Page 1

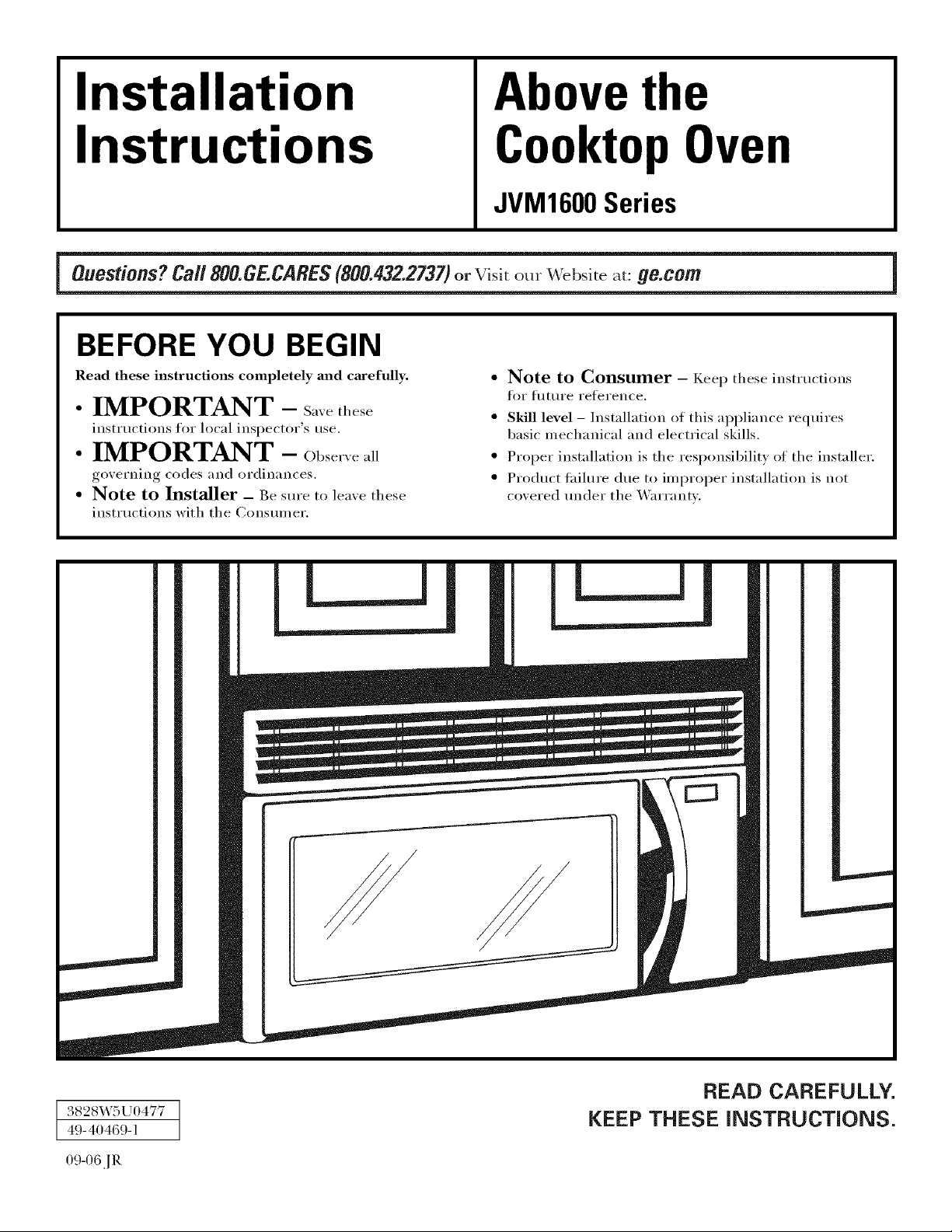

Installation

Abovethe

Instructions

CooktopOven

JVM1600Series

Questions? CM1800.GECARES (800.432.2737) or Visit our Websiteat: ge.com

BEFORE YOU BEGIN

Read these instructions completely and carefully.

• IMPORTANT - S_,,ethese

instructions for local inspector's use.

• IMPORTANT - Obse,,e_,ll

governing codes and ordinances.

• Note to Installer - Besure to leave these

instructions with the Consumer.

• Note to Consumer - KeeI)these instructions

for fllture reference.

• Skill level - Installation of this appliance requires

basic mechanical and electrical skills.

• Proper installation is the responsibility of the installer.

• Product tailure due to improper installation is not

coxered under the _'arrantx.

3828W5U0477

49-40469-1

09-06 JR

READ CAREFULLY.

KEEP THESE iNSTRUCTiONS.

