Page 1

g

Auxiliary Drive to ISBus Interface Board

Safety Symbol Legend

Indicates a procedure or

condition that, if not strictly

observed, could result in

personal injury or death.

GEI-100305

GE Industrial Systems

IS200ADIIH_A_ _

These instructions do not purport to cover all details or variations in equipment, nor to

provide every possible contingency to be met during installation, operation, and

maintenance. If further information is desired or if particular problems arise that are not

covered sufficiently for the purchaser’s purpose, the matter should be referred to GE

Industrial Systems.

This document contains proprietary information of General Electric Company, USA, and is

furnished to its customer solely to assist that customer in the installation, testing,

operation, and/or maintenance of the equipment described. This document shall not be

reproduced in whole or in part, nor shall its contents be disclosed to any third party

without the written approval of GE Industrial Systems.

Section Page

Indicates a procedure or

condition that, if not strictly

observed, could result in damage

to or destruction of equipment.

Note Indicates an essential or

important procedure or

statement.

Functional Description............................................................................................ 2

ISBus ............................................................................................................... 3

Connections ................................................................................................ 3

Performance................................................................................................ 4

Data Mapping.............................................................................................. 5

Drive Parameters ............................................................................................. 7

LAN Validation .......................................................................................... 7

LAN Faults ................................................................................................. 8

Application Data..................................................................................................... 9

LED Indicators............................................................................................... 11

Testpoints....................................................................................................... 12

Connectors..................................................................................................... 12

Installation and Renewal/Warranty Replacement................................................. 14

How to Order a Board.................................................................................... 14

Board Identification .................................................................................. 14

Warranty Terms ........................................................................................ 15

Placing the Order ...................................................................................... 15

Handling Precautions..................................................................................... 15

New Installations ........................................................................................... 16

ADII Required Parts ................................................................................. 16

Installation Procedures.............................................................................. 17

Replacement Procedures................................................................................ 18

Innovation Series is a trademark of General Electric Company, USA

Page 2

••••

Functional Description

The IS200ADII Auxiliary ISBus (Innovation Seriesä Bus) Interface board (ADII)

interfaces an AcDc2000 drive to an ISBus Local Area Network (LAN). The ADII

board resides on the backside of the first board carrier of the AcDc2000 drive.

The ADII board connects to the DS200LDCC Drive Control/LAN Communications

board (LDCC) through the LNPL ribbon cable and COM1 wire. The ADII board

receives power through the 2PL power cable from the AcDc2000 drive's power

supply board. The ADII board includes a bypass relay to maintain ISBus electrical

continuity if the drive is powered down (no external bypass module is required).

The interface signal map is derived from the Innovation Series drive system

applications signal map. Many references and feedbacks are generic and AcDc2000

drive blockware must be created to imitate the Innovation Series drive functionality.

The ADII board provides an integer variable map between the drive and controller.

