GE Profile JD968, Profile PD900DP, JD968BKBB - Profile, JDP47BFBB Installation Instructions Manual

Page 1

Installation

Self-Cleaning Radiant

Electric Drop-In Range

Instructions

JDP47, JD968, JD900

If you have questions, call 1.800.GE.CARES or visit our website at:

ge.com

Before You Begin

Read these instructions carefully and completely.

• IMPORTANT—Save these

instructions for local inspector’s use.

• IMPORTANT—Observe all

governing codes and ordinances.

• Note to Installer—Be sure to leave these

instructions with the consumer.

• Note to Consumer—Keep these

instructions for future reference.

• Proper installation is the responsibility

of the installer and product failure due

to improper installation is NOT covered

under the warranty.

• NOTE—This appliance must be properly

grounded.

• ATTENTION INSTALLER

All electric drop-in ranges must be hard

wired (direct wired) into an approved

junction box. A plug and receptacle is NOT

permitted on these products.

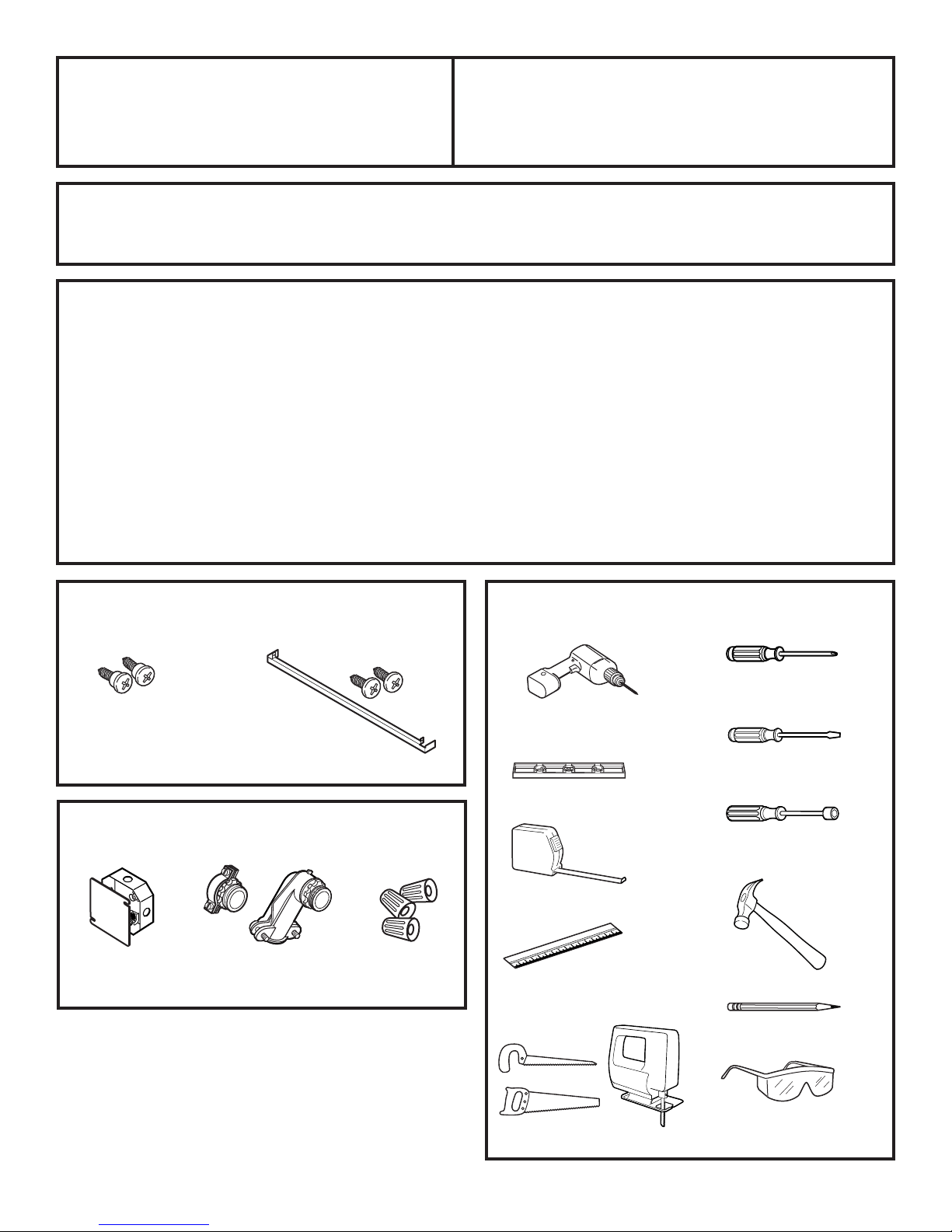

Parts Included

2 Shoulder Screws

(for stop device)

Lower Trim

2 Screws

Materials Needed

Junction Box

for 1/2” conduit

Tools You Will Need

Phillips Screwdriver

1/8” Drill Bit and

Electric or Hand Drill

Standard Screwdriver

Level

Nut Driver

Tape Measure

Wire NutsStrain Relief Clamp

Straight Edge

or Square

Hammer

Pencil

31-10622-1 1-07 JR

Safety Glasses

Hand or Sabre Saw

1

Page 2

Installation Instructions

IMPORTANT SAFETY INSTRUCTIONS

For Your Safety

WARNING:

safety, remove house fuse or

open circuit breaker before

beginning installation. Failure to do so

could result in serious injury or death.

