Page 1

Use and Care of Recirculation Hood Model JN322

and Ventilating Hood Models JV322, JV332 & JV346

IMPOR TANT SAFETY

INSTRUCTIONS

READ AND SAVE THESE

INSTRUCTIONS.

WARNING– TO REDUCE THE RISK

OF FIRE, ELECTRIC SHOCK OR

INJURY T O PERSONS, OBSERVE

THE FOLLOWING:

A. Use this unit only in the manner intended

by the manufacturer. If you have any questions,

contact the manufacturer.

B. Before servicing or cleaning unit, switch

power off at service panel and lock service

panel to prevent power from being switched

on accidentally.

For general ventilating use only. Do not use

to exhaust hazardous or explosive materials

and vapors.

When you get your new hood…

• Have it installed and properly grounded by a

qualified technician in accordance with the

installation instructions.

• Have the installer show you the location of

the hood circuit breaker or fuse and mark it for

easy reference.

• Take the time to read our suggestions for best use.

WARNING– TO REDUCE THE RISK

OF FIRE, ELECTRIC SHOCK OR

INJURY T O PERSONS, OBSERVE

THE FOLLOWING:

A. Installation work and electrical wiring must be

done by qualified person(s) in accordance with

all applicable codes and standards, including

fire-rated construction.

B. The combustion airflow needed for safe

operation of fuel-burning equipment may be

affected by this unit’s operation. Follow the

heating equipment manufacturer’s guideline and

safety standards such as those published by the

National Fire Protection Association (NFPA),

and the American Society for Heating

Refrigeration and Air Conditioning Engineers

(ASHRAE), and the local code authorities.

C. When cutting or drilling into wall or ceiling,

do not damage electrical wiring and other

hidden utilities.

D. Ducted fans must always be vented to

the outdoors.

E. If this unit is to be installed over a tub or

shower, it must be marked as appropriate

for the application.

WARNING– To reduce the risk of fire,

use only metal ductwork.

When using your hood…

• Never leave surface units unattended at high

settings. Boilover causes smoking and greasy

spillovers that may ignite and spread if hood is

used. Use surface unit heat settings recommended

by the manufacturer and adequate-size utensils.

• Never use your cooking appliance for warming

or heating the room. The electrical wiring of your

range hood may not withstand the resulting

excessive heat.

• Keep the hood clean and clean grease filter or

replace combination filter as recommended to

maintain good venting and to avoid grease fires.

WARNING–TO REDUCE THE RISK

OF A RANGE TOP GREASE FIRE:

A. Keep fan, filters and grease laden

surfaces clean.

B. Always turn hood ON when cooking

at high heat.

C. Use high range settings on range only

when necessary. Heat oil slowly on low

to medium setting.

D. Don’t leave range unattended when cooking.

E. Always use cookware and utensils appropriate

for the type and amount of food being prepared.

(continued next page)

Turn the page for Operation and Maintenance instructions.

GE Quality Product

Page 2

IMPOR TANT SAFETY

INSTRUCTIONS (continued)

WARNING– TO REDUCE THE RISK

OF INJURY T O PERSONS IN THE

EVENT OF A RANGE TOP GREASE

FIRE, OBSERVE THE FOLLOWING:

A. SMOTHER FLAMES with a close-fitting lid,

cookie sheet, or metal tray, then turn off the burner.

BE CAREFUL TO PREVENT BURNS.

If the flames do not go out immediately

EVACUATE AND CALL THE

FIRE DEPARTMENT.

B. NEVER PICK UP A FLAMING PAN.

You may be burned.

C. DO NOT USE WATER, including wet dishcloths

or towels—a violent steam explosion will result.

D. USE AN EXTINGUISHER ONLY IF:

1. You know you have a Class ABC extinguisher,

and you already know how to operate it.

2. The fire is small and contained in the area

where it started.

3. The fire department is being called.

4. You can fight the fire with your back to an exit.

WARNING: The electrical wiring and fan

motor in this range hood are not intended

for use with, or provided with, a solid state

speed control. Any such alteration from

original factory wiring concept could result

in damage to the unit and/or create an

electrical safety hazard.

