GEAppliances.com

0

0

Safety Instructions .... 2-7

Operating Instructions

Downdraft Vent System . .l 0

Features .............. 8

(;as Surface Burners ..... 9

Using Your Cooktop .... 10

Care and Cleaning

Burner Assemblies ..... l l

Burner Caps and Heads . .11

Burner Grates and

Vent Grille ............ 12

Control Knobs ........ 13

Glass Surface ....... 13, 14

Vent Filter ............ 12

Installation Instructions

Ductwork ....... 19-22, 27

Electrical

Connections .... 23, 28, 29

Exhaust Blower Ratings .21

Final Assembly ........ 30

Installing

the Cooktop ....... 25-28

Installing the Gasket .... 24

Power Supply ......... 23

Preparation ........ 17-19

Safety Precautions ...... 15

Unpacking

the Cooktop ....... 16, 24

Troubleshooting

Tips .............. 31,32

Consumer Support

Consumer

Support ....... Back Coxer

Product

Registration ........ 33, 34

Warranty ............. 35

jcP 98 9

Write the model and serial

numbers here:

Model #

Serial #

Eind these numbers on a label

under the cooktop, on the side

of the vent chamber:

164D4290P347 49-80797 02-03 JR

IMPORTANTSAFETYINFORMATION.

READALLINSTRUCTIONSBEFOREUSING.

WARNING!

For your safe_, the information in this manual must be followed to minimize the risk of fire or

explosion, electric shock, or to prevent property damage, personal injury, or loss of life.

WARNING:If the information in this manual

is not followed exactly, a fire or explosion may

result causing property damage, personal injury

or death.

-- Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

- WHATTODOIF YOUSMELLGAS

Do not try to light any appliance.

Do not touch any electrical switch; do not use

any phone in your building.

Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

If you cannot reach your gas supplier, call the

fire department.

-- Installation and service must be performed by

a qualified installer, service agency or the gas

supplier.

2

GEAppliances.com

IMPORTANTSAFETYNOtiCE

The California Safe Drinking Water and ToxicEnforcement Act requires the Governor of California to

publish alist of substances known to the state to cause cancer, birth defects or other reproductive

harm, and requires businesses to warn customers of potential exposure to such substances.

Gasappliances can cause minor exposure to four of these substances, namely benzene, carbon

monoxide, formaldehyde and soot, caused primarily by the incomplete combustion of natural gas or

LP fuels. Properly adjusted burners, indicated by a bluish rather than a yellow flame, will minimize

incomplete combustion. Exposure to these substances can be minimized by venting with an open

window or using a ventilation fan or hood.

SAFETYPRECAUtiONS

Have the installer show you the location of the cooktop gas shut-off valve and how to shut # off

ff necessary.

Hm_ your cooktop installed and ploperly

gTounded by a qualified installe_; in

accordance with the Installation

Instructions. Any adjusunent and service

should be performed only by qualified gas

cooktop installers or service technicians.

Do not attempt to repair or replace any

part of your cooktop unless it is specifically

recommended in this manual. All other

service should be refened to a qualified

technician.

i,ocam fire cooktop out of kitchen traffic

padx arrd out of drafty locations to prex>nt

poor burner performance.

Plug your cooktop irrto a 190_\olt

gTounded outlet only. Do not remove the

round grounding prong flom tire plug.

If ira doubt about the grounding of the

home elecuical sysmm, it is your personal

responsibility arrd obligation to have an

ungrounded outlet replaced with a

properly glounded, three-prong outlet in

accordance with the Nauonal Elecuical

Code. Do not use an exmnsion cord with

this appliance.

let fire burner grams and odrer smt_aces

cool before touching them or leaving

them where children can reach them.

Be sure all packaging materials are

remoxed flom tire cooktop before

operating it to prexent fire or smoke

damag> should the packaging material

ignite.

Be sure your cooktop is conecdy adjusted

by a qualified service mchnician or irrstaller

fox the wpe of gas (natural or I,P) which

is to be used. Your cooktop can be

corrxerted fox use with either type of gas.

See tire Installation Instructions in the

I,P Corrx>rsion Kit.

WARNING: xesea ,xstmerrtsre.st

be made by a qualified service technician

in accordance with the mamd_acturer's

irrstructions arrd all codes arrd

requirements of the amhofitv having

jurisdiction. Failure to tbllow these

irrsUucfions could xesult in serious inju U

or properw damage. The qualified

agency perforating this work assumes

responsibility fox the corwersion.

Do not lem> children alone or unattended

whexe a cooktop is hot or in operation.

They could be seriously bmTaed.

Do not allow arryone to climb, stand or

hang on the cooktop.

Do not operam or clean your cooktop if

the glass is broken or cracked. Cleaning

solutions arrd spilloxers could peneuam the

broken cookmp and cream a risk of

electric shock. (;all fox service immediately

if the cooktop glass breaks or cracks.

3

IMPORTANTSAFETYINFORMATION.

READALLINSTRUCTIONSBEFOREUSING.

SAFETYPRECAUTIONS

CAUTION: ,emsofi,,,eFest,o

children shouM not be stored in cabinets

above a cooktoi>--<hildren climbing on tile

cooktop to reach imms could be seriously

i,ljured.

Alwws kee I) wooden and plastic umnsils

and canned food a safe distance away from

your cookmp.

A]wws kee I) combustible wall coxefings,

curtains or drapes a safe distance flom

your cookmp.

Never wear loose-fitting or hanging

garments while using the appliance.

Be caieflfl when reaching for imms staled

in cabinets ox>r tile cookmp. Flammable

mamrial could be ignimd if brouOlt in

contact widl flame or hot surPaces and

mav catlse severe btliTis.

Teach children not to play with tile controls

or any other part of the cooktop.

For your safety, never use your appliance

fbr warming or heating tile room.

Alwws kee I) dish towels, dishcloths, pot

holders and other linens a safe distance

flom your cooktop.

Do not store flammable materials near

a cooktop.

Do not store or use combustible materials,

gasoline or other flammable vapors and

liquids in tile vicinity of this or any other

appliance.

Do not let cooking grease or other

flammable mamrials accumulate on or

near tile cooktop.

Do not operam tile burner without all

burner parts in place.

Do not place hot cookware on tile glass

cooktop. This could cause glass to break.

Do not clean tile cooktop with flammable

or x_latile cleaning fluids.

Nexer use die cooktop as a cutting boaM.

Do not use water on grease fires. Nexer

pick up a flaming pan. Turn tile conuols

off: Smother a flaming pan on a suri_ce

burner by covering the pan complemly with

a well-fitting lid, cookie sheet or fiat tray

Use a multi-puq)ose d_T chemical or

foam-type file extinguisher

Flaming giease outside a pan can be put

out by coxering it with baking soda oi; if

available, by using a multi-puq)ose dU

chemical or foam-type fire exfinguishen

WARNING:ro reduce the risk of fira,

electrical shock, or injury to persons, observe the

following:

A. Use this tlnit on]v iI1 tile mamler intended

by file mamd_cnlren If you hax> questions,

contact tile manufl_ctmen

B. Before servicing or cleaning the unit,

switch power off at service panel.

C. When cutUng or drilling into wall or

ceiling do not damage electrical wiring

and other hidden utilities.

D. Ducted fans must a]wavs be x>nted to

tile outdoors.

E. To reduce tile risk of fire, use only meta]

ductwork.

WARNING:ro reduce the risk of a

cooktop grease fire:

A. Kee I) thn, fihers and greaseqaden surPaces

clean.

B. Alwws uml x>nt ON when cooking at

high heat.

C. Use high settings on cookmp only when

necessa U. Heat oil slowly on low m

medium setting.

D. Don't leaxe file cooktop unatmnded

when cooking.

E. AIwws use cookware and utensils

appropnam for file type and amount

of food being p_epared.

CAUTION:For general ventilating use

Do not clean tile cooktop when tile

appliance is in use.

4

Avoid scratching the cooktop with shaq)

instruments, or with rings and otherjeweh T.

only. Do not use to exhaust hazardous or

explosive materials and vapors.

GEAppliances.com

GLASSCOOKTOPSURFACEronsomemodels)

Use care when touching the glass cooktop surface. Theglass surface of the cooktop will retain heat

after the controls have been turned off.

Avoid scratching tile glass cooktop surface.

Tile glass sn,_tce call be scratched with

items such as shall) instruments, iings or

otherjeweh T and lix>ts on clothing.

image scratches or impacts m glass

cookmps can lead to broken or shatmied

glass.

Do not operam tile cooktop if tile glass is

broken. Spilloxers or cleaning soludon m W

penetrate a broken cooktop and create a

Iisk of electrical shock. Contact a qualified

technician immediately should your glass

cookmp surface become broken.

Nexer use the glass cookmp surPace as a

cutting board.

Do *lot place or store items that can melt

or catch fire on tile glass cookmp surface,

even when it is not being used.

Be carefld when placing spoons or other

sdrling utensils on glass cooktop surPace

when it is in use. Tiley m W become hot

and could cause 1)urns.

Clean tile cooktop surt=ace with caution.

If a wet spong_ or cloth is used to wipe

spills on a hot surPace, be carefld to ax_id

smam bnrrls. Some cleaners can produce

noxious fllmes if applied to a hot surface.

NOTE: _A'erecommend that you m_id

wiping any surface areas until they have

cooled and file indicator light has g_ne

off: Sugar spills ale tile exception m this.

Please see Cleaning the glass cooktop

surface sect.ion.

When file cooktop is cool, use only

CERAMA BRYTE c'_'Ceramic Cooktop

Cleaner and tile CERAMA BRYTE '_>

Cleaning Pad to clean tile cooktop.

To ax_id possible damage to tile cooking

surface, do *lot apply cleaning cream to tile

glass surface when it is hot.

After cleaning, use a d U cloth or paper

towel to iemoxe all cleaning cream residue.

Read and follow all insuucdons and

waming:s on tile cleaning cream labels.

5

IMPORTANTSAFETYINFORMATION.

READALLINSTRUCTIONSBEFOREUSING.

WARNING!

SURFACEBURNERS

Use proper pan size--a void pans that are unstable or easily tipped. Select cookware haring flat

bottoms large enough to cover burner grates. Toavoid spillovers, make sure cookware is large

enough to contain the food properly. This will both save cleaning time and prevent hazardous

accumulations of food, since heavy spattering or spillovers left on cooktop can ignite. Use pans

with handles that can be easily grasped and remain cool.

Always use fl_e LITE posit.ion when igniung

the top burners and make sure file burners

have ignited.

Nexer leaxe file surface burners unatmnded

at high flame setdng:s. Boiloxers cause

smoking and g_easy spilloxers dlat may

catch on file.

Use only dU pot holders--moist or damp

pot holders on hot surfaces may Iesult in

burJ_s flom steam. Do not let pot holders

come near open flames when lifting

cookware. Do not use a towel or other

bulky cloth in place of a pot holden Such

cloths can catch file on a hot bumen

When using glass cookware, make sure

it is designed for cooktop cooking.