• All rough-in and spacing dimensions must be

met for safe use of your range.

• To reduce the risk of burns or fire when

reaching over hot surface elements, cabinet

storage space above the cooktop should be

avoided. If cabinet storage space is to be

provided above the cooktop, the risk can be

reduced by installing a range hood that sticks

out at least 5” beyond the front of the

cabinets. Cabinets installed above the

cooktop must be no deeper than 13”.

• Be sure your appliance is properly installed

and grounded by a qualified technician.

For personal

Electrical

Requirements

This appliance must be supplied with the

proper voltage and frequency, and connected

to an individual, properly grounded branch

circuit, protected by a circuit breaker or fuse

having amperage as noted on rating plate.

(Rating Plate is located behind the oven door

on the range.)

We recommend you have the electrical wiring

and hookup of your range connected by a

qualified electrician. After installation, have

the electrician show you where your main

range disconnect is located.

Check with your local utilities for electrical

codes which apply in your area. Failure to

wire your range according to governing codes

could result in a hazardous condition. If there

are no local codes, your range must be wired

and fused to meet the requirements of the

National Electrical Code, ANSI/NFPA No. 70–

Latest Edition. You can get a copy by writing:

National Fire Protection Association

Batterymarch Park

Quincy, MA 02269

Effective January 1, 1996, the National

Electrical Code requires that new, but not

existing, construction utilize a four-conductor

connection to an electric range. When

installing an electric range in new construction,

a mobile home, recreational vehicle or an area

where local codes prohibit grounding through

the neutral conductor, follow the instructions in

the section on NEW CONSTRUCTION AND

FOUR-CONDUCTOR BRANCH CIRCUIT

CONNECTION.

You must use a three-wire, single-phase A.C.

208Y/120 Volt or 240/120 Volt, 60 hertz

electrical system. If you connect to aluminum

wiring, properly installed connectors approved

for use with aluminum wiring must be used.

