GE JGRP20BEJ1BB, JGRP20BEJ2BB, JGRP20SEN1SS, JGRP20SEN2SS, JGRP20WEJ1WW Installation Guide

...Page 1

Installation

24" Gas

Instructions

Built-In Oven

JGRP20

"_ Questions? Call 800.GE.CARES (800.432.2737) or Visit our Website at: www.GEAppliances.com I

BEFORE YOU BEGIN

Read these instructions and warnings

completely and carefully,

IN THE COMMONWEALTH

OF MASSACHUSETTS:

• This product must be installed by a licensed

plumber or gas fitter.

• When using ball-type gas shut-off valves,

they shall be the T-handle type.

• A flexible gas connector, when used, must

not exceed 3 feet.

• IMPORTANT - Savethese

instructions for local inspector's use.

• IMPORTANT - Observeall

governing codes and ordinances.

• IMPORTANT - Leak testing of the

appliance shall be conducted according to

the manufacturer's instructions.

• Note to Installer- Be sure to leave these

instructions with the Consumer.

• Note to Consumer- Keep these

instructions for future reference.

• Skill level - Installation of this appliance

requires basic mechanical skills.

• Completion time- 1 to 3 hours

• Proper installation is the responsibility

of the installer.

• Product failure due to improper installation

is not covered under the Warranty.

WARNING - Thisappliance must

be properly grounded.

FOR YOUR SAFETY:

-&WARNING -If theinformation

in this manual is not followed exactly, a fire,

explosion or gas leak may result, causing

property damage, personal injury or death.

DO NOT STORE OR USE GASOLINE OR

OTHER FLAMMABLE VAPORS AND LIQUIDS

IN THE VICINITY OF THIS OR ANY OTHER

APPLIANCE!

WHAT TO DO IF YOU

SMELL GAS:

Do not try to light any appliance.

Do not touch any electrical switch; do not

use any phone in your building.

Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call

the fire department.

Installation and service must be performed by

a qualified installer, service agency or the gas

supplier.

Be sure your oven is installed properly by

a qualified installer or service technician.

Be sure the oven is securely installed in a

cabinet that is firmly attached to the house

structure. Weight on the oven door could

cause the oven to tip, resulting in serious

personal injury or death. Never allow

anyone to climb, sit, lean, stand or hang

on the oven door.

229c4053P578

31-10584 12-03 JR

Page 2

Installation Instructions

PREPARE TO INSTALL THE OVEN

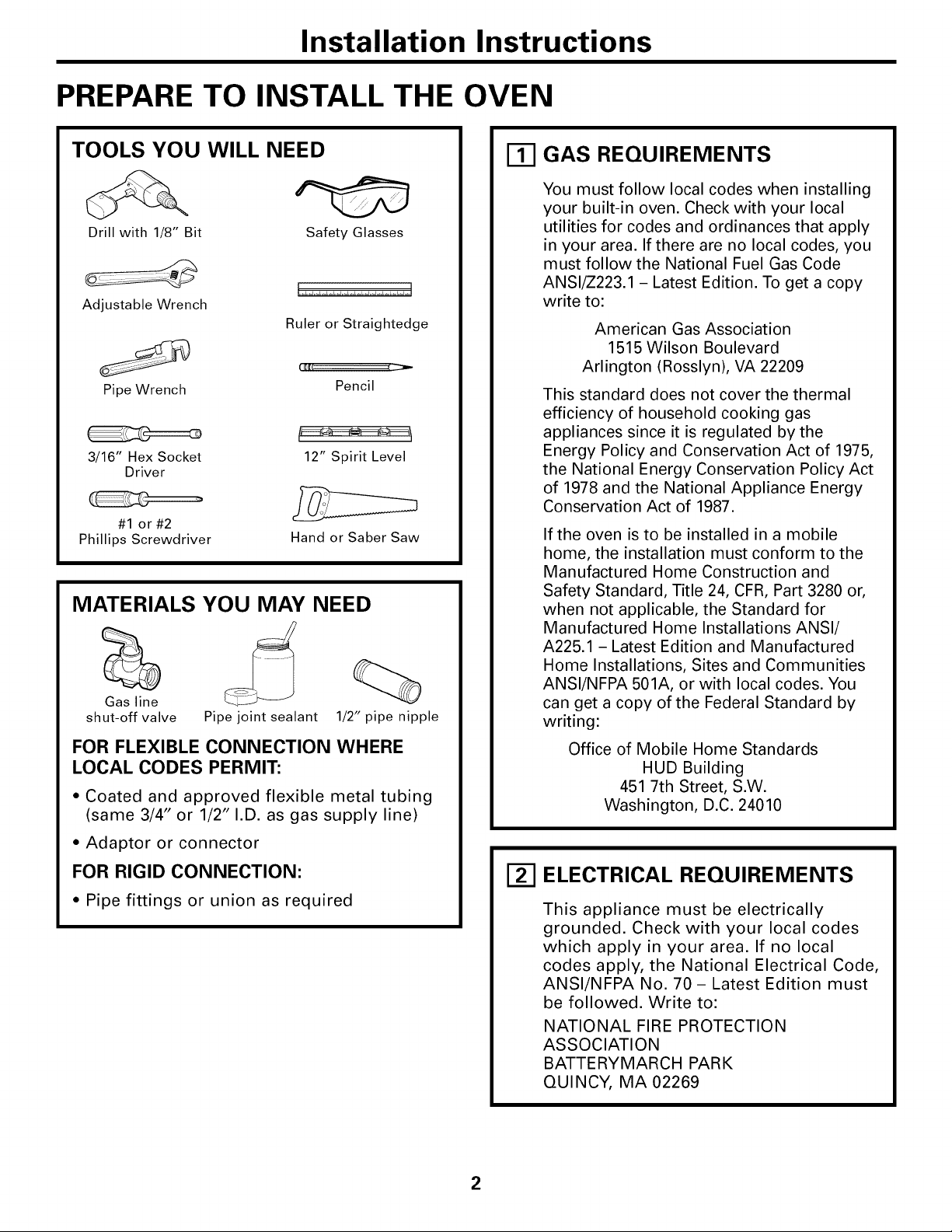

TOOLS YOU WILL NEED

Drill with 1/8" Bit Safety Glasses

Adjustable Wrench

Ruler or Straightedge

Pipe Wrench

3/16" Hex Socket

Driver

#1 or #2

Phillips Screwdriver

Pencil

12" Spirit Level

Hand or Saber Saw

MATERIALS YOU MAY NEED

Gas line

shut-off valve Pipe joint sealant 1/2" pipe nipple

FOR FLEXIBLE CONNECTION WHERE

LOCAL CODES PERMIT:

• Coated and approved flexible metal tubing

(same 3/4" or 1/2" I.D. as gas supply line)

GAS REQUIREMENTS

You must follow local codes when installing

your built-in oven. Check with your local

utilities for codes and ordinances that apply

in your area. If there are no local codes, you

must follow the National Fuel Gas Code

ANSI/Z223.1 - Latest Edition. To get a copy

write to:

American Gas Association

1515 Wilson Boulevard

Arlington (Rosslyn), VA 22209

This standard does not cover the thermal

efficiency of household cooking gas

appliances since it is regulated by the

Energy Policy and Conservation Act of 1975,

the National Energy Conservation Policy Act

of 1978 and the National Appliance Energy

Conservation Act of 1987.

If the oven is to be installed in a mobile

home, the installation must conform to the

Manufactured Home Construction and

Safety Standard, Title 24, CFR, Part 3280 or,

when not applicable, the Standard for

Manufactured Home Installations ANSI/

A225.1 - Latest Edition and Manufactured

Home Installations, Sites and Communities

ANSI/NFPA 501A, or with local codes. You

can get a copy of the Federal Standard by

writing:

Office of Mobile Home Standards

HUD Building

451 7th Street, S.W.

