Page 1

6

If you have questions, call 800.GE.CARES or visit our Website at: www.GEAppliances.com

REMOVE PACKAGING

Open the carton and remove parts package.

Check contents to be sure all pieces are

present. (The parts package may be attached

to the power cord.)

Remove the shipping materials. Remove the

carton and set aside. The carton can be used

as a pad when changing or adjusting vent

direction.

Installation Downdraft Vent

Instructions System

BEFORE YOU BEGIN

Read these instructions completely and

carefully.

•

IMPORTANT — Save these

instructions for local inspector’s use.

•

IMPORTANT — Observe all

governing codes and ordinances.

• Note to Installer – Be sure to leave these

instructions with the Consumer.

• Note to Consumer – Keep these

instructions for future reference.

• Note – This appliance must be properly

grounded.

• Proper installation is the responsibility of

the installer.

• Product failure due to improper installation

is not covered under the Warranty.

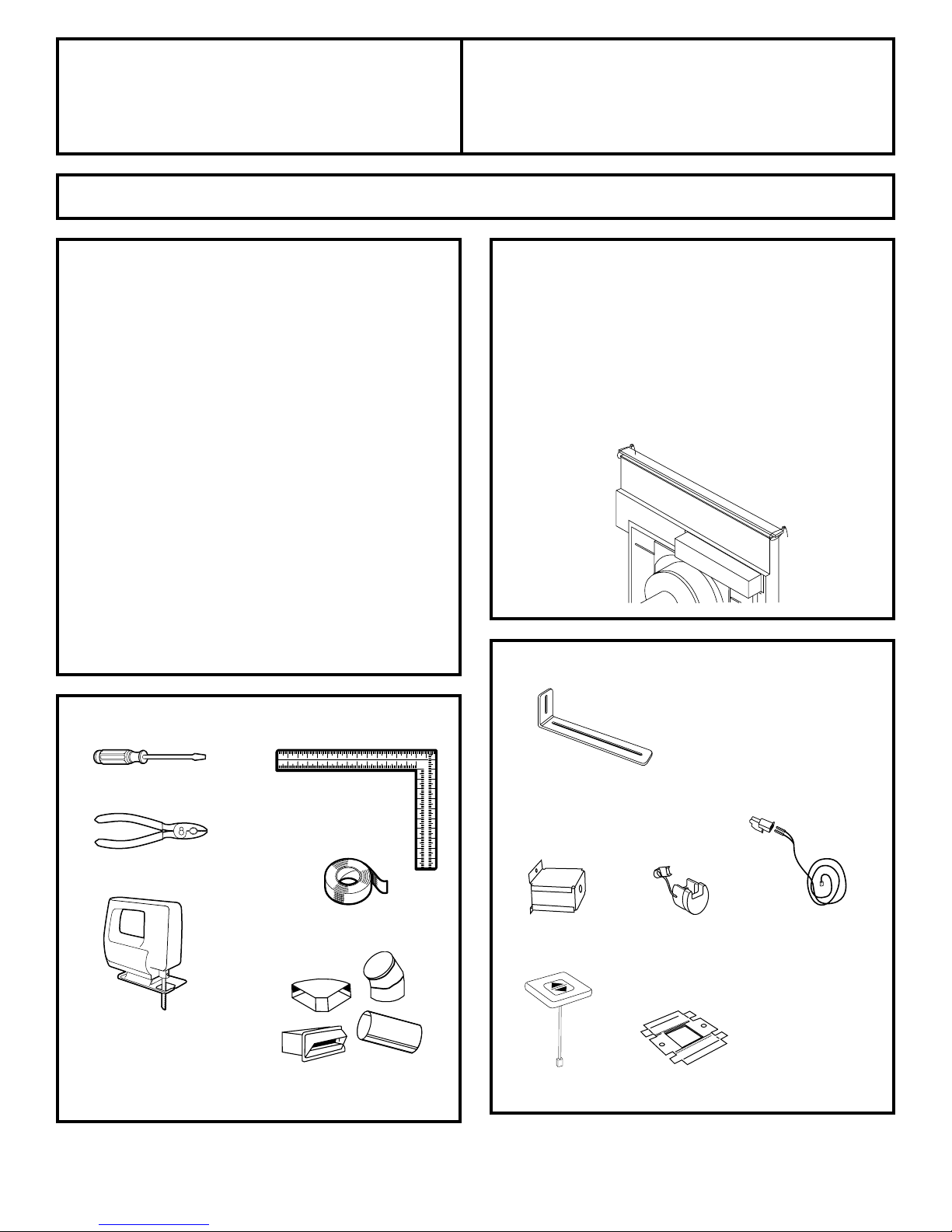

TOOLS YOU WILL NEED

Flat-blade screwdriver

Jig saw

Ductwork to suit

the installation

Carpenter square

PARTS INCLUDED

Remote raise/lower assembly (for 36″ models only)

