Page 1

C

GE Consumer Service Training

TECHNICAL SERVICE GUIDE

Radiant Downdraft Cooktop

MODEL SERIES:

JP989

PUB # 31-9055 06/00

Page 2

!

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by

individuals possessing adequate backgrounds of electrical,

electronic, and mechanical experience. Any attempt to repair a

major appliance may result in personal injury and property

damage. The manufacturer or seller cannot be responsible for the

interpretation of this information, nor can it assume any liability in

connection with its use.

WARNING

T o a void personal injury , disconnect power bef ore servicing this product. If electrical power is required for diagnosis or test purposes,

disconnect the power immediately after performing the necessary

checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used to

complete a path to ground are removed for service, they must be

returned to their original positions and properly fastened.

GE Consumer Service Training

Technical Service Guide

Copyright © 2000

All rights reserved. This service guide may not be reproduced in whole or in par t

in any form without written permission from the General Electric Company.

Page 3

Table of Contents

Cooktop Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Cooktop Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Care and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Unpacking Cooktop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Cabinet Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Ductwork Calculations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Ductwork Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cooktop Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Removal and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Control Assembly Servicing . . . . . . . . . . . . . . . . . . . . . . . . . 20

Blower Assembly Replacement. . . . . . . . . . . . . . . . . . . . . . . 20

Capacitor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

HOT Light Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Glass Cooktop Removal from Countertop . . . . . . . . . . . . . . . . . 22

Heater Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Broken Glass Replacement. . . . . . . . . . . . . . . . . . . . . . . . . 25

Reinstalling Glass Cooktop . . . . . . . . . . . . . . . . . . . . . . . . . 27

Rocking or Uneven Glass in Countertop .. . . . . . . . . . . . . . . . . 28

Illustrated Parts Breakdown . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Troubleshooting Information . . . . . . . . . . . . . . . . . . . . . . . . . 32

Schematics and Strip Circuits . . . . . . . . . . . . . . . . . . . . . . . . . 34

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

– 1 –

Page 4

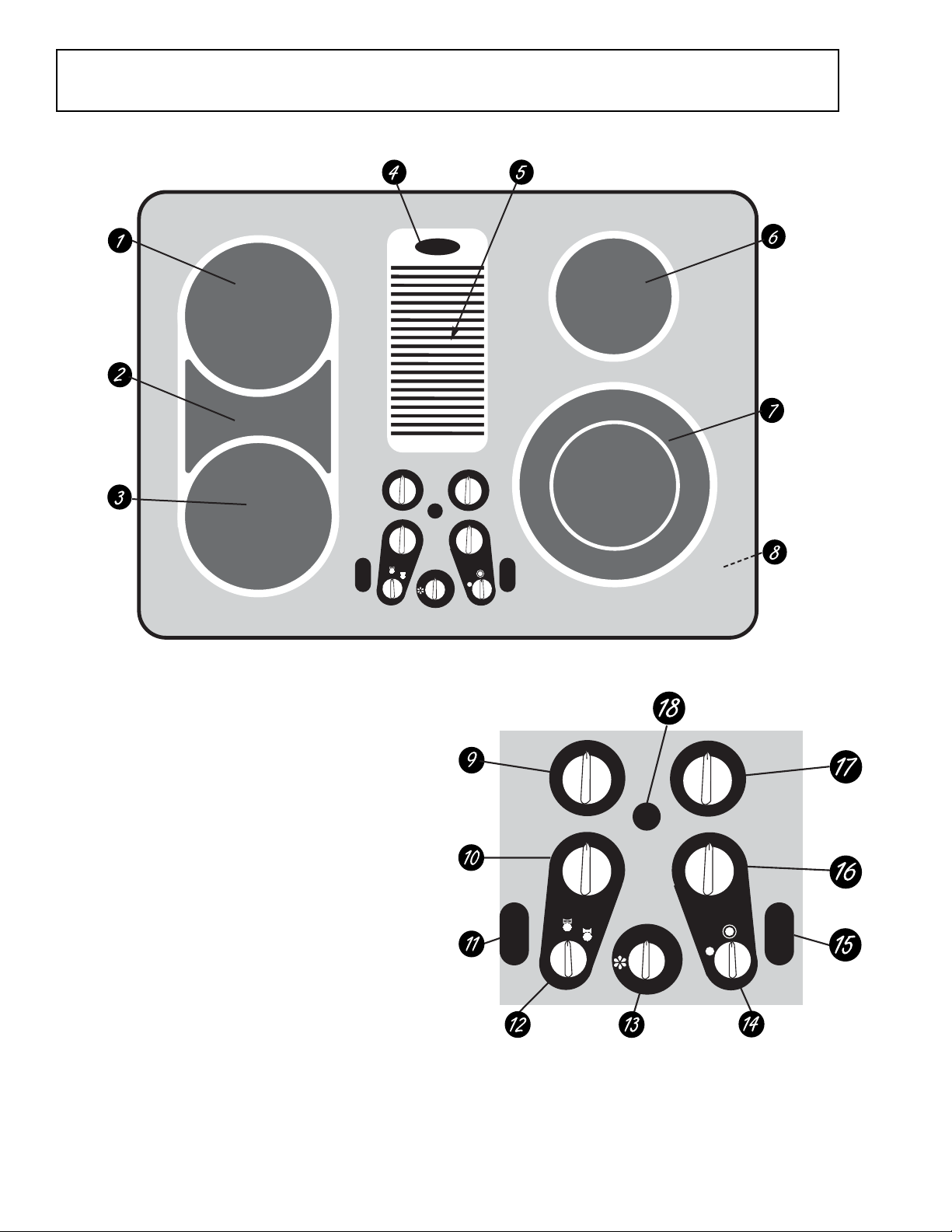

Cooktop Features

Throughout this manual, features and appearance may vary from the customer’s model.

OFF

HI

O

L

1

9

2

8

3

7

4

6

5

ON

OFF

HI

O

L

1

9

2

8

3

7

4

6

5

HOT HOT

OFF

B

E

R

G

I

D

Feature Index (Features and appearance may vary)

1 Left Rear Surface Unit

2 Bridge Surface Unit

3 Left Front Surf ace Unit

4 V ent Grille

5 V ent Filter

6 Right Rear Surface Unit

7 Dual Surface Unit

8 Model and Serial Number Label

on the right side of the vent chamber)

9 Left Rear Surface Unit Control

10 Left Front/Bridge Surface Unit Control

11 Left Side HOT Surface Indicator Lights

surface unit)

12 Bridge Select

13 V ent F an Speed Control

14 Coil Size Select

15 Right Side HOT Surface Indicator Lights

surface unit)

16 Dual Surface Unit Control

17 Right Rear Surface Unit Control

18 Surface Unit ON Indicator Light

(below the vent grille)

(under the cooktop,

(one for each

(one for each

OFF

HI

O

L

1

9

2

8

3

7

4

6

5

OFF

HI

O

L

1

9

2

8

3

7

4

6

5

HI

M

E

D

C

E

O

Z

I

I

L

S

LO

GEA00181

OFF

HI

LO

1

2

3

4

LO

1

2

3

4

HOT HOT

B

R

G

I

D

OFF

E

9

8

7

6

5

ON

HI

9

8

7

6

5

OFF

OFF

HI

LO

1

2

3

4

LO

1

2

3

4

5

OFF

9

8

7

6

HI

9

8

7

6

5

HI

M

ED

C

E

O

Z

I

I

L

LO

S

GEA00182

– 2 –

Page 5

Cooktop Controls

OFF

HI

9

8

7

6

5

ON

HOT

LO

1

2

3

4

Be sure you turn the control knob to

OFF when you finish cooking.

GEA00183

OFF

HI

9

8

7

6

5

Large 9"

LO

1

2

3

4

surface unit

setting

Small 6"

surface unit

setting

C

E

O

Z

I

I

L

S

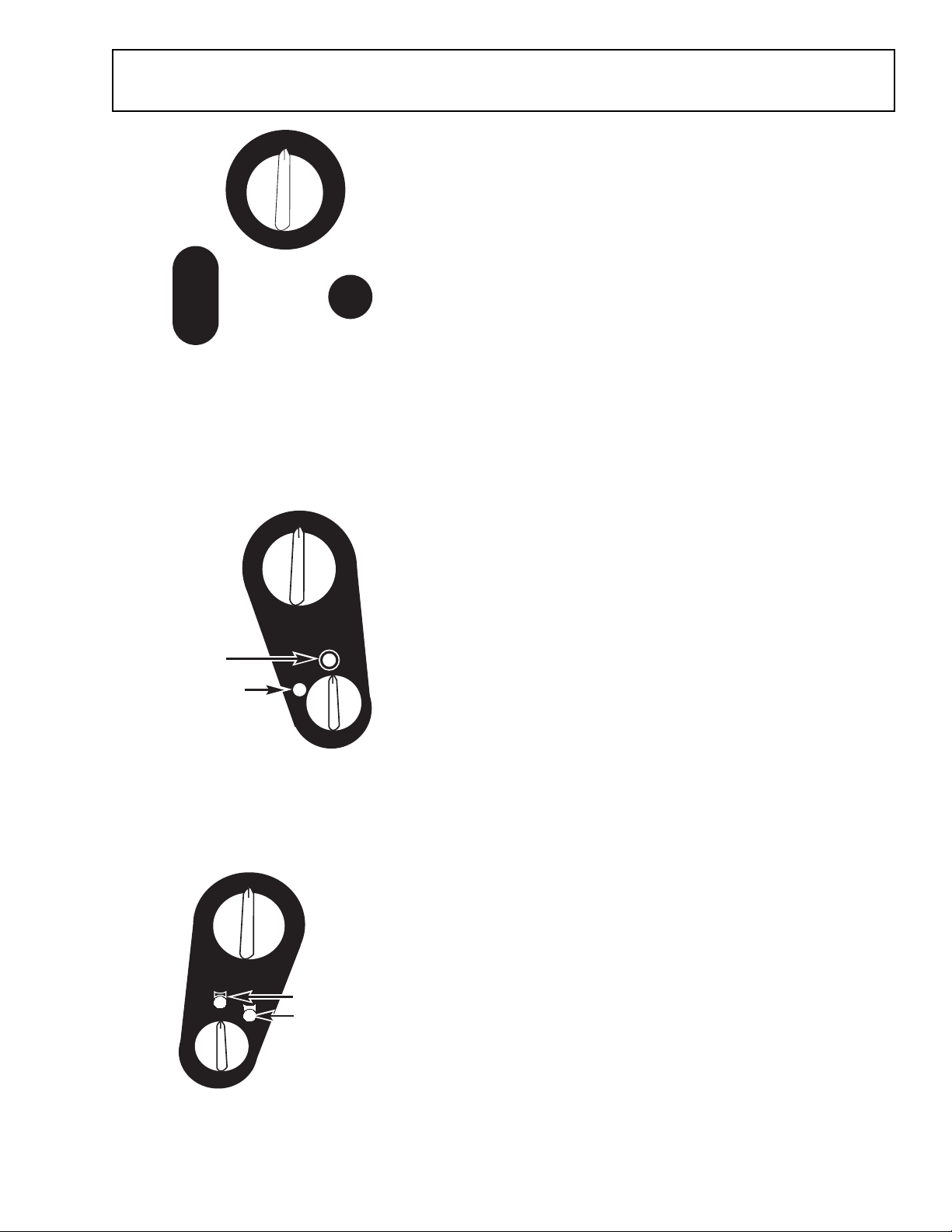

Radiant Surface Units

The control for the radiant surface unit can be set anywhere between LO and HI for an unlimited number of

heat settings. With the infinite switch, the coil cycles on

and off to maintain the selected control setting.

