Page 1

Installation

Instructions

30" Built In Wall Oven

JTP15AA, JTP15BA, JTP17SC, JTP18WA, JTP18AA,

JTP18BA, JTP18WA, JTP27BA, JTP27WA, JTP45BA,

JTP45WA, JTP47SC, JTP56AA, JTP56BA, JTP56WA,

JT910AA, JT910BA, JT910CA, JT910SA, JT910WA,

JT950AA, JT950BA, JT950CA, JT950SA, JT950WA,

ZET737BA, ZET737WA, ZET757BA, ZET757WA

Questions? Call GE Answer Center at 800.626.2000 orvisitour

Website at: www.geappliances.com

Before you begin

Read these instructions carefully and completely

• IMPORTANT-Save these instructions for

local inspector's use.

• IMPORTANT-Observe all governing

codes and ordiances.

• Note to Installer- Be sure to leave these

instructions with the consumer.

• OWNER- Keep these instructions for future

reference.

• NOTE- This appliance must be properly

grounded.

IPa s.nc.u,e,IIMa,eria.s,ee,e,I

Wire Nuts

36" of String

4 screws (single)

8 screws (double)

Bottom Trim

Junction

Strain Relief Box k_

Clamp

I Tools You Will Need I

1/8" Drill Bit & Phillips

Electric or Screwdriver

Hand Drill

Pub. No. 31-10435

229c4053P417 1

Page 2

Installation Instructions

IMPORTANT SAFETY INSTRUCTIONS

For Your Safety

• Be sure your oven is installed properly by

a qualified installer or service technician.

• Be sure the oven is securely installed in a

cabinet that is firmly attached to the

house structure. Weight on the oven door

could cause the oven to tip and result in

injury. Never allow anyone to climb, sit,

stand or hang on the oven door.

• Make sure the cabinets and wall cover-

ings around the oven can withstand the

temperatures (up to 200°F.) generated by

the oven.

CAUTION: The electrical power

to the oven supply line must be

shut off while line connections

are being made. Failure to do so

could result in serious injury or

death.

Electrical

Requirements

This appliance must be supplied with the

proper voltage and frequency, and connected

to an individual, properly grounded branch

circuit, protected by a circuit breaker or fuse,

having amperage as noted on rating plate.

(Rating Plate is located on oven frame.)

We recommend you have the electrical wiring

and hookup of your oven connected by a

qualified electrician. After installation, have the

electrician show you where your main range

disconnect is located.

Check with your local utilities for electrical

codes which apply in your area. Failure to

wire your oven according to governing codes

could result in a hazardous condition. If there

are not local codes, your range must be wired

and fused to meet the requirements of the

National Electrical Code, ANSI/NFPA No. 70-

Latest Edition. You can get a copy by writing:

National Fire Protection Association

Battery March Park

Quincy, MA 02269

Effective January 1, 1996, the National

Electrical Code requires that new, but not

existing, construction utilize a 4 conductor

connection to an electric range. When

installing an electric range in new

construction, follow the instructions in the

section on NEW CONSTRUCTION AND

FOUR CONDUCTOR BRANCH CIRCUIT

CONNECTION.

You must use a three-wire, single-phase A.C.

208Y/120 Volt or 240/120 Volt, 60 hertz

electrical system. If you connect to aluminum

wiring, properly installed connectors approved

for use with aluminum wiring must be used.

2

Page 3

Installation Instructions

Pre-Installation Checklist

ON THE FOLLOWING PAGES ARE III

TO BE USED FOR SINGLE AND III

DOUBLE OVEN INSTALLATION! III

Remove packaging materials.

Check behind hinges, and under

false bottom. Remove labels on

door, plastic on trims and panel,

and all tape around oven.

I_ Open the door to the stop position.

I -- 1

Oven Rack_s

Open oven door and remove literature

pack, broiler pan and grid, and oven

racks.

Remove Installation Instruction from

literature pack and read them carefully

before you begin.

Be sure to place all literature, Use and

Care, Installations, etc. in a safe place

for future reference.

Grasp the door on both sides and

lift up and off the hinges.