Stabilizing brackets

(all models) (4)

Wire box (2)

and screws (4)

Plastic strain

relief (2)

Wire and white

connector (1)

Switch cover

plate (1)

Attachment

bracket (1)

Pliers

Duct tape

Page 2

7

Installation Instructions

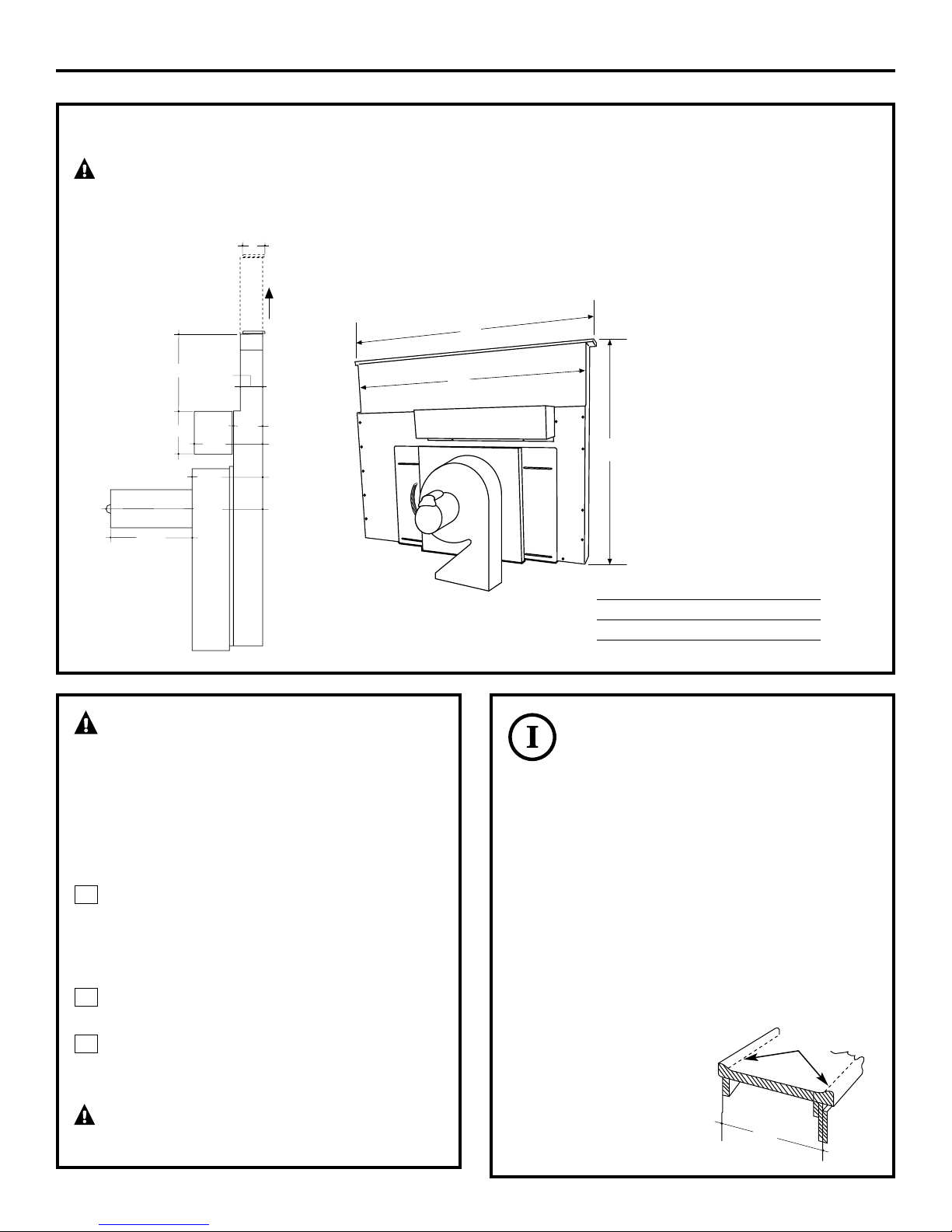

DIMENSIONS AND CLEARANCES

CAUTION — Wall coverings, countertops and

cabinets should withstand 200°F. heat generated by

any cooktop.

