Page 1

GE Consumer Products

TECHNICAL SERVICE GUIDE

2003 Slide-In, Single and Double Wall

Ovens with TrivectionTM Cooking

MODEL SERIES:

JS998

JT930

JT980

ZET3038

ZET3058

PUB # 31-9115 3/04

Page 2

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by

individuals possessing adequate backgrounds of electrical,

electronic, and mechanical experience. Any attempt to repair a

major appliance may result in personal injury and property

damage. The manufacturer or seller cannot be responsible for the

interpretation of this information, nor can it assume any liability in

connection with its use.

WARNING

To avoid personal injury, disconnect power before servicing this

product. If electrical power is required for diagnosis or test

purposes, disconnect the power immediately after performing the

necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used to

complete a path to ground are removed for service, they must be

returned to their original position and properly fastened.

PRECAUTIONS TO AVOID POSSIBLE EXPOSURE TO

EXCESSIVE MICROWAVE ENERGY

A. Do not attempt to operate this oven with the door open since

open-door operation can result in harmful exposure to microwave

energy . It is important not to tamper with the safety interlocks.

B. Do not place any object between the oven front face and the door

or allow soil or cleaner residue to accumulate on sealing surfaces.

C. Do not operate the oven if it is damaged. It is particularly important

that the oven door close properly and that there is no damage to

the:

• Door (bent)

• Hinges and latches (broken or loosened)

• Door seals and sealing surfaces

D. The oven should not be adjusted or repaired by anyone except

properly qualified service personnel.

GE Consumer Products

Technical Service Guide

Copyright © 2003

All rights reserved. This service guide may not be reproduced in whole or in part

in any form without written permission from the General Electric Company .

– 2 –

Page 3

Table of Contents

Basics of Element Cycling ..............................................................................................33

Component Locator Views ..............................................................................................12

Components Requiring Oven Removal...........................................................................15

Control Boards Connector Locator..................................................................................28

Control Features................................................................................................................8

Control Panel (

Control Panel Insert (Slide-In Range).................................................................................25

Cooktop (Slide-In Range) ...................................................................................................25

Current Limit Board (

Diagnostics and Service Information ...............................................................................32

Door Switches ................................................................................................................. 24

Failure Codes ..................................................................................................................32

Glass T ouch Assembly (

High Limit Thermal One-Shot TCO .................................................................................23

HVT Cooling Fan (

Introduction ........................................................................................................................4

Left and Right Thermal TCO's (

Left Cooling Fan (

Lower Cooling Fan (Double Wall Oven Only).............................................................................20

Lower Oven Bake and Clean Thermal TCO's (

Magnetron Capacitor and Diode ......................................................................................27

Magnetron Cooling Fan and Thermal TCO (

Microwave Components ..................................................................................................26

Microwave Fuse...............................................................................................................27

Microwave Leakage Test..................................................................................................39

Nomenclature ....................................................................................................................7

Operational Notes ............................................................................................................10

Oven Components ..........................................................................................................15

Oven Light Bulb Assembly...............................................................................................17

Oven Temperature Sensor (

Oven Vent Fan.................................................................................................................2 1

Right Cooling Fan ............................................................................................................20

Sail Switches (

Schematics and Wiring Diagrams ...................................................................................70

Self-Clean Latch Motor ....................................................................................................23

Service Mode ...................................................................................................................34

Stirrer Motor .....................................................................................................................27

Trivection

Trivection

TrivectionTM Door Assembly .............................................................................................16

Trivection

Troubleshooting ...............................................................................................................40

Troubleshooting Cooking Loads in Service Mode ............................................................35

TM

Convection Fan Assembly............................................................................19

TM

Convection Fan Motor...................................................................................19

TM

Bake, Broil and Convection Elements..........................................................18

Double and Single Wall Ovens) ....................................................................25

Slide-In Range) .................................................................................29

Slide-In Range) ............................................................................25

Double and Single Wall Ovens) ...............................................................27

Slide-In Range).................................................................22

Slide-In Range).......................................................................................26

Double Wall Ovens)...................................... 22

Wall Ovens) ..................................................26

RTD) .....................................................................................20

Double and Single Wall Ovens).....................................................................21

– 3 –

Page 4

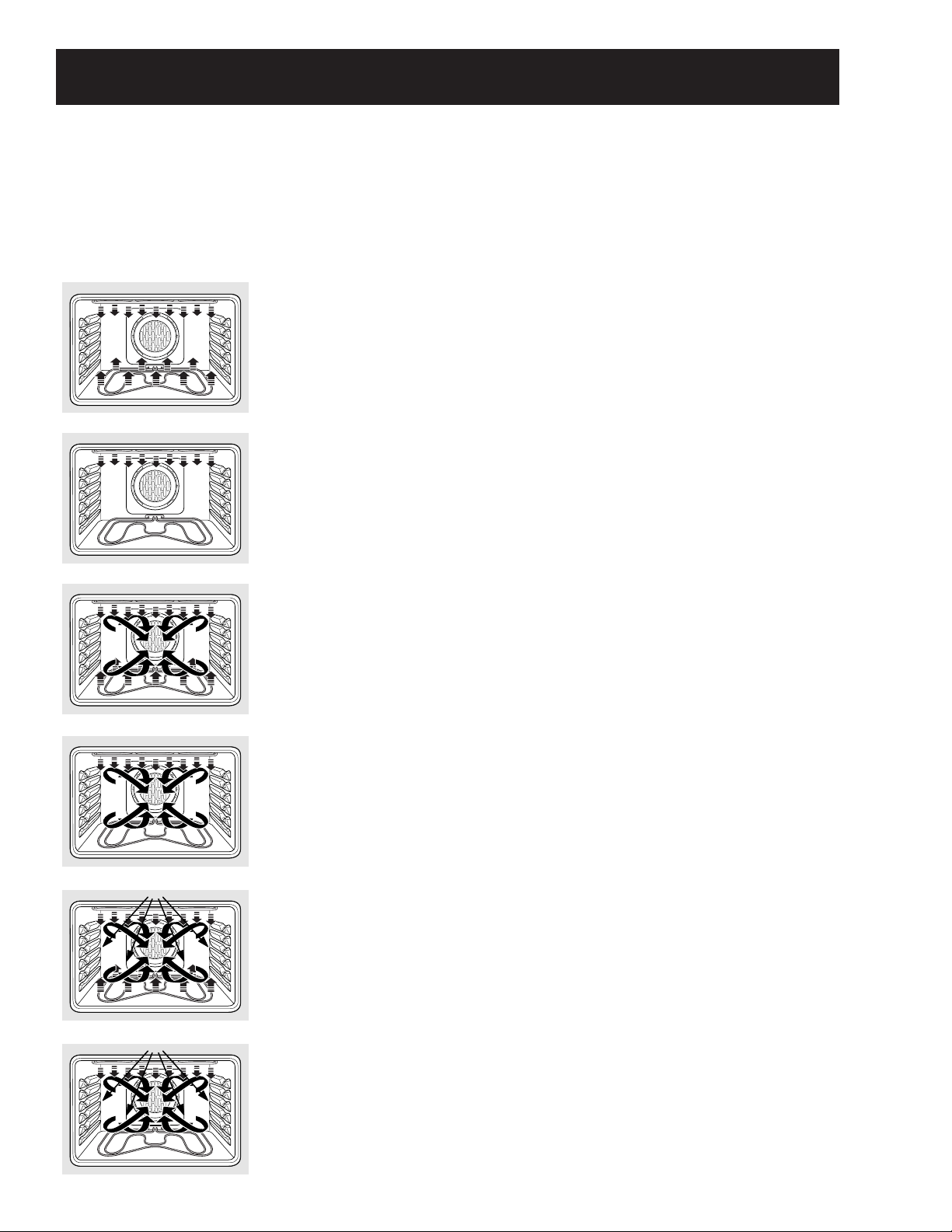

Bake

Baking is cooking with heated air. The

upper and lower elements cycle back and

forth to heat the air and maintain

temperature. Used for traditional baking

and roasting. Best for delicate items.

Broil

Heat is provided by the upper element

to broil your food. May be used with the

oven door open or closed.

Convection Bake—Multi and Single Rack

Heat is provided by the element in the

back of the oven, along with the upper

and lower elements. The air is circulated

with a reversing fan system. The fan will

change directions to provide optimal

evenness and browning. The Multi Rack

option is ideal for evenly baking foods

when using more than one rack. The

1 Rack option, used for one rack of food,

cooks food faster than BAKE mode.

Convection Roast

Heat is provided by the upper element

and circulated with the reversing fan

system. The fan will change directions to

provide optimal evenness and browning.

Good for roasting large tender cuts of

meat or poultry, uncovered. Roasts foods

up to 25% faster.

Speed Bake

Heat is provided by the three elements

and microwave. The exact combination

of elements is automatically determined

by the food category selected. Air is

circulated with the reversing fan system

described above. Ideal for baking and

roasting foods up to five times faster.

Speed Broil

Heat is provided by the upper element

and microwave. Air is circulated with the

reversing fan system described above.

Oven door must be closed. Ideal for

broiling foods to medium to well done

doneness levels two times faster than

traditional broil.

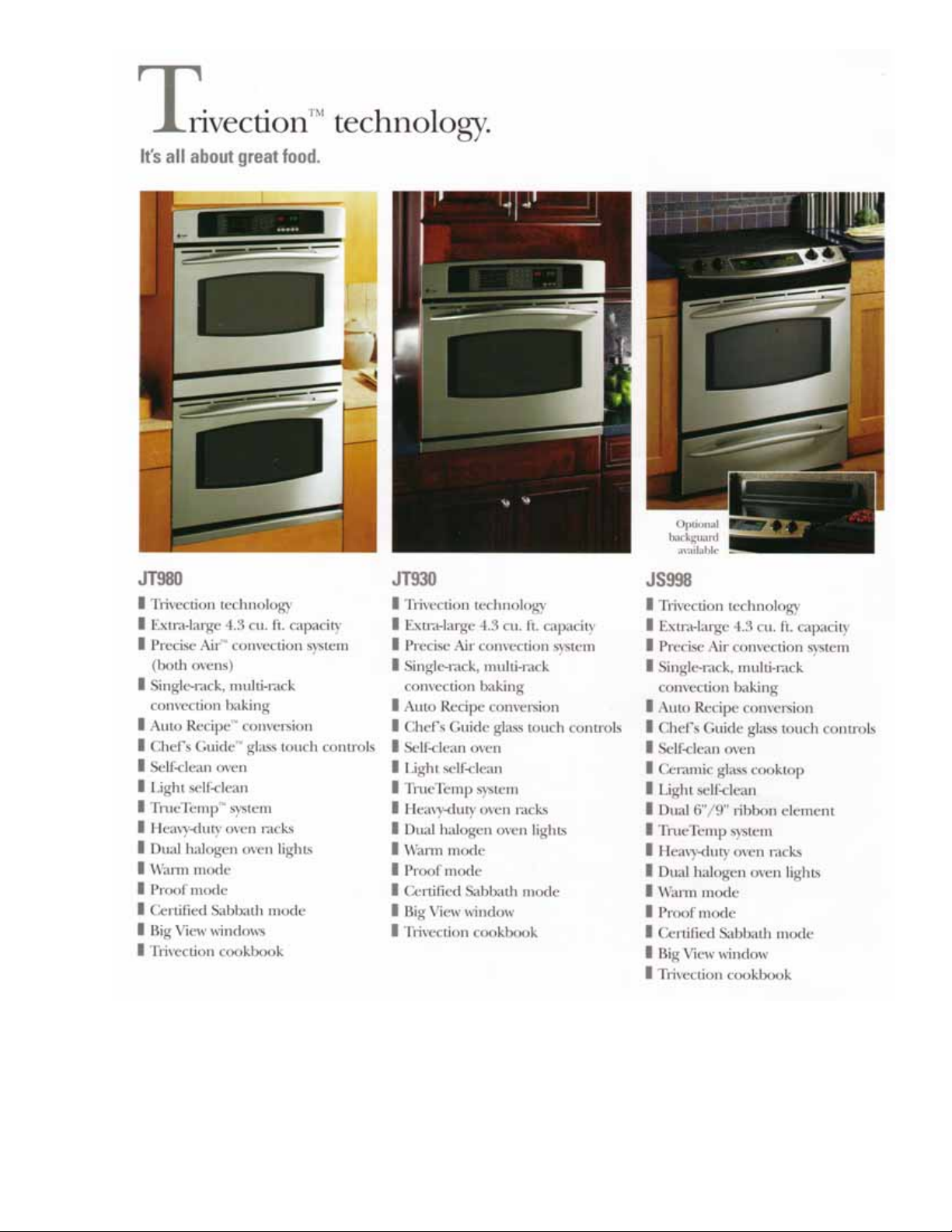

Introduction

The GE Profile oven with Trivection™ technology is a microwave-assist wall oven designed to cook food

up to five times faster than a traditional oven. This oven gives the user the flexibility to cook food in

traditional cooking modes (bake or broil), convection modes (convection bake and convection roast) or

in speedcook modes (speed bake and speed broil). This oven features easy-to-use controls that will

guide you through oven operations.

– 4 –

Page 5

– 5 –

Page 6

– 6 –

Page 7

Model Number

Nomenclature

J T 9 8 0 B H 1 B B

GE Cooking Product

J = GE

ZE = Monogram Electric

Configuration

S = 30-in. Slide-In Oven

T = 30-in. Wall Oven

Feature Pack

Designates features–the higher

the number, the more features.

Nomenclature

Product Color

CC = Bisque WW = White

BB = Black

SS = Stainless Steel

Indicator for Engineering and

Product Service Only

Model Year Designator

Glass Color

C = Bisque W = White

B = Black

S = Stainless Steel

Serial Number

The first two numbers of the serial number

identify the month and year of manufacture.

Example: AF123456S = January, 2003

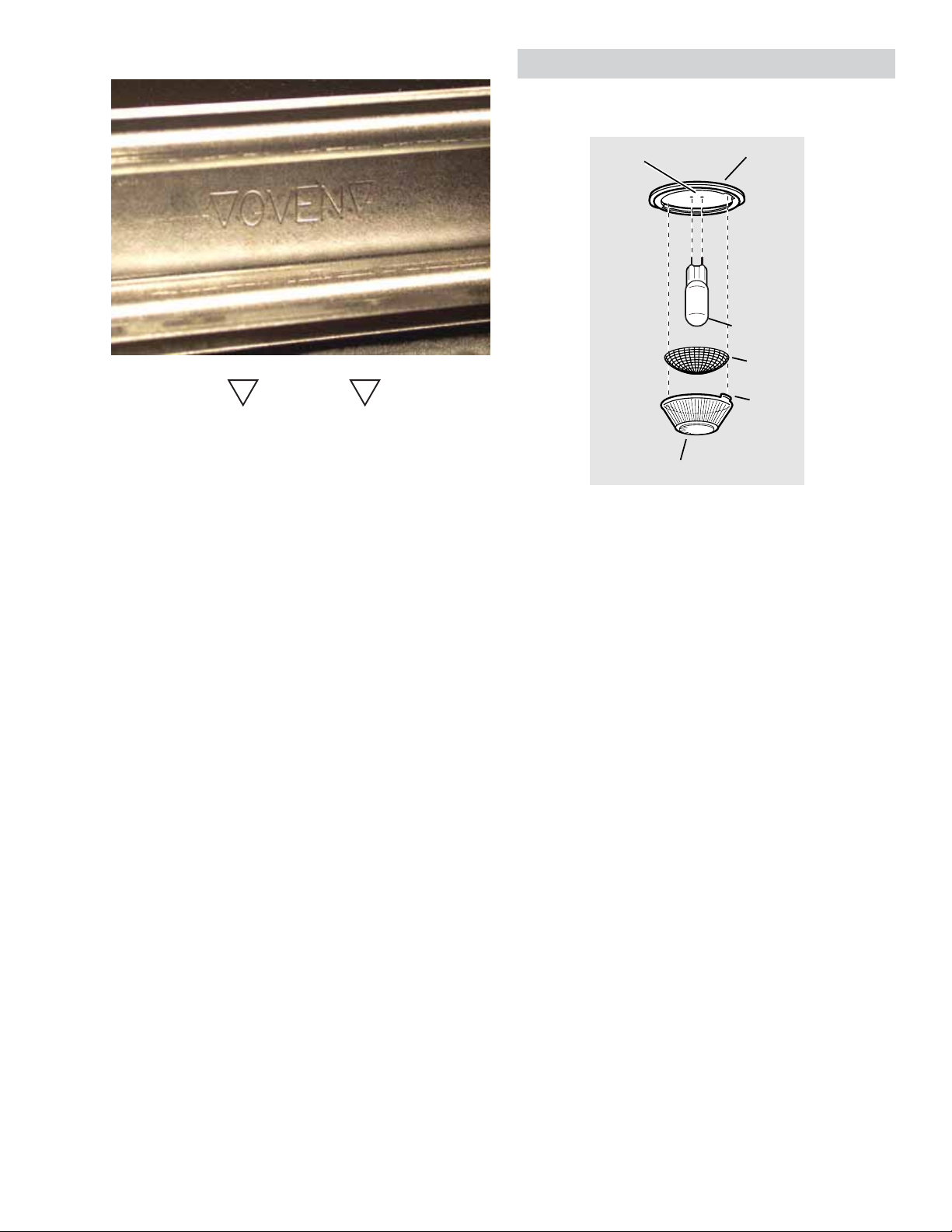

The nomenclature plate of the oven is

located on the left side of the front frame.

