Page 1

C

GE Consumer Home Services Training

TECHNICAL SERVICE GUIDE

Electronic Touch Control

&

Electric Manual Control

Cooktops

MODEL SERIES:

Electronic: JP938

JP968

Electric: JP340

JP350

JP930

JP960

PUB # 31-9070 01/01

Page 2

!

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by

individuals possessing adequate backgrounds of electrical,

electronic, and mechanical experience. Any attempt to repair a

major appliance may result in personal injury and property

damage. The manufacturer or seller cannot be responsible for the

interpretation of this information, nor can it assume any liability in

connection with its use.

WARNING

To avoid personal injury , disconnect power before servicing this

product. If electrical power is required for diagnosis or test

purposes, disconnect the power immediately after performing the

necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used

to complete a path to ground are removed for service, they must

be returned to their original position and properly fastened.

GE Consumer Home Services Training

Technical Service Guide

Copyright © 2000

All rights reserved. This service guide may not be reproduced in whole or in part

in any form without written permission from the General Electric Company.

Page 3

Table of Contents

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Specifications and Nomenclature5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Warranty Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Cooktop Features and Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Mechanical Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Component and Connector Locator Views . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Quiz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

[[Title]]

– 1 –

Page 4

Introduction

The new electronic cooktops make an eloquent

statement of style, convenience, and kitchen

planning flexibility . The electronic touch controls

are simple to understand and easy to operate–just

read and touch.

These cooktops include many helpful features. The

pan detection feature automatically shuts the

heating element OFF after 60 seconds of removing

a metallic pan from the heater . The pan sizing

feature adjusts the heated portion of the dual

element to fit the size of a metallic pan. And the

new warming feature keeps sauces and gravies

warm–or can be used as a normal heating element.

The controls lockout feature protects against

power activation to a heating element during times

of unintended usage or when cleaning the cooktop.

And the convenient kitchen timer can be used with

or without operating the heating elements to

simplify any kitchen task that requires a countdown timer.

It’s easy to see how GE’s fresh ideas can make

anyone more creative in the kitchen!

The information on the following pages will help

you service these new electronic and electric

cooktops effectively and efficiently.

– 2 –

Page 5

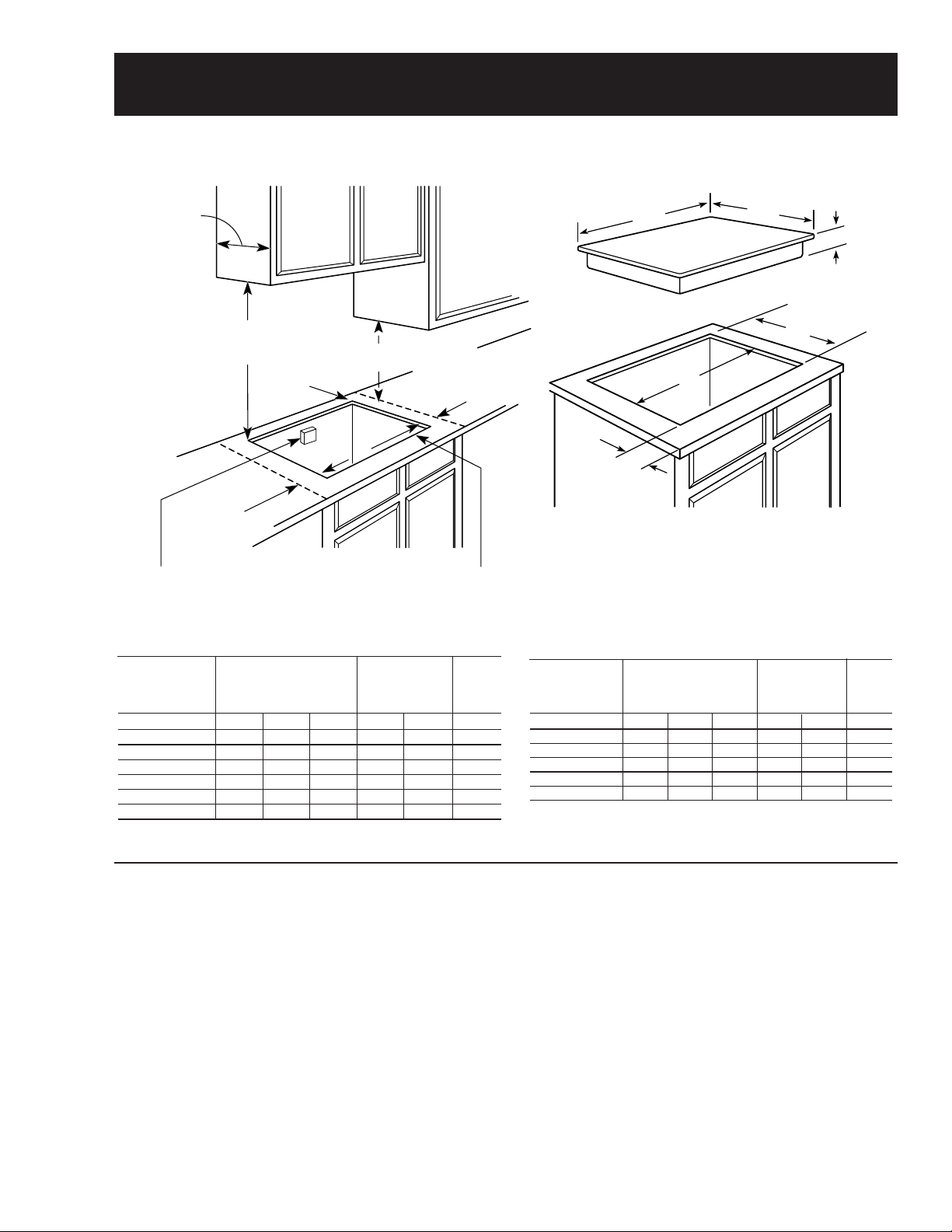

Installation

Electrical junction

box 16" MIN.

below countertop

30" MIN. to

unprotected

cabinet

Cut should not interfere

with cabinet structure

at front

1-3/4" MIN.

clearance to

side wall

from cut-out

1-1/2" MIN.

clearance to

side wall

from cut-out

18" MIN.

to cabinet

1-3/4" to

rear wall

13" MAX.

depth

A

Cooktop

G

E

F

W

D

Counter Installation Dimensions (in inches)

Required

Cooktop Dimensions (in inches)

GEA00791

Dimensions (in inches)

Overall

Model

JP968WC/CC/BC 36 20-3/8 3-1/4* 33-7/8 19-1/8 2-1/2

JP960TC/CC/BC 36 20-3/8 3-1/4* 33-7/8 19-1/8 2-1/2

JP938WC/CC/BC 29-3/4 20-7/8 3-1/4* 28-1/2 19-5/8 2-1/2

JP930TC/CC/BC 29-3/4 20-7/8 3-1/4* 28-1/2 19-5/8 2-1/2

JP350TC/WC/CC/BC

JP340WC/BC 29-3/4 20-7/8 3-1/4* 28-1/2 19-5/8 2-1/2

*Depth of unit at conduit connection location (rear) is 6-1/4" on models JP968/938

and 4-5/8" on models JP960/930/350/340.

WD A E FG

29-3/4 20-7/8 3-1/4* 28-1/2 19-5/8 2-1/2

36-in. and 30-in. Cooktops

Refer to installation instructions. Installation

requires an 18-in. minimum distance from

cooktop to adjacent overhead cabinets. Units are

furnished with a 48-in. flexible armored cable.

Cooktop installation requires a 5-in. free area

between the bottom of the cooktop and any

combustible material, such as shelving. This 5-in.

area is not required when installing a wall oven

underneath the cooktop.

The 36-in. cooktops are approved for use over

GE 30-in. single wall ovens only. The 30-in.