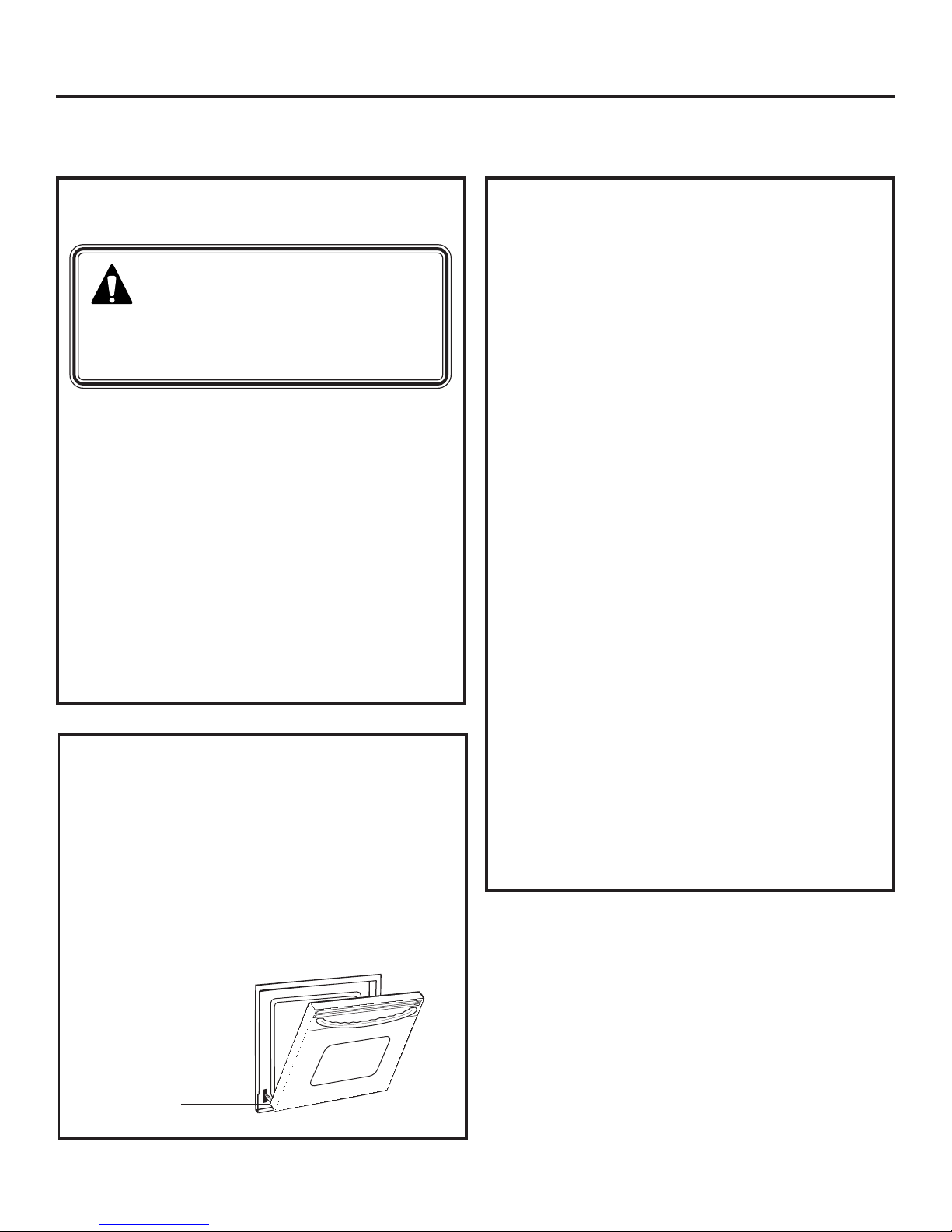

Rating Plate

Location

2

Page 3

Installation Instructions

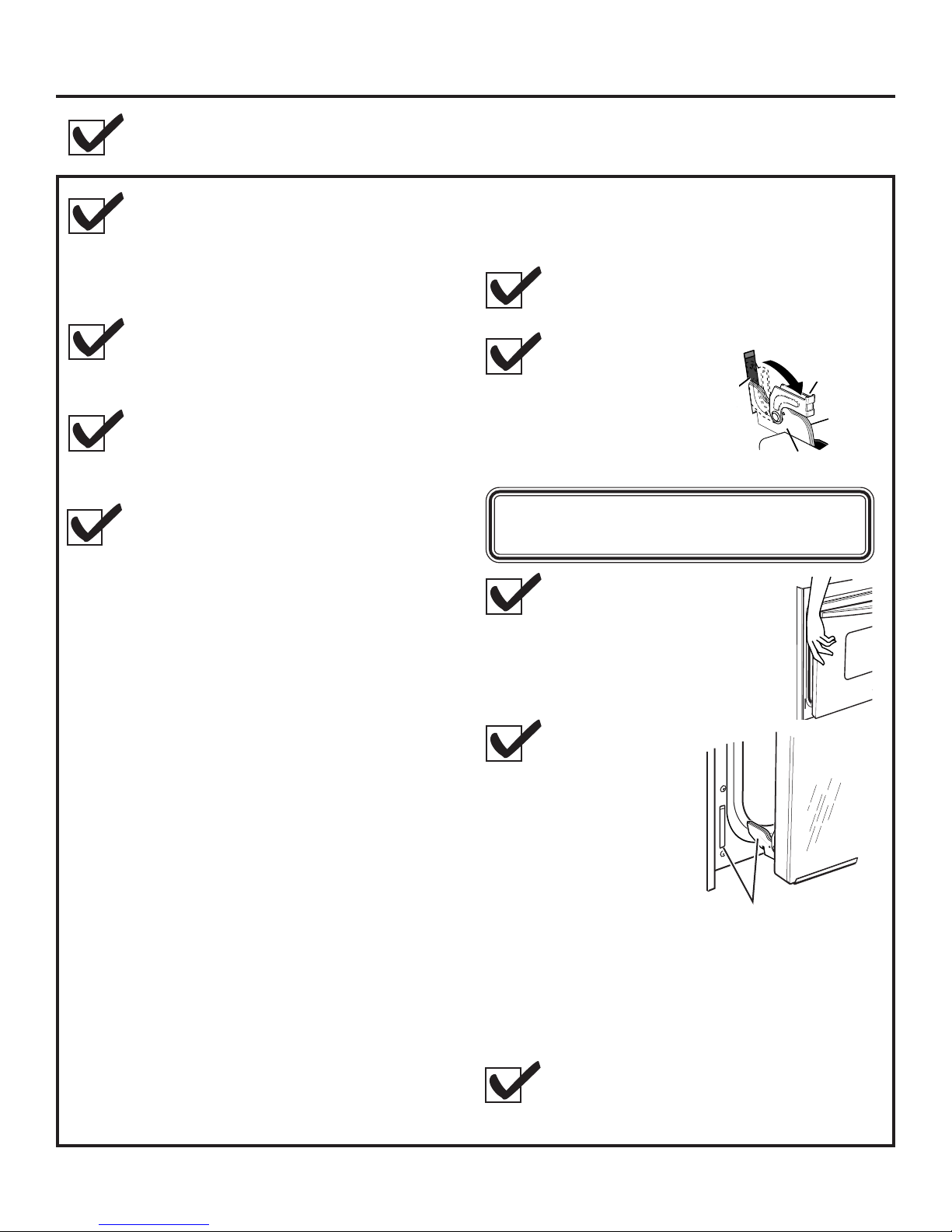

Pre-Installation Checklist

Move Range Indoors In Front of

Cabinet Opening

(Do not use hand trucks when

moving the unpackaged range.

Cooktop glass may be broken.)

Protect the kitchen floor! Flatten and

place a piece of the shipping carton in

front of the installation location to protect

the flooring.

Do not remove the protective

channel from the sides of the glass

cooktop until later in installation.

(If supplied)

Inspect Installation Location

Inspect cutout dimensions and location

of electrical junction box to be sure it fits

within the layout location. See page 4.

Refer to alternate construction section for

the following non-standard installations.

a.

Counter opening extends to the wall:

Maintop Filler Kit (JXS66XX), or

Backguard Kit (JXS36XX or JXS39SS).

WARNING: If you do not use these

kits, the anti-tip bracket must fit under

an attachment to the wall that can

withstand a force of 200lbs. in the

upward direction. See Section D1.

b. Island Installation:

To provide an optimum installation, the

top surface of the countertop must be

level and flat (lie on the same plane)

around the 3 sides that are adjacent to

range cooktop. Proper adjustments to

