Page 1

www.GEAppfiances.com

Safety Instructions ....... 9, 3, 7

Opera6ng ImtrucCions

Cooking Tips ................ 5

Raise/Lower Switch ........... 4

Using the Cooktop ........... 4

Using the Downdraft Svsmm ...4

Care and Cleaning

Grease Fihers ................ 5

Painted or Metal Surl2_ces ...... 5

Stainless Steel Surfaces ........ 5

Installation Instructions

Advance Planning .......... 8, 9

Before You Begin ............. 6

30" Cooktop/Downdraft

Units.[VB37 and.[VB94 ....... 10

36" Cooktop/Downdraft

Units.[VB67 and.[VB98 ....... 11

Dimensions and Clearances . .7, 8

Ductwork ............. 8, 13, 15

Electrical and Gas Location .... 8

Installation Possibilities ........ 9

Installing the Downdraft

Vent System ............. 10-17

Optional Kits ............... 17

Power Supply ............... 12

Raise/i,ower Switch .......... 16

Venting Options ............ 14

yvB 7

Troubleshooting Tips ....... 18

Consumer Support

Consumer Support ........... 20

_'arrantv ................... 19

Writethemodelandserial

numbershere:

Model #

Serial #

You can find them on alabel on

the side ot the blower housing.

959-0445-000 16404290P368 49-80216 06-03 JR

Page 2

IMPORTANTSAFETYINFORMATION.

READALLINSTRUCTIONSBEFOREUSING.

PLEASENOTE: The downdraft ventsystem you have purchased was designed to be used

with GE, GEProfile and GEProfile Performance cooktops listed in this manual

it WARNING!

For your safety, the information in this manual must be followed to minimize the risk of fire or

explosion, electric shock, or to prevent property damage, personal injury, or loss of life.

It WARNING:TOREDUCETHERISKOFFIRE.

ELECTRICSHOCK,ORINJURYTOPERSONS.

OBSERVETHEFOLLOWING:

A. Use this unit one in the manner intended

by tile manufi_cture_: If }ou haxe questions,

cont;ict tile i/lant/tilcttli'ei',

B. gefln'e se_Mdng or cleaning refit, switch power

off at se_wice panel and lock the service

discmmecting means m prevent power from

being switched on accidentally. X._]/en the service

discmmecting means cmmot be locked, secm'elv

fi_sten a prominent warning device, such as a tag,

to the se_Mce panel.

It CAUTION:For_o_ora/vo_,/a_,n_.s_o_/_

Do not use to exhaustt_azardousorexp/osivematena/s

and vapors.

Installation work and electrical wiring must be

done by qualified pe_on (s) in accordance with

all applicable codes and st;mdards, including

fire-rated constrtlction.

SAFETYPRECAUtiONS

Sufficient air is needed fin" proper combustion

and exhausting of gases through tile flue

(chimney) of flml-bm'ning equipment to prevent

back drafting. Follow tile heating equipment

illantlfilcttlrer's guideline and salbty standards

such as those published by tile National Fire

Protection _&ssociation (NFPA), and tile

JMnerican Socie_' fin" Heating, Refligeration

and Air Conditioning Enginee_ (ASHI_¢E),

and tile local code authorities.

When cutting or drilling into wall or ceiling,

do not damaoe electrical wiring and other

hidden utilities.

Ducted rims must alwms be vented to tile

o/ItdooI_.

To reduce tile risk of fire, use only metal

ductwork.

PVC sewer pipe can be used as duct under

concrete slab if allowed b', local code board.

This mfit must be gro/mded.

it WARNING!

Never leave stm'i_ce units tmattended at high

settings. Boilove_ cause smoking and greasy

spillove_ that may ignite. Heat oils slowly on

low or medium settings.

Mwavs mrn hood ON when cooking at high

heat or when cooking flaming foods.

TOREDUCE THERISK OFA RANGE TOPGREASEFIRE

Clean ventilating rims ti'equentlv. Grease should

not be allowed to accumulate on tim or filter

Use proper pan size. M\vm:s use cookware

appropriam for tile size of tile s/iYl'ilce element.

Page 3

www.GEAppliances.com

SAFETYPRECAUTIONS

^..WARNING'-ToR o.c R,sKoFA To oF

A RANGE TOPGREASEFIRE, OBSERVE THE FOLLOWING:*

A. SMOTHER FI_d_<IESwith a close-fitting lid,

cookie sheet, or metal tray, then ttlrn ()fl tile

burner. BE (_AI).EFUI, TO PREVENT BURNS.

If tile flames do not go out immediatel>

EM__CUI.ATEAND CAI,I, THE FIRE

DEPARTMENT.

B. NEVER PICK UP A Fi._d'dlNG E__N_)u may

be bm'ned.

C. DO NOT USE X4;__TER,including wet dishcloths

or tm_vls-a violent steam explosion will result.

O. Use an extinguisher ONLY if."

I. You know you have a Class ABC extinguishe_;

and vou ah'eadv know how to operate it.

2. The fire is small and contained in the area

where it started.

3. Tile fire depamnent is. bein(,., called.

4. You can fi(*ht tile fire with your back to an exit.

*Basedon "KitchenFiresafety Tips"publishedby NFPA.

