GE JGBP25DEM1BB, JGBP25DEM1WW, JGBP25DEM2BB, JGBP25DEM2WW, JGBP25DEM3BB Installation Guide

...Page 1

L.R CONVERSION

INSTRUCTIONS

WARNING: This conversion

must be performed bg a

qualified installer or gas

supplier in accordance with the

manufacturer's instructions and

all codes and requirements of

the authoritg having jurisdiction.

Failure to follow ALL

instructions could result in

serious injurg or propertg

damage.

The qualified agencg

performing this work assumes

responsibilitg for the conversion.

The pressure regul(]tor (]nd the

burner orifices (]re set for n(]tur(]l

g(]s. To use Liquid Prop(]ne Gas,

the regul(]tor (]nd burner orifices

must be converted. The L.R

orifices for the cooktop burners

(]re shipped on the regul(]tor

bracket behind the stor(]ge

drGwer. Also, in the s(]me (]re(], is

(] second brGcket holding the L.R

15K orifice extended spud, choke

(]nd set screw for the front right

Extr(] L(]rge cooktop burner {on

models so equipped). Remove the

stor(]ge dr(]wer to Ioc(]te.

cooktop or oven burners

Do not operate the

of this range when using

L.P. (bottled) gas before

converting the pressure regulator

and burner orifices for L.P. gas use.

Failure to do so could cause high

flames and toxic fumes which can

result in serious injury.

To adjust your range for use with

/.R gas, follow these instructions:

1. Disconnect all electrical power,

at the main circuit breaker or fuse

box.

2. Shut off the gas supply to the

range by closing the manual

shut-off valve.

a,

Remove the storage drawer,

kick panel and if applicable

the access panel to access

the regulator. (Some models

will have a metal shield

protecting the regulator that

must be removed for

conversion and reinstalled

when conversion is

complete.) The pressure

regulator is located in the

lower, left hand rear corner of

the range as viewed from the

Bracket-LP Orifice Spud

Pressure Regulator

r

_ CAUTION: If you are

before you make any burner

adjustments.

>using L.P. (bottled) gas, all

adjustments described in

the following steps must be made

Gas valve

/

b. Unscrewthe plastic-

protected hex-nut cap.

c. Completely remove the

protective plastic cap off the

threaded metal cap.

d. Turn the metal cap so the

type of gas being converted

to is displayed and replace

the protective plastic cover.

e. Screw the hex-nut cap back

into the regulator. (Do not

over tighten)

Rotate Cap counter

clockwise to l....._@__kp_

Cap Assembly

Lever shown closed (Oven ShutO ffonly).

PUSH LEVER TOWARD REGUL ATOR TO OPEN.

a,

Remove the top grates,

burner caps and burner

heads.

Front right burner (on some

models), front left, back right,

back left and center burners.

Burner Cap

ORIFICE

SPUD

LOCATED

THRU THIS

OPENING

b. Using a 7 mm or 9/32" nut

driver, remove the top burner

orifices. These may be

accessed through the burner

opening in the base.

Save these orifices for

I_ IMPORTANT: ol

future conversion back t

natural gas.

c. locate the 1.P.orifices. The

/.R orifices for the cooktop

burners are shipped on the

regulator bracket behind the

storage drawer. Also, in the

same area, is a second

bracket holding the L.R 15K

orifice extended spud, choke

and set screw for the front

right Extra Large cooktop

burner (on models so

equipped). Remove the

storage drawer to locate.

d. Remove the LP orifice spuds,

from the metal bracket. LP

orifice spuds have the letter

"L" on the top.