The surface unit’s ON indicator light will glow when any

surface unit is on.

Note: The surface unit’s ON indicator light ma y glow

between the surface control settings of LO and OFF, but

there is no power to the surface units.

The HOT surface indicator lights will glow when any

radiant element is turned on, and will remain on until the

surface is cooled to approximately 150°F.

Dual Surface Unit

To use the large (9-in.) surface unit, turn the COIL SIZE

knob clockwise to the 12 o’clock position. Push the

control knob in and turn it to the desired setting. The unit

will heat the entire area inside the larger circle.

To use the small (6-in.) surface unit, turn the COIL SIZE

knob counterclockwise to the 10 o’clock position. Push

the control knob in and turn it to the desired setting. The

unit will only heat the area inside the smaller circle.

GEA00184

OFF

LO

1

2

3

B

R

I

HI

9

8

4

E

G

D

7

6

5

Front Burner

only

Front

Burner and

Bridge

GEA00185

Bridge Surface Unit

Make sure the pan rests flat on the glass cooktop.

When the burner select knob points to the 12 o’clock

position, the control knob controls the left front surface

unit only.

When the burner select knob points to the 1 o’clock

position, the control knob controls both the left front

surface unit and the bridge area. Choose pans that

match the circle/bridge area as closely as possible.

The customer can create an oblong heated area by

using the left rear unit in addition to the front unit bridge

combination.

– 3 –

Page 6

Temperature Limiter

Every radiant surface unit has a temperature limiter. The

temperature limiter protects the glass cooktop from

getting too hot.

The temperature limiter may cycle the units off for a time

if:

• The cooktop is on while cooking.

• The pan boils dry.

• The pan bottom is not flat.

• The pan is off center.

• There is no pan on the unit.

OFF

HI

MED

LO

GEA00186

How to Operate the Vent System

To operate the downdraft vent system, turn the vent fan

speed control knob to HI, MED, or LO, as needed.

– 4 –

Page 7

Care and Cleaning

SURFACE

COOKING

Never cook directly on the glass.

Always use cookware.

OFF CENTER

Always place the pan in the center of

the surface unit you are cooking on.

DRAGGING

Do not slide cookware across the

cooktop because it can scratch the

glass. The glass is scratch resistant,

not scratch proof.

GEA00227

Radiant Surface Units

The radiant cooktop features heating units beneath a

smooth glass surface.

Do not store heavy items above the cooktop. If they drop

onto the cooktop, they can cause damage.

Do not use the surface as a cutting board.

A slight odor is normal when a new cooktop is used for

the first time. The odor is caused by the heating of new

parts and insulating materials, and will disappear in a

short time.

On models with a white glass cooktop, it is normal for

the surface to appear discolored when it is hot. This is

temporary and will disappear as the glass cools.

The surface unit will cycle on and off to maintain the

selected control setting.

It is safe to place hot cookware from the oven or surface

on the glass surface when the surface is cool.

Water stains (mineral deposits) are removable using the

cleaning cream or full-strength white vinegar.

Window cleaner may leave an iridescent film on the

cooktop. The cleaning cream will remove this discoloration.

Daily Cleaning

WARNING: Be sure electrical power is off and all sur-

faces are cool before cleaning any part of the cooktop.

Use only a recommended cleaning cream, such as the

Cerama Brite brand or the Cooktop Cleaning Cream

brand, on the glass cooktop.

To maintain and protect the surface of the glass cooktop,

follow these steps:

• Before using the cooktop for the first time, clean it

with cleaning cream. This helps protect the top and

makes cleanup easier.

• Clean the surface with cleaning cream after each

use.

• Rub a few drops (less is better) of the cleaning

cream onto soiled areas using a damp paper towel.

Buff with a dry paper towel until all soil and cream

are removed.

– 5 –

Page 8

Using a razor scraper will not

damage the surface if the 45 angle

is maintained.

GEA00192

Note: On models with a white glass cooktop, any g rease

spatter or greasy residue from a dish towel will burn on

the cooktop when the surface units are heated, leaving a

brown stain. This can be removed with the cooktop

cleaning cream and the razor scraper. To avoid this

brown discoloration, remove any spatter with paper

towels and cooktop cleaning cream before heating any

surface unit.

Heavy, Burned-On Soil

1. Allow the cooktop to cool.

2. Apply a few drops (less is better) of cleaning cream

to the cool, soiled area. Spread the cream across the

entire soiled area.

3. Hold scraper at a 45° angle against the glass ceramic surface. This 45° angle makes the scraping

easier.

Caution: Be sure to use a new sharp razor scraper. Do

not use a dull or nicked blade.

4. Scrape soil with the enclosed razor scraper. Keep a

small amount of cream on the soil as you scrape.

Heavily soiled areas may require repeated applications of cream. It will be necessary to press down on

the razor scraper while scraping the soiled area with

cooktop cream.

5. If any soil remains, repeat the steps listed above.

To order more cream and/or scrapers for cleaning the

glass cooktop, please call our toll-free number:

National Parts Center.............................. 800-626-2002

Cleaner ....................................................... #WX10X300

Scraper.......................................................#WX5X1614

Cream Scraper Kit................................... #WB64X5027

Special Care for Sugary Spills

Caution: Be sure to use a new sharp razor scraper. Do

not use a dull or nicked blade.

Sugary spills (such as jellies, fudge, candy syrups) or

melted plastics can cause pitting of the surface of your

cooktop unless the spill is removed while still hot. This

pitting damage is not covered by the warranty. Special

care should be taken when removing these hot substances.

1. Turn off all surface units affected by the spill. Remove hot pans.

2. Wearing an oven mitt, hold the razor scraper at a 45°

angle to the cooktop. Scrape the hot spill to a cool

area outside the surface unit.

3. With the spill in a cool area, use a dry paper towel to

remove any excess. Any remaining spillage should

– 6 –

Page 9

be left until the surface of the cooktop has cooled.

Do not continue to use the soiled surface unit until all

of the spillage has been removed. Follow the steps

under Heavy, Burned-On Soil to continue the

cleaning process.

Caution: If pots with a thin overlay of aluminum, copper,

or enamel are allowed to boil dry, the overlay may bond

with the glass cooktop and leave a b lac k discolor ation.

This should be removed immediately before heating

again or the discoloration may be permanent.

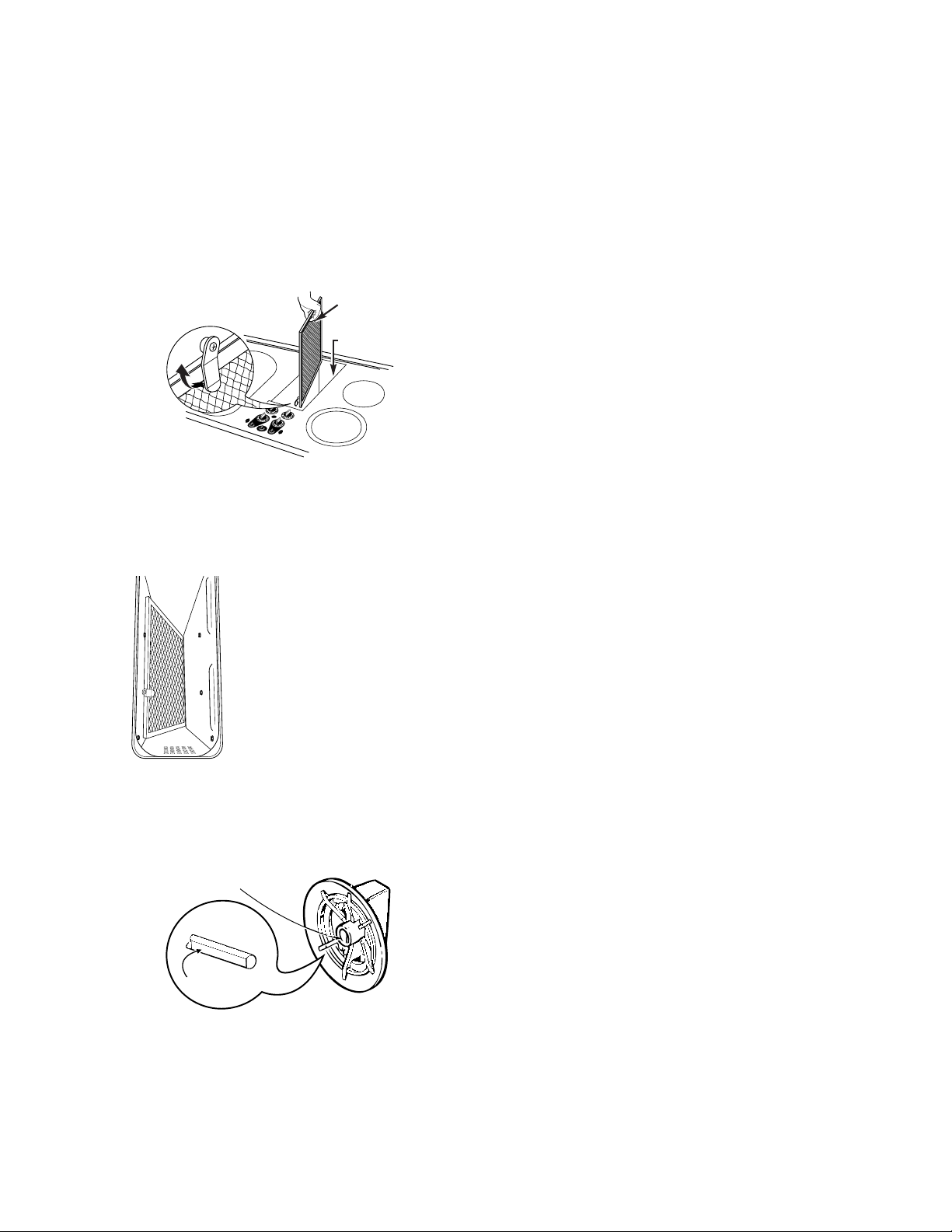

Vent Filter

Vent

Chamber

GEA00190

Remove and replace the filter diagonally through the

vent opening.

When replacing the filter, make

sure it rests, at an angle, on the

supports in the vent opening.

Latch it in place.

Vent System

WARNING: Before cleaning the vent grille, be sure the

exhaust blower is turned off.

To clean the vent grille,

remove it from the cooktop by

lifting it up and off. Wipe the vent grill with a damp cloth.

