Page 1

Downdraft

GE Appliances

Owner’s Manual

JVB36

JVB66

Vent Systems

Part No. 164D3333P024–3 Pub. No. 49-8768–3 D-959-0176-002 12-98 CG

Page 2

Safety Information

Safety Precautions . . . . . . . .3, 4

Safety Instructions

Operating Instructions

Congratulations!

You Are Now Part of the GE Family.

Welcome to the GE family. We’re proud of our quality products and we are committed

to providing dependable service. You’ll see it in this easy-to-use Owner’s Manual and

you’ll hear it in the friendly voices of our customer service department.

Best of all, you’ll experience these values each time you use your vent. That’s important,

because your new vent will be part of your family for many years. And we hope you will be

part of ours for a long time to come.

We thank you for buying GE. We appreciate your purchase, and hope you will continue

to rely on us whenever you need quality appliances for your home.

Using the Downdraft

System . . . . . . . . . . . . . . . . .5, 6

Using the Controls . . . . . . . . . .5

Care and Cleaning . . . . . . . . . .6

Operating Instructions

Installation Instructions

Before You Begin . . . . . . . . . . .7

Measurements . . . . . . . . . . .7–9

Planing the Ductwork . . . . . . .10

Planing the Wiring . . . . . . . . .11

Installing the

Downdraft . . . . . . . . . . . . .11, 12

Installing the

Electrical Wiring . . . . . . . . . . .13

Installation Instructions

Troubleshooting Tips

GE & You, AService Partnership.

IMPORTANT!

Fill out and return the Consumer Product Registration Card that is

packed with this product. If you cannot find it, please send in the

duplicate card printed in the back of this manual.

FOR YOUR RECORDS

Write the model and serial numbers here:

#

#

Staple sales slip or cancelled check here.

PLEASE NOTE: The downdraft vent system you have purchased was

designed to be used with GE Profile cooktops listed in this manual.

Proof of the original purchase date is needed to obtain service under

the warranty.

Before You Call

For Service . . . . . . . . . . . . . . . 14

Troubleshooting TipsCustomer Service

Customer Service

Product Registration . . . . . . . .17

Warranty . . . . . . . . . . . . . . . . .19

Service Telephone

Numbers . . . . . . . . . Back Cover

2

READ THIS MANUAL

Inside you will find many helpful hints on how to use and maintain your

vent properly. Just a little preventive care on your part can save you a great

deal of time and money over the life of your vent.

IF YOU NEED SERVICE

You’ll find many answers to common problems in the

Service

may not need to call for service at all.

If you do need service, you can relax knowing help is only a phone call

away. A list of toll-free customer service numbers is included in the back

section of this guide. Or you can always call the GE Answer Center® at

800.626.2000, 24 hours a day, 7 days a week.

section. If you review our chart of Troubleshooting Tips first, you

Before You Call For

Page 3

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

WARNING!

For your safety, the information in this manual must be followed to minimize the risk of fire or explosion,

electric shock, or to prevent property damage, personal injury, or loss of life.

WARNING—TO REDUCE THE RISK OF FIRE,

Safety Instructions

ELECTRIC SHOCK, OR INJURY TO PERSONS,

OBSERVE THE FOLLOWING:

A.

Use this unit only in the manner intended by

the manufacturer. If you have any questions

contact the manufacturer.

B.

Before servicing or cleaning unit, switch

power off at service panel and lock the

service disconnecting means to prevent

power from being switched on accidentally.

When the service disconnecting means

cannot be locked, securely fasten a

prominent warning device, such as a tag, to

the service panel.

CAUTION:

Do not use to exhaust hazardous or explosive

materials and vapors.

■Installation work and electrical wiring must

be done by qualified person(s) in

accordance with all applicable codes and

standards, including fire-rated construction.

■When cutting or drilling into wall or ceiling,

do not damage electrical wiring and other

hidden utilities.

For general ventilating use only.

■Ducted fans must always be vented to the

outdoors.

■Sufficient air is needed for proper

combustion and exhausting of gases through

the flue (chimney) of fuel-burning

equipment to prevent backdrafting. Follow

the heating equipment manufacturer’s

guideline and safety standards such as those

published by the National Fire Protection

Association (NFPA), and the American

Society for Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE), and the

local code authorities.

■To reduce the risk of fire, use only metal

ductwork.

■PVC sewer pipe can be used as duct under

concrete slab if allowed by local code board.

■This unit must be grounded.

Operating Instructions

Installation Instructions

Troubleshooting Tips

SAFETY PRECAUTIONS

WARNING—TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

■Keep fan, filters and grease laden

surfaces clean.

■Always turn hood

at high heat.

■Use high range settings on range only when

necessary. Heat oil slowly on low to

medium setting.

ON

when cooking

■Don’t leave range unattended when cooking.

■Always use cookware and utensils

appropriate for the type and amount

of food being prepared.

■When flaming foods under the hood, turn

the fan on.

Customer Service

3

Page 4

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

WARNING!