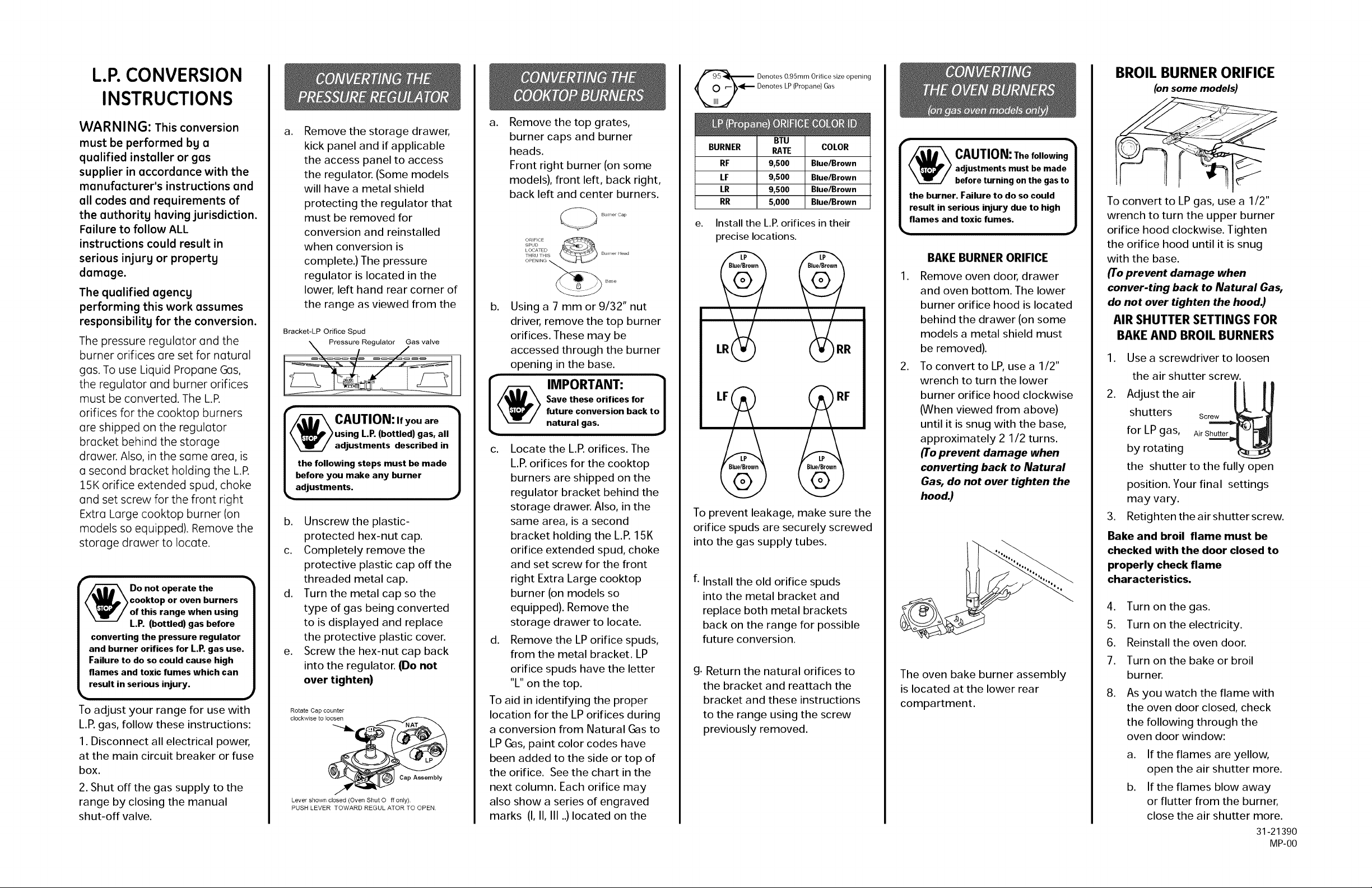

To aid in identifying the proper

location for the/P orifices during

a conversion from Natural Gas to

I_PGas,paint color codes have

been added to the side or top of

the orifice. See the chart in the

next column. Each orifice may

also show a series of engraved

marks (I, II, III ..)located on the

_ enotes 0.95mm Orifice size opening

BURNER RATE COLOR

RF 9,500 Blue/Brown

LF 9,500 Blue/Brown

LR 9,500 Blue/Brown

RR 5,000 Blue/Brown

e.

Installthe L.Rorifices in their

Denotes LP (Propane) Gas

BTU

precise locations.

To prevent leakage, make sure the

orifice spuds are securely screwed

into the gas supply tubes.

f. Install the old orifice spuds

into the metal bracket and

replace both metal brackets

back on the range for possible

future conversion.

g. Return the natural orifices to

the bracket and reattach the

bracket and these instructions

to the range using the screw

previously removed.

r

_-_ CAUTION:The

\ _'/adjustments must be made

before turning on the gas to

the burner. Failure to do so could

result in serious injury due to high

flames and toxic fumes.

following

BAKE BURNER ORIFICE

,

Remove oven door, drawer

and oven bottom. The lower

burner orifice hood is located

behind the drawer (on some

models a metal shield must

be removed).

,

To convert to LID,use a 1/2"

wrench to turn the lower

burner orifice hood clockwise

(When viewed from above)

until it is snug with the base,

approximately 2 1/2 turns.

(To prevent damage when

converting back to Natural

Gas, do not over tighten the

hood.)

The oven bake burner assembly

is located at the lower rear

compartment.