The integers must be scaled to the AcDc2000 units (given in the signal map

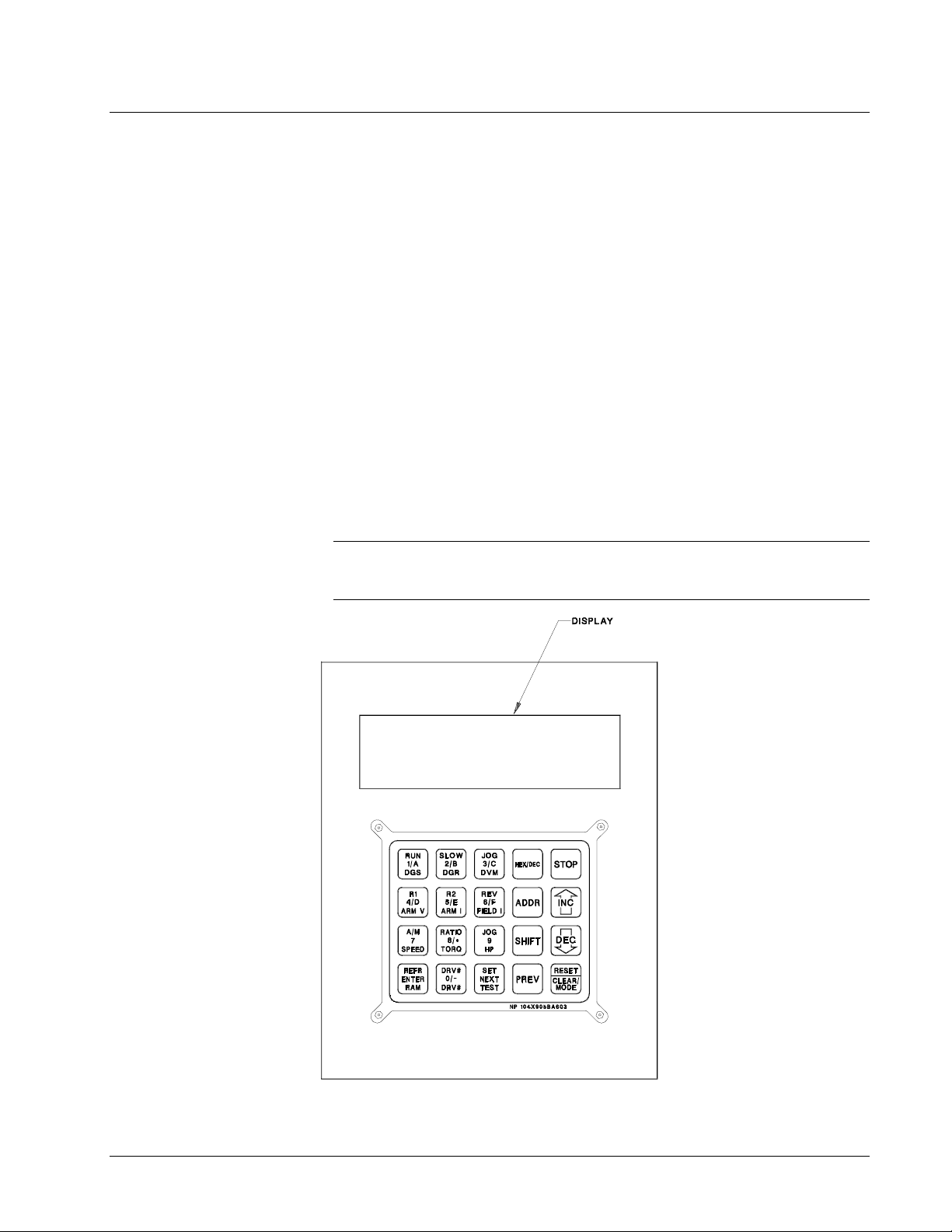

definition). Configuration of the interface is done with either the local keypad on the

LDCC board (see Figure 1) or the GE Control System Toolbox (toolbox). Refer to

the section, Data Mapping.

The ADII board has no fuses or hardware jumpers. Refer to the section, Application

Data for information on the LED indicators, testpoints, and connectors that are on

the board.

Note The ADII board can only be used in AcDc2000 drives that have the LDCC

board. It cannot be used with previous design drive control and LAN communication

boards.

Figure 1. Keypad with Display

2

Auxiliary Drive to ISBus Interface Board IS200ADII GEI-100305

Page 3

••••

ISBus

The ISBus has one controller (drop 0) and no more then 31 nodes (1-31). The master

sends out a stream of bytes containing each ISBus node's references. As the nodes

receive the stream of bytes, they pass the stream on to the next node substituting

their own feedback data in place of their reference data in the stream. When the

stream of bytes return to the master, it contains each nodes feedback data.