make the top flat should be made or

gaps between the countertop and

range cooktop may occur. Forcing the

cooktop to fit may cause excessive

gaps, or could break the glass cooktop

and void the warranty.

Door removal is not a requirement for

installation of the product, but is an added

convenience. To remove the door:

Open the oven door as far as it will go.

Hinge

Push both hinge

locks down toward

the door frame,

to the unlocked

Hinge

Hinge

Slot

Slot

Hinge

Unlocked

Unlocked

Position

Position

position. This may

require a flat blade

screwdriver.

Hinge

Hinge

Arm

Arm

DO NOT LIFT THE DOOR

BY THE HANDLE!

Place hands on both sides of

the door, and close the oven

door to the removal position.

This is half way between the

broil stop and fully closed.

Lift door up and

out until the

hinge arms

clear the slots.

Hinge Clears Slot

NOTE: The oven door is very heavy.

Be sure you have a firm grip before lifting

the oven door off the hinges. Use caution

once the door is removed. Do not lay the

door on its handle. This could cause dents

or scratches.

To obtain Kits:

a. Visit GE Web Site (See page 1)

b. Call GE Answer Center (See page 1)

c. Contact Dealer

Remove packing materials. Remove

labels on door, plastic on trims and

panel, and all tape around the range.

3

(Continued on following page)

