Page 1

Model: JGP645

Use and Care & Installation Guide

Gas Downdraft Cooktop

GE Quality Product

Safety Instructions................... 3 –5

Operating Instructions, Tips

Controls............................................................ 8

Cooktop Comparison.................................... 7

Cookware ........................................................ 9

Electric Ignition............................................... 8

Features ........................................................... 6

Using Your Cooktop ................................. 8, 9

Vent System ................................................. 10

Care and Cleaning ................... 11, 12

Before You

Call For Service ......................... 26

More questions?…call

GE Answer Center® 800.626.2000

Installation Instructions... 13–25

Converting to LP Gas .......................... 24, 25

Downdraft ............................................. 16–18

Consumer Services.................. 27

Appliance Registration................................. 2

Important Phone Numbers....................... 27

Model and Serial Numbers ......................... 2

Warranty ....................................... Back Cover

Page 2

2

HELP US HELP YOU…

Read this guide carefully.

It is intended to help you operate and maintain your

new cooktop properly.

Keep it handy for answers to your questions.

If you don’t understand something or need more

help, call:

GE Answer Center

®

800.626.2000

24 hours a day, 7 days a week

Write down the model and serial

numbers.

You’ll find the model and serial numbers on a label

located on the underside of the cooktop.

These numbers are also on the Consumer Product

Ownership Registration Card that came with your

cooktop. Before sending in this card, please write

these numbers here:

Model Number Serial Number

Use these numbers in any correspondence or service

calls concerning your cooktop.

If you received a damaged cooktop…

Immediately contact the dealer (or builder) that sold

you the cooktop.

Save time and money. Before you

request service…

Check the Before You Call for Service section in the

back of this guide. It lists causes of minor operating

problems that you can correct yourself.

IF YOU NEED SER VICE

To obtain service, see the Consumer Services page in

the back of this guide.

We’re proud of our service and want you to be

pleased. If for some reason you are not happy with

the service you receive, here are three steps to follow

for further help.

FIRST, contact the people who serviced your

appliance. Explain why you are not pleased.

In most cases, this will solve the problem.

NEXT, if you are still not pleased, write all the

details—including your phone number—to:

Manager, Consumer Relations

GE Appliances

Appliance Park

Louisville, KY 40225

FINALLY, if your problem is still not resolved, write:

Major Appliance Consumer Action Program

20 North Wacker Drive

Chicago, IL 60606

— Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

•Do not try to light any appliance.

•Do not touch any electrical switch; do

not use any phone in your building.

•Immediately call your gas supplier from

a neighbor’s phone. Follow the gas

supplier’s instructions.

•If you cannot reach your gas supplier,

call the fire department.

— Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

WARNING: If the information in this

guide is not followed exactly, a fire or

explosion may result causing property

damage, personal injury or death.

Page 3

Important Safety Instructions

IMPOR TANT SAFETY INSTRUCTIONS

Read all instructions before using this appliance.

IMPORTANT SAFETY NOTICE

• The California Safe Drinking Water and

Toxic Enforcement Act requires the Governor

of California to publish a list of substances

known to the state to cause cancer, birth

defects or other reproductive harm and requires

businesses to warn customers of potential

exposure to such substances.

• Gas appliances can cause minor exposure to

four of these substances, namely benzene,

carbon monoxide, formaldehyde and soot, caused

primarily by the incomplete combustion of natural

gas or LP fuels. Properly adjusted burners,

indicated by a bluish rather than a yellow flame,

will minimize incomplete combustion. Exposure

to these substances can be minimized further by

venting with an open window or using the

ventilation fan.

When You Get Your Cooktop

When you get your cooktop, have the installer

show you the location of the gas cut-off valve

and how to shut it off if necessary.

• Have your cooktop installed and properly

grounded by a qualified installer, in accordance

with the Installation Instructions. Any adjustment

and service should be performed only by qualified

gas range installers or service technicians.

• Plug your cooktop into a 120-volt grounded

outlet only. Do not remove the round grounding

prong from the plug. If in doubt about the

grounding of the home electrical system, it is your

personal responsibility and obligation to have an

ungrounded outlet replaced with a properly

grounded three-prong outlet in accordance with

the National Electrical Code. Do not use an

extension cord with this appliance.

• Be sure all packing materials are r emoved from

the cooktop before operating it, to prevent fire or

smoke damage should the packing material ignite.

• Be sure your cooktop is correctly adjusted by a

qualified service technician or installer for the

type of gas (natural or LP) which is to be used.

Your cooktop can be converted for use with either

type of gas. See the Installation Instructions.

• Do not attempt to repair or replace any

part of your cooktop unless it is specifically

recommended in this guide. All other servicing

should be referred to a qualified technician.

WARNING—TO REDUCE THE RISK OF

FIRE, ELECTRIC SHOCK, OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING:

A. Use this unit only in the manner intended

by the manufacturer. If you have questions,

contact the manufacturer.

B. Before servicing or cleaning the unit, switch

power off at the service panel.

C. When cutting or drilling into wall or ceiling

do not damage electrical wiring and other

hidden utilities.

D. Ducted fans must always be vented to the

outdoors.

E. To reduce the risk of fire, use only metal

ductwork.

WARNING—TO REDUCE THE RISK

OF A COOKTOP GREASE FIRE:

A. Keep fan, filters and grease laden surfaces clean.

B. Always turn vent ON when cooking at high heat.

C. Use high settings on cooktop only when

necessary. Heat oil slowly on low to medium

setting.

D. Don’t leave the cooktop unattended when

cooking.

E. Always use cookware and utensils appropriate

for the type and amount of food being prepared.

CAUTION—For general ventilating use only.

Do not use to exhaust hazardous or explosive

materials and vapors.

(continued next page)

3

Page 4

4

IMPOR TANT SAFETY INSTRUCTIONS

(continued)

Using Your Cooktop

• Do not leave children alone or unattended

where a cooktop is hot or in operation. They

could be seriously burned.

• CAUTION: Items of interest to children should

not be stored in cabinets above a cooktop—

children climbing on the cooktop to reach items

could be seriously injured.

• When raising or lowering the vent, keep fingers

away from all vent parts; assure that cookware,

pans and handles will not be struck and tipped

when raising the vent.

• Do not operate or clean your cooktop if the

glass is broken or cracked. Cleaning solutions

and spillovers could penetrate the broken cooktop

and create a risk of electric shock. Call for service

immediately if the cooktop glass breaks or cracks.

• Clean the cooktop with caution. If a wet sponge

or cloth is used to wipe spills on a hot cooktop, be

careful to avoid steam burns.

• Do not clean the cooktop with flammable or

volatile cleaning fluids.

• Do not clean the cooktop when the appliance

is in use.

• Avoid scratching the cooktop with sharp

instruments, or with rings and other jewelry.

• Never use the cooktop as a cutting board.

• Let the burner grates and other surfaces cool

before touching them or leaving them where

children can reach them.

• Never wear loose-fitting or hanging garments

while using the appliance. Be careful when

reaching for items stored in cabinets over the

cooktop. Flammable material could be ignited if

brought in contact with flame or hot surfaces and

may cause severe burns.

• For your safety, never use your appliance for

warming or heating the room.

• Do not use water on grease fires.

Never pick up a flaming pan.

Turn the controls off. Smother a

flaming pan on a surface burner by covering the

pan completely with a well-fitting lid, cookie

sheet or flat tray. Use a multi-purpose dry

chemical or foam-type fire extinguisher.

Flaming grease outside a pan can be put out

by covering it with baking soda or, if available,

by using a multi-purpose dry chemical or foamtype fire extinguisher.

• Do not store flammable materials near the

cooktop. Do not store or use gasoline or other

flammable vapors and liquids in the vicinity of

this or any other appliance.

• Do not let cooking grease or other

flammable materials accumulate

on or near the cooktop.

• Never leave surface burners unattended at

high flame settings. Boilovers cause smoking

and greasy spillovers that may catch on fire.

• Adjust surface burner flame size so it does

not extend beyond the edge of the cookware.