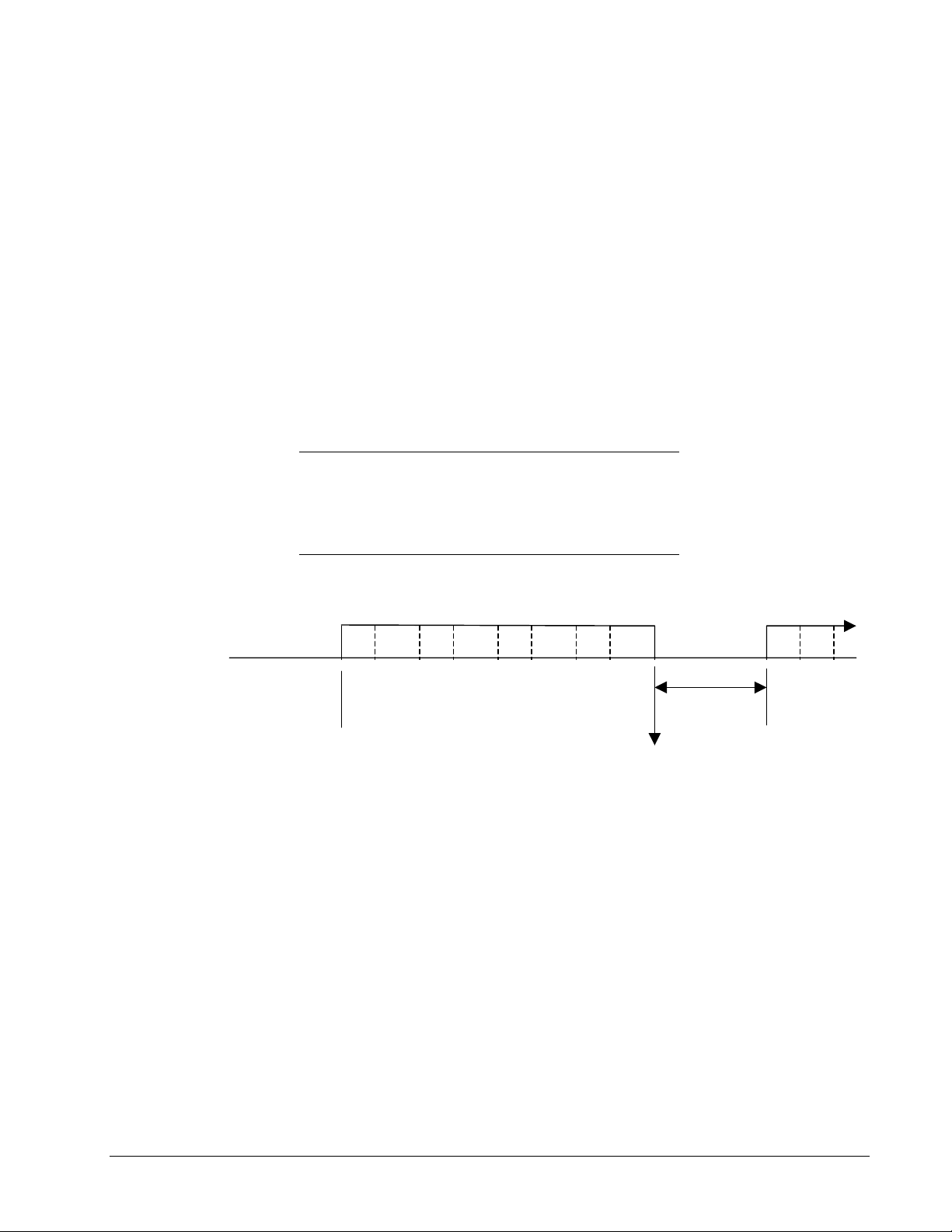

The ISBus frame rate is programmable and can be 1, 2, 4, or 8 milliseconds (ms).

The ADII board requires a time delay of 200 µsec. This allows the LAN Control

Processor (LCP on the LDCC board) to write the drive’s feedbacks into the ISBus

controller prior to the start of the next frame. The delay time at the end of a frame is

shown in Table 1. This time is valid as long as the number of pages per the frame

rate is not exceeded.

Table 1. Frame End Delay Time

Frame

Rate (ms)

1 4 200

2 8 400

4 16 800

8 32 1600

*AcDc2000 drives use a double page (refer to the following timing diagram).

Number of

AcDc2000 drives*

End of Frame

Delay Time (µµµµs)

pg

time delay

Frame à Frame à

2 µs per byte (5 Mbits/s baud rate)

64 µs per page

1 page = 1 cell = 8 variables (variable = 4 bytes in length)

1 double page = 2 cells = 16 variables

End Of Serial Data (EOSD)

(ADII ISBus controller introduction to LCP)

Connections

The ADII board interfaces to the ISBus through two RJ45 connectors, P2 (TX/OUT)

and P3 (RX/IN). The user’s cables are run into the drive package and directly to the

ADII board.

The TX/OUT connector (P2) ties to the RX/IN connector (P3) of the next device on

the ISBus. The RX/IN connector (P3) ties to the TX/OUT connector (P2) of the

previous device on the ISBus.

GEI-100305 Auxiliary Drive to ISBus Interface Board IS200ADII

3

Page 4

••••

Performance

On the ISBus, the controller sends control bits and references for each drive in a

single stream of bytes. The first drive wired to the controller receives the stream of

bytes, retrieves its command bits and references, and passes the stream of bytes onto

the next drive substituting its feedback bits and variables for the command bits and

references. When the controller receives the stream of bytes from the bus, it is

receiving the feedback bits and feedback variables from the drives.