If necessary , the vent grille can be washed in the sink.

Use dishwashing liquid for cleaning. Do not use abrasive

cleaners, they will damage the vent grille’s finish.

Do not clean the vent grille in the dishwasher.

To clean the vent chamber,

use hot, soapy water. Do

not use abrasive cleaners, they will damage the vent

chamber’s finish.

Vent Filter

Caution: Do not operate the vent without the filter in

place.

The filter is held in place with a metal latch. Move the

latch up in either direction and lift the filter diagonally up

and out of the vent opening.

GEA00189

Molded flat area

Flat

GEA00191

Clean the filter by swishing it in hot, soapy water. Rinse

well and dry thoroughly.

To order filters, please call our toll-free number :

National Parts Center..............................800-626-2002

Filter ...................................................... # WB02X10651

Control Knobs

The control knobs may be removed for easier cleaning.

Before removing the knobs for cleaning, be sure they are

in the OFF position. When replacing the knobs, check

the OFF position to insure proper placement.

Wash knobs in soap and water, but do not soak them.

Avoid getting water into the knob stem holes.

The knob stem is flat on one side (see illustration).

Check the inside of the knob and find the molded flat

area.

Replace the knob by fitting the molded flat area inside

the knob onto the flat area of the stem.

– 7 –

Page 10

Installation Requirements

Before you begin, read these instructions

completely and carefully.

Note: Save these instructions for local inspector’s

use.

• Observe all governing codes and ordinances.

• Installation of this unit requires 2 people. Do not

attempt to install without assistance.

• This appliance must be properly grounded.

Tools and Materials You Will Need:

•Saw

• Flat blade screwdriver

• Electrician’s pliers

• Duct tape

• Measuring tape or scale

• Carpenter’s square

• Wrench or socket set

• Drill and drill bit

• Sheet metal screws

• Junction box*

• 1/2 in. flexible conduit*

• Electrical cable per local code*

• Wire nuts*

• Duct work

*Note: Electrical installation kit JXCK89 may be

ordered separately and includes all the parts

necessary to connect the cooktop to typical roughin wiring.

Electrical Requirements

WARNING: F or personal saf ety, remove house fuse

or circuit breaker before beginning installation.

This appliance must be supplied with the proper

voltage and frequency, as listed in these Installation Requirements, and connected to an individual, properly grounded branch circuit, protected

by a 40-amp circuit breaker or time-dela y fuse.

All wire connections must be made in accordance

with local codes and properly insulated. Check

with your local utility for governing electrical codes

and ordinances. In the absence of local electrical

codes, the National Electrical Code, ANSI/NFPA

No. 70–Latest Edition, governing electric range

installations, must be follo wed.

A copy of the National Electrical Code can be

obtained by writing to:

National Fire Protection Association

Batterymarch Park

Quincy, MA 02260

Effective January 1, 1996, the National Electrical

Code requires that new, but not existing, construction utilizes a four-conductor connection to an

electric range. When installing an electric range in

new construction, follow the instructions in New

Construction and Four-Conductor Branch

Circuit Connection.

You must use a three-wire, single-phase AC

208Y/120-Volt or 240/120-Volt, 60-Hertz electrical

system with separate ground. If you connect to

aluminum wiring, properly installed connectors

approved for use with aluminum wiring must be

used.

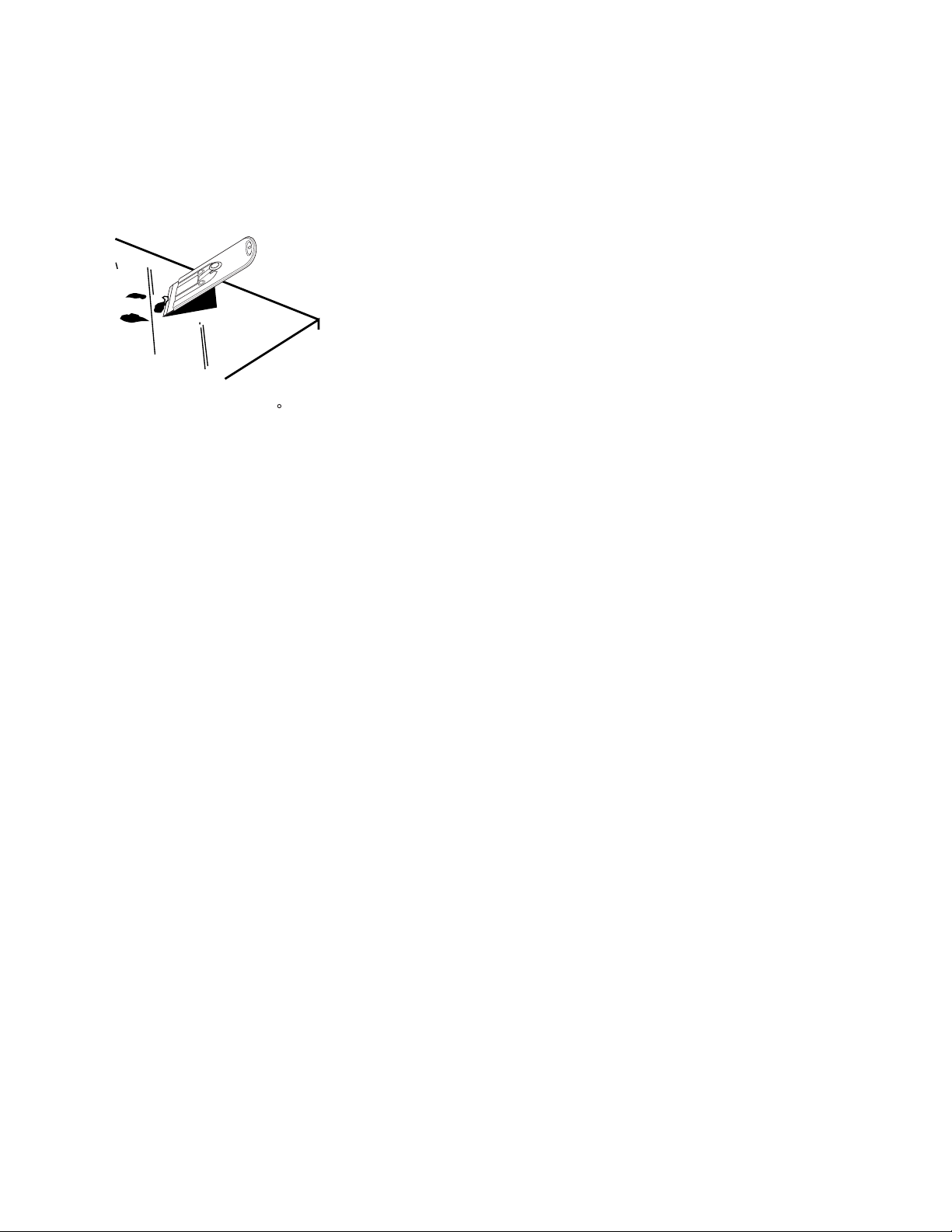

30" Cooktop (Dimensions for reference only)

Nomenclature

(on other side)

Mini-manual

located behind

cover

– 8 –

7

21 "

1

20 "

Unit must be vented to the outside!

8

19"

6"

Dia.

2

29 "

28 "

7

8

6"

7

8

GEA00193

Page 11

Sufficient air is needed for proper combustion and exhausting of gases through the flue (chimney)

of fuel-burning equipment to prevent back drafting. Follow the heating equipment manufacturer’s

guidelines and safety standards such as those published by the National Fire Protection Association (NFPA), the American Society for Heating, Refrigeration and Air Conditioning Engineers

(ASHRAE), and the local code authorities.

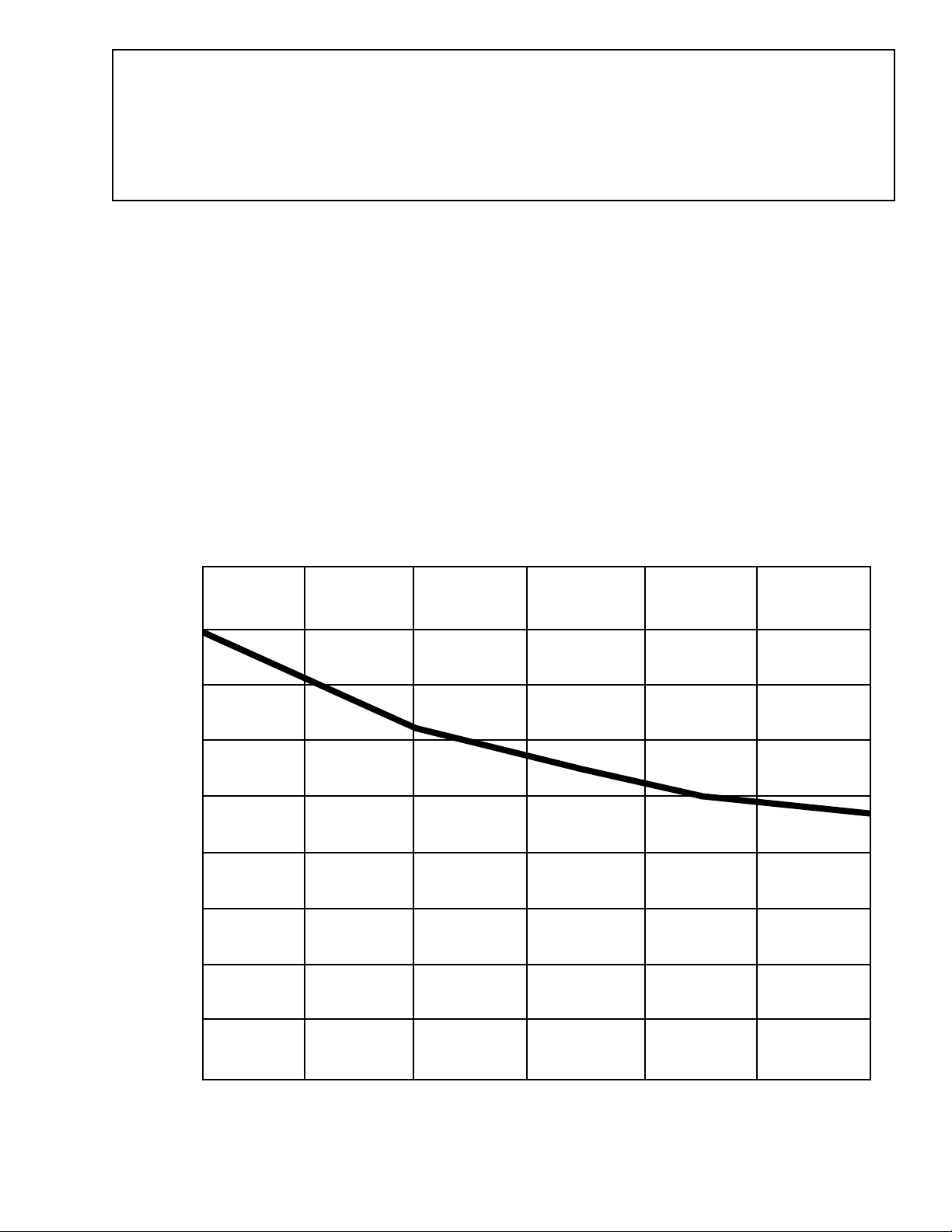

Note: The exhaust blower output is approximately 400 CFM (cubic feet per minute) without ductwork.