SERVICING

-&CAUtiON:For_e_eralve_t,lati_useo_l_

Do not use to exhausthazardousorexplosivematerials

andvapors.

Make sure all fingers are away from the downdraft top

when it is lowered.

If YouNeed Service...

Do not attempt to repair (:,rreplace any part (ff

tile down(h'alt system tmless it is spedfically

recommended in this guide. M1 other servicing

should be referred to a qualified technician.

Be sure electrical power is off before servicing the unit.

It may be necessarx to remove tile downdralt blower

svsteI// iI1 oi'der to set\ice COllll)onents Stlch _lS tile

blower IIIOtOI" OI" air _,ent illechanisi//.

Disconnect l)ower to tile cooktop and i'elllO_,e it

fi_st. Reve_e tile steps in tile Install the Oowndraft

section to i'elllo_,e tile bh)wer.

Service parts are available fl'om a (;E Service and

Parts Center:

READANDFOLLOWTHISSAFETYINFORMATIONCAREFULLY.

SAVETHESEINSTRUCtiONS

3

Page 4

Usingthe downdraftsystem.

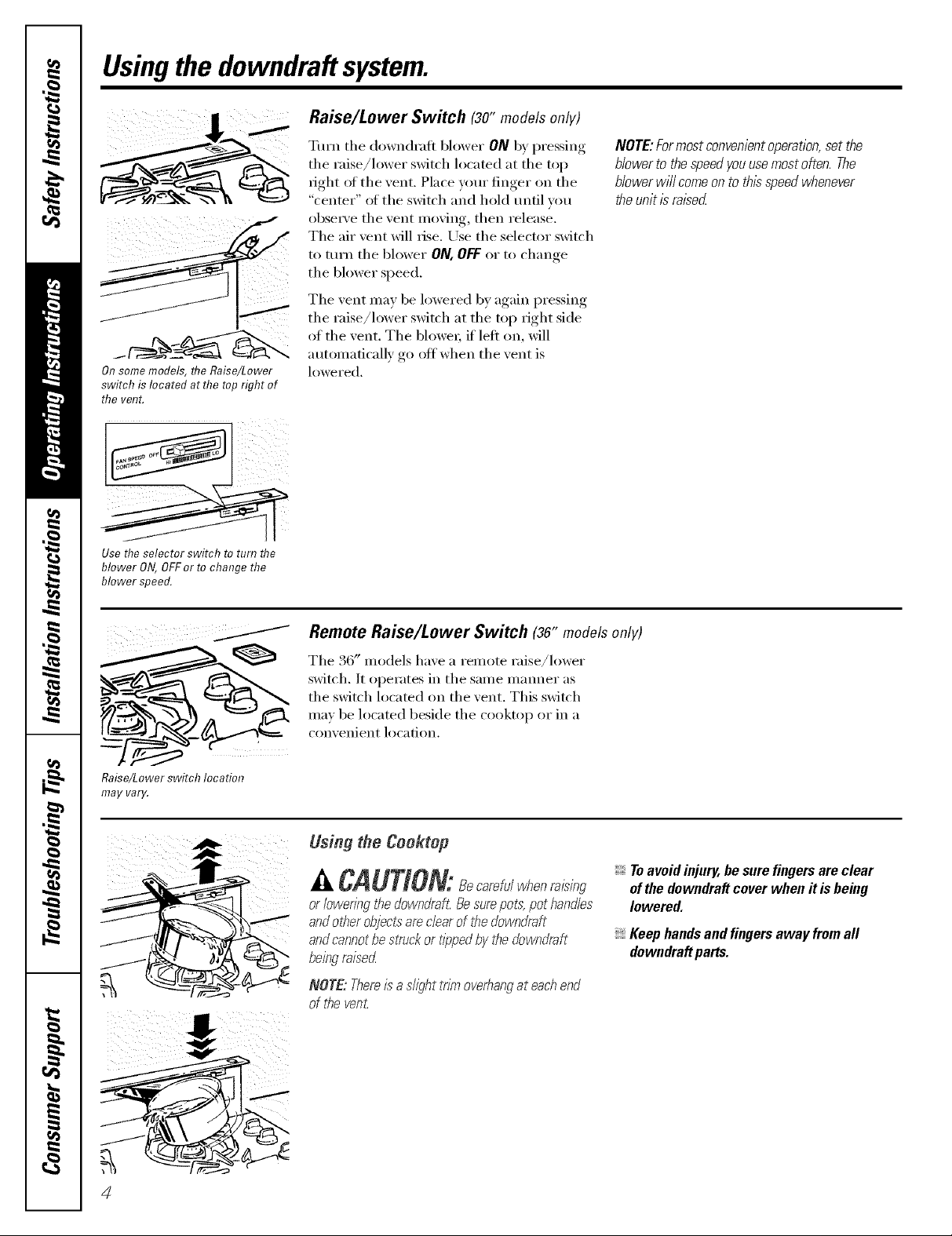

Raise/Lower Switch (3o"modelsonly)

Turn the down(h'aft blower ON b) pressing,,

the raise/lower switch located at the top

fight of the vent. Place your finger on the

"center" of the switch and hold until _ou

obse_a'e the vent moving, then release.