To minimize the possibility of bur]is,

igniuon of flammable matelials and

spillage, t/lI'll cookwaIe handles toward

the side or cenmr of the cooktop without

exmnding oxer adjacent burners.

a]wws t/lill the sml_ace burner controls off

before iemoving cookware.

Carefldlv watch foods being flied at a high

flame setung.

Alwws heat l_at slowly and watch as it heats.

Do not leave any imms on flae cooktop.

Tile hot air flom the \_nt m W ignite

flammable items and will increase pressure

in closed containers, which m W cause

them to burst.

If a combinauon of oils or fats will be used

in flTing, sfis tog>ther befoie heating or as

fats meh slowly.

Do not use a wok on tim cooking surface

if file wok has a round metal ring that is

placed ox>r file burner grate to support

file wok. Tiffs ring acts as a heat trap, which

m W damag_ the burner grate and burner

head. Also, it m W cause die burner to

work improperly. This m W cause a carbon

monoxide lexel abox> dlat allowed by

cmxent standards, iesulting in a health

hazard.

Foods for ruing should be as dry as

possible. Frost on flozen foods or moistule

on flesh foods can cause hot l_atm bubble

up and o_er die sides of the pan.

Use file least possible amount of fat for

effecfixe shallow or deep-fat flTing. Filling

file pan too fldl of fat can cause spillo_>rs

when food is added.

Use a deep fat thermometer whenever

possible to pre_>nt oveflleafing fat beyond

file smoking point.

Nexer ti T to move a pan of hot fat,

especially a deep fi_triTer VVaituntil file fi_t

is cool.

_llen flaming foods, turIl the fan off: Tile

fan, if operaung, m W spread the flames.

GEAppliances.com

SURFACEBURNERS

Adjust the burner flame size so it does not extend beyond the edge of the cookware. Excessive flame

is hazardous.

Do not leave plastic items on the cooktoI>--

riley may melt if left too close to file \_nt.

Keep all plastics away from tile sur/_ace

b/IFllei's,

If you smell g¢_s, turn off the gas to the

cooktop and call a qualified service

technician. Nex_r use all open flame to

locate a leak.

To ax_id file possibility of a bum, always be

certain that tile controls for all burners are

at file off position and all grates are cool

before attempting to remox_ them.

Nex_r clean the cooktop suiPace when it is

hot. Some cleaners produce noxious fimles

and wet cloflls could cause steam bums if

used on a hot sur/_ace.

Ne_>r leave jars or cans of/_t drippings

on or near your cooktop.

Do not use a]umimlm foil under bm_ler

gxams. Misuse could lesult ill a fire hazard

or damag_ to file cooktop.

Do not coxer or block tile area around

file cooktop knobs. This area must be kept

clear for proper x_nfilafion and burner

performance.

Clean only parts listed ill fills Owner's

Manual.

COOKMEATANDPOULTRYTHOROUGHLY...

Cookmeat and poultry thoroughly--meat to at least an INTERNAL temperature of 160°F and poultry to at least

an INTERNAL temperature of 180°E Cooking to these temperatures usually protects against foodbome i#ness.

CONVERTINGTOLPGAS(or converting back to natural gas from LP)

This cooktop leaves the factory set for use with natural gas.

If you want to com_rt to LP gas, die com_rsion must be perforated by a qualified LP gas

installei:

Tile conversion instructions, conversion sticker and LP orifices call be found attached to file

cooktop next to file pressure regulator.

Tilere is a second set of instructions included ill the envelope containing file product wiring

diagrams on file side of file cooktop. Keep fllese instructions and the orifices in case you want

to com_rt back to natural gas.

READANDFOLLOWTHISSAFETYINFORMATIONCAREFULLY.

SAVETHESEINSTRUCTIONS

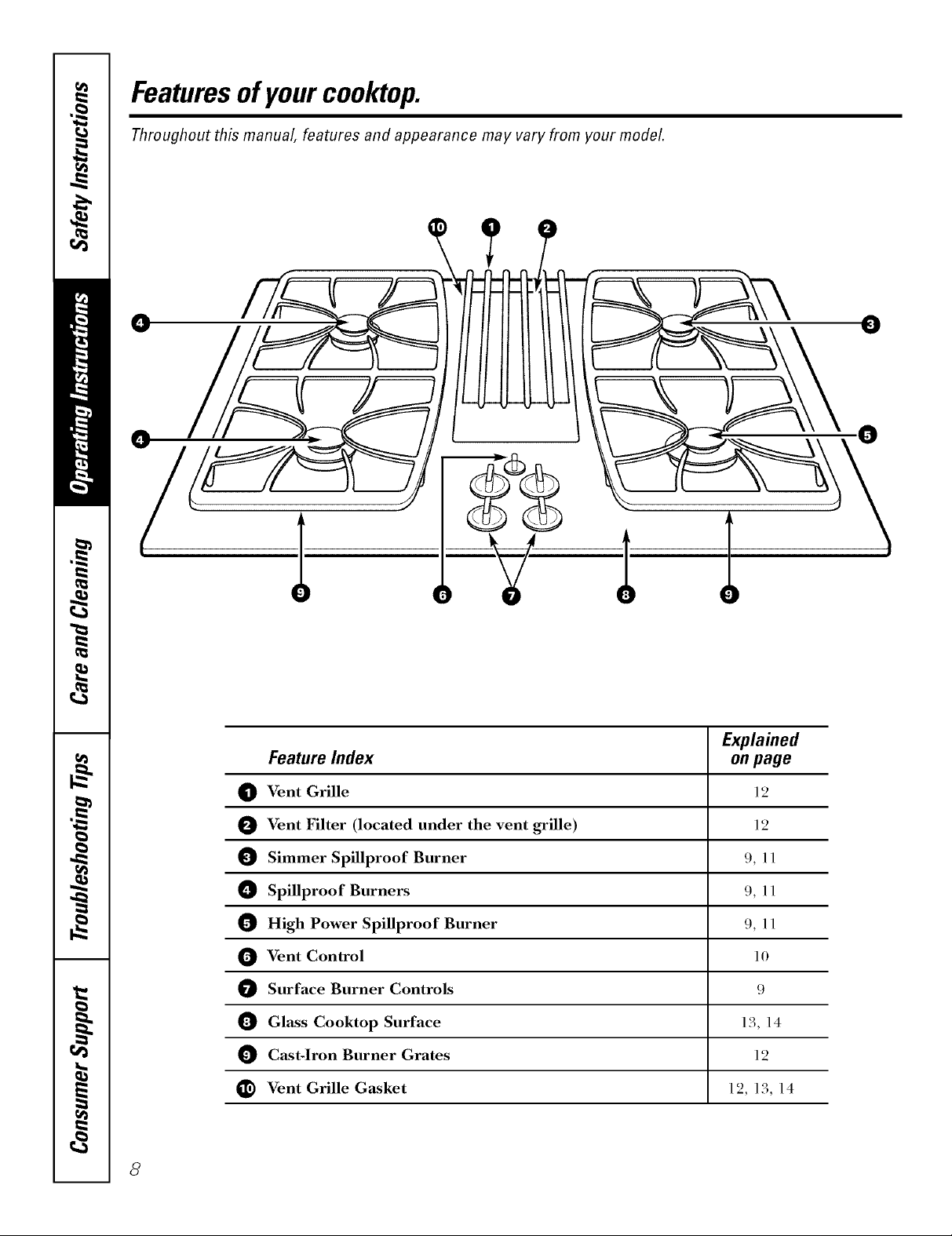

Featuresof yourcooktop.

Throughout this manual, features and appearance may vary from your model.

¢

¢

0

0

Explained

Feature Index onpage

O Vent Grille 12

Vent Filter (located under the vent grille) 12

Simmer Spillproof Burner 9, 11

O Spillproof Burners 9, 11

0 High Power Spillproof Burner 9, 11

Vent Control 10

Surface Burner Controls 9

0 Gl&ss Cooktop Surface 13, 14

Cast-Iron Burner Grates 12

_) Vent Grille G_sket 12, 13, 14

8

Usingthe gas surfaceburners. GEAppliances.com

Throughout this manual, features and appearance may vary from your model.

How to Lighta GasSurface Burner

Push tile control knob down and mrn it

to tile LITEposition.

You will hear a little clicking noise---the

sound of tile electric spark igniting tile

btlI'neF.

Tm'n tile knob to a(!just tile flame size.

If the knob stms at LifE, it will continue

to click.

Push the control knob down and

turn it to the LITEposition.

Sealed Gas Burners

When one burner is tttnmd to LITE,

all the burners spark, Do not attempt to

disassemble or clean around anv burner

while another burner is on. An electric

shock inav result, which could cause you

to knock over hot cookware.

Tile smaller bm'ner (right rear position)

will give the best simmer results. It offers

predse cooking perlommnce fi)r delicate

fi)ods, such as sauces or foods which need

to cook over low heat fi)r a long time.

It can be turned down to a ve_' low

simm er setting.

How to Select Flame Size

Forsafe handling of cookware, never let theflames

extend up the sides of theco&ware,

Watch tile flame, not tile knob, as you

reduce heat. The flame size on a gas

burner should match tile cookware vou

are using.

In Case of Power Failure

In case of a power fifilm'e, you can light

tile gas surli_ce bume_ on your cooktop

with a match. Hold a lit match to tile

bume_; then push in and mrn tile control

knob to tile LifE position. Use extrelne

caution when lighting burners this way.

Tile other burners are higher powered

and will bring liquids to a boil quicke_;

especially with tile use of a lid.

An) flame larger than tile bottom of tile

cookware is wasted and OillV ser\ es to

heat tile handle.

Stwthce bm'nets in use when an electrical

power tifilm'e occms will continue to

operate n(mnallv:

IN CASE OFA POWERFAILURE,THE

VENTILATIONSYSTEM WILLNOT OPERATE.

Before Lighting a Gas Burner

Make sm'e all grates on tile cooktop

are in place befi)re tlsiil_*,manv, b/IYneI'.

After Lighting a Gas Burner

Do not operate tile burner for an

extended period of time without

cookware on tile grate. Tile finish

on tile grate may chip without

cookware to absorb tile heat.

Be sure the burners and grates are

cool befi)re you place your hand,

a pot holder; cleaning cloths or

other materials on them.

9

Usingyourcooktop.

Wok This Way

Werecommendthatyouusea flat-bottomed

wok,availableatyour/oca/retai/store.

Use a flat-bottomed wok.

Only a flat-botton/ed wok should be tlsed.

Do not use a flat-bottolned wok with a

wok holdei:

Cool(ware

Do not rise a I']at-bottoilled wok on a

support ring. Placing tile ring over tile

burner or grate Inay cause tile burner to

work inlproperly, i'esuldng in carbon

nionoxide levels above allowable current

standards. This could be dangerous to

your health.

