Page 1

nstructlons Electric Slide-In Range JS998

!Insta"ationlse'ceann°"a°antveOon+MI

I r-?-i Questions? Call 800.GE.CARES (800.432.2737) or Visit our Website at: www.GEAppliances.com I

BEFORE YOU BEGIN

Read these instructions completely

and carefully.

• IMPORTANT - Savethese

instructions for local inspector's use.

• IMPORTANT - Observeall

governing codes and ordinances.

• Note to Installer - Be sure to leave these

instructions with the Consumer.

• Note to Consumer - Keep these

instructions for future reference.

• Skill level - Installation of this appliance

requires basic mechanical and advanced

electrical skills.

• Completion time - 1 to 3 hours

• Proper installation is the responsibility of

the installer.

• Product failure due to improper installation

is not covered under the Warranty.

_WARNING - This appliance must

be properly grounded.

FOR YOUR SAFETY:

-&WARNING - Forpersonal safety,

do not use an extension cord with this

appliance. Remove house fuse or open circuit

breaker before beginning installation. Failure

to do so could result in serious injury or

even death.

• All rough-in and spacing dimensions

must be met for safe use of your range.

Electricity to the range can be disconnected

at the outlet without moving the range if

the outlet is in the preferred location

(remove lower drawer).

FOR YOUR SAFETY: (cont.)

• To reduce the risk of burns or fire when

reaching over hot surface elements, cabinet

storage space above the cooktop should be

avoided. If cabinet storage space is to be

provided above the cooktop, the risk can

be reduced by installing a range hood that

protrudes at least 5" beyond the front of

the cabinets. Cabinets installed above a

cooktop must be no deeper than 13;'

• Be sure your appliance is properly installed

and grounded by a qualified technician.

• To prevent damage to the door and to

prevent excessive microwave leakage,

do NOT remove the door on the oven.

ANTI-TIP DEVICE

Z_WARNING - Toreducetherisk

of tipping, the appliance must be secured by

properly installed Anti-Tip bracket packed

with this appliance.

• If the Anti-Tip device supplied with the

range does not fit this application, use the

universal Anti-Tip device WB2X7909.

-&WARNING -

• All ranges can tip

• Injury to persons could result

• Install Anti-Tip bracket packed

with range

• See Installation Instructions

• If you pull the range out and away from the

wall for any reason, make sure the Anti-Tip

bracket is engaged when the range is

pushed back against the wall.