SAFETY PRECAUTIONS

WARNING—TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT OF A RANGE TOP GREASE

Safety Instructions

Operating Instructions

FIRE, OBSERVE THE FOLLOWING:*

A.

SMOTHER FLAMES with a close-fitting

lid, cookie sheet, or metal tray, then turn

off the burner. BE CAREFUL TO

PREVENT BURNS. If the flames do not go

out immediately, EVACUATE AND CALL

THE FIRE DEPARTMENT.

B.

NEVER PICK UP A FLAMING PAN—

You may be burned.

C.

DO NOT USE WATER, including wet

dishcloths or towels—a violent steam

explosion will result.

D.Use an extinguisher ONLY if:

You know you have a Class ABC

1.

extinguisher, and you already know how to

operate it.

2.

The fire is small and contained in the area

where it started.

3.

The fire department is being called.

4.

You can fight the fire with your back

to an exit.

*Based on “Kitchen Firesafety Tips” published by NFPA.

CAUTION:

Do not use to exhaust hazardous or explosive

materials and vapors.

Make sure all fingers are away from the downdraft

top when it is lowered.

If You Need Service…

Do not attempt to repair or replace any part of

the downdraft system unless it is specifically

recommended in this guide. All other servicing

should be referred to a qualified technician.

For general ventilating use only.

SERVICING

Be sure electrical power is off before servicing the unit.

Installation Instructions

It may be necessary to remove the downdraft

blower system in order to service components

such as the blower motor or air vent

mechanism.

Read and follow this Safety Information carefully.

Troubleshooting TipsCustomer Service

READ AND SAVE THESE INSTRUCTIONS

Disconnect power to the cooktop and remove

it first. Reverse the steps in the

Downdraft

Service parts are available from a GE Service

and Parts Center.

section to remove the blower.

Install the

4

Page 5

Using the downdraft system.

Safety Instructions

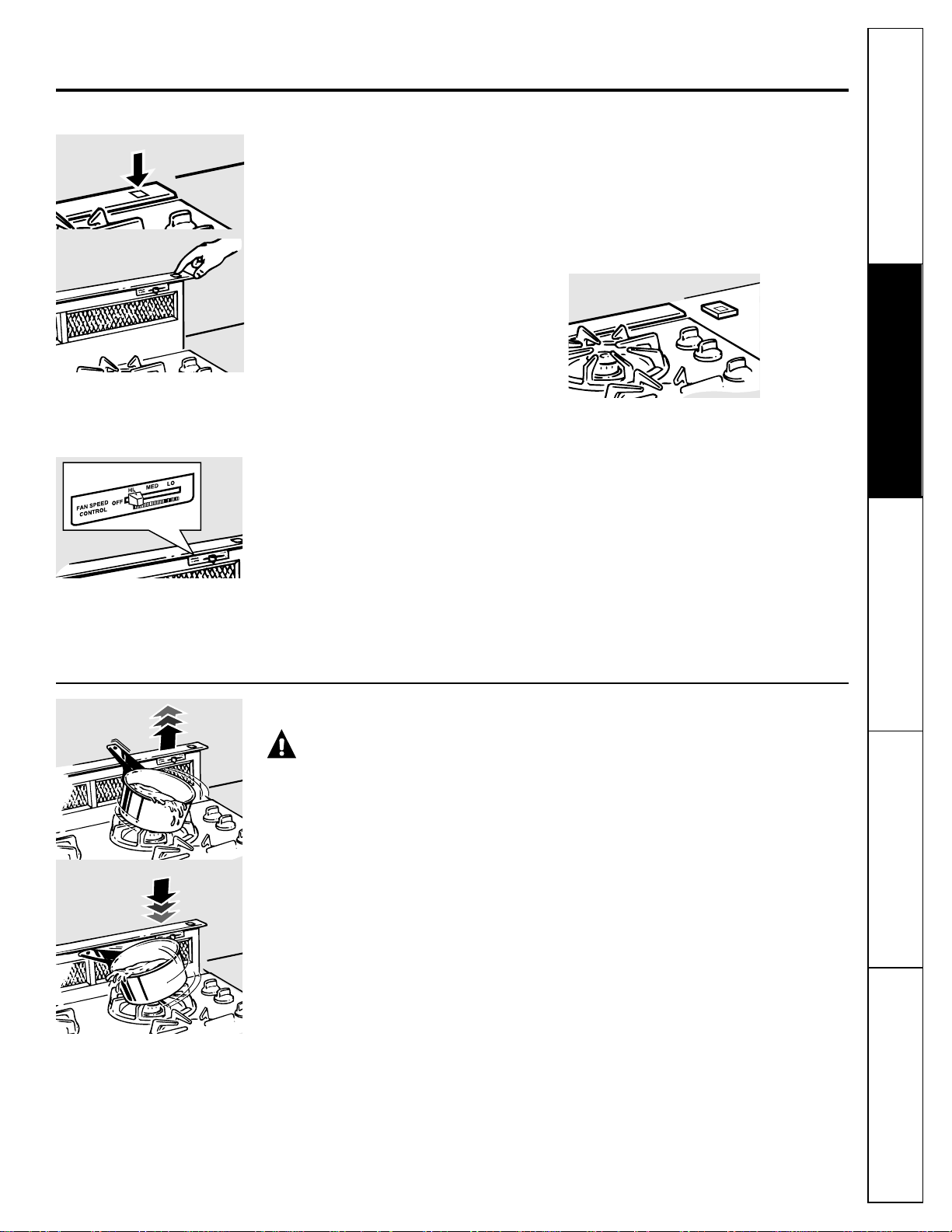

On some models, the RAISE/LOWER

switch is located at the top right of

the vent.