The Mini-manual is located in the control

compartment taped to the right side wall.

The nomenclature plate for the double wall

oven is located on the lower oven left side

of the front frame.

A

- JAN 2005 - H

D - FEB 2004 - G

F - MAR 2003 G - APR 2002 - D

H - MAY 2001 - A

L - JUN 2000 - Z

M - JUL 1999 - V

R - AUG 1998 - T

S - SEP 1997 - S

T - OCT 1996 - R

V - NOV 1995 - M

Z - DEC 1994 - L

– 7 –

F

The letter designating

the year repeats every

12 years.

Example:

T - 1974

T - 1986

T - 1998

Page 8

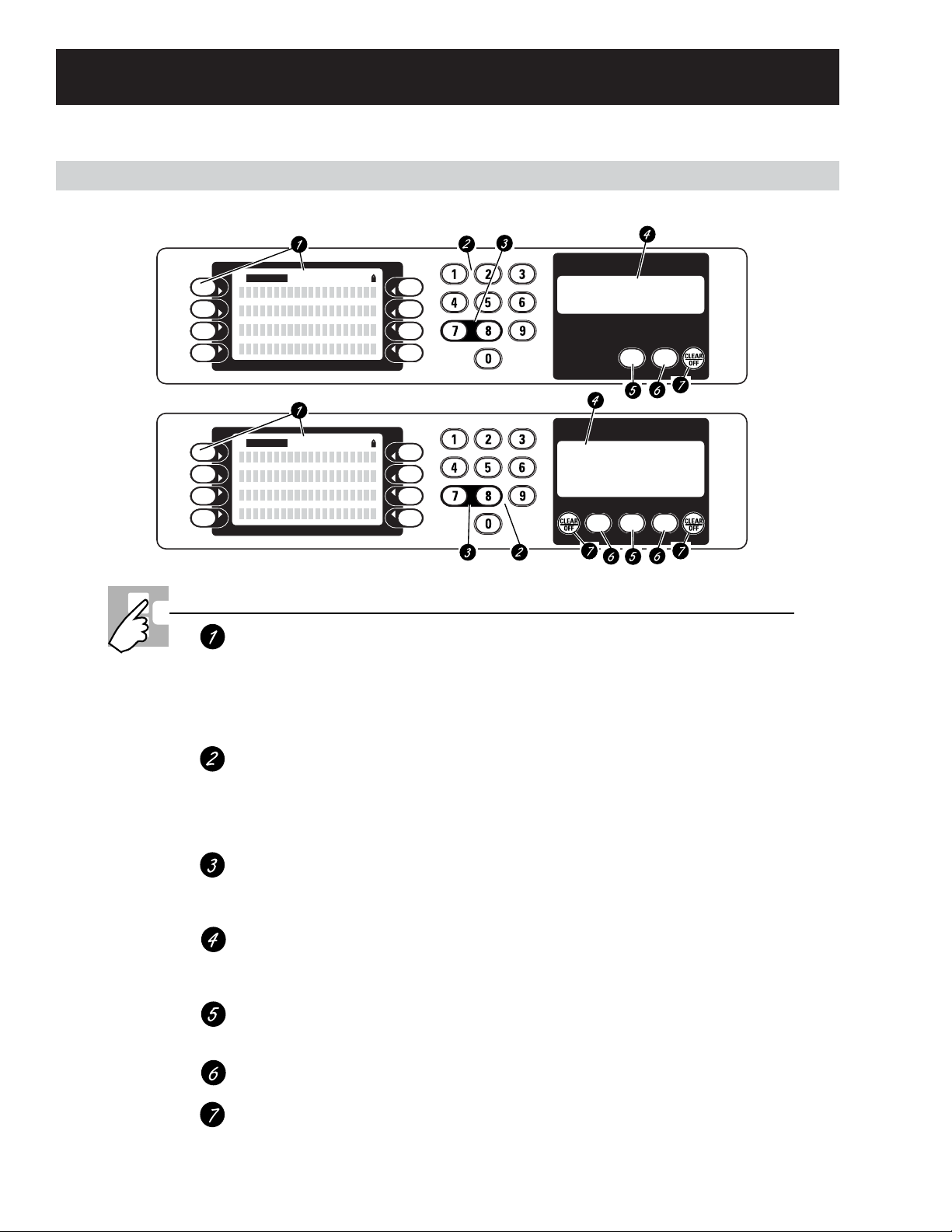

Using the Oven Controls

SELECT

Control Features

Single oven control.

Double oven control.

CONTROL LOCK

SELECT

CONTROL LOCK

Oven Control Layout and Description

Control Screen & Keypad

All cooking modes, special features and

oven settings are directed and operated

from the control screen. Directions for

operating the oven and prompting for

required information are displayed within

the control screen.

Numeric Keypad

Used to enter information requiring

numbers such as time of day on the clock,

timer, oven temperature, start time and

length of operation for timed baking and

self-cleaning.

Control Lockout

Allows the user to lock the control so that

the touch pads cannot be activated when

pressed.

Time and Temperature Display

All time and temperature information

is displayed in this area as feedback to

the user.

Kitchen Timer

Turns the kitchen timer on and off.

Does not control the oven.

Oven Light

Turns oven light on or off.

Clear/Off

Cancels ALL oven operations EXCEPT the

clock and timer.

If “F– and a number or letter” flash in the display and

the oven control signals, this indicates a function

error code. Press the CLEAR/OFF pad. Allow the oven to

cool for one hour. Put the oven back into operation. If the

function error code repeats, disconnect the power to the

oven and call for service.

If your oven was set for a timed oven operation

and a power outage occurred, the clock and all

programmed functions must be reset.

The time of day will flash in the display when there

has been a power outage.

OVEN

KITCHEN

TIMER

LIGHT

ON/OFF

UPPER OVEN LOWER OVEN

OVEN

LIGHT

KITCHEN

TIMER

ON/OFF

OVEN

LIGHT

– 8 –

Page 9

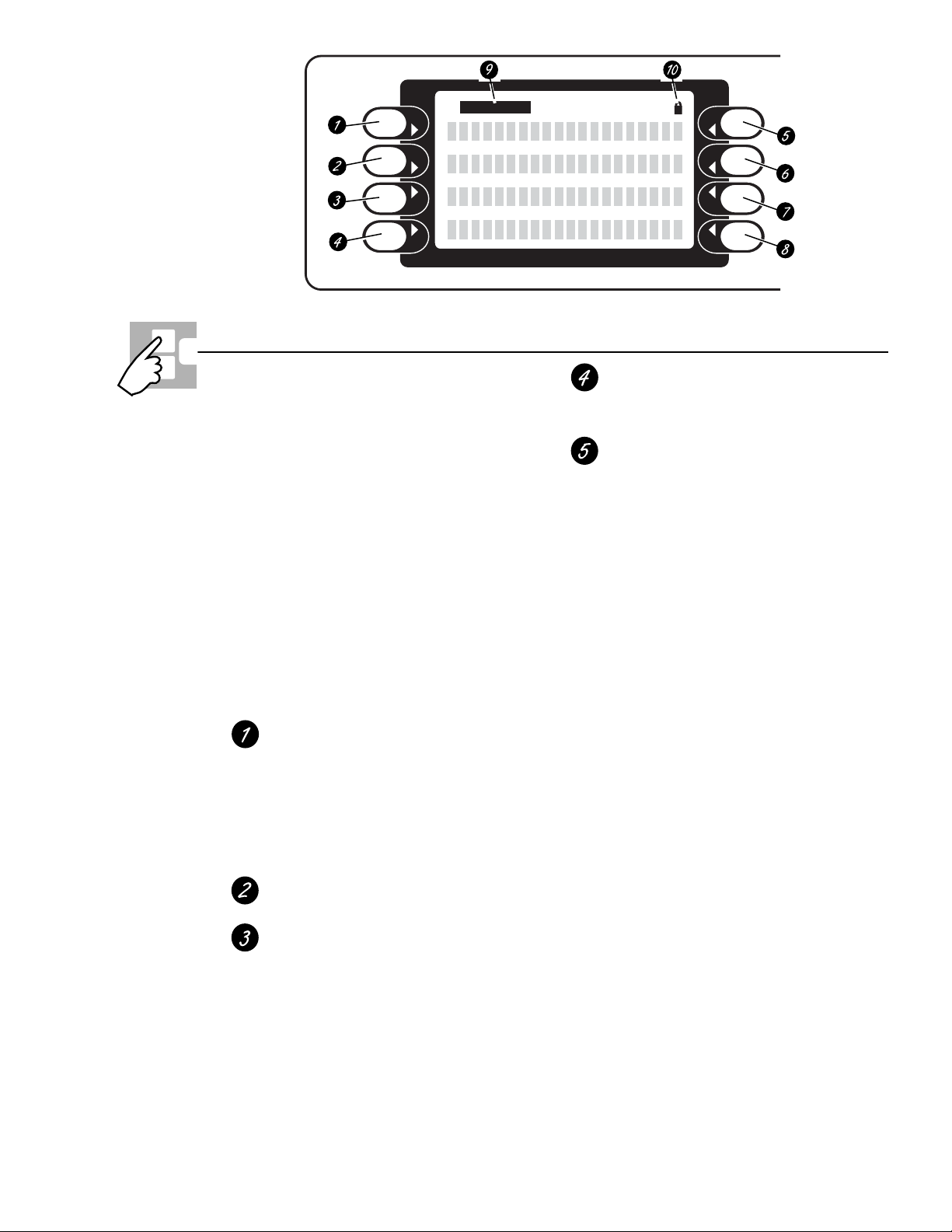

Press pad beside display to select item

in display.

Oven Control Sleep Feature—Any time the oven is

not in use (no cooking, no cleaning, no help and

no timers) for more than 10 minutes, the oven

control will go to sleep. While sleeping, the

control display will not show any text; it will go

blank. The clock will remain displayed in the time

and temperature display unless the “no clock”

option has been selected.

There will be no audible signal given to indicate

that the control is entering the sleep feature.

The control will enter the sleep feature even

when the control is locked.

The user cannot turn this feature OFF.

How to Exit the Sleep Feature—Touch any key. The

function associated with that key will not be started,

but the control display main menu will reappear.

Speedcook

In Speedcook mode, the user will be

prompted to enter food category,

temperature and cooking time.

Speed bake—Bakes food faster than

traditional cooking modes.

Speed broil—Broils food faster than

traditional Hi/Lo Broil.

Bake

Traditional bake mode.

Convection

Conv 1-Rack—Convection bake function

used for baking on one rack.

Conv Multi—Convection bake function

used for baking on more than one rack.

ConvRoast—Convection roast function.

Broil

LO & HI—Traditional broil function.

Speed broil

Features

Additional cooking-related features.

Defrost—This feature is used to thaw

frozen foods.

Self-Clean—This feature cleans the oven.

See the Using the self-cleaning oven section.

Warmer—This feature keeps hot, cooked

food warm for up to 3 hours. It is not

intended for reheating cold food.

Proof—This feature maintains a warm

environment useful for rising yeastleavened products. It is not intended to

keep food warm or reheat cold food.

Warm (Cook & Hold)—When this feature is

turned on, it will keep hot, cooked foods

warm for up to 3 hours following a Timed

Bake function.

Sabbath—Designed for use on the Jewish

Sabbath and Holidays.

SELECT

Control Screen and Keypad

(Continued next page)

– 9 –

Page 10

Control Screen and Keypad

Settings

This oven has additional settings that you

may choose to use.

NOTE: On double wall ovens, Recipes is

available only on the upper oven.

This oven feature allows the user

to store up to six temperature/cooking

time combinations. The user can then

speed bake, bake or convection bake/roast

one of the six stored favorite recipes

without having to choose the settings

each time.

Operational Notes

• The cooking loads (bake, broil, convection

elements, and microwave) are not energized

for 15 seconds after the cycle is started.

• In SPEEDCOOK, the time countdown will not

start until after the oven is preheated, the door

is opened then closed and START is pressed.

If START is not pressed, the microwave does

not start and the timer does not count down.

Help

Provides basic information on each

function and how to find the function.

If selected from the home screen, it gives

general help. If selected while performing

a function, it gives help on that function.

Select Exit to leave Help.

Select Prompt

Visual prompt to the user indicating

that a selection needs to be made from

the control screen.

Door Lock Indicator

Indicates that the oven door is locked

for self-clean.

• The convection fan may cycle on and off and

change direction while cooking to best

distribute hot air in the oven. The convection

fan shuts off when the oven door is opened.

• At least one cooling fan will automatically turn

on during all cooking modes. This fan turns on

to cool internal parts. It may run for up to 20

minutes (up to 85 minutes for double oven

models) after the oven is turned off,

regardless of oven temperature.

• In SPEEDCOOK, if the door is opened during

the cooking cycle, the timer, microwave and

convection fan will stop. The elements will

continue to cycle on when necessary. Once

the door is closed, the convection fan and

microwave will operate and the timer

countdown will resume.

• In DEFROST, the microwave turns off and the

cook time stops counting down when the oven

door is opened. They will resume when the

door is closed.

• PROOF will not operate when oven is above

125°F. OVEN TOO HOT will show in the

display.

• In PROOF and DEFROST, the convection fan

will rotate for 1 minute in one direction, then

turn off for 10 minutes. Af ter 10 minutes, the

fan will rotate for 1 minute again, in the

opposite direction.

• When the oven first starts heating, the

temperature display will start at 100°F.

• On double oven models, you can set a delay

clean in both ovens. However, the second

oven set will automatically delay the start of

cleaning until the end of the first oven’s clean

cycle.

• The RECIPES feature allows you to preset up

to six temperature/cooking time combinations

with this function. You can then bake,

convection bake/roast or speed bake any of

these six favorite recipes without choosing

settings each time. You cannot program broil,

defrost, warmer, proof, speed broil, delay bake

or self-clean in RECIPES.

• The oven will remember RECIPES that have

been programmed, even after a power outage.

The cooking time you enter does not include

preheat time. The oven will begin to count

down the cooking time after the oven has

completed preheating. RECIPES are only

available on the upper oven of a double wall

oven.

– 10 –

Page 11

• On double oven models, you can use timed

baking or roasting in one oven while using

self-clean in the other; you can also use timed

baking or roasting in both ovens at the same

time. You will hear a fan while cooking with

these features.

Control Lockout (Single and Double Wall

Ovens)

• Press the 7 & 8 pads at the same time for 3

seconds. The screen will display CONTROL

IS LOCKED.

• To unlock the control, press the 7 & 8 pads for

3 seconds. The display will return to the home

screen.

• To turn this feature off, press the BACK pad

for 3 seconds. The control returns to the

FEATURES screen where SABBATH was

originally selected.

Note: This feature remains active even after loss

of power to the oven. The only way to exit

SABBA TH is to hold the BACK p ad for 3 seconds.

If power is lost while the Sabbath mode is in a

heating cycle, the heat will be off when the power

is restored.

Sales Mode

• Becomes active upon powering up with 120V

only (L1-L2 = 120V , L2 connected to N).

Control Lockout (Slide-In Range)

• Press the CONTROL LOCK pad for 3

seconds. The screen will display CONTROL

IS LOCKED.

• To unlock the control, press the CONTROL

LOCK pad for 3 seconds. The display will

return to the home screen.

If any cooking/cleaning modes are running,

entering control lockout will cancel the cooking/

cleaning modes. Then when exiting control

lockout, it will go to the home screen.

Sabbath Feature

• This feature disables all but the bake and

timed bake modes. Additionally the display

does not show the temperature and the sound

is disabled.

• The element and oven icons will light

randomly within one minute to indicate that the

oven is operating. All time functions will remain

displayed and active.

• To access the sabbath feature, press the

FEA TURES pad, then the MORE p ad.

• To turn this feature on, press the SABBATH

pad.

• This mode is NOT accessible on 240V/208V

power input. Sales mode requires a special

120 V AC cord (oven L1 connected to power

cord L, oven L2 and N connected to power

cord N).

• Wall Oven cord kit is Pub # 3-A063

Slide-In cord kit is Pub #3-A073.

Time Settings

• To access the time settings, press the

SETTINGS pad on the home screen, then

press the appropriate time function pad.

Oven Calibration

Oven calibration offset can be adjusted for the

bake mode only . No other cooking modes are

affected by changing the bake mode temperature.

1. Press the SETTINGS pad.

2. Press the MORE pad until ± TEMP appears in

the display .

3. Press the ± TEMP pad. (Select upper or lower

oven for double oven models.)

4. Press the INCREASE or DECREASE pads to

change the cooking temperature in 1°

increments up to ±35°F.

Note: Oven calibration offset can also be

accessed through the service mode under

OFFSET. (See

Service Mode.)

