Page 1

GE Consumer & Industrial

TECHNICAL SERVICE GUIDE

Over the Range

Microwave Oven

MODEL SERIES:

JVM2070_H

PUB # 31-9111 2/04

Page 2

!

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by

individuals possessing adequate backgrounds of electrical,

electronic, and mechanical experience. Any attempt to repair a

major appliance may result in personal injury and property

damage. The manufacturer or seller cannot be responsible for the

interpretation of this information, nor can it assume any liability in

connection with its use.

WARNING

To avoid personal injury , disconnect power before servicing this

product. If electrical power is required for diagnosis or test

purposes, disconnect the power immediately after performing the

necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used

to complete a path to ground are removed for service, they must

be returned to their original position and properly fastened.

GE Consumer & Industrial

Technical Service Guide

Copyright © 2004

All rights reserved. This service guide may not be reproduced in whole or in part

in any form without written permission from the General Electric Company.

– 2 –

Page 3

PRECAUTIONS TO BE OBSERVED BEFORE AND DURING

SERVICING TO AVOID POSSIBLE EXPOSURE TO EXCESSIVE

MICROWAVE ENERGY.

A. DO NOT OPERATE OR ALLOW THE OVEN TO BE OPERATED

WITH THE DOOR OPEN.

B. IF THE OVEN OPERA TES WITH THE DOOR OPEN, INSTRUCT

THE USER NOT TO OPERATE THE OVEN AND CONTACT THE

MANUFACTURER IMMEDIA TEL Y .

C. MAKE THE FOLLOWING SAFETY CHECKS ON ALL OVENS TO

BE SERVICED BEFORE ACTIV A TING THE MAGNETRON OR

OTHER MICROWA VE SOURCE, AND MAKE REPAIRS AS

NECESSARY:

1. INTERLOCK OPERA TION.

2. PROPER DOOR CLOSING.

3. SEAL AND SEALING SURF ACES (ARCING , WEAR AND

OTHER DAMAGE).

4. DAMAGE TO OR LOOSENING OF HINGES AND LA TCHES.

5. EVIDENCE OF DROPPING OR ABUSE.

D. BEFORE TURNING ON MICROWAVE POWER FOR ANY TEST

OR INSPECTION WITHIN THE MICROWA VE GENERA TING

COMP ARTMENTS, CHECK THE MAGNETRON, WA VE GUIDE

OR TRANSMISSION LINE AND CA VITY FOR PROPER

ALIGNMENT , INTEGRITY AND CONNECTIONS.

E. ANY DEFECTIVE OR MISADJUSTED COMPONENTS IN THE

INTERLOCK MONITOR, DOOR SEAL AND MICROW AVE

GENERATION AND TRANSMISSION SYSTEMS SHALL BE

REPAIRED, REPLACED OR ADJUSTED BY PROCEDURE

DESCRIBED IN THIS MANUAL BEFORE THE OVEN IS

RELEASED TO THE OWNER.

F . A MICROW AVE LEAKAGE CHECK TO VERIFY COMPLIANCE

WITH THE FEDERAL PERFORMANCE STANDARD SHOULD

BE PERFORMED ON EACH OVEN PRIOR TO RELEASE TO

THE OWNER.

– 3 –

Page 4

Table of Contents

Bottom and Hood Thermal Cutout (TCO) ....................................................................................................18

Cavity Thermal Cutout (TCO) ......................................................................................................................13

Component Locator Views .......................................................................................................................... 7

Components................................................................................................................................................ 9

Control Features ......................................................................................................................................... 6

Control Panel .............................................................................................................................................16

Control Performance T est ...........................................................................................................................20

Cooling F an and Mot or ...............................................................................................................................12

Demonstration Mode ..................................................................................................................................21

Diagnostics Test ........................................................................................................................................21

Door Interlock Switches .............................................................................................................................16

Exhaust Fan ............................................................................................................................................... 9

Fuses ........................................................................................................................................................13

Gas Sensor................................................................................................................................................14

Hidden Vent Motor .....................................................................................................................................15

High Voltage Capacitor...............................................................................................................................18

Illustrated Parts Catalog .............................................................................................................................30

Interior Light ...............................................................................................................................................15

Magnetron..................................................................................................................................................14

Magnetron Thermal Cutout (TCO) ...............................................................................................................13

Microwave Leakage T est ............................................................................................................................22

Microwave Removal and Component Access.............................................................................................. 9

Nomenclature.............................................................................................................................................. 5

Performance T est .......................................................................................................................................22

Primary Interlock System Test ...................................................................................................................17

Schematic..................................................................................................................................................29

Sensor T est (Quick Test)............................................................................................................................20

Side Stirrer.................................................................................................................................................10

Side Stirrer Motor .......................................................................................................................................10

Smart Board...............................................................................................................................................23

Strip Circuits ..............................................................................................................................................24

Surface Lamp Assemblies..........................................................................................................................19

Surface Lamps...........................................................................................................................................19

T op S tirrer................................................................................................................................................... 11

T op S tirrer Motor......................................................................................................................................... 11

Touchscreen Display.................................................................................................................................. 6

Transformer ................................................................................................................................................14

Troubleshooting ..........................................................................................................................................20

Turntable Motor ..........................................................................................................................................18

Warranty ....................................................................................................................................................33

Wiring Diagram ..........................................................................................................................................28

– 4 –

Page 5

Model Number

Nomenclature

J V M 2 0 7 0 W H

Product

J = GE Cooking Product

Microwave Oven

V = Over-the-Range Model

Installation

M = Mounts Under Cabinet

Cavity Size (cu. ft.)

20 = 2.0 cu. ft.

The nomenclature plate is located on the

microwave cabinet inside the door. In

addition to model and serial number, this

plate also shows power ratings.

The Mini-manual is located behind the

hidden vent.

Nomenclature

Model Year

Designator

Case Color

S = Stainless

W = White

C = Bisque

B = Black

Feature Pack

Designates features–the higher

the number, the more features.

Serial Number

The first two numbers of the serial number

identify the month and year of manufacture.

Example: AG123456S = January, 2004

A - JAN 2005 - H

D - FEB 2004 - G

F - MAR 2003 - F

G - APR 2002 - D

H - MA Y 2001 - A

L - JUN 2000 - Z

M - JUL 1999 - V

R - AUG 1998 - T

S - SEP 1997 - S

T - OCT 1996 - R

V - NOV 1995 - M

Z - DEC 1994 - L

The letter designating

the year repeats every

12 years.

