Page 1

“

‘

Gas

Range

Safe* Instrudons....................2-5

Anti-Tip

Deviw

.............................2, 3, 19,28

Operating Instructions,

Ttps

Aluminum Foil ............................5, 14, 16, 17

Features

............................................................7

Flooring/Leveling ...........................................6

@en.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

l&18

Baking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

13, 14

Broiling, Broiling

Guide...........,.........l7,

18

Oven Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

10

Roasting,

Roast;ng

Guide................l5, 16

Shelves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

11, 13

Sutiace

Cooking .........................................8, 9

Control Settings ..........................................8

Electric Ignition .......................................8, 9

Care and Cleaning

....................l

9-24

Broiler Pan and

Rack..........................................22

Burner

.mbW...........

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

19-21

Coomp ..........................................................2 1

Door

Removal

......................:........,...............23

@en'.~~orn.................................................22

~~Oj-lejD~~w6r

.

,, .,..

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22

Problem Solver.

..............................34

Thermostat

Adjustment-

Do It

Yourself

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

12

More questions

?...call

GEAnswer Cente~

80~626.2000

consumer Services ...................36

Appliance

Registration..................................2

Imponant Phone Numbers .......................36

Model and Serial Number Location ...........2

Warranw

......................,.................Back

Cover

Models:

JGAS02PN

JGAS02EN

JMS02PN

,,

. . .

Page 2

=LP

US

~LP

YOU

Read this book

carefdy.

~

you received a damaged

rarige...

It is intended to help you operate and maintain your

tiediately

contict the alder (or builder) that sold

new range properly.

you

the

range.

Keep it handy for answers to your questions.

Save time and money. Before you

If you don’t understmd something or need more help,

requ=t service...

write (include your phone number):

Consumer Affairs

Check the Problem Solver in

tie

GE Appliances

back of this book. It lists causes of

Appliance Park

minor operating problems that you

Louisville, KY 40225

cm

correct yourself.

@

@m’Mn

Write

dom

the model and serial numbers.

You’ll find the model and

senrd

numbers on two labels

on the range front frame near the broiler drawer.

These numbers are

dso

on the Consumer Product

Ownership Registration Card that came with your

range. Before sending in this card, please write these

numbers here:

Model Number

Setial

Number

Use these numbers in any correspondence or service

calls concerning your range.

a

4

A WAWNG

h

●

ALL RANGES CAN

TW.

●

INmRY

TO PERSONS

w

COULD RESULT.

@

●

~STALL

THE

ANTI-TW

b,

DEVICE

PAC~D

WITH

THE RANGE.

●

SEE THE

~STALLATION

~STRUCTIONS.

~

YOU

~ED

SERWCE

To obtain service, see the

Consumer Services page in the

back of this book.

To obtain replacement parts, contact

G~otpoint

Service Centers.

We’re proud of our service and

want you to be pleased. If for some

reason you are not happy with the

service you receive, here are three

steps to follow for further help.

HRST, contact

the

people who

serviced your appliance. Explain

why you are not pleased. In most

cases, this will solve

the

problem.

NEXT, if you are

sti~

not pleased,

write dl the details-including

your phone number—to:

Manager, Consumer Relations

GE Appliances

Appliance Park

Louisville, KY 40225

~ALLY,

if your problem is still

not resolved, write:

Major

Appliance Consumer

Action Panel

20 North

Wacker Wve

Chicago, ~ 60606

.., .

WAHG: Mthe

information in this

mand is

not

fotiowed emctiy,

a fire or

e~losion

may

At

musing

property damage,

persod tijury

or

dmth.

—Do

not store or use gasotie or other

●

-ediately d

your gas

suppher

from a

flammable vapors and

Mquids

in the vicinity

neighbor’s phone.

FOUOW

the gas

supptier’s

of this or any other

apptiance.

instructions.

—WHAT

TO DO ~ YOU

S~LL

GAS

c M

you

mot mch

your gas

supptier, ~

the fw department

●

Do not try to

tight

any

apptie.

—btiation

and

service

must be performed

●

Do

not touch any

el~trid swikh;

do not

by a

qtiled Mer,

service agency or

use any phone in your btiding.

the gas

supptier.

Page 3

WORTW

S~TY

NO~CE

●

The

Mornia

Safe

Brirddng

Water M

Tom

Enforcement Act

requires

the

Governor of

C~ornia to pubtishatist

of substances hownto

the

state to cause

canmr, birth

clef* or

other

reproductive harm, and requires businesses to warn

customers

ofpotenthd

exposure to

such

substanm.

●

Gas

apptim can muse

minor

exposw

to

four

of tiese substances,

namely beme,

carbon

monotide,

formaldehyde and

soog

caused

primdy by the incomplete combustion

of

nati

gas or

LP hels,

Properly

adjusted burners,

indicated

by

a bluish rather b a

yeflow flame,

m~

incomplete combustion.

&posm

to

thes6’subs~ces canbe

. “ “

@by vendng

with

an

open window or using a ventilation fan or hood.

~enYou &t Yom -e

●

Have

the Mer sbow

you

fie

location of

the

qe w

at-off

vdveti

how

toshutit off

Mnecessary.

●

Have yon -e Wed

and

pro~rly

grounded by a q-cd

Mer,

in

accordanm

with the

kstiation

ktructions. Any

adjustment

and service

shotid

be

perfomed o~y

by

q-cd

gas range

instiers

or service *hrdcians.

●

Phg

your

~~

into a

l~volt ~unded

outie$ dy. Do

not remove

tbe

round

grountig

prong

bmthe

plug.

Ein doubt

about the

grounding of the

home electrid system it is yom

personal

respomibfity and ~tigation

to have

m

ungrounded

outiet repl*

with a properly

grounm-prong outiet in

accordance

witb

the

Nstiti MectridCode. h C-

the

apphana

must

be

electri@y @unded

in

accordance with

the Ctian M=trical.

Code.

Do

not use

an extension

cord

with this

app~an%.

Q Do not

zttempt

to

_

or

rephee

ay

partofyourrange

urdessittispecifi*y

recommended &

M

@da M other

servicing

shodd

be referred to a

q~ed tecMcian.

Q -te _

out of Mtien

tic pati

and

out of

-

btiow

to

prevat pnot

OU*

(onstanding@ot rnod~)

and poor air

*tiom

Q

Be

m

W

pa-

mated*

are removed

from

the range

before operating it

to~vent * or

smoke damage

shotid

the packing material

ignite.

●

Be sure

your range is

co-y

adjusted by a

q-cd

servim t-cian

or ●

~for

the

type of ~

(uati

or.W)thatis to

be

used.

Your range can be converted for use with either

type of gas. Seethe

btiation kstructions.

W-G:

These adjustments must be made by

a ~dified

serviee tihnician

in accordance with

the

manufactir’s

instructions and W codes and

requirements of

the

authority

having

jurisdiction.

Failure

tofo~ow

these instructions

codd resdt in

setious

injury or property damage. The

q~ed

agency performing this work assumes

responsibtity

for

the

conversion

*After prolonged

w ofa _

~

kr

~peram

may

wtit

and

many floor

#V~ti& @

not

tihd

~ Md of

m

Never

@til b

range

over

vinyl

tie

or holerun

that

cannot

withstand such type of use, Never

instil it -y

over

interior

kitchen carpeting.

WAmNG–M_

m

tipand~~atit

~

prev@nt8WidenM@pingof

the

~% ~h~

approved

~ti-~q

device

to tie

wW. (SW kstiation

@

hstructions.)

To

chd

if the device

is

in-

and

engaged

properly,

care~y

tip

tie range

forward, The

Anti-Tip device

shotid engage

and

@

prevent

therauge from

tipping

over. Hyoupdl

the

range out from the wd for any

reaso~

make

sw

the Anti-Tip device is engaged

when

you push the

range

back

agtist

the

wW.

Hit

is

not

there is a possible risk of the range

tipping over if you

or

a

c~d stan~

sit or lean on

an open

door.

3

Page 4

●

Do not

leave

Mdren #one or

unattended

where a range is

hot or

in operatia

They

cordd

be seriously burned,

●

Do

not

Uow

anyone to ebb, stand or hang on

the

door,

brotierdrawer

or range

top.

They

cordd

damage the range and even tip it over,

causing severe

perso~ ~~.

●

Ut

burner

grab

and

other surfam cool

before

tonctig

them or leaving them where

Mdren

can reaeh

them.

●

Never wear loose

fitig

or

hanging

garments

whtie wing

the

apptian%

Be careti

when

reaching for items

stored

in

Mbinets

over

the

cooktop. H_le

rnaterhd

codd be ignited if

brought

in contact witi

tie or

hot oven

sti~~s

and

may

cause severe

burns.

●

For

your safety, never use

your apphce

for

we

or heating the

room.

e

e Do not m

water on grease

m.

Never pickup

ating

pan. Turn off

burner, then

smotberfbuning

p~. by

wvering

pan

mmpletely

with

wefl-fitting HA

cookie sheet or fiat tray.

Haming -e

outside a

pan

can

be put out by covering with baking

soda

or, if

avdable, a muki-purpose

dry chemical or

foam-type

fix

extinguisher.

* Do

not store

tible

rnaterkds

in an

oven>

a range

brotier

drawer or near a

cooktop.

s Do

not

store

or

use combmtihle materkds$

gasotineor

other

fhunmablevapors

and

tiquids

in the

victity of

this or any other

app~anee.

s Do

not let cooking grease ar other

tible

materkds ac-tite h or

near the range.

●

men coo- pork$

follow thedirections

exacdy

and always

cook

the

meat

to an internal

temper- of

at

least 170°F.