– 11 –

Page 12

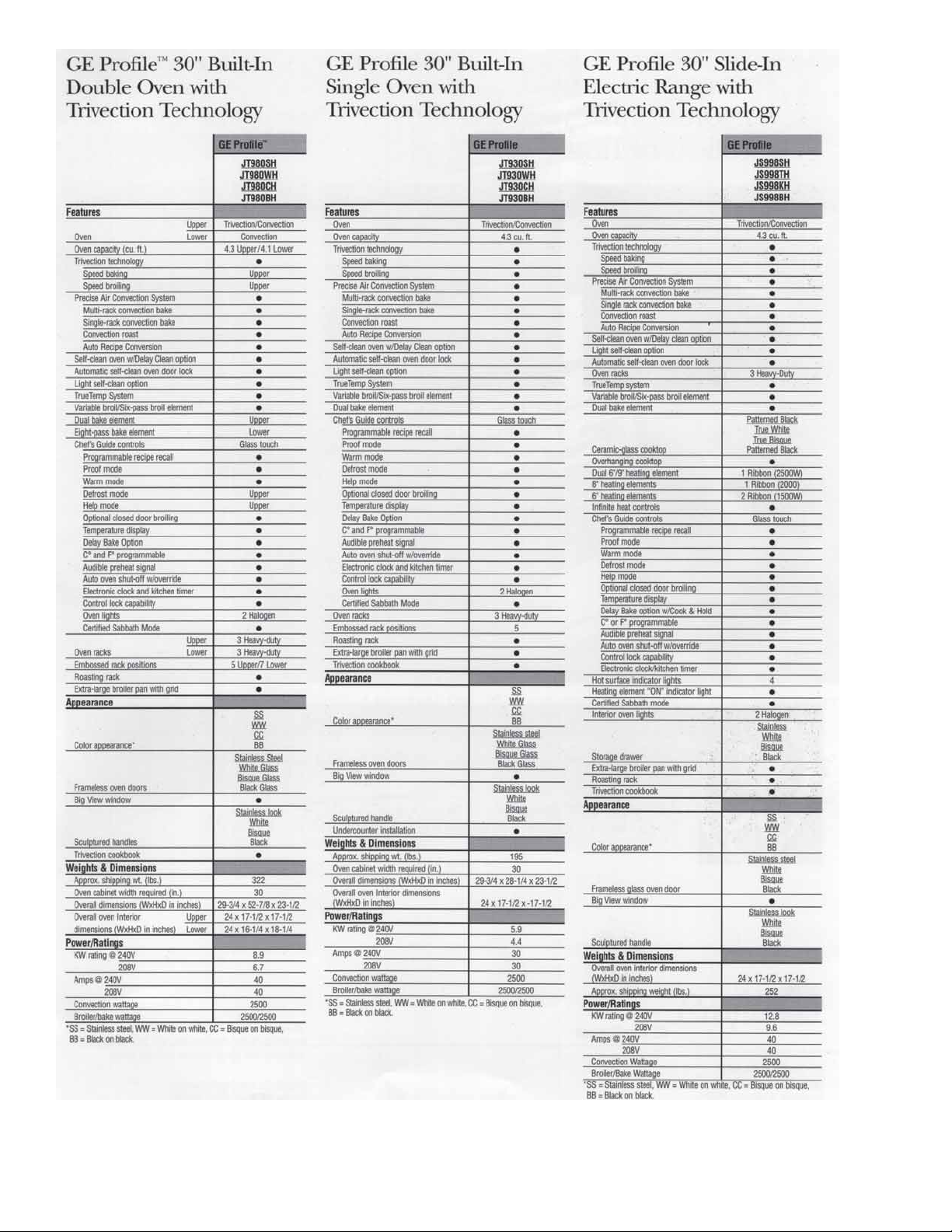

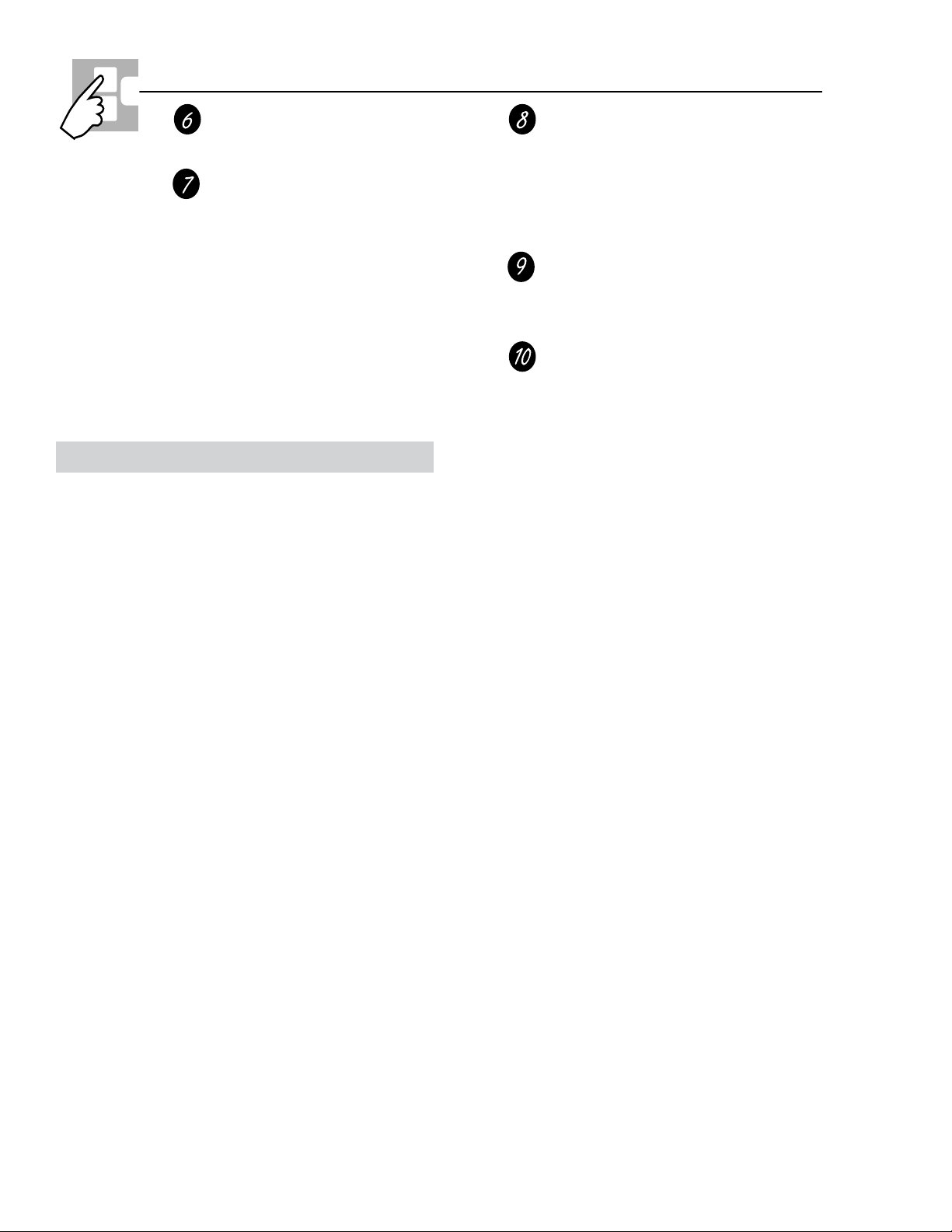

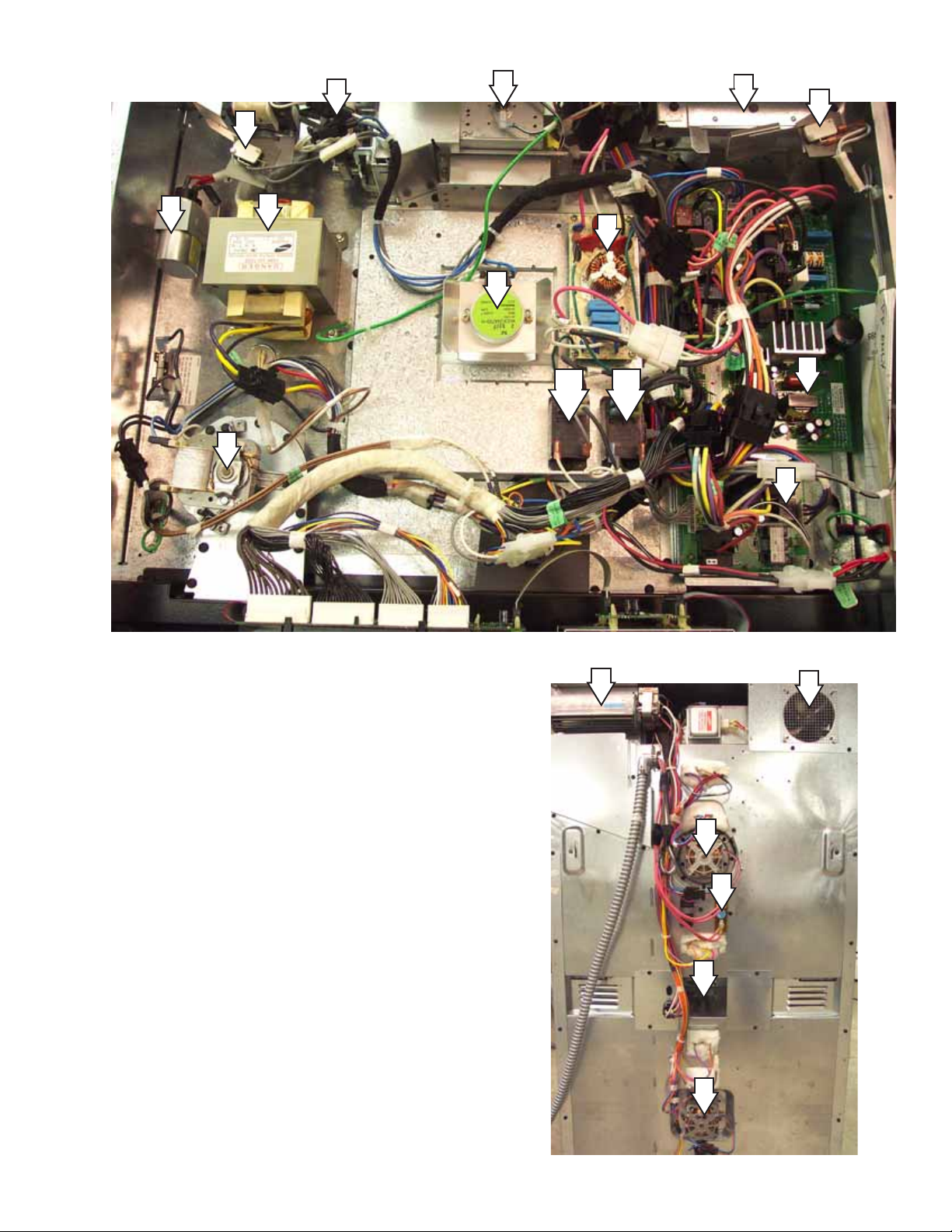

30-in. Single Wall Oven

Component Locator Views

11

3

5

4

10

2

1

6

7

12

9

8

15

1 - Magnetron Thermal TCO (Thermal Cutout)

2 - High Voltage T ransformer

3 - Magnetron Cooling Fan

4 - High Voltage Capacitor

5 - Left Sail Switch

6 - Stirrer Motor

7 - EMI Filter Board

8 - R1 Sail Switch Relay

9 - Right Sail Switch

10 - Oven Vent Fan

11 - High Voltage T ransformer (HVT) Fan

12 - Right Cooling Fan

13 - Convection Fan

14 - High Limit Thermal One-Shot (TCO)

15 - Main Power Board (MPB)