SAVE THESE

INSTRUCTIONS

Models: JN322 & JV346 non-ducted

Your hood is equipped with a replaceable combination

filter. When the fan is operated, air is drawn through the

filter and discharged into the room through the hood.

Model: JV322

Your hood is equipped with a metal grease filter. When

the fan is operated, air is drawn through the filter and

discharged to the outside.

Models: JV332 & JV346 ducted

Your hood is equipped with a metal grease filter. When

the fan is operated, air is drawn through the filter and

discharged to the outside.

CAUTION–before operating the hood:

•

Install the lamp bulb (not provided). See the

Lamp Replacement instructions.

If You Need Service…

• Do not attempt to repair or replace any part of

your hood unless it is specifically recommended

in this book. All other servicing should be

referred to a qualified technician.

• Disconnect hood circuit breaker or fuse before

performing any service.

2

Replaceable combination filter

Grease filter

(Some models have

a lamp cover.)

(Some models

have a lamp

cover.)

Lamp

holder

Grease filter

(Some models have

a lamp cover.)

Lamp

holder

Lamp holder

Page 3

To Operate

Lamp Switch

Models: JN322, JV322, JV332

Press for OFF and ON.

Lamp Switch

Model: JV346

Rotate clockwise, first position for NIGHT LIGHT,

second position for BRIGHT LIGHT.

Fan Switch

Models: JN322, JV322, JV332

CENTER position OFF, LEFT position LOW SPEED,

RIGHT position HIGH SPEED.

Model: JV346

Rotate Clockwise, FIRST position HIGH, SECOND

position MEDIUM, THIRD position LOW.

To Maintain

Replaceable Filter

JN322, JV346 non-ducted installation

The efficiency of your hood depends upon a clean filter ,

the frequency of filter replacement depends upon the type

of cooking you do; however, with average, normal usage,

replacement should be every 6 to 12 months.

NEVER OPERATE THE HOOD WITHOUT THE

FILTER IN PLACE.

When to replace the filter: JN322

The filter has distinct color stripes of indicating material on

the visible surface. It is TIME TO CHANGE when the filter

stripes have either blended together or faded completely.

Model JV346 non-ducted installations

The filter supplied with the hood does not have

indicating stripes and should be replaced after 6 months.

Replacement filters will have the indicating stripes as

described under the filter for Model JN322.

To remove: Pull down on the center of the front edge of

the filter. The filter will then slip out of the retaining tabs

on the back.

To replace:

Slip the back edge of the filter into the retaining

tabs and push the front edge up until it snaps in place.

Replace with genuine GE part: filter part number

WB02X8406.

Grease Filter “JV” models only

The efficiency of your hood depends on a clean filter.

Frequency of cleaning depends on the type of cooking you

do. BUT GREASE FILTER SHOULD BE CLEANED

AT LEAST ONCE A MONTH. NEVER OPERATE

THE HOOD WITHOUT THE FILTER IN PLACE.

To remove: Pull down on the center of the front edge of

the filter. The filter will then slip out of the retaining tabs

on the back.

To clean: Soak and then agitate in a hot detergent

solution. Light brushing may be used to remove imbedded

soil. Rinse, shake and remove moisture before replacing.

With careful handling, the filter will last for years.

If replacement becomes necessary, order the part from

your dealer.

To replace: Slip the back edge of the filter into the

retaining tabs and push the front edge up until it snaps

into place.

Hood

Clean grease laden surfaces of the hood frequently.

Use warm detergent solution. About 1 tablespoon of

ammonia may be added to the water. TAKE CARE TO

NOT COME IN CONTACT WITH FILTERS AND

OTHER NON-ENAMELED SURFACES. The hood

shell can be washed, rinsed and dried with a soft cloth.

Motor and Fan

To Clean Motor and Fan

1. DISCONNECT THE HOOD POWER SUPPLY AT

THE HOUSEHOLD DISTRIBUTION PANEL BY

REMOVING THE FUSE OR SWITCHING OFF

THE CIRCUIT BREAKER.