Each installation is different and ductwork affects blower output accordingly. Actual blower exhaust CFM

can be approximated using the graph below.

Step 1: Calculate the “equivalent duct length” using Table 1 on page 13 of these instructions for

your installation.

Step 2: Find the approximate intersection point of the blower exhaust perfor mance curve with the

equivalent duct length to estimate the actual maximum blower output for your installation.

Examples: 50 equivalent ft of ductwork have approximately 320 CFM. 100 equivalent ft of ductwork

have approximately 265 CFM.

450

400

350

300

250

200

Air Flow (CFM)

150

100

JP989 Downdraft Cooktop Exhaust Blower CFM

50

0

0 25 50 75 100 125 150

6-in. Diameter Equivalent Duct Length

6 in. Diameter Equivalent Duct Length

– 9 –

GEA00303

Page 12

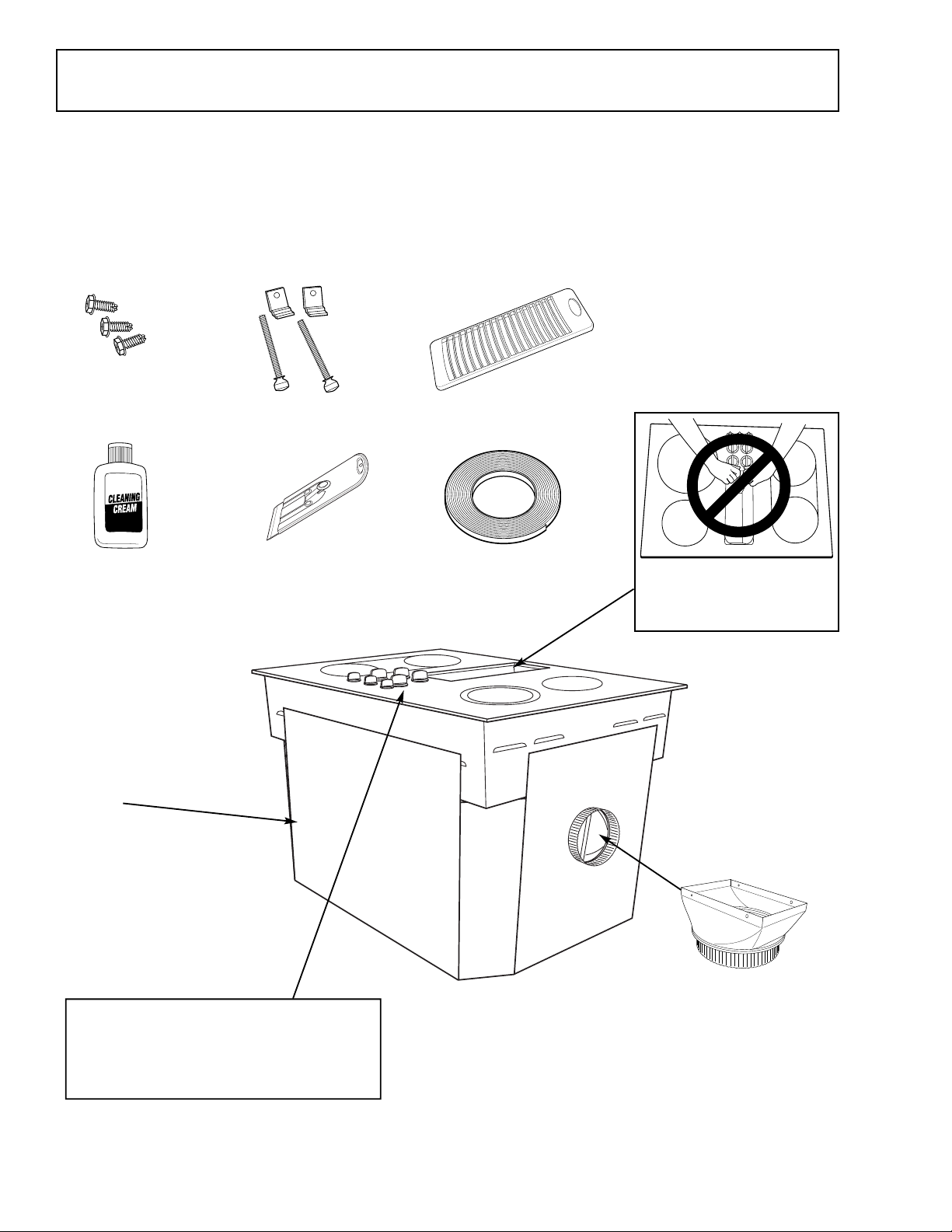

Unpacking Cooktop

Parts Included:

• (2) Hold-down retainers and screws

• Blower discharge duct transition to 6-in. round

pipe

• (3) Sheet metal screws

• Foam gasket tape (9-ft. roll)

• Vent grille

• Cleaning cream

• Cleaning Scraper

Sheet Metal

Screws

Cleaning Cream

Note: Leave the

cooktop resting

on the cardboard

sleeve until ready

to install in the

cabinet.

Hold-down Retainers

and Screws

Cleaning Scraper

Vent Grille

Foam Gasket Tape

CAUTION:

DO NOT LIFT FROM

VENT OPENING

CAUTION: GLASS IS FRAGILE

DO NOT BUMP EDGE OF GLASS

DURING INSTALLATION

– 10 –

Blower Discharge

Transition Duct

(Packed in Cardboard

Sleeve)

GEA00304

Page 13

Cabinet Preparation

5

3

4

"

Approx.

5

3

4

" Approx.

for European

cabinets

GEA00196

Step 1 – Preparing for Installation

Positioning the cooktop

The cooktop is designed to look best when cen-

tered in a cabinet its same width.

The exhaust vent beneath the cooktop must be

located between wall studs or floor joists so that

ductwork may be installed properly.

At least 6 in. must be allowed between side edges

of cooktop and adjacent walls.

1/2" Flat area

30"

15"

1

1

2"

for support

6 " Min. to

side wall

Step 2 – Preparing the Base Cabinet

This cooktop is designed to fit easily into a variety

of cabinets. However, some cabinets may require

modifications.

Preparing a cabinet that is against a wall

In some cabinets, the sides may need to be

scooped or cut down 5-3/4 in. as shown, and the

corner braces need to be removed in order to

accommodate the unit.

In 75-cm and 90-cm frameless European cabinets, the back panel may need to be cut down

5-3/4 in. to accommodate the unit.

Preparing a peninsula- or island-type cabinet

In a peninsula- or island-type cabinet, the sides

may need to be scooped or cut down, and the

corner braces need to be removed in order to

accommodate the unit.

GEA00195

Avoid placing cabinets above the cooktop unit, if

possible, in order to reduce the hazards caused by

reaching over heated surface units. If cabinets are

placed over the cooktop, the risks can be reduced

by installing a range hood that projects horizontally a minimum of 5 in. beyond the bottom of the

cabinets.

If cabinetry is used above cooktop, allow a minimum 30-in. clearance between the cooking surface and the bottom of any unprotected cabinet.

If clearance between cooktop and cabinetry is less

than 30-in., cabinet bottom must be protected with

flame-retardant millboard at least 1/4-in. thick,

covered with 28-gauge sheet steel or 0.020-in.

thick copper. Clearance between cooktop and

protected cabinetry must never be less than 24 in.

Exception: Installation of a listed microwave oven

or cooking appliance over the cooktop shall conform to the installation instructions packed with

that appliance.

A 15-in. minimum must be kept from the side edge

of cooktop to the bottom of any cabinet not directly

above cooktop. If clearance is less than 15 in.,

adjacent cabinets should be at least 6 in. from

side edges of cooktop.

– 11 –

Step 3 – Rough Preparation of Junction Bo x

WARNING: For personal safety, remove house

fuse or open circuit breaker before preparing

junction box.

Install an approved junction box within shaded

area shown in diagram. Junction box must be at

least 10-1/2 in. below the top of the cabinet.

Run conductors from residence wiring to junction

box according to local electrical codes.

C

L

9"

4"

16 "

20"

10

1

2

"

GEA00197

Page 14

Step 4 – Preparing the Countertop

Step 5A – Blower to Ductwork Alignment

Clearance between inside front of cabinet and rear

of countertop cutout must be 20-5/8 in. in order to

accommodate cooktop depth.

5

20

8"

3

8" Min.

2

GEA00198

A 1/2-in.-wide flat area is required around the

edge of the opening to support the unit. The

cooktop unit must be level and sit squarely into the

countertop opening.

Carefully cut countertop opening according to the

dimensions shown in the illustration. Be sure the

opening is cut squarely, with sides parallel to each

other and rear exactly perpendicular to sides.

5

20

8

"

In general, the use of flexible ducting is discouraged because it can cause severely restricted

airflow. However, if the blo wer outlet and the floor

or wall duct location do not align well, then flexible

metal ducting can be used to adapt to an offset.

Good alignment without use of flexible ducting is

best.

Note: Do not exceed the maximum recommended

offset of 6 in.

• Do not allow the flexible ducting to kink or

collapse.

• Do stretch the flexible ducting as much as

possible to eliminate as much of the corrugation

as possible.

6" Max.

Centerline

to Centerline

Offset

25"

2

3

8

" Min.

28

7

8

"

GEA00199

Step 5 – Preparing for Ductwork

Note: Ductwork must be vented to outside. Do

not vent into a wall, ceiling, crawl space, attic, or

other concealed space.

• When cutting or drilling into wall or ceiling, do

not damage electrical wiring or other hidden

utilities.

Cut hole in cabinet wall or floor as appropriate for

your installation. Make sure exhaust duct is located between wall studs or floor joists.

1

9

8

"

3

4

"

8

1

8

"

10

6

Bottom Venting

Back Venting

(Requires Kit JXRW89)

Step 5B – Determine Flexible Ducting’s

Equivalent Length

1. Measure the actual amount of offset (maximum of 6 in. is recommended). The effect

upon airflow is dependent upon the amount of

offset.

2. Calculate the equivalent ducting allowances

using:

(___ in. offset) x (5 ft. per inch)

= ___ ft. equivalent length

3. Enter the calculated value into Table 1 of

1

8

"

Ductwork Calculations.

4. Ensure that the total equivalent length of

ducting does not exceed the maximum recommendation of 100 ft.

GEA00305

Rear Wall Venting

Downward Venting

GEA00201

– 12 –

Page 15

Ductwork Calculations

Equivalent Number Equivalent

Duct Pieces Length* x Used = Length

6" round

to 3

1

4

" x 10 "

transition

90 elbow 20 ft. x ( ) = ft.

3

1

4

" x 10"

to 6"round

transition 5 ft. x ( ) = ft.