Stainless Steel Cooktop Dimensions (in inches)

To Edge

of Front

Cutout (Min.)

Counter

Model

JP968SC 36-1/8 21 3-1/4* 33-7/8 19-1/8 2-1/2

JP960SC 36-1/8 21 3-1/4* 33-7/8 19-1/8 2-1/2

JP938SC 29-7/8 21-1/2 3-1/4* 28-1/2 19-5/8 2-1/2

GEA00792

JP930SC 29-7/8 21-1/2 3-1/4* 28-1/2 19-5/8 2-1/2

JP350SC 29-7/8 21-1/2 3-1/4* 28-1/2 19-5/8 2-1/2

*Depth of unit at conduit connection location (rear) is 6-1/4" on models JP968/938

and 4-5/8" on models JP960/930/350.

cooktops are approved for use over select GE

27-in. and GE 30-in. single wall ovens.

Note: If installing with a GE Profile Performance™

or GE Profile™ Telescopic Downdraft System,

consult both cooktop and downdraft installation

instructions packed with the products before

installing. Cooktop electric supply may need to be

rerouted to install the downdraft ventilation.

Note: Consult the cabinet and countertop

manufacturer’s specs for flush-mount installation

prior to installing.

– 3 –

Overall

WD A E FG

Cutout (Min.)

To Edge

of Front

Counter

GEA00793

Page 6

Grounding Specifications

Ground Path Resistance 0.10 ohms Max.

Insulation Resistance 250K ohms Min.

Power Supply Requirements

The cooktop must be connected to a supply

circuit of the proper voltage and frequency as

specified on the rating plate. The rating plate is

located on the side of the component box. Wire

size must conform to the National Electrical

Code or the prevailing local code.

Overcurrent Protection for

Counter-Mounted Cooktops

for a counter-mounted cooktop and not more

than two wall-mounted ovens – all supplied from

a single branch circuit and located in the same

room – shall be computed by adding the nameplate ratings on the individual appliances and

treating this total as equivalent to one range.

Wiring

Built-in power leads are U.L. approved for connection to larger gauge household wiring. The

insulation of these leads is rated at temperatures

much higher than the temperature rating of household wiring. The current carrying capacity of a

conductor is governed by the temperature rating

of the insulation around the wire rather than the

wire gauge alone.

NEC RATING

20 Amp

30 Amp

35 Amp

40 Amp

50 Amp

MAXIMUM KILOWATT RATING

208V 236V 240V

4.2 4.7 4.8

6.2 7.1 7.2

7.3 8.3 8.4

8.3 9.4 9.6

10.4 12.0

11.8

GEA00794

The branch circuit load for one countermounted cooktop is the rating on the nameplate of the appliance. The branch circuit load

WARNING: Improper connection of aluminum

house wiring to these copper leads can result in a

serious problem. Use only connectors designed

for joining copper to aluminum and follow the

manufacturer’s recommended procedure closely.

– 4 –

Page 7

Specifications and Nomenclature

For specifications table, refer to Cooktop Features and Controls, page 11.

Model Number

J P 9 6 8 B C

Product

J = GE Cooking Product

Configuration

P = Cooktop

Feature Pack

Designates features–the higher

the number, the more features.

The serial plate of your cooktop is located

on the bottom of the burner box. In addition

to the model and serial numbers, this plate

tells you the power ratings of the supply

circuit for the cooktop.

Grate Type

C = Continuous

Glass Color

B = Black glass

Serial Number

The first two numbers of the serial number

identify the month and year of manufacture.

Example: AZ123456S = January, 2000

A - JAN 2005 - H

D - FEB 2004 - G

F - MAR 2003 - F

G - APR 2002 - D

H - MAY 2001 - A

L - JUN 2000 - Z

M - JUL 1999 - V

R - AUG 1998 - T

S - SEP 1997 - S

T - OCT 1996 - R

V - NOV 1995 - M

Z - DEC 1994 - L

The letter designating the

year repeats every 12

years.

Example:

T - 1974

T - 1986

T - 1998

Note: The technical sheet is located under the

control panel.

– 5 –

Page 8

Warranty Information

Sales slip or cancelled check is required as proof of original purchase date to obtain

service under warranty.

All warranty service is provided by our Factory Service Centers or an authorized Customer Care® technician.

For The Period Of:

One Year

From the date of the

original purchase

Five Years

From the date of the

original purchase

GE Will Replace:

Any part of the cooktop that fails due to a defect in materials or workman-

ship. During this full one-year warranty, GE will also provide, free of

charge, all labor and in-home service to replace the defective part.

Glass-Ceramic Cooktop, Ribbon Heating Elements and Rubber Seal, if

any of these parts should fail due to a defect in materials or workmanship.

During this limited additional four-year warranty, GE will replace the

defective part free of charge, you will be responsible for service trips and

labor charges.

What GE Will Not Cover:

• Service trips to your home to teach you

how to use the product.

• Improper installation.

• Failure of the product if it is abused, misused, or used for other than the intended

purpose or used commercially.

• Damage to the glass cooktop caused by

use of cleaners other than the recommended cleaning creams.

• Replacement of house fuses or resetting of

circuit breakers.

• Damage to the product caused by accident,

fire, floods, or acts of God.

• Incidental or consequential damage to

personal property caused by possible

defects with this applicance.

• Damage to the glass cooktop caused by

hardened spills of sugary materials or

melted plastic that are not cleaned according to the directions in the Owner’s Manual.

This warranty is extended to the original purchaser and any succeeding owner for products purchased

for home use within the USA. In Alaska, the warranty excludes the cost of shipping or service calls to

your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

To know what your legal rights are, consult your local or state consumer affairs office or your state’s

Attorney General.

Warrantor: General Electric Company, Louisville, KY 40225

– 6 –

Page 9

Cooktop Features and Controls

Throughout this manual, features and appearances may vary from the customer’s model.

The new Electronic Touch Control and Electric Manual Control Cooktops encompass over 20 models of

cooktops. They include 30-in., 4-burner and 36-in., 5-burner radiant glass cooktop configurations.

Feature Index

1. Frameless Glass Cooktop

2. Electronic Touch Controls*

3. Pan Detection*

4. Pan Sizing*

5. Control Lock-out*

6. Kitchen Timer*

7. Ribbon-T ype Heating Elements

8. 7-in. Heating/Warming Element*

*Some Models, JP938 & JP968

JP938 (30-in.) Electronic Cooktop

JP968 (36-in.) Electronic Cooktop

JP930 (30-in.) Electric Cooktop

Ceramic Glass Surface

These cooktops feature a ceramic glass cooking

surface over an electric radiant surface element.

The electronic models feature touch controls on

this glass surface that take the place of control

knobs.

Appearance Defects

Scratches, marks from cooking utensils, discoloration, stains, spots, etc. can be caused by food

soils, cookware, cleaning solutions, or water

marks.

Before replacing the cooktop, try using the

cooktop cleaning procedure outlined in the

Owner’s Manual, using the cleaning cream and

Scotch Brite® pad shipped with the product.

Note: When servicing the cooktop, care must be

taken not to scratch or damage the glass.

– 7 –

Page 10

Heating Element Systems

Bridge Element

The Haliant Surface Element consists of a ribbontype resistance wire attached to the support insulation with molded ceramic fiber walls in a corrosionprotected metal dish.

These circular heating elements come in the three

sizes listed below.

Ceramic

Fiber

Molded

Wall

Hot

Light

9" Dual Unit 240 Volt 2500 Watts

9" Ribbon Heating

Element

4

4

Supporting

Insulation

Ceramic Fiber

Molded Wall

6" Ribbon Heating

Element

(6"-1000W., 9"-1500W)

GEA00798

Ribbon Heating

Element

7" 240 Volt-1500 Watts

Hot Light

6" 240 Volt-1200 Watts

Supporting

Insulation

– 8 –

The Bridge Element is made up of two 7-in.,

1800 watt elements plus an 800 watt element

between the two 7-in. elements. The elements

consist of a ribbon-type resistance wire attached

to support insulation with molded ceramic walls.

