Page 1

Part No. t64D3333P024-2 Pub, No, 49-8768-2 D-959-0776-002 7-98 CG

Page 2

Safety Information

5atetyPrecautions..... 3,4

Operating instructions

Usingthe Downdroft

5_sten ........ 5 o

Usingme 6brttroz_ 5

CJJreand Cleanir_g ..... 6

GE& YOUrA ServicePartnership.

IMPORTANT!

Insta#ation lnstl_ctions

Before YouB_ln ....... 7

/_-85ui'et_sn[s 7 9

P/zTningt:heLJuctwod(....... 70

Plan/ngt;helitlirTr_ ..... 77

lnstollin9 toe

[Jowndrafr .... 77 72

sn_//ir1_ the

[7ectrid_7/l}iirmcj....... 73

Troubleshooting Tips

Betor_7ou(;_lll

f-orSavlce ..... 74

Customer Service

ProductReais_ml/on. . . 17

W_Trmnty ..... l_

Service,>ie,pnone

NumbeLs ...... BackCJver

Fill out and return tile Consumer 1)r(iduct Regism_fion Card that is

pa(ked xdih tllis produ(L Ifvou (annl)l find it, please send in tile

dupli(ate (at(] printed in tile ba(k of this manual.

FORYOURRECORDS

Write the model and serial numbers here:

#

#

Staple sales slip or cancelled check here.

PLEASE NOTE: The downdraft vent systemyou have purchased was

designed to be used with GEProfile cooktops listed in this manual

Proof of tile original purchase date is needed 1(/(/blain ser_i(e under

tile W;lI'I_<ln/y,

READTHISMANUAl_

Inskle you will find many h elpfill hints on how to use and maintain your

vent properly.Just a little preventive care on your pro1 can save you a great

deal of time and money over tile lif> of yore vent.

You Hfind man) answers to cflmmon problems in die Before YouCafl For

Service secdon. If you re_ex_ our (:harl of Troubleshooting Tips first, you

may not need t11call for service at all.

IFYOUNEEDSERVICE

If you do need seixice, you can relax knox,ing help is only a phone call

away. A list of toll-flee customer sei_ice numbers is included in the back

2

section 11tthis guide. Or y()u can always call the GE Answer (enter (' at

800.6'26.2000, 24 h(/urs a (1W, 7 (la}:s a week.

Page 3

IMPORTANTSAFETYINFORMATION.

READALLINSTRUCTIONSBEFOREUSING.

a, WARNING!

Foryour safety, the information in this manual must be followed to minimize the risk of fire or explosion,

electric shock, or toprevent property damage, personal injury, or loss of life.

WARNING--TOREDUCETHERISKOFFIRE,

ELECTRICSHOCK,ORINJURYTOPERSONS,

OBSERVETHEFOLLOWING:

A. Use this refit only in the manner intended by

the mant/f_tcturer. Ifyou have any questions

(ontact the rnantff_cttHer.

R Befbre servicing or cleaning unit, switch

power offat sewice panel and lock fl_e

service disconnecting means to prevent

power fi_m being switched on accidentally.

\,_l_en the service disconnecting means

cannot be locked, securely fhsten a

pr_)minent wanting device, such as a tag, m

the set_ice panel.

CAUTION: For general ventilating use only.

Do not use to exhaust hazardous or explosive

',, Installation wofl< and electrical wiring must

be done by qualified person(s) in

ac(:o_dan(:e with all applicable codes and

slandmds, including fire-rated (:onstmction.

When cutting or (killing into wall or ceiling,

do not damage electrical wiring and other

hidden utilities.

Dncted f_lns must always be vented to file

outdoors.

S_ttficient air is needed for proper

combustion and exhausting of gases through

the flue (chimney) offilel-burning

equipment to prevent bacl;drafling. Follow

the heating e(pfipment manttthcmrer's

glfideline and safety standards such as those

published by the National Fire Protection

Association (NFI'A), and the American

Society for Heating, Refiigeration and Air

Conditioning Engineers (ASHRAE), and the

local code authorities.

To reduce the risk of fire, use only metal

ductwork.

PVC sewer pipe can be used as duct under

concrete slab if allowed by local code board.

This unit must be grounded.

SAFETYPRECAUTIONS

WARNING--TO REDUCETHERISK OFA RANGE TOPGREASEFIRE,"

Keep fan, filters and gTease laden

surfaces clean.

:Always turn hood ON when cooking

at high heat.

Use high range settings on range onlywhen

necessary. Heat oil slowly on low to

medium setting.

:i Don't leave range unattended when cooking.

Ahvays use cookware and utensils

appropriate for the type and amount

of food being prepared.

3

Page 4

IMPORTANTSAFETYINFORMATION

READALL INSTRUCTIONSBEFOREUSING.

A WARNINGf

SAFETYPRECAUTIONS

TOPERSONSIN THEEVENTOFA RANGE TOPGREASE

FIRE,OBSERVETHEFOLLOWING/

A.

SMOTHER FI[AMES with a close-fitting

lid, cookie sheet, or metal tray, then turn

off the burner. BE CAREFUL TO

PREVENT BURNS. If the flames do not go

out immediamly, E%a_CLTATE AND CALL

THE FIRE DEPARTMENT.

B. NEVER PICK UPA FI[AMING PAN--

Y(_u may be burned.

C. DO NOT USE _,%_TER, indudingwet

dishcloths or toweh-a violent steam

explosion will resuh.

D. Use an extinguisher ONLYif:

L Y(m know you h_we a Class ABC

exting_flsher, and you abeady know how u_

operate it.

Z The fire is small and contained in the m>a

where it started.

3. The fire department is being called.

4. You can fight the fire with your back

to an exit,

2%sodon "KitchenF/?esafelyTIps"publishedhyNFPA

CAUTtON: For g_nera] ventilating use onlyo

Do not use to exhaust hazmdous or explosive

Make sure aft fingers are away from the downdraR

top when it is lowered

ff YouNeed Service...

Do not attempt to l_pair or replace any part of

the downdrafi system unless it is specifically

recommended in this gafide. All other secvicing

should be refen_d to a qualified mchnician.

SERVIC/NC

Be sure electrical power is off before servicing the unit,

It may be necessa_ 7 to remove the @)wndrafi

blower system in o_,ter to sewice (omponems

suth as the blower mou)r or air vent

methanism.

Readandfollow this Informationcarefull'

READAND SAVETHESEINSTRUCTIONS

Disconnect power to fl_e cooktop and remo_v

it first. Reverse the steps in the Install the

Downdraft set fion to remove the blower.

Sel-vice parts are avaihble from a GE Service

and Parts Center.

4

Page 5

Usingthedowndraftsystem.

RAISE/LOWERSwitch (3o"models only)

Tmn tile dox_ll(hafi blower ONby pressing

the PAISE/LOWER switch located at the top

right of the vent (oil some models). Place

y{)ur finger oil the "center" of the s_xitch

and hold until you observe the vent rot)ring,

then release. The air vent will rise. Use the

sele(tor s_dtch to mrn tile blower ON,OFF

or to dlange the blower speed.

Tile vent may be lowered by again pressing

the PAISE/LOWERs_a_itchat the top right side

of the vent. The blower, if left on, will

On some models, the RAISE/LOWER

switch is located at the top right of

the vent,

mltomafically go offwhen tile vent is

lowered.

NOTE:Formostconvenientoperation,set the

blower tothe speedyou usemostoften. The

blower will come onto thisspeed whenever

theunit is raised.

iii ii! i

RemoteRAISE/LOIIVERswitch

(36"modelsonly)

36" models havea remote RAISE/LOWER

sx_ch. I_ operates in _t_esame manner as

fl_es_dt(:h lot ated on the vent.

RAISE/LOWERswitch location may vary,

Use the selector switch to turn the

blower ON,OFFor to change the

blower speed,

Using the Cooktop

Caution

Be caretnl when raising or lowering tile

dox_lldrafl. Be sure pots, pot handles and

other objecls are clear of tile do_ll(hafl and

cannot be su_uckor tipped by the dox_lldrafi

being raised.

NOTE"Thereisa slight trimoverhangat each

end ofthe vent.

To avoid h-tj_v, be sure f'mgers are clear

of the dow_draft cover when it is behrig

lowered.

Keep hands and f'mgers away from all

downdraft parts.

Page 6

Using the downdraft system.

Cooking Tips

The high air m_)vement of this dox_i_drafl

system can increase tile cooking times tot

some fi)ods. It may take longer to reach

high cooking temperatures ifthe (h_wndrafi

is turned to high right away. A(!just the tim

speed tor best cooking resuhs.

For best resuhs when heating oil fi_rdeep

fl)qng or when boiling water, use the fiont

smtace uniLsor wait until the water is

boiling or the oil is at flying temperatures

befi)re turning on the (h)wnchafi.

Thedowndralt may not completelycapture aft the

steamfrom panson the front burners,

Careand cleaning of the downdraft system.

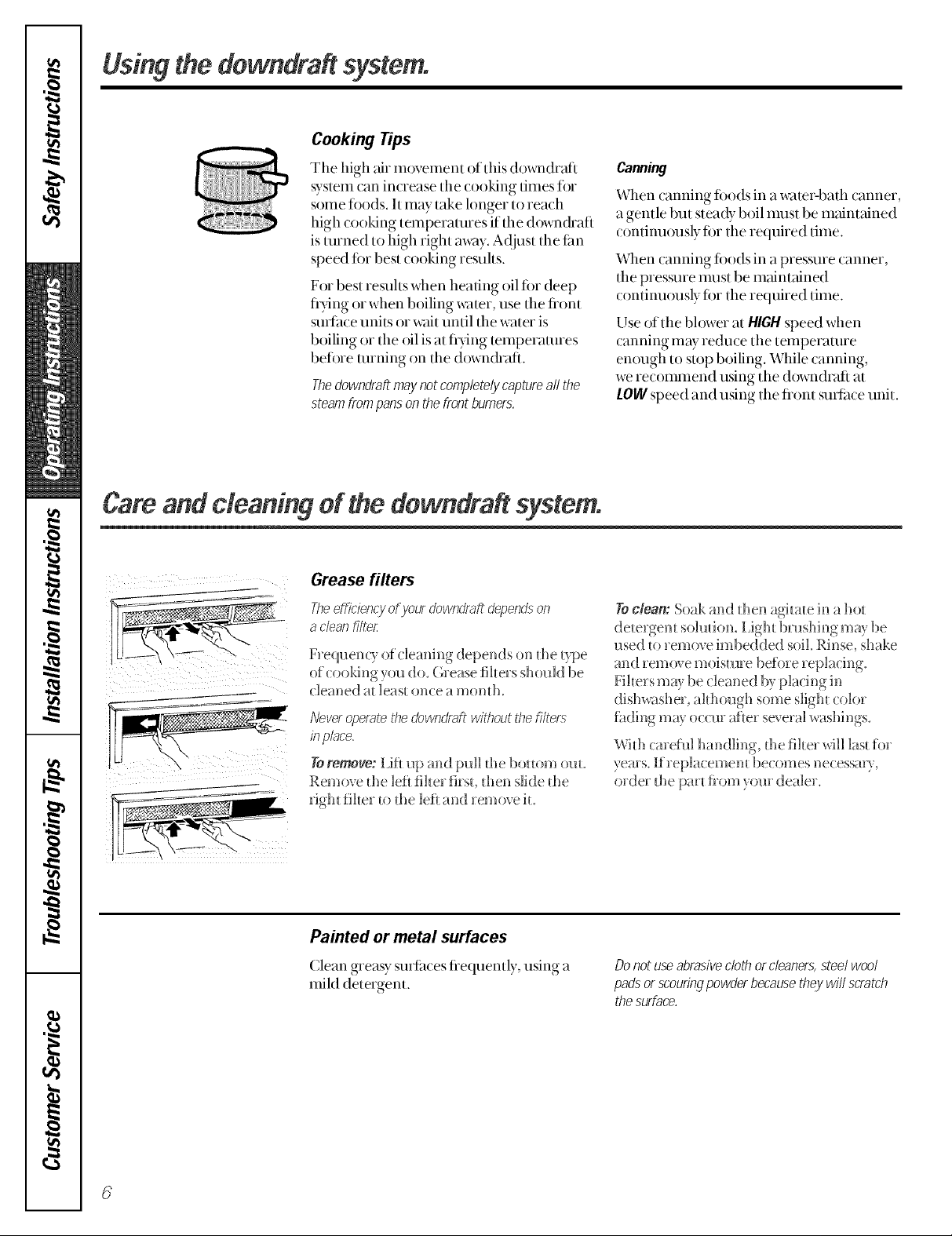

Grease filters

Theefficiencyofyourdowndmftd_pendson

acbanfilter

Frequen( 7 of cleaning depends on the tTpe

of cooking you do. Grease fil_ers should be

cleaned at leas[ once a month.