2. Remove the filter.

3. Wipe the fan blade and motor with cloth, dampened

only in ammonia and warm water solution.

4. Replace the filter.

5. Reconnect the hood power supply.

CAUTION: Be certain when cleaning the hood

surfaces you do not touch the lamp bulb with moist

hands or cloth. A warm or hot lamp bulb may break

if touched with a moist surface. ALWAYS let lamp

cool COMPLETELY before cleaning around it.

3

Vents

(JN322 & JV346)

Lamp switch Fan switch Trim

Page 4

JN322

JV322

JV332

JV346

Installation Instructions for General Electric Hood

Models: JN322, JV322, JV332, JV346

Important—Save for the local electrical inspector’s use

Power supply connection box

on underside of hood.

Exhaust

Outlet

115⁄8″

23⁄8″

23⁄8″

115⁄8″

73⁄8″

73⁄8″

115⁄8″

23⁄8″

18″

18″

73⁄8″

18″

30″

Power supply connection box

on underside of hood.

Exhaust

Outlet

30″

Exhaust Outlet

Knockouts

4

Power supply connection box

on underside of hood.

30″

73⁄8″

115⁄8″

23⁄8″

18″

Exhaust Outlet

Knockouts

Power supply connection box

on underside of hood.

30″

Page 5

1. PREPARATION OF WALL CABINET

AND WALL

NOTE: For easier installation make all hood and

vent cutouts in the cabinet and wall before cabinet is

permanently fastened in place. It is recommended that

the power supply be brought into the hood from the wall

below the cabinet as shown in Fig.1. However, an

optional location is shown in Fig. 2, where the power

supply enters the top of the hood by passing through

the wall cabinet.

A. WALL CABINET WITH RECESSED BOTTOM:

Add the 2 required filler strips as shown in Fig. 3.

B. WALL CABINET WITH FLUSH BOTTOM: In

some cases it may be necessary to provide clearance

for the connection box cover mounting screw which

extends slightly through the top of the hood. Clearance

can be provided, if necessary, by carefully positioning

the hood against the bottom of the cabinet and marking

the screw position; clearance may then be provided

by drilling a 1/4″ hole in the cabinet bottom.

NOTE: Hood Model JV346 is shipped set up in the

non-ducted configuration.

2. DUCT INSTALLATION

Model JV322 See Figs. 4 & 9

The hood has been designed to mate with a standard 7″

round duct. (A round damper kit may be ordered. Order

GE model number JXDA22.)*

A. If a rectangular duct is desired, a round to rectangular

adapter must be used. Install a 4″ minimum length of

7″ round duct between the hood and adapter to obtain

proper operation of the outlet damper.

B. If a 6″ round duct is desired a 7″ to 6″ reducer is

required. Install a 4″ minimum length of 7″ round

duct between the hood and adapter to obtain proper

operation of the outlet damper.

CAUTION: Do not fasten the duct to the flange on the

top of the hood with screws. The screws will interfere

with the fan blade damaging the motor.

5

RECESSED BOTTOM

FIGURE 3

Filler

strip

2

1

⁄2″ min.

These filler strips

support the entire

weight of the hood.

Make sure they are

mounted firmly and

are flush with the

cabinet bottom.

FLUSH OR RECESSED BOTTOM CABINET

FIGURE 1

1

1

⁄2″ dia. clearance hole in wall for

recommended power supply location

Centerline matches up with

center of range or cooktop.

1

1

⁄2″ dia.

clearance holes

for optional power

supply location

FIGURE 2

66″ from bottom

of cabinet to floor

1

1

⁄4″

73⁄4″

11⁄4″

Cabinet

Ceiling

1

1

⁄4″

73⁄4″

Center line

Soffit

(optional)

Page 6

Models JV332, JV346

Model JV346 ducted installation: Remove the charcoal

pad from the filter. Remove the baffle from the top of the

hood. Re-install the baffle so the short side marked

“VENTED’ is visable. The long side of the baffle should

be inside the hood.

The hood has been designed to mate with a standard 3!4”

x 10“rectangular or 7“ diameter round duct.