BROIL BURNERORIFICE

(on some models)

To convert to LP gas, use a 1/2"

wrench to turn the upper burner

orifice hood clockwise. Tighten

the orifice hood until it is snug

with the base.

(Toprevent damage when

conver-ting back to Natural Gas,

do not over tighten the hood.)

AIR SHUTTER SETTINGS FOR

BAKE AND BROIL BURNERS

1. Use a screwdriver to loosen

the air shutter screw.

2. Adjusttheair I t !!

for LP gas, Air S_ _J

by rotating

the shutter to the fully open

position. Your final settings

may vary.

3. Retighten the air shutter screw.

Bake and broil flame must be

checked with the door closed to

properly check flame

characteristics.

,

Turn on the gas.

5.

Turn on the electricity.

6.

Reinstall the oven door.

7.

Turn on the bake or broil

burner.

,

As you watch the flame with

the oven door closed, check

the following through the

oven door window:

a. If the flames are yellow,

open the air shutter more.

b. If the flames blow away

or flutter from the burner,

close the air shutter more.

31-21390

MP-00

Page 2

I Y/If youattemp to measure

I _ the inner cone of the

|flame, please use caution; burns

Lcould result.

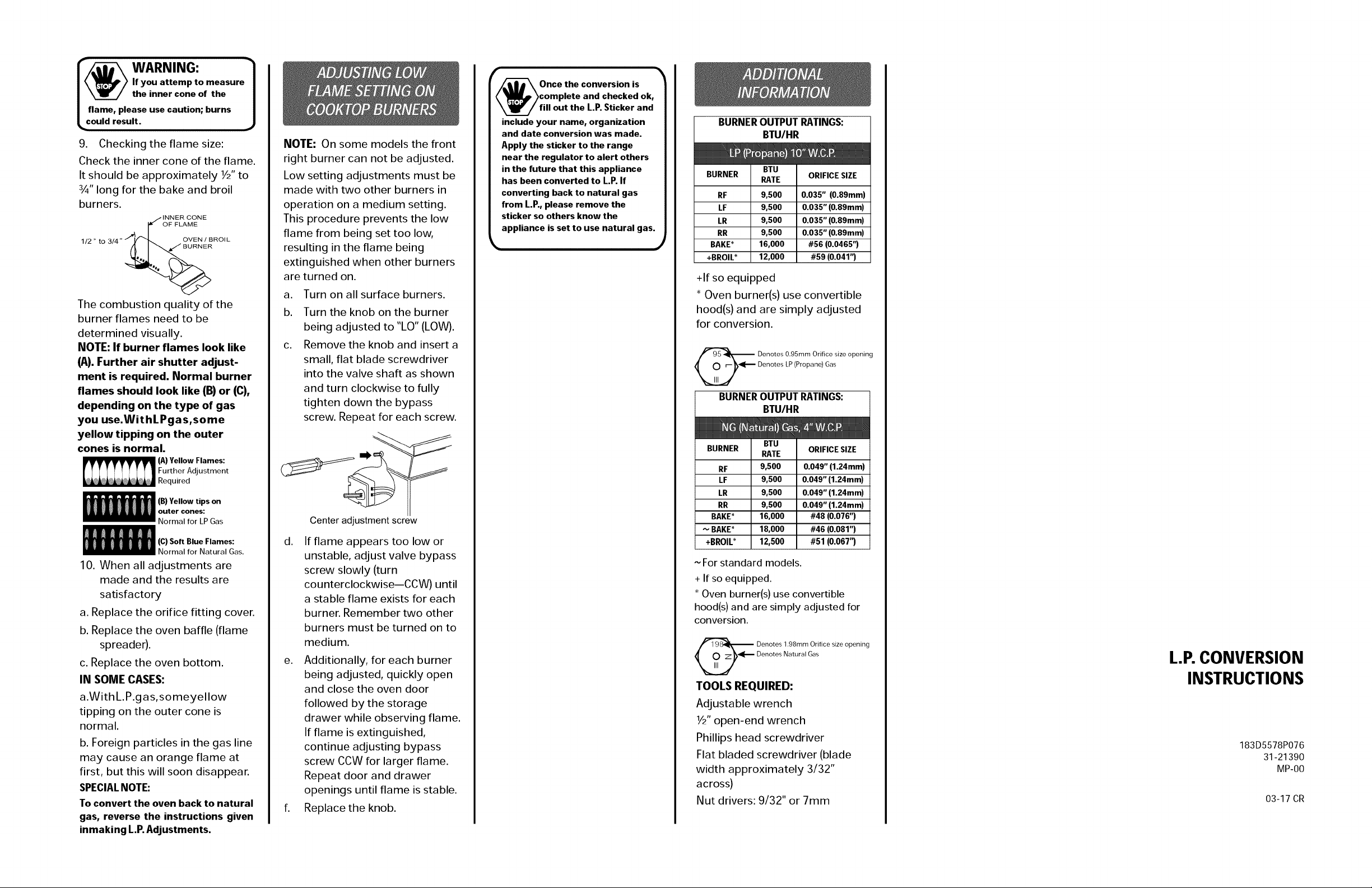

9. Checking the flame size:

Check the inner cone of the flame.