RAISE/LOWER Switch

Turn the downdraft blower ONby pressing

the

RAISE/LOWER

right of the vent (on some models). Place

your finger on the “center” of the switch

and hold until you observe the vent moving,

then release. The air vent will rise. Use the

selector switch to turn the blower

or to change the blower speed.

The vent may be lowered by again pressing

the

RAISE/LOWER

of the vent. The blower, if left on, will

automatically go off when the vent is

lowered.

NOTE: For most convenient operation, set the

blower to the speed you use most often. The

blower will come on to this speed whenever

the unit is raised.

switch located at the top

switch at the top right side

(30” models only)

ON, OFF

Remote RAISE/LOWER switch

(36″ models only)

36″models have a remote

switch. It operates in the same manner as

the switch located on the vent.

RAISE/LOWER switch location may vary.

RAISE/LOWER

Operating Instructions

Installation Instructions

Use the selector switch to turn the

blower ON, OFF or to change the

blower speed.

Using the Cooktop

Caution

Be careful when raising or lowering the

downdraft. Be sure pots, pot handles and

other objects are clear of the downdraft and

cannot be struck or tipped by the downdraft

being raised.

NOTE: There is a slight trim overhang at each

end of the vent.

■ To avoid injury, be sure fingers are clear

of the downdraft cover when it is being

lowered.

■ Keep hands and fingers away from all

downdraft parts.

Troubleshooting Tips

Customer Service

5

Page 6

Using the downdraft system.

Cooking Tips

The high air movement of this downdraft

system can increase the cooking times for

some foods. It may take longer to reach

Safety Instructions

high cooking temperatures if the downdraft

is turned to high right away. Adjust the fan

speed for best cooking results.

For best results when heating oil for deep

frying or when boiling water, use the front

surface units or wait until the water is

boiling or the oil is at frying temperatures

before turning on the downdraft.

The downdraft may not completely capture all the

steam from pans on the front burners.

Operating Instructions

Care and cleaning of the downdraft system.

