Page 1

GEAppliances.com

Vented

Safety Instructions ........... 2

Operating Instructions

Fan Control ......................3

Light Control .....................4

Care and Cleaning

Grease Filters ....................5

Hood Lights ......................6

Stainless Steel Surfaces ..........5

Installation Instructions . . 6–17

Troubleshooting Tips .......18

Consumer Support

Consumer Support .............. 22

Owner Registration ...........19, 20

Warranty ....................... 21

Owner’s Manual

and Installation

Instructions

JV936

JV966

CV936

CV966

Write the model and serial

numbers here:

Model # _______________

Serial # ________________

You can find them on a label

Range Hoods

on the inside of the hood.

LI275B 49-80520-5 01-13 GE

Page 2

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

SAFETY PRECAUTIONS

WARNING – TO REDUCE THE RISK OF FIRE,

ELECTRIC SHOCK OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

A. Use this unit only in the manner intended by the manufacturer.

If you have questions, contact the manufacturer.

B. Before servicing or cleaning unit, switch power off at service

panel and lock the service disconnecting means to prevent

power from being switched on accidentally. When the service

disconnecting means cannot be locked, securely fasten a

prominent warning device, such as a tag, to the service panel.

C. Do not use this unit with any solid-state speed control device.

D. This unit must be grounded.

CAUTION – FOR GENERAL VENTILATING USE ONLY.

DO NOT USE TO EXHAUST HAZARDOUS OR EXPLOSIVE MATERIALS

AND VAPORS.

WARNING – TO REDUCE THE RISK OF INJURY TO

PERSONS IN THE EVENT OF A RANGE TOP GREASE FIRE, OBSERVE

THE FOLLOWING*:

A. SMOTHER FLAMES with a close-fitting lid, cookie sheet or metal

tray, then turn off the burner. BE CAREFUL TO PREVENT BURNS. If

the flames do not go out immediately, EVACUATE AND CALL THE

FIRE DEPARTMENT.

B. 1(9(53,&.83$)/$0,1*3$1³<RXPD\EHEXUQHG

C. '212786(:$7(5LQFOXGLQJZHWGLVKFORWKVRUWRZHOV³D

violent steam explosion will result.

D. Use an extinguisher ONLY if:

1. You know you have a Class ABC extinguisher, and you

already know how to operate it.

2. The fire is small and contained in the area where it started.

3. The fire department is being called.

4. You can fight the fire with your back to an exit.

* Based on “Kitchen Fire Safety” published by NFPA.

WARNING – TO REDUCE THE RISK OF A RANGE

TOP GREASE FIRE:

A. Never leave surface units unattended at high settings. Boilovers

cause smoking and greasy spillovers that may ignite. Heat oils

slowly on low or medium settings.

B. Always turn hood ON when cooking on high heat or when

flambéing food (i.e. Crepes Suzette, Cherries Jubilee, Peppercorn

Beef Flambé).

C. Clean ventilating fans frequently. Grease should not be allowed

to accumulate on fan or filter.

D. Use proper pan size. Always use cookware appropriate for the

size of the surface element.

WARNING – TO REDUCE THE RISK OF FIRE,

ELECTRIC SHOCK OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

A. Installation work and electrical wiring must be done by qualified

person(s) in accordance with all applicable codes and standards,

including fire-rated construction.

B. Sufficient air is needed for proper combustion and exhausting

of gases through the flue (chimney) of fuel burning equipment

to prevent back drafting. Follow the heating equipment

manufacturer’s guideline and safety standards such as

those published by the National Fire Protection Association

(NFPA), the American Society for Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE) and the local code authorities.

When applicable, install any makeup (replacement) air system

in accordance with local building code requirements. Visit

GEAppliances.com for available makeup air solutions.

C. When cutting or drilling into wall or ceiling, do not damage

electrical wiring and other hidden utilities.

D. Ducted fans must always be vented to the outdoors.

WARNING – TO REDUCE THE RISK OF FIRE AND TO

3523(5/<(;+$867$,5%(685(72'8&7$,52876,'(³'2127

VENT EXHAUST AIR INTO SPACES WITHIN WALLS OR CEILINGS OR

INTO ATTICS, CRAWL SPACES OR GARAGES.

WARNING – TO REDUCE THE RISK OF FIRE, USE

ONLY METAL DUCTWORK.

Do not attempt to repair or replace any part of your hood unless

it is specifically recommended in this guide. All other servicing

should be referred to a qualified technician.

READ AND FOLLOW THIS SAFETY INFORMATION CAREFULLY.

READ AND SAVE THESE INSTRUCTIONS

2

Page 3

Using the hood controls. GEAppliances.com

Throughout this manual, features and appearance may vary from your model.

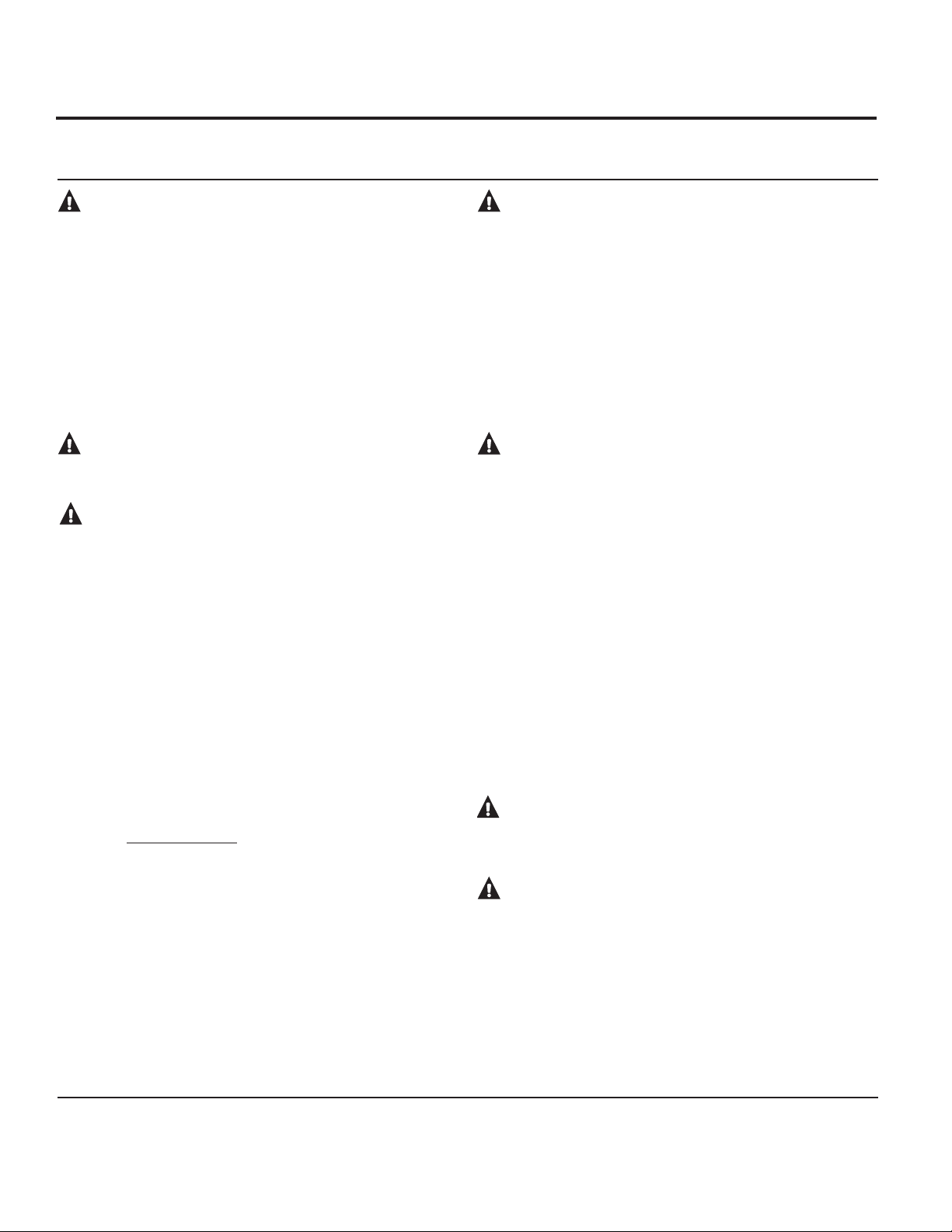

FAN Control

Turn the FAN speed control to LO, MED LO,

MED HI or HI, as needed.

Continuous use of the fan system while cooking helps

keep the kitchen comfortable and less humid. It also

reduces cooking odors and soiling moisture that

create a frequent need for cleaning.

NOTE: When the fan is operating on the LO setting,

it will be very quiet. Always make sure that the fan is

turned OFF when you are finished in the kitchen.

LIGHT Control

Turn the LIGHT control to HI for bright light while

cooking. Turn to NITE for use as a night light.

3

Page 4

Care and cleaning of the vent hood.

Be sure electrical power is off and all surfaces are cool before cleaning or servicing any part of the vent hood.

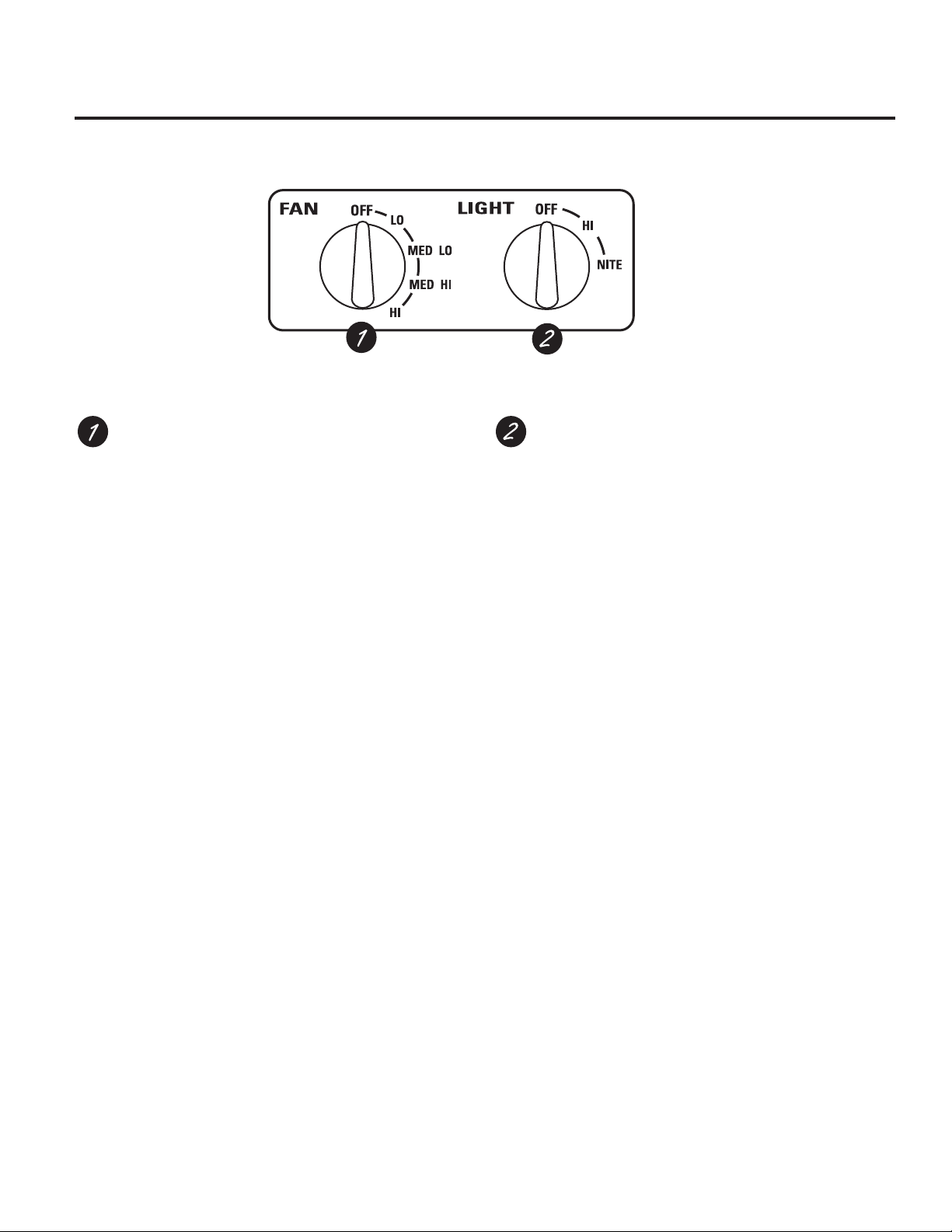

Reusable Metal Grease Filters

The hood has 2 metal reusable grease

filters.

The metal filters trap grease released

by foods on the cooktop. They also

help prevent flaming foods on the

cooktop from damaging the inside of

the hood.

For this reason, the filters must

ALWAYS be in place when the hood

is used. The grease filters should be

cleaned once a month, or as needed.

To clean the grease filters, soak

them and then swish them around

in hot water and detergent. Don’t

use ammonia or ammonia products

because they will darken the metal.

Do not use abrasives or oven cleaners.

Light brushing can be used to remove

embedded dirt. Rinse, shake and let

them dry before replacing.

To remove:

Grasp the filter handle and pull it up,

forward and out.

To replace:

Hold the filter at the bottom with

the handle.

Place the top end of the filter

against the inside front of the

hood.

Slide it up until it stops and push

the bottom end back until it snaps

into place.

Stainless Steel Surfaces

Do not use a steel wool pad; it will

scratch the surface.

To clean the stainless steel surface,

use warm sudsy water or a stainless

steel cleaner or polish. Always wipe the

surface in the direction of the grain.

Follow the cleaner instructions for

cleaning the stainless steel surface.

To inquire about purchasing stainless

steel appliance cleaner or polish, or to

find the location of a dealer nearest

you, please call our toll-free number:

National Parts Center

800.626.2002

GEAppliances.com

4

Page 5

GEAppliances.com

Be sure electrical power is off and all surfaces are cool before cleaning or servicing any part of the vent hood.