229c4053P547-4

31-10558-4 05-04 JR

Page 2

Installation Instructions

PREPARE TO INSTALL THE RANGE

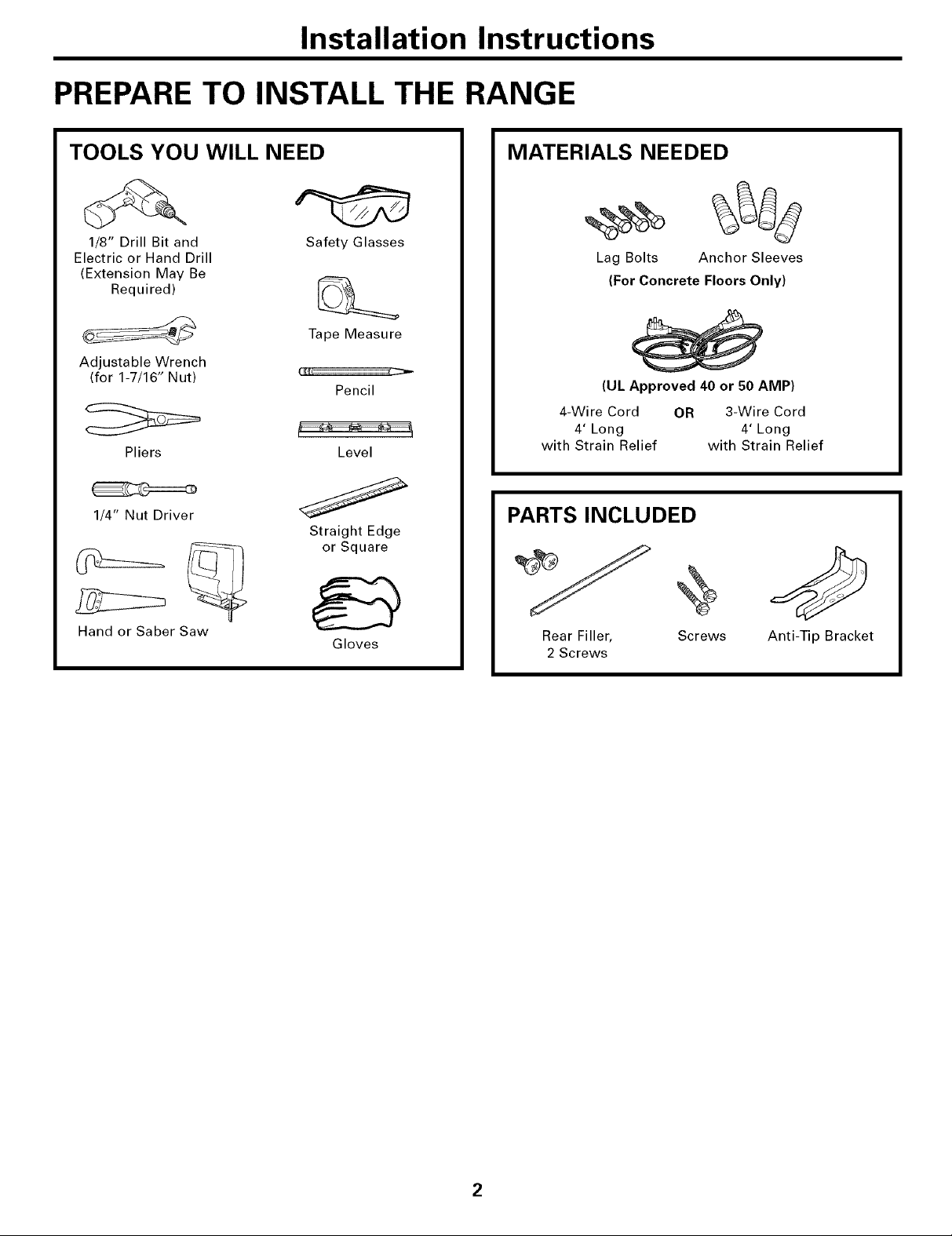

TOOLS YOU WILL NEED

1/8" Drill Bit and

Electric or Hand Drill

(Extension May Be

Required)

Adjustable Wrench

(for 1-7/16" Nut)

Pliers

1/4" Nut Driver

Safety Glasses

S

Tape Measure

Pencil

Level

Straight Edge

or Square

MATERIALS NEEDED

Lag Bolts Anchor Sleeves

(For Concrete Floors Only)

(UL Approved 40 or 50 AMP)

4-Wire Cord OR 3-Wire Cord

4' Long 4' Long

with Strain Relief with Strain Relief

PARTS INCLUDED

Hand or Saber Saw

Gloves

Rear Filler,

2 Screws

Screws

Anti-Tip Bracket

2

Page 3

Installation Instructions

PRE-INSTALLATION CHECKLIST

INSPECT INSTALLATION LOCATION

• Counter opening extends to the wall:

Maintop Filler (supplied with the range).

(See Alternate Construction section for

Installation Instructions) or Backguard Kit

(Kit JXS37XX) (See Alternate Construction

section)

• Counter height greater than 36-3/4":

Lower Trim Slide-In Kit (Kit JXS56XX)

• One side is not enclosed by a cabinet:

Bodyside Kit (Kit JXS76XX)

• Island Installation:

To provide an optimum installation, the

top surface of the countertop must be level

and flat (lie on the same plane) around the

3 sides that are adjacent to the range

cooktop. Proper adjustments to make the

top flat should be made or gaps between

the countertop and range cooktop may

occur. Forcing the cooktop to fit may cause

excessive gaps and could break the glass

and void the warranty.

To obtain kits, visit the GE Website or call

the GE Answer Center (800.432.2737), or

contact your dealer.

• Move range indoors in front of cabinet

opening.

(Do not use hand trucks when moving the

unpackaged range. Cooktop glass may be

broken.)

• Protect the kitchen floor! Flatten and place

a piece of the shipping carton in front of the

installation location to protect the flooring.

_-I PRE-INSTALLATION CHECKLIST

(cont.)