Excessive flame is hazardous.

• Use only dry pot holders—

moist or damp pot holders on hot

surfaces may result in burns from

steam. Do not let pot holders come near open

flames when lifting cookware. Do not use a towel

or other bulky cloth in place of a pot holder.

• To minimize the possibility of burns, ignition

of flammable materials and spillage, turn

cookware handles toward the side or center

of the cooktop without extending over adjacent

burner or vent area.

Page 5

5

Important Safety Instructions

• Always turn the surface burners to off before

removing the cookware.

• Carefully watch foods being fried at high

flame setting.

• Foods for frying should be as dry as possible.

Frost on frozen foods or moisture on fresh

foods can cause hot fat to bubble up and over the

sides of the pan.

• Use least possible amount of fat for effective

shallow or deep fat frying. Filling the pan too

full of fat can cause spillovers when food is

added.

• If a combination of oils or fats will be used

in frying, stir together before heating, or as fats

melt slowly.

• Always heat fat slowly, and watch as it heats.

• Use a deep fat thermometer whenever

possible to prevent overheating fat beyond

the smoking point.

• Use proper pan size—avoid pans that are

unstable or easily tipped. Select cookware having

flat bottoms large enough to properly contain food

and avoid boilovers and spillovers, and large

enough to cover burner grate. This will both save

cleaning time and prevent hazardous

accumulations of food, since heavy spattering or

spillovers left on cooktop can ignite. Use pans

with handles that can be easily grasped and

remain cool.

• Do not place hot cookware on the glass

cooktop. This could cause glass to break.

• Keep all plastics away from burners.

• To avoid the possibility of a burn, always be

certain that the controls for all burners are at

the off position and all grates are cool before

attempting to remove a grate.

• If the cooktop is located near a window,

do not use long curtains which could blow

over the burners and create a fire hazard.

• If you smell gas, turn off the gas to the cooktop

and call a qualified service technician. Never use

an open flame to locate a leak.

• Do not cover or block the area around the

cooktop knobs. This area must be kept clear for

proper ventilation and burner performance.

• When cooking pork, follow the directions

exactly and always cook the meat to an internal

temperature of at least 170°F. This assures that,

in the remote possibility that trichina may be

present in the meat, it will be killed and the meat

will be safe to eat.

• Do not use a wok on the cooking surface if

the wok has a round metal ring which is placed

over the burner grate to support the wok.

This ring acts as a heat trap which may damage

the burner grate and burner head. Also, it may

cause the burner to work improperly. This may

cause a carbon monoxide level above that allowed

by current standards, resulting in a health hazard.