Washington, D.C. 24010

• Adaptor or connector

FOR RIGID CONNECTION:

• Pipe fittings or union as required

ELECTRICAL REQUIREMENTS

This appliance must be electrically

grounded. Check with your local codes

which apply in your area. If no local

codes apply, the National Electrical Code,

ANSI/NFPA No. 70- Latest Edition must

be followed. Write to:

NATIONAL FIRE PROTECTION

ASSOCIATION

BATTE RYMARCH PAR K

QUINCY, MA 02269

2

Page 3

Installation Instructions

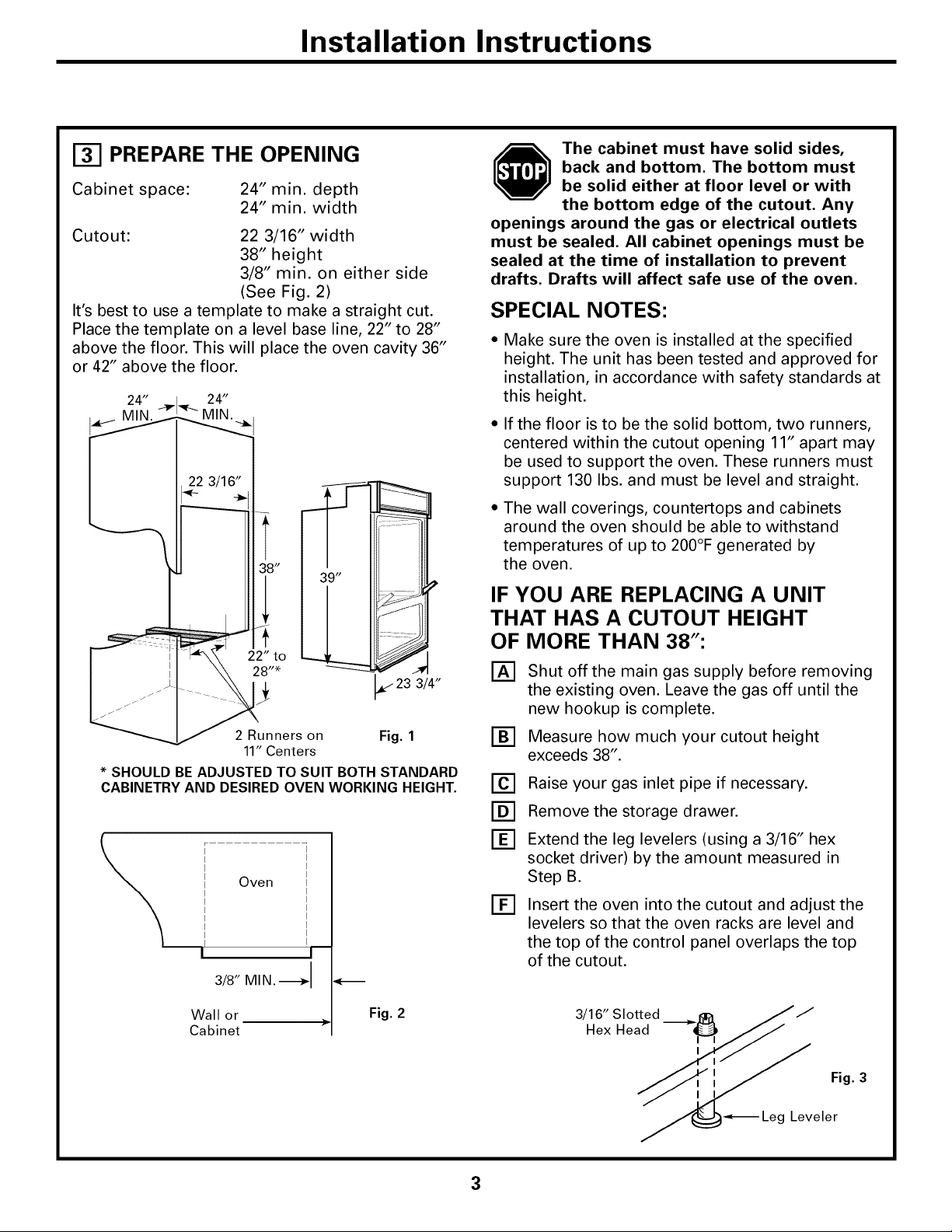

PREPARE THE OPENING

Cabinet space: 24" min. depth

24" min. width

Cutout: 22 3/16" width

38" height

3/8" min. on either side

(See Fig. 2)

It's best to use a template to make a straight cut.

Place the template on a level base line, 22" to 28"

above the floor. This will place the oven cavity 36"

or 42" above the floor.

24" 24"

39"

I 22" to

I

I 28"*

2 Runners on Fig. 1

11" Centers

* SHOULD BE ADJUSTED TO SUIT BOTH STANDARD

CABINETRY AND DESIRED OVEN WORKING HEIGHT.

2_

j_- 23 3/4"

The cabinet must have solid sides,

back and bottom. The bottom must

be solid either at floor level or with

the bottom edge of the cutout. Any

openings around the gas or electrical outlets

must be sealed. All cabinet openings must be

sealed at the time of installation to prevent

drafts. Drafts will affect safe use of the oven.

SPECIAL NOTES:

• Make sure the oven is installed at the specified

height. The unit has been tested and approved for

installation, in accordance with safety standards at

this height.

• If the floor is to be the solid bottom, two runners,

centered within the cutout opening 11" apart may

be used to support the oven. These runners must

support 130 Ibs. and must be level and straight.

• The wall coverings, countertops and cabinets

around the oven should be able to withstand

temperatures of up to 200°F generated by

the oven.

IF YOU ARE REPLACING A UNIT

THAT HAS A CUTOUT HEIGHT

OF MORE THAN 38":

Shut off the main gas supply before removing

the existing oven. Leave the gas off until the

new hookup is complete.

[] Measure how much your cutout height

exceeds 38".

r-cq

Raise your gas inlet pipe if necessary.

@

Remove the storage drawer.

I

i

I

I Oven

I

I

I

I

I

I

I

I I

3/8" MI N. -_

Wall or

Cabinet

[]

Extend the leg levelers (using a 3/16" hex

socket driver) by the amount measured in

Step B.

B3

Insert the oven into the cutout and adjust the

levelers so that the oven racks are level and

the top of the control panel overlaps the top

of the cutout.