A B

30″ Models 30″ 281⁄4″

36″ Models 36″ 333⁄4″

A

B

2″

8

1

⁄2″

3

1

⁄8″

33⁄8″

10

1

⁄2″

71⁄8″

71⁄2″

3

3

⁄4″

2

1

⁄4″

6

1

⁄4″

WARNING!

INSTALLATION SAFETY

INSTRUCTIONS

TO REDUCE THE RISK OF FIRE, ELECTRIC

SHOCK, OR INJURY TO PERSONS, OBSERVE

THE FOLLOWING:

Installation work and electric wiring

must be done by qualified person(s)

in accordance with all applicable codes

and standards, including fire-rated

construction.

Ducted fans must always be vented to

the outdoors.

When cutting or drilling into wall or

ceiling, do not damage electrical wiring

and other hidden utilities.

WARNING — To reduce the risk of

fire, use only metal ductwork.

C

B

A

IMPORTANT: These vents are

recommended for island installations.

Against-the-wall installations are

limited due to countertop depth

requirements. The vent and cooktop

combined depth requires an extra

deep flat countertop surface.

The countertop must be at least 26″ deep

with a flat surface area of 23

1

⁄2″ or more, front

to back. (NOTE: JGP932S, JP350SC, JP930SC

and JP938SC require 23

5

⁄8″ flat surface area.)

In addition, other clearances to the front

edge of the countertop must be considered.

• See specific cutout illustrations with your

cooktop model to determine requirements.

• A countertop with

a raised lip or rolled

front edge may not

allow enough flat

area for installation.

Flat surface

area

24″

27″

Page 3

Installation Instructions

8

ADVANCE PLANNING

DUCTWORK

Prepare ductwork to vent to the outdoors.

• Use the shortest and straightest duct run

possible.

The maximum permissible length for duct

run is 150 feet.

Refer to Duct Fittings chart to calculate

equivalent length for various duct

configurations.

• The downdraft blower system is designed

to use 3

1

⁄4″ x 10″ ductwork. It can be

transitioned to 6″ round.

• Ductwork MUST be vented to the outside—

never into a crawl space, attic or other

enclosed space.

• Determine the need for a wall cap or roof

cap. Purchase the cap in advance from

your home building center or plumbing

supply.

CLEARANCES

• Installation must conform with local codes.

• The downdraft system with blower, motor

and duct work will occupy the cabinet

below the countertop and cooktop.

• The blower/motor assembly can be located

below the cabinet floor. The assembly will

fit between 16″ floor joists.

In this installation a transition to 6 ″ round

is required.

• The blower motor assembly can also be

installed outdoors. Order JXBC67 for

remote blower installations outdoors.

• Refer to Dimensions and Clearances for

information on appropriate placement

and necessary clearances when planning

installation.

• Refer to your specific cooktop installation

instruction for other appropriate clearances.

• Avoid placing cabinetry directly above the

cooking surface when possible.

• If cabinetry is used above the cooking

surface:

Installation must conform with local codes.

Use cabinets no more than 13″ deep.

Maintain 30″ minimum clearance between

cooktop and unprotected cabinets directly

above cooktop.

If clearance is less than 30″, protect cabinet

bottoms with flame-retardant millboard at

least 1/4″ thick or gypsum board at least

3/16″ thick covered with 28 gauge sheet

steel or .02″ thick copper.

Clearance between cooktop and protected

cabinetry must not be less than 24″.

EXCEPTION: Installation of a listed

microwave oven or cooking appliance over

the cooktop shall conform to the installation

instructions packed with that appliance.

• Working areas adjacent to the cooktop

should maintain 18″ minimum clearance

between countertop and cabinet bottom.

COOKTOP ELECTRICAL AND

GAS LOCATION

Plan the placement of the electrical outlet

and gas (if used) carefully. Gas or electrical

outlets cannot be placed on the back wall of

the cabinet because it may interfere with the

downdraft plenum.

Install a standard electrical outlet within

reach of the vents’ 2 foot long power cord.

• The vent and a gas cooktop combination

can operate from the same 120V standard

duplex outlet.

• Electric cooktops must operate from

a separate 240V junction box.

REMOTE SWITCH

(for 36″ models only)

The downdraft vent has a separate

raise/lower switch. Plan to install the switch

in a convenient location outside of the

vent/cooktop cutout.