The air vent will rise. Use the selector switch

to ttlrn the blower ON,OFFor to change

the blower speed.

The vent may be lowered by again pressing

the raise/lower switch at the top right side

of the vent. The blowex; it left on, will

automatically go off when the vent is

On some models, flTe Raise/Lower

switchis locatedatthetoprightof

thevent.

lowered.

NOTE:Formostconvenientoperation,setthe

blowerto thespeedyouusemostoften.The

blowerwi//comeonto thisspeedwhenever

theunitisraised

Use the selector switch to turn the

blower ON, OFFer to change the

blower speed.

Raise/Lowerswitch location

may varg.

Remote Raise/Lower Switch (36" modelsonly)

The 36" models have a remote raise/lower

switch. It operates in the same manner as

the switch located on the vent. This switch

may be located beside the cooktop or in a

convenient location,

Using the Coektop

A CAUTION:8ec ref, /whenr isin

or bwering the downdraft. Besurepot,s:pot Mnd/es

andother object:s"arechar of tile downdraft

andcannotbe struckor tipped by the downdraft

being raised

NOTE: Thereis adight trim ovebang at eachend

of tl_even£

Toavoid injury, be sure fingers are clear

ofthe downdraft cover when it is being

lowered.

Keephandsandfingersawayfromall

downdraftparts.

4

Page 5

Cooking Tips

www.GEAppliances.com

The high air moven_ent ot this down(h'att

system can increase the cooking times fi)r

some fi)o(ls. It may take hmger to reach

high cooking temperatures if the down(h'afl

is turned to high fight away. A(!iust the lira

speed tot best cooking results.

For best results when heating oil fiw deep

flTing or when boiling wateL use the fl'ont

surti_ce units or wait until the water is

boiling or the oil is at ti'ying mml)emtm'es

before turning on the (h)wndratt.

Thedown&aft may not completely captureall the

steam frompanson thefront burners.

Careand cleaning ofthe downdraftsystem.

Grease Filters

The eflicienc)of _om" downdralt depends

on a clean filte_: Frequency of cleaning

del)ends on the t},I)e of cooking )ou do.

(;tease tilte_ should be cleaned at least

once a month. Never operate the downdrafl

without the filte_s in place.

Toremove: Pull the filte_s out by grasping

them and pulling straight up.

Toclean: Soak and then agitate in a hot

(lete_gent solution. I,ight brushing may

Canning

When canning fi)ods in a wate_q)ath canne_;

a gentle ])tit stead)' boil m list be maintained

continuously fi)r the required time.

When canning toods in a pressure canne_;

the pressure illtlst be maintained

continuously for the required time.

Use of the blower at HIGHspeed when

canning may reduce the temperature

enough to stop boiling. While canning,

we _ecommend using the down(h'alt at

LOWspeed and using the fl'ont SUll'ilce unit.

be used to remove embedded soil. Rinse,

shake and remove moisture befi)re

replacing.

Filters may also be cleaned in the

dishwasher:

X_\]th carefifl handling, the filter will last fi)r

yem_. If replacement becomes necessm T,

order the part ti'om your (leale_:

Painted or Metal Surfaces

Clean greasy surti_ces ti'equently, using

a mild detergent.

Stainless Steel Surfaces (onsomemode/s)

Donotusea steel-woolpad;it will scratchthe

surface.

[] Shake bottle well.

[] Place a <small alllOt/nt of CEIL_dVIA

BRYTE _'Stainless Steel Appliance

Cleaner on a damp ch)th or damp

paper towel.

[] Clean a small area (approximately

8" x 8"), rubbmg wKh the g_am of the

stainless steel if api)licable.

[] Dr) and buff with a clean' dr) I)al)er

towel or sott cloth.

[] Repeat as necessm_.

NOTE:If a mineral oil4)ased stainless steel

al)pliance cleaner has been used befi)re to

clean the appliance, wash the surfi_ce with

Do not useabrasive cloth, steel wool pads or

scouring powder because they will mar the

surface.

dish soap and water prior to using the

CEIL_JA BRYTE ') Stainless Steel Appliance

Cleane_: _Mter washing the surfi_ce with dish

soap arid wateI; rise a generotls }li//otlnt ot

CEIL_4A BRYTE <'_Stainless Steel Appliance

Cleaner to clean the appliance.

To Order

To order CEIL_dX4ABRYTE <':Stainless Steel

Appliance Cleane_; please call ore" toll-ti'ee

ntllllbeY:

National Parts Center 800.626.2002

www.GEAppliances.com

CERAMABRYTP _

Stainless Steel Appliance

Cleaner ....................... _ PM]O)(3] ]

Page 6

Installation

Downdraft Vent

Instructions

mfyou have questions, call 800.GE.CARES or visit our Website at: www.GEAppliances.com

BEFORE YOU BEGIN

Read these instructions completely and

carefully.

• IMPORTANT - Savethese

instructions for local inspector's use.

• IMPORTANT - Observeall

governing codes and ordinances.

• Note to Installer - Be sure to leave these

instructions with the Consumer.