12

Rear View

11

13

14

– 12 –

Page 13

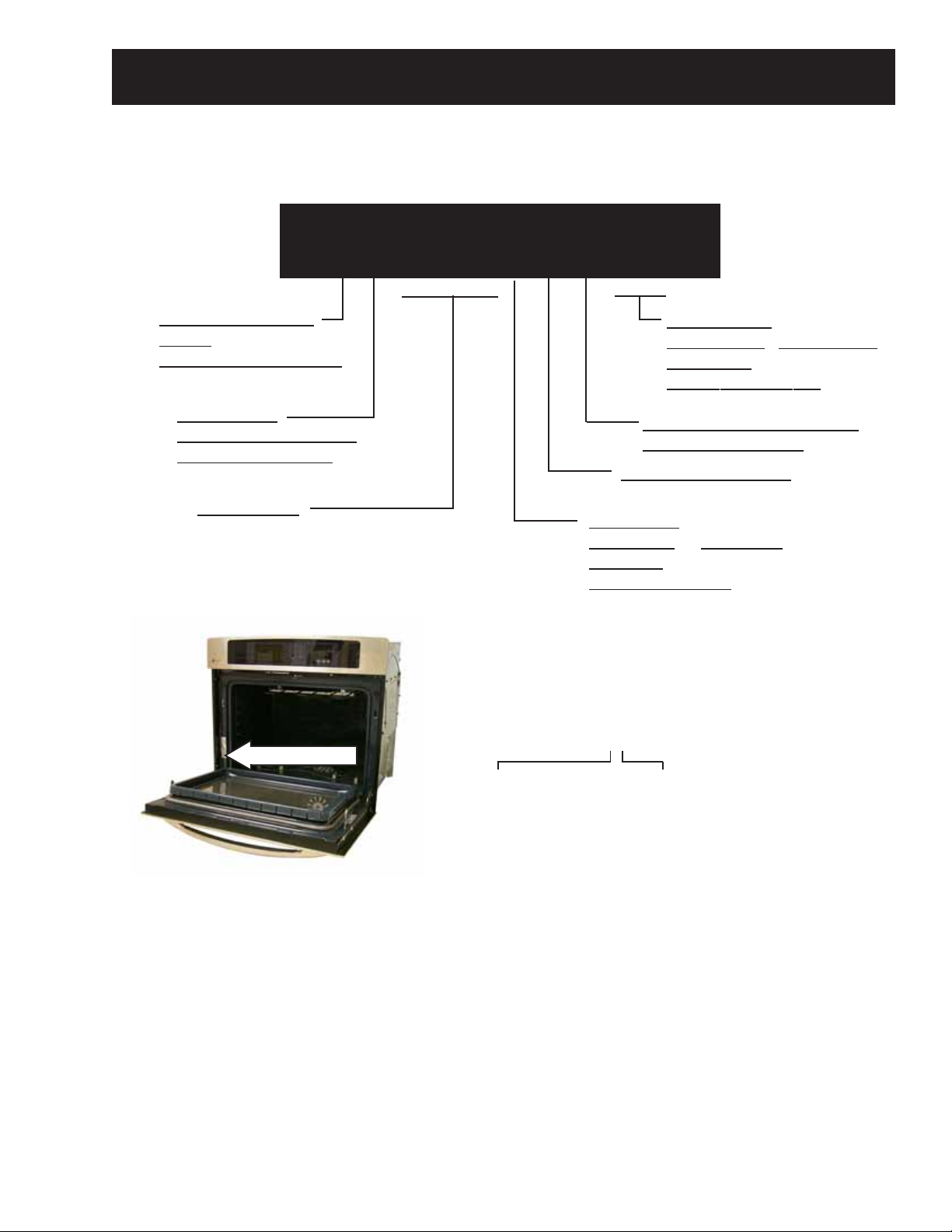

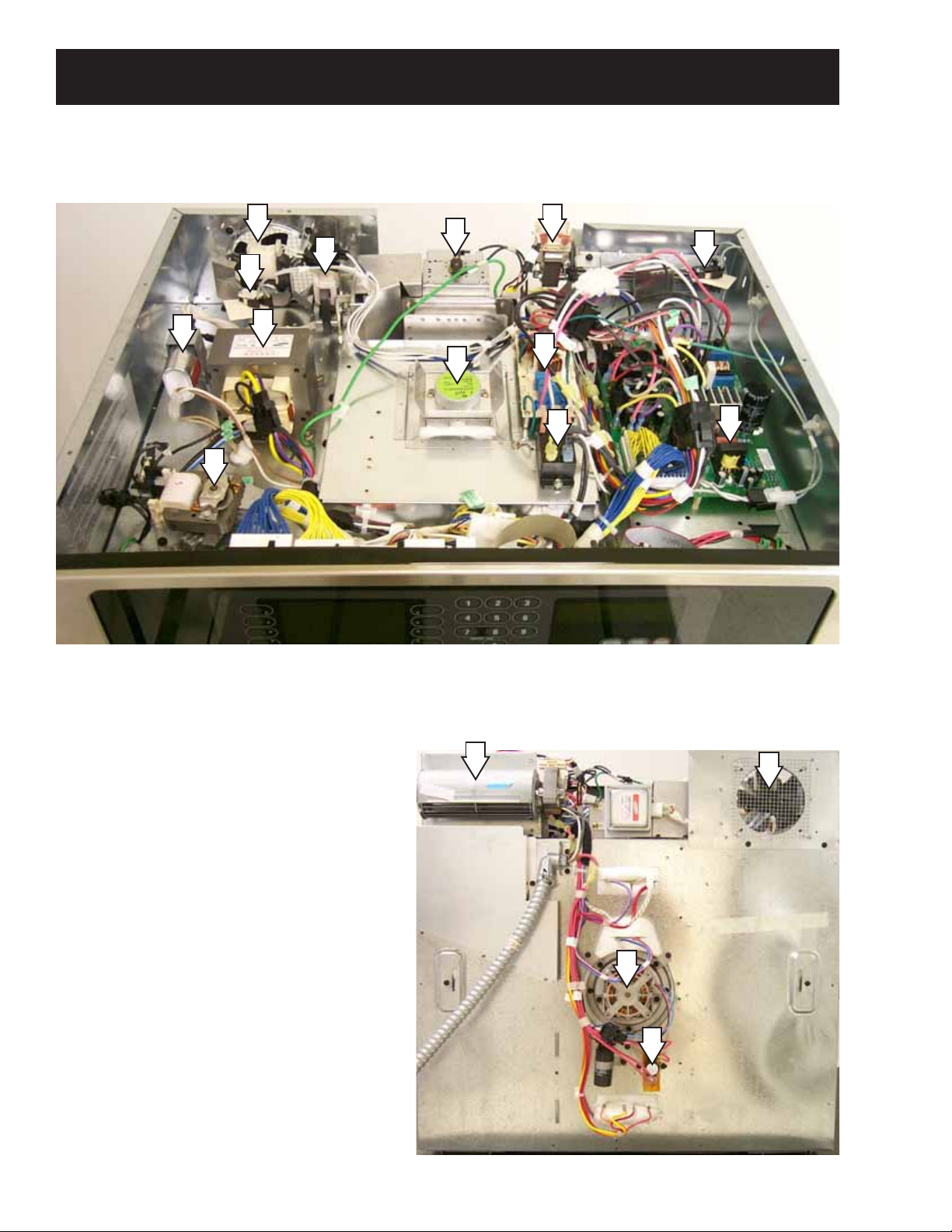

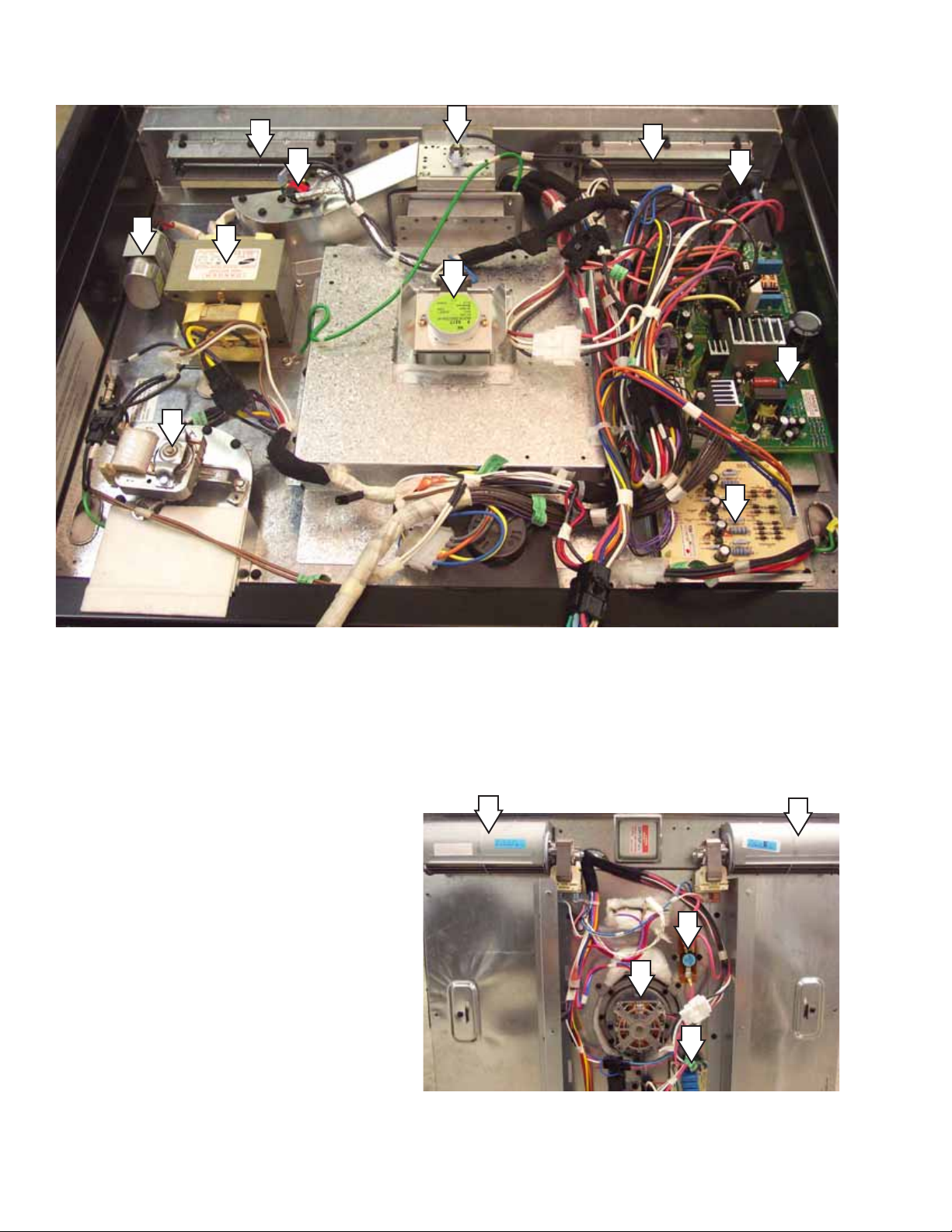

30-in. Double Wall Oven

5

3

1

12

9

4

2

7

6

17

8a 8b

10

15

1 - Magnetron Thermal TCO (Thermal Cutout)

2 - High Voltage T ransformer

3 - Magnetron Cooling Fan

4 - High Voltage Cap acitor

5 - Left Sail Switch

6 - Stirrer Motor

7 - EMI Board

8 - (a) R2 and (b) R1 Sail Switch Relay

9 - Right Sail Switch

10 - Oven Vent Fan

11 - High Voltage T ransformer (HVT) Fan

12 - Right Cooling Fan

13 - Convection Fan

14 - High Limit Thermal One-Shot (TCO)

15 - Lower Oven Relay Board

16 - Lower Oven Cooling Fan

12

Rear View

11

13

14

16

13

17 - Main Power Board (MPB)

– 13 –

Page 14

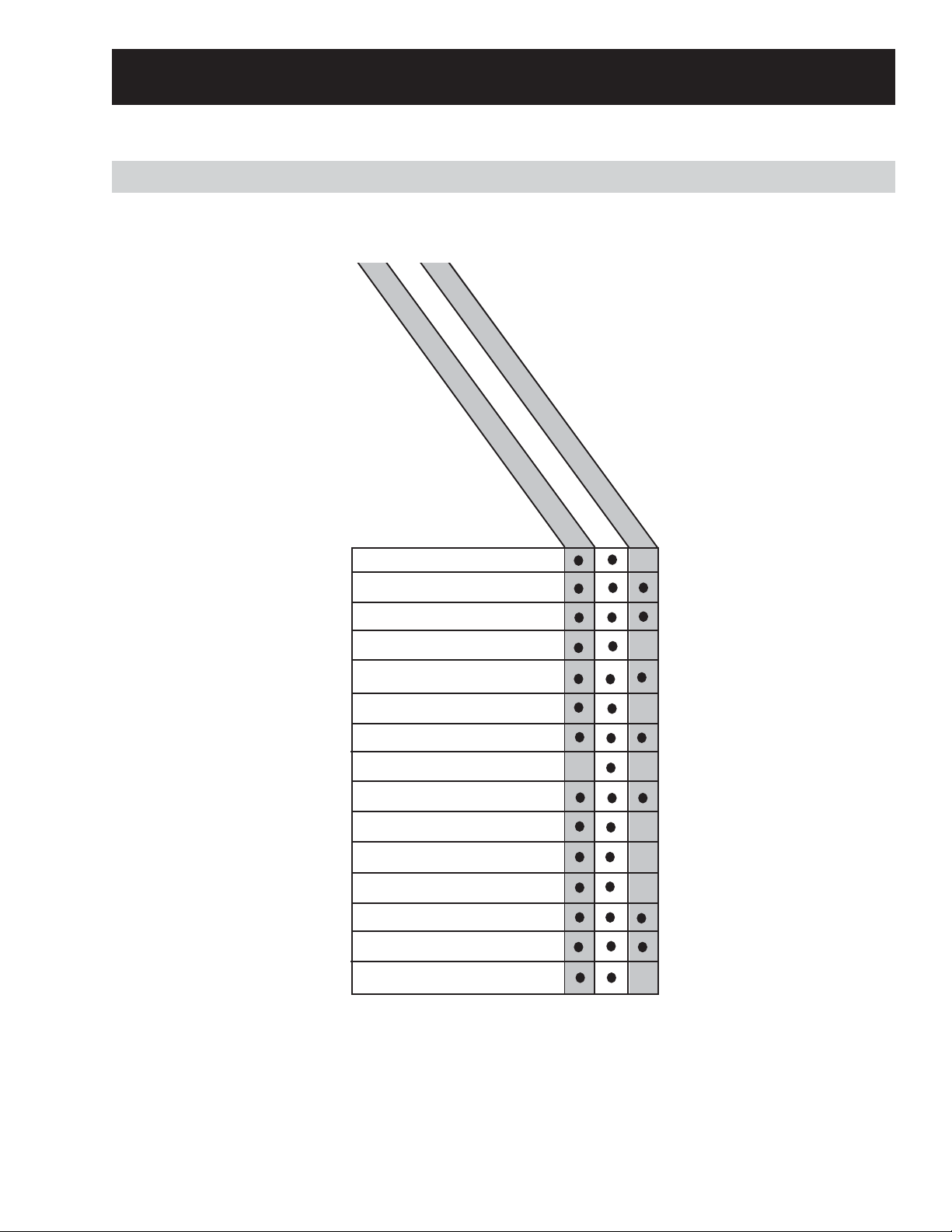

30-in. Slide-In Range (

Shown with Cooktop Removed)

8

3

5

7

2

1

9

4

6

14

12

1 - Magnetron Thermal TCO

2 - High Voltage T ransformer

3 - Left F AD (Fan Apparency Device) TCO

4 - Right FAD TCO

5 - High Voltage Capacitor

6 - Stirrer Motor

7 - Oven Vent Fan

8 - Left Cooling Fan

9 - Right Cooling Fan

10 - High Limit Thermal One-Shot (TCO)

11 - Convection Fan

12 - Current Limit Board (CLB)

13 - EMI Filter Board

14 - Main Power Board (MPB)

Rear View

9

8

10

11

13

– 14 –

Page 15

Oven Components

Components Requiring Oven Removal

To replace the components listed below, the oven must be removed from its installation.

Double Wall Oven

Single Wall Oven

Slide-In Range

Capacitor

Convection Fan Capacitor

Convection Fan Motor(s)

Diode

EMI Board

High Volt age Transformer

Left Cooling Fan

Lower Oven Cooling Fan

Magnetron

Magnetron Cooling Fan

Magnetron TCO

Main Power Board

One-Shot Thermostat

Right Cooling Fan

Sail Switches

NA

Note: When assembling, the elements, convection fan, and oven light contain special radiation screens

and chokes. Be sure to replace these in the oven cavity. Take special care not to strip any screws when

replacing these components.

– 15 –

Page 16

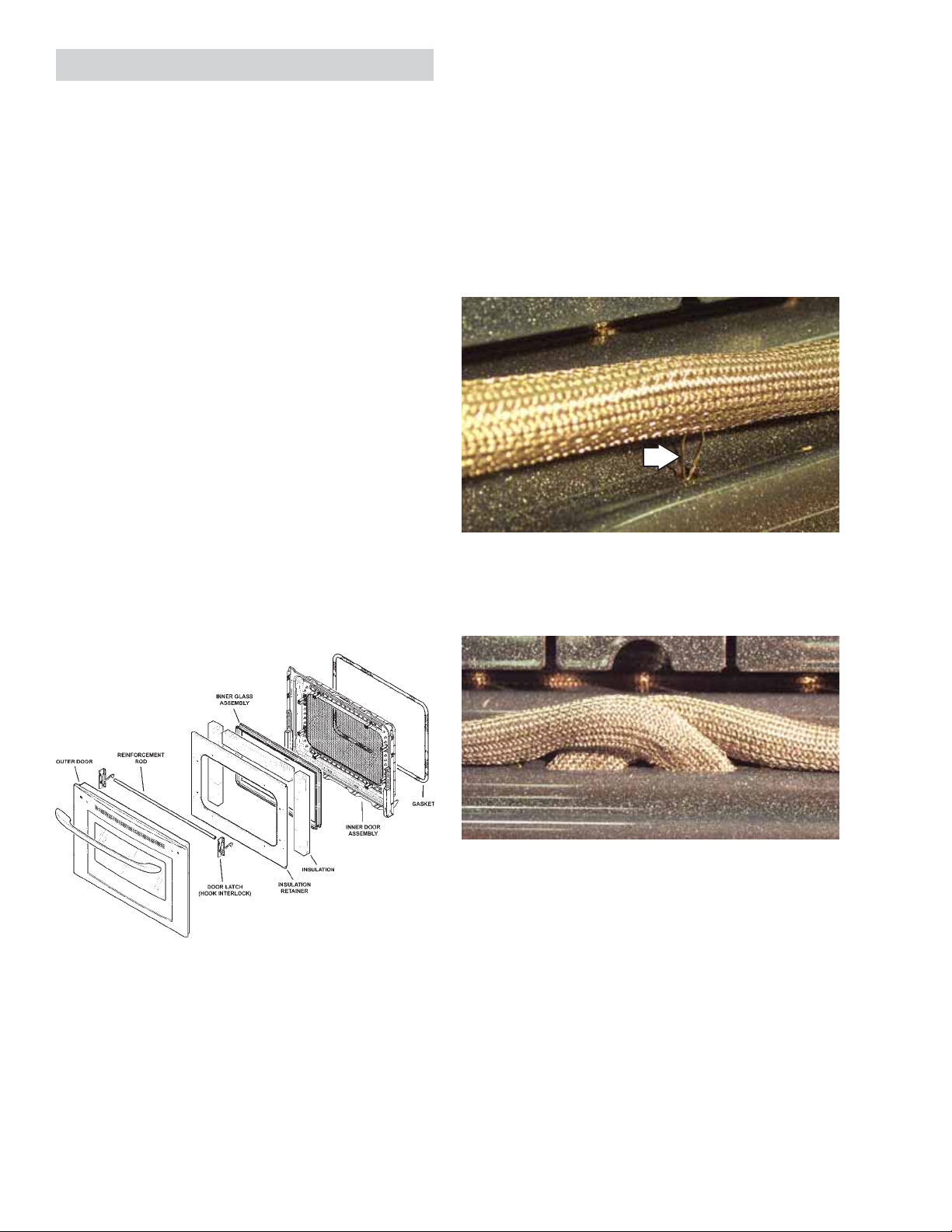

TrivectionTM Door Assembly

WARNING: A microwave leakage test must be

performed any time a door is removed, replaced,

disassembled, or adjusted for any reason. The

maximum leakage is 4 MW/cm

Microwave Leakage Test).

2

(see

Caution: Care must be taken if reinstalling the

door handle. Overtightening screws can damage

handle. Hand-tighten screws and make sure

handle fits snugly to door panel (do not use

electric driver).

To remove the Trivection

TM

Door Gasket:

Caution: The door is very heavy. Use the correct

lifting procedures. Do not lift the door by the

handle.

To remove the Trivection

TM

door:

1. Fully open the door.

2. Remove the security screws and clips on

each hinge with a Torx 20 (T20) screwdriver.

3. Pull the hinge locks down toward the door

frame, to the unlocked position. (This may

require a flat-blade screwdriver to start the

hinge locks moving).

4. Firmly grasp both sides of the door at the top.

5. Close the door to the door removal position,

which is halfway between the broil stop

position and fully closed.

6. Lift the door up and out until the hinge arm is

clear of the slot.

The door gasket is attached to the inner door

panel by spring clips. In addition to being a selfclean gasket, the door gasket has a wire mesh to

help seal microwave energy .

Cross the gasket and tuck loose ends into the

slots at the bottom of inner panel as shown below.

To remove the outer door:

1. Place the inner door side down on the work

area.

2. Remove the eight T15 Torx screws from the

outer door (two on each side, four across the

bottom).

3. Lift the outer door and handle off the door

assembly.

Note: There is no gap at the bottom of the gasket

on the TrivectionTM oven door.

To remove the inner glass assembly:

1. Remove the eight

1

/4-in. hex head screws

holding the insulation retainer .

2. Remove the retainer and insulation.

3. Lift the inner glass assembly off the inner

door.