Page 4

Installation Instructions

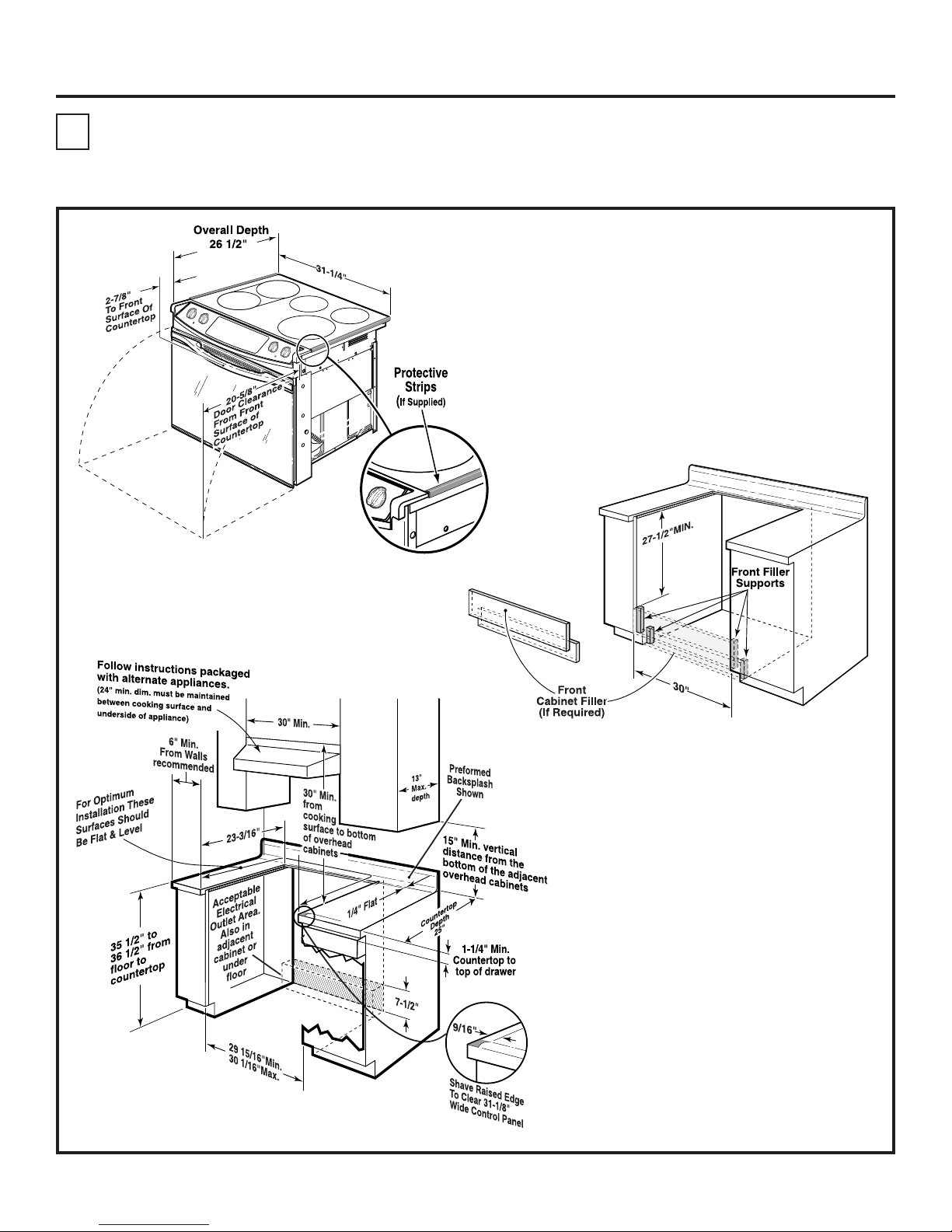

A

Pre-Installation Cutout and Required

Clearances

NOTE: Drop-In Ranges are designed to

hang from the countertop only. Do not

install on a platform or support rails.

If cabinets are placed less than

30” min. above the range, see

alternate construction.

30” ranges conform to U.L.

requirements for 0” spacing

from vertical walls below

countertops. Allow 1/4”

minimum clearance at the back

wall above the countertop.

Wall coverings, counters and

cabinets around range must

withstand heat (up to 194°F)

generated by the range.