Page 2

Installation Instructions

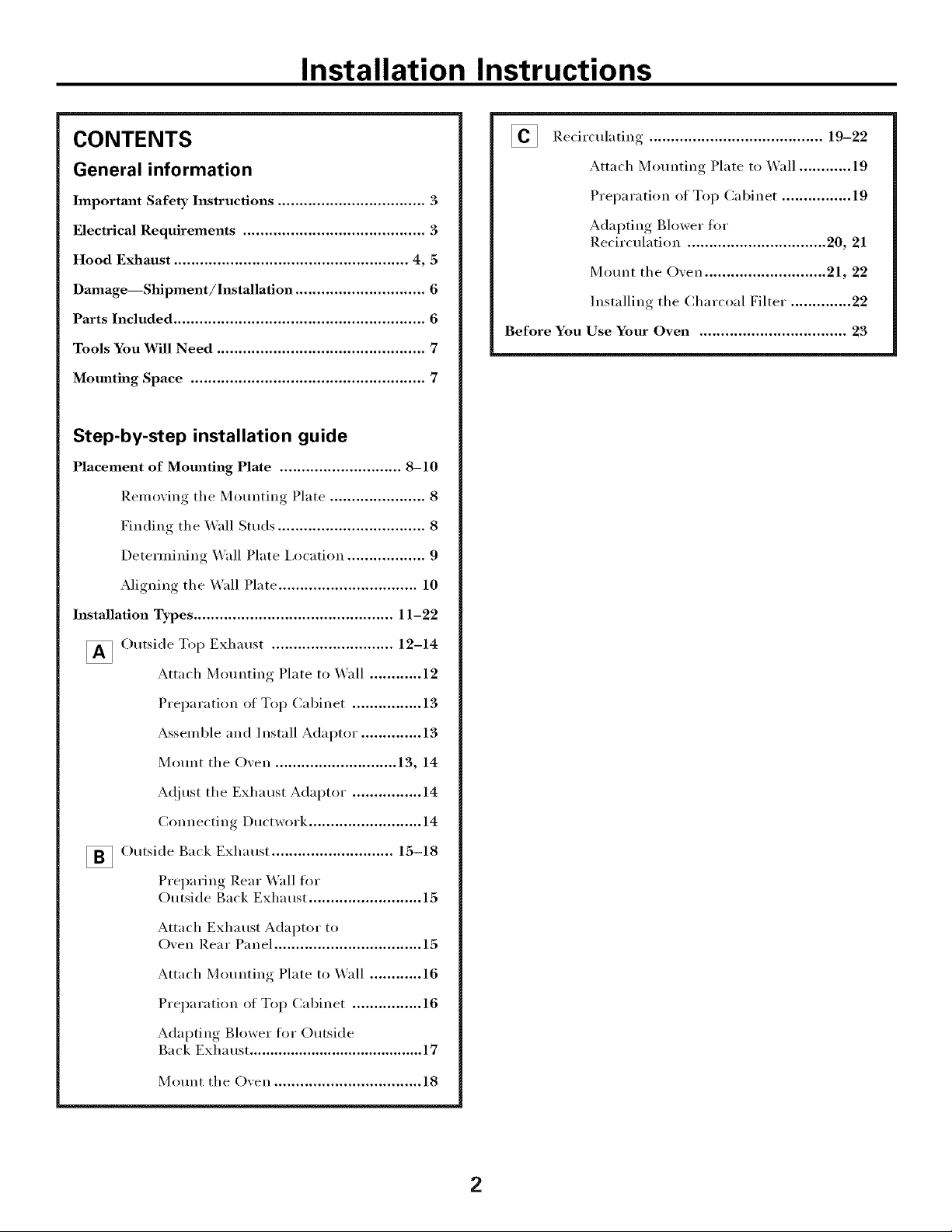

CONTENTS

General information

Important Safety Instructions .................................. 3

Electrical Requirements .......................................... 3

Hood Exhaust ....................................... 4, 5

Damage--Shipment/Installation .............................. 6

Parts Included. ......................................... 6

Tools You Will Need ............................................... 7

Mounting Space ...................................................... 7

Step-by-step installation guide

Placement of Mounting Plate ............................ 8-10

Removing tire Mounting Plate ...................... 8

Finding the _4all Studs ................................. 8

Determining _all Plate Loration .................. 9

Aliguiug the Wall Plate ............................... 10

_] Redrculating ........................................ 19-22

Attach Mounting Plate to _'dl ....... 19

Prepal_ltion of Top Cabinet .......... 19

Adapting Blower tor

Recirculation .............................. 20, 21

Mount the Oveu .................... 21, 22

Installing the Charcoal Filter ...... ........ 22

Before You Use Your Oven .................................. 23

Installation Types .................................. 11-22

[] ()utside Top Exhaust ............................ 12-14

Attach Mounting Plate to _'dl ....... 12

Prepa_ltion of Top Cabinet .......... 13

Assemble and Install Adaptor. ............. 13

Mount the Oveu .................... 13, 14

A(!just the Exhaust Adaptor .......... 14

Connecting Durtwork .......................... 14

_ Outside Back Exhaust ............................ 15-18

Preparing Rear _all ti)r

Outside Back Exhaust .......................... 15

Attach Exhaust Adaptor to

Oven Rear Panel .................................. 15

Attach Mounting Plate to _4"dl ....... 16

Prepa_ltion of Top Cabinet .......... 16

Adapting Blower tor Outside

Back Exhaust. ......................................... 17

Mount the Oveu .................................. 18

2

Page 3

Installation Instructions

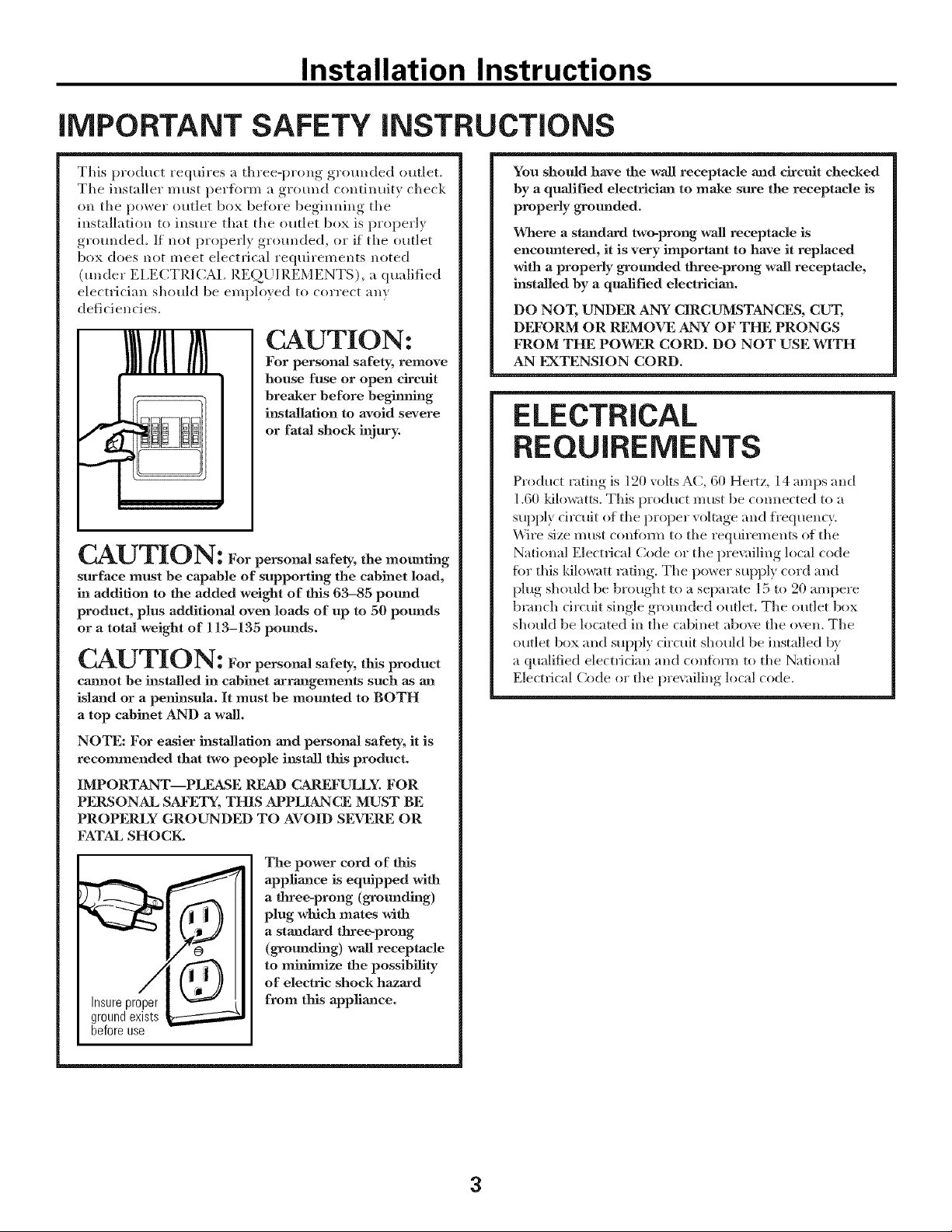

iMPORTANT SAFETY iNSTRUCTiONS

This product requires a three-i)rong grounded outlet.

Tile installer must perform a ground contimfitv check

oil the power outlet box before beginning tile

installation to insure that the outlet box is properly

grounded. If not properly gromlded, or if tile outlet

box does not meet electrical requirements noted

(under EI,ECTRICAI, REQLIIREMENTS), a qualified

electrician should be employed to correct any

deficiencies.

CAUTION:

lll//ll// 1

w

p

CAUTION: ForpersonalsafeS,themounting

surface must be capable of supporting the cabinet load,

in addition to the added weight of this 63-85 pound

product, plus additional oven loads of up to 50 pounds

or a total weight of 113-135 pounds.

CAUTION: For personal safety, this product

ca_mot be installed in cabinet arrangements such as an

island or a peninsula. It must be mounted to BOTH

a top cabinet AND a waJL

NOTE: For easier installation and personal safety, it is

recommended that two people install tlfis product.

IMPORTANT--PLEASE READ CAREFULLY. FOR

PERSONAL SAFETY, THIS APPLIANCE MUST BE

PROPERLY GROUNDED TO AVOID SEVERE OR

FATAL SHOCK.

For personal safety, remove

house fuse or open circuit

breaker before beginning

installation to avoid severe

or fatal shock injury.

You should have the wall receptacle and circuit checked

by a qualified electrician to make sure the receptacle is

properly grounded.

Where a standard two-prong wall receptacle is

encountered, it is very important to have it replaced

with a properly grounded three-prong wa3l receptacle,

installed by a qualified electriciaaa.

DO NOT, UNDFa;t ANY CIRCUMSTANCES, CUT,

DI?_'ORM OR REMOVE ANY OF THE PRONGS

FROM THE POWER CORD. DO NOT USE WITH

AN EXTENSION CORD.

ELECTRICAL

REQUIREMENTS

Produrt rating is 120 volts AC, 60 He_z, 14 amps and

1.60 kilowatts. This product must be connected to a

supply drcuit of tile proper voltage and _'equencv.

Wire size must confimn to the requirements of the

National Electrical (?,ode or the l)re\;filing local code

for this kilowatt rating. The power supply cord and

plug should be brought to a separate l 5 to 20 ampere

branch drcuit single grotmded outlet. The outlet box

should be located in the cabinet abo\v the oren. The

outlet box and supply drctfit should be installed by

a qualified electddan and confiwm to the National

Electrical Code or the pre\uiling local code.