– 16 –

Page 17

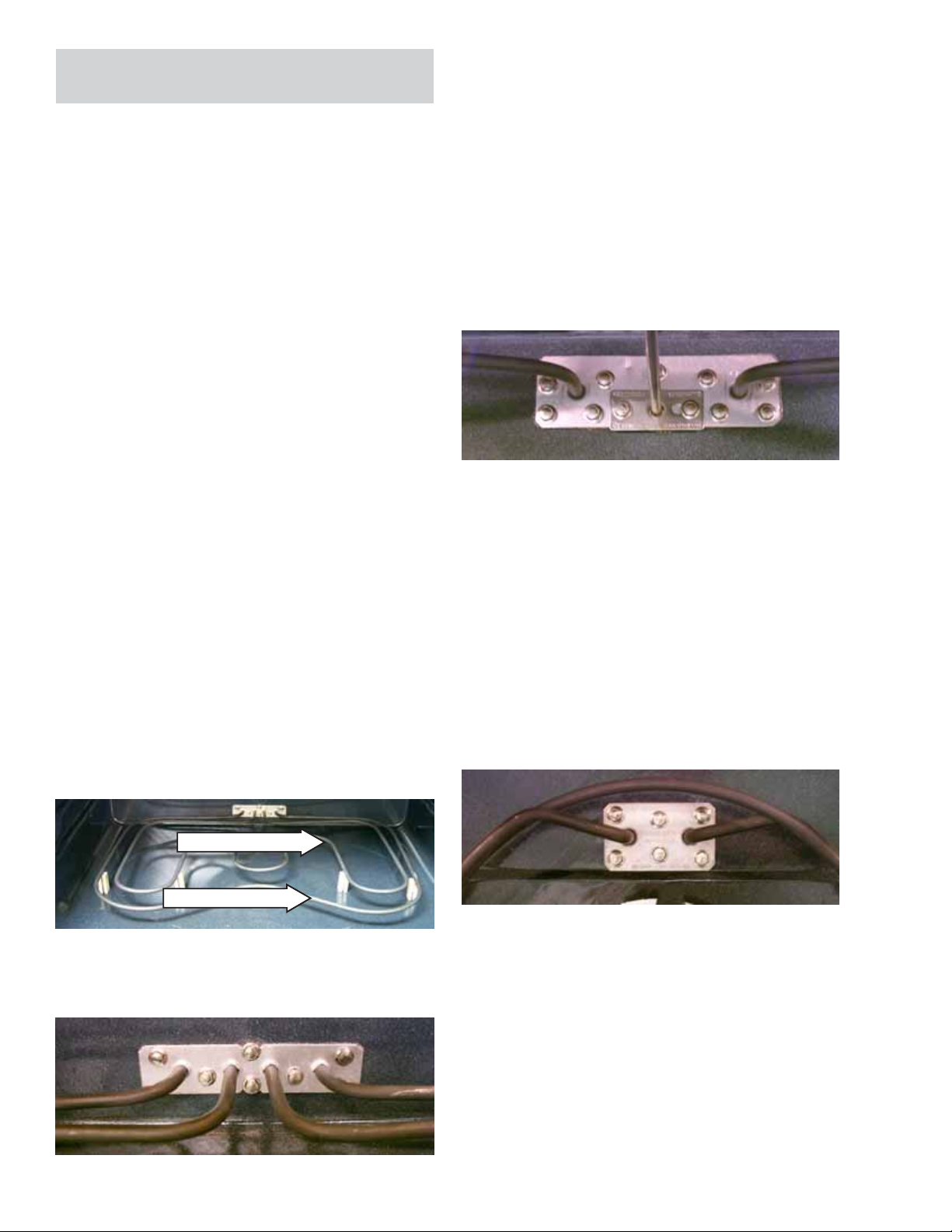

Bulb

Socket

Ta b

Glass cover

Receptacle

Screen

Inner Glass Assembly

OVEN

Note: Arrows on the side of the inner glass

assembly indicate the direction in which the oven

door glass is installed. The arrows should be

pointing toward the oven cavity .

Oven Light Bulb Assembly

Inner Door Assembly

The inner door liner, glass and hinges are one

assembly and should NOT be separated. All the

screws on the inner door assembly have been

®

torqued to a specific setting and Loctite

sealant

applied to prevent microwave leakage.

To replace the Trivection

TM

door:

1. Firmly grasp both sides of the door at the top.

2. With the door at the same angle as the

removal position, seat the indentation of the

hinge arm into the bottom edge of the hinge

slot. The notch in the hinge arm must be fully

seated into the bottom of the slot.

3. Fully open the door. If the door cannot be fully

opened, the hinge is not properly seated.

4. Push the hinge locks up against the front

frame of the oven cavity , to the locked

position.

5. Reinstall the security screws on each hinge.

6. Close the oven door and check for proper

alignment, rubbing, etc.

7. Perform the Microwave Leakage Test.

Note: On slide-in models, the door rubbing on the

oven cavity may be due to the leveling legs. If the

oven is not level it can "rack" the cavity and cause

rubbing.

Note: The glass cover should be removed only

when cold. Be sure to let the light cover and bulb

cool completely . Do not touch a hot bulb with bare

hands or a damp cloth.

Replace with a new 130V halogen bulb, not to

exceed 50 watts.

Note: Bulbs are 50 watt in Trivection

TM

oven, and

30 watts in the lower oven of double oven.

To remove and replace the oven light bulb:

1. Turn the glass cover counterclockwise

1

/4 turn

until the tabs of the glass cover clear the

grooves of the socket.

2. Using gloves or a dry cloth, remove the bulb

by pulling it straight out.

3. Using gloves or a dry cloth, remove the new

bulb from its packaging. Do not touch the bulb

with bare fingers.

4. Push the bulb straight into the receptacle all

the way. Then replace the screen.

Note: The screen must be replaced or the life of

the bulb will be reduced.

– 17 –

Page 18

TrivectionTM Bake, Broil and Convection

Elements

WARNING: A microwave leakage test must be

performed any time an element is removed,

replaced, or adjusted for any reason. The

maximum leakage is 4 MW/cm

Microwave Leakage Test).

Caution: Use caution when removing element

from inside oven cavity due to wire harness

layout. There is a possibility of the wire terminals

coming loose from the element when pulling the

wires through the oven cavity .

Note: When reconnecting the elements, make

sure the connectors are securely attached to the

element terminals.

The bake and broil elements have special gaskets

that keep microwave energy from leaking out of

the oven cavity . Replace any worn or damaged

gaskets.

2

(see

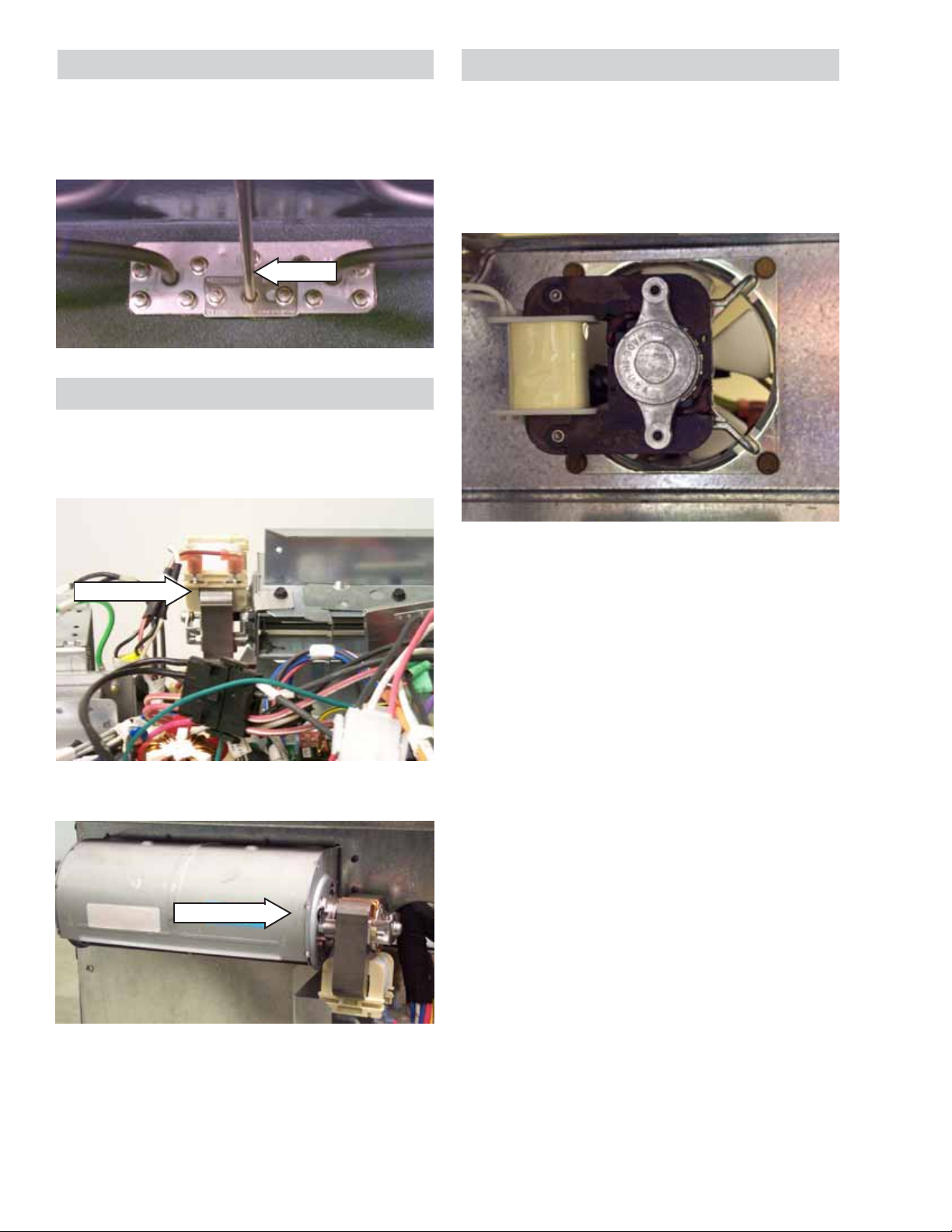

Broil Element

• The broil element is rated at 2500 watts, has

an approximate resistance value of 22 Ω, and

draws approximately 9 amps.

• The broil element is held is place on the back

oven wall by:

a. Eleven

1

/4-in. hex head screws on the

mounting plate.

1

b. T wo

-

/4

in. hex head screws on the left and

right element brackets.

Convection Element

Bake Element

• The bake element is composed of an inner

and an outer element. It is replaced as one

unit.

• The inside element is rated at 2500 watts, has

an approximate resistance value of 22 Ω, and

draws approximately 9 amps.

• The outside element is rated at 900 watts, has

an approximate resistance value of 63 Ω, and

draws approximately 3.2 amps.

Inner Element

Outer Element

• The bake element is held is place on the back

oven wall by six 1/4-in. hex head screws.

• The convection element is rated at 2500

watts, has an approximate resistance value of

22 Ω, and draws approximately 9 amps.

• The convection element is held in place on the

back oven wall by:

a. Six

1

/4-in. hex head screws on the

mounting plate.

b. One

1

/4-in. hex head screw on the bottom

element bracket.

Note: Production will be using Torx (T20H)

security screws on all elements in the Trivection

TM

oven in the near future.

– 18 –

Page 19

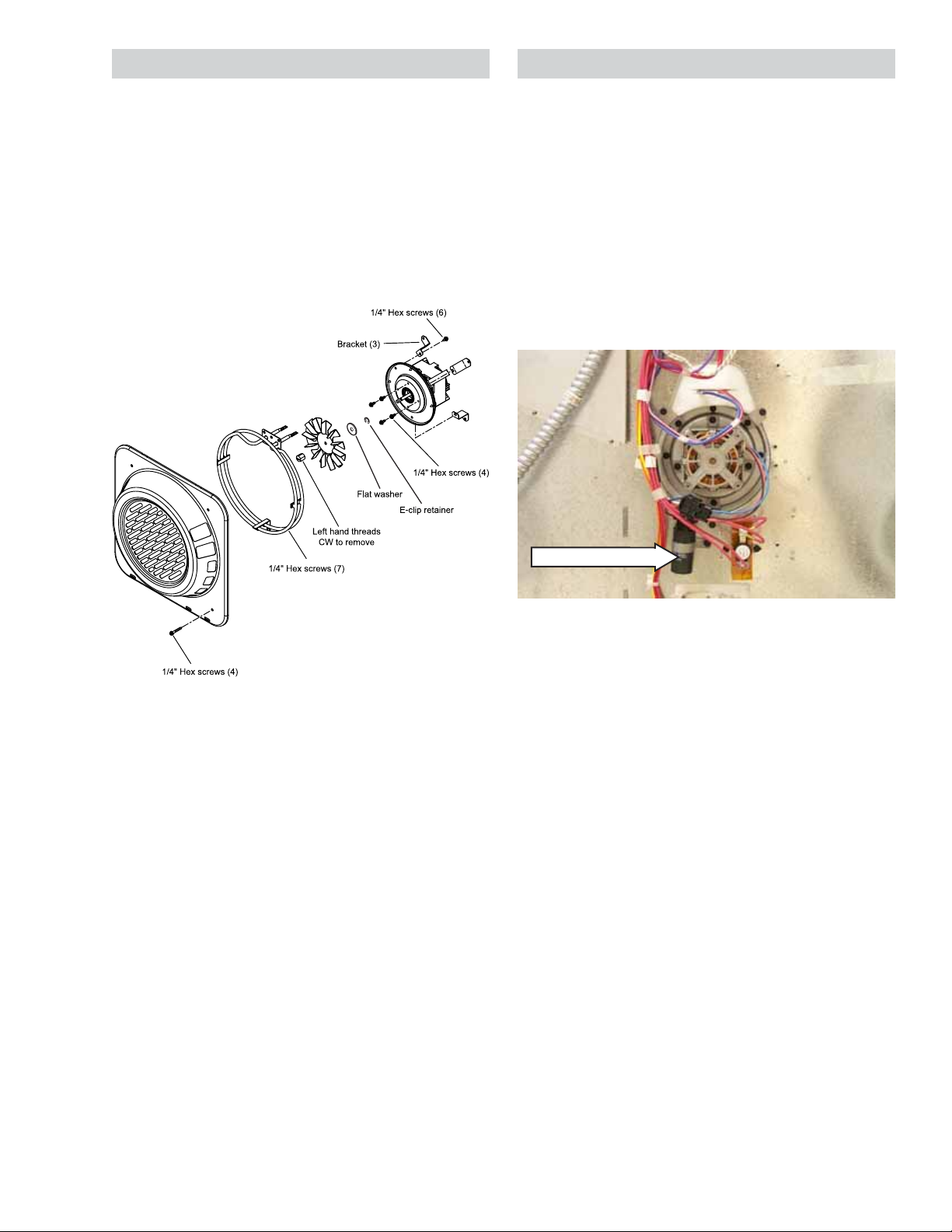

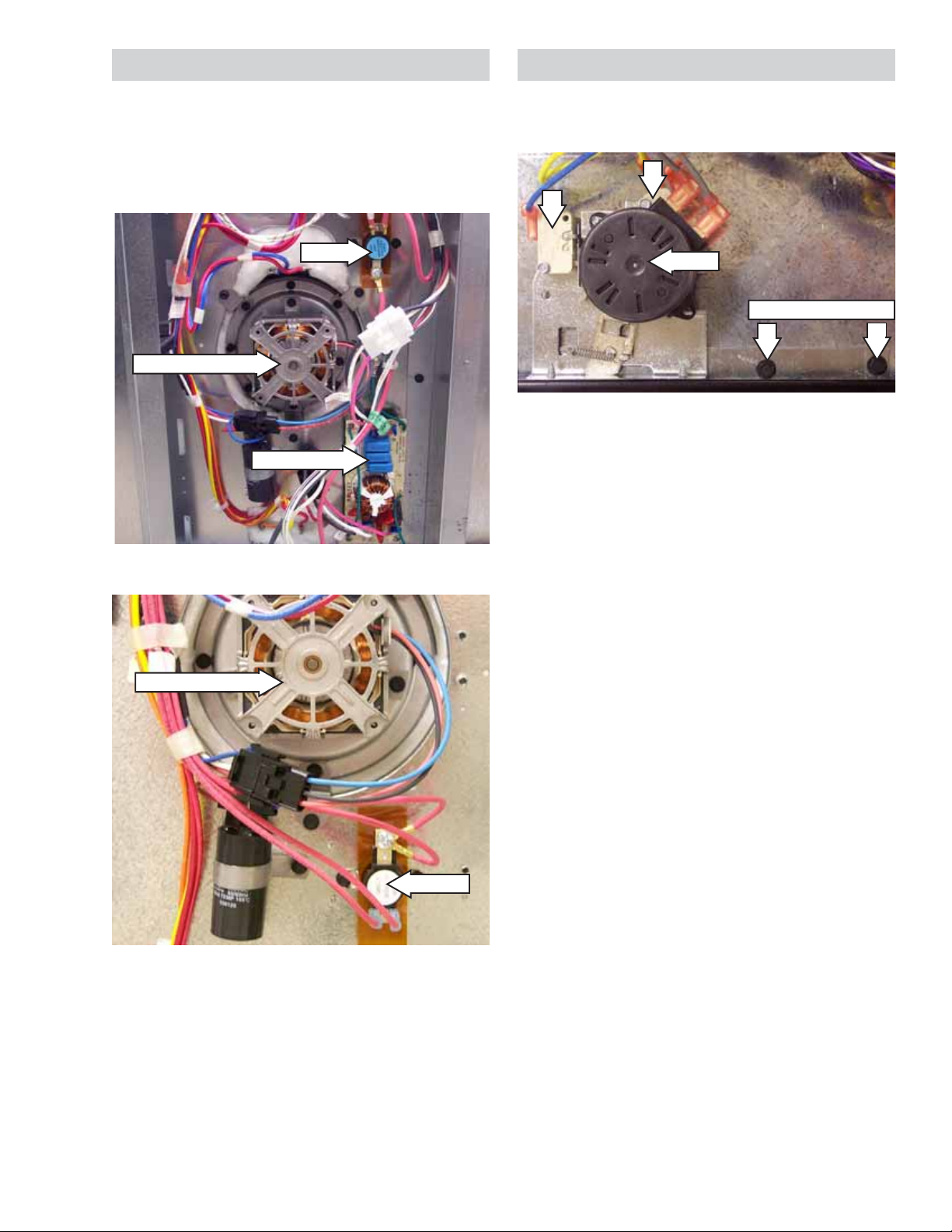

Trivection

TM

Convection Fan Assembly

TrivectionTM Convection Fan Motor

The convection fan assembly consists of the fan

guard, element, fan blade, and motor.

Refer to the schematic in the back of this manual

for circuitry for your specific model.