This assures M4

k

the

remote

possibfity

that trichina may be pment

in

the meat, it

til

be

ki~ed

and the meat W be

safe to eat

Stiace CMQ

●

Always w the L~ position (on

electic

ignition

rnodek)

or the ~ position (on standing

pflot modek)

when igniting top burners and

make sw the

burnem

have ignited.

●

Never leave tiace

burners unattended at

Mgh tie

settings.

Boilovercauses

smoking

and greasy

spi~overs

that may catch on

fie.

●

Adjust

the top

burner

flame* so it does not

e~nd

beyond the edge of the cookware.

Excessive flame is

Wardous.

o

Use O* dry pot

holde-moist

or damp potholders on hot surfaces

may

resuk

in burns from steam. Do

not

let

pot

holders come

near open

flames when

~g

cookware. Do not use a towel orotherb@

cloth in place of a

pot

holder.

●

To

~

the

possibtity

of burns,

ignition

of

flmable

materials, and

$pWge,

turn

cookware hmdes toward the side or back of the

range without extending over adjacent burners.

●

Always b the

stiaee burner

to 0~ before

removing the cookware.

“ CareMy wati foods

being fried at a high

flame setting.

●

Never

blti

the

venb (tir

openings) of the

rangk

They provide

the h

Met

and

outiet

that

are necessary for

the mge to operate

properly

with

corrwt

combustion. W openings are located

at.the

rear of the

cooktop,

at

tie

top and

bottom

of

the

oven door,

and

at the bottom of the range

mder the

broiler drawer.

●

~

not

use a wok on

modeh

with

-ed

burners

Uthe

wok

has a

round

mettd

ring that is

phced

over the

burner

grate to

snpport

the wok.

This

ring

acts as a heat

#p,

which

may

damage the

burner grate

and buraer

head. Aso, it may cause

tie

burner to work

@properly.

This may cause a

carbon

monofide level

above that

Wowed

by

current standards,

resdtig

in a

heakh -.

4

Page 5

● Foods for-

shotid

be as dry as

possible

Frost on

tiomn

foods or moisture on fresh foods

can

cause

hot fat to bubble up and

over

sides of

the

pan.

●

Use least possible

am-t

of fat

for

effective

shtiow or deepfat =.

Filhg

the

pan too

W

of fat

can cause spflovers

when food is added.

●

Ka

cornbtiation

of & or

fa~ ~

be used

k f-,

stir

together

before

heating or as fats

melt

#owly.

●

Use a deep fat thermometer whenever

possible

to

prevent

overheating

tit beyoudthe

Smotig point.

*Use

proper

~

&Avoidpms

that are

uustable

or

dy tip Sel@ mkware hatig U

bottoms &

6nough

to properly contain

food

and

avoid

botiovers

and

sptiovers

and ~e

mou@ to

cover burner grate. ~s W both save cleaning

time nd prevent

=ous accmmdatiom aff~

since heavy

s-g

or

spMovers

left on range

can ignite. Use pans with

han~es

that can be

easfly

wm

and remain cool,

●

men X -

cookware,

make

snre

it is

designed for top-of-range cooking.

. Keep fl

p~es away

from top

buraers.

*

M

not leave

pktic i-

on the

cooktop

they may

melt if left too close to the

vent,

●

M

not bve ~

items

@n the

eooktop.

me

hot

air from the

vent may

ignite

tible

items

and

til inmepresswin closed

containers,

which

may

canse

them to

burs~

●

To avoid

the possibtity

ofa

bum akways

be

certain that

the controb

for ~ bmers are at

the OFF petition and

W

grates are-before

attemp~ to

remove

them.

amen -

foods are

mder

the hood, turn

the fan

off. me f- ifoperatig, may

spread

the

ti~

c W mge &

located near a

fidow,

do not hang

long curtains that

codd

blow over the top burners

and create afire

h-.

*men

a

ptiot gw

out (on

s~ding

@ot

models),

you til detwt

a faint odor of gas as your

sigmd

toretight the pfi~t. men

refighting the

ptio~

make snre

burner controk

are in

the Om

position,

and

fo~ow

instructions in this book to

re~ght.

●

Hyou smM

gas,

and you have

hdy made

sure

pdots me tit (on staatig pilot

models),

turn off the gas to W

mge

and

eti

a qualified

service

t~hnician.

Never

use

an open

flame

to

~ate

a leak.

cl-

Yow -e

●

Clean ody parts M k W Use =d

~re Nde.

~

Keep_

d-and k of aeeumrdations

of

-

or

spWoVem

which my @k

* W mti

when

you

clean the

cooktop

because

5

Page 6

Your range,

tike

many other household items,

The range should be

instiled

on a l/4-inch thick

is hwvy and can settle into soft floor coverings

sheet of plywood (or similar

materird)

as

fo~ows:

such as cushioned vinyl or

arpeting.

men

the floor covering ends at the front of the

men

moving the range on this type of flooring, use

range, the area that the range

wi~ rest on should be

care, and it is recommended that these simple

built up with plywood to the same level or higher than

instructions be followed.

the floor covering. This

wfll tiow

the range to be

moved for cleaning or servicing.

Leveling legs are located on each corner of the base

of the range. Your range must be level in order to

produce proper cooking and baking results. Merit is

in its

find

location, place a level

horizontily

on any

oven shelf and check the levelness front to back and

side to side. Level the

rmge

by adjusting the leveling

legs or by placing shims under the comers as needed.

One of the rear leveling legs will engage the

hti-Tip

device (allow for some side to side adjustment).

Mlow a minimum clearance of 1/8 inch between the

range and the

levehng

leg that is to be

instrdled

into

the

hti-Tip

device.

6

Page 7

Y

I

+

Shnding

Pilot Models

JGAS02PN

JLAS02PN

\

Electtic Ignition Model

JGAS02EN

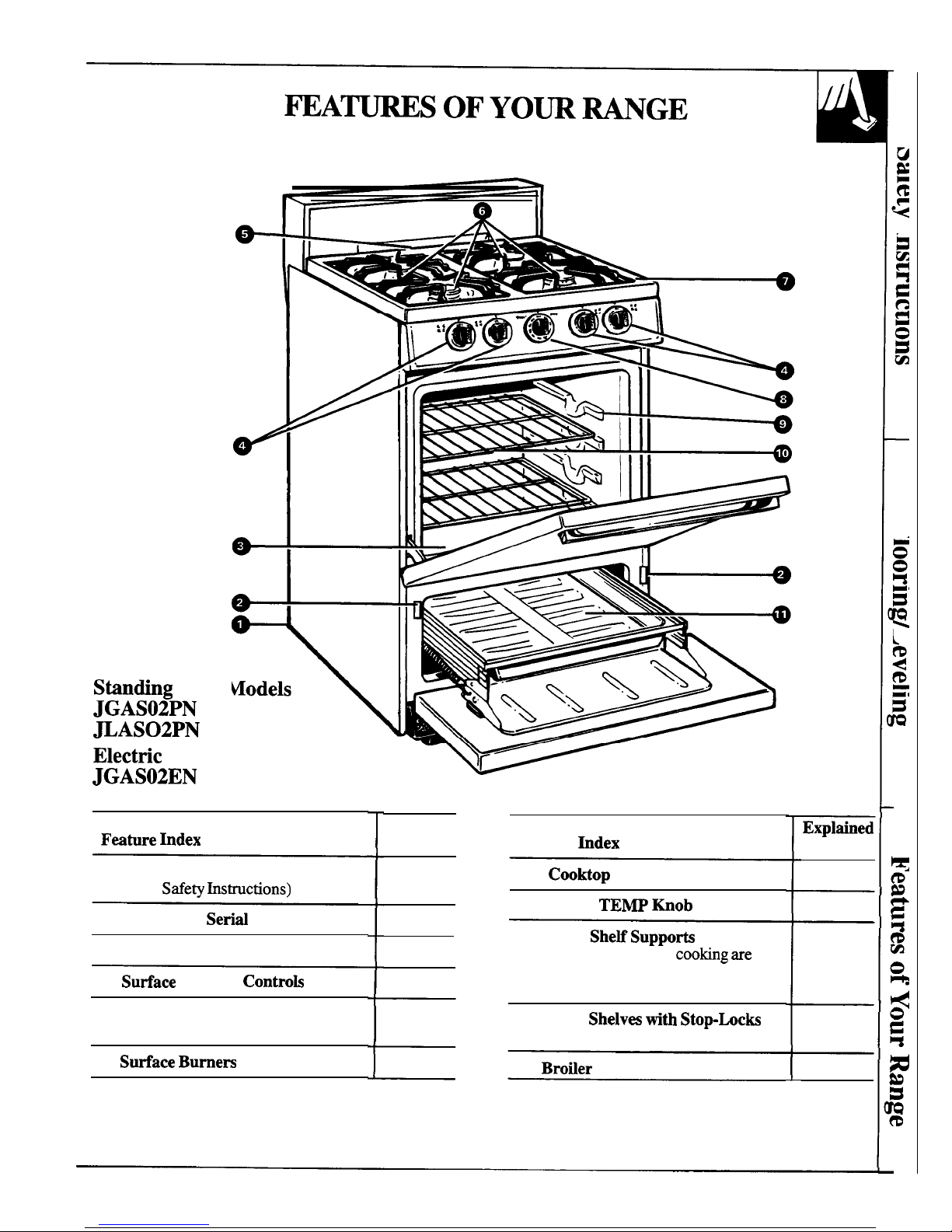

Fwture hdex

1 Anti-Tip Device

(see

Safe~ hstructions)

2 Model and

Serbd Number

3 Removable Oven Bottom

4

Sutiace Burner Controk

5 Oven Vent

(located in center of rear of range)

6 Sutiace Bumem and Gratin

Explained

on page

3,5

2

16

7

9

Feature

hdex

7 Cooktop

8 OVEN

TEMP

Mob

9 Oven

SheHSuppoti

Shelf positions for

coobg are

suggested in the Baking, Roasting

and Broiling pages.