• Note to Consumer - Keep these

instructions for future reference.

• Note - This appliance must be properly

grounded.

• Proper installation is the responsibility of

the installer.

• Product failure due to improper installation

is not covered under the Warranty.

System

REMOVE PACKAGING

Open the carton and remove parts package.

Check contents to be sure all pieces are

present. (The parts package may be attached

to the power cord.)

Remove the shipping materials. Remove the

carton and set aside. The carton can be used

as a pad when changing or adjusting vent

direction.

PARTS INCLUDED

TOOLS YOU WILL NEED

Flat-blade screwdriver

Carpenter square Ill

Pliers

Jig saw

Ductwork to suit

the installation

Duct tape

Stabilizing brackets

(all models) (4)

Remote raise/lower assembly (for 36" models only)

Wire box (2)

and screws (4)

Switch cover

plate (1)

Plastic strain

relief (2)

Attachment

bracket (1)

Wire and white

connector (1)

Page 7

JnstaJJation instructions

DiMENSiONS AND CLEARANCES

A CAUTION -WaUcoverings,countertops and

cabinets shouJd withstand 200°R heat generated by

any cooktop.

tt

_2

8½"

................. A ...................

4_.......

............ g ...........

7V_ 21/4- _

33/T 6_I/4," i/j,

71/8"_

101/2H

_33/d '

AWARNING!

INSTALLATION SAFETY

INSTRUCTIONS

TO REDUCE THE RISK OF FIRE, ELECTRIC

SHOCK, OR INJURY TO PERSONS, OBSERVE

THE FOLLOWING:

[]

Installation work and electric wiring

must be done by qualified person(s)

in accordance with all applicable codes

and standards, including fire-rated

construction.

[]

Ducted fans must always be vented to

the outdoors.

[]

When cutting or drilling into wall or

ceiling, do not damage electrical wiring

and other hidden utilities.

A WARNING - To reduce the risk of

fire, use only metal ductwork.

27 tt

A B

30" Models 30" 281¼"

36" Models 36" 333A"

recommended for island installations.

IMPORTANT: These vents are

Against-the-wall installations are

limited due to countertop depth

requirements. The vent and cooktop

combined depth requires an extra

deep flat countertop surface.

The countertop must be at least 26" deep

with a flat surface area of 231/2" or more, front

to back. (NOTE: JGP932S, JP350SC, JP930SC

and JP938SC require 23%" flat surface area.)

In addition, other clearances to the front

edge of the countertop must be considered.

• See specific cutout illustrations with your

cooktop model to determine requirements.

A countertop with

a raised lip or rolled

front edge may not

allow enough flat

area for installation.

/0 Flat surface

area

Page 8

mnstaaiation mnstructions

ADVANCE PLANNING

CLEARANCES

• Installation must conform with local codes.

• The downdraft system with blower, motor

and duct work will occupy the cabinet

below the countertop and cooktop,

• The blower/motor assembly can be located

below the cabinet floor. The assembly will

fit between 16" floor joists.

In this installation a transition to 6" round

is required.

• The blower motor assembly can also be

installed outdoors. Order JXBC67 for

remote blower installations outdoors.

• Refer to Dimensions and Clearances for

information on appropriate placement

and necessary clearances when planning

installation.

• Refer to your specific cooktop installation

instruction for other appropriate clearances.

• Avoid placing cabinetry directly above the

cooking surface when possible.

• If cabinetry is used above the cooking

surface:

Installation must conform with local codes.

Use cabinets no more than 13" deep.

Maintain 30" minimum clearance between

cooktop and unprotected cabinets directly

above cooktop.

If clearance is less than 30'; protect cabinet

bottoms with flame-retardant millboard at

least 1/4" thick or gypsum board at least

3/16" thick covered with 28 gauge sheet

steel or .02" thick copper,

Clearance between cooktop and protected

cabinetry must not be less than 24':

EXCEPTION: Installation of a listed

microwave oven or cooking appliance over

the cooktop shall conform to the installation

instructions packed with that appliance,

• Working areas adjacent to the cooktop

should maintain 18" minimum clearance

between countertop and cabinet bottom.

DUCTWORK

Prepare ductwork to vent to the outdoors.

Use the shortest and straightest duct run

possible.

The maximum permissible length for duct

run is 150 feet.

Refer to Duct Fittings chart to calculate

equivalent length for various duct

configurations.

• The downdraft blower system is designed

to use 31/4" x 10" ductwork. It can be

transitioned to 6" round.

• Ductwork MUST be vented to the outside i

never into a crawl space, attic or other

enclosed space.

• Determine the need for a wall cap or roof

cap. Purchase the cap in advance from

your home building center or plumbing

supply,

COOKTOP ELECTRICAL AND

GAS LOCATION

Plan the placement of the electrical outlet

and gas (if used) carefully. Gas or electrical

outlets cannot be placed on the back wall of

the cabinet because it may interfere with the

downdraft plenum.

Install a standard electrical outlet within

reach of the vents' 2 foot long power cord.

• The vent and a gas cooktop combination

can operate from the same 120V standard

duplex outlet.

• Electric cooktops must operate from

a separate 240V junction box.