Page 4

9

Installation Instructions

Base

cabinet

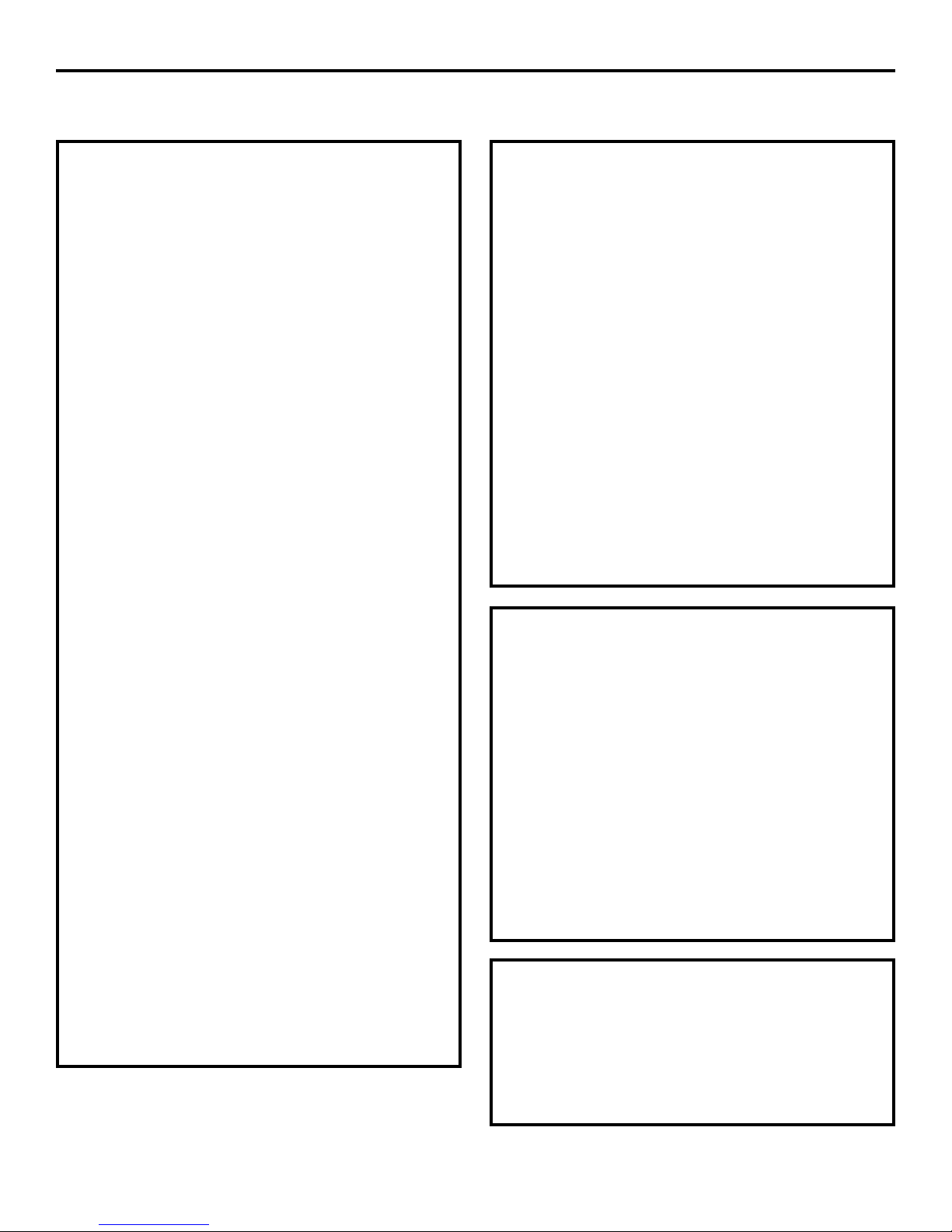

INSTALLATION POSSIBILITIES

When the kitchen design calls for an against

the wall installation, move 24″ deep base

cabinet forward, 3″ to 5″. Filler panels can

be angled or flat to fill the space between

adjacent cabinets.

Maintain cutout clearances to front edge as specified.

In an island or peninsula, the countertop can

be extra deep to provide seating opposite of

the cooktop. Adding base cabinets on each

side of the cooktop provides extra storage

and countertop work space.