10 Oven

Shelv~ tith Stop-bcks

14, 15, 17

11 Brotier Pan and Rack

Expltied

on page

14

9

9

9, 15, 17

13, 15, 17

7

Page 8

SMACE

COO~G

Lighting Instructions for Electric Ignition Models

JGAS02EN

The surface burners on some models me lighted by

electric ignition, eliminating the need for standing pilot

The electrode of the spark igniter is exposed.

lights witi

constandv

burning

flames.

men

one burner is turned to

LITE, W tie

burners

-

In me of a power failure, you can light the surface

spark. Do not attempt to disassemble or clean

burners on your range with a match. Hold a

hghted

around any burner while another burner is on.

match to the burner, then turn the knob to the

L~

An electric shock may result, which could cause

msition. Use extreme mution when

ti~hti

burners

you to knock over hot cookware.

I

I

hs

way.

--

Surface burners in use when an electrical power failure

occurs will continue to operate normally.

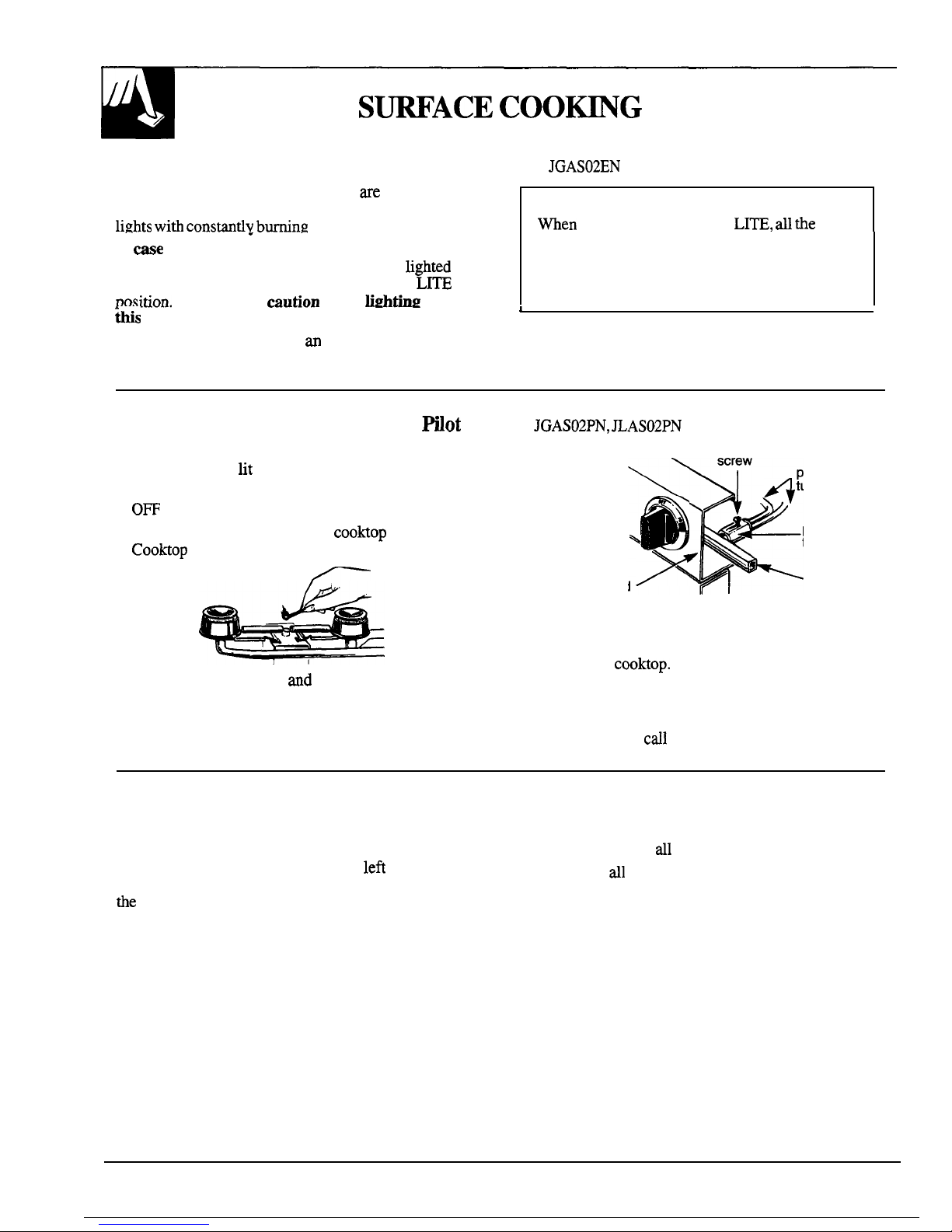

Lighting Instructions for Standing

mot

Models

JGAS02PN, JLAS02PN

The surface burners on these ranges have standing

pilots that must be

tit

initially. To light them:

1. Be sure surface burner control knobs are in the

0~

position.

-

2. Remove the grates and lift the

cooktop

up (see the

Cooktop

section).

3. Locate the 2 pilot ports

ad

light each of them with

a match.

pilot

adjustment

%

screw

&

4

pilot

tubes

2

\

pilot

filter

manifold

7

manifold

panel

pipe

4.

If the pilots need adjusting, turn the adjusting screw

located on the pilot filter.

5. Lower the

cooktop.

Your surface burners are now

ready for use.

6. Observe lighted burners. Compare the flames to

pictures in the Problem Solver. If any flame is

unsatisfactory,

crdl

for service.

Surface Burner Controls

Before Lighting a Burner

The knobs that turn the surface burners on and off are

●

If drip pans are supplied with your range, they

located on the control panel on the front of the range.

should be used at

dl

times.

The two knobs on the left control the

lefi

front and

left rear burners. The two knobs on the right control

●

Make sure dl the grates on the range are in place

the

right front and right rear burners.

before using any burner.

8

Page 9

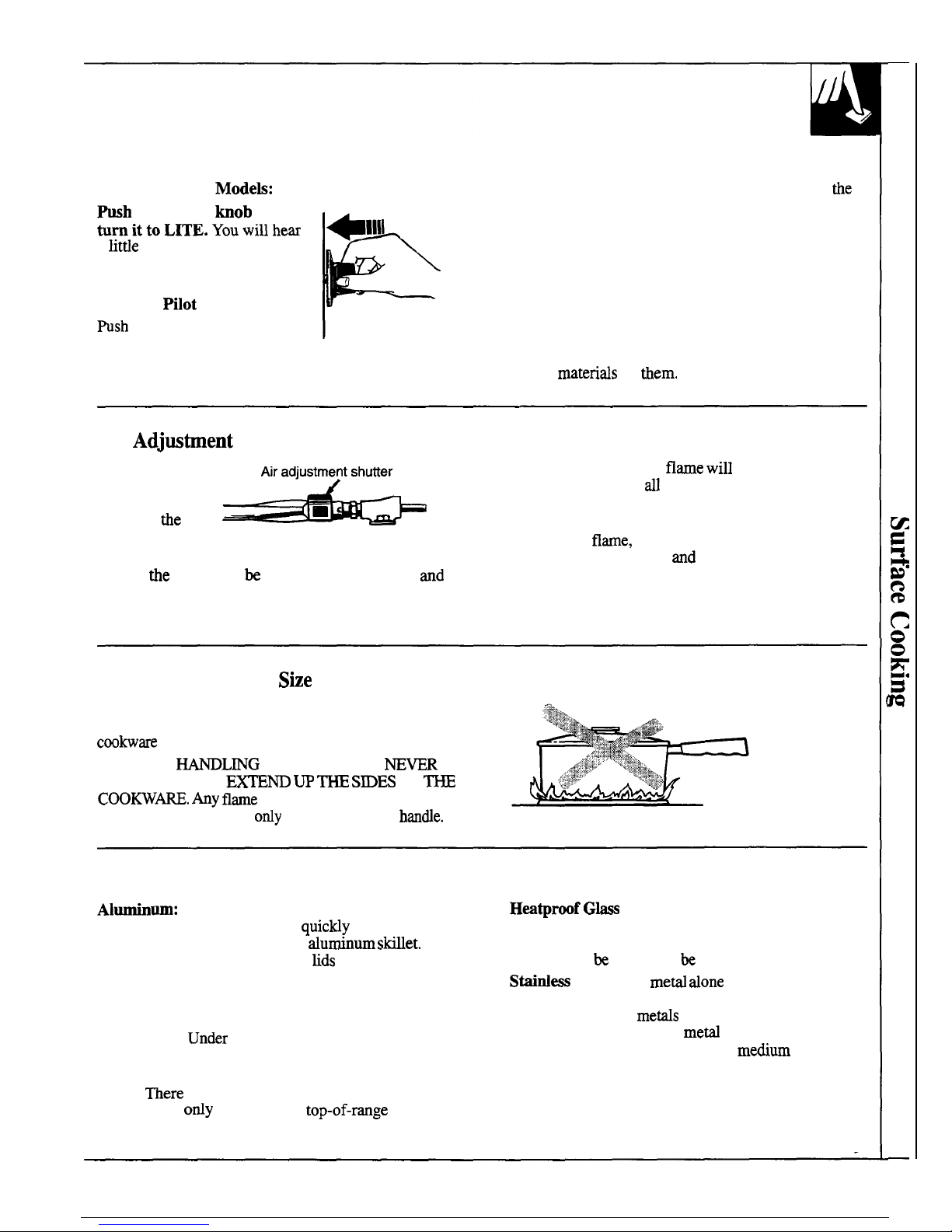

To Light a Surface Burner

After Lighting a Burner

Electric Ignition Modeh:

~h

the control

hob

in and

tumittoLITE.Youwillhem

~1111

a litde “clicking” noise—the

sound of the electric spark

igniting the burner.