Example:

T - 1974

T - 1986

T - 1998

– 5 –

Page 6

Control Features

Touchscreen Display

The touchscreen display provides the access to

all cook and defrost controls. If the touchscreen is

dark, press the HOME button, the touchscreen,

or open the door to access the menu.

For diagnostics displays, see page 20.

• Press TROUBLESHOOTER to find

troubleshooting tips for common microwave

problems.

• Press SPACEMAKER 2.0 OVERVIEW to find

an overview of the features of your

microwave.

OFF

WARNING: Pressing OFF does not disconnect

the appliance from the power supply .

Pressing OFF while on the HOME screen will put

the touchscreen into standby mode, and the

display will be dark. Press the touchscreen or

HOME, or open the door to “wake up” the display .

Pressing OFF while on any other screen will

cancel the current screen and return the display

to the HOME screen.

HOME

HELP

Pressing HELP from the HOME screen allows

you to locate feature information and helpful hints.

After pressing HELP:

• Press PRODUCT DETAILS to find information

concerning your model and serial number .

• Press FEA TURE HELP to find help locating

information on the microwave features.

• Press SAFETY GUIDE to find help locating

microwave safety information.

HOME returns the display to the HOME screen

(displayed) at any time. The HOME screen is the

starting point for setting any cooking or defrost

program, or for setting microwave options. If the

touchscreen is dark, press the HOME button to

activate the screen.

VENT

Press VENT once for high fan speed. Press a

second time for medium fan speed, a third time

for low fan speed, and a fourth time to turn the fan

off. Press BOOST for extra fan speed.

BOOST

The BOOST button turns the vent fan on HIGH.

LIGHT

Press LIGHT once for bright light. Press a

second time for the night light. Press a third time

to turn the light off.

– 6 –

Page 7

Top View

Component Locator Views

4

7

10

6

1

1 - Interior Light

2 - Main and HV Transformer Fuses

9

5

3

8

2

3 - Hidden V ent Switch and Motor

4 - V ent Fan and Motor

5 - Top Stirrer Motor

6 - Cavity Thermal Cutout (TCO)

7 - Side Stirrer Motor

8 - Magnetron Antenna Waveguide

9 - Vent Tunnel

10 - Gas Sensor

– 7 –

Page 8

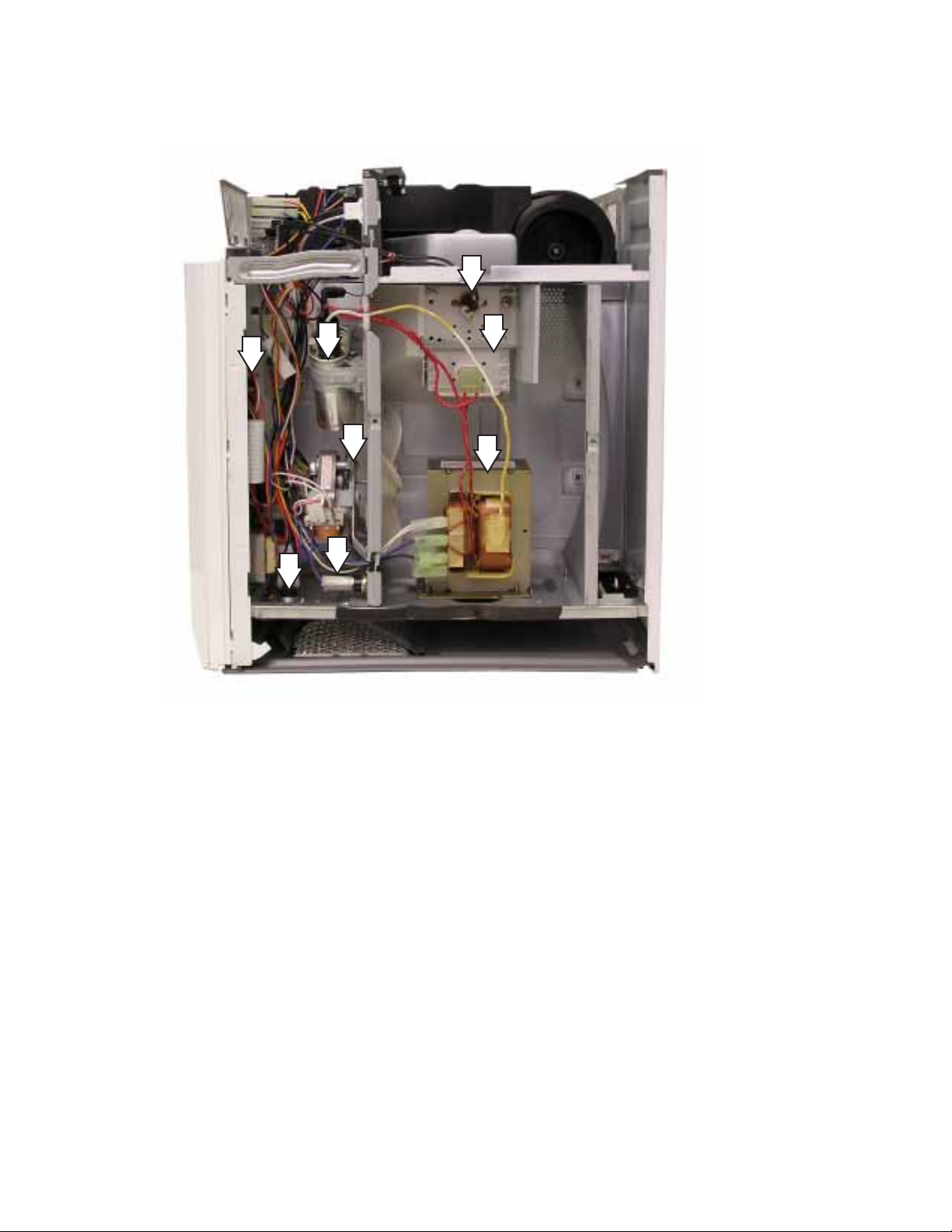

Right Side View

2

6

5

7

1 - Magnetron

2 - Magnetron Thermal Cutout (TCO)

1

4

8

3

3 - High Voltage Transformer

4 - Magnetron Cooling Fan Motor and Blade

5 - High Voltage Capacitor

6 - Door Sensing Switch (Primary Interlock and Monitor Switch in plastic mount - not shown)