Neverof)eratethe dowrl(2a)withoutthefilter:5

snplace.

Toremove:Lift up and pull _hebo{um_ ore,

Remove d_e left fil_erfirst, d_en shde d_e

righ_ fil_er u_the lef_and remo_ e h.

Catlll_

When canning tbods in a wa/er-bath canner,

a gentle but steady boil nmst be maintained

contimu)usly fi)r the required time.

When canning toods in a pressure canner,

the pressure nmst be re>tint>fined

contimu)usly fi)r the required time,

Use of the blower at HIGHspeed when

canning may reduce the temperature

enough to stop boiling. While canning,

we recommend using the downdmfi at

LOW speed and using the flont surlime unit.

Toclean: Soak and d_en agha_e in a ho_

de_ergem solution. Ligh_ brushing may be

used _o remove imbedded soil. Rinse, shake

and remove moisture before replacing.

Fil_ers may be cleaned by placing in

dishwasher, alfi_ough some sligh_ color

fT_dingmay occur afler several washings.

Whh care_ifi handling, the fiber will lasl for

yems. Ifrepla(emen[ becomes necessary,

order the par{ flom yore dealer.

Painted or metal surfaces

Clean greasysm_ilcesfiequently, using a

miM detergent.

Do not useabrasivecloth or cleaners,steel wool

padsor scouringpowder becausethey will scratch

the surface,

Page 7

Installationof thedowndraft

WARNING--TO REDUCETHERiSK OFFIRE,ELECTRICSHOCK,ORiNJURY

TOPERSONS,OBSERVETHEFOLLOWING:

system. Read meso instructionscompletely and carefully

A. lns_alla_ior_ work and ele(:_rical wiring mus_ be

done by qualified persons(s) in accord race _d_

all applicable codes and s_andards, inchMing fire-

ra_edcons_rucdon.

B. Ducked f_u_s mus_ always be vetoed _o _he

outdoors.

WARNING--Toreducethe risk of fire, use onlymetal

ductwork.

Before YouBegin

IMPORTANT:Save t,_eseinstructions for the local

electrical inspector's use.

IMPORTAN_ OBSERVEALL GOVERNINGCODES

AND ORDINANCES.

NOTE TOINSTAL£ER:Leave these instructions with

the appliance after installation is completed.

NOTE TOCONSUMER:Keep this Owner's Manual

and installation instructions for future use.

NOTE."This appliance must be properly grounded.

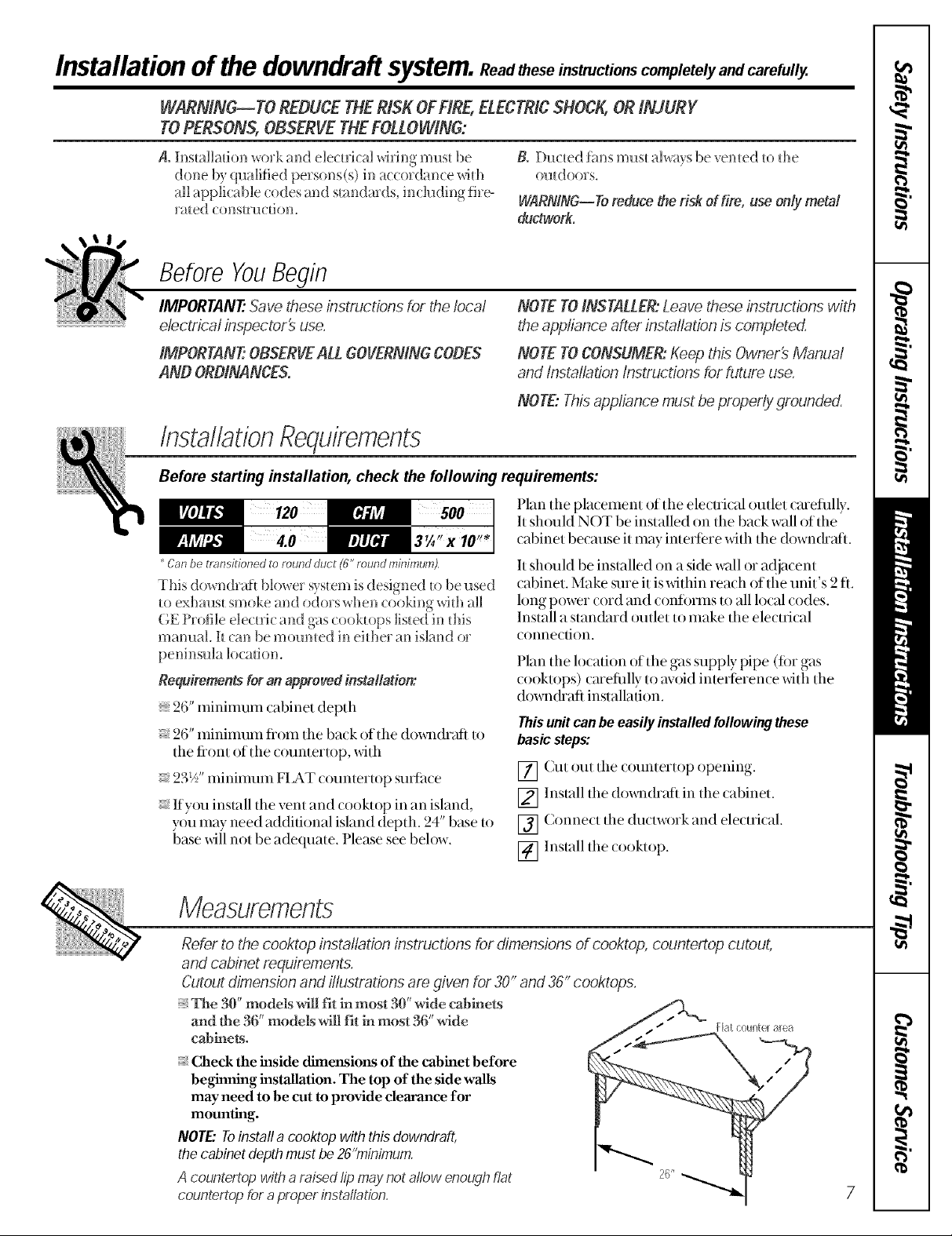

InstallationRequirements

Before starting installation, check the following requirements:

120

4.0

Canbe tmnsitioned to round duct (6" round minimum),

This downdrah blo_ er system is designed u) be used

u_ exhaus_ smoke and odors when cooking with aH

(;E Profile electric and gas cooku_pshs_edh_dfis

manual h (::ar_be mourned in either an island or

500

3_ " X 10"_

Plan the placement of the elecuical outlet carefiflly.

It should NOT be installed on the back wall of the

cabinet be(rauseit may inter{ere with the down&aft.

It should be installed on a side wall or a(!jacent

cabinet. Make sure it iswithin reach of the unit's 2 ft.

long power cord and conforms to all local codes.

Install a stan&ud outlet to make the electrical

connection.

Plan the locathm of the gas supply pipe (for gas

Requirements for an approved installation:

26" minimum cabinet depth

_ 26" minimum flora the back of the &)_lldrafi to

the fiont of the countertop, with

23%" mininmm FIAT countertop smthce

:_Ifyou install the vent and cookt op in an island,

you may need additional island depth. 24" base to

base will not be adequate. Please see below.

cooktops) carefiflly to avoid inter[erence with the

downchaft installation.

Thisunit canbeeasilyinstalledfollowingthese

basicsteps:

[] Cut out the (ountertop opening.

[] Install the (lo_i_(hafl in the cabinet.

[] ( onnect the duclwork and electrical.

[] Install the cooklop.

Measurements

Refer to the cooktop installation instructions tot dimensions of cooktop, countertop cutout,

and cabinet requirements.

Cutout dimension and illustrations am given for 30" and 36" cooktops.

_,The 30" models will fit in most 30" wide cabinets

and the 36"models will fit ir_most 35"wide

cablneN.

:_ Check the inside dimensions of the cabinet before

beginning installation. The top of the side walls

may need to be cut to provide clearance for

mounting.

NOTE" Toinstafl a cooktop with this downdraft,

the cabinet depth must be 26"minimum

A countertop with a raised lip may not allow enough flat

countertop for a proper installation,

Page 8

Installation of the downdrafl system.

Read these instructions completely and carefully.

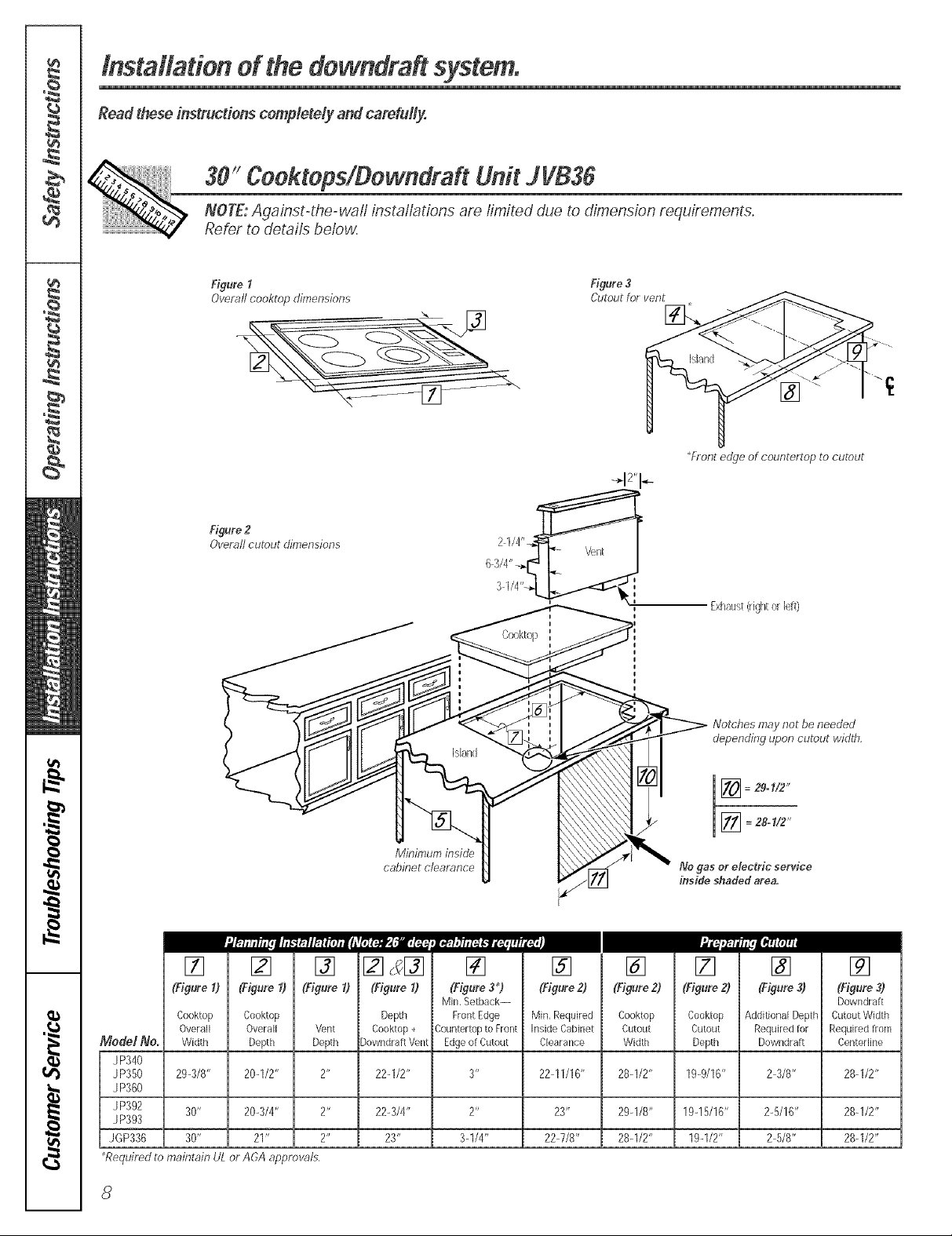

30_!Ceektops/Dewndraft Unit J VB36

NOTE: Against-the-waft instaflations are limited due to dimension requirements.