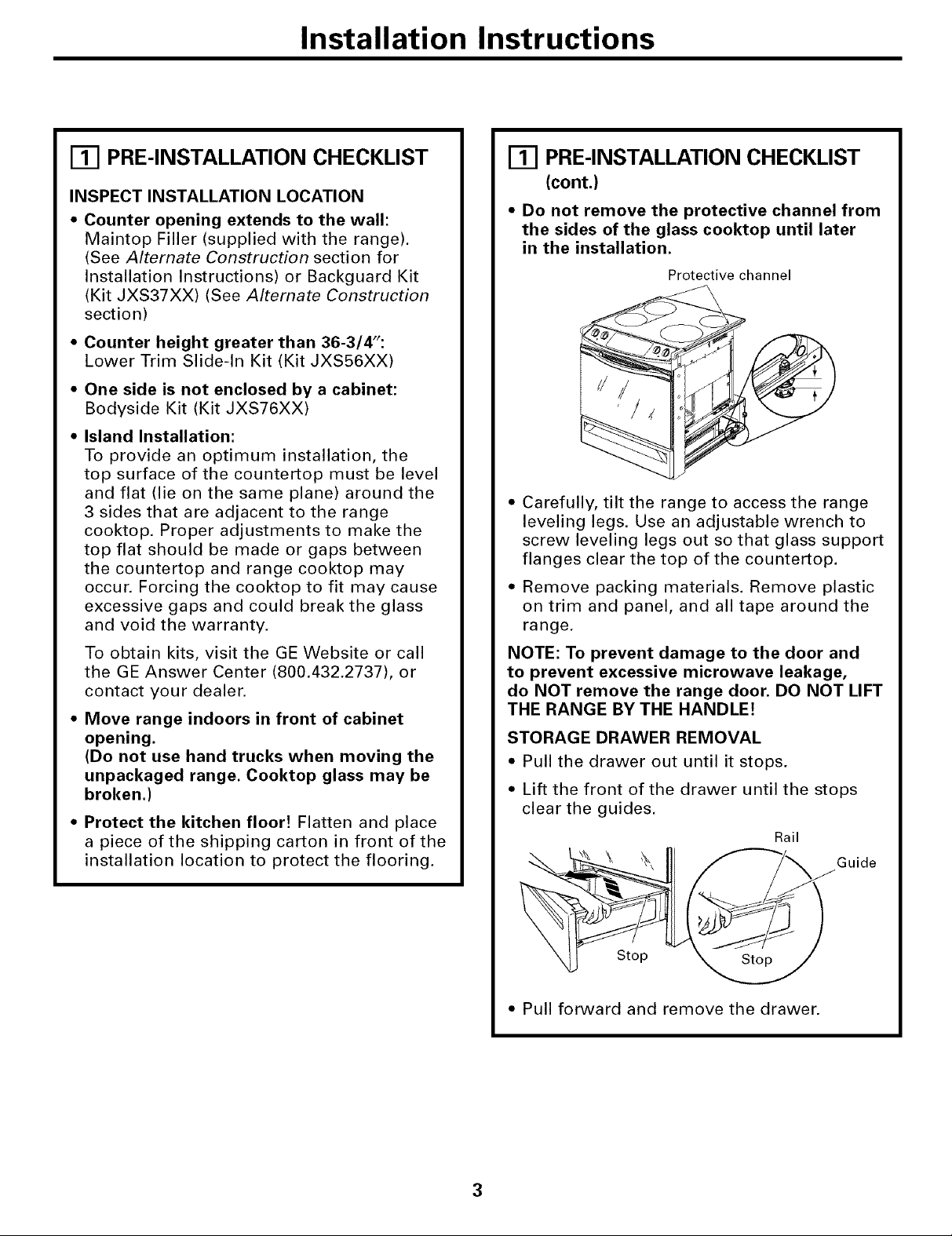

• Do not remove the protective channel from

the sides of the glass cooktop until later

in the installation.

Protective channel

• Carefully, tilt the range to access the range

leveling legs. Use an adjustable wrench to

screw leveling legs out so that glass support

flanges clear the top of the countertop.

• Remove packing materials. Remove plastic

on trim and panel, and all tape around the

range.

NOTE: To prevent damage to the door and

to prevent excessive microwave leakage,

do NOT remove the range door. DO NOT LIFT

THE RANGE BY THE HANDLE!

STORAGE DRAWER REMOVAL

• Pull the drawer out until it stops.

• Lift the front of the drawer until the stops

clear the guides.

Rail

Guide

Stop

• Pull forward and remove the drawer.

3

Page 4

Installation Instructions

PREPARE TO INSTALL THE RANGE (cont.)