7 - Bottom Thermal Cutout (TCO)

8 - Hood Thermal Cutout (TCO)

– 8 –

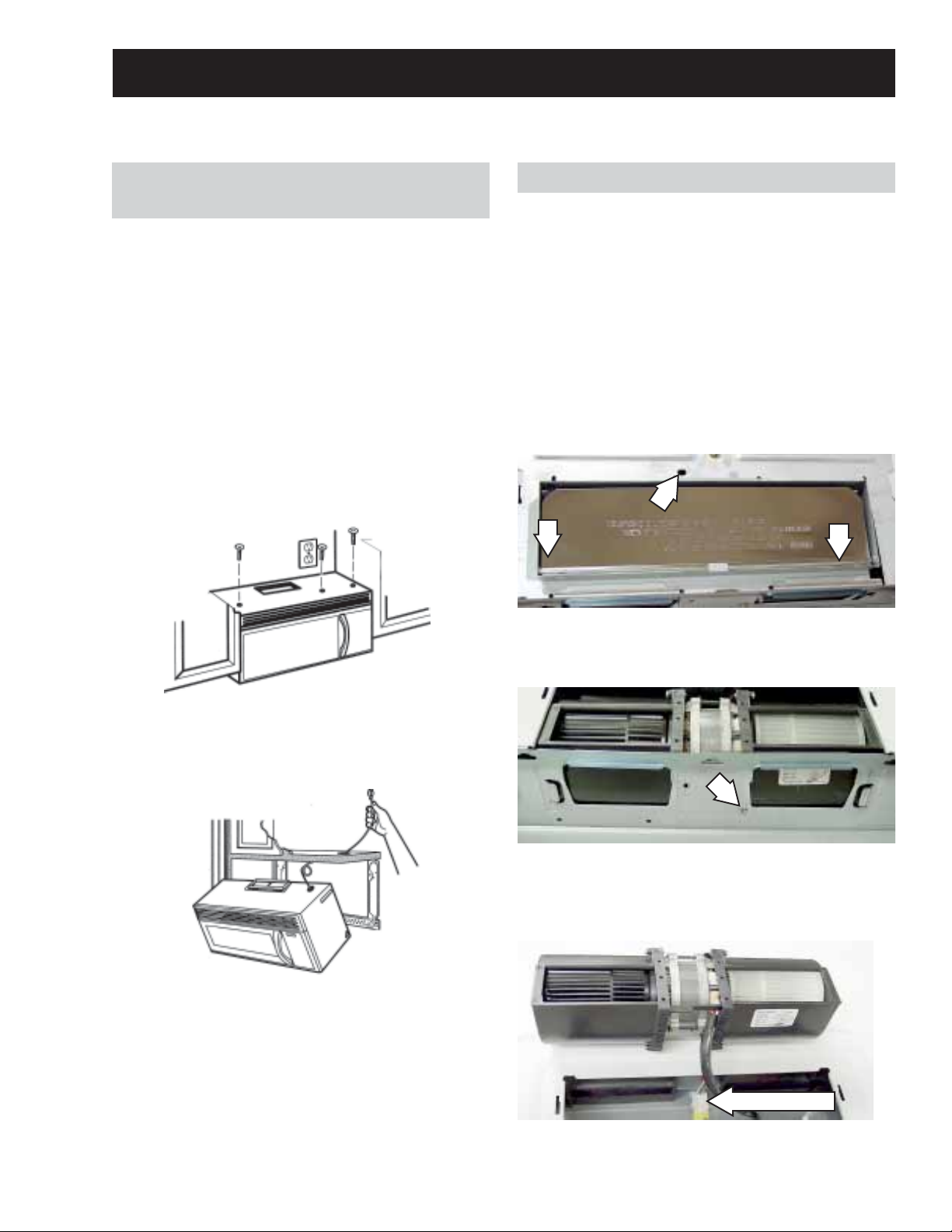

Page 9

Components

Microwave Removal and Component

Access

Note: Some components can be accessed

without removing the microwave. If the 2 end

screws on top of the outer cover are accessible

see illustration below), the hidden vent can be

(

removed without removing the microwave from its

installation.

Note: For easier removal and personal safety , it

is recommended that 2 people remove the

microwave.

Unplug the microwave and remove it from the wall

by removing three screws in the cabinet above

the microwave.

Exhaust Fan

Resistance through the exhaust fan from the

power cord (N) to CN03 pin 7 is approximately

28.7 ohms.

Removal

Remove the microwave (see

and Component Access). Remove the screw on

top of the microwave holding the exhaust adapter

in place, then slide the exhaust adapter to the rear

and remove.

Top View

Microwave Removal

Tilt the microwave forward and lif t it of f the lower

tabs of the rear mounting plate. Route the power

cord through the hole.

Place the microwave on a protected counter or

table.

To remove the cover, remove 2 screws from the

left side, 3 screws from the right side, 5 screws

from the top, 5 screws from the rear, and 2

screws from the bottom of the outer cover.

Remove the screw holding the fan in place.

Lift the fan out of the microwave and disconnect

the electrical connector.

Disconnect

Open the microwave oven door . Slide the hidden

vent to the left and remove the hidden vent.