4

Page 5

Installation Instructions

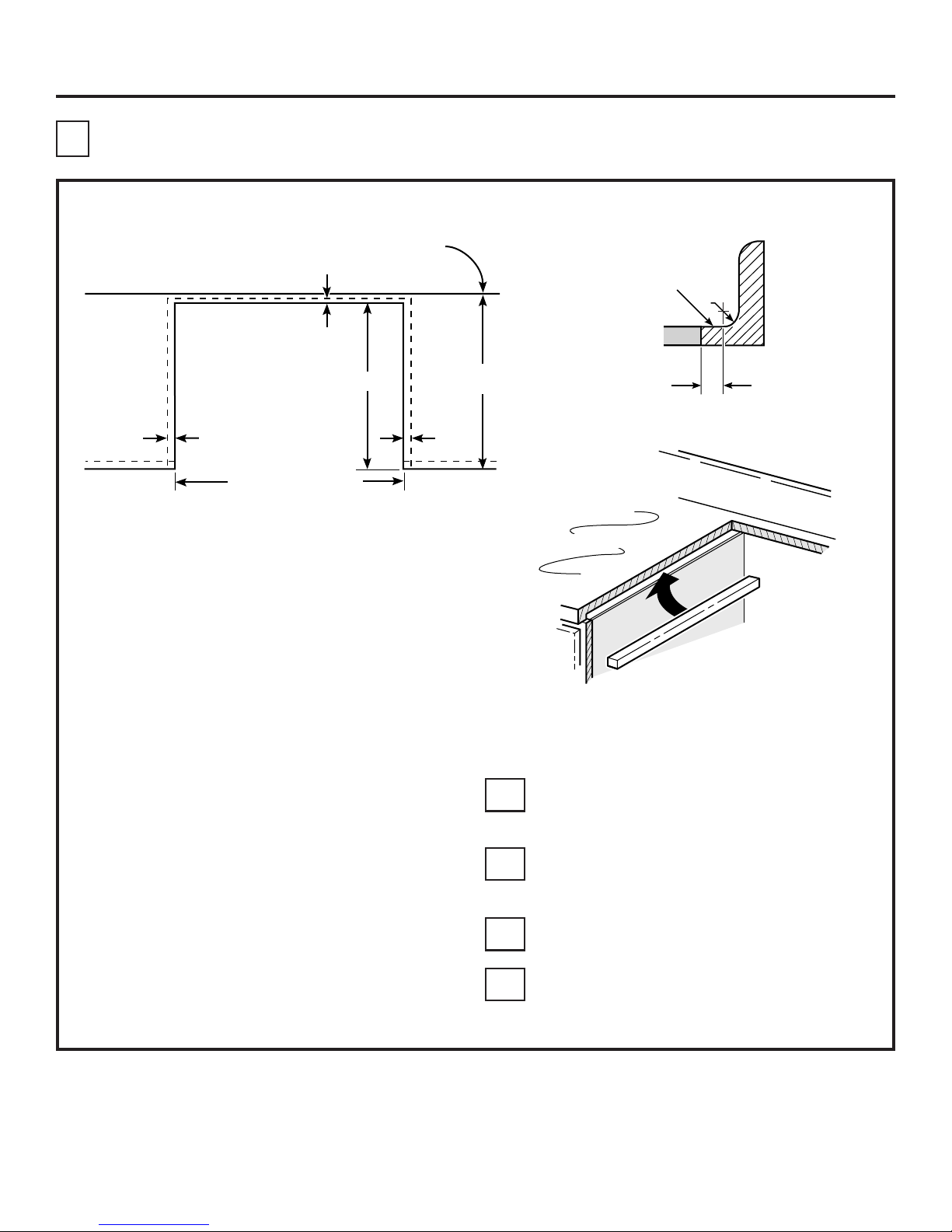

B

Standard Installation Preparation

STANDARD INSTALLATION

Wall

Flat

Area

1/4” Min.

Flat

23-3/16”

25”

Typically

1/4”

R

9/16” Min.

Flat

29-15/16”– 30-1/16”

Smooth Cut

9/16” Min.

The Standard Installation of this Drop-In

Range is to hang by the countertop on the

side metal flanges under glass cooktop.

This Range must not be installed on a

base or sub structure (2”x 4” support).

If the construction of your cabinet cannot

provide a 1/4” flat area at the back of the

countertop opening, consider changing the

countertop to accommodate this dimension.

If the area is not flat, excess tension may

be applied to the glass cooktop, causing

breakage and voiding the warranty.

Flat

B1

B2

B3

B4

Range Support

Countertop

Braces secured between the

underside of the countertop

and the cabinet if required to

obtain 1-1/4” minimum

thickness (two sides)

Center the 30” wide opening over the

adjacent cabinets and mark with a

straight edge.

Using a straight edge, mark the back line

at 23-3/16” from the front edge of the

counter.

Be careful not to damage the adjacent

cabinets while cutting the countertop.

Remove countertop raised edge, if

incorporated. (See illustration on page 4)

5

Page 6

Installation Instructions

C

Electrical Connections

C1

C2

C3

C4

Remove house fuse or open circuit

breaker.

Loosen screws for the junction box

cover and rotate out of place or remove

the cover.

Examine the junction box location to

determine the best routing of the

conduit, and select the best available

7/8” diameter knockout. Avoid using

holes in the top of the junction box to

prevent the conduit from interfering

with the back of the range.

Break open the selected knockout by

placing a bladed screwdriver on the

scored opening in the junction box and

striking the screwdriver with a hammer.

(Pliers may be required to complete the

removal of the knockout.)

WARNING:

connection of aluminum house

wiring to copper leads can

result in an electrical hazard or fire.

Use only connectors designed for

joining copper to aluminum and follow

the manufacturer’s recommended

procedure closely.

GENERAL NOTE FOR ALL WIRE NUT

APPLICATIONS: THE PROPER SIZE WIRE

NUT SHALL BE PLACED OVER THE

STRIPPED LEADS AND THE WIRE NUT

TWISTED UNTIL THE WIRE NUT CAN

NOT BE PULLED FROM THE LEADS.

NO CONDUCTOR SHALL BE EXPOSED

IN THE CONNECTION. THE EXCEPTION

TO THE CONDUCTOR BEING EXPOSED

IS THE BARE COPPER GROUND

CONNECTION.

Improper

C5

C6

7/8” Knockout

Cover Rotated

From Box Opening

Position the range in front of the

opening, but slightly to the side,

in a manner so that a person can enter

the opening to wire the range to the

house wiring in the junction box.

Feed wires and conduit through the

open hole and snap the conduit fitting

into the hole. Route the conduit in a

manner that will not interfere with the

rear wire cover. The conduit must be

routed below the wire cover.

BREAKER OR FUSE SIZE

240V 40 Amps +

208V 40 Amps +

+ NOTE: Check Local Codes for

required breaker size.

6

(Continued on following page)

Page 7

Installation Instructions

C

Electrical Connections cont.