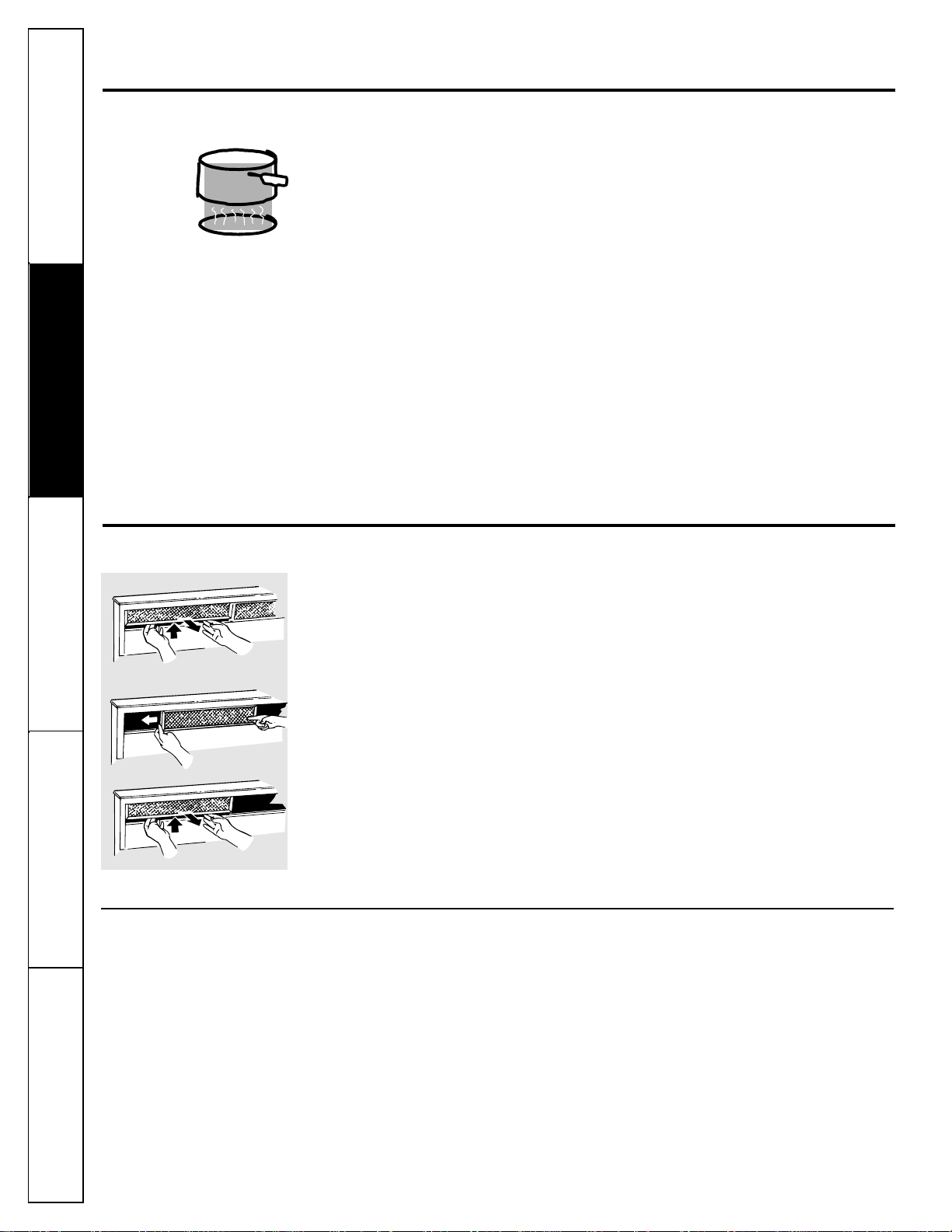

Grease filters

The efficiency of your downdraft depends on

a clean filter.

Frequency of cleaning depends on the type

of cooking you do. Grease filters should be

cleaned at least once a month.

Installation Instructions

Never operate the downdraft without the filters

in place.

To remove:

Remove the left filter first, then slide the

right filter to the left and remove it.

Lift up and pull the bottom out.

Canning

When canning foods in a water-bath canner,

a gentle but steady boil must be maintained

continuously for the required time.

When canning foods in a pressure canner,

the pressure must be maintained

continuously for the required time.

Use of the blower at

canning may reduce the temperature

enough to stop boiling. While canning,

we recommend using the downdraft at

LOW

speed and using the front surface unit.

To clean:

detergent solution. Light brushing may be

used to remove imbedded soil. Rinse, shake

and remove moisture before replacing.

Filters may be cleaned by placing in

dishwasher, although some slight color

fading may occur after several washings.

With careful handling, the filter will last for

years. If replacement becomes necessary,

order the part from your dealer.

Soak and then agitate in a hot

HIGH

speed when

Troubleshooting TipsCustomer Service

6

Painted or metal surfaces

Clean greasy surfaces frequently, using a

mild detergent.

Do not use abrasive cloth or cleaners, steel wool

pads or scouring powder because they will scratch

the surface.

Page 7

Installation of the downdraft system.

WARNING—TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY

TO PERSONS, OBSERVE THE FOLLOWING:

A.

Installation work and electrical wiring must be

done by qualified persons(s) in accordance with

all applicable codes and standards, including firerated construction.

Read these instructions completely and carefully.

B.

Ducted fans must always be vented to the

outdoors.

WARNING—To reduce the risk of fire, use only metal

ductwork.

Safety Instructions

Before You Begin

IMPORTANT: Save these instructions for the local

electrical inspector’s use.

IMPORTANT: OBSERVE ALL GOVERNING CODES

AND ORDINANCES.

NOTE TO INSTALLER: Leave these instructions with

the appliance after installation is completed.

NOTE TO CONSUMER: Keep this Owner’s Manual

and Installation Instructions for future use.

NOTE: This appliance must be properly grounded.

Installation Requirements

Before starting installation, check the following requirements:

VOLTS 120

AMPS 4.0

* Can be transitioned to round duct (6″ round minimum).

This downdraft blower system is designed to be used

to exhaust smoke and odors when cooking with all

GE Profile electric and gas cooktops listed in this

manual. It can be mounted in either an island or

peninsula location.

Requirements for an approved installation:

■26″minimum cabinet depth

■26″minimum from the back of the downdraft to

the front of the countertop, with

1

2

■23

⁄

″minimum FLAT countertop surface

■If you install the vent and cooktop in an island,

you may need additional island depth. 24″base to

base will not be adequate. Please see below.

CFM 500

DUCT 3

1

⁄4″ x 10″*

Plan the placement of the electrical outlet carefully.

It should NOT be installed on the back wall of the

cabinet because it may interfere with the downdraft.

It should be installed on a side wall or adjacent

cabinet. Make sure it is within reach of the unit’s 2 ft.

long power cord and conforms to all local codes.

Install a standard outlet to make the electrical

connection.

Plan the location of the gas supply pipe (for gas

cooktops) carefully to avoid interference with the

downdraft installation.

This unit can be easily installed following these

basic steps:

Cut out the countertop opening.

Install the downdraft in the cabinet.

Connect the ductwork and electrical.

Install the cooktop.

Operating Instructions

Installation Instructions

Troubleshooting Tips

Measurements

Refer to the cooktop installation instructions for dimensions of cooktop, countertop cutout,

and cabinet requirements.