Reter to details below,

Figure I Figure 3

Overall cooktop dimensions Cutoutfor vent

Front edge of countertop to cutout

Figure 2

Overall cutout dimensions

Minimum inside

cabinet clearance

[] [] [] [] s[] [] []

(Figure 1) (F,(gureI) (Figure I) (Figure I) (Fig_,,re3,_) (Figure 2)

Cooktop Cooktop Depth FrontEdge Min,Required

ModelNe. Width Depth Depth )owndraRVent EdgeotCutout Clearance

J P340

JP350 29-3/8" 20-1/2" 2" 22-1/2" 3" 22-11/16"

J P360

J P392 30" 20-3/4" 2" 22-3/4" 2" 23"

J P393

JGP336 30" 21" 2" 23" 3-1/4" 22-7/8"

Required to maintain UL or A6A approvals,

Overall Overall Vent Cooktop+ CounterloptoFront hside Cabinet

Min,Setback--

Exhaust(rightorleft)

Notches may not be needed

depending upon cutout width,

No gas orelectric service

inside shaded area,

[] [] [] []

(Figure2) (Figure2) CFigure3) (Figure3)

Cooktop Cooktop AdditionalDepth CutoutWidth

Cutout Cutout Required tot Required from

Width Depth Downdra[t Centerline

28_1/2" 19_9/16" 2-3/8" 28q/2"

29q/8" 19q5/16" 2-5/16" 28q/2"

28q/2" 19-1/2" 2-5/8" 28q/2"

Dewndraft

Page 9

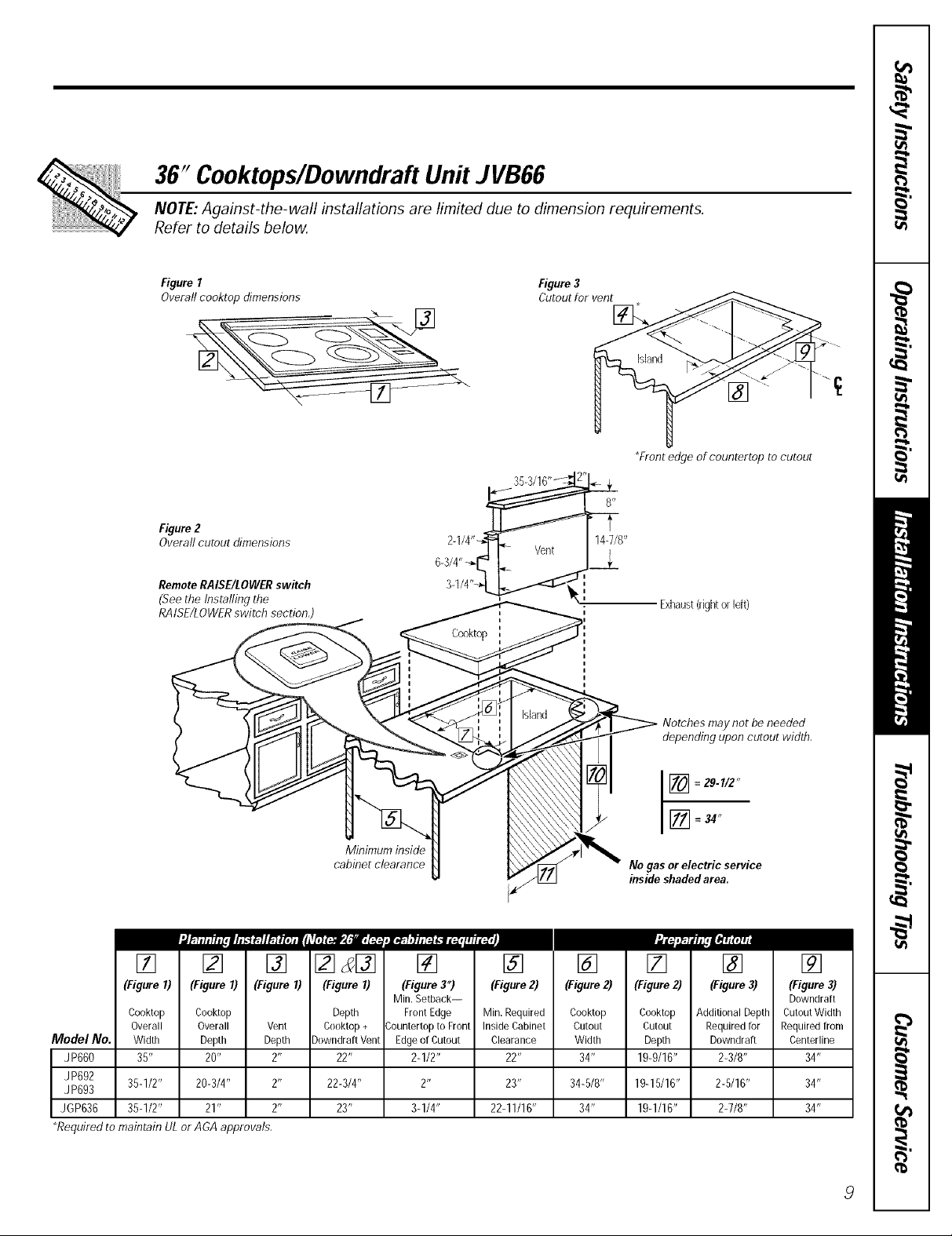

36" Cooktops/Downdraft Unit JVB66

NOTE: Against-the-wall installations are limited due to dimension requirements.

Refer to details below.

Figure I Figure3

Overall cooktop dimensions Cutoutfor vent

Island

Front edge of countertop to cutout

Figure2

Overall cutout dimensions

RemoteRAISE/LOWERswitch

(Seethe Installing the

RAISE/LOWERswitch section,)

[] [] [] [] _[]

(FigureI) (Figure I) (Figure I) (FigureI)

Cooktop Ceoktop Depth

Model No.

JP660

JP692

JP693

JGP636

*Required to maintain ULor AGA approvals.

Overall Overall Vent Ceektop +

Width Depth Depth DewndraRVent

35" 20" 2" 22"

35-1/2" 20-3/4" 2" 22-3/4"

35-1/2" 21" 2"

2-1/4"_

6-3/4"_[_

3-1/4"-_.

Exhaust(rightorleft)

Notches maynot be needed

depending upon cutout width,

Minimum inside

cabinet clearance

No gas or electric service

inside shaded area.

......... II'11'I'i

[] [] [] [] [] []

(Figure3*) (Figure2) (Figure2) (Figure2) (Figure3) (Figure 3)

Min.Setback-- DewndraR

FrontEdge Min.Required Cooktop Ceektop AdditienalDepth CuteutWidth

;ounterteptoFrent InsideCabinet Cutout Cutout Requiredfor Requiredfrom

Edgeof Cuteut Clearance Width Depth Downdraft Centerline

2-1/2" 22" 34" 19-9/16" 2-3/8" 34"

23" 34-5/8" 19-15/16" 2-5/16" 34"

23" 3-1/4" 22-11/16" 34" 19-1/16" 2-7/8" 34"

Page 10

Installationofthe downdrafl system.

Read these instructions completely and carefully.

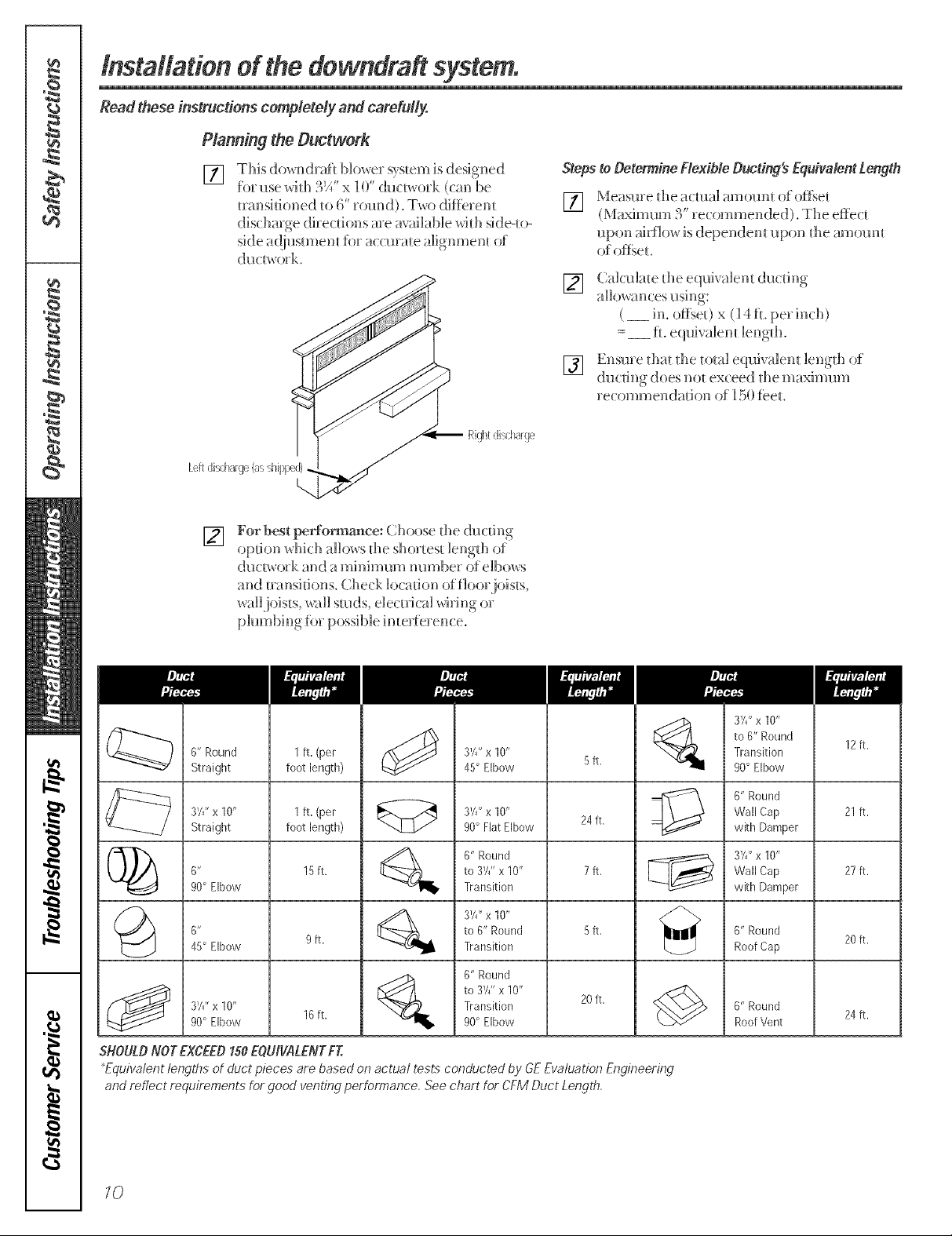

Planning the Ductwork

[] This downdrafl Uower system is designed

for use _dfl_ 3/i" x 10" (h_dwork (cm_be

mmsifi(med to 6' _ound). Two diffe_ em

discharge (]i_Te(:tionsave mailable xdd_ sMeqo-

side a({iusmmm _br accurate alignment of

Rightdis/barge

Stepsto DetermineFlexible Ducting'sEquivalentLength

] Measme the a(mal amom_t of()f_set

(Maximum 3" re(ommended). The effect

upol_ airflow is dependent upon d_e amomu

of of_get.