Standing Hlot Model:

Wsh control knob in and turn

P

it to HI position. The burner

should light within a few seconds.

●

After the burner ignites, turn the knob to adjust

tie

flame size.

●

Check to be sure the burner you turned on is the one

you want to use.

●

Do not operate a burner for an extended period of

time without cookware on the grate. The finish

on the grate may chip without cookware to absorb

the heat.

●

Be sure the burners and grates are cool before you

place your hand, a pot holder, cleaning cloths or

other

matends

on

them.

Air

Adjw@ent

An air adjustment

shutter for each

surface burner

regulates

the

flow

of air to the flame.

When the right amount of air flows into the

burner,

the

flame will be steady, relatively quiet

and

have approximately 3/4-inch sharp blue cones. This is

usually the case with factory preset shutter settings.

With too much air, the

flame will

be unsteady,

possibly won’t burn

rdl

the way around, and will be

noisy, sounding like a blowtorch.

With not enough air, you won’t see any sharp blue

cones in the

flame,

you may see yellow tips and soot

may accumulate on pots

and

pans.

To adjust the flow of air to the burners, rotate the

shutters to allow more or less air into the burner tubes

as needed.

How to Select Name Sbe

Watch the flame, not the knob, as you reduce heat.

The flame size on a gas burner should match the

cookw~e you are using.

FOR SAFE

WL~G

OF COOKWARE

~WR

LET THE FLAME

EKTE~ W ~ S~ES

OF

~

COOKW~. Any flame

larger than the bottom of the

cookware is wasted and

ordy

serves to heat the

hande.

Top of Range Cookware

Almnin

um: Medium-weight cookware is

recommended because it heats

quictiy

and evenly.

Most foods brown evenly in an

durrdnum

stiet.

Use saucepans with tight-fitting

tids

when cooking

with minimum amounts of water.

Cast-iron: If heated slowly, most skillets will give

satisfactory results.

Enamelware:

Un&r

some conditions, the enamel

of some cookware may melt. Follow cookware

manufacturer’s recommendations for cooking methods.

Glass:

There

are 2 types of glass cookware-those

for oven use

ody

and those for top-of-rmge cooking

(saucepans, coffee and teapots). Glass conducts heat

very slowly.

Hwtproof Gks

Ceramic: Can be used for either

surface or oven cooking. It conducts heat very slowly

and cools very slowly. Check cookware manufacturer’s

directions to

be

sure it can be used on gas ranges.

Stahdess

Steel: This

meti done

has poor heating

properties and is usually combined with copper,

aluminum or other

metis

for improved heat

distribution. Combination

meti

skillets usually work

satisfactorily if they are used with

medium

heat as the

manufacturer recommends.

9

Page 10

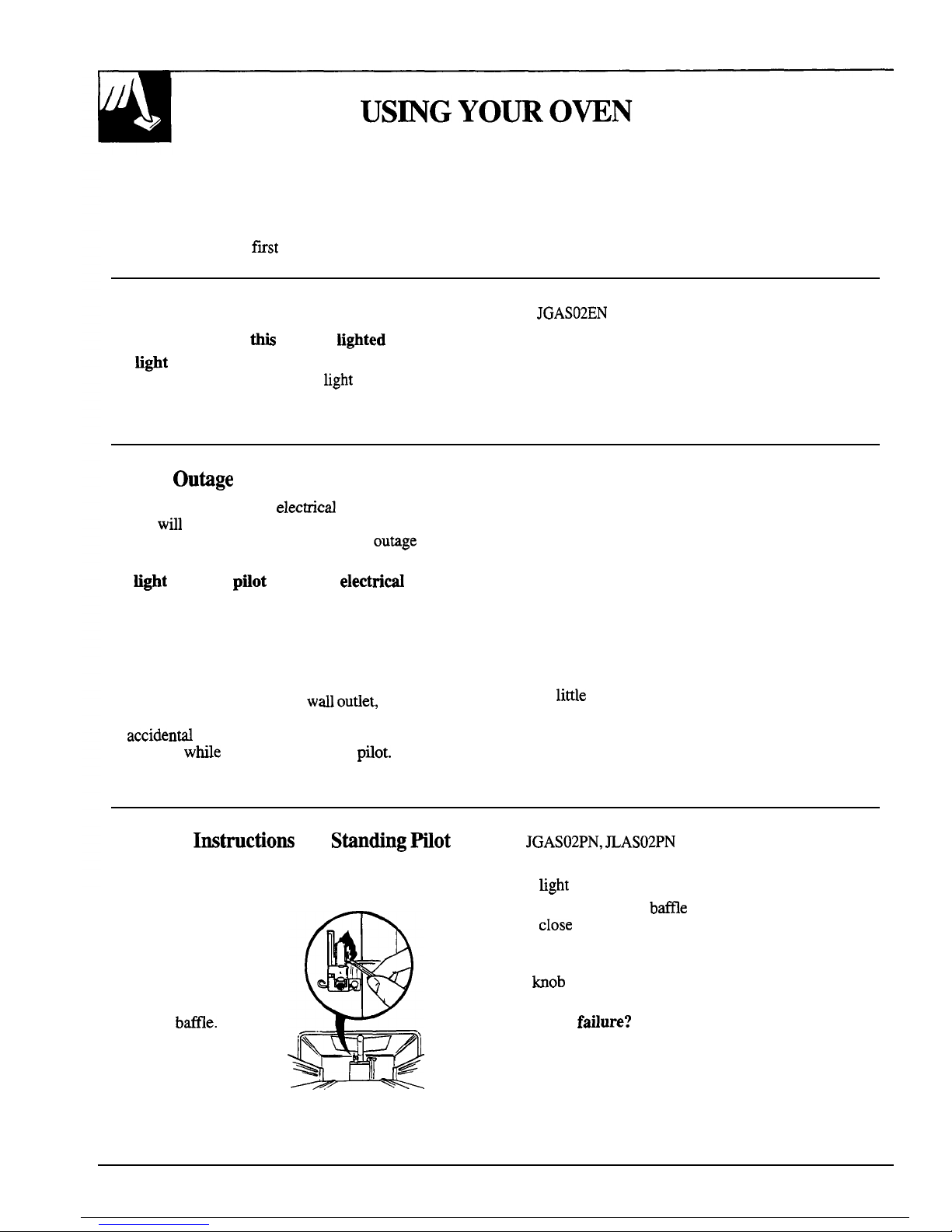

Before Using Your Oven

Be sure you understand how to set the controls properly. Practice removing

and replacing the shelves while the oven is cool. Read the information and

tips on the following pages. Keep this book handy where you can refer to it,

especially during the

fwst

weeks of using your new range.

Lighting Instructions for Electric Ignition Model

JGAS02EN

The oven burner on ti range is tighted by electric ignition.

To

tight

the burner, turn the OVEN TEMP knob to the desired

temperature. The burner should

fight

within 30-90 seconds. After the oven

reaches the selected temperature the oven burner cycles on and off to

maintain the selected temperature.

Power Outige

A burner in use

when an

electricrd

power failure

occurs

wdl

continue to operate normally. Your oven

may be used during an electrical power

outige by

carefully following the steps below:

To tight the oven ptiot during an

electrid

power outage:

1. Be sure the OVEN TEMP knob is in the

OFF position.

2. Open both the oven and broiler doors and wait 5

minutes to allow any pilot gas to dissipate.

3. Unplug the range from the

wdl outiet,

turn off the

circuit breaker, or remove the fuse to avoid

accidenti

ignition of the oven if electrical power is

restored

wtie

you are lighting the

pflot.

4. Remove the broiler pan.

5. Locate the oven pilot assembly by looking into the

broiler opening. The pilot is at the back of the

broiler compartment, on the right side of the burner.

NOTE: The oven must beat room temperature

before you should attempt to light the oven pilot

manually.

6. Turn the OVEN TEMP knob to the desired

temperature setting.

7. Light the pilot with a match and withdraw your arm

immediately because the oven burner may light in

as

litie

as 20 seconds.

8. Replace the broiler pan and close the oven and

broiler doors.

NOTE: It is necessary to light the pilot manually

each time the oven is used during a power outage.

Lighting

htructions

for

Stiding mot

Models

JGAS02PN, JLAS02PN

These ranges have standing oven pilots that must be

4. Using a long match or match holder, reach in and

lit initially. tight

the oven pilot.

To light the oven pilot:

1. Be sure the OVEN

TEMP knob is in the

OFF position.

2. Remove the oven

bottom and the

burner

btie.

See the Care and

Cleaning section.

3. Find the oven pilot

port at the back of

the oven.

5. Place the burner

btie

and the oven bottom and

cIose

the door. Your oven and broiler are now ready

for use.

● To light the oven burner, turn the OVEN TEMP

bob

to the desired temperature. The burner should

light within 60 seconds.

●

Power

faflure?

An electrical power failure will not

affect the standing oven pilot.

10

Page 11

Oven Control

Your oven is controlled by an

OWN TE~

knob.

After the oven reaches the selected temperature, the

It will

norrndly take 30-90 seconds before the flame

oven burner

cycles+ff

completely, then on with a

comes on.

full flame-to maintain the selected temperature.

