Page 1

g

GE Consumer Service Training

TECHNICAL SERVICE GUIDE

1999 SPECTRA™ SERIES - FREE-STANDING

ELECTRIC RANGES W/ TRUETEMP

TM

MODEL SERIES:

JB960_B

JB940_B

JBP79_B

JBP78_B

JBP63_B

JBP64_B

JBP66_B

JBP60_B

JBP48_B

JBP35_B

JBP30_B

JBP26_B

JBP24_B

JBP21_B

JBP19_B

03/99

Page 2

IMPORTANT SAFETY NOTICE

The information in this service guide is intended

for use by individuals possessing adequate

backgrounds of electrical, electronic and

mechanical experience. Any attempt to repair a

major appliance may result in personal injury and

property damage. The manufacturer or seller

cannot be responsible for the interpretation of this

information, nor can it assume any liability in

connection with its use.

CAUTION

To avoid personal injury while servicing this unit,

disconnect power before servicing. If grounding

wires, screws, straps, clips, nuts, or washers used

to complete a path to ground are removed for

service, they must be returned to their original

position and properly fastened.

Page 3

Table of Contents

Features and Benefits

Cooktop Configuration

Model Series / Installation

Use and Care Information

Cooktop Light Replacement

Door Removal

Cooktop Removal

Bake Element Removal

Door Switch Removal

Oven Liner Removal

2-3

4

5-8

9-12

13

13

14

15-17

18

18-19

Control Console Access

Infinite Heat Controls

Thermal Limiter Switch

ERC Special Features

ERC Fault Code Memory Test

ERC On-board Diagnostic Tests

Door Latch Mechanism

TrueTemp™ Cooking

Schematic & Strip Circuits

Exploded Parts Views

20

21

21

22-23

24-25

26-28

28

29

30-33

34-37

– 1 –

Page 4

1999 SPECTRA™ series - Free Standing Electric Ranges w/ TrueTemp™

Pages 5 through 8 of this service guide show all of the models in the new series of Spectra™ ranges. This

service guide will focus primarily on the JB960, GE Profile Performance models listed on page 5. The JB960

models reflect most of the changes that are incorporated in the new series of electric ranges (Spectra

series). This service guide will focus primarily on the NEW features introduced in the Spectr a™ model series.

What this service guide will not cover is basic component servicing common to most of our previous year

models (component removal/installation and diagnostics).

The information in this service guide is intended for use by individuals possessing adequate backgrounds of

electrical, electronic and mechanical experience. All resistances listed in this guide are approximate resistances and will vary depending on the type and condition of the meter being used. All disassembly procedures should be performed with power removed from the unit.

GE Profile Performance Series™

JB960AB

• Almond on almond • Largest oven in America* • Selfcleaning convection ov en with dedicated third, dual-loop

heating element • Super large 4.5 cu. ft. capacity oven

• CleanDesign oven interior • Right rear 6” element with

warming function • QuickSet V ov en controls (see page

6, QuickSet V) • Two 7” ribbon heating elements with

connecting bridge element • One dual 6”/9” and one 6”

ribbon heating element • Easy-view hot lights • Onepiece upswept cooktop • Frameless glass oven door

with Sure Grip handle • Automatic self-clean oven latch

• Big View window • Fluorescent night light • Three

oven shelv es - one off-set • Automatic meat thermometer

™

GE Convection ranges use the European or “true” convection system. The difference between “us and them”

is a third dual loop heating element that surrounds the

convection fan in the back wall of the oven. The convection fan at the rear of the oven, gently circulates

heated air evenly throughout the entire oven cavity, under and around the food. The moving air penetrates

foods faster than stationary air.

* Among leading manufacturers

+40

+30

+20

+10

Baking

T emp.

-10

-20

-30

-40

SmartLogic Electronic Control delivers more consistent oven temperatures for exceptional cooking results.

TrueTemp

GE

Other

Manufacturers'

Average

– 2 –

Page 5

Ten exclusives make it super versatile,

super accurate and easy-to-clean

➊

➋

➌

➍

1.1.

1. Seamless backguard Design

1.1.

2.2.

2. Bridge element

2.2.

3.3.

3. Frameless glass oven door

3.3.

4.4.

4. TrueTemp™

4.4.

➎

➑

➓

5.5.

5. 5.0 cu. ft. oven capacity

5.5.

6.6.

6. Largest usable capacity

6.6.

7.7.

7. Six rack design

7.7.

8.8.

8. Six-Pass bake element

8.8.

➏

➐

➒

9.9.

9. CleanDesign Interior

9.9.

10.10.

10.Largest broiler pan

10.10.

With the largest, most accurate oven in america and a variety of cooktop elements, the

GE Spectra™ Range lets you cook e xactly what you want to cook. And with CleanDesign,

cleanup has never been easier or faster!

Exclusive CleanDesign

As for cleanability, the CleanDesign oven interior* conceals the lower oven element under a porcelain-coated

steel surface. All you see and clean is a flat, smooth ov en

surface.

* on select models

Convenient New Warming Option

Keeps soups, sauces, breads and pancakes warm, or

melts butter and chocolate. Or use this new burner as

you would any other element.

– 3 –

Page 6

– 4 –

OFF

FRONT

REAR

HOT

COOKTOP

LARGE

BURNER

SMALL

BURNER

OFF

OFF

FRONT

REAR

Profile Performance

HOT

COOKTOP

BRIDGE

BURNER

FRONT

BURNER

OFF

TrueTemp

Convection

1

CLEAR

OFF

PROBE

SELF

CLEAN

COOKING

TIME

KITCHEN

TIMER

OVEN

LIGHT

DELAY

START

CLOCK

TOP

LIGHT

BAKE

BAKE

CONVECTION

ON OFF

ROAST

CONVECTION

BROIL

START

2

3

4

5

6

7

8

9

0

OVEN

TIME CONTROLS

HS

2

DUAL

ELEMENT

1000 W

2500 W

HS

4

2

SINGLE

ELEMENT

1500 W

W

M

REAR

H

I

8

8

H

I

6

6

4

2

L

O

L

O

2

4

SMALL

BURNER

LARGE

BURNER

OFF

W

M

FRONT

BRIDGE SURFACE

ELEMENT ASSY.

1800 W

1800 W

LR

LF

BRIDGE

2600 W

RR

RF

SMALL

RF

LARGE

(Inner & Outer)

RF SMALL 1000 W

RF LARGE 2500 W

(BOTH ELEMENTS)

RR 1500 W

LF SINGLE 1800 W

LF BRIDGE 2600 W

(LF + CENTER)

LR 1800 W

LOCATION WATT AGE

COOKTOP CONFIGURATION

H

I

8

8

H

I

6

6

4

2

L

O

L

O

2

4

BRIDGE

BURNER

OFF

FRONT

BURNER

FRONT

REAR

TrueTemp

Convection

OVEN

BAKE

PROBE

SELF

CLEAN

CLEAR

OFF

BAKE

12345678

CONVECTION

ROAST

CONVECTION

BROIL

CLOCK

START

HI LO

KITCHEN

TIMER

OVEN

LIGHT

TOP

LIGHT

COOKING

TIME

DELAY

START

TIME CONTROLS

ON OFF

90

CONTROL LOCKOUT

= LF Element Only

= LF Element + Center Bridge Element

= RF Inner & Outer Element

= RF Inner Element Only

H1

P

H2

L2

L1

CURRENT

SENSITIVE

CONTROL

5

N

2

3

L1

H1

TOP

4

P

L2

H2

GRND

VOLTAGE

SENSITIVE

CONTROL

(DUAL)

5

N

2

3

L1

H1

TOP

4

P

L2

H2

GRND

VOLTAGE

SENSITIVE

CONTROL

(DUAL)

VOLTAGE

SENSITIVE

CONTROL

H1

P

H2

L1

L2

TOP

ERC V (QUICKSET V) - WITH CAPACITANCE TOUCH CONTROLS

Page 7

30" F

REE-STANDINGCLEANDESIGNELECTRIC

R

ANGES

GE Profile Performance Series

™

GE Profile™GE

JB960WB JB940WB JBP79WB JBP78WB JBP66WB

JB970SB JB960BB JB940BB JBP79BB JBP78BB JBP66BB JBP64BB JBP63BB JBP60BB

JB960AB JB940AB JBP79AB JBP78AB JBP66AB

Features

Self-cleaning oven Convection Convection Convection

Self-clean latch Auto Auto Auto Auto

Oven capacity (cu. ft.) 3.7 4.5 4.5 5.0 5.0 5.0 5.0 3.7 3.7

CleanDesign Oven Interior (hidden bake)

Oven shelves 3 (1 off-set) 3 (1 off-set) 3 (1 off-set) 2 2 2 2 2 1

Patterned glass-ceramic cooktop Black Black Black Black Black Black Black Black Black

One-piece upswept cooktop

Dual 6"/9" heating element (1000/2500 watt) (1000/2500 watt) (1000/2500 watt) (1000/2500 watt) (1000/2500 watt)

8" heating elements (2000 watt) (2000 watt) (2000 watt) (2000 watt) (2000 watt) (2000 watt) (2000 watt)

7" heating element (1800 watt) (1800 watt)

Bridge element 1 (800 watt) 1 (800 watt)

Total wattage 4400 4400

6" heating elements (1500 watt) (1500 watt) (1500 watt) (1500 watt) (1500 watt) (1500 watt) (1500 watt) (1500 watt) (1500 watt)

Warming option (75 watt) (75 watt) (75 watt) (75 watt)

Warming zone 1 (120 watt)

Infinite heat controls

TrueTemp™ System

SmartLogic™ controls

Six-pass power bake element

Convection Bake

Convection Roast

Convenience Controls

QuickSet oven controls QuickSet V QuickSet V QuickSet V QuickSet IV QuickSet III QuickSet III QuickSet II QuickSet II QuickSet I

Digital temperature display

Oven function icons

Glass touch controls

Digipad numeric entry

Convection conversion

Delay bake

Oven light pad

Control lock capability

Start pad

Self-clean cool-down time display

Auto self-clean

Delay clean option

Auto oven shut-off w/override w/override w/override w/override w/override w/override w/override w/override