Calculate die equivalent duding

[]

allo_%inces using:

( __ h-l.o*_se0 x (14ft. per inch)

=__ tL e(pfi_ alent length.

Ensme diat die total e(lui_ alem lengd_ of

[]

(]u(ting does not ex(eed the maximum

recommendation o_ 150 f>et.

For best perfo_nm'_ee: ( hoose file ducd_lg

[]

option which allows d_e shortest lengfli of

dudwo_ k and a minimum mm_be_ of elbows

and transitions. Check location offiooLjoists,

waffjoists, wall studs, de( tvical _dring ov

plumbing fi, possibD int err>fence.

3X" x 10"

to 6"Round

6" Round 1ft. (per 35" x 10" 5ft.

Straight foot length) 45° Elbow

37Fx 10" 1 ft. (per 37Fx 10" Wall Cap 21 ft.

Straight foot length) 90° FlatElbow 24ft. with Damper

(_ _ 0" Round 35" x 10"

6" 15ft. to 3Y/'x 10" 7ft. Wall Cap 27 ft.

90° Elbow Transition with Damper

0" to 6" Round 5ft. 0" Round

45° Elbow 9 ft. Transition Roof Cap 20 ft.

_ 3W'x 10"

Transition

90° Elbow

0" Round

12ft.

374"x 10" Transition 20ft. 0" Round

90° Elbow 10 ft. 90° Elbow RoofVent 24 ft.

SHOULDNOTEXCEED150EOU/VALENTFT.

*Equivalentlengths of duct pieces are based on actual tests conducted by GEEvaluation Engineering

and reflect requirements for good venting performance. See chart for CFMDuct Length.

0" Round

to 3Y/'x 10"

10

Page 11

Planning the Wiring

All wire connections and installations must be in

compliance with local codes In the absence of loca!

electrical codes consult the National Electric Code

The (]o_ndraf_ blower system draws 4 AMPS

[]

and requires a 120 VAt!, 60 Hz circuit,

Plan to provide a grom_ded outlet in a

[]

location _dfi(:h will all(m die mlit's p(mer

cord _o reach.

Theoutlet cannotbe located onaback wall,

The outlet needs to be momlted on the side _all

of the (abinet or it (ould be on the ba(k _all of an

adjacent (abinet _dth access dlrough an o _ening

in the sk]e wall. (Based on h)(:al (:odes,)

[_] ()n 36'model, )ian tile P_ISEt£OWER s_d_(:h.

Tile lead _o _he sx_(:h is /= long.

• . _Ott

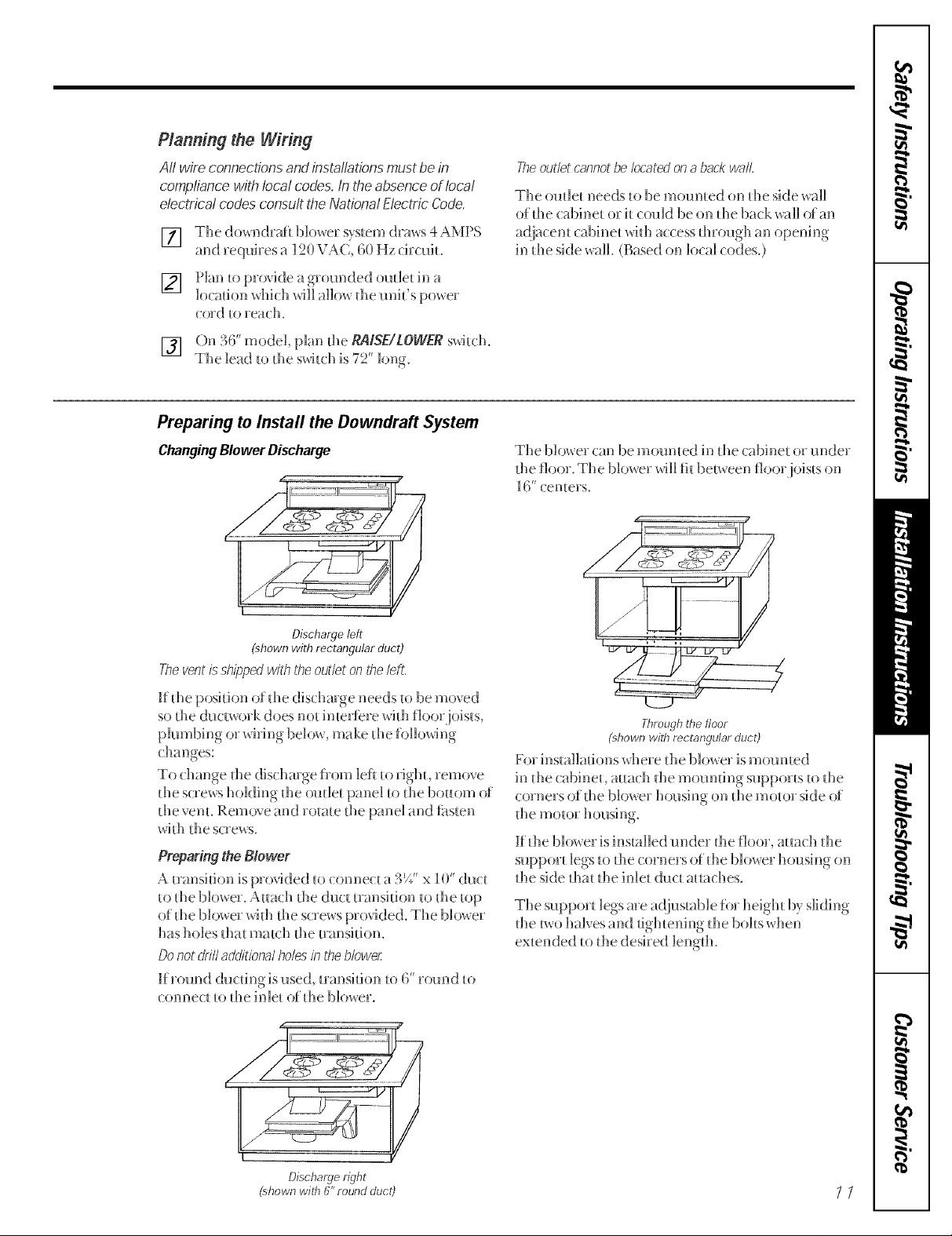

Preparing to Install the Downdraft System

ChangingBlower Discharge

Discharge left

(shown with rectangular duct)

The vent is shipped wfih the outlet on the leR,

If die position of die dischmge needs _obe moved

so the ductwork does not inteHere with floor joists,

plumbing or wMng below, make die following

changes:

To change die dischmge ii()m left _orighh remove

the screws holding die outle_ panel _odie bottom ()i

the venL Remove and rotate the panel and fi_sten

wi_h the screws.

Preparing the Blower

A transition is provided to (onne( t a 3E" x 10" (h]ct

_o die blowe_. A_ach _he (]ud mmsi_ion _o _he _op

of die blower wi_h the screws provided. The blower

has holes dlat ma_(h die _ransifion.

Donot driftadditional holesin the blower

If r(nmd ducfing is used, mmsidon to 6' _Druid to

connect _o_he inle_ of the blower.

The bl()v, er can b e m (mn ted in tlle ca bi net (,7u nd er

die floor. The blower will fit between fl()or ioisls on

-t

_6 (:ente_ s.

/

Throughthefloor

phown withrectangularduct)

For installations where the blower is mourned

in die cabineL a_tach _he moml_ing suppo_ _sto file

corners of die blower housing on die motor side of

_hemotor housing

K Ihe blo_x er is installed raider Ihe floor, at_a(:h tlle

suppor_ legs to the corners of die blower housing on

Ihe side dla_ tlle inlet duct a_taches.

The support legs are a(]iusmble for heigh_ by sliding

die _wo halves and tightening die bobs xdlen

ex_ended to tlle desired lengdl.

Discharge right

(shown wiffl (V'round duct) _ /

Page 12

Installationofthe downdraflsystem.

Read these instructions completely and carefully.

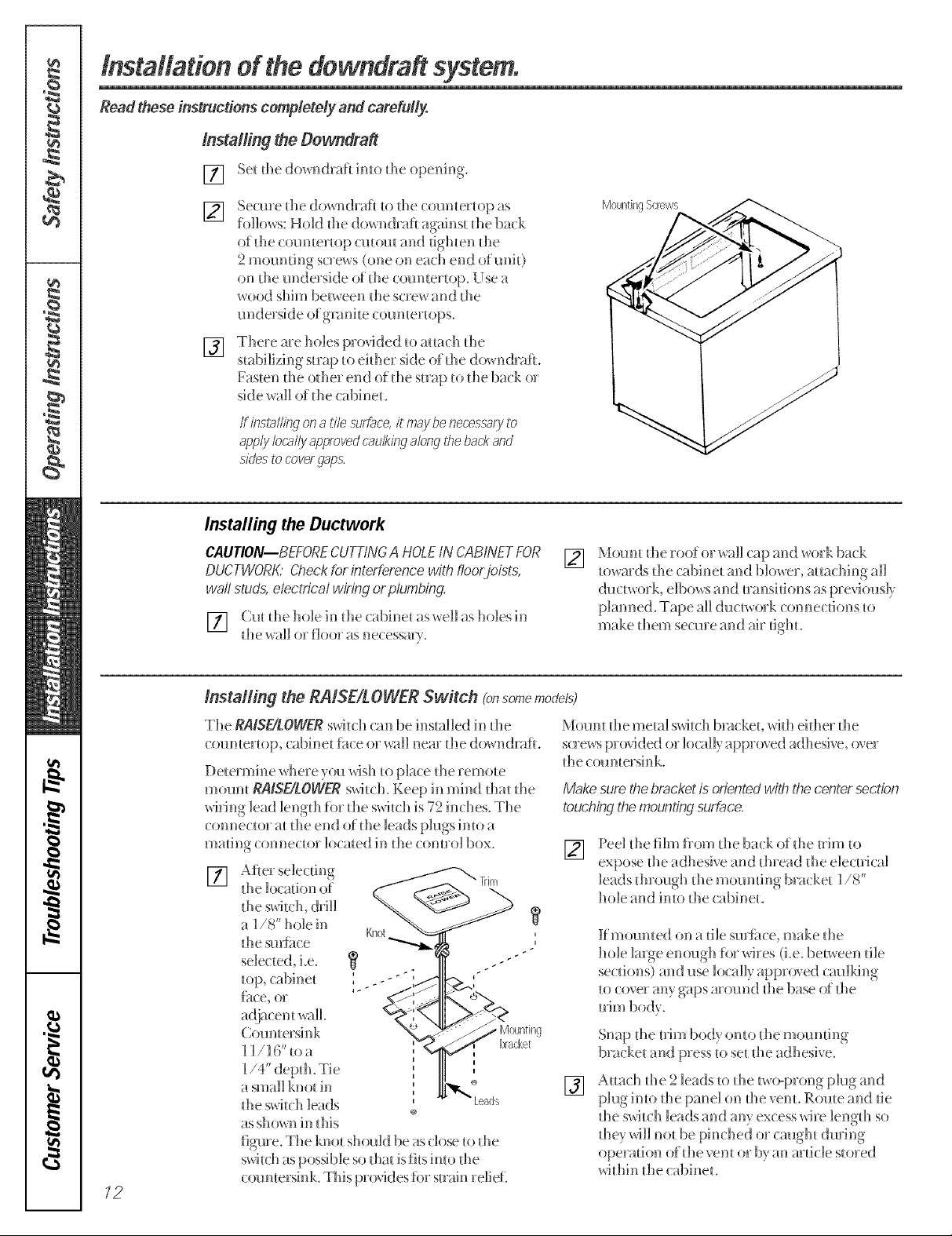

Installing the Dewndraft

[] Se_ d_e dowr_draf_ imo d_e operfir_g.