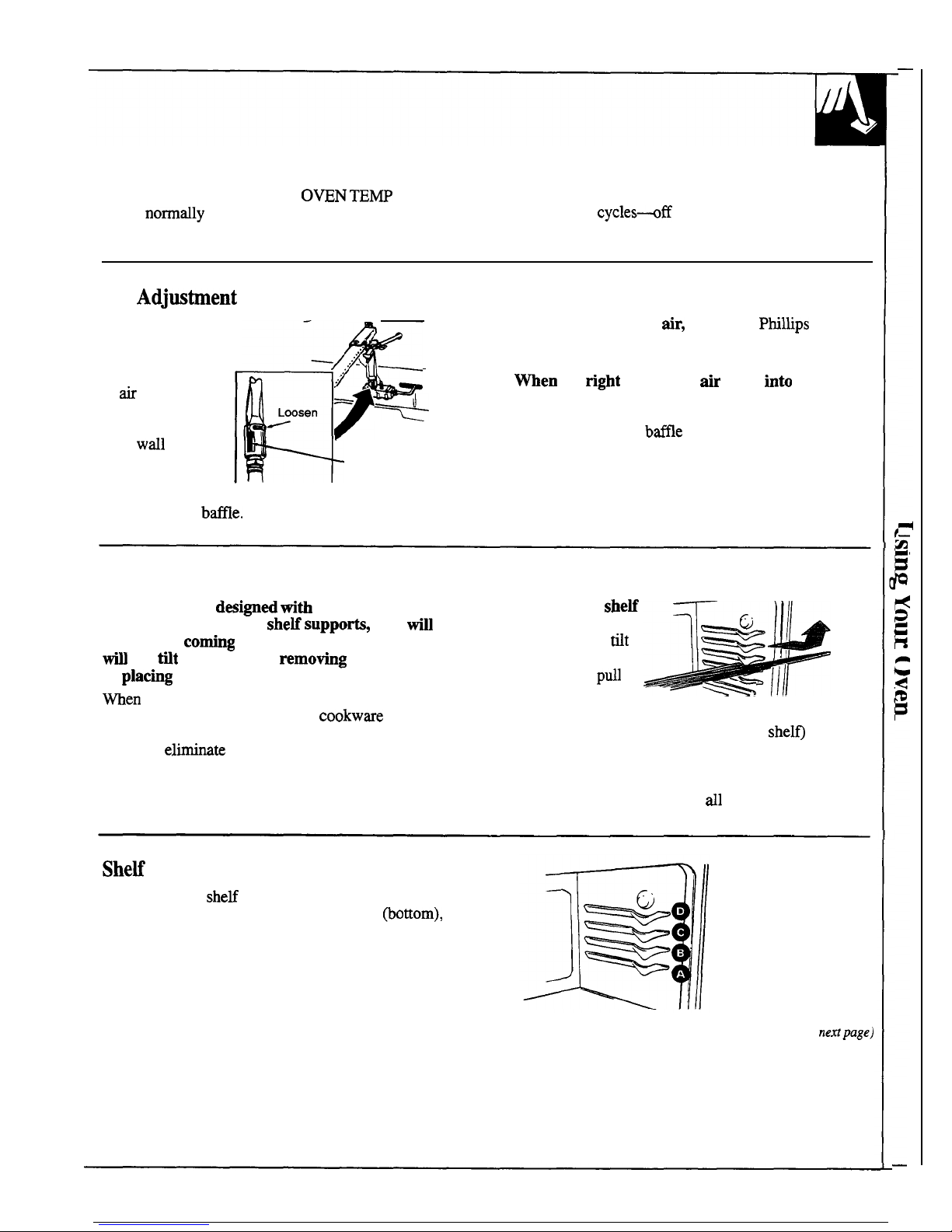

Air

Adjw@ent

An air adjustment

shutter for the

oven burner

regulates the flow

of

air

to the flame.

You’ll find the

shutter against the

back

wdl

behind

the broiler drawer.

To reach it remove

&

/

.,’

—

,.’.-

,..

ti

. .

.

Loosen

/

‘+

Air

adjustment

shutter

the oven bottom (see the Care and Cleaning section)

and the burner

btie.

To

adjust the flow of tir,

loosen the

Philhps

head

screw and rotate the shutter to allow more or less air

into the burner tube as needed.

men

the tight amount of Ar flows

kto

the

burner, the flame

should be steady, with

approximately 1/2 inch blue cones, and should not

extend out over the

btie

edges.

Oven Shelves

The shelves are

des~ed tith

stop-lock so when

placed correctly on the

sheM suppo~,

they

till

stop before

co~ng

completely out of the oven and

fi

not

tit

when you are

remotig

food from them

or

plachg

food on them.

men

placing cookware on a shelf, pull the shelf out

to the “stop” position. Place the

cookwme on the

shelf, then slide the shelf back into the oven.

This will

elimimte reaching into the hot oven.

To remove a sheti

from the oven, pull

it toward you,

tit

the front end

upward and

pull

the shelf out.

*

6

-1

1-

Iill

To

replace,

place the shelf on the shelf support with

the top-locks (curved extension of the

shel~ facing up

and toward the rear of the oven. Tilt up the front and

push the shelf toward the back of the oven until it

goes past “stop” on the oven wall. Then lower the

front of the shelf and push it

dl

the way back.

SheM

Positions

The oven has 4 she~ supports for normal baking and

roasting identified in this illustration as A

~ottom),

B, C, D (top).

Shelf positions for cooking are suggested on the

Baking, Broiling and Roasting pages.

(continued

ne~page)

11

Page 12

USmG

YOUR

O~N

(continued)

Oven Vents

The

oven is vented

tiough

duct openings at the rear

●

Handles of pots

and

pans on the cooktop may

of the cooktop. See

the

Features section. Do not block

become hot if left too close to the vent.

the

opening when cooking in the oven—it is

●

Meti

items

til

become very hot if they are left

important that the flow of hot air from the oven and

fresh

air

to the oven burner be uninterrupted.

on the cooktop and

codd ause

burns.

●

Do not leave any items on the cooktop. The

hot air

●

The vent openings and

n-rby

surfaces may

become hot during baking and

brofing.

from the vent may ignite flammable items and will

Do not touch them.

increase pressure in closed containers, which may

cause them to burst.

● Do not leave plastic items on the

cooktop

they may meit if left too close to the vent.

Do Zt

Yourse~—Adjmt

the Oven

Themosbt

ffyou

don’t think the oven is heating at the right

temperature when you are baking or roasting, you

m

reset the thermostat

yourseM.

When cooking food for the f~st time in your new

oven, use time given on recipes as a guide. Oven

thermostats, over a period of years, may “drift” from

the factory setting

and

the differences in timing

between an old and a new oven of 5 to 10 minutes are

not unusual. Your oven has been set

correctiy

at the

factory and is more likely to be accurate than the oven

which it replaced.

We do not recommend the use of inexpensive

thermometers,

such as those found in the grocery

store, to check the temperature setting of your new

oven. These thermometers can vary by

2M0

degrees.

To

decide how much to change

the

temperature,

set the oven temperature

25°F.

higher or lower than

the temperature in your recipe, then bake. The results

of this “test” should give you an idea of how much the

temperature should be changed.

@

Note

~sition

of Winter

before adjustment.

~fl-~ %4

@

●

ao

L

P&@’

,

to

marks

~\

Loosen only the locking screws.

Note to which

mmk

the pointer is pointing.

To make an adjustment

carefully loosen

(approximately one turn), but do not completely

remove the two screws that hold the

skin to the knob.

Hold the knob blade in one hand and the outer

skirt

in

the other hand.

To raise the oven temperature,

move the pointer in

the direction of the arrow for

MSE.

To

lower the

temperature,

move the pointer in the direction of

arrow for LOWER. Each mark

WW

change the oven

temperature approximately

25°F.

We suggest that you

make

tie

adjustment one mark

from the original setting and check oven performance

before making any

additiond adjustments.

After the adjustment is made,

press skirt and knob

together and

retighten

screws so they are snug, but be

careful not to

overtighten. Re-instil

knob on range

and check performance.

NO~: -ran

adjustment has been made, the OFF

and

BROL

positions

wi~

not

tie

up with the indicator

mark on the control panel as they previously did. This

condition is normal and

wi~

not create a problem.

Page 13

How to Set Your Range For Bating

To avoid possible

bum,

place the shelves in the

2. Check the food for doneness at the minimum time

correct position before you turn on the oven.

on the recipe. Cook longer if necessary. Turn the

1.

Close the oven door. Then turn the OVEN

OVEN

~MP

knob to OFF and remove the food.

~MP

knob to the desired temperature.

For best baking results, follow these suggestions:

Oven Shelves

Arrange

the

oven

shelf or shelves in

the desired locations

while the oven is

cool. The correct

shelf position

depends on the kind

of food and the

browning desired.

As a general rule,

]

Type of Food

]

SheEPositio”

Angel food cake

A

Biscuits or muffins

B or C

Cooties or cu~akes

B or C

Brownies B or C

Layer cakes

B or C

place-most foods in the

tiddle

of the oven, on either

the shelf position B or C. See the chart for suggested

Bundt

or pound cakes

A or B

shelf positions.

Pies or pie shells

B or C

Frozen pies

A (on cookie sheet)

I

Casseroles

I BorC

Preheating

Reheat

the oven if the recipe

cds

for it. Preheat

Preheating is necessary for good results when baking

means bringing the oven up to the specified

cakes, cookies, pastry and breads. For most casseroles

temperature before putting in the food. To preheat,

and

roasts, preheating is not necessary. For ovens

set the oven at the correct temperature-selecting a

without a preheat indicator light or tone, preheat

higher temperature does not shorten the preheat time.

10 minutes. After the oven is preheated place the food

in the oven as

quic~y

as possible to prevent heat

from escaping.

BaKng

Pans

Use the proper baking pan. The type of

ftish

on the

pan determines the amount of browning that

wfll

occur.

●

Dark, rough or dull pans absorb heat resulting in a

browner, crisper crust. Use this type for pies.

●

Shiny, bright

rmd

smooth pans reflect heat, resulting

in a lighter, more delicate browning. Cakes and

cookies require this type of pm.