3/16" Slotted

Hex Head

Fig. 3

Leg Leveler

3

Page 4

Installation Instructions

INSTALL THE OVEN

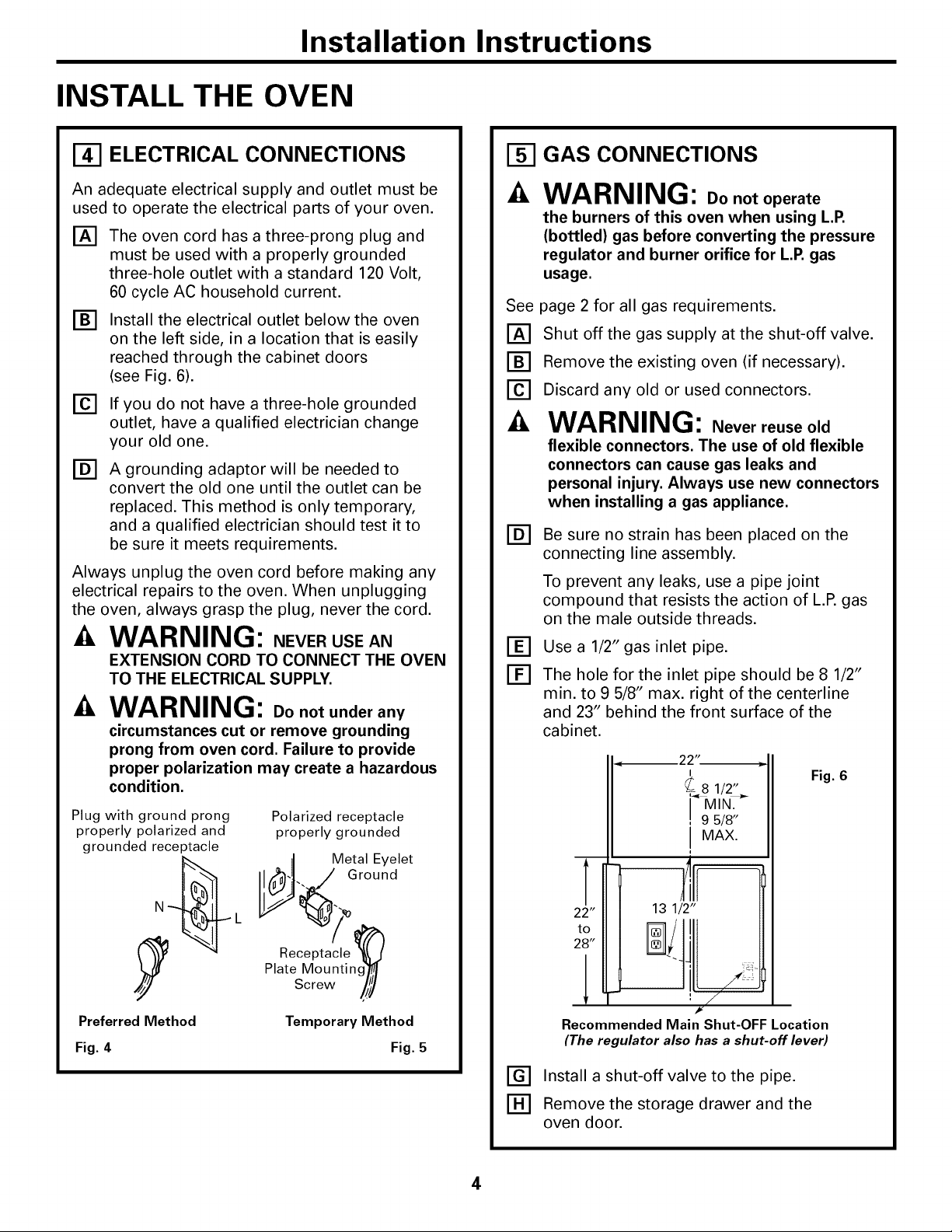

ELECTRICAL CONNECTIONS

An adequate electrical supply and outlet must be

used to operate the electrical parts of your oven.

r_ The oven cord has a three-prong plug and

must be used with a properly grounded

three-hole outlet with a standard 120 Volt,

60 cycle AC household current.

Install the electrical outlet below the oven

@

on the left side, in a location that is easily

reached through the cabinet doors

(see Fig. 6).

If you do not have a three-hole grounded

[]

outlet, have a qualified electrician change

your old one.

A grounding adaptor will be needed to

@

convert the old one until the outlet can be

replaced. This method is only temporary,

and a qualified electrician should test it to

be sure it meets requirements.

Always unplug the oven cord before making any

electrical repairs to the oven. When unplugging

the oven, always grasp the plug, never the cord.

WARNING: NEVERUSEAN

EXTENSION CORD TO CONNECT THE OVEN

TO THE ELECTRICAL SUPPLY.

WARNING: oonotunderany

circumstances cut or remove grounding

prong from oven cord, Failure to provide

proper polarization may create a hazardous

condition,

Plug with ground prong

properly polarized and

grounded receptacle

g

Polarized receptacle

properly grounded

Metal Eyelet

Ground

Rece

Plate Mountin(

Screw

I-_ GAS CONNECTIONS

WARNING: oonotoperate

the burners of this oven when using L.P.

(bottled) gas before converting the pressure

regulator and burner orifice for L.P. gas

usage.

See page 2 for all gas requirements.

_] Shut off the gas supply at the shut-off valve.

_'] Remove the existing oven (if necessary).

_'] Discard any old or used connectors.

WARNING: Never reuse old

flexible connectors. The use of old flexible

connectors can cause gas leaks and

personal injury. Always use new connectors

when installing a gas appliance.

[_] Be sure no strain has been placed on the

connecting line assembly.

To prevent any leaks, use a pipe joint

compound that resists the action of L.R gas

on the male outside threads.

Use a 1/2" gas inlet pipe.

The hole for the inlet pipe should be 8 1/2"

min. to 9 5/8" max. right of the centerline

and 23" behind the front surface of the

cabinet.

22"

I

8 1/2"

_MIN_

9 5/8;'

J MAX.

i

Fig. 6

[

22"

to

28"

1

Preferred Method

Fig. 4

Temporary Method

Fig. 5

Recommended Main Shut-OFF Location

(The regulator also has a shut-off lever)

[] Install a shut-off valve to the pipe.

[_ Remove the storage drawer and the

oven door.

4

Page 5

Installation Instructions

GAS CONNECTIONS (cont.)

Ill Place the oven in the cutout.

r_ Level the oven:

1. Place a spirit level on one of the oven

racks.

2. If the oven is not level, adjust the leg

levelers.

3. Remove regulator cover at the back of

the storage drawer area by removing

4 screws.

With the oven in place, the pressure

regulator inlet is accessible through the

opening in the main back.

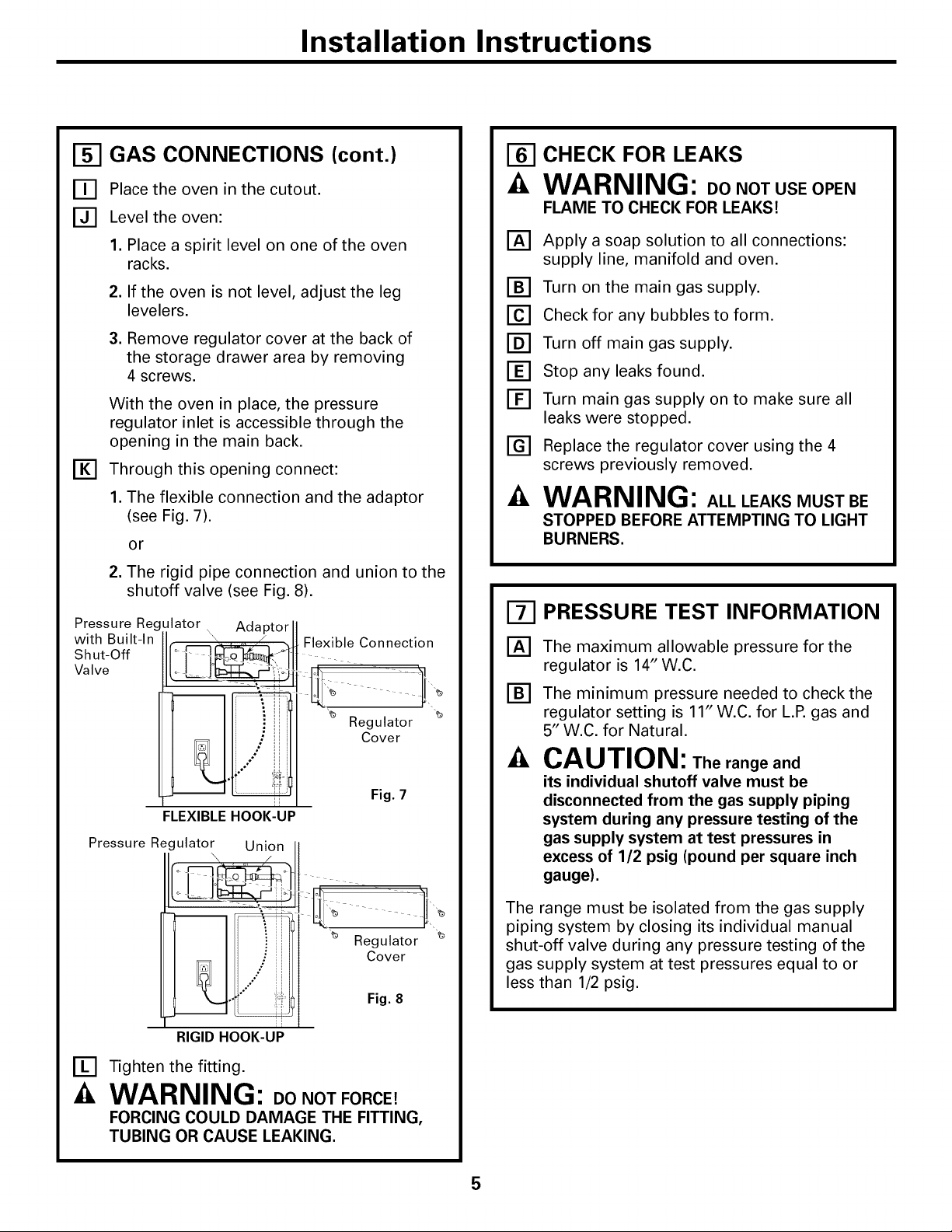

_] Through this opening connect:

1. The flexible connection and the adaptor

(see Fig. 7).

or

2. The rigid pipe connection and union to the

shutoff valve (see Fig. 8).