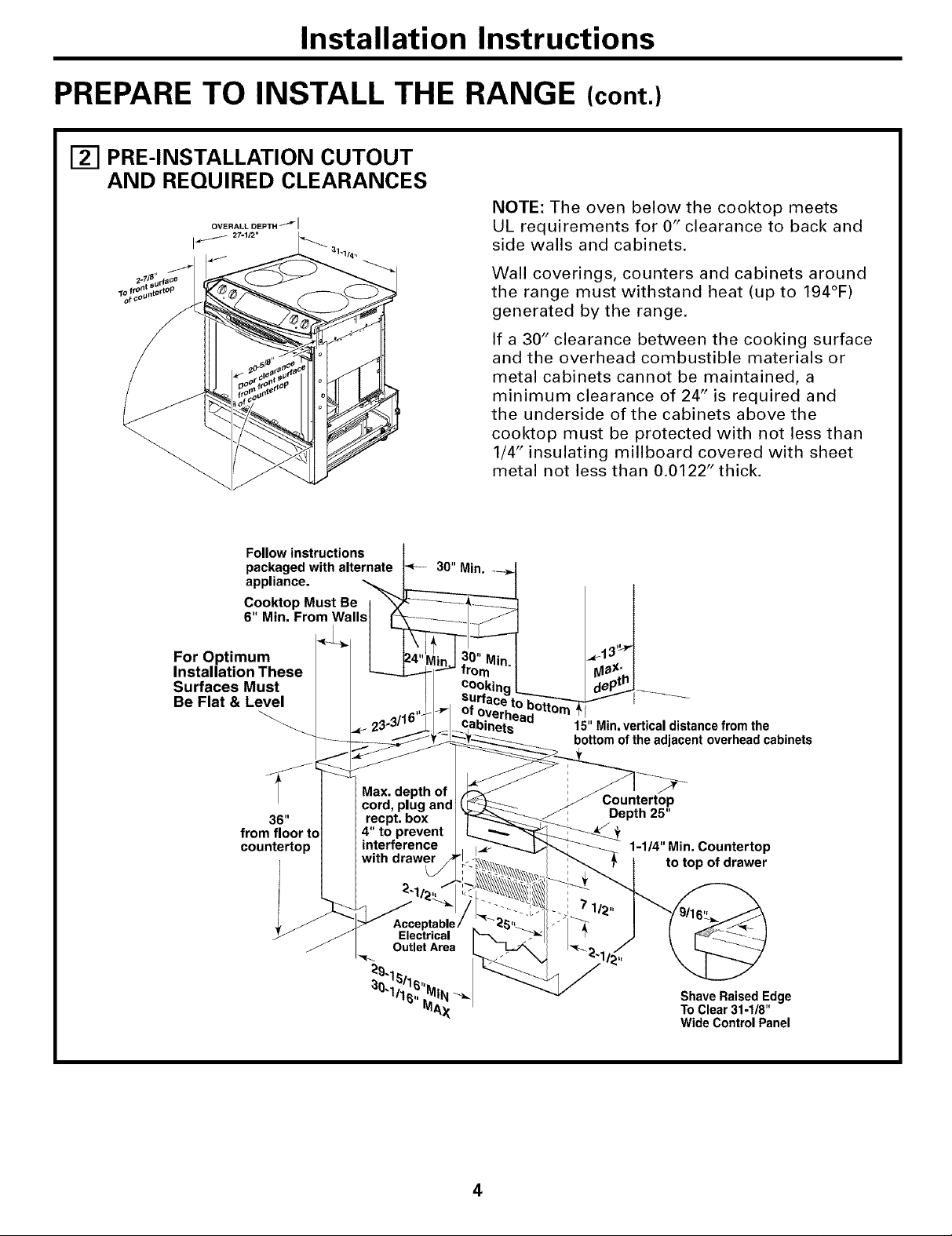

[] PRE-INSTALLATION CUTOUT

AND REQUIRED CLEARANCES

NOTE: The oven below the cooktop meets

UL requirements for 0" clearance to back and

side walls and cabinets.

Wall coverings, counters and cabinets around

the range must withstand heat (up to 194°F)

generated by the range.

If a 30" clearance between the cooking surface

and the overhead combustible materials or

metal cabinets cannot be maintained, a

minimum clearance of 24" is required and

the underside of the cabinets above the

cooktop must be protected with not less than

1/4" insulating millboard covered with sheet

metal not less than 0.0122" thick.

Follow instructions

packaged with alternate

appliance.

Cooktop Must Be

6" Min. From Walls

For Optimum

Installation These

Surfaces Must

Be Flat & Level

36"

from floor to

countertop

15" Min.vertical distancefrom the

bottomofthe adjacent overheadcabinets

Countertop

Depth 25"

1-114"Min. Countertop

to top of drawer

ShaveRaisedEdge

ToClear 31-1/8"

WideControlPanel

4

Page 5

Installation Instructions

PRE-INSTALLATION CUTOUT

AND REQUIRED CLEARANCES (cont.)

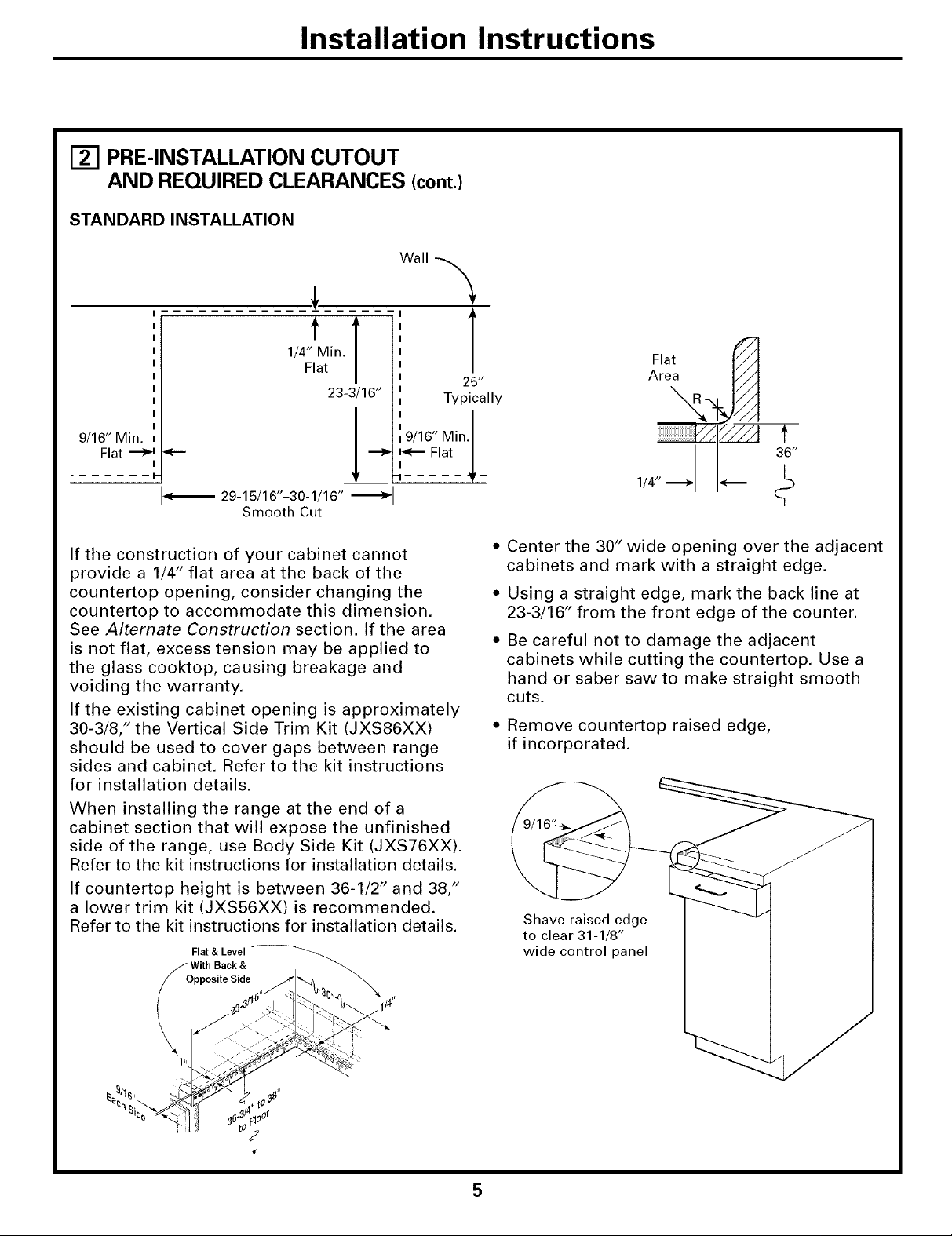

STANDARD INSTALLATION

Wall

1/4" Min.