3

1

4

" x 10"

to 6"round

transition

90 elbow 12 ft. x ( )= ft.

6"round

wall cap

with damper 21 ft. x ( ) = ft.

3

1

4

" x 10"

wall cap

with damper 27 ft. x ( ) = ft.

6"round

roof cap 20 ft. x ( ) = ft.

6"round

roof vent 24 ft x ( ) = ft.

Subtotal Column 2 = ft.

Subtotal Column 1 =

Should not exceed 100 feet.

ft.

TOTAL DUCTWORK =

ft.

GEA00203

TABLE 1

Calculate Total Equivalent Ductwork Length

Duct Pieces Length*x Used = Length

6" round

straight 1 ft. x ( )= ft.

1

3

4

" x 10"

straight 1 ft. x ( ) = ft.

6", 90

elbow 15 ft. x ( ) = ft.

6", 45

elbow 9 ft. x ( )= ft.

Flexible

Metal Offset See Calculations

Adapter in Steps 5A and 5B ft.

Equivalent Number Equivalent

1

3

4

" x 10"

90 elbow 16 ft. x ( ) = ft.

1

3

4

"x 10"

45 elbow 5 ft. x ( )= ft.

1

3

4

" x 10"

90 flat elbow 18 ft. x ( )= ft.

6" round

1

to 3

4

"x 10"

transition 7 ft. x ( ) = ft.

*

Equivalent lengths of duct pieces are based on actual tests

and reflect requirements for good venting performance with

any downdraft cooktop.

†

Measure and list feet of straight duct used. Count and list

the quantity of all other duct pieces for the “Number Used”

of each type.

Note: For maximum efficiency, use the shortest

and straightest duct run possible, with as few

fittings as possible.

the duct run should not exceed 100 ft equivalent

length.

Subtotal Column 1 = ft.

For satisfactory performance,

GEA00202

Note: Do not use flexible plastic ducting.

If flexible metallic ducting is used, all the equiva-

lent feet values in the table should be doubled.

The flexible metallic duct should be straight,

smooth, and extended as much as possible.

Vent installation should not exceed the equivalent

ductwork length of 100 ft.

Blower is rated at 400 CFM at 0.1 inch of water

back pressure.

Venting performance is improved by using larger

diameter duct.

– 13 –

Page 16

Ductwork Installation

Step 6 – Installing the Ductwork

Note: Local building code must be followed in

specifying approved type and schedule of all duct

used.

Use galvanized or aluminum duct in 6-in. round or

3-1/4-in. x 10-in. size, or a combination of both.

PVC duct should be used if installing under a

poured concrete slab.

Always use an appropriate roof or wall cap with a

damper. Laundry-type wall caps should never be

used.

Thru Cabinet Toe Space Between Floor Joist

Downward Venting

GEA00204

Install ductwork, making male-female connections

in the direction of airflow as shown. Secure all

joints with sheet metal screws and duct tape to

assure an airtight seal.

for rear wall and retrofit installations.

A 5-in. round duct may be used on short duct runs

of 3 ft or less, such as direct to outside wall venting.

Inside Wall to Roof Direct to Outside

Rear Wall Venting

GEA00206

To convert blower exhaust direction, remove

7/16-in. nuts (behind the filter) that hold blower

and wire finger guard. Remove blower and install

Special Offset Adapter Kit JXRW89 with sheet

metal screws.

Duct Tape Over Seam

and Screw

Air Flow

Screw

GEA00205

Use the shortest and straightest duct run possible.

For satisfactory performance, the duct run should

not exceed the equivalent ductwork length of 100

ft. Use Table 1 to calculate the total equivalent

length of the ductwork.

Optional Installation: Rear Wall Venting

Rear wall venting requires a special offset duct

adapter (JXRW89) that is not included with your

cooktop. This adapter has a 5-in. diameter outlet

4 Nuts

Behind Filter

(7/16"socket

required)

GEA00306

Rotate blower and reinstall to vent chamber, as

shown above. Retighten nuts, but do not overtighten.

– 14 –

Page 17

Step 7 – Installing the Foam Gasket

GEA00310

Underside of Glass

1

8

"max. to

Glass Edge

Foam Gasket

Tape

Do not tape

over four

metal

brackets

Caution: Do not install the cooktop into the

countertop without installing the foam gasket, as

shown below. The foam gasket protects the bottom edge of the glass from the countertop and

seals the cooktop to protect it from spills.

Foam Gasket Installation Notes:

• The foam gasket tape should be installed

within 1/8 in. of the edge of the glass. Do not

stretch or twist the foam gasket tape.

• Use care not to stretch the foam gasket tape

while it is installed or it will not stay in place.

Start with the cooktop on the cardboard base with

all four sides easily accessible.

GEA00307

Locate the foam gasket tape included with

the cooktop.

• Do not place foam gasket tape over the four

metal mounting brackets.

• Butt the foam gasket tape ends together at each

corner without overlapping.

• Trim the foam gasket tape to length without

stretching.

• Mitre cut outside corners of foam gasket tape

slightly if necessary for appearance.

• Do not scratch the glass while cutting the foam

gasket tape.

GEA00308

Peel off the white backing to install the foam

gasket tape on the bottom side of the cooktop

glass, as shown below.

GEA00309

– 15 –

Page 18

Cooktop Installation

Step 8 – Installing the Cooktop

Place the vent grille in position on the glass top

vent opening. Remove the tape holding the cardboard base to the bottom of your cooktop.

CAUTION:

DO NOT LIFT

FROM VENT

OPENING

Step 9 – Checking for Flatness

Inspect the cooktop glass for rocking or uneven

gap on all four sides at the countertop surface. Do

not attempt to force the glass to meet the

countertop.

Check for

uneven gaps

Note: If the cooktop edge is perfectly flat with the

countertop surface, skip to Step 10.

If there is rocking or an uneven gap, use a 1/4-in.

nut driver to loosen the 18 sheet metal screws on

the bottom panels of the cooktop while it is still in

the countertop.

GEA00209

GEA00311

Caution: Do not use the glass top vent opening to

lift or move the cooktop into position.

Using two people, lift the cooktop by the glass side

edges as shown. Remove the cardboard base.

GEA00208

Lower the cooktop into the countertop opening,

guiding it into position until the glass is approximately 1/2-in. above the countertop surface.

Carefully remove your fingers one corner at a time

to lower the cooktop into position.

Note: Do not use Silicone RTV or caulk to bond

cooktop glass to countertop.

Loosen

screws

1-2 turns

Loosen

screws

1-2 turns

GEA00210

Loosen each bottom panel screw 1 or 2 turns.

After all 18 screws are loosened, recheck the

cooktop for flatness with the countertop surface.

Gently bump your hand along the outside edge of

the cooktop if needed to help the edge settle

evenly onto the countertop surface.

Retighten all 18 sheet metal screws.

Grounding Specifications:

Ground Path Resistance: 0.10 Ohm Max.

Insulation Resistance: 250K Ohm Min.

– 16 –

Page 19

Step 10 – Installing the Hold-Down

Screws

Screw

(on other side)

GEA00212

Retainers

Step 11 – Attaching the Blower T ransition

Duct

Note: Check for glass flatness discussed in Step 9

before installing hold-down retainers.

Countertop

Thumb screw

Use slot position

appropriate for

countertop thickness

Hold-down retainer

GEA00211

Hold down

retainer

GEA00312

Secure cooktop to the counter using the side

retainers and thumb screws shipped with the unit

(one on each side).

Use the blower transition duct that is packed with

your cooktop for all downward duct installations to

connect to 6-in. round standard ductwork.

Note: Use Rear Wall Adapter Kit JXRW89 for duct

installations through the rear cabinet wall and

retrofits of older 5-in. duct size cooktops.

Remove the cardboard packing in the blower

outlet.

Install the transition duct to the blower outlet with

the 3 sheet metal screws that are provided.

Step 12 – Connecting the Ductwork

Connect the ductwork prepared in Steps 5 and 6

to the blower transition duct.

– 17 –

Page 20

Electrical Installation

Step 13 – Before Making Electrical

Connections

Note to Electrician: The power leads supplied

with this appliance are U.L. recognized for connection to large-gauge household wiring.

The insulation of these leads is rated at temperatures much higher than the temperature rating of

household wiring. The current-carrying capacity of

a conductor is governed by the wire gauge and

the temperature rating of the insulation around the

wire.

Aluminum Wiring

WARNING: Improper connection of aluminum

house wiring to the copper leads can result in

serious problems.

Attach copper wires to aluminum wiring using

special connectors designed and U.L. listed for

joining copper to aluminum. Follow the connector

manufacturer’s recommended procedure closely.

Service Loop

Leave a loop in the wires to the cooktop so the

cooktop can be lifted 12 in. without having to

disconnect the wiring.

Electrical Requirements*

Model # Voltage Frequency kW

JP989 120/240 V 60 Hz 8.8 kW

120/208 V 60 Hz 6.7 kW

*For reference only. Verify with product rating plate.

Step 14 – Install 1/2-in. Flexible Conduit

With Supplied Clamp

Note: A clamp has

been included with the

cooktop for installing

the 1/2-in. flexible

conduit.

Remove the screws

holding the wire

compartment cover

and remove the cover.

Alternate

External

Ground

Screw

Clamp

Stop Tab

Clamping

Screw

Clamping Tab

Feed the power supply

leads through the

conduit; be sure to

leave enough length

to properly connect

these leads to the

cooktop power leads.

Thread the leads

through an anti-short

bushing and firmly seat

the anti-short bushing

in the end of the

conduit.

Feed the leads through

the hole in the wire

compartment.

Lay the conduit against

the side of the wire

compartment.

Place the clamp over

the conduit. Make sure

the bushing is fully

seated against the

stop tab in the clamp.

Tighten the clamping

screw until the

clamping tab is fully

seated against the

wire compartment.

When complete,

reinstall the wire compartment cover.

Power Supply

Leads

Bushing (Fully Seated)

Clamp

Stop Tab

Clamping

Tab

Clamping

Screw

Clamping

Tab

Anti-Short

Bushing

Conduit

GEA00214

GEA00215

GEA00216

GEA00217

Remove the clamping screw

and the clamp.

GEA00213

– 18 –

Page 21

Step 15 – Making Electrical Connections

3-Conductor Branch Circuit

Branch Circuit

Power

Supply

Leads

Cooktop

Power

Leads

Red Red Red

White or

Gray

White or

Gray White

Black Black Black

Green

NEUTRAL

120V AC

120V AC

GEA00218

Effective January 1, 1996, the National Electrical

Code requires that new, but not existing, construction utilizes a four-conductor connection to an

electric range. When installing an electric range in

new construction, follow the instructions in New

Construction and Four-Conductor Branch

Circuit Connection.

You must use a three-wire, single-phase AC 208Y/

120-Volt or 240/120-Volt, 60-Hertz electrical

system with separate ground. If you connect to

aluminum wiring, properly installed connectors

approved for use with aluminum wiring must be

used.