Cutout dimension and illustrations are given for 30″and 36″cooktops.

■The 30″models will fit in most 30″wide cabinets

and the 36″models will fit in most 36″wide

cabinets.

■Check the inside dimensions of the cabinet before

beginning installation. The top of the side walls

may need to be cut to provide clearance for

mounting.

NOTE: To install a cooktop with this downdraft,

the cabinet depth must be 26″minimum.

A countertop with a raised lip may not allow enough flat

countertop for a proper installation.

26″

Flat counter area

Customer Service

7

Page 8

Installation of the downdraft system.

Read these instructions completely and carefully.

30″ Cooktops/Downdraft Unit JVB36

Safety Instructions

Refer to details below.

Figure 1

Overall cooktop dimensions

Operating Instructions

Figure 2

Overall cutout dimensions

NOTE: Against-the-wall installations are limited due to dimension requirements.

2-1/4″

6-3/4″

3-1/4″

Cooktop

Figure 3

Cutout for vent

2″

Vent

*

Island

*Front edge of countertop to cutout

Exhaust (right or left)

Installation Instructions

Troubleshooting TipsCustomer Service

(Figure 1) (Figure 1) (Figure 1) (Figure 1) (Figure 3*) (Figure 2) (Figure 2) (Figure 2) (Figure 3) (Figure 3)

Model No.

JP340

JP350 29-3/8″ 20-1/2″ 2″ 22-1/2″ 3″ 22-11/16″ 28-1/2″ 19-9/16″ 2-3/8″ 28-1/2″

JP360

JP392

JP393

JGP336 30″ 21″ 2″ 23″ 3-1/4″ 22-7/8″ 28-1/2″ 19-1/2″ 2-5/8″ 28-1/2″

*Required to maintain UL or AGA approvals.

Planning Installation (Note: 26″ deep cabinets required) Preparing Cutout

Cooktop Cooktop Depth Front Edge Min. Required Cooktop Cooktop Additional Depth Cutout Width

Overall Overall Vent Cooktop + Countertop to Front Inside Cabinet Cutout Cutout Required for Required from

Width Depth Depth Downdraft Vent Edge of Cutout Clearance Width Depth Downdraft Centerline

30″ 20-3/4″ 2″ 22-3/4″ 2″ 23″ 29-1/8″ 19-15/16″ 2-5/16″ 28-1/2″

Island

Minimum inside

cabinet clearance

&

Min. Setback— Downdraft

Notches may not be needed

depending upon cutout width.

=

29-1/2″

=

28-1/2″

No gas or electric service

inside shaded area.

8

Page 9

36″ Cooktops/Downdraft Unit JVB66

NOTE: Against-the-wall installations are limited due to dimension requirements.

Refer to details below.

Safety Instructions

Figure 1

Overall cooktop dimensions

Figure 2

Overall cutout dimensions

Remote RAISE/LOWER switch

(See the Installing the

RAISE/LOWER switch section.)

2-1/4″

6-3/4″

3-1/4″

Cooktop

Figure 3

Cutout for vent

35-3/16″

Vent

Island

2″

*

Island

*Front edge of countertop to cutout

8″

14-7/8″

Exhaust (right or left)

Notches may not be needed

depending upon cutout width.

Operating Instructions

Installation Instructions

Troubleshooting Tips

=

29-1/2″

=

34″

Minimum inside

cabinet clearance

No gas or electric service

inside shaded area.

Planning Installation (Note: 26″ deep cabinets required) Preparing Cutout

&

(Figure 1) (Figure 1) (Figure 1) (Figure 1) (Figure 3*) (Figure 2) (Figure 2) (Figure 2) (Figure 3) (Figure 3)

Cooktop Cooktop Depth Front Edge Min. Required Cooktop Cooktop Additional Depth Cutout Width

Model No.

JP660 35″ 20″ 2″ 22″ 2-1/2″ 22″ 34″ 19-9/16″ 2-3/8″ 34″

JP692

JP693

JGP636 35-1/2″ 21″ 2″ 23″ 3-1/4″ 22-11/16″ 34″ 19-1/16″ 2-7/8″ 34″

*Required to maintain UL or AGA approvals.

Overall Overall Vent Cooktop + Countertop to Front Inside Cabinet Cutout Cutout Required for Required from

Width Depth Depth Downdraft Vent Edge of Cutout Clearance Width Depth Downdraft Centerline

35-1/2″ 20-3/4″ 2″ 22-3/4″ 2″ 23″ 34-5/8″ 19-15/16″ 2-5/16″ 34″

Min. Setback— Downdraft

Customer Service

9

Page 10

Installation of the downdraft system.

Read these instructions completely and carefully.

Planning the Ductwork

This downdraft blower system is designed

for use with 31⁄

transitioned to 6″round). Two different

Safety Instructions

discharge directions are available with side-toside adjustment for accurate alignment of

ductwork.

Operating Instructions

Left discharge (as shipped)

For best performance: Choose the ducting

option which allows the shortest length of

ductwork and a minimum number of elbows

and transitions. Check location of floor joists,

wall joists, wall studs, electrical wiring or

plumbing for possible interference.