– 9 –

Page 10

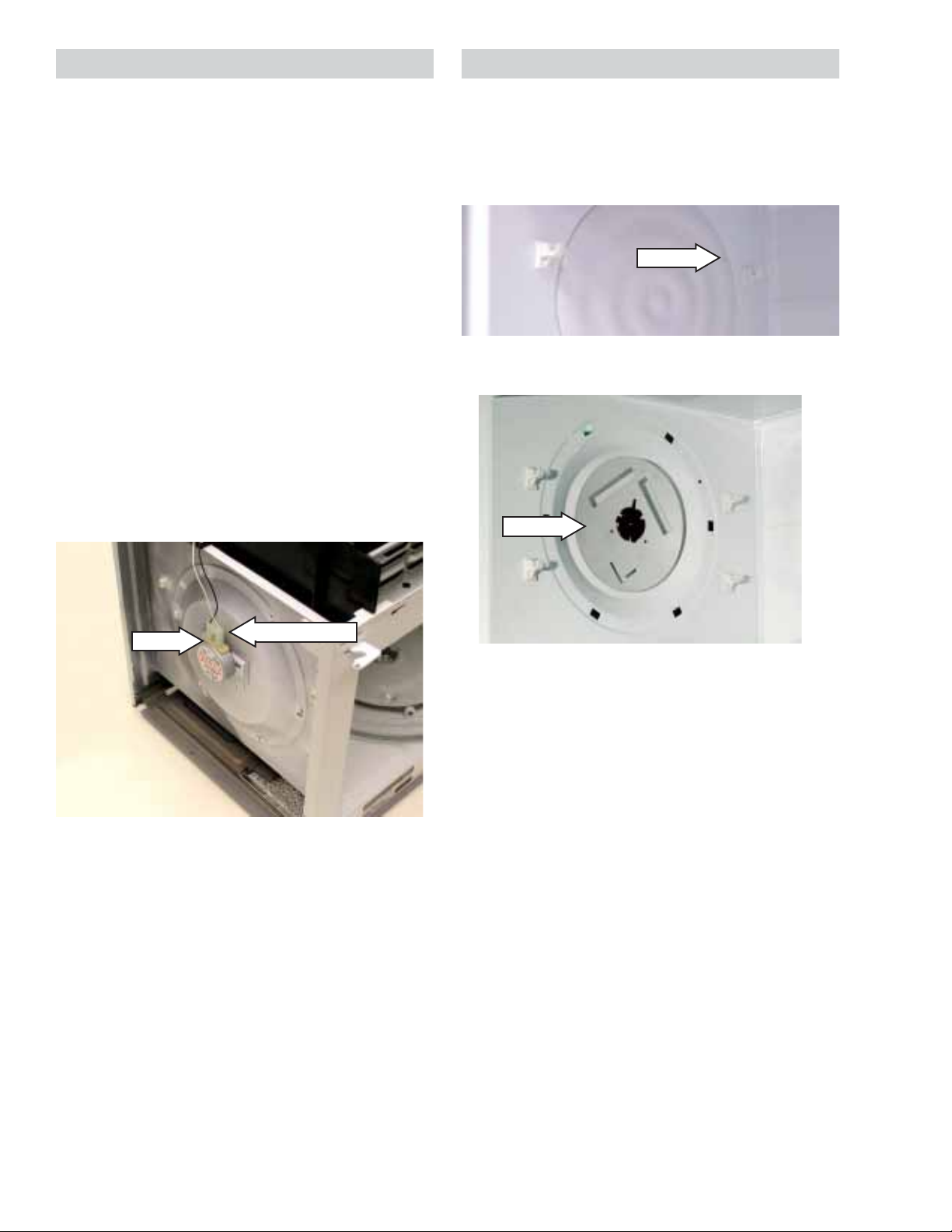

Side Stirrer Motor

Side Stirrer

The side stirrer motor is located on the left side of

the microwave oven.

Resistance through the side stirrer motor from

the power cord (L) to CN04 pin 5 is approximately

6.7 ohms. Isolated, the side stirrer motor is

approximately 7.0 ohms. The door (primary

interlock) must be closed to complete circuit.

Check motor circuit for 21 V AC when operating.

Removal

Remove the microwave (see

and Component Access).

Microwave Removal

Disconnect the wire connector to the side stirrer

motor. Remove the screw and turn the motor

1

/8

turn CCW.

Note: When installing stirrer motor, be sure the

locating pin is inserted in the motor mounting tab

and the side stirrer is resting on the support in the

cover prior to installing the screw .

Removal

Open the oven door . Pull the plastic rivet out of the

stirrer cover. Rotate the stirrer cover CCW until it

stops and remove the stirrer cover.

Rivet

Remove the stirrer.

Stirrer

Screw

Disconnect

Note: When assembling, assure that the stirrer

rides on the support in the cover .

– 10 –

Page 11

T op Stirrer Motor

T op Stirrer

Resistance through the top stirrer motor from the

power cord (L) to CN04 pin 5 is approximately

6.7 ohms. Isolated, the top stirrer motor is

approximately 7.0 ohms. The door (primary

interlock) must be closed to complete circuit.

Check motor circuit for 21 V AC when operating.

Removal

Remove the microwave (see

and Component Access).

Microwave Removal

Disconnect the side stirrer motor electrical

connector. Remove 2 screws and ground wire

from the duct and move the duct out of the way .

Removal

Open the oven door. Pull the plastic rivet out of the

stirrer cover. Rotate the stirrer cover CCW until it

stops and remove the stirrer cover.

Rivet

Remove the stirrer.

Disconnect the electrical connector from the

motor. Remove 2 screws that hold the motor in

place and remove the motor .

Disconnect

Note: When assembling, assure that the stirrer

rides on the support in the cover.

– 11 –

Page 12

Cooling Fan and Motor

Resistance through the cooling fan motor from

the power cord (L) to CN04 pin 7 is approximately

24.7 ohms. The door (primary interlock) must be

closed to complete circuit.

The cooling fan motor, in series with the drive

motors, provides voltage reduction to 21 VAC.

Removal

Remove 3 screws from the fan motor mounting

plate. Slide the mounting plate forward to allow

access to the fan blade. Slide the fan blade off of

the fan motor shaft.

Remove the microwave (see

and Component Access). Remove the screw at the

top of the control panel.

Slide the control panel up and remove it.

Disconnect 8 electrical connectors and the

ground wire from the control panel.

Microwave Removal

Move the TCO out of the way. Disconnect the

power transformer.

Remove 2 screws from the fan motor.

Remove the fan motor from the fan mounting

plate and remove the 2 wires.

– 12 –

Page 13

Cavity Thermal Cutout (TCO)

The cavity TCO is located on the top of the

microwave oven on the left side of the forward

vent duct. The microwave oven shuts off when

the temperature of the cavityTCO reaches 212°F

(100°C).

The cavity TCO is a normally closed switch. An

open reading across the TCO indicates an

overtemperature condition or failed TCO. The

cavity TCO is not resettable.

Removal

Remove the microwave (see

and Component Access

).

Microwave Removal

Slide the cavity TCO from the two tabs and

remove the 2 connectors.

Cavity TCO

Fuses

The main and high voltage transformer fuses are

located behind the hidden vent, above the control

panel.

Removal

Remove the hidden vent (see

and Component Access).

Remove the grille to access the fuses.

Microwave Removal

Magnetron Thermal Cutout (TCO)

The magnetron TCO is located on the magnetron

and shuts off when the magnetron temperature

reaches 150°F (65.5°C).

The magnetron TCO is a normally closed switch.