The digital control on the electronic models (or

the infinite heat switches on the electric models)

regulates the 7-in. units independently of each

other, or in combination when the bridge operating mode (or switch) is selected. The bridge and

the left front element are regulated by the same

controls.

7"-1800 Watt

Elements

Molded

Ceramic

Wall

RTD

RTD

800 Watt

Bridge

Element

GEA00902

Page 11

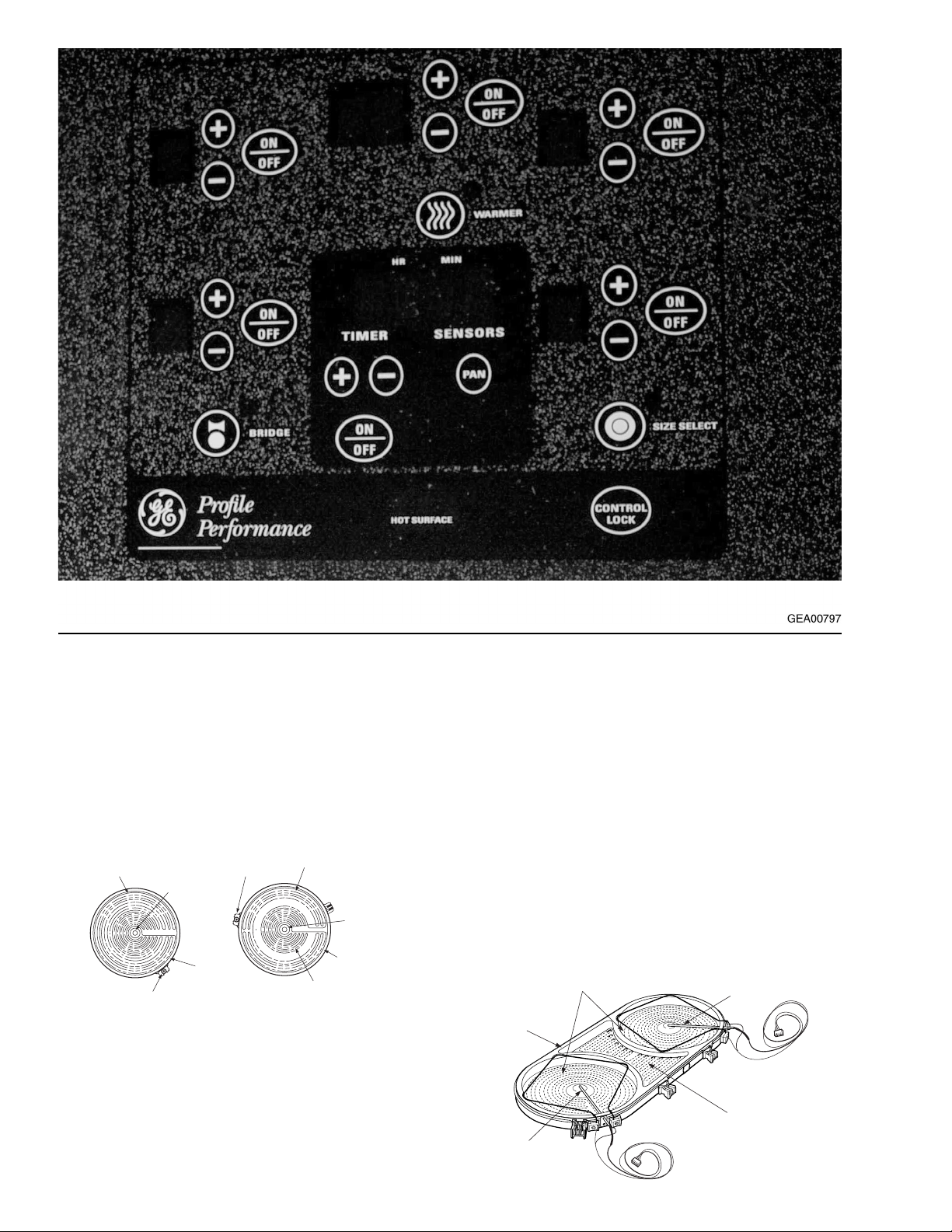

Electronic T ouch Controls (Some Models,

JP938 & JP968)

The touch controls provide precise control of the

surface elements. You can quickly switch from a

steady low heat to full power or any setting in

between.

To turn ON a standard surface element, touch the

ON/OFF pad, then touch the (+) or (-) pad. The

surface element will energize to power setting 5.

Use the (+) or (-) pads to choose the desired

setting: L (low), 1-9, or H (high). The control will

beep each time the pad is touched. To turn the

surface element OFF, touch the ON/OFF pad

again.

To turn ON the bridge element, set the left front

surface element to the desired setting. Touch the

BRIDGE pad. The bridge element will energize to

the same level as the left front surface element

...or, touch the ON/OFF pad for the left front

surface element, then touch the BRIDGE pad.

The left front and bridge elements will both

energize to power setting 5. Using the (+) or (-)

pads will control the setting for both elements. To

turn the bridge element OFF, touch the BRIDGE

pad again. Touching the ON/OFF pad will turn

OFF both the left front and the bridge elements.

To turn ON a 9-in. dual surface element, touch the

ON/OFF pad, then touch the (+) or (-) pad. The

small surface element will energize to power

setting 5. Touch the SIZE SELECT pad to energize

both large and small surface elements. Use the (+)

or (-) pads to choose the desired setting. To turn

the large surface element OFF, touch the SIZE

SELECT pad again. To turn both the large and

small surface elements OFF, touch the ON/OFF

pad.

– 9 –

To turn ON the warmer surface element, touch

the ON/OFF pad, then touch the WARMER pad.

If the surface element is already in use, touch the

WARMER pad. The surface element will energize

to the warmer power setting W1. Use the (+) or

(-) pads to choose the desired warmer setting:

W1, W2, or W3.

To turn OFF the warmer power setting, touch the

WARMER pad again. The surface element will

remain ON in power setting L (low). To turn OFF

the surface element, touch the ON/OFF pad

again.