SAVE THESE

INSTRUCTIONS

Page 6

6

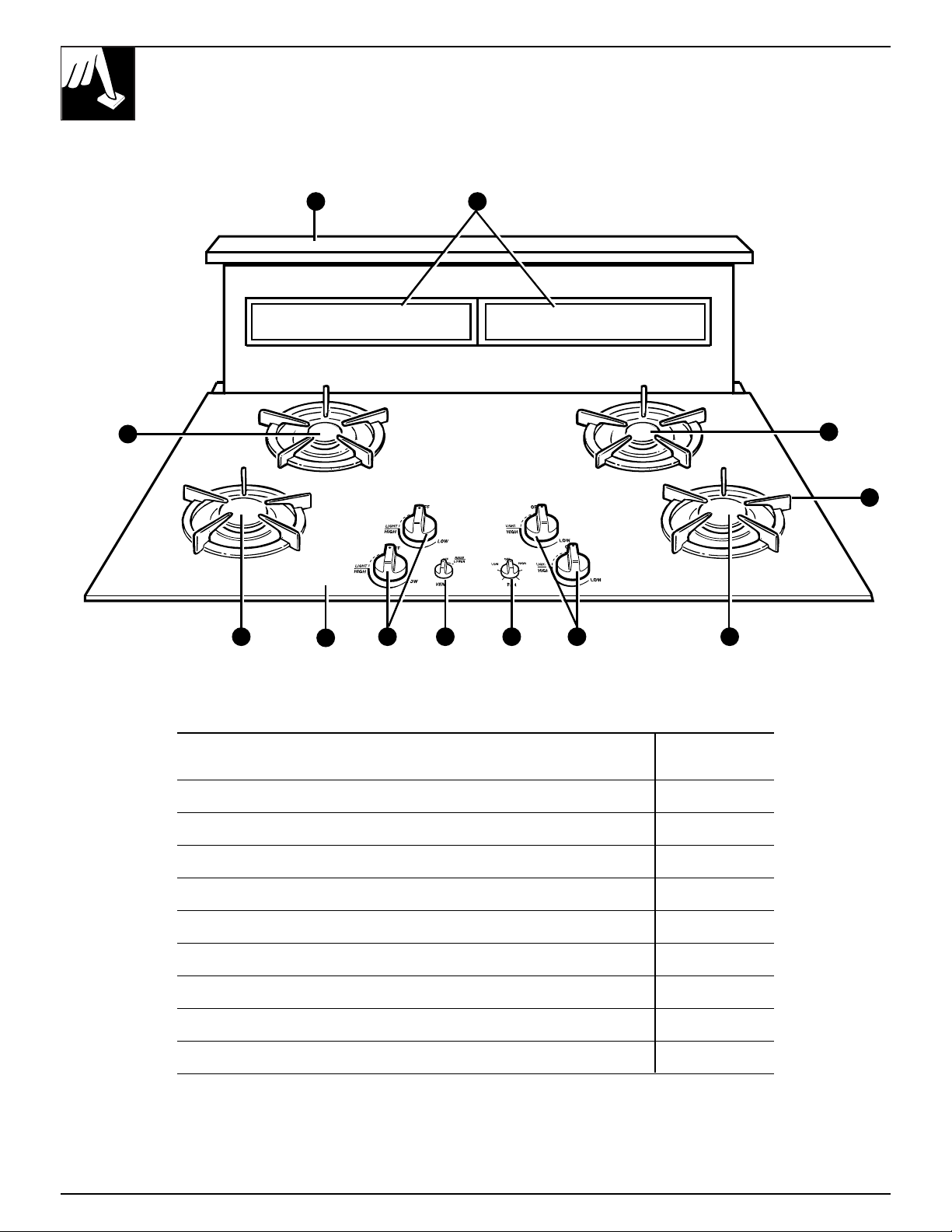

FEATURES OF YOUR COOKTOP

1

5

4

4

3

9

7 6 5

Explained

Feature Index on page

1 Vent 10

2 Vent Filters 11

3 Cast-Iron Burner Grates 12

4 Spillproof Burners 12

5 High Power Spillproof Burners 8

6 Fan Speed Control 10

7 Vent Control 10

8 Surface Unit Controls 8

9 Glass Cooktop Surface 11

2

8 8

Page 7

7

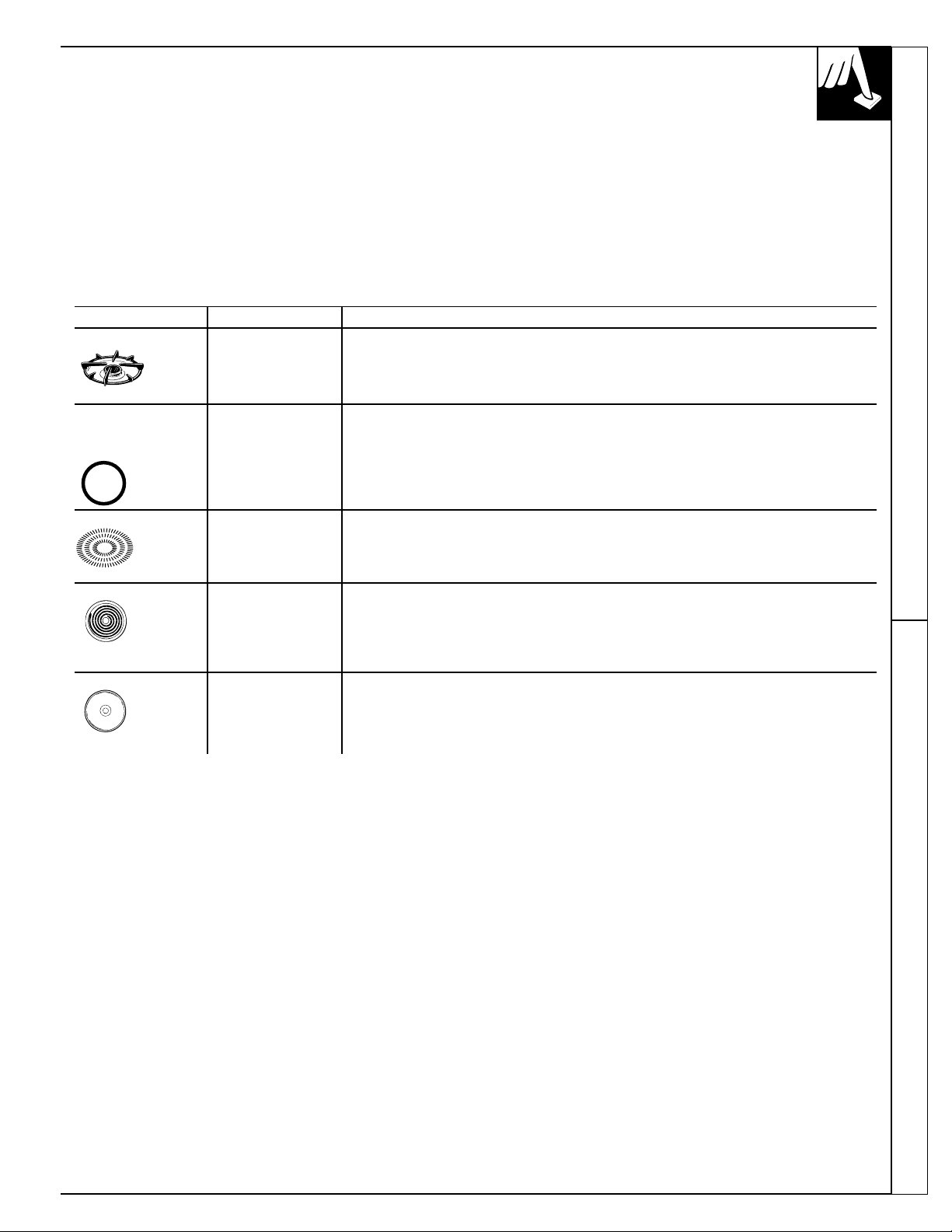

HOW DOES THIS COOKTOP COMPARE

TO YOUR OLD ONE?

Y our new cooktop has gas burners. If you are used

to cooking with induction or other electric surface

units, you will notice some differences when you use

gas burners.

The best types of cookware to use, plus heat-up and

cool-down times, depend upon the type of burner or

surface unit you have.

The following chart will help you to understand the

differences between gas burner cooktops and any

other type of cooktop you may have used in the past.

Type of Cooktop Description How It Works

Gas Burners Regular or sealed Flames heat the pans directly. Pan flatness is not critical to cooking results, but

gas burners use pans should be well balanced. Gas burners heat the pan right away and change

either LP gas heat settings right away. When you turn the control off, cooking stops right away.

or natural gas.

Radiant Electric coils Heat travels to the glass surface and then to the cookware, so pans must be flat on

(Glass Ceramic) under a glass- the bottom for good cooking results. The glass cooktop stays hot enough to

Cooktop ceramic cooktop. continue cooking after it is turned off. Remove the pan from the surface unit if

you want cooking to stop.

Induction High frequency Pans must be made of ferrous metals (metal that attracts a magnet). Heat is

induction coils produced by a magnetic circuit between the coil and the pan. Heats up right away

under a glass and changes heat settings right away, like a gas cooktop. After turning the control

surface. off, the glass cooktop is hot from the heat of the pan, but cooking stops right away.

Electric Coil Flattened metal Heats by direct contact with the pan and by heating the air under the pan. For best

tubing containing cooking results, use good quality pans. Electric coils are more forgiving of

electric resistance warped pans than radiant or solid disks. Heats up quickly but does not change

wire suspended heat settings as quickly as gas or induction. Electric coils stay hot enough to

over a drip pan. continue cooking for a short time after they are turned off.

Solid Disk Solid cast iron Heats by direct contact with the pan, so pans must be flat on the bottom for good

disk sealed to the cooking results. Heats up and cools down more slowly than electric coils. The

cooktop surface. disk stays hot enough to continue cooking after it is turned off. Remove the pan

from the solid disk if you want the cooking to stop.

Features of Your Cooktop Cooktop Comparison

Page 8

8

USING YOUR COOKTOP

Electric Ignition

Your surface burners are lighted by electric ignition,

eliminating the need for standing pilot lights with

constantly burning flames.

The igniters make clicking sounds and spark even

when only a single burner is being turned on. Do not

touch any of the burners when the igniters are clicking.

In case of a power outage, you can light the surface

burners on your cooktop with a match. Hold a lighted

match to the burner, then turn the knob to the HIGH

position. Use extreme caution when lighting

burners this way.

Surface burners in use when an electrical power

failure occurs will continue to operate normally.

8

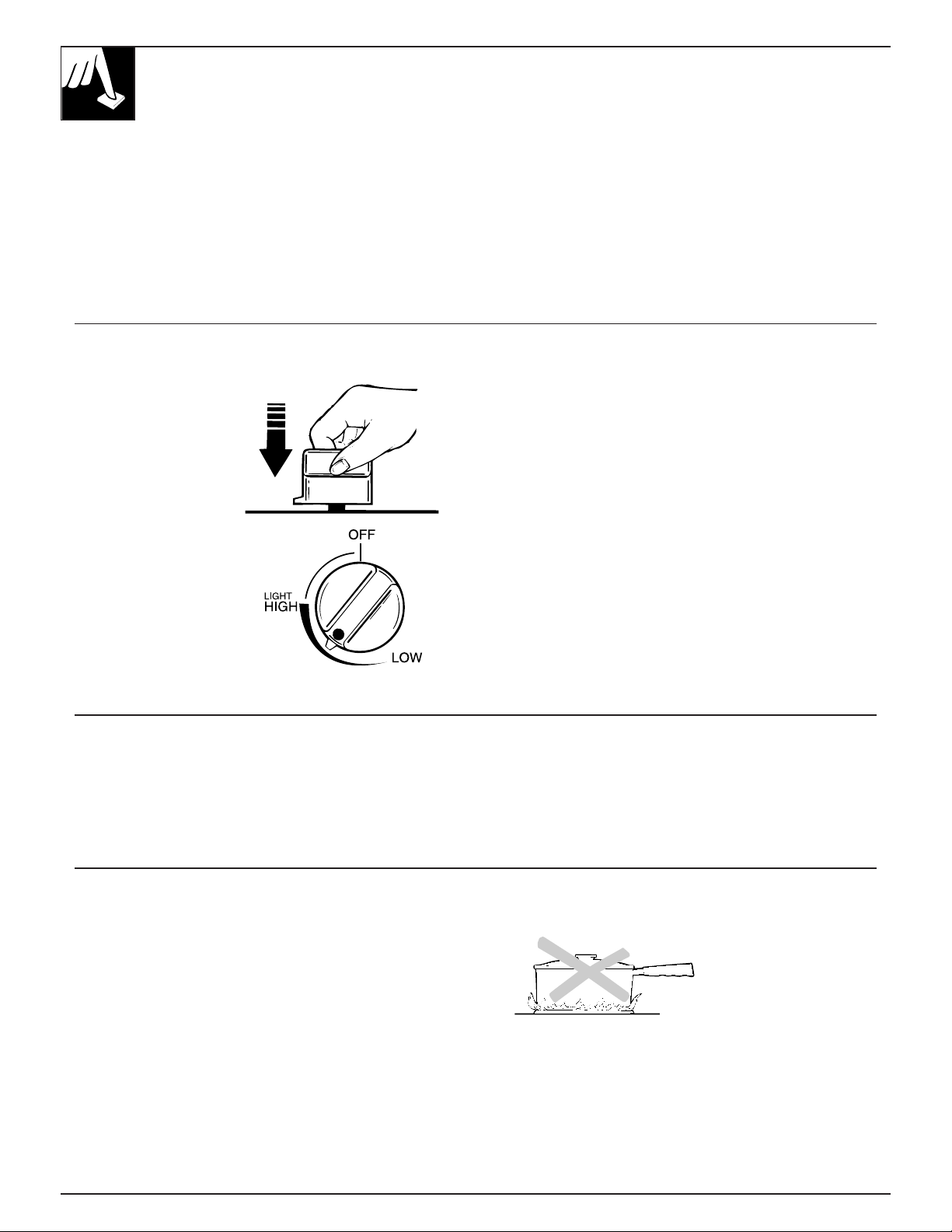

To Light a Burner

Push the control knob

in and turn it

counterclockwise to

desired position from

HIGH to LOW.