New Construction and Four-Conductor Branch

Circuit Connection

• When installing in new construction, or

• When installing in a mobile home, or

• When local codes do not permit grounding

through neutral:

Three-Conductor Branch Circuit Connection

• When installing in existing construction built prior

to January 1, 1996 and if permitted by local codes:

3-Conductor Branch Circuit

When connecting the cooktop to a 3-conductor

circuit, connect the red leads of the cooktop and

the power supply to the branch circuit’s red lead;

connect the black leads to each other. Connect the

green and white leads of the cooktop to the power

supply and branch circuit neutral leads, which are

white or gray.

4-Conductor Branch Circuit

When connecting the cooktop to a 4-conductor

circuit, connect the red leads of the cooktop and

the power supply to the branch circuit’s red lead;

connect the black leads to each other. Separate

the green and white leads of the cooktop. Connect

the cooktop’s white lead to the power supply and

branch circuit neutral leads, which are white or

gray. Ground the unit by connecting the green

conductor of the cooktop to the bare or green

leads of the power supply and branch circuit

(ground leads).

4-Conductor Branch Circuit

120V AC

120V AC

NEUTRAL

Branch Circuit Power

Red Red Red

White or

Gray

Black Black Black

Supply

Leads

White or

Gray White

Cooktop

Power

Leads

Bare or

GND

Green

Bare or

Green Green

GEA00219

– 19 –

Page 22

Removal and Replacement

Control Assembly Servicing:

Infinite Switches, Coil Select Switches,

Blower Switch, and ON Lamp Servicing

Caution: This cooktop has instant-on HOT surface

indicator lights. Wiring reversals can cause a direct

electrical short after all 4 surface units heat up and

close all 4 limiter switches. Check the wire termina-

tions for proper polarity of all L1 and L2 wires, H1 and

H2 wires, and heater HOT light terminals #2 and #4.

Note: Control assembly can be removed from the

cooktop without removing the cooktop from the

countertop.

1. Remove all 7 knobs from the cooktop.

Note: Remove any knob clips that remain on the control

shafts and reinsert clips inside knob stems.

2. Remove 4 screws and the wiring access cover

located below the controls. Disconnect the white 5pin blower connector inside.

3. Remove 3 screws that hold the component plate to

the cooktop. The screws are above the wiring with 2

toward the front and 1 toward the rear.

A

Screws

Screw

(on other side)

GEA00232

Caution: Save and replace with the exact screws to

prevent glass breakage (#8-18 x 1/4-in.).

4. Unplug the 2 red and 2 white connector housings.

5. Lower the control assembly and rotate the front side

down to remove.

Blower Assembly Replacement (WB26X10072)

Note: Blower assembly can be removed from the cook-

top without removing the cooktop from the countertop.

• The blower is a three-speed tapped winding design

with a permanent run/start capacitor.

1. Remove the access wiring cover located below the

controls (4 screws, see figure).

2. Unplug the blower connector and remove the wires

from the access cover.

3. Disconnect the transition duct from the blower

assembly.

4. Remove the intake grille and filter.

5. Support the blower assembly and remove the

7/16-in. nuts (A) inside the intake plenum.

GEA00300

Parts available: Complete bl o w er assembly with capacitor or replacement capacitor WB27X10363.

– 20 –

Page 23

GEA00319

Terminals

GEA00320

Terminals

Terminals

Capacitor Replacement (WB27X10363)

WARNING: Disconnect the electrical power supply

before servicing the capacitor. The capacitor is capable

of storing voltage that could be lethal. Do not touch the

bare connector terminals.

1. Remove the guard surrounding the capacitor shell.

Some models have a flat plastic spacer between the

capacitor shell and the motor. Retain the guard and

the spacer for reassembly.

2. Firmly push upward on the capacitor shell to remove

the capacitor from motor bracket cap.

WARNING: Make sure the stored electrical charge has

been dissipated by placing a 100-ohm, 2-watt resistor

across the terminals, or by placing a screwdriver blade

between the terminals and grounding the screwdriver to

the cooktop for several seconds.

3. Carefully discharge both capacitor wire harness

terminals as described above.

Note: Record wire harness connections.

4. Disconnect terminals using needle nose pliers and

reconnect in same orientation on new capacitor.

5. Firmly snap new capacitor shell casing into motor

bracket cap.

6. Replace plastic spacer (if so equipped) and guard

around capacitor.

GEA00321

HOT Light Replacement

AA

Note: HOT lights can be removed from the cooktop

without removing the cooktop from the countertop.

CC

BB

• The HOT lights and the surface heater ON light are

120-V lights with dual bulbs (WB25K10003).

• It is recommended to remove the blower if ser vicing

the left side HOT lights.

1. Remove the large bottom cover under the HOT

GEA00236

lights.

2. Remove 2 screws (A) and the HOT light bracket.

Caution: Save and replace with the exact screws to

prevent glass breakage (#8-18 x 1/4-in.).

3. Remove the wires (B) to the HOT lights.

4. Compress the HOT light wings (C) and remove

them.

– 21 –

Page 24

Countertop

Hold-down retainer

Glass Cooktop Removal from Countertop

(Required for heater replacement or broken glass

cooktop replacement.)

WARNING: To avoid injury to eyes from ceramic fiber

dust, heater assemblies should be serviced by removing

the entire cooktop from the countertop opening and

removing the glass assembly from the chassis.

Caution: Fiber ceramic material on the heating element

is very fragile–avoid contact.

• When servicing cooktop, care must be taken not to

scratch the glass.

1. Remove the wiring access cover located below the

controls (4 screws). Do not remove flex cable clamp

from wiring access cover. Disconnect the white 5-pin

blower connector inside.

2. Remove all cooktop hold-down retainers from

underneath the counter top’s edge.

3. Remove the blower (see Blower Assembly

Replacement) to reduce the weight of the cooktop

for safe removal from countertop. Do not remove

wires from access cover.

4. Protect the counter with two strips of wood or cardboard as shown.

Thumb screw

GEA00211

GEA00231

Caution: T o avoid

cooktop glass breakage,

do not lift or support the

cooktop using the

downdraft vent opening.

5. Reach up from inside the cabinet and push upward

on the burner box bottom enough to shim with

protective wood or a cardboard piece under one end.

Repeat for the other end.

Caution: Screws on the bottom of the burner box can

scratch the countertop surface. Use care to protect

countertop appearance.

6. Using the shims to get a handhold under the left and

right sides of the glass, carefully raise the cooktop

up about 7 inches, rotate slightly left or right (to best

working advantage), and set down as shown. Lift

each end slightly and adjust wood or cardboard as

shown to prevent scratching the countertop.

Note: Have an 18- to 24-in. prop rod (stiff enough to

hold 15 lbs. of compression) at hand.

– 22 –

Page 25

Side Wall

Side Wall

2 White

Spring Clip and

Coil Spring

7. Remove (12) 1/4-in. chassis screws (A) that hold the

glass and metal subplate to the cooktop box (3

screws from each side).

8. Raise the front of the glass and metal subplate

assembly slightly and use pliers to bend 2 tabs (B)

approximately 45 degrees outward.

9. Carefully raise the glass and metal subplate assembly from the cooktop box. Do not force it. Wires may

be caught on the flanges of the cooktop box.

CBAA

GEA00234

10. Insert the 2 tabs (B), on the front of the metal

subplate, into the 2 slots (C) on the top front flange

of the cooktop box.

11. Tilt the glass and metal subplate up and temporarily

install the prop rod near the center as shown.

Note: If you are replacing only 1 defectiv e heater using

Heater Replacement Method 1, skip to that section to

Prop

Rod

continue. Otherwise, go on to step 12.

12. Remove all 7 knobs from the cooktop.

Note: Remove any knob clips that remain on the control

shafts and reinsert clips inside knob stems.

Side Wall

Side Wall

Slot Opening

Slot Opening

2 White

2 White

Connectors

Connectors

Screws

Screws

GEA00233

Side Wall

Side Wall

Slot Opening

Slot Opening

2 Red

2 Red

Connectors

Connectors

GEA00301

13. Unplug the 4 connectors below the controls (2 red

and 2 white connectors).

14. Push the heater side of the connectors through the

sidewall slot openings (2 red connectors go to the

right and 2 white connectors to the left).

15. Have a 1/4-in. nut driver ready, then tilt the glass and

metal subplate assembly up to a fully vertical position and remove 2 screws from the bottom of the

center control panel plate.

Caution: Save and replace with the exact screws to

prevent glass breakage (#8-18 x 1/4-in.).

16. Retur n the glass and metal subplate back to the

tilted position supported by the prop rod, then remove the top screw from the center control panel

plate.

17. Pull the control panel plate away from the glass until

all 7 shafts pull out of the rubber grommets. Let the

control panel rest on the top of the burner box

chassis.

Note: If you are replacing a broken glass cooktop, skip

to Broken Glass Replacement section.

• If you are replacing a defective heater, skip to the

Heater Replacement Method 2 section.

– 23 –

Page 26

Heater Replacement Method 1 –

Using the prop rod.

This method has fewer steps than Method 2, but has a

higher risk of twisting and breaking the glass during

replacement of the heater. Use this method only if you

have good access to reaching around the propped

cooktop to replace the heater.

Perform Steps 1. thru 11. in the Glass Cooktop Re-

moval from Countertop section, then skip to Step 20.

in Method 2 below.

Note: To avoid glass breakage, use care not to twist or

lean on the glass cooktop while it is supported by the

prop rod.

Heater Replacement Method 2 –

Using a tabletop.

Perform Steps 1. thru 17. in the Glass Cooktop Re-

moval from Countertop section.

Metal

Tabs

HOT Light

Bracket Screws

Hairpin Cotter

Clips and Springs

Rubber Grommets

GEA00302

18. Have a clean, flat tabletop or countertop (at least

30 in. wide) available. Remove the prop rod and lift

the glass and metal subplate assembly away from

the burner box chassis.

19. Place the glass and metal subplate assembly appearance side down on the table with the 7 grommets off the front of the table. This is to prevent

glass breakage while replacing heaters.

Caution: Only about 2/3 of the glass is resting on the

table. Do not push down on the front 1/3 without supporting the front of the glass with your hand. Do not

force the glass assembly forward, as it will damage the

Left-Rear and Right-Rear infinite switch grommets.

20. Remove the heater’s hairpin cotter clips and springs

from the defective heater.

21. Remove the defective heater with wiring intact and

lay to one side.

22. Install the new heater in position. Make sure the

metal locating tabs do not go inside the metal heater

can during assembly.

23. Reinstall the springs and hairpin cotter clips.

Note: If you are replacing either the bridge heater or the

dual heater, it is easier to complete the wiring if you

temporarily remove the HOT light bracket to provide

hand access to terminals.

Caution: Save and replace with the exact screws to

prevent glass breakage (#8-18 x 1/4-in.).

24. Remove heater wires, one at a time, from the defective heater and place them on the exact terminal

positions on the new heater.