Page 12

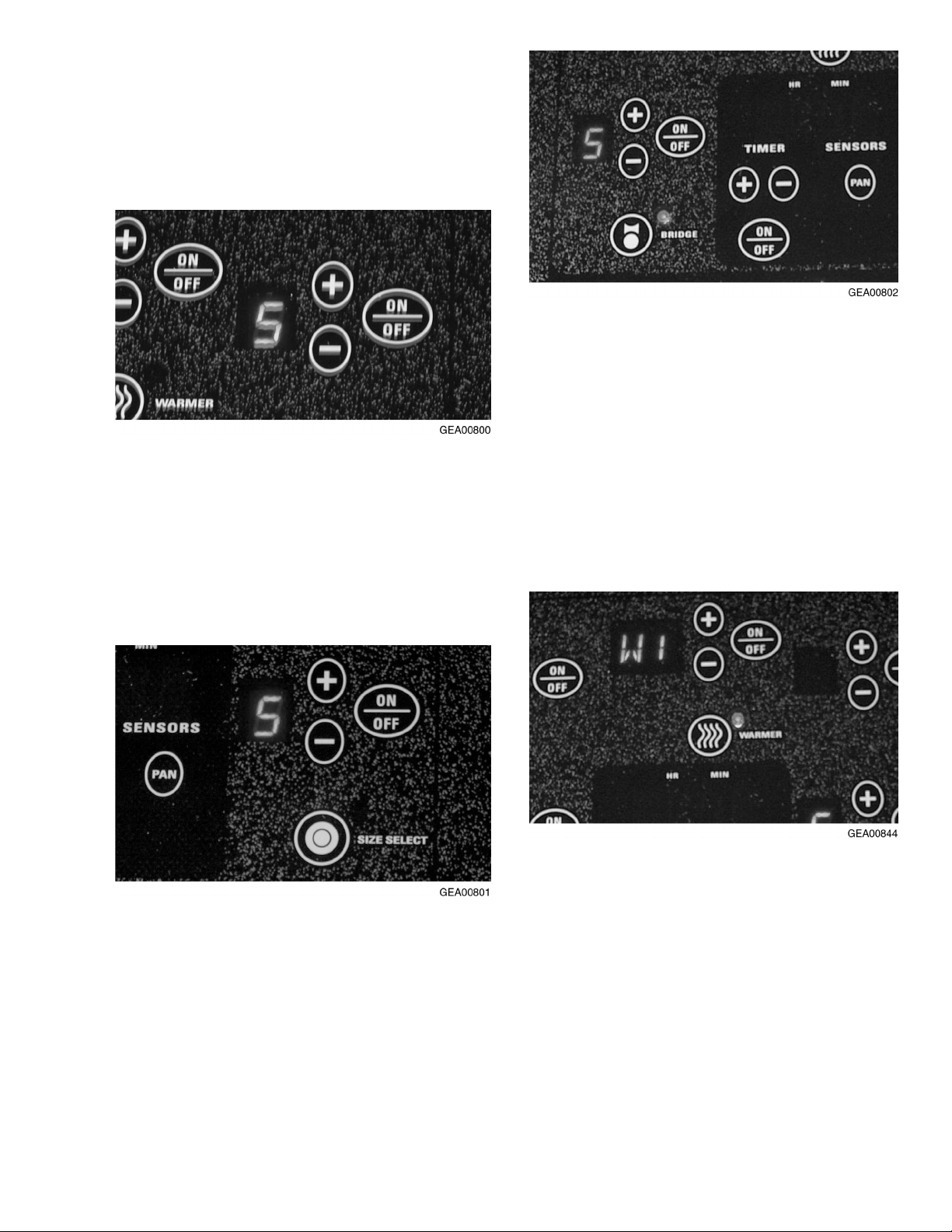

Indicator Lights

Lights will come ON next to the bridge, warmer ,

dual unit, or control lockout pads when touched,

to indicate the surface element or feature is

energized. The light will go OFF when the surface element or feature is turned OFF.

HOT SURF ACE Indicator Lights

The HOT SURFACE indicator lights will glow

when any surface unit is turned ON and will

remain on until the surface has cooled to approximately 150°F.

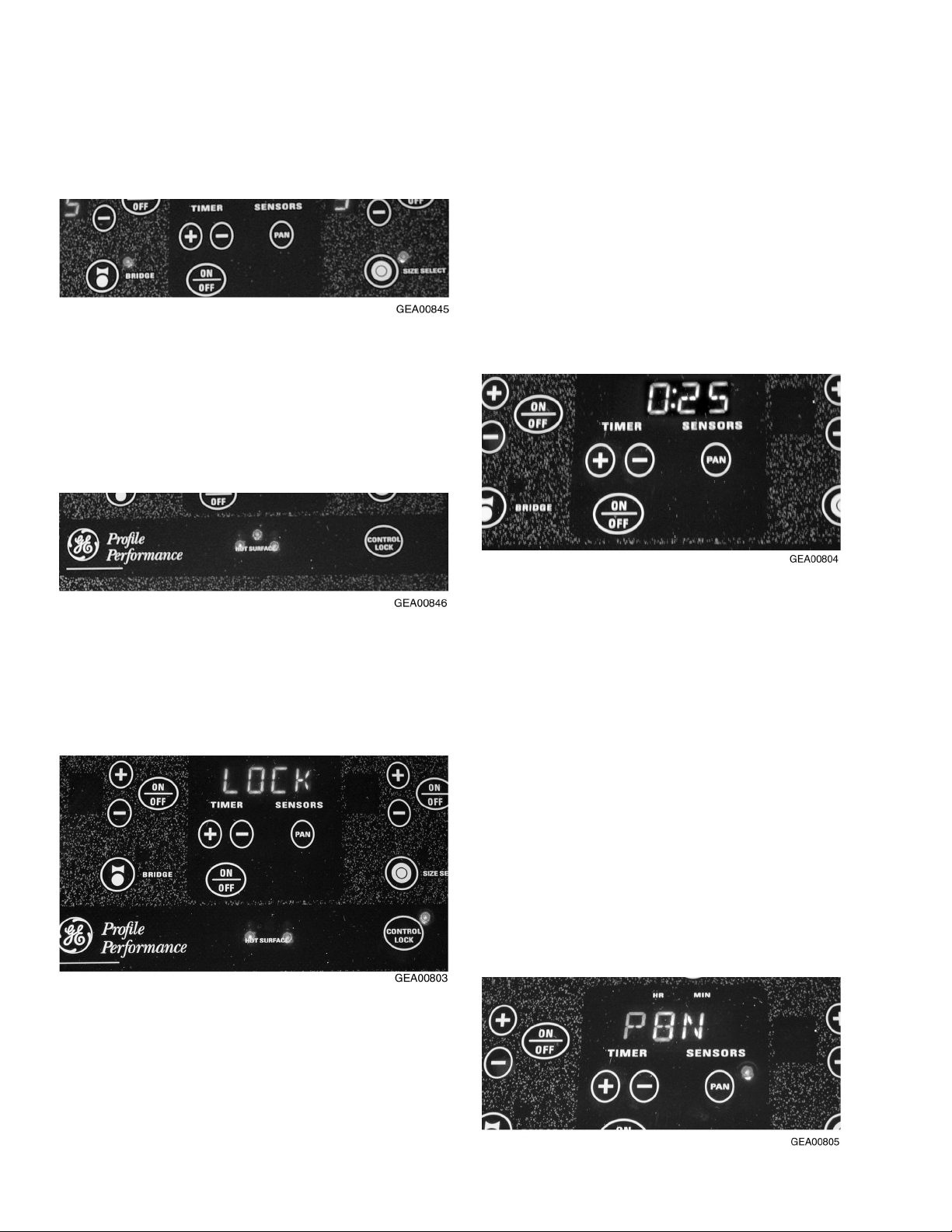

TROL LOCK pad again for 3 seconds. A

2-beep signal will sound and the light will go

out, indicating the cooktop is unlocked.

Locking the cooktop will prevent surface

elements from accidentally being energized by

children or pets. You may lock the cooktop

when not in use or before cleaning.

Kitchen Timer

Operate the timer using the pad below the timer

display . Touch the ON/OFF pad, then touch the

(+) or (-) pad to choose the desired time setting.

If the (+) or (-) pad is held for several seconds,

Controls Lockout

Note: For your convenience, the entire cooktop

can be locked at any time.

To lock the cooktop, touch and hold the CONTROL LOCK pad for 3 seconds. A 2-beep signal

will sound, the word LOCK will appear in the

timer display, and the CONTROL LOCK light will

turn ON indicating the cooktop is locked. If the

cooktop is locked while the surface elements or

timer are in use, they will automatically turn OFF.

the timer will increase or decrease at a faster

rate. After choosing your desired time, the timer

will automatically start to count down from the

hours/minutes you have selected. When the

timer reaches 1 minute, the control will beep

once and the timer will display the remaining

time in seconds until 00:00. The control will then

beep twice every 5 seconds until the timer is

turned OFF.

Pan Detection

Note: For this feature to function properly, the

metallic pan must be at least 4 in. in diameter

and centered on the surface element. This

feature will not work with glass cookware and

must be turned OFF when glass cookware is

used.