Rectangular Duct See Fig. 5,6 & 10: The exhaust outlet

can be installed as either the top or rear by removing the

desired rectangular knockout. A rectangular damper is

supplied with the hood.

Round Duct See Fig. 4 &9: If round duct is desired

either of the following methods must be used:

1.2.Install a 4“ minimum length of rectangular duct

between the hood and adapter to obtain proper

operating of the outlet damper, or

Remove the round knockout on the ton of the hood.

Drill an appropriate size hole in each ‘ofthe three tabs.

Using pliers, bend the three tabs perpendicular to the

hood top. Insert the first piece of 7“ diameter duct so

the tabs are outside of the duct. Mark on the duct the

locations of the holes in the tabs. Drill the appropriate

size hole and, using screws, fasten the duct.

CAUTION: If rear or horizontal exhaust is to be

used, care should be taken to align exhaust with

space between 2 studs, or wall should be prepared at

the time it is constructed, by leaving enough space

between wall studs to accommodate exhaust.

MAXIMUM DUCT LENGTH: For satisfactory air

movement (CFM) the total duct length should not exceed

65 equivalent feet of 3%’x 10”rectangular duct. Equivalent

feet are defined as total feet straight duct plus equivalent

feet of elbows, transitions, wall caps, etc. Figure 7a shows

theapproximateequivalentfeet of some typicalround(6”dia)

duct elements and rectangular (3%” x 10”) duct elements.

Equivalentlengthin feet

3J0

b 200

150

:

~ 100

9 50

25 50 75 100

--

-----3!4” x 1o“

----

------

7

------

125

6“

Dia.

w -

Total

Duct Pieces

~ 6 round,

~ straight

3%” x 10”

D

Q)

@

G!@

63

a

%

%

%

@

@

@

*To order call: your local GE dealer, GE Service & Parts

Center (see the telephone white Daaes) or the GE Answer

Center,”1-800-626-2000. ‘ “ ‘”

straight

6“

90° elbow

6

45° elbow

3X” x 10”

90° elbow

3W’X1O”

45° elbow

3X” x 10”

90° flat elbow

6“ round

to 3%” x 1

transition

3%” x 1o“

6“ round

to

transition

6“ round to

3%” x 1

transition

90° elbow

3X” x 1o“to

6“ round

transition

900 elbow

6 round

wall cap

with damper

3%” x 1o“

wall cap

with damper

6“ round

roof cap

=4=

--i-

o“

o“

14.5

11.5

T

6 W/O

damper

7 Wlo

damper

4-

FIGURE 7a

8

6.5 I

8.5

7

4.5 I

34

45

30

I

I

I

m

I

I

Equivalent

Length

Flush or recessed bottom cabinet

7mdia.

duct

cutout

Flush or recessed bottom cabinet

line -

Center

W:;ss’

FIGURE 5

?4”

Flush or recessed bottom cabinet

FIGURE6 5~” 5X”

X C@out

exhaust

Cabinet

flush with

top of

opening

in wall.

for rear

Page 7

?

1

3. POWER SUPPLY

A! CIRW~ VOLTAGE: This hood must be connected

~~

.,,

.-_

to a SUPPIYcircuit of the proper voltage and frequency

as sPecified on the rating @ate. Wire size must

“}

conform to the requirements of the National Electrical

Code or the prevailing local code for hoods of this ‘sting” The rating plate is located on the rear wall

of the hood.

B. FUSE RATING: 15

c.

unless otherwise specified by local codes, bring

anlPS.

.

a 15amp 2 wire circuit with ground to the area of

the power supply connection box.

D.