NOTE:The oven door is very heavy. Be

sure you have a firm grip before lifting the

oven door off the hinges. Use caution

once the door is removed. Do not lay the

door on its handle. This could cause

dents or scratches

3 (Continued on following page)

Page 4

Installation Instructions

Pre-Installation Checklist cont

Cover hinge with paper towel rolls

or toweling.

CAUTION: When the door is

removed and the hinge arms

are at the stop postion, DO

NOT bump or try to move the

hinge arms. The hinges could

snap back causing an injury to

the hands. Cover the hinges with

toweling or empty towel rolls

while working in the oven area.

Place the oven on a table or

platform even with the cutout

opening. (Platform must support

150 Ibs. single, 275 Ibs double.)

Remove the bottom trim from the

top of the oven. It will be installed at

the end of installation. The trim is

wrapped separately and taped to the

top of the unit.

Bottom Trim

Shipping Location

, Side Trim

4

Page 5

Installation Instructions

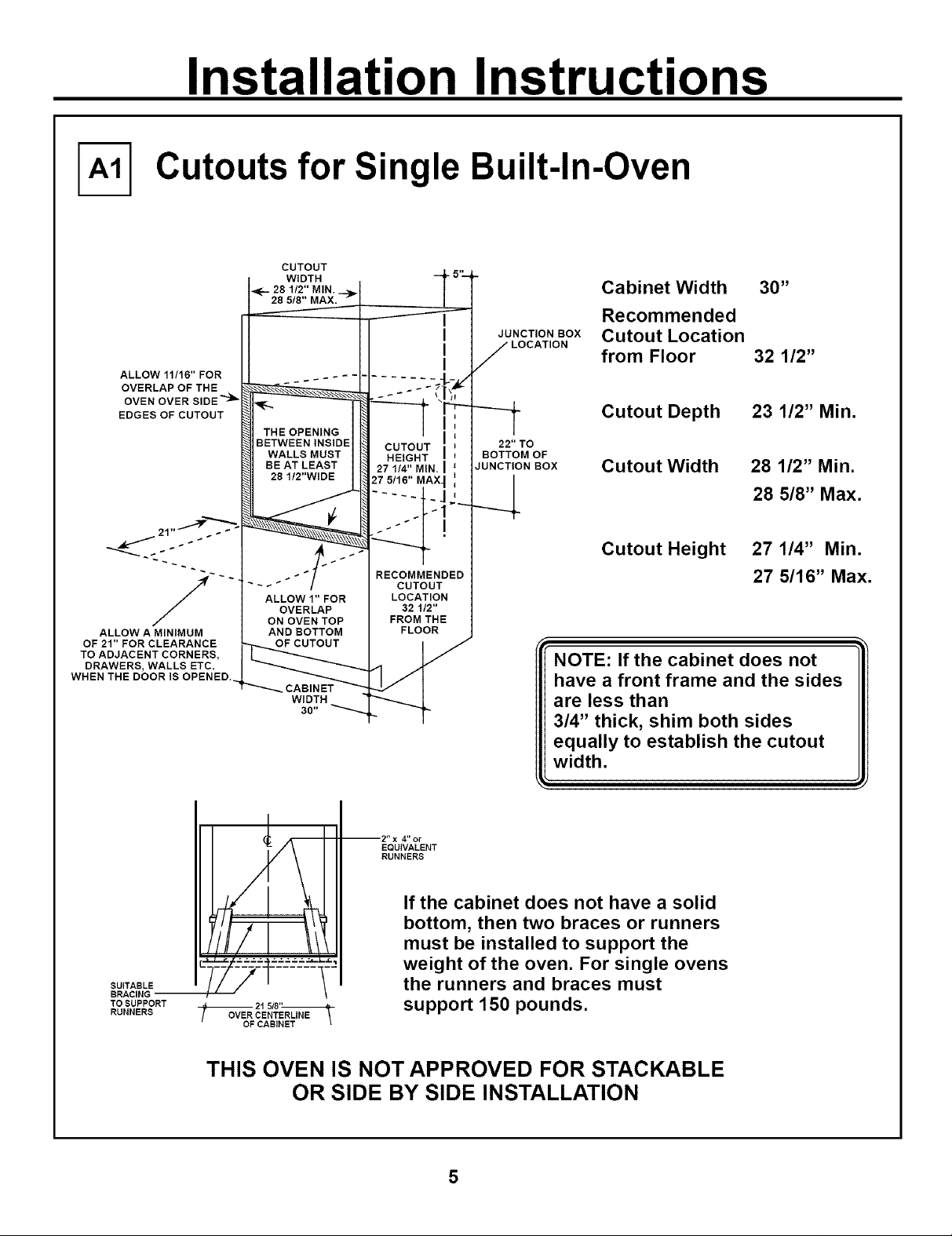

Cutouts for Single Built-In-Oven

ALLOW 11/16"FOR

OVERLAPOFTHE

OVEN OVER SIDE _

EDGES OF CUTOUT

J 21" _ _ _ _

ALLOW A MINIMUM

OF 21" FOR CLEARANCE

TO ADJACENT CORNERS,

DRAWERS, WALLS ETC.

WHEN THE DOOR IS OPENED.

CUTOUT

WIDTH

_--.-28112"MIN._..,_

285/8"MAX.--

THE OPENING

BETWEEN INSIDE

WALLS MUST

BE AT LEAST

28 1/2"WIDE

ALLOWl"FOR

OVERLAP

ON OVEN TOP

ANDBOTTOM

OFCUTOUT

WIDTH

30"

CUTOUT

HEIGHT

27 1/4" MIN

27 5/16"

RECOMMENDED

CUTOUT

LOCATION

321/2"

FROM THE

FLOOR

I

I

I

JUNCTION BOX

JUNCTION BOX

J LOCATION

22"TO

BOTTOM OF

=

Cabinet Width 30"

Recommended

Cutout Location

from Floor 32 1/2"

Cutout Depth

Cutout Width