Pressure Regulator Adantor

with Built-In \ _"

Shut-Off r° __

Flexible Connection

CHECK FOR LEAKS

44,WARNING: DO NOT USE OPEN

FLAME TO CHECK FOR LEAKS!

r_ Apply a soap solution to all connections:

supply line, manifold and oven.

_'] Turn on the main gas supply.

_'] Check for any bubbles to form.

[_] Turn off main gas supply.

[_] Stop any leaks found.

[_] Turn main gas supply on to make sure all

leaks were stopped.

r-G-] Replace the regulator cover using the 4

screws previously removed.

WARNING: ALL LEAKS MUST BE

STOPPED BEFORE ATTEMPTING TO LIGHT

BURNERS.

PRESSURE TEST INFORMATION

The maximum allowable pressure for the

regulator is 14" W.C.

Va,ve

II

FLEXIBLEHOOK-UP

Pressure Regulator Union

"_ Regulator t_

RIGID HOOK-UP

_-_ -Iqghten the fitting.

WARNING: DO NOT FORCE!

FORCING COULD DAMAGE THE FITTING,

TUBING OR CAUSE LEAKING.

Regulator

Cover

Fig. 7

Cover

Fig. 8

The minimum pressure needed to check the

regulator setting is 11" W.C. for L.P. gas and

5" W.C. for Natural.

CAUTION: The range and

its individual shutoff valve must be

disconnected from the gas supply piping

system during any pressure testing of the

gas supply system at test pressures in

excess of 1/2 psig (pound per square inch

gauge).

The range must be isolated from the gas supply

piping system by closing its individual manual

shut-off valve during any pressure testing of the

gas supply system at test pressures equal to or

less than 1/2 psig.

5

Page 6

Installation Instructions

INSTALL THE OVEN (CONT.)

I-8-1CHECK THE BURNER FLAMES

FOR NATURAL GAS

The oven is factory-adjusted for use with Natural

Gas in most areas. But, since the gas in some

areas may vary, you should check all adjustments

described below. If you are to use L.P. Gas, see

L.P.Adjustments at the back of this guide.

NOTE: Bake and broil flame must be checked

with the door closed to properly check flame

characteristics. To properly check the bake burner,

the oven bottom and oven baffle must be removed.

Turn on the bake or broil burner.

As you watch the flame with the oven door

closed, check the following through the oven

door window:

1. Burner flames should not flutter or blow

away from the burner.

2. They should be blue in color with no trace

of yellow.

3. The inner cone of the flame should be

approximately 1/2" to 3/4" long.

BURNERS SHOULD BE CHECKED FREQUENTLY.

I-9-1MAKE THE BURNER FLAME

ADJUSTMENTS (CONT.)

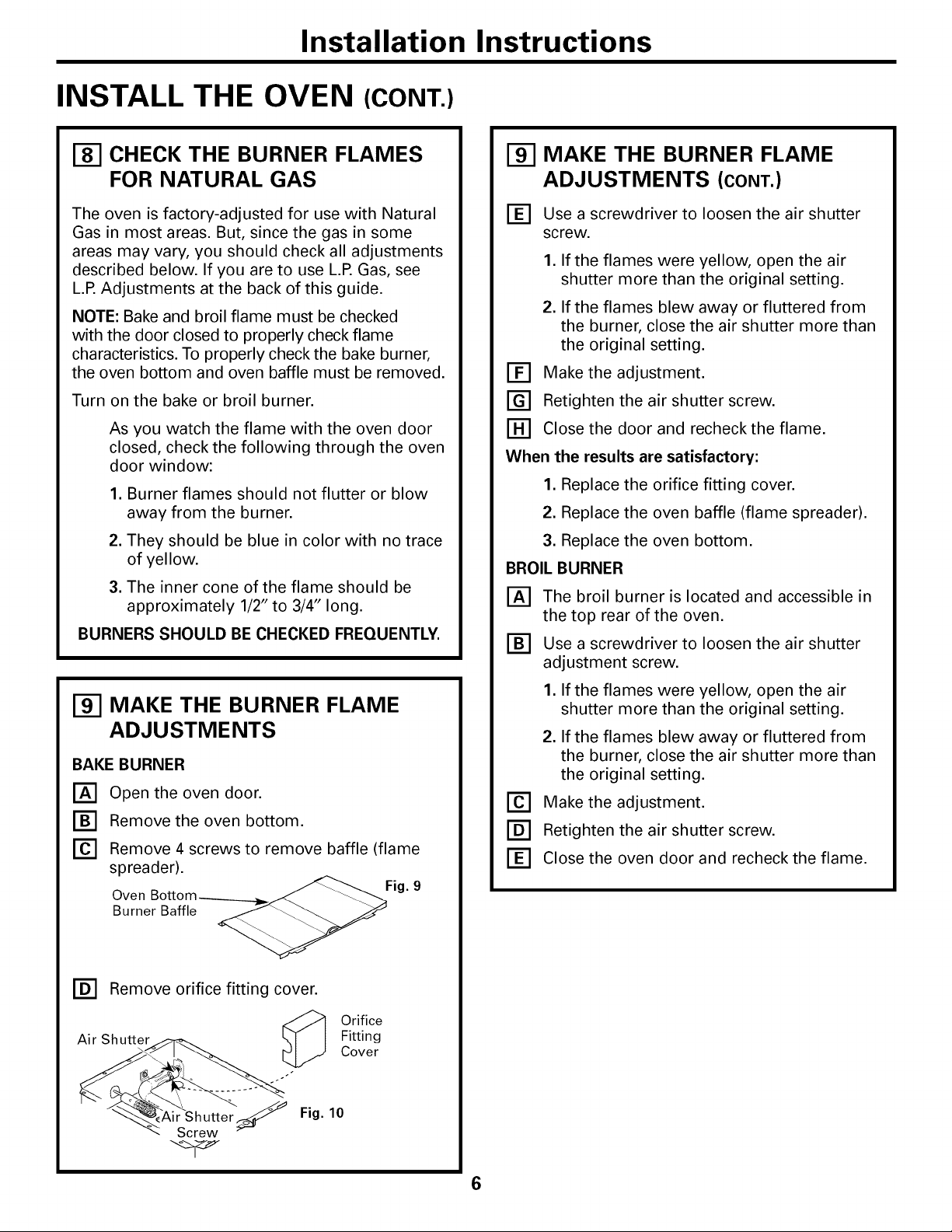

[] Use a screwdriver to loosen the air shutter

screw.

1. If the flames were yellow, open the air

shutter more than the original setting.

2. If the flames blew away or fluttered from

the burner, close the air shutter more than

the original setting.

Make the adjustment.

r-G-] Retighten the air shutter screw.

[] Close the door and recheck the flame.

When the results are satisfactory:

1. Replace the orifice fitting cover.

2. Replace the oven baffle (flame spreader).

3. Replace the oven bottom.

BROIL BURNER

I_] The broil burner is located and accessible in

the top rear of the oven.

Use a screwdriver to loosen the air shutter

adjustment screw.

I-9-1MAKE THE BURNER FLAME

ADJUSTMENTS

BAKE BURNER

[] Open the oven door.

F_ Remove the oven bottom.

[] Remove 4 screws to remove baffle (flame

spreader).

Oven Bottom _ _Fig. 9

Burner Baffle_

F_ Remove orifice fitting cover.

Orifice

Air Shutter

Fitting

Cover

1. If the flames were yellow, open the air

shutter more than the original setting.

2. If the flames blew away or fluttered from

the burner, close the air shutter more than

the original setting.

Make the adjustment.

FDI Retighten the air shutter screw.

Close the oven door and recheck the flame.

6

Page 7

Installation Instructions

SECURE THE OVEN

IMPORTANT: Remove

all packing material and literature

from the oven before connecting

any electrical supplies,

Using a 1/8" drill bit, drill holes through the

[]

side trim and into the cabinet front.

With the screws provided, secure the oven

@

to the wall.

If the cabinet cutout is 38" high, use the

[]

short trim and attach to the bottom of the

front frame, with screws provided.

(If the cutout is higher than 38", use the taller trim.)

[_ RECHECK STEPS

Double check to make sure everything in this

guide has been completed. Rechecking steps will

ensure safe use of the oven.

WARNING: The trim permits air

entry into the cabinet below the unit and

must not be blocked.