Filler

panel

Filler

panel

Base sink

30″ Min. for JVB37

36″ Min. for JVB67

18″

Base to sink

30″ to 42″

Cover

panel

Countertop

overhang

per cooktop

clearances

must be

maintained

End

panel

18″

Page 5

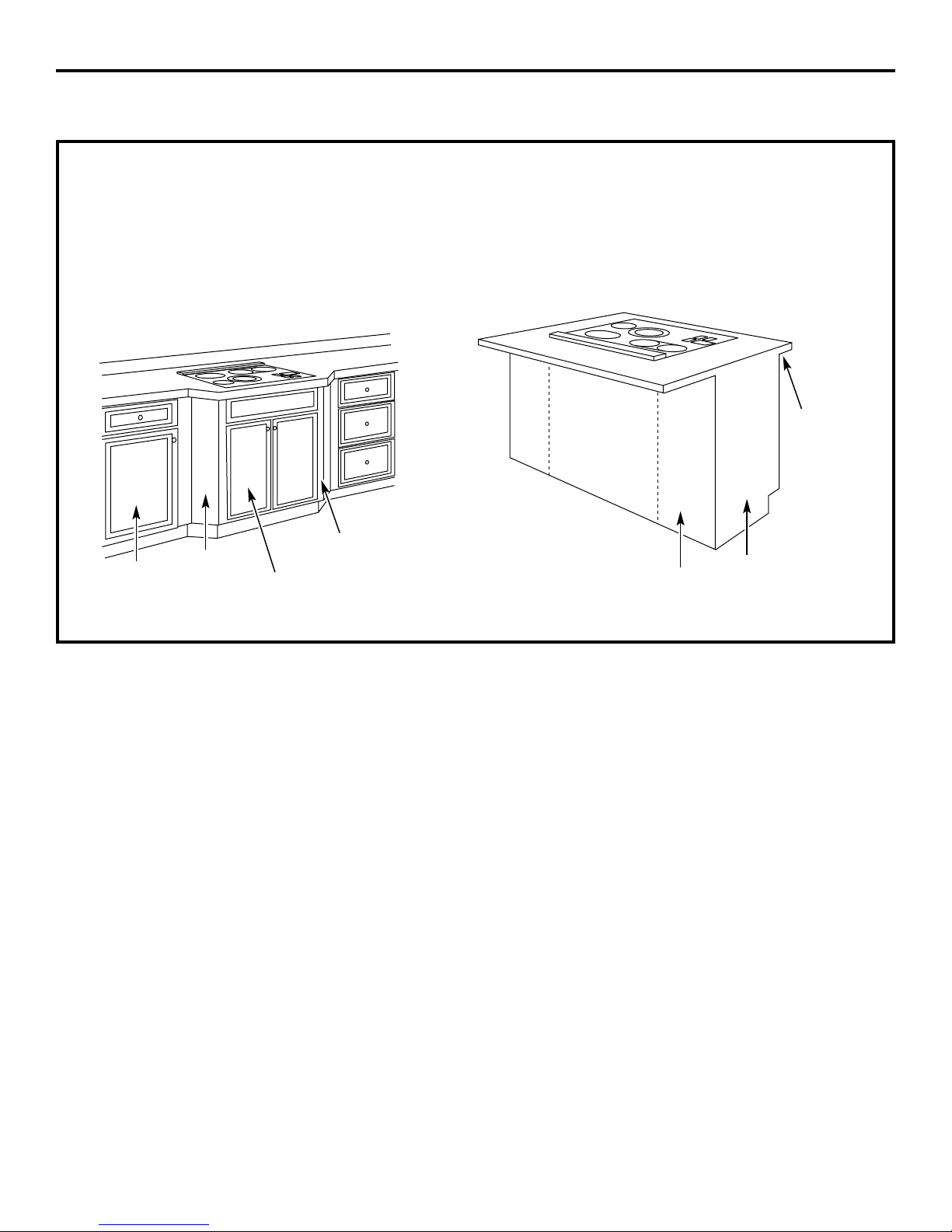

30″ COOKTOP/DOWNDRAFT

UNIT JVB37

NOTE: Before you begin, measure and mark

Dimension 3 to ensure that adequate flat

countertop surface is available.

Identify the cutout illustration for the cooktop

model you are installing with this downdraft

vent system.

• Draw lines on the countertop to follow

as a cutting guide.

• Make sure sides of the opening are

parallel and rear and front cuts are exactly

perpendicular (right angle) to sides.