23 1/2" Min.

28 1/2" Min.

28 5/8" Max.

Cutout Height 27 1/4" Min.

27 5/16"Max.

NOTE: If the cabinet does not

have a front frame and the sides

are less than

3/4" thick, shim both sides

equally to establish the cutout

width.

SUITABLE

TO SUPPORT

RUNNERS

4" or

EQUIVALENT

RUNNERS

If the cabinet does not have a solid

bottom, then two braces or runners

must be installed to support the

weight of the oven. For single ovens

the runners and braces must

21 5/8"

OVER CENTERLINE

support 150 pounds.

THIS OVEN IS NOT APPROVED FOR STACKABLE

OR SIDE BY SIDE INSTALLATION

Page 6

Installation Instructions

Cutouts for Double Built-In-Oven

CUTOUT

WIDTH

_F- 28 1/2" MIN.

28 5/8" MAX.

Cabinet Width 30"

I

ALLOW 11/16"

FOR OVERLAP

OFTHE OVEN

OVER SIDE EDGES

OF CUTOUT

JUNCTION BOX

LOCATION

J

Recommended

Cutout Location

from Floor 12"

Cutout Depth

23 1/2" Min.

ALLOW A MINIMUM OF 21"

FOR CLEARANCE TO

ADJACENT CORNERS,

DRAWERS, WALLS ETC.

WHEN THE DOOR

IS OPENED.

21" _

THE OPENING

BETWEEN INSIDE

WALLS MUST

BE AT LEAST

28 1/2"WIDE

ALLOW 1"FOR

OVERLAP

ON OVEN TOP

AND BOTTOM

OFCUTOUT

CABINET

WIDTH

CUTOUT

HEIGHT

51 13/16" MIN.

51 15/16" MAX.

RECOMMENDED

CUTOUTLOCATION

-12"FROM THE FLOOR

2" x 4" or

EQUIVALENT

RUNNERS

47" TO

BOTTOM OF

/UNCTION BOX

Cutout Wdth

28 1/2" Min.

28 5/8" Max.

Cutout Height

51 13/16" Min.

51 15/16" Max.

NOTE: If the cabinet does not

have a front frame and the

sides are less than

3/4" thick, shim both sides

equally to establish the cutout

width.

SUITABLE

BRACING

TO SUPPORT

RUNNERS

-_'_'_O_ CENTERLINE

OF CABINET

If the cabinet does not have a solid bottom,

then two braces and runners must be

installed to support the weight of the oven.