THREE-CONDUCTOR BRANCH

CIRCUIT CONNECTION

When connecting to a 3-conductor branch

circuit, if local codes permit:

C7a

C7b

Range Conduit

Snaps Into Box

Connect the bare oven ground

conductor with the crimped neutral

(white) lead to the branch circuit

neutral (white or gray in color),

using wire nuts.

Connect the oven red lead to the

branch circuit red lead, and the oven

black lead to the branch circuit black

lead in accordance with local codes,

using wire nuts. If the residence red,

black or white leads are aluminum

conductors, see “WARNING” note

(See page 6).

Black

Branch

Circuit

Red

Ground and

Neutral Wires

(White)

Neutral Bare Wire

Connection

Alternate

Knockout

NEW CONSTRUCTION AND

FOUR-CONDUCTOR BRANCH

CIRCUIT CONNECTION

• When installing in new construction, or

• When installing oven in a mobile home or

recreational vehicle, or

• When local codes do not permit grounding

through neutral:

C7a

C7b

C7c

Cut the neutral (white) lead from the

crimp. Re-strip the neutral (white)

lead to expose the proper length of

conductor and connect it to the white

or gray branch circuit neutral in

accordance with local code using

wire nuts.

Attach the appliance grounding lead

(green or bare copper) in accordance

with local codes. If the residence

grounding conductor is aluminum,

see WARNING note (See page 6).

Connect the oven red lead to the

branch circuit red lead and the oven

black lead to the branch circuit black

lead in accordance with local codes,

using wire nuts. If the residence red,

black or white leads are aluminum

conductors, see “WARNING” note

(See page 6).

Black

7

Range Conduit

Snaps Into Box

Red

Branch

Circuit

Ground

Wires

Alternate

Knockout

White

(Continued on following page)

Page 8

Installation Instructions

C

Electrical Connections cont.

C8

Do not shorten the flexible conduit. The conduit strain relief clamp must be securely

attached to the junction box and the flexible conduit must be securely attached to the

clamp. If the flexible conduit will not fit within the junction box, do not install the oven

until a clamp of the proper size is obtained.

NOTE TO ELECTRICIAN: The 3 power leads supplied with this appliance are UL recognized

for connection to larger gauge household wiring. The insulation of these 3 leads is rated at

temperatures much higher than the temperature rating of household wiring. The current carrying

capacity of the conductor is governed by the temperature rating of the insulation around the wire,

rather than the wire gauge alone.

Reinstall Junction box cover.

8

Page 9

Installation Instructions

D

Standard Installation Instructions

D1

Installing the Anti-Tip Bracket

The anti-tip bracket is attached to

the back of the Drop-In Range. It is

designed to fit under the bottom of the

countertop opening at the rear. Measure

counter thickness at back of cutout to

determine correct bracket location.

1/4” Min. Flat Area

Glass

Maintop

Anti-Tip

Bracket

Bottom of

Countertop

to Engage

Bracket by

1/2” Min.

ANTI-TIP INSTALLATION

Interior Wall

Wall Stud

Countertop

Thickness

Bottom of

Countertop

Wire Cover

Select the proper position for the countertop

thickness and move bracket to proper position.

(Unit is supplied with bracket in position 1.)

1 For 3/4” Counter

2 For 1.18” (3 cm) Counter

3 For 1.5” Counter

Anti-Tip Bracket Location

Glass Cooktop

4 For 3.5”

5 Alternate

(shown below)

(Rear of Range)

ALTERNATE

ANTI-TIP INSTALLATION

Interior Wall

Non-Kit Application

Glass Maintop

Wall Stud

Countertop

Surface

Attachment

Position #5

Non-Kit

Application

Anti-Tip Bracket

*Attachment

To Engage

Bracket By 1/2” Min.

9

10-3/8”

Wire

Cover

1-1/2”

Attachment

Anchored

To Wall Stud

Is Required

(Continued on following page)

Page 10

Installation Instructions

D

Standard Installation Instructions cont.

D2

Install Stop Screw

These screws prevent the range from

sliding out of position during operation.

Carefully mark the cabinet for the

location of the stop screws. Drill 1/8”

pilot holes into the cabinet, each side

of the range. (Make sure not to drill

entirely through the cabinet wall.)

Carefully turn the shoulder screws into

the pilot holes until they are tight.

D3

Range

Placing the Range into the

Opening

It is suggested that two people lift the

range into place, carefully setting the

side metal flanges under the glass on

the edges of the countertop opening.

The protective channels must be in

place (if supplied) during this operation.

Carefully slide the range toward the

back of the opening. In the last 1” of

travel, lift the front of the range approx.

1/2” to clear the stop screws located in

the sides of the cabinet and slide the

range until the range is seated. Lower

front of the range on countertop.

Lift and Slide

Range on

Countertop

Countertop

10

Cabinet

Countertop

Make sure the edge

of the countertop

fits flush against

the end of the

Front Control Panel

(Continued on following page)

Page 11

Installation Instructions

D

Standard Installation Instructions cont.