“

Glass baking dishes

dso

absorb heat.

men

baking

in glass baking dishes, lower the temperature by

25°F.

and use the recommended cooking time in

the recipe. This is not necessary when baking pies

or casseroles.

Pan

Placement

For even cooking

and

proper browning, there must be

enough room for air circulation in the oven. Baking

results will be better if baking pans

are

centered as

much

as

possible ramer than being placed to the front

or to the back of

the

oven.

Pans

shotid

not touch each other or

tie

walls of the

oven. Allow

1

to 1X inch space between pans as well

as from the back of the oven, the door and the sides. If

you use 2 shelves, stagger the pans so 1 is not

direcdy

above the other.

(continued

mxtpage)

13

-

..- .—

——

Page 14

BA~G

(continued)

Bahg Guides

men

using prepared baking mixes, follow package recipe or instructions

for the best baking results.

Cooties

men bting

cookies, flat cookie sheets (without

sides) produce better-looking cookies. Cookies

b~ed

in a jelly roll pan (short sides

rdl

around) may have

darker edges and

pde

or light browning may occur.

Do not use a cookie sheet so large that it touches the

walls or the door of the oven. Never entirely cover a

shelf with a large cookie sheet.

For best results, use

ody

1 cookie sheet in the oven

at a time.

Cakes

For best results, bake pies in dark, rough or dull pans

men

baking cakes, warped or bent pans will cause

to produce a browner, crisper crust. Frozen pies in foil

uneven baking results and poorly shaped products.

pans should be placed on an aluminum cookie sheet

A cake baked in a pan larger than the recipe

for baking since the shiny foil pan reflects heat away recommends will usually be crisper, thinner and drier

from the pie crust; the cookie sheet helps

retin

it. than it should be. H baked in a pan smaller than

recommended, it maybe undercooked and batter may

oveflow.

Check the recipe to make sure the pan size

used is the one recommended.

Altinu

Fofl

Never entirely cover a shelf with durninum foil.

This will disturb the heat circulation and result in poor

baking. A smaller sheet of foil maybe used to catch a

spillover

by placing it on a lower shelf several inches

below the food.

Don’t Peek

Set the timer for the estimated cooking time and do

DO NOT open the door to check until the

not open the door to look at your food. Most recipes

minimum time. Opening the oven door frequently

provide minimum and maximum baking times such

during

coo~ng

allows heat to escape and makes

as “bake 30-40 minutes.”

baking times longer. Your baking results may

dso

be affected.

14

——._..—.

Page 15

Roasting is cooking by dry heat. Tender meat or poultry can be roasted

uncovered in your oven. Roasting temperatures, which should be low and

steady, keep spattering to a minimum.

Roasting is

redy

a baking procedure used for meats. Roasting is easy;

just follow these directions:

1.

Place the shelf in the A or B position.

No preheating is necessary.

2. Check the weight

of the meat. Place

it, fat side up, (or

for poultry,

breast-

side-up) on the

roasting rack in a

shallow

pan.

The

melting

Fat

will baste the meat. Select a pan m

close to the size of the meat as possible. (The

broiler pan with rack is a good

pan

for this.) Line

the broiler pan with

rduminum

foil when using the

pan for marinating, cooking

witi

fruits, cooking

heavily cured meats, or basting food during

cooking. Avoid spilling these materials inside the

oven or inside the oven door.

3. Turn the OVEN

TEMP

knob to the desired setting.

4. After roasting is complete, turn the OVEN

TE~

knob to OFF and then remove the food from

the oven.

Most meats continue to cook

stightiy

while standing,

after being removed

horn the oven. Standing time

recommended for roasts is 10 to 20 minutes. This

allows roasts to

fm

up and makes them easier to

carve.

ktemd

temperature will rise about 5° to

10°F.

To compensate for temperature increase, if desired,

remove the roast from the oven sooner (at 5° to

10°F.

less than the temperature in the Roasting Guide).

NOTE: Remember that the food

wfl

continue

to cook in a hot oven and therefore should be

removed when the desired

intemd

temperature has

been reached.

Frozen

Romk

Frozen roasts of beef, pork, lamb, etc. can be started

Thaw most frozen poultry before roasting to ensure

without thawing, but allow 10 to 25 minutes per

even doneness. Some commercial frozen poultry can

pound

additiond time (10 minutes per pound for

be cooked successfully without

tiawing. Follow the

roasts under 5 pounds, more time for larger roasts).

directions given on the package label.

(continued

nat

page)

15

Page 16

ROASTmG

(continued)

Questions and Answers

Q.

Is it necessary to check for donenws with a

Q.

h

I need to preheat my oven

wch

time I cook

meat thermometer?

a roast or

potitry?

A.

Checking the finished

intemd

temperature at the

A.

It is

unnecessary to preheat your oven.

completion of cooking time is recommended.

Temperatures are shown in Roasting Guide. For

Q.

men

buying a roast, are there any special tips

that

wodd

help me cook it more

everdy?

roasts over 8 lbs., check with thermometer at

hdf-

hour interv~s after

hdf

the time has passed.

A. Yes. Buy a roast as even in thickness as possible,

Q.

my

is

my roast crmnbting when I try to

or buy

ro~ed

roasts.

carve it?

Q. Can I seal the sides of my foil

‘tent”

when

A.

Roasts are easier to slice if allowed to cool 10 to

roasting a turkey?

20

minutes after removing them from the oven.

A.

Sealing the foil will steam the meat. Leaving

Be sure to cut across the grain of the meat.

it unsealed

Wows

the air to circulate and brown

the meat.

Meat

Tender

cuts; rib, high quality sirloin

tip, rump or top round*

Lamb leg or bone-in shoulder*

Verd

shoulder, leg or loin*

Pork loin, rib or shedder*

Ham,

vrecooked

Podtry

Chicken or Duck

Chicken pieces

Turkey

ROAS~G

G~E

Oven

temperature

325°

325°

325°

325°

325°

325°

350°

325°

Doneness

Rare:

Medium:

WeH

Done:

Rare:

Medium:

Well Done:

Well Done:

WeU

Done:

To Warm:

Well Done:

Well Done:

Well Done:

Approtiate

Roasting Time

h

Minutes

Per

Pound

3

to 5 lbs.

2635

35-39

3945

21-25

25-30

3G35

35–45

3545

6

to 8 lbs.

18-25

25-31

31-33

2&23

2&28

28-33

3&40

3G40

18–23 minutes per pound

(any

weigh(

3 to 5

Ibs.

Over 5 lbs.

3540

3&35

35-40

10 to 15 lbs.

Over 15 lbs

1622

12-19

*For boneless rolled roasts over 6 inches thick, add 5 to 10 minutes per pound to times given above.

hternd

Temperature

‘F.

140°–1500t

150°–1600

170°–1850

140°-15007

150°–1600

170°–1850

170°–1800

170°–1800

115°–1250

185°–1900

185°-1900

h

Wgh:

185°–1900

tThe

U.S. Department of Agriculture says “Rare beef is popular, but you should know that cooking it to only

140°F.

means

some food poisoning organisms may survive.” (Source: Safe Food Book. Your

Ktchen

Guide. USDA Rev. June 1985.)

16

Page 17

How to

Broti

Broiling is cooking food by direct heat horn above the

Your range has a compartment below the oven for

food. Most fish and tender cuts of meat can be

broiling. A specially designed broiler pan and rack

broiled. Follow these steps to keep spattering and

allow dripping fat to drain away from the food and

smoking to a minimum.

keeps it away from the high heat of the gas flame.

Both the oven and broiler compartment doors

shodd

be closed during

broiting.

1.

You can change the distance of the food from the

heat source by positioning the broiler pan and rack

on one of three shelf positions in the broiler

compartment-A (bottom of broiler compartment),

B

(midde)

and C (top).

2. Reheating the broiler or oven is not necessary and

can produce poor results.

3.

H

the meat has fat or

gristie

near the edge, cut

vertical slashes through it about 2 inches apart, but

don’t cut into the meat.

We recommend that you

tim

the fat to prevent excessive smoking, leaving a

layer about 1/8 inch thick.

4. Arrange the food on rack and position the broiler

pan on the appropriate shelf in the oven or broiling

compartment. Placing the food closer to the flame

increases the exterior browning of food, but

dso

increases spattering md the possibility

of the

fats

and the meat juices igniting.

5. Close the oven and broiler compartment door.

6. Turn the OVEN

TEMP knob to

BRO~.

7. Turn most foods once during cooking (the

exception is thin

fdlets

of fish; oil one side, place

that side down on broiler rack and cook without

turning until done). Time foods for about one-half

the

toti

cooking time, turn food, then continue to

cook to

prefemed

doneness.

8. Turn the OVEN

TEMP knob to OFF. Remove the

broiler pan from the broiler compartment and seine

the food immediately.

bave

the pan outside the

range to cool.

Use of

Altim

Foti

You can use

rduminum fofi

to be your

brofier

pan and

brofler

rack. However, you must mold the foil

tighdy

to the rack and cut slits in it just like the rack.

Without the slits, the

foti

will prevent fat and meat

juices from draining to the broiler pan. The juices

could become hot enough to catch on

fie.

If you do

not cut the slits, you are frying, not broiling.

Questiom

&

Amwers

Q. When

brotiing,

is it necessary to always use a

rack in the pan?

A. Yes.

Using the rack suspends the meat over

the

pm. As the meat cooks, the juices

fdl

into the pan,

thus keeping meat drier. Juices are protected by the

rack and stay cooler, thus preventing excessive

spatter and smoking.

Q. Shodd I At the

m=t

before brofing?