An open reading across the TCO indicates a

failed TCO. The magnetron TCO is resetable

Removal

Remove the microwave (see

and Component Access). Disconnect the 2 wires

and remove the screws from the magnetron TCO

Microwave Removal

.

– 13 –

Page 14

Magnetron

Transformer

The magnetron is located behind the fan mounting

plate.

Removal

WARNING: Prior to servicing the magnetron, be

certain the capacitor is discharged. Manually

discharge by placing an insulated-handle

screwdriver between the diode connection of the

capacitor and the oven chassis ground.

Remove the microwave (see

and Component Access

Microwave Removal

). Remove the TCO and

the magnetron electrical connectors. Remove 4

nuts from the top of the magnetron and remove

the screw and brace. Remove the magnetron.

The transformer is located behind the fan

mounting plate below the magnetron.

Resistance through the transformer from the

power cord (L) to the high-power secondary

interlock (blue wire) is approximately 0.32 ohms.

The door (primary and monitor interlock) must be

closed.

Resistance through the transformer from the

high-power secondary interlock (blue wire) to the

low-power secondary interlock (single white wire)

is approximately 28.7 ohms. The door (monitor

interlock) must be closed.

Removal

WARNING: Prior to servicing the transformer, be

certain the capacitor is discharged. Manually

discharge by placing an insulated-handle

screwdriver between the diode connection of the

capacitor and the oven chassis ground.

Remove the microwave (see

and Component Access). Remove the screws and

Microwave Removal

the bottom panel. Disconnect electrical

connectors. Remove the white and red wires

from the capacitor and the red wires from the

magnetron.

Gas Sensor

The gas sensor detects humidity changes during

sensor cook functions and transmits this

information to the main board.

The gas sensor is located in the air exhaust duct,

behind the grille on the left side.

T o check, run diagnostics (

Removal

Remove the hidden vent (see

and Component Access). Slide white plastic

retainer forward and pull the gas sensor down.

see Diagnostics Test).

Microwave Removal

Caution: The transformer is heavy.

Remove 4 screws from the bottom that hold the

transformer in place.

Gas Sensor

– 14 –

Page 15

Hidden Vent Motor

Interior Light

The hidden vent motor is located behind the

hidden vent on the right side.

Resistance through the hidden vent motor from

the CN03 pin 1 to the power cord (N) is

approximately 28.8 ohms.

Removal

Note: This component may be able to be

accessed without removing the microwave. If the

2 end screws on top of the outer cover are

accessible, the hidden vent can be removed

without removing the microwave from its

installation.

Remove the hidden vent (see

and Component Access). Remove 2 screws and

Microwave Removal

the motor.

Resistance through the interior light from the

CN02 pin 7 to the power cord (L) is approximately

24.9 ohms.

Removal

Note: This component may be able to be

accessed without removing the microwave. If the

2 end screws on top of the outer cover are

accessible, the hidden vent can be removed

without removing the microwave from its

installation.

Remove the hidden vent (see

and Component Access). Press the tab with a

Microwave Removal

small screwdriver and lift the interior light cover up

and out.

Squeeze the 2 tabs of the light socket and remove

the light assembly .

Note: When installing a new halogen bulb, be

sure to handle the bulb with a clean, dry cloth.

Replace the halogen lamp with a 120V AC, 20W

GE halogen lamp bulb (WB36X10213).

– 15 –

Page 16

Control Panel

Door Interlock Switches

The control panel contains the smart board, the

touchscreen panel, and a three-button circuit

board. Run the test for the control panel (see

Control Performance Test). The control panel is

replaced as an assembly.

Removal

Remove the hidden vent (see

and Component Access). Remove the grille. Lift up

Microwave Removal

on the control panel and remove.

Disconnect 8 electrical connectors and the

ground wire from the control panel.

The oven has 3 interlock switches. All switches

are removed the same.

Door Sensing and Primary Interlock Switches

The primary interlock and monitor switches are

located on the bottom of the plastic switch

bracket. The power relay is mounted on the smart

board. They are activated by the latch heads on

the door. When the door is opened, the switches

interrupt the circuit to all components, except the

oven lamp. A cook cycle cannot take place until

the door is firmly closed, thereby activating both

interlock switches. The primary interlock system

consists of the door sensing switch, primary

interlock switch, and power relay .

Monitor Switch

The monitor switch is operated indirectly by the

bottom latch pawl. The pawl operates a cam

switch, which in turn, activates the monitor

switch. The switch is intended to render the oven

inoperative by means of blowing the monitor fuse

when the contacts of the primary interlock switch

and power relay fail to open when door is opened.

Functions

When the door is opened, the monitor switch

contact closes. At this time, the primary interlock

switch and power relay are in the closed position.

As the door goes to a closed position, the monitor

switch contacts are first opened and then the door

sensing switch and the primary interlock switch

contacts close.The oven has 3 interlock switches.

All switches are removed the same.

Removal

Remove the hidden vent (see

and Component Access). Remove the grill. Lift up

Microwave Removal

the control panel and remove.

Remove the 2 T20 Torx screws from the front of

the frame and remove the door switch bracket.

– 16 –

Page 17

Using a small screwdriver, release the tab and

remove the door interlock switch from the door

switch bracket. Disconnect the electrical

connector.

Primary Interlock System T est

WARNING: Disconnect the oven from the power

supply.

Door Sensing Switch

Isolate the switch and connect the ohmmeter to

the common (COM.) and normally open (NO)

terminal of the switch. The meter should indicate

an open circuit with the door open and a closed

circuit with the door closed.

Power Relay

Interlocks (Door Latch Switches)

Interlocks are designed as follows:

Door Sensing Switch (top)

Monitor Interlock Switch (middle)

Disconnect 2 wires from the tab terminals on the

circuit board provided in the control panel

assembly. The tab terminals are located in the

area of the circuit board on the component side,

and are connected to the contacts of the power

relay. Check the state of the relay contacts using

an ohmmeter. The relay contacts should be open.

If the relay contacts are closed, replace the circuit

board.

Primary Interlock Switch Test

Isolate the switch and connect the ohmmeter to

the common (COM.) and normally open (NO)

terminal of the switch. The meter should indicate

an open circuit with the door open and a closed

circuit with the door closed. If improper operation

is indicated, replace the primary interlock switch.

Note: The primary interlock switches are not

adjustable and must be replaced if test is failed.