For double ovens the runners and braces

must support 275 pounds.

Page 7

Installation Instructions

Cutouts For Single Oven Under Counter

Gas or electric cooktops

may be installed over this

oven. See cooktop installation

instructions for cutout size.

See label on top of oven for

approved cooktop models.

\

25 '°

Top and/or side

fillers may be

necessary if

unit is positioned

between existing

cabinets. Be sure

they are attached

securely since

they will anchor

the oven in the

cabinet.

28 1/2" MIN.

28 5/8" MAX.

I

27 1/4" MIN.

27 5/16" MAX.._

4

S #

240V / 208V

Junction Box

Location

Overlap Top

of Oven &

Side Edges

of Cutout

Gas and electrical connections

for 30" gas cooktop must be

located in an adjacent accessible

location to the right. For a 36"

gas cooktop the connections

may be made to the left.

22" MIN.

Above

Support

Platform

fj

24"

36"

Typical

Countertop

Height

t

3/4" Support

Platform

Required

MUST SUPPORT 150 LBS.

5 9/16"

Reference dimension

for maximum support height

with typical 36" countertop

height

NOTE: This Oven is not approved

to be installed under a Solid Disk,

Induction or Downdraft Modular

Cooktop.

i

Page 8

Installation Instructions

Turn off the circuit breaker or remove

fuses to the oven branch circuit.

With the oven in front of the cabinet

opening, on a table or platform, connect

the flexible conduit to the electrical

junction box as shown below. You will

need to purchase a strain relief clamp

to complete the connection of the

conduit to the junction box.

JUNCTION BOX

NC

NEW CONSTRUCTION AND FOUR-

CONDUCTOR BRANCH CIRCUIT

CONNECTION

I'_ • When installing in a new

a.Cut the neutral (White) lead from the crimp.

Re-strip the neutral (white) lead to expose

the proper length of conductor.

construction, or

• When installing oven in a mobile

home, or

• When local codes do not permit

grounding through neutral:

Grounc

/ Wires

Junction

Box Cover

PLACE OVEN ON

A SUPPORT

TO ASSISTIN

CONNECTING

CONDUIT

STRAIN RELIEF CLAMP

( NOT INCLUDED )

MUST BE USED

AT JUNCTION BOX

b.Attach the appliance grounding lead (green

or bare copper) in accordance with local

codes. If the residence grounding conductor

is aluminum, see WARNING note.

c.Connect the oven neutral (white)lead to

the branch circuit neutral (white or gray) in

accordance with local codes, using wire

nut.

d.Connect the oven red lead to the branch

circuit red lead and the oven black lead to

the branch circuit black lead in accordance

with local codes, using wire nuts. If the

residence red, black or white leads are

aluminum conductors, see "WARNING"

note.

e. Install Junction Box Cover.

8 ( Continued on Next Page)

Page 9

Installation Instructions

Electrical Connections cont.

OR

I THREE-CONDUCTORBRANCH I

-_ When connecting to a 3-conductor

a.Connect the bare oven ground conductor

CIRCUIT CONNECTION

branch circuit, if local codes permit:

with the crimped neutral (white) lead to the

branch circuit neutral (white or gray in

color), using wire nut.

Do not shorten the flexible conduit.The

conduit strain Relief Clamp must be

securely attached to the junction box

and the flexible conduit must be

securely attached to the clamp. If the

flexible conduit will not fit within the

clamp, do not install the oven until a

clamp of the proper size is obtained.

NOTE TO ELECTRICIAN: The 3 power

leads supplied with this appliance are UL

recognized for connection to larger gauge

household wiring. The insulation of these 3

leads is rated at temperatures much higher

than the temperature rating of household

wiring. The current carrying capacity of the

conductor is governed by the temperature

rating of the insulation around the wire,

rather than the wire gauge alone.

Junction

-- Box Cover

b.Connect the oven red lead to the branch

circuit red lead, using wire nut.

c. Connect the oven black lead to the branch

circuit black lead in accordance with local

codes, using wire nut.

d.lnstall Junction Box Cover.