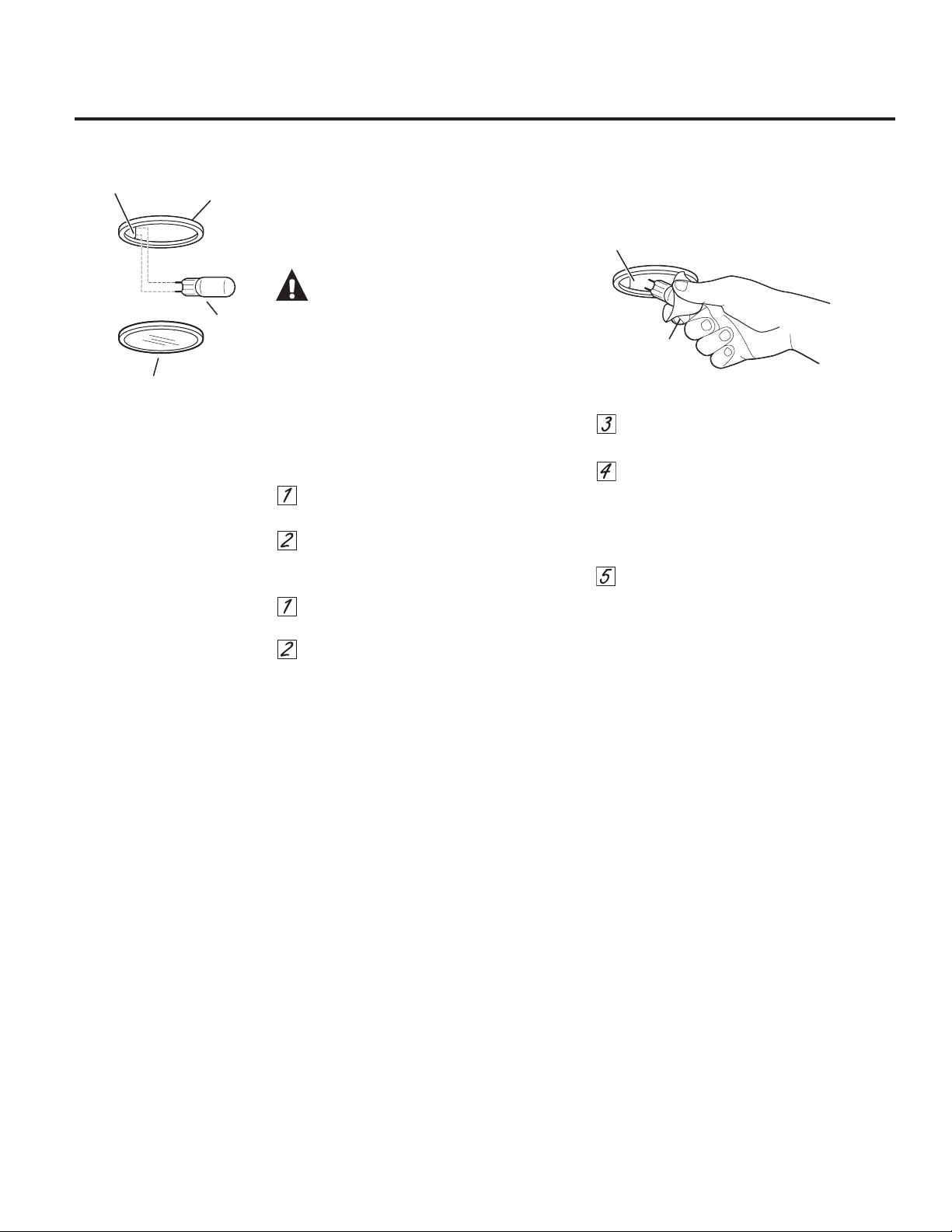

Receptacle

Glass cover

Socket

Bulb

Hood Lights

NOTE: The glass cover should be removed

only when cold. Wearing latex gloves may

offer a better grip.

CAUTION: Before replacing your

light bulb, disconnect the electrical power to

the hood at the main fuse or circuit breaker

panel.

Be sure to let the light cover and bulb cool

completely.

For your safety, do not touch a hot bulb with

bare hands or a damp cloth.

To remove:

Turn the glass cover counterclockwise until

the glass cover clears the socket.

Using gloves or a dry cloth, remove the

bulb by pulling it straight out.

To replace:

Use a new 12-volt, 20-watt (maximum)

Halogen bulb for a G-4 base.

Receptacle

Use gloves

or cloth

Push the bulb straight into the receptacle

all the way.

Place the glass cover onto the socket and

turn clockwise until secure.

For improved lighting, clean the glass cover

frequently using a damp cloth. This should

be done when the hood is completely cool.

Reconnect electrical power to the hood.

Using gloves or a dry cloth, remove the

new bulb from its packaging.

NOTE: Do not touch the new halogen bulb

with bare fingers. Touching the bulb with

bare fingers will significantly reduce the life

of the bulb.

5

Page 6

Installation

Range Hoods

Instructions

Questions? Call 800.GE.CARES (800.432.2737) or visit our Website at: www.GEAppliances.com.

BEFORE YOU BEGIN

Read these Instrucitons completely and carfully.

•

IMPORTANT³ Save these instructions

for local inspector’s use.

•

IMPORTANT³Observe all governing

codes and ordinances.

• Note to Installer ³Be sure to leave these

instructions with the Consumer.

• Note to Consumer ³Keep these instrucitons

for future reference.

• Skill Level³ Installation of this vent hood

requires basic mechanical and electrical skills.

• Completion time ³ 1 to 3 hours.

• Proper installation is the responsibility of the

installer.

• Product failure due to improper installation is

not covered under the Warranty.

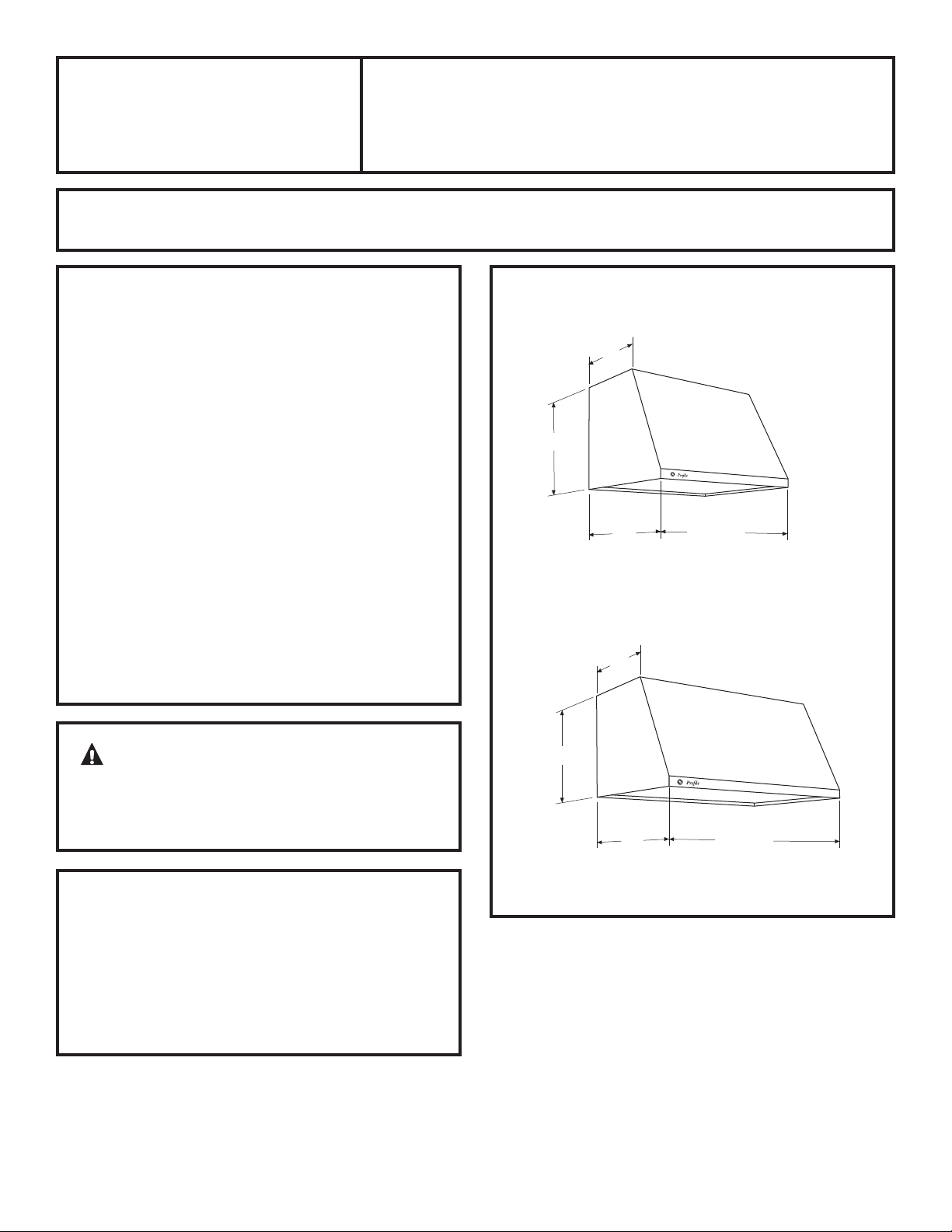

PRODUCT DIMENSIONS

12”

18”

21”

30” Models

Requires a 30” opening.

12”

29-7/8”

CAUTION :

Due to the weight and size of these vent hoods

and to reduce the risk of personal injury or

damage to the product, TWO PEOPLE ARE

REQUIRED FOR PROPER INSTALLATION.

FOR YOUR SAFETY :

Before beginning the installation, switch power

off at service panel and lock the service

disconnecting means to prevent power from

being switched on accidentally. When the service

disconnecting means cannot be locked, securely

fasten a prominent warning device, such as a tag

to the service panel.

18”

36” Models

Requires a 36” opening.

6

21”

35-7/8”

Page 7

Installation Instructions

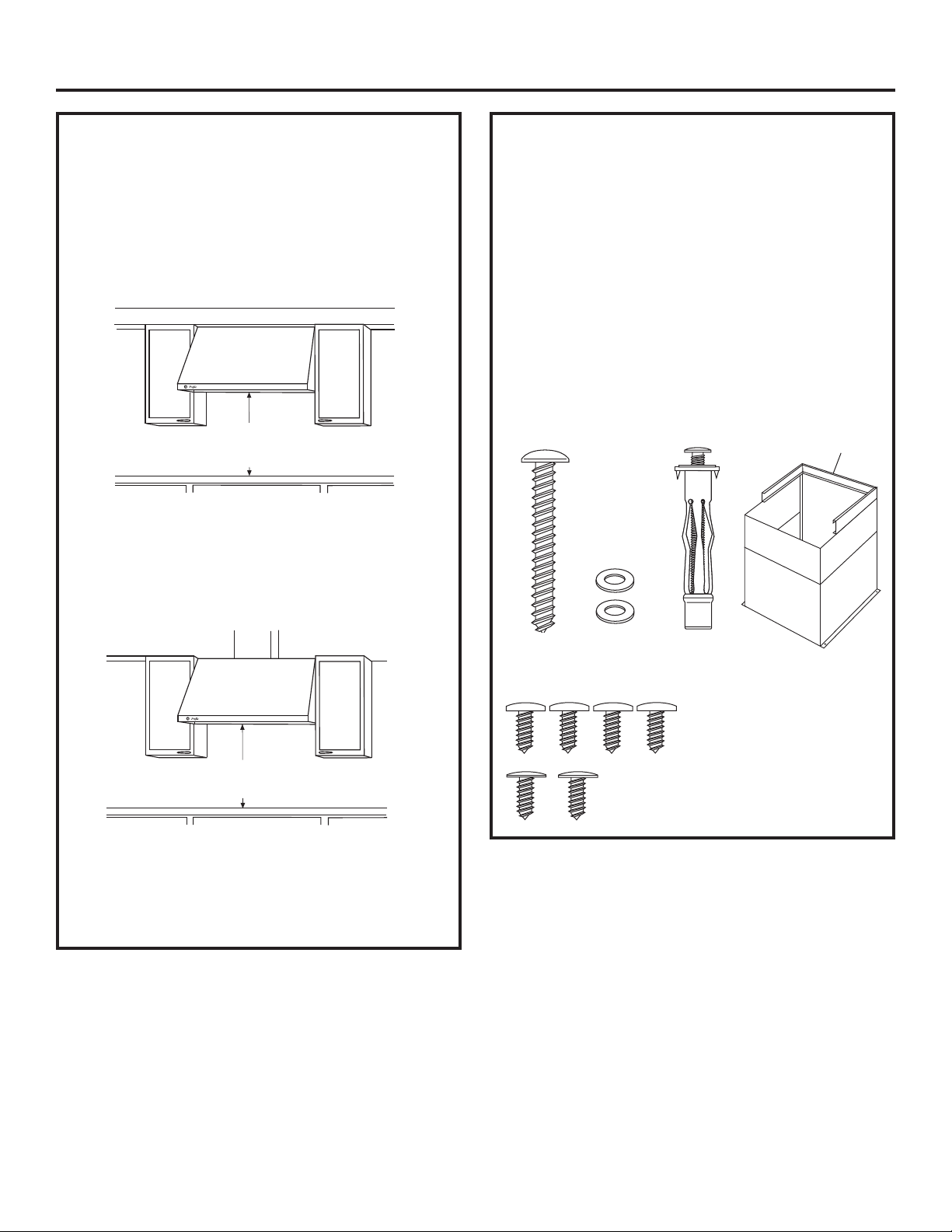

INSTALLATION CLEARANCES

These vent hoods are designed to be installed onto

a wall. They may be installed beneath a soffit or

cabinet.

• Install these hoods 24” Min. to 36” Max. above the

cooking space.

SOFFIT INSTALLATION

SOFFIT

24” MIN.

36” MAX.

In this installation, the ductwork running from the

top of the hood will be concealed in the soffit or

upper cabinetry.