– 24 –

Page 27

Caution: The cooktop has instant-on HOT surface

indicator lights. Wiring reversals can cause a direct

electrical short after all 4 surface units heat up and

close all 4 limiter switches. Check the wire termina-

tions for proper polarity of all L1 and L2 wires, H1 and

H2 wires, and heater HOT light terminals #2 and #4.

25. Carefully shape the heater and HOT light wires to

avoid the center chassis rails, but do not allow the

wires to touch the metal heater cans.

26. Skip to Reinstalling Glass Cooktop section to

complete reassembly and installation into

countertop.

Broken Glass Replacement

Caution: Fiber ceramic material on the heating element

is very fragile–avoid contact.

• When servicing the cooktop, care must be taken not to

scratch the glass.

• The cooktop has instant-on HOT surface indicator

lights. Wiring reversals can cause a direct electrical

short after all 4 surface units heat up and close all 4

limiter switches. Check the wire terminations for proper

polarity of all L1 and L2 wires, H1 and H2 wires, and

heater HOT light terminals #2 and #4.

Shorter Tabs

Foam Tape

GEA00322

Note: The glass cooktop should be serviced by removing the entire cooktop from the countertop opening. The

glass and metal subplate are sealed together and are

replaced as an assembly.

1. Carefully open one end of the package containing

the replacement glass cooktop, then slide out the

B

glass and protective styrofoam packaging. Save a

packet of 1/4-in.-wide foam gasket tape for Step 4.

2. Place one piece of the flat syrofoam packaging on a

smooth tabletop and place the new glass subassembly face up. Check for any breakage or damage

before proceeding. Flip the glass face down onto the

styrofoam block with the control holes toward you.

Do not remove nylon filament tape from the glass

edge.

3. Using a pair of pliers, gently bend back only the

shorter tabs around each heater opening about 5

degrees to ease assembly of the heaters later.

4. Install new 1/4-in.-wide foam gasket tape

(WB25K10003) along the outer edge of the glass, on

top of the nylon filament tape.

5. Place the other piece of flat styrofoam packaging

beside the new glass subassembly as a place to put

the old glass subassembly when removed from the

cooktop chassis. This provides a side-by-side work

area to transfer heaters and HOT lights safely to the

new glass subassembly.

– 25 –

Page 28

6-in. Heater

Metal

Tabs

Dual

Heaters

Hairpin Cotter

Clips and Springs

HOT Light

Bracket Screws

Bridge

Heater

Rubber Grommets

GEA00323

Perform Steps 1. thru 17. in Glass Cooktop Removal

from Countertop section.

18. Verify that the flat styrofoam packing material from

the new glass subassembly is in place on a table or

countertop to be used as a work surface.

19. Place the broken glass and metal subplate assembly

appearance-side down on the above-mentioned

styrofoam packing surface.

20. Remove 7 rubber grommets from the broken glass.

Wet the rim of all 7 holes in the new glass by using a

drop of liquid soap on your fingertip to lubricate the

hole before reinstalling the grommets. Gently twist

(do not force) the grommet through the hole.

21. Remove the heater’s hairpin cotter clips and springs

from the 6-in. heater, the bridge heater, and the dual

heater.

22. Remove 2 special screws from each HOT light

bracket on the left and right sides.

Caution: To prevent glass breakage, save and replace

with exact screws (#8-18 x 1/4-in.).

23. Lift out the bridge heater with the wiring and HOT

lights intact and transfer to the new glass. Make

sure the metal locating tabs do not go inside the

metal heater can during assembly.

24. Lift out the 6-in. and dual heaters together with

wiring and HOT lights intact and transfer them to the

new glass assembly in a similar manner.

25. Reinstall all heater springs and cotter hairpin clips.

26. Reinstall both left and right HOT light brackets using

the special #8-18 x 1/4-in. screws.

Caution: The cooktop has instant-on HOT surface

indicator lights. Wiring reversals can cause a direct

electrical short after all 4 surface units heat up and

close all 4 limiter switches. Check the wire termina-

tions for proper polarity of all L1 and L2 wires, H1 and

H2 wires, and heater HOT light terminals #2 and #4 if

any wires were removed.

27. Carefully shape the heater and HOT light wires to

avoid the center chassis rails, but do not allow the

wires to touch the metal heater cans.

Proceed to Reinstalling Glass Cooktop section to

complete reassembly and installation into countertop.

– 26 –

Page 29

Reinstalling Glass Cooktop

Side Wall

Side Wall

2 White

B

1. Verify that the burner box chassis is sitting level in a

stable position, diagonally across the countertop

cutout.

2. Transfer the serviced or new glass and metal

subplate back to the burner box chassis and insert

guide tabs (B) into the slots (C) on the chassis front

flange. Temporarily insert the prop rod.

Side Wall

Side Wall

Slot Opening

Slot Opening

2 White

2 White

Connectors

Connectors

C

AA

Screws

Screws

GEA00234

Side Wall

Side Wall

Slot Opening

Slot Opening

2 Red

2 Red

Connectors

Connectors

GEA00301

3. Reinsert all 7 control shafts through the grommets.

Install only the top center screw using the special

#8-18 x 1/4-in. scre w.

4. Have a 1/4-in. nut driver and 2 special #8-18 x 1/4-in.

screws ready, then remove the prop rod and raise

the glass up to a fully vertical position. Insert the 2

special screws at the bottom of the control panel.

5. Return the cooktop to the tilted position supported

by the prop rod.

6. Push the 2 red and 2 white heater and HOT light

connectors back through the slot in the chassis and

into the center wiring compartment.

7. Reconnect the 2 red and 2 white heater and HOT

light connectors.

8. Verify that all heater wires are clear of the center

chassis flange and are not touching any of the metal

heater cans prior to lowering cooktop onto chassis.

9. Lift the glass subplate assembly out of the guide slots

and gently lower it straight down over the chassis.

Caution: When installing the glass and metal subplate

assembly, if any of the 12 side screw holes do not line

up, do not force the top down. Look for wires trapped

between the cooktop box flanges and the glass subplate.

Push the wires out of the way–trapped wires can

cause glass breakage.

10. Raise the front of the glass slightly and use pliers to

straighten 2 tabs (B).

11. Replace 12 side screws (A) to secure the glass and

metal subplate to the chassis.

12. Carefully lift each end of the cooktop to remove the

protective wood or cardboard.

Caution: Glass is fragile; do not allow glass to drop

more than about 1/2-in. onto the countertop.

13. Lower chassis back into the countertop opening.

Caution: Do not attempt to force the glass to meet the

cooktop.

14. Inspect the cooktop glass for rocking or uneven

gaps. If the glass cooktop does not sit evenly on the

countertop, skip to the next section, Rocking or

Uneven Glass in Countertop, before proceeding.

– 27 –

Page 30

15. Reinstall 7 knobs.

16. Reinstall the blower and reconnect the 5-pin white

blower connector inside the center wiring compartment.

17. Reinstall wiring access cover with 4 screws, verifying

that no wires are pinched under the cover.

18. Reinstall ductwork in blower outlet.

Caution: Install hold-down clamps finger-tight only.

Overtightening will break glass.

19. Reinstall hold-down retaining clamps (if used).

20. If a new glass cooktop was installed, clean it with the

cleaning and conditioning cream (WX10X300). This

will make future cleaning much easier.

21. Turn on all 4 bur ners for a couple of minutes until all

4 HOT lights stay on by themselves with the infinite

switches in the OFF position. This checks for proper

polarity of all L1 and L2, H1 and H2, and HOT light

wires.

GEA00297

Rocking or Uneven Glass in Countertop

Caution: To avoid glass breakage, do not attempt to

force the glass to meet the cooktop.

1. Inspect all four sides for cooktop glass rocking or

uneven gaps at the countertop surface.

2. If there is rocking or an uneven gap, use a 1/4-in. nut

driver to loosen 18 sheet metal screws on the burner

box bottom panels while the cooktop is in the

countertop (see figure). Loosen each screw approximately 1 or 2 turns.

3. After all 18 screws are loosened, recheck the

cooktop for flatness. If needed, gently “bump” your

hand downward along the outside edge of the

cooktop’s glass surface.

4. If this still does not correct a rocking problem, the

cooktop will have to be pulled from the countertop to

slightly loosen (about 1 turn) the 12 side screws that

attach the glass and metal subplate to the burner

box chassis. Lower the chassis back into position

and recheck for rocking.

5. Tighten all 18 bottom screws.

– 28 –

Page 31

Notes

– 29 –

Page 32

Illustrated Parts Breakdown

Parts list for Model No. JP989.

Refer to microfiche for other model information.