_ ARNING: Improper

can result in an electrical hazard or

fire. Use only connectors designed

for joining copper to aluminum and

follow the manufacturer's

recommended procedure closely.

connection of aluminum

house wiring to copper leads

9

Page 10

Installation Instructions

Securing the Oven

I_ With the conduit connected, the oven

is ready to be slid into the cutout

opening.

a. Loop a 36" string around the conduit

before the oven is slid into place. This

will keep the conduit from falling be-

hind the oven.

I, Pull out on

,;_ • string loop

l" while pushing

the oven into

the cabinet

.............. .'\\\\\\\.' ....................... \\ ....

b. Lift oven into cabinet cutout using the

oven opening as an grip. Carefully

push against oven front frame. Do not

push against outside edges.

c. As you slide the oven back, pull the

string so that the conduit will lie on top

of the oven in a natural loop.

d. When you are sure the conduit is out

of the way, slide the oven all the way

back into the opening. Remove the

string.

IC---_ Drill four-I/8" pilot holes through the

mounting holes (top and bottom) of the

side trim, for the four #8 screws

provided. Drill eight holes for the

Double Oven.

The screws must be a

minimum of 1/4" from

the front of the cutout.

MOUNTING

HOLE

LOCATIONS

_--_ Secure the oven to cabinet with screws

provided.

Note: Before drilling the pilot holes

make sure the oven is pushed as far

back into the opening as it will go

and centered.

m n

10

Page 11

Installation Instructions

I-D-1Installing the Bottom Trim

-_ ake sure the flat side is up on the

-_ ind the Key Slot on the back of the

--_ atch the key slot with the rivet on the

--_ Push the trim down until it into

bottom trim.

trim.

bottom of the side trim

snaps

place.

Key hole slot and wide flange at top

\

Lower trim mounting rivet on bottom of side

trim.

Push trim down at both ends until it snaps into

place.

may bend the bottom trim. The bottom trim provides an opening for cooling

[_ AUTION: Be sure you do not tip the oven foward during installation or you [1[

air to enter the cabinet. This opening should never be blocked.

11

Page 12

Installation Instructions

Replacing the Oven Door

Make sure the hinge is in the door stop

position.

Remove the toweling or paper towel holder

from the hinge.

Grasp the door on both sides.

Hold the door over the hinges lining up the

hinges with the hinge slots on the bottom of

the door.

Slide the door down onto the hinges as far

as it will go.

Close the door.

The oven door is heavy. You may need help lifting the door high enough to slide it

down onto the hinges. Do not lift the door by the handle.

12

Page 13

Installation Instructions

Pre-Test Check List

Remove all protective film if

present, and any stickers.

Check to be sure that all wiring is

secure and not pinched or in

contact with moving parts.

Operation Checklist

Remove all items from the inside I_kfl

of the oven.

Turn on the power to the oven.

(Refer to your Use and Care

Manual.) Verify that the bake and

broil units, and all cooking

functionsoperate properly.

Check that the circuit breaker is

not tripped or the house fuse is

blown.

[_ heck that conduit is securely

connected to the junction box.

Check that the bottom trim is installed

properly (see page 11).

Check to be sure the mounting

screws are installed and flush with the

side trim, (see page 10).

NOTE TO ELECTRICIAN:

The power leads supplied with this

appliance are UL recognized for

connections to larger gauge

household wiring. The insulation of

these leads is rated at temperatures

much higher than the temperature

rating of household wiring. The

current carrying capacity of a

conductor is governed by the wire

gauge and also the temperature rating

of the insulation around the wire.

NOTE: ALUMINUM WIRING

A. WARNING:

IMPROPER CONNECTION OF

ALUMINUM HOUSE WIRING TO

THE COPPER LEADS CAN

RESULT IN A SERIOUS PROBLEM.

[_ See Use & Care manual for

troubleshooting list.

B. Splice copper wires to aluminum

wiring using special connectors

designed and UL approved for

joining copper to aluminum and

follow the manufacturer's

recommended connector

procedure closely.

NOTE:Wire used, location and

enclosure of splices, etc., must

conform to good wiring practice and

local codes.

13

Page 14

NOTES

14

Page 15

NOTES

15

Page 16

NOTES

Pub. No. 31-10435

16 229c4053P417

Loading...

Loading...