Planning Installation 30″ Electric and Gas Cooktops with Downdraft Vents Preparing Cutout

Overall Cooktop Surface Surface Depth Minimum Setback Combined Combined

Model No. Width Overall Depth with Downdraft* Cutout to Front Edge** Cutout Width Cutout Depth

JP326 30-1/4″ 21-1/4″ 23-3/8″ 2-1/2″ 28-1/2″ 22-3/8″

JP340

JP350

29-3/4″ 20-7/8″ 23″ 2-1/2″ 28-1/2″ 22-1/4″

JP930

JP931

JP938

JP939

JP350SC

JP930SC 29-7/8″ 21-1/2″ 23-5/8″ 2-1/2″ 28-1/2″ 22-3/8″

JP938SC

JGP328

JGP933 30″ 21″ 23-1/8″ 2-1/2″ 28-1/2″ 22-3/8″

JGP933S

JGP336 30″ 21″ 23-1/8″ 2-1/2″ 28-1/2″ 22-1/4″

JGP932 29-3/4″ 21″ 23-1/8″ 2-1/2″ 28-1/2″ 22-1/4″

JGP930S 30″ 21-1/4″ 23-3/8″ 2-1/2″ 28-1/2″ 22-1/4″

JGP932S 29-7/8″ 21-5/8″ 23-3/4″ 2-1/2″ 28-1/2″ 22-5/8″

**Includes 1/8″ gap between cooktop and vent trim

**Required to maintain UL or AGA approvals

654321

10

Installation Instructions

INSTALLING THE DOWNDRAFT VENT SYSTEM

21⁄8″

8

1

⁄2″

1

2

3

4

5

6

Page 6

Planning Installation 36″ Electric and Gas Cooktops with Downdraft Vents Preparing Cutout

Overall Cooktop Surface Surface Depth Minimum Setback Combined Combined

Model No. Width Overall Depth with Downdraft* Cutout to Front Edge** Cutout Width Cutout Depth

JP626 35-1/2″ 21″ 23-1/8″ 2-1/2″ 34″ 21-1/8″

JP960

JP961

JP968

JP969

36″ 20-3/8″ 22-1/2″ 2-1/2″ 34″ 21-3/4″

JP960S

JP968S

36-1/8″ 21″ 23-1/8″ 2-1/2″ 34″ 21-7/8″

JGP628

JGP963 36″ 21″ 23-1/8″ 2-1/2″ 34″ 21-7/8″

JGP963S

JGP636 36″ 21″ 23-1/8″ 2-1/2″ 34″ 21-7/8″

JGP960S 36″ 21-1/4″ 23-1/8″ 2-1/2″ 34″ 22-7/8″

JGP962 36″ 20-7/16″ 22-9/16″ 2-1/2″ 34″ 21-3/4″

JGP962S 36-1/8″ 21-1/16″ 23-3/16″ 2-1/2″ 34″ 22-1/8″

**Includes 1/8″ gap between cooktop and vent trim

**Required to maintain UL or AGA approvals

654321

11

Installation Instructions

36″ COOKTOP/DOWNDRAFT

UNIT JVB67

NOTE: Before you begin, measure and mark

Dimension 3 to ensure that adequate flat

countertop surface is available.

Identify the cutout illustration for the cooktop

model you are installing with this downdraft

vent system.

• Draw lines on the countertop to follow

as a cutting guide.

• Make sure sides of the opening are

parallel and rear and front cuts are

exactly perpendicular to sides.

21⁄8″

8

1

⁄2″

1

2

3

4

5

6

Page 7

12

Installation Instructions

INSTALLING THE DOWNDRAFT VENT SYSTEM

POWER SUPPLY

This downdraft vent must be supplied with

120V, 60Hz., and connected to an individual,

properly grounded branch circuit, protected

by a 15 or 20 ampere circuit breaker or time

delay fuse.

Gas Cooktops

If this vent is installed in combination with a

gas cooktop, it may operate from the same

duplex outlet.

Electric Cooktops

If this vent is installed in combination with an

electric cooktop, the vent must operate from

a separate 120V outlet.

A properly grounded 3-prong receptacle

should be located within reach of the vents’

2 foot power cord.

• Locate the receptacle inside the cabinet on

the right side wall. The receptacle cannot

be placed on the back of the cabinet wall

where it may interfere with the downdraft

plenum. See illustration.

NOTE: Do not use an extension cord or

adapter plug with this appliance. Follow

National electrical codes or prevailing local

codes and ordinances.

Electrical outlet

12″ above

cabinet floor

34″ for 36″ models

28

1

⁄2″ for 30″ models

Do not leave gas or electrical

connections within shaded area.

291⁄2″

Page 8

Installation Instructions

13

DUCTWORK LENGTH AND DUCT FITTINGS

NOTE: Do not exceed 150 foot maximum permissible equivalent lengths!

Flexible ducting: If flexible metal ducting is used, all equivalent feet values in the table should be

doubled. The flexible metal duct should be straight and smooth and extended as much as possible.

DO NOT use flexible plastic ducting.

Add equivalent lengths for all duct pieces and transitions used to ensure that the duct run does not

exceed the maximum 150 feet.

