Page 1

Questions? Call 800.GE.CARES (800.432.2737) or Visit our Website at: www.GEAppliances.com

LP Conversion Gas Cooktop

Instructions

JGP985

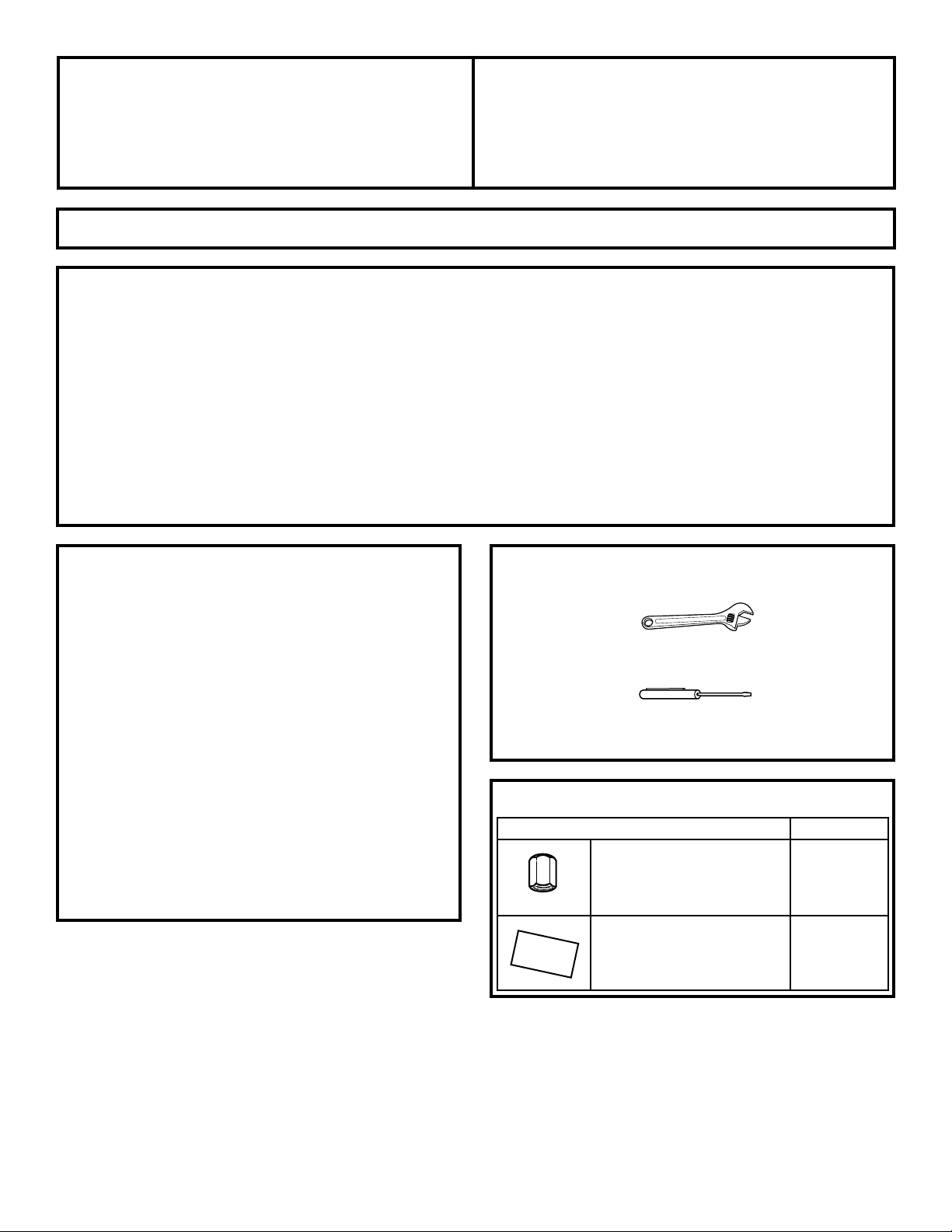

Adjustable wrench

PART QUANTITY

Brass orifices 4

Stick-on conversion label 1

Small, thin-blade flat screwdriver with approximately 1/8″

blade width is needed to access the calibration screw.