Audible preheat signal

Dual element bake

Automatic meat thermometer

Hot surface lights

Oven “ON” light

Self-clean cycle light

Interior oven light Auto/Pad Auto/Pad Auto/Pad Auto/Pad Switch Switch Switch Switch Switch

Full-width fluorescent cooktop night light

Storage drawer Stainless steel Black Black Black Black CM* CM* CM* CM*

Broiler pan/grid

Roasting rack

1 Ribbon 1 Ribbon 1 Ribbon 1 Ribbon 1 Ribbon

2 Ribbon 2 Ribbon

1 Ribbon 1 Ribbon 2 Ribbon 2 Ribbon 2 Ribbon 2 Ribbon 2 Ribbon 2 Ribbon 2 Ribbon

●●●●●●●●●

●●●●●●

●●●●●●

●●●●●●

●●●

●●●

●●●●●●●●●

●●●●●●●●

●●●●

●●●●

●●●

●●●●●●

●●●

●●●●

●●●●

●●●●●●●●

●●●●●●●●●

●●●●●●

●●●●●●●●

●●●●●●●●●

●●●

●●●●●●●●●

●●●●●●●●●

●●●●●●●●●

●●●●

●●●●●●●●●

●●●

●●

White White White White White

Almond Almond Almond Almond Almond

●●●●●●●●

1 Ribbon 1 Ribbon 1 Ribbon 2 Ribbon 2 Ribbon 2 Ribbon 2 Ribbon

●●

White White White White White

Almond Almond Almond Almond Almond

●●●●●●

●●●●●

Appearance

WW WW WW WW WW

Color appearance* SS BB BB BB BB WH/AD WH/AD WH/AD WH

Frameless glass oven door Stainless steel Black Black Black Black Black Black Black Black

Oven door with window

Designer-style handle Tubular Sure Grip Sure Grip Sure Grip

Easy Level System

●

●●●●●●●●●

AA AA AA AA AA

White White White White White

Almond Almond Almond Almond Almond

Big View Big View Big View Big View

●●●●●

●●●

Weights & Dimensions

Overall oven interior dimensions 22-3/4 x 15-7/8

(WxHxD in inches) x 15-7/8 x 17-3/4

Approx. ship. wt. (lbs.) 194 206 206 198 198 175 174 165 165

24-1/4 x 19 x 17 24-1/4 x 19 x 19

23 x 16

Power/Ratings

KW rating @ 240V 11.9 12.4 11.5 11.0 11.0 10.5 10.5 10.5 10.5

208V 8.9 9.3 8.6 8.3 8.3 7.9 7.9 7.9 7.9

Accessories

Cooktop cleaning creme and scraper

*SS = Stainless steel, BB = Black on black, WW = White on white, AA = Almond on almond, WH = White, AD = Almond, CM = Color-Matched indicates color of drawer matches range cooktop (either white or almond).

●●●●●●●●●

– 5 –

Page 8

I

NSTALLATION/SPECIFICATIONS FOR

30" F

REE-STANDINGCLEANDESIGNELECTRICRANGES

Dimensions and Installation Information (in inches)

2-1/2

Acceptable electrical

outlet area

A

B

C*

D

30

25

2-1/2

7-1/2

Preferred electrical

outlet area

Roughed-in dimensions

Warranty Information

Full one-year warranty (parts and labor at no additional charge)

applies to the entire range. Additional limited four-year warranty

on glass-ceramic cooktop (parts only). See written warranty for

complete details.

Cabinet Dimensions (in inches)

Model A B C* D

JB970SB 30 48-1/4 26-5/8 45-1/8

JB960WB/AB/BB 29-7/8 46-1/2 25-3/8 47-5/8

JB940WB/AB/BB 29-7/8 46-1/2 25-3/8 47-5/8

JBP79WB/AB/BB 29-7/8 46-1/2 25-3/8 47-5/8

JBP78WB/AB/BB 29-7/8 44-7/16 25-3/8 47-5/8

JBP66WB/AB/BB 29-7/8 44-7/16 25-3/8 47-5/8

JBP64BB 29-7/8 44-7/16 25-3/8 47-5/8

JBP63BB 29-7/8 44-1/2 25-7/16 46-1/8

JBP60BB 29-7/8 44-1/2 25-7/16 46-1/8

*Dimension from wall to front of closed oven door handle is

28-7/8" on model JB970; 27-3/8" on models JB960/940, JBP79;

27-3/4" on models JBP78/66/64; and 27-1/2" on model JBP63/60.

Note: Conforms to U.L. requirements for 0” spacing for adjacent walls

below countertops. To reduce possibility of scorching of walls, it is

recommended a minimum of 1-1/2” spacing be allowed from adjacent

side walls to allow for possible extended, high-heat, no-load heating

element operation.

Installation Information:

Before installing, consult installation instructions packed with range

for current dimensional data.

Receptacle Locations: For 30” Free-Standing Ranges locally approved

flexible service cord or conduit must be used because terminals are not

accessible after range installation. See shaded area drawing for location

of electrical outlet box. Recommended outlet locations allow range to

be installed directly against wall.

All GE ranges are equipped

with an Anti-Tip device. The

installation of this device is an

important, required step in the

installation of the range.

QUICKSET I

• Auto self-clean • 2-step self-clean • Preheated oven light • Dual element

bake • Quick turn oven control • Platinum-tipped electronic oven sensor

QUICKSET II

Same as QuickSet I, plus:

• Digital temperature display with recall • Electronic digital clock • Electronic

reminder timer, up to 12 hours • Audible Preheat signal • 12 hour automatic

oven shut-off • Self-clean countdown digital display, includes cook down

QUICKSET III

Same as QuickSet II, plus:

• Automatic oven control • Delay Bake • Delay Self-Clean • Adjustable selfclean cycle time

QUICKSET IV

Same as QuickSet III, plus:

• Automatic self-clean • All touchpad control • Large digital temperature

display • Variable broil

QUICKSET V

Same as QuickSet IV, plus:

• Convection bake/roast • Temperature probe • Extra-large graphics and

extra-large touchpads • Digital glass capacitance touch control (0-9) entry

• Oven function icons

– 6 –

Page 9

30" F

REE-STANDINGQUICKCLEAN

™

S

ELF-CLEANELECTRICRANGES

™

GE Profile

JBP48WB JBP30WB JBP26WB

JBP48AB

JBP48BB JBP35BB JBP30BB JBP26BB JBP24BB JBP21BB JBP19BB

GE

JBP30AB JBP26AB JBP21WB

Features

Oven cleaning Self-Clean Self-Clean Self-Clean Self-Clean Self-Clean Self-Clean Self-Clean

Oven capacity (cu. ft.) 5.0 5.0 5.0 5.0 5.0 3.7 3.7

Oven shelves 2 2 2 2 2 2 1

Upswept porcelain-enameled

cooktop ●●●●●●●

Clean-Well™ Cooktop System ●●●●●●●

Lift-up cooktop w/dual support rods ●●●●●●

8" heating elements 2 (6 turns) 2 (6 turns) 2 (6 turns) 2 (5 turns) 2 (5 turns) 2 (5 turns) 1 (5 turns)

6" heating elements 2 (5 turns) 2 (5 turns) 2 (5 turns) 2 (4 turns) 2 (4 turns) 2 (4 turns) 3 (4 turns)

Warming option ●

Infinite heat controls ●●●●●●●

Plug-in Calrod® heating elements Deluxe Deluxe Deluxe ●●●●

Removable 1-piece drip bowls Black Black Black Chrome Chrome Chrome Chrome

TrueTemp™ System ●●●●

SmartLogic™ controls ●●●●

Six-pass power bake element ●●●●

Convenience controls ●●●●●●●

QuickSet oven controls QuickSet IV QuickSet III QuickSet III QuickSet III QuickSet II QuickSet II QuickSet I

Digital temperature display ●●●●●●

Electronic oven controls ●

Auto oven shut-off w/override w/override w/override w/override w/override w/override

Control lock capability ●

Start pad ●

Delay clean option ●●●●

Auto self-clean ●●●●●●●

Self-clean cool down display ●●●●●●

Audible preheat signal ●●●●●●

Clock and minute timer ●●●●●●

Dual element bake ●●●●●●●

Heating element “ON” indicator light ●●●●●●●

Interior oven light Auto/Switch Switch Switch Switch Switch Switch

Preheated oven light in display ●●●●●●

Removable full-width Almond Almond Almond White

storage drawer Black CM* CM* CM* CM* CM* White

Broiler pan with grid ●●●●●●●

Grey Grey

Black Black

White White White

Appearance

WW WW WW

Color appearance* BB WH/AD WH/AD WH/AD WH/AD WH/AD WH

Frameless oven door* BG BG BG BG BG BG BG

Oven door with window Big View Big View ●●● ●

Lift-off oven door ●●●●●●●

Designer-style handle Sure Grip ●●●●●●

Easy Level System ●●●●●●●

Textured steel side panels ●●●●●●●

AA AA AA WW

WG WG WG

AG AG AG WG

Weights & Dimensions

Overall oven interior dimensions

(WxHxD in inches)

Approx. shipping weight (lbs.) 176 173 170 172 170 144 141

24-1/4 x 19 x 19 23 x 16 x 17-3/4

Power/Ratings

KW rating @ 240V 11.7 11.7 11.7 11.7 11.7 10.8 9.7

208V 8.8 8.8 8.8 8.8 8.8 8.1 7.3

*WW = White on white, AA = Almond on almond, BB = Black on black, WH = White, AD = Almond, CM = Color-Matched indicates color of oven door or

storage drawer matches range cooktop (either white or almond),

WG = White Glass, AG = Almond Glass, BG = Black Glass.