USE OF OPTIONAL TOP POWER SUPPLM

l“hepower supply can be attached through the top

knockout if desired, but only the top or back knockout

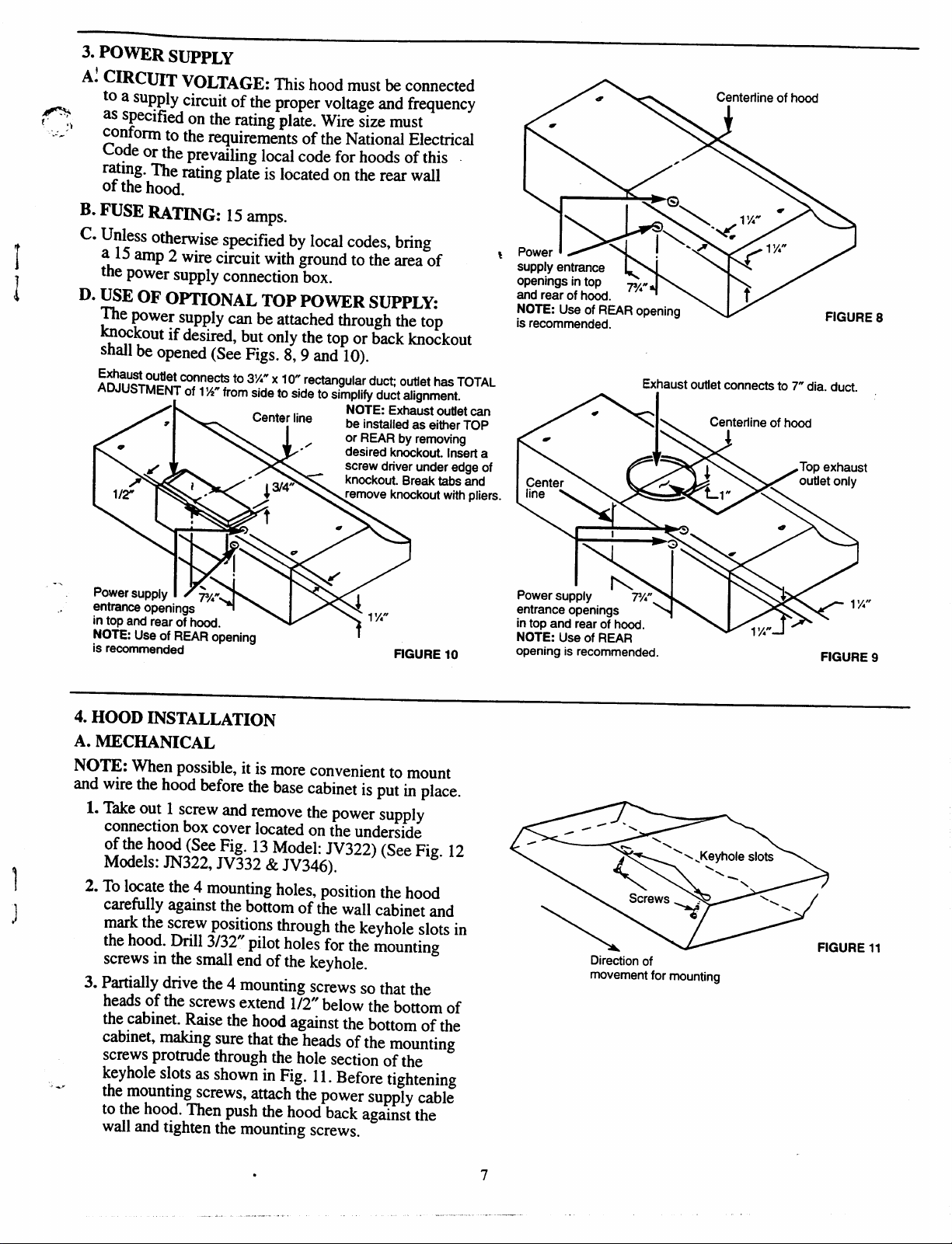

shall be opened (See Figs. 8,9 and 10).

Exhaustoutietconnects to 3x” x 10“ rectangular duct outlet has TOTAL

ADJUSTMENT of 1%“ from side to side to simplify duct alignment.

NOTE: Exhaust outiet can

be installed as either TOP

or REAR by removing

desired knockout. Insert a

screw driver under edge of

knockout. Break tabs and

1//

remove knockout with pliers.

Power

t

Supply entrance

openings in

and rear of hood.

NOTE: Use of REAR opening

is recommended.

top

7??”~

Al.