OPTIONAL ACCESSORIES

Duct Cover

A decorative duct cover is available to

accommodate 8 to 10 ft. ceiling heights. The duct

cover will expand from 12” Min. or 24” to 36” Max.

height.

• The duct cover conceals the ductwork running

from the top of the hood to the ceiling.

• The duct cover accessory fits both 30” and 36”

wide models. Order the duct cover accessory at

the same time as the vent hood. All accessories

should be on site at the time of hood

installation.

Order JXCHSS

Ceiling

Bracket

WALL MOUNT INSTALLATION

24” MIN.

36” MAX.

For this isntallation, a decorative duct cover is

available to conceal the ductwork running from

the top of the hood. Use of the duct cover requires

special consideration to the installation height above

the countertop. See page 12 for details.

2 Wood

Screws

2

Washers

2 Phillips Head

Decorative Scews

2 Wall

Fasteners 2-Piece Duct

Cover with

Ceiling Bracket

4 Phillips

Head Screws

7

Page 8

Installation Instructions

ADVANCE PLANNING

Ductwork Planning

• This hood may be vented vertically through upper cabinets,

soffit or ceiling. A duct transition piece is supplied for vertical

exhaust. Use locally supplied elbows to vent horizontally

through the rear wall. See page 13.

• Determine the exact location of the vent hood.

• Plan the route for venting exhaust to the outdoors.

• Use the shortest and straightest duct route possible. FFor

satisfactory performance, duct run should not exceed 100

equivalent length for any duct configurations.

• Use metal ductwork only.

• A transition piece for 7” round duct is supplied. Use 7” round

duct or you may use 3-1/4” x 12” rectangular.

• Install a wall cap or roof cap with damper at the exterior

opening. Order the wall or roof cap and any transition

needed in advance.

• When applicable, install any makeup (replacement) air

system in accordance with local building code requirements.

Visit GEAppliances.com for available makeup air solutions.

Kit - JXDW1

Order kit JXDW1 if your installation requires horizontal ducting

from the top of the hood through the back wall and:

• You have an 8 ft. ceiling and need to use a JXCH Series

Chimney Cover, or

• You have a 12” cabinet or 12” soffit that the hood is to be

mounted beneath.

This kit provides a duct transition from 7” round to 3-1/4” x 10”

rectangular for through-the-wall venting.

Wall Framing for Adequate Support

• This vent hood is heavy. Adequate structureal support must

be provided. The hood must be secured to vertical studs in

the wall. See page 14.

• We strongly recommend that the vent hood with duct cover

be on site before final framing and wall finishing. This will

also help to accurately locate the ductwork and electrical

service.

DECORATIVE DUCT COVERS

A decorative duct cover is available to fit both model widths.

The duct cover conceals the ductwork running from the top of

the hood to the ceiling or soffit. The duct cover will fit 8 ft. to 10

ft. ceiling heights. See page 12 for details.

POWER SUPPLY

IMPORTANT - (Please read carefully)

WARNING:

FOR PERSONAL SAFETY, THIS APPLIANCE MUST BE PROPERLY

GROUNDED.

Remove house fuse or open circuit breaker before beginning

installation.

Do not use an extension cord or adapter plug with this

appliance. Follow National electrical codes or prevailing local

codes and ordinances.

Electrical supply

This vent hood must be supplied with 120V, 60 Hz, and

connected to an individual, properly grounded branch circuit,

and protected by a 15 or 20 amp circuit breaker or time delay

fuse.

• Wiring must be 2 wire with ground.

• If the electrical supply does not meet the above

requirements, call a licensed electrician before proceeding.

• Route house wiring as close to the installaton location as

possible in the ceiling, soffit or wall. See page 13 for details.

• Connect the wiring to the house wiring in accordance with

local codes.

Grounding instructions

The grounding conductor must be connected to a ground

metal, permanent wiring system, or an equipment-grounding

terminal or lead on the hood.

WARNING: The improper connection of the

equipment-grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative if you are

in doubt whether the appliance is properly grounded..

Page 9

Installation Instructions

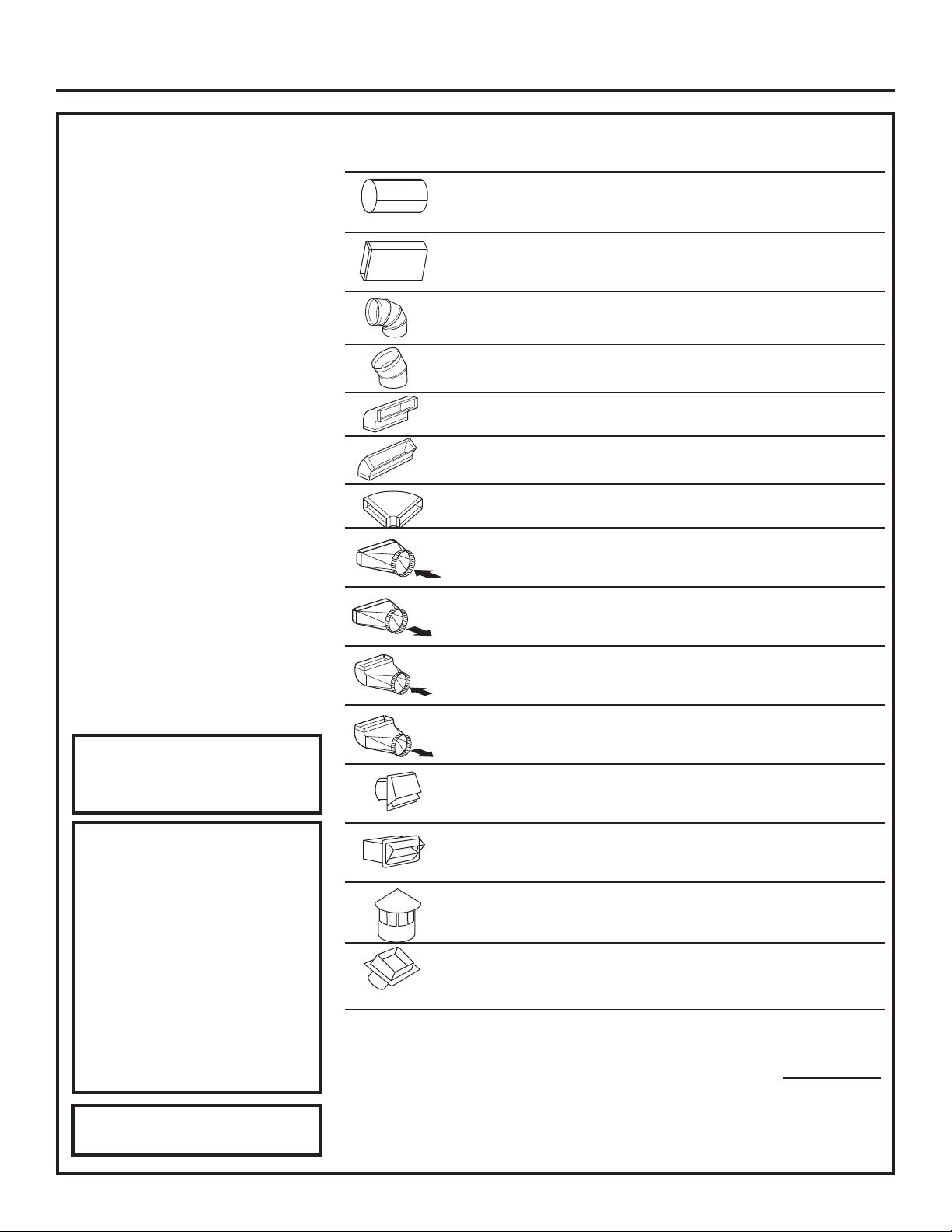

DUCT FITTINGS

Use this chart to compute maximum

permissible lengths for duct runs to

outdoors.

Note: Do not exceed maximum

permissible equivalent lengths!

Maximum duct length:

100 foot for vent hoods.

Flexible ducting:

If flexible metal ducting is used, all

the equivalent feet values in the table

should be doubled. The flexible metal

duct should be straight and smoot

and extended as much as possible.

Do NOT use flexible plastic ducting.

Note

: Any home ventilation system,

such as a ventilation hood, may interrupt

the proper flow of combustion air

and exhaust required by fireplaces,

gas furnaces, gas water heaters and

other naturally vented systems. To

minimize the chance of interruption of

such naturally vented systems, follow

the heating equipment manufaturer’s

guidelines and safety standards such as

those published by NFPA and ASHRAE.

When applicable, install any makeup

(replacement) air system in accordance

with local building code requirements.

Visit GEAppliances.com for available

makeup air solutions.

This Hood Must Use 7” Round

Duct. It Can Transition To

3-1/4” x 12” Duct.

Total

Equivalent Quantity Equivalent

Duct Piece Dimensions Length* Used Length

7” Round 1 ft.

straight (per foot

length)

3-1/4” x 12” 1 ft.

straight (per foot

length)

7” 90° elbow 14 ft.

7” 45° elbow 9 ft.

3-1/4” x 12” 15 ft.

90° elbow

3-1/4” x 12” 9 ft.

45° elbow

3-1.4” x 12” 36 ft.

90° flat elbow

7” round to

3-1/4” x 12” 1 ft.

transition

3-1/4” x 12”

to 7” round 1 ft.

transition

7” round to

3-1/4” x 12” 4 ft.

transition 90° elbow

3-1/4” x 12” to

7” round 4 ft.

transition 90° elbow

7” round

wall cap 28 ft.

with damper (21 ft. without damper)

Kit - JXDW1

Order kit JXDW1 if your installation

requires horizontal ducting from the

top of the hood through the back

wall and:

• You have an 8 ft. ceiling and need

to use a JXCH Series Chimney Cover,

or

• You have a 12” cabinet or 12” soffit

that the hood is to be mounted

beneath.

This kit provides a duct transition

from 7” round to 3-1/4” x 10”

rectangular for through-the-wall

venting.

Using a smaller diameter duct size

will reduce performance.

3-1/4” x 12”

wall cap 26 ft.

with damper (19 ft. without damp

7” round 39 ft.

roof cap

Round 24 ft.

roof vent

* Actual length of straight duct plus duct fitting

equivalent. Equivalent length of duct pieces are

based on actual tests conducted by GE Evaluatioin

Engineering and reflect requirements for good

venting performance with any ventilation hood.

Total Duct Run

9

Page 10

Installation Instructions

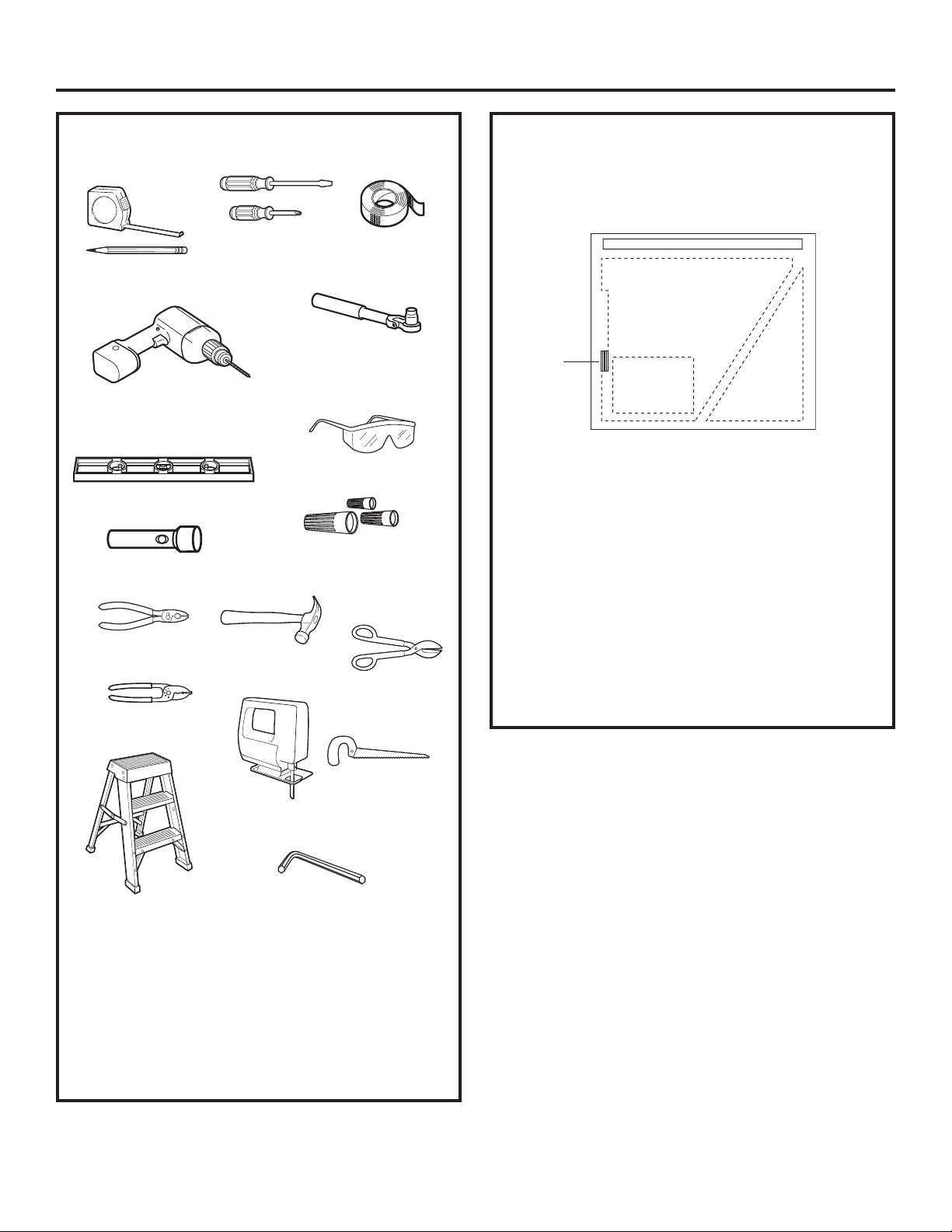

TOOLS AND MATERIALS REQUIRED

(NOT SUPPLIED)

Phillips and

Pencil and tape

measure

Electric drill with 1/8” and

3/8” bits

Spirit level

Flashlight

Pliers

Wire Cutter/

Stripper

Flat blade

screwdirvers

Hammer

1/4” pivoting hex

socket

UL Listed Wire nuts

Duct tape

Safety glasses

Tin Snips

REMOVE THE PACKAGING

• Remove the small box housing the motor.