After the burner

ignites, turn the knob

in either direction to

adjust the flame size.

To turn a burner

off, turn the knob

clockwise, as far

as it will go, to the

OFF position.

• The center and two rear burners are best for smaller

pans and cooking operations requiring carefully

controlled simmering conditions. The two front

burners are the high power burners for larger pans

and fast boiling operations.

• Do not operate a burner for an extended period

of time without cookware on the grate. The finish

on the grate may chip without cookware to absorb

the heat.

• Check to be sure the burner you turned on is the

one you want to use.

• Be sure the burners and grates are cool before you

place your hand, a pot holder, cleaning cloths or

other materials on them.

How to Select Flame Size

Watch the flame, not the knob, as you reduce heat.

The flame size on a gas burner should match the

cookware you are using.

FOR SAFE HANDLING OF COOKWARE, NEVER

LET THE FLAME EXTEND UP THE SIDES OF

THE COOKWARE. Any flame larger than the bottom

of the cookware is wasted heat and only serves to heat

the handle.

Auto Relight

The burners on this cooktop relight automatically if the flame goes out.

This helps prevent the inconvenience of having to manually relight a burner.

As with electric ignition, all of the burner igniters spark while a burner is

relighting. Do not touch any of the burners when the igniters are clicking.

Page 9

9

Using Your Cooktop

9

Cookware

Aluminum: Medium-weight cookware is

recommended because it heats quickly and evenly.

Most foods brown evenly in an aluminum skillet.

Use saucepans with tight-fitting lids for cooking with

minimum amounts of water.

Cast Iron: If heated slowly, most skillets will give

satisfactory results.

Enamelware: Under some conditions, the enamel of

some cookware may melt. Follow cookware

manufacturer’s recommendations for cooking methods.

Glass: There are two types of glass cookware—

those for oven use only and those for surface cooking

(saucepans, coffee and teapots). Glass conducts heat

very slowly.

Heatproof Glass Ceramic: Can be used for

either surface or oven cooking. It conducts heat

very slowly and cools very slowly. Check cookware

manufacturer’s directions to be sure it can be used

on gas cooktops.

Stainless Steel: This metal alone has poor heating

properties, and is usually combined with copper,

aluminum or other metals for improved heat

distribution. Combination metal skillets generally

work satisfactorily if they are used at medium heat

as the manufacturer recommends.

Wok Cooking

We recommend that you

use only a flat-bottomed

wok. They are available

at your local retail store.

Do not use woks that

have support rings.

Use of these types of

woks, with or without

the ring in place, can be

dangerous. Placing the

ring over the burner

grate may cause the burner to work improperly

resulting in carbon monoxide levels above allowable

current standards. This could be dangerous to your

health. Do not try to use such woks without the ring.

You could be seriously burned if the wok tipped over.

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

Stove Top Grills

Do not use stove top grills on your sealed gas burners.

If you use the stove top grill on the sealed gas burner it

will cause incomplete combustion and can result in

exposure to carbon monoxide levels above allowable

current standards. This can be hazardous to your health.

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

Page 10

10

COOKTOP VENT SYSTEM

The built-in vent system helps remove cooking vapors, odors and

smoke from foods prepared on the cooktop.

Continuous use of the vent system helps keep the kitchen comfortable and

less humid, reducing cooking odors and soiling moisture that normally

creates a frequent need for cleaning.

Raising or Lowering the Vent

To raise the vent, turn the VENT knob to the

RAISE/LOWER position. The vent will rise to the

fully extended position. There is no intermediate

position.

To lower the vent, turn the VENT knob again to the

RAISE/LOWER position. The vent will then descend.

The vent fan will only operate in the fully extended

position.

CAUTION: Be careful when raising or lowering

the vent. Be sure pots, pot handles and other objects

are clear of the vent cover and cannot be struck or

tipped by the vent being raised. Keep hands and

fingers away from all vent parts.

How to Operate the Vent System

Turn the FAN knob to HIGH position to turn it on.

If you continue turning the FAN knob, you can select

a fan speed between HIGH and LOW.

The FAN knob does not have to be turned to OFF

before the vent is lowered. The fan will automatically

turn off when the

vent is lowered.

If the fan was not turned off when the vent

was lowered, it will automatically come on

at the previously selected speed when the vent

is fully raised.

Page 11

11

CARE AND CLEANING

Proper care and cleaning are important so your

cooktop will give you efficient and satisfactory

service. Follow these directions carefully in caring

for it.

Before cleaning any part of your cooktop, be sure all

burners are off and DISCONNECT ELECTRICAL

POWER TO THE COOKTOP at the fuse box or

circuit breaker panel, or pull the cooktop power plug,

located beneath the cooktop and inside the cabinets.

Glass Cooktop

T o keep the cooktop looking its best, wipe up any

spills as they occur. This will keep them from burning

on and becoming more difficult to remove.

As soon as the cooktop is cool, wash the glass surface

with a cloth moistened with warm, soapy water; rinse

with clean water, and dry with a soft cloth. You can

use any liquid household detergent.

Do not use abrasive materials such as metal pads,

cleansing powder and scouring pads—they may

scratch the surface. Do not use harsh chemicals such

as bleach or chemical oven cleaners.

CAUTION: DO NOT COOK ON OR CLEAN A

BROKEN OR CRACKED COOKTOP. Cleaning

solutions and spillovers penetrating the cooktop can

create a risk of electric shock. Call for a service

technician immediately.

Grease Filters

The efficiency of your downdraft depends on a clean

filter. Frequency of cleaning depends on the type of

cooking you do. Grease filters should be cleaned at

least once a month. Never operate the downdraft

without the filters in place.

To remove: Lift up and pull the bottom out. Remove

the left filter first, then slide the right filter to the left

and remove it.

To clean: Soak and then agitate in a hot detergent

solution. Light brushing may be used to remove

imbedded soil. Rinse, shake and remove moisture

before replacing. Filters may be cleaned by placing in

dishwasher, although some slight color fading may

occur after several washings.

With careful handling, the filter will last for years. If

replacement becomes necessary, order the part from

your dealer.

Control Knobs

The control knobs may be removed for cleaning.

To remove knob, pull it straight up.

Wash knobs in soap and water but do not soak.

Avoid getting water down into the knob stem holes.

(continued next page)

Cooktop Vent System Care and Cleaning

Page 12

12

CARE AND CLEANING

(continued)

Burner Assembly

The burner assemblies should be wiped clean often.

Turn all controls OFF before removing burner parts.

The electrode of the spark igniter is exposed

when the top of the burner is removed. Be careful

not to push in any surface unit controls while the

top of a burner is removed. A slight electrical

shock might result which could cause you to

knock over hot cookware.

CAUTION: DO NOT OPERATE THE BURNER

WITHOUT ALL BURNER PARTS IN PLACE.

The burner grates and caps can be lifted off, making

them easy to clean. Removing them gives you access

to the burner base and burner bowl. Wash the grate

and cap in hot, soapy water and rinse with clean

water. Dry them with a cloth—don’t reassemble them

wet. When replacing these parts, be sure they fit

securely into position over the burners.