] Secure die do_,_ndraf_ _o_he (:()_]]_]_e__op as Mounting%revvs

follow, s: Hold d_e do_ ndrafi agains_ d_e ba(k

of the ( oumertop cutout and tighten the

2 ]{]]()l]n[ii]g scKews (one on erich ef]d ()f!]ni[)

on d_e underside of d_e ('oun_er_op. Use 7_

wood shim between _he soew kind _he

underside of gnmi_e coun_eHops.

Thele me holes p_()_ded _o aHa(::h die

[]

stabilizing-map u) eidler side of tile do_ ndrafi.

Fasten die odle_ end of tile sin@ to tile ba(k or

side wall of die cabinet.

If insta/fingon atile sur£ace,it may be necess-afyto

app/'/locallyapprovedcaulking alongthe back arid

sidesto coverg@s,

Installing the Ductwork

CAUTION--BEFORE CUTTkYGA HOLEIN CABINET FOR

DUCTWORK' @eck for interference with fioo,,joists,

wall studs, electrical wiring or plumbing.

[] Cut die hole in die cabinet as_ell as holes in

tile wall o_ f]oo_ as ne(:essm}.

Mount die roof or _all cap and work back

[]

to_ards tile (abinet and blo_er, mmching all

duc[v_oFk, e]bov, sand t_a_lsJtions aspfevio_as]}

}Janned. Tape aH du(:t_, ork (:onne(:dons to

make them se(:ure and air dgb.

Installing the RAISEtLOWER Switch Ig_somemodels)

The RAiSE/LOWER swit dl can be installed in tile

(:ounter_op, (abinet fh(:e or wail near tile do_ n(kafl.

Detem_ine where you t_4sh to place tile remote

mount RAISE/LOWER switch, Keep in mind t]lat the

wiring lead ]engdl for die switch is 72 inches. The

connector at die end of die leads plugs into a

madng (onnector loomed h-_the ( omro] box.

Aft e_ se]ecdng

[]

the ]ocadon of

the _witc]< dd]]

_ ]/8" hole in

the smii_ce

sele(ted_ i.e.

Countersink

] ]/]6"toa

a small knot in

tile switch leads

asshown in this

figure. The knot shouk] be as (:lose U) tile

s_,@thas possible so flint is fits imo tile

(:ountersink. This provides fi)r suain relief.

Mount tile mem] switch bracket, _it]l eidler the

s(:re_sprovided or locally approved adhesi,,e, over

the countersink.

Make surethebracket is orientedwith the centersection

touchingthemountingsurbce.

Peel tile film flom tile ba(:k of tile trim to

[]

expose die adhesi,,e and dlread die e]e(:uica]

leads dlrou£h tile moundng b_a(:ket ]/8'

hole and into tlle cabinet.

Kmounted on a tilesm_hce,make the

hole ]mge enough for wi_es (i.e. between die

se(:dons) and use locally approved cm_]king

to cover any gaps m'ound the base ()f the

Snap tile Uim body onto tile mounting

bracket and press to set die adhesive.

Attach die 2 leads to tile two-prong }Jug and

[]

p]u_int()thepan e]on tile_ent.R()_]teand tie

tile s_4t(;]l leads and any excesswi_e ]en_lh so

die,, wi]] not be phlched or caught dmin_

operadon of tile vent o_"b) an mdc]e sto_ed

_4dlin tile cabinet.

/2

Page 13

Installing the Electrical Wiring

[] MomH a s_anda_d wiring box, wi_h _-p_onged,

120 vdL 60HZ omieL insk]e d_e (abine_

Make sme the downdrafl'g power cord can

Rm_ fl_e appropriate po_ er cable imo fl_e

[]

cabinet an(] (:()nnect it t() the o!]t]et.

Plug tile downdrafl's power cord into tile

[]

omiet.

For Remote Installations

For tocM Insta#ation

Theconduitorl the blo_xer/3-of suFicierlt /erlgth to connectto

the downdf_fl when the blower ismounted inthe cabinetand

for some/rlstallst/ons urlderthe floor

Plug die blowe5 conduit into die mating connector

on the bottom of wising con_pmtment covey on the

down(karl, ffasten the vds:ebox to the main refit

wiring comp>wmlem _dth die screws pro@led.

If the blower conduit isnot longenoughto reachthe wiHr_q

compar_Tnentorl the dowrldr_lfi,the leadscarlbe extendet_

[] Cm the b]o_er lea(Is ap[)roximate]y 3" fl:om

tile plug on tile end of the b]o_ er 5:on(]uit.

Blowerwife

I:)oX,4, _))_x _ 3-Wireconnector

Blower_ _

{ onduit

[] Remove tile wis:e box and conduit fitfingflom

tile end of tile blo_ es conduit b} loosening tile

screw on tile fitting.

Mountingscrew _____o

Wire to outdoor / _J J

enclosure ,__ J jJ

"_ 3-Wire

Blowerwirebox Wirenuts

connectors

Saxe the wive box and plug to complete tile

[]

5:onne(fion at the (]own(]_aft vent in the ]louse.

Use electsk:al (able _m(] conne(toFs that

[]

(:onfom_ to local codes ( 14 gmlge rain. is

recommended), Att_wh tile wise box removed

flom die blower conduit to die end of the wis:e

rml at the venL Attach the plug an(] 3" ]ends to

the cable at the (]own(kn_ vent. Insert die plug

into the nlatin_ pbl_ on the re]lit, Attach wile

box _lt]l scsews to the vent.

Install appropriate eles:tvic_d box sddl conduit

[]

C( 555n e c{ o5"s 55 e f!5" t ]le 1) ] (5we 5",

Ches:k fllat tile 5ed plastic anti-short bushing is

[]

ses:med in file end 5)_tile con(brit. ]install the

1)]o_es csm(]uh into the con(]uit 5:onnectsn on

die eles:{fis:al box.

Att_ch the gseen gsomld lead flom tile blower

[]

to tile groined lead of tile _dfing of tile

(]()wn (]faf_ vent.

[] Connes:t die neutral and })55wetleads flom die

blower t55the leads fl55m the (](5_n(]r:4ft _ent.

Installing the Cooktop

Align the (ooktop with the down(karl and

fhsten ( ooktop in pla(e.

NOTE:Accurate alignment of cooktop and downdraft is

necessary to ensure that there is not interference when

air vent is raised and lowered. There should be a gap of

1/16"- 1/8" between the back of the cooktop and the

front of the downdraf_ cover

/3

Page 14

Before YouCarlFor Service...

Troubleshooting tip

Save time and money'! Review the tip below andyou may"

not need to call tot service,

Possible Causes What ToDo

Fan doesnot work

The vent ls not fulIyextendedo * hessd_egAISE/LOWEg s_dl(:h.

The blower control switch may * Shde h to d_e figh_.

be in the OFF position°

14

Page 15

Notes

m

w

w

m

m

_a

m

to

/g

Page 16

Notes

m_

1C

Page 17

GE Service Protection Plus TM

GE, a name recognized worldwide for qualib_ and dependabilib_, offbrs you Se_ice

Protection Plus'-comprehensive protection on all your appliances-No Matter

What Brand!

Benefits Include:

*Backed by GE

°All brands covered

oUnlimited service calls

oAll parts and labor costs included

°No outoofopocket expenses

°No hidden deductibles

°One 800 number to call

You will be completely satisfied _d_h our senice pro_ecdon or )ou may reques_ your mone) back

on [l_e remaining value ofyour comracu No questions asked, h's d_a_ simple.

Protect your refiigerator, dishwasher, washer and dryer, range, TV, V(R and mu(h more-any brand!

1lus d_ere.......s no exua (haroe_.....for emeroencv_. sen,ice and lo_ momhly fir_ancing is a_ailable. E_en icemaker

coverage and food spoilage pro_ecfion is offered. You can res_ easy knowing d_a_all your valuable

household produc_s are pro_ec_ed agains_ expensive repairs.

We'll Cover Any Appliatlce.

Anywhere. Anydme. *

Pl'._e,,,., _:,,._demei. (;Ea.d _all._ i. _heU.S..,ll-hee a_800-62(b2224

for more hfforma_ion,

I'\]] brmds (:ovel ed, up to 20 yetrs old, in file (OllIilleIll}I] [[ ,S.

Please place in envelope and mail to:

General Electric Company

Warranty Registration Department

P.O. Box 34070

Louisville, KY 402324070

_(:ul h(q()

17

Page 18

Consumer Product Ownership Registration

Dear Customer:

Thank you for purchasing our produc_ and _hank you %r placing your

c(mf]dence in us. \_;e are proud to have y(m as a custoi_er!

Follow these three steps to protect your new appliance investment:

( ompiele and

mail yore (:onsm_er

Product Own( rship

Rt)gis!l 3iiol] loday.

Have lho peace of

mind of knowing we

(ill] COI]_IC[ yOll ill

lhe m_likely evem of

a safflv modificalion.

Ariel" mailing

Ill( regisiralion

below, store fills

(]OC!l!lleI!l ill 3 Sa_[

place. 11_(Olll_ills

inf?)rmaiion you

wil! need should

yoll re(itlire s(ixice.

()ur se_ ic( mmfl)ei

is 800-GE4;ARES

(8(/0-452-2737).

Read your Owner's

Manual carefi_lly.

it will help you

operale }O!lr new

applian(e properly.

Kyou h_ c questions,

or need more illf_)l'-

Ill31iOll (all lhe

(;E Answer Cemer

800.626.2000.

Model Number Serial Number

Important: If you did not get a re_stradon card with your product,

ddtach and reffurn the-form below to ensdre thgt your

product is registered.

Consumer Product Ownership Reg

Model Number SeriN Number

Mr. MS. Miss

l;irsl [

Nam( I I I I I I I I I I I I I [

L_S1 [Nam_ [ [ [ [ [ [ [ [ [ [ [ [ [ [ [ [ [ [ [

Addr(ss [ [ [ [ [ [ [ [ [ [ [ [ [ [ [ [ [ [ [ [ [ [

Api. # I I I I I

(:i,?[llllllll IIIIII I I I I I I I I [

S/_tt_. [_ Zip( _K ( I I I I [

] );l[( P[ I((d

N!lmb_t_

BR)'[POINT RCIBI

GEApp/iancos

GeneralE/ectnc CornparO_

Loul:_vd/eKentucky 40225

/8

Page 19

GEDowndraftSystemWarranty

All warranty service provided by our Factory" Service Centers,

or an authorized Customer Care_) technician. For service,

carl 800-GE-CARES.

GE Will Replace, At No Charge ToYou:

One Year

Fromthedateof the

originalpurchase

:_ Service trips to your home to teach you how to use the

product.

:_ Improper installation.

:_ Failure of the product if it is abused, misused, or used for

other than the intended purpose or used commercially.

Anypart of the d_)wn&afi sFslem which f,fils due to a deiect in materials or w_)rkmanship.

During this full one-year warranty, GE will also provide, free of charge, all labor

and in-home sevvice to replace the detective part.

:_ Replacement of house fuses or resetting of circuit

breakers.

:{ Replacement of the replaceable filters.

:, Damage to the product caused by accident, fire, floods or

acts of God.

:, Incidental or consequential damage to personal property

caused by possible defects with this appliance.

This warranty is extended to the original purchaser and any succeeding owner for products purchased for home

use within the USA. In Alaska, the warranty excludes the cost of shipping or service calls to your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state. To know what your

legal rights are, consult your local or state consumer affairs office or your state's Attorney General.

Ifyou have an installation problem, contact your dealer or installer. Youare responsible for providing adequate

electrical, gas, exhausting and other connecting facilities as described in the Installation Instructions provided

with the product.

Warrantor:General Electric Company.Louisville,KY 40225

19

Page 20

Service TelephoneNumbers.

CEAnswerCenteF_soo._2_.2ooo

The (,E Answe_ (eme_ is open 24 hou_ s a day 7 days a week.

/n-HomeRepsi; ServiceSOOoCE-CARES(800-432-2737)

SpecialNeedsServiceso#._2_.2_o

800- TDD-GEAC (800-833°4322)

(;E offers, fiee of (barge, a bye( huve _o assis_ in planning a bavviev-fiee ki_( hen fov persons

wilh limited mobiiib,.