REMOTE SWITCH

(for 36" models only)

The downdraft vent has a separate

raise/lower switch. Plan to install the switch

in a convenient location outside of the

vent/cooktop cutout.

Page 9

Installation Instructions

INSTALLATION POSSIBILITIES

When the kitchen design calls for an against

the wall installation, move 24" deep base

cabinet forward, 3" to 5" Filler panels can

be angled or flat to fill the space between

adjacent cabinets.

Maintain cutout clearances to front edge as specified.

Filler

JJ_ Filler panel

Base panel

cabinet Base sink

30" Min. for JVB37 and JVB94

36" Min, for JVB67 and JVB98

In an island or peninsula, the countertop can

be extra deep to provide seating opposite of

the cooktop. Adding base cabinets on each

side of the cooktop provides extra storage

and countertop work space.

i

18"i

I Base to sink

30" to 42"

18"

Countertop

overhang

per cooktop

clearances

must be

maintained

End

Cover panel

panel

Page 10

Installation Instructions

INSTALLING THE DOWNDRAFT VENT SYSTEM

30" COOKTOP/DOWNDRAFT

UN{TS JVB37 AND JVB94

NOTE: Before you begin, measure and mark

Dimension 3 to ensure that adequate flat

countertop surface is available.

Identify the cutout illustration for the cooktop

modet you are installing with this downdraft

vent system.

e Draw lines on the countertop to follow

as a cutting guide.

Make sure sides of the opening are

parallel and rear and front cuts are exactly

perpendicular (right angle) to sides.

21/8"

[] [] [] [] [] []

Overall Cooktop Surface Surface Depth Minimum Setback Combined Combined

Model No. Width Overall Depth with Downdraft* Cutout to Front Edge** Cutout Width Cutout Depth

JP326 30-1/4" 21-1/4" 23-3/8" 2-1/2" 28-1/2" 22-3/8"

JP340

JP350

J P930 29-3/4" 20-7/8" 23" 2-1/2" 28-1/2" 22-1/4"

JP931

JP938

JP939

JP350SC

JP930SC 29-7/8" 21-1/2" 23-5/8" 2-1/2" 28-1/2" 22-3/8"

JP938SC

JGP328

JGP933 30" 21" 23-1/8" 2-1/2" 28-1/2" 22-3/8"

JGP933S

JGP336 30" 21" 23-1/8" 2-1/2" 28-1/2" 22-1/4"

JGP932 29-3/4" 21" 23-1/8" 2-1/2" 28-1/2" 22-1/4"

JGP930S 30" 21-1/4" 23-3/8" 2-1/2" 28-1/2" 22-1/4"

JGP932S 29-7/8" 21-5/8" 23-3/4" 2-1/2" 28-1/2" 22-5/8"

*Includes 1/8" gap between cooktop and vent trim

**Required to maintain UL or AGA approvals

10

Page 11

Installation Instructions

36" COOKTOP/DOWNDRAFT

UNITS JVB67 AND JVB98

NOTE: Before you begin, measure and mark

Dimension 3 to ensure that adequate flat

countertop surface is available.

Identify the cutout illustration for the cooktop

model you are installing with this downdraft

vent system.

• Draw lines on the countertop to follow

as a cutting guide.

• Make sure sides of the opening are

parallel and rear and front cuts are

exactly perpendicular to sides.

21/8t_

[] [] [] [] [] []

Overall Cooktop Surface Surface Depth Minimum Setback Combined Combined

Model No. Width Overall Depth with Downdraft* Cutout to Front Edge** Cutout Width Cutout Depth

JP626 35-1/2" 21" 23-1/8" 2-1/2" 34" 21 -1/8"

JP960

JP961

JP968 36" 20-3/8" 22-1/2" 2-1/2" 34" 21-3/4"

J P969

JP960S

JP968S 36-1/8" 21" 23-1/8" 2-1/2" 34" 21-7/8"

JGP628

JGP963 36" 21" 23-1/8" 2-1/2" 34" 21-7/8"

JGP963S

JGP636 36" 21" 23-1/8" 2-1/2" 34" 21-7/8"

JGP960S 36" 21 -1/4" 23-1/8" 2-1/2" 34" 22-7/8"

J GP962 36" 20-7/16" 22-9/16" 2-1/2" 34" 21-3/4"

JGP962S 36-1/8" 21-1/16" 23-3/16" 2-1/2" 34" 22-1/8"

*Includes 1/8" gap between cooktop and vent trim

**Required to maintain UL or AGA approvals

11

Page 12

mnstaaiation mnstructions

INSTALLING THE DOWNDRAFT VENT SYSTEM

POWER SUPPLY

This downdraft vent must be supplied with

120V, 60Hz., and connected to an individual,

properly grounded branch circuit, protected

by a 15 or 20 ampere circuit breaker or time

delay fuse.

Gas Cooktops

If this vent is installed in combination with a

gas cooktop, it may operate from the same

duplex outlet.

Electric Cooktops

If this vent is installed in combination with an

electric cooktop, the vent must operate from

a separate 120V outlet.

A properly grounded 3-prong receptacle

should be located within reach of the vents'

2 foot power cord.