Burner

grate

Burner cap

Burner bowl

Slot

Burner

base

Burner Grates

Cast-iron burner grates should be washed regularly

and, of course, after spillovers.

Wash them in hot, soapy water and rinse with clean

water. Dry the grates with a cloth—don’t put them

back on the cooktop wet. When replacing the grates,

be sure they’re positioned securely over the burners.

To get rid of burned-on food, place the grates in

a covered container or plastic bag. Add 1/4 cup

ammonia and let them soak for 30 minutes. Wash,

rinse well, and dry.

To prevent rusting, apply a light coating of cooking

oil on the bottom of the grates.

Although they’re durable, the grates will

gradually lose their shine, regardless of the best care

you can give them. This is due to their continual

exposure to high temperatures.

Do not operate a burner for an extended period

of time without cookware on the grate. The finish

on the grate may chip without cookware to absorb

the heat.

Page 13

13

INSTALLATION INSTRUCTIONS

PARTS LIST

Cooktop

• 4 burner grates

• 4 burner caps

• Gas pressure regulator with attached 1/2

″ to

3/8″ reducing bushing and 3/8″ pipe nipple

• 2 clamping brackets with screws

• Attached 120 volt grounded plug cord

• Self adhesive gasket

1/4″ x 36″ (1)

3/16″ x 36″ (2)

Downdraft Unit

• Downdraft unit

• Downdraft stability brackets

• Two filters

Blower Unit

JXBA55 motor and blower assembly is required

for both models.

JXBC55 optional outdoor cover accessor y may

be ordered for installation of blower and motor

assembly on the outside wall.

• Blower

• Nuts and washers

TOOLS AND PARTS NEEDED

• Large flat blade screwdriver

• Saw

• Carpenter’s square

• Pipe wrench

• Manual gas line shut-of f valve

• Pipe joint sealant that resists action of LP gas

• Ductwork to suit the installation.

For flexible connection where local

codes permit:

• Flexible metal tubing (same 3/4″ or 1/2″ I.D.

as gas supply line)

• Flare union adapter for connection to supply line

(3/4″ NPT x 3/4″ I.D. or 1/2″ NPT x 1/2″ I.D.)

• Flare union adapter for connection to

regulator (1/2″ NPT x 3/4″ I.D. or 1/2″ I.D.)

For rigid connection:

• Pipe fittings as required

BEFORE YOU BEGIN

Read these instructions completely and

carefully.

Save these instructions for local inspector’s

use.

IMPOR T ANT–OBSER VE ALL GOVERNING

CODES AND ORDINANCES.

NOTE TO INSTALLER: Be sure to leave

these instructions with the consumer.

FOR YOUR SAFETY

If YOU SMELL GAS:

1. Open windows.

2. Don’t touch any electrical switches.

3. Extinguish any open flame.

4. Immediately call your gas supplier.

for your safety

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity

of this or any other appliance.

(continued next page)

Page 14

14

INSTALLATION INSTRUCTIONS

(continued)

DIMENSIONS AND CLEARANCES

The downdraft system with blower, motor and

ductwork will occupy the cabinet below the

cooktop. Drawers cannot be installed below

this cooktop.

Avoid placing cabinets above the cooktop unit,

if possible, in order to reduce the hazards caused

by reaching over heated surface units.

If the cabinetry is used above the cooktop,

allow a minimum 30

″ clearance between the

cooking surface and the bottom of the

unprotected cabinet.

If the clearance between the cooktop and the

cabinetry is less than 30″, the cabinet bottom

must be protected with a flame retardant

millboard at least 1/4″ thick, or gypsum board

at least 3/16″ thick, covered with 28 gauge sheet

steel or 0.020″ thick copper. Clearance between

the cooktop and the protected cabinetry

MUST

NEVER BE LESS THAN 24″.

EXCEPTION: Installation of a listed microwave

oven or cooking appliance over the cooktop shall

conform to the installation instructions packed

with that appliance.

Working areas adjacent to the cooktop should

have an 18″ minimum clearance between the

countertop and the bottom of the cabinet.

If the clearance is less than 18″, the adjacent

cabinets should be at least 8″ from the side

of the cooktop.

IMPORTANT SAFETY INSTRUCTIONS

The cooktop has been design certified by the

American Gas Association. As with any appliance

using gas and generating heat, there are certain

safety precautions you should follow. You’ll find

these precautions in this Use and Care Guide;

read it carefully.

• Be sure your cooktop is installed properly

by a qualified installer or service technician.

• The cooktop must be electrically grounded in

accordance with local codes, or in their absence,

with the National Electrical Code ANSI/NFPA

No. 70–Latest Edition.

• Installation of this cooktop must conform with

local codes, or in the absence of local codes, with

the National Fuel Gas Code. ANSI Z223.1–Latest

Edition.

• Disconnect electrical supply before servicing.

• Make sure the wall coverings around the

cooktop can withstand heat generated by the

cooktop up to 200°F.

• Avoid placing cabinets above the cooktop.

• If cabinets are placed above the cooktop, allow

a minimum clearance of 30″ between the cooking

surface and the bottom of unprotected cabinets.

• If cabinets are placed above the cooktop, use

cabinets no more than 13″ deep.

• If a 30″ clearance between cooking surface and

overhead combustible material or metal cabinets

cannot be maintained, protect the underside of

the cabinets above the cooktop with not less than

1/4″ insulating millboard or gypsum board at

least 3/16″ thick covered with 28 gauge sheet

steel or 0.020″ thick copper.

• Clearance between the cooking surface and

protected cabinets MUST NEVER BE LESS

THAN 24″. The vertical distance from the plane

of the cooking surface to the bottom of adjacent

overhead cabinets extending closer than 1″ to

the plane of the cooktop sides must not be less

than 18″.

2″

2″

36″

22

1

⁄4″

8

3

⁄4″

15″

13″

Max.

8″ Min. to

wall when

installed

8″ Min. to

wall when

installed

30″

Min.

18″

Min.

Page 15

15

CUT THE OPENING

Measure carefully when cutting countertop.

Make sure sides of opening are parallel and rear

and front cuts are exactly perpendicular to sides.

The gas downdraft cooktop is designed to fit in a

36″ or larger base cabinet.

The countertop cutout for the cooktop

must be:

• 34

9

⁄16″ at the front of the counter and 3315⁄16″ at

the back

• 19″ front to back notch

• 21″ front to back of cutout

The notches at the back of the cutout are:

• 2″ forward and 5/16″ to the inside.

Follow the illustration shown.

• Allow at least 1

1

⁄4″ clearance between back of

cutout and wall.

• Allow at least 8

13

⁄16″ clearance from right and

left sides of cutout to adjacent wall.

• Allow at least 2

1

⁄4″ clearance between front of

cutout and front edge of countertop.

CAUTION: Wall coverings, countertops and

cabinets should be able to withstand 200°F. heat

generated by the cooktop.

PREPARING THE COUNTERTOP

Countertop cut-out dimensions

Cut out the opening as shown in the diagram.

Measure carefully when cutting the countertop.

Making sure the sides of the opening are parallel

and the front and rear cuts are exactly

perpendicular to the sides.

The front of the opening must clear the front

support rail on the cabinet and the rear of the

opening must clear the rear support of the cabinet.

(continued next page)

21″

19″

21″

1

1

⁄4″

Min.

2

1

⁄4″

Min. to

front

edge

8

13

⁄16″

Min. to

side walls

8

3

⁄4″

22

1

⁄4″

33

15

⁄16″

34

9

⁄16″

15″

36″

19″

2″

2″

2″

5

⁄16″

2″

5/16″

3315⁄16″

Back of countertop

Front of countertop

349⁄16″

Page 16

16

INSTALLATION INSTRUCTIONS

(continued)

DUCTWORK ARRANGEMENT

The downdraft vent is shipped with the

discharge outlet on the left side. It can be

changed to the right side to avoid inter ference

in routing the ductwork.

• To change the ductwork to the right side,

remove the screws holding the outlet panel to

the bottom of the vent.