Flat

23-3/16"

9/16" Min.

Flat

....... ]-

If the construction of your cabinet cannot

provide a 1/4" flat area at the back of the

countertop opening, consider changing the

countertop to accommodate this dimension.

See Alternate Construction section. If the area

is not flat, excess tension may be applied to

the glass cooktop, causing breakage and

voiding the warranty.

If the existing cabinet opening is approximately

30-3/8," the Vertical Side Trim Kit (JXS86XX)

should be used to cover gaps between range

sides and cabinet. Refer to the kit instructions

for installation details.

When installing the range at the end of a

cabinet section that will expose the unfinished

side of the range, use Body Side Kit (JXS76XX).

Refer to the kit instructions for installation details.

If countertop height is between 36-1/2" and 38,"

a lower trim kit (JXS56XX) is recommended.

Refer to the kit instructions for installation details.

I

29-15/16"-30-1/16" "_

Smooth Cut

Flat & Level

oWith Back &

pposite Side

T

25"

Typically

Flat

Area

• Center the 30" wide opening over the adjacent

cabinets and mark with a straight edge.

• Using a straight edge, mark the back line at

23-3/16" from the front edge of the counter.

• Be careful not to damage the adjacent

cabinets while cutting the countertop, Use a

hand or saber saw to make straight smooth

cuts.

• Remove countertop raised edge,

if incorporated.

Shave raised edge

to clear 31-1/8"

wide control panel

5

Page 6

Installation Instructions

ELECTRICAL CONNECTIONS

ELECTRICAL REQUIREMENTS

CAUTION: For personal safety,

do not use an extension cord with this

appliance. Remove house fuse or open

circuit breaker before beginning

installation.

This appliance must be supplied with the

proper voltage and frequency, and connected

to an individual properly grounded branch

circuit, protected by a circuit breaker or fuse

having amperage as specified on the rating

plate. The rating plate is located on the

oven frame.

We recommend you have the electrical wiring

and hookup of your range connected by a

qualified electrician. After installation, have

the electrician show you where your main

range disconnect is located.

Check with your local utilities for electrical

codes which apply in your area. Failure to

wire your range according to governing

codes could result in a hazardous condition.

If there are no local codes, your range must

be wired and fused to meet the requirements

of the National Electrical Code, ANSI/NFPA

No. 70--Latest Edition. You can get a copy

by writing:

National Fire Protection Association

Batterymarch Park

Quincy, MA 02269

Effective January 1, 1996, the National

Electrical Code requires that new construction

(not existing) utilize a 4-conductor connection

to an electric range.

Use only a 3-conductor or a 4-conductor

UL-listed range cord. These cords may be

provided with ring terminals on wire and a

strain relief device.

A range cord rated at 40 amps with 125/250

minimum volt range is required. A 50 amp

range cord is not recommended but if used, it

should be marked for use with nominal 1-3/8"

diameter connection openings. Care should

be taken to center the cable and strain relief

within the knockout hole to keep the edge

from damaging the cable.

,, Because range terminals are not accessible

after range is in position, flexible service

conduit or cord must be used.

NOTE: If conduit is being used, go to Step 3D

and then to Step 6 or 7.

* On some models, a filter capacitor may be

connected between the black and white

leads on the junction block.

ALL NEW CONSTRUCTIONS,

MOBILE HOMES AND

INSTALLATIONS WHERE

LOCAL CODES DO NOT

ALLOW GROUNDING

THROUGH NEUTRAL,

REQUIRE A 4-CONDUCTOR

UL-USTED RANGE CORD.

When installing an electric range in new

construction, follow Steps 3 and 5 for 4-wire

connection.

You must use a 3-wire, single-phase A.C.

208Y/120 Volt or 240/120 Volt, 60 hertz

electrical system.

If the electrical service provided does not

meet the above specifications, have a

licensed electrician install an approved outlet.

6

Page 7

Installation Instructions

[] POWER CORD AND STRAIN

RELIEF INSTALLATION

[] Remove the wire cover

(on the back of the

range) by removing 2

screws, using a 1/4"

nut driver.

Do not discard these

screws.

[] Remove the knockout ring (1-3/8")

located on bracket directly below the

terminal block. To remove the knockout,

use a pair of pliers to bend the knockout

ring away from the bracket and twist

until ring is removed.

0

er

[]

For power cord installations only (see

the next step if using conduit), assemble

the strain relief in the hole. Insert the

power cord through the strain relief and

tighten. Allow enough slack to easily

attach the cord terminals to the terminal

block. If tabs are present at the end of

the winged strain relief, they can be

removed for better fit.