Trivection

TM

Convection Fan Assembly

The convection fan motor is located on the back

of the oven.

The convection fan motor has approximate

resistance values between the following wires:

• Red and Blue: 118 Ω

• Red and Black: 58 Ω

• Blue and Black: 58 Ω

Wall Oven Shown

• The element cover is held in place by four

1

/4-in. hex head screws.

• The convection fan blade nut has left-hand

threads. Turn nut clockwise to remove.

Motor Capacitor

• To remove the convection fan motor:

a. Remove the four

1

/4-in. hex head screws

on the inside of the oven cavity .

b. On the back on the oven, remove the 3

1

outer

/4-in. hex head screws from the 3

brackets that hold the convection motor in

place.

Note: The convection fan assembly in the lower

oven of the double oven mounts the same as

previous convection fan assemblies.

– 19 –

Page 20

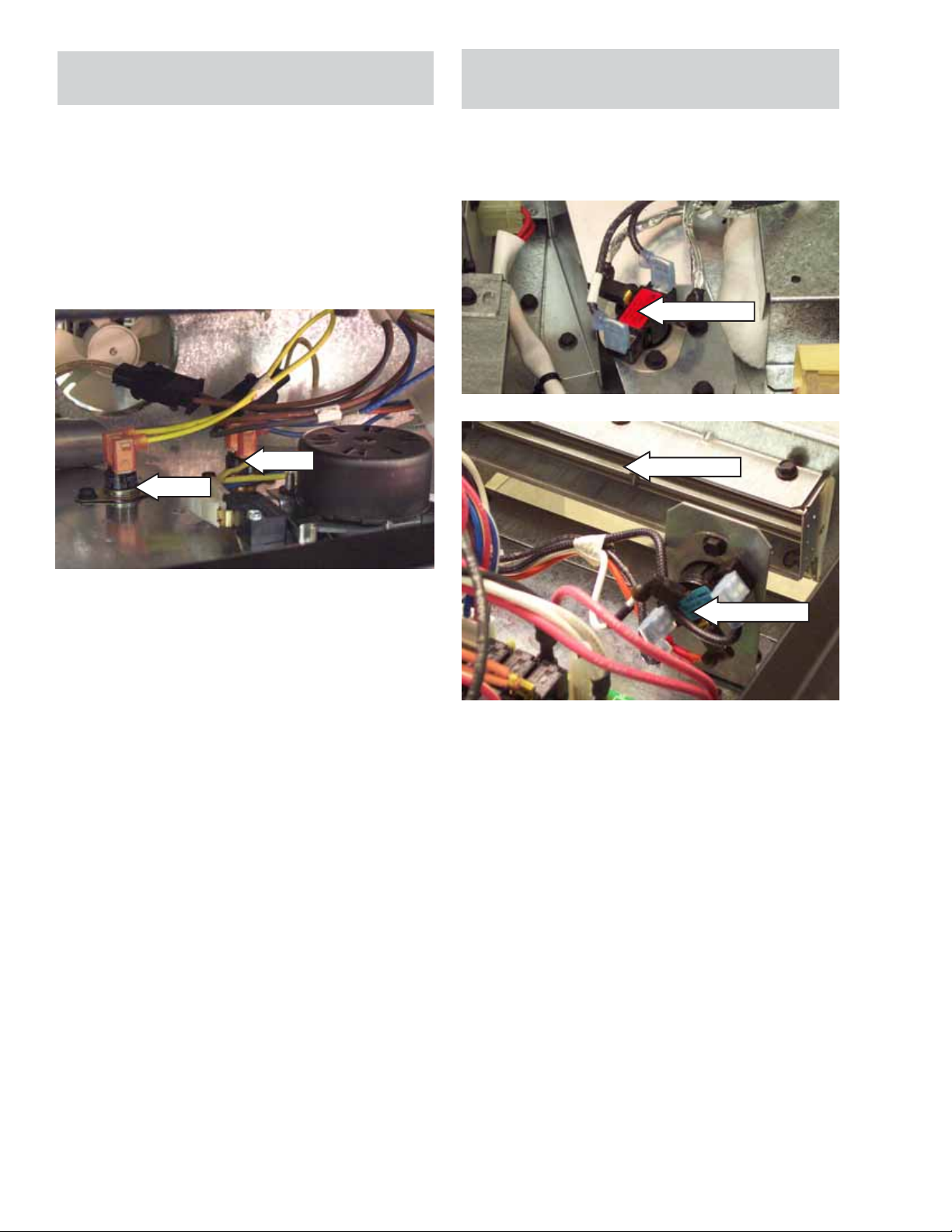

Oven T emperature Sensor (RTD)

Lower Cooling Fan (Double Wall Oven Only)

The RTD ( Resistive Thermal Device) has a

resistance of 1100 Ω at room temperature and

2650 Ω at clean temperature.

Sensor

Right Cooling Fan

The right cooling fan is located in the right rear

corner of the control compartment and has an

approximate resistance value of 19 Ω.

The lower cooling fan is located between the

upper and lower ovens, and has an approximate

resistance value of 68 Ω.

The fan can only be removed from the back of the

oven.

Right Fan

Rear View

Note: The right cooling fan and the lower cooling

fan of the Double Wall Oven are controlled by a

single relay .

Right Fan

– 20 –

Page 21

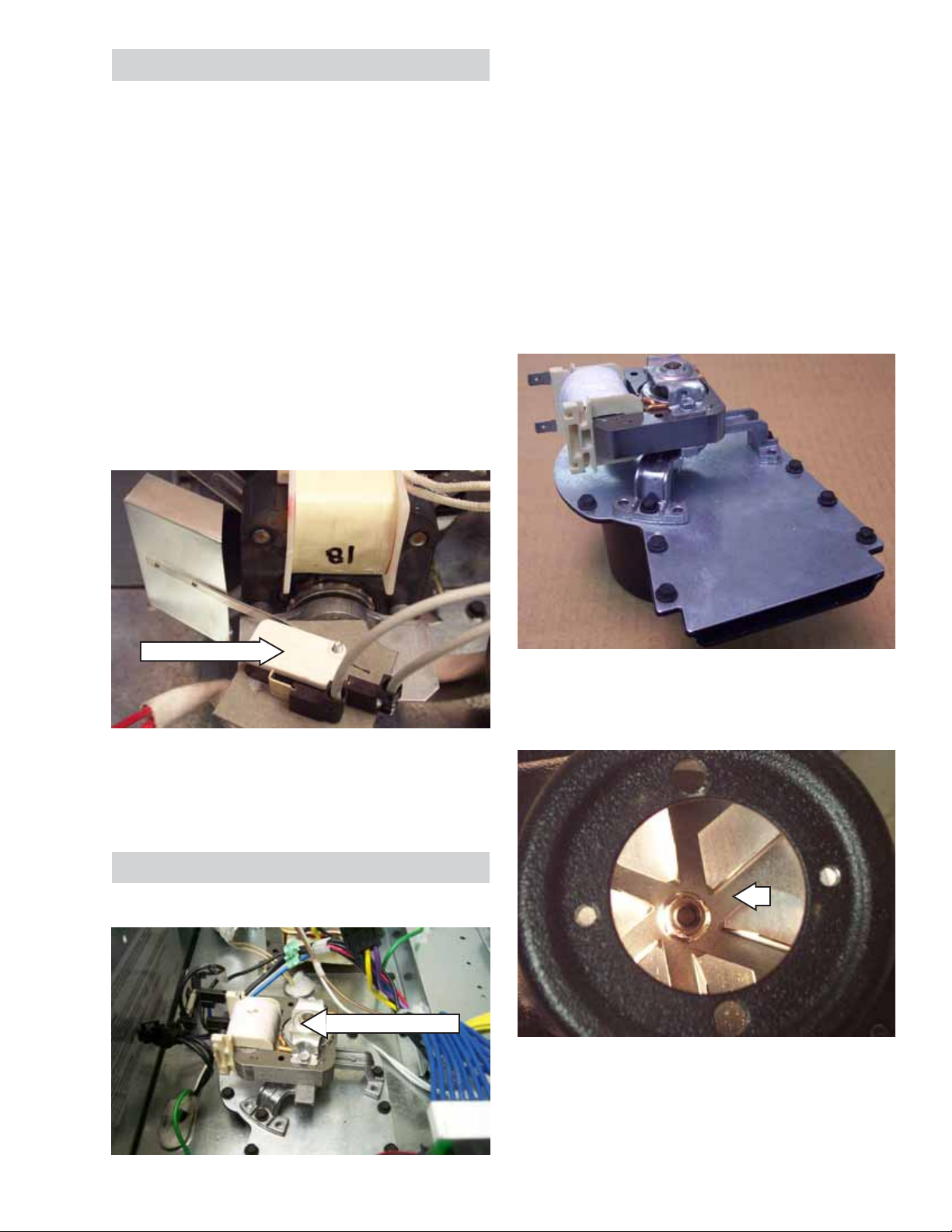

Sail Switches (Double and Single Wall Ovens)

• The left and right sail switches are normally

open limit switches located at the rear of the

component compartment in front of the

cooling fans.

• The sail switches monitor the presence of the

airstream from the fans. If either fan (HVT fan

or right cooling fan) malfunctions, the

applicable sail switch opens and opens relay

R1, which disables power to the microwave

HVT and oven cooking elements. In addition, if

the right cooling fan malfunctions on the

double oven, the right sail switch opens and

opens relay R2, which disables the lower

oven cooking elements.

• The relay coil resistance is approximately

920 Ω.

• It is normal for steam to come out of this vent

and the area around the vent to become hot

during oven use. It is important to keep the

vent unblocked to ensure proper air

circulation.

• The oven vent fan motor has an approximate

resistance value of 20 Ω and rotates

clockwise as viewed from the top.

• To remove the vent fan assembly, remove the

four 1/4-in. hex nuts from inside the oven

cavity.

Vent Fan

Left Sail Switch

• Both R1 relay and R2 relay (double oven only)

are double pole single throw relays. Both

contacts are used on R1, only one contact is

used on R2.

Oven V ent Fan

The oven is vented above the left side of the door .

Vent Fan Motor

Note: All vent fan p arts are available sep arately.

Vent Fan Blade

The vent fan blade nut has right-hand threads.

Turn nut counterclockwise to remove.

– 21 –

Page 22

Lower Oven Bake and Clean Thermal

TCO's (Double Wall Ovens)

Left and Right Thermal TCO's (Slide-In

Range)

The bake and clean FAD's (Fan Apparency

Device) TCO's are located between the upper

and lower ovens on the floor of the component

compartment in front of the fan motor. They are

monitored by the controls software.

Both lower oven clean and bake FAD's are

ignored by the control when the upper oven is in

self-clean.

Bake

Clean

The left and right F AD's (Fan App arency Device)

TCO’s are located at the rear of the component

compartment, in front of the respective cooling

fan.

Left FAD

Right Fan

Bake FAD

• Is wired in series with the lower door unlock

motor switch.

• Opens at 185°F and closes when cooled

below 158°F .

• The bake FAD can only be detected by the

control when in non self-clean operations

(unlock switch closed, lock switch open).

Higher Temperature (

Clean) FAD

• Is wired in series with the common of the lock/

unlock switch.

• Opens at 275°F and closes when cooled

below 205°F .

• The clean FAD is always detected by the

control.

If the thermal switch opens in any mode of

operation, the control will display F9 failure code.

When this condition exists, check for proper fan

operation (look for obstructions), and inspect oven

installation (make sure grille areas are not

blocked), oven insulation and lock/unlock circuit of

lower door lock.

Right FAD

• Both remove power from the controls when

open.

• Both are normally closed and wired in series

with the magnetron TCO, supplying L1 to the

main power board to power the controls.

• The left F AD opens at 185°F and closes when

cooled below 158°F. The right TCO opens at

194°F and closes when cooled below 167°F.

• If either FAD opens, check for proper fan

operation.

• Each FAD has an internal heater. N is

connected to one side of the heaters, and L2

is connected to the other side through the

convection DLB relay. The heaters are

powered when the DLB relay is energized.

The DLB relays are energized continuously in

in Service Mode and any cooking or clean

mode.

– 22 –

Page 23

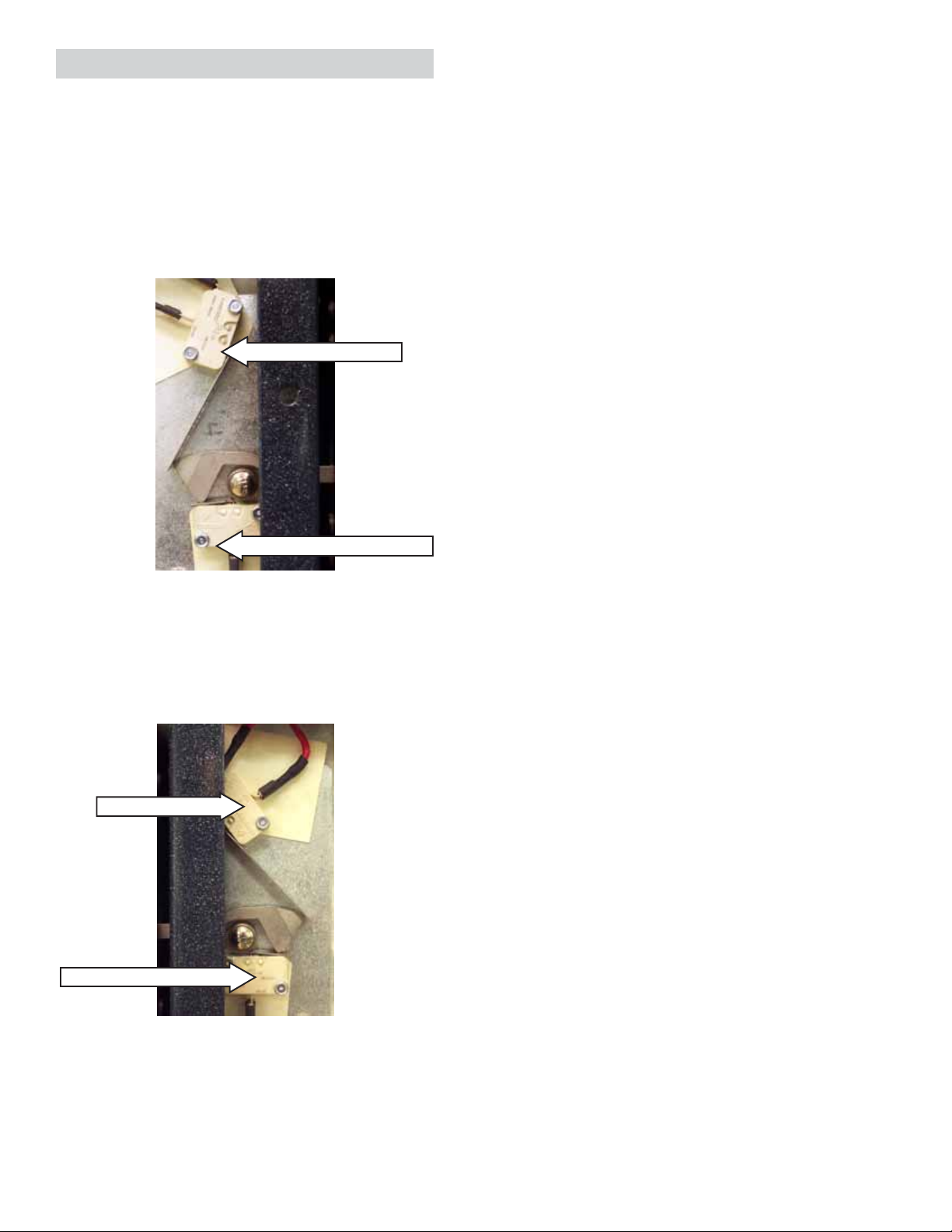

High Limit Thermal One-Shot TCO

Self-Clean Latch Motor

The high limit thermal one-shot TCO is located on

the rear of the oven behind the center cover and is

wired in series with L2 from the terminal block.

Slide-In Range

TCO

Convection Fan

EMI Board

To remove the self-clean latch motor assembly,

remove the two 1/4-in. hex head screws.

2

1

Motor

Hex Head Screws

1 - Unlock Switch

• Blue and yellow wires.

• Reads closed when the door is unlocked.

Single and Upper Double Wall Ovens

Convection Fan

TCO

• These thermal switches are a non-resettable

device and will open at 302°F, indicating a

thermal runaway condition.

2 - Lock Switch

• Orange and yellow wires

• Reads infinity when the door is unlocked.

• If tripped, the oven must be removed from

installation in order for the one-shot TCO to be

replaced.

• Cause of overheating should be determined

before replacing the TCO.

– 23 –

Page 24

Door Switches

Oven Door Sense Switch

Safety Interlocks

The microwave interlock system has a left and a

right interlock assembly.

Left Interlock Switch Assembly - Door sense

switch (NO) and secondary interlock switch (NO)

with two 2 position connectors with black and

brown wire outputs.

Left Side Door Switches

Door Sense Switch

Secondary Interlock Switch

The oven door sense switch is located in the left

interlock assembly on the Trivection

TM

oven.

Proper operation of the door sense switch is

required for proper operation of the microwave,

oven light, convection fan and the door lock.

To check the door sense switch:

1. Enter the service mode (see

Service Mode).

2. Select DOOR POSITION option and observe

the display as the door is opened and closed.

3. If the state (open/closed) does not change on

the display , turn of f power and check wiring

and switch with ohmmeter.