4

″x 10″ ductwork (can be

Right discharge

Steps to Determine Flexible Ducting’s Equivalent Length

Measure the actual amount of offset

(Maximum 3″recommended). The effect

upon airflow is dependent upon the amount

of offset.

Calculate the equivalent ducting

allowances using:

( ___ in. offset) x (14 ft. per inch)

= ___ ft. equivalent length.

Ensure that the total equivalent length of

ducting does not exceed the maximum

recommendation of 150 feet.

Duct Equivalent Duct Equivalent Duct Equivalent

Pieces Length* Pieces Length* Pieces Length*

Installation Instructions

6″ Round 1 ft. (per 31⁄4″ x 10″ Transition

Straight foot length) 45° Elbow

31⁄4″ x 10″ 1 ft. (per 31⁄4″ x 10″ Wall Cap 21 ft.

Straight foot length) 90° Flat Elbow

6″ Round 31⁄4″ x 10″

6″ 15 ft. to 31⁄4″ x 10″ 7 ft. Wall Cap 27 ft.

90° Elbow Transition with Damper

31⁄4″ x 10″

Troubleshooting TipsCustomer Service

SHOULD NOT EXCEED 150 EQUIVALENT FT.

*Equivalent lengths of duct pieces are based on actual tests conducted by GE Evaluation Engineering

and reflect requirements for good venting performance. See chart for CFM Duct Length.

6″ to 6″ Round 5 ft. 6″Round

45° Elbow

31⁄4″ x 10″ Transition

90° Elbow

9 ft.

16 ft.

Transition Roof Cap

6″ Round

to 31⁄4″ x 10″

90° Elbow Roof Vent

5 ft.

24 ft.

20 ft.

31⁄4″ x 10″

to 6″ Round

90° Elbow

6″ Round

with Damper

6″ Round

12 ft.

20 ft.

24 ft.

10

Page 11

Planning the Wiring

Safety Instructions

All wire connections and installations must be in

compliance with local codes. In the absence of local

electrical codes consult the National Electric Code.

The downdraft blower system draws 4 AMPS

and requires a 120 VAC, 60 Hz circuit.

Plan to provide a grounded outlet in a

location which will allow the unit’s power

cord to reach.

On 36″model, plan the

The lead to the switch is 72″long.

RAISE/ LOWER

switch.

Preparing to Install the Downdraft System

Changing Blower Discharge

The outlet cannot be located on a back wall.

The outlet needs to be mounted on the side wall

of the cabinet or it could be on the back wall of an

adjacent cabinet with access through an opening

in the side wall. (Based on local codes.)

Operating Instructions

The blower can be mounted in the cabinet or under

the floor. The blower will fit between floor joists on

16″centers.

Installation Instructions

Discharge left

(shown with rectangular duct)

The vent is shipped with the outlet on the left.

If the position of the discharge needs to be moved

so the ductwork does not interfere with floor joists,

plumbing or wiring below, make the following

changes:

To change the discharge from left to right, remove

the screws holding the outlet panel to the bottom of

the vent. Remove and rotate the panel and fasten

with the screws.

Preparing the Blower

A transition is provided to connect a 31⁄

to the blower. Attach the duct transition to the top

of the blower with the screws provided. The blower

has holes that match the transition.

Do not drill additional holes in the blower.

If round ducting is used, transition to 6″round to

connect to the inlet of the blower.

4

″ x 10″duct

Through the floor

(shown with rectangular duct)

For installations where the blower is mounted

in the cabinet, attach the mounting supports to the

corners of the blower housing on the motor side of

the motor housing.

If the blower is installed under the floor, attach the

support legs to the corners of the blower housing on

the side that the inlet duct attaches.

The support legs are adjustable for height by sliding

the two halves and tightening the bolts when

extended to the desired length.

Troubleshooting Tips

Customer Service

Discharge right

(shown with 6″ round duct)

11

Page 12

Installation of the downdraft system.

Read these instructions completely and carefully.

Installing the Downdraft

Set the downdraft into the opening.

Secure the downdraft to the countertop as

Safety Instructions

follows: Hold the downdraft against the back

of the countertop cutout and tighten the

2 mounting screws (one on each end of unit)

on the underside of the countertop. Use a

wood shim between the screw and the

underside of granite countertops.

There are holes provided to attach the

stabilizing strap to either side of the downdraft.

Fasten the other end of the strap to the back or

side wall of the cabinet.

If installing on a tile surface, it may be necessary to

apply locally approved caulking along the back and

sides to cover gaps.

Operating Instructions

Installing the Ductwork

CAUTION—BEFORECUTTING A HOLE IN CABINET FOR

DUCTWORK: Check for interference with floor joists,

wall studs, electrical wiring or plumbing.

Cut the hole in the cabinet as well as holes in

the wall or floor as necessary.

Mounting Screws

Mount the roof or wall cap and work back

towards the cabinet and blower, attaching all

ductwork, elbows and transitions as previously

planned. Tape all ductwork connections to

make them secure and air tight.