Duct Equivalent Duct Equivalent Duct Equivalent

Pieces Length* Pieces Length* Pieces Length*

31⁄4″ x 10″

to 6″ Round

6″ Round 1 ft. (per 31⁄4″ x 10″ Transition

12 ft.

Straight foot length) 45° Elbow

5 ft.

90° Elbow

6″ Round

31⁄4″ x 10″ 1 ft. (per 31⁄4″ x 10″ Wall Cap 21 ft.

Straight foot length) 90° Flat Elbow

24 ft.

with Damper

6″ Round 31⁄4″ x 10″

6″ 15 ft. to 31⁄4″ x 10″ 7 ft. Wall Cap 27 ft.

90° Elbow Transition with Damper

31⁄4″ x 10″

6″ to 6″ Round 5 ft. 6″ Round

45° Elbow

9 ft.

Transition Roof Cap

20 ft.

6″ Round

to 31⁄4″ x 10″

31⁄4″ x 10″ Transition

20 ft.

6″ Round

90° Elbow

16 ft.

90° Elbow Roof Vent

24 ft.

SHOULD NOT EXCEED 150 EQUIVALENT FEET

*Equivalent lengths of duct pieces are based on actual tests conducted by GE Evaluation Engineering

and reflect requirements for good venting performance. See chart for CFM Duct Length.

Page 9

14

Installation Instructions

INSTALLING THE DOWNDRAFT VENT SYSTEM

VENTING OPTIONS

Side-to-Side Adjustments

The entire blower mounting plate can be

adjusted 3

1

⁄2″ to the left or right. This will help

to align vent discharge to house ductwork.

Discharge Direction

The blower assembly may be removed and

turned 90° for a left or right side discharge.

• The downdraft vent is shipped with the

discharge outlet pointing straight down

and can be changed to the left or right side.

• A left or right 90° direction adjustment

should be performed before dropping into

the countertop opening.

• Flatten the shipping box to use as a pad.

• Lay the vent on its back onto the pad.

To Change to a Left or Right Discharge

Remove the 4 screws holding the blower

to the mounting plate assembly. Retain

screws.

Remove the blower assembly, turn it

over to access the 4 nuts holding the

blower to the mounting plate. Remove

the nuts.

IMPORTANT: Do not lift the motor

by the power cable.

Turn the blower to the left or right

discharge direction and reinstall the 4

nuts.

Reinstall the blower and mounting plate

with original screws.

To Locate the Ductwork Holes in the Cabinet

Floor or Side Walls

Temporarily, put vent into the countertop

opening.

Push the vent all the way to the back of

the opening.

If you are transitioning to 6″ round,

place transition (obtained locally) over

the discharge outlet.

• Mark the location and remove the

assembly.

• Cut holes and install ductwork

connections.

Order JXRB67 for installation of the blower

and motor below the floor.

Order JXBC67 for installation of the blower

and motor outdoors.

3

2

1

4

3

2

1

Loosen screws to adjust

blower left to right

Discharge down

(as supplied)

Discharge right

Discharge left

Page 10

15

Installation Instructions

INSTALL THE DUCTWORK

Use minimum 26″ gauge galvanized or

24 gauge aluminum duct 3

1

⁄4″ x 10″ or

6″ round. PVC duct should be used if

installing under a poured concrete slab.

DO NOT USE flexible ducting.

• Always use appropriate roof or wall

cap with damper. Laundry type wall

caps should never be used. See the

Ductwork Length and Duct Fittings

chart.

• Use the straightest duct run possible.

• For satisfactory performance the duct

run should not exceed 150 feet or its

equivalent length when bends or

various fittings are used. Refer to the

table of equivalent lengths to calculate

your installation.

• Install ductwork so the piece of duct

nearest the downdraft unit slots INTO

the next piece of the duct. Secure the

joints with self-tapping screws and

apply duct tape around the joints to

ensure an airtight seal.

2

INSTALL THE DOWNDRAFT VENT

Place the downdraft vent into the

countertop cutout, against the back side.

Secure the downdraft to the countertop

supplied brackets. See illustration.

Fasten 2 brackets to vent side and secure

to cabinet back wall.

Install 2 brackets on the bottom of the

vent. Attach brackets to slide screws on

the vent and to the floor using wood

screws (not supplied).

When installing in a tile countertop

surface, it may be necessary to apply

a locally approved caulking to cover

any gaps.

C

B

A

1

Airflow

Screw

Duct tape over

seam and screw

Secure the lower brackets

to blower housing

Preferred

method

Secure

the upper

brackets

with screws

located on

the side

of case

and attach

to back of

cabinet

Page 11

INSTALL THE RAISE/LOWER

SWITCH

NOTE: Step 3 is for 36″ models only.