Insure proper

ground exists

before use

Tile power cord of this

appliaJace is equipped with

a three-prong (grounding)

plug which mates with

a standard three-prong

(grounding) wall receptacle

to m_ize the possibility

of electric shock hazard

from tlfis appliance.

3

Page 4

Installation Instructions

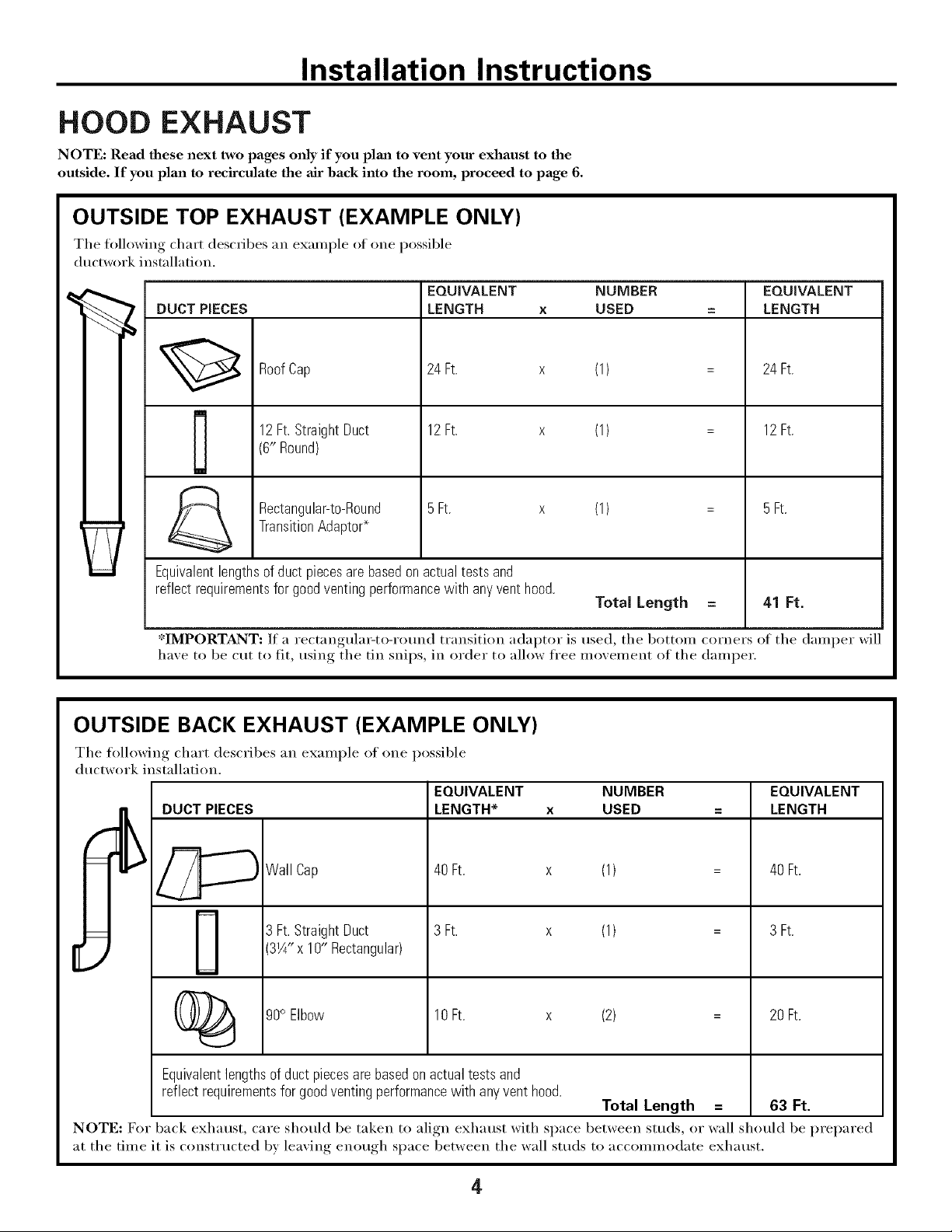

HOOD EXHAUST

NOTE: Read these next two pages only if you plml to vent your exhaust to the

outside. If you plan to recirculate the air back into the room, proceed to page 6.

OUTSIDE TOP EXHAUST (EXAMPLE ONLY)

The following chart describes an example ot one possible

ductwork instnllation.

EQUIVALENT NUMBER

DUCT PIECES

12Ft.StraightDuct 12Ft. x

RoofCap 24 Ft. x

(6" Round)

-_ Rectangular-to-Round 5Ft. x

Equivalentlengthsof duct piecesarebasedonactualtestsand

reflectrequirementsfor goodventingperformancewith anyventhood.

*IMPORTANT: If a rectangula_to-rotmd transition adaptor is used, the bottom corners of the damper will

haxe to be cut to fit, using the tin snips, in order to allow free moxement of the damper.

TransitionAdaptors

LENGTH x USED

OUTSIDE BACK EXHAUST (EXAMPLE ONLY)

(1)

(1)

(1)

Total Length

EQUWALENT

LENGTH

24 Ft.

12Ft.

5Ft.

41 Ft.

The following chart describes an example ot one possible

ductwork installation.

EQUIVALENT NUMBER EQUIVALENT

_Wall Cap 40Ft. x (1) 40Ft.

DUCT PIECES LENGTH* x USED -- LENGTH

(_ 90° Elbow 10Ft. x (2) 20Ft.

Equivalentlengthsof ductpiecesarebasedonactualtestsand

reflectrequirementsfor goodventingperformancewith anyvent hood.

NOTE: For back exhaust, care should be taken to align exhaust with space between studs, or wall should be prepared

at the time it is constructed by leaving enough space between the wall studs to accommodate exhaust.

3 Ft.StraightDuct 3 Ft. x (1) 3 Ft.

3W' x 10" Rectangular)

Total Length = 63 Ft.