– 30 –

Page 33

#feRnoitpircseD#traP.ytQ

000 3HCTIWSLORTNOCETINIFNI94001X12BW4

000 4)KCALB(.MSABONK.U.S98001X30BW4

000 4)ETIHW(.MSABONK.U.S19001X30BW4

000 4)EUQSIB(.MSABONK.U.S09001X30BW4

00 11DEEPS-3,HCTIWSREWOLB55001X42BW1

00 21)KCALB(BONKROTCELES53001T30BW3

00 21)ETIHW(BONKROTCELES43001T30BW3

00 21)EUQSIB(BONKROTCELES39001T30BW3

00 61LB(ELLIRGTNEVCAK) 64301X70BW1

00 61)ETIHW(ELLIRGTNEV84301X70BW1

00 61)EUQSIB(ELLIRGTNEV74301X70BW1

00 91HCTIWSROTCELES9440X42BW2

00 62LB(RETLIFCA)K15601X20BW1

00 72LAESLORTNOCETINIFNI4059X20BW7

00 82DRAUGERIW25601X20BW1

00 03MUNELP75001X94BW1

00 33THGILROTACIDNI30001K52BW5

00 83PMALCTIUDNOC8541X20BW1

00 93PMALCTIUDNOC4103X20BW1

00 04DEEPS-3,.MSAREWOLB27001X62BW1

00 14ROTICAPACREWOLB36301X72BW1

00 44NOITISNARTTSUAHXE43001X83BW1

00 15LB(.MSAPOTSSALGCA)K36001T16BW1

00 15)ETIHW(.MSAPOTSSALG66001T16BW1

00 15)ETIHWEURT(.MSAPOTSSALG56001T16BW1

00 15)EUQSIB(.MSAPOTSSALG46001T16BW1

00 65"6,TNEMELETNAILAH74001T03BW1

00 75EGDIRB,TNEMELETNAILAH75001T03BW1

00 85"9,TNEMELETNAILAH44001T03BW1

00 06GNIRPS.GTMRETAEH9115X90BW01

00 16RETTOCNIPRIAH47001X10BW01

00 09.TKRB.GTMTNEMELE35601X20BW01

0 008EPATMAOF37501X20BW1

0 108PILCRETLIF5187X20BW1

0 208LB(WERCSCA)K6175X10BW1

0 308PILCRENIATER97001X10BW2

0 408WERCSBMUHT08001X10BW2

0 999RENAELC003X01XW

0 999REPARCS203X01XW

0 999LAUNAM-INIM67702-13

0 999SNOITCURTSNINOITALLATSNI51008-94

LAUNAMS’RENWO41008-94

– 31 –

Page 34

Troubleshooting Information

melborPsesuaCelbissoPoDottahW

tonlliwstinuecafruS

liobgnilloraniatniam

tsaftonsignikoocro

.hguone

tonodstinuecafruS

.ylreporpkrow

yam(sehctarcsyniT

ro)skcarcsaraeppa

tnaidarnosnoisarba

.ecafrusssalgpotkooc

.desu

.deppirt

.tes

.hctiws

.tnemeleytluaF

.desugnieb

.potkooceht

gnieberawkoocreporpmI

ebyamemohehtniesufA

rekaerbtiucricehtronwolb

ylreporpmislortnocpotkooC

.desugnieb

lortnoctinuecafrusytluaF

sdohtemgninaelctcerrocnI

hguorhtiwerawkooC

rodesugniebsmottob

rotlas(selcitrapesraoc

ehtneewteberew)dnas

foecafrusehtdnaerawkooc

.gninaelcfotlusera

hctamdnatalfyletulosbaeratahtsnapesU

.detcelestinuecafrusehtforetemaideht

.rekaerbtiucricehtteserroesufehtecalpeR

tinuecafrusehtroftessilortnoctcerrocehteesotkcehC

.evitcefedfiecalperdnahctiwsfoytiunitnockcehC

.evitcefedfiecalperdnatnemelefoytiunitnockcehC

.erudecorpgninaelcdednemmoceresU

erofebnaelceraerawkoocdnasmottoberawkooceruseB

sehctarcsyniT.smottobhtoomshtiwerawkoocesU.esu

saemitnielbisivsselemoceblliwtub,elbavomertonera

dilsneebsaherawkooC

.ecafruspotkoocehtssorca

noitarolocsidfosaerA

.potkoocehtno

roserutximragustoH

ehtotdetlemcitsalp

.ecafrus

ffognilcyctneuqerF

ecafrusfonodna

.stinu

.desu

esehthtiwtcatnoc

.secnatsbus

.desu

gnieberawkoocreporpmI

.maercgninaelceht

htiwledomanoecafrustoH

.potkoocssalgetihwa

.slooc

otniemacpotkooctoH

gnieberawkoocreporpmI

ehteeS gninaelCdnaeraC .noitces

.noitcesgninaelCdnaeraCehteeS

sallewsasnapreppocdnamunimulamorfskraM

htiwdevomerebnacdoofroretawmorfstisopedlarenim

nehwderolocsidraeppayamecafrusehT.lamronsisihT

ssalgehtsaraeppasidlliwdnayraropmetsisihT.tohsiti

.gnilcyceziminimoterawkooctalfylnoesU

– 32 –

Page 35

melborPsesuaCelbissoPoDottahW

.tohsleefpotkooCgnieberawkoocreporpmI

.desu

.talfyletulosbaera

.ylwolskoocsdooFgnieberawkoocreporpmI

.desu

yam(skramlateM

.)skcarcsaraeppa

roskaertskraD

.skceps

tonlliwbonklortnoC

.nrut

.gnitnevrooP.retlifdeggolC.snoitcurtsnirepretlifnaelC

.tes

.desugnieb

.desu

.thgitriaootesuoH .ecruosriahserfedivorpotylthgilswodniwanepO

sdohtemgninaelctcerrocnI

dilsneebsaherawkooC

.ecafruspotkoocehtssorca

gnieberawkoocreporpmI

ylreporpmislortnocpotkooC

.detcurtsbopacllaW.pacllawroiretxemorfegakcolbevomeR

ehteeS gninaelCdnaeraC .noitces

ehteeS gninaelCdnaeraC .noitces

.detcelestinuecafrusehtsaretemaidemas

.serudecorpgninaelcdednemmoceresU

ehtnahtrettohmeesyamecafruspotkoocssalgehT

hcihwsnapehtesU.lamronsisihT.otdesusiremusnoc

.reloocpotkoocehtpeekplehlliwtnevehtgnisU

ehtdna,thgiewyvaehylriaf,talfebdluohssmottobnaP

dehsupebtsumti,noitisopFFOehtnisibonkehtnehW

rehtoynanisibonkehtnehW.denrutebnactierofebni

.nidehsupgniebtuohtiwdenrutebnacti,noitisop

.kcutsroodrepmadpacllaW tnemevomeerfrofroodrepmadpacllawroiretxekcehC

.noitcurtsboro

sdeecxehtgneltcuD

001dednemmocer

.mumixamtftnelaviuqe

.hctiwsrewolbytluaF .evitcefedfiecalperdnahctiwsfoytiunitnockcehC

.rotomrewolbytluaF.roticapackcehC

ehtforenrocenO

tsniagatonsipotkooc

.potretnuoceht

.nurtcud

.evitcefedfiylbmessa

nierudecorpwolloF noitallatsnIpotkooC .noitces

yfilpmisotswobleforebmunecuderrenwoemohevaH

rewolbecalperdnarotomrewolbfoytiunitnockcehC

– 33 –

Page 36

Schematics and Strip Circuits

4

Y

N

WARNING

1500W

P1

2

LIMITER

THERMAL

R/W

RR

SINGLE

R/W

V

2

LIMITER

THERMAL

R

H

S

RF

1000W

1500W

DUAL

4

P1

4

H

4A

S

W/R

O

W/R

LIT

HOT

R

C

GND

R

B

PL

MTG

W

NATURAL

54321

R

R

54321

R

HOT

PL1L2

PL1L2

LIT

YNVCO

RR

LR

W

NATURAL

21

P

R

L1L2

SW

H2 H1

B

SU

LIT

R

SW

H2 H1

B

YNVCO

RF

SW

H2 H1

R

PL1L2

LF

SW

H2 H1

R

N

SYMBOL

COLOR

RED

BLUE

Y

B

YELLOW

BLACK

R

W

O

2

4

SW

SEL

3

1

5

4

2

BLO SW

24

SW

SEL

O

G

W

ORANGE

GREEN

WHITE

O

V

C

VIOLET

BROWN

G

R

W/R

NOTE:

FOR SERVICE REPLACEMENT ON ALL LEADS TO

RADIANT UNITS, USE 16GA. 200 C WIRE.

FOR SERVICE REPLACEMENT ON ALL OTHER

LEADS, USE 16GA. 150 C WIRE EXCEPT AS

INDIVIDUALLY NOTED ON LEADS.

B

CCCC

BR

RW

B-10GAR-10GAW-12GAG-10GA

POWER MUST BE DISCONNECTED

BEFORE SERVICING THIS APPLIANCE

WIRING DIAGRAM/SCHEMATIC DIAGRAM

N/W

S

H

N/W

R

LIMITER

THERMAL

2

P1

1800W

LR

Y

4

RED

N

C

800W

LC

R

W/N

S

H

W/N

LIMITER

THERMAL

2

P1

1800W

LF

V

O

4

HOT

BRIDGE

LIT

W

LIT

HOT

RED

21

W

R

W

B

R

N

54321

N

R

B

BLO

G

W

G

W

GEA00220

– 34 –

Page 37

Strip Circuits

Blower

BLO

N

5

R

4

B

3

W

2

G

1

N

R

B

314

5

G

W

W-12GAG-10GA

BLO SW

2

CC

R

C

R-10GA

GND

COLOR

RED

BLUE

YELLOW

BLACK

ORANGE

GREEN

WHITE

VIOLET

BROWN

SYMBOL

R

N

Y

B

O

G

W

V

C

GEA00221

Left Rear Surface Unit

GND

N/W

H4S

LR

1800W

THERMAL

P1

LIMITER

2

N/W

R

RED

Y

5

4

N

2

1

WW

REDHOT LIT

C

W-12GA

B

PL1L2

LR

R

SW

H2 H1

SU LIT

R

R

C

R-10GACB-10GA

R

B

GEA00222

LC

800W

BRIDGE

Bridge Surface Unit

CC

RED

2

3V

V

LF

SW

H2 H1

PL1L2

O

GEA00223

SEL

SW

24

– 35 –

Page 38

Strip Circuits

Left Front Surface Unit

GND

W/N

H4S

LF

1800W

THERMAL

P1

LIMITER

2

W/N

R

RED

V

O

WW

V

3

1

2

1

REDHOT LIT

O

C

W-12GA

B

L2

PL1

LF

SW

H2 H1

SU LIT

R

R

C

R-10GACB-10GA

R

R

B

GEA00224

Right Rear Surface Unit

RF

RR

1500W

1000W

DUAL

1500W

SINGLE

GND

B

L2

PL1

RR

SW

H2 H1

SU LIT

R

R

C

R-10GACB-10GA

R

R

B

GEA00225

H4S

P1

R/W

THERMAL

LIMITER

2

R/W

R

NATURAL

Y

N

WW

NATURALHOT LIT

Y

5

4

2

1

N

C

W-12GA

Right Front Surface Unit

4A

4

W/R

H

P1

4

S

2

THERMAL

LIMITER

R/W

W/R

2

SEL

SW

4

NATURAL

O

R

C

V

WW

NATURALHOT LIT

O

1

2

C

3

2

1

V

C

W-12GA

GND

B

R

L2

PL1

RF

SW

H2 H1

O

SU LIT

R

R

C

R-10GACB-10GA

R

B

GEA00226

– 36 –

Page 39

Warranty Information

Sales slip or cancelled check is required as proof of original purchase date to

obtain service under warranty.

All warranty service is provided by our Factory Service Centers or an authorized Customer

Care® technician. For service, call 800.GE.CARES.

For The Period Of:

One Year

From the date of the

original purchase

Five Years

From the date of the

original purchase

GE Will Replace:

Any part

ship. During this

charge

A replacement glass cooktop

discolor; or if the pattern wears off.

A replacement radiant surface unit

During this

for any labor or in-home service.

of the cooktop that fails due to a defect in materials or workman-

full one-year warranty

, all labor and in-home service to replace the defective part.

limited additional four-year warranty

What GE Will Not Cover:

• Service trips to your home to teach you

how to use the product.

• Improper installation.

• Failure of the product if it is abused, misused, or used for other than the intended

purpose or used commercially.

• Damage to the glass cooktop caused by

use of cleaners other than the recommended cleaning creams.

, GE will also provide,

if it should: crack due to thermal shock;

if it should burn out.

, you will be responsible

• Replacement of house fuses or resetting of

circuit breakers.

• Damage to the product caused by accident,

fire, floods, or acts of God.

• Incidental or consequential damage to

personal property caused by possible

defects with this applicance.

free of

• Damage to the glass cooktop caused by

hardened spills of sugary materials or

melted plastic that are not cleaned according to the directions in the Owner’s Manual.

This warranty is extended to the original purchaser and any succeeding owner for products purchased

for home use within the USA. In Alaska, the warranty excludes the cost of shipping or service calls to

your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

To know what your legal rights are, consult your local or state consumer affairs office or your state’s

Attorney General.

Warrantor: General Electric Company. Louisville, KY 40225

– 37 –

Loading...

Loading...