• Lift the hood out of the box.

Hood

Wood

Mounting

Support

• Remove shipping screws holding the wood mounting

piece to the back side of the hood. Set aside wood

mounting piece and screws for later installation. Do

not discard.

• Remove the “V” shaped carton insert.

• Remove parts package from the “V” shaped

cardboard insert.

• Remove junction box cover and knockout.

• Install strain relief onto back or top of hood.

• Remove all tape and packing material from the hood,

duct transition and motor.

Motor

Shipping Carton

Parts

Package

Saber saw or Key Hole Saw

Ladder

Additional Materials:

• 120V 60Hz, 15 or 20 Amp, 2 wire with ground.

Properly grounded branch circuit.

• Strain relief for junction box.

7” round metal duct, 3-1/4” x 10” rectangular duct

•

or 3-1/4” x 12” rectangular duct length to suit

installatoin.

Allen Wrench

10

Page 11

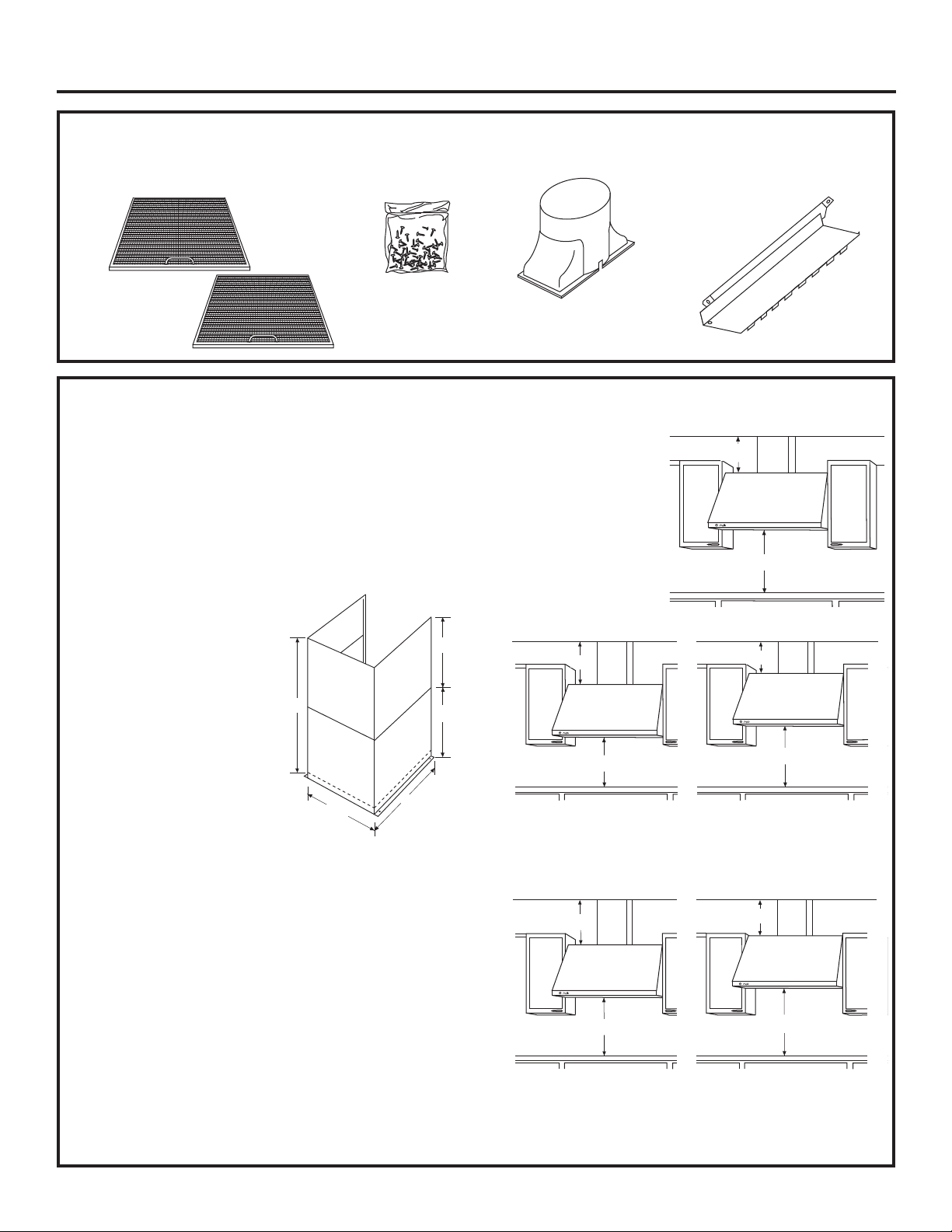

Installation Instructions

PARTS PROVIDED

Locate the hardware accessory box packed with the hood

and check contents.

2 Aluminum

Grease Filters

Screws, wall

fasteners,

washers

DUCT COVER REQUIREMENTS

We recommend that the vent hood and decorative duct

cover (if used) be on site before final framing and wall

finishing. This will help to accurately locate studs, ductwork,

and electrical service. Read these instructioins to determine

if the duct cover accessory can be used for your installation

situation.

Duct Cover Accessory:

• Use the decoroative duct cover to conceal ductwork

running from the top of the hood to the ceiling.

• The duct cover accessory

consists of 2 pieces. The

outside piece is 12” high,

the inside piece is 22”.

Nested together they are

24” min. expanding to a total

maximum height of 34”.

• The outside piece can be

22”

used alone to fill a 12”

height.

• For heights over 12”, the

ceiling bracket must be

installed to secure the cover

at the top.

11”

To avoid unsightly gaps, plan

the hood installation height for duct cover use.

• The cover will fit a 12” min. height from the top of the

hood to the ceiling or 24” min. and expanding up to 34”

from the top of the hood to the ceiling.

THE DUCT COVER CANNOT BE USED WHEN THE DISTANCE

ABOVE THE TOP OF THE HOOD IS BETWEEN 12” AND 24”.

12”

12”

12”

Duct Transition

with Damper

Filter

Support

Review the following examples to ensure a trouble free

installation using the duct cover

accessory.

8ft. Ceilings:

8 ft. Ceiling

12”

The hood must be installed

at 30” above the cooking

surface (or 66” above the

floor). the duct cover will not

fit if the hood is isntalled at

a lower or higher height.

Use the outside 12” section,

30”

discard the inside section.

9 ft. Ceiling

30”

24”

24”

30”

9 ft Ceiling: Install the hood 24” min. and up to a maximum

of 30” above the cooking surface. The duct cover will expand

to reach ceiling height.

10 ft. Ceiling

34”

30”

32”

36” Max

10 ft. Ceiling: Install the hood 32” min to 36” max. above the

cooking surface. The duct cover will expand to a maximum

of 34” above the top of the hood to meet the ceiling.

11

Page 12

Installation Instructions

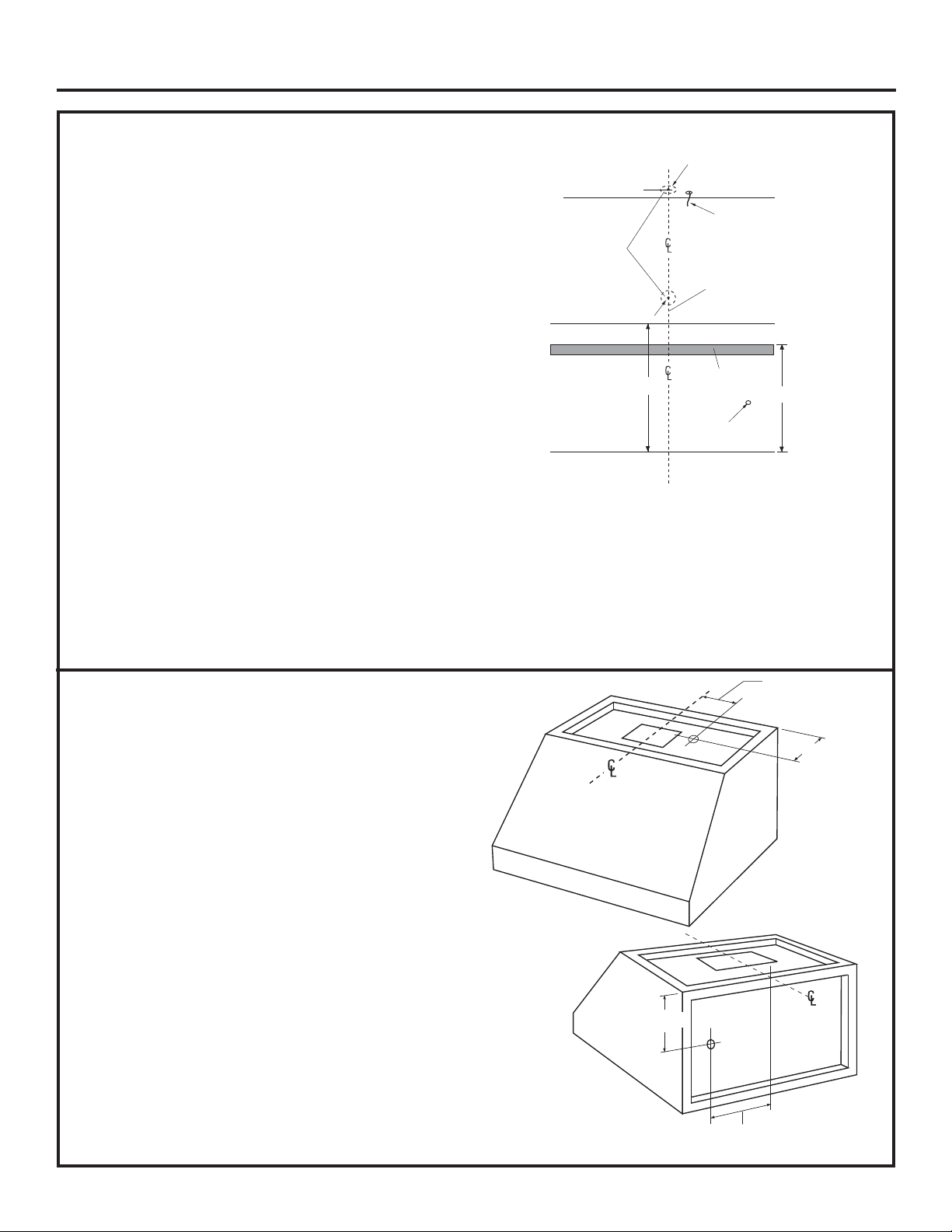

DETERMINE HOOD, DUCTWORK AND WIRING LOCATIONS

• Keep the wood support piece and its screws for later

installaton. Do not discard.

• Measure desired distance from the bottom of the hood

to the cooking surface, 24” min. to 36” max. Refer to the

previous page if the accessory duct cover will be used.

• Use a level to draw a horizontal line indicating the bottom

of the hood.

• Use a level to draw the cooktop centerline location.

• Measure 15-3/8” up from the horizontal lline for the

bottom of the hood. Draw another horizontal line.

• Measure 18” up from the line for the bottom of the hood,

draw another horizontal line to indicate the top of the

hood.

FOR VERTICAL (Straight Up) DUCTING:

• If venting out the ceiling, extend the centerline forward on

the ceiling.

- Measure 6-7/8” from drywall to mark centerline for a

7-1/2” dia. duct hole on the ceiling.

- If drywall is not present, add drywall thickness to the

6-7/8” dimension.

Venting through a soffit or upper cabinet:

• Follow the same procedure for ceiling ducting to cut the

7-1/2” dia. hole through the top of the cabinet or soffit.

• See Step 4, page 15 for details to cut opening for duct

transition.

6-7/8”

Centerline to Wall

7-1/2” Dia.

Hole

FOR WALL VENT DUCT

Top of Hood

18”

Bottom of Hood

FOR CEILING

VENT DUCTING

Electrical

Centerline 8” Min.

above Top of

Hood

Wood

Support

Electrical

15-3/8”

FOR DUCTING THROUGH REAR WALL:

• Measure the supplied duct transition with any straight

run length of duct used, plus 90” elbow height. Draw a

horizontal line on the wall intersecting the centerline.

House Wiring Location:

• The junction box is fastenend to the back of the hood

on the right side. See illustrations for hood knockout

locations.

Note:The junction box can be relocated to the inside top of

the hood.

House wiring may enter the junction box from the rear or

the top of the hood at the right side.

To route house wiring through the ceiling or soffit:

– Cut a hole approximately 1” dia., 5-7/8” forward on

the ceiling; 11-1/8” to the right of the centerline for 30”

models or 14-1/8” to the right of the centerline for 36”

models.

To route house wiring through the wall:

– Cut a hole approximately 1” dia. 10-1/16” down from the

top of the hood, 11-1/8” to the right of the centerline for

30” models or 14-1/8” to the right of the centerline for 36”

models..

• Remove top or rear knockout depending on your

installation.

• Install strain relief onto back or top of hood.

