Page 1

ADJUSTING

BURNER FLAMES

1. Turn all burners full on and check the

flames. They should be blue in color with

some yellow tipping at the ends of the

flame. Foreign particles in the gas line

may cause an orange flame at first, but

this will soon disappear.

NOTE: For the 18,000 BTU/HR burner

(on some models) the cooktop burner

knob should be turned to the setting

before the lowest setting. This will

ensure that the entire burner is

operating.

2. Turn the cooktop burner knob to the

lowest setting while observing the

flame.

Adjust the low flame setting using the

valve bypass screw as follows:

Low-setting adjustments must be made

with two other burners in operation on

a medium setting. This prevents the low

flame from being set too low, resulting in

the flame being extinguished when other

burners are turned on.

3. To adjust the

flame, remove

the knobs. Insert

a screwdriver

through the

access hole in

valve switch.

Engage

adjustment

screw in valve.

Refer to the

illustration

at right that

matches the

adjustment

screw location

for your model.

18K burner

only

a. If the flames were too small or

fluttered, open the valve more than

the original setting.

b. If the flames blew away from the

burner, close the valve more than the

original setting.

4. Make the adjustment by slowly turning

the screw until flame appearance is

correct.

Note: Some models may contain a

silicone shield which covers the valve

switch and access hole. A flashlight may

be required to locate the access hole. To

access the valve adjusting screw, push

the screwdriver through this shield. After

adjustment, reseat the shield around

the switch hub with your fingers, after

withdrawing the screwdriver.

Reseat silicone shield

CORRECT INCORRECT

5. Testing flame stability:

Test 1 – Turn the knob from “HI” to the

lowest setting quickly. If the flame goes

out at the lowest setting, increase the

flame size and test again.

Test 2 – With the burner on the lowest

setting, open and close the cabinet

door under the cooktop. If the flame is

extinguished by the air currents created

by the door movement, increase the flame

height and test again.

6. Flame recheck:

After the adjustment is made, turn all

burners off. Ignite each burner individually.

Observe the flame at the “HI” position.

Rotate the valve to the lowest setting and

be sure that the flame size decreases as

the valve is rotated counterclockwise.

TO CONVERT THE COOKTOP BACK TO

NATURAL GAS, REVERSE THE STEPS

UNDER MAKING THE L.P. CONVERSION.

Once the conversion is complete and

checked ok, fill out the LP sticker and

include your name, organization and

date conversion was made. Apply

the sticker near the cooktop gas

inlet opening to alert others in the

future that this appliance has been

converted to LP. If converting back to

natural gas from LP, please remove

the sticker so others know the

appliance is set to use natural gas.

The L.P. orifice spuds for the cooktop burners

are attached to the regulator along with

separate LP conversion instructions.

CAUTION: The counter unit, as

shipped from the factory, is set for

use with natural gas. If you wish

to use your unit with Liquefied

Petroleum (Propane) gas, you must

first replace the orifices and convert

the pressure regulator.

WARNING: This conversion must be

performed by a qualified installer or

gas supplier in accordance with the

manufacturer’s instructions and all codes

and requirements of the authority having

jurisdiction. Failure to follow instructions

could result in serious injury or property

damage. The qualified agency performing

this work assumes responsibility for the

conversion.