49-80298

4226-0018-00

01-05 JR

Printed in Korea

1

BEFORE YOU BEGIN

Read these instructions completely and carefully.

•

IMPORTANT – Save these instructions for

local inspector’s use.

•

IMPORTANT – Observe all governing codes

and ordinances.

• Note to Installer – Be sure to leave these instructions

with the Consumer.

• Note to Consumer – Keep these instructions

for future reference.

• This cooktop is factory set for natural gas operation.

Conversion to LP operation should be performed by a

qualified technician or installer. Keep these instructions

for future reference. When converting to LP, save the

original parts for possible future use.

• Product failure due to improper installation is not covered

under the GE Appliance Warranty.

FOR YOUR SAFETY

WARNING – If you are using LP (bottled) gas,

all adjustments described in the following steps must be

made before attempting burner adjustments or use of the

cooktop.

WARNING – This conversion kit shall be

installed by a qualified service agency in accordance with

the manufacturer’s instructions and all applicable codes

and requirements of the authority having jurisdiction.

If the information in these instructions is not followed

exactly, a fire, explosion or production of carbon

monoxide may result, causing property damage, personal

injury or loss of life. The qualified service agency is

responsible for the proper installation of this kit. The

installation is not proper and complete until the operation

of the converted appliance is checked as specified in the

manufacturer’s instructions supplied with the kit.