NOTE: Do not install the power cord

without a strain relief. The strain relief

bracket should be installed before

reinstalling the rear range wiring cover.

Terminal

block

Knockout ring

in bracket

Terminal

block

J (appearance

may vary)

©

/

Knockout

ring removed

Skip to Step 4 or 5.

For conduit installations only, purchase

[]

a squeeze connector matching the

diameter of your conduit and assemble

it in the hole. Insert the conduit through

the squeeze connector and tighten. Allow

enough slack to easily attach the wires

to the terminal block.

NOTE: Do not install the conduit without

a squeeze connector. The squeeze

connector should be installed before

reinstalling the rear range wiring cover.

Terminal

block

cSquei_!_duit _ l

Skip to Step 6 or 7.

Bracket

Page 8

Installation Instructions

ELECTRICAL CONNECTIONS (cont.)

3-WIRE POWER CORD

INSTALLATION

WARNING: Theneutralor

ground wire of the power cord must be

connected to the neutral terminal located

in the center of the terminal block. The

power leads must be connected to the

lower left and the lower right terminals

of the terminal block.

Remove the 3 lower terminal screws from

[]

the terminal block. Insert the 3 terminal

screws through each power cord terminal

ring and into the lower terminals of the

terminal block. Be certain that the center

wire (white/neutral) is connected to the

center lower position of the terminal

block. Tighten screws securely into the

terminal block.

DO NOT remove the ground strap

connection.

Ground

plate

Terminal

block

(appearance

may vary)

Neutral

terminal

Ground

strap

[] 4-WIRE POWER CORD

INSTALLATION

-& WARNING: The neutral wire of

the supply circuit must be connected to

the neutral terminal located in the lower

center of the terminal block. The power

leads must be connected to the lower

left and the lower right terminals of the

terminal block. The 4th grounding lead

must be connected to the frame of the

range with the ground plate and the

ground screw.

[] Remove the 3 lower terminal screws from

the terminal block. Remove the ground

screw and ground plate and retain them.

[] Cut and discard the ground strap. DO

NOT DISCARD ANY SCREWS.

[] Insert the one ground screw into the

power cord ground wire terminal ring,

through the ground plate and into the

frame of the range.

[] Insert the 3 terminal screws (removed

earlier) through each power cord terminal

ring and into the lower terminals of the

terminal block. Be certain that the center

wire (white/neutral) is connected to the

center lower position of the terminal

block. Tighten screws securely into the

terminal block.

Before ////\\ Ground strap

Terminal // _h_;\\ "_--I l_In

b ock "-'--'--"-_:LT,_'_-_,IIIM_-_ _-L

[_@_i_J@_s_J,I_Au_'_l__I or

Power cord

[] Skip to Step 8 and proceed with the

installation.

Groun_ [_1

strap -

After

Terminal _._//_/_ _.._ Ground

block __ _/._._ plate.

Ground__

screw __tf_ _

[] Skip to Step 8 and proceed with the

installation.

8

Neutral

terminal

(grounding

to range)

Page 9

Installation Instructions

3-WIRE CONDUIT INSTALLATION

[] Loosen the 3 lower terminal screws from

the terminal block. Insert the center bare

wire (white/neutral) tip through the

bottom center terminal block opening.

On certain models, the wire will need to

be inserted through the ground strap

opening and then into the bottom center

block opening. Insert the two side bare

wire tips into the lower left and the lower

right terminal block openings. Tighten the

screws until the wire is firmly secured (35 to

50 inch-lbs.). Do not over-tighten the

screws since it could damage the wires.

NOTE: ALUMINUM WIRING:

Aluminum building wire may be used but

it must be rated for the correct amperage

and voltage to make connection. Connect

wires according to this Step 6 or Step 7

depending on number of wires.

Terminal //L---_i L _\

,ock

4-WIRE CONDUIT INSTALLATION

[]

Loosen the three lower terminal screws

[]

from the terminal block. Remove the

ground screw and ground plate and retain

them. Cut and discard the ground strap.

DO NOT DISCARD ANY SCREWS.

Insert the ground bare wire tip between

[]

the range frame and the ground plate

(removed earlier) and secure it in place

with the ground screw (removed earlier).

Insert the bare wire (white/neutral) tip

through the bottom center of the terminal

block opening. Insert the two side bare

wire tips into the lower left and the lower

right terminal block openings. Tighten the

screws until the wire is firmly secured (35 to

50 inch-lbs.). Do not over-tighten the

screws since it could damage the wires.

Wire tips ..._...__ _

i

Bracket

Conduit

Wire used, location and enclosure of

splices, etc., must conform to good

wiring practices and local codes.

[] Skip to Step 8 and proceed with the

installation.

Neutral

After _/___j___ terminal

biTeorcn_ina I------'-"_'_ _'(_l(_ Glratu nd

• . to range)

Wire tips _/r

screw / /

[] Proceed to Step 8.

_._.,_'_l O !_ [__ (grounding

_- Bracket

9

Page 10

Installation Instructions

INSTALL THE ANTI-TIP BRACKET

REPLACE THE WIRE COVER

[]

Replace the wire cover

(on the back of the range)

by replacing the 2 screws

removed earlier.

NOTE: When reinstalling

the wire cover, make sure

that wires do not become pinched

between the wire cover and the housing.