Dimensions and Installation Information

(in inches)

B

Roughed-in dimensions

C*

D

30

25

2-1/2

7-1/2

Preferred electrical

outlet area

2-1/2

Acceptable electrical

outlet area

A

Cabinet Dimensions (in inches)

Model A B C* D

JBP48WB/AB/BB 29-7/8 44-7/16 25-3/8 47-5/8

JBP35BB 29-7/8 44-7/16 25-3/8 47-5/8

JBP30WB/AB/BB 29-7/8 44-7/16 25-3/8 47-5/8

JBP26WB/AB/BB 29-7/8 44-7/16 25-3/8 47-5/8

JBP24BB 29-7/8 44-7/16 25-3/8 47-5/8

JBP21WB/BB 29-7/8 45-1/8 25-7/16 46-1/8

JBP19BB 29-7/8 45-1/8 25-7/16 46-1/8

*Dimension from wall to front of closed oven door handle is

27-3/8" on model JBP48; 27-3/4" on models JBP35/30/26/24;

27-1/2" on models JBP21/19, JBS27 and JBS03V; and 27-1/8"

on models JBS26/07/05/03GV.

Warranty Information

Full one-year warranty (parts and labor at no additional charge)

applies to the entire range.

Note: 30" ranges conform to U.L. requirements for 0" spacing

from adjacent walls below countertops. To reduce possible

scorching of walls, engineering recommends a minimum of

1-1/2" spacing to allow for possible extended, high heat, no-load

heating element operation.

Receptacle Locations:

Locally approved flexible service cord or conduit must be used

because terminals are not accessible after range installation.

See shaded area in drawing for location of electrical outlet box.

Recommended outlet locations allow range to be installed

directly against wall.

Installation Information: Before installing, consult installation

instructions packed with product for current dimensional data.

All GE ranges are equipped

with an Anti-Tip device. The

installation of this device is an

important, required step in the

installation of the range.

– 7 –

Page 10

30" F

REE-STANDINGQUICKCLEAN

™

S

TANDARDCLEANELECTRICRANGES

GE

JBS27WY

JBS27AY JBS03GV

Features

Oven cleaning Standard Standard Standard Standard Standard Standard Standard

Oven capacity (cu. ft.) 3.7 3.7 3.7 3.5 3.7 3.7 3.7

Oven shelves 2 2 2 2 2 2 1

Upswept porcelain-enameled

cooktop

Clean-Well™ Cooktop System

Lift-up cooktop w/dual support rods

8" heating elements 2 (6 turns) 1 (6 turns) 2 (6 turns) 1 (6 turns) 1 (6 turns) 1 (6 turns) 1 (6 turns)

6" heating elements 2 (5 turns) 3 (5 turns) 2 (5 turns) 3 (5 turns) 3 (5 turns) 3 (5 turns) 3 (5 turns)

Infinite heat controls

Plug-in Calrod® heating elements

Removable 1-piece drip bowls Chrome Chrome Chrome Chrome Chrome Chrome Chrome

Clock and minute timer

Dual element bake

Heating element “ON” indicator light

Interior oven light Switch Switch Switch Switch Auto/Switch

Removable full-width Almond

storage drawer CM* CM* CM* White CM* CM* CM*

Broiler pan with grid

Appearance

Color appearance* WH/AD WH/AD WH/AD WW WH/AD WH/AD WH

Frameless oven door* BG CM BG White CM CM BG

Oven door with window

Lift-off oven door

Designer-style handle

Easy Level System

Textured steel side panels

Weights & Dimensions

Overall oven interior dimensions 23 x 16 x 23 x 16 x 22-3/4 x 23 x 16 x 23 x 16 x

(WxHxD in inches)

Approx. shipping weight (lbs.) 141 144 146 141 153 139 141

Power/Ratings

KW rating @ 240V 10.9 9.8 10.4 9.8 9.3 9.8 9.8

*WW = White on white, AA = Almond on almond, BB = Black on black, WH = White, AD = Almond, CM = Color-Matched indicates color of oven door or

storage drawer matches range cooktop (either white or almond),

WG = White Glass, AG = Almond Glass, BG = Black Glass.

208V 8.4 7.4 8.4 7.4 6.9 7.4 7.6

JBS27BY JBS26W JBS23BB JBS07V JBS05Y JBS03V JBS02BB

●●●●●●●

●●●●●●●

●

●●●●●●●

●●● ●●●

●●●

●●●●●●●

●●●●●●●

White

●●●●●●●

WW

AA

WG

AG BG

●●●●●

●●●●●●●

●

●●● ●●●

●●●●●●●

Visor Visor Visor Visor Visor Visor

23 x 16 x 17-7/8

17-3/4 17-7/8 15-3/4 x 17 17-7/8 17-3/4

●

141

Dimensions and Installation Information

(in inches)

B

Roughed-in dimensions

C*

D

30

25

2-1/2

7-1/2

Preferred electrical

outlet area

2-1/2

Acceptable electrical

outlet area

A

Cabinet Dimensions (in inches)

Model A B C* D

JBS27WY/AY/BY 29-7/8 45-1/8 25-7/16 46-1/8

JBS26W 29-7/8 45-1/8 25-5/16 46-3/8

JBS23BB

JBS07V 29-7/8 45-1/8 25-5/16 46-3/8

JBS05Y 29-7/8 44-5/8 25-5/16 45-1/2

JBS03GV 29-7/8 45-1/8 25-5/16 46-1/8

JBS03V 29-7/8 45-1/8 25-5/16 46-3/8

JBS02BB

*Dimension from wall to front of closed oven door handle is

27-3/8" on model JBP48; 27-3/4" on models JBP35/30/26/24;

27-1/2" on models JBP21/19, JBS27 and JBS03V; and 27-1/8"

on models JBS26/07/05/03GV.

All GE ranges are equipped

with an Anti-Tip device. The

installation of this device is an

important, required step in the

installation of the range.

40" E

LECTRICRANGES

GE

Features

Oven cleaning Companion Oven—Standard Standard

Oven shelves Companion Oven—1 Master Oven—2

8" heating elements 2 2

6" heating elements 2 2

Removable drip bowls One-Piece Chrome One-Piece Chrome

Clock and minute timer Electronic Electronic

Automatic oven timer Master

Heating element “ON” indicator light

Interior oven light

Full-width fluorescent

cooktop night light

Oven cycling light 2

Storage drawer

Broiler pan with grid Companion Oven—1 Master Oven—1

Appearance

Color appearance* WW WW

Oven door with window Master Oven

Lift-off oven door Master

Weights & Dimensions

Overall oven interior dimensions Companion Oven—

(WxHxD in inches) 9-9/16 x 16 x 19-1/2 22-5/8 x 15-7/8 x 18-1/8

Approx. shipping weight (lbs.) 224 197

Power/Ratings

KW rating @ 240V 14.2 12.6

*WW = White on white.

208V 10.7 9.5

JCP67Y JCS57Y

Master Oven—Self-Clean

Master Oven—2

●●

●●

●●

●●

Master Oven—1

Master Oven—

22-5/8 x 15-7/8 x 18-1/8

●

●

●

Warranty Information

Full one-year warranty (parts and labor at no additional charge) applies to

the entire range. See written warranty for complete details.

40" Range Dimensions and Installation Information (in inches)

44-1/8**

40-1/8

47-1/4

27-3/8*

*Dimension from wall to front of closed oven door handle.

**Includes required 4" door swing allowance for side-hinged

oven or storage compartment door.

of range

C

L

10

7" MAX.

20

Floor

18-1/2

10

Locate outlet

in shaded area.

Wall mount only.

Wall

4

Receptacle Locations: For all 40" Free-Standing

Ranges locally approved flexible service cord or

conduit must be used because terminals are not

accessible after range installation. See shaded

area in drawing for location of electrical outlet

box. Recommended outlet locations allow range

to be installed directly against rear wall.

Top View

40-1/8

– 8 –

Page 11

– 9 –

Using the convection oven.

The convection oven fan shuts off when the oven door is opened.

DONOTleave the door open for long periods of time while using convection

cooking or you may shorten the life of the convection heating element.

To help you understand the difference between

convection bake and roast and traditional bake and

roast, here are some general guidelines.

Convection Bake

■

Ideal for evenly browned baked foods cooked on all 3 shelves.

■

Good for large quantities of baked foods.

■

Good results with cookies, biscuits, muffins, brownies, cupcakes,

cream puffs, sweet rolls, angel food cake and bread.

Heat comes from the heating element in the rear of the

oven. The convection fan circulates the heated air

evenly, over and around the food. Preheating is not

necessary with foods having a bake time of over 15

minutes.

Convection Roast

■

Good for large tender cuts of meat, uncovered.

Heat comes from the top heating element. The

convection fan circulates the heated air evenly over and

around the food. Meat and poultry are browned on all

sides as if they were cooked on a rotisserie. Using the

roasting rack provided, heated air will be circulated

over, under and around the food being roasted. The

heated air seals in juices quickly for a moist and tender

product while, at the same time, creating a rich golden

brown exterior.

Roasts or poultry should be cooked on the lowest

shelf position (A) on a shelf.

When you are convection roasting it is important that

you use the broiler pan and grid and the special roasting

rack for best convection roasting results. The pan is used

to catch grease spills and the grid is used to prevent

grease spatters. Place the meat on the special roasting

rack. The rack holds the meat. The rack allows the

heated air to circulate under the meat and increase

browning on the underside of the meat or poultry.

■ Place the shelf in the lowest shelf position (A).

■ Place the grid on the broiler pan and put the roasting

rack over them making sure the posts on the roasting

rack fit into the holes in the broiler pan.

In a convection oven, a fan circulates

hot air over, under and around the

food. This circulating hot air is evenly

distributed throughout the oven cavity.

As a result, foods are evenly cooked

and browned—often in less time with

convection heat.

You can use your favorite recipes in the convection oven. Recipe

conversion is as easy as 1, 2, 3.

When baking, reduce baking temperature by 25˚ F.

No need to preheat when cooking longer than 15 minutes.

■

For more information on adapting recipes, see the

Convection Cookbook.

■

Use pan size recommended.

■

Some package instructions for frozen casseroles or main

dishes have been developed using commercial convection

ovens. For best results in this oven, preheat the oven and

use the temperature on the package.

2

1

Adapting Recipes…

Before using your convection oven, check to see if your cookware

leaves room for air circulation in the oven. If you are baking with

several pans, leave space between them. Also, be sure the pans do

not touch each other or the walls of the oven.

Paper and Plastic

Heat-resistant paper and plastic containers that are recommended

for use in regular ovens can be used in convection ovens.