ServiceCent;actssee-szs-zzz4

subs[ands] dis(:ounL (;E Consumer Service will sdH be there after )out wavTanty expi;es.

PartsandAccessoriessoooszs-zeez

h_di_iduals qualified to se_xice d_ei_7own appliances can have pmts o_7a( cessories seflt di_Tecdy

to d_eh: homes (VISA, MasterCmd and Discover7 cm'ds me accepted).

Instructions contained in this manual cover procedures to be.performed by any user. Other servicimj

generally should be referred to qualified service personnel Caution must be exercised, since

improper servicing may cause unsafe operation.

ServiceSatisfaction

I_}:ou me not s_tisfied with the se_x:ice you ;e( eive fiom GE:

First,(ontad d_e people who sevviced your appliance.

Next,if you ave sdll not please(], write all d_e details--including your phone numbe;-to:

Manager, Consumer Relations

GE Appliances

Louisville, KY 40225

Finally,if your probDm is sdll not resoDed, write:

M_jor Appliance Consumer Acdon Pvogrm_

20 No_lh Wacke_ Drive

20 Printed in file United States

Page 21

Part No. t64D3333P024-2 Pub, No, 49-8768-2 D-959-0776-002 7-98 CG

Page 22

Safety Information

5atetyPrecautions..... 3,4

Operating instructions

Usingthe Downdroft

5_sten ........ 5 o

Usingme 6brttroz_ 5

CJJreand Cleanir_g ..... 6

GE& YOUrA Service Partnership.

IMPORTANT!

Insta#ation lnstl_ctions

Before YouB_ln ....... 7

/_-85ui'et_sn[s 7 9

P/zTningt:heLJuctwod(....... 70

Plan/ngt;helitlirTr_ ..... 77

lnstollin9 toe

[Jowndrafr .... 77 72

sn_//ir1_ the

[7ectrid_7/l}iirmcj....... 73

Troubleshooting Tips

Betor_7ou(;_lll

f-orSavlce ..... 74

Customer Service

ProductReais_ml/on. . . 17

W_Trmnty ..... l_

Service,>ie,pnone

NumbeLs ...... BackCJver

Fill out and return tile Consumer 1)r(iduct Regism_fion Card that is

pa(ked xdih tllis produ(L Ifvou (annl)l find it, please send in tile

dupli(ate (at(] printed in tile ba(k of this manual.

FORYOURRECORDS

Write the model and serial numbers here:

#

#

Staple sales slip or cancelled check here.

PLEASE NOTE: The downdraft vent systemyou have purchased was

designed to be used with GEProfile cooktops listed in this manual

Proof of tile original purchase date is needed 1(/(/blain ser_i(e under

tile W;lI'I_<ln/y,

READTHISMANUAl_

Inskle you will find many h elpfill hints on how to use and maintain your

vent properly.Just a little preventive care on your pro1 can save you a great

deal of time and money over tile lif> of yore vent.

You Hfind man) answers to cflmmon problems in die Before YouCafl For

Service secdon. If you re_ex_ our (:harl of Troubleshooting Tips first, you

may not need t11call for service at all.

IFYOUNEEDSERVICE

If you do need seixice, you can relax knox,ing help is only a phone call

away. A list of toll-flee customer sei_ice numbers is included in the back

2

section 11tthis guide. Or y()u can always call the GE Answer (enter (' at

800.6'26.2000, 24 h(/urs a (1W, 7 (la}:s a week.

Page 23

IMPORTANTSAFETYINFORMATION.

READALLINSTRUCTIONSBEFOREUSING.

a, WARNING!

Foryour safety, the information in this manual must be followed to minimize the risk of fire or explosion,

electric shock, or toprevent property damage, personal injury, or loss of life.

WARNING--TOREDUCETHERISKOFFIRE,

ELECTRICSHOCK,ORINJURYTOPERSONS,

OBSERVETHEFOLLOWING:

A. Use this refit only in the manner intended by

the mant/f_tcturer. Ifyou have any questions

(ontact the rnantff_cttHer.

R Befbre servicing or cleaning unit, switch

power offat sewice panel and lock fl_e

service disconnecting means to prevent

power fi_m being switched on accidentally.

\,_l_en the service disconnecting means

cannot be locked, securely fhsten a

pr_)minent wanting device, such as a tag, m

the set_ice panel.

CAUTION: For general ventilating use only.

Do not use to exhaust hazardous or explosive

',, Installation wofl< and electrical wiring must

be done by qualified person(s) in

ac(:o_dan(:e with all applicable codes and

slandmds, including fire-rated (:onstmction.

When cutting or (killing into wall or ceiling,

do not damage electrical wiring and other

hidden utilities.

Dncted f_lns must always be vented to file

outdoors.

S_ttficient air is needed for proper

combustion and exhausting of gases through

the flue (chimney) offilel-burning

equipment to prevent bacl;drafling. Follow

the heating e(pfipment manttthcmrer's

glfideline and safety standards such as those

published by the National Fire Protection

Association (NFI'A), and the American

Society for Heating, Refiigeration and Air

Conditioning Engineers (ASHRAE), and the

local code authorities.

To reduce the risk of fire, use only metal

ductwork.

PVC sewer pipe can be used as duct under

concrete slab if allowed by local code board.

This unit must be grounded.

SAFETYPRECAUTIONS

WARNING--TO REDUCETHERISK OFA RANGE TOPGREASEFIRE,"

Keep fan, filters and gTease laden

surfaces clean.

:Always turn hood ON when cooking

at high heat.

Use high range settings on range onlywhen

necessary. Heat oil slowly on low to

medium setting.

:i Don't leave range unattended when cooking.

Ahvays use cookware and utensils

appropriate for the type and amount

of food being prepared.

3

Page 24

IMPORTANTSAFETYINFORMATION

READALL INSTRUCTIONSBEFOREUSING.

A WARNINGf

SAFETYPRECAUTIONS

TOPERSONSIN THEEVENTOFA RANGE TOPGREASE

FIRE,OBSERVETHEFOLLOWING/

A.

SMOTHER FI[AMES with a close-fitting

lid, cookie sheet, or metal tray, then turn

off the burner. BE CAREFUL TO

PREVENT BURNS. If the flames do not go

out immediamly, E%a_CLTATE AND CALL

THE FIRE DEPARTMENT.

B. NEVER PICK UPA FI[AMING PAN--

Y(_u m ay be burned.

C. DO NOT USE _,%_TER, indudingwet

dishcloths or toweh-a violent steam

explosion will resuh.

D. Use an extinguisher ONLYif:

L Y(m know you h_we a Class ABC

exting_flsher, and you abeady know how u_

operate it.

Z The fire is small and contained in the m>a

where it started.

3. The fire department is being called.

4. You can fight the fire with your back

to an exit,

2%sodon "KitchenF/?esafelyTIps"publishedhyNFPA

CAUTtON: For g_nera] ventilating use onlyo

Do not use to exhaust hazmdous or explosive

Make sure aft fingers are away from the downdraR

top when it is lowered

ff YouNeed Service...

Do not attempt to l_pair or replace any part of

the downdrafi system unless it is specifically

recommended in this gafide. All other secvicing

should be refen_d to a qualified mchnician.

SERVIC/NC

Be sure electrical power is off before servicing the unit,

It may be necessa_ 7 to remove the @)wndrafi

blower system in o_,ter to sewice (omponems

suth as the blower mou)r or air vent

methanism.

Readandfollow this Informationcarefull'

READAND SAVETHESEINSTRUCTIONS

Disconnect power to fl_e cooktop and remo_v

it first. Reverse the steps in the Install the

Downdraft set fion to remove the blower.

Sel-vice parts are avaihble from a GE Service

and Parts Center.

4

Page 25

Usingthedowndraftsystem.

RAISE/LOWERSwitch (3o"models only)

Tmn tile dox_ll(hafi blower ONby pressing

the PAISE/LOWER switch located at the top

right of the vent (oil some models). Place

y{)ur finger oil the "center" of the s_xitch

and hold until you observe the vent rot)ring,

then release. The air vent will rise. Use the

sele(tor s_dtch to mrn tile blower ON,OFF

or to dlange the blower speed.

Tile vent may be lowered by again pressing

the PAISE/LOWERs_a_itchat the top right side

of the vent. The blower, if left on, will

On some models, the RAISE/LOWER

switch is located at the top right of

the vent,

mltomafically go offwhen tile vent is

lowered.

NOTE:Formostconvenientoperation,set the

blower tothe speedyou usemostoften. The

blower will come onto thisspeed whenever

theunit is raised.

iii ii! i

RemoteRAISE/LOIIVERswitch

(36"modelsonly)

36" models havea remote RAISE/LOWER

sx_ch. I_ operates in _t_esame manner as

fl_es_dt(:h lot ated on the vent.

RAISE/LOWERswitch location may vary,

Use the selector switch to turn the

blower ON,OFFor to change the

blower speed,

Using the Cooktop

Caution

Be caretnl when raising or lowering tile

dox_lldrafl. Be sure pots, pot handles and

other objecls are clear of tile do_ll(hafl and

cannot be su_uckor tipped by the dox_lldrafi

being raised.

NOTE"Thereisa slight trimoverhangat each

end ofthe vent.

To avoid h-tj_v, be sure f'mgers are clear

of the dow_draft cover when it is behrig

lowered.

Keep hands and f'mgers away from all

downdraft parts.

Page 26

Using the downdraft system.

Cooking Tips

The high air m_)vement of this dox_i_drafl

system can increase tile cooking times tot

some fi)ods. It may take longer to reach

high cooking temperatures ifthe (h_wndrafi

is turned to high right away. A(!just the tim

speed tor best cooking resuhs.

For best resuhs when heating oil fi_rdeep

fl)qng or when boiling water, use the fiont

smtace uniLsor wait until the water is

boiling or the oil is at flying temperatures

befi)re turning on the (h)wnchafi.

Thedowndralt may not completelycapture aft the

steamfrom panson the front burners,

Careand cleaning of the downdraft system.

Grease filters

Theefficiencyofyourdowndmftd_pendson

acbanfilter

Frequen( 7 of cleaning depends on the tTpe

of cooking you do. Grease fil_ers should be

cleaned at leas[ once a month.

Neverof)eratethe dowrl(2a)withoutthefilter:5

snplace.

Toremove:Lift up and pull _hebo{um_ ore,

Remove d_e left fil_erfirst, d_en shde d_e

righ_ fil_er u_the lef_and remo_ e h.

Catlll_

When canning tbods in a wa/er-bath canner,

a gentle but steady boil nmst be maintained

contimu)usly fi)r the required time.

When canning toods in a pressure canner,

the pressure nmst be re>tint>fined

contimu)usly fi)r the required time,

Use of the blower at HIGHspeed when

canning may reduce the temperature

enough to stop boiling. While canning,

we recommend using the downdmfi at

LOW speed and using the flont surlime unit.

Toclean: Soak and d_en agha_e in a ho_

de_ergem solution. Ligh_ brushing may be

used _o remove imbedded soil. Rinse, shake

and remove moisture before replacing.

Fil_ers may be cleaned by placing in

dishwasher, alfi_ough some sligh_ color

fT_dingmay occur afler several washings.

Whh care_ifi handling, the fiber will lasl for

yems. Ifrepla(emen[ becomes necessary,

order the par{ flom yore dealer.

Painted or metal surfaces

Clean greasysm_ilcesfiequently, using a

miM detergent.

Do not useabrasivecloth or cleaners,steel wool

padsor scouringpowder becausethey will scratch

the surface,

Page 27

Installationof thedowndraft

WARNING--TO REDUCETHERiSK OFFIRE,ELECTRICSHOCK,ORiNJURY

TOPERSONS,OBSERVETHEFOLLOWING:

system. Read meso instructionscompletely and carefully

A. lns_alla_ior_ work and ele(:_rical wiring mus_ be

done by qualified persons(s) in accord race _d_

all applicable codes and s_andards, inchMing fire-

ra_edcons_rucdon.

B. Ducked f_u_s mus_ always be vetoed _o _he

outdoors.