The ISBus scan time can be selected to be 1, 2, 4, or 8 ms. These times are limited to

the number of devices on the bus. See Table 2 for performance factor descriptions.

Performance

Factor Description

Table 2. Performance Factors

Control logic

sweep rate

Configured frame

time of the ISBus

Types of devices

on the bus

Quantity of

devices on the bus

AC/DC2000 LCP

to DCP

AD/DC2000 DCP

Algorithms

AD/DC2000 DCP

Algorithms

LCP to ISBus LCP obtains drive feedbacks from the LCP/DCP dual-port RAM at the

Time required for a sweep of the control logic being executed in the

controller (typically measured in ms).

1, 2, 4, or 8 milliseconds (Set by the master).

The contribution of each device to the bus sweep rate varies with the

quantity of I/O data being exchanged with the controller. Each AcDc2000

drive contributes about 0.20 ms (200 µs). This data is used in calculating

what the frame time should be.

As the number of devices on the bus grows, so does the bus sweep rate.

This data is used in calculating what the frame time should be.

LCP will pass the reference bits and references to the drive control

processor (DCP) in one ms time with an average of 500 µs.

Many of the references are passed to the DCP in generic setpoint

variables. These variables are read by the DCP at different update times

(11, 22, or 44 ms).

Many of the feedbacks are passed from the DCP in generic feedback

variables. These variables are written by the DCP at different update

times (11 ms, 22 ms, 44 ms).

end of a frame and loads these feedbacks into the controller. These

feedbacks are sent to the master in the next ISBus frame.

4

Auxiliary Drive to ISBus Interface Board IS200ADII GEI-100305

Page 5

••••

Data Mapping

The drive is configured through its keypad or by the toolbox. Once configured, the

drive exchanges a fixed set of integer variables with the controller during each ISBus

scan.

• Variables sent to the drive are defined as references

• Variables retrieved from the drive are defined as feedbacks.

The integer variable interface map consists of 17 words of reference and 17 words of

feedback. The first two words of reference and feedback contain 32 bits. The

remaining 15 words of reference and feedback contain signed integer variables.

Tables 3 and 4 define the system application signal map and Boolean signals. Table

5 contains AcDc2000 reference and feedback values.