Skip this step if installing a 30″ model.

NOTE: Determine the location for the

Raise/Lower switch. The wiring lead is

68″ long.

Drill a 3/8″ hole into the desired

location. Use the mounting bracket

as a template to locate the hole

accurately. Check for interference

between the switch cover, adjacent

objects and cooktop/vent overlaps.

If switch is mounted into a tile

surface, drill the hole between tiles.

Use locally approved caulking to

cover any gaps.

Center the mounting bracket over the

hole and mark pilot holes. Remove

and drill holes according to type of

countertop.

Mount the metal switch bracket

with screws (not provided). Choose

screws for your type of countertop

or use locally approved adhesive.

D

C

B

A

3

16

Installation Instructions

INSTALLING THE DOWNDRAFT VENT SYSTEM

WARNING — Disconnect electrical

power from the unit before beginning switch

installation. Failure to do so could result in

personal injury or damage to the electrical

controls.

Remove protective film from the top of

the switch trim.

Peel film from the adhesive strips on the

back of the switch trim. Thread the wire

lead through the mounting bracket and

countertop. Press trim over the mounting

bracket to set the adhesive.

Connect Raise/Lower Wire Lead to Wire Box

Thread wire end with the connector

through the hole on the end of a wire

box. Pull approximately 3″ additional

wire length beyond the open end of

the box.

Connect the mating wire connectors.

Install the wire box onto the bottom of

the countertop or directly behind the

switch. Use screws or adhesive

appropriate for the type of countertop.

Place plastic strain relief over the wire,

just outside of the hole at the end of the

wire box. Do not pinch or twist the wire.

Snap the strain relief closed and press

into the hole.

Connect Wire Lead to Control Box

Thread the long 68″ wire lead through

the end of the other wire box.

Push wire leads into the white connector

provided.

Push wire connector into the mating

connector on the control box. Install the

wire box onto the end of the control box

with screws provided.

Place plastic strain relief over the wire,

just outside of the hole at the end in the

wire box. Do not pinch or twist the wire.

Snap the strain relief closed and press

into the hole.

Coil the excess wire and position away

from moving parts and cabinet contents.

E

D

C

B

A

D

C

B

A

F

E

Trim

Mounting

bracket

3/8″ Hole

Raise/Lower

switch

2 Pin

connector

Strain relief

Pull 3″

length

out of

box

Control box

Page 12

OPTIONAL KITS

JXRB67 optional accessory for indoor remote

location of the blower/motor assembly. Use

this kit when the blower and motor assembly

will be located below the cabinet floor.

JXBC67 optional outdoor cover accessory

for remote installation of blower and motor

assembly on an outside wall.

17

Installation Instructions

CONNECT THE POWER

Plug power cord into a properly grounded

receptacle.

4

INSTALL THE COOKTOP

• With the downdraft in the “down” position,

place the cooktop into the cutout.

• Push the cooktop back until the back edge

of the cooktop just barely touches the front

edge of the downdraft cover.

• Using a dime as a thickness gauge, align

the cooktop so that there is a minimum

uniform gap of 0.05″ (the thickness of

a dime) between the cooktop and the

downdraft cover.

NOTE: Do not force the downdraft cover to

move rearward when aligning the cooktop.

This may cause the downdraft cover to

impact and damage the cooktop when the

vent is raised and lowered.

NOTES:

• Accurate alignment of cooktop and

downdraft is necessary to ensure that there

is no interference when air vent is raised

and lowered. There should be a gap of

0.05″ (the thickness of a dime) between the

back edge of the cooktop and the front

edge of the downdraft cover.

• Radiant cooktop cannot be flush mounted

when using this downdraft vent.

Mounting

brackets

Page 13

Operating Instructions Safety InstructionsInstallation InstructionsTroubleshooting Tips

Consumer Support

18

Troubleshooting Tips

Save time and money! Review the chart below first

and you may not need to call for service.

Problem Possible Causes What To Do

Fan does not work The vent is not fully extended. • Press the Raise/Lower switch.

The blower control switch • Slide it to the right.

may be in the OFF position.

Vent does not rise Vent not plugged into an outlet. • Plug vent into a 120V power outlet.

Raise/Lower switch did not • Hold switch down for a couple of seconds to

engage lift motor. activate motor.

Circuit breaker may have • Check circuit breaker. Reset if necessary.

tripped.

Remote switch not plugged in. • Check all connections between the remote switch

and vent body.

Before you call for service…

Loading...

Loading...