4

Page 5

Installation Instructions

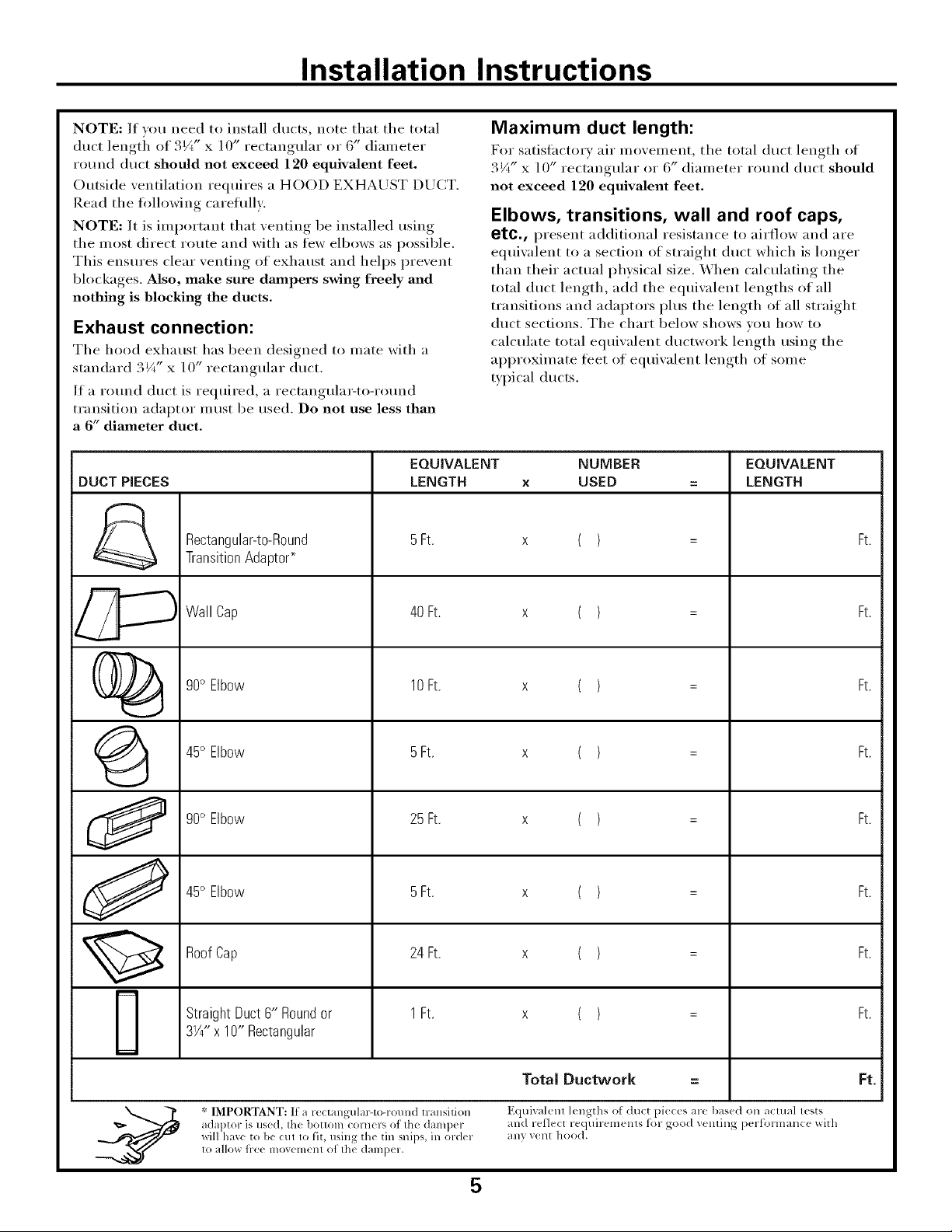

NOTE: If wm need to install ducts, note that the total

duct lengti_ of 3¼" x ] 0" rectangular or 6" diameter

round duct should not exceed 120 equivalent feet.

Outside ventilation requires a HOOD EXHAUST DUCT.

Read the fi_llowing careflfllv:

NOTE: It is important that venting be installed using

the most direct route and with as few elbows as possible.

This ensures clear venting of exhaust and helps prevent

blockages. Also, make sure dmnpers swing freely and

nothing is blocking the ducts.

Exhaust connection:

The hood exhaust has been designed to mate with a

standard 3¼" x 10" rectangular duct.

If a round duct is required, a rectangula_to-round

transition adaptor must be used. Do not use less than

a 6" diameter duct.

EQUIVALENT NUMBER EQUIVALENT

DUCT PIECES LENGTH x USED = LENGTH

Rectangular-to-Round 5Ft. x ( ) = Ft.

TransitionAdapto¢

Maximum duct length:

For s;Kislhctorv air movement, the total duct length of

3¼" x 10" rectangular or 6" diameter round duct should

not exceed 120 equivalent feet.

Elbows, transitions, wall and roof caps,

etc., present additional resistance to airth,w and are

eqtfiwdent to a section of straight duct which is longer

than their actual physical size, When calculating the

total duct length, add the eqtfiwdent lengths of all

transitions and adaptors plus the length of all straight

duct sections, The chart below shows you how to

calculate total eqtfiwdent ductwork length using the

approximate leer of eqtfiwdent length of some

typical ducts.

Wall Cap 40 Ft. x ( ) = Ft.

()_ 90° Elbow 10Ft. x ( ) = Ft.

45° Elbow 5Ft. x ( ) = Ft.

90° Elbow 25 Ft, x ( ) = Ft,

45° Elbow 5Ft. x ( ) = Ft.

RoofCap 24 Ft. x ( ) = Ft.

StraightDuct6" Roundor 1Ft. x ( ) = Ft.

3W' x 10" Rectangular

Total Duetwork = Ft.

adaptor is use(L the bottom corners of Ihe d_llllpeF _/lld reflect requirem_ nls tk)r good venling performance x_itll

xdll have to be Ctll tO _lt, using the tin snips, in order any vent hood.

* IMPORTANT: If a re<tangtdar-to-round transilion Equivalenl 1<ngths o[ du<t pie_ es are bas(d on aclual lests

to allm_fl-eellll)_,{_lll( 111 of Ih( d{llllpel.

5

Page 6

Installation Instructions

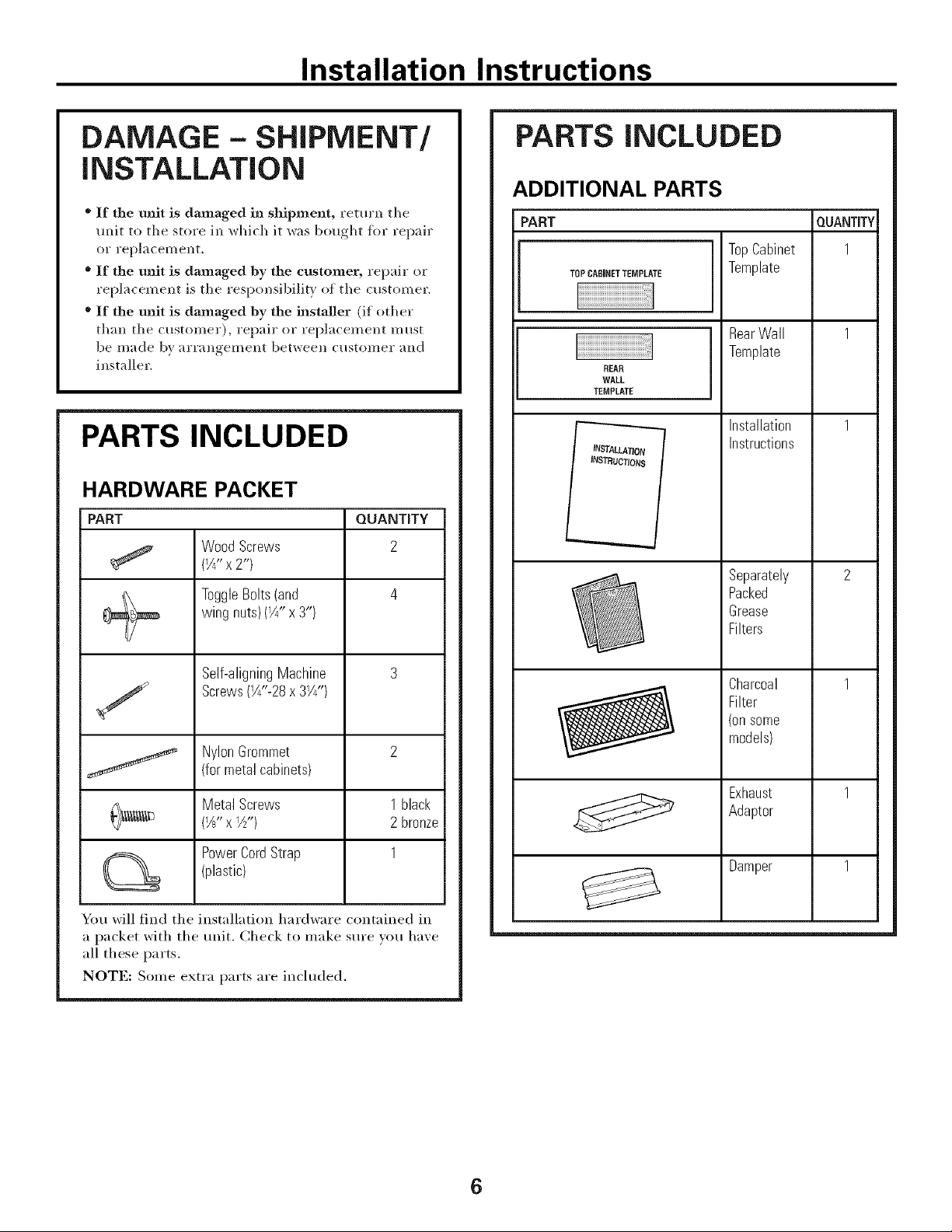

DAMAGE - SHIPMENT/

iNSTALLATiON

* If the unit is damaged in shipment, retm'n the

unit to the store in which it was bought fl)r repair

or replacement.

o If the _it is damaged by the customer, repair or

replacement is the Iesponsibility of the customer.

o If the unit is damaged by the installer (if other

than the customer), repair or replacement must

be made by arrangement between customer and

installer.