• Remove and rotate the panel and fasten with

screws.

• The blower can be mounted in the cabinet or

under the floor. The blower will fit between floor

joists on 16

″ centers.

PLAN THE DUCTWORK

Prepare ductwork to vent to outdoors:

• Use the shor test and straightest duct run

possible.

• Duct run should not exceed equivalent length

of 150 feet. Refer to “Duct Fittings” char t to

calculate equivalent length for various duct

configurations.

• This downdraft blower system is designed for

use with 3

1

⁄4″ x 10″ ductwork. It can be

transitioned to 6″ round.

• Ductwork MUST be vented to the outside.

Never vent into a crawl space, attic or other

enclosed space.

2″

15″

10″

Adjustable

5″ to 8″

Transition (supplied

with blower/motor)

21⁄4″

3

1

⁄4″

3

1

⁄4″

3

1

⁄4″

7

1

⁄2″

131⁄4″

Right

discharge

Left discharge

(as shipped)

Page 17

17

C

L

C

L

To accurately locate the ductwork holes in

the cabinet floor:

• Place the downdraft vent against the back of

the cutout.

• Place the transition duct supplied on top of the

blower/motor assembly.

• Position the transition duct and assembly

below the discharge outlet.

• Position a transition duct (not supplied) to the

end of the blower in the direction of desired

discharge.

• Mark the location and remove the assembly.

• Cut the holes and install ductwork connection.

Through the floor shown with rectangular duct

(not shown to scale)

Discharge left shown with rectangular duct

(not shown to scale)

Discharge right shown with 6″ round duct

(not shown to scale)

(continued next page)

10

5

⁄16″

11⁄4″ From

back wall

1

1

⁄4″ From

back wall

1

1

⁄4″ From

back wall

3

1

⁄4″ x 10″

3

1

⁄4″ x 10″

3

1

⁄4″ x 10″

10

5

⁄16″

7

1

⁄16″

Page 18

18

INSTALLATION INSTRUCTIONS

(continued)

DUCT FITTINGS

Use the char t at the right to compute maximum

permissible lengths for duct r uns to outdoors.

NOTE: Do not exceed maximum permissible

equivalent lengths!

Flexible ducting:

If flexible metal ducting is used, all the

equivalent feet values in the table should be

doubled. The flexible metal duct should be

straight and smooth and extended as much

as possible.

Do NOT use flexible plastic ducting.

NOTE: Any home ventilation system, such as a

cooktop with a downdraft exhaust mechanism,

may interrupt the proper flow of combustion air

and exhaust required by fireplaces, gas

furnaces, gas water heaters and other naturally

vented systems. To minimize the chance of

interruption of such naturally vented systems,

follow the heating equipment manufacturer’s

guidelines and safety standards such as those

published by NFPA and ASHRAE.

Total

Equivalent Number Equivalent

Duct Pieces Length* Used Length

1 ft.

6″ round, (per foot

straight length) feet

1 ft.

31⁄4″ x 10″ (per foot

straight length) feet

6″, 90°

elbow 15 ft.

6″, 45°

elbow 9 ft.

31⁄4″ x 10″

90° elbow 16 ft.

31⁄4″ x 10″

45° elbow 5 ft.

31⁄4″ x 10″

90° flat elbow 18 ft.

6″ round

to 3

1

⁄4″ x 10″

transition 7 ft.

31⁄4″ x 10″

to 6″ round

transition 5 ft.

6″ round

to 3

1

⁄4″ x 10″

transition

90° elbow 20 ft.

31⁄4″ x 10″

to 6″ round

transition

90° elbow 12 ft.

6″ round wall

cap with damper 21 ft.

31⁄4″ x 10″ wall

cap with damper 27 ft.

6″ round

roof cap 20 ft.

6″ round

roof vent 24 ft.

Total duct run should not exceed 150 ft.

*Actual length of straight duct plus duct fitting

equivalent. Equivalent length of duct pieces are

based on actual tests conducted by GE Evaluation

Engineering and reflect requirements for good

venting per for mance with any downdraft cooktop.

Page 19

19

Electrical Supply:

The built-in gas downdraft cooktop features

pilotless electric ignition for energy savings and

reliability. It operates on a 120 volt, 60 Hz power

supply. A separate circuit, protected by a 15 amp

time delay fuse or circuit breaker, is required.

• A properly grounded 3-prong receptacle

should be located within reach of cooktop’s four

foot power cord.

IMPORTANT : (Please read carefully.)

FOR PERSONAL SAFETY, THIS

APPLIANCE MUST BE PROPERLY

GROUNDED.

The power cord of this appliance is equipped

with a three-prong (grounding) plug which

mates with a standard three-prong grounding

wall receptacle to minimize the possibility of

electric shock hazard from this appliance. The

customer should have the wall receptacle and

circuit checked by a qualified electrician to

make sure the receptacle is properly grounded

and has correct polarity.

Where a standard two-prong wall receptacle is

encountered, it is the personal responsibility and

obligation of the customer to have it replaced

with a properly grounded three-prong wall

receptacle.

Do Not, Under Any Circumstances, Cut Or

Remove The Third (ground) Prong From

The Power Cord.

Do not use an extension cord.

POWER SUPPLY LOCATIONS

Gas Supply:

These cooktops are designed to operate on

natural gas at 4″ of water column pressure or

on LP gas at 10″ of water column pressure.

• These cooktops are shipped from the factory

set for natural gas. If you decide to use this

cooktop with LP gas, conversion adjustments

must be made by a ser vice technician or other

qualified person.

•The pressure regulator must be connected in

series with the manifold of the cooktop and must

remain in series with the supply line regardless

of type of gas being used.

For proper operation, the maximum inlet

pressure to the regulator must be no more than

10″ water column pressure for natural gas and

14″ water column pressure for LP gas.

• When checking the regulator, the inlet

pressure must be at least 1″ greater than the

regulator output setting.

If the regulator is set for 4″ of water column

pressure, the inlet pressure must be at least 5″.

If the regulator is set for 10″ of water column

pressure, the inlet pressure must be at least 11″.

For ease of installation, and if local codes permit,

the gas supply line into the cooktop should be

1/2″ or 3/4″ ID flexible metal appliance

connector, thr ee to five feet long.

NOTE: Purchase a new flexible line. DO NOT

USE AN OLD PREVIOUSLY USED LINE.

•Make gas connection through rear wall, or on

cabinet floor at rear, as illustrated.

(continued next page)

19″

4″

14″

Gas location

Electric location

Page 20

20

INSTALLATION INSTRUCTIONS

(continued)

STEP 3

Install the Motor/Blower Assembly

• Secure the transition duct to the top of the

assembly with 2 screws on each side.

• Position the assembly with duct below the

vent discharge.

• Adjust the height by sliding the brackets up or

down until the assembly is tight against the vent

discharge.

• Tighten all nuts and bolts on the brackets.

• Install discharge transition onto the blower

and connect to ductwork. If round ducting

is used, transition to 6

″ round to connect to

the inlet.

STEP 4

Install the Ductwork

Use minimum 26 gauge galvanized or 24 gauge

aluminum duct in 6″ round or 31⁄4″ x 10″ size, or

a combination of both. PVC duct should be used

if installing under a poured concrete slab. DO

NOT use flexible plastic ducting.

• Always use an appropriate roof or wall cap

with damper. Laundry type wall caps should

never be used.

• Use the straightest duct run possible.

• For satisfactor y performance the duct r un

should not exceed 150 ft. or its equivalent length

if bends or other various fittings are used. Refer

to table of equivalent lengths for various duct

configurations.

• Install ductwork so that the piece of duct

nearest the downdraft unit slots INTO the next

piece of the duct. Secure the joints with selftapping screws and apply duct tape around the

joints to ensure an air tight seal.

Air

Flow

Duct Tape

Over Seam and Screw

Screw

STEP 1

Install Downdraft Vent

Place the downdraft vent into the counter top

cutout, against the back side.

• Secure the downdraft to the counter top with

mounting screws provided. (One on each side.)

Tighten the mounting screws against the

underside of the counter top.