To unlock the cooktop, touch and hold the CON-

The pan detection feature works in the following

– 10 –

Page 13

Built-In CleanDesign Cooktops

GE Profile Performance Series

Ribbon

JP968SC JP960SC JP938SC JP930SC JP350TC

JP968WC JP960TC JP938WC JP930TC

JP968CC JP960CC JP938CC JP930CC JP350CC

JP968BC JP960BC JP938BC JP930BC JP350BC JP340BC

Features

Patterned White

Glass-ceramic surface

Number of elements

Dual 6"/9" heating elements

8" heating elements

7" heating element

7" heating elements

Bridge element

Total wattage

6" heating elements

Hot surface indicator lights

Electronic touch controls

Pan presence sensor

Pan size sensor

Patterned Black

5 Ribbon

1 Ribbon w/Warmer

(1500W)

2 Ribbon (1800W)

1 Ribbon (800W)

4400W 4400W 4400W 4400W

1 Ribbon (1200W)

554441

!!

!!

!!

Appearance

SS SS SS SS WW

WW WW WW WW WW

Color appearance*

Frameless

CC CC CC CC CC WW

BB BB BB BB BB BB

Weights & Dimensions

Cooktop width (in inches)

Approx. shipping weight (lbs.)

36 36 30 30 30 30

45 44 38 38 38 35

Power/Ratings

KW rating @ 240V

208V 7.2 7.2 6.1 6.1 5.8 4.8

Amps @ 240V

208V 40 40 40 30 30 30

*SS = Stainless Steel, WW = White on white, CC = Bisque, BB = Black on black.

9.6 9.6 8.1 8.1 7.7 6.4

40 40 40 40 40 30

Patterned BlackPatterned Black

TrueWhite

Patterned BisquePatterned Bisque

Patterned Black

5 Ribbon

1 Ribbon (2500W)1 Ribbon (2500W)

1 Ribbon (1500W)

2 Ribbon (1800W)

1 Ribbon (800W)

1 Ribbon (1200W)

™

Patterned Black

True White

Patterned Bisque

Patterned Black

4 Ribbon

1 Ribbon (2500W)

2 Ribbon (1800W)

1 Ribbon (800W)

1 Ribbon w/Warmer

(1200W)

Patterned Black

True White

Patterned Bisque

Patterned Black

4 Ribbon

2 Ribbon (2500W)

2 Ribbon (1800W)

1 Ribbon (800W)

1 Ribbon (1200W)

GE Profile

™

Ribbon

JP350SC

JP350WC

Patterned Black

True White

Patterned White

Patterned Bisque

Patterned Black

4 Ribbon

2Ribbon (2500W)

2 Ribbon (2000W)

2 Ribbon (1200W)

SS

GE

Ribbon

JP340WC

Patterned White

Patterned Black

4 Ribbon

2 Ribbon (2000W)

2 Ribbon (1200W)

GEA00806

manner: after energizing one of the heating

elements, a pan must be placed on the surface

element within 60 seconds. If a pan is not placed

on the surface element within 60 seconds, the

surface element will turn OFF. If a pan is removed from the surface element, the user has

60 seconds to replace it before the surface

element is automatically turned OFF. The power

level display will flash when the control on the

surface element detects the absence of a pan.

To activate or deactivate the pan detection

feature for all surface elements, touch the PAN

pad. A signal will sound and a light next to the

P AN p ad will indicate whether the feature is

active. If the light is ON, then the pan detection

feature is ON. When the pan detection feature is

OFF, the pan sizing feature is also OFF.

Pan Size Sensor

Note: This feature is only for the dual unit

surface elements and functions only when the

pan detection feature is turned ON.

When a small pan is placed on the surface

element, the small surface element will activate.

When a large pan is placed on the surface

element, the small and large surface elements

will activate. This feature may be overridden for

a single cooking session while leaving the pan

detection feature ON.

To activate or deactivate this feature and the

pan detection feature, touch the P AN pad. The

light next to the P AN pad will go out, indicating

that both pan detection features are turned

OFF.

– 11 –

Page 14

Diagnostics

Table of Contents

Digital Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Triac Voltage Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Pan Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Technician Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Fault Codes (F-codes) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Line-In Voltage Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Temperature Check (in Celsius) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Frequency Check (in Hertz) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Calibration of the Inductive Pan Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Fault Code Behavior Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

– 12 –

Page 15

Digital Control System

The control system consists of four circuit boards:

the touch board (which is permanently adhered to

the ceramic glass panel) that senses the user

input, the display board that contains the panel

displays, the logic board that contains the microprocessor , and the power board that does the

power switching and control of the heating units.

Ceramic

Glass With

Touch Board

Display

Board

Logic

Board

Power Board

Permanently

Adhered

Burner

Box

Drop Box

Cover

GEA00807

• If the touch board is damaged, the entire glass

assembly must be replaced.

• If the display board is damaged, it can be

replaced by removing the glass top and disconnecting the display board from the touch board.

• If the logic board is damaged, it can be replaced

by removing the glass top and removing the logic

board from the area under the keypad.

• If the power board is damaged, it can be accessed by removing the drop box cover that is

under the cooktop.

Note: No individual components on the boards

are replaceable.

Triac Voltage Control

A triac-fired control replaces the usual rheostat

temperature control for each surface element. The

control receives feedback from the temperature

sensor to allow for precise control of the heating

element power.

– 13 –

Page 16

Pan Detection

Temperature Sensor

Sensor Connectors

Technician Mode

The pan detection system includes a pan sensor,

an inductive sensor interface chip (ISIC) permanently mounted on the logic board, and a signal

wiring harness connecting the sensor with the

ISIC.

Temperature Sensor

Temperature Sensor Sensor Connectors

Sensor Connectors

Logic BoardLogic BoardHeaterHeaterPan SensorPan Sensor

GEA00766

The pan sensor determines the presence or

absence of a pan through a change in the magnetic field. When a metal pan is near the sensor ,

the resonant frequency of the pan increases. This

information is passed to the ISIC, which determines a pan to be present. When the frequency

drops to a specified level, the ISIC determines the

pan to not be present and turns the surface

element OFF after 1 minute.

To enter the Technician Mode, lock the cooktop by

holding the CONTROL LOCK key for 3 seconds.

The control will beep 2 times and the word LOCK

will be displayed in the timer display . Press the

timer ON/OFF key and simultaneously press the +

keys of the LF and LR surface elements. The timer

display will flash TECH MODE when the cooktop

is in Technician Mode.

Pan Size Feature

When the pan detection feature is active, the pan

size feature is also active. The pan size feature is

designed to automatically recognize the size of a

pan placed on the dual heater and energize one or

both cooking zones to match the size of the pan.

The pan size feature is overriden when the DUAL

key is pressed.

To exit the Technician Mode, simultaneously press

the timer ON/OFF key and the (+) keys of the LF

and LR surface elements, or unlock the cooktop

by holding down the CONTROL LOCK key for 3

seconds. The control will beep 2 times and the

CONTROL LOCK LED will turn OFF.

– 14 –

Page 17

Fault Codes (F-codes)

When a fault code (F-code) occurs, an alarm will

sound for 1 minute, the F-code will flash in the

timer display, and F will flash in the display in the

window of the failed surface element until acknowledged by touching the CONTROL LOCK key. The

displays are then cleared. If the fault still exists, or

if it recurrs when the user tries to activate a surface element, the F-code will redisplay .

To clear the F-code register , enter Technician

Mode. While the timer display flashes TECH

MODE, simultaneously press the BRIDGE and

WARMER keys. The timer display will display

DONE and the F-codes will be permanently

deleted from the register .

Note: A complete fault codes table can be found

at the end of this section.