A. No.

Sdt

draws out the juices and

rdlows

them to

evaporate. Always

sdt

after cooking. Turn meat

with tongs; piercing meat with a fork

dso rdlows

juices to escape. When

brofling

poultry or fish,

brush each side

ofien

with butter.

Q. Why are my

mats

not turning out as

brown

as they

shodd?

A. Check to see if you are using the recommended

shelf position. Broil for longest period of time

indicated in the

Broitig

Guide. Turn the food only

once during broiling.

(continued next page)

17

—... .-. -.—

————

Page 18

BRO~~G

G~E

The oven and

brofler

compartment doors must be

3. If desired, marinate meats or chicken before

closed duting

brotikg.

broiling.

Or,

brush with barbecue sauce the last

1. Always use the broiler pan and rack that comes with

5 to 10 minutes.

your range. It is designed to minimize smoking

and

4.

men

arranging food on pan, do not let fatty edges,

spattering by trapping the juices in

the

shielded which could soil oven with fat dripping, hang over

lower part of the pan.

the sides.

2. For steaks and chops, slash fat evenly around

5. Broiler compartment does not need to

be

preheated.

outside edges of meat. To slash, cut crosswise However, for very thin foods, or to

kcrease

through outer fat surface just to the edge of the browning, preheat if desired.

meat. Use tongs to turn meat over to prevent

6. Frozen steaks can be broiled by positioning the shelf

piercing meat and losing juices.

at next lowest

she~ position and increasing cooking

time given in this guide

1Y2

times per side.

Quanti@ mdor

ThichMs

1/2

lb. (about 8

thin

shces)

I I

SheM

1st

Side

2nd Side

Position

Minutes

Mnutes

Comments

Food

B

3%

3

Arrange

in single layer.

A

lG1l

45

Spa@

evenly. Up to 8 patties take

about same time.

Ground Beef

1 lb. (4 patties)

1/2 to

314

inch thick

Beef

St*

Rare

Medium

Well Done

B

B

A

9

12

13

7

54

%9

Steaks less than 1 inch

tick

cook

through before browning. Pan frying

is recommended.

1 inch thick

(1 to 1% lbs.)

Slash fat.

Rare

Medium

Well Done

1 inch thick

(2 to 2% lbs.)

c

B

A

10

12–15

25

67

IG12

1618

1 whole

(2 to 2% lbs.),

split lengthwise

Chi&en

25–30

Reduce times about 5 to 10 minutes

per side for cut-up chicken. Brush

each side with melted butter. Broil

skin-sidedown

first.

Btieq

Produ&

Bread (Toast) or

Toaster Pastries

c

2-3

Space evenly. Place

Enghsh mufins

cut-side-up and brush with butter

if desired.

2 to 4 shces

1 pkg. (2)

1/2-1

c

I 3-5

English

MuffIns

2,

split

Cut through back of

she~

and spread

open. Brush with melted butter

before

broihng

and after hdf of time.

Do not

turn over.

Lobster

Tds

2 to 4

(6 to 8 oz. each)

+

A

13-16

B, C

5

Fish

l-lb. fillets

1/4 to 1/2 inch thick

Handle and turn very

carefsdly.

Brush

with lemon butter before broiling and

during

broihng

if desired. Preheat

broiler to increase browning.

5

Hm Sliw

Prxooked

1 inch thick B

8

8

Inmease

time 5 to 10 minutes per side

for 1% inch thick or home cured.

B

10

Slash fat.

B

13

9:;2

B

8

47

Slash fat.

B

10

10

B

10

B

17

12–14

B, C

6

1-2

If desti, spht

sausages in

hatf

lengthwise; cut into 5-to 6-inch

pi~es.

Pork Chops

Well Done

2 (1/2 inch thick)

2(1 inch

tick),

about 1 lb.

Lamb

Chops

Medium

Well Done

Medium

Well Done

2(1 inch thick),

about 10 to 12 oz.

2

(1X

inch thick),

about 1 lb.

Wieners

similar precooked

sausages, bratwurst

l-lb. pkg. (10)

18

Page 19

Proper care and

cleming

are important so your range will give you efficient

and satisfactory service. FO11

OW

these directions carefully in

ctig

for it to

help assure safe and proper maintenance.

BE SURE

ELEC~C PO~R

IS 0~ BEFORE

CLEMG

ANY PART

OF

T~

RANGE.

m

P

,4

A

Myour range is removed for

cl-g,

servicing or any mmon,

be sure anti-tip device is

re-engaged

properly when the range

is replaced.

Fdure

to

tie tti pre~ution codd resdt

in tipping of

M

A

the range and cause injury.

How to Remove the Range for Cleaning and Servicing

Follow these steps to remove the range for servicing

5. Reverse these steps to

re-instil

the range. If the

or cleaning hard to reach surfaces.

gas line has been disconnected, check for gas leaks

1. Shut off the gas supply to the range.

after reconnection. See the Initiation kstructions

2. Disconnect the electrical supply to the range.

for the gas lead test method.

3. Disconnect the gas supply tubing to the range.

NO~:

A trained technician should make the gas

installation, disconnection and

re-connection

of the

4. Slide the range forward to free the range foot from gas supply the appliance.

the Anti-Tip bracket. See the

kstilation

Instructions for the location of the bracket.

Lift-Up/Off Cooktop

Clean the area under the cooktop often. Built-up soil,

especially grease, may catch on

fwe.

To make cleaning easier, the cooktop may be Mted

up or off.

Be sure

M

burners are turned off before raising

the cooktop. Then remove the grates. Grasp the two

front burner wells and

hft the cooktop up or off. Be

careful of the pilots when the cooktop is up.

After cleaning underneath the cooktop with hot,

soapy water and a clean cloth, lower or replace the

cooktop. Be careful not to pinch your fingers.

To replace the cooktop if you have removed it,

insert

tie

two tabs at the back of the cooktop into slots

at the base of the

backguard.

Lower

the

cooktop into place, applying pressure

until

the tab on the underside snaps into the catch at the top

front center of the range.

19

Page 20

CA~ ~

CLEHG

(continued)

Burners

To remove burned-on food, soak the

surface burner

in a solution of mild liquid detergent and hot water.

Soak the surface burner for 20 to 30 minutes. For

more stubborn stains, use a cleanser like Soft

Scrub”

brand or Bon

tie

brand. Rinse well to remove any

traces of the cleanser that might clog the surface

burner openings. Do not use steel wool because it will

clog the surface burner openings and scratch the

surface burners. If the holes become clogged, clean

them with a small pin or sewing

neede.

Before putting the surface burner back, shake out

excess water and then dry it

thoroug~y

by setting it in

The holes in the surface burners of

vour ranze

must a warm oven for 30 minutes. Then

ulace

it back in the

be kept clean at dl times for proper”ignition”ad an range, making sure it is properly se;ted and level.

even, unhampered flame.

NO~:

a screw holds each of the burners in place to

You

shotid dean

the surface burners routinely,

keep them from

wobbting

around during shipment.

especitiy

after bad

spi~overs,

which could clog

Remove and discard the shipping screw. Tilt the

these holes. Wipe off the surface burners. H heavy

burner to one side at the end closest toward the back

spillover

occurs, remove the

stiace

burners from of the range. This disengages it from the gas

vrdves

at

range. The burners

fift

out for cleaning. Lift up the

the front of the range, it

hfts

out easily

cooktop

and then lift out the surface burners.

20

Page 21

Burner

Gratw

Lift them out when cool. Grates should be

washed regularly and, of course, after

sptiovers.

Wash them in hot, soapy water and rinse with clean

water. After cleaning, dry thoroughly by putting them

in a warm oven for a few minutes. Don’t put the

grates back on the range while they are wet. When

replacing the grates, be sure they’re positioned

securely over the burners.

To prevent rusting on =t iron grates, apply a light

coating of cooking oil on the bottom of the

gates.

To get

rid

of burned-on food, place the grates in a

covered container (or plastic bag) with 1/4 cup

ammonia to loosen the soil. Then scrub with a

soap-filled scouting pad if necessary.

Although they’re durable, the grates will gradudly

lose

theti

shine,

regardess

of the best care you can

give them. This is due to their continual exposure to

high temperatures.

Do not operate a burner for an extended period of

time

M&out

cookwm

on

tie

grate. The finish on

tie

grate may chip without cookware to absorb the heat.

When replacing a pair of grates, the irregular sides

should meet in the middle.

Control Panel and

mobs

It’s a good idea to wipe the control panel after each

The control knobs may

use of the oven. Clean with mild soap and water or

be removed for easier

vinegar and water, rinse with clean water and polish

cleaning. To remove the

dry with a soft cloth.

knob, pull it straight off

Do not use abrasive cleansers, strong

fiquid

cleaners,

the stem. If knob is

plastic scouring pads or oven cleaners on the control

difficult to remove,

ulace

panel-they will damage the finish. A 50/50 solution

a towel or dishcloth-between the knob and control

of vinegar and hot water works well.

panel and

pull gently. Wash the knobs in soap and

water or a vinegar and hot water solution but do

not soak.

Oven Shelves

The

shelves can be cleaned by hand using soap and

water or with an abrasive cleaner. After cleaning,

rinse the shelves with clean water and dry.

To remove heavy, burned-on soil, you may use

scouring pads. After scrubbing, wash with soapy

(continued next page)

water rinse and dry.

21

Page 22

CAm ~

CLE-G

(continued)

Removable Oven

Botiom

The

oven bottom can be removed to make cleaning

easier. Make sure the oven is completely cool.

To remove:

1.

Loosen (but do not remove) the 2 screws at the

front of

the

oven bottom.

2. Slide the screws back to release the front of the

oven bottom.

3. Lift

tie

oven bottom up ad pull forward until the

rear tabs release from

the

back

wd.

4. Take

the

oven bottom out of the oven.