TOOLS YOU WILL NEED

PARTS INCLUDED

Page 2

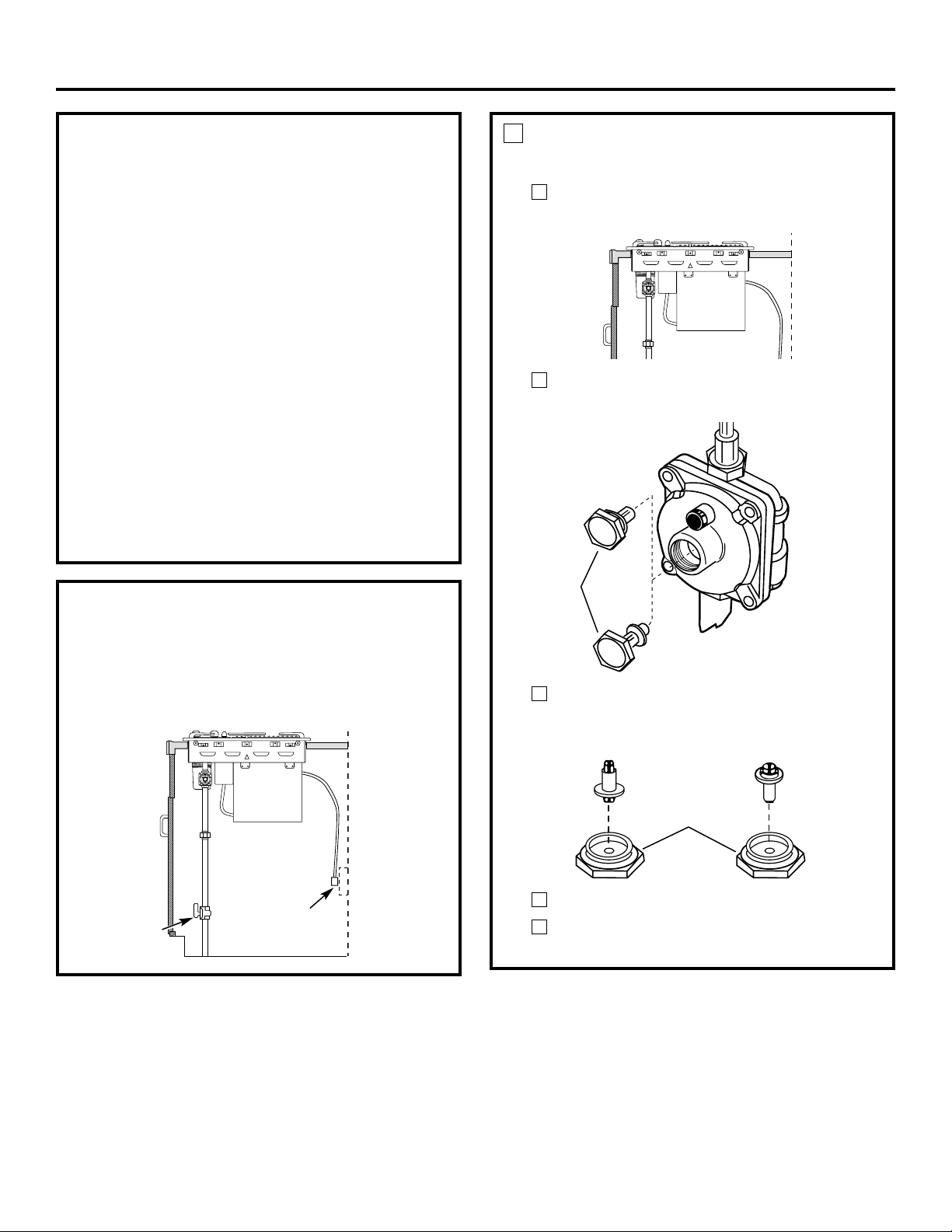

CONVERT THE PRESSURE REGULATOR

Locate the pressure regulator under the front of

the cooktop.

Remove the nut from the pressure regulator with

an adjustable wrench.

Remove the plastic pin from the inside of the

nut, turn the pin 180° and snap the pin back

into the nut.

Re-install the nut onto the regulator.

Apply the LP Conversion label next to the

Rating Plate.

E

D

C

B

A

1

2

LP Conversion Instructions

Nut

Natural gas

LP gas

Nut

Natural gas LP gas

GAS SUPPLY

• With the installation of this conversion kit, the cooktop

should operate on LP gas at 10″ of water column

pressure.

• The pressure regulator must be connected in series

with the manifold of the cooktop and must remain in

series with the supply line. For proper operation, the

maximum inlet pressure to the regulator must be no

more than 14″ water column pressure for LP gas.

• When checking the regulator, the inlet pressure must

be at least 1″ greater than the regulator output setting.

If the regulator is set for 10″ of water column pressure,

the inlet pressure must be at least 11.″

IMPORTANT – Disconnect the cooktop

and the individual shut-off valve from the gas supply piping

system during any pressure testing of that system at test

pressures greater than 1/2 psig. Isolate the cooktop from

the gas supply piping system by closing the individual

manual shut-off valve to the cooktop during any pressure

testing of the gas supply piping system at test pressures

equal to or greater than 1/2 psig.

TURN OFF GAS AND ELECTRIC SUPPLY

BEFORE YOU BEGIN, TURN OFF THE GAS SUPPLY

AT THE SHUT-OFF VALVE. DISCONNECT THE

ELECTRICAL SUPPLY FROM THE COOKTOP.

Shut-off valve

Electrical supply

Page 3

CHECK IGNITION

Connect electrical supply cord.

Turn on the gas; check for leaks using a liquid leak

detector at all joints in the system.

WARNING: DO NOT USE A FLAME

TO CHECK FOR GAS LEAKS.

Push in one control knob and

turn to the LITE position. The

igniter will spark and the burner

will light. The first test may

require some time while air is

flushed out of the gas line. After

ignition, turn the control knob to

the HI position and wait until the flame settles.

Check to determine if your burner flames are

normal. If burner flames look like A, turn off the

burner and make sure all parts are assembled

correctly. Reassemble and check.

Normal burner flames should look like B or C,

depending on the type of gas you use. With LP gas,

some yellow tipping on outer cones is normal.

Turn the knob to OFF.

Repeat the procedure for each burner.

E

D

C

B

A

4

ADJUST GRILL BURNER AIR SHUTTER

The air shutters for the grill burner may need to

be adjusted to get better flame appearance and

ignition. The air shutters for the grill burner are

located on the bottom of the grill burner. To access

the air shutters, remove the grill grate, and then the

grill burner. Slide air shutter backward or forward

to increase or decrease the size of the air opening.

Air shutters fit snugly on the grill burner, so a

screwdriver blade may be required to make this

adjustment (see illustration). The snug fit of the air

shutter assures it will remain positioned correctly.

3

CONVERT SURFACE BURNERS

Remove all grates and burner modules.