14-1/8” for 36” Models

11-1/8” for 30” Models

5-7/8”

Knockout

Locations

10-1/16”

12

14-1/8” for 36” Models

11-1/8” for 30” Models

Page 13

Installation Instructions

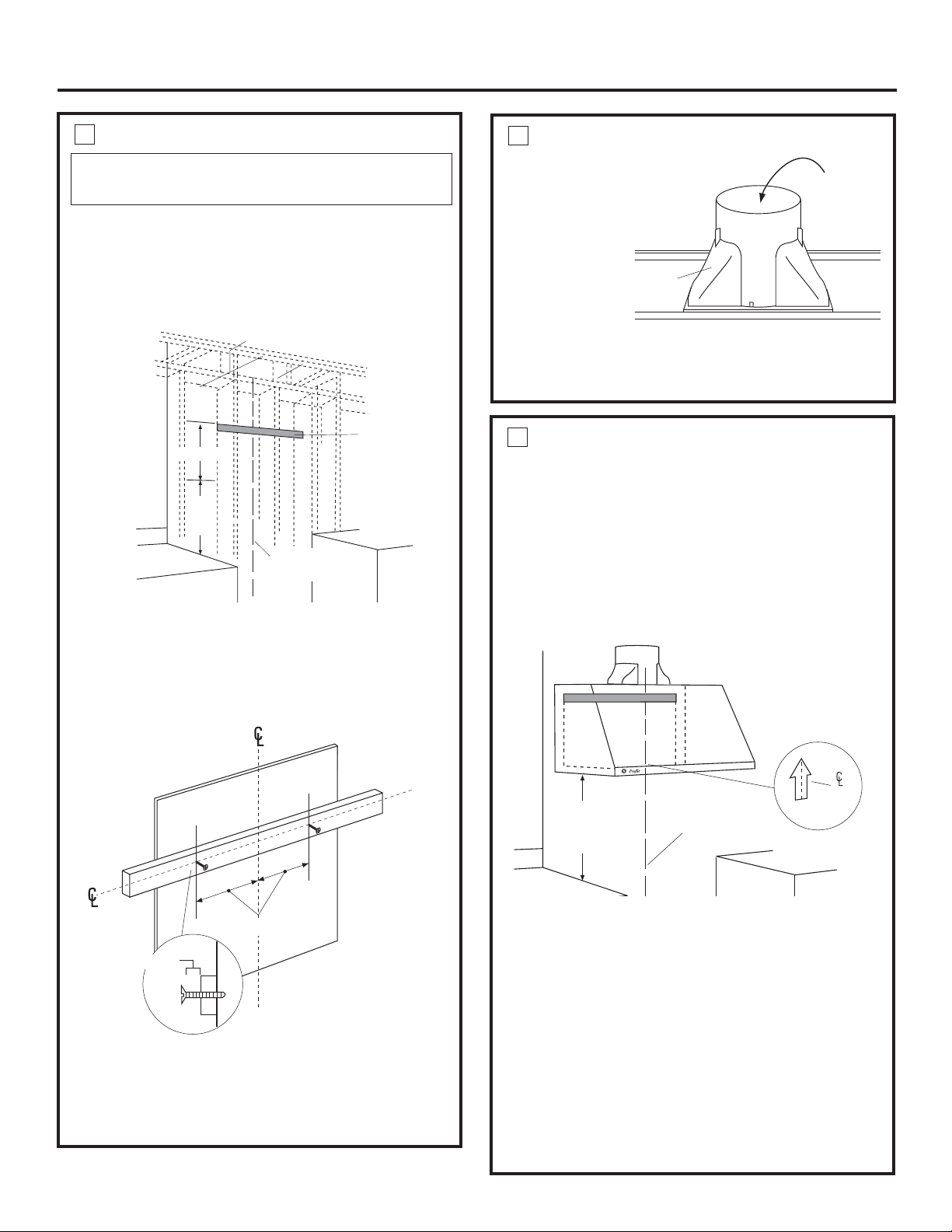

1

INSTALL HOOD SUPPORT

IMPORTANT : Framing must be capable of supporting

100 lbs.

• Locate at least 2 vertical studs at the wood mounting

location by tapping drywall with a hammer or use a stud

finder.

• Center the supplied wood horizontal support, left to right,

and below the marked line.

2

INSTALL TRANSITION

IMPORTANT: Remove shipping

tape from damper and check

that damper moves freely.

Duct

Transition

Remove

Shipping Tape

on Damper

Top of

Hood

7” Min. Opening for Ductwork

Wood Support

15-3/8”

24”

to

36”

Centerline of

Installation Space

• Drill 1/8” pilot holes through the support, drywall and into

the studs. Secure the support to 2 or more vertical studs

with supplied wood screws.

IMPORTANT : Screws must penetrate at least 1-1/2” into

vertical studs. Countersink screws into support.

• Place the transition piece over the hood exhaust. Secure

transition to hood with 4 screws provided.

• Use duct tape to seal the connection.

3

INSTALL HOOD ONTO WALL

• Lift the hood and place over the wood support. The top

keyhole slots in the hood should engage the protruding

mounting screws. Allow the hood to slide down into

position.

• Pull house wiring through knockout at the rear or top of

the hood.

•

Check to be sure the hood is level and centered. The arrow

shaped cutout in the back of the hood allows viewing the

marked centerline.

• Remove cover from junction box.

13-1/16”

1/4” gap

• Install mounting screws in the center of the wood suppor,

13-1/6” from the centerline. The screws should protrude

forward 1/4”. This 1/4” gap will provide clearance to hang

the hood.

24”

to

36”

Centerline of

Installation

Space

Drill Bottom Mounting Hole Locations

• Drill 1/8” pilot holes into the two lower mounting holes.

Enlarge the holes if they do not enter studs to 3/8”. Tap

anchors for wall fasteners into bottom holes. Install

screws by hand into the fasteners to allow anchors to

expand against the wall. Remove screws.

•

Using two large flat washers (supplied), install wood screws or

wall fastener screws, loosely, into lower mounting holes. Do

not tighten.

• Check hood level. Tighten upper screws. Tighten lower

mounting screws..

• For additional security, drive screws through the original

wood support screw holes in the back of the hood.

13

Cutout

Page 14

Installation Instructions

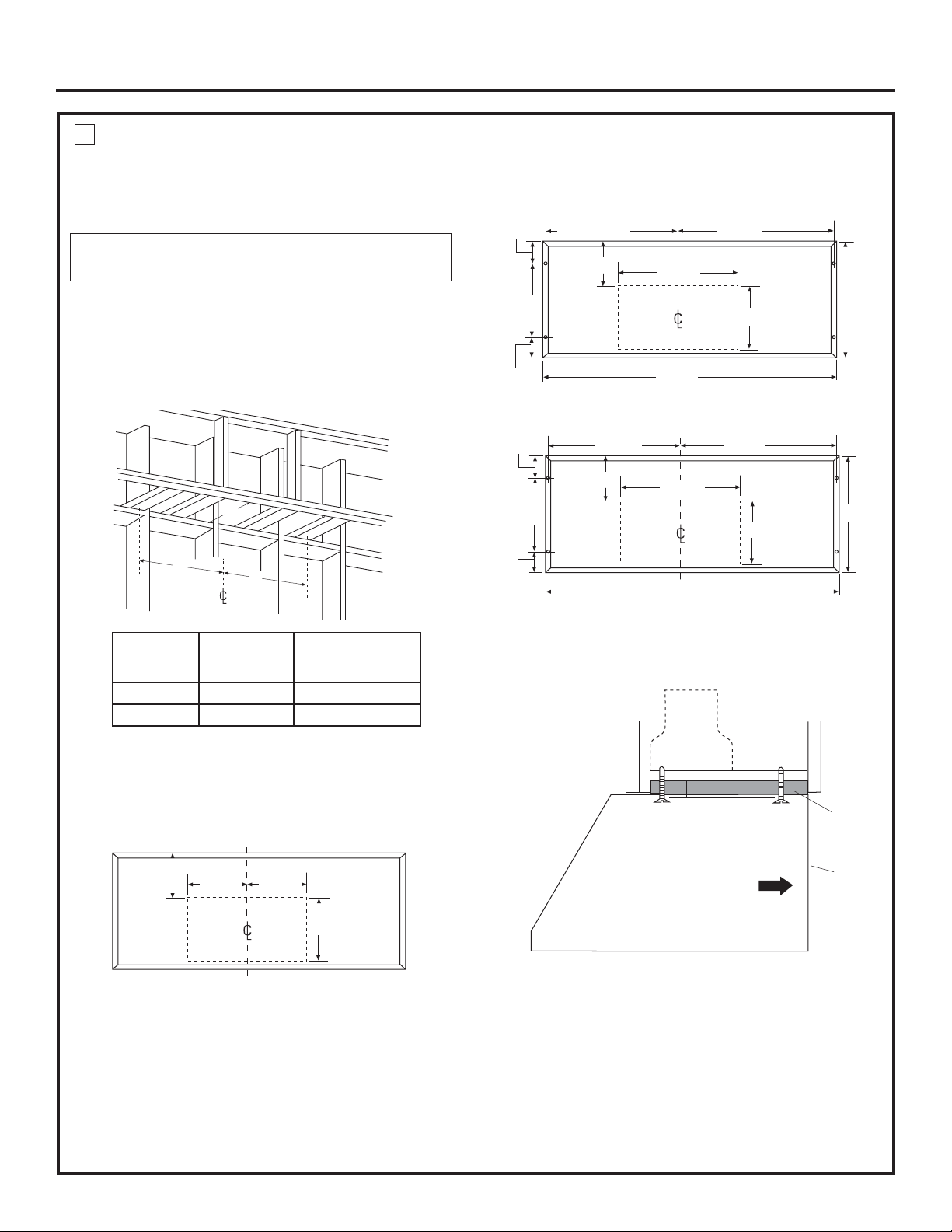

4

Alternate Mounting Method

INSTALL HOOD TO SOFFIT OR

BENEATH CABINETS

SKIP THIS STEP IF USING WALL MOUNTING METHOD

IMPORTANT : Soffit framing must be capable of

supporting 100 lbs.

When necessary the hood may be installed so that it is

supported by the soffit.

• The soffit should be constructed with 2x4’s.

• Determine the installation location..

• Continue the centerline forward on the bottom of the

cabinet or soffit.

B

A

A

IMPORTANT : For additional support and to minimize

vibration during operation, we strongly recommend

that the hood also be secured to the back wall with wall

fastners.

30” Models

2-9/16”

7-1/16”

2-1/4”

2-9/16”

7-1/16”

2-1/4”

14-1/2”

2-3/8”

2-3/8”

10-3/4”

29-7/8”

Top View, Front Side

36” Models

17-1/2”

10-3/4”

35-7/8”

Vue de dessus, partie avant

14-1/2”

12”

8-7/16”

17-1/2”

12”

8-7/16”

“A”

Centerline to

Center of Stud

30” Models 14-1/2” 10-3/4” W x 8-7/16 D

36” Nideks 17-1/2” 10-3/4” W x 8-7/16 D

“B”

Opening for

Ductwork

• Mounting screws must be secured to 2 x 4 studs (Dim. “A”)

at locations shown in the above chart.

• Allow minimum opening (Dim. “B”) to accommodate

the duct transition in the soffit

Rear Wall

2-3/8”

5-3/8”

Top View, Front Side

5-3/8”

8-7/16”

Cut a 10-3/4” x 8-7/16” hole through bottom of soffit or

cabinet for duct transition as shown.

• Drill four 1/8” pilot holes in locations show.

– If mounting to the underside of a cabinet with a

recessed bottom, install shims to fill the gap.

Cabinet

Transition

1/4” Gap

Engage Keyhole Slots

and Push Back at Wall

or Soffit

Add

Shimms if

Bottom is

Recessed.

Back

Wall

• Drive mounting screws int the studs until they

protrude 1/4”. This 1/4” gap will provide clearance to

engage the keyhole slots in the top of the hood.

• Lift hood onto mounting screws. slide back against

the rear wall.

• Pull house wiring through the knockout at the rear or

top of the hood.

• Tighten mounting screws.

14

Page 15

Installation Instructions

5

INSTALL CEILING BRACKET

The ceiling bracket must be installed when the duct

cover is used to span 24” or more height above the hood.

The bracket will hold the decorative duct cover in place

at the top.

Note: The ceilling bracket is not required when using only

the 12” section of the duct cover.

• Install the 2 small screws into the sides of the duct

bracket. remove the screws. Pre-tapping the holes will

insue ease of final installation.

• Match center notch on the bracket to the centerline

on the wall and flush against the ceiling.

• Mark the 2 screw hole locations.

• Drill 2/8” pilot holes in marked bracket location.

• If pilot holes do not enterstuds, enlarge the holes to

3/8” and install wall fastener anchors.

• Secure the bracket to the rear wall with wood screws

and washers. Use wall anchors if needed.

Note: Bracket has 2 sets of holes. Use larger holes

for wall fasheners or wood screws with washers. Use

smaller holes for wood screws with washers.

6

CONNECT DUCTWORK

• Push duct over the end of the transition until it

reaches the stop tabs.

• Install ductwork, making connections in direction of

airflow as illustrated.

• Secure joints in ductwork with sheetmetal screws.

• Wrap all duct joints with duct tape for an airlight seal.

• Use duct tape to seal the flange connection

House

Ductwork

Duct Tape Over

Seam and Screw

Duct Tape Only for Proper

Operation of Damper

Air Flow

Screw

Ductwork

Duct Stops

Transition

Install Ceiling

Bracket When

Duct Cover is

Used to Span 24”

or more

Duct Tape Over

Flange

CAUTION: Do not use sheet metal screws

at the transition to ductwork connection. Doing se will

prevent proper damper operations. Seal connection with

tape only.

See Step

9 to Install

Duct

Cover.

15

Page 16

Installation Instructions

7

INSTALL MOTOR

• Align and engage the slots

in the blower assemly to

the 3 hooks at the rear of

the exhaust opening.

• Rotate motor uplards until it

aligns with the attachment

screw location.

• Secure the motor to

attachment bracket at

the front of the opening

with washer and screw

provided.

• Plug the motor

connector into the

mating hood connector.

Seethe illustration for

the hood connector location. Touch

the hood to locate and make the

connection.

IMPORTANT : Hold the connector so

the two square corner terminals are

at the top as you position the connector

to plug it in.

Motor Attachment

Bracket

Motor Hooks

INSTALL DUCT COVERS

9

To install the 12” duct cover alone:

• Place the 12” section of the decorative duct cover on

top of the hood.

• Secure the cover on the top of the hood with 4 screws

provided.

To install the 2-piece duct cover:

• Place the 2-piece duct cover on the top of the hood.