7

Page 8

Installation Instructions

MAKE THE L.P. GAS CONVERSION

WARNING: ,fyouare using L.P.

(bottled) gas, all the adjustments described

below must be made before you make any

burner adjustments or use the oven.

WARNING: This conversion must

be performed by a qualified installer or gas

supplier in accordance with the

manufacturer's instructions and all codes

and requirements of the authority having

jurisdiction. Failure to follow instructions

could result in serious injury or property

damage. The qualified agency performing

this work assumes responsibility for the

conversion.

NOTE: Disconnect all electrical power and turn

off the gas supply at the shut-off valve before

beginning the conversion.

Ill ADJUST PRESSURE

REGULATOR FROM NATURAL

GAS TO L.P.

Remove regulator cover at the back of the

storage drawer area by removing 4 screws.

Locate the regulator.

Ill ADJUST PRESSURE

REGULATOR FROM NATURAL

GAS TO L.P. (CONT.)

[-_ Remove the retainer from the cap.

[-_ Turn the retainer over so L.R is showing on

the bottom of the retainer.

[-_ Return the retainer inside the cap.

r-G-] Replace the cap on the regulator.

_] Replace the regulator cover using the

4 screws that held the cover originally.

_-I ADJUST BURNER ORIFICE

FROM NATURAL TO L.P. GAS

CAUTION: The adjustments in the

next column must be made before turning

on the burners. Failure to do so could result

in serious injury due to high flames and

toxic fumes.

Your Broil burner is located in the upper portion

of the oven and is easilly accessible.

To access your Bake burner follow the steps

below:

Pressure Regulator Adaptor tl

with Built-In , \ ..... i .ll Flexible Connection

Shut-OffIlk__ .....

Valve °- J° --LJll I _ -- "11

Fig. 11 [[!_------__ _1__ - -- 1,,t_

[] Unscrewthe cap.

Fig. 12

i %' -. ",,

II II _i 11 "_ Regulator "t_

FLEXIBLE HOOK-UP Cover

_ .Cap

Gasket

4r-,Z.

NAT. II I._-_ L.R

Spring

Retainer

V--I_

_]- - -_ #=-'--

:q- ,===',--_--F_r r-_ q_-- =:

'_ I I I I I I II II I I I =.._.B/,\

I I _ I _

,'-, ,==-, _-1--I I_--_-=_ I---L....

r_ Open the oven door.

[] Remove the oven bottom.

Remove 4 screws holding the oven baffle

(flame spreader).

Oven

Burner Baffle

[-_ Remove the orifice fitting cover.

Air Shutter

_f

Air Shutter

Screw _'-

Fig. 13

Orifice

Fitting

Cover

Fig. 14

8

Page 9

Installation Instructions

FOR BAKE AND BROIL

BURNERS

Use a 1/2" open end or adjustable wrench to turn

the orifice hood in the L.P. direction, about 1 1/2

turns, until snug.

Broil Burner

2tter

Air Shutter Screw

__'_S_h _tPi r

Made To Orifice Hood

IMPORTANT: Do not overtighten or you may

bend the orifice hood or needle.

Fig. 15

Bake Burner

Fig. 16

ADJUST AIR SHUTTER

NOTE: The Bake and Broil burner flame must be

checked with the door closed to properly check

flame characteristics.

Turn on the bake or broil burner.

As you watch the flame with the oven door

closed, check the following through the oven

door window:

r_ Burner flames should not flutter or blow

away from the burner.

_'] They should be blue in color with no trace

of yellow.

_'] The inner cone of the flame should be

approximately 1/2" to 3/4" long.

IN SOME CASES

[]

With L.P. gas, some yellow tipping on the

outer cone is normal.

[]

Foreign particles in the gas line may cause

an orange flame at first, but this will soon

disappear.

Fig. 18

HAtl

Yellow Flames

Call for Service

CHECK FLAME SIZE

Check the inner cone of

the flame. It should be

approximately 1/2" to 3/4"

long for the oven and

broil burners until snug.

If the flame size is too

long, use a 1/2" open-end

wrench or adjustable joint

pliers to adjust the orifice

hood, by turning in the L.P. direction.

1/2"

to 3/4"1 ....

Inner Cone "_

of Flame

-4,WARNING: .youattemptto

measure the inner cone of the flame, please

use caution; burns could result.

HStl

Yellow "lipping

Normal for LP Gas

HCtl

Soft Blue Flames

Normal for Natural Gas

9

Page 10

Installation Instructions

MAKE THE L.P. GAS CONVERSION (CONT.)

ADJUST AIR SHUTTER (CONT.)

BAKE BURNER

Orifice

Air Shutter

Air Shutter S

Screw

_] Use a screwdriver to loosen the air shutter

screw.

1. If the flames were yellow, open the air

shutter more than the original setting.

2. If the flames blew away or fluttered from

the burner, close the air shutter more than

the original setting.

_'] Make the adjustment.

_'] Retighten the air shutter screw.

[_] Close the oven door and recheck the flame.

_-_ When all adjustments are made and the

results are satisfactory:

1. Replace the orifice fitting cover.

2. Replace the oven baffle (flame spreader).

3. Replace the oven bottom.

Fitting

Cover

Fig. 19

ADJUST AIR SHUTTER (CONT.)

BROIL BURNER

_] The broil burner is located and accessible

in the top rear of the oven.

[_] Use a screwdriver to loosen the air shutter

adjustment screw.

1. If the flames were yellow, open the air

shutter more than the original setting.

2. If the flames blew away or fluttered from

the burner, close the air shutter more than

the original.

_'] Make the adjustment.

[_] Retighten the air shutter screw.

[_] Close the oven door and recheck the flame.

Fig. 20

j

'Air Shutter Screw

SPECIAL NOTE: To convert the oven back to

natural gas, reverse the instructions given in

making L.P. Adjustments.

-& WARNING: Once the conversion is

complete, locate the L.P. Conversion Sticker

under the storage drawer on the main

bottom. When the Conversion checks OK,

fill out the L.P. sticker and include your

name, organization and date conversion

was made. Apply the sticker to the front

frame opposite the name and number plate

behind the storage drawer to alert others

in the future that this appliance has been

converted to L.P. If converting back to

natural gas from L.P., please remove the

sticker so others know the appliance is

set to use natural gas.

10

Page 11

Instrucciones

Horno A Gas

de Instalaclon

Empotrado de 24"

JGRP20

I r?-i _Preguntas? Llame al 1.800.GE.CARES (800.432.2737) o bien visite nuestra pagina Web: www.GEAppliances.com I

ANTES DE EMPEZAR:

Lea estas instruccionesy lasadvertencias completa

y cuidadosamente.

EN LA MANCOMUNIDAD DE

MASSACHUSETTS:

• Este producto debe ser instalado por un plomero

licenciado o por un tecnico de gas.

• Cuando se encuentre usando valvulas de

desconexion de gas tipo bola, deben ser del tipo T.

• Un conectador de gas flexible, cuando se use, no

debe exceder los 3 pies.

•IMPORTANTE- Guardeestas

instrucciones para su uso por el inspector local.

• IMPORTANTE --Observe todos los

codigos y ordenanzas vigentes.

•IMPORTANTE-,a prueba deescape

de gas del aparato debera conducirse de acuerdo a

las instrucciones del fabricante.

• Nota al instalador - AsegQrese de dejar estas

instrucciones con el cliente.

• Nota al consumidor - Guarde estas instrucciones

para referencia futura.

PARA SU SEGURIDAD:

iADVERTENCIA! - sila

informacion en este manual no se sigue exactamente,

podria resultar un incendio, una explosion o un escape

de gas que causen daSo a la propiedad, heridas

personales o muerte.

iNO ALMACENE O USEGASOLINA U OTROS

VAPORES O LIQUIDOS INFLAMABLES CERCA DE

ESTE O CUALQUIER APARATO ELECTRODOMI_STICO!

QUE HACER SI HUELE GAS:

• No trate de encender ningen aparato.

• No toque ningen interruptor electrico; no use ningen

telefono en su edificio.

• Inmediatamente Ilame a su abastecedor de gas

usando el telefono de un vecino. Siga las

instrucciones del abastecedor de gas.

• Si no puede comunicarse con el abastecedor

de gas, Ilame a la compaSia de bomberos.