It should be approximately 1/2"to

%" long for the bake and broil

burners.

1/2 " to __

The combustion quality of the

burner flames need to be

determined visually.

NOTE: If burner flames look like

(A). Further air shutter adjust-

ment is required. Normal burner

flames should look like (B) or (C),

depending on the type of gas

you use.WithLPgas,some

yellow tipping on the outer

cones is normal.

10. When all adjustments are

a. Replace the orifice fitting cover.

b. Replace the oven baffle (flame

c. Replace the oven bottom.

IN SOME CASES:

a.With L.P.gas,someyellow

tipping on the outer cone is

normal.

b. Foreign particles in the gas line

may cause an orange flame at

first, but this will soon disappear.

SPECIALNOTE:

Toconvert the oven back to natural

gas, reverse the instructions given

inmaking L.P.Adjustments.

WARNING: 1

//INNER CONE

3/4" _ _ OVEN / BROIL

made and the results are

satisfactory

spreader).

F OF FLAME

(B)Yellow tips on

outer cones:

Normal for LP Gas

(C) Soft Blue Flames:

Normal for Natural Gas.

NOTE: On some models the front

right burner can not be adjusted.

Low setting adjustments must be

made with two other burners in

operation on a medium setting.

This procedure prevents the low

flame from being set too low,

resulting in the flame being

extinguished when other burners

are turned on.

Turn on all surface burners.

a,

Turn the knob on the burner

b.

being adjusted to "LO" (LOW).

Remove the knob and insert a

C,

small, flat blade screwdriver

into the valve shaft as shown

and turn clockwise to fully

tighten down the bypass

screw. Repeat for each screw.

Centeradjustmentscrew

d,

If flame appears too low or

unstable, adjust valve bypass

screw slowly (turn

counterclockwise--CCW) until

a stable flame exists for each

burner. Remember two other

burners must be turned on to

medium.

e. Additionally, for each burner

being adjusted, quickly open

and close the oven door

followed by the storage

drawer while observing flame.

If flame is extinguished,

continue adjusting bypass

screw CCW for larger flame.

Repeat door and drawer

openings until flame is stable.

f. Replacethe knob.

complete and checked ok,

Once the conversion is

fill out the L.P. Sticker and

include your name, organization

and date conversion was made.

Apply the sticker to the range

near the regulator to alert others

in the future that this appliance

has been converted to L.P. If

converting back to natural gas

from L.P., please remove the

sticker so others know the

appliance is set to use natural gas.

BURNER OUTPUT RATINGS:

BTU/HR

BURNER RATE ORIFICESIZE

RF 9,500 0.035" (0.89mm)

LF 9,500 0.035" (0.89mm)

LR 9,500 0.035" (0.89mm)

RR 9,500 0.035" (0.89mm)

BAKE* 16,000 #56 (0.0465'_

+BROIL* 12,000 #59 (0.041'1

BTU

+If so equipped

* Oven burner(s) use convertible

hood(s) and are simply adjusted

for conversion.

_ enotes 0.95mm Orifice size opening

Denotes LP (Propane) Gas

BURNEROUTPUTRATINGS:

BTU/HR

BURNER ORIFICESIZE

RF 9,500 0.049" (1.24mm)

LF 9,500 0.049" (1.24mm)

LR 9,500 0.049" (1.24mm)

RR 9,500 0.049" (1.24mm)

BAKE* 16,000 #48 (0.076")

BAKE* 18,000 #46 (0.081")

+BROIL* 12,500 #51 (0.067'_

~For standard models.

+ If so equipped.

* Oven burner(s) use convertible

hood(s) and are simply adjusted for

conversion.

_ Denotes 1.98mm Orifice size opening

BTU

RATE

Denotes Natural Gas

TOOLS REQUIRED:

Adjustable wrench

1/2"open-end wrench

Phillips head screwdriver

Flat bladed screwdriver (blade

width approximately 3/32"

across)

Nut drivers: 9/32" or 7mm

L.P.CONVERSION

INSTRUCTIONS

183D5578P076

31-21390

MP-00

03-17 CR

Loading...

Loading...