Plastic cookware that is heat-resistant to temperatures of 400˚ F.

can also be used.

Metal and Glass

Any type of cookware will work in your convection oven.

However, metal pans heat the fastest and are recommended

for convection baking.

■

Darkened or matte-finished pans will bake faster than shiny pans.

■

Glass or ceramic pans cook more slowly.

When baking cookies, you will get the best results if you use a flat

cookie sheet instead of a pan with low sides.

For recipes like oven-baked chicken, use a pan with low sides. Hot

air cannot circulate well around food in a pan with high sides.

Cookware for Convection Cooking

Page 12

– 10 –

Using the convection oven.

How to Set the Oven for Convection

Baking or Roasting

Press the

CONVECTION BAKE

or

CONVECTION

ROAST

pad.

Press the number pads to set the desired

oven temperature.

Press the

START

pad.

To change the oven temperature, press the

CONVECTION

BAKE

or

CONVECTION ROAST

pad and then the number

pads to set the new temperature.

When the oven starts to heat the changing temperature,

starting at100˚ F., will be displayed. When the oven

reaches the temperature you set, 3 beeps will sound.

Press the

CLEAR/OFF

pad when finished.

NOTE:

■

You will hear a fan while cooking with convection. The fan will

stop when the door is opened but the heat will not turn off.

■

You may hear the oven clicking during baking. This is normal.

4

3

2

1

Multi-Shelf Baking

How to Set the Oven for Convection Roasting

when Using the Probe

Do not lock the oven door with the latch during convection roasting.

The latch is used for self-cleaning only.

The display will flash

PROBE

and the oven control will

signal if the probe is inserted into the outlet, and you

have not set a probe temperature and pressed the

START

pad.

Place the shelf in the lowest position (A). Insert the

probe into the meat.

Plug the probe into the outlet on the oven wall. Make

sure it is pushed all the way in. Close the oven door.

Touch the

CONVECTION ROAST

pad.

Touch the number pads to set the desired internal

probe temperature.

Touch the

PROBE

pad.

Touch the number pads to set the desired internal

food temperature.

Touch the

START

pad.

When the oven starts to heat, the word

LO

will show

in the display. After the internal temperature of the

food reaches 100˚ F., the changing internal temperature will show in the display.

When the internal temperature of the food reaches

the number you have set, the probe and the oven

turn off and the oven control signals. To stop the

signal, press the

CLEAR/OFF

pad. Use hot pads to

remove the probe from the food. Do not use tongs

to pull on it—they might damage it.

CAUTION: To prevent possible burns, do not unplug the probe from

the oven outlet until the oven has cooled. Do not store probe in oven

NOTE:

■

If the probe is removed from the food before the final

temperature is reached, a tone will sound and the display

will flash until the probe is removed from the oven.

■

You will hear a fan while cooking with this feature. The fan will

stop when the door is opened but the heat will not turn off.

■

You can use the timer even though you cannot use

timed oven operations while using the probe.

8

7

6

5

4

3

2

1

For best results when roasting large

turkeys and roasts, we recommend

using the probe included in the

convection oven.

To change the oven temperature

during the Convection Roast cycle,

press the

CONVECTION ROAST pad

and then press the number pads to

set the new desired temperature.

START

CLEAR

OFF

Because heated air is circulated evenly through out

the oven, foods can be baked with excellent results

using multiple shelves.

Multi-shelf baking may increase cook times slightly

for some foods but the overall result is time saved.

Cookies, muffins, biscuits, and other quick breads

give very good results with multi-shelf baking.

When baking on 3 shelves, place one shelf in the

bottom (B), one on the 4th (D) position and the

offset shelf in the 6th (F) position.

When convection baking with only

1 shelf, follow the shelf positions

recommended in the Using the

oven section.

START

CLEAR

OFF

Page 13

– 11 –

Convection roasting guide.

*

†

Using Convection Conversion

By using the Convection Conversion feature you can automatically

convert the oven temperature from regular baking to Convection

Bake temperatures.

To convert the oven temperature for convection baking,

follow the steps below.

Press and hold the

CONVECTION BAKE

pad for

4 to 5 seconds.

Using the number pads enter the temperature

recommended in the recipe.

Press the

START

pad.

The display shows the converted (reduced)

temperature. For example, if you entered a recipe

temperature of 350˚ F., the display will show 325˚ F.

when it is converted.

Press the

CLEAR/OFF

pad when baking is finished.

NOTE: Conversion must be set each time you want to use it. It is

not held in memory.

4

3

2

1

Stuffed birds generally require 30-45 minutes additional roasting time. Shield legs and breast with

foil to prevent over-browning and drying of skin.

The U.S. Department of Agriculture says "Rare beef is popular, but you should know that cooking it

to 140˚ F. means some food poisoning organisms may survive." (Source: Safe Food Book. Your

Kitchen Guide. USDA Rev. June 1985.)

START

CLEAR

OFF

Convection Roasting Guide

Meats Minutes/Lb. Oven Temp. Internal Temp.

Beef Rib (3 to 5 lbs.) Rare

†

20–24 325˚F. 140˚F.

Medium 24–28 325˚F. 160˚F.

Well 28–32 325˚F. 170˚F.

Boneless Rib, Top Sirloin Rare

†

20–24 325˚F. 140˚F.

Medium 24–28 325˚F. 160˚F.

Well 28–32 325˚F. 170˚F.

Beef Tenderloin Rare

†

10–14 325˚F. 140˚F.

Medium 14–18 325˚F. 160˚F.

Pot Roast (2½to 3 lbs.) chuck, rump 35–45 300˚F. 170˚F.

Pork Bone-in (3 to 5 lbs.) 23–27 325˚F. 170˚F.

Boneless (3 to 5 lbs.) 23–27 325˚F. 170˚F.

Pork Chops (1/2 to 1″ thick) 2 chops 30–35 total 325˚F. 170˚F.

4 chops 35–40 total 325˚F. 170˚F.

6 chops 40–45 total 325˚F. 170˚F.

Ham Canned (3 lbs. fully cooked) 14–18 325˚F. 140˚F.

Butt (5 lbs. fully cooked) 14–18 325˚F. 140˚F.

Shank (5 lbs. fully cooked) 14–18 325˚F. 140˚F.

Lamb Bone-in (3 to 5 lbs.) Medium 17–20 325˚F. 160˚F.

Well 20–24 325˚F. 170˚F.

Boneless (3 to 5 lbs.) Medium 17–20 325˚F. 160˚F.

Well 20–24 325˚F. 170˚F.

Seafood Fish, whole (3 to 5 lbs.) 30–40 total 400˚F.

Lobster Tails (6 to 8 oz. each) 20–25 total 350˚F.

Poultry Whole Chicken (2½ to 3½ lbs.) 24–26 350˚F. 180˚–185˚F.

Cornish Hens Unstuffed (1 to 1½lbs.) 50–55 total 350˚F. 180˚–185˚F.

Cornish Hens Stuffed (1 to 1½lbs.) 55–60 total 350˚F. 180˚–185˚F.

Duckling (4 to 5 lbs.) 24–26 325˚F. 180˚–185˚F.

Turkey, whole

*

Unstuffed (10 to 16 lbs.) 8–11 325˚F. 180˚–185˚F.

Unstuffed (18 to 24 lbs.) 7–10 325˚F. 180˚–185˚F.

Turkey Breast (4 to 6 lbs.) 16–19 325˚F. 170˚F.

Page 14

– 12 –

Cleaning the glass cooktop.

Clean the glass surface with cleaning cream before you use the cooktop for the first time. Also, clean

the glass surface after each use. This helps protect the top and makes clean-up easier.

To clean the cooktop seal around the edge of the glass,let a wet cloth rest on it for a few minutes, then wipe clean.

Use a mild detergent if needed.

Do not use a knife or any sharp object on the seal because it will cut or damage it.

Normal Cleaning

Use only a recommended cleaning cream,

such as Cerama Brite or another cooktop

cleaning cream, on the glass cooktop.

To maintain and protect the surface of

your new glass cooktop follow these steps.

Before you use the cooktop for the

first time, clean it with cleaning

cream. This helps protect the top

and makes clean-up easier.

Clean the surface with the cleaning

cream after each use.

Rub a few drops (less is better) of the

cleaning cream onto soiled area

using a damp paper towel. Buff with

a dry paper towel until all soil and

cream are removed.

For Heavy, Burned-On Soil…

Allow the cooktop to cool.

Apply a few drops of the cleaning

cream to the (cool) soiled area.

Using a damp paper towel, rub the

cream into the burned-on area. As

with any burned-on spill, this may

require some effort.

Carefully scrape soil with razor

scraper. Hold scraper at a 30˚angle

against the glass cooktop.

Be sure to use a new sharp razor scraper. Do not

use a dull or nicked blade.

If any soil remains, repeat the steps

listed above. For additional

protection, after all soil has been

removed, polish the entire surface

with the cleaning cream.

Buff with a dry paper towel.

To order more cream and/or scrapers for

cleaning your glass cooktop, please call

our toll-free number:

National Parts Center . . . . . . . . .800-626-2002

Cleaner . . . . . . . . . . . . . . . . . . . . . .# WX10X300

Scraper . . . . . . . . . . . . . . . . . . . . .# WX5X1614

Cream & scraper kit . . . . . . . . .# WB64X5027

Special Care

Be sure to use a new sharp razor scraper. Do not

use a dull or nicked blade.

Sugary spillovers (such as jellies, fudge,

candy syrups) or melted plastics can

cause pitting of the surface of your

cooktop (not covered by the warranty)

unless the spill is removed while still hot.

Special care should be taken when

removing hot substances.

Turn off all surface units affected by

the spillover. Remove hot pans.

Wearing an oven mitt, hold the razor

scraper at a 30˚angle to the cooktop.

Scrape the hot spill to a cool area

outside the surface unit.

With the spill in a cool area, use a dry

paper towel to remove any excess.

Any spillover remaining should be

left until the surface of the cooktop

has cooled. Do not continue to use

the soiled surface unit until all of the

spillover has been removed. Follow

the steps under

Heavy Burned-On Soil

to continue the cleaning process.