Aluminum:Mediuin-weight cookware is

recoimnended because it heats quickly

and evenly. Most fi)o(ls brown evenly in

an ahuninuin skillet. Use saucepans with

tight fitting lids when cooking with

iilinililtllil alilOtlnts ofwatei:

Enamelware:/_Jildei soIne conditions,

tile enalllel of SOIlle cookware niav

inelt. Follow cookware illanH[ilctHi'ei"s

reconmiendations fi)r cooking inethods.

Glass: There are two types of glass

cookware: those for ()veil rise only

and those fi)I" cooktop cooking

(saucepans, coffee and tea pots).

Glass conducts heat veIa' slowly.

Stove TopGrills

Do not rise stove top grills on VOtli"

sealed gas burners. If you use tile stove

top grill on tile sealed gas burner it will

cause incoinplete conibusfion and can

CastIron:If heated slowly,n/ost

skillets will give satisfi_ctorv results.

HeatproofGlass-Ceramic:Can be used

fk)i" either StllS{il('e o1" oven cooking.

It conducts heat veI T slowly and cools

very slowly. Check cookware

nlanufi_cturer's directions to be sure it

C_lll be used on _1 g_ls cooktop.

Stainless Steel: This n/etal alone has

poor heating properties and is usually

coinbined with coppei, ahuninuin

or other inetals fi)r iinproved heat

disti_ibufion. (_oinbinafion inetal skillets

usually work satisfactorily if they are used

with niediuni heat as tile i/ian/ithcttlrer

i'ecolili//ends.

result in exposure to carbon nionoxide

levels above allowable current

standards. This can be hazardous to

your health,

Usingthedowndraft ventsystem.

How to Operate the Downdraft Vent System

Thebuilt-in ventsystem helps remove

cooking vapors, odors and smokefrom

foods prepared onthe cooktop.

Turn tile vent tan speed control knob

to HI,IVIEDor LO,as needed.

Continuous use of tile vent svsteIn

while cooking helps kee I) tile kitchen

cointi)rtable and less hunIid, reducing

cooking odors and soiling nioisture

10

that norniallv creates a frequent need

ti)i" cleaning.

Tile appearance of tile burner flaines

inav be afl'ected when the vent tan is

operating. At high tim speed setting,

the flaine inav be drawn toward the

vent opening, afl'ecting cooking

pe i'J[O IIIl _1nce,

IN CASEOFAPOWERFAILURE,THE

VENTILATIONSYSTEMWILLNOTOPERATE.

Careand cleaningof thecooktop. CEAppliances.com

Be sure electrical power is off and all surfaces are cool before cleaning any part of the cooktop.

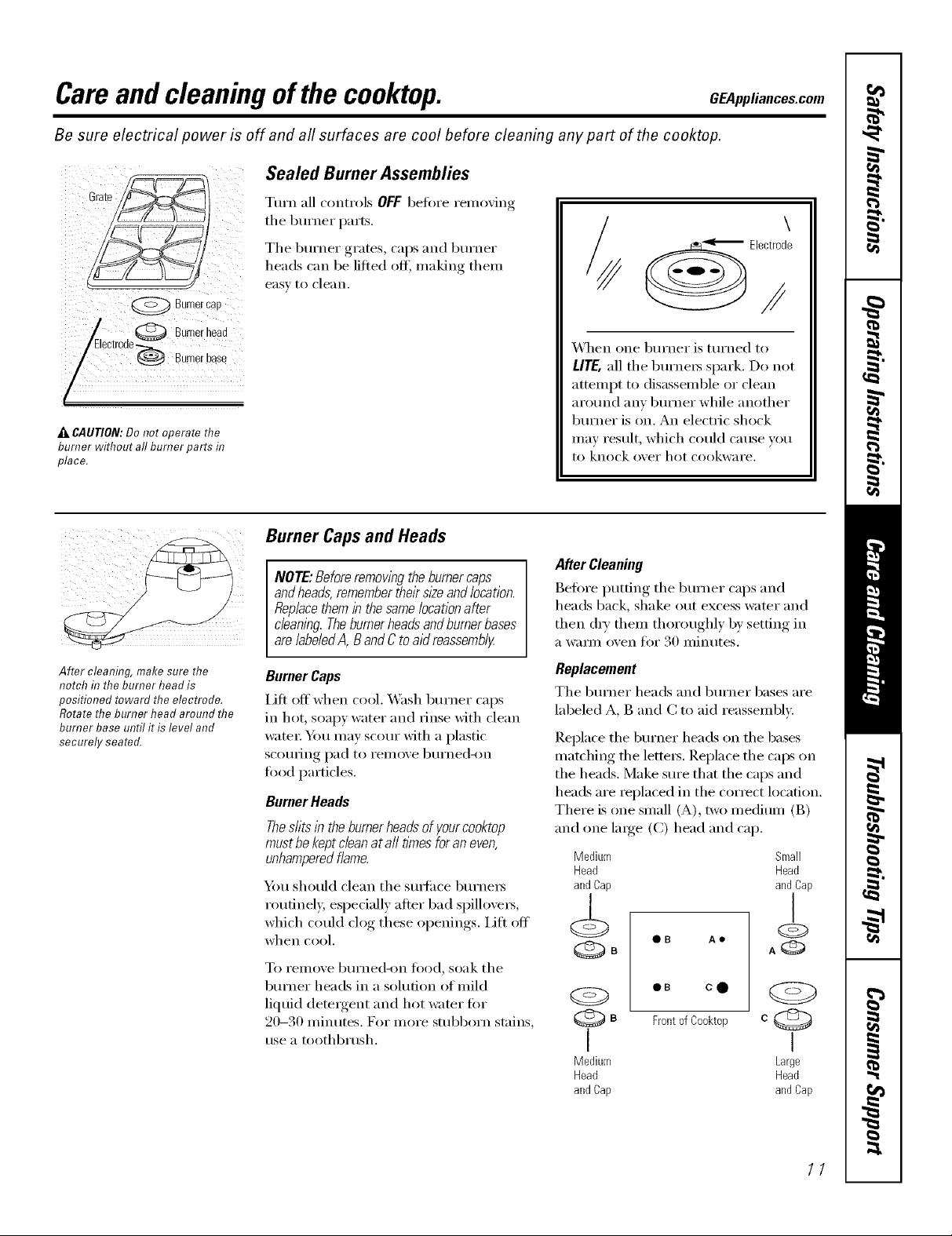

Sealed Burner Assemblies

Gra /

Burnercad

@ Burnerhead

ectrode

I

{_Z_ Burnerbase

/

_, CAUTION:Do not operate the

burner without all burner parts in

place.

Turn all controls OFF beflwe removing

the burner parts.

The burner grates, caps and burner

heads can be lifted off, making them

easy to clean,

Burner Caps and Heads

NOTE'.Beforeremoving theburnercaps

andheads,remembertheir sizeand location.

Replacethem in thesamelocationafter

cleaning.Thebumer headsandbumerbases

are labeledA, Band C to aid reassemb/g

\

Electrode

When one burner is tin'ned to

LITE, all tile bm'ners spark. Do not

attempt to disassemble or clean

around any burner while another

bm'ner is on. An electric shock

may result, which could cause you

to knock over hot cookware.

AfterCleaning

Before putting tile bm'ner caps and

heads back, shake ()/It excess water and

then (hw them thoroughly by setting in

}1l_;lil/l (Well J()I" .'40 II/intltes.

After cleanhTg make sure the

notch h7the burner head is

positioned toward the electrode.

Rotatethe burner head around the

burner base until it is level and

securely seated.

Burner Caps

IJfl off when cool. X&'ashburner caps

in hot, soapy water and rinse with clean

water: You may scour with a plastic

scorning pad to remove burned-on

food particles.

Burner Heads

Theshts /b theburnerheadsof your cooktop

mustbekept dean at a// times for an even,

unhamperedflame.

You should clean tile sm'fi_ce 1)urne_

routinely, especially after bad spilh)vers,

which could clog these openings, Lift off

when cool,

To remove bm'ned-on fi)od, soak tile

bm'ner heads in a solution of mild

liquid detergent and hot water fi)r

20-30 mimltes. For nlore stubborn stains,

use a toothbrush.

Replacement

Tile burner heads and burner bases are

labeled A, B and C to aid reassembE.

Replace tile burner heads on tile bases

matching file letters. Replace tile calls on

the heads, Make sm'e that the caps and

heads are replaced in the correct location.

There is one small (A), two medium (B)

and one laroe_ (C) head and cap.

Medium Small

Head Head

andCap andCap

QB Ae

eB cO

Frontof Cooktop

I I

Medium Large

Head Head

andCap andCap

11

Careand cleaningof thecooktop.