PARTS INCLUDED

HARDWARE PACKET

PART QUANTITY

Wood Screws 2

(¼" x2")

ToggleBolts(and 4

wing nuts)(¼" x 3")

PARTS iNCLUDED

ADDITIONAL PARTS

TopCabinet

TOPCABINETTEMPLATE

REAR

WALL

TEMPLATE

-------._.__.__

INSTALLATION

iNSTRUCTIONS

Template

RearWall

Template

Installation

Instructions

Separately

Packed

Grease

Filters

QUANTITY

Self-aligningMachine 3

Screws(W'-28 x3Y4")

NylonGrommet 2

(for metal cabinets)

Metal Screws 1 black

(W' x 1_,,) 2 bronze

Power Cord Strap 1

(plastic)

You will find the installation hardware contained in

a packet with the unit. Check to make sure w)u have

all these parts.

NOTE: Some extra parts are included.

Charcoal

Filter

(onsome

models)

Exhaust

Adaptor

Damper

6

Page 7

Installation Instructions

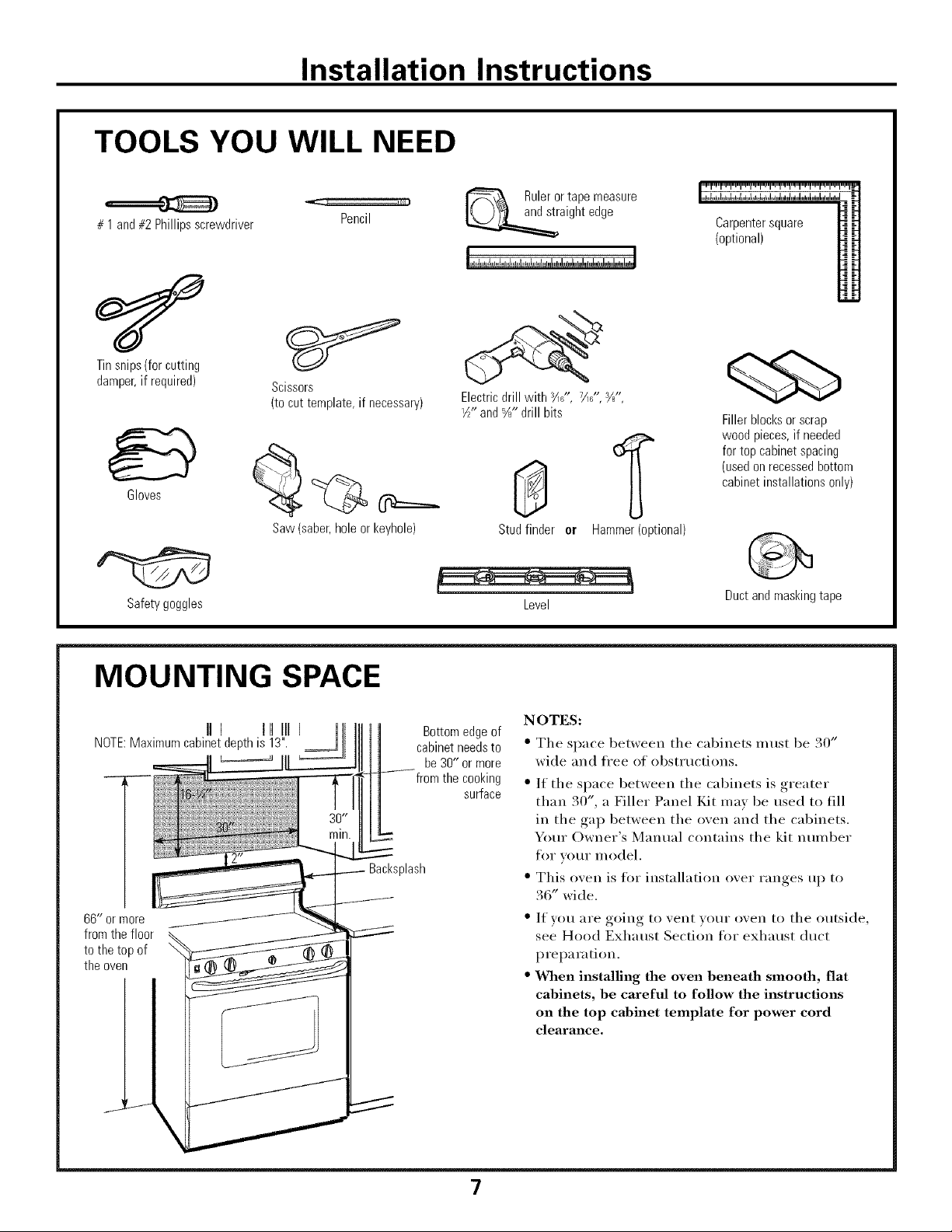

TOOLS YOU WILL NEED

# 1and#2Phillipsscrewdriver

Tinsnips(forcutting

damper,if required)

Gloves

Scissors

(tocut template,if necessary)

Pencil

Rulerortapemeasure

aightedge

Electricdrill with s/116",7/11g',syu,-

1½-and%" drillbits

(optional)

Carpentersquare

Fillerblocksor scrap

woodpieces,if needed

fortop cabinetspacing

(usedonrecessedbottom

cabinetinstallationsonly)

Saw(saber,holeor keyhole)

Safetygoggles

MOUNTING SPACE

II] t[] III

NOTE:Maximumcabinetdepthis 13".

ill

66" ormore

fromthe floor

tothe top of

theoven

cabinetneedsto

fromthe cooking

Backsplash

Bottomedgeof

be30" or more

surface

Studfinder er Hammer(optional)

Level

NOTES:

" The space between the cabinets must be 30"

wide and fl'ee of obst_ uctions.

• If the space between the cabinets is greater

than 30", a Filler Panel Kit may be used to fill

in the gap between the oven and the cabinets.

Yore" Owner's Manual contains the kit nmnber

for vour model.

• This oven is tot installation over ranges up to

36" wide.

• If win are going to vent w)m" oven to the outside,

see Hood Exhaust Section for exhaust duct

preparation.

• When installing the oven beneath smooth, flat

cabinets, be careful to follow the instructions

on the top cabinet template for power cord

clearance.