Primary Interlock Switch (bottom)

Door Sensing Switch:

• Door Closed - 0 ohms

• Door Open - Infinite ohms

Monitor Interlock Switch:

• Door Closed - Infinite ohms

• Door Open - 0 ohms

Primary Interlock Switch:

• Door Closed - 0 ohms

• Door Open - Infinite ohms

Note: Remove the wires from the switches

before checking continuity .

– 17 –

Page 18

High Voltage Capacitor

Removal and Replacement

WARNING: Prior to servicing, be cert ain the

capacitor is discharged. Manually discharge by

placing an insulated-handle screwdriver between

the diode connection of the capacitor and the

oven chassis ground.

Remove 2 wires from the TCO. Remove the

screw that holds the TCO in place and slide the

tab of the TCO out of the oven frame.

Hood TCO

Remove the hidden vent (see

and Component Access

). Remove the screw and

Microwave Removal

grill. Lift the control panel up and remove.

Remove the screw from the capacitor brace.

Disconnect 3 wires from the capacitor. Remove

the capacitor and brace from the oven.

Bottom TCO

Turntable Motor

Resistance through the turntable motor from the

CN02 pin 4 to the power cord (L) is approximately

158.5 ohms. The door (primary and monitor

interlock) must be closed.

Removal

Remove 5 screws from the bottom of the

microwave oven cabinet and remove the bottom

plate.

Remove the capacitor from the capacitor brace.

Bottom and Hood Thermal Cutout (TCO)

The bottom TCO will interrupt the operation of the

oven when it reaches 248°F (120°C).

The hood TCO is a normally open switch. When it

reaches 158°F (70°C), the vent motor turns on.

Removal procedures are the same for both TCOs.

Removal and Replacement

Remove the hidden vent (see

and Component Access). Remove the screw and

the grill (see Hidden Vent Motor). Lift the control

panel up and remove.

Microwave Removal

Remove the screw, then rotate the motor CCW 1/

8 turn. Remove the turntable motor. Disconnect 2

wires from the motor.

Screw

Disconnect

– 18 –

Page 19

Surface Lamp Assemblies

Surface Lamps

Resistance through the surface lamps from the

CN04 pin 3 to the power cord (N) is approximately

62 ohms.

Removal

Remove 5 screws from the bottom of the

microwave oven cabinet and remove the bottom

plate.

Remove the screw from each lamp socket and

remove the lamp assembly from the oven.

Disconnect the electrical connector.

Removal

Remove the screw on the surface lens panel and

open the panel.

Pull the light out of the socket.

Note: When installing a new halogen bulb, be

sure to handle the bulb with a clean, dry cloth.

Replace the halogen lamp with a 120V AC, 20W

GE halogen lamp bulb (WB36X10213).

– 19 –

Page 20

Troubleshooting

Control Performance Test

Set Time:

1. Touch OPTIONS on the HOME display .

2. Touch SET CLOCK on the OPTIONS display.

3. Using the numbers on the touchscreen, enter

the time of day. Press ENTER when finished

or CLEAR to erase the time you entered.

4. Select AM or PM from the touchscreen. Press

ENTER when finished or BACK to enter a new

time.

• Alternately touch each function pad and

enter time, temperature, and power level

selection for the function.

• Touch CLEAR after each function test to

clear that function.

• Repeat the procedure for each function to

exercise each pad.

• Control and display should respond to

each entry .

• Display should revert to Time-Of-Day af ter

each CLEAR.

Sensor T est (Quick Test)

Press and hold the OFF and LIGHT buttons for 3

seconds. Note diagnostic number displayed.

15 to 185 = Normal

213 or higher = Sensor failed to open, sensor

unplugged, wiring, or smart board.

Less than 6 = Shorted sensor or smart board.

Caution: Do NOT check the white and orange

sensor leads. Checking could damage sensor.

Note: Black and red heater terminal leads should

read 30 Ω.

– 20 –

Page 21

Diagnostics Test

Simultaneously press the LIGHT and OFF keys

for 3 seconds. The diagnostics screen will appear

in the LCD display.

Sample Diagnostics Screen

Error Message

F1 Convection - Open thermal sensor

F2 Convection - Shorted thermal sensor

F3 - Keypanel shorted for more than 60 seconds

F4 - Open humidity sensor

F5 - Shorted humidity sensor

F10 - Shorted touch panel

Note: Any “F” code will cause an error sound to

beep for 3 cycles. One cycle will sound 2

seconds on, 1 second off.

Sample “F” Code page

Displayed Information

• MODEL - Identified at power-up by the keytail

ID option.

• CODE VERSION - The date the code file was

sent to GEA for testing (MM-DD-YY).

• HUMIDITY SENSOR - The CUR (current),

DET (detection point), MIN (minimum), MAX

(maximum) humidity sensor data will update

continuously .

The CUR value is the present A/D value of the

sensor. DET is the value at the moment the

humidity detection point was reached. MIN is the

lowest humidity point measured during entire

feature’s run. MAX is the highest humidity value

measured during the feature’s run. These data

points are the dynamic measurements of the

sensor, not the calculated values.

Pressing the DONE key terminates the diagnostic

screen. The screen returns to the previous or

HOME screen. The diagnostic screen will timeout

and return to the previous screen after receiving

no input for 5 minutes.

Demonstration Mode

In demonstration mode, everything will operate on

the unit except the high voltage section.

To enter the demonstration mode, disconnect the

power for 30 seconds then reapply power.

Simultaneously press the HELP screen pad and

the BOOST button for 3 seconds. The word

DEMO will appear in the LCD display .

To exit the demonstration mode, disconnect the

power for 30 seconds then reapply power.

– 21 –

Page 22

Microwave Leakage Test

Performance Test

1. Place 275 ml. of water in a 600 ml beaker

(WB64X5010).

2. Place the beaker in the center of the oven

shelf.

3. Set the meter to the 2450 MHz scale.

4. Turn the oven on for 5 minutes.

5. Hold the probe perpendicular to the surface

being tested and scan the surfaces at a rate

of 1 inch/sec.

Test the following areas:

• The entire perimeter of the door and

control panel.

• The viewing surface of the door window.

• The exhaust vents.

6. The maximum leakage is 4 MW/CM

2

.

7. Record data on the service invoice and

microwave leakage report.

1. Measure the line voltage (loaded). This test is

based on normal voltage variations of 108V to

132V. Low voltage will lower output power and

temperature rise.