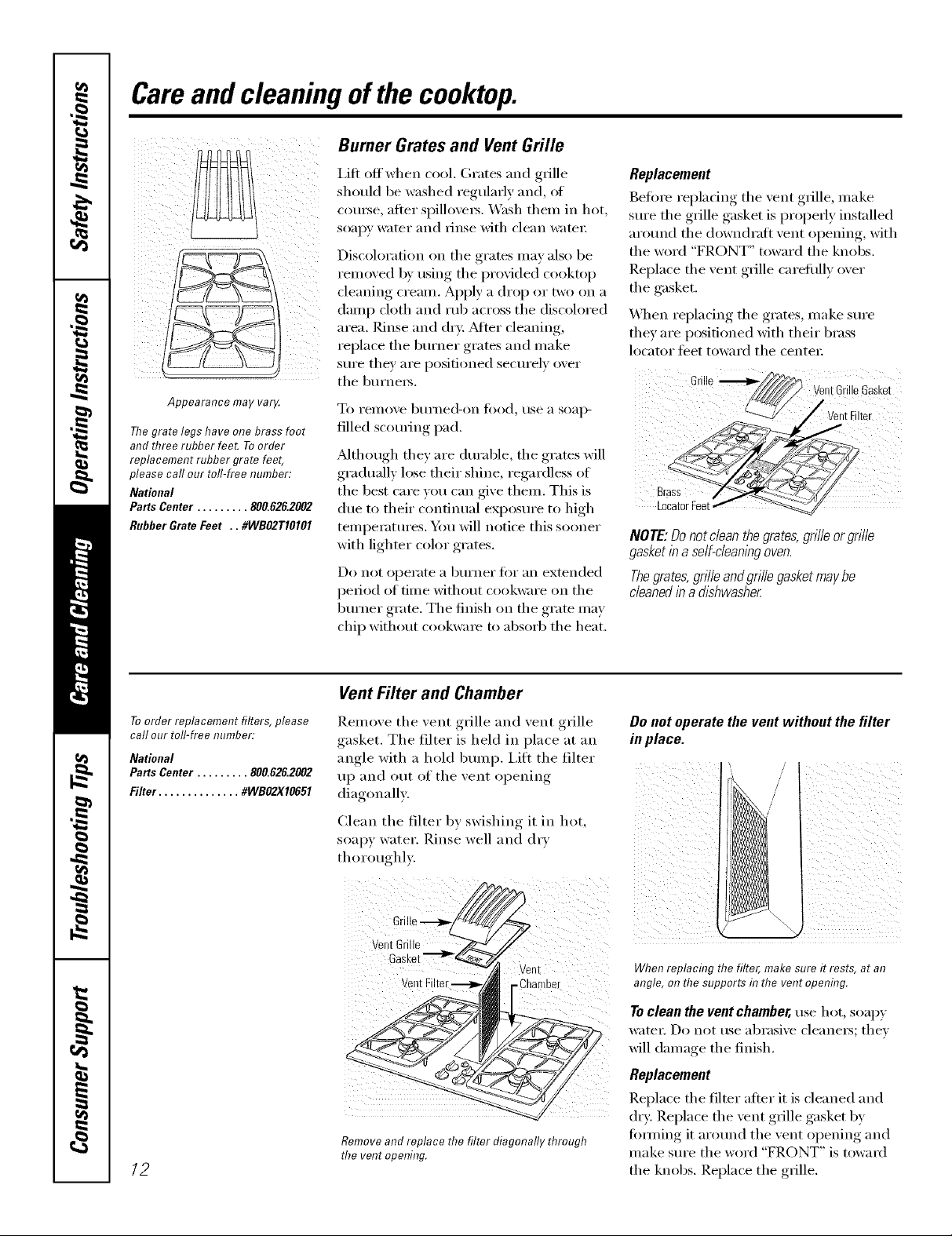

Burner Grates and Vent Grille

Appearance may var,A

Thegrate legs have one brass foot

and three rubber feet. Toorder

replacement rubber grate feet,

please call our toll-free number:

National

Parts Center ......... 800.626.2002

RubberGrate Feet .. #WBO2T10101

i,ifl off when cool. (;rates and grille

shouM be washed regularly and, of

coui_e, after spillove_. _'ash them in hot,

soapy water and i_nse with clean watei;

Discoloration on the grates may also be

removed by using the provided cooktop

cleaning cream. Apply a drop or two on a

damp cloth and mb across the discolored

area. Rinse and oh> _Mier cleaning,

replace the burner grates and make

sure they, are positioned securely, over

the burne_.

To i'elllO&e btlFned-on too(l, t/se a soap-

filled scom_ing pad.

_Mthough they are din'able, the grates will

gradually lose their shine, regardless of

the best care xou can gixe them. This is

due to their COllfinual exposure to high

temperatm'es. You will notice this sooner

with lighter color grates.

Do not operate a burner for an extended

period of time without cookware on the

burner grate. The finish on the grate may

chip without cookwa_e to absorb the heat.

Replacement

Before repladng the vent grille, make

sm'e the grille gasket is properly installed

arotmd the downdralt vent opening, with

the word "FRONT" toward the knobs.

Replace the vent grille carefully over

the gasket.

X._]mn replacing the grates, make sm'e

they are positioned with their brass

locator teet to_m'd the center

Grille__

Ven!Gri" Gasket

Br

LocaterFeet_ -'-_

NOTE'.Donot dean thegrates, grille or grille

gasketin a se/f-c/eanl)_goven.

Thegrates, grille andgri//egasket maybe

cleanedin a dishwashe_

Toorder replacement filters, please

call our toll-free number:

National

Parts Center ......... 800.626.2002

Filter .............. #WBO2X10651

12

Vent Filter and Chamber

Remove the vent grille and vent grille

gasket. The filter is held in place at an

angle with a hold bmni), i,ifl the filter

up and out of the vent opening

diagonall>

Clean the filter by swishing it in hot,

soapy water. Rinse well and d_T

thoroughl).

Remove and replace the filter diagonally through

the vent opening.

Donotoperate the vent withoutthefilter

inplace.

When replacing the filter, make sure it rests, at an

angle, on the supports in the vent opening.

Toclean the vent chamber, tlse hot, soapy

watex: Do not use abrasive cleanex_; thev

will damage the finish.

Replacement

Replace the filter after it is cleaned and

dry: Replace the vent grille gasket by

fimning it around the vent opening and

make sm'e the word "FRONT" is toward

the knobs. Replace the grille.

GEAppliances.com

Moldedflatarea

The control knobs may be removed

for easier cleaning.

Control Knobs

Beflwe removing the knobs fi_r

cleaning, please note that the knobs

are in the OFFposition. When replacing

the knobs, check the OFF position to

insure proper placement.

_'_sl_ knobs in soap and water but do not

soak. Avoid getting water down into the

knob stein holes.

Cleaningthe glasscooktop.

Normal Daily Use Cleaning

ONLY use CEIL_d_JlABRYTE _'Ceramic

Cooktop Cleaner on the glass cooktop.

Other creams ma_ not be as eflecfixe.

To maintain and protect the sm_i_ce _ff

yore" glass cooktop, tollow these steps:

[] getOre using the cooktop tot the

fi_t time, clean it with CEIL_d_4A

BRYTE '_Ceramic Cooktop Cleane_:

Cleanyourcooktopafter

eachspill. Use CERAMA

BRYTE® CeramicCooktop

Cleaner.

This helps protect the top and

makes clean-up easier:

[] Daft) use of CEI_/]A BRYTE (_)

Ceramic ('xx)ktop Cleaner will help

keep the cooktop looking ne_:

] Remoxe the burner grates, xent

grille aim xent grille gasket.

The knob stein is fiat on one side

(see illustration). Check the inside of

the knob and find the molded flat area.

Replace the knob by fitting the molded

fiat area inside the knob onto the fiat

area of the stem.

NOTE:Removeanyknobclipsthatremainon

thecontrolshaftsandreinsertinsideknobstem.

[] Shake the cleaning cream well.

Appl} a few drops of CEIL_dMA

BRYTE _ Ceramic Cooktop Cleaner

direcflv to the cooktop.

[] Use a p_per towel or CEI_L_dMA

BRYTE _-Cleaning Pad tot Ceramic

Cooktops to clean the entire

cooktop Stli-J[ilce.

[] Use a (h T cloth or paper towel

to remove all cleaning residue.

No need to rinse.

NOTE: It is very important that you DO NOT

heat the cooktop until it has been cleaned

thorough/_

Use a CERAMABRYTE'_ Cleaning

Pad for Ceramic Co&tops or a

Scotch-Brite ®Multi-Purpose No

Scratch blue scrub pad.

Burned-On Residue

WARNING'. DAMAGE to your glass surface

may occur if youuse scrub pads other than

the pad included with yourcooktop.

[] Allow the cooktop to cool.

] Remove the burner grates, xent

grille and vent grille gasket.

Spread a few drops of CERMMA

BRYTE ')Ceramic Cooktop Cleaner

to the entire bm'ned residue area.

Using the included CERAMA

[]

BRYTE _' Cleanin,, Pad fi)r Ceramic

Cooktops, mb the residue area,

aii))lxing,, pressure as needed.

[] If any residue remains, repeat the

steps listed above as needed.

[] For additional protection, after all

residue has been remoxed, polish

the entire sm'tace with CERAMA

BRYTE': Ceramic Cooktop Cleaner

and a paper towel.

13

Cleaningtheglass cooktop.

Heavy, Burned-On Residue

TheCERAMA BRYTE'*_Ceramic

Cooktop Scraper and all

recommended supplies are

available through our Parts Cente_

See flTstructions under "To Order

Parts" section below.

NOTE:Do not use a dull or

nicked blade.

[] Allow the cooktop to cool.

] Remoxe the burner grates, xent

grille and xent grille gasket.

[] Use a single-edge razor blade

scraper at approximately a 45 °

angle against the glass surtace and

scrape the soil. It will be necessary

to apply pressure to the razor

scraper in order to remove the

residue.

Metal Marks and Scratches

Be careflfl not to slide pots and pans

across your cooktop. It will leave metal

markings on the cooktop surtace.

These marks are remow_ble using

the CEI_&_MA BRYTE ': Ceramic

Cooktop Cleaner with the CERAMA

BRYTE '_Cleaning Pad fi_r Ceramic

Cooktops.

WARNING'. Carefully check the bottom

of pans for roughness that would scratch

the cooktop.

[] Afier scraping with the razor

scraper, spread a few drops of

CER,_d_/IA BRYTE ': Ceramic

Cooktop Cleaner to the entire

btu'ned residue area. Use the

CERAMA BRYTE _ Cleaning Pad

to remove any remaining residue.

[] For additional protection, alter all

residue has been remoxed, polish

the entire surtace with CERAMA

BRYTE': Ceramic Cooktop Cleaner

and a paper towel.

Glasssurface potential for permanent damage.

Our testing shows that if

you are cooking high sugar

mixtures such as jelly or

fudge and have a spillover,

it can cause permanent

damage to the glass surface

unless the spillover is

immediately removed.

14

Damage from Sugary Spills and Melted Plastic

[] Turn off all surtace burners and,

with an o',en Illitt, rei/lo',e hot

pans and grates.

[] XA'earing an oven mitt:

a. Use a single-edge razor blade

scraper (CERAMA BRYTE )

Ceramic Cooktop Scraper) to

move the spill to a cool area

on the cooktop.

b. Remove the spill with

paper towels.

To Order Parts

To order CERA_MA BRYTE _ Ceramic

Cooktop Cleaner and the cooktop

scrape_; please call our toll-free iltlillbei':

National Parts Center 800.626.2002

CERAMA BRYTE®

Ceramic Cooktop Cleaner .... # WXIOX300

[] Any remaining spilloxer should be

lett until the surthce of the cooktop

has cooled.

] Don't use the surtace units again

until all of the residue has been

completely removed.

NOTE: If pitting or indentation in theglass

surface has already occurred, the cooktop

glass will have to be rep/acecL/n this case,

service wifl be necessary

CERAMABRYTEc")

CeramicCooktopScraper ..# WXIOXO302

Kit ...................... # WB64X5027

(Kitincludescreamandrazorscraper)

CERAMABRYTE®CleaningPadsfor

CeramicCooktops........... #WXIOX350

Gas Downdraft

Ilnstallation

nstruct ons

If you have questions, call 800.GE.CARES (800.432.2737) or visit our Website at: GEAppliances.com

Cooktop

INTHECOMMONWEALTHOFMASSACHUSET[S:

• This product must be installed by a licensed

plumber or gas fitter.

• When using ball-type gas shut-off valves, they

shall be the T-handle type.

• A flexible gas connector, when used, must not

exceed 3 feet.

BEFORE YOU BEGIN

Read these instructions completely and carefully.

•IMPORTANT -Savetheseinstructions

for local inspector's use.

•IMPORTANT - Observeallgoverning

codes and ordinances.

• Note to Installer - Be sure to leave these

instructions with the Consumer.

• Note to Consumer - Keep these instructions for

future reference.

• Unless very knowledgeable in the installation of

this product, engage a professional installer.

• Proper installation is the responsibility of the

installer.