Table 3. Signal Map

Page 1 References

Innovation Series

1 Request Bits

2 Auto Speed Ref LAN_SPD_REF MMSSETP (V.204)

3 Spd Ref Aux RPM LAN_AUX_RPM SPDSETP (V.205)

4 Torque Ref LAN_TRQ_REF LOADADJ (V.225)

5 Spd Ref Aux Appl LAN_AUX_SPD GS1 (V.218,219) DW5LCPCFB (V.559) LAN_I_MAG Motor Current

6 Ramp Time Ref LAN_RAMP_TM GS3DWA (V.1438)

7 GP LAN Ref 1 LAN_R01_REF LANV0SP (V.206)

8 GP LAN Ref 2 LAN_R02_REF LANV1SP (V.207)

Page 2 References

Innovation Series

1 Torque Ref Aux LAN_TRQ_AUX GS3DWB (V.1439) 1 (EE.771) LFBVAR5 (V.588) LAN_R05_ADR GPLAN Fbk Reg 5

2 Speed Ratio LAN_SPD_ADJ DRAWSETP (V.209) 2 (EE.772) LFBVAR6 (V.589) LAN_R06_ADR GPLAN Fbk Reg 6

3 Diameter Ratio LAN_DIAM_ADJ DIAMSETP (V.224) 3 SPEEDREF (V.560) LAN_SREF_FBK Net Spd Ref Fbk

4 Inertia Ref LAN_J_REF GS2 (V.220,221) DW 4 Undefined

5 Undefined

6 Undefined

7 GP LAN Ref 3 LAN_R03_REF LANV2SP (V.208) 7 (EE.743) LFBVAR3 (V.568) LAN_R03_ADR GP LAN Fbk Reg 3

8 GP LAN Ref 4 LAN_R04_REF LANV3SP (V.210) 8 (EE.744) LFBVAR4 (V.569) LAN_R04_ADR GP LAN Fbk Reg 4

Innovation

AcDc2000 Feedbacks

Series

Mnemonic

Innovation

Request Bits

AcDc2000 Feedbacks

Series

Mnemonic

AcDc2000

Innovation

Series

Innovation

Series

Mnemonic

Feedback Bits

1

FAULT (V.500) LAN_FLT_CODE Fault Number

2

LCPSFB (V.558) LAN_SPD_FBK Speed Feedback

3

(EE.5627) LFBVAR7 (V.593) LAN_TRQ_FBK Motor Torque

4

Undefined

6

(EE.769) LFBVAR1 (V.566) LAN_R01_ADR GP LAN Fbk Reg 1

7

(EE.770) LFBVAR2 (V.567) LAN_R02_ADR GP LAN Fbk Reg 2

8

Innovation

AcDc2000

Series

Feedback Bits

Innovation

Series

Mnemonic

5 Undefined

6 Undefined

GEI-100305 Auxiliary Drive to ISBus Interface Board IS200ADII

5

Page 6

••••

Table 4. Boolean Signals

Request Bits

Innovation Series

bit #

0

Heartbeat ref, lan LAN_HTBT_REF AUXCMD00

1

Fault reset req, lan LAN_FLT_RST SOFTRES

2

Trip request, lan LAN_TRP_REQ CFGCMD32 (V.1422)

3

Alarm request, lan LAN_ALM_REQ CFGCMD33 (V.1423)

4

Undefined

5

Undefined

6

Undefined

7

Undefined

8

Run request, lan LAN_RUN_REQ RUNRQ (V.650)

9

Jog request, lan LAN_JOG_REQ JOGRQ (V.651)

10

X stop request, lan LAN_XSTP_REQ CFGCMD34 (V.1424)

11

Full flux req, lan LAN_FFLX_REQ CFGCMD35 (V.1425)

12

Rev mode req, lan LAN_REV_REQ REVCMD (V.675)

13

Torque mode req, lan LAN_TREF_ENB CURFOLRQ (V.684)

14

Droop disab req, lan LAN_DRP_INH BIASDINH (V.724)

15

Trq lim 2 sel, lan LAN_TLIM_SEL RCLILIM (V.695)

16

Ramp rate 2 sel, lan LAN_RMP_SEL ALTRAJSU (V.643)

17

Ramp hold req, lan LAN_RMP_HOLD HOLDSPD (V.699)

18

Auto mode req, lan LAN_AUTO_REQ AUTOCMD (V.683)

19

Undefined

20

Undefined

21

Undefined

22

Undefined

23

Undefined

24

GP lan req bit 1 LAN_B01_REQ AUXCMD01 (V.661)

25

GP lan req bit 2 LAN_B02_REQ AUXCMD02 (V.662)

26

GP lan req bit 3 LAN_B03_REQ AUXCMD03 (V.663)

27

GP lan req bit 4 LAN_B04_REQ AUXCMD04 (V.664)

28

GP lan req bit 5 LAN_B05_REQ AUXCMD05 (V.665)

29

GP lan req bit 6 LAN_B06_REQ AUXCMD06 (V.666)

30

GP lan req bit 7 LAN_B07_REQ AUXCMD07 (V.667)

31

GP lan req bit 8 LAN_B08_REQ AUXCMD08 (V.738)

Innovation

AcDc2000 Feedback Bits

Series

Mnemonic

Innovation

AcDc2000

bit #

0

AUXFB00 LAN_HTBT_FBK Heartbeat fbk, lan

1

NOFAULT NO_FLT No faults active

2

TRIPFLT TRIP_FLT Trip fault active

3

AUXFBW32.0 LOC_FLT Local Fault string

4

AUXFBW32.1 SYS_FLT System fault string

5

AUXFBW32.2 RUN_RDY Ready to Run

6

MPWRENAB BRG_PWR_ENB Bridge is on

7

RUNNING RUNNING Running

8

RUNACT RUN_ACT Run Active

9

JOGACT JOG_ACT Jog Active

10

AUXFBW32.3 X_STP_CMD X stop active

11

AUXFBW32.4 FLX_ENB_STAT Flux enable status

12

AUXFBW32.5 REVERSE Reverse mode

13

AUXFBW32.6 TRQ_MODE_ACT Torque mode

14

AUXFBW32.7 SPD_MODE_ACT Speed mode active

15

AUXFBW32.8 TRQ_LIM_ACT In cur or trq limit

16

AUXFBW32.9 LOCAL_MODE Local mode active

17