NOTE: If pots with a thin overlay of aluminum,

copper or enamel are allowed to boil dry, the

overlay may bond with the glass cooktop and

leave a black discoloration. This should be

removed immediately before heating again

or the discoloration may be permanent.

Using a razor scraper will not

damage the surface if the 30˚ angle

is maintained.

Using the self-cleaning oven.

The oven door must be closed and all controls set correctly for the cycle to work properly.

Before a Clean Cycle

We recommend venting your kitchen

with an open window or using a

ventilation fan or hood during the first

self-clean cycle.

Remove the shelves, broiler pan, broiler

grid, probe, all cookware and any

aluminum foil from the oven.

The oven shelves and convection roasting

rack can be self-cleaned, but they will

darken, lose their luster and become

hard to slide.

Soil on the front frame of the range and

outside the gasket on the door will need

to be cleaned by hand. Clean these areas

with hot water, soap-filled steel-wool pads

or cleansers such a Soft Scrub®. Rinse well

with clean water and dry.

Do not clean the gasket. The fiberglass

material of the oven door gasket cannot

withstand abrasion. It is essential for the

gasket to remain intact. If you notice it

becoming worn or frayed, replace it.

Wipe up any heavy spillovers on the oven

bottom.

Make sure the oven light bulb cover is in

place and the oven light is off.

IMPORTANT:

The health of some birds is

extremely sensitive to the fumes given off

during the self-cleaning cycle of any

range. Move birds to another well

ventilated room.

Wipe up heavy soil on the oven

bottom.

How to Set the Oven for Cleaning

Touch the

SELF CLEAN

pad.

Using the number pads, enter the

desired clean time, if a time other

than 4 hours, 30 minutes is needed.

Clean cycle time is normally 4 hours, 30

minutes. You can change the clean time

to any time between 3 hours and 5 hours,

depending on how dirty your oven is.

Touch the

START

pad.

The door locks automatically. The display

will show the clean time remaining. It will

not be possible to open the oven door

until the temperature drops below the

lock temperature and the

LOCKED DOOR

light goes off.

When the

LOCKED DOOR

light is off, open

the door.

The oven shuts off automatically when

the clean cycle is complete.

■The words

LOCK DOOR

will flash and

the oven control will signal if you set

the clean cycle and forget to close the

oven door.

■To stop a clean cycle, touch the

CLEAR/OFF

pad. When the

LOCKED

DOOR

light goes off indicating the

oven has cooled below the locking

temperature, open the door.

Page 15

COOKTOP LIGHT REPLACEMENT

SCREWS

A

2"

HAND

GRIPS

COOKTOP

LIGHT

HOUSING

B

LIGHT BULB

SOCKET

C

COOKTOP

LIGHT

HOUSING

HAND

GRIPS

D

HINGE LOCK

(UNLOCKED POSITION)

HINGE LOCK

(LOCKED POSITION)

SLOT

HINGE ARM

SEATED HINGE

ARM

To Remove The Old Bulb:

1. Remove power to the unit.

2. Pull the range away from the wall.

3. Remove the tw o screws from the top edge

on the back of the range (A).

4. Pull up on the hand grips on the back of

the range (B) until the tabs at the bottom

of the cooktop light housing separate from

the back of the range.

5. Pull out the cooktop light housing as far as

possible - approx. 2 inches (C).

6. Remov e the light bulb by unplugging it from

both sockets with one motion.

To Install The New Bulb:

1. Install the new light bulb b y plugging it into

both sockets with one motion.

2. Using the hand grips on the cooktop light

housing (D), lift up and push the housing

back into the rear wall of the range. Then

lower the housing until the bottom tabs are

inserted back into the range.

3. Reinstall the two screws along the top edge

on the back of the range.

OVEN DOOR REMOVAL

The oven door is locked to the range cabinet

with hinge locks, located on top of both door

hinges.

To Remove The Oven Door:

1. Fully open the oven door.

2. Push the hinge locks down to ward the door

frame, to the unlocked position.

3. Raise the door to the broil position.

4. Firmly grasp both sided of the door about

center ways down the door and lift upw ards

to disengage the hinge arm from the hinge

slot. At the same time, pull the door towards you while lifting it away from the

range.

To Reinstall Oven Door:

1. Firmly grasp both sides of the door and

insert the hinge ar ms into the door hinge

slots, while holding the door angle in the

broil position.

2. Lower the hinge arms downward, aligning

the hinge arm indentation to the lower portion of the hinge slot.

3. Fully open the door.

4. Push the hinge locks up against the front

frame of the oven cavity, to the locked position.

LOWER HINGE ARM

INTO HINGE SLOT

– 13 –

Page 16

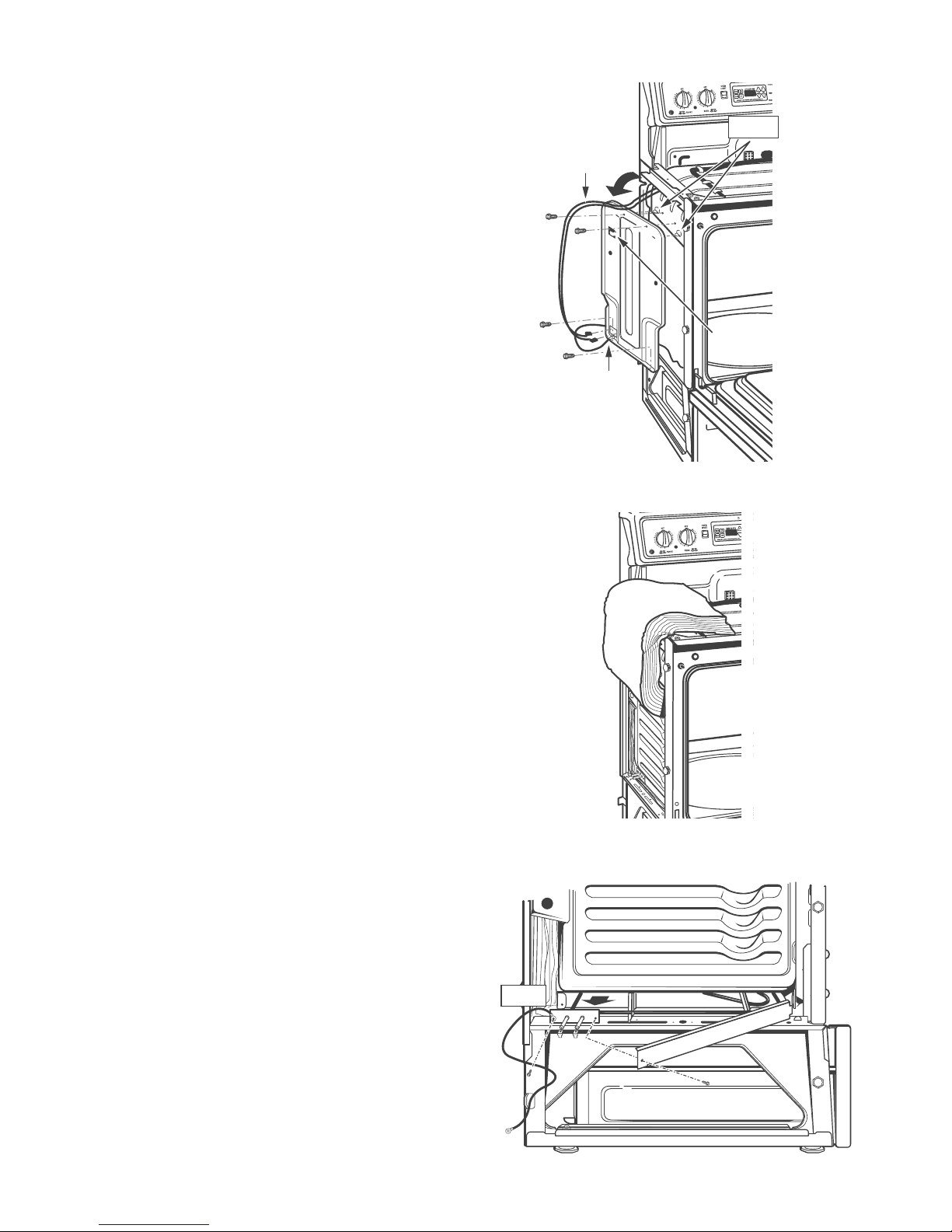

COOKTOP REMOVAL

The ceramic glass cooktop is sealed into the

porcelain cooktop frame and is not replaceable

as a separate part. The cooktop comes as a

complete assembly (porcelain frame and ceramic glass).

To remove the cooktop:

1. Remove power to the unit.

2. Remove the tw o screws which secure the

cooktop to the front frame.

3. Lift the front of the cooktop upward (no

more than 45°). NOTE: lifting the front of

the cooktop too high, can break the glass.

4. Unplug the two electrical connector plugs

and remove the ground wire from the

cooktop (located at the rear of the

cooktop).

5. While grasping both sides of the cooktop ,

lift the front of the cooktop upward approximately 30 to 40° (see illustration A, lower

right).

6. While holding the front of the cooktop upward, lower the rear of the cooktop in order to disengage the cooktop hinges from

the hinge pins (see illustration B, lower

right).

7. Once the cooktop hinges are disengaged

from the hinge pins, lift the rear of the

cooktop upward and over the hinge pins

while pulling the cooktop forward to remov e

(see illustration C, lower right).

COOKTOP REMOVAL

HINGE

PIN

HINGE

Once the cooktop is removed, the oven vent

tube, and latch motor assembly are accessible.

Important note: prior to reinstalling the cooktop,

study the hinge mechanism for a f ew moments,

noting the location of the hinge pins and the

design of the hinges. Doing so will allow for a

much easier reinstallation.

– 14 –

LIFT UPWARDS

ON FRONT OF

COOKTOP TO A

45˚ ANGLE

A

B

C

LOWER THE REAR

OF THE COOKTOP

TO DISENGAGE

THE HINGES FROM

THE HINGE PINS

LIFT THE COOKTOP

UPWARDS AND

OVER THE HINGE

PINS

Page 17

HIDDEN BAKE ELEMENT

The bake element is located underneath the

oven liner (hidden bake), where it is protected

from spillage and oven cleaning agents which

can shorten the life of the element.