• Secure the bottom cover to the top of the hood with 4

screws provided. See illustration, page 16.

• Extend the inside section upwards to meet the ceiling

and ceiling bracket

• Secure the duct cover to the bracket with the 2 small

Phillips screws provided.

10

INSTALL FILTER SUPPORT

• Tip filter support into the rear of the hood.

• Insert support tabs into the slots at the rear of the

hood.

8

CONNECT ELECTRICAL

Verify that power is turned off at the source.

WARNING: If house wiring isnot 2-wire

with a ground wire, a ground must be provided by the

installer. When house wiring is aluminum, be sure to use

UL approved anti-oxidant compound and aluminum-tocopper connectors.

A Remove

Junction Box

Cover

B Check that White, Black and

Gree Hood Wires are Threaded

thru Small Hole in Bracket.

• Use wire nuts to connect incoming ground to green,

white to white, and black to black.

• Push wires into junction box and replace cover. Be

sure wires are not pinched.

C Insert Power

Conduit thru Strain

Relief and Tighten

Ground

D Use UL Listed Wire Nuts

White

Black

Insert Tabs into Slots

Install 2 Screws

• Secure the support to the hood with screws as

shown..

16

Page 17

Installation Instructions

11

INSTALL FILTERS

• Remove protective film covering the filters.

• Insert the filter into the “C” clips mounted to the top of

the vertical front panel.

• Tap the filter against one side to align with outside

opening.

• Pull the filter down into the lower slots at the bottom

of the filter support.

Juntion Box

“C” Clip

12

FINALIZE INSTALLATION

• Refer to the operating instructions to test all controls.

Filter

Filters

• To remove the filters, grasp the handle, push the filter

up, and pull forward.

Support

17

Page 18

Before you call for service…

Troubleshooting Tips

Save time and money! Review the chart below first and you

may not need to call for service.

Problem Possible Causes What To Do

Fan does not operate A fuse may be blown or a • Replace fuse or reset circuit breaker.

when the switch is on circuit breaker tripped.

The blower connector is loose • Disconnect power to the unit. Remove the filters

or not plugged into its mating and look up at the blower. If the blower connector

connector. plug is loose or you see the connector dangling,

the installer failed to plug it in securely. Although it

is a blind connection, it is easy to plug in. See the

Installation Instructions in this manual for the plug

location and how to plug the connector in.

Fan fails to circulate air Excessively soiled filters. • Remove the filters, clean if necessary and replace

or moves air slower than them. If cleaning and replacing the filters does not

normal correct the problem, call for service.

• Sufficient makeup (replacement) air is required for

exhausting appliances to operate to rating. Check with

local building codes, which may require or strongly advise

the use of makeup air. Visit GEAppliances.com for available

makeup air solutions.

18

Page 19

Please place in envelope and mail to:

Veuillez mettre dans une enveloppe et envoyez à :

OWNERSHIP REGISTRATION

P.O. BOX 1780

MISSISSAUGA, ONTARIO

L4Y 4G1

(FOR CANADIAN CONSUMERS ONLY)

19

Page 20

20

Page 21

GE Range Hood Warranty.

All warranty service provided by our Factory Service Centers,

®

or an authorized Customer Care

technician. To schedule

service on-line, visit us at GEAppliances.com, or call 800.

GE.CARES (800.432.2737). Please have serial number and

Staple your receipt here.

Proof of the original purchase

date is needed to obtain service

under the warranty.

model number availa ble when calling for service.

For The Period Of: GE Will Replace:

One Year Any part of the range hood which fails due to a defect in materials or workmanship.

From the date of the During this limited one-year warranty, GE will also provide, free of charge, all labor and

original purchase in-home service to replace the defective part.

What GE Will Not Cover:

Service trips to your home to teach you how to use

the product.

Improper installation, delivery or maintenance.

Product damage or failure of the product if it is abused,

misused, modified, used for other than the intended

purpose, or used commercially.

Replacement of house fuses or resetting of circuit

breakers.

Damage to the product caused by accident, fire, floods

or acts of God.

Incidental or consequential damage caused by possible

defects with this appliance.

Damage caused after delivery.

Product not accessible to provide required service.

Installation or service for a makeup (replacement) air

system.

(;&/86,212),03/,(':$55$17,(6³<RXUVROHDQGH[FOXVLYHUHPHG\LVSURGXFWUHSDLUDVSURYLGHG

in this Limited Warranty. Any implied warranties, including the implied warranties of merchantability

or fitness for a particular purpose, are limited to one year or the shortest period allowed by law.

This warranty is extended to the original purchaser and any succeeding owner for products purchased for home use

within the USA. If the product is located in an area where service by a GE Authorized Servicer is not available, you may

be responsible for a trip charge or you may be required to bring the product to an Authorized GE Service Location for

service. In Alaska, the warranty excludes the cost of shipping or service calls to your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state. To know what your

legal rights are, consult your local or state consumer affairs office or your state’s Attorney General.

Warrantor: General Electric Company. Louisville, KY 40225

21

Page 22

Consumer Support.

GE Appliances Website

Have a question or need assistance with your appliance? Try the GE Appliances Website 24 hours a day,

any day of the year! For greater convenience and faster service, you can now download Owner’s Manuals,

order parts or even schedule service on-line.

GEAppliances.com

Schedule Service GEAppliances.com

Expert GE repair service is only one step away from your door. Get on-line and schedule your service at

your convenience any day of the year! Or call 800.GE.CARES (800.432.2737) during normal business hours.

Real Life Design Studio GEAppliances.com

*(VXSSRUWVWKH8QLYHUVDO'HVLJQFRQFHSW³SURGXFWVVHUYLFHVDQGHQYLURQPHQWVWKDWFDQEHXVHGE\

people of all ages, sizes and capabilities. We recognize the need to design for a wide range of physical and

mental abilities and impairments. For details of GE’s Universal Design applications, including kitchen design

ideas for people with disabilities, check out our Website today. For the hearing impaired, please call

800.TDD.GEAC (800.833.4322).

Extended Warranties GEAppliances.com

Purchase a GE extended warranty and learn about special discounts that are available while your warranty

is still in effect. You can purchase it on-line anytime, or call 800.626.2224 during normal business hours.

GE Consumer Home Services will still be there after your warranty expires.

Parts and Accessories GEApplianceParts.com

Individuals qualified to service their own appliances can have parts or accessories sent directly to their homes

(VISA, MasterCard and Discover cards are accepted). Order on-line today, 24 hours every day or

by phone at 800.626.2002 during normal business hours.

Instructions contained in this manual cover procedures to be performed by any user. Other servicing generally

should be referred to qualified service personnel. Caution must be exercised, since improper servicing may

cause unsafe operation.

Contact Us GEAppliances.com

If you are not satisfied with the service you receive from GE, contact us on our Website with all the details

including your phone number, or write to: General Manager, Customer Relations

GE Appliances, Appliance Park

Louisville, KY 40225

Register Your Appliance GEAppliances.com

5HJLVWHU\RXUQHZDSSOLDQFHRQOLQH³DW\RXUFRQYHQLHQFHTimely product registration will allow for enhanced

communication and prompt service under the terms of your warranty, should the need arise.

You may also mail in the pre-printed registration card included in the packing material.

Printed in Mexico

Page 23

www.electromenagersge.ca

Consignes de sécurité ........ 2

Directives de fonctionnement

Commande de la lampe .......... 3

Commande du ventilateur ........3

Entretien et nettoyage

Filtres à graisses ................. 4

Lampe de la hotte ................ 5

Surfaces en acier inoxydable .....4

Directives d’installation . . .6–17

Dépannage ...................18

Service à la clientèle

Garantie ........................ 21

à évacuation

Service à la clientèle .............. 22

Manuel d’utilisation et

directives d’installation

JV936

JV966

CV936

CV966

Hotte de cuisine

Inscrivez ci-dessous les numéros de

modèle et de série :

N° de modèle __________

N° de série ____________

Ils se trouvent sur une étiquette sur la

paroi intérieure de la hotte.

LI275B 49-80520-5 01-13 GE

Page 24

CONSIGNES DE SÉCURITÉ IMPORTANTES.

VEUILLEZ LIRE TOUTES LES CONSIGNES AVANT D’UTILISER L’APPAREIL.

CONSIGNES DE SÉCURITÉ

AVERTISSEMENT – AFIN DE

RÉDUIRE LES RISQUES D’INCENDIE, DE CHOC

ÉLECTRIQUE OU DE BLESSURES, VEUILLEZ OBSERVER

LES CONSIGNES QUI SUIVENT :

A. N’utilisez cet appareil que pour l’usage pour lequel

il a été conçu par le fabricant. Pour toute question,

communiquez avec le fabricant.

B. Avant de réparer ou de nettoyer l’appareil, coupez

l’alimentation électrique au panneau de distribution

électrique et bloquez le disjoncteur afin d’éviter que

le courant ne soit accidentellement rétabli. Lorsqu’il

n’est pas possible de bloquer le disjoncteur, apposez

un dispositif d’avertissement bien visible, comme

une étiquette, sur le panneau de distribution.

C. N’utilisez pas cet appareil avec un dispositif

électronique de contrôle de la vitesse.

D. Cet appareil doit être mis à la terre.

ATTENTION – Pour une évacuation de

type général seulement. N’utilisez pas cet appareil

pour évacuer des substances ou des vapeurs

dangereuses ou explosives.

AVERTISSEMENT – POUR RÉDUIRE

LES RISQUES DE BLESSURES EN CAS DE FEU DE

GRAISSE SUR LA CUISINIÈRE, OBSERVEZ LES

CONSIGNES QUI SUIVENT* :

A.

ÉTOUFFEZ LES FLAMMES en couvrant l’ustensile de

cuisson à l’aide d’un couvercle, d’une plaque à biscuits

ou d’un plateau en métal, puis éteignez l’élément. FAITES

ATTENTION DE NE PAS VOUS BRÛLER. Si les flammes ne

s’éteignent pas immédiatement, ÉVACUEZ LES LIEUX ET

APPELEZ LES POMPIERS.

B. N’ESSAYEZ JAMAIS DE SOULEVER UN USTENSILE EN

FEU – vous pourriez vous brûler.

C. N’UTILISEZ PAS D’EAU, de linge à vaisselle ou de

serviette; cela pourrait provoquer une violente

explosion de vapeur.

D. Utilisez un extincteur SEULEMENT si :

1. Vous avez en votre possession un extincteur de

classe ABC et vous savez vous en servir.

2.

Le feu est petit et contenu dans l’endroit où il s’est déclaré.

3. Vous avez appelé les pompiers.

4.

Vous pouvez combattre le feu en faisant dos à une sortie.

*Selon le document intitulé «Kitchen Fire Safety Tips»

publié par la NFPA.

AVERTISSEMENT – POUR RÉDUIRE

LES RISQUES DE FEU DE GRAISSE SUR LA CUISINIÈRE :

Ne laissez jamais sans surveillance les éléments de surface

A.

à des réglages élevés. Les débordements peuvent produire

de la fumée et prendre feu. Faites chauffer les matières

grasses doucement au réglage minimum ou moyen.

B. Mettez toujours la hotte en MARCHE lorsque vous

cuisinez à feu fort ou lorsque vous faites flamber

des aliments (p. ex. crêpes Suzette, cerises jubilé,

bifteck au poivre flambé).

Nettoyez fréquemment les ventilateurs. Ne laissez pas

C.

de graisse s’accumuler sur les ventilateurs ou le filtre.

D. Utilisez des ustensiles de cuisson de dimensions

appropriées. Utilisez toujours des ustensiles dont la

taille correspond à celle de l’élément.

AVERTISSEMENT – POUR RÉDUIRE

LES RISQUES D’INCENDIE, DE CHOC ÉLECTRIQUE OU DE

BLESSURES, OBSERVEZ LES CONSIGNES QUI SUIVENT :

Les travaux d’installation et de câblage électrique doivent

A.

être effectués par une personne qualifiée, conformément

à tous les codes et normes applicables, y compris ceux

concernant la résistance au feu de la construction.

B.

Il faut une quantité d’air suffisante pour assurer une

combustion et une évacuation appropriées des gaz par

le conduit d’évacuation (cheminée) de l’équipement à

combustible afin d’éviter tout refoulement d’air. Observez

les directives et normes de sécurité du fabricant de

l’équipement, par exemple celles publiées par la National Fire

Protection Association (NFPA), l’American Society for Heating,

Refrigeration and Air Conditioning Engineers (ASHRAE) et

les autorités locales. Le cas échéant, installez un système

de compensation d’air (remplacement) conformément aux

conditions des codes locaux du bâtiment. Visitez le site

GEAppliances.com pour connaître les solutions offertes en

matière de système de compensation d’air.

C.

Lorsque vous coupez ou percez un mur ou un plafond,

évitez d’endommager le câblage électrique ou les

installations des services publics.

D.

Les conduits d’évacuation des ventilateurs doivent

toujours être acheminés vers l’extérieur.

AVERTISSEMENT

risques d’incendie et assurer une évacuation adéquate de

l’air, assurez-vous d’acheminer les conduits vers l’extérieur.

N’évacuez pas l’air dans les espaces entre les murs, dans le

plafond ou le grenier, ni dans un vide sanitaire ou un garage.

AVERTISSEMENT

RISQUES D’INCENDIE, N’UTILISEZ QUE DES CONDUITS EN MÉTAL.

Ne tentez pas de réparer ou de remplacer toute

pièce de la hotte, sauf si cela est spécifiquement

recommandé dans le présent manuel. Confiez toutes

les autres réparations à un technicien qualifié.

– Pour réduire les

– POUR RÉDUIRE LES

VEUILLEZ LIRE ET SUIVRE À LA LETTRE CES CONSIGNES DE SÉCURITÉ.

2

VEUILLEZ LIRE ET CONSERVER CES DIRECTIVES

Page 25

Utilisation des commandes de la hotte. www.electromenagersge.ca

Dans le présent manuel, les caractéristiques et l’apparence peuvent être différentes de celles de votre modèle.