Ductandmaskingtape

\

7

Page 8

Installation Instructions

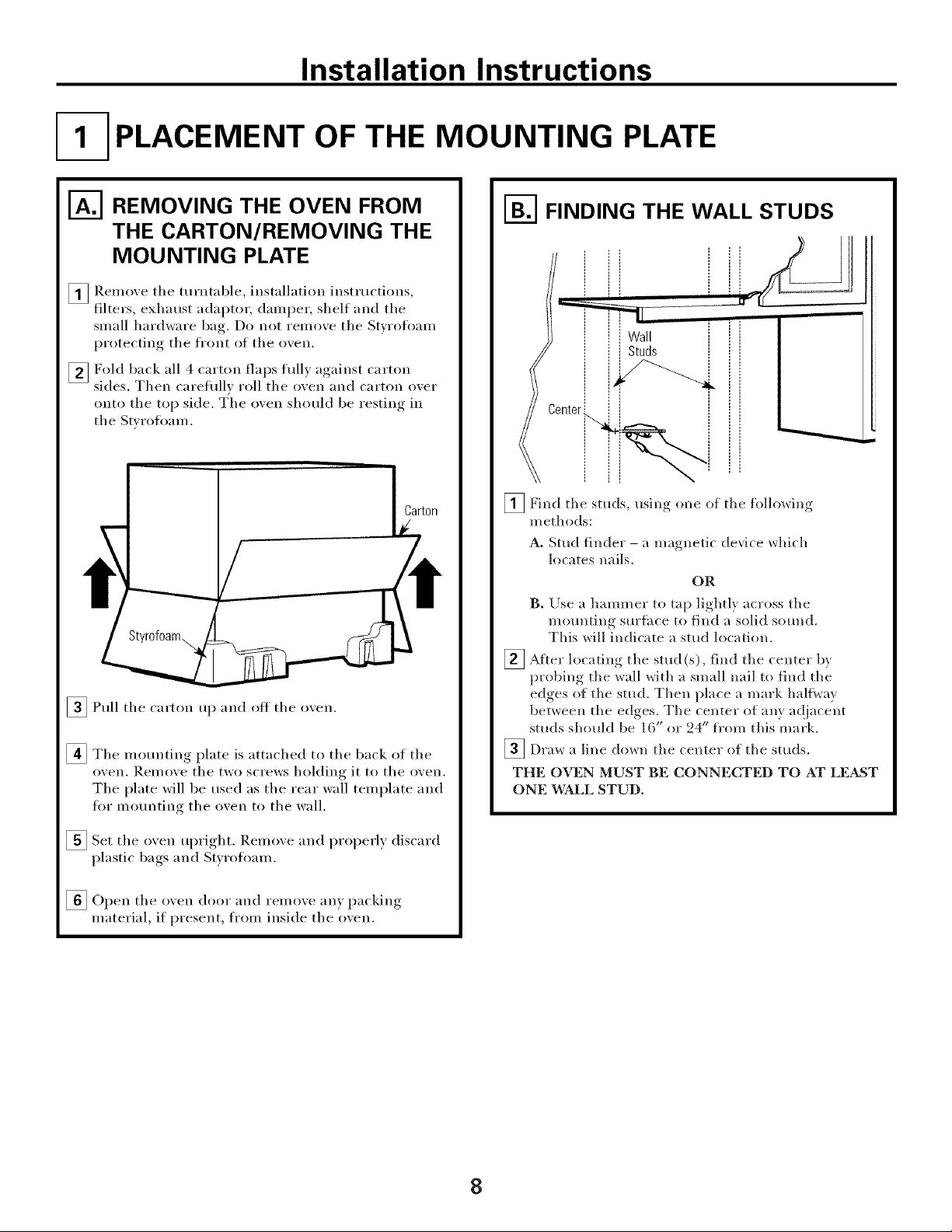

I-]PLACEMENT OF THE MOUNTING PLATE

I_ REMOVING THE OVEN FROM

THE CARTON/REMOVING THE

MOUNTING PLATE

_ Remo_e the turntable, installation instructions,

filters, exhaust adaptor; (lampe_; shelf and the

small hardware bag. Do not reillo'_e the St_rofimm

protecting the front of the o_en.

_Fold back all 4 carton flaps full) against carton

sides. Then carefifllx roll the oxen and carton oxer

onto the top side. T'he oxen should be restino, ,., in

the St_ toil)am.

Carton

_Pull the carton up and off the oven.

_The motmting plate is attached to the back of the

oxen. I_einoxe the two screws holding it to the oxen.

The plate will be used as the rear wall template and

for motmting the oxen to the wall.

1-_ FINDING THE WALL STUDS

Wall

Studs

i

_Find the studs, usino one of the foHo_dn,,

methods:

A. Stud finder - a magnetic device which

locates nails.

OR

B. Use a hammer to tap lightly across the

mounting surthce to find a solid sound.

This will indicate a stud location.

_ Aiter locating the stud(s), find the center by

probing the wall with a small nail to find the

edges of the stud. Then place a mark halt\ray

between the edges, The center of any ac!jacent

studs should be 16" or 24" fl'om this mark.

_Draw a line down the center of the studs.

THE OVEN MUST BE CONNECTED TO AT LEAST

ONE WALL STUD.

_Set the oxen upright Remoxe and properl) discard

I)lastic bags, and St_roflmm.

[] )acking

Open the o_en door and relnoxe an} I

material, if present, fi'om inside the oxen.

8

Page 9

Installation Instructions

DETERMINING WALL PLATE LOCATION UNDER YOUR CABINET

Plate position - beneath flat bottom

cabinet

Mounting Plate Tabs

Bottom

""S,

At least 30", up to 36"

! the Cabinet

Plate position - beneath framed recessed

cabinet bottom

Mounting Plate Tabs

Touching the Bacl<

Frame

\

\

\

30" to Cool<top

!

Plate position - beneath recessed bottom

cabinet with front overhang

Mounting Plate with

TabsBelow Cabinet

Bottom the Same

Distance as the Front

Overhang Depth

, II

30"to Cool<top

Your cabinets may have decorative trim that interferes

with the oven installation. Remove the decorative trim

to install the oven properly and to make it level.

THE OVEN MUST BE LEVEL

Use a level to make sure the cabinet bottom is level.

If the cabinets have a fl'ont overhang only, with no

back or side fi'ame, install the mounting plate down

the same distance as the fi'ont overhang depth. This

will keep the oven level.

[]Measure the inside depth of the fi'ont overhang.

[] Draw a horizontal line on the back wall an equal

distance below the cabinet bottom as the inside

depth of the fi'ont overhang.

_For this b'pe of installation with fl'ont overhang only,

align the mounting tabs with this horizontal line, not

touching the cabinet bottom as described in Step D.

9

Page 10

Installation Instructions

ALIGNING THE WALL PLATE

\

^ _ LineonWall

H_lole iI Drawa Vertical

HoleC_/' _ _ _ .........................................5 ° ° s_ _s_6 _,__

I

CAUTION: Wear glo_es I

to a_oid cutting fingers on

sharp edges.

[]Draw a vertical line on the wall at the center of the 30"

wide space.

_Use the moui_ting plate as the template for the rear

wall. Place the mom_ting plate on the wall, making

sure that the tabs are touching the bottom of the

cabinet or the level line drawn in Step C for cabinets

with front overhm_g. Line up the notch mid center line

on the mounting plate to the center line on the wall.

[] X._l_ileholding the mounting plate with one hand,

draw drcles on the wall at holes A, B, C and D (see

illustration above/actual plate marked with arrows).

Four holes must be used for mounting.

,_, ,I,

AreaE I

[] Dlill holes on the circles. If there is a stud, chill a :"A(;"

-_------ HoleB

I<_ fromCenterof

i TopCabinet

i

/

/

/

/

i

HoleD

NOTE: Appearance and

shape of the motmting

plate may wu'v ti'om vom"

model.

NOTE: Holes C and D are inside area E. If neither

C nor D is in a stud, find a stud s()mewhere in area E

and draw a fifth drcle to line up with the stud. It is

important to use at least one wood screw nlounted

firmly in a stud to sui_port the weight of the oven.

Set the mounting plate aside.

hole fin" wood screws. For holes that don't line up with

a stud, dlill a %" hole fin" toggle bolts.

NOTE: DO NOT MOUNT THE PLATE

AT THIS TIME.

10

Page 11

Installation Instructions

INSTALLATION TYPES

This oven is designed h)r adaptation to the fi)llowing three

types of ventilation:

A. Outside Top Exhaust (Vertical Duct)

B. Outside Back Exhaust (Horizontal Duct)

C. Recirculating (Non-Vented Ductless)

OUTSIDE TOP EXHAUST

(VERTICAL DUCT)

1

(Choose A, B or C)

NOTE: This ()veil is shipped assembled fin" Outside Top

Exhaust (except for non-vented models). Select the type

of ventilation required for vom" installation and proceed

to that section.

_-] OUTSIDE BACK EXHAUST

(HORIZONTAL DUCT)

RECIRCULATING

(NON-VENTED DUCTLESS)

11

On models shipped fi)r

non-vented exhaust, a

disposable charcoal filter is

included with the oven and

needs to be installed to help

reulove si/loke and odors.

On models shipped fi)r

outside top exhaust, a

Charcoal Filter Accessory Kit

is required for the non-vented

exhaust. (See your Owner's

Manual fin" the kit nmnber.)

Page 12

Installation Instructions

OUTSIDE TOP EXHAUST (Vertical Duct)

INSTALLATION OVERVIEW

A1. Attach Mounting Plate to Wall

A2. Prepare Top Cabinet

A3. Install Adapter

A4, Mount Oven

A5. Ac!j ust Exhaust Adaptor

A6. Connect Ductwork

I-_ ATTACH THE MOUNTING

PLATE TO THE WALL

Attach the plate to the wall using toggle bolts. At least

one wood screw must be used to attach the plate to a

wall stud.