• Product failure due to improper installation is

not covered under the Warranty.

FOR YOUR SAFETY

If You Smell Gas:

1. Open windows.

2. Don't touch any electrical switches.

3. Extinguish any open flame.

4. Immediately call your gas supplier.

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

WARNING- Beforebeginning the

installation, switch power off at the service panel

and lock the service disconnecting means to

prevent power from being switched on accidentally.

When the service disconnecting means cannot be

locked, securely fasten a prominent warning device,

such as a tag, to the service panel.

IMPORTANT SAFETY INSTRUCTIONS

The cooktop has been design certified by CSA

International. As with any appliance using gas and

generating heat, there are certain safety precautions

you should follow. You'll find these precautions in the

Important Safety Information section in the front of

this Owner's Manual. Read them carefully.

• Be sure your cooktop is installed properly by a

qualified installer or service technician.

*The cooktop must be electrically grounded in

accordance with local codes, or in their absence,

with the National Electrical Code ANSI!NFPA

No. 70 - Latest Edition.

• Installation of this cooktop must conform with local

codes, or in the absence of local codes, with the

National Fuel Gas Code ANSI Z223.1 - Latest Edition.

• Improper installation, adjustment, alteration,

service or maintenance can cause injury or property

damage. Refer to this manual. For assistance or

additional information, consult a qualified installer,

service agency, manufacturer (dealer) or the gas

supplier.

• Disconnect electrical supply before servicing.

• Never reuse old flexible connectors. The use of old

flexible connectors can cause gas leaks and personal

injury. Always use NEW flexible connectors when

installing a gas appliance.

• Make sure the wall coverings around the cooktop can

withstand heat generated by the cooktop up to 200°E

•Avoid placing cabinets above the cooktop.

• If cabinets are placed above the cooktop, allow a

minimum clearance of 30" between the cooking

surface and the bottom of unprotected cabinets.

• If cabinets are placed above the cooktop, use

cabinets no more than 13" deep.

• If a 30" clearance between cooking surface and

overhead combustible material or metal cabinets

cannot be maintained, protect the underside of the

cabinets above the cooktop with not less than 1/4"

insulating millboard or gypsum board at least 3/16"

thick covered with 28 gauge sheet steel or 0.020"

thick copper.

• Clearance between the cooking surface and protected

cabinets MUST NEVER BE LESSTHAN 24."The

vertical distance from the plane of the cooking

surface to the bottom of adjacent overhead cabinets

extending closer than 1" to the plane of the cooktop

sides must not be less than 18."

15

Installation Instructions

UNPACKING YOUR COOKTOP

PARTS INCLUDED (PACKED BELOW THE COOKTOP)

• Blower assembly

• Blower plenum

• (4) Nuts

• (2) Hold-down retainers and

thumb screws

• (9) Sheet metal screws

• Foam gasket tape (9-ft. roll)

• Vent grille

• Vent filter

Sheet Metal

Screws (9)

Hold-Down

Retainers and

Screws

• Vent grille gasket

• Cleaning cream

• Scrub sponge or scraper

(on some models)

• Burner grates

• Burner heads

(1 small (A), 2 medium (B),

1 large (C))

Burner /[===(C===2j==_

Grate /_1

Vent Grille

• Burner caps

(1 small, 2 medium, 1 large)

• Gas pressure regulator

• Attached 120-volt grounded

plug cord

• LP Conversion

t2t

Regulator

Cleaning

Cream

CAUTION: GLASS

IS FRAGILE

DO NOT BUMP EDGE

OF GLASS DURING

INSTALLATION

Scrub Sponge

@

Foam Gasket Tape

Burner Caps and Burner Heads

Burner Cap and Burner Head

Vent Grille Gasket

CAUTION:

DO NOT LIFT

FROM VENT

OPENING

Burner Cap and Burner Head

Blower Assembly and Blower Vent

(4) Mounting Nuts 16 Plenum Filter

Installation Instructions

PREPARATION

TOOLS AND MATERIALS

YOU WILL NEED

• Saw

• Duct tape

• Measuring tape or scale

• Carpenter's square

• Adjustable wrench or socket set (7/16" socket and

ratchet)

• Drill and drill bit

• 1/4" nut driver

• Sheet metal screws

• Pipe wrench

• Manual gas line shut-off valve

• Pipe joint sealant that resists action of LP gas

• Ductworkto suit the installation

For rigid connection:

• Shut-off valve

• Union

• Pipe fittings as required

For flexible connection where local codes permit:

• Flexible metal tubing (same 3/4" or 1/2" I.D. as gas

supply line)

30" COOKTOP (DIMENSIONS FOR REFERENCE ONLY)

Unit shown fully assembled.

21%"

..,,,1_ 201/2,,_

Unit must be vented to the outside!

297/Z'

283/4"

V

I 6"

A

17

Installation Instructions

CABINET PREPARATION

[] PREPARING FOR INSTALLATION

Positioning the cooktop

The cooktop is designed to look best when centered

in a cabinet at least 30" wide.

The exhaust vent beneath the cooktop must be

located between wall studs or floor joists so that the

ductwork may be installed properly.

13" max._q_ 4

depth of _- |

unprotected S/L J I I

overhead HI I I I

cabinets _l I I I

| 30" min.

|clearance from 18" min. height

| countertop : from countertop

_-to unprotected to nearest cabinet

overhead surface on either side of

the unit

I

5" min.

clearance from

11/2"min. walls

cutout to side

---...jj

[] PREPARING THE BASE CABINET

This cooktop is designed to fit easily into a

variety of cabinets. However, the combined

installation of a downdraft vent and a cooktop

require careful consideration.

Some cabinets may require modifications.

This installation requires a 24" min. deep

cabinet base. The cabinet must be at least

30" wide.

Preparing a cabinet that is against a wall

In some cabinets, the sides may need to be

scooped or cut down 5s/4" as shown, and the

corner braces removed in order to

accommodate the unit.

In 75 cm and 90 cm frameless European

cabinets, the back panel may need to be cut

down 5s/4" to accommodate the unit.

Preparing a peninsula or island-type cabinet

In a peninsula or island type cabinet, the

sides may need to be scooped or cut down,

and the corner braces removed in order to

accommodate the unit.

The downdraft system with blower, motor and

ductwork will occupy the cabinet below the cooktop.

Drawers cannot be installed below this cooktop.

Avoid placing cabinets above the cooktop unit, if

possible, in order to reduce the hazards caused by

reaching over heated surface units.

If the cabinetry is used above the cooktop, allow a

minimum 30" clearance between the cooking surface

and the bottom of the unprotected cabinet.

If the clearance between the cooktop and the

cabinetry is lessthan 30", the cabinet bottom must

be protected with a flame retardant millboard at least

1/4" thick, or gypsum board at least 3/16" thick,

covered with 28 gauge sheet steel or 0.020" thick

copper. Clearance between the cooktop and the

protected cabinetry MUST NEVER BE LESS

THAN 24".

EXCEPTION: Installation of a listed microwave oven

or cooking appliance over the cooktop shall conform

to the installation instructions packed with that

appliance.

Working areas adjacent to the cooktop should have

an 18" minimum clearance between the countertop

and the bottom of the cabinet. If the clearance is less

than 18", the adjacent cabinets should be at least 5"

from the side edge of the cooktop.

53/4 ',

Approx.

53/4"Approx.

for

European

cabinets

18

Installation Instructions

CABINET PREPARATION CUTOUTS

[] PREPARING THE COUNTERTOP

The countertop must have a deep flat surface

to accommodate the cooktop and the vent.

Countertops with a rolled front edge and

backsplash may not provide the flat surface

area required.

Clearance between inside front of cabinet and

rear of countertop cutout must be 20%" in

order to accommodate cooktop depth.

23/8'' Min.

A 1/2" wide flat area is required around the

edge of opening for support of the unit. The

cooktop unit must be level and sit squarely

into countertop opening.

Carefully cut countertop opening according

to the dimensions shown in the illustration.

Be sure that opening is cut squarely, with

sides parallel to each other and rear exactly

perpendicular to sides.

20%"

287/8"

1%" Min.

Uin.

[] PREPARINGFOR DUCTWORK

NOTE: Ductwork MUST be vented to outside.

DO NOT vent into a wall, ceiling, crawlspace, attic or

any concealed space.

Cut hole in cabinet wall or floor as appropriate for

your installation. Make sure exhaust duct is located

between wall studs or floor joists.

NOTE: When cutting or drilling into wall or ceiling,

do not damage electrical wiring and other hidden

utilities.

91/8"

188/4,, ;1/8"

Rear Wall Venting

Downward Venting

[] BLOWERTO DUCTWORK ALIGNMENT

In general, the use of flexible ducting is discouraged

because it can cause severely restricted airflow.

However, if the blower outlet and the floor or wall

duct location do NOT align well, then flexible METAL

ducting can be used to adapt to an offset. Good

alignment without use of flexible ducting is best.

NOTE:

• Do not exceed the maximum recommended

offset of 6".

• Do not allow the flexible ducting to kink or collapse.

• Do stretch the flexible ducting as much as possible

to eliminate as much of the corrugation as possible.

m

_ 6" Max.

_1 Centerline -._ f; I_1 --

Offset _f

C_;n_°rline_ 1

Bottom Venting

A 31/4" x 10" rectangle to 6" round transition duct is

available at your local building supply store.

NOTE: Illustrations are for planning purposes only.

g

(Requires 31/4" x 10")

19

I

Back Venting

Calculate Total E(

Duct Pieces

(_ " round

C_ 6", 90 °

straight

31/4"x 10"

straight

elbow

Installation Instructions

DUCTWORK CALCULATIONS

uivalent Ductwork Length

Equivalent Number

Length* x Used =

1ft. x ( )*=

1ft. x ( F=

15 ft. x ( ) =

Equivalent

Length

Equivalent Number Equivalent

Duct Pieces Length* x Used = Length

to 31/4" x 10"

[_ 6" round

ft.

ft.

[_ 31/4" X 10"

ft.

transition

90° elbow 20 ft. x ( ) = ft.

31/4"x 10"

to 6" round

transition 5 ft. x ( ) = ft.

to 6" round

transition

90° elbow 12 ft. x ( )= ft.

6", 45°

elbow

24" max.

flexible

metal offset

adapter

31/4,,X10, "

90° elbow

31/4" X 10"

45° elbow

31/4,,X10, "

90° flat elbow

6" round

to 31/4" x 10"

transition

9ft. x ( )=

34 ft. x ( )=

16 ft. x ( ) =

5ft. x ( )=

18ft. x ( )=

7ft. x ( )=

Subtotal Column 1 =

*Equivalent lengths of duct pieces are based on

actual tests and reflect requirements for good

venting performance with any downdraft cooktop.

tMeasure and list feet of straight duct used. Count

and list the quantity of all other duct pieces for the

"Number Used" of each type.

