470 Revision A 6 - 20 [EN] English

Page 66

PACE Pressure Indicators User Manual

b. Use the UP and DOWN arrows to highlight the desired setting. The setting

is either ON or OFF.

c. Press the top touch pad on the screen to set the new setting.

12. To change ACCESS MODE, complete the following:

a. On the ETHERNET PARAMETER screen, use the UP and DOWN arrows on

the right of the screen to highlight the ACCESS CONTROL field.

[EN] English 6 - 21 K0470 Revision A

Page 67

6 Reference and Specification

b. Press the ACCESS CONTROL OPEN touch pad on the top of the screen to

open the ACCESS MODE screen.

c. Use the UP and DOWN arrows to highlight the required parameter. The

choices are OPEN or RESTRICTED.

K0470 Revision A 6 - 22 [EN] English

Page 68

PACE Pressure Indicators User Manual

d. Press the ACESS MODE OPEN or ACCESS MODE RESTRICTED touch pad at

the top of the screen to set the required access mode.

13. To change CONTROLLER IP ADDRESS complete the following:

a. On the ETHERNET PARAMETER screen, use the UP and DOWN arrows on

the right of the screen to highlight the ACCESS CONTROL field.

b. Press the ACCESS CONTROL touch pad on the top of the screen.

c. Use the UP and DOWN arrows to highlight the CONTROLLER IP ADDRESS

field.

[EN] English 6 - 23 K0470 Revision A

Page 69

6 Reference and Specification

d. Use the number touch pad at the bottom of the screen to input the new IP

address and press the CONTROLLER IP ADDRESS touch pad at the top of

the screen to set the new IP address.

14. To view the recent IP addresses, complete the following:

a. On the ETHERNET PARAMETER screen, use the UP and DOWN arrows on

the right of the screen to highlight the ACCESS CONTROL field.

b. Press the ACCESS CONTROL button on the top of the screen.

c. Use the UP and DOWN arrows to highlight the SELECT FROM RECENT field.

K0470 Revision A 6 - 24 [EN] English

Page 70

PACE Pressure Indicators User Manual

Reference

Level

d. Press the SELECT FROM RECENT button at the top of the screen to view

the IP address history.

Head Correction

Corrects pressure reading for the height difference

between instrument reference level and UUT. For

accuracy, head correction must be enabled and the

parameters set for each sensor:

• for UUT positioned higher than the reference level

of the PACE1000 enter a positive height correction.

• for UUT positioned lower than the reference level of the PACE1000 enter a negative

height correction.

[EN] English 6 - 25 K0470 Revision A

Page 71

6 Reference and Specification

Lock Tasks

Individual tasks

:

Allows any combination of individual tasks to be disabled.

Note: Restricts operation of the instrument to specific tasks or functions, recommended for

production procedures.

All

:

Disables all tasks.

Change PIN

Changes the Supervisor PIN: enter the existing PIN, then the new PIN and confirmation of the

new PIN.

Note: Confirmation of the new PIN permanently

replaces the old PIN. Record this new PIN and

keep in a safe place. If new PIN is lost it can only be reset by returning the instrument to

a GE service centre.

User defined units

Permits the user to define a set of units. Following the on-screen prompts special units may

be set by selecting a Pascal multiplier and assigning a five character name.

Instrument alias name

Permits the user to define a 20 character alias name for the instrument. The instrument

returns this name through the communications interfaces.

Language

Operation in any of the languages refer to the SDS. Further languages can be up-loaded.

Restore as shipped settings

Restores instrument settings to factory default.

Note: Does not affect PIN settings.

K0470 Revision A 6 - 26 [EN] English

Page 72

PACE Pressure Indicators User Manual

6.8 Calibration

The calibration menu provides facilities for programming settings for maintenance as

follows:

Note: A PIN protects the Calibration menu against unauthorised use. Each instrument, on

delivery, contains the factory set PIN (4321). To continue protecting the supervisor setup menu, the PIN should be changed as soon as possible.

sensor correction

• Selects the range for a three-point calibration routine.

screen calibration

• Selects touch screen calibration routine.

Time & Date

• Sets instrument clock and date.

Change PIN

• Changes the Calibration PIN.

a. Enter the existing PIN

b. Enter the new PIN

c. Confirm the new PIN

Note: Confirmation of the new PIN permanently

keep in a safe place. If new PIN is lost it can only be reset by returning the instrument to

a GE service centre. For more information regarding calibration, refer to PACE

Calibration Manual K0450.

6.9 Specification

Refer to the PACE1000 data sheet for details.

Note: The data sheet is contained in the CD shipped with the product.

replaces the old PIN. Record this new PIN and

[EN] English 6 - 27 K0470 Revision A

Page 73

6 Reference and Specification

Selects Analogue

Output Range

On/Off

Update rate of Analogue Output

option from the control module.

Analogue Output Bandwidth = 0.5 x Update Rate (Hz)

30V maximum with respect to

chassis.