Installing the RAISE/LOWER Switch

Installation Instructions

Troubleshooting TipsCustomer Service

The

RAISE/LOWER

countertop, cabinet face or wall near the downdraft.

Determine where you wish to place the remote

mount

wiring lead length for the switch is 72 inches. The

connector at the end of the leads plugs into a

mating connector located in the control box.

RAISE/LOWER

After selecting

the location of

the switch, drill

a 1/8″hole in

the surface

selected, i.e.

top, cabinet

face, or

adjacent wall.

Countersink

11/16″to a

1/4″depth. Tie

a small knot in

the switch leads

as shown in this

figure. The knot should be as close to the

switch as possible so that is fits into the

countersink. This provides for strain relief.

12

(on some models)

switch can be installed in the

switch. Keep in mind that the

Trim

Knot

Leads

Mounting

bracket

Mount the metal switch bracket, with either the

screws provided or locally approved adhesive, over

the countersink.

Make sure the bracket is oriented with the center section

touching the mounting surface.

Peel the film from the back of the trim to

expose the adhesive and thread the electrical

leads through the mounting bracket 1/8″

hole and into the cabinet.

If mounted on a tile surface, make the

hole large enough for wires (i.e. between tile

sections) and use locally approved caulking

to cover any gaps around the base of the

trim body.

Snap the trim body onto the mounting

bracket and press to set the adhesive.

Attach the 2 leads to the two-prong plug and

plug into the panel on the vent. Route and tie

the switch leads and any excess wire length so

they will not be pinched or caught during

operation of the vent or by an article stored

within the cabinet.

Page 13

Installing the Electrical Wiring

Safety Instructions

Mount a standard wiring box, with 3-pronged,

120 volt, 60HZ outlet, inside the cabinet.

Make sure the downdraft’s power cord can

easily reach it.

Run the appropriate power cable into the

cabinet and connect it to the outlet.

Plug the downdraft’s power cord into the

outlet.

For Remote Installations

If the blower conduit is not long enough to reach the wiring

compartment on the downdraft, the leads can be extended.

Cut the blower leads approximately 3″from

the plug on the end of the blower conduit.

3″

Blower wire box

3-Wire connector

Blower

conduit

For Local Installation

The conduit on the blower is of sufficient length to connect to

the downdraft when the blower is mounted in the cabinet and

for some installations under the floor.

Plug the blower conduit into the mating connector

on the bottom of wiring compartment cover on the

downdraft. Fasten the wire box to the main unit

wiring compartment with the screws provided.

Save the wire box and plug to complete the

connection at the downdraft vent in the house.

Use electrical cable and connectors that

conform to local codes (14 gauge min. is

recommended). Attach the wire box removed

from the blower conduit to the end of the wire

run at the vent. Attach the plug and 3″leads to

the cable at the downdraft vent. Insert the plug

into the mating plug on the vent. Attach wire

box with screws to the vent.

Install appropriate electrical box with conduit

connectors near the blower.

Operating Instructions

Installation Instructions

Remove the wire box and conduit fitting from

the end of the blower conduit by loosening the

screw on the fitting.

Wire to outdoor

enclosure

Mounting screw

Blower wire box

Wire nuts

Installing the Cooktop

Align the cooktop with the downdraft and

fasten cooktop in place.

3-Wire

connectors

Check that the red plastic anti-short bushing is

secured in the end of the conduit. Install the

blower conduit into the conduit connector on

the electrical box.

Attach the green ground lead from the blower

to the ground lead of the wiring of the

downdraft vent.

Connect the neutral and power leads from the

blower to the leads from the downdraft vent.

NOTE: Accurate alignment of cooktop and downdraft is

necessary to ensure that there is not interference when

air vent is raised and lowered. There should be a gap of

1/16″–1/8″ between the back of the cooktop and the

front of the downdraft cover.

Troubleshooting Tips

Customer Service

13

Page 14

Before You Call For Service…

Troubleshooting Tip

Save time and money! Review the tip below and you may

not need to call for service.

Problem Possible Causes What To Do

Safety Instructions

Fan does not work

Operating Instructions

The vent is not fully extended. • Press the

The blower control switch may • Slide it to the right.

be in the

OFF

position.

RAISE/LOWER

switch.

Installation Instructions

Troubleshooting TipsCustomer Service

14

Page 15

Notes

Safety Instructions

Operating Instructions

Installation Instructions

15

Troubleshooting Tips

Customer Service

Page 16

Notes

Safety Instructions

Operating Instructions

Installation Instructions

Troubleshooting TipsCustomer Service

16

Page 17

GE Service Protection Plus

™

GE, a name recognized worldwide for quality and dependability, offers you Service

™

Protection Plus

—comprehensive protection on all your appliances—No Matter

What Brand!

Benefits Include:

• Backed by GE

• All brands covered

• Unlimited service calls

• All parts and labor costs included

• No out-of-pocket expenses

• No hidden deductibles

• One 800 number to call

You will be completely satisfied with our service protection or you may request your money back

on the remaining value of your contract. No questions asked. It’s that simple.