La instalacion y el servicio deben ser hechos por un

instalador competente, una agencia de servicio o

el abastecedor de gas.

• Nivel de destreza - La instalacion de este aparato

requiere de destrezas mecanicas basicas.

• "13empode instalacion - 1 a 3 horas

• La instalacion apropiada es la responsabilidad

del instalador.

• La falla del producto debido a una instalacion

inadecuada no esta cubierta por lagarantia.

_4,ADVERTENCIA- Esteaparato

debe hacer tierra adecuadamente.

229c4053P578

31-10584 12-03 JR

AsegQrese que su homo sea instalado

adecuadamente por un instalador competente oun

tecnico de servicio.

Asegerese que el horno quede bien instalado en un

gabinete que este firmemente pegado a la estructura

de la casa. Peso sobre la puerta puede causar que

el horno se vuelque resultando en serias heridas

personales o muerte. Nunca permita que alguien se

suba, se afirme, se pare o se cuelgue de la puerta

del horno.

Page 12

Instrucciones de Instalacion

PREPARACION PARA LA INSTALACION DEL HORNO

LISTA DE HERRAMIENTAS

Taladro con Punta de 1/8" Gafas de seguridad

Llave inglesa

ajustable

Llave inglesa para Lapiz

caherfas

Soquete hexagonal

de 3/16"

Destornillador

Phillips No. 1 o No. 2

Regla y vara derecha

para medir

Nivel de espfritu de 12"

Sierra manual o

electrica

MATERIALES ADICIONALES QUE

PODRiA NECESITAR:

S

Valvula de cierre

para lalfneadelgas Selloparalas

uniones de

caherfas

Tubo de 1/2"

_-I REQUERIMIENTOS DE GAS

Usted debe cumplir con los codigos locales

cuando instale su horno. Consulte con su

compafifa de gas local acerca de las leyes y

ordenanzas locales que se aplican en su area.

Si no existen codigos locales, usted debe cumplir

con el National Fuel Gas Code ANSI/Z223.1 -

Latest Edition. Para obtener una copia escriba a:

American Gas Association

1515 Wilson Boulevard

Arlington (Rosslyn), VA 22209

Esta norma no cubre laeficiencia termal de los

aparatos para cocinar a gas de la casa ya que

esto es regulado por la Energy Policy and

Conservation Act de 1975, la National Energy

Conservation Policy Act de 1978 y la National

Appliance Energy Conservation Act de 1987.

Si el horno va a ser instalado en una casa movil,

la instalacion debe cumplir con Manufactured

Home Construction and Safety Standard, Title 24,

CFR, Part 3280 o, cuando no es aplicable, el

Standard for Manufactured Home Installations

ANSI/A225.1 - Latest Edition and Manufactured

Home Installations, Sites and Communities

ANSI/NFPA 501A, o con los codigos locales.

Usted Puede obtener una copia del Federal

Standard escribiendo a:

Office of Mobile Home Standards

HUD Building

451 7th Street, S.W.

Washington, D.C. 24010

PARA CONEXIONES FLEXIBLES DONDE

LAS PERMITAN LOS CODIGOS LOCALES:

• Tuberia flexible de metal revestida y aprobada

(3/4" o 1/2" I.D. igual a la Ifnea abastecedora del

gas)

• Adaptador o conector

PARA CONEXIONES RiGIDAS:

• Junturas o uniones para caherfas requeridas

_-I REQUERIMIENTOS ELECTRICOS

Este aparato debe hacer tierra. Consulte los

codigos locales que se aplican en su area. Si no

existen codigos locales, debe cumplir con el

National Electrical Code, ANSI/NFPA No. 70-

Latest Edition. Escriba a:

NATIONAL FIRE PROTECTION

ASSOCIATION

BATTERYMARCH PARK

QUINCY, MA 02269

2

Page 13

Instrucciones de Instalacion

PREPARE LA ABERTURA

Espacio del gabinete: 24" min. de profundidad

24" min. de anchura

Abertura: 22 3/16" de anchura

38" de altura

3/8" min. en ambos lados

(Vea Fig. 2)

Es buena idea usar un molde para hacer un corte

derecho. Coloque el molde sobre una linea base

nivelada, 22" a 28" del piso. Esto colocara la cavidad

del horno a 36" o 42" del piso.

22 3/16"

39"

El gabinete debe tener fondo, posterior y

lados solidos. Elfondo debe ser solido, a nivel

del piso o con el borde solido del fondo del

corte. Todas lasaberturas del gabinete deben

estar selladas en el momento de la instalacion para

prevenir corrientes de aire. Lascorrientes de aire

afectaran el uso seguro del horno.

NOTAS ESPECIALES:

• Asegerese de instalar el homo a la altura especificada.

La unidad ha sido probada y aprobada para la

instalacion de acuerdo alas normas de seguridad

a esta altura.

• Si el piso va a ser el fondo solido, dos soportes,

centrados a 11" uno del otro dentro del corte pueden

ser usados para sujetar el homo. Estos soportes deben

sostener 130 libras y deben ser nivelados y derechos.

• Los revestimientos de las paredes, la superficie de los

mesones y los gabinetes alrededor del homo deberian

soportar temperaturas hasta 200°F generadas por

el horno.

SI ESTA REEMPLAZANDO UNA

UNIDAD QUE TIENE UN CORTE DE

MAS DE 38" DE ALTURA:

I

I

I

2 Soportes Fig. 1

Centrados a 11"

* DEBERIA SER AJUSTADO PARA ACOMODAR LOS

GABINETES NORMALES Y LA ALTURA DEL HORNO.

I

I

I

I Horno

I

I

I

I

I

I

I

I I

3/8" MIN.-_

Pared o

Gabinete

2_

23 3/4"

Fig. 2

r_ Cierre el suministro de gas principal antes de sacar

el homo existente. Deje el gas apagado hasta que

la nueva conexion haya sido completada.

Mida la cantidad del corte que excede 38".

Levante la car_eria de entrada del gas si

es necesario.

Saque el cajon.

@

Extienda los niveladores de las patas (con un

[]

soquete hexagonal de 3/16") por la cantidad

medida en Paso B.

Encaje el horno en el corte y ajuste los niveladores

r-cq

de manera que las parrillas del horno queden

niveladas y que la parte de arriba del panel de

control quede sobre la parte superior del corte.

Cabeza

Hexagonal de

3/16"

Fig. 3

Nivelador

de Pata

3

Page 14

Instrucciones de Instalacion

INSTALACION DEL HORNO

CONEXIONES ELC:CTRICAS

Un abastecimiento y receptaculo electrico adecuado

debe ser usado para operar las partes electricas de

su homo.

r_ El cord6n del homo tiene un enchufe de tres

patas y debe ser usado con un receptaculo de

tres hoyos que haga tierra adecuadamente con

corriente alterna normal de casa de 120 Voltios,

60 Ciclos.

[]

Instale el receptaculo electrico mas abajo del

homo en el lado izquierdo, en un lugar donde se

pueda alcanzar facilmente a traves de las puertas

del gabinete. (Vea Fig. 6).

[]

Si no tiene un receptaculo de tres hoyos que

haga tierra, haga que un electricista calificado

le cambie el antiguo.

@

Un adaptador para hacer tierra se necesitara para

convertir el receptaculo viejo hasta que pueda

ser reemplazado. Este metodo es s61oprovisorio,

y un electricista calificado Io deberfa probar para

estar seguro que cumple con los requerimientos.

Siempre desenchufe el cord6n del homo antes

de hacer cualquier reparaci6n al homo. Cuando

desenchufe el homo, siempre tome el enchufe,

nunca el cord6n.

ADVERTENClA: NuNcAUSEUN

CORDON DE EXTENSION PARACONECTAR EL

HORNO A LAELECTRICIDAD.

ADVERTENCIA: Bajo ninguna

circunstancia corte o saque la pata para hacer

tierra del cordon del horno. No proveer una

polarizacion adecuada podria crear una

condicion peligrosa.

Enchufe con pata para

hacer tierra polarizado

adecuadamente y

receptaculo que hace

Receptaculo polarizado

que hace tierra

adecuadamente

Ojo de metal para

hacer tierra

CONEXIONES DEL GAS

ADVERTENCIA: Nohaga

funcionar los quemadores de este horno cuando

use gas L.P.(embotellado) antes de convertir el

regulador de presion y el orificio del quemador

para uso con gas L.P.