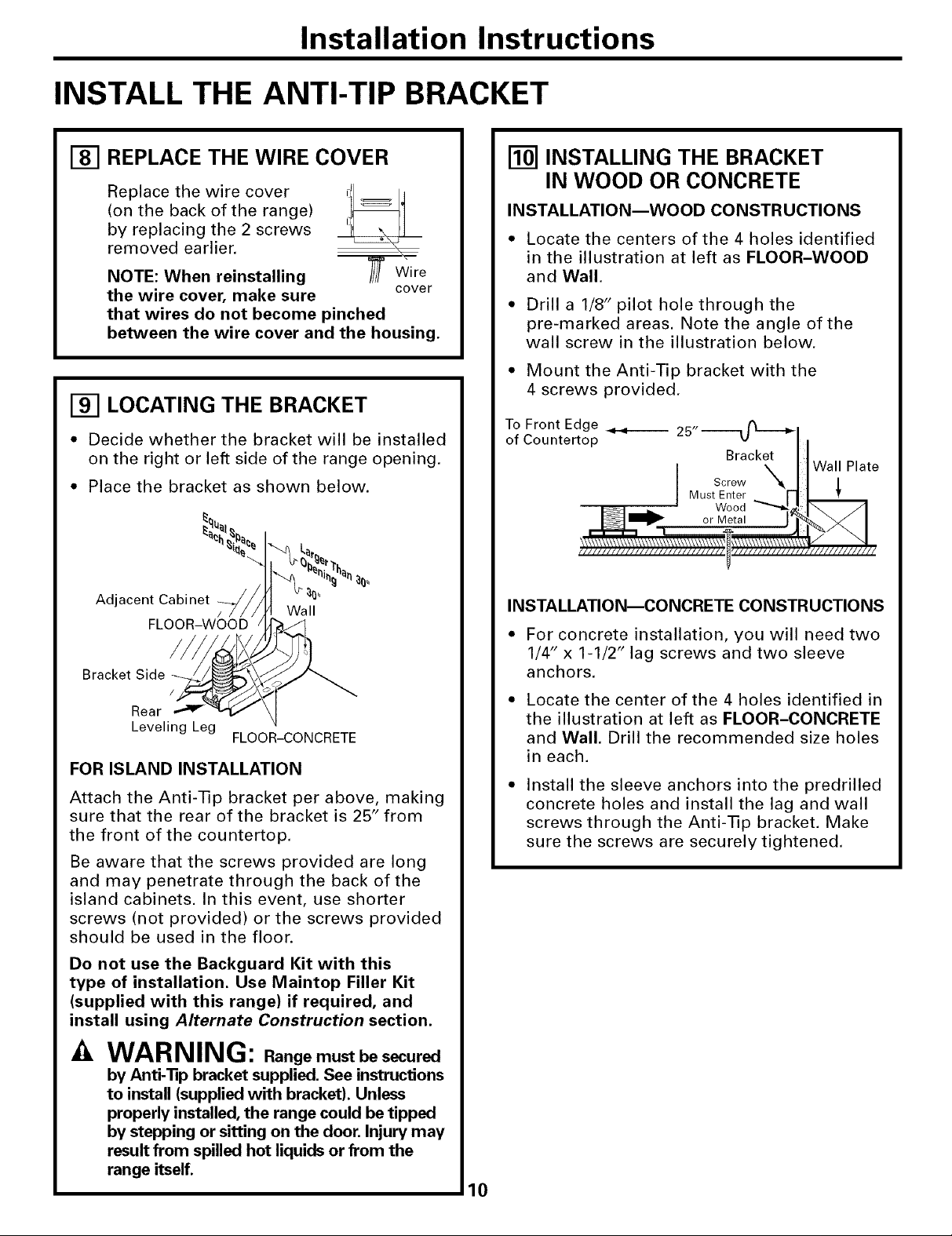

I-9-1LOCATING THE BRACKET

• Decide whether the bracket will be installed

on the right or left side of the range opening.

• Place the bracket as shown below.

re

cover

[] INSTALLING THE BRACKET

INSTALLATION--WOOD CONSTRUCTIONS

• Locate the centers of the 4 holes identified

in the illustration at left as FLOOR-WOOD

and Wall.

• Drill a 1/8" pilot hole through the

pre-marked areas. Note the angle of the

wall screw in the illustration below.

• Mount the Anti-Tip bracket with the

4 screws provided.

To Front Edge _ 25"--

of Countertop

IN WOOD OR CONCRETE

Bracket

Wall Plate

Adjacent Cabinet

FLOOR-WOOD /

Bracket Side/__

Rear _r+_

Leveling Leg

FOR ISLAND INSTALLATION

Attach the Anti-Tip bracket per above, making

sure that the rear of the bracket is 25" from

the front of the countertop.

Be aware that the screws provided are long

and may penetrate through the back of the

island cabinets. In this event, use shorter

screws (not provided) or the screws provided

should be used in the floor.

Do not use the Backguard Kit with this

type of installation. Use Maintop Filler Kit

(supplied with this range) if required, and

install using Alternate Construction section.

/

FLOORqCONCRETE

Wall

or Metal

INSTALLATION--CONCRETE CONSTRUCTIONS

• For concrete installation, you will need two

1/4" x 1-1/2" lag screws and two sleeve

anchors.