Commande du VENTILATEUR

Tournez la commande de vitesse FAN (Ventilateur) à

LO (Minimum), MED LO (Minimum/moyen),

MED HI (Moyen/maximum) ou HI (Maximum), selon le

besoin.

Lorsque vous cuisinez, un fonctionnement continu du

système de ventilation permet de garder

la cuisine agréable et moins humide. Cela diminue

également les odeurs de cuisson et la saleté

attribuable à la condensation et qui exige

un nettoyage fréquent.

REMARQUE : Lorsque le ventilateur fonctionne

au réglage LO (Minimum), il est très silencieux. Assurez-

vous toujours que la commande de vitesse du

ventilateur est à OFF (Arrêt) lorsque vous avez terminé la

cuisson dans la cuisine.

Commande de la LAMPE

Tournez la commande LIGHT (Lampe) à HI (Maximum)

pour éclairer la surface de cuisson. Tournez-la à NITE

(Veilleuse) pour l’utiliser comme veilleuse en soirée ou

pendant la nuit.

3

Page 26

Entretien et nettoyage de la hotte.

Assurez-vous que l’alimentation électrique est coupée et que toutes les surfaces sont froides avant

de nettoyer ou de réparer toute partie de la hotte.

Filtres à graisses métalliques réutilisables

La hotte est dotée de deux filtres

à graisses métalliques réutilisables.

Les filtres métalliques retiennent la

graisse qui s’échappe des aliments

qui cuisent sur la surface de cuisson.

Ces filtres empêchent également les

flammes des aliments flambés sur la

surface de cuisson d’endommager

l’intérieur de la hotte.

C’est pourquoi, il faut TOUJOURS que

les filtres soient en place lorsque la hotte

fonctionne. Il faut nettoyer les filtres à

graisses une fois par mois ou lorsque

cela est nécessaire.

Pour nettoyer les filtres à graisses,

faites-les tremper, puis agitez-les dans

un mélange d’eau chaude et

de détergent. N’utilisez pas de produits

contenant de l’ammoniaque, car ces

produits ternissent le métal. N’utilisez pas

de produits nettoyants abrasifs

ou conçus pour le nettoyage des fours.

Vous pouvez brosser légèrement

les filtres pour déloger la saleté incrustée.

Rincez, secouez et laissez sécher

les filtres avant de les remettre en place.

Pour enlever les filtres :

Saisissez la languette du filtre et tirez-la

vers le haut, puis vers l’avant.

Pour les remettre en place :

Tenez la partie inférieure du filtre

par la languette.

Placez la partie supérieure

du filtre contre le côté intérieur

de l’avant de la hotte.

Faites glisser le filtre jusqu’à ce

qu’il bloque, puis appuyez sur

l’extrémité inférieure du filtre

jusqu’à ce qu’il tombe en place

par pression.

Surfaces en acier inoxydable

N’utilisez pas de tampons en laine

d’acier pour ne pas égratigner

la surface.

Pour nettoyer les surfaces en acier

inoxydable, utilisez de l’eau chaude

savonneuse ou un produit nettoyant ou

un poli pour l’acier inoxydable. Essuyez

toujours la surface dans le sens du grain.

Suivez les directives données sur le

contenant pour nettoyer les surfaces en

acier inoxydable.

Pour de plus amples renseignements

sur l’achat d’un produit nettoyant ou

d’un poli pour électroménagers en acier

inoxydable, ou pour connaître l’adresse

du détaillant le plus près de chez vous,

veuillez appeler sans frais au numéro

suivant :

Centre national de pièces

800.661.1616

www.electromenagersge.ca

4

Page 27

www.electromenagersge.ca

Assurez-vous que l’alimentation électrique est coupée et que toutes les surfaces sont froides avant

de nettoyer ou de réparer toute partie de la hotte.

Prise

Capot en verre

Douille

Ampoule

Lampe de la hotte

REMARQUE : Enlevez le capot en verre

lorsqu’il est froid seulement. Vous pouvez

porter des gants en latex pour le saisir plus

facilement.

ATTENTION :

Avant de remplacer l’ampoule, coupez

l’alimentation électrique de la hotte

en enlevant le fusible ou en déclenchant

le disjoncteur au panneau de distribution

électrique.

Laissez refroidir complètement le capot

en verre et l’ampoule.

Pour votre sécurité, ne touchez pas l’ampoule

chaude à main nue ou avec un chiffon humide.

Pour enlever l’ampoule :

Tournez le capot en verre dans le sens

antihoraire, jusqu’à ce que la douille

de l’ampoule soit accessible.

À l’aide de gants ou d’un chiffon sec, retirez

l’ampoule en tirant dessus.

Pour la remettre en place :

Utilisez une ampoule halogène neuve de

12 V et 20 W (maximum) pour culot G-4.

Prise

Utilisez des

gants ou un

chiffon

Poussez l’ampoule à fond dans la prise.

Remettez en place le capot en verre

sur la douille et tournez-le dans le sens

horaire jusqu’à ce qu’il bloque en place.

Pour un meilleur éclairage, nettoyez

fréquemment le capot en verre à

l’aide d’un chiffon humide. Cependant,

faites-le lorsque la hotte a complètement

refroidi.

Rétablissez l’alimentation électrique

de la hotte.

À l’aide de gants ou d’un chiffon sec, retirez

l’ampoule neuve de son emballage.

REMARQUE : Ne touchez pas à l’ampoule

neuve avec vos doigts afin de ne pas

raccourcir de façon appréciable sa durée de

vie utile.

5

Page 28

Directives

Hottes de cuisine

d’installation

Des questions? Appelez au 1.800.561.3344 ou visitez notre site Web à l’adresse www.electromenagersge.ca

AVANT DE COMMENCER

Veuillez lire attentivement toutes les directives

qui suivent.

•

IMPORTANT³ Conservez les présentes

directives pour l’inspecteur local.

•

IMPORTANT³Observez tous les codes

et règlements en vigueur.

• Note à l’installateur ³Veuillez laisser

les présentes directives au consommateur.

• Note au consommateur ³Veuillez conserver

les présentes directives pour consultation

ultérieure.

• Compétences requises ³ L’installation de

cette hotte de cuisine exige des compétences

de base en mécanique et en électricité.

• Durée de l’installation ³ Entre 1 et 3 heures.

• L’installateur est responsable de la qualité

de l’installation.

• Toute défaillance du produit attribuable

à une installation inadéquate n’est pas couverte

par la garantie.

DIMENSIONS DU PRODUIT

30,4 cm

(12 po)

45,7 cm

(18 po)

53,3 cm

(21 po)

Les modèles de 76,2 cm (30 po)

Exigent une ouverture de 76,2 cm (30 po) de largeur

30,4 cm

(12 po)

45,7 cm

(18 po)

75,8 cm

(29 7/8 po)

ATTENTION :

Compte tenu du poids et de la dimension de cette

hotte, et pour réduire les risques de blessures et

de dommages au produit, L’INSTALLATION DOIT

ÊTRE EFFECTUÉE PAR DEUX PERSONNES.

POUR VOTRE SÉCURITÉ :

Avant de commencer l’installation, coupez

l’alimentation électrique et bloquez le

disjoncteur afin d’éviter que le courant ne soit

accidentellement rétabli. Lorsqu’il n’est pas

possible de bloquer le disjoncteur, apposez un

dispositif d’avertissement bien visible, comme

une étiquette, sur le panneau de distribution

électrique.

53,3 cm

(21 po)

Les modèles de 91,4 cm (36 po)

Exigent une ouverture de 91,4 cm (36 po) de largeur

6

91,1 cm

(35 7/8 po)

Page 29

Directives d’installation

DÉGAGEMENTS POUR L’INSTALLATION

Cette hotte à évacuation a été conçue pour être

installée sur un mur. Elle peut être installée sous

une retombée de plafond ou une armoire.

• Installez la hotte à une hauteur variant entre

60,9 cm (24 po) et 91,4 cm (36 po) au-dessus

de la surface de cuisson.

INSTALLATION SOUS UNE RETOMBÉE DE PLAFOND

RETOMBÉE DE PLAFOND

60,9 cm (24 po) min.

91,4 cm (36 po) max.

Dans le cas de cette installation, le conduit

d’évacuation à la partie supérieure de la hotte

sera dissimulé à l’intérieur de la retombée de

plafond ou de l’armoire supérieure.

ACCESSOIRES FACULTATIFS

Couvre-conduit

Il existe un couvre-conduit décoratif pour

les installations lorsque la hauteur du plafond

varie entre 2,4 m (8 pi) et 3,0 m (10 pi). Ce couvreconduit d’une longueur de 30,4 cm (12 po) peut

s’allonger à une hauteur max. de 60,9 cm (24 po)

ou 86,3 cm (34 po).

• Ce couvre-conduit décoratif dissimule le conduit

entre le dessus de la hotte et le plafond.

• Ce couvre-conduit décoratif convient aux

modèles de 76,2 cm (30 po) et de 91,4 cm (36

po) de largeur. Commandez le couvre-conduit

décoratif en même temps que la hotte. Vous

devez avoir tous les accessoires en main lors

de l’installation de la hotte.

Commandez la pièce : JXCHSS

Support de

plafond

INSTALLATION MURALE

60,9 cm (24 po) min.

91,4 cm (36 po) max.

Dans le cas de cette installation, un couvreconduit décoratif permet de dissimuler le conduit

d’évacuation à la partie supérieure de la hotte.

L’utilisation d’un couvre-conduit décoratif exige

une hauteur d’installation spécifique au-dessus

du comptoir. Pour de plus amples renseignements,

reportez-vous à la page 12.

2 vis

à bois

2

rondelles

2 vis décoratives

d’ancrage pour

à tête Phillips

2 chevilles

mur creux

4 vis à tête

Phillips

Couvre-conduit

décoratif de

2 pièces

avec support de

plafond

7

Page 30

Directives d’installation

PRÉPARATIFS

Préparatifs concernant le conduit d’évacuation

• Cette hotte peut être dotée d’un conduit d’évacuation

vertical à travers les armoires supérieures, la retombée

de plafond ou le plafond. Un conduit de transition

est fourni pour l’évacuation à la verticale. Utilisez des

coudes disponibles en quincaillerie pour évacuer l’air

horizontalement à travers

le mur arrière. Reportez-vous à la page 13.

• Déterminez l’emplacement exact de la hotte.

• Planifiez le parcours qu’empruntera le conduit pour

l’évacuation vers l’extérieur.

• Utilisez la longueur de conduit la plus courte et la plus

rectiligne possible. Pour obtenir un rendement satisfaisant,

le conduit ne doit pas avoir une longueur équivalente

supérieure à 30,4 m (100 pi), quelle que soit sa configuration.

• N’utilisez que des conduits en métal seulement.

• Un conduit de transition pour conduit circulaire de 17,8 cm

(7 po) est fourni dans l’ensemble. Utilisez un conduit

circulaire de 17,8 cm (7 po) ou un conduit rectangulaire de

8,2 cm (3 1/4 po) x 30,4 cm (12 po).

• Installez dans l’ouverture extérieure un évent mural ou

de toiture doté d’un registre. Commandez à l’avance l’évent

mural ou de toiture, ainsi que tous les conduits de transition

nécessaires.

• Le cas échéant, installez un système de compensation d’air

(remplacement) conformément aux conditions des codes

locaux du bâtiment. Visitez le site GEAppliances.com pour

connaître les solutions offertes en matière de système de

compensation d’air.

Ensemble JXDW1

Commandez l’ensemble JXDW1 si votre installation exige

un conduit horizontal à partir du dessus de la hotte vers le mur,

et si :

• Votre plafond est à une hauteur de 2,4 m (8 pi) et que vous

devez utiliser un capuchon de cheminée JXCH, ou

• Votre hotte sera fixée sous une armoire ou une retombée

de plafond de 30,4 cm (12 po).

Cet ensemble comprend un conduit de transition pour

installation entre un conduit circulaire de 17,8 cm (7 po) et un

conduit rectangulaire de 8,2 cm (3 1/4 po) x 25,4 cm (10 po)

pour une évacuation à travers le mur.

Charpente murale pour un soutien adéquat

• Cette hotte est très lourde. Pour la soutenir, il faut une

charpente murale adéquate. La hotte doit être fixée aux

montants verticaux du mur. Reportez-vous à la page 14.

• Nous vous recommandons fortement d’avoir à portée de la

main la hotte et le couvre-conduit décoratif avant d’effectuer

les travaux d’ajustement de la charpente et de finition du

mur. Vous pourrez ainsi déterminer l’emplacement précis

pour le conduit et le câblage électrique.

COUVRE-CONDUIT DÉCORATIF

Il existe un couvre-conduit décoratif convenant aux deux

modèles. Ce couvre-conduit dissimule le conduit d’évacuation

entre le dessus de la hotte et le plafond ou la retombée de

plafond. Il convient aux plafonds dont la hauteur varie entre

2,4 m (8 pi) et 3,0 m (10 pi). Pour de plus amples

renseignements, reportez-vous à la page 12.

ALIMENTATION ÉLECTRIQUE

IMPORTANT - (Veuillez lire attentivement)

AVERTISSEMENT :

POUR VOTRE SÉCURITÉ, CET APPAREIL DOIT ÊTRE

CORRECTEMENT MIS À LA TERRE.

Avant d’entreprendre l’installation, enlevez le fusible ou

déclenchez le disjoncteur au panneau de distribution électrique.

N’utilisez pas de rallonge électrique, ni de fiche d’adaptation

avec cet appareil. Observez le Code national de l’électricité

ou les codes et règlements locaux en vigueur.

Alimentation électrique

Cette hotte est conçue pour une alimentation électrique de

120 V et 60 Hz, et doit être branchée à un circuit de dérivation

individuel correctement mis à la terre et protégé par un

disjoncteur de 15 ou 20 ampères ou par un fusible temporisé.

• Le câblage électrique doit être constitué de deux fils, plus un

fil de mise à la terre.

• Si votre alimentation électrique ne répond pas aux

exigences ci-dessus, veuillez appeler un électricien qualifié

avant d’entreprendre l’installation.