Interlock and Monitor Switches

Proper operation of the interlock switches and

monitor switch are required for proper operation of

the microwave system. When troubleshooting or

replacing interlock switch assembly, follow the

procedure outlined below to verify proper switch

operation.

Right Interlock Switch Assembly - Interlock

monitor switch (NC) and primary interlock switch

(NO) with one 4-position connector with red and

black wire outputs.

Right Side Door Switches

Monitor Switch

Primary Interlock Switch

Note: Replace entire left side door switch

assembly or right side door switch assembly. Do

not replace the individual switches. Switch

positions and interlock actuation distance are

controlled by assembly of switch-to-mounting

bracket. Do not replace or adjust individual

switches on door switch assembly.

To check the primary and secondary interlock

switches:

1. With power off, attach meter probes to the

leads of each switch.

2. Verify the following:

• Closed door circuit must have continuity.

• Opened door circuit must read open.

To check the monitor switch:

1. With power off, attach meter probes to the

leads of each switch.

2. Verify the following:

• Closed door circuit must read open.

• Opened door circuit must have continuity.

Important: Any defective or misadjusted

components in the interlock monitor , door seal,

microwave generation and transmission systems

shall be repaired, replaced, or adjusted by

procedures described in this manual before the

oven is released to the owner.

– 24 –

Page 25

Control Panel (Double and Single Wall Ovens)

Cooktop (Slide-In Range)

Removal and Replacement

1. Remove the three 1/4-in. hex head screws

securing the control panel to the vent trim.

Note: Screws are located under the control panel

and can be accessed by opening the oven door

and removing them from the bottom.

2. The panel has keyhole slots at the top and is

held very tight. Carefully push the panel up,

then pull out at the bottom.

Glass Touch Assembly (Slide-In Range)

Removal and Replacement

1. Disconnect power to the range.

2. Remove all surface unit knobs.

3. Unscrew the four plastic crystal retainers on

the infinite switches by turning counterclockwise.

Removing and Replacement

1. Remove the Glass Touch Assembly.

2. Remove the

Control Panel Insert.

3. Remove the control panel trim by removing

the five

front edge of the cooktop and the five

1

/4-in. hex head screws attached to the

1

/4-in.

hex head screws at the bottom attached to the

vent trim.

Note: The retainers should only be hand tightened

when reinstalling.

4. Lift the glass touch assembly 3 inches away

from the control panel and unplug the ribbon

cable from the assembly.

Note: The ribbon cable and connector are very

fragile. Take extra care when removing. When

reassembling, do not pinch the ribbon connector

between the glass and control trim.

Control Panel Insert (Slide-In Range)

Removal and Replacement

1. Remove the

2. Remove the four

securing the metal control panel insert to the

control panel trim.

3. Disconnect the two wiring harnesses by

unplugging the 9-pin and 15-pin connector

blocks.

Glass Touch Assembly.

1

/4-in. hex head screws

4. Remove the two

1

/4-in. hex head screws

securing the cooktop to the body side

extensions (1 screw per side).

5. Slide the cooktop assembly forward and lift

the cooktop off.

Note: Take extra care with the harness when

reinstalling the cooktop.

The 4 heating elements come in 3 sizes:

4. Disconnect the 4 connectors on the main

logic board (MLB).

Note: When reassembling, carefully position the

harness wires when reinserting the control panel

insert.

• Two 6-in. 240V, 1500W

• One 9-in. 240V, 2500W (dual unit 6-in. and 9in.)

• One 8-in. 240V, 2000W

– 25 –

Page 26

Microwave Components

PRECAUTIONS TO BE OBSERVED

BEFORE AND DURING SERVICING TO

AVOID POSSIBLE EXPOSURE TO

EXCESSIVE MICROWAVE ENERGY

A. Do not operate or allow the oven to be

operated with the door open.

B. If the oven operates with the door open,

instruct the user not to operate the oven and

contact the manufacturer immediately.

C. Make the following safety checks on all ovens

to be serviced before activating the magnetron

or other microwave source, and make repairs

as necessary:

D. Before turning on microwave power for any

test or inspecting within the microwave

generating compartments, check the

magnetron, wave guide or transmission line

and cavity for proper alignment, integrity and

connections.

E. Any defective or misadjusted components in

the interlock monitor, door seal and

microwave generation and transmission

systems shall be repaired, replaced or

adjusted by procedure described in this

manual before the oven is released to the

owner.

F. A microwave leakage check to verify

compliance with the federal performance

standard should be performed on each oven

prior to release to the owner.

WARNING: To prevent electrical shock, use

extreme caution when diagnosing oven with outer

covers removed and power on. The high voltage

circuit of the magnetron power area (HVT,

capacitor , diode, magnetron) is 4400V potential

with respect to ground. Wait at least 5 minutes

after disconnecting power before servicing the

magnetron power area.

TCO

Magnetron Fan

• The magnetron cooling fan motor has an

approximate resistance value of 68 Ω.

• The magnetron TCO is located on top of the

magnetron housing and is wired in series with

L1 to the main power board.

• Check for proper magnetron cooling fan

operation (blockage, blades not turning).

• When the temperature on the magnetron TCO

reaches 320°F, the magnetron TCO opens

and removes power to the controls. When

cooled below 140°F, it closes and restores

power to the controls.

• The magnetron fan, HVT fan, and magnetron

stirrer are controlled by a single relay on the

single and double wall ovens.

Left Cooling Fan (Slide-In Range)

The left cooling fan cools the HVT and magnetron

and is located in the left rear corner of the control

compartment. It has an approximate resistance

value of 13 Ω.

The left cooling fan and the magnetron stirrer are

controlled with a single relay .

Left Fan

Magnetron Cooling Fan and Thermal TCO

(Wall Ovens)

Note: The magnetron is covered under an

additional 4 year warranty. The customer is

responsible for any labor or in-home service

during this time.

– 26 –

Page 27

HVT Cooling Fan (Double and Single Wall

Ovens)

• Located in the left rear corner of the control

compartment.

• Has an approximate resistance value of

14.5 Ω.

Stirrer Motor

HVT Fan

High Voltage Transformer

Magnetron Capacitor and Diode

Caution: The capacitor holds its 4400V charge

for at least 2 minutes after power is removed.

Always be certain that the capacitor is discharged

before servicing. Mechanically discharge by

placing an insulated handle screwdriver between

the diode connection of the capacitor and oven

chassis ground.

The magnetron capacitor and diode are located in

the left rear corner of the control compartment

next to the high voltage transformer .

High Voltage Transformer

Microwave Fuse

The microwave fuse is located in the front corner

of the control compartment next to the vent fan.

Vent Fan

Microwave Fuse

When replacing the microwave fuse, use only the

20 amp fuse, WB08T10027.

If the door interlock switches fail (monitor switch

fails to open when door is closed, or the right

primary interlock switch fails to open when door is

opened), the fuse will open due to having 240V/

208V across it. The fuse may open if there is

arcing across the switches or they open/close too

slowly . The fuse may also open due to a voltage

or current spike during normal operation.

Capacitor

Diode

Stirrer Motor

The stirrer motor drives the antenna assembly

and is located in the center of the control

compartment.

The stirrer motor has an approximate resistance

value of 3.4K Ω. The motor rotation direction is

random at each start.

– 27 –

Page 28

Control Boards Connector Locator

WARNING: Components are electrically HOT when voltage is connected to oven.

Main Logic Board

When installing a new main logic board, the type of oven (Profile, Monogram or Kenmore) needs to be

entered once power is reconnected. Follow the instructions on the display.

If the oven control type needs to be re-entered, enter special modes screen by pressing 0803 within 5

minutes of reconnecting power.

1. Press Factory1 to enter the factory mode.

2. Press CHANGE to choose a different oven type.

3. Press ACCEPT to confirm.

4. Press EXIT.

J7

J9

J4

J3

J9 - DC power output and serial data bus to/from Glass Touch Signal Board J2

J7 - Input from Switches and Sensors

J4 - (Single Wall Oven) - No connection

J5

J2

(Double Wall Oven) - DC power output and relay control outputs to Lower Oven Relay Board J9

(Slide-In Oven) - 5 VDC power output and 4 surface unit status signals inputs to J4 Main

Logic Board

J3 - Relay control outputs to Main Power Board J1

J5 - DC power input and line monitor signals from Main Power Board J3

J2 - DC power output and data output to Text Display Board J1

– 28 –

Page 29

Main Power Board

J102

K11

J117

J114

J113

J112

J101

J4

J103

K103

COM

NO

K102

NO

COM

COM

K7

J108

K8

NC

NO

COM

NO

J111 J107

J1 - Relay control inputs from Main Logic Board J3

J3 - DC power output and line monitor signals to

K11 - L2 Double Line Break Relay for upper oven

Main Logic Board J5

broil, bake, and bake 2 elements

NO

K10

COM

J105

J109

J3

J1

Note: Although the board is

marked SWO, it is used in

all ovens.

K7 - Broil ON/OFF

Relay

K8 - Bake ON/OFF Relay

J4 - Output to 120 VAC loads (lamps/motors/fans)

K102 - L2 Double Line Break Relay for convection element

K10 - Convection Element ON/OFF Relay

K103 - Bake 2 ON/OFF Relay

Current Limit Board (Slide-In Range Only)

J2 - L2 and power signals from surface unit

elements

J1 - 5 VDC power input and 4 surface unit

status signals output to J4 Main Logic

Board

The current limit board receives power signals from

the infinite switches and converts them to logic

signals so the main logic board can detect on/off

status.

J2

J1

– 29 –

Page 30

Lower Oven Relay Board (Double Wall Oven

Only)

K121 - Double Line Break (DLB) Relay (Broil/Bake/

Convection)

NO

J9

K20

K121

COM

K20 - Convection Element ON/OFF Relay

K17 - Bake Element ON/OFF Relay

K14 - Broil Element ON/OFF Relay

J9 - DC power input and relay control inputs

from Main Logic Board J4

J11 - Latch motor, oven lamps and convection

fan outputs

J123

COM

J121

J11

K17

K14

COM

NO

COM

NO

NC

NO

NC

Glass Touch Signal Board

J1 - Input and output signals from/to Glass

Touch Board J1

J2 - DC power input and serial data bus to/

from Main Logic Board J9

1 - LED Status Light

The glass touch signal board provides a serial

communication interface between the glass touch

board and the main logic board.

The glass touch signal board has an LED status

light which should light anytime a pad is touched

on the glass touch assembly.

– 30 –

J2

1

J1

Page 31

Control Panel and Board Layout

1

2

1 - Time/Temperature Display Board

2 - Glass Touch Signal Board

3 - Glass Touch Board

4 -Main Logic Board

5 -Text Display Board

Glass Touch Board

J1

3

4

5

J1 - Output and input signals from/to Glass Touch Signal Board J1

Text and Time/Temperature Display Boards

1

1 - DC power and serial data from Text Display Board to Time/Temperature Display Board (hard

wired to T ime/Temperature Display Board)

2 - DC power input and data Input from Main Logic Board J2 (hard wired to Text Display Board)

2

– 31 –

Page 32

POWER MONITOR ERROR CODES

During Power-Up (occurs only during power-up)

Normal Power– L1-L2 L1-N

No message >150VAC >90VAC AND <150VAC

SUPPLY OPEN L1-L2 L1-N

NEUTRAL NA <90VAC

SUPPLY L1-L2 L1-N

MISWIRED <90VAC >90VAC AND <150VAC

L1-L2 L1-N

NA >150VAC

SENSE 120V L1-L2 L1-N

ENTERING >90VAC and <150VAC >90VAC AND <150VAC

SALES MODE

After Power-Up (can occur anytime during operation)

Normal Power– L1-L2 L1-N

No message NA >90VAC AND <150VAC

SUPPLY OPEN L1-L2 L1-N

NEUTRAL NA <90VAC

SUPPLY L1-L2 L1-N

MISWIRED NA >150VAC

LOW POWER L1-L2 L1-N

<150VAC NA

Note: Low Power supersedes Supply Open Neutral

Diagnostics and Service Information

WARNING: To prevent electrical shock, use

extreme caution when diagnosing oven with

outer covers removed and power on. The

high voltage circuit of the magnetron power

area (HVT, capacitor, diode, magnetron) is

4400V potential with respect to ground. Wait

at least 5 minutes after disconnecting

power before servicing the magnetron

power area.

WARNING: Heat sinks on main power

board are electrically live. Take special

precautions when troubleshooting the main

power board with power on. If the main

power board has failed, the board capacitor

can hold a voltage charge on the heat sinks.

Wait at least 5 minutes after disconnecting

power before servicing the main power

board.

– 32 –

Page 33

Basics of Element Cycling

q

q

q

q

q

TrivectionTM Oven

Lower Oven

Bake

Broil

Convection Bake Multi

Convection Bake 1-Rack

Convection Roast

Self-Clean

bake & broil as required

broil as re

convection as re

bake & broil as re

bake & broil as re

bake & broil as re

uired

uired

uired

uired

uired

Double Wall Oven - Left cooling fan turns OFF after 5 minutes if the current oven operation does not

require it ON. The vent fan turns OFF after a minimum of 7 minutes and the sensor temperature <200°F

for 2 minutes. The right & lower oven cooling fans turn OFF after a minimum of 7 minutes and the

sensor temperature <200°F for 2 minutes or after about 20 to 85 minutes, whichever comes first (time

varies depending on which oven was used last).

Single Wall Oven - Left cooling fan turns OFF af ter 5 minutes if the current oven operation does not

require it ON. The vent fan turns OFF after a minimum of 7 minutes and the sensor temperature <200°F

for 2 minutes. The right cooling fan turns OFF after a minimum of 7 minutes and the sensor

temperature <200°F for 2 minutes or after about 20 minutes, whichever comes first.

option to use in

Preheat

NO NA ----- ON

YES NA ----- ON

YES NA ----- ON

YES NA ----- ON

NO NA ----- ON

NA ----- ON

Slide-In Range - The vent fan turns OFF after 22 minutes and the sensor temperature <200°F for 2

minutes. Both cooling fans turn OFF after about 20 minutes.

Note: For the Trivection

TM

oven bake, broil or convection elements or the microwave to operate, BOTH

THE LEFT AND RIGHT COOLING FANS MUST BE ON and engage the sail switches.

Note: For the lower oven bake, broil or convection elements to operate, THE RIGHT COOLING FAN

MUST BE ON and engage the right sail switch.

– 33 –

Page 34

Service Mode

The service mode allows the service technician to

make adjustments and run several important

tests on critical oven components.

MAG TAP - Forces the control to use either the

208 or 240 volt tap on the high voltage

transformer. DO NOT use this service feature at

this time. Allow the control to select the

transformer voltage.

To enter the service mode:

1. Disconnect main power to the oven for at

least 15 seconds.

2. Reconnect power and enter 0803 on the

keypanel within 5 minutes after the control

initializes. The SPECIAL MODES screen is

displayed.

3. Press the SERVICE pad on the SPECIAL

MODES screen. The SERVICE MODE

screen is displayed.

4. Press the NEXT and BACK pads to scroll

through the test list. Choose a test by

pressing the appropriate pad.

Service Mode Tests

COOKING LOADS - Verifies proper operation of

cooking elements and convection fan. (See

Troubleshooting Cooking Loads in Service

Mode to perform tests.)

Note: There is a 5 second delay in the electronic

control activating cooking loads in service mode.

DOOR LA TCH - Verifies proper operation of door

lock motor and switches. Press the LOCK pad: a

red lock icon in the display flashes during

transition from unlock to lock, then becomes solid

on when the door is locked. Press the UNLOCK

pad: the red lock icon flashes during transition

from lock to unlock, then turns off when the door

is unlocked.

DOOR POSITION - Verifies proper operation of

door sense switch. Open and close the oven

door: the Time/Temperature display indicates the

door is open or closed.

RTD - Displays oven sensor temperature in red

on Time/Temperature display of the control panel.

VENT F AN - V erifies proper operation of the

ventilation fan. Press the ON and OFF pads to

cycle the fan. The T ime/Temperature display

indicates the fan is ON or OFF.

R COOLING FAN - V erifies proper operation of the

right cooling fan. Press the ON and OFF pads to

cycle the fan. The T ime/Temperature display

indicates the fan is ON or OFF.

L COOLING F ANS - V erifies proper operation of

the mag cooling fan, HVT fan and mag stirrer fan

(Wall Ovens) or the Left Cooling fan (Slide-in

range). Press the ON and OFF pads to cycle the

fan. The T ime/Temperature display indicates the

fan is ON or OFF.

OVEN LIGHT - V erifies proper operation of oven

light. Press the pads ON and OFF to cycle the

light. The T ime/Temperature display indicates the

light is ON or OFF.

OFFSET - To adjust the oven calibration offset in

bake mode. Press the INCREASE or DECREASE

pads to change the cooking temperature in 1°

increments up to ±35°F. Press the CONFIRM pad

to set.

DISPLA Y - Verifies operation of display segments.

Press the ON and OFF pads to cycle the display

test. Press the CLEAR/OFF key to return display

to normal.

KEYS - Verifies proper operation of keyp anel.

Press the number pads on the keypanel to test.

Each number appears in the Time/Temperature

display as the corresponding pad is pressed.

LINE VOL T AGE - Displays line volt age L1-L2 in

the upper temperature display .

F CODES - Displays up to last 7 ERC failure

codes. Note: Always check failure codes, then

clear them.

COOKTOP STAT (Slide-in range) - Indicates the

ON/OFF status of the radiant surface elements.