[]Remove the toggle wings fl'om the bolts.

[]Insert the bolts into the mounting plate

through the holes designated to go into drwvall

and reattach the toggle wings to '_A"onto each bolt.

To use toggle bolts:

Spacingfor Toggles

MoreThanWall

+l.-,-[._Thickness

Mounting

Plate

BoltEnd

_ Place the mounting plate against the wall and

insert the toggle wings into the holes in the wall to

mount the plate.

NOTE: Betore tightening toggle bolts and wood

scre_, make sure the tabs on the mounting plate

touch the bottom of the cabinet when pushed

flush against the wall and that the plate is properly

centered under the cabinet.

CAUTION: Be careflfl to axoid I)inchin'*_ fingers

between the back of the mounting plate and the wall.

_ Tighten all bolts. Pull the plate awax from the wall

to hel I) tighten the bolts.

12

Page 13

Installation Instructions

I-_ USE TOP CABINET TEMPLATE

FOR PREPARATION OF TOP

CABINET

You need to drill holes for the top sui)port screws, a

hole large, enouoh_ for the power cord to fit through,

and a cutout large enough for the exhaust adaptor.

" Read the instructions on the TOP CABINET

TEMPLATE.

" Tape it tmderneath the top cabinet.

" Drill the holes, following the instructions on the

TOP CABINET TEMPLATE.

CAUTION: _4ear safety o-oo-des when drillim, holes

in the cabinet bottom.

ASSEMBLE AND

INSTALL ADAPTOR

Damper

-- Exhaust

Adaptor

BlowerPlate

Backof

Oven

I-_ MOUNT THE OVEN

FOIl EASIER INSTAI,IATION AND PERSONAl,

SAFETY, WE RECOMMEND THAT TWO PEOPLE

INSTALL THIS OVEN.

IMPORTANT: Do not grip or use handle

during installation.

NOTE: If your cabinet is metal, use the nylon

grommet around the power cord hole to prevent

cutting of the cord,

NOTE: We recommend using filler blocks if the

cabinet fl'ont hangs below the cabinet bottom shelf.

IMPORTANT: If filler blocks are not

used, case damage may occur from over

tightening screws.

NOTE: When mounting the

oven, thread power cord

through hole in bottom

of top cabinet. Kee I) it tight

throughout Steps 1-3.

Do not pinch cord or lift

oxen by pulling cord.

_I,ifl tilt itoven,

fi)rward and hook

slots at back bottom

edge onto two lower

tabs of mounting

plate.

NOTE: On some models, the exhaust adaptor and

damper assembly may ah'eadv be assembled to the oven.

_ Place the oven in its ul_right position, with the top

of the trait lacing up.

NOTE: Make sure the blower fan blades are visible

and are pointing up.

_ Insert the tabs on each side of the damper into the

holes at the inside rear of the adaptor.

_ Attach the exhaust adaptor to the blower plate with

the two bronze metal screws provided.

Make sure that the damper pivots easily before

mounting oven.

You will need to make a(!iustments to assure proper

alignment with your house exhaust duct after the

()veil is installed'.

[_ Rotate front of

up against cabinet

bottoI//.

13

o_en

Page 14

Installation Instructions

MOUNT THE OVEN (continued)

CabinetFront

F/ CabinetBottomShelf

Equivalent

I !! III NLI! /I[IItODepth

z!/_ FilleI Block

Self-AligningScrew

OvenTop

[]Attach tile (wen to the top cabinet by inserting

3 sell'aligning screws through outer top cabinet

holes. Turn two hill turns on each screw. Be sure

to keep power cord tight. Be caacefnl not to pinch

the cord, especially when mounting flnsh to

bottom of cabinet.

ofCabinet

Recess

L_I

ADJUST THE EXHAUST

ADAPTOR

Open tile top cabinet and a(!iust tile exhaust adaptor

to connect to tile house duct.

Damper

1

Backof

Oven

I-_ CONNECTING DUCTWORK

HouseDuct

[] Tighten tile three screws to tile top of tile oxen

completely. (X._hile tightening screws, hold the

oxen ill place against tile wall and tile top cabinet.)

[]Install filters. See tile Owner s Manual

grease

packed with tile oxen.

-i

[] ExteIld tile hot/se dt/ct dowll to COIlllect to

tile exhaust adaptor.

Seal exhaust durt ioints using

] . , duct tape.

14

Page 15

Installation Instructions

OUTSIDE BACK EXHAUST IHorJzo.talD.ctl

INSTALLATION OVERVIEW

B1. Prepare Rear _,_all

B2. Attach Exhaust Adaptor to

_,_all Plate

B3, Attach Mounting Plate

to X,Vdl

B4. Prepare Top Cabinet

BS. A¢!just Blower

B6. Motmt the Oven

1

Kmmmmmmmmmd

PREPARING THE REAR WALL

FOR OUTSIDE BACK EXHAUST

You need to cut an I

outside exhaust.

_Read the instructions on the REAR X,VAI,I,

TEMPLATE.

_Tape it to the rear wall, lining up with the holes

pre_iously drilled for holes A and B in the wall

pla re.

_Cut the )enino the instHictions of theI _, following

REAR _£M,I, TEMPI,ATE.

O

o )eniw, in the rear wall tot

ATTACH THE EXHAUST

ADAPTOR TO THE OVEN REAR

PANEL

_ Unscrew and remove the exhaust adaptor

assembly fl'om the top of the oven.

[ _ _ Exhaust

i ___ Adaptor

_Attach the exhaust adaptor to the oxen rear

panel bx sliding it into the guides at the top

center of the back of the oxen.

__ Damper

Exhou t ,o ..

._i_ Guide

Guide _ Locking

Push in securely tmtil it is in the lower locking tabs.

Take care to assure the damper hinge, is installed so

that it is at the top and that the damper .swin,,s.,.freely.,

0 Tabs

15

Page 16

Installation Instructions

ATTACH THE MOUNTING

PLATE TO THE WALL

Attach the plate to the wall using toggle bolts. At least

one wood screw must be used to attach the plate to a

wall stud.

[] I/emove the toggle wings fi'om the bolts.

[]Insert the bolts into the mounting plate through

the holes designated to go into dr}svall and reattach

the toggle wings to :_A"onto each bolt.

To use toggle bolts:

Spacingfor TogglesMore

-,-I_,-,,-!_,_ThanWallThickness

i

Mounting

Plate

ToggleWings

[=ff_ USE TOP CABINET TEMPLATE

FOR PREPARATION OF TOP

CABINET

You need to drill holes for the top support screws and

a hole large enouoh for the power cord to fit throu ,h

® Read the instructions on the TOP CABINET

TEM PI,ATE.

* Tape it underneath the top cabinet.

* Drill the holes, following the instructions on the

TOP CABINET TEMPLATE.

CAUTION: \'_Teal"safet) goggles when drilling holes in

the cabinet bottom.

B01tEnd

_ Place the mounting plate against the wall and

insert the toggle wings into the holes in the wall

to mount the plate.

NOTE: Betore tightening toggle bolts and wood

scre_, make sure the tabs on the mounting plate

touch the bottom of the cabinet when pushed flush

against the wall and that the plate is properly

centered under the cabinet.

CAUTION: Be careflfl to axoid I)inching, finge_

between the back of the mounting, I)late and the wall.

_ Tighten all bolts. Pull the from the wall

to help tighten the bolts.

plate

16

Page 17

Installation Instructions

ADAPTING BLOWER FOR

OUTSIDE BACK EXHAUST

[] Renmve the two screws that hold the blower plate

and remove the screw holding the blower motor

to the oven. Slide blower plate fl'om trader its

retaining flange.

Retaining 1_ _

Flange ,_,4k _,___.._.._ Blower Plate

--_

[] Careflflly the blower trait. The wirespull

will extend far enough to allow you to a(!just

the blower unit.

O[lt

_] Place the 1)lox_er unit back into the opening.

CAUTION: Do not pull or stretch the blower

refit wiring. Make sure the wires axe not pinched.