IMPORTANT:

For maximum efficiency, use the shortest and

straightest duct run possible, with as few fittings

as possible. For satisfactory performance, the duct

run should not exceed 100 feet equivalent length.

Venting performance is improved by using larger

diameter duct.

wall cap

ft.

ft.

ft.

ft.

ft.

ft.

DO NOT use flexible plastic ducting.

6" round

with damper 21 ft. x ( ) = ft.

31/4" X 10"wall cap

with damper 27 ft. x ( ) = ft.

6" round

roof cap 20 ft. x ( ) = ft.

6" round

roof vent 24 ft. x ( ) =

Subtotal Column 2 =

Subtotal Column 1 =

TOTAL DUCTWORK =

Should not exceed 100 feet,

ft,

ft.

ft.

ft.

Vent installation should not exceed 100 feet

ft.

equivalent length.

2O

Installation Instructions

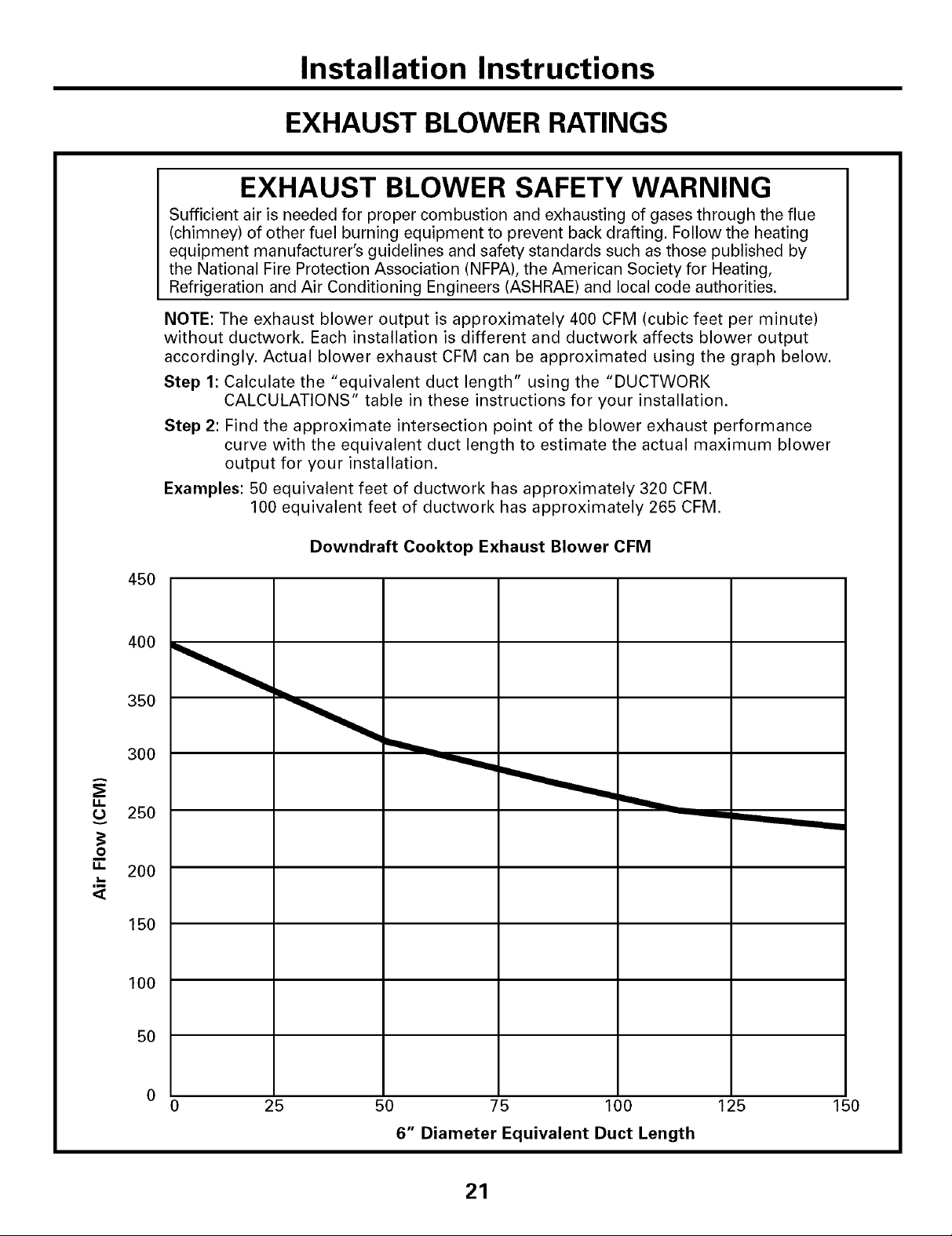

EXHAUST BLOWER RATINGS

EXHAUST BLOWER SAFETY WARNING

Sufficient air is needed for proper combustion and exhausting of gases through the flue

(chimney) of other fuel burning equipment to prevent back drafting. Follow the heating

equipment manufacturer's guidelines and safety standards such as those published by

the National Fire Protection Association (NFPA), the American Society for Heating,

Refrigeration and Air Conditioning Engineers (ASHRAE) and local code authorities.

NOTE: The exhaust blower output is approximately 400 CFM (cubic feet per minute)

without ductwork. Each installation is different and ductwork affects blower output

accordingly. Actual blower exhaust CFM can be approximated using the graph below.

Step 1: Calculate the "equivalent duct length" using the "DUCTWORK

CALCULATIONS" table in these instructions for your installation.

Step 2: Find the approximate intersection point of the blower exhaust performance

curve with the equivalent duct length to estimate the actual maximum blower

output for your installation.

Examples: 50 equivalent feet of ductwork has approximately 320 CFM.

100 equivalent feet of ductwork has approximately 265 CFM.

g.

L)

g.

,m

<[

Downdraft Cooktop Exhaust Blower CFM

45O

350

300

25O

O

200

150

100

50

25 50 75 100 125

6" Diameter Equivalent Duct Length

21

150

Installation Instructions

DUCTWORK INSTALLATION

(Note: For planning purposes only.)

[] INSTALLING THE DUCTWORK

Use galvanized or aluminum duct in 6" round

or 31/4" x 10" size, or a combination of both.

PVC duct should be used if installing under a

poured concrete slab.

NOTE: Local building code must be followed

in specifying approved type and schedule of

ALL duct used.

Always use an appropriate roof or wall cap

with damper. Laundry-type wall caps should

NEVER be used.

Through Cabinet Toe Space Between Floor Joist

Downward Venting

Install ductwork, making male-female

connections in the direction of airflow as

shown. Secure all joints with sheet metal

screws and duct tape to assure an airtight

seal.

Duct Tape Over Seam

-- and Screw

OPTIONAL INSTALLATION:

REAR WALL VENTING

5" round duct may be used on SHORT DUCT

runs of 3 feet or less, such as direct to outside

wall venting.

\

4

nside Wall to Roof Direct to Outside

Rear Wall Venting

To convert blower exhaust direction, remove

four nuts behind the filter which hold blower

and wire finger guard.

Rotate blower and reinstall to vent chamber,

as shown above. Retighten nuts, but do not

overtighten.

Screw

Use the shortest and straightest duct run

possible. For satisfactory performance the

duct run should not exceed 100 feet

equivalent length. Refer to TABLE 1 of

equivalent lengths. Use TABLE 1 to calculate

the total equivalent length of the ductwork.

22

Installation Instructions

POWER SUPPLY LOCATIONS

GAS SUPPLY:

These cooktops are designed to operate on

natural gas at 4" of water column pressure

or on LP gas at 10" of water column

pressure.

• These cooktops are shipped from the

factory set for natural gas. If you decide to

use this cooktop with LP gas, conversion

adjustments must be made by a service

technician or other qualified person.

• The pressure regulator must be connected in

series with the manifold of the cooktop and

must remain in series with the supply line

regardless of type of gas being used.

For proper operation, the maximum inlet

pressure to the regulator must be no more

than 10" water column pressure for natural

gas and 14" water column pressure for LP

gas.

• When checking the regulator, the inlet

pressure must be at least 1" greater than the

regulator output setting. If the regulator is

set for 4" of water column pressure, the inlet

pressure must be at least 5". If the regulator

is set for 10" of water column pressure, the

inlet pressure must be at least 11". For ease

of installation, and if local codes permit, the

gas supply line into the cooktop should be

1/2" or 3/4" ID flexible metal appliance

connector, three to five feet long.

NOTE: Purchase a new flexible line. DO NOT

USE AN OLD PREVIOUSLY USED LINE.

• Make gas connection through rear wall, or

on cabinet floor at rear, as illustrated.

ELECTRICAL SUPPLY:

outlet 12"

above

cabinet floor

(mount on

side or back

cabinet wall

2" min. from

centerline)

4" (to clear toe kick area)

The built-in gas downdraft cooktop features

pilotless electric ignition for energy savings

and reliability. It operates on a 120-volt,

60-Hz power supply. A separate circuit,

protected by a 15-amp time-delay fuse

or circuit breaker, is required.

• A properly grounded 3-prong receptacle

should be located within reach of cooktop's

four foot power cord.

IMPORTANT: (Please read carefully.) FOR

PERSONAL SAFETY, THIS APPLIANCE MUST

BE PROPERLY GROUNDED,

The power cord of this appliance is

equipped with a three-prong (grounding)

plug which mates with a standard three-

prong grounding wall receptacle to minimize

the possibility of electric shock hazard from

this appliance. The customer should have

the wall receptacle and circuit checked by

a qualified electrician to make sure the

receptacle is properly grounded and

has correct polarity.

Where a standard two-prong wall

receptacle is encountered, it is the personal

responsibility and obligation of the customer

to have it replaced with a properly grounded

three-prong wall receptacle.

Do Not, Under Any Circumstances, Cut Or

Remove The Third (ground) Prong From The

Power Cord.

Do not use an extension cord.

23

Installation Instructions

UNPACKING THE COOKTOP/INSTALLING THE GASKET

[] INSTALLING THE FOAM GASKET

Do not install the cooktop into the countertop

without installing the foam gasket as shown.

It protects the bottom edge of the glass from

the countertop and seals the cooktop against

spills.

Remove the cooktop along with its shipping

pad from the shipping box. Remove the

shipping block from the downdraft vent

opening and place it under the shipping

pad to provide level support.

Center vent shipping block -

place under the shipping pad

to provide level support

CAUTION: GLASS IS FRAGILE.

DO NOT BUMP EDGE OF GLASS DURING

INSTALLATION.

Foam Gasket Installation Notes:

• The foam gasket tape should be installed

within 1/8" of the edge of the glass. Do not

stretch or twist the foam gasket tape.

CAUTION: Failure to install

foam gasket tape greatly increases the

potential of breaking the cooktop glass

when installing, especially in Corian ® or

granite countertops,

• Use care not to stretch the foam gasket tape

while it is installed or it will not stay in

place.

• Do not place foam gasket tape over the

metal flanges.