Vea la pagina 2 para todos los requerimientos de gas.

[]

Cierre el suministro del gas en la valvula de cierre.

Saque el horno existente (si es necesario).

Bote todos los conectores viejos o usados.

r-cq

ADVERTENCIA: Nuncareutilice

conectores flexibles viejos. El uso de conectores

flexibles viejos puede causar escapesde gas y

heridas personales. Siempre utilice conectores

nuevos cuando instale una estufa a gas.

[-_ Asegerese de no ejercer presi6n sobre el juego

de la Ifnea de conexi6n.

Para prevenir cualquier escape, use un

compuesto para uni6n de caflerfas que sea

resistente al gas L.P.sobre los hilos machos

exteriores.

Use una caflerfa de entrada de 1/2".

El hoyo para la caflerfa de entrada deberfa ser de

8 1/2" mfn. a 95/8" max. a la derecha de la Ifnea

de centro y 23" detras del frente de la superficie

del gabinete.

,_ 22" ,_

H 9 5/8)'

/

8 1/2"

i_Mia. _

Fig.

6

Fig. 4 tierN._Lra_ L

IVletodoPreferido

montaje para I

Tornillo de a._

placa del

receptaculo

Metodo Provisorio

Fig. 5

Ubica¢ion Recomendada del Cierre Principal

(Elregulador tambi#n tiene una manilla de cierre)

I-G-'] Instale lavalvula de cierre en la caflerfa.

_] Saque el caj6n y la puerta del horno.

4

Page 15

Instrucciones de Instalacion

CONEXIONES DEL GAS (cont.)

ITI Coloque el horno en el corte.

r_ Nivele el horno:

1.Coloque el nivel de espiritu sobre una de las

parrillas del horno.

2. Si el homo no esta nivelado, ajuste los

niveladores de las patas.

3. Remueva la cubierta del regulador en

la parte posterior del area del caj6n de

almacenamiento, removiendo los 4 tornillos.

Con el horno en su lugar, la entrada del

regulador de presi6n es accesible a traves de

la abertura en la espalda principal.

A traves de esta abertura conecte:

Rq

1. La conexi6n flexible y el adaptador (vea Fig. 7).

2. Laconexi6n de caflerias rigidas y la uni6n a la

valvula de cierre (vea Fig. 8).

Regulador de

con Valvula

de Cierre

Incorporada

Presi6n Adaptador

\__ Conexidn Flexible

REVISE QUE NO HAYAN

ESCAPES

-& ADVERTENCIA: i.oUSEUNA

LLAMA ABIERTA PARA VER Sl EXlSTEN

ESCAPES DE GAS!

r_ Aplique una soluci6n de jab6n a todas las

conexiones: linea de abastecimiento, caflerias

y homo.

[] Abra el suministro principal del gas.

F_ Vea si se forman burbujas.

F_ Cierre el suministro principal del gas.

F_ Detenga cualquier escape que haya encontrado.

[_ Abra el suministro principal del gas para

asegurarse que todos los escapes han sido

detenidos.

Coloque nuevamente la cubierta del regulador

@

usando los 4 tornillos que se removieron

previamente.

_4,ADVERTENCIA: TODOSLOS

ESCAPES DE GAS DEBEN SER DETENIDOS

ANTES DE TRATAR DE ENCENDER LOS

QUEMADORES.

Regulador

__]_ "_ Cubierta del '_

== Fig. 7

INSTALACION FLEXIBLE

Regulador de Presi6n Uni6n

\ /

_Cubierta del _

Regulador

Fig. 8

INSTALACION RiGIDA

[_ Apriete las conexiones.

ADVERTENCIA: i.OFUE.CE

Sl FUERZA PODRIA DAI_IARLAS UNIONES, LAS

CAI_IERIAS0 CAUSAR ESCAPES.

m INFORIVIACION PARA PRUEBAS

DE PRESION

La presi6n permisible maxima para el regulador

es de 14" W.C. (Columna de Agua).

La presi6n minima necesitada para probar la

calibraci6n del regulador es de 11" W.C. para gas

L.P.y 5" W.C. para gas natural.

PRECAUCION: Elhornoy

su valvula de cierre individual debe ser

desconectado del sistema de la linea

abastecedora de gas durante cualquier

prueba de presion en exceso de 1/2 psig

(libra por pulgada cuadrada gauge).

El horno debe ser aislado del sistema de

abastecimiento de gas cerrando su valvula de cierre

manual durante cualquier prueba al sistema de

abastecimiento de gas igual o menor a 1/2 psig.

5

Page 16

Instrucciones de Instalacion

INSTALACION DEL HORNO (CONT.)

I-8-1COIVIO REVISAR LAS LLAMAS

DE LOS QUEMADORES A GAS

NATURAL

El horno viene ajustado de fabrica para ser usado con

gas natural en la mayorfa de las areas. Pero, como el

gas en algunas areas varfa, usted debe revisar todos

los ajustes que se describen mas abajo. Si usted va a

usar gas L.P.,mire los Ajustes para Gas L.P.en la parte

final de esta gufa.

NOTA: La llama para hornear y asar a la parrilla

debe ser revisada con la puerta cerrada para revisar

adecuadamente las caracterfsticas de la llama. Para

revisar correctamente el quemador para hornear, el

fondo del horno y el esparcidor de llamas deben ser

removidos.

Encienda el quemador para hornear o asar.

Mientras mire la llama con la puerta del homo

cerrada, revise Io siguiente a traves de la ventana

de la puerta:

1. Las llamas del quemador no deberfan

pestaSear o soplar en direccion opuesta

al quemador.

2. Deberfan ser de color azul sin muestras

de amarillo.

3. El cono interior de la llama deberfa ser

de 1/2" a 3/4" de Iongitud.

LOS QUEMADORES DEBERIAN SER REVlSADOS

FRECUENTEMENTE.

I-9--ICOIVIO AJUSTAR LAS LLAMAS

DEL QUEMADOR (CONT.)

Saque la cubierta del orificio.

Obturador

de Aire

Tornillo del _f Fig. 10

Obturador de Aire

[-_ Use un destornillador para soltar el tornillo del

obturador de aire.

1. Si las llamas estaban amarillas, abra el

obturador masque la posici6n original.

2. Si las llamas soplaban en direcci6n opuesta

al quemador, cierre el obturador masque

la posici6n original.

[-_ Haga el ajuste.

r-G-] Apriete nuevamente el tornillo del obturador.

_] Cierre la puerta y revise nuevamente la llama.

Cuando los resultados son satisfactorios:

1. Coloque nuevamente la cubierta del orificio.

2. Coloque el esparcidor de llamas en su lugar.

3. Coloque nuevamente el fondo del homo.

Cubierta del

Orificio

I-9--ICOIVIO AJUSTAR LAS LLAMAS

DEL QUEMADOR

QUEIVIADOR DEL HORNEAR

r_ Abra la puerta del horno.

[] Saque el fondo del horno.

1-_ Saque los 4 tornillos para remover el esparcidor

de llamas.

Esl: Fig. 9

quemador fondo

del horno

QUENIADOR PARA ASAR

r_ El quemador para asar esta ubicado y es

accessible en la parte superior trasera del homo.

[_] Use un destornillador para soltar el tornillo de

ajuste del obturador.

1. Si las llamas estaban amarillas, abra el

obturador masque la posici6n original.

2. Si las llamas soplaban en direcci6n opuesta

al quemador, cierre el obturador masque la

posici6n original.

[-_ Haga el ajuste.

[_] Apriete nuevamente el tornillo del obturador.

[_ Cierre la puerta del homo y revise nuevamente

la llama.

6

Page 17

Instrucciones de Instalacion

COMO COLOCAR BIEN

EL HORNO

IMPORTANTE: Saque todos los

materiales de empaque y la literature del horno

antes de hacer cualquier conexion electrica.

r_ usando un barreno de 1/8", haga hoyos a traves

de las molduras laterales y en el frente del

gabinete.

[] Con los tornillos que se proveen, asegure el

horno a la pared.

Si el corte del gabinete es de 38" de altura, utilice

la moldura corta y peguela al fondo del marco

frontal con los tornillos que se proveen.