• Use a wood shim when installing in stone

counter tops.

• When installing in a tile counter top surface, it

may be necessar y to apply a locally appr oved

caulking to cover any gaps.

• Fasten stabilizing straps to each side with

screws provided.

• Secure the other end of the strap to the back

or side wall of the cabinet.

Countertop

Tighten

Bolt

Against

Countertop

STEP 2

Install Adjustable Support Brackets

• Place 2 brackets together, with ends facing the

same direction. Secure with bolts, lock washers

and nuts. Do not tighten.

• Assemble all 4 brackets and secure to the

bottom of the blower/motor assembly.

• For installation where the blower is mounted

inside the cabinet, attach the suppor t brackets to

the corners of the blower housing.

• If the blower is installed under the floor, attach

the suppor t brackets to the top of the blower.

Provide a sur face to attach the entir e assembly

to the underside of the floor.

• Suppor t brackets are adjustable fr om 5″ to 8″.

Countertop

Tighten bolt

against

countertop

Duct tape over

seam and screw

Screw

Air flow

Page 21

21

STEP 6

Install the Cooktop

NOTE: If the cooktop is installed into a 36″

base cabinet, the pressure regulator MUST BE

installed to the bottom of the cooktop before the

cooktop is placed into the cabinet.

• Remove packaging from the cooktop.

• To insure a good fit, position the cooktop over

the cutout opening and carefully lower into

place. Check edges all the way around to be

sure all cutout edges are concealed and there

are no gaps.

• Carefully lift and remove the cooktop.

STEP 5

Install the Pressure Regulator

• Install the supplied pressure regulator and

nipple in the gas line as close to the cooktop

inlet as possible. Allowances for ventilation

ducting may be necessar y.

Make sure the regulator is installed in the right

direction.

• Install a manual shut-of f valve in the gas line

in an easily accessible location.

NOTE: Instead of using solid piping to connect

to pressure regulator, an approved flexible metal

appliance connector may be used between the

pipe stub and the shut-of f valve and the pressur e

regulator, if local codes permit.

Appropriate flare nuts and adapters are required

at each end of the flexible connector.

• Tur n on the gas. Check for leaks using a

liquid leak detector at all joints in the system.

(The pressure test nipple is adjacent to the gas

inlet pipe on the rear right hand side of the

cooktop bottom.)

CAUTION: DO NOT USE A FLAME TO

CHECK FOR GAS LEAKS.

IMPOR T ANT : Disconnect the cooktop and the

individual shut-of f valve from the gas supply

piping system during any pressure testing of

that system at test pressures greater than 1/2

psig. Isolate the cooktop from the gas supply

piping system by closing the individual manual

shut-of f valve to the cooktop during any

pressure testing of the gas supply piping system

at test pressures equal to or less than 1/2 psig.

Regulator

Solid piping or

flexible connector

Pipe stub

Shut-off

valve

(continued next page)

Page 22

22

INSTALLATION INSTRUCTIONS

(continued)

STEP 7

Electrical Connections

• Connect the 3-pin plastic plug from the

blower/motor assembly to the 3-pin plastic

socket on the underside of the vent, next to the

conduit.

• Slide the metal cover over the connection and

secure with screws.

• Connect the 6-pin plastic plug from the

downdraft assembly to the 6-pin plastic socket

on the underside of the cooktop, next to the

power cord.

• Slide the metal cover over the connection and

secure with screws.

STEP 8

Connect Power

Plug power cord into properly grounded

receptacle.

STEP 6

Install the Cooktop (continued)

• Cut a 3/16″ gasket strip in half. Peel off the

backing and apply to the underside of the glass

cooktop edge, on each side at least 3/8″ from

the back and as close to the edge as possible

without protr uding.

• Apply the other gasket strip to the underside

of the glass at the front of the cooktop.

• Remove remaining adhesive backing.

• Position the cooktop over the opening, making

sure that the power cord is dropped into the

cabinet.

• Lower the cooktop into the cutout, pressing

gently and evenly to seat.

NOTE: If the cooktop is installed in a 36″ base

cabinet, the mounting brackets cannot be used

because of inter ference with the cabinet sides.

In this case, the cooktop can be secured to the

cabinet with angle brackets (not supplied).

Remove one screw

at the bottom of

the cooktop body

on both sides and

secure the bracket

with those screws.

Then, secure the

brackets to the

cabinet sides.

• Inser t hold-down

bracket into

highest slots on

the right and left

sides of the

cooktop.

Cooktop has three slots, the highest available will

depend on the thickness of the counter top.

• Secure the brackets to the underside of the

counter top with screws pr ovided.

Gasket

Countertop

Gasket

Countertop

1/16″

3/8″

Electrical

6-pin socket

Pressure

regulator

Metal

cover

6-Pin

plug

Electrical

supply cord

Service

plate

Page 23

23

STEP 10

Install Filters, Check Operation of Downdraft

To raise the vent, turn the VENT knob to

RAISE/LOWER.

• Hold the knob until the vent begins to raise.

The vent will automatically stop when it is fully

extended.

• Tip filter into the opening and pull straight

down so that the filter rests on slides.

• Slide the filter to the right side.

• Tip the other filter into the opening and pull

straight down.

• To turn the fan on, tur n the FAN knob to

HIGH. Continue turning the FAN knob to select

a fan speed between HIGH and LOW.

NOTE: It is not necessary to tur n the fan

OFF before lowering the vent. The fan will

automatically turn off when the vent is lowered.

When the fan is not turned off befor e lowering

the vent, it will automatically come on at the

previously selected speed when the vent is

fully raised.

To lower the vent, turn the VENT knob to

RAISE/LOWER. Hold the knob until the vent

begins to lower.

STEP 9

Assemble Burners, Check Ignition

Assemble burner as shown.

Check for proper ignition:

• Push in one control knob and turn 90° to

HIGH position.

• The igniter will spark and the burner will

light; the igniter will cease sparking when the

burner is lit.

• First test may require some time, while air is

flushed out of the gas line.

• Tur n knob to OFF.

• Repeat the procedure for each bur ner.

Top grate

Burner cap

Page 24

24

CONVERTING T O LP GAS

or Converting Back to Natural Gas from LP

CONVERT THE SURFACE KNOBS

1. Remove the knobs and lift off the microswitch

operating cams from the valve shafts.

2. Fully screw down the brass low flame

adjustment screws into the valve bodies with a

clockwise rotation.

3. Replace the knobs and cams.

2

CONVERT THE SURFACE BURNERS

1. Remove grates and burner caps.

2. Using the 7 mm nut driver,

remove and replace the brass

orifice spud inside each burner

chimney as follows:

• Replace the large orifices with

the spuds that are stamped 104.

• Replace the small orifices with

the spuds that are stamped 82.

NOTE:

• Each orifice has a number and the letter “L”

indicating LP gas.

• There will be one extra orifice spud when

converting a four burner cooktop.

3

WARNING: If you are using LP (bottled) gas, all

adjustments described in the following steps must be

made before attempting burner adjustments or use of

the cooktop.

This cooktop leaves the factory set for use with

natural gas. If you convert to LP gas, keep these

instructions and orifices in case you want to convert

back to natural gas.

The conversion should be done by a qualified

technician or installer.

PARTS:

Check the contents of the kit, which should

contain the following:

• 2 Orifices—Large size—104-WB28K0093

• 3 Orifices—Small size—82-WB28K0094

• 1 Maxitrol LP adapter—WB01K055

• 1 Tie-on card/label for regulator

If you do not have all the above listed components,

or if you are in any doubt, please contact the nearest

GE Service and Parts Center.

USE ONLY APPROVED PIPE DOPE RESISTANT

TO LP GAS.

Total input rating after conversion:

• 4 burner cooktop 34,000 Btu/hr.

TOOLS REQUIRED:

Adjustable wrench

Nut drivers: 9/32

″ or 7 mm

PREPARE COOKTOP FOR CONVERSION

(1) Turn off gas supply at the shut-off valve.

(2) Turn off the electrical power to the cooktop.