Line-In Voltage Check

To check the line-in voltage, press the timer ON/

OFF key while in Technician Mode. Line-in voltage

will appear in the timer display .

Only the severest F-codes are immediately displayed. Less severe F-codes are recorded, then

displayed based on the number of repeated occurrences.

The Technician Mode allows the last 9 F-codes to

be recalled from the register and displayed on the

timer display . The most recent F-code is displayed

first (as #1). Pressing the TIMER (+) and TIMER

(-) keys will scroll up and down the last 9 recorded

F-codes.

The cooktop has multiple sensors, one for each

surface element. Some F-codes include a sensor

number associated with a surface element. The

illustration below shows the sensor/surface element number for both cooktop configurations.

2

1

34

5

2

1

4

5

Temperature Check (in Celsius)

To check the temperature of a specific surface

element, press that element’s ON/OFF key while

in T echnician Mode. C will display in the window of

the specific surface element and the temperature

will appear in the timer display .

– 15 –

Page 18

Frequency Check (in Hertz)

To check the frequency of a specific pan sensor,

press the (-) key of that element while in Technician Mode. H will display in the window of the

specific surface element. The frequency will

appear in the timer display .

Calibration of the Inductive Pan Sensors

Calibration of the inductive sensors is performed

to permanently store the pan detection thresholds

in a new logic board that has never been calibrated. Calibration is also performed to update the

pan detection thresholds due to a physical change

in the pan detection circuit, wiring, or sensor .

Calibration of the inductive sensors is necessary

and must be performed when any of the radiant

surface elements (with an inductive sensor) are

replaced or when the logic board is replaced.

Note: The procedure for calibration of the inductive sensors can be found in the Mechanical

Disassembly section.

– 16 –

Page 19

Fault Code Behavior Table

– 17 –

Page 20

Mechanical Disassembly

Table of Contents

Nonelectronic Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Glass and Cooktop Removal from Countertop . . . . . . . . . . . . . . . . . . . . . . . 19

Broken Glass Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

ON Light Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Switch Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

HOT SURFACE Light Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Burner Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Electronic Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Glass and Cooktop Removal from Countertop . . . . . . . . . . . . . . . . . . . . . . . 21

Touch Board and Cooktop Glass Replacement . . . . . . . . . . . . . . . . . . . . . . 22

Display Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Logic Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Power Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Calibration Instructions for the Inductive Sensors. . . . . . . . . . . . . . . . . . . . 24

Surface Element Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

– 18 –

Page 21

NONELECTRONIC MODELS

WARNING: Before servicing the cooktop,

power must be removed from the cooktop by

pulling the plug out of the outlet or turning the

power off at the circuit breaker.

Remove these screws

Glass and Cooktop Removal from

Countertop

1. Remove all cooktop hold-down retainers from

below the edge of the countertop.

2. Protect the counter with two strips of wood or

cardboard as shown below.

3. Reach up from inside the cabinet and push

upward on the bottom of the burner box enough

to shim with protective wood or cardboard

under one end. Repeat for the other end.

Caution: Screws on the bottom of the burner box

can scratch the countertop surface. Use care to

protect the countertop appearance.

6. Remove all screws from along the top edge on

all 4 sides of the burner box. Remove the

cooktop glass and place it top side down on a

protected surface.

Broken Glass Replacement

1. Remove the glass and cooktop from the

countertop (see the previous procedure).

2. Remove the rubber grommets from the broken

glass.

3. With a drop of liquid soap on your fingertip, wet

the rims of all holes in the new glass and gently

twist (do not force) the grommets through the

holes.

ON Light Replacement

1. Remove the glass and cooktop from the

countertop (see procedure).

GEA00847

4. Using the shims to get a handhold under the left

and right sides of the glass, carefully raise the

cooktop up about 4 in., rotate slightly left or

right (to the best working advantage), and set

down as shown. Lift each end slightly and

adjust the wood or cardboard to prevent

scratching the countertop.

5. Remove all knobs from the cooktop.

2. Compress the ON light wings, as shown, and

pull down to remove from the bracket.

3. Remove the wires from the ON light.

Switch Replacement

1. Remove the glass and cooktop from the

countertop (see procedure).

– 19 –

Page 22

2. Remove 4 screws from the switch mounting

bracket (2 from each end).

3. Remove 2 screws and the switch from the

mounting bracket.

4. Tag and remove the wires from the switch.

HOT SURFACE Light Replacement

1. Remove the glass and cooktop from the

countertop (see procedure).

2. Remove 2 screws from the burner box and

remove the HOT SURFACE light mounting

bracket.

LR Burner SwitchLR Burner Switch

GEA00814

4. Remove 4 screws from the switch mounting

bracket (2 from each end) and remove the red

wire from the switch for the left rear burner .

5. Note the location and color of the wires in the

wire harness, disconnect them from the burners, and remove.

Note: When installing the new HOT SURF ACE

light, be sure to feed the harness under the brace

below the right-hand burners.

Burner Replacement

1. Remove the glass and cooktop from the

countertop (see procedure).

3. With a small screwdriver , push in on the first

light tab while pushing down on the light. Push

in on the second light tab, while still pushing the

light down, to release the light.

2. Note the position of the wires to the burner.

Remove the wires.

– 20 –

Page 23

Mark Numbers

Mark Numbers

Mark Numbers

Next to Tabs

Next to Tabs

ELECTRONIC MODELS

WARNING: Before servicing the cooktop,

power must be removed from the cooktop by

pulling the plug out of the outlet or turning the

power off at the circuit breaker .

Glass and Cooktop Removal from

Countertop

Note: The ceramic glass and touch board shall be

supplied as a complete assembly.

1. Remove all cooktop hold-down retainers from

below the edge of the countertop.

2. Protect the counter with two strips of wood or

cardboard as shown below.

3. Reach up from inside the cabinet and push

upward on the bottom of the burner box enough

to shim with protective wood or cardboard

under one end. Repeat for the other end.

Caution: Screws on the bottom of the burner box

can scratch the countertop surface. Use care to

protect the countertop appearance.

GEA00817

3. Lift the burner off the springs and mark the

numbers on the bottom of the burner next to the

tabs.

4. Remove the tabs and install them on the new

burner in the same numbered position.

Note: When installing the new burner , make sure

the 2 springs are on the 2 posts.

GEA00847

4. Using the shims to get a handhold under the left

and right sides of the glass, carefully raise the

cooktop up about 4 in., rotate slightly left or

right (to the best working advantage), and set

down as shown. Lift each end slightly and

adjust the wood or cardboard to prevent

scratching the countertop.

Remove these screws

5. Remove all screws from along the top edge on

all 4 sides of the burner box and slowly lift the

front of the glass off the burner box.

– 21 –

Page 24

6. With the glass tilted at an angle, disconnect the

wire harness that extends from the logic board

to the user interface by pulling upward on the

connector. Do not pull on the wires.

7. Remove the glass from the top of the burner

box and place top side down on a protected

surface.

3. Prop the glass on the back of the cooktop.

Using one hand to lower the glass, use the

other hand to connect the wire harness from the

display board to the 10-pin header on the logic

board.

4. Lower the glass onto the burner box, being sure

not to pinch any wires between the frame and

the burner box.

Touch Board and Cooktop Glass

Replacement

Note: The ceramic glass and touch board shall be

supplied as a complete assembly . Remove and

replace the cooktop ceramic glass (see previous

procedure).

Display Board Replacement

1. Remove the display board from the damaged

piece of cooktop glass.

5. Apply power to the cooktop. Once the cooktop

appears to be in working order, remove power

from the cooktop and insert all the screws to

secure the glass to the burner box.

Logic Board Replacement

1. Remove the glass and cooktop from the

countertop (see procedure).