WARNING--Toreducethe risk of fire, use onlymetal

ductwork.

Before YouBegin

IMPORTANT:Save t,_eseinstructions for the local

electrical inspector's use.

IMPORTAN_ OBSERVEALL GOVERNINGCODES

AND ORDINANCES.

NOTE TOINSTAL£ER:Leave these instructions with

the appliance after installation is completed.

NOTE TOCONSUMER:Keep this Owner's Manual

and installation instructions for future use.

NOTE."This appliance must be properly grounded.

InstallationRequirements

Before starting installation, check the following requirements:

120

4.0

Canbe tmnsitioned to round duct (6" round minimum),

This downdrah blo_ er system is designed u) be used

u_ exhaus_ smoke and odors when cooking with aH

(;E Profile electric and gas cooku_pshs_edh_dfis

manual h (::ar_be mourned in either an island or

500

3_ " X 10"_

Plan the placement of the elecuical outlet carefiflly.

It should NOT be installed on the back wall of the

cabinet be(rauseit may inter{ere with the down&aft.

It should be installed on a side wall or a(!jacent

cabinet. Make sure it iswithin reach of the unit's 2 ft.

long power cord and conforms to all local codes.

Install a stan&ud outlet to make the electrical

connection.

Plan the locathm of the gas supply pipe (for gas

Requirements for an approved installation:

26" minimum cabinet depth

_ 26" minimum flora the back of the &)_lldrafi to

the fiont of the countertop, with

23%" mininmm FIAT countertop smthce

:_Ifyou install the vent and cookt op in an island,

you may need additional island depth. 24" base to

base will not be adequate. Please see below.

cooktops) carefiflly to avoid inter[erence with the

downchaft installation.

Thisunit canbeeasilyinstalledfollowingthese

basicsteps:

[] Cut out the (ountertop opening.

[] Install the (lo_i_(hafl in the cabinet.

[] ( onnect the duclwork and electrical.

[] Install the cooklop.

Measurements

Refer to the cooktop installation instructions tot dimensions of cooktop, countertop cutout,

and cabinet requirements.

Cutout dimension and illustrations am given for 30" and 36" cooktops.

_,The 30" models will fit in most 30" wide cabinets

and the 36"models will fit ir_most 35"wide

cablneN.

:_ Check the inside dimensions of the cabinet before

beginning installation. The top of the side walls

may need to be cut to provide clearance for

mounting.

NOTE" Toinstafl a cooktop with this downdraft,

the cabinet depth must be 26"minimum

A countertop with a raised lip may not allow enough flat

countertop for a proper installation,

Page 28

Installation of the downdrafl system.

Read these instructions completely and carefully.

30_!Ceektops/Dewndraft Unit J VB36

NOTE: Against-the-waft instaflations are limited due to dimension requirements.

Reter to details below,

Figure I Figure 3

Overall cooktop dimensions Cutoutfor vent

Front edge of countertop to cutout

Figure 2

Overall cutout dimensions

Minimum inside

cabinet clearance

[] [] [] [] s[] [] []

(Figure 1) (F,(gureI) (Figure I) (Figure I) (Fig_,,re3,_) (Figure 2)

Cooktop Cooktop Depth FrontEdge Min,Required

ModelNe. Width Depth Depth )owndraRVent EdgeotCutout Clearance

J P340

JP350 29-3/8" 20-1/2" 2" 22-1/2" 3" 22-11/16"

J P360

J P392 30" 20-3/4" 2" 22-3/4" 2" 23"

J P393

JGP336 30" 21" 2" 23" 3-1/4" 22-7/8"

Required to maintain UL or A6A approvals,

Overall Overall Vent Cooktop+ CounterloptoFront hside Cabinet

Min,Setback--

Exhaust(rightorleft)

Notches may not be needed

depending upon cutout width,

No gas orelectric service

inside shaded area,

[] [] [] []

(Figure2) (Figure2) CFigure3) (Figure3)

Cooktop Cooktop AdditionalDepth CutoutWidth

Cutout Cutout Required tot Required from

Width Depth Downdra[t Centerline

28_1/2" 19_9/16" 2-3/8" 28q/2"

29q/8" 19q5/16" 2-5/16" 28q/2"

28q/2" 19-1/2" 2-5/8" 28q/2"

Dewndraft

Page 29

36" Cooktops/Downdraft Unit JVB66

NOTE: Against-the-wall installations are limited due to dimension requirements.

Refer to details below.

Figure I Figure3

Overall cooktop dimensions Cutoutfor vent

Island

Front edge of countertop to cutout

Figure2

Overall cutout dimensions

RemoteRAISE/LOWERswitch

(Seethe Installing the

RAISE/LOWERswitch section,)

[] [] [] [] _[]

(FigureI) (Figure I) (Figure I) (FigureI)

Cooktop Ceoktop Depth

Model No.

JP660

JP692

JP693

JGP636

*Required to maintain ULor AGA approvals.

Overall Overall Vent Ceektop +

Width Depth Depth DewndraRVent

35" 20" 2" 22"

35-1/2" 20-3/4" 2" 22-3/4"

35-1/2" 21" 2"

2-1/4"_

6-3/4"_[_

3-1/4"-_.

Exhaust(rightorleft)

Notches maynot be needed

depending upon cutout width,

Minimum inside

cabinet clearance

No gas or electric service

inside shaded area.

......... II'11'I'i

[] [] [] [] [] []

(Figure3*) (Figure2) (Figure2) (Figure2) (Figure3) (Figure 3)

Min.Setback-- DewndraR

FrontEdge Min.Required Cooktop Ceektop AdditienalDepth CuteutWidth

;ounterteptoFrent InsideCabinet Cutout Cutout Requiredfor Requiredfrom

Edgeof Cuteut Clearance Width Depth Downdraft Centerline

2-1/2" 22" 34" 19-9/16" 2-3/8" 34"

23" 34-5/8" 19-15/16" 2-5/16" 34"

23" 3-1/4" 22-11/16" 34" 19-1/16" 2-7/8" 34"

Page 30

Installationofthe downdrafl system.

Read these instructions completely and carefully.

Planning the Ductwork

[] This downdrafl Uower system is designed

for use _dfl_ 3/i" x 10" (h_dwork (cm_be

mmsifi(med to 6' _ound). Two diffe_ em

discharge (]i_Te(:tionsave mailable xdd_ sMeqo-

side a({iusmmm _br accurate alignment of

Rightdis/barge

Stepsto DetermineFlexible Ducting'sEquivalentLength

] Measme the a(mal amom_t of()f_set

(Maximum 3" re(ommended). The effect

upol_ airflow is dependent upon d_e amomu

of of_get.

Calculate die equivalent duding

[]

allo_%inces using:

( __ h-l.o*_se0 x (14ft. per inch)

=__ tL e(pfi_ alent length.

Ensme diat die total e(lui_ alem lengd_ of

[]

(]u(ting does not ex(eed the maximum

recommendation o_ 150 f>et.

For best perfo_nm'_ee: ( hoose file ducd_lg

[]

option which allows d_e shortest lengfli of

dudwo_ k and a minimum mm_be_ of elbows

and transitions. Check location offiooLjoists,

waffjoists, wall studs, de( tvical _dring ov

plumbing fi, possibD int err>fence.

3X" x 10"

to 6"Round

6" Round 1ft. (per 35" x 10" 5ft.

Straight foot length) 45° Elbow

37Fx 10" 1 ft. (per 37Fx 10" Wall Cap 21 ft.

Straight foot length) 90° FlatElbow 24ft. with Damper

(_ _ 0" Round 35" x 10"

6" 15ft. to 3Y/'x 10" 7ft. Wall Cap 27 ft.

90° Elbow Transition with Damper

0" to 6" Round 5ft. 0" Round

45° Elbow 9 ft. Transition Roof Cap 20ft.

_ 3W'x 10"

Transition

90° Elbow

0" Round

12ft.

374"x 10" Transition 20ft. 0" Round

90° Elbow 10 ft. 90° Elbow RoofVent 24 ft.

SHOULDNOTEXCEED150EOU/VALENTFT.

*Equivalentlengths of duct pieces are based on actual tests conducted by GEEvaluation Engineering

and reflect requirements for good venting performance. See chart for CFMDuct Length.

0" Round

to 3Y/'x 10"

10

Page 31

Planning the Wiring

All wire connections and installations must be in

compliance with local codes In the absence of loca!

electrical codes consult the National Electric Code

The (]o_ndraf_ blower system draws 4 AMPS

[]

and requires a 120 VAt!, 60 Hz circuit,

Plan to provide a grom_ded outlet in a

[]

location _dfi(:h will all(m die mlit's p(mer

cord _o reach.

Theoutlet cannotbe located onaback wall,

The outlet needs to be momlted on the side _all

of the (abinet or it (ould be on the ba(k _all of an

adjacent (abinet _dth access dlrough an o _ening

in the sk]e wall. (Based on h)(:al (:odes,)

[_] ()n 36'model, )ian tile P_ISEt£OWER s_d_(:h.

Tile lead _o _he sx_(:h is /= long.

• . _Ott

Preparing to Install the Downdraft System

ChangingBlower Discharge

Discharge left

(shown with rectangular duct)

The vent is shipped wfih the outlet on the leR,

If die position of die dischmge needs _obe moved

so the ductwork does not inteHere with floor joists,

plumbing or wMng below, make die following

changes:

To change die dischmge ii()m left _orighh remove

the screws holding die outle_ panel _odie bottom ()i

the venL Remove and rotate the panel and fi_sten

wi_h the screws.

Preparing the Blower

A transition is provided to (onne( t a 3E" x 10" (h]ct

_o die blowe_. A_ach _he (]ud mmsi_ion _o _he _op

of die blower wi_h the screws provided. The blower

has holes dlat ma_(h die _ransifion.

Donot driftadditional holesin the blower

If r(nmd ducfing is used, mmsidon to 6' _Druid to

connect _o_he inle_ of the blower.

The bl()v, er can b e m (mn ted in tlle ca bi net (,7u nd er

die floor. The blower will fit between fl()or ioisls on

-t

_6 (:ente_ s.

/

Throughthefloor

phown withrectangularduct)

For installations where the blower is mourned

in die cabineL a_tach _he moml_ing suppo_ _sto file

corners of die blower housing on die motor side of

_hemotor housing

K Ihe blo_x er is installed raider Ihe floor, at_a(:h tlle

suppor_ legs to the corners of die blower housing on

Ihe side dla_ tlle inlet duct a_taches.

The support legs are a(]iusmble for heigh_ by sliding

die _wo halves and tightening die bobs xdlen

ex_ended to tlle desired lengdl.

Discharge right

(shown wiffl (V'round duct) _ /

Page 32

Installationofthe downdraflsystem.

Read these instructions completely and carefully.

Installing the Dewndraft

[] Se_ d_e dowr_draf_ imo d_e operfir_g.

] Secure die do_,_ndraf_ _o_he (:()_]]_]_e__op as Mounting%revvs

follow, s: Hold d_e do_ ndrafi agains_ d_e ba(k

of the ( oumertop cutout and tighten the

2 ]{]]()l]n[ii]g scKews (one on erich ef]d ()f!]ni[)

on d_e underside of d_e ('oun_er_op. Use 7_

wood shim between _he soew kind _he

underside of gnmi_e coun_eHops.

Thele me holes p_()_ded _o aHa(::h die

[]

stabilizing-map u) eidler side of tile do_ ndrafi.

Fasten die odle_ end of tile sin@ to tile ba(k or

side wall of die cabinet.

If insta/fingon atile sur£ace,it may be necess-afyto

app/'/locallyapprovedcaulking alongthe back arid

sidesto coverg@s,

Installing the Ductwork

CAUTION--BEFORE CUTTkYGA HOLEIN CABINET FOR

DUCTWORK' @eck for interference with fioo,,joists,

wall studs, electrical wiring or plumbing.

[] Cut die hole in die cabinet as_ell as holes in

tile wall o_ f]oo_ as ne(:essm}.