L.P. CONVERSION

INSTRUCTIONS

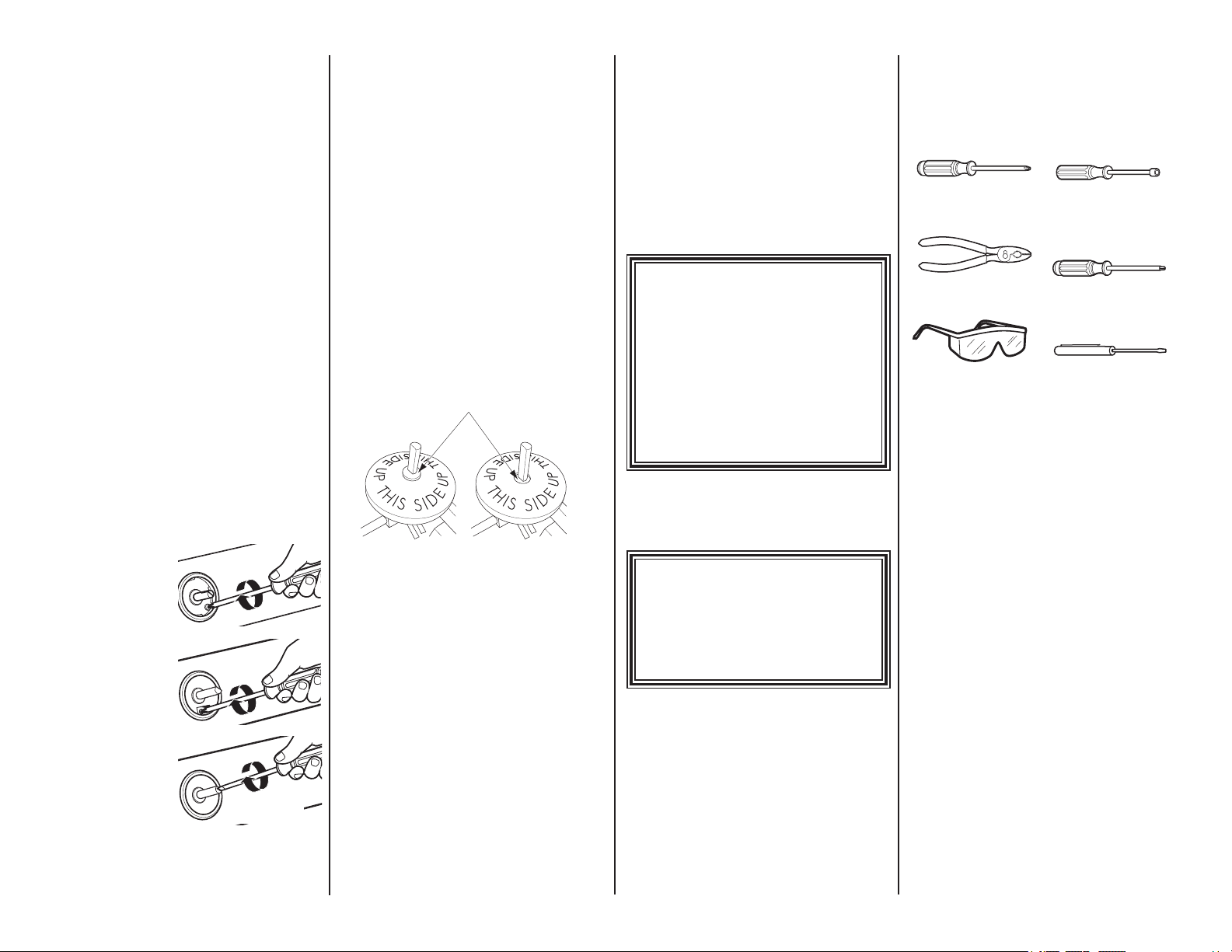

Tools you will need:

Phillips Head

Screwdriver

Pliers

Safety Glasses

7mm Nutdriver

No. 15 Torx-Head Driver

Small Flat-Head

Screwdriver

(4mm or 5/32” tip size,

60mm or 2-3/8” long)

Pub. No. 31-10600-3

(06 -12 GE)