D4

D5

Remove the Protective

Channels (if provided)

Carefully remove the protective

channels from the sides of the glass

cooktop. This may require a slight

lifting of the range to remove the

weight of the range from the protective

channels.

Glass Cooktop

Remove Protective Cover From

Both Sides After Range Is In Cabinet

Protective Cover

Check For Proper Installation

of the Stop Screw

D6

Attach the Lower Trim

Attach the lower trim (supplied

separately with the range) to the

bottom of the vertical side trim with

the 2 screws supplied.

Side

Trim

End Flange

& Tab On Lower

Trim Fits Inside

Side Trim

Lower

Trim

Top Flange

1/2” Wide

Attach

1 Screw

Each Side

Lower

Left

Corner

Front

Frame

Look at both sides of the range under

the door. The stop screws must be

located in the notch on the sides of the

range, and not touch the top of the

notch when the range is fully seated

on the countertop. If the screws do not

meet the requirements, move the

screws to a position that meets these

requirements. (See illustration below.)

Notch in Bottom

of Side Trim

Side

Trim

Shoulder

Screw

Clear

11

(Continued on following page)

Page 12

Installation Instructions

D

Standard Installation Instructions cont.

Replacing the Oven Door

NOTE:

may need help lifting the door high

enough to slide it into the hinge slots.

Do not lift the door by the handle.

D7

D8

The oven door is heavy. You

Lift the oven door by

placing one hand on

each side. The door is

heavy, so you may need

help. Do not lift the door

by the handle.

With the door at the same angle as

the removal position (halfway between

the closed and broil stop position,

seat the notch of the hinge arm into

the bottom edge of the hinge slot.

The notch of the hinge arm must be

fully seated into the bottom of the slot.

Hinge Arm

Bottom Edge

of Slot

D10

D11

D12

Push the hinge locks up against the

front frame of the oven cavity, to the

locked position.

Hinge in

Locked Position

Notch of Hinge

Securely Fitted

into Bottom of

Hinge Slot

Close the oven door.

Check for Proper Installation

of Anti-Tip Bracket

Lower the oven door and gently apply

medium force at the handle end until

movement of the range is detected.

Continue pressing until the anti-tip

bracket is engaged and movement

stops. A small amount of movement is

acceptable at the back of the range

top, but it should be stable and not tip

once the anti-tip bracket is engaged.

Hinge Notch

Open the oven door as far as it

D9

will open.

12

Page 13

Installation Instructions

Final Checklist

Check to make sure the circuit breaker is closed (Reset) or the circuit fuses are

replaced.

Be sure power is in service to the building.

Check to be sure that all packing materials and tape on metal panel (if applicable)

under control knobs and drawer have been removed.

Operation Checklist

Check to make sure the Clock display is energized. If a series of horizontal red lines

appear in the display, disconnect power immediately. Recheck the range wiring

connections. If change is made to connections, retest again. If no change is required,

have building wiring checked for proper connections and voltage. It is recommended

that the clock be changed if the red lines appear.

Push down and turn any one of the four surface knobs to “MED” setting to observe

that the element glows within 15 seconds. Turn the knob off when glow is detected.

If the glow is not detected within the time limit, recheck the range wiring connections.

If change is required, retest again. If no change is required, have building wiring

checked for proper connections and voltage.

13

Page 14

Installation Instructions

Alternate Construction Preparation

AA

Optional Maintop Filler or

Backguard Kit

If counter opening extends to the wall, it

will require Maintop Filler Kit (JXS66XX)

or Backguard Kit (JXS36XX or JXS39SS)

to close the gap.

NOTE: If the countertop is greater than

25”, it will show a gap between the

backguard and wall or between filler kit

and the wall.

If the countertop is less than 25”, a gap

will occur between the countertop front

and the control panel ends.

(See page10, D3).

Wall

25”

Must Be

Level

AB

AC

Island Installation

When installing in an island or other

non-standard location, countertop cutout

dimensions must be according to page 5.

For the anti-tip bracket instructions, see

page 9.

In this application, do not use Backguard

Kit (JXS36XX or JXS39SS).

Cabinets Over The Range

Less Than 30”

If a 30” clearance between cooking

surface and overhead combustible

material or metal cabinets cannot be

maintained, protect the underside of

the cabinets above the cooktop with

not less than 1/4” insulating millboard

covered with sheet metal not less than

0.0122” thick.

9/16”

Must Be

Flat

9/16”

30”

Smooth Cut

Must Be Level

Refer to the Filler or Backguard Kit

instructions for Installation details.

Must Be

Flat

14

Page 15

NOTES

15

Page 16

NOTES

1-07 JR

16

31-10622-1

Loading...

Loading...