NOTE: The blower unit exhaust openhlgs should

match exhaust openh_gs on rear of oven.

] Replace the blower plate in the same position

as before and replace the screws for the

blower plate and blower motor.

BlowerPlateScrews

BlowerPlate

.,_ BackofOven

BlowerMotor Screw

_ Rotate blower trait counterclockwise 180 °.

Before Rotation

Back of

Oven

After Rotation

_Roll the blower trait 90 ° so that tan blade

openings are facing ot/t the back of the

o_, eIl.

Before Rolling --_ After Rolling _

t o °

Backof

Oven

Back of

Oven

_17

_ " Oven

ackof

Backof

Oven

Page 18

Installation Instructions

MOUNT THE OVEN

CabinetFront

CabinetBottomShelf

FillerBlock

to Depth

of Cabinet

T quivalent

Recess

FOIl EASIER INSTAI,IATION AND PERSONAI,

SAFETY, X.VERECOMMEND THAT TWO PEOPLE

INSTALL THIS OVEN.

IMPORTANT: Do not grip or use handle

during installation.

NOTE: If vour cabinet is metal, use the nylon

gronmlet around tile power cord hole to prevent

cutting ot tile cord.

NOTE: We recoumlend using filler blocks if tile

cabinet front hangs below tile cabinet bott(nn shelf.

IMPORTANT: If filler blocks are not

used, case damage may occur from over

tightening screws.

NOTE: When mounting

tile oven, thread power

cord through hole ill

bottonl of top cabinet.

Kee I) it tight throughout

Steps 1-3. Do not pinch

cord or lifi oven bv

Imllin(*', cord.

[]I,ifl ()veil, it

fin'ward and hook

slots at back l)()ttom

edge onto two lower

tabs of mounting plate.

tilt

Self-AligningScrew

OvenTop

[]Attach tile oven to tile top cabinet by inserting

3 sell=aligning screws through outer top cabinet

holes. Turn two fllll ttu'ns on each screw. Be sure

to keep power cord tight. Be careful not to pinch

the cord, especially when mounting flush to

bottom of cabinet.

[] Tighten tile three screws to tile top of tile oven

c(mlpletely. (X.Vhile tightening screws, hold the

oxen in place against tile wall and tile top

cabinet.)

/

_ Rotate front (If oven lip

against cabinet 1)()ttom.

\

_ Install grease filters. See tile Owner's Manual

packed with tile oxen.

18

Page 19

Installation Instructions

RECIRCULATING INon-VentedDuctless)

INSTALLATION OVERVIEW

C1. Attach Mounting Plate to _'all

C2. Prepare Top Cabinet

C3. Adjust Blower

C4. Mount the Oven

C5. Install Charcoal Filter

I-_ ATTACH THE MOUNTING

PLATE TO THE WALL

l

Attach the plate to the wall using toggle bolts. At

least one wood screw I/ltlSt be used to attach the

plate to a wall stud.

[]Remove the toggle wings fl'om the bolts.

[]Insert the bolts into the mounting plate through

the holes designated to go into dr xsvall and

reattach the toggle wings to :Y," onto each bolt.

To use toggle bolts:

Spacingfor Toggles

MoreThanWall

-,.-I..-,.-i_,_Thckness

_ Place the mounting plate against the wall and

insert the toggle wings into the holes in the wall to

mount the plate.

NOTE: Betore tightening toggle bolts and wood

scre_, make sure the tabs on the mounting plate

touch the bottom of the cabinet when pushed flush

against the wall and that the plate is properly

centered under the cabinet,

CAUTION: Be careflfl to axoid I)inchin<*_ fingers,

between the back of the mounting plate and the wall.

_ Tighten all bolts. Pull the plate away fi'om the wall

to hel I) tighten the bolts.

| USE TOP CABINET TEMPLATE

FOR PREPARATION OF TOP

CABINET

You need to drill holes fl)r the top sui)port screws and

a hole large enotwh for the power cord to fit throuoh

Mounting

Plate

" Read the instructions on the TOP CABINET

if,

BoltEnd

TEMPI,ATE.

" Tape it underneath the top cabinet.

" Drill the holes, fl_llowing the instructions on the

TOP CABINET TEMPLATE.

CAUTION: X_'ear safety goggles when drilling holes

in the cabinet bottom.

19

Page 20

Installation Instructions

ADAPTING BLOWER

FOR RECIRCULATION

NOTE: The exhaust adaptor with dmnper is not

needed for recirculating models. Ym may want to

sa',e then/ for possible flmu'e use.

[]Remove and that hold blower andplate

blower trait to the oxen.

Blower Plate Screws

sa',e screws

B,owerP,ate

Back of Oven

_ Slide the blower plate from trader its retainim,

flanoe and lift it off.

letaining

Blower Plate

_Roll the blower rant 30 so that tim blade o )enings

are thcing toward the fi'(mt ()f the oxen.

B011

Careflfllv roll out the blower trait The wires

will extend far en u,,h to allow }(m to a(!lUSt the

blower trait.

0 (Y "

2O

Page 21

Installation Instructions

ADAPTING BLOWER FOR

RECIRCULATION (continued)

_] Place the blower unit back into the o )ening.

CAUTION: Do not pull or stretch the blower unit

wiring, Make sure the wires are not pinched,

[] Replace blower plate and replace screws for blower

plate and blower motor remoxed in Step 1.

Blower Plate Screws

__ Blower Plate

I Back of Oven

l

NOTE: When motmting

the oven, thread power

cord through hole in

bottom of top cabinet.

Kee I) it tight throughout

Steps 1-3. Do not pinch

cord or lift oven by

mllin , cord

/

_ Rotate fFont of oxen

up against cabinet

bottoln.

CabinetFront

CabinetBottomShelf

_I,ifl oven, tilt it

flwward and hook

slots at back bottom

edge onto two lower

tabs of mounting plate.

MOUNT THE OVEN

FOIl EASIER INSTAI,I.¢TION AND PERSONAI,

SAFETY, WE RECOMMEND THAT TWO PEOPLE

INSTALL THIS OVEN.

IMPORTANT: Do not grip or use handle

during installation.

NOTE: If yore" cabinet is metal, use the nylon

grommet around the power cord hole to prevent

cutting of the cord.

NOTE: We recommend using filler blocks if the

cabinet front hangs below the cabinet bottom shelf.

IMPORTANT: If filler blocks are not used,

case damage may occur from over tightening

screws.

Equivalent to Depth

f Cabinet Recess

Self-Aligning Screw

Oven Top

21

Page 22

Installation Instructions

MOUNT THE OVEN

(continued)

_Attach the oven to the top cabinet by inserting

3 self aligning screws through outer top cabinet

holes. Turn two fllll ttlI'IIS on each screw. Be sure

to keep power cord tight. Be careful not to pinch

the cord, especially when mounting flush to

bottom of cabinet.

[] Tighten the three screws to the top of the oxen

completely. (X_hile tightening screws, hold

the oxen in place against the wall and the top

cabinet.)

INSTALLING THE CHARCOAL

FILTER

_ Remoxe 2 screws on to ) of grille using a

Phillips screwdrix er.

_Open the door .)0 .

_ Remoxe the grille.

J

J

_ ]nsert the filter into the of the )enintop

between the side support slots,

( o

o

_CL_

Filter

_lnstall filters. See the Owner Manual

grease

packed with the o_en.

S /

_Push the filter all the wax in where it will rest at

an angle,

[] Replace the grille and the 2 ,_crews.

_ Close the door.

c S

_j__j

Insertmesh-sideup

22

Page 23

Installation Instructions

BEFORE YOU USE YOUR

[_ ake sure the o_en h;Js been installed

according to instructions.

_3

_ Remove all packing materi_d from the o_en.

OVEN

[_ Read the O_ner's Manual.

['_ KEEP INS%M,LATION INSTRUCTIONS

FOR THE I.OCAI. INSPECTOR'S USE.

_ Repl_lce house fuse or turn breaker back on.

IllIIII

Plug po_,,,er cord into a dedicated 15 to 20 amp

%

electrical outlet.

Insure proper

23

Page 24

Printed in (]hina

Loading...

Loading...