The bake element is accessible from the left side

(facing the unit) of the range. T o access the bake

element, carefully remove the range from its installation taking care to protect the customer’s

floor.

HIDDEN BAKE

Bake Element Removal:

1. Remove power to the unit.

2. Remove the cooktop f ollowing the instruc-

tions outlined on page 14.

3. Remove the seven screws shown in the

illustration to the right.

4. At the front corner of the panel, near the

leveling leg, is a hidden scre w. Access to

this screw is obtained by removing the storage drawer. From inside the storage

drawer area, located just above the left

front leveling leg (as y ou face the unit), are

two 1 inch holes. If you shine a light into

the top hole you will be able to see the ¼

inch hex screw that will need to be removed, in order to remov e the side panel.

5. Facing side of the panel, grasp the front

and rear portion of the panel. Pull the rear

of the panel towards you (A) appro ximately

2-3 inches, while lifting upwards on the front

of the panel (B) approximately 1 inch. Notice in the illustration to the right that the

panel is held to the range frame with 2 nylon grommets (top and center of panel),

which fit into holes in the side panel. By

lifting upwards on the front panel (B), while

at the same time pulling the panel towards

you (C), you are able to disengage the

panel from the rubber grommets.

¼ HEX

¼ HEX

¼ HEX

¼ HEX

#10 TORX

PHILLIPS

¼ HEX

A

B

C

– 15 –

Page 18

Bake Element Removal (cont.)

6. Disconnect the electrical terminals from the

bake element and remove the bake element wires from the retaining clip on the

metal cover plate (remember to reinstall the

wires back into the retainer clip during reinstallation to prevent pinched wires). Remove the four ¼ inch hex screws which

secure the metal insulation cover plate to

the frame. Remove the metal plate.

Note: that one of the screws holding the

metal plate to the frame, also secures a

ground wire to the cabinet. Also notice that

the frame has two locator tabs which align

the plate to the frame during reinstallation.

BAKE ELEMENT

WIRES

GROUND

WIRE

LOCATOR

TABS

BAKE ELEMENT

WIRE RETAINER

CLIP

7. Using rubber gloves to protect y our hands,

carefully grasp the insulation which covers the side of the range and roll it upwards

to the top of the range. Tuck the end of it

under the brace which runs from the front

of the oven to the back of the oven. This

will hold the insulation in place while you

service the bake element.

8. Remove the tw o scre ws which mount and

secure the bake element to the frame.

Note: remember the screw on the left is

the one which secures the ground wire.

Don’t forget to reattach this wire when reinstalling the bake element (this is the other

end of the ground wire referred to in step

5).

GROUND

WIRE

INSULATION

9. Grasp the retaining channel on the left side

and swing it outwards and to the left. Notice that the channel is hinged on the right

side (fits into a slot in the frame). You are

now able to see into the area which houses

the bake element.

RETAINING CHANNEL

– 16 –

Page 19

Bake Element Removal (cont.)

10. Grasp the bak e element on both sides and

gently pull it towards you as you remove

it from its housing. IMPORTANT: notice

that the opposite end of the bake element

has two alignment tabs which must fit into

slots on the other side of the housing.

When reinstalling the element, be sure

that the tabs are engaged into the locator

slots on the opposite end. If y ou fail to do

this, the bake element will not fit flush

against the frame and will protrude

enough that you will not be able to remount it to the frame.

Tip: The bottom area of the bake element housing bows slightly upward in the

center - this is due to insulation underneath it which forces it slightly upward.

Using a long bladed screw driver, gently

push downward on the bake element

housing while pushing the element forward. This is also helpful in forcing the

backside of the element downward

enough so that it can align with the locator slots on the opposite side.

NOTE: TWO LOCATOR

TAB SLOTS

BAKE

ELEMENT

LOCATOR

TAB

REFLECTOR

– 17 –

ALIGNMENT

CHANNELS

LOCATOR

SLOT

PAN

INSULATION

Page 20

DOOR SWITCH REMOVAL

The door switch can be accessed through two

methods. If you have small hands you can access the switch from the top of the range. If you

have large hands, you will need to remove the

left side of the range to access the switch.

If You Have Small Hands:

1. Remove the cooktop.

2. Remove the bracket across the top/front

of the range. This bracket is held in place

with 6 torx screws. Once the bracket is

removed, you can access the switch.

3. To remove the switch, depress inward on

the locking tabs while pulling outward on

the switch body.

If you Have Lar ge Hands:

1. Remove the cooktop.

2. Remove the left side panel of the range.

3. To remove the switch, depress inward on

the locking tabs while pulling outward on

the switch body.

DEPRESS SWITCH

LOCKING TABS

TO RELEASE

OVEN LINER REMOVAL

Should it ever become necessary to replace the

oven liner (customer damage), you can do so,

following the steps listed below:

1. Remove the cooktop.

2. Remove both side panels and metal cov-

ers (metal insulation covers).

3. Remove the bake element.

4. Remove two ¼ inch screws in the back of

the cabinet (A) which secure the liner to

the rear wall of the range.

5. From the back of the range disengage the

two metal hooks of the liner , which engage

into the back wall of the range (B). Do this

by pushing upward on the hooks with a

metal object (screwdriver blade) while

pushing forward at the same time

6. From the back of the range, disengage the

oven lamp clip which secures the lamp to

the rear wall of range (C).

7. From the back of the range, remove the

following.

a. Convection f an wiring (caution: term-

inal connections are tight & fragile).

b. Oven lamp wiring

c. Sensor wiring (disconnect plug)

d. Broil element wiring

e. Convection element wiring

A

B

BACK OF RANGE WITH ELECTRICAL

SHIELD AND LAMP SOCKET COVER

REMOVED

C

A

B

– 18 –

Page 21

Oven Liner Removal (cont).

8. Remove 7 screws from inside the oven

cavity (see illustration to right), which secure the oven liner to the frame/cabinet (1

on each front side of the liner, 2 on lower

back wall of liner and 3 across the top front

of the liner).

9. From inside the oven cavity, remove the

smoke eliminator chimney (2 screws).

10. Remove the oven vent chimney - if this is

not removed the ov en liner can catch on it

during reinstallation.

11. Remove the meat probe recepticle from

inside the oven cavity top (2 screws).

12. Remove the two front screws which se-

cure the front edge of the broil element

bracket to the top of the ov en liner (do not

remove the screws which mount the broil

element to the back wall).

13. Gently pull the liner forward, making sure

to keep the liner evenly spaced on each

side as you pull it forward. Note: you will

be removing the oven liner with the broil

element, convection fan assembly, and

oven lamp assembly still mounted to the

liner.

OVEN LINER REINSTALLATION

1. After transfering the convenction fan as-

sembly, lamp assembly, sensor, and broil

element to the new liner; slide the new liner

back into the cabinet frame.

2. Install the two screws from the back of the

range which secure the oven liner to the

oven frame, taking care to ensure that the

2 liner hooks catch into the slots in the back

wall of the oven.

3. Install the two screws which mount the

oven liner to the bake element housing pan

(2 screw holes located inside oven liner,

lower back wall). You will need to move/

adjust the bake element housing pan in

order to line up the holes in the liner with

those in the pan.

4. Reinstall the oven vent and smoke elimi-

nator chimney, taking care to properly

mate the chimney to the ov en vent located

directly above it (secured with 2 screws).

5. Reinstall the meat probe receptical, and

all remaining interior oven liner hardware.

6. Reinstall the bake element and cooktop,

taking care to reconnect all ground straps

and ensure that all wiring is relocated back

into its original holding restraints.

– 19 –

Page 22

CONTROL PANEL

The electronic touch controls, located on the front

of the control console, are capacitance touch

design. The crystal keypanel assembly has the

capacitance touch circuit board bonded to its

surface on the rear side.

Keypanel Removal

1. Remove power to the unit.

2. Remove all four control knobs.

3. Remove the four nylon retainer nuts which

secure the crystal keypanel assembly to

the control console. Important note:

when reinstalling the nylon retainer nuts,

tighten only hand tight. Be sure that each

nylon retainer nut is flush with the glass

keypanel (the shoulder of the nylon retainer nut is seated into the glass

keypanel). Over tightening can damage

crystal keypanel assembly.

4. With all four nuts removed, the keypanel

assembly can now be pulled away from

the control console to gain access to the

connector plug. This plug connects the

keypanel to the ERC (Electronic Range

Control).

Control Panel Access

1. Remove power to the unit.

2. Lay a protective cloth on the cooktop sur-

face.

3. T o obtain access to the control panel com-

ponents, remove the four screws which

secure it to the range frame (see illustration to the right). Gently pull f orward from

the bottom the control panel while lifting

upward.

4. Lay the control panel on the protected

cooktop surface (components facing upward).

Infinate Heat Switch Removal

1. Remove power to the unit.

2. Remove the crystal keypanel assembly

following the steps listed above.

3. Remove the crystal mounting plate which

secures the infinate heat switch to the control console (2 small phillips head screws).