Center

line

Centerfine of hood

FIGURE 8

Exhaust outlet connects to 7“ dia. duct,

Centerline of hood

-.

Power supply

entrance openings

,

in

top and rear of hood.

NOTE: Use of REAR opening

is recommended

T

FIGURE 10

NOTE: Use of REAR

opening is recommended.

v

1

y,”--l

FIGURE 9

4. HOOD INSTALLATION

A. MECHANICAL

NOTE: When possible, it is more convenient to mount

and wire the hood before the base cabinet is put in date.

1. Take out 1 screw and remove the power

SUppl~

connection box cover located on the underside

of the hood (See Fig. 13 Model: JV322) (See Fig. 12

Models: JN322, JV332 &JV346).

1

2. Tolocate the 4 mounting holes, position the hood

carefully against the bottom of the wall cabinet and

)

mark the screw positions through the keyhole slots in

the hood. Drill 3/32” pilot holes for the mounting

screws

%rtially drive the 4 mounting screws so that the

3.

in the small end of the keyhole.

.

Direction of

FIGURE 11

movement for mounting

heads of the screws extend 1/2” below the bottom of

the cabinet. Raise the hood against the bottom of the

cabinet, making sure that the heads of the mounting

screws protrude through the hole section of the

-+.

keyhole slots as shown in Fig. 11. Before tightening

the mounting screws, attach the power supply cable

to the hood. Then push the hood back against the

wall and tighten the mounting screws.

●

7

Page 8

B. ELECTRICAL CONNECTION

1. Be sure the power supply is disconnected before

making electrical connections.

2.

Remove the connection box cover located on the

left side of the fan unit.

3. Attach the power supply through the knockout hole

in the back or top of the hood.

4. Connect the colored incoming power supply

lead to the stripped black lead and connect the

incoming white neutral lead to the stripped white

lead in the connection box as shown in Figs. 12

and 13. Make connections in the hood in accordance

with local codes.

5. A ground lug is provided for proper grounding

of the hood frame. It is recommended that the

hood frame be grounded in accordance with

National Electrical Code and local codes (see

Figs. 12 and 13).

6. All electrical connections should be inspected

carefully before the power is turned on to make

certain that none have come loose during shipment.

7. Reinstall the connection box cover.

8. Install a lamp (not supplied with hood in the socket).

(CAUTION: Maximum wattage on the lamp should

not exceed 60 watts.)

WARNING: IMPROPER CONNECTION OF

ALUMINUM

HOUSE WIRING TO THESE

COPPER LEADS CAN RESULT IN A

SERIOUS PROBLEM. USE ONL

Y

CONNECTORS DESIGNED FOR JOINING

COPPER TO ALUMINUM AND FOLLOW

THE MANUFACTURER’S

RECOMMENDED PROCEDURE CLOSELY.

8

FIGURE 12

FIGURE 13

Top of hood

Cut off excess wire length so wires will

be easy to position under cover

Knockout

plate

Power

supply

Power supply

connection

box cover

Mounting screw

Ground lug

(ground per para B3 colored leads)

Ground

(green)

lead

White

lead

Wire nuts

Connection

box cover

mounting

screw

Wire nuts

Power supply

Grounding lug

Ground

wire

Light box

Connection

box cover

White

leads

Colored leads

Page 9

Lamp Replacement

Model JV346 has a lamp cover.

The lamp cover need not be removed for lamp removal

or installation.

Remove the lamp and replace with an ordinary screwbase lamp bulb NOT MORE THAN 60 WATTS.

To remove the lamp cover, if desired:

• Press the sides with 2 fingers until the side prongs

are released.

• Lift the lamp cover and slide towards you in one

motion.

To replace the lamp cover:

• Insert the prong located at the end of the cover into

the top opening.

• Gently push the cover up and press the sides to fit

the side prongs into the side openings.

• Release and the cover will lock in position.

CAUTION: Let the lamp cool completely before

removing. A warm or hot bulb may break if

touched with a moist cloth or hand.