SensorSensor

GEA00822

2. Place the display board on the new cooktop

glass, making sure to connect the 8-pin ribbon

cable to the touch board and the wire harness

to the display board.

2. Disconnect the sensor connectors from the

logic board by pulling upward on the connectors. Do not disconnect the connectors by

pulling on the sensor wires.

– 22 –

Page 25

Press Down on Latching TabsPress Down on Latching Tabs

26-Pin

26-Pin

Ribbon Cable

Ribbon Cable

GEA00823

3. Disconnect the 26-pin ribbon cable from the

logic board by pressing down on the latching

tabs of the header .

10-Pin

10-Pin

Header

Header

GEA00848

8. Prop the glass onto the back of the cooktop.

Using one hand to lower the glass, use the

other hand to connect the wire harness from the

user interface to the 10-pin header on the logic

board.

TabsTabs

GEA00824

4. Remove the logic board by using needle nose

pliers to press in on the tabs of the logic board

standoffs, and lifting the board. Do not remove

the logic board standoffs. Repeat this procedure for all 5 board standoffs.

Caution: To avoid delivering an electric shock to

the new logic board, place your hand on the

burner box for at least 2 seconds before reaching

for the new logic board.

5. Remove the new logic board from the antistatic

bag and place it on top of the standoffs.

Note: 30-in. cooktops do not have a connector

placed on J503 (for the CR heater of a 36" unit),

and the connectors are keyed to prevent a

misconnection.

9. Lower the glass onto the burner box, being sure

not to pinch any wires between the frame and

the burner box.

10. Apply power to the cooktop. An F161 is ac-

ceptable if a surface element is turned on with

the pan detection feature active. This indicates

the need to calibrate the inductive sensors.

11. Once the cooktop appears to be in working

order , remove power from the cooktop and

insert all the screws to secure the glass to the

burner box.

Note: After the cooktop has been placed back into

the consumer’s counter and power has been

applied, the cooktop must be calibrated. Proceed

to the Calibration Instructions for the Inductive

Sensors.

Power Board Replacement

1. Remove the glass and cooktop from the

countertop (see procedure).

2. Turn the cooktop 180 degrees and prop the

cooktop up to access the drop box. Be careful

not to damage the counter.

6. Reconnect the 26-pin wire harness and the

sensor connectors to their original positions.

7. Examine the inside of the cooktop (heaters,

sensors, wires, and thermal wall) for anything

that does not look normal.

– 23 –

Page 26

3. Remove 5 screws and the ground screw from

26-Pin Cable

Main Power Connector

Power

Connector

the drop box cover and lower the cover.

Main Power Connector

Main Power Connector

26-Pin Cable

26-Pin Cable

GEA00826

4. Disconnect the main power connector in the

drop box.

5. Disconnect the 26-pin ribbon cable from the

power board by pressing down on the latching

tabs of the header .

Power

Power

Connector

Connector

9. Prop the glass onto the back of the cooktop.

Using one hand to lower the glass, use the

other hand to connect the wire harness from

the user interface to the 10-pin header on the

logic board.

10. Lower the glass onto the burner box, being

sure not to pinch any wires between the frame

and the burner box.

11. Apply power to the cooktop. Once the cooktop

appears to be in working order , remove power

from the cooktop and insert all the screws to

secure the frame to the burner box.

6. Disconnect the power connector in the burner

box.

Caution: To avoid delivering an electric shock to

the new power board, place your hand on the

burner box for at least 2 seconds before reaching

for the new power board.

7. Remove the new power board from the anti-

static bag and reconnect the 26-pin wire harness, the main power connector , and the burner

box power connector to their original positions.

8. Examine the inside of the cooktop (heaters,

sensors, wires, and thermal wall) for anything

that does not look normal.

Calibration Instructions

for the Inductive Sensors

Note: Calibration of the inductive sensors must

begin with the LF surface element and proceed in

a clockwise direction around the cooktop. All of

the sensors must be calibrated to complete the

calibration procedure.

• Calibration of the inductive sensors must begin

within 15 minutes of applying power to the

cooktop.

1. Clear everything from the top of the glass.

2. Lock the control by pressing the control LOCK

key for 3 seconds. The control LOCK LED will

turn ON.

3. Enter tech mode by pressing the TIMER

ON/OFF, LF (+), and LR (+) keys at the same

time. The TIMER window will flash the words

TECH MODE.

4. Begin the calibration procedure by pressing the

TIMER ON/OFF, LF (+), and RF (+) keys at

the same time. The TIMER window will flash

CAL and the LF surface element power window will flash the U symbol.

– 24 –

Page 27

5. When the TIMER window displays DISC and

the U symbol stops flashing in the LF surface

element power window, center the aluminum

disk on the LF surface element.

6. Press the PAN and LF (+) keys at the same

time. The electronic control will perform the

calibration on the LF sensor and then proceed

to the next surface element. The TIMER

window will flash CAL and the U symbol will

flash in the LR surface element power window.

7. Repeat steps 5 and 6 for the LR, CR (if

present), RR, and RF surface elements.

8. After the RF surface element has been calibrated, the timer window will display a PASS or

F AIL message for the entire calibration procedure. An F will be displayed in the surface

element power window of any sensor that fails

the process. Acknowledge this message and

exit the calibration procedure by pressing the

PAN and RF (+) keys at the same time.

Note: If the calibration proceedure is interupted for

any reason, exit the calibration proceedure by

pressing the PAN and RF (+) keys at the same

time.

Note: Failure of the calibration procedure may

occur for several reasons. If the calibration procedure fails, follow these steps:

• T ry calibrating the cooktop again, beginning with

step 1 from above.

2. Disconnect the appropriate sensor connector

from the logic board by pulling upward on the

connector. (Do not disconnect the connector by

pulling on the sensor wires.) T race the sensor

wires back to the appropriate surface element,

making note of where and how the wires are

routed.

Caution: Do not cut the wire ties from the wire

harness. Care must be taken to ensure that

only the sensor wires to the surface element

being replaced are cut.

Caution: Routing of the wires is extremely

critical. Care must be taken to ensure the wires

are routed exactly the way they were originally.

Remove Cut Wires

From Wire Bundle

Sensor Wire

Harness

• Identify the sensor(s) that fails the calibration

procedure.

• If multiple sensors fail the calibration procedure,

replace the logic board.

• If only one sensor fails the calibration procedure,

replace the corresponding surface element.

Surface Element Replacement

Note: The surface element, pan sensor, and

temperature sensor are only replaceable as an

assembly, which includes the sensor wire harness

and connector.

1. Remove the glass and cooktop from the

countertop (see the procedure).

– 25 –

Old Heating

Element

Tie Wrap (Do Not Cut)

To Power Board

Surface Element

Power Wires

GEA00756

3. Using diagonal cutters, snip both the tempera-

ture sensor and the pan sensor wires and

remove them from the wire harness leading

from the logic board to the surface element.

Note: When installing the new surface element,

tie-wrap temperature sensor and pan sensor wires

to the existing wire harness. Do not cut existing

wire harness. Do not cut existing tie wraps.

Existing Wire Ties

(Do Not Cut)

Tie-Wrap New Wires

To Wire Bundle

New Heating

Element

To Power Board

Surface Element

Power Wires

GEA00861

Page 28

4. Remove the electrical connectors form the

heater.

5. Lift the heater off the springs and mark the

numbers on the bottom of the heater next to the

tabs.

6. Remove the tabs and install them on the new

surface element in the same numbered position.

Note: When installing the new surface element,

make sure a spring is beneath every mounting

bracket.

7. Place the new surface element on the mounting

posts.

8. Position the sensor harness in the same manner

as the original harness was oriented, being sure

to keep all wires away from all surface elements.

9. Using a nut driver, remove the necessary

screws from the outside of the burner box and

lift the surface element support bracket to

route the sensor wires beneath the bracket.