(Si el corte es de mas de 38" de altura, use la moldura

mas alta).

[_] REVISE LOS PASOS

Revise varias veces para asegurarse que todo en esta

gufa ha sido completado. El revisar los pasos le

asegurara la utilizaci6n segura del horno.

44,ADVERTENCIA: Lamoldura

permite la entrada del aire al gabinete bajo

la unidad y no debe ser obstruida.

7

Page 18

Instrucciones de Instalacion

COMO HACER LA CONVERSION PARA GAS L.P.

ADVERTENCIA: Si usted va

a usar gas L.P.(embotellado), todos los ajustes

descritos masabajo deben hacer antes de

hacer cualquier ajuste a losquemadores o

usar el horno.

-_ ADVERTENCIA: Estaconversion

debe ser hecha por un instalador competente o

por el abastecedor de gas de acuerdo con las

instrucciones del fabricante y todos loscodigos

y requerimientos de las autoridades que tienen

jurisdiccion. El no seguir las instrucciones podria

resultar en serias heridas o dafio a la propiedad.

La agencia calificada que hace este trabajo

asume la responsabilidad de la conversion.

NOTA: Desconecte toda la electricidad y cierre el paso

del gas en la valvula de cierre antes de empezar la

conversi6n.

Ill AJUSTE EL REGULADOR DE

PRESION DE GAS NATURAL

A GAS L.P.

r_ Remueva la cubierta del regulador en la parte

posterior del area del cajon de almacenamiento

removiendo los 4 tornillos.

F_ Ubique el regulador.

Fig. 11

ReguladordePresion Adaptador

_1:nciVa_rVeula ro ___:t1 C°nexidn Flexible

Incorporada I 1_ " ' '_!

1I 11 i i II _Cubiertadelt_

Regulador

I-_ Destornille la tapa,

AJUSTE EL REGULADOR DE

PRESION DE GAS NATURAL

A GAS L.P. (CONT.)

@

Saque el retenedor de la tapa.

F_

Invierta el retenedor de manera que L.P.se vea

sobre el fondo del retenedor.

Coloque nuevamente el retenedor dentro de

[]

la tapa.

@

Coloque nuevamente la tapa sobre el regulador.

[]

Coloque nuevamente la cubierta del regulador

usando los 4 tornillos que sostenfan

originalmente la cubierta del regulador.

_-I COMO AJUSTAR EL ORIFIClO

DEL QUEMADOR DE GAS

NATURAL A GAS L.P.

-_ PRECAUCION: Losajustesen

la siguiente columna se deben hacerantes de

encender los quemadores. Si no se hace de esa

manera podrian resultar heridas serias debido a

llamas altas y vapores toxicos.

Su quemador para asar a la parrilla esta Iocalizado

en la porcion superior de su horno y el accesoa este

es facil.

Para Iograr accesoa su quemador para hornear siga

las instrucciones mas adelante:

r_ Abra la puerta del horno.

Saque el fondo del horno.

[] Saque los 4tornillos que sujetan el esparcidor

de llamas.

Fig. 12

Tapa

Sello... _. Sujetadode

_/. Resorte

NAT.__lll _ L.P.

==-- _

= _

Esparcidor del__ _ Fig. 13

quemaaor fonao__._

del horno

[] Saque la cubierta del orificio.

Obturador

de Aire

Tornillo del

Obturador de Aire

8

Fig.

Cubierta del

Orificio

14

Page 19

Instrucciones de Instalacion

PARA QUEMADORES PARA

HORNEAR Y ASAR

Use una Ilave de 1/2" o una Ilave ajustable para hacer

girar la tapa del orificio en direccion de L.P.,aprox.

1 1/2 vuelta, hasta que quede apretada.

para asar

/ Oue a.or

or de Aire

Tornillo del Obturador de Aire

Quemador

.R

• _'_ 6btu_ado-_r'"

": de Aire ,,./

Ajustes de eas'_ <_,,_._

NAT. - L.R _'"_ --

Hechos a la Tapa del Orificio

IMPORTANTE: No apriete demasiado o podria doblar

la tapa del orificio o la aguja.

para hornear

Fig. 16

AJUSTE EL OBTURADOR

DE AIRE

NOTA: Las llamas para hornear y asar se deberian

revisar con la puerta cerrada para revisar

correctamente las caracteristicas de la llama.

Encienda el quemador para hornear o para asar.

Mientras mira la llama con la puerta cerrada, revise

Io siguiente a traves de la ventana de la puerta:

r_ Las llamas del quemador no deberian pestaSear

o soplar en direccion opuesta al quemador.

Deberian ser de color azul sin muestras de

[]

amarillo.

r-cq

El cono interior de la llama deberia ser de aprox.

1/2" a 3/4" de Iongitud.

EN ALGUNOS CASOS

_] Con el gas L.P.,un poco de amarillo en las puntas

es normal.

_'] Particulas extrar_as en la linea del gas podrian

causar una llama anaranjada al principio, pero

esto desaparecera pronto.

Fig. 18

Llame para un Servicio

iiAtl

Llamas Amarillas

COIVIO REVISAR EL TAIVIAI_IO

DE LA LLAMA

Revise el cono interior de la

llama. Deberia ser de aprox.

1/2" a3/4" de Iongitud para

los quemadores para

hornear y para asar.

Si el tamar_o de la llama esta

para alargar, use una Ilave

abierta de 1/2" o un alicate

ajustable para ajustar la tapa del orificio, haciendola

girar hacia L.P.

1/2" _./

a 3/41 "_ Fig. 17

de la Uama

-AADVERTENCIA: Sitratade

medir el cono interior de la llama, por favor

use precaucion; se podria quemar.

HStl

Puntas Amarillas

Normal para Gas LP

HCtl

Llamas de Azul Suave

Normal para Gas Natural

9

Page 20

Instrucciones de Instalacion

COMO HACER LA CONVERSION PARA GAS L.P. (CONT.)

AJUSTE EL OBTURADOR

DE AIRE (CONT.)

QUEIVIADOR PARA HORNEAR

Obturador

de Aire

Tornillo del

Obturador de Aire

r_ use un destornillador para soltar el tornillo del

obturador.

1.Si las llamas estaban amarillas, abra el

obturador de aire mas que la posicion original.

2. Si las llamas soplaban en direccion opuesta al

quemador, cierre el obturador de aire masque

la posicion original.

F_ Haga el ajuste.

[] Apriete nuevamente el tornillo del obturador.

Cierre la puerta del horno y revise nuevamente

la llama.

Cuando todos los ajustes sean hechos y los

resultados son satisfactorios:

1.Coloque nuevamente cubierta del orificio.

2. Ponga en su lugar el esparcidor de llamas.

3. Coloque el fondo del horno nuevamente

en su lugar.

Cubierta del

Orificio

Fig. 19

AJUSTE EL OBTURADOR

DE AIRE (CONT.)

QUEIVIADOR PARA ASAR

1_] El quemador para asar esta ubicado yes

accesible en la parte superior trasera del horno.

[] Use un destornillador para soltar el tornillo del

ajuste del obturador de aire.

1. Si las llamas estaban amarillas, abra el

obturador mas que la posicion original.

2. Si las llamas soplaban en direccion opuesta

al quemador, cierre el obturador de aire mas

que la posicion original.

Haga el ajuste.

Apriete nuevamente el tornillo del obturador.

F_ Cierre la puerta del horno y revise nuevamente

la llama.

_/ Fig. 20

'Tornillo del Obturador de Aire

NOTA ESPECIAL:Para convertir el horno de vuelta a

gas natural, invierta las instrucciones dadas para hacer

los ajustes para gas L.P.

ADVERTENCIA: Una vez que la

conversion esteterminada y funcionando bien,

Ilene la etiqueta de L.P.Iocalizada en el paquete

enviado con su estufa e incluyasu nombre,

organizacion y la fecha en que la cinversion fue

hecha. Pegue la etiqueta al marco frontal de la

estufa cerca de la placa de identificacion detras

del cajon y advierta a otros en elfuturo que esta

estufa ha sido convertida para ser usada con gas

L.P.Si se convierte de vuelta de gas L.P.a gas

natural, por favor saque la etiqueta para que

otros sepan que la estufa esta programada para

ser usada con gas natural.

10

Loading...

Loading...