CRYSTAL

MOUNTING

PLATE

CONTROL PANEL

ACCESS

– 20 –

NYLON

RETAINER

NUT

CONTROL

KNOB

Page 23

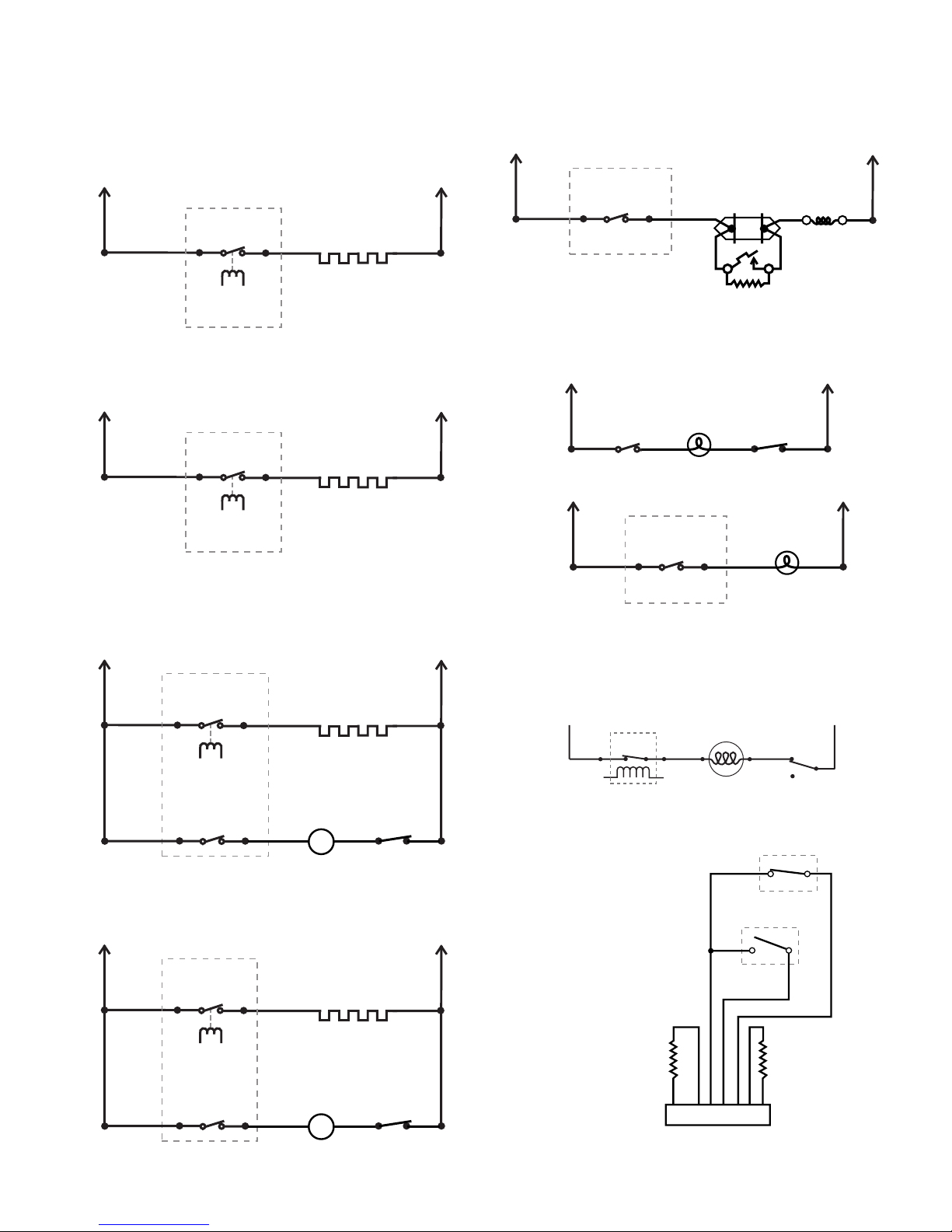

INFINITE HEAT CONTROLS

Infinite heat controls are used to regulate the

wattage of the surface units. The infinite heat

control is essentially a timing device, and its onoff time is not related to any temperature sensing element at the surface unit (such as the sensor head of an automatic surface unit).

The controls have two detent positions - OFF

and HIGH. Between the these two positions is

an infinite r ange of heat selections. At the high

detent setting, the surface unit is energized continuously .

There are two basic types of infinite heat con-

™

trols used on the new Spectra

series of ranges.

One is a Voltage Sensitive control and the other

is a Current Sensitive control.

Internally both controls (voltage sensitive and

current sensitive) contain a bi-metal control which

regulates the switch ON-OFF time. The bi-metal

has a heater wrapped around it which supplies

heat to the bi-metal, opening and closing the

control cycling contacts. As you will note from

the illustrations to the right, the heater is only

energized when the cycling contacts are

closed.

THERMAL LIMITER SWITCH

Attached to each surface element is a thermal

limit switch. This switch serves two purposes.

1. Controls cooktop surface “HOT” light operation.

2. Removes po wer to the surface element, in

the event that the cooktop glass directly

above the element e xceeds 1031° F.

N

L1

L2

P

CYCLING

CONTACT

L1

GRND

N

L2

L1

PILOT

PILOT

P

N

32

H1

15.59K Ω

P

H1

RR

SURFACE

H2

< 1 Ω

H2

4

H2

H1

UNIT

BRIDGE ELEMENT

LR

SURFACE

UNIT

LF SURFACE ELEMENT

L1

L2

L2

5

10.45 KΩ

H1

P

H2

L1

L2

CURRENT

SENSITIVE

L2

N

5

P

2

L1

L1

P

H1

VOLTAGE SENSITIVE

TOP

GRND

VOLTAGE

SENSITIVE

L2

4

3

H1

TOP

H2

H2

When the temperature of the cooktop glass,

above the heating element, reaches 150° F., a

set of contacts in the thermal switch will close

and provide power to the HOT light. The hot

light will remain on until the glass surface abov e

the element cools below 150° F. The HOT light

is mounted to the control panel and is located

just below each control knob (see Illustration to

the right).

The second set of contacts in the thermal limit

switch remove po wer to the element in the ev ent

the cooktop glass above the element exceeds

1031° F. If this condition should ever occur the

contacts in the thermal limit switch will open and

remove power to the element. Once the cooktop

glass cools below 1031° F., the contacts in the

thermal limit switch will close and the element

will resume operation.

– 21 –

THERMAL LIMITER

SWITCH

FRONT

BURNER

I

H

8

6

4

2

L

O

FRONT

BRIDGE

BURNER

OFF

H

I

8

6

4

2

O

L

HOT LIGHT LOCATIONS

HOT

Therm.

Limit Sw.

L2

Hot Light

REAR

SURFACE

ELEMENT

THERMAL LIMITER

SCHEMATIC

Page 24

ERC V SPECIAL FEATURES

The "SPECIAL FEATURE" modes can only be activated while the display is showing the time of day clock. These

special features remain in the ERC's memory until you or the consumer change them. When the display shows your

choice press the START pad. The special feature you selected will remain in memory even after a power failure.

OVEN

BAKE

BROIL

HI LO

CONVECTION

BAKE

ROAST

Convection

12345678

ERC V

PROBE

SELF

CLEAN

CLEAR

OFF

CONVECTION

TO ADJUST THE THERMOSTAT (MODELS WITH

NUMBER PADS)

Press the BAKE and BROIL HI/LO pads

at the same time for 2 seconds until the

display shows "SF".

Press the BAKE pad. A two digit

number shows in the display. Press the

BAKE pad once to increase (+) the

oven temp. or twice to decrease (-).

The oven temp. can be adjusted up to

(+) 35˚F. hotter or (-) 35˚F. cooler. Press

the number pads the same way you

read them. For example, to change the

over temperature 15˚F., press 1 and 5.

When you have made the adjustment,

START

press the START pad to go back to the

time of day display.

NOTE: Adjustments will not affect the

broiling or self-cleaning temperatures.

It will be retained in memory after a

power failure.

COOKING/SELF-CLEAN LOCKOUT

The ERC control will allow you to lock out the

COOKING and SELF CLEAN pads so that they

cannot be activated when touched.

Press the BAKE and BROIL HI/LO pads

at the same time for 3 seconds until the

display shows "SF".

Press the SELF CLEAN pad. The

SELF

CLEAN

display will show "Loc OFF." If this is

your choice, press START.

Press the SELF CLEAN pad again. The

SELF

CLEAN

display will show "Loc On." If this is your

choice, press START.

START

When this feature is on and the touch

pads are pressed the control will beep

and the display will show "LOC."

NOTE: The control lockout mode will not

affect the clock, kitchen timer on/off and

oven light touch pads

TrueTemp

TIME CONTROLS

COOKING

TIME

CLOCK

DELAY

START

KITCHEN

TIMER

ON OFF

90

CONTROL LOCKOUT

TOP

LIGHT

OVEN

LIGHT

START

12 HOUR SHUT-OFF

With this feature, should you forget and leave the

oven on, the control will automatically turn off the

oven after 12 hours, during baking functions, or after

3 hours during a broil function. If you wish to turn off

this feature, follow the steps below:

Press the BAKE and BROIL HI/LO pads

at the same time for 2 seconds until the

display shows "SF".

Press the DELAY START or START

TIME pad. The display will show "12

Shdn" (12 hour shut-off). Press the

DELAY START or START TIME pad

again and the display will show "no

Shdn" (no shut-off).

Press the START pad to activate the no

START

shut-off and leave the control set in this

special features mode.

12 HOUR, 24 HOUR OR CLOCK BLACK-OUT

The ERC control is set to use a 12 hour clock. If the

customer prefers to have a 24 hour militar y time clock

or black-out the clock display, follow the steps below.

Press the BAKE and BROIL HI/LO pads

at the same time for 2 seconds until the

display shows "SF".

Press the CLOCK pad once. The display

will show "12 hr."

Press the CLOCK pad again to change

to the 24 hour military time clock. The

display will show "24 hr." If this is your

choice, press START.

Press the CLOCK pad again to black-out

the clock display. The display will show

"OFF." If this is your choice, press

START

START.

If the clock is in the black-out mode and

you want to restore it to the display,

repeat steps 1 and 2.

NOTE: If the clock is in the black-out

mode you will not be able to use the

DELAY START function.

– 22 –

Page 25

ERC V SPECIAL FEATURES

COOK AND HOLD

The cook and hold feature keeps cooked foods warm

for up to 3 hours after the cooking function is

finished. To activate this feature, follow the steps

below:

Press the BAKE and BROIL HI/LO pads

at the same time for 2 seconds until the

display shows "SF".

Press the COOKING TIME pad. The

display will show "HLd OFF." Press the

COOKING TIME pad again to activate

the feature. The display will show "HLd

On."

Press the START pad to activate the

START

cook and hold feature and leave the

control set in this special features

mode.

SALES MODE

Display continuously scrolls through cooking

functions, display icons, and numbers.

To activate this feature: Press the

BAKE and BROIL HI/LO pads at the

same time for 2 seconds, until the

display shows "SF". Press and hold

both the CLOCK and KITCHEN

TIMER pads until the display starts

scrolling.