Page 2

CAUTION: The following adjustments

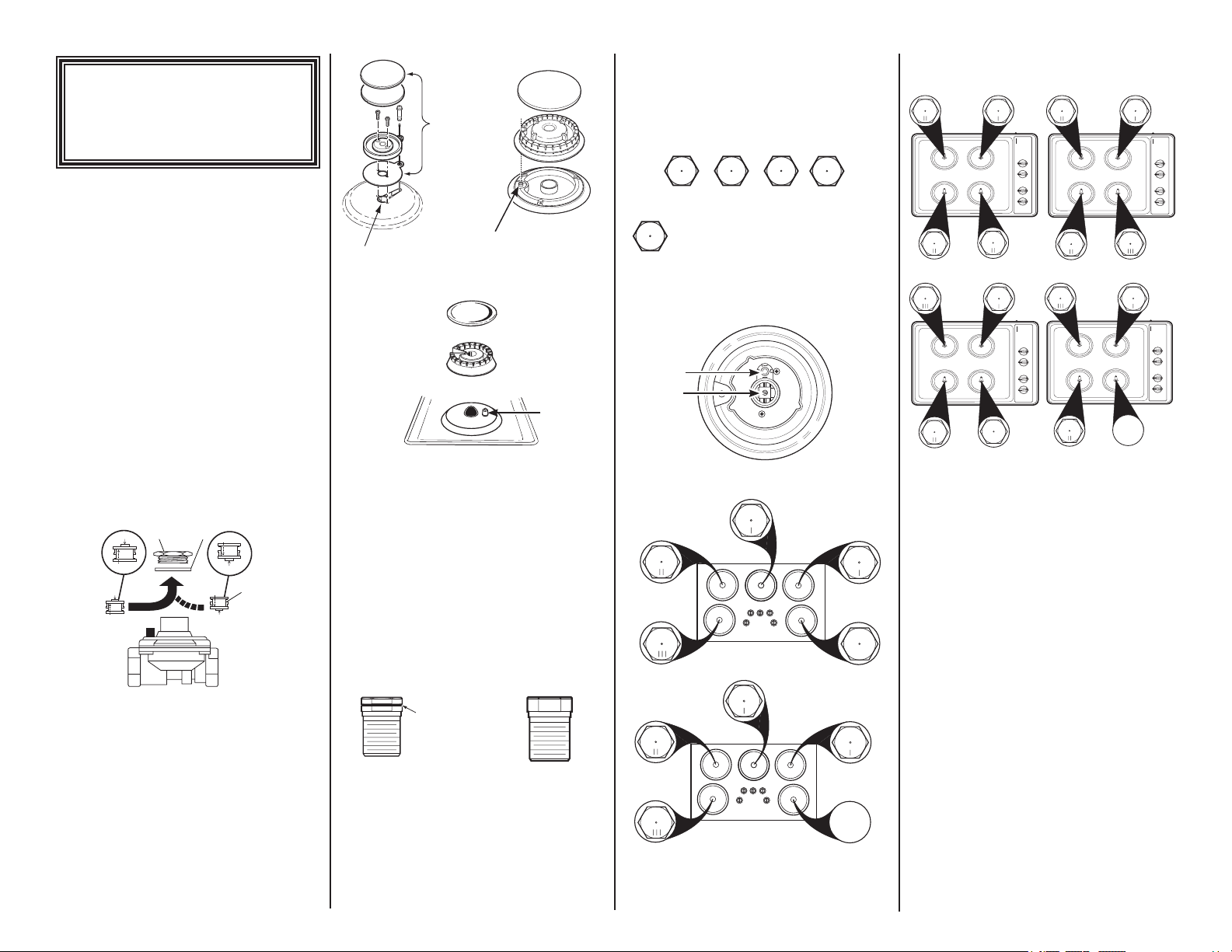

I II III

X

must be made before turning on the

burner. Failure to do so could result

in serious injury. Be sure pressure

regulator has been converted.

Remove

This

Assembly

Burner

head

Burner cap

Each orifice will also show a series of

engraved marks, (I, II, III, X, or none), located

on the top.

These marks denote the precise location of

each orifice to the cooktop burner.

Units with 4 burners

JGP328

86 L 63 L

JGP330

86 L

63 L

To adjust your cooktop for use with L.P. gas,

follow these instructions:

1. Disconnect all electrical power, at the main

circuit breaker or fuse box.

2. Shut off the gas supply to the cooktop by

closing the manual shut-off valve.

3. Adjust the Pressure Regulator:

a. Unscrew the cap.

b. Carefully look at the spring retainer to

locate the NAT or LP position.

c.

Turn the spring retainer over by

rotating it 90 deg., pull it from the

cap, turn the spring retainer over so

that LP is showing, insert it back into

the cap, and then rotate it 90 deg.

into position.

d.

Screw the cap back onto the

regulator and tighten.

Cap

LP

NAT

LP

NAT

NAT.

Position

Pressure Regulator

Gasket

NAT

LP

NAT

LP

LP/Propane

Position

4. Change the cooktop burner orifices:

a. Remove the top grates, burner caps and

burner head.

b. Remove the spark igniter from the burner

base (if required to access orifices). Use a

No. 15 torx head driver bit to remove the

screws holding the burner base in position.

c. Using a 7mm nut driver, remove the top

burner orifices. These may be accessed

through the hole in the maintop.

Spring

Retainer

Burner

base

Spark

igniter

Orifice Spud Located

Through This Opening

Burner

base

Spark igniter

18,000 BTU Burner

(on some models)

Burner

cap

Burner

head

The orifices have a spring loaded retaining

ring around the hex head to hold the orifice

in the nut driver during installation and

removal. A slight amount of force is required

to push the nut driver down over the ring.

NOTE: For orifices that do not have a spring-

loaded retaining ring, use pliers to hold

the orifice in position during initial thread

engagement or final removal to avoid

dropping the orifice in the cooktop. Then use

the nut driver to tighten or loosen.

IMPORTANT: Save the orifices removed from

the appliance for future use.

Retainer

Ring

5.

Locate the LP orifices attached to

the regulator along with separate LP

conversion instructions. They will have a

digit for size and a letter for type of gas,

on the top or side. (Important: Save the

orifices removed from the appliance

for future use.)

I II III

X

18,000 BTU/HR Burner (on some models)

The 18,000 BTU/HR burner has 2 orifices

with markings located on the side only.

(See rating plate on bottom of cooktop.)

NOTE: The main orifice is located low in the

center of the burner while the simmer orifice is

located higher behind the center of the burner.

Simmer

orifice

Main

orifice

Units with 5 burners

JGP963

86 L

92 L

JGP975

86 L

92 L

63 L

63 L

63 L

104 L

X

63 L

See

Below

Main: 108 XL

Simmer: 34 SL

JGP933

86 L

104 L

86 L

92 L

JGP945

92 L 63 L

X

86 L

See

Below

Main: 108 XL

Simmer: 34 SL

86 L

92 L 63 L

86 L

6. Install the L.P orifices in their precise

locations.

7. Replace the burner bases, heads, caps, and

top grates.

NOTE: When reattaching the burner

bases to glass top units, tighten to

10 in. lbs. max. torque.

8. Return the orifices to the bracket and

reattach the bracket with instruction sheet

to the pressure regulator using the screw

previously removed

.

conversion continued

Loading...

Loading...