To replace the oven bottom:

1.

hsert the tabs into the slots in the rear of the

oven wall.

NOTE:

If the

oven

bottom is replaced incorrectly,

2. Slide the 2

screws

at the front of the oven bottom

it may warp and cause undesirable baking results.

forward and tighten them to secure the oven bottom

in place.

The oven bottom has a porcelain enamel

ftih.

To make cleaning easier, protect the oven bottom

from excessive

spi~overs.

This is particularly

important when baking a fruit pie or other foods with

high acid content. Hot fruit

fi~ings

or foods that are

acid in content such as

mik,

tomato or sauerkraut,

and

sauces

with vinegar or lemon juice, may cause

pitting and damage to the porcelain enamel surface.

To protect the oven bottom surface, place a piece of

durninum

foil

stightiy

larger than

the

baking dish on

the shelf below to catch

any boilovers.

It should not

completely cover

the

shelf as this wotid cause uneven

heat in the oven. Aluminum foil should not be placed

on the oven bottom.

Ma

spflover d~

occur on the oven bottom,

allow the oven to cool

fust.

You can clean the bottom

with soap and water, a mild abrasive cleanser,

soap-

filled abrasive pads or an oven cleaner following

package directions.

Broiler Drawer

To remove:

1.

men

the broiler is cool, remove the rack and pan.

2. Pull the broiler drawer half-way out.

WU

the

metrd

clip located in the center of the drawer bottom

upward as far as it will go (abut 2 inches). Pull

the

drawer dl the way out of

the

compartment.

3. Clean the broiler drawer with hot soapy water.

To replace:

1. Slide

the

broiler drawer onto the guide rails at the

sides of the broiler compartment. Push the drawer

until completely closed.

Page 23

Brofler

Pan and Rack

After brofing, remove the broiler pan and rack from Wash; scour if

necess~.

Rinse and dry. The broiler

the oven.

~ait

until the oven is cool.) Remove the

pan and rack may

dso

be cleaned in a dishwasher.

rack from

the

pan.

Cmefully

pour out the grease in the

Do not store a sofied broiler pan and rack anywhere in

pan into a proper container. the range.

If food has burned on,

sptie

the rack with

detergent while hot and cover with wet paper towels

or a dishcloth. Burned-on foods will soak loose while

the

med

is being served.

Oven Door

TO CLEAN T~ DOOR:

Inside of door:

●

Soap and water ti normally do the job.

Heavy spattering or

spfiovers

may require cleaning

with a mild abrasive cleaner. Soapy, wet

meti

pads

may

dso

be used.

Do

not

rdlow

food spills with a

high sugar or acid content (such as

mik,

tomatoes,

sauerkraut, fruit juices or pie

fi~ing)

to remain on

the surface. They may cause a dull spot even

after cleaning.

● H

nec-sary,

you may use an oven cleaner.

Follow package directions.

●

Clean the inside of the oven window with a mild

non-scratching cleaner and a damp cloth.

Outside of door:

●

Use soap and water to thoroug~y clean the top,

sides and front of the oven. DO NOT let water run

down through openings in the top of the door.

Rinse

we~.

You may

dso

use a glass cleaner to

clean the glass on the outside of the door.

●

Spillage of marinades, fruit juices, tomato sauces

and basting

materirds

containing acids may cause

discoloration and should be wiped up immediately.

When surface is cool, clean and rinse.

“

Do not

use

oven cleaners, cleansing powders or

harsh

abrasiva

on the outiide of the door.

(continmd nextpage)

23

Page 24

CA~

&

CLEA~G

(continued)

Porceltin

Oven

htefior

With proper care, the

porcelain enamel

ftish

on

the inside of the oven will

stay new-looting for years.

Let the range cool before

cleaning. We recommend

that you wear rubber gloves

when cleaning the range.

Soap and water

W

normdy

do the job. Heavy

spattering or

spillovers

may require cleaning with a mild abrasive cleaner.

Soapy, wet

meti

pads may

dso

be used. Do not

mow

food spills with a high sugar or acid content (such as

mik,

tomatoes,

sauerbaut,

fruit juices or pie

filfing)

to

remti

on the surface. They may cause a dull spot

even after cleaning.

Household ammonia may

mke

the

cldng

job

easier. Place 1/2 cup in a shallow glass or pottery

container in a cold oven overnight. The ammonia

fumes will help loosen the burned-on grease and food.

H

necessary, you may use an oven cleaner.

Follow

pacbge

directions.

Cautions about using spray-on oven cleaners:

●

Do not spray on the electrical controls and switches

because it could cause a short circuit and result in

sparting

or

fwe.

●

Do not allow a

fdm

from the cleaner to build up

on the temperature sensor—it could cause the oven

to heat

imDroDerlv. (The

sensor is located at the

toD

‘,

.

.

of the oven.) Carefully wipe the sensor clean

after’

each oven cleaning, being careful not to move the

sensor as a change in its position could affect how

the oven

b~es.

● Do not spray any oven cleaner on the oven door,

handes

or any exterior surface of the oven,

wood or painted surfaces. The cleaner can damage

these surfaces.

Meti Pafi

Do not use steel wool, abrasives, ammonia or commercial oven

cleaners. To safely clean surfaces; wash, rinse and then dry with a

soft cloth.

24

Page 25

BEFORE YOU

BEGIN

Read these instructions complete~ and

tiefu~.

IMPORT~:

Save these instructions

for the

lod electrid

inspectors use.

INST~E

kve

these instructions

tith

the

appfiance

after

ins-tion

is

completed.

CONSUMER:

~ep

this Use and

tie

Guide and the

ks~tion

kstructions

for future use.

This

apptice

must be proper~

sounded.

FOR YOUR SAFETY

~you smefl

@s:

1. Open

tidom.

2. Don’t touch

electrid @tches.

3.

ash

any open

~e.

4.

tie~te~

d your es

suppfier.

Do not store or use combustible

materials,

@soke

or other

~ble

vapors and fiquids in the vicinity of this

or any other

apptiance.

WARNING

Improper initiation,

adjustmen~

alteration, service or maintenance can

ause

injury or

proper~ dam~e.

Refer to

this manual. For assistance or

additiond

information,

constit

a

qu~ed ins~er,

service

~ency, manficturer

(alder) or

tie

@s

supptier.

lM~~ANT

Remove M

pac~

material and

literature from oven before

connec@

@s

and

electrid supp~

to

-e.

DIMENSIONS AND

CL~CES

Protide

adequate clearances

be~een tie

range

and adjacent combustible surfaces.

r20”>

T

%7

24%”

39%”

A

~

:

L

36”

41 %’-

\

\

\

\

\

\

\

\

\

>

---

\

--

J---

-

●

With door dow-n;llowlng for backsplash overhang

n

~

,;

n[

55*

ran~

rmmum

wall on ●

ther

side

range

It

30”

t

Mlmmum

to

Mmlmum

18” ~mets

on

L

13”-

nw

36”

?I ht

I

either side

of range

000 e

36”

‘~

5

n[

I

O“ clearance below cookng top and at rear of range

*3”

mmlmum

to wall on either side of range above 36” height

25

Page 26

lMW~ANT WHY lHSTRU~IOHS

ks*tion

of

tis -e

must conform

titb

10A

codes, or h

the

absence of

lod

codes,

titb

the

National Fuel Gas Code, ANSI

=23.1, k=t dtion. h k~

htion

must conform

titb

the current

Nati

Gas

Ins@ation Code, CAN/CGA-B149.l or the

current Propane

hation Me, CAN/CGA-

B149.2,

and

witb Id

codes

where

applicable.

~is

range has been

design+ertied

by the

American Gas Association according to ANSI

221.1, latest edition and Canadian Gas Association

according to CAN/CGA-l.l

htest

edition. As with

any

apptiance using gas and generating hea~

there

are certain safety

pre~utions

you should

fo~ow.

You ~ find these precautions in the

hnportant Safety

hstructions

in the front of this

book. Read them

carefufly

● Be sure your range is properly

instied

by a

qutied instier

or service technician.

● This range must be

electridly

grounded

in

accordance with

Iod

codes, or in their absence,

with the National

Electrid

Code ANSI/NFPA

No. 70, latest edition and Canadian Gas

Association according to

CAN/CGA-l.l latest

edition. See

Electrid

Connection Mormation.

G

Before

instig

the range in an area covered

with

koleurn

or any other synthetic floor

covering, make sure the floor covering

can

withstand heat at least

WOE

above room

temperature without shrinking, warping or

discoloring.

c

A range should NOT be

ins~ed

directiy over

kitchen carpeting unless

an insubting pad of 1/4

inch thick piece of

pl~ood

is placed

be~een

the

range

and

carpet

. Make sure the

wdl

coverings around the range

can withstand the heat generated by the range.

. Make sure

M

controls remain in the OFF

position when the range is not in use.

TOOLS YOU WILL NEED

~R HWG

~G&

● Channel lock pfiers

For gas supply

connection—

. Pipe wrench

For conversion for Natural to

U

gas—

. l/2-inch

open+nd wrench

For burner flame

adjustment—

●

PhWps

head and

bladetype

screwdrivers

ADDITIOW mTERWS

YOU

MY

NEED

● Gas

tie

shut-off valve.

● Pipe joint sealant that resists

afion

of U gas.

● l/2-inch pipe nipple.

For

Ntible

Connection:

.

~exible meti

appfiance connector (same as

3/4inch

or l/2-inch

I.D,

as gas supply

he).

●

me

union adapter

tie (1/2~ich NPTx

3/4

inch or l/2-inch I.D.).

For

~~d

Connection:

c

Pipe fitdngs as required.

26

Page 27

❑

~KGUMD lHfiMWTIOH

1. Place backguard assembly into position on

the black

pedesti

at rear of range.

backguard