With an adjustable wrench or an open end

wrench, remove the brass orifices.

Find the inscribed LP orifices in the holder in the

front of the electric cover beneath the cooktop.

Install the inscribed LP orifices in place of the

natural gas orifices.

Replace the burner modules and grates.

Keep all the spuds with your cooktop so you have

them if you move or get a different gas hook-up.

F

E

D

C

B

A

2

3

LP (Propane) Gas 10″ W. C . P.

Burner Output Rating in BTU/HR

Location BTUs Orifice Size Engraving

Left Rear (LR) 9,100 .0354 LP

Left Front (LF) 9,100 .0354 LP

Right Rear (RR) 9,100 .0354 LP

Right Front (RF) 9,100 .0354 LP

Turn counterclockwise to remove

Orifice

Turn clockwise to tighten

Air shutter

Insert screwdriver blade in

slot and twist with slight

pressure to allow air shutter

to slide easily

A–Yellow flames

Not normal;

check alignments

B–Yellow tips

Normal for

LP gas

C–Soft blue flames

Normal for

natural gas

LP Conversion Instructions

Page 4

CONVERTING BACK TO NATURAL GAS

To convert the cooktop back to natural gas, reverse

the steps taken to convert to LP.

Once the conversion is complete and checked OK,

fill out the LP sticker and include your name,

organization and date conversion was made. Apply

the sticker near the cooktop gas inlet opening to

alert others in the future that this appliance has been

converted to LP gas. If converting back to natural gas

from LP, please remove the sticker so others know

the appliance is set to use natural gas.

NOTE: For operation at elevations above 5000 ft.

(1500 m), equipment ratings shall be reduced at a

rate of 2% for each 1000 ft. (300 m) above sea level

before selecting appropriately sized equipment, i.e.:

Use smaller orifices.

6

ADJUST THE LOW FLAME (SIMMER) SETTING

The top burner valves have low flame/simmer

adjustment screws accessible through the valve

switches. A flashlight may be needed to locate the

screw. A small, thin-blade screwdriver (approximately

1/8″ blade width) is needed to access the screw.

Light two other burners and set the knobs to

a medium to high setting.

Light the burner to be adjusted and turn the knob

to LOW.

To make adjustment, remove the control knobs.

Insert a screwdriver through the access hole in

the valve switch. Engage the adjustment screw

in the valve.

If the flames were

too small or fluttered,

open the valve more

than the original setting.

If the flames are too

large, close the valve

more than the original

setting.

Make the adjustment by slowly turning the screw

until the flame appearance is correct. For the left

side, install the grill burner for the adjustment.

The left side cannot be turned down as low as the

right side if the grill burner is to be used.

Adjust the low flame setting using the valve bypass

screw as follows:

Low setting adjustments must be made with two

other burners in operation on a medium setting.

This prevents the low flame from being set too low,

resulting in the flame being extinguished when

other burners are turned on.

Testing Flame Stability:

Test 1: Turn the knob from HI to LOW quickly.

If the LOW flame goes out, increase the

flame size and test again.

Test 2: With the burner on the LOW setting,

open and close the cabinet door under the

cooktop. If the flame is extinguished by the

air currents created by the door movement,

increase the flame height and test again.

Test 3: With the burner on the LOW setting, turn

the downdraft vent fan to the HI position.

If the flame is extinguished by the air

currents created by the downdraft vent fan,

increase the flame size and test again.

E

D

C

B

A

5

4

Natural Gas 5″ W. C . P.

Burner Output Rating in BTU/HR

Location BTUs Orifice Size Engraving

Left Rear (LR) 10,000 .0550 NAT

Left Front (LF) 10,000 .0550 NAT

Right Rear (RR) 10,000 .0550 NAT

Right Front (RF) 10,000 .0550 NAT

LP Conversion Instructions

ADJUST THE LOW FLAME

(SIMMER) SETTING

(cont.)

Flame Recheck:

Repeat the adjustment for each burner. After the

adjustment is made, turn all burners off. Ignite

each burner individually. Observe the flame at the

HI position. Rotate the valve to the LOW position

and be sure that the flame size decreases as the

valve is rotated counterclockwise.

F

5

Loading...

Loading...