Protect your refrigerator, dishwasher, washer and dryer, range, TV, VCR and much more—any brand!

Plus there’s no extra charge for emergency service and low monthly financing is available. Even icemaker

coverage and food spoilage protection is offered. You can rest easy knowing that all your valuable

household products are protected against expensive repairs.

Place your confidence in GE and call us in the U.S. toll-free at 800-626-2224

for more information.

*All brands covered, up to 20 years old, in the continental U.S.

We’ll Cover Any Appliance.

Anywhere. Anytime.*

Please place in envelope and mail to:

General Electric Company

Warranty Registration Department

P.O. Box 34070

Louisville, KY 40232-4070

✁

Cut here

17

Page 18

GE Appliances

General Electric Company

Louisville, Kentucky 40225

Consumer Product Ownership Registration

Dear Customer:

Thank you for purchasing our product and thank you for placing your

confidence in us. We are proud to have you as a customer!

Follow these three steps to protect your new appliance investment:

1

Complete and

mail your Consumer

Product Ownership

Registration today.

Have the peace of

mind of knowing we

can contact you in

the unlikely event of

a safety modification.

23

After mailing

the registration

below, store this

document in a safe

place. It contains

information you

will need should

you require service.

Our service number

is 800-GE-CARES

(800-432-2737).

Model Number Serial Number

Read your Owner's

Manual carefully.

It will help you

operate your new

appliance properly.

If you have questions,

or need more information call the

GE Answer Center®

800.626.2000.

Important: If you did not get a registration card with your product,

detach and return the form below to ensure that your

product is registered.

Cut here

✁

Consumer Product Ownership Registration

Model Number Serial Number

Important

Mail

Today!

First

Name

Last

Name

Street

Address

Apt. #

City

State

Date Placed

In Use

Month

Phone

Number

18

Mr. ■■ Ms. ■■ Mrs. ■■ Miss ■■

Zip

Code

Day Year

__

Page 19

GE Downdraft System Warranty

All warranty service provided by our Factory Service Centers,

or an authorized Customer Care® technician. For service,

call 800-GE-CARES.

For The Period Of: GE Will Replace, At No Charge To You:

Safety Instructions

One Year Any part

From the date of the

original purchase

During this

and in-home service to replace the defective part.

of the downdraft system which fails due to a defect in materials or workmanship.

full one-year warranty,

GE will also provide,

free of charge,

all labor

What GE Will Not Cover:

■Service trips to your home to teach you how to use the

product.

■Improper installation.

■Failure of the product if it is abused, misused, or used for

other than the intended purpose or used commercially.

This warranty is extended to the original purchaser and any succeeding owner for products purchased for home

use within the USA. In Alaska, the warranty excludes the cost of shipping or service calls to your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state. To know what your

legal rights are, consult your local or state consumer affairs office or your state’s Attorney General.

If you have an installation problem, contact your dealer or installer. You are responsible for providing adequate

electrical, gas, exhausting and other connecting facilities as described in the Installation Instructions provided

with the product.

■Replacement of house fuses or resetting of circuit

breakers.

■Replacement of the replaceable filters.

■Damage to the product caused by accident, fire, floods or

acts of God.

■Incidental or consequential damage to personal property

caused by possible defects with this appliance.

Operating Instructions

Installation Instructions

Warrantor: General Electric Company. Louisville, KY 40225

Troubleshooting Tips

Customer Service

19

Page 20

Service Telephone Numbers.

GE Answer Center

The GE Answer Center® is open 24 hours a day, 7 days a week.

Safety Instructions

In-Home Repair Service

Expert GE repair service is only a phone call away.

Special Needs Service

800-TDD-GEAC (800-833-4322)

GE offers, free of charge, a brochure to assist in planning a barrier-free kitchen for persons

with limited mobility.

Operating Instructions

Service Contracts

Purchase a GE service contract while your warranty is still in effect and you’ll receive a

substantial discount. GE Consumer Service will still be there after your warranty expires.

®

800.626.2000

800-GE-CARES (800-432-2737)

800.626.2000

800-626-2224

Parts and Accessories

Individuals qualified to service their own appliances can have parts or accessories sent directly

Installation Instructions

to their homes (VISA, MasterCard and Discover cards are accepted).

Instructions contained in this manual cover procedures to be performed by any user. Other servicing

generally should be referred to qualified service personnel. Caution must be exercised, since

improper servicing may cause unsafe operation.

Service Satisfaction

If you are not satisfied with the service you receive from GE:

First,

contact the people who serviced your appliance.

Next,

Troubleshooting TipsCustomer Service

if you are still not pleased, write all the details—including your phone number—to:

Manager, Customer Relations

GE Appliances

Appliance Park

Louisville, KY 40225

Finally,

if your problem is still not resolved, write:

Major Appliance Consumer Action Program

20 North Wacker Drive

Chicago, IL 60606

800-626-2002

20

Printed in the United States

Loading...

Loading...