10. Run the connector through the gap between

the insulating strip and the thermal wall,

making a slit in the insulating strip if necessary.

11. Place the connector on the appropriate header

on the logic board.

12. Beginning at the end of the wire harness

closest to the surface element, secure the

sensor wires to the existing wire harness with

wire ties. Trim the excess material from the

wire ties and make sure the new wire harness

is in the same position as the original.

– 26 –

Page 29

Heater

Component and Connector Locator Views

JP968 (36-in.) Electronic Cooktop

26-Pin Ribbon

26-Pin Ribbon

Connector

Connector

Main Power

Main Power

Connector

Connector

Power BoardPower Board

Ceramic Glass TopCeramic Glass Top

Display BoardDisplay Board

Touch BoardTouch Board

Ceramic

Ceramic

Glass Top

Glass Top

Sensor

Sensor

Connector

Connector

26-Pin Ribbon

26-Pin Ribbon

Connector

Connector

Display Board/Touch

Display Board/Touch

Board Assembly

Board Assembly

User Interface to Logic

User Interface to Logic

Board Wire Harness

Board Wire Harness

Temperature

Temperature

Sensor (RTD)

Sensor (RTD)

10-Pin Header10-Pin Header

– 27 –

Pan SensorPan Sensor

Support BracketSupport Bracket Heater

HeaterBurner BoxBurner BoxLogic BoardLogic Board

GEA00834

Page 30

JP938 (30-in.) Electronic Cooktop

26-Pin Ribbon

26-Pin Ribbon

Connector

Connector

Main Power

Main Power

Connector

Connector

Power

Power

Board

Board

Ceramic

Ceramic

Glass Top

Glass Top

User Interface to Logic

User Interface to Logic

Board Wire Harness

Board Wire Harness

Pan

Pan

Sensor

Sensor

Burner

Burner

Box

Box

Display

Display

Board

Board

Temperature Sensor (RTD)Temperature Sensor (RTD)HeaterHeater

Power ConnectorPower Connector

Touch

Touch

Board

Board

26-Pin Ribbon

26-Pin Ribbon

Connector

Connector

Sensor

Sensor

Connectors

Connectors

10-Pin

10-Pin

Header

Header

– 28 –

Logic BoardLogic BoardSupport BracketSupport Bracket

GEA00835

Page 31

JP350 (30-in.) Electric Cooktop

HOT SURFACE

Burner BoxBurner Box HOT SURFACE

HOT SURFACE

Lights

Lights

HeaterHeater

Support

Support

Bracket

Bracket

Thermal LimiterThermal Limiter

ON LightON Light

SwitchSwitch

Switch

Switch

Mounting

Mounting

Bracket

Bracket

GEA00838

– 29 –

Page 32

– 30 –

INDUCTIVE

SENSOR

LF

BRIDGE

LB

LR

WIRE

1800W

R

T

D

1

2

J501 CONNECTOR

800W

2

1

1800W

R

T

D

1

Yellow

with

traces

(jumper

wire)

9-PIN POWER

CONNECTOR

3

12

6

4

5

9

7

CONDUIT

WIRING CHART

COLOR NUMBER (PIN #) (PIN #) TERMINAL #

YELLOW J101 1 LF1

YELLOW J102 11 LF2

ORANGE J103 13 LR2

ORANGE J104 4 LR1

GRAY J105 5 CR1

BROWN J106 12 RR2

BROWN J107 2 RR1

VIOLET J108 3 RF21

BLUE/BLK J109 15 RF22

BLUE J110 6 RF12

GRAY J111 14 CR2

YEL/BLK J112 10 LB2

GEA00903

BOARD REFERENCE CONNECTOR HEATER CONNECTOR BURNER

8

J122

J107

J115 / J116

J109

K107

J110

K106

POWER 9-PIN POWER 15-PIN CONTROL/

J113 L1 1

J114 L1 3

J115 L1 2

J116 L1 2

J117 L1 4

J118 L2 7

J119 L2 6

J120 L2 9

J121 L2 9

J122 a 8

K105

J120/J121

2

J106

J108

J117

K

1

0

4

J502

J102

J120 / J121

RELAYS

JP968 MODEL ONLY

CR

1500W

R

T

D

1

2

J104

J114

J111

J118

J113

J101

K102 K101

POWER BOARD

J112

J503

J105

K

1

0

3

RR

1200W

R

T

D

1

2

1

2

J505

15-PIN CONTROL

HEATER CONNECTOR

J115 / J116

J103

J119

J100

J504

1

3

2

6

4

5

9

7

8

12

11

10

15

13

14

J503

J501

J502

J504

J505

J602

MAIN BOARD

26 PIN

RIBBON

Caution: Label all wires prior to disconnection when

servicing the controls. Wiring errors can cause

improper and dangerous operation. Verify proper

operation after servicing.

RF2

1500W

1000W

R

T

D

Example:

Empty Pin

10 Pin Ribbon

8 PIN

RIBBON

RF1

Blue

RTD Wire

(Pin 5)

2

1

4

E

DISPLAY

BOARD

TOUCH

BOARD

Blue

with

Black

Traces

Inductive

Sensor

123

(Pin 1)

Schematics

Page 33

Notes

– 31 –

Page 34

Parts List

– 32 –

Page 35

Ref No. Part No. Description Qty.

16 WB27T10293 Logic Board 1

18 WB27T10294 Display Board 1

44 WB02T10092 Burner Box Grommet 1

51 WB62T10088 Glass Maintop Asm 36” 1

54 WB02K5328 Hold Down Bracket 1

56 WB30T10066 Element Radiant Asm 1

56 WB30T10067 Element Radiant Asm 1

57 WB30T10065 Element Radiant Asm 1

58 WB30T10062 Element Radiant Asm 1

60 WB09K5014 Radiant Spring 8

61 WB64T10021 Burner Box Bottom 1

62 WB02K5318 Radiant Heater Bracket 8

63 WB02T10090 Element Support Bracket 2

63 WB02T10091 Element Support Bracket 1

65 WB34T10034 Drop Box Top 1

67 WB02X9502 Radiant Heater Stud 8

80 WB34T10033 Burner Box Bottom Shield 1

82 WB23T10014 Power Board Asm 1

93 WB34T10031 Thermal Barrier- Inner 1

93 WB34T10032 Thermal Barrier- Outer 1

101 WB35T10047 Burner Box Bottom Insulation 1

200 WB06T10007 Tape 1

200 WB06K5042 Foam T ape 2

595 WB02X9867 Harness Plate 1

600 WB1BT10160 Conduit Wire Harness 1

691 WB01K5162 Screw-Black 20

699 WB01K5150 Screw ST10-16X.437 Hex zn 31

809 WB01X1137 Screw 2

813 WB01X1261 Screw 2

– 33 –

Page 36

– 34 –

Page 37

Ref No. Part No. Description Qty.

820 WB01X1424 Screw 2

875 WH02X0930 Screw 8-18 AB HXW 3/8 8

925 WB01K5117 Washer .250IDX.8120D 8

926 WB01X1260 Ground Washer 1

962 WB02T10093 Standoff PCB 10

999 49-80021 Use & Care Manual 1

999 WB18T10162 Power Control Harness 1

999 WB18T10163 Heater Control Harness 1

999 WB18T10164 Logic Control Harness 1

999 WB18T10166 Logic Display Harness 1

999 WB18T10165 Main Wire Harness 1

999 WB64X0093 Glass Cleaner 1

999 31-10429 Instruction Install 1

999 WB50T10040 AASM Kit Flush (JXFMBB) 1

999 31-10034 PM Sheet Mini Manual 1

999 WB06K5036 Razor Blade Scraper 1

– 35 –

Page 38

Page 39

Loading...

Loading...