The ON indication will occur when the respective

infinite switch hot light is lit.

CO SENSOR (Kenmore models only) - Turns the

CO sensor and heater on and off.

Press the EXIT pad to return to the home screen.

– 34 –

Page 35

Troubleshooting Cooking Loads in Service Mode

g

Cooking loads (bake, broil, convection elements and convection fan) can be energized individually

:

through the service mode (press the key next to COOKING LOADS, then appropriate load).

Note: There is a 5-second delay in the electronic control activating cooking loads in service mode.

When the appropriate load is turned on in the service mode, first verify that the element is heating or the

fan is turning. If load is not energized, check AC relay volt ages according to the second column in the

following tables:

Note: Oven must be in the service mode for proper reading. DC voltages are read between the

reference pin in the table and ground. See note below table.

RELAY CONTROL TABLE - SINGLE WALL OVEN

SERVICE MODE

Function

Right Cooling Fan

R CoolingFan -> On/Off

Left Cooling Fans

Mag Stirrer

Mag Fan

HVT Fan

L CoolingFans -> On/Off

Oven Light

Ovenlight -> On/Off

Microwave

CookingLoads -> MW

Vent Fan

VentFan -> On/Off

Convection Element

CookingLoads -> ConvElem

Convection Fan

Clockwise

CookingLoads

-> ConvFan -> CW

Convection Fan

Counter Clockwise

CookingLoads

-> ConvFan -> CCW

Broil Element

CookingLoads -> Broil

Bake Element

CookingLoads -> Bake

Bake2 Element

CookingLoads -> Bake2

Door Latch

DoorLatch -> Lock/Unlock

AC VOLTAGES

Main Pwr Board Relay

ON=120VAC (L1-N or L2-N)

or 240VAC (L1-L2)

OFF=0V

L2 = J4-8 (K1-NO)

N = J103

L2 = J4-7 (K5-NO)

N = J103

L1 = J4-5 (K13-NO)

N = J103

HVT T2 = L2 = J107 (K9-NO)

HVT T3 = L2 = J105 (K9-NC)

OR

HVT T1 = L1 = J114

L2 = J4-9 (K106-NO)

N = J103

L1 = K10-NO

L2 = K102-NO (DLB)

L1 = J4-2 (K105-NC)

N = J103

L1 = J4-3 (K105-NO)

N = J103

L1 = K7-NO

L2 = K11-COM (DLB)

L1 = K8-NO

L2 = K11-COM (DLB)

L1 = J113 (K103-NO)

L2 = K11-COM (DLB)

L1 = J4-1 (K2-COM)

N = J103

Relay Control

ON = 0Vdc

OFF = 12Vdc

MPB J1-10

MLB J3-10

MPB J1-9

MLB J3-9

MPB J1-4

MLB J3-4

MPB J1-3

MLB J3-3

MPB J1-16 OFF

MLB J3-16 OFF

MPB J1-16

MLB J3-16

MPB J1-18

MLB J3-18

MPB J1-14

MLB J3-14

DC VOLTAGES

Relay Control

ON = 4.6Vdc

OFF = -14Vdc *

MPB J1-17

MLB J3-17

OR

MPB J1-17 OFF

MLB J3-17 OFF

MPB J1-8

MLB J3-8

MPB J1-12

MLB J3-12

MPB J1-6

MLB J3-6

MPB J1-11

MLB J3-11

MPB J1-7

MLB J3-7

MPB J1-11

MLB J3-11

MPB J1-11

MLB J3-11

Enable = 4.2Vdc

Disable = -14.0Vdc

MPB J1-1

MLB J3-1

MPB J1-1

MLB J3-1

MPB J1-1

MLB J3-1

MPB J1-1

MLB J3-1

MPB J1-1

MLB J3-1

Notes

Fan comes on when entering the

cooking loads menu.

Fan comes on when entering the

cooking loads menu.

K6 (Mag Main Relay) must be energized

MPB J1-5 ON (4.6Vdc)

MLB J3-5 ON (4.6Vdc)

Note: MagTap is automatically selected

by Line Voltage

Fan comes on when entering the

cooking loads menu.

K4 (Convection Fan Relay) must be

K4 (Convection Fan Relay) must be

energized

MPB J1-15 ON (0Vdc)

MLB J3-15 ON (0Vdc)

energized

MPB J1-15 ON (0Vdc)

MLB J3-15 ON (0Vdc)

Broil element must be turned off

Broil element must be turned off

Note: Ground reference for dc volta

is J3-2 or J3-4 on MPB or J5-2 or J5-4 on MLB MLB = Main Logic Board

e measurements

MPB = Main Power Board * OFF = 0Vdc if Disable = -14Vdc

– 35 –

Page 36

g

g

RELAY CONTROL TABLE - SLIDE IN RANGE

SERVICE MODE

Function

Right Cooling Fan

R CoolingFan -> On/Off

Left Cooling Fans

Mag Stirrer

Left Cooling Fan

L CoolingFans -> On/Off

Oven Light

Ovenlight -> On/Off

Microwave

CookingLoads -> MW

Vent Fan

VentFan -> On/Off

Convection Element

CookingLoads -> ConvElem

Convection Fan

Clockwise

CookingLoads

-> ConvFan -> CW

Convection Fan

Counter Clockwise

CookingLoads

-> ConvFan -> CCW

Broil Element

CookingLoads -> Broil

Bake Element

CookingLoads -> Bake

Bake2 Element

CookingLoads -> Bake2

Oven Door Latch

DoorLatch -> Lock/Unlock

AC VOLTAGES

Main Pwr Board Relay

ON=120VAC (L1-N or L2-N)

or 240VAC (L1-L2)

OFF=0V

L2 = J4-8 (K1-NO)

N = J103

L2 = J4-7 (K5-NO)

N = J103

L1 = J4-5 (K13-NO)

N = J103

HVT T2 = L2 = J107 (K9-NO)

HVT T3 = L2 = J105 (K9-NC)

OR

HVT T1 = L1 = J114

L2 = J4-9 (K106-NO)

N = J103

L1 = K10-NO

L2 = K102-NO (DLB)

L1 = J4-2 (K105-NC)

N = J103

L1 = J4-3 (K105-NO)

N = J103

L1 = K7-NO

L2 = K11-COM (DLB)

L1 = K8-NO

L2 = K11-COM (DLB)

L1 = J113 (K103-NO)

L2 = K11-COM (DLB)

L1 = J4-1 (K2-COM)

N = J103

Relay Control

ON = 0Vdc

OFF = 12Vdc

MPB J1-10

MLB J3-10

MPB J1-9

MLB J3-9

MPB J1-4

MLB J3-4

MPB J1-3

MLB J3-3

MPB J1-16 OFF

MLB J3-16 OFF

MPB J1-16

MLB J3-16

MPB J1-18

MLB J3-18

MPB J1-14

MLB J3-14

DC VOLTAGES

Relay Control

ON = 4.6Vdc

OFF = -14Vdc *

MPB J1-17

MLB J3-17

OR

MPB J1-17 OFF

MLB J3-17 OFF

MPB J1-8

MLB J3-8

MPB J1-12

MLB J3-12

MPB J1-6

MLB J3-6

MPB J1-11

MLB J3-11

MPB J1-7

MLB J3-7

MPB J1-11

MLB J3-11

MPB J1-11

MLB J3-11

Enable = 4.2Vdc

Disable = -14.0Vdc

MPB J1-1

MLB J3-1

MPB J1-1

MLB J3-1

MPB J1-1

MLB J3-1

MPB J1-1

MLB J3-1

MPB J1-1

MLB J3-1

Notes

Fan comes on when entering the

cooking loads menu.

Fan comes on when entering the

cooking loads menu.

K6 (Mag Main Relay) must be energized

MPB J1-5 ON (4.6Vdc)

MLB J3-5 ON (4.6Vdc)

Note: MagTap is automatically selected

by Line Voltage

Fan comes on when entering the

cooking loads menu.

K4 (Convection Fan Relay) must be

K4 (Convection Fan Relay) must be

energized

MPB J1115 ON (0Vdc)

MLB J3-15 ON (0Vdc)

energized

MPB J1-15 ON (0Vdc)

MLB J3-15 ON (0Vdc)

Broil element must be turned off

Broil element must be turned off

Note: Ground reference for dc volta

is J3-2 or J3-4 on MPB or J5-2 or J5-4 on MLB MLB = Main Lo

e measurements

MPB = Main Power Board * OFF = 0Vdc if Disable = -14Vdc

ic Board

– 36 –

Page 37

g

RELAY CONTROL TABLE - DOUBLE WALL OVEN

AC VOLTAGES

SERVICE MODE

Function

Right Cooling Fans

Right Cooling Fan Upr

Cooling Fan Lwr

R CoolingFans -> On/Off

Left Cooling Fans

Mag Stirrer

Mag Fan

HVT Fan

L CoolingFans -> On/Off

Oven Lights Upper

Ovenlight -> up-arrow -> On/Off

Microwave

CookingLoads -> up arrow

-> MW

DWO Board Relay

ON=120VAC (L1-N or L2-N)

or 240VAC (L1-L2)

OFF=0V

L2 = J4-8 (K1-NO)

N = J103

L2 = J4-7 (K5-NO)

N = J103

L1 = J4-5 (K13-NO)

N = J103

HVT T2 = L2 = J107 (K9-NO)

OR

HVT T3 = L2 = J105 (K9-NC)

Relay Control

ON = 0Vdc

OFF = 12Vdc

MPB J1-10

MLB J3-10

MPB J1-9

MLB J3-9

MPB J1-4

MLB J3-4

Main Pwr Board /

HVT T1 = L1 = J114

Vent Fan

VentFan -> On/Off

Convection Element

Upper

CookingLoads -> up arrow

-> ConvElem

Convection Fan

Upper Clockwise

CookingLoads -> up arrow

-> ConvFan -> CW

Convection Fan

Upper Counter

Clockwise

CookingLoads -> up arrow

-> ConvFan -> CCW

Broil Element Upper

CookingLoads -> up arrow

-> Broil

Bake Element Upper

CookingLoads -> up arrow

-> Bake

Bake2 Element Upper

CookingLoads -> up arrow

-> Bake2

Door Latch Upper

DoorLatch -> up-arrow

-> Lock/Unlock

Broil Element Lower

CookingLoads

-> down arrow -> Broil

Bake Lower

CookingLoads

-> down arrow -> Bake

Convection Element

Lower

CookingLoads

-> down arrow -> ConvElem

Oven Light Lower

Ovenlight -> down arrow

-> On/Off

Door Latch Lower

DoorLatch -> down arrow

-> Lock/Unlock

Convection Fan

Lower Clockwise

CookingLoads

-> down arrow

-> ConvFan -> CW

Convection Fan

Lower Counter

Clockwise

CookingLoads

-> down arrow

-> ConvFan -> CCW

Note: Ground reference for dc volta

is J3-2 or J3-4 on MPB or J5-2 or J5-4 on MLB MLB = Main Logic Board ** Lower oven cooling fan may take up to 90 min. to turn off.

L2 = J4-9 (K106-NO)

N = J103

L1 = K10-NO

L2 = K102-NO (DLB)

L1 = J4-2 (K105-NC)

N = J103

L1 = J4-3 (K105-NO)

N = J103

L1 = K7-NO

L2 = K11-COM (DLB)

L1 = K8-NO

L2 = K11-COM (DLB)

L1 = J113 (K103-NO)

L2 = K11-COM (DLB)

L1 = J4-1 (K2-COM)

N = J103

L1 = K14-NO

L2 = K121-COM (DLB)

L1 = K17-NO

L2 = K121-COM (DLB)

L1 = K20-NO

L2 = K121-COM (DLB)

N = J11-1 (K16-NO)

OR

Plunger Switch - NO

L1 = J114

N = J11-3 (K15-COM)

AND

Plunger Switch - NC

L1 = J114

L1 = J11-4 (K122-NC)

N = J103

L1 = J11-5 (K122-NO)

N = J103

e measurements

MPB J1-3

MLB J3-3

MPB J1-16 OFF

MLB J3-16 OFF

MPB J1-16

MLB J3-16

MPB J1-18

MLB J3-18

MPB J1-14

MLB J3-14

MPB J9-10

MLB J4-10

MPB J9-13

MLB J4-13

MPB J9-12

MLB J4-12

MPB J9-12

MLB J4-12

MPB = Main Power Board * OFF = 0Vdc if Disable = -14Vdc

LRB = Lower Oven Relay Board

DC VOLTAGES

Relay Control

ON = 4.6Vdc

OFF = -14.0Vdc *

MPB J1-17

MLB J3-17

OR

MPB J1-17 OFF

MLB J3-17 OFF

MPB J1-8

MLB J3-8

MPB J1-12

MLB J3-12

MPB J1-6

MLB J3-6

MPB J1-11

MLB J3-11

MPB J1-7

MLB J3-7

MPB J1-11

MLB J3-11

MPB J1-11

MLB J3-11

LRB J9-4

MLB J4-4

LRB J9-7

MLB J4-7

LRB J9-5

MLB J4-5

LRB J9-7

MLB J4-7

LRB J9-6

MLB J4-6

LRB J9-7

MLB J4-7

Enable = 4.2Vdc

Disable = -14.0Vdc

MPB J1-1

MLB J3-1

MPB J1-1

MLB J3-1

MPB J1-1

MLB J3-1

MPB J1-1

MLB J3-1

MPB J1-1

MLB J3-1

LRB J9-2

MLB J4-2

LRB J9-2

MLB J4-2

LRB J9-2

MLB J4-2

Fan comes on when entering the

cooking loads menu.

Fan comes on when entering the

cooking loads menu.

K6 (Mag Main Relay) must be energized

MPB J1-5 ON (4.6Vdc)

MLB J3-5 ON (4.6Vdc)

Note: MagTap is automatically selected

by Line Voltage

Fan comes on when entering the

cooking loads menu.

K4 (Convection Fan Relay) must be

energized

MPB J1-15 ON (0Vdc)

MLB J3-15 ON (0Vdc)

K4 (Convection Fan Relay) must be

energized

MPB J1=15 ON (0Vdc)

MLB J3-15 ON (0Vdc)

Broil upper must be turned off

Broil upper must be turned off

Broil Lower must be turned off

Broil Lower and Bake Lower must be

turned off

Door Latch Motor Disabled by Plunger

Switch when Door is Open

ConvFan Disabled by Plunger Switch

when Door is Open

K18 (Conv Fan Low Relay) must be

energized

LRB J9-11 ON (0Vdc)

MLB J4-11 ON (0Vdc)

ConvFan Disabled by Plunger Switch

when Door is Open

K18 (Conv Fan Low Relay) must be

energized

LRB J9=11 ON (0Vdc)

MLB J4-11 ON (0Vdc)

Notes

– 37 –

Page 38

To turn off all loads that are energized in COOKING LOADS, press the CLEAR/OFF key or exit the

COOKING LOADS menu.

• If load is not turned off, additional loads can be turned on at the same time.

• If AC volt age measures OK, then check the load (element, fan, lock motor, HVT, etc.) and/or wiring to

the load and repair/replace as required.

• If there is no AC voltage supplied to the load through the power relays per the wiring schematic, then

check the DC power supply voltages from the main power board (MPB-J3 connector) to the main

logic board (MLB-J5 connector) according to the following table:

CONTROLS DC POWER SUPPLY VOLTAGE TABLE

MPB MLB Signal Name Min Max

J3-1 J5-1 +12Vdc 11.00Vdc 12.75Vdc

J3-2 J5-2 12Vdc, 5Vdc Ground — —

J3-3 J5-3 +5Vdc 4.7Vdc 5.3Vdc

J3-4 J5-4 12Vdc, 5Vdc Ground — —

J3-5 J5-5 -14Vdc -14.75Vdc -12.75Vdc

J3-6 J5-6 Not Connected —

J3-7 J5-7 L1 thru 2M ohm/.47 uF cap on MPB

J3-8 J5-8 L1 thru 2M ohm/.47 uF cap on MPB

J3-9 J5-9 Not Connected —

J3-10 J5-10 NT thru 2M ohm/.47 uF cap on MPB

J3-11 J5-11 Not Connected —

J3-12 J5-12 L2 thru 2M ohm/.47 uF cap on MPB

240VAC line monitor

120VAC line monitor

120VAC line monitor

240VAC line monitor

• If voltages do not measure according to the table above, replace Main Power Board.

• If voltages measure OK, then measure DC voltages according to the previous relay control table

(relay control signals columns 3, 4 and 5).

• If the MLB J3 pins do not provide the correct DC voltages, then replace the main logic board.

• If display is blank, the oven light does not operate when the oven door is opened, and the keypanel

does not respond, first check DC power supply voltages. Next, check DC voltages at MLB J2: J2-2,

J2-4, J2-6, J2-8. They should be +12VDC. If not, replace text display and/or time/temp display .

• If DC power supply voltages are OK, the display is blank, and the keyboard is not responding,

replace MLB. If just the display is blank, replace the display . If only the keyboard is not responding,

check glass touch display . If OK, replace MLB.

• If oven light does not turn on when door is opened, check oven light relay per relay troubleshooting

table. If relay voltages are OK, check door sense switch (see

Door Switches).

– 38 –

Page 39

Microwave Leakage Test

1. Place 275 mL of water in a 600-mL beaker.

2. Place beaker in center of oven shelf.

3. Set meter to 2450-Hz scale.

Microwave Scan Pattern (Scan Highlighted