• Locate the receptacle inside the cabinet on

the right side wall. The receptacle cannot

be placed on the back of the cabinet wall

where it may interfere with the downdraft

plenum. See illustration.

Do not leave gas or electrical

connections within shaded area.

outlet

12" above

cabinet floor

281½" for 30" model,'

NOTE: Do not use an extension cord or

adapter plug with this appliance. Follow

National electrical codes or prevailing local

codes and ordinances.

12

Page 13

Installation Instructions

DUCTWORK LENGTH AND DUCT FiTTiNGS

NOTE: Do not exceed 150 foot maximum permissible equivalent lengths!

Flexible ducting: If flexibte metal ducting is used, all equivalent feet values in the table should be

doubled. The flexible metal duct should be straight and smooth and extended as much as possible.

DO NOT use flexible plastic ducting.

Add equivalent lengths for all duct pieces and transitions used to ensure that the duct run does not

exceed the maximum 150 feet.

31/4"x 10"

to 6" Round

6" Round 1ft. (per 31/4" x 10" 5 ft.

Straight foot length) 45° Elbow

31/4"x 10" 1ft. (per 31/4"x 10" 24ft. Wall Cap 21 ft.

Straight foot length) 90 ° Flat Elbow with Damper

6" Round 31/4" x 10"

6" 15 ft. to 31/4" x 10" 7 ft. Wall Cap 27 ft.

90° Elbow Transition with Damper

31/4"X 10"

6" to 6" Round 5 ft. 6" Round

45° Elbow Transition Roof Cap

31/4" x 10" Transition 6" Round

90° Elbow 90° Elbow Roof Vent

9 ft. 20 ft.

6" Round

to 31/4 " x 10"

16 ft. 24 ft.

20 ft.

ds

Transition

g0 ° Elbow

6" Round

12ft.

SHOULD NOT EXCEED 150 EQUIVALENT FEET

*Equivalent lengths of duct pieces are based on actual tests conducted by GE Evaluation Engineering

and reflect requirements for good venting performance. See chart for CFM Duct Length.

13

Page 14

mnstaaiation mnstructions

INSTALLING THE DOWNDRAFT VENT SYSTEM

VENTING OPTIONS

Side-to-Side Adjustments

The entire blower mounting plate can be

adjusted 31/2" to the left or right. This will help

to align vent discharge to house ductwork.

Loosen screws to adjust

blower left to right _ j ........ .....

/ i ii "_

[ /

Discharge Direction

The blower assembly may be removed and

turned 90 ° for a left or right side discharge.

• The downdraft vent is shipped with the

discharge outlet pointing straight down

and can be changed to the left or right side.

[ ,'

J

j..

To Change to a Left or Right Discharge

[] Remove the 4 screws holding the blower

to the mounting plate assembly. Retain

screws.

[]

Remove the blower assembly, turn it

over to access the 4 nuts holding the

blower to the mounting plate. Remove

the nuts.

(_ MPORTANT: Do not lift the motor

[]

Turn the blower to the left or right

discharge direction and reinstall the

4 nuts.

Discharge left Discharge right

by the power cable.

'[ ....

Discharge down

(as supplied)

• A left or right 90 ° direction adjustment

should be performed before dropping into

the countertop opening.

• Flatten the shipping box to use as a pad.

• Lay the vent on its back onto the pad.

[] Reinstall the blower and mounting plate

with original screws.

To Locate the Ductwork Holes in the Cabinet

Floor or Side Walls

[]

Temporarily, put vent into the countertop

opening.

[]

Push the vent all the way to the back of

the opening.

[]

If you are transitioning to 6" round,

place transition (obtained locally) over

the discharge outlet.

• Mark the location and remove the

assembly.

• Cut holes and install ductwork

connections.

Order JXRB67 for installation of the blower

and motor below the floor.

Order JXBC67 for installation of the blower

and motor outdoors.

14

Page 15

mnstaaiation mnstructions

[] INSTALL THE DOWNDRAFT VENT

_ _ red

\_ method

_k Secure

the upper

brackets

with screws

located on

the side

of case

and attach

to back of

cabinet

Secure the lower brackets

to blower housing

Place the downdraft vent into the

countertop cutout, against the back side.

[]

Secure the downdraft to the countertop

supplied brackets. See illustration.

Fasten 2 brackets to vent side and secure

[]

to cabinet back wall.

Install 2 brackets on the bottom of the

[]

vent. Attach brackets to slide screws on

the vent and to the floor using wood

screws (not supplied).

When installing in a tile countertop

surface, it may be necessary to apply

a locally approved caulking to cover

any gaps,

[] iNSTALL THE DUCTWORK

Use minimum 26" gauge galvanized or

24 gauge aluminum duct 31/4" x 10" or

6" round. PVC duct should be used if

installing under a poured concrete sJab.

DO NOT USE flexible ducfing.

Always use appropriate roof or wail

cap with damper. Laundry type wail

caps shouJd never be used. See the

Ductwork Length and Duct FJtdngs

chart.

o

Use the straightest duct run possible.