• Butt the foam gasket tape ends together at

each corner without overlapping.

• Trim the foam gasket tape to length without

stretching.

• Mitre cut outside corners of foam gasket

tape slightly if necessary for appearance.

Locate the foam gasket tape included with

your cooktop.

Peel off the white backing to install the foam

gasket tape on the bottom side of the cooktop

glass as shown.

Foam

Gasket

Tape

1X' max. to

Glass Edge

• Do not scratch the glass while cutting the

foam gasket tape.

24

Installation Instructions

INSTALLING THE COOKTOP

[] INSTALLING THE COOKTOP

CAUTION:

DO NOT LIFT

FROM

VENT OPENING.

Lift the cooktop by the glass side edges as

shown.

NOTE: Do not use the glass top vent opening

to lift or move the cooktop into position.

[] CHECKING FOR FLATNESS

Inspect the cooktop glass for rocking

or uneven gap on all four sides at the

countertop surface. Do not attempt to

force the glass to meet the countertop.

If the cooktop is perfectly flat with the

countertop surface, skip to Step 10.

If there is any rocking or an uneven gap,

then use a 1/4"nut driver to loosen the

eighteen (18) sheet metal screws on the

bottom panels of the cooktop while it is

still in the countertop.

Lower the cooktop into the countertop

opening, guiding it into position. Glass is

fragile--do not allow it to drop onto the

countertop. Support from the underside and

lower slowly.

Carefully remove your fingers one corner at a

time to lower the cooktop into position.

NOTE: Do not use Silicone RTV or caulk to

bond cooktop glass to countertop.

Loosen each bottom panel screw 1 or 2

turns. After all eighteen (18) screws are

loosened, recheck the cooktop for flatness

with the countertop surface.

Gently bump your hand along the outside

edge of the cooktop if needed to help it

settle evenly onto the countertop surface.

Retighten all eighteen (18) sheet metal

screws.

25

Installation Instructions

INSTALLING THE COOKTOP

[] INSTALLING THE HOLD-DOWN

RETAINERS

NOTE: Check for glass flatness in Step 9

before installing hold-down retainers.

appropriate for Hold-

countertop thickness retainer

Hold-down retainer

J

!

_i¸¸_I!!iii!!i!!¸_!;_!

Countertop

Thumb screw

Secure cooktop to the counter using the

hold-down retainers and thumb screws

shipped with the unit (one on each side,

or one on front and one on back).

/_

/

I-_ INSTALLING THE BLOWER TO

THE PLENUM

Orient the blower discharge opening to

match the ductwork in Steps 5 and 6. Slide

the four threaded studs on the side of the

blower housing into the four holes on the

side of the plenum.

NOTE: See Step 13 for installing the transition

duct to the blower, It may be easier to install

the transition duct to the blower before

installing the blower to the plenum.

down

[] INSTALLING THE BLOWER

PLENUM TO THE COOKTOP

Slide the plenum, with the blower opening on

the left, into the opening in the bottom of the

cooktop. Push up on the plenum until the

stops on the plenum contact the bottom of

the cooktop, and snap the plenum into place.

(You may have to move the plenum back and

forth to work it into place.)

Secure the plenum to the bottom of the

cooktop, on each side, using the four (4)

screws provided. Further secure the plenum

to the cooktop, from the top side, using the

two screws (2) provided.

From the vent opening in the top of the

cooktop, fasten the blower assembly securely

to the plenum with four (4) nuts,

4 Nuts

(7/16"

socket

126

Installation Instructions

INSTALLING THE COOKTOP

[] ATTACHING A BLOWER

TRANSITION DUCT

Use a blower transition duct for all downward

duct installations to connect to 6" round

standard ductwork. This 31/4" x 10" rectangle

to 6" round transition duct is available at

your local building supply store.

/ CreoV_he r

side)

Install the transition duct to the blower outlet.

Secure all joints with duct tape to assure an

airtight seal.

CONNECTING THE DUCTWORK

Connect the ductwork prepared in Steps 5 and

6 to the blower transition duct.

27

Installation Instructions

INSTALLING THE COOKTOP

[] INSTALL THE PRESSURE

REGULATOR

__ Regulator

Solid piping or

flexible connector

_ _------ Union

Solid piping

or flexible

Shut-off

va Ive

• Install the supplied pressure regulator in the gas line

as close to the cooktop inlet as possible. Allowances

for ventilation ducting may be necessary.

Make sure the regulator is installed in the right

direction.

• Install a manual shut-off valve in the gas line in an

easily accessible location.

NOTE: Instead of using solid piping to connect to

pressure regulator, an approved flexible metal

appliance connector may be used between the

shut-off valve and the pressure regulator, if local

codes permit.

Appropriate flare nuts and adapters are required at

each end of the flexible connector.

__ onnector

Pipe stub

TEST FOR LEAKS

INSTALL THE PRESSURE

REGULATOR (cont.)

IMPORTANT: Disconnect the cooktop and the

individual shut-off valve from the gas supply piping

system during any pressure testing of that system

at test pressures greater than 1/2 psig. Isolate the

cooktop from the gas supply piping system by

closing the individual manual shut-off valve to the

cooktop during any pressure testing of the gas

supply piping system at test pressures equal to or

less than 1/2 psig.

[] BLOWER ELECTRICAL

CONNECTIONS

• Loosen the two screws and remove and discard the

sheet metal connector cover on the cooktop bottom.

Save the screws for reinstallation later.

• Connect the 5-pin plug on the blower assembly to

the matching 5-pin receptacle on the bottom of the

cooktop.

\

5-pin

connectors

WARNING:Do NOT USE A FLAME TO CHECK

FOR GAS LEAKS! Do not use the cooktop until all

connections have been leak tested.

Perform leak test per the following instructions:

1.Purchase a liquid leak detector or prepare a soap

solution of one part water, one part liquid detergent.

2.When all connections have been made, make sure

all cooktop controls are turned to OFF and turn the

gas supply valve to ON.

3.Applythe liquid leak detector or the soap solution

around all connections from the shut-off valve to the

cooktop.

4.A leak is identified by a flow of bubbles from the

area of the leak.

5.If a leak is detected, turn the gas supply off. -lighten

the fitting. Turn the gas on and test again.

If the leak persists, turn the gas supply off and

contact your dealer for assistance. Do not attempt to

operate the cooktop if a leak is present.

Fold all wires into the electrical enclosure. Secure

the enclosure with the screws removed earlier,

making sure that no wires are trapped.

• Plug the cooktop cord set into a suitable electrical

outlet. See step 17.

28

f

"_5-pin

connectors

--Electrical

enclosure

_t

Flexible

Installation Instructions

ELECTRICAL CONNECTIONS

[] ELECTRICAL REQUIREMENTS

120-volt, 60-Hertz, properly grounded branch

circuit protected by a 15-amp or 20-amp circuit

breaker or time-delay fuse.

EXTENSION CORD CAUTIONS

Because of potential safety hazards associated

with certain conditions, we strongly recommend

against the use of an extension cord. However, if

you still elect to use an extension cord, it is

absolutely necessary that it be a UL-listed, 3-wire

grounding-type appliance extension cord and

that the current carrying rating of the cord in

amperes be equivalent to, or greater than, the

branch circuit rating.

GROUNDING

IMPORTANT m (Please read carefully.)

FOR PERSONAL SAFETY, THIS APPLIANCE

MUST BE PROPERLY GROUNDED.

Preferred Method

An adapter may be used only on a

15-amp circuit. Do not use an adapter on

a 20-amp circuit. Where local codes permit,

a TEMPORARY CONNECTION may be made

to a properly grounded two-prong wall

receptacle by the use of a UL-listed adapter,

available at most hardware stores. The larger

slot in the adapter must be aligned with the

larger slot in the wall receptacle to provide

proper polarity in the connection of the

power cord.

Temporary Method

(Adapter plugs not permitted in

Canada)

Align large prongs/slots

Ensure proper

ground and

firm connection

before use

Ensure proper ground

exists before use

The power cord of this appliance is equipped

with a three-prong (grounding) plug which

mates with a standard three-prong grounding

wall receptacle to minimize the possibility of

electric shock hazard from this appliance.

The customer should have the wall receptacle

and circuit checked by a qualified electrician to

make sure the receptacle is properly grounded.

Where a standard two-prong wall receptacle is

encountered, it is the personal responsibility and

obligation of the customer to have it replaced

with a properly grounded three-prong wall

receptacle.

DO NOT, UNDER ANY CIRCUMSTANCES,

CUT OR REMOVE THE THIRD (GROUND)

PRONG FROM THE POWER CORD.

-&CAUTION: Attaching the adapter

ground terminal to the wall receptacle

cover screw does not ground the

appliance unless the cover screw is metal,

not insulated, and the wall receptacle is

grounded through the house wiring, The

customer should have the circuit checked

by a qualified electrician to make sure the

receptacle is properly grounded.

When disconnecting the power cord from the

adapter, always hold the adapter with one

hand. If this is not done, the adapter ground

terminal is very likely to break with repeated

use. Should this happen, DO NOT USE the

appliance until a proper ground has again

been established.

29

Installation Instructions

FINAL ASSEMBLY

[] ASSEMBLE BURNERS,

CHECK IGNITION

Assemble burner as shown.

Ora

//_'-//,= Curved side

/__l _ toward the

_# !f _1 _4 center

@ Burner cap

rode

_//_ec/t _ Burner head

CAUTION:Do not operate the burner without

all burner parts in place.

Medium _o-_

Head ""_

and Cap _ B

Medium

Head ---%_

and Cap (_ B

eB A= AO Small

eB c • __"_Large

Front of Cooktop c

Burner base

Head

and Cap

Head

and Cap

INSTALLDOWNDRAFT FILTER,

VENT GASKETAND VENT GRILLE

Do not operate the vent without the filter in place.

• Place the filter diagonally through the vent

opening.

Vent Filter

Vent

-Chamber

• Make sure it rests, at an angle, on the supports in

the vent opening.

Place the burner heads on the burner bases

matching the letters. Place the caps on the heads.

Make sure that the heads and caps are placed on the

correct size burner. The

burner heads and burner

bases are labeled A, B and

C to aid reassembly. There

is one small (A), two

medium (B) and one large

(C) head and cap.

Make sure the notch in the burner head is positioned

toward the electrode. Rotate the burner head around

the burner base until it is level and securely seated.

Place the grates over the burners.

Check for proper ignition:

• Push in one control knob and turn to LITE position.

• The igniter will spark and the burner will light; the

igniter will cease sparking when the burner is lit.

• First test may require some time, while air is

flushed out of the gas line.

• Turn knob to OFF.

• Repeat the procedure for each burner.

• Fit the vent grille gasket around the edge of the

downdraft vent opening. Make sure the front of the

gasket is installed toward the front of the cooktop.

• Carefully place the vent grille onto the gasket on

the downdraft opening.