Locate the center of the 4 holes identified in

the illustration at left as FLOOR-CONCRETE

and Wall. Drill the recommended size holes

in each.

Install the sleeve anchors into the predrilled

concrete holes and install the lag and wall

screws through the Anti-Tip bracket. Make

sure the screws are securely tightened.

-& WARNING: Range must be secured

by Anti-Tip bracket supplied. See instructions

to install (supplied with bracket). Unless

properly installed, the range could be tipped

by stepping or sitting on the door. Injury may

result from spilled hot liquids or from the

range itself.

10

Page 11

Installation Instructions

INSTALL THE RANGE

[] SLIDE RANGE INTO OPENING

Position the range in front of the cabinet

[]

opening.

Make sure that the glass that overhangs

[]

the countertop clears the countertop.

If necessary, raise the unit by lowering

the leveling legs.

[]

Push while lifting the range into the

opening, until the range is within 2"

of engaging the anti-tip bracket.

[]

Remove the protective trim from the side

of glass (if provided).

[]

Using the adjustable pliers or wrench,

carefully screw in the back leveling leg

until the glass overhang comes to rest

on the countertop.

[_] SLIDE RANGE INTO OPENING (cont.)

Plug the range cord into the receptacle.

[]

Locate the cord in the back of the range

in a manner that it will not touch or be

moved by the drawer.

Position range cord so that

there is no interference with

the storage drawer

HH_HHH_HHHHHHHHHHHHH_

I1

/\

I/

/////

I-_ FINAL CHECK OF THE ANTI-TIP

BRACKET

[] Then carefully screw in the front two

leveling legs (similar to E above) until the

glass overhang touches the countertop.

[] Carefully push the range into the opening

until the countertop fully engages the

control panel. The back glass overhang

should cover the cutout opening.

ountertop

Make sure the edge

of the countertop

fits flush against

the end of the

Front Control Panel

When installation is

complete and the range is

in place, check to be sure

that the rear leveling leg is

fully inserted into the slot

of the Anti-Tip Bracket.

11

Page 12

Installation Instructions

INSTALL THE RANGE (cont.)

[] REPLACE THE STORAGE

DRAWER

[] Place the drawer rail on the guides,

[] Push the drawer in until it

[] Lift the front of the drawer and push in

until the stops clear the guides.

[] Lower the front of the drawer and

in until it closes.

SPECIAL INSTRUCTIONS IF YOU ARE

HAVING PROBLEMS WHILE REPLACING

THE STORAGE DRAWER

If Drawer Won't Close:

Drawer does panel tipped

not close away from

_ _-Ptwe[i c J d_',i_{[ , guide rail

!ili bod.ide

completely _ _i I_

H Rear drawer support

stops.

push

Drawer front

is resting on top of

r_-4]FINAL INSTALLATION

CHECKLIST

* Check to make sure the circuit breaker is

closed (RESET) or the circuit fuses are

replaced.

. Be sure power is in service to the building.

. Check to be sure that all packing materials

and tape on metal panel (if applicable)

under control knobs and drawer have been

removed.

r_ OPERATION CHECKLIST

Push down and turn any one of the four

surface knobs to MED setting to observe

that the element glows within 15 seconds.

Turn the knob off when glow is detected.

If the glow is not detected within the time

limit, recheck the range wiring connections.

If change is required, retest again. If no

change is required, have building wiring

checked for proper connections and voltage,

Turn on the power to the oven, (Refer to

your Owner's Manual). Verify that the bake

and broil functions make the oven hot by

feeling heat coming off the elements within

20 seconds.

Remove and replace, making sure the

power cord is not obstructing the drawer

and/or the rail is in the guide.

ff Drawer Is Crooked:

Rear drawer

support is on

top of guide rail Drawer front panel

on the high side F tipped to one side

!

Remove and replace, making sure the

rail is in the guide.

12

Page 13

Installation Instructions

ALTERNATE CONSTRUCTION

OPTIONAL MAINTOP FILLER

OR BACKGUARD KIT

If counter opening extends to the wall, it will

require Maintop Filler Kit (supplied with the

range) or Backguard Kit JXS37XX) to close

the gap.

NOTE: If the countertop is greater than 25';

it will show a gap between the backguard

and wall or between filler kit and the wall.

If the countertop is less than 25'; a gap will

occur between the countertop front and the

control panel ends (see Step 2).

If you are using the optional backguard kit,

refer to the backguard kit instructions for

installation details.

] T

Must Be

25" Level

OPTIONAL MAINTOP FILLER

OR BACKGUARD KIT (cont.)

If you use the filler kit, place the metal filler

piece supplied with the range to the back of

the range as shown in the illustration below.

Start the 2 screws into the upper holes at the

outside rear of the range above the louvers

and through the slots in the trim, holding the

filler piece centered on the maintop frame

and pushing upward to close the gap between

the bottom of the glass and the filler trim.

When the trim is set in the proper position,

tighten the 2 mounting screws. The top of the

trim should be located below the top surface

of the glass to prevent pots, pans and skillets

from damaging the painted parts.

Refer to Step 2.

Cooktop

30"

Smooth Cut

Must Be Level

31-1/8"

1

Be Flat

• -_- Must

Range

_ Maintop

Filler

, #8 Screws

13

Page 14

Notes

14

Page 15

Notes

15

Page 16

16

Printed in the United States

Loading...

Loading...