@

For satisfactory performance the duct

run shouJd not exceed 150 feet or its

equivalent tength when bends or

various fittings are used. Refer to the

tame of equivaJent tengths to calculate

your installation.

i Duct tape over

seam and screw

Airflow

i

Screw

, install ductwork so the piece of duct

nearest the downdraft unit slots iNTO

the next piece of the duct. Secure the

joints with self-tapping screws and

apply duct tape around the joints to

ensure an airtight seat.

15

Page 16

mnstaaiation mnstructions

INSTALLING THE DOWNDRAFT VENT SYSTEM

[] iNSTALL THE RAiSE/LOWER

NOTE: Stop 3 is for 36" models onmy.

Skip this stop if installing a 30" model.

-4,WARNING - Disconnectelectrical

power from the unit before beginning switch

installation. Failure to do so could result in

personal injury or damage to the electrical

controls.

NOTE: Determine the location for the

Raise/Lower switch. The wiring lead is

68" tong.

Raise/Lower

switch

Mounting

bracket

i

i

i

i

_!_'3/8" Hole

[]

Remove protective film from the top of

the switch trim.

[]

Peel film from the adhesive strips on the

back of the switch trim. Thread the wire

lead through the mounting bracket and

countertop. Press trim over the mounting

bracket to set the adhesive.

Connect Raise/Lower Wire Lead to Wire Box

[] Thread wire end with the connector

through the hole on the end of a wire

box. Pull approximately 3" additional

wire length beyond the open end of

the box.

[] Connect the mating wire connectors.

[] Install the wire box onto the bottom of

the countertop or directly behind the

switch. Use screws or adhesive

appropriate for the type of countertop.

[] Place plastic strain relief over the wire,

just outside of the hole at the end of the

wire box. Do not pinch or twist the wire.

Snap the strain relief closed and press

into the hole.

connector

relief

[] Drill a 3/'8" hole into the desired

location. Use the mounting bracket

as a template to locate the hole

accurately. Check for interference

between the switch cover, adjacent

objects and cooktop/vent overlaps.

[] tf switch is mounted into a tile

surface, drilt the hole between tiles.

Use locally approved caulking to

cover any gaps.

[] Center the mounting bracket over the

hole and mark pilot holes. Remove

and drill holes according to type of

countertop.

[] Mount the metal switch bracket

with screws (not provided). Choose

screws for your type of countertop

or use locally approved adhesive.

Control box I/ _i-!11.:¢_.._ _ -'_

Connect Wire Lead t t

[] Thread the long 68" wire lead through

the end of the other wire box.

[] Push wire leads into the white connector

provided.

[] Push wire connector into the mating

connector on the control box. Install the

wire box onto the end of the control box

with screws provided.

[] Place plastic strain relief over the wire,

just outside of the hole at the end in the

wire box. Do not pinch or twist the wire.

Snap the strain relief closed and press

into the hole.

[] Coil the excess wire and position away

from moving parts and cabinet contents.

16

Page 17

Installation Instructions

[] CONNECT THE POWER

Plug power cord into a properly grounded

receptacle.

INSTALL THE COOKTOP

• With the downdraft in the "down" position,

place the cooktop into the cutout.

• Push the cooktop back until the back edge

of the cooktop just barely touches the front

edge of the downdraft cover.

• Using a dime as a thickness gauge, align

the cooktop so that there is a minimum

uniform gap of 0.05" (the thickness of

a dime) between the cooktop and the

downdraft cover.

NOTE: Do not force the downdraft cover to

move rearward when aligning the cooktop.

This may cause the downdraft cover to

impact and damage the cooktop when the

vent is raised and lowered.

NOTES:

• Accurate alignment of cooktop and

downdraft is necessary to ensure that there

is no interference when air vent is raised

and lowered. There should be a gap of

0.05" (the thickness of a dime) between the

back edge of the cooktop and the front

edge of the downdraft cover.

OPTIONAL KiTS

JXRB67 optional accessory for #)door remote

location of the blower,/motor assembly. Use

this kit when the blower and motor assembly

witI be located below the cabinet floor.

MoL ring

brackets

JXBC67 optional outdoor cover accessory

for remote installation of blower and motor

assembly on an outside watt.

• Radiant cooktop cannot be flush mounted

when using this downdraft vent.

/

17

Page 18

Beforeyoucall forservice...

Troubleshooting -tips

Save time and money/.Review the chart below first

and you may not need to call for service.

i Possible Causes What To Do

Fan does not work The vent is not fully extended. * Press tile Raise/Lower switch.

The blower control switch * Slide it to tile right.

may be in the OFFposition.

Vent does not rise Vent not plugged into an outlet. * Plug vent into a 120V power outlet.

Raise/Lower switch did not * Hold switch down fin" a couple of seconds to

engage lift motor, actiwlte motor.

Circuit breaker may have * Check circuit breaker. Reset it necessary.

tripped.

Remote switch not plugged in. * Check all connections between the remote switch

and vent body.

18

Page 19

GEDowndraftSystemWarranty.

All warranty service provided by our Factory Service Centers,

or an authorized Customer Care®technician. Toschedule service,

on-line, 24 hours a day, visit us at www.GEAppliances.com, or

call 800.GE.CARES (800.432.2737).

Staple your receipt here.