Rated output = 24V

30Vmax

To maintain PACE product safety, external

circuits connected to the instrument must meet

Safety Extra-Low Voltage (SELV) requirements.

15-way female D connector

Front view of Analogue

Option PCB connector

123

4

5

6

7

8

15 14 13 12 11 10 9

30Vmax

22Vto 26V

ANALOGUE1

ANALOGUE2

15

CONSULTHANDBOOK

analogue connections

6.10 Options

Option enable process

To enable soft options on a PACE instrument, use the following:

1. Touch the top Measure area of the screen.

2. Select Global Setup.

3. Select Calibration.

4. Enter a Calibration PIN 1234.

5. Enter new option key xxxxxxxxxx (10 digits).

6. After entry of this key PACE confirms the options have been enabled.

Note: Hardware options automatically enable post installation

K0470 Revision A 6 - 28 [EN] English

Page 74

PACE Pressure Indicators User Manual

Pin number Function Pin number Function

1 not used 9 not used

2 not used 10 0V return

3 not used 11 +24V DC OUT @ 100mA

4 not used 12 SW IN 1

5 not used 13 SW IN 2

6 not used 14 analogue +

7 not used 15 analogue -

8not used

[EN] English 6 - 29 K0470 Revision A

Page 75

6 Reference and Specification

Each selection has

three Volts-free

Contacts.

Selection of trigger

conditions.

Selection of trigger

conditions.

30V maximum with respect to

chassis.

Rated output = 24V

30Vmax

To maintain PACE product safety, external

circuits connected to the instrument must meet

Safety Extra-Low Voltage (SELV) requirements.

0V

+V

event

trigger

24 Vdc maximum

30 Vdc wrt chassis

1 A resistive maximum

Typical Volts-free

schematic

Relay contacts rated at 30 Vdc, 1 A resistive,

200 mA inductive.

22Vto 26V

ANALOGUE1

ANALOGUE2

15

CONSULTHANDBOOK

volts-free connections

Volts-free Contact Option

The Volts-free Contact option provides a selectable relay contact toggle depending on conditions

set in the PACE instrument.

Pin number Function Pin number Function

1 Relay 1 normally CLOSED 9 Relay 3 common

2 Relay 1 normally OPEN 10 0V return

3 Relay 1 common 11 +24V DC OUT @ 100mA

4 Relay 2 normally CLOSED 12 SW IN 1

5 Relay 2 normally OPEN 13 SW IN 2

6 Relay 2 common 14 not used

7 Relay 3 normally CLOSED 15 not used

8 Relay 3 normally OPEN

K0470 Revision A 6 - 30 [EN] English

Page 76

PACE Pressure Indicators User Manual

6.11 Installation and Ancillary Equipment Kit

Refer to the PACE1000 data sheet for details.

6.12 Return Goods/Material Procedure

If the unit requires calibration or is unserviceable return it to the nearest GE Service Centre

listed at www.gemeasurement.com

Contact the Service Department to obtain a Return Authorisation (Worldwide excluding USA).

In the USA obtain a Return Material Authorization [RMA].

Providing the following information on either a RGA or RMA:

• Product (i.e. PACE1000)

• Serial number

• Details of defect/work to be undertaken

• Calibration traceability requirements

• Operating conditions

Safety Precautions

You must inform GE if the product has been in contact with any hazardous or toxic

substance.

The relevant COSHH or in the USA, MSDS, references and precautions to be taken when

handling.

Important notice

Service or calibration by unauthorized sources will affect the warranty and may not

guarantee further performance.

6.13 Packaging Procedure

1 The instrument should be at zero/ambient pressure.

2. Switch off and isolate the electrical power supply to the instrument.

3. Shut off the pneumatic pressure and vacuum supplies to the instrument.

4. Remove the instrument from the equipment rack to access the rear panel.

5. Disconnect the power supply cable and the pneumatic supply hose assemblies.

6. Stow the power supply cable in the packaging below.

7. Remove any pressure adaptors, diffusers and restrictors.

If available, use the original packing material. When using packing materials other than the

original, do the following:

8. Fit protection to all the ports to prevent ingress of moisture and dirt.

Note: Use the original red plastic plugs or low tack masking tape.

9. Wrap unit in polyethylene sheeting.

[EN] English 6 - 31 K0470 Revision A

Page 77

6 Reference and Specification

10. Select a double-wall cardboard container.

• Inside dimensions must be at least 15 cm (6”) greater than the equipment

• The carton must meet test strength requirements of >

11. Protect all sides with shock-absorbing material to prevent equipment movement

within the container.

12. Seal carton with approved sealing tape.

13. Mark carton “FRAGILE” on all sides, top, and bottom of shipping container.

Environment

The following conditions apply for both shipping and storage:

• Temperature range-20° to +70°C (-4° to +158°F)

125 kg (275 lbs).

K0470 Revision A 6 - 32 [EN] English

Page 78

www.gemeasurement.com

Loading...

Loading...