TONES AT THE END OF A TIMED CYCLE

At the end of a timed cycle, 3 short beeps will sound

followed by one beep every 6 seconds, until the

CLEAR/OFF pad is pressed. This continuous 6

second beep may be canceled.

To cancel the 6 second beep:

Press the BAKE and BROIL HI/LO pads

at the same time for 2 seconds until the

display shows "SF".

Press the KITCHEN TIMER ON/OFF

pad. The display shows "Con bEEP"

(continuous beep). Press the KITCHEN

TIMER ON/OFF pad again. The display

shows "bEEP." This cancels the one

beep every 6 seconds.

START

Press the START pad.

FAHRENHEIT OR CENTIGRADE TEMPERATURE

The ERC control is set to use the Fahrenheit

temperature selections, but you may change this to

use the Centigrade selections.

Press the BAKE and BROIL HI/LO pads

at the same time for 3 seconds until the

display shows "SF".

Press the BROIL HI/LO pad. The display

will show "F" (Fahrenheit). If this is your

choice, press START.

Press the BROIL HI/LO pad again. The

display will show "C" (Centigrade). If this

is your choice, press START.

HELPFUL USE AND CARE INFORMATION

CLOCK - The clock must be set before the control for the

oven will work. the time of day clock cannot be changed

during DELAY START. It can be changed during a

regular bake or broil operation.

KITCHEN TIMER - Does not control oven operation. You

may program the timer for activities up to 9 hours and 59

minutes. When the timer reaches " :00," the control will

beep 3 times followed by one beep every 6 seconds until

the KITCHEN TIMER ON/OFF pad is pressed. To cancel

the timer, press and hold the KITCHEN TIMER ON/OFF

until the word "TIMER" disappears from the display.

POWER FAILURE - If a flashing time is in the display,

you have experienced a power failure. Reset the clock.

PREHEAT NOTIFICATION TONE - When you set an

oven temperature the oven automatically star ts to heat.

When the temperature inside the oven reaches your set

temperature a tone will sound to let you know to place

the food in the oven.

– 23 –

CONTROL LOCKOUT FUNCTION - press and hold the

9 + 0 key pads for approximately 4 seconds. The control

will beep twice and display "Loc".

90

CONTROL LOCKOUT

SELF CLEANING - We recommend venting with an

open window or using a ventilation fan or hood during

the first self-clean cycle.

Do not use commercial oven cleaners or oven protectors

in or near the self-cleaning oven. A combination of any

of these products plus the high clean cycle temperatures

may damage the porcelain finish of the oven.

The oven front frame and the oven door outside the

gasket do not get cleaned by the self-clean cycle. On

these areas use detergent and hot water or a soap-filled

steel wool pad. Rinse well with a vinegar and water

solution. This will help prevent a brown residue from

forming when the oven is heated. Buff these areas with

a dry cloth. Do not clean the gasket.

Page 26

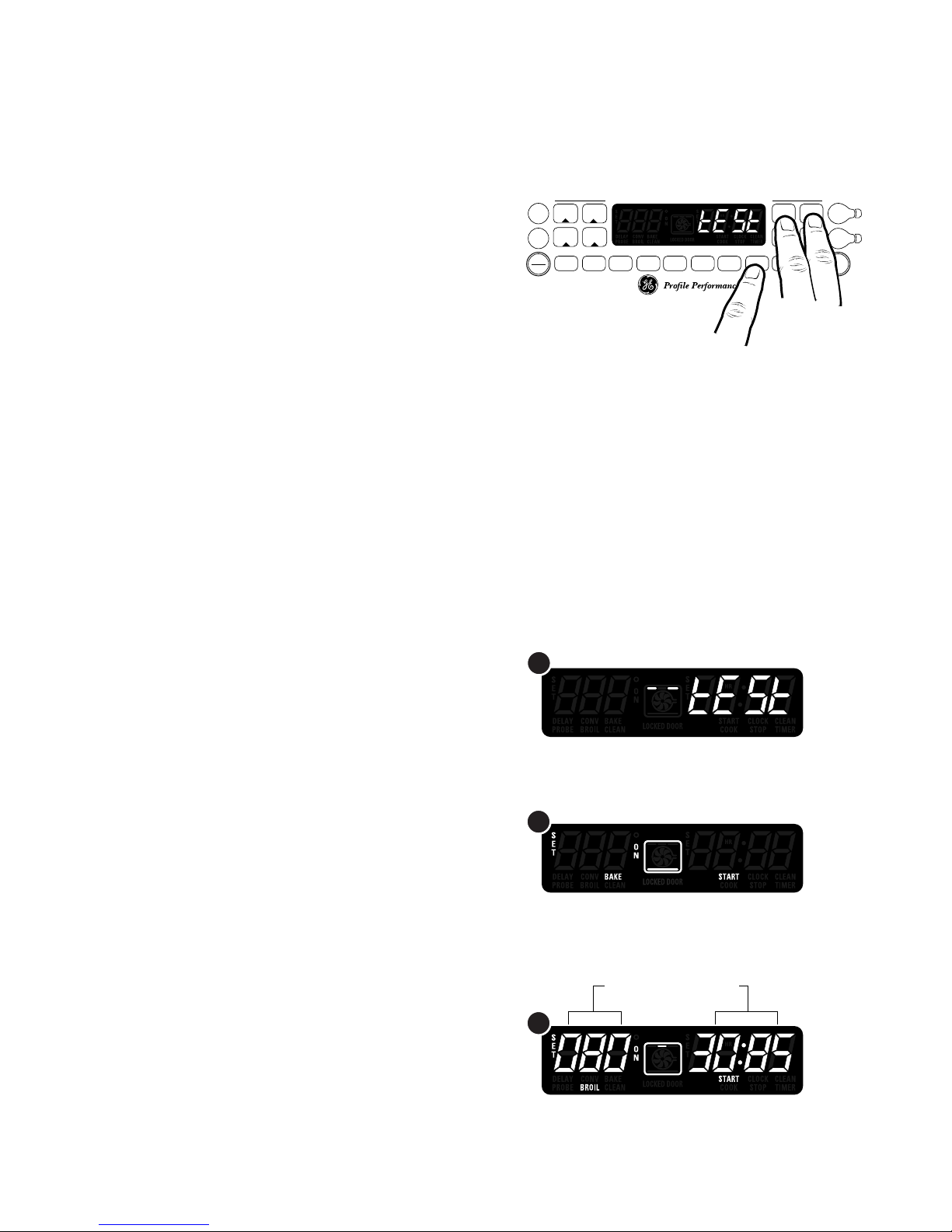

ERC FAULT CODE MEMORY DISPLAY

Have you ever run a service call and been told by the consumer

that their range displayed an "F" fault code and when you arrive

the fault is gone (cleared by the consumer) and the consumer

can not remember what the code was?

Well there is a way to "recall" the last four fault codes from the

ERC memory. These codes are stored in short term memory

(RAM) and can be recalled by the service Technician; however, it

is important to note that once power is lost to the appliance

the memory (RAM) is cleared and "reset" to all eights. When

servicing a range for a fault code problem, always remove power

to the unit. This will protect you from electrical hazards and will

also reset the fault code memory storage back to all eights.

HOW TO DISPLAY THE FAULT CODES IN MEMORY

To read the fault code memory, follow the steps below:

1.

Simultaneously press and hold the COOKING TIME and

DELAY START pads. While holding these two pads press

the number 9 pad. A history of the last four fault codes will

appear in the display. NOTE: If no keypad entry is made

within 5 minutes, the ERC test mode will "time out".

2.

To terminate the memory fault mode press the CLEAR /

OFF key pad

ERC FAULT CODE MEMORY TEST

OVEN

BAKE

PROBE

CLEAN

CLEAR

SELF

OFF

BROIL

HI LO

CONVECTION

CONVECTION

BAKE

ROAST

1234567890

TrueTemp

Convection

TIME CONTROLS

COOKING

TIME

CLOCK

DELAY

START

KITCHEN

TIMER

ON OFF

LIGHT

OVEN

LIGHT

START

TOP

HOW FAULT CODES ARE STORED IN MEMORY - EXAMPLE

A

If we displayed the fault code memor y of the range just after

power had been applied/reapplied, we would see four eights in

the display, meaning that no fault codes are stored in memory.

B

The first time a fault code occurs, the ERC display will store

the fault code in its memory. When you read the fault code,

which is stored in memory, the code will display in the far right

hand digit of the clock display.

C

If a second fault code occurs, it too is stored in the ERC

memory. The first fault code stored in memor y scrolls to the left,

and the new fault code now displays in the far right hand digit of

the clock display.

D

If the same fault code repeats itself (sequencially), without

being separated by a different fault code, then the repeated fault

code will "stack" in memory. In other words, the repeated fault

code will only display once, unless separated by a different fault

code. In this example, F3 repeats itself twice, the resulting fault

code memory display only shows one 3. The same would also

be true if F3 repeated itself four times, the result showing in the

fault code memory display would be one "3", NOT four "3"'s.

E

If a fourth fault code occurs, the ERC will scroll the previous

fault codes stored in memory to the left, one digit, and store the

new fault code in the far right hand digit of the clock display.

F

If a fifth fault code occurs, the ERC will continue to scroll the

previous fault codes to the left, and store the new fault code in

the far right hand digit of the clock display.

G

If a sixth fault code occurs, the ERC will once again scroll the

previous fault codes to the left. Notice in this example the first

fault code (F1), previously stored in memory is now lost. The

ERC will continue to scroll the previous fault codes to the left and

store the new fault code in the far right hand digit of the clock

display.

A

No Fault codes

Power-up

B

First fault code -

F1

scrolls left

C

Second fault code -

F3 (scrolls left

scrolls left

)

D

Third fault code -

F3

(

stacks

)

Stacks

E

Fourth fault code -

F1

(

scrolls left

scrolls left

)

F

Fifth fault code -

F5

(

scrolls left

scrolls left

)

G

Sixth fault code -

FF

(

scrolls left

scrolls left

)

– 24 –

Page 27

ERC FAILURE CODES

FAILURE

CODE

-F0-

-F1-

-F7-

-F2-

Also see

fan

thermal

switches

the door circuit in the unlock mode.