1

Top grate

Valve

shaft

Burner cap

Cam

Page 25

25

CHECK QUALITY OF FLAMES

The combustion quality of burner flames needs

to be determined visually.

(A) Yellow flames—

Call for service

(B) Yellow tips on

outer cones—

Normal for LP gas

(C) Soft blue flames—

Normal for natural gas

If burner flames look like (A), call for service.

Normal burner flames should look like(B)or

(C), depending on the type of gas you use.

With LP gas, some yellow tipping on outer

cones is normal.

6

FINAL STEPS

Fill in the date plus the name and address of the

service organization performing the conversion

in the spaces provided on the conversion label.

Remove the backing from the label and stick it in

a convenient place on the underside of the

cooktop near the Rating Plate. Make sure the

area is clean and dry before applying the label.

The conversion is now complete.

7

CONVERTING T O LP GAS

or Converting Back to Natural Gas from LP

CONVERT THE PRESSURE REGULATOR

1. Locate the pressure regulator under the rear

of the cooktop.

2. Use an adjustable wrench to remove the

nut from the pressure regulator.

3. Insert the LP Adapter into the nut.

4. Reinsert the assembly into the regulator and

attach the tie-on label to the regulator using the

string provided.

WARNING: Do not remove the pressure

regulator from the cooktop.

4

CHECK FOR LEAKS

Check for leaks before attempting to light the

burners.

When all connections have been made, make

sure all cooktop controls are in the OFF position

and turn on the main gas supply valve. Use a

liquid leak detector at all joints and connections

to check for leaks in the system.

When using test pressures greater than 1/2 psig

to pressure test the gas supply system of the

residence, disconnect the cooktop and individual

shut-off valve from the gas supply piping. When

using test pressures of 1/2 psig or less to test the

gas supply system, simply isolate the cooktop from

the gas supply system by closing the individual

shut-off valve.

CAUTION: DO NOT USE A FLAME TO

CHECK FOR GAS LEAKS.

5

LP

Nut

Gas flow

into range

NAT

LP adapter

NAT

LP

adapter

Nut

LP

Page 26

26

QUESTIONS?

BEFORE YOU CALL FOR SER VICE…

PROBLEM POSSIBLE CAUSE

BURNERS DO NOT • Make sure electrical plug is plugged into a live power outlet.

LIGHT

• Slot in burner base may be clogged. Remove the obstruction.

• Burner parts not replaced correctly.

• Hole in burner cap behind igniter may be clogged.

BURNERS HAVE

YELLOW OR

YELLOW-TIPPED

FLAMES

(A) Yellow flames — (B) Yellow tips on outer (C) Soft blue flames —

Call for service cones — Normal for Normal for

LP gas natural gas

• If burner flame looks like (A), call for service. Normal burner flames

should look like (B) or (C), depending on the type of gas.

BURNER FLAMES VERY • If cooktop is connected to LP gas, check all steps in

LARGE OR YELLOW the Installation Instructions.

BURNER CONTROL • When the knob is at the OFF position, it must be pushed in before it can be

KNOB WILL NOT TURN turned, and it can only be turned in a counterclockwise direction. When the

knob is at any other position, it can be turned in either direction without being

pushed in.

FAN DOES • The vent must be fully extended before fan will work.

NOT WORK

• Fan control knob must be turned in clockwise direction to turn fan on.

If you need more help…call toll free:

GE Answer Center

®

800.626.2000

consumer information service

Page 27

27

GE offers, free of charge, a

brochure to assist in planning a

barrier-free kitchen for persons

with limited mobility.

Consumers with impaired hearing or speech who have

access to a TDD or a conventional teletypewriter may

call 800-TDD-GEAC (800-833-4322) to request

information or service.

We’ll Be There

With the purchase of your new GE appliance, receive the assurance that if you ever need

information or assistance from GE, we’ll be there. All you have to do is call—toll-free!

In-Home Repair Service

800-GE-CARES (800-432-2737)

A GE consumer service professional will provide expert repair service,

scheduled at a time that’s convenient for you. Many GE Consumer Service

company-operated locations offer you service today or tomorrow, or at your

convenience (7:00 a.m. to 7:00 p.m. weekdays, 9:00 a.m. to 2:00 p.m. Saturdays).

Our factory-trained technicians know your appliance inside and out—so most

repairs can be handled in just one visit.

GE Answer Center®

800.626.2000

Whatever your question about any GE major appliance, GE Answer Center®

information service is available to help. Your call—and your question— will be

answered promptly and courteously. And you can call any time. GE Answer

Center® service is open 24 hours a day, 7 days a week.

Service Contracts

800-626-2224

You can have the secure feeling that GE Consumer Service will still be there

after your warranty expires. Purchase a GE contract while your warranty is still

in effect and you’ll receive a substantial discount. With a multiple-year contract,

you’re assured of future service at today’s prices.

Parts and Accessories

800-626-2002

Individuals qualified to service their own appliances

can have parts or accessories sent directly to their home.

The GE parts system provides access to over 47,000

parts…and all GE Genuine Renewal Parts are fully

warranted. VISA, MasterCard and Discover cards

are accepted.

User maintenance instructions contained in this guide

cover procedures intended to be performed by any user.

Other servicing generally should be referred to qualified

service personnel. Caution must be exercised, since

improper servicing may cause unsafe operation.

For Customers With Special Needs…

800.626.2000

SINGLE CONTROL

FAUCET

TBXTOLITE

ON WALL

6’ 10"

5"

8"

6"

5"

7"

1’ 0"

R SHALLOW DEPTH SINKS (6") WITH REAR DRAIN.

SINK SHOULD ALSO BE UNDERCOATED

2’ 10"

3’

1/8

"

SCALE 1’

=

1"

SECTION A-A

FLUORESCENT

FIXTURE

THIS LIGHT CAN

BE INSTALLED

IN BOTTOM OF

WALL CABINETS

2’ 6"

Before You Call for Service Consumer Services

Page 28

Part No. 183D5580P039

Pub No. 49-8837

WHA T IS COVERED

FULL ONE-YEAR WARRANTY

For one year from date of original

purchase, we will provide, free of

charge, parts and service labor in

your home to repair or replace

any part of the cooktop

that fails

because of a manufacturing

defect.

This warranty is extended to

the original purchaser and any

succeeding owner for products

purchased for ordinary home use

in the 48 mainland states, Hawaii

and Washington, D.C. In Alaska the

warranty is the same except that it

is LIMITED because you must pay

to ship the product to the service

shop or for the service technician’s

travel costs to your home.

All warranty service will be

provided by our Factory Service

Centers or by our authorized

Customer Care®servicers during

normal working hours.

Should your appliance need

service, during warranty period or

beyond, call 800-GE-CARES

(800-432-2737).

WHA T IS NOT COVERED

• Service trips to your home to teach

you how to use the product.

Read your Use and Care material.

If you then have any questions

about operating the product,

please contact your dealer or our

Consumer Affairs office at the

address below, or call, toll free:

GE Answer Center

®

800.626.2000

consumer information service

• Improper installation.

If you have an installation problem,

contact your dealer or installer.

You are responsible for providing

adequate electrical, gas, exhausting

and other connecting facilities as

described in the Installation

Instructions provided with the

product.

• Replacement of house fuses or

resetting of circuit breakers.

• Failure of the product if it is used

for other than its intended purpose

or used commercially.

• Damage to product caused

by accident, fire, floods or acts

of God.

WARRANTOR IS

NOT

RESPONSIBLE FOR

CONSEQUENTIAL DAMAGES.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion

may not apply to you. This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

To know what your legal rights are in your state, consult your local or state consumer affairs office or your state’s Attorney General.

Warrantor: General Electric Company

If further help is needed concerning this warranty, write:

Manager—Consumer Affairs, GE Appliances, Louisville, KY 40225

JGP645

4-97 CG

YOUR GE COOKTOP

WARRANTY

Staple sales slip or cancelled check

here. Proof of original purchase date

is needed to obtain service

under warranty.

Printed in Mexico

Loading...

Loading...