Mount die roof or _all cap and work back

[]

to_ards tile (abinet and blo_er, mmching all

duc[v_oFk, e]bov, sand t_a_lsJtions aspfevio_as]}

}Janned. Tape aH du(:t_, ork (:onne(:dons to

make them se(:ure and air dgb.

Installing the RAISEtLOWER Switch Ig_somemodels)

The RAiSE/LOWER swit dl can be installed in tile

(:ounter_op, (abinet fh(:e or wail near tile do_ n(kafl.

Detem_ine where you t_4sh to place tile remote

mount RAISE/LOWER switch, Keep in mind t]lat the

wiring lead ]engdl for die switch is 72 inches. The

connector at die end of die leads plugs into a

madng (onnector loomed h-_the ( omro] box.

Aft e_ se]ecdng

[]

the ]ocadon of

the _witc]< dd]]

_ ]/8" hole in

the smii_ce

sele(ted_ i.e.

Countersink

] ]/]6"toa

a small knot in

tile switch leads

asshown in this

figure. The knot shouk] be as (:lose U) tile

s_,@thas possible so flint is fits imo tile

(:ountersink. This provides fi)r suain relief.

Mount tile mem] switch bracket, _it]l eidler the

s(:re_sprovided or locally approved adhesi,,e, over

the countersink.

Make surethebracket is orientedwith the centersection

touchingthemountingsurbce.

Peel tile film flom tile ba(:k of tile trim to

[]

expose die adhesi,,e and dlread die e]e(:uica]

leads dlrou£h tile moundng b_a(:ket ]/8'

hole and into tlle cabinet.

Kmounted on a tilesm_hce,make the

hole ]mge enough for wi_es (i.e. between die

se(:dons) and use locally approved cm_]king

to cover any gaps m'ound the base ()f the

Snap tile Uim body onto tile mounting

bracket and press to set die adhesive.

Attach die 2 leads to tile two-prong }Jug and

[]

p]u_int()thepan e]on tile_ent.R()_]teand tie

tile s_4t(;]l leads and any excesswi_e ]en_lh so

die,, wi]] not be phlched or caught dmin_

operadon of tile vent o_"b) an mdc]e sto_ed

_4dlin tile cabinet.

/2

Page 33

Installing the Electrical Wiring

[] MomH a s_anda_d wiring box, wi_h _-p_onged,

120 vdL 60HZ omieL insk]e d_e (abine_

Make sme the downdrafl'g power cord can

Rm_ fl_e appropriate po_ er cable imo fl_e

[]

cabinet an(] (:()nnect it t() the o!]t]et.

Plug tile downdrafl's power cord into tile

[]

omiet.

For Remote Installations

For tocM Insta#ation

Theconduitorl the blo_xer/3-of suFicierlt /erlgth to connectto

the downdf_fl when the blower ismounted inthe cabinetand

for some/rlstallst/ons urlderthe floor

Plug die blowe5 conduit into die mating connector

on the bottom of wising con_pmtment covey on the

down(karl, ffasten the vds:ebox to the main refit

wiring comp>wmlem _dth die screws pro@led.

If the blower conduit isnot longenoughto reachthe wiHr_q

compar_Tnentorl the dowrldr_lfi,the leadscarlbe extendet_

[] Cm the b]o_er lea(Is ap[)roximate]y 3" fl:om

tile plug on tile end of the b]o_ er 5:on(]uit.

Blowerwife

I:)oX,4, _))_x _ 3-Wireconnector

Blower_ _

{ onduit

[] Remove tile wis:e box and conduit fitfingflom

tile end of tile blo_ es conduit b} loosening tile

screw on tile fitting.

Mountingscrew _____o

Wire to outdoor / _J J

enclosure ,__ J jJ

"_ 3-Wire

Blowerwirebox Wirenuts

connectors

Saxe the wive box and plug to complete tile

[]

5:onne(fion at the (]own(]_aft vent in the ]louse.

Use electsk:al (able _m(] conne(toFs that

[]

(:onfom_ to local codes ( 14 gmlge rain. is

recommended), Att_wh tile wise box removed

flom die blower conduit to die end of the wis:e

rml at the venL Attach the plug an(] 3" ]ends to

the cable at the (]own(kn_ vent. Insert die plug

into the nlatin_ pbl_ on the re]lit, Attach wile

box _lt]l scsews to the vent.

Install appropriate eles:tvic_d box sddl conduit

[]

C( 555n e c{ o5"s 55 e f!5" t ]le 1) ] (5we 5",

Ches:k fllat tile 5ed plastic anti-short bushing is

[]

ses:med in file end 5)_tile con(brit. ]install the

1)]o_es csm(]uh into the con(]uit 5:onnectsn on

die eles:{fis:al box.

Att_ch the gseen gsomld lead flom tile blower

[]

to tile groined lead of tile _dfing of tile

(]()wn (]faf_ vent.

[] Connes:t die neutral and })55wetleads flom die

blower t55the leads fl55m the (](5_n(]r:4ft _ent.

Installing the Cooktop

Align the (ooktop with the down(karl and

fhsten ( ooktop in pla(e.

NOTE:Accurate alignment of cooktop and downdraft is

necessary to ensure that there is not interference when

air vent is raised and lowered. There should be a gap of

1/16"- 1/8" between the back of the cooktop and the

front of the downdraf_ cover

/3

Page 34

Before YouCarlFor Service...

Troubleshooting tip

Save time and money'! Review the tip below andyou may"

not need to call tot service,

Possible Causes What ToDo

Fan doesnot work

The vent ls not fulIyextendedo * hessd_egAISE/LOWEg s_dl(:h.

The blower control switch may * Shde h to d_e figh_.

be in the OFF position°

14

Page 35

Notes

m

w

w

m

m

_a

m

to

/g

Page 36

Notes

m_

1C

Page 37

GE Service Protection Plus TM

GE, a name recognized worldwide for qualib_ and dependabilib_, offbrs you Se_ice

Protection Plus'-comprehensive protection on all your appliances-No Matter

What Brand!

Benefits Include:

*Backed by GE

°All brands covered

oUnlimited service calls

oAll parts and labor costs included

°No outoofopocket expenses

°No hidden deductibles

°One 800 number to call

You will be completely satisfied _d_h our senice pro_ecdon or )ou may reques_ your mone) back

on [l_e remaining value ofyour comracu No questions asked, h's d_a_ simple.

Protect your refiigerator, dishwasher, washer and dryer, range, TV, V(R and mu(h more-any brand!

1lus d_ere.......s no exua (haroe_.....for emeroencv_. sen,ice and lo_ momhly fir_ancing is a_ailable. E_en icemaker

coverage and food spoilage pro_ecfion is offered. You can res_ easy knowing d_a_all your valuable

household produc_s are pro_ec_ed agains_ expensive repairs.

We'll Cover Any Appliatlce.

Anywhere. Anydme. *

Pl'._e,,,., _:,,._demei. (;Ea.d _all._ i. _heU.S..,ll-hee a_800-62(b2224

for more hfforma_ion,

I'\]] brmds (:ovel ed, up to 20 yetrs old, in file (OllIilleIll}I] [[ ,S.

Please place in envelope and mail to:

General Electric Company

Warranty Registration Department

P.O. Box 34070

Louisville, KY 402324070

_(:ul h(q()

17

Page 38

Consumer Product Ownership Registration

Dear Customer:

Thank you for purchasing our produc_ and _hank you %r placing your

c(mf]dence in us. \_;e are proud to have y(m as a custoi_er!

Follow these three steps to protect your new appliance investment:

( ompiele and

mail yore (:onsm_er

Product Own( rship

Rt)gis!l 3iiol] loday.

Have lho peace of

mind of knowing we

(ill] COI]_IC[ yOll ill

lhe m_likely evem of

a safflv modificalion.

Ariel" mailing

Ill( regisiralion

below, store fills

(]OC!l!lleI!l ill 3 Sa_[

place. 11_(Olll_ills

inf?)rmaiion you

wil! need should

yoll re(itlire s(ixice.

()ur se_ ic( mmfl)ei

is 800-GE4;ARES

(8(/0-452-2737).

Read your Owner's

Manual carefi_lly.

it will help you

operale }O!lr new

applian(e properly.

Kyou h_ c questions,

or need more illf_)l'-

Ill31iOll (all lhe

(;E Answer Cemer

800.626.2000.

Model Number Serial Number

Important: If you did not get a re_stradon card with your product,

ddtach and reffurn the-form below to ensdre thgt your

product is registered.

Consumer Product Ownership Reg

Model Number SeriN Number

Mr. MS. Miss

l;irsl [

Nam( I I I I I I I I I I I I I [

L_S1 [Nam_ [ [ [ [ [ [ [ [ [ [ [ [ [ [ [ [ [ [ [

Addr(ss [ [ [ [ [ [ [ [ [ [ [ [ [ [ [ [ [ [ [ [ [ [

Api. # I I I I I

(:i,?[llllllll IIIIII I I I I I I I I [

S/_tt_. [_ Zip( _K ( I I I I [

] );l[( P[ I((d

N!lmb_t_

BR)'[POINT RCIBI

GEApp/iancos

GeneralE/ectnc CornparO_

Loul:_vd/eKentucky 40225

/8

Page 39

GEDowndraftSystemWarranty

All warranty service provided by our Factory" Service Centers,

or an authorized Customer Care_) technician. For service,

carl 800-GE-CARES.

GE Will Replace, At No Charge ToYou:

One Year

Fromthedateof the

originalpurchase

:_ Service trips to your home to teach you how to use the

product.

:_ Improper installation.

:_ Failure of the product if it is abused, misused, or used for

other than the intended purpose or used commercially.

Anypart of the d_)wn&afi sFslem which f,fils due to a deiect in materials or w_)rkmanship.

During this full one-year warranty, GE will also provide, free of charge, all labor

and in-home sevvice to replace the detective part.

:_ Replacement of house fuses or resetting of circuit

breakers.

:{ Replacement of the replaceable filters.

:, Damage to the product caused by accident, fire, floods or

acts of God.

:, Incidental or consequential damage to personal property

caused by possible defects with this appliance.

This warranty is extended to the original purchaser and any succeeding owner for products purchased for home

use within the USA. In Alaska, the warranty excludes the cost of shipping or service calls to your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state. To know what your

legal rights are, consult your local or state consumer affairs office or your state's Attorney General.

Ifyou have an installation problem, contact your dealer or installer. Youare responsible for providing adequate

electrical, gas, exhausting and other connecting facilities as described in the Installation Instructions provided

with the product.

Warrantor:General Electric Company.Louisville,KY 40225

19

Page 40

Service TelephoneNumbers.

CEAnswerCenteF_soo._2_.2ooo

The (,E Answe_ (eme_ is open 24 hou_ s a day 7 days a week.

/n-HomeRepsi; ServiceSOOoCE-CARES(800-432-2737)

SpecialNeedsServiceso#._2_.2_o

800- TDD-GEAC (800-833°4322)

(;E offers, fiee of (barge, a bye( huve _o assis_ in planning a bavviev-fiee ki_( hen fov persons

wilh limited mobiiib,.

ServiceCent;actssee-szs-zzz4

subs[ands] dis(:ounL (;E Consumer Service will sdH be there after )out wavTanty expi;es.

PartsandAccessoriessoooszs-zeez

h_di_iduals qualified to se_xice d_ei_7own appliances can have pmts o_7a( cessories seflt di_Tecdy

to d_eh: homes (VISA, MasterCmd and Discover7 cm'ds me accepted).

Instructions contained in this manual cover procedures to be.performed by any user. Other servicimj

generally should be referred to qualified service personnel Caution must be exercised, since

improper servicing may cause unsafe operation.

ServiceSatisfaction

I_}:ou me not s_tisfied with the se_x:ice you ;e( eive fiom GE:

First,(ontad d_e people who sevviced your appliance.

Next,if you ave sdll not please(], write all d_e details--including your phone numbe;-to:

Manager, Consumer Relations

GE Appliances

Louisville, KY 40225

Finally,if your probDm is sdll not resoDed, write:

M_jor Appliance Consumer Acdon Pvogrm_

20 No_lh Wacke_ Drive

20 Printed in file United States

Loading...

Loading...