9

Page 10

PROBLEM POSSIBLE CAUSE

FAN DOES NOT

•

A fuse may be blown or a circuit breaker tripped. Replace fuse or reset circuit breaker.

OPERATE WHEN

THE SWITCH IS ON

FAN FAILS TO

•

Fan blade striking the hood shell.

CIRCULATE AIR

•

Excessively soiled filter should be checked and corrected before using the hood again.

FAN OPERATES BUT

•

Check to be sure the filter is clean. If replacing the filter does not correct the problem,

MOVES AIR SLOWER call for service.

THAN NORMAL

FAN KEEPS GOING

•

The motor is probably overheating and turning itself off. This can be harmful to the

OFF AND ON motor. Check to be sure the filter is clean. If off and on cycling continues, call for

service.

Questions?

Use This Problem Solver

If you need more help…call, toll free:

GE Answer Center

®

800.626.2000

consumer information service

10

Page 11

Help Us Help You…

Write down the model and serial

numbers.

You’ll find them on a label on the back wall of

the hood. These numbers are also on the Consumer

Product Ownership Registration Card that came with

your hood. Before sending in this card, please write

these numbers here:

Model Number Serial Number

Use these numbers in any correspondence or service

calls concerning your hood.

If You Need Service

To obtain service, see your warranty on the back

page of this guide.

We’re proud of our service and want you to be

pleased. If for some reason you are not happy with

the service you receive, here are three steps to follow

for further help.

FIRST, contact the people who serviced your

appliance. Explain why you are not pleased. In most

cases, this will solve the problem.

NEXT, if you are still not pleased, write all the

details—including your phone number—to:

Manager, Consumer Relations–GE Appliances

Appliance Park

Louisville, KY 40225

FINALLY, if your problem is still not resolved, write:

Major Appliance Consumer Action Panel

20 North Wacker Drive

Chicago, IL 60606

11

Page 12

WHAT IS COVERED

FULL ONE-YEAR WARRANTY

For one year from date of original

purchase, we will provide, free of

charge, parts and service labor in

your home to repair or replace

any

part of the hood

that fails because

of a manufacturing defect.

*******************

This warranty is extended to

the original purchaser and any

succeeding owner for products

purchased for ordinary home use in

the 48 mainland states, Hawaii and

Washington, D.C. In Alaska the

warranty is the same except that it is

LIMITED because you must pay to

ship the product to the service shop

or for the service technician’s tra v el

costs to your home.

All warranty service will be

provided by our F actory Service

Centers or by our authorized

Customer Care®servicers during

normal working hours.

Should your appliance need

service, during warranty period

or beyond, call 800-GE-CARES

(800-432-2737).

WHAT IS NOT COVERED

• Service trips to your home to

teach you how to use the product.

Read your Use and Care material.

If you then have any questions

about operating the product,

please contact your dealer or our

Consumer Affairs office at the

address below, or call, toll free:

GE Answer Center

®

800.626.2000

consumer information service

• Improper installation.

If you have an installation

problem, contact your dealer or

installer. You are responsible for

providing adequate electrical, gas,

exhausting and other connecting

facilities as described in the

Installation Instructions provided

with the product.

• Replacement of the replaceable

filters.

• Replacement of house fuses or

resetting of circuit breakers.

• Failure of the product if it is used

for other than its intended

purpose or used commercially.

• Damage to product caused by

accident, fire, floods or acts

of God.

WARRANTOR IS

NOT

RESPONSIBLE FOR

CONSEQUENTIAL DAMAGES.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion

may not apply to you. This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

To know what your legal rights are in your state, consult your local or state consumer affairs office or your state’s Attorney General.

Warrantor: General Electric Company

If further help is needed concerning this warranty, write:

Manager—Consumer Affairs, GE Appliances, Louisville, KY 40225

JN322

JV322

JV332

JV346

Part No. 164D2966P178

Pub No. 49-8664

D-945-613-0

2-95 CG

YOUR RANGE HOOD

WARRANTY

Staple sales slip or cancelled check

here. Proof of original purchase date

is needed to obtain service

under warranty.

Printed in the United States

Loading...

Loading...