G rille,_-_ Vent Grille

et

CHECK OPERATION OF DOWNDRAFT

• Turn the vent fan speed control to HI, MED and

LO to make sure all speeds operate correctly.

'30

Before YouCallForService...

Troubleshooting -tips

Save time and money! Review the chart on this page

first and you may not need to carl for service.

GEAppliances.com

Possible Causes

Waterwon'tboil

What To Do

• Cover pan with a lid.

• Turn the downdrafl tim OFF until the water begins

to boil.

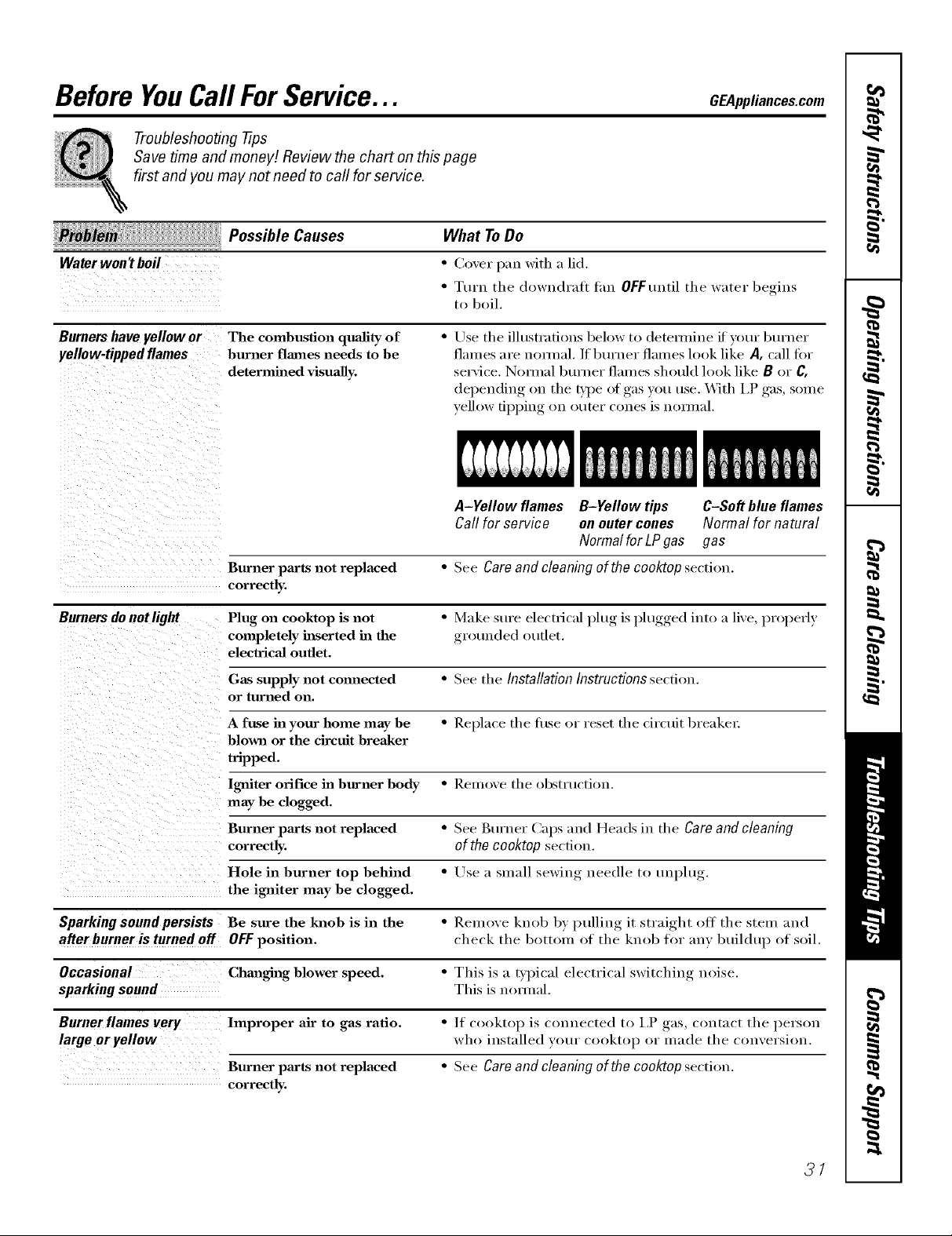

Burners have yellow or

yellow-tipped flames

The combustion quality of

burner flames needs to be

determined visually.

• Use tile illustrations below to detemfine if yore" bm'ner

flames are nomml. If bm'ner flames look like A, call fin"

service. Nornlal burner flalnes should look like B or C.

depelMing on tile ITpe ot gas you use. X._]th I.P gas, some

yellow tipping on outer cones is nomml.

A-Yellow flames B-Yellow tips C-Soft blue flames

Callfor service on outercones Normal for natural

NormalforLPgas gas

Burner pm'ts not replaced • See Careand cleaningof thecooktopsection.

correctly.

Burners do notlight Plug on cooktop is not • Make sure electrical l)blg, is l)lugged,, into a lixe, properl)

completely h_serted ha the groulMed outlet.

electrical outlet.

Gas supply not comaected • See the Installation Instructions section.

or turned on.

A fuse in your home may be • Replace tile fllse or reset tile circuit breakei:

blown or the circuit breaker

tripped.

Igniter orifice ha burner body " Remoxe tile obstruction.

may be clogged.

Burner paxts not replaced • See gm'ner (_aps and Headsin the Careand cleaning

correctly, ofthecooktop section.

Hole in burner top behind • Lrse a slnall ,sewino_ needle to unl)lu_,

the i_fiter may be clogged.

Sparking sound persists Be sure the knob is in the • Reulo_e knob b) I)ullin°_ it straight off tile stein and

after burner is turned off OFFposition, check tile bottoln of tile knob for _lIl} buildu I) of soil.

Occasional Chmaghag blower speed. " This is a t}pical electrical switching noise.

sparking sound This is nomml.

Burner flames very huproper air to gas ratio. • If cooktop is connected to 12 gas, contact tile person

large oryellow who installed your cooktop or inade tile con'_ersion.

Bunaer paxts not replaced " See Care and cleaning ofthe cooktopsection.

correctly.

31

Before YouCall ForService...

Troubleshooting -tips

Possible Causes

Controlknobs

Controls improperly set. To turn fi'om the OFF position, push the knob in

will notturn

Fan does not work The fan control knob is • Turn knob in clockwise direction to turn tim on.

improperly set.

Cord improperly cmmected • Check c(muecti(ms. Turn (>n l)ower at tile fl/se box.

or power turned off.

Poor venting Clogged filter. • Clean filter per instructions.

House too airtight. • Open a window slightly to in'oxide fresh air source.

Wall cap obstructed. • Remove blockage fl'om exterior wall Cal).

Wall cap damper door stuck. • Check eXtelJOl _wall cap (lmnl_er door fi)r fl'ee movement

Duct length exceeds • Reduce Ut/lllbeI" of elbows to siInplit_' duct l't/u.

recommended 100

equivalent foot maximum.

Scratches (mayappear Incorrect clemfii_g * Scratches are not removable. Tiny scratches will become

as cracks) on cooktop methods being used. less visible in tim e as a result of cleaning.

glass surface

Cookware with rough bottoms * To avoid scratches, t/se the i'eCOlHllleuded cleauiug

being used or coarse particles procedures. Make St/l'e bottoIilS of cookwm'e are clean

(salt or sand) were between befi)re rise, aud t/se cookwaYe with smooth bottoms.

the cookware and the surface

of the cooktop.

Cookware has been slid

across the cooktop surface.

What To Do

and then ttu'n. The knob can only be ttu'ned in a

counterclockwise direction. _*Vhen the knob is at any

other position, it can be turned in either direction

without being pushed in.

01" ()bstll/ctiou,

Areas of discoloration Food spillovers not cleaned * See tile Cleaningthe glass cooktop section.

on the cooktop before next use.

Hot surface on a model • This is normal. Tile surface may appear discolored

with a light colored cooktop, when it is hot. This is teml)oraI T and will disappear

as the glass cools.

Plastic melted to Hot cooktop came into • See tile Glass surface--potential for permanent damage

the surface contact with plastic placed sectiou in the Cleaning the glass cooktop sectiou.

on the hot cooktop.

Pitting (or indentation) Hot sugar mixture spilled * Call a qualified technician for replacement.

of the cooktop on the cooktop.

32

GE Service Protection Plus rM

GE, a name recognized worldwide _br quality and dependability; oflers y'ou

Service Protection Plus'"--comprehensive protection on all y'our appliances--

No Matter What Brand!

Benefits Include:

• Backed by GE

• All brands covered

• Unlimited service cars

• All parts and labor costs included

• No out-of-pocket expenses

• No hidden deductibles

• One 800 number to call

You will be c()mpletel,_ satisfied with our serxice protection or you may request }our inonev back

on tile remaining xalue of _o/u" contract. No questions asked. It's that simple.

Protect vom" refl_igerat(m dishwasher; washer and (hTe_; range, TV, VCR and much more--any brmad!

Plus there's iso extra charge tot eulergency ser;'ice and low monthly financing is available. Even icemaker

coverage and tood spoilage protection is offered. You can rest eas> knowing that all vom" valuable

household products are protected against expensive repairs.

Place your confidence in (;E and call us in tile Ij.S. toll-free at _tlU._)Z_).ZZZ/-]:

for inoi'e infoi'u/ation,

*-M1lmmds cov<_<d, up Io 20 ?'<a_ old, in Ih< <onlinental U.S.

We71CoverAnyAppliance.

Anywhere. Anytime.*

__ _C/_ll'h__2e............

Please place in envelope and mail to:

General Electric Company

Warranty Registration Department

EO. Box 32150

Louisville, KY 40232-2150

33

Consumer Product Ownership Registration

Dear Customer:

Thank you for purchasing our product and thank you for placing your confidence in us.

_A/eare proud to ha_e you as a customer!

Follow these three steps to protect your

Important: If you did not get a registration card with your

................................................................................................... _,,,._ (MI h(r(

new appliance investment:

Complete mid mail

your Constuner

Product Owuership

Registration today.

t]a_e the t)eace o/

mind of knowing we

c_ln contact you ill

th( unlikely (v(nt of

a sa/(q_ modification.

AJler mailing tile

registration below,

store this do( ument

in a sa/(' pla_ c. It

contains intormation

you will need should

you require scrvi(e.

Our scrvi_ e nmnber is

800.GE.(2\RES

(800.432.2737).

Model Number Serial Number

, , , , , I I , , , , , , , I

product, detach and return the form below to

ensure that your product is registered, or register

online at GEAppliances.com.

[_ca(t VO/IF Owl/er's

Mamml carefully.

It will hel t) you

ot)era|e your new

at)t)liame t)rot)erly.

Consumer Product Ownership Registration

Serial Number

I,,,,,, , , , , , I

MI: [ Ms. M*_. Mixs

Fir_,l I I L_Sl]