Page 1

Installation

Abovethe

Instructions

I Questions? Carl 800-GE-CARES (800-432-2737) orvisit ore"Websit_ at: www.GEAppliances.com I

CooktopOven

JVM1490,SCA1000andSCA1001

BEFORE YOU BEGIN

Read these instructions completely and carefully.

• IMPORTANT - Savethese

instructions for local inspector's use.

• IMPORTANT - Obsc_-_oall

governing codes and ordinances.

• Note to Installer _ Be sure to leavethese

instructions with the Consumer.

• Note to Consumer - Keep these

instructions for future reference.

• Skill level - Installation of this appliance requires

basic mechanical and electrical skills.

• Proper installation is the responsibility of the installm:

• Product failure due to improper installation is not

covered under the Warranty.

I!! Ii

LA SECCION EN ESPAI_IOL

EMPIEZA EN LA PAGINA 25.

READ CAREFULLY.

KEEP THESE INSTRUCTIONS.

Page 2

Installation Instructions

CONTENTS

General information

Important Safety Instructions .................................. 3

Electrical Requirements .......................................... 3

Hood Exhaust ...................................................... 4, 5

Damage - Shipment/Installation .............................. 6

Parts Included .......................................................... 6

Tools You Will Need ................................................ 7

Mounting Space ...................................................... 7

Step-by-step installation guide

Placement of Mounting Plate ............................ 8-10

Rcmox_mg the Mounting Plate ...................... 8

Finding tile Wall Studs .................................. 8

Determining Wall Plate Location .................. 9

] Recirculating ........................................ 19-22

Attach Mounting Plate to Wall ............ 19

Preparation of Top Cabinet ................ 19

Adapting Blower

for Recirculation .......................... 20, 21

Mount the Oven ............................ 21, 22

Installing the Charcoal Filter .............. 22

Before You Use Your Oven .................................. 23

Secci6n en Espafiol ........................................ 2547

Aligning the Wall Plate ................................ 10

Installation Types .............................................. 11-22

_] Outside Top ............................

Attach Mounting Plate to Wall ............ 12

Preparation of Top Cabinet ................ 13

Checking for Proper Damper

Exhaust

12-14

Operation ............................................ 13

Mount the Oven ............................ 13, 14

Adjust the Exhaust Adaptor ................ 14

Connecting Ductwork .......................... 14

_] Outside Back Exhaust 15-18

Preparing Rear Wall for

Outside Back Exhaust .......................... 15

Attach Mounting Plate to Wall ...... 15, 16

Preparation of Top Cabinet ................ 16

Adapting Blower for Outside

Back Exhaust .................................... 16, 17

Mount the Oven .................................. 18

2

Page 3

Installation Instructions

IMPORTANT SAFETY INSTRUCTIONS

This product requires a three-prong grounded

outlet. The installer must peribrm a ground continuity

check on the power outlet box beibre beginning the

installation m insure that tile outlet box is properly

grounded, if not properly grounded, or if the

outlet box does not meet electrical requirements

noted (under ELECTRICAL REQUIREMENTS),

a qualified electrician should be employed to

correct any deficiencies.

CAUTION: For personal

safety, remove house fuse

or open circuit breaker

before beginning installation

to avoid severe or fatal

shock injury.

CAUTION: For personal safety, the momaling surface

must be capable of supporting the cabinet load, ha

addition to the added weight of this 63-85 pound

product, plus additional oven loads of up to 50 pounds

or a total weight of 113-135 pounds.

CAUTION: For personal safety, this product cannot

be installed ha cabinet arrangements such as an island or

a peninsula. It must be mounted to BOTH a top cabinet

AND a wall.

You should have the wall receptacle and circuit checked

by a qualified electricima to make sure the receptacle is

properly grounded.

Where a standard two-prong wall receptacle is

encomatered, it is very important to have it replaced

with a properly grounded three-prong wall receptacle,

installed by a qualified electrician.

DO NOT, UNDER ANY CIRCUMSTANCES, CUT,

DEFORM, OR REMOVE ANY OF THE PRONGS

FROM THE POWER CORD. DO NOT USE WITH

AN EXTENSION CORD.

ELECTRICAL

REQUIREMENTS

Product rating is 120 volts AC, 60 Hertz, 15 amps, and

1.70 kilowatts. This product must be connected to

a supply circuit of the proper voltage and fi'equency.

Wire size must conform to the requirements of the

National Electrical Code or the prevailing local code

for this kilowatt rating. The power supply cord and

plug should be brought to a separate 15 to 20 ampere

branch circuit single grounded outlet. The outlet box

should be located in the cabinet above the oven. The

outlet box and supply circuit should be installed by

a qualified electrician and conform to the National

Electrical Code or the prevailing local code.

NOTE: For easier installation and personal safety, it is

recommended that two people install this product.

IMPORTANT--PLEASE READ CARF_UIIY. FOR

PERSONAL SAFETY, THIS APPLIANCE MUST BE

PROPERLY GROUNDED TO AVOID SEVERE OR

FATAL SHOCK.

The power cord of this appliance is equipped with

a three-prong (grounding)

plug which mates with

a standard three-prong

(grounding) wall receptacle

to minimize the possibility

of electric shock hazard

from this appliance.

insureproper

groundexists

beforeuse

3

Page 4

Installation Instructions

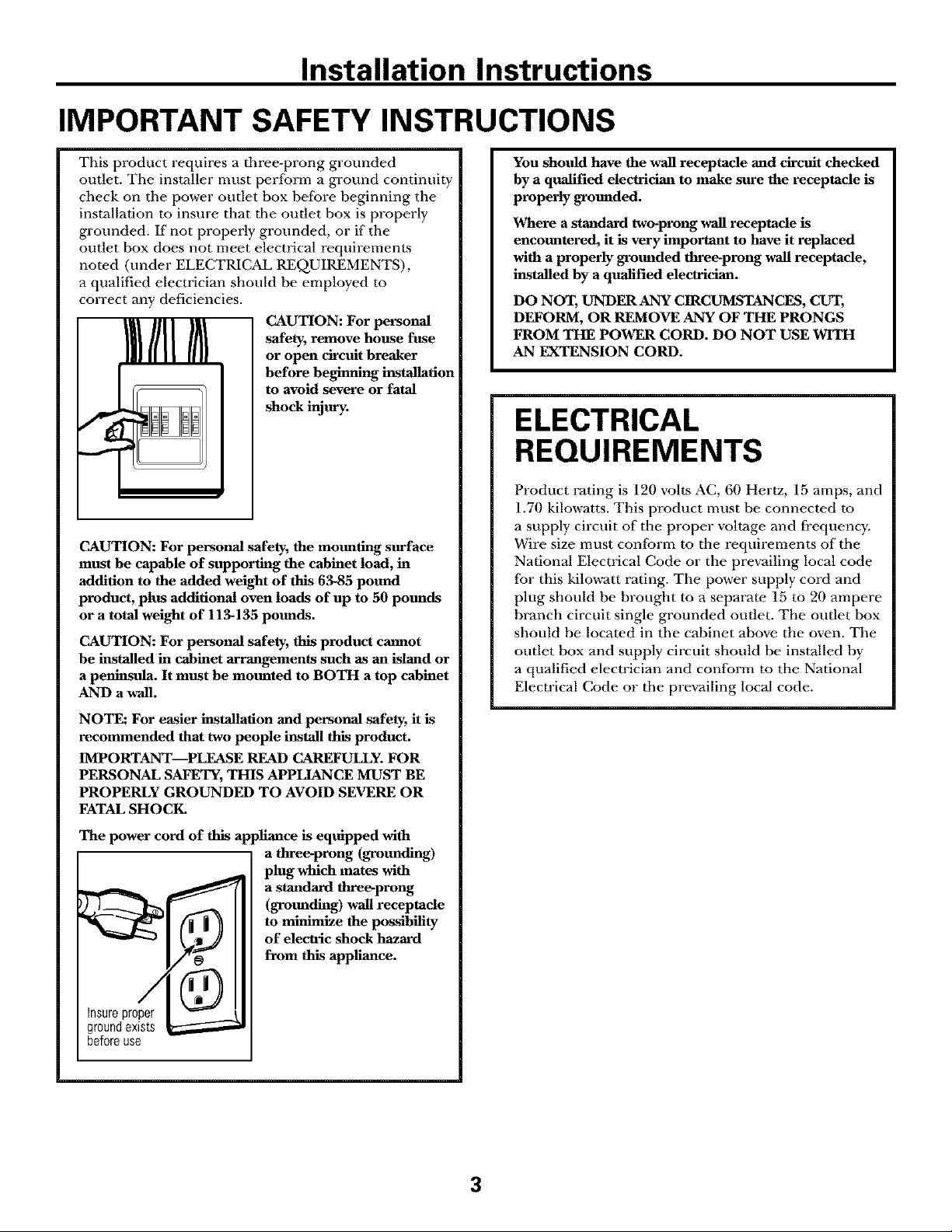

HOOD EXHAUST

NOTE: Read these next two pages only if you plan to vent your exhaust to the outside.

If you plan to recirculate the air back into the room, proceed to page 6.

OUTSIDE TOP EXHAUST (EXAMPLE ONLY)

The fbllowing chart describes an example of one possible

ductwork installation.

EQUIVALENT NUMBER EQUIVALENT

DUCT PIECES LENGTH x USED = LENGTH

12Ft.StraightDuct 12Ft. x (1) = 12Ft.

RoofCap 24 Ft. x (1) = 24 Ft.

(6" Round)

TransitionAdaptor*

Rectangular4o-Round 5Ft. x (1) = 5Ft.

Equivalentlengthsofductpiecesarebasedonactualtests and

reflectrequirementsforgoodventingperformancewith anyventhood.

*IMPORTANT: If a rectangular-to-round transition adaptor is used, the bottom corners of the damper

will have to be cut to fit, using the tin snips, in order to allow fi'ee movement of the damper.

OUTSIDE BACK EXHAUST (EXAMPLE ONLY)

The following chart describes an example of one possible

ductwork installation.

EQUIVALENT NUMBER EQUIVALENT

_,.....__ Wall Cap 40Ft. x (1) 40Ft.

DUCT PIECES LENGTH* x USED = LENGTH

3 Ft.StraightDuct 3Ft. x (1) 3Ft.

37g"x 10"Rectangular)

Total Length = 41 Ft.

90° Elbow 10Ft. x (2) 20Ft.

Equivalentlengthsof ductpiecesarebasedonactualtests and

reflectrequirementsforgoodventingperformancewith anyventhood.

NOTE: For back exbaust, care sbould be taken to align exhaust witb space between studs, or wall should be prepared

at the time it is constructed by leaving enough space between the wall studs to accommodate exhaust.

Total Length = 63 Ft,

4

Page 5

Installation Instructions

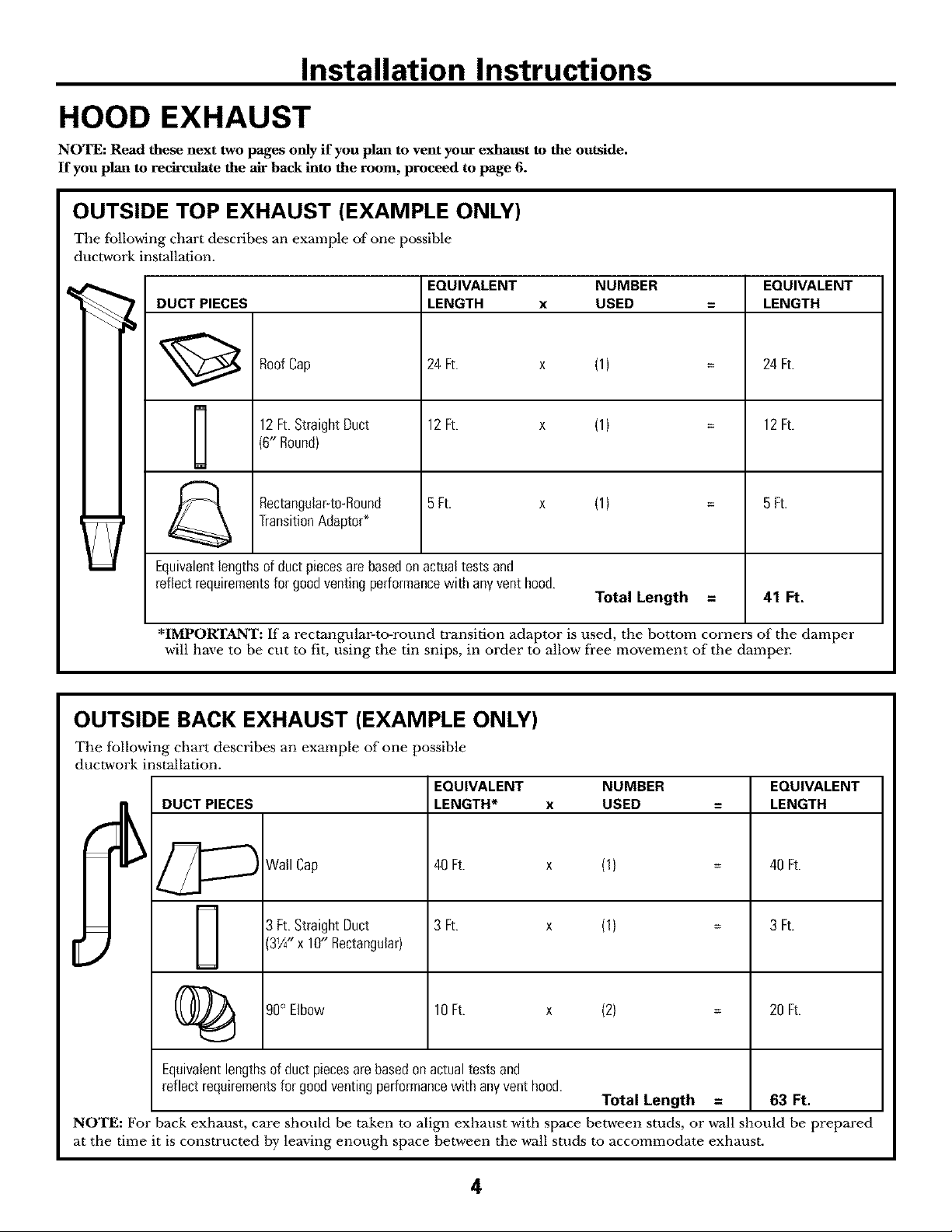

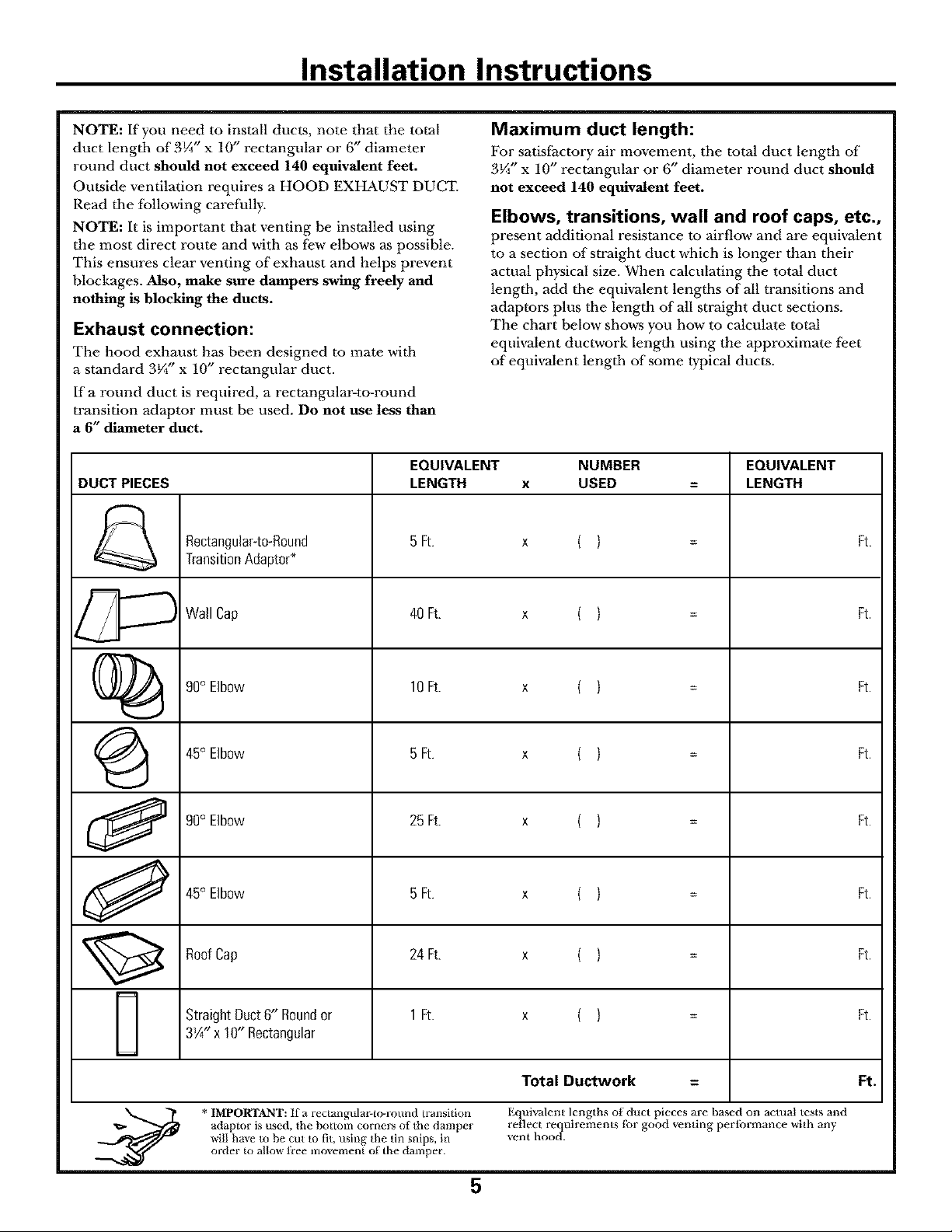

NOTE: If you need to install ducts, note that the total

duct lengtb of 3¼" x 10" rectangular or 6" diameter

round duct should not exceed 140 equivalent feet.

Outside ventilation requires a HOOD EXHAUST DUCT.

Read tile following carefully.

NOTE: It is important tbat venting be installed using

the most direct route and with as few elbows as possible.

This ensures clear venting of exhaust and helps prevent

blockages. Also, make sure dampers swing freely and

nothing is blocking the ducts.

Exhaust connection:

The hood exhaust has been designed to mate witb

a standard 3¼" x 10" rectangular duct.

If a round duct is required, a rectangular-to-round

transition adaptor must be used. Do not use less than

a 6" diameter duct.

EQUIVALENT NUMBER EQUIVALENT

DUCT PIECES LENGTH x USED = LENGTH

Rectangular_to-Round 5 Ft. x ( ) Ft.

TransitionAdaptor*

Maximum duct length:

For satisfhctory air movement, the total duct length of"

3¼" x 10" rectangular or 6" diameter round duct should

not exceed 140 equivalent feet.

Elbows, transitions, wall and roof caps, etc.,

present additional resistance to airflow and are equivalent

to a section of straight duct which is longer than their

actual physical size. When calculating the total duct

lengtb, add tbe equivalent lengtbs of all transitions and

adaptors plus tbe length of all straight duct sections.

The chart below shows you how to calculate total

equivalent ductwork length using the approximate feet

of equivalent lengtb of some typical ducts.

Wall Cap 40 Ft. x ( ) Ft.

(i)_ 9O°EIbow lOFt. x ( ) Ft.

(_ 45° Elbow 5 Ft. x ( ) Ft.

90° Elbow 25 Ft. x ( ) Ft.

45° Elbow 5 Ft. x ( ) Ft.

RoofCap 24 Ft. x ( ) Ft.

StraightDuct6" Roundor 1 Ft. x ( ) Ft.

3¼" x 10" Rectangular

Total Ductwork = Ft.

adaptor is used, the bottom cornm_ of the damper reflect requirements for good venting performance with any

_'iU ha_e to be cut to fit, t_sing the tin snips, in _ent hood.

* IMPORTANT: if a iectangtflm_to-round transition Equiwflent lengths of duct pieces are based on actual tests and

order to aUo_ fi'ee inovement of the damper.

5

Page 6

Installation Instructions

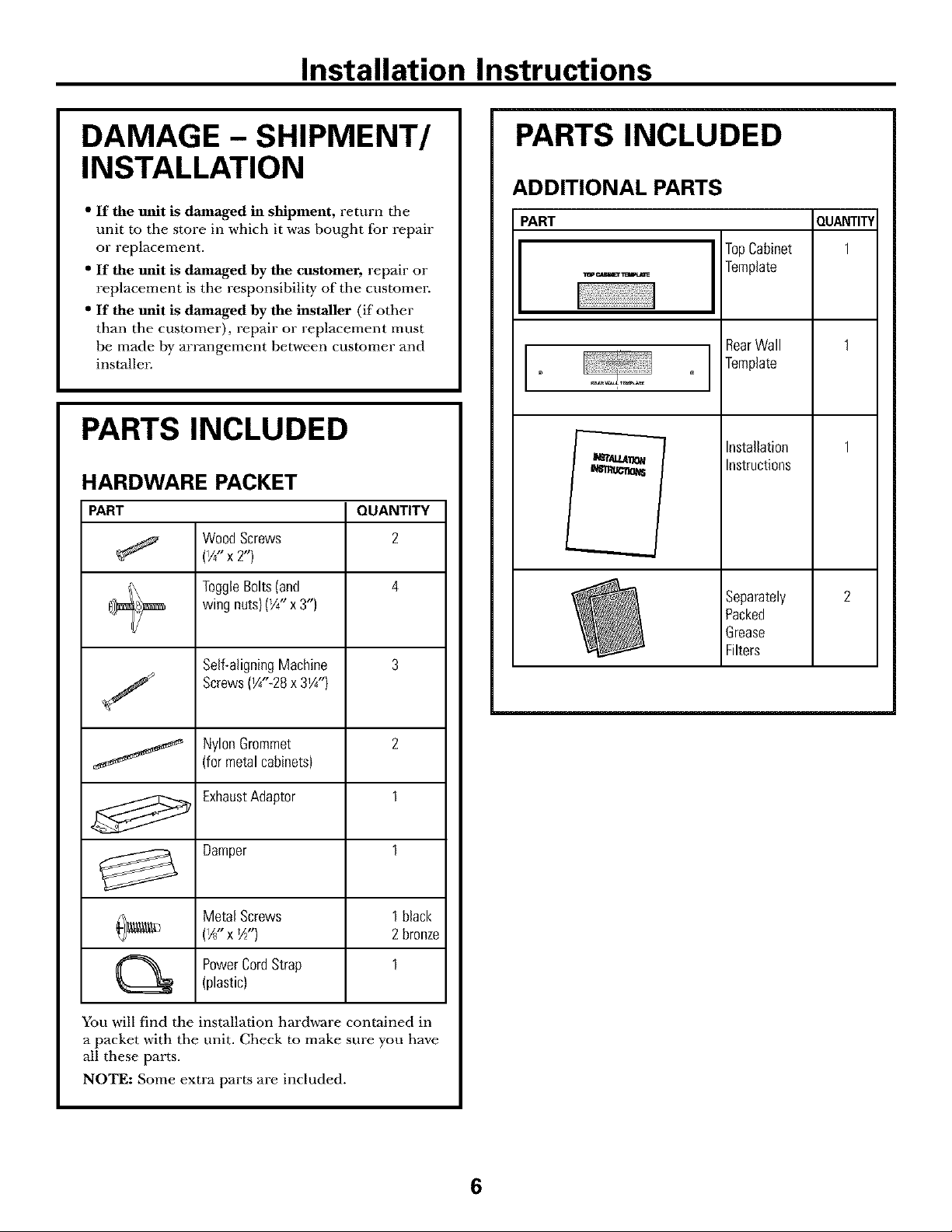

DAMAGE - SHIPMENT/

INSTALLATION

" If the unit is damaged in shipment, return tile

unit m the store in which it was bought J[br repair

or replacement.

" If the unit is damaged by the customer, repair or

replacement is the responsibility of the customer.

" If the unit is damaged by the installer (if other

than the customer), repair or replacement must

be made by arrangement between customer and

installmz

PARTS INCLUDED

HARDWARE PACKET

PART QUANTITY

WoodScrews 2

(I/4_1 X 2")

PARTS INCLUDED

ADDITIONAL PARTS

PART

TopCabinet

_ _msEr w

L

Template

RearWall

Template

Installation

Instructions

QUANTITY

1

I\ Togg{eBolts(and 4

_ wingnuts)(_A"x 3")

Se{f-a{igningMachine 3

Screws(IA"_28x 3_A")

NylonGrommet 2

(formetalcabinets)

ExhaustAdaptor 1

_ Damper 1

Metal Screws 1black

(IA"x *A") 2bronze

PowerCordStrap 1

(plastic)

You will find the installation hardware contained in

a packet with the unit. Check to make sure you have

all these parts.

NOTE: Some extra parts are included.

®

Sepamtely

Packed

Grease

Filters

6

Page 7

Installation Instructions

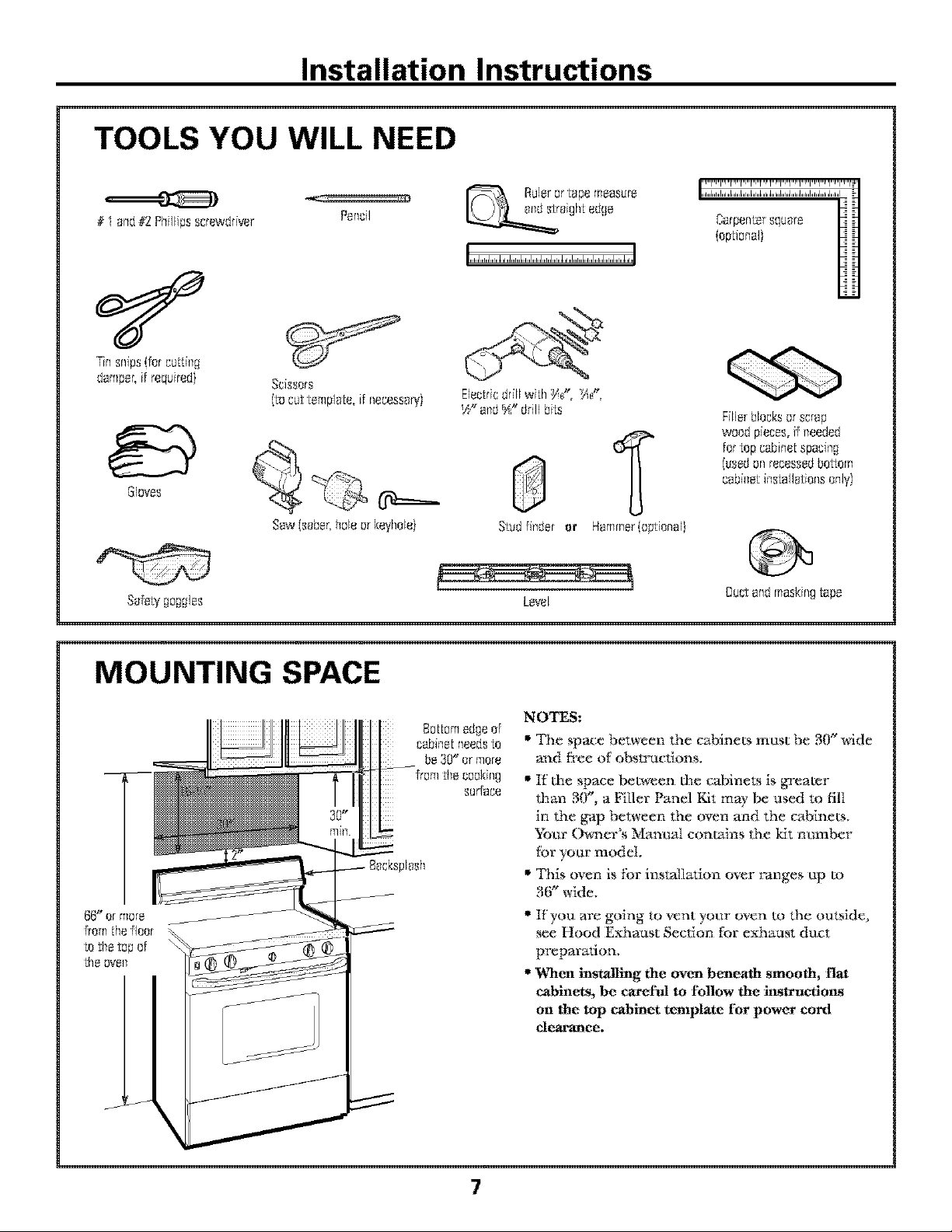

TOOLS YOU WILL NEED

# I o_d#2 Phifiipsscrewdriver

_n snips {fer [:u[[ill[_

_cissers

Pencil

Ruleror 1:apemeasure

figh[ edge

{ep[i_nal)

Electricdrill wi[h :_(", _i(',

_" a_d_" driftbi[s Fillerblocks_r scrap

fer [epcabine[spacfl_g

Gloves

Sofe_goggles

MOUNTING SPACE

plosh

cebfl_etfl_stallotiensonly)

weedpieces,if ileeded

(usedonrecessedbottom

Studffl_der or

@

Level

NOTES:

" _I_e space between dm cabinets must be NY" wide

m_d tYee of' obstructions.

" If the space between the cabinets is greater

than BO", a Filler Panel Kit may be used to fill

in ti_e g_ap between lhe oven and the cabinets.

}%ar (_cr's ManuN contains the kit number

tbr your model.

• This oven is tbr installation over ranges tip m

36" wide,

" If you are going m vent your oven m lhe outside,

see Hood Exhaust Section tbr exhaust duct

preparation.

•When installing the oven beneath smooth, flat

cabinets, be care[_l to follow the instruc_ons

on the top cabinet template For power cord

clearance.

Ductandmaskingtape

7

Page 8

Installation Instructions

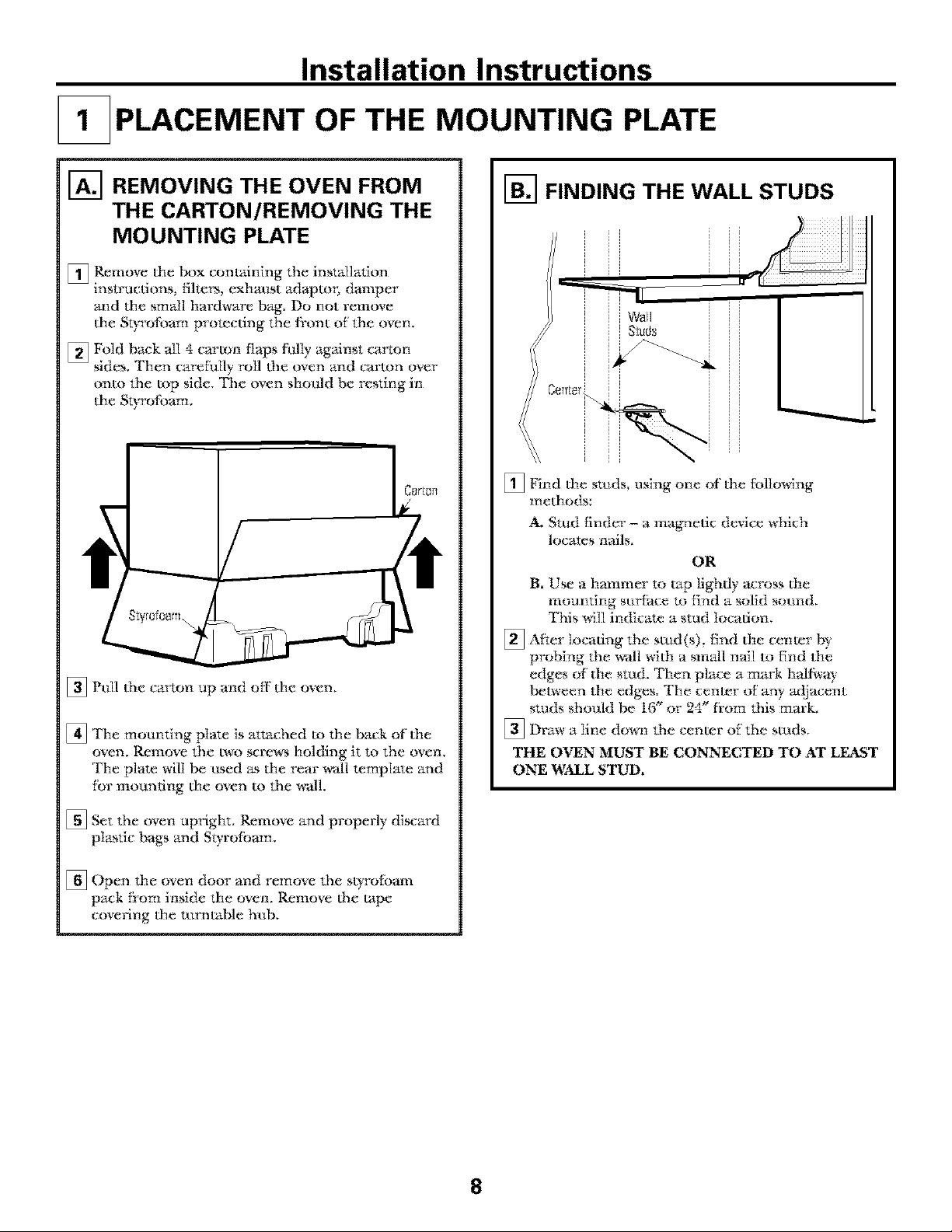

PLACEMENT OF THE MOUNTING PLATE

[] REMOVING THE OVEN FROM

THE CARTON/REMOVING THE

MOUNTING PLATE

[]Remove the box conudning the instMlation

instructions, filters, exhaust adaptm; damper

and the small hardware bag. Do not remove

the Styrofbam protecting the fl:ont of the oven,

[] Fold back all 4 carton flaps fully against c_u'ton

sides. Then carefully roll 0_e oven and era:ton over

onto the top side. The oven should be resting in

the Styrofbam.

[] Pull Ihe car_on up and off the oven.

[] The motmting plate is attached to the back of the

oven. Remove the two screws holding it to the oven,

The plate will be used as the rear wall template and

fbr mounting the oven to the wall.

[-_ FINDING THE WALL STUDS

[] Find the studs, using one of the fbllowing

methods:

A. Stud finder - a magnetic device which

locates nails.

OR

B T

• Use a hmnmer to tap lightly across the

mounting surfhce to find a solid sound,

This will indicate a stud location,

[] After locating Ihe stud(s), tind the center by

probing Ihe v#all with a sm_dl nail to find the

edges of the stud, Then place a mark halgva)

between the edges. The center of any _ljacent

studs should be 16_"or- 24" fi'om Ibis mark,

]Draw a line down the center of the studs,

THE OVEN MUST BE CONNECTED TO AT LEAST

ONE WALL STUD•

[] Set the oven upright. Remove and properly discard

plastic bags and Styrofbwn.

[] Open the oven door and remove 1he st}rotbarn

pack Dora inside the oven. Remove Ihe tape

covering the tumlable hub,

8

Page 9

Installation Instructions

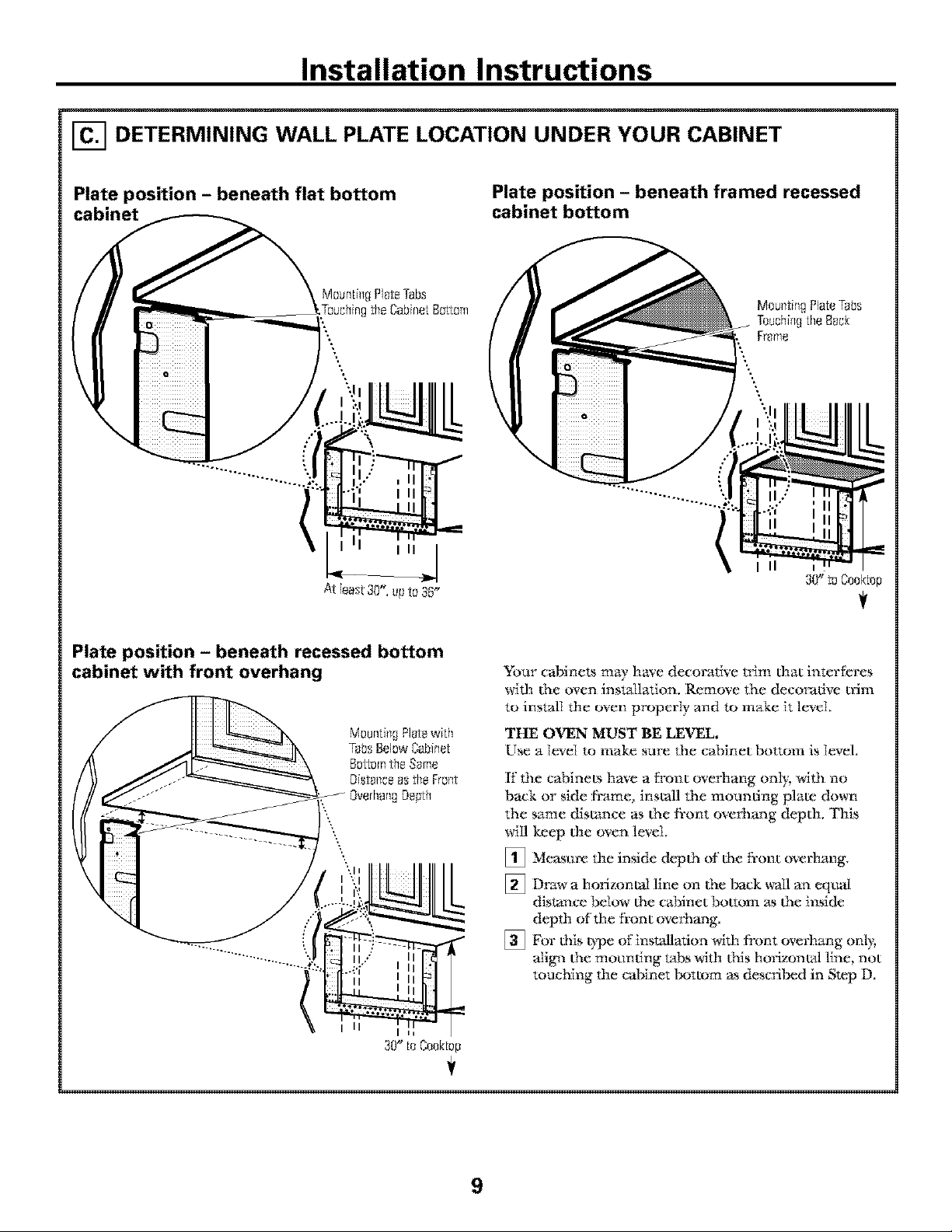

[] DETERMINING WALL PLATE LOCATION UNDER YOUR CABINET

Plate position - beneath flat bottom

cabinet

Maunth_gPI_teTabs

Plate position - beneath framed recessed

cabinet bottom

Moum:ingPlateTabs

Teuchi_gthe Back

Frame

Plate position - beneath recessed bottom

cabinet with front overhang

II

30" to Cooktap

S%ur cabinets may have decorative trim that intertcres

with d_e oven inst_dlation. Remove the decorative n'im

to install the oven properI_ and to make it level.

THE OVEN MUST BE LEVEL.

Use a l_'eI to make sure the cabinet bottom is level.

If' the cabinets have a lyon t overhang only, Mth no

back or side &ame, install the moundng plate down

the same distance as the &ont ore€hang depth. This

will keep the oven level.

[] Measure the inside depth of the fl'ont overhang.

[] Draw a horizontal line on Ihe t_ck _vall

distal_ce below the c_binet bottom ;_ the inside

depth of the fi'ont ove_:hal_g.

[] For I}fis t}_e of inst_dlation with front

align Ihe moundng u4bs with Ih:is horizonud line, not

touching the cabinet tx_ttom as descrit_d in Step D.

all

eqt_]

overhal]g onl}_

9

Page 10

Installation Instructions

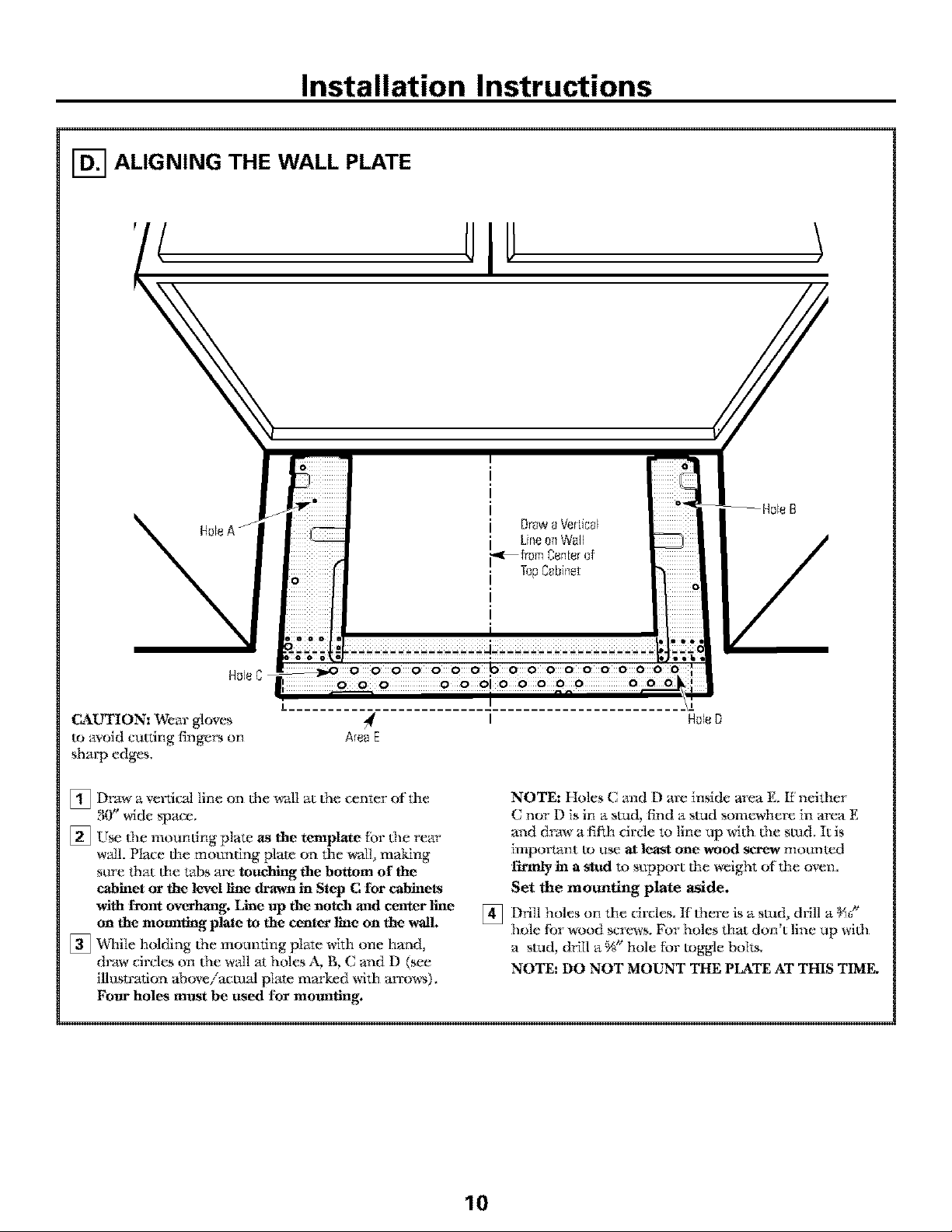

[] ALIGNING THE WALL PLATE

HoleC _ 0 0 0 0 b 0000000000

CAUTION: Wear gloves

to avoid cutdng fingers on

sharp edges,

Draw a ve*_ictd line on the wall at (he center of the

[]

3(Y' wide space.

[] Use (he mounting plate as the template [br (he rear

wtdl. Place the mortaring plato on the wall, making

sttre lhat the tabs are touching the bottom o1' the

cabinet or the level llne dl_awn in Step C [or cabinets

with [font overhang. Line up the notch and center line

on the monnting plate to the center line on the wall.

[] Dc]ai[e holding (he mounting plate with one hand,

draw circles on (he wall tat holes A, B, C and D (see

illustration aboveiactuM plate marked with an:ows).

Fore* holes mttst be used for mounting,

0 0 0 O 0 OI 0000O 000

Area E

I

NOTE: Holes C and D are inside area E. ff neilher

C nor D is in a stud, find a stud som_here in area E

and draw a fifth circle to Iine up M(I_ (he stud. It is

imporlant to tt_ at least one wood screw mortared

firmly in a stud to support the weight of the oven.

Set the mounting plate aside.

Drill holes on 1he circles. K there is a stud, drill a _a"

[]

HoleD

hole tbr wood screws. For holes that don't line up wifl_

a stud, drill a %" hale tbr toggle bolts.

NOTE: DO NOT MOUNT THE PLATE AT THIS TIME.

10

Page 11

Installation Instructions

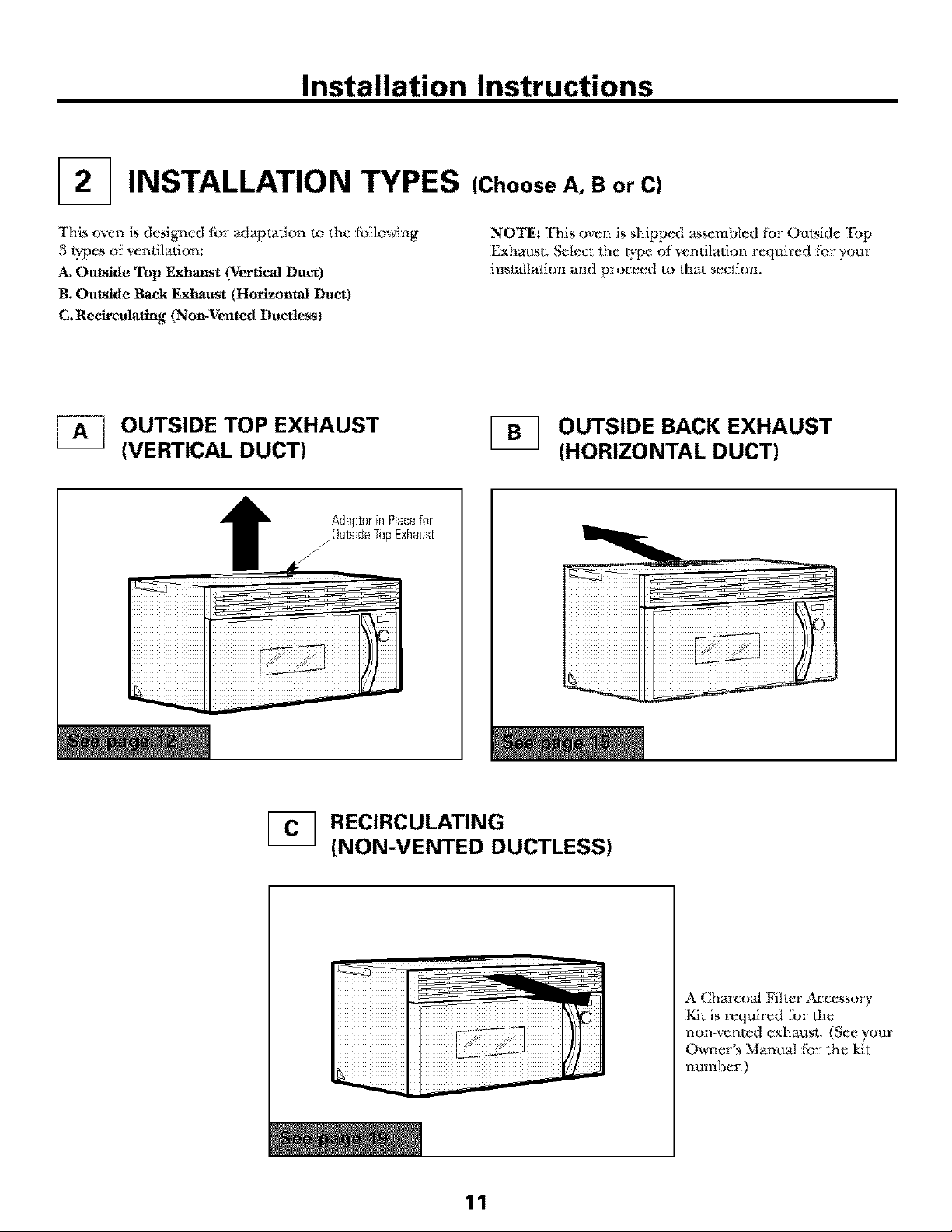

INSTALLATION TYPES (Choose A, B or C}

This oven is designed fbr adaptation to the fbllowing

3 t}pes of ventilation:

A_Outside Top ExhatJst (Vertical Duct)

B÷Outside Back Exhaust (Horizontal Duct)

C. Recirculatmg (Non-Vented Ductless)

OUTSIDE TOP EXHAUST

(VERTICAL DUCT}

NOTE: This oven is shipped assembled fbr Outside Top

Exhaust, Select 1he t)pe ofventiIadon required fbr your

installation and proceed to that section,

OUTSIDE BACK EXHAUST

(HORIZONTAL DUCT}

RECIRCULATING

(NON-VENTED DUCTLESS}

11

A Charco;d Filter i_cessory

Kit is required tor the

non-vented exhaust, (See your

(_er's ManuN fbr the kit

numbe_:)

Page 12

Installation Instructions

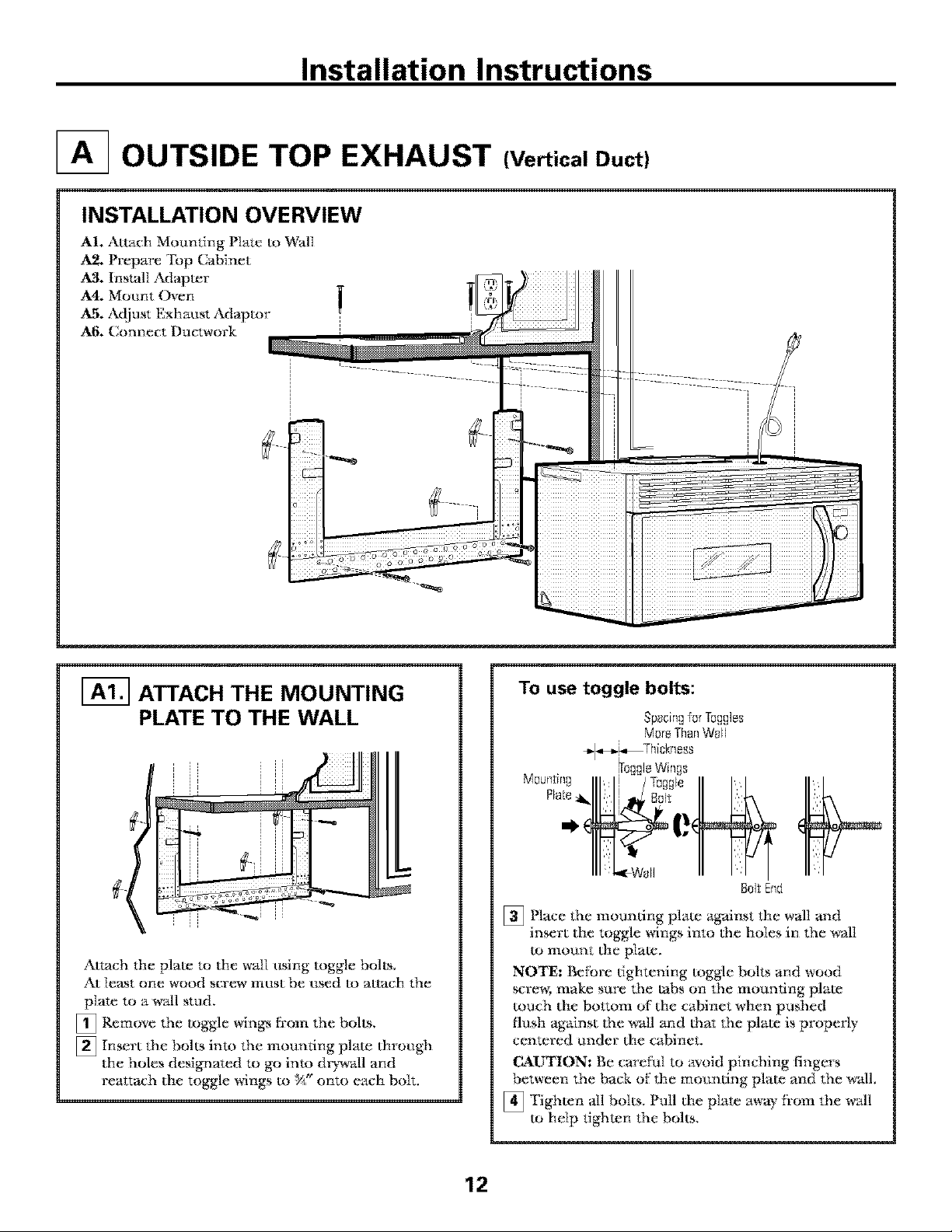

OUTSIDE TOP EXHAUST (Vertical Duct)

INSTALLATION OVERVIEW

AI÷ Attach Mounting Plate m Wal]

A2. Prepare "Fop Cabinet

A3. Install sL_apter

A4. Moant Oven

A_. Adjust Exhat_st Adaptor

A6. Connect Ductwork

m

ATTACH THE MOUNTING

PLATE TO THE WALL

Attach the plate to the wtdl rising toggle bolts,

At least one wood screw most be osed to attach the

p]ate to a wall stud,

[] Remove the toggle win_ ti'om the bolts.

[] Insert the bolts into the mounting plate through

the holes designated to go into dD_dl and

reattach tile toggle wings to %_"onto e_ch bolt.

To use toggle bolts:

Sp_cin__orIo,agles

MoreThanWoll

_l,,,_Thickn ess

Iro_leWin_s

Mou_tin_ IIl, lJ /To!NI'_ II II

BoltEnd

[] Place the mounting plate against the wall m_d

insert the toggle wings into the holes in the wal]

to mount the plate.

NOTE: Befbre tightening toggle bolts and wood

screw, make sure the tabs on the mounting plato

touch the bottom of the cabinet when pushed

flush against (he wMl and (hat the plato is properly

centered trader the cabinet,

CALrTION: Be carefuI to avoid pinching fingers

between the back of' the moondng plate and the wM1.

_ Tighten all bolts. Pull the p]ate away fi'om the wM1

to help tighten the bolts,

12

Page 13

Installation Instructions

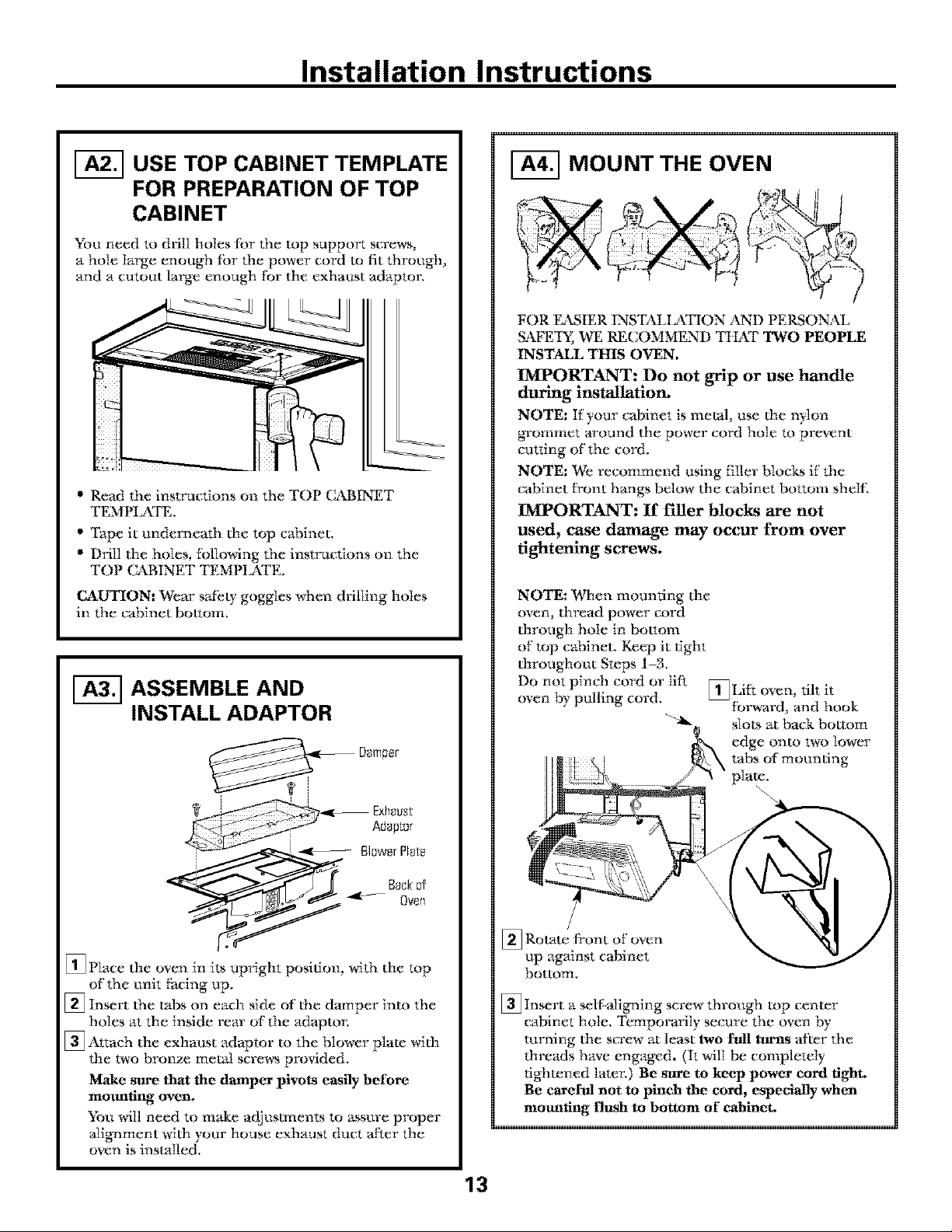

[-_ USE TOP CABINET TEMPLATE

FOR PREPARATION OF TOP

CABINET

You need to drill holes fbr the top support screws,

a hole large enough fbr 1he power cord to fit through,

and a cutout large enough fbr the exhaust adaptor:,

• Read the instructions on the TOP CABINET

TEMPIJVFF.

• Tape it underneath the top c_4binet.

• Drill the holes, fblloMng the instructions on the

TOP CABINET TEMPIATE.

CAUTION: Wear s_4"et}goggles When dfilEng holes

in the cabinet bottom.

[-_ ASSEMBLE AND

INSTALL ADAPTOR

MOUNT THE OVEN

FOR E_IER INSTALIz_-TION AND PERSONAL

SAFE'I'_ V_ RECOMMEND THAT TWO PEOPLE

INSTALL THIS OVEN.

IMPORTANT: Do not grip or use handle

during installation.

NOTE: If yore" cabinet is metal, use the n) ion

grommet around the power cord hole 1o prevent

cutting of Ihe cord,

NOTE: We recommend using filler blocks if the

cabinet front hangs below the cabinet bottom shelf

IMPORTANT: If filler blocks are not

used, case damage may occur from over

tightening scwews.

NOTE: When mounting the

oven, thread power cord

through hole in bottom

of top c_,/binet, Keep it tight

throughout Steps 1-_L

Do not pinch cord or lift

oven by p_flling cord,

_Liff tilt itoven,

forward, and hook

slo_ at back bottom

edge onto two lower

tabs of mounting

plam.

\

[_ Place the oven in its upright position, with the top

of the unit tacing up.

[] Insert 0_e tabs on each side of 0_e damper into the

holes at the inside *:ear:of the adaptor.

_ Attach the exhaust adaptor to the blower plate with

the two bronze metal screws provided.

Make salre that the damper pivots easily before

mounting oven.

_'_u wit1 need to make adjusmaents to asstu'e proper

_dignmen t with your house exhaust duct after the

oven is installed.

]Rotate front of

up against cabinet

bottom.

_ Insert a self-aligning screw Ihrough top center

cabinet hole, "I_mporarily secure the oven by

turning the screw at least two full mrus after the

thrmuls have engaged. {It MII be completely

tightened iatm;) Be sure to keep power cord tight.

Be careful not to pinch the cord, especially when

mounting flush to bottom of cabinet.

oven

13

Page 14

Installation Instructions

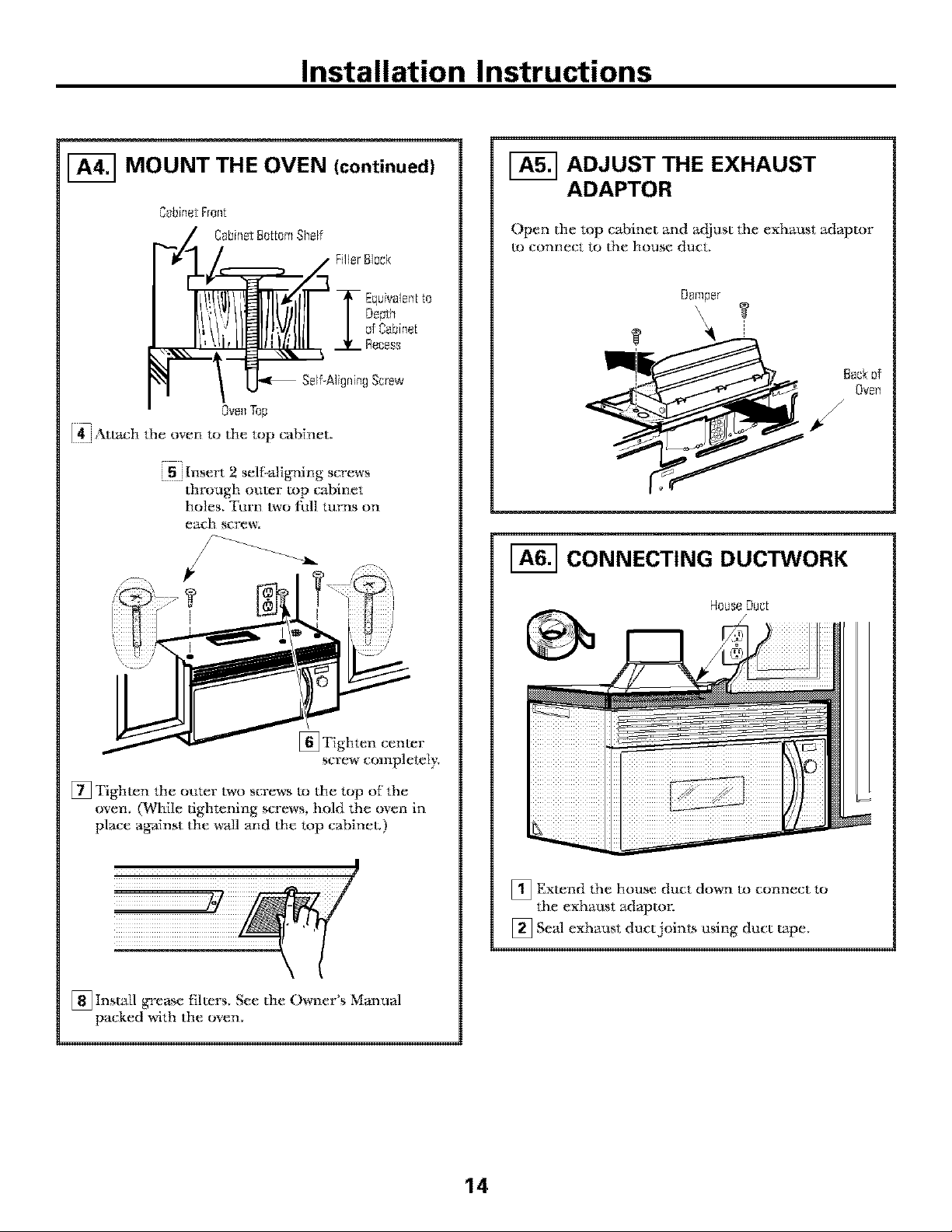

MOUNT THE OVEN (continued)

@bineJ:Front

:'Z C_;bineJ:BottomShelf

Iia_A FillerBlock

. T' i.alo,,"o

/K'F//BI!II /IIJI/0%,,0,

--Ove_l Top

I:_"-t'_:htI,eoventothetopca_>h_et,

r l

j 5 jInsert 2 sel_:Migning screws

through outer top cabinet

holes, Turn two rid] turns on

each screw;

[-_ ADJUST THE EXHAUST

ADAPTOR

()pen the topcM)inet and a_itiust the exhaust adaptor

to connect to I]_e house duct,

D_mper

Back_f

Ove_

#

[-_ CONNECTING DUCTWORK

House DUC[

[]Tighten cenmr

screw completely,

[] Tighmn the outm: two screws to the top of the

oven, (While tightening screws, hold the oven in

place against the wall and the top cabinet,)

[] Insudl grease tilmrs, See the Owner's Manual

packed with the oven,

_ Exmnd the house duct down to connect to

the exhaust adaptor;

[] Stud exhaust duct joints using duct tape,

14

Page 15

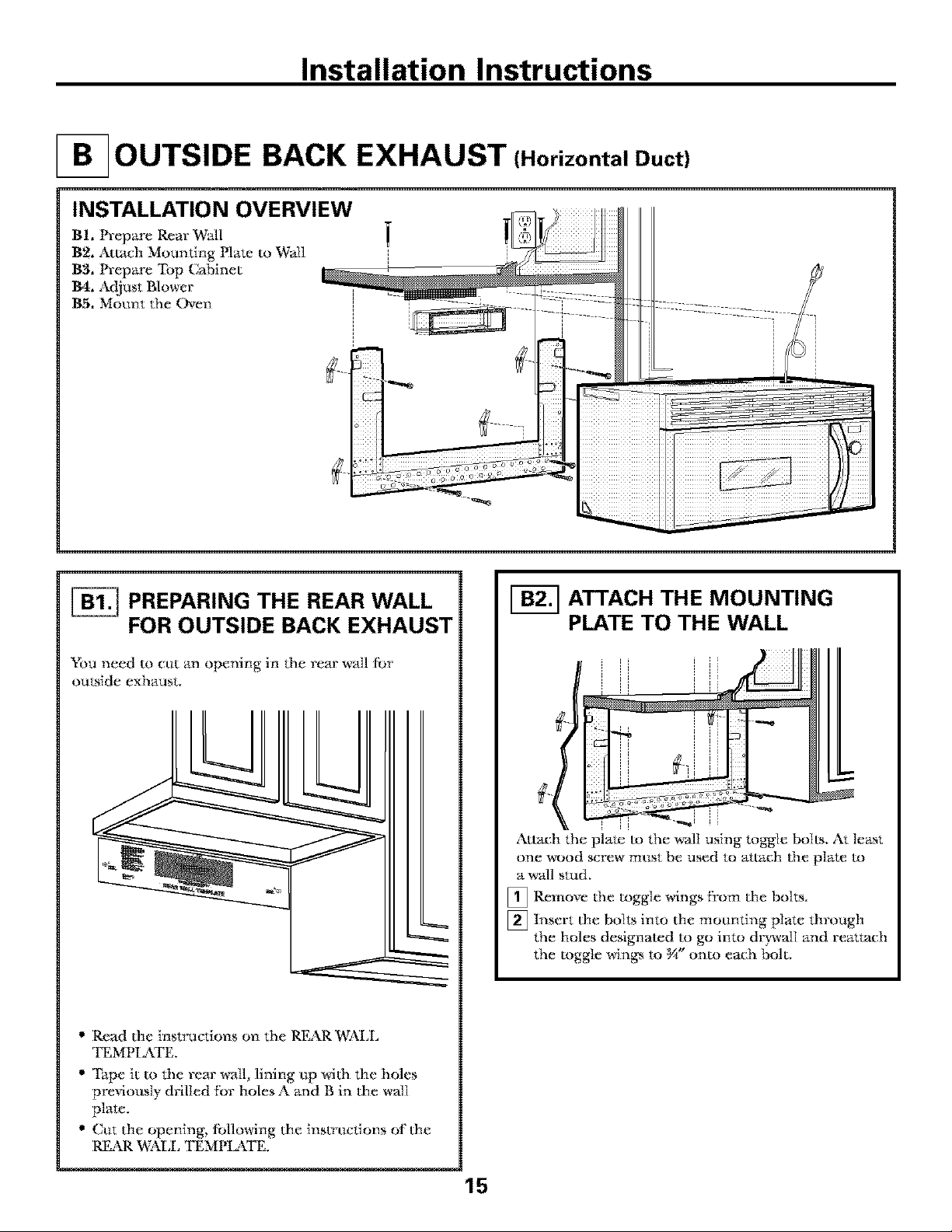

Installation Instructions

OUTSIDE BACK EXHAUST (Horizontal Duct)

INSTALLATION OVERVIEW

B1, Prepare Rear Wall

B2, Attach Mounting Hate m Wail

B3, Prepare "Fop Cabinet

B4, Adjust Blower

B5, Motmt the Oven

PREPARING THE REAR WALL

FOR OUTSIDE BACK EXHAUST

You need to cttt an opening in the rear wall [br

outside exhaust.

• Read the instructions on the REAR WALL

TEMPI_TE,

• Tape it m the rear" _all, lining ap wi(h the holes

previously drilled tot holesA and B in the wall

plate,

• Cut the opening, [bllowing the instrnctions of the

REAR W_\LL TEMPI_\TE,

ATTACH THE MOUNTING

PLATE TO THE WALL

Attach the plate m the wall using toggle bolts, At least

one wood screw mnst be used to attach (he plate to

a _all stud,

[] Remove the toggle wings from the bolts.

[] Insert the bolts into the mounting plate through

the holes designated m go into dlwwalI and reattaeh

the toggle win_ to g*'_ onto each bolt,

15

Page 16

Installation Instructions

To use toggle bolts:

Spacingfer Tu!NlesMore

_ ThanWaft Thickness

ITe_lsw,n_s

M_um:ing i 7 I"

• ', 0!Ne ,

'a e41.'l,.Zgo,II I:1-,

" I't

II U I

golt End

[] Place dm mounting plato _ainst the wall and

insert the toggle wings into the holes in the wall

to mount the plate,

NOTE: getbre tightening toggle bolts and wood

screw; make sure the tabs on the mounting pla_

touch (he bottom of"the cabinet when pushed flush

against the wall and that the plate is properly

centered trader the cabinet,

CAUTION: Be caref'uI to avoid pinching fingers

between the back of' the moun ling plate and dm wall,

[] Tighten all bolts, Pull the plate awW from the wall

to help tighten the bolts,

F-_ ADAPTING BLOWER FOR

OUTSIDE BACK EXHAUST

[] Remove the three scr_wcs that hold the blower

plate to (he oven. Slide blower plate from trader

its retaining flange. Remove and save (he screw

that holds Mower motor to oven.

glower Rate

_ (]areftfily tim blower unit. The wirespuI1

will extend Jar enough to allow you to adjust

the blower unit,

out

EndB

USE TOP CABINET TEMPLATE

FOR PREPARATION OF TOP

CABINET

You need to drill holes fbr the top support screws and

a hole lm:ge enough fbr the power cord to fit through,

%

%

• Read tim instructions on the TOP CABINET

"rI?]MPIz\TE.

• Tape it underneath (he mp cabinet.

• Drill the hoIes, fbllowing the instructions on the

TOP CABINET "rI?;MPI J\TE.

CAUTION: WEar safe g goggles when drilling holes

in the cabinet bottom,

_ Rotate blower unit counterclockwise 180%

Be[oreRototion After Rototion

Oven

[] (_ntly remove the wires fi:om the

Reroute the wires through grooves on other side

of"the blower unit,

Be[oreRerouting Aher Reroudng

grooves,

gockof

Oven

16

Page 17

Installation Instructions

[]Roll the blower trait 90 ° so that ffan blade

openings are f_acing out the back of' the oven,

8ockef 8ockef

[] Locam the two "knockout" plains, on the rear

oven pm_el, near the top of the oven.

Using tin snips, carefully cut the web area f}'om

the two holes side-by-side (I;hat sectlre 1he

knockouts to the oven). Ct_t all fbtlr webs on bolh

rear knockouts; Lhis will M]ow the yen tilation fian

_dr flow to exhat_st ot_t the rear of' Lhe oven.

CAUTION: Be sure to trim the sharp edges from

the openings af*er removing the knockout plates.

Oven Rear Panel

Snipall 4webs

_neachk_ockeul:

g_el o_dremove

t]_emetal knock_u[s

f_rre_ra_rflo_,',,_

[] Replace the blower plate in the same position

as befi)re with the screws.

BlowerPlo[eScrews

J

_ 8lower Plate

[] Insert the tabs on each side of' the dt_per into

the holes at the inside rear of (he adapto_;

Adep[or

_ Attach the exhat_st adaptor to Lhe rear of the

oven b> sliding it into the gtlides at the top

cenmr of' the back of the oven.

E×houstAdeptor

_.._ Damper

(hhlgesideup)

[] Place the blower unit back into the opening.

CAUTION: Do not pull or stretch the blower

unit wiring. Make sure the wires are not pinched.

NOTE: The blower unit exhaust openings should

match exhaust openings on rear of oven.

Slideexhaust

adaptorinto

guides0n

ovenfear

dF .

"V'Scre''s

Tabs Guides

Pt_sh in sec_rely until it is in the lower locking

tabs. Take care to t_ss_re the damper hinge is

installed so that it is at fhe mp and Lhat the

damper swings ffreeI};

_ Secure the exhaust adaptor m the oven wiLh the

two bronze meted screws provided.

17

Page 18

Installation Instructions

MOUNT THE OVEN

FOR FgkSIER INSTIM,I_\TION AND PERSONAL

St_'_TIS_ V_ RECOMMEND THAT TWO PEOPLE

INSTALL THIS OVEN.

IMPORTANT: Do not grip or use handle

during installation.

NOTE: Ifyonr cabinet is metal, use the nylon

grommet arotmd the power cord hole m prevent

ct*tdng of the cord.

NOTE: D¢_ recommend using t_ller Mocks if the

cabinet ti'ont han_ below the cabinet bottom shelf.

IMPORTANT: If filler blocks are not

used, case damage may occur from over

tightening screws.

0ve_Top

[_Attach the oven to the top cabinet.

[] Insert 2 self:_digning screws

through ot_ter top cabinet

holes, Tm'n two titll turns on

each screw;

iiiiiiiii!

NOTE: When moundng

film oven, thread power

cord through imle in

bottom of top c_4binet.

_ep it tight throughot_t

Steps I-3. Do not pinch

cord or lit_ oven by

p_flling cord.

[_ Lit:t oven, dlt it

fbrwm'd, m_d hook

slots at back bottom

edge onto two lower

tabs of' mounting plate.

[_ Rotate tYont of oven up

against ct-fbinet bottom.

[] Insert a self:tdigning screw through top center

c_/binet hole. Temporarily secure the oven b)

turning _he screw at least two fMI turns afl.er the

threads have engaged. (It will be completely

tightened late*:.) Be sure to keep power cord tight.

Be carefxd not to pinch the cord, especially when

mounting flush to bottom of cabinet.

[]Tighten cenmr

screw completely.

[] Tighmn the oater two screws to the top of the

oven. (While tightening screws, hold the oven

in place against the wall and the top cabinet.)

[] Insudl grease filmrs. See the Owner's Manual

packed with the oven.

18

Page 19

Installation Instructions

RECIRCULATING {Non-Vented Ductless)

INSTALLATION OVERVIEW

C1. At:ach Mounting Plate to Wall

C2. Prepare Top Cabinet

C3. Adjust Blower

CA. Mount the Oven

C5. Insudl Charcoal Filter

[_ ATTACH THE MOUNTING

PLATE TO THE WALL

Attach the plate m the wtdl using toggle bolts. At

least one wood screw must be used to attach the

plate to a wall stud.

[]Remove the toggle win_ Dora the bolts.

[nsert the bolts into the nlountin ' la_ throu 'h

[] gP g

the holes designated to go into d*)wldl and

reattach the toggle wings m _A_'onto each bolt.

To use toggle bolts:

SpacflLaforTuggles

MoreThanW_fll

4_Thickness

%ggleWin£s

Mounting i -/Toggl'e

[] Place 1he mounting plate against the wall m_d

insert the toggle wings into (he holes in the wall

to mount the plate.

NOTE: Betbre tightening toggle bolls and wood

screw, make sure 1he tabs on the mounting plato

much the bottom of the cabinet when pushed flush

agtdnst the wall and that the plate is properly

centered under the cabinet.

CAL_TION: Be carefuI to avoid pinching fingers

between the back of' the mortaring plate and the wtdL

[] Tighten all bolts. Pull the plate away ti:om (he w_dl

to help tighten the boils.

USE TOP CABINET TEMPLATE

FOR PREPARATION OF TOP

CABINET

_,_u need to drill holes [br the top support screws and

a hole large enough fbr the power cord to fit (hrough.

_=========_

• Read the instructions on the TOP CABINET

TEMPLATE.

• Tape it underneath the mp cabinet.

• Drill ttm holes, tbllo_ng the instructions on the

TOP CABINET "rEMPIJ\TE.

m t,qr_Wall , P i

BollEnd

CAIYrION: Wear safer) goggles when drilling holes

in the c_-ff_inetbottom.

19

Page 20

Installation Instructions

ADAPTING BLOWER

FOR RECIRCULATION

NOTE: The exhaust t_laptor with dmnper is not

needed tor recircularSng models, You may want to

save (hem _br possible t'umre use,

[]Remove and save screws that hold blower plum to

(}le oven,

_ _ 8lowerPlateScrews

II

I i .....

2 j Shde (he blower plum from under its relammg

flange and I ti it off; Remove and save screw fihat

holds the blower motor to oven,

_1 Carefullv ptfll out the blower unit. The wires

' will exm]_d tar enough m allow you to a([iust the

blower unit.

_i Roll the blower unit 90 ° so that tan bl;_le openin_

Jare fiming toward the &ont of the oven.

_j glowerRate

I : _ Screw

R011

NOTE: Make sure wires remain toured in the

grooves of the motor fi'ame,

2O

Page 21

Installation Instructions

ADAPTING BLOWER FOR

RECIRCULATION (continued)

[] Place the blower trait back into tim opening.

CAUTION: Do not pull or stretch the blower unit

wiring. Make sure tile wirc_ are not pinched,

[] Secure blower trait to oven with the screw

removed in Step 2, Insert the screw in bottom

right screw hole on the back of the oven.

[] Replace b]ower p]ate wi(h the screws removed in

Step I.

_'_ BlowerPIsteScrews

NOTE: When mounting

the oven, thread power

cord throt*gh hole in

boltom of mp cabinet,

Keep it tight throt_ghot_t

Steps l-& Do not pinch

cord or lift oven b_

pulling cord. _ I

[_ Rotate fl:ont of oven

up against cabinet

bottom,

_Insert a self-aligning screw throt_gh top center

cabinet hoIe, Temporarily secm'e the oven by

turning the screw at least two f_ tarns after the

threads have engaged÷ (It will be compIetely

tightened late*;) Be sure to keep power cord fight.

Be careful not to pinch the cord, especially when

mounting lllJsh to bottom or cabinet.

[] Lig oven, tilt it

forward, and hook

slots at bt_k bottom

edge onto two lower

tabs of mounting plate,

\

\

MOUNT THE OVEN

FOR E_[ER INSTALIzkTION AND PERSONAL

SAFE°In*, WE RECOMMEND THAT TWO PEOPLE

INSTALL THIS OVEN.

IMPORTANT: Do not grip or use handle

during installation.

NOTE: If your cabinet is meLtd, use the nylon

grommet around the power cord hole _.oprevent

ctttting of the cord.

NOTE: We recommend t_sing fleer blocks if 0_e

cabinet front hangs beIow the cabinet bottom she]£

IMPORTANT: If filler blocks are not used,

case damage may occur from over tightening

screws,

C_;binel:Front

?A C_;binel:Be[IotaShelf

r---¢1/ . FillerBk_ck

r,-,v

I[,!,.,'_/]]--1Tao,_,e..: l:oDep.:,,

/ /0rc_,_*.0.:Rece.

,. !

Ove_Top

_Attach the oven to the top cabineL

21

Page 22

Installation Instructions

MOUNT THE OVEN

(continued)

[] Insert 2 self-aligning screws

throngh outer" top cabinet

holes. Turn two full tm'ns on

each screw,

[] Tighmn center

screw complemly.

[] Tighten (he outer two screws to the top of the

oven. (While dghmning screws, hold the oven

in place agMnst (he wNl and (he top cabinet.)

[-_ INSTALLING THE

CHARCOAL FILTER

[] Remove 2 screws on top of grille using a

Phillips screwdriver;

[] Open the door;

[] Remove the grille.

[_ Insert the filter into the

maneuvering it behind the plastic grille tmfil it its

squarely into place. It will rest at an angle behind

the plastic grille on two side support tabs and in

fi'ont of the right rear tab. When properly

installed, the wire mesh of the filter should be

vMbIe fi:om the fi'ont.

shown_oven as

[] Install grease filters. See the Owner's Man ual

packed with the oven.

[] Replace the grille and the 2 screws,

[6_ Close the door,

h_sertmesh-siOedow_

22

Page 23

Installation Instructions

BEFORE YOU

M_fke s{_re the oven has been inst;dled

;_:cord_ng to b_structions,

USE YOUR OVEN

Read the Owner's Manual,

KEEP [NSTALI_\TI()N INSTRE CTI()NS

FOR THE LOCAI, INSPECTOR S USE,

ial fl'om the oven,

[] Replace house gtse or turn bretfker back on,

_] Plug power cord into a dedicated 15 to 20 amp

electrical outlet,

f

Insure _r0[_er

_rt_u_dexis[s/ @_ef_re use

23

Page 24

24

Page 25

Instrucciones

ornopara,colocar

de instalacibn

enczma la estufa

JVM1490,SCA1000y SCA1001

j iPreguntas? Uame 800-GE-CARES(800-432-2737)o ,_ite,_,_e_trap':_i,-,_enJ',_rede,,: j

www.GEAppliances.com

ANTES DE EMPEZAR

Lea estas instrucciones completa y cuidadosameme.

IMPORTANTE

• _ (_Ll_tlTde esLas

instmcciones para el t_so dei inspector local,

IMPORTANTE - Comp,._on

todos ios c6digos _ ordenanzas gubernamentales,

• Nota para el instalador _ Asegfirese de dcjar

e_ta_ J_[rtl_:cione_ con e] co,_lmJdor,

• Nota para el consumidor _ Gtiarde estas

instr,IccJones para fimira ret_:rencia.

• Nivel de destrezas - La instah_cidn de este apm'ato

veqtfiere dc dcstrezas b;_sicas de mecSnica y electficidad.

• La insudaci6n apropiada es responsabilidad

del instaladm;

• La tal]a del producto debido a una instalaci6n

inapropiada no estfi cubierta pot In g_avantfa.

25

LEA CUlDADOSAMENTE.

GUARDE ESTAS INSTRUCCIONES.

Page 26

Instrucciones de instalacibn

B

CONTENIDO

Informacibn general

lnstrucciones de seguridad importantes ................ 27

Requisitos el6ctricos .............................................. 27

Campana de escape .......................................... 28, 29

Dafios - Envio / lnstalaci6n .................................. 30

Partes inchfidas ...................................................... 30

Herramientas que necesitarfi .................................. 31

Espacio de montaje ................................................ 31

Guia de instalaci6n paso por paso

C6mo colocar el plato de montaje .................... 32-34

C6mo remover d plato de montaje ............ 32

C6mo encontrar madera s6lida

en ]a pared .................................................. 32

C6mo determinar [a [ocalizaci6n

de las plac_ de la pared ............................ 33

] Recircnlaci6n ........................................ 45-46

C6mo adherh eI plato de

monU_e a ]a pared .............................. 43

C6mo prepm_ar el gabinete snperior..43

C6mo adaptar el cMefacmr

pm'a ]a recircOaci6n ...................... 44, 45

C6mo montar el horno .................. 45_ 46

C6mo insudar el filtro de carbonilla..4fi

Antes de comenzar a usar su homo ...................... 47

C6mo alinear [a plata de la pared .............. 34

Tipos de instalaci6n .......................................... 35-46

[]Escape snperior ........................

C6mo adherir ia placa de

montaje a la pared .............................. 36

Preparacidn de] gabinete superior ...... 37

C6mo inspeccionar si Ia operacidn

de] regulador de Iiro es apropiada ...... 37

C6mo montar d homo .................. 37, 38

C6mo ajustar el adaptador de escape .38

C6mo conectar ]a red de conductos.÷÷38

_ Escape posterior externo ...................... 39-42

(176mo preparar ]a pared poslcrior

para el escape posterior exmfior ........ 39

C6mo adherir el plato de

montaje a la pared ........................ 39_ 40

(i_6tno preparar el gabinete superior..A0

ex_rior 36-38

C6mo adaptar el cMePacmr para

el escape exterior posterior ........... A0_ 41

C6mo montar d homo ........................ 42

26

Page 27

Instrucciones de instalacibn

INSTRUCCIONES DE SEGURIDAD IMPORTANTES

Estc producto requiere un u>maco_¢ientc ddctrico

de u'es patas conectado a tierra. E1 _nsttdador debe

]le_r a ct(bo tma _nspe_ cidn de confinu_dad a fiesta

en la c;_a eldctvica antes de comenzar la insl_flad6n

para asegurar qt_e la caja tom_orrienm esl_i conectada

a derra de manera apropiada, N no lo esul, o si el

tomacorTientc no cumple con log requisitos

eldctricos _ndic_los (bajo ]a seccidn REQL'ISYFOS

ELECTRICOS), se deber_i recurcir a tm tdcnico

cMificado para corregir cuNqu_er defidencia,

PREC&UCION:

Para segLwidad personal

remuc_a el fusible de

la casa o abra el intemq)tor

de circxfito ant_ de

comenzar la imtalad6n

para c_itar d_cargas

el_ctricas se_ras o l'al_.

PRECAUCION: En pos de la segaridad personal,

la superficle de montaje debe ser capaz de soportar

la cargm dcl gabinetc, adem_ de1 peso adicional

(de 63 a 85 libras) de _te producto, mils las cargas

adicionales del homo de lmsta 50 Flbras o un p_ total

entre 113 y 135 libras,

PRECAUCION: En pos de la segnridad personal,

este producto no puede set instMado en sistemas de

gabinet¢_ tales como los llamados "islas" o "l_nim'_-flas",

Este debe set montado tanto a un gabinete superior

como a tma pared.

NOTA: Para tma instalaciOn n_s fMl y en pos de la

segt_idad personal, se reconfienda que (los personas

instalen este produc*o÷

IMPORTANTE: POR FAVOR, LEA

CUIDADOSAMENTE. EN POS DE LA SEGURIDAD

PERSONAL, ESTE APARATO DEBE SER

CONECTADO A TIERRA APROPIADAMENTE PARA

EVITAR DESC&RGAS SEVERAS 0 FATALES.

E1 cable el_c_co de este

aparato esN eqnipado con

tm cnclmfc de tres paras

(c_n conexidn a ti_),

lo carol reqlfiere que el

mismo enc_je con un

tomacorriente para tres

paros (con conexiOn a tierra

de pared para min'unizar

la posibilidad de

descm'gms clfic_s.

Deberft lmcer que un t_cnico calificado inspeccione el

tomacorriente de pared y el circttito para _gtma'se de

que el tomacorriente _t6 conectado a tierra de manera

apropiada.

Domle usted encuemre tm tomacomente est_mlm- de

dos paras, ¢_ m W hnportante quc lmga que d mismo se

cambie pcsr tmo de trc_ paras apropiadamcnle conec_ado

a fierl_ imtalado pot" tm elec_ricista catificado.

RAJO NINGUNA CIRCUNSTANCIA NO CORTE,

DEFORME, O REMUE$_ NINGUNA DE LAS PATAS

DElL C&BLE EI_CTRICO÷ NO IX) USE CON UNA

EXTENSION ELI_CTRICA.

REQUISITOS

ELECTRICOS

La dasiflcaci6n de} producto es de 120 ratiosCA

(AC), 60 herlz, 15 ampefios, y 1,70 kilovafios, Esm

producm debe estar conectado a un circuim de

stmfin_stro de} vo}taie y ti'ectlenda aprop_ados, E1

tamafio de} _/lmnbre debe contbrmarse a }os requ_shos

del NafionM Electric Code o M cdd_go loom en egccto

para este fnd_ce de kilowafios, El cable eldctrico de

Mimentacidn y el _nwrruptor deberan lle_r._e a m_

tomacorfiente finico conecmdo a fierra de 15 a

20 amperios, La ct&ia del tomt_:ovcienm deberfi estar

locMizada en el gabinem encima del homo, La

c_a de} tomacovcienm debe ser instalada por tm

elecu'_cista cM_ficado y debe confbr_arse _d NadonM

Electrical Code o aI cdd_go ]oc_d en egecto,

27

Page 28

Instrucciones de instalacibn

CAMPANA DE ESCAPE

NOTA: Lea las siguientes dos p_inas solamc_nte si planea venfilar el escape hacia el exterior.

Si por el contrario planea rccircular el sire de vuelta hacia el sal6n_ con_fie en la pfigina 30.

ESCAPE SUPERIOR EXTERNO (EJEMPLO SOLAMENTE)

La _iguientc u4bla describe _m ejemplo de una po_ible

instt_ilacidn de red de conductos.

LONGITUD NUMERO LONGITUD

PARTES DEL CONDUCTO EQUlVALENTE x USADO = EQUlVALENTE

_ Tape del techo 24 pies x (1} = 24 pies

Cenducte recto de 12 pies 12 pies x (1} = 12 pies

La lengitud de las partes de los cenductes equivalentes est_ basedean pruebas reales y reflejan los

requisites pare bgrar unabuena ventilacidn con cualquier campana de escapeLongitud total 41

IMPORTANTE• SI se t_sa un adapmdor de trm_sici(m de recffmguto a redondo, ias es_ ulnas del tbrldo

deI ye_'ulador de tiros deberfin cortm:se para qua encajen, tlsando ]as tijeras de corm, para permidr e]

mo_arnmnto libra del regu]ador de tiros.

ESCAPE POSTERIOR EXTERNO (EJEMPLO SOLAMENTE)

La sigtfiemc tabla desclibe an _emplo de nna posiMe

instaltcci6n de red de conducms.

LONGITUD NOMERO LONGITUD

PARTES DEL CONDUCTO EQUlVALENTE x USADO = EQUlVALENTE

Conducto recto de 3 pies 3 pies x tl} 3 pies

trectangular de 3W" × 10"}

pies

Codede gO* 10 pies x t2} 20 pies

ka bngitud de los partes de los conductos equivalentes est_ basada en pruebas reales y reflejen los

requisites pare Iograr una buena ventilecidn con cualquier carnpana de escapeLongitud

NOTA: Pant el e_ _tpe pc_reriol; _e debe tener cuidado _d al_near el escape entre los e_pac_ de los pc_ms de vi_t de 1_1pared

o la pared deberfa _er preparada en el momenta de _u con_rruccidn deiando _ufidentt _,espacio entre 1o_ postt_,_ de riga de la

pared para acomodar el escape.

total 63

pies

28

Page 29

Instrucciones de instalacibn

NOT.&: Si osled neceska instaIar conduc_.os, tonga

pendlente quc la longitud tomI del c*)nductu redangular

de 3¼"x I0" o e1 condt*c:to redondo de W de di_metro

nO debe sotn*cpasar 140 pies equivalcntes,

La vendlaci6n extema requiere un CON_UCTO DE

CAMI)ANA DE ES(_M)E. Lea Io siguJente cuidadosamenm.

NOTA: Es importm_m qtle Ia x_cnd]aci6n _a insud_la

usa_do ]art:_Vam_s direcm y c_n la menor canf*&adde codus

pmible. Esto asegum la _cntilaci6n del e_'ape ywuda a

prevenir bloqtmos. Tambi_n, cexvi6rese de qam d _gtlladoi"

de tim pende libremente ynada bloquea los conductos.

Conexiones de escape:

La campana de escape ha sido di_fia&a pz_a encajar con

un c*mducto rectangtflar de _¼" x i0" esl_ndar.

Si un c*mducm redondo es necesm4-o, s_ debt usa*"un

adaptador de wansici6n de rectangaJar a redondo.

No use on conducto menor de 6" de di_imetro.

LONGITUD

PARTES DE CONDUCTO

Adaptadorde transiciOnde

rect_nguloa redondo*

EQUIVALENTE x

5 pies x

Longitud mfixima del conducto:

Pare logrm" un movimiento satisfactorio de1 aire, ia

longimd total del conducto rectangtflar de B_A_'x i0"

o eI conducm redondo de W de di_metro no dcbe

sobrepasar 140 pies equivalentes.

Los codos, transiciones, paredes y tapas

de techo, etc., presentan resistencia adicional al

flt_jo de aire y son equivalentes a una secci6n de

conducm recto el ctudes m_s largo que su tamafio tTdco

real Cuando c_dcule Ia Iongimd toud del conducm,

agregue 1as Iongitudes eqtfivalentes de todas 1as

transiciones y adapta_:lores, mas la Iongitud de mdas

1_ secciones de conducto rectus. La table mg_sadelante

muestra c6mo puede calcular la longimd aproximada

de la red de conducms usando pies aproximados de

longitudes equivdlenms de algunos conductos tfpicos.

NUMERO

USADO

( )

= EQUIVALENTE

LONGITUD

pies

(:

J

Tapade pared

Codode90'>

Codode45'>

Codode90'>

Codode45'>

Tapade techo

m

Conductorectode6_"redondo

o rectangularde 3W' x 10"

40 pies x

10 pies x

5 pies x

25 pies

5 pies

24 pies

1 pies

x ( )

x ( )

x ( )

x ( )

( )

( )

( )

pies

pies

pies

pies

pies

pies

pies

Total red de conductos =

recv;_Ntdo a rcdondo, 1ascsql_ina_ del tb_Ido dd rf%ulador cn pn_cl_s reales y r_tlqjan los requisltos pare Iog_ar _ma buena

d_,! eros tt(_i _r col-_y, bl_ p_ t_[l__ (_rlc_i_ I/_ldo |a,s _z! (ilal_erl cori (:_q/l[_r ca_ipa_ia dc _,_cap_%

* IMYOR'I}kR't*: 81 _c ttsu m adapmdor d_: wansil:iezi d< La longiVad de la.__t:s de condm:ros cquiwtk m*'s ¢-st;i{_l_a

_.ic_ de co_t_, p_ pe_ni_r d mo_micn_ librc dd

rcg_d_or de drop,

pies

29

Page 30

Instrucciones de instalacibn

DAI_iOS - ENV|O /

INSTALACION

" Si la _midad se dafia durante el cnvio_ devuciva la

mfidt_l td tdmacdn donde la adqtfiri6 para s(l

repavaci6n o rcemplaxo.

" Si el cliente *Jaffa la uffldad, ]a rcparaddn o c]

reemplaxo es responsab_lidad del c]Jente.

" Si el instalador dafia la uffldad (si no es el cl_enm),

la repavaci6n o reemplaxo se debe hater par

media de un arreglo entre el cl_enm y el instMador;

PARTES INCLUIDAS

PAQUETE DE ELEMENTOS

PARTE CANTIDAD

TorNI!os de madere 2

(_'_"x 2'1

/ a rornil!os besculantas 4

_ (ytuercas de mariposa)

/

(_'t"x Y')

rornil!os de m_quina 3

autoalineables

(_'_"-28x 3W')

PARTES INCLUIDAS

PARTES ADICIONALES

PART

Plantillapara

etgabineta

supenor

Plantillapare

M_

®

le pared

_osterior

Instruccienes

deinstaleeidn

Filtrosde

grese

empecades

par separado

Arandele eislante de

hilton(pare gabinetas

rnet_licos)

Adaptador del escape 1

Regulador de tiro 1

rornil!os pare metal 1 negro

(7," x _'Z') 2 de bronce

Abrezadere del cable 1

el_ctrico (pl_stice}

Usmd encontrara los clementos de insudacidn en

un paquemjtmm con la tmi&_l. Inspeccionc para

cerciovarse de quc fienc mdas las partes.

NOTA: Se incluyen Mgtmas parma adicionMes.

2

30

Page 31

Instrucciones de instalacibn

HERRAMIENTAS QUE NECESITARA

Destornflladoresdeestrella

#Iy#2

Tijeras para cortar laJ:6_

de Lifo,si es i_ecesorio}

plom:illa,siesilel:esario}

L_lpiz

T_flodroel_cLrico co_ brocos de

Guantes Detecterde

Sierra(desableaguieroo de posiesderig 1 e ulllrlartfllo{opcionol)

oiodecerrador;}

ecto y Ci_[a m_Lrica

Nivel

Escuadrode

carpintero

(epcio_fl)

Bequesderelle_me

pedazosdemodero,si so_

necesoriospararellenorel

enIofl_stalasidnde

£abi_etes_pey_des)

Cintadeco_ductoso

cim:oodhesivapro[ectora

ESPACIO DE MONTAJE

desalpicaduras

66" 0Irl_s

desdeel

pisohasto

la parle

superiorde]

hgrf_o

pesterior

NOTAS:

" El espacio entre los g_/binems debe set de B0"

de ancho y debe estar ]ibre de obstrucciones,

• Si el espacio entre los gabinetes es mwor de

30_ tm "Fil]er Panel Kit" podrfa ser necesario

para rellenar 1as bre_:has entre eI homo y los

g;{binems. Su Manu_(l del Propietario condene

el ndmero de k_t pava su modeIo.

• Este honm es para set instal;_lo por encima de

estuarieshasta _6" de ancho,

• Si usted se dispone a vend]ar su horno hacia el

exteHo*; ver Ia Secci6n de Campana de Escape

para la preparaci6n del cond_mto de escape,

" Cuando se instale d homo debajo de gabinetes

de rondos lisos y planos, tenga cuidado de seguir

cuidadosamente las instrucdones en la planfilla

del gabinete superior para el espacio de

tolerancia del cable el6ctrico,

31

i

Page 32

Instrucciones de instalacibn

C()MO COLOCAR EL PLATO DE MONTAJE

[] COMO REMOVER EL HORNO

DEL EMBALAJE / COMO

REMOVER EL PLATO

DE MONTAJE

[] gemtmva la caja qtm contiene las instrucciones de

instalaci6n, los fiitros, el adaptador de escape,

el regulaxlor de tiro y Ia pequefia bolsa con los

elementos de instalaci6n. No remueva Ia espuma

de poIiestireno que protege el fPente del horno.

[] Pliegue hacia arras 1as _ilas de Ia caja. Ltmgo,

cuidadosmnente ruede el horno hasta que quede

apoyado sobre Ia parm st_perior. E1 homo deber5

descansar sobre la espuma de poliesth:eno.

[] Tire de la caja hacia m:riba y retfrela de] homo.

[] E1 plam de montaje est_ pegado a la parm posmrior

de1 homo. Remoeva los dos tomillos que Io

sosfienen pegado _/l homo. E1plato serfi nsado

como Ia plantilla de Ia pared posmrior y para

montar el horno a la pm:ed.

_Pare el homo, Ren_tleva y descartc de manera

apropiada las bolsas plf_sticas y el poliestireno.

[-_ COMO ENCONTRAR LOS

POSTES DE VIGA EN LA PARED

[] Enctmmre los postes, usando tmo de los

mdtodos siguientes:

*S

A_ U.,e un detector de postes - un dispositivo

magn6tico que ]ocaliza clavos.

O

B. Use un marti]lo para golpear ]igeramenm a

travi3s de la super|_cie de montaie hasla

encomrar un sonido s61ido. Esto indicated que

hW tm posm de riga en ese ]ugm:

[]

Desptl6s de loc;dizar el posm o los postes de riga,

encuentre el cemro mediante el amilisis de la pared

usando tm davo pequefio para darse cuenta de

d6nde estfln los hordes del posm. Luego co]oque

una marca en el centro de los hordes. El centro de

cm/lquier poste adyacenm deber_ set" entre I_-7'6

24" desde esta marca.

[] Trace una ]_nea hacia abajo indicando el centro

del poste.

EL HORNO DEBE CONECTARSE POR LO MENOS

A UN POSTE DE L_ PARED.

[] Abra la puer_a deI homo y remueva el paquete de

esptmm de poliestireno de] interior; Remueva ]a

cinta adhesiva qne cubre el m:o giratorio.

32

Page 33

Instrucciones de instalacibn

[] C. C()MO DETERMINAR LA LOCALIZACI()N DEL PLATO DE MONTAJE

DEBAJO DE SU GABINETE

Posici6n del plato - debajo de gabinetes de

fondo piano

Posici6n del plato - debajo de gabinetes de

fondo apoyado en un marco

\

L

ill

3Wh_;stalaestufa

Posici6n del plato - debajo de gabinetes de

fondo apoyado con frente saliente Stts gabinetes podrfan tener marcos de decorad6n

que interI_eran con la instalaci6n del homo,

Remtteva los marcos decorativos para instalar el homo

apropiadamente y para hater que quede nivelado,

EL HORNO DEBE QLFEDARNIVEI.&I)O,

Use tm nivel para cerciorm:se de que el tbndo de]

gabinete est_ nivelado,

Si los g-abinetes tienen un s;diente &ont_il solmnente,

sin m:_co posterior o later_d, insttde e] pIato de

montaje a Ia misma disumcia de la prof'undidad

de] saliente, Esm mantendr_ e] homo nive]ado,

[] Mida Ia proftmdidad intema del tYente del stdiente,

[] Trace una I_nea horizontal en la pared posterior a

una distancia debaio del fbndo de] gabinete igmd

a la profundidad interna del fi'ente _liente,

_ Parer esm tipo de instalaci6n con sidienm t-i:ontal

so]amente, tdinee las or_iIlas de mont_{e con la I_nea

horizont_d, sin tocar el rondo del gabinete como se

desa'vibi6 en e] Pt_s_ D,

33

Page 34

Instrucciones de instalacibn

F- COMO ALINEAR EL PLATO DE MONTAJE SOBRE LA PARED

'L UU

w

O Zxx i

i

iVERTEAL ENLA

PAREDA PARTIR

DELCENTRODEL

i GABINETESUPERIOR

_ i TRACEUNA L[N_

AguieroC _ o o o o b o o o o o o o o o o

PRECAUCION: Use ,

gtt_mtes de protecci6n I Aguiem D

para cvi_a.r co_adums AreaE

en s_ dedos con los

[] Trace una lfneaverdcaI en ]a pared en e] cemro de]

esptu:io de 30" de ancho,

[] Use el plato de monmje como la plantilla para Ia pared

posteHm: Coloque el plato de monmje en la pared_

cerdor_ndose de que las orejiIlas se enctmntran

tocando el rondo del gabinete o la Ymea maxc_da ea

el Paso C para los gabinetes con saliemes fa_amles.

Alinee la muesca y llnea del centro en el plato de

momaje con la Ymea de centro en la pa_ed.

[] Mientras sosdene el plato de momaje con tma mano_

Wace clrcttlos en Ia paved en los agujeros A, B, C y D

(ver la ilustraci6n anmfior / Ia plata real es_ marctula

con flechas), Deben _e euatro agujeros para el

In O]31_tj e.

0 O 0 0 0 01 0 0 0 0 0

i

i

NOT,&," Los agujeros C y D van en el interior del _rea

E, Si ni el C ni el D esr_n en tin poste de riga,

encuentre tm poste en algfin otto lugar en el _rea E y

marque un qtfinto cfrculo para _ilinearse con el poste,

Es imporvante t_sar pot" lo menos un tornillo de madera

mom_ulo Fwmemente en un poste para apo}ar el pe_

del homo,

Aparte el plato de montaje.

[] Pertbre aguieros en los cfrculos. Si ha> tm poste de

dga, pertbre un agt_jero de 3/16" para ios tornillos de

m;ulera. Para los agttjeros que no quedaron _flineados

con el poste de rig% perfbre un agK]ero de 5/8 _'para

los tornillos b_:tfi_mtes.

NOTA: TODAVf.A NO MONTE EL PLATO.

34

Page 35

Instrucciones de instalacibn

_ TIPOS DE INSTALACION (Escoja A, B o C)

Este horno est_ disefiado para adaptarse a los siguientcs

tres tipos de vendlaci6n:

A. Escape superior exterior (Condu_to vertical)

B+Escape posterior exterior (Condncto horizontal)

C+Recirculaci6n (Sin conducto de ventilaci6n)

[_] ESCAPE SUPERIOR EXTERIOR

(CONDUCTO VERTICAL)

Elmdmpl.ado_esl:Oensu

!

NOTA_ Este honm es enviado ya ensamblado para un

escape s_perior ex_rior, Selecdone el fipo de ventilaci6n

requerido pawa sa instglaci6n y proceda a rid secci6n,

ESCAPE POSTERIOR EXTERIOR

(CONDUCTO HORIZONTAL)

C. RECIRCULACION (SIN

CONDUCTO DE VENTILACION)

35

Un I_t de accesorios de filtro

de carbonilla es necesafio

pava el sistclna sin yen tiIaci6n,

(Consulte st_ Manual de1

Propietario para obmner

el ntimem del kit,)

Page 36

Instrucciones de instalacion

ESCAPE SUPERIOR EXTERIOR (Conducto vertical)

PERSPECTIVA GENERAL DE

LA INSTALAClON

AI. Como adherir el plato de

montaje a la pared

A2. Prepare el gabinete superior

A3. lnstale el adaptador

A4. Monte el horno

AS. Ajuste el adaptador

de escape

A6. Conecte el conducto

[-_ COMO ADHERIR LA PLACA

DE MONTAJE A LA PARED

Pegue el plato a la pared usando los tornillos

basculantes. Por 1o menos un tornillo de madera debe

set usado para pegar el plato al poste de la pared.

Remueva las mariposas del basculante de los

tornillos.

[] Inserte los tornillos en el plato de montaje a tray,s

de los agujeros disefiados para set insertados en la

pared de mamposterfa seca y pegue otra vez las

mariposas de ¾" en cada tornillo.

Para usar los tornillos basculantes:

Espaciadoresparalos

bascuiantesmayores

_-_.J_que elanchodelapared

I

Platode i / Tomillode

montaje_llMiJd, mafiposaII 14_

Alasdemanposa

-p.

lip ,_Pared II I I

[] Coloque el plato de montaje contra la pared e

inserte las alas de mariposa en los agujeros de la

pared para montar el plato.

NOTA: Antes de apremr los tornillos basculantes y los

tornillos de madera, cercidrese de que las orejillas en el

plato de montaje toquen el rondo del gabinete cuando

son empujadas comra la pared y de que el plato est_

centrado apropiadamente debajo del gabinete.

PRECIAUCI6N: Tenga cuidado de evimr pellizcar sus

dedos entre la parte posterior del plato de montaje y

la pared.

[] Apriete todos los tornillos. Tire del plato en

direcci6n opuesta a la pared para ayudar a apretar

los tornillos.

Extremodeltornillo

36

Page 37

Instrucciones de instalacion

USE LA PLANTILLA DEL

GABINETE SUPERIOR PARA LA

PREPARACI( N DEL GABINETE

Deberg perfbrar agt0eros para los tornillos de

apoyo superiores, un agt0ero suficientemente

grande para que el cable el_ctrico quepa, y un

recorre 1o suficientemente grande como para

que el adaptador de escape pueda set introducido.

• Lea las instrucciones sobre la PKKNTILL_K DEL

GAB1NETE SUPERIOR.

• P4guelo debajo del gabinete superior.

• Taladre los agtoeros, siguiendo las instrucciones en

la PLANTILLA DEL GABINETE SUPERIOR.

PRECAUCION: Use galas de seguridad cuando

perfore los agtoeros en el fbndo del gabinere.

ENSAMBLAJE E INSTALAClON

DEL ADAPTADOR

_ Regulador de tiro

COMO MONTAR EL HORNO

PAP,A OBTENER UNA 1NSTALACION Mf\S FACIL

YEN POS DE b\ SEGURIDAD PERSONAL, SE

RECOMIENDA QUE DOS PERSONAS INSTALEN

ESTE HORNO.

IMPORTANTE: No agarre ni use la manija

de la puerta durante la instalaci6n.

NOTA: Si su gabinete es de metal, use la arandela de

nil6n alrededor del cable el_crrico para evitar que el

mismo sea cortado.

NOTA: Recomendamos el uso de bloques de relleno

si el frenre del gabinete cuelga por debajo del

estanre del rondo del gabinete.

IMPORTANTE: Si no se usan bloques de

relleno, podrian ocurrir dafios por apretar

demasiado los tornillos.

NOTA: Cuando se encuentre

montando el horno, enrosque

el cable el_Sctrico a travds del

agujero en el fbndo del gabinete

superion Mant_ngalo tenso a

travds de los Pasos del 1-3. No

pellizque el cable ni tire del

horno por el cable.

Levante el horno,

mclfnelo hacla

adelante, y enganche

las ranuras en el

extremo in[erior

posterior en dos

orgjillas inR.riores del

plato de montaje.

i

de escape

[] Coloque el homo en su posici6n vertical, con la

parte superior hacia arriba.

[] Inserte las orejillas en cada lado del regulador de tiro

en los agujeros en el interior posterior del adaptado_:

[] Pegue el adaptador de escape al plato calefactor con

los dos tornillos de bronce que le proporcionamos.

Cerd6rese de que el regulador de tim gira

flicilmente antes de montar el horno.

Deber_ hacer ajustes para asegurarse de que existe

alineacidn apropiada con el sistema de conductos

de su casa despu& de la instalaci6n del horno.

[_ Gire el ffente del horno

contra el tbndo del gabinete.

] lnserte un tornillo de autoalineaci6n a trav_Ss del

agujero central superior del gabinete. Asegure el

horno temporahnente girando el tornilh) por 1o menos

dos vueltas eompletas despu_Ss de que las roscas hayan

agarrado. (Luego quedat_an totalmente apretadas).

Cerci6rese de mantener el cable el6ctrico esfirado.

Tenga cuidado de no pellizcar el cable, especialmente

cuando se monte al nivel del fondo del gabinete.

37

Page 38

Instrucciones de instalacion

[-_ C(_MO MONTAR EL HORNO

{continuacibn)

Frentedel gabinete

Estantedel fondodel gabinete

BIoquederelleno

| la profundidad

>" Tortlilloautoalineable

--Parte superiordelhomo

[_ Pegue el horno a la parte superior del gabinete.

_Inserte 2 tornillos autoalineables

a trav_Ss de los aguieros exteriores

snperiores del homo. Gire dos

vueltas completas en cada tornillo.

_Ll°e', 0

C(_MO AJUSTAR EL

ADAPTADOR DE ESCAPE

Abra el gabinete superior y ajuste el adaptador de

escape para conecmrlo al conducto de la casa.

Reguladordetiro

\

\

Parteposterior

delhorno

[-_ C(_MO CONECTAR

EL CONDUCTO

Conductode lacasa

[_Apriete el tornillo del

centro completamente.

[] Apriete los dos tornillos exteriores hacia la parte

de arriba del horno. (Mientras aprieta los tornillos,

mantenga el homo en su lugar contra la pared y el

gabinete snperioE)

[_ lnstale los filtros de grasa. Ver el Manual del Propietario

que viene con el homo.

38

Extienda el conducto de la casa hacia

conectarlo con el adapmdor de escape.

[] Selle lasjuntas del conducto de escape usando

cinta adhesiva de conductos.

abajo

para

Page 39

Instrucciones de instalacion

ESCAPE POSTERIOR EXTERNO (Conducto horizontal)

PERSPECTIVA GENERAL DE

LA INSTALACI(_N

BI. Prepare la pared posterior

B2. Pegue el plato de montaje

a la pared

B3. Prepare el gabinete superior

B4, Ajuste el calef_actor

BS. Monte el horno

l

[_ C(_MO PREPARAR LA PARED

POSTERIOR PARA EL ESCAPE

POSTERIOR

Necesita cortar tma abertura en la pared posterior

para el escape exterior.

• Lea las instrucciones en la PLANTILLX PARA I_\

PARED POSTERIOR.

• Pdguela con cinta adhesi'ra a la pared posterior,

aline_indola con los agl!jeros prex4amente perforados

para los agujeros A y Ben el plato de la pared.

• Corte la apertura, siguiendo las instrucciones de la

PLANTILLX PAI,bX I_X PARED POSTERIOR.

[-_ C(_MO ADHERIR EL PLATO DE

MONTAJE A LA PARED

_-I 5_

°i

_ 5_=.

Pegue el plato a la pared usando los tornillos basculantes.

Por 1o menos un mrnillo de madera debe ser usado para

peg_ar el plato al poste de viga de la pared.

[] Remueva las mariposas de los tornillos.

[] Inserte los mrnillos en el plato de montaje a trav_s

de los agtoeros disefiados para colocarse contra la

pared de mamposteri'a seca y pegue otra vez las

mariposas de ¾" a cada tornillo.

39

Page 40

Instrucciones de instalacion

Para usar los tornillos basculantes:

Espaciadoresparalosbasculantes

_1_ mayoresqueelanchodelapared

I

Alasdemanposa

t°t1 41Ii"d::rni"°l°%tl" Ik

Extremodeltomillo

[] Coloque el plato de montaje contra la pared e

inserte las alas de mariposa en los agujeros de

la pared para montar el plato.

NOTA: Antes de apremr los tornillos basculantes y el

tornillo de madera, cerci6rese de que las orejillas en

el plato de montaje toquen el tbndo del gabinete

cuando se empujen contra la pared y de que el plato

est_ centrado apropiadamente debajo del gabinere.

PliEQAUCI6N: Tenga cuidado de evitar pellizcar sus

dedos entre la parre posterior del plato de montaje y

la pared.

[] Apriete todos los tornillos. Tire del plato en direcci6n

opuesta a la pared para ayudar a aprerar los tornillos.

[-_ COMO ADAPTAR ELCALEFACTOR

PARA EL ESCAPEEXTERIOR

[] Remueva los tornillos sostienen elguardeY que

plato del calefactor en el homo. Deslice el plato

del calefactor de abajo de su reborde de retenci6n.

Remueva y gllarde los tornillos que sostienen el

motor del caletactor en el homo.

Rebordede

retenci0n

Plato

calefactor

Tornillodelmotor

delcalefactor

[] Cuidadosamente tire del calefhcto_: Los alambres

se extender_in 1o suficiente como para permitirle

que usted ajuste la unidad del calefgctot:

ExtremoB

USE LA PLANTILLA DEL

GABINETE SUPERIOR PARA

PREPARAR EL GABINETE

SUPERIOR

Necesita perforar agt0eros para los tornillos de apoyo

superiores y un agt0ero suficientemente grande para

que el cable eldctrico quepa.

• Lea las instrucciones sobre la PK\NTILLA DEL

GABINETE SUPERIOR.

• Pdguela debajo del gabinete superior.

• Taladre los agujeros, siguiendo las instrucciones en

la Pb\NT1LL\ DEL GABINETE SUPERIOR.

]Rote la unidad 180° en sentido contrario alas

agujas del reloj.

Antesdelarotaci6n

delhomo

[] Suavemente los alambres de las

Redirija los alambres a tray& de las ranuras en el

otro lado de la unidad del caletactor.

Antesde redirigirlos Despu6sderedidgirlos

remueva ranuras.

Despu0sdela rotaci6n

rior

Parteposterior

del homo

PREQAUCI6N: Use galas de seguridad cuando

perfore los agujeros en el rondo del gabinete.

Alambresdirigidosatrav0sdel AlambresdirigidosatravOsdel

ladoderecho ladoizquierdo

4O

Page 41

Instrucciones de instalacion

[] Ruede la unidad del calefl_ctor 90° de forma tal

que las aberturas de la paleta del ventilador estdn

orientadas hacia la parte posterior del homo.

Antesde la rotaciOn Despu_sde la

rotaciOn

_arteposterior

Parteposterior delhomo

del homo

[] Localice los dos platos removibles en el panel

posterior del homo, cerca de la parte superior

del homo.

Usando t!jeras, cuidadosamente corte el grea

de telarafia de los dos agujeros lado a lado (que

aseguran los plains removibles al homo). Corte

las cuatro telarafias en ambos platos removibles

posteriores; esto permitirg que el flujo de aire

del ventilador escape hacia la parte posterior

del homo.

PRECAUCION: Cerci6rese de reeortar los

extremos f'dosos de las aberturas despu_s de

remover los platos.

[] Coloque el plato calefhctor en la misma

posici6n como estaba antes con los tornillos.

$ _ Tornillosdelplatocalefactor

i,i

_'___ Parte posterior

_._ delhomo

[] lnserte las orejillas en cada lado del regulador

de tiro en los agujeros en el lado interior

posterior del adaptador.

Platocalefactor

i

['_ __--_ Adaptador

deescape

[_ Pegue el adaptador de escape a la parte posterior

del homo deslizgndolo en las gufas en la parte

superior central de la parte posterior del homo.

,._ . _ Reguladordetire

Parte posterior del horno Cortecontijeras las

_ uatrotelarafiasde

cadapanelremovible

y remuevalosdiscos

removiNesde metal

para.permitirel flujo

de age posterior

[] Coloque la unidad del calefhctor de nuevo en

la abertura.

PRECAUCION: No tire ni estire los cables del

calefactor. Cerci6rese de que los alambres no

est_n pellizcados.

NOTA: Las aberturas del escape del calefactor

deberfin encajar con las aberturas del escape en

la parte posterior del horno.

deescape -.. .....

Desliceel _

adaptadorde /-"_ v /" Parteposterior

escapeen,as ""_"""-...45__:e, horno

parteposteriorj,"',,._ I1_ J#_Y "_r'_"Ir'T°rnill°s

delhomo _"_ )_ _

L[L_o_ ° decierre Guias

Empuje firmemente hasta que est{3en las orejillas

de cierre inferiores. Tanga cuidado de asegurarse

de que la bisagra del regulador de tiro estd

instalada de forma que estd en la parte superior

y que el regulador de tiro gire libremente.

[_ Asegure el adaptador de escape al homo

con los dos tornillos metglicos de bronce

que proporcionamos.

41

Page 42

Instrucciones de instalacion

MONTAJE DEL HORNO

Frentedelgabinete

Estantedelfondo delgabinete

uederelleno

uivalentea

la profundidad

delretroceso

Dbinete

PAth\ UNA INSTALAC1ON MfkS FACIL Y EN POS

DE LA SEGURIDAD PERSON_-YL, SE RECOMIENDA

QUE DOS PERSONAS INSTALEN ESTE HORNO.

IMPORTANTE: No agarre ni use la manija

de la puerta dttrante la instalaci6n.

NOTA: Si su gabinete es de metal, use la arandela de

nil6n alrededor del cable el6ctrico para evitar que el

mismo sea cortado.

NOTA: Recomendamos el uso de bloques de relleno

si el fi'ente del gabinete cuelga por debajo del

esmnte del fbndo del gabinete.

IMPORTANTE: Si no se usan bloques de

relleno, podrian ocurrir dafios por apretar

demasiado los tornillos.

NOTA: Cuando se encuentre

montando el homo, enrosque el

cable el_ctrico a travds del

agujero en el rondo del gabinete

superion Mam6ngalo tens() a

trav_Ssde los Pasos del 1-3. No

pellizque el cable ni tire del

horno pot el cable. _ inclfnelo hacia adelante, y

r7

Levante el horn(),

enganche las ranuras ene

extremo inferior

Tomillosautoalineables

Partesuperiordelhomo

[] Pegue el horno a la parte superior del gabinete.

[] lnserte 2 tornillos autoalineables

tray& de los agujeros exteriores del

homo. Gire dos vueltas completas

en cada tornillo.

_Apriete el tornillo del

centro complemmente.

[] Apriete los dos mrnillos exteriores hacia el

horno superiol: (Miemras aprieta los mrnillos,

mamenga el homo en su lug_r contra la pared

y el gabinete superior:)

a

Gire el flente del horn() contra

gabinete.

[]Inserte un tornillo de autoalineaci6n a trav_s del

agtljero central superior del gabinete. Asegure el

horno temporalmente girando el tornillo por 1o

menos dos vueltas completas despu_Ss de que las

roscas hayan agarrado. (Luego quedat_an totalmente

apretadas). Cerci6rese de mantener el cable el6ctrico

estirado. Tenga cuidado de no pellizcar el cable,

especialmente cuando se monte al nivel del fondo

del gabinete.

[] Instale los filtros de grasa. Ver el Manual del

Propietario que viene con el homo.

42

Page 43

Instrucciones de instalacion

RECIRCULACION (Sin conducto de ventilacion)

PERSPECTIVA GENERAL

DE LA INSTALACI(_N

el. Pegue el plato de montaje

a la pared

C2. Prepare el gabinete superior

C3. Ajuste el calefhctor

C4. Monte el homo

C5. Instale el filtro de carbonilla

[-_ C(_MO ADHERIR LA PLACA

DE MONTAJE A LA PARED

Peglm el plato a la pared usando los mrnillos

basculantes. Pot 1o menos un tornillo de madera debe

ser usado para pegm" el plato al poste de la pared.

[] Remueva las mariposas del basculante de

los tornillos.

_] lnserte los tornillos en el plato de montaje a u'av_s

de los agujeros disefiados para ser insertados en la

pared de mamposterfa seca y pegue otra vez las

• 3 /* .

manposas de ¾ en cada tormllo.

Para usar los tornillos basculantes:

[] Coloque el plato de montaje contra la pared e

inserte las alas de mariposa en los agujeros de la

pared para montar el plato.

NOTA: Antes de apremr los tornillos basculantes y los

tornillos de madera, cercidrese de que las orejillas en el

plato de montaje toquen el rondo del gabinete cuando

son empujadas contra la pared y de que el plato est_

centrado apropiadamente debajo del gabinete.

PRECAUCION: Tenga cuidado de evitar pellizcar

sus dedos entre la parte posterior del plato de

montaje y la pared.

[] Apriete todos los tornillos. Tire del plato en direccidn

opuesta a la pared para ayudar a apretar los tornillos.

USE LA PLANTILLA DE

GABINETE SUPERIOR

PARA LA PREPARACI(_N

DEL GABINETE

Deber_i perforar agtoeros para los tornillos de apoyo

superiores y un agujero suficienremente grande para

que el cable el_ctrico quepa.

Espaciadoresparalosbasculantes

_.._a_amayoresqueelanchode[apared

q--

Platode [ /Tornii[ode II I

_lasdemariposa

m°ntaje llHl_ m°rip° °II Ih

iii _Pared II U I

ExtremodeltomiHo

• Lea las instrucciones sobre la PK_NTILI_\ DEL

GABINETE SUPERIOR.

• Pdguela debajo del gabinete superim:

• Taladre un agujero, siguiendo las insu'ucciones

en la PKMNTILL,\ DEL GAB1NETE SUPERIOR.

PRECAUCION: Use galas de seguridad cuando

perfore los agujeros en el rondo del gabinete.

4a

Page 44

Instrucciones de instalacion

COMO ADAPTAR EL

CALEFACTOR PARA

LA REClRCULAClON

NOTA: El adaptador de escape con calef_actor no

es necesario para los modelos de recirculaci6n.

()uizgs desee guardarlos para posibles usos f_mlros.

[] Remueva y guarde los tornillos que sostienen el

plato del calefactor en el homo.

'_Tornillos delplatodelcalefactor

fi

[] Deslice el plato calef_actor pot debajo de su reborde

de retenci6n. Remueva y guarde los tornillos que

sostienen el motor del calefactor al homo.

Plato

[_] Cuidadosamente tire del calefactor. Los alambres

se extendergn lo suficiente para permitirle que

usted ajuste la unidad del calefhctm:

[_ Ruede la unidad del calef_actor 90° de forma tal

que las aberturas de la paleta del ventilador estdn

orientadas hacia el frente del microondas.

Rebordede _calefactor

retenci6n \

_'_ _"_delcalefactor

Tornillodel motor

Ruede

44

NOTA: Cerci6rese de que los alambres permanecen

encaminados en las ranuras del marco del motor:

Page 45

Instrucciones de instalacion

COMO ADAPTAR EL

CALEFACTOR PARA LA

REClRCULACI(_N {continuacibn)

[] Coloque la unidad del calefactor de nuevo

en la abertura.

PRECAUCION: No tire ni estire los cables dd

calefactor. Cerci6rese de que los alambres no

es_n pellizcados.

_ksegure la unidad del calefactor en el horno con los

] . . ,

tormllos removldos en el Paso 2. Inserte el tormllo

en el portador de tornillo inferior derecho en la

parte posterior del homo.

Reemplace el plato calefhctor con los tornillos

removidos en el Paso 1.

_ ToreiUosdel

_i' i Natocalefactor

'i i