• Acheminez le câblage électrique le plus près possible

de la hotte, de préférence dans le plafond, la retombée

de plafond ou le mur. Pour de plus amples renseignements,

reportez-vous à la page 13.

• Effectuez les raccordements des fils au câblage de

la résidence, conformément aux codes locaux en vigueur.

Directives de mise à la terre

Le conducteur de mise à la terre doit être raccordé à un

système de câblage métallique permanent ou à une borne

ou un câble de mise à la terre de la hotte.

AVERTISSEMENT : Un raccordement

incorrect du fil de mise à la terre peut présenter un risque de choc

électrique. Consultez un électricien ou un technicien qualifié si vous

n’êtes pas certain que l’appareil est correctement mis à la terre.

8

Page 31

Directives d’installation

RACCORDS DE CONDUIT

Utilisez ce tableau pour calculer

la longueur maximale permise du

conduit d’évacuation vers l’extérieur.

Remarque : Ne dépassez pas la longueur

équivalente maximale permise!

Longueur maximale du conduit :

30,4 m (100 pi) pour une hotte.

Conduit flexible :

Si vous utilisez un conduit flexible

en métal, il faut doubler toutes les

longueurs équivalentes indiquées

dans le tableau. Le conduit métallique

flexible doit être droit et souple, et

étiré le plus possible.

N’utilisez PAS de conduit flexible en

plastique.

Remarque : Tout système de ventilation résidentiel,

comme une hotte à évacuation, peut affecter le débit

approprié de l’air de combustion et d’évacuation

des foyers, des systèmes de chauffage à gaz,

des chauffe-eau à gaz et autres systèmes à

circulation d’air naturelle. Pour réduire au minimum

la modification du débit d’air de ces systèmes,

veuillez suivre les lignes directrices données par le

fabricant de l’appareil de chauffage et les normes de

sécurité, par exemple celles publiées par la NFPA et

la ASHRAE. Le cas échéant, installez un système de

compensation d’air (remplacement) conformément

aux conditions des codes locaux du bâtiment.

Visitez le site GEAppliances.com pour connaître

les solutions offertes en matière de système de

compensation d’air.

Cette hotte doit être raccordée

à un conduit circulaire de 17,8 cm

(7 po). Vous pouvez installer

un conduit de transition pour

raccordement à un conduit

rectangulaire de 8,2 cm

(3 1/4 po) x 30,4 cm (12 po).

Ensemble JXDW1

Commandez l’ensemble JXDW1 si

votre installation exige un conduit

horizontal à partir du dessus de la

hotte vers le mur, et si :

• votre plafond est à une hauteur

de 2,4 m (8 pi) et que vous devez

utiliser un capuchon de cheminée

JXCH, ou

• votre hotte sera fixée sous une

armoire ou une retombée de

plafond de 30,4 cm (12 po).

Cet ensemble comprend un conduit

de transition pour installation entre

un conduit circulaire de 17,8 cm

(7 po) et un conduit rectangulaire

de 8,2 cm (3 1/4 po) x 25,4 cm (10 po)

pour une évacuation à travers le mur.

L’utilisation d’un conduit d’un

diamètre plus petit affectera

le rendement de l’appareil

Longueur

Section de Longueur Quantité équivalente

conduit Dimensions équivalente* utilisée totale

Droit, circulaire de 0,3 m/1 pi

17,8 cm (7 po) (par pied

de longueur)

Droit, 8,2 cm (3 1/4 po) 0,3 m/1 pi

x 30,4 cm (12 po) (par pied

de longueur)

Coude de 17,8 cm

(7 po) de 90° 4,2 m/14 pi

Coude de 17,8 cm

(7 po) de 45° 2,7 m/9 pi

Coude de 8,2 cm (3 1/4 po)

x 30,4 cm (12 po) de 90° 4,5 m/15 pi

Coude de 8,2 cm (3 1/4 po)

x 30,4 cm (12 po) de 45° 2,7 m/9 pi

Coude plat de 8,2 cm

(3 1/4 po) x 30,4 cm

(12 po) de 90° 10,0 m/36 pi

Conduit de transition circulaire

de 17,8 cm (7 po) à conduit

rectangulaire de 8,2 cm

(3 1/4 po) x 30,4 cm (12 po) 0,3 m/1 pi

Conduit de transition rectangulaire

rectangulaire de 8,2 cm (3 1/4 po)

x 30,4 cm (12 po) à un conduit

circulaire de 17,8 cm (7 po) 0,3 m/1 pi

Coude de transition de 90° circulaire

de 17,8 cm (7 po) à conduit

rectangulaire de 8,2 cm

(3 1/4 po) x 30,4 cm (12 po) 1,2 m/4 pi

Code de transition de 90° circulaire

de 17,8 cm (7 po) à conduit

rectangulaire de 8,2 cm

(3 1/4 po) x 30,4 cm (12 po) 1,2 m/4 pi

Évent mural pour conduit 8,5 m/28 pi

circulaire de 17,8 cm (6,4 m/21 pi

(7 po), avec registre sans registre)

Évent mural pour conduit de 7,9 m/26 pi

de 8,2 cm (3 1/4 po) x 30,4 cm (5,8 m/19 pi

(12 po), avec registre sans registre)

Évent de toiture pour conduit

circulaire de 17,8 cm (7 po) 11,8 m/39 pi

Évent de toiture circulaire 7,3 m/24 pi

* Longueur réelle du conduit droit, plus la longueur

équivalente du raccord. Les longueurs équivalentes des

sections de conduit ont été établies à la suite d’essais réels

effectués par le service de l’Ingénierie d’évaluation de GE et

représentent les longueurs nécessaires pour assurer une

Longueur

totale de

conduit

bonne ventilation de tout type de hotte.

9

Page 32

Directives d’installation

MATÉRIEL ET OUTILS NÉCESSAIRES

(NON FOURNIS)

Tournevis Phillips

et à lame plate

Crayon et ruban

à mesurer

Perceuse électrique avec

forets de 3,1 mm (1/8 po) et

9,5 mm (3/8 po)

Niveau à bulle

Lampe de poche

Pince

Marteau

Douille hexagonale

pivotante de

6,3 mm (1/4 po)

Lunettes de sécurité

Connecteurs vissables

homologués par UL

Ruban adhésif

pour conduit

Cisailles à tôles

DÉBALLAGE

• Enlevez la petite boîte qui protège le moteur.

• Sortez la hotte de la boîte.

Hotte

Support

de fixation

en bois

• Enlevez les vis d’expédition qui retiennent le support

de fixation en bois à la paroi arrière de la hotte.

Mettez de côté le support de fixation en bois et

les vis pour les réinstaller plus tard. Ne les jetez pas.

• Retirez la section de carton en V.

• Retirez l’emballage de pièces de la section de carton en V.

• Retirez le couvercle de la boîte de jonction et l’entrée

défonçable.

• Installez un serre-câble sur la paroi arrière ou sur

le dessus de la hotte.

• Enlevez le ruban gommé et le matériel d’emballage

de la hotte, du conduit de transition et du moteur.

Moteur

Boîte d’expédition

Emballage

de pièces

Pince coupante

à dénuder

Scie sauteuse ou scie à

guichet

Escabeau

Clé Allen

Matériel supplémentaire :

• 2 fils de 120 V, 60 Hz de 15 ou 20 A, avec

fil de mise à la terre. Circuit de dérivation

adéquatement mis à la terre.

• Serre-câble pour boîte de jonction.

Conduit circulaire en métal de 17,8 cm (7 po) ou

•

rectangulaire de 8,2 cm (3 1/4 po) x 25,4 cm (10 po)

ou de 8,2 cm (3 1/4 po) x 30,4 cm (12 po) d’une

longueur suffisante pour l’installation.

10

Page 33

Directives d’installation

PIÈCES FOURNIES

Repérez la boîte contenant les accessoires fournis avec

la hotte, et vérifiez-en le contenu.

2 filtres à graisses

en aluminium

Vis, chevilles

d’ancrage,

rondelles

EXIGENCES CONCERNANT

LE COUVRE-CONDUIT

Nous vous recommandons d’avoir à portée de la main

la hotte et le couvre-conduit décoratif (le cas échéant)

lors des travaux d’ajustement de la charpente et de

finition du mur. Vous pourrez ainsi repérer avec précision

l’emplacement des montants, du conduit et du câblage

électrique. Veuillez lire les directives qui suivent pour savoir

si vous pouvez utiliser le couvre-conduit décoratif pour votre

installation.

Couvre-conduit décoratif :

• Utilisez le couvre-conduit

décoratif pour dissimuler

le conduit d’évacuation

entre le dessus de la hotte

et le plafond.

• Ce couvre-conduit est

formé de deux pièces.

55,9 cm

(22 po)

La section extérieure

mesure 30,4 cm (12 po) de

hauteur, alors que la section

intérieure mesure 55,9 cm

(22 po). Une fois insérées

l’une dans l’autre, les deux

sections forment une

27,9 cm

(11 po)

structure dont la hauteur

peut varier entre 60,9 cm (24 po) et 86,3 cm (34 po).

• La section extérieure peut être utilisée seule pour

dissimuler un conduit de 30,4 cm (12 po) de hauteur.

• Pour une hauteur de conduit supérieure à 30,4 cm

(12 po), il faut installer le support de plafond pour fixer

le couvre-conduit à la partie supérieure.

Pour éviter les jeux peu esthétiques, prévoyez installer

la hotte à une hauteur permettant l’installation du

couvre-conduit décoratif :

• Le couvre-détecteur convient à une hauteur minimale de

30,4 cm (12 po) entre le dessus de la hotte et le plafond,

ou entre 60,9 cm (24 po) et 86,3 cm (34 po) entre

le dessus de la hotte et le plafond.

VOUS NE POUVEZ PAS UTILISER LE COUVRE-DÉTECTEUR

SI LA DISTANCE ENTRE LE DESSUS DE LA HOTTE ET

LE PLAFOND VARIE ENTRE 30,4 CM (12 PO) ET

60,3 CM (24 PO).

30,4 cm

(12 po)

30,4 cm

(12 po)

30,4 cm

(12 po)

Conduit de

transition avec

Support

de filtre

registre

Passez en revue les exemples qui suivent afin d’installer sans

problème le couvre-conduit décoratif.

Plafond de 2,4 m (8 pi) :

La hotte doit être installée

30,4 cm (12 po)

Plafond de 2,4 m (8 pi)

à une hauteur de 76,2 cm

(30 po) au-dessus de la

surface de cuisson (ou

à 167,6 cm [66 po] du sol).

Le couvre-conduit ne peut

pas être utilisé si la hotte

est installée à une hauteur

76,2 cm (30 po)

inférieure ou supérieure.

Utilisez la section de

30,4 cm (12 po) et jetez

la section intérieure.

76,2 cm (30 po)

60,9 cm (24 po)

Plafond de 2,7 m (9 pi)

60,9 cm (24 po)

76,2 cm (30 po)

Plafond de 2,7 m (9 pi) : Installez la hotte à une hauteur d’au

moins 60,9 cm (24 po) et d’au plus 76,2 cm (30 po) au-dessus

de la surface de cuisson. Le couvre-conduit peut être

allongé pour dissimuler le conduit jusqu’au plafond.

Plafond de 3,0 m (10 pi)

86,3 cm (34 po)

81,3 cm (32 po)

76,2 cm (30 po)

91,4 cm (36 po) max.

Plafond de 3,0 m (10 pi) : Installez la hotte à une hauteur

d’au moins 81,3 cm (32 po) et d’au plus 91,4 cm (36 po)

au-dessus de la surface de cuisson. Le couvre-conduit

peut être allongé jusqu’à 86,3 cm (34 po) entre le dessus

de la hotte et le plafond.

11

Page 34

Directives d’installation

EMPLACEMENT DE LA HOTTE, DU CONDUIT ET DU CÂBLAGE

• Conservez le support de fixation en bois et ses vis pour

les réinstaller plus tard. Ne les jetez pas.

• Mesurez la distance voulue entre le dessous de la hotte

et la surface de cuisson, c’est-à-dire entre 60,9 cm (24

po) et 91,4 cm (36 po). Si vous utilisez le couvre-conduit

décoratif, reportez-vous à la page précédente.

• À l’aide d’un niveau, tracez une ligne horizontale pour

marquer l’emplacement du dessous de la hotte.

• À l’aide d’un niveau, tracez une ligne correspondant

au centre de la surface de cuisson.

• À 39,0 cm (15 3/8 po) au-dessus de la ligne horizontale

correspondant au dessous de la hotte, tracez une autre

ligne horizontale.

• À 45,7 cm (18 po) au-dessus de la ligne correspondant

au dessous de la hotte, tracez une autre ligne horizontale

pour indiquer le dessus de la hotte.

POUR UN CONDUIT VERTICAL (droit) :

• Si le conduit passe à travers le plafond, prolongez la ligne

centrale jusqu’au plafond

- À 17,4 cm (6 7/8 po) de la cloison sèche, marquez

l’emplacement du centre de l’orifice de 19,0 cm (7 1/2

po) de diamètre pour le passage du conduit.

- IS’il n’y a pas encore de cloison sèche au mur, ajoutez

l’épaisseur de la cloison sèche à la mesure de 17,4 cm

(6 7/8 po).

Conduit à travers une retombée de plafond ou une

armoire supérieure :

• Suivez la procédure indiquée pour l’installation du conduit

dans le plafond pour pratiquer un orifice de 19,0 cm

(7 1/2 po) de diamètre à travers la retombée de plafond

ou l’armoire.

• Reportez-vous à l’étape 4 de la page 15 pour pratiquer

l’ouverture pour le conduit de transition.

17,4 cm (6 7/8 po) entre

le mur et la ligne centrale

Orifice de 19,0 cm

(7 1/2 po) de diamètre

ÉVACUATION À

TRAVERS LE MUR

Dessus de la hotte

45,7 cm

(18 po)

Dessous de la hotte

ÉVACUATION À

TRAVERS LE PLAFOND