Proofof the original purchase

date is needed to obtain service

under the warrant_

GEWill Replace:

Anypattof the downdraft system which fails due to a defect in materials or workmanship.

Fromthedateof the

origina!purchase

i ii iiiff i i i !_iii! iDii iliiiliii!i iiii iiiiiii

Service trips to your home to teach you how to use

the product.

Improper hlstallation, delivery or mah_tenm_ce.

Failure of the product if it is abused, misused,

or used for other thml the intended purpose or

used commerciaJly.

Replacement of the replaceable filters.

This warranty is extended to the original purchaser and any succeeding owner for products purchased for home

use within the USA. In Alaska, the warranty excludes the cost of shipping or service calls to your home.

During this full one-year warranty, GE will also provide, free of charge, all labor and in-home

service to replace the (lefective part.

iiiili!Replacement of house fuses or resetting of circuit

breakers.

iiiilii!Damage to the product caused by accident, fire, floods

or acts of God.

iiiili!h_cidentaJ or consequential damage caused by possible

defects with this applimlce.

Dmnage caused after delivery.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state. Toknow what your

legal rights are, consult your local or state consumer affairs office or your state's Attorney General.

If you have an installation problem, contact your dealer or installer. Youare responsible for providing adequate

electrical, gas, exhausting and other connecting facilities as described in the Installation Instructions provided

with the product.

Warrantor:General Electric Company.Louisville,KY 40225

19

Page 20

ConsumerSupport.

6EApp/iancesWebsite www.GEApp/iances.cem

Ha_e a (plest]o]_ or _eed assistm_ce wkh your apphauce? Try the (}E Appl]aN_ces Website 24 hems a day.

am_y day of the year! For greater c(mvem_ie]_ce amid {i_ster sePdce, )oil can now dowi_]oad Owi_er's Mamla]s,

order parts, catalogs, or e', el/schedule service on-Him/e. Yell cam/also "Ask Our Team of Experts ......

Vollr (]lies[iota/s, amid so m]/llCh more...

Schedu/e Serw;ce mw GEApp/iances.com

Expert (;E repair se]_,_ice is o]]h, o]_e seep awa',' {_'om _,our doon (;eC o]_-lim_e and sc]]edu]e _,our service ac

xour, com'en i en ce 24 h ours _?r (1_?' of the ?rea 1"!()Y ca]] SO0.1 ;E.( :Z_RES ( SO0.432.2737) duri m_g m_urma]

H)10sim/ess h(]10]s.

flea/Life Des,;gnStudio www.CE@plia.ces.com

GE slq_purCs d_e [ Im_iversal Design com_cepc-produccs, services m_d envirom]]encs chac cam_ be used bv

people of a]] ages, sizes amid capabi]ides. We recognize die m_eed to design fin" a wide nmge o{ ph}_ica] m_d

m e m_Ca] abi]i des a _ d im pai rm encs. Fur derails of GE's [ in_iversa] Design a pp]i ca d on s, i_ c] _di _ g ]d cchen

design ideas %r people _rdt]_ disab]]kies, d_eck ouC our Webs]ce cedar. Fur cite heari_g h_paired, []]ease ca]]

S00.TDD.(;EAC (800.833.4322).

ExtendedWarranties m v GEAppfiances.com

is still i_ effect. _'ou can_ purd_ase it (m-]i_e m_ytime, or ca]] S00.621L2224 duri_g nom_al b_si_ess hours.

(;E C] m s_m_ er Hom e Servi c es wi]] sd]] be ch e]'e a_er )o _u" wa rra _ b expi res.

Parts and Accessories m v GE pp/iances.com

}[]]dhidua]s qualified co se_ice d_eir _r_ _)[)]i_CeS C;_ ha_e []arCs or accessuries se]_C directly co their homes

(VISA, MasterCard a_d Discover cards are accepted). Order on-li_e coda 5 24 hours e_ ery (lay or by phoebe

at 800.626.2002 dmi_g normal bush_ess hours.

_nstruotie_s oe_taineff in this mantra/oover preoedures to he performed by a_y use_, Other set_ioinff ffenera//y

shmdd he referred to qua/ified service personnel Ca_tien must he exer_beg Mnoe improper se_fioing may cause

tmeMe operation.

ontact Us wmw.GE pp/iances, com

[_ _o_ are _oC sadsfied _rdt]] Cite service _o_ receive [_'om GE, contact us (m our WebsiCe _rd_]_ _]] d_e details

i_c]udh_g your phone mm_be_; or w_Jce to: (;enend Manage_; (5_scomer Reladons

GE App]im_ces, Appliaure Park

I ,ouisvi]]e, KY 40225

RegisterYourApp/iance www.GEAppiiances.cem

Register your new appliance on=line-at your eolivel_enee! Timely [>ro(l!ur[ reg]sCmdon,, wi]] allow [br

enha_?ced commlmicacio]? al/d pr]mlpc service imder tile terms of_ol0]" _r_I']_][_;' S]?()II](] tile _?eed arise.

'_i_u ma',' also mail i_ d_e [_re-[_ri_ced regiscrado_, card i_ch_ded i_ cite [_ac]d_g_ material.

20 Printed in the United States

Loading...

Loading...