2. Place a beaker (WB64X0073) containing

1 liter of water (1000ml, 59°F - 75°F) on the

turntable and record the starting water

temperature with a thermometer. (Do not use

any other load or dish as results will very from

standard).

3. Set the microwave oven at HIGH power for

2 minutes and 3 seconds.

4. Turn on the oven.

5. Record the water temperature.

The minimum difference between the initial and

ending temperature should be 40°F at 120V.

Note: The maximum allowable leakage is 5 MW/

2

CM

. 4 MW/CM2 is used to allow for measurement

and meter accuracy.

Inform the manufacturer of any oven found to

have emission in excess of 5 MW/CM

2

. Make

repairs to bring the unit into compliance at no cost

to the owner and try to determine the cause.

Instruct the owner not to use the oven if it has not

been brought into compliance.

High Voltage Capacitor

The high voltage capacitor has an internal shunt

resistor to automatically discharge the capacitor

when the oven turns off. Under normal operation,

the capacitor should fully discharge within 30

seconds.

– 22 –

Page 23

Smart Board

The smart board contains the power relay, LVT,

vent blower triac, surface light relays, and other

components to perform the proper switching

circuits. Several disconnect plugs are also

located on the smart board.

CN01 - Ribbon connector.

Interfaces the smart board and the touch pad.

CN02 - Primary LTV, Main Relay, Inrush Relay,

and Turntable.

Interfaces the smart board and the key module.

CN03 - Vent Blower Connector

Pin 1 AZU-1

Pin 3 VIL-1

Pin 5 GRA-1

Pin 7 BRN-1

Hood TCO

Hood TCO

Main Fuse

Louver Motor

CN04 - Cooktop Lamp Relay Connector

Pin 4 ORG-1

Pin 5 PIN-1

Pin 7 WHT-9

Pin 9 BLK-7

Turntable Motor

Fan Motor

Fan Motor

Oven Lamp

CN05

Pin 1 BLU-2

Pin 3 YEL-1

Cooktop Lamps

Cooktop Lamps

CN06 - Door Sensing Connector

Pin 1 ORG

Pin 2 ORG

Door Sense Switch

Door Sense Switch

CN07 - Louver Motor Switches Connector

Pin 1 YEL

Pin 2 BLU

Pin 3 RED

Louver Switch

Louver Switch

Louver Switch

CN08

CN06

CN07

CN01

CN03

Low-Power Secondary Interlock

CN05

CN08 - Gas Sensing Connector

Pin 1 ORG

Pin 2 WHT

Pin 3 BLK

Pin 4 RED

Gas Sensor

Gas Sensor

Gas Sensor

Gas Sensor

Low-Power Secondary Interlock

WHT/WHT

WHT/WHT

WHT

T o High Power Interlock

Cooktop Lamps

HV Transformer

High-Power Secondary Interlock

WHT/WHT

WHT/WHT

WHT

To Low Power Interlock

Power Cord N

HV Transformer Fuse

High-Power Secondary Interlock

CN04

CN02

– 23 –

Page 24

Strip Circuits

Louver Motor Does Not Work

Vent Motor Does Not Work

Fan Motor Does Not Work

– 24 –

Page 25

Top Stirrer, Side Stirrer, or Drive Motor Does Not Work

Dead Unit - Cavity or Magnetron TCO Does Not Work

FAN MOTOR

BLK

120V

DRIVE MOTOR

BLK

FM

DM

21V

0V

PIN

ORG

Pin 4

Dead Unit - Bottom TCO Does Not Work

Note: The Magnetron Tube TCO automatically

resets when the conditions return to normal. The

Cavity TCO is not resetable. It must be replaced.

Note: The Bottom TCO is not resetable. It must be

replaced.

– 25 –

Page 26

Interior Light Does Not Work

Surface Lamps Do Not Work

– 26 –

Page 27

Magnetron Does Not Work

Does conti nuity exist betw een the HV

transformer black wire and power cord with

primary interlock closed (door closed)?

Yes

Does conti nuity exist betw een the HV

tran s former blue wire and secondary interlock - 2

blue wire thru HV transformer fuse?

Yes

Does conti nuity exist between the secondary

interlock-2 blue wire and power cord?

Yes

Does conti nuity exist betw een the HV

transformer white wire to power cord thru

secondary interlock - 1 (door closed) and

monitor interlock s witch open (door closed)?

No

No

No

No

Replace the primary interlock switch or repair

faulty wiring betwee n the HV transformer and

the primary in terlock switch.

Replace the HV tra nsform er fuse or

repair faulty wiring.

Repair faulty wiring.

Repair faulty wiring.

Yes

Replace the main control board.

Does the magnetron work?

No

Replace the HV capacitor.

Does the magnetron work?

No

Replace the HV transformer.

Does the magnetron work?

No

Replace the magnetron.

1

1 - Red

2

2 - White

3 - Blue

4 - Black

2

3

4

– 27 –

Page 28

Wiring Diagram

WARNING: Power must be disconnected before servicing this appliance.

Note: For servicing replacement use 16GA. 105°C thermoplastic covered leads or as noted on special leads.

– 28 –

Page 29

Schematic

WARNING: Power must be disconnected before servicing this appliance.

Code No. : DE99-00125F

– 29 –

Page 30

Illustrated Parts Catalog

– 30 –

Page 31

VI EW NUM BER CATAL O G NUMBER DESCRIP TION QUANT ITY

1 WB15X10135 HANDLE WH 1

5 WB55X10673 DOOR-A ASM 1

6 WB55X10668 DOOR MAIN ASM 1

7 WB05X10012 DOOR-KEY 2

8 WB05X10006 SPRING-KEY 2

9 WB06X10060 PIN-HINGE 2

10 WB06X10516 FILM-DOOR 1

11 WB55X10669 CHOKE COVER 1

12 W B 56X10461 DOOR ASM W H 1

17 WB27X10725 KEY-MODULE 1

20 WB18X10140 WIRE LEAD-F 1

21 WB27X10726 SMART BOARD 1

25 W B 07X10730 GRILLE COVER A SM WHT 1

26 WB01X10246 SPRING-LOUVER 1

27 WB02X10970 EARTH-GRILLE "A" 1

28 WB02X10967 HINGE-GRILLE "R" 1

29 WB02X10968 HINGE-GRILLE "M" 1

30 WB02X10969 HINGE-GRILLE "L" 1

31 WB07X10724 GRILLE WH 1

32 W B 36X10273 GRILLE AS M W HT 1

33 WB06X10450 BRACKET-BOTTOM LAMP 1

34 W B36X10213 BULB HA LO GEN (120V 20W) 2

35 WB06X10517 BRACKET-ENCLOSURE 1

36 WB08X10026 SOCKET LAMP 1

37 WB56X10450 BASE BOTTOM SUB ASM 1

38 WB36X10071 GLASS-COOKTOP LAMP 1

39 WB36X10217 COVER-GLASS 1

41 WB06X10126 BUTTON-LOCK 2

42 WB06X10518 COVER-STIRRER(TOP) 1

48 WB06X10519 STIRRER(TOP) ASM 1

49 WB06X10520 COUPLER-TT 1

50 WB06X10521 HOLDER-RACK 8

51 WB06X10522 COVER-STIRRER(SIDE) 1

54 WB06X10523 STIRRER(SIDE) ASM 1

55 WB26X10136 MOTOR TURNTABLE 1

56 WB06X10524 COVER-FRONT 1

57 WB01X10065 NUT MAGNETRON 4

58 WB26X10037 MOTOR STIRRER 1

59 WB27X10195 TCO CAVITY 1

60 WB26X10137 MOTOR-DRIVE(SIDE) 1

62 WB27X10170 CAPACITOR-MOTOR 1

63 WB24X10070 SWITCH-MICRO 1

64 WB24X10069 SWITCH-MICRO 1

65 WB06X10283 BRACKET-CAM PLATE 1

66 WB38X10057 CAM-LOUVER 1

67 WB26X10112 MOTOR-DRIVE 1

69 WB07X10442 CAM LOUVER ASS'Y 1

70 W B18X10122 W IRE GRND PC B 1

71 WB06X10525 COVER-HALOGEN LAMP 1

72 WB08X10027 SOCKET HAL/LAMP ASM 1

74 WB36X10260 FRAME GLASS HOLDER 1

75 WB02X10955 BKT-BARRIER 1

76 WB18X10241 WIRE HARNESS-S 1

77 WB27X1170 GAS SENSOR 1

78 WB06X0549 HOLDER-SENSOR 1

– 31 –

Page 32

VIEW NUMBER CATALOG NUMBER DESCRI PTION Q UANTI TY

81 WB06X10436 HOOD DAMPER ASM 1

82 WB06X10165 BRACKET-V/T MOTOR 1

83 WB26X10138 MOTOR-VENTILATION 1

84 W B 56X10446 P LA TE MOUNTING AS M 1

85 W B 01X10071 NUT TOP MOUNTING 1

86 WB06X10122 BRACKET-POWER CORD 1

87 W B56X10462 CAS E OUTER WH 1

88 WB27X10735 MAGNETRON ASM 1

90 W B27X10166 TCO - MAGNE TRON 1

91 WB06X10526 BRACKET-MGT 1

92 W B18X10200 POWER CORD ASM 1

93 WB01X10119 SCREW-TAPPING 2

94 WB06X10289 LATCH-BODY 1

95 WB24X0829 SWITCH-MICRO 2

96 WB24X0830 SWITCH-MICRO 1

97 WB06X10128 LEVER-SWITCH LOWER 1

98 WB18X10055 WIRE HARNESS-B 1

99 W B 06X10527 COVE R MOTOR SUB AS M 1

100 WB06X10463 FUSE-HOLDER 2

101 WB27X10474 FUSE 2

102 WB06X10528 SUPPORTER-CAVITY 1

103 WB26X10090 BLADE-FAN 1

104 WB27X10194 TCO HOOD 1

105 WB26X10089 MOTOR-FAN 1

106 WB27X10011 CAPACITOR 1

107 WB06X10287 BRACKET-HVC 1

108 WB27X1160 H.V. DIODE 1

109 WB26X10139 DUCT REAR ASM 1

110 WB27X10724 TRANS-H.V 1

111 WB27X1127 TCO -BOTTOM 1

112 WB56X1 0448 BASE-PLATE 1

113 WB01X10084 SCREW-WASHER HVT 4

114 WB06X10529 ROLLER GUIDE RING 1

115 WB49X10063 TRAY-COOKING 1

116 WB01X10181 HARDWARE INSTALLATION 1

122 WB02X10956 CHARCOAL FILTER-OPTIONAL 1

123 WB48X10038 RACK WIRE AS M 2

124 WB01X10183 HARDWARE BAG 1

125 49-40335 LABEL-COOKING GUIDE 1

126 WB18X10235 WIRE HARNESS-A 1

127 WB18X10232 WIRE HARNESS-C 1

128 WB06X10288 FILTER GREASE 2

129 WB01X0861 SCREW,DOOR BRKT-BOTTOM 2

130 WB07X10734 CTRL P ANE L S UB A S M WHT 1

9999 31-40025 MINI-MANUAL 1

9999 49-40137-1 TEMPLATE-TOP 1

9999 49-40239-1 REA R W A LL TEMPLA TE 1

9999 49-40329 USE & CARE 1

9999 49-40330 INSTALLATION INSTRUCTION 1

– 32 –

Page 33

W arranty

OTR MICROWAVE OVEN WARRANTY

For the period of: GE will replace:

Full one-year Entire oven

From the date of the

original purchase

Limited ten-year Magnetron tube

Any part of the oven which fails due to a defect in materials or

workmanship. During this full one-year warranty, GE will also provide,

free of charge, all labor and in-home service to replace the defective part.

From the second

through the tenth year

from the date of the

original purchase

What GE will not cover

• Service trips to your home to teach you how to use the product.

• Replacement of home fuses or resetting of circuit breakers.

• Incidental or consequential damage caused by possible defects with this appliance.

• Damage to the product caused by accident, fire, floods, or acts of God.

• Failure of the product if it is used for other than its intended purpose or used commercially .

• Improper installation.

This warranty is extended to the original purchaser and any succeeding owner for products purchased

for home use within the USA. In Alaska, the warranty excludes the cost of shipping or service calls to

your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitation or exclusion may not apply to you. This warranty gives you specific legal rights, and

you may also have other rights which vary from state to state.

The magnetron tube, if the magnetron tube fails due to a defect in

materials or workmanship. During the additional limited nine-year

warranty, you will be responsible for any labor or in-home service costs.

To know what your legal rights are in your state, consult your local or st ate consumer affairs office or

your state’s Attorney General.

Warrantor: General Electric Company, Louisville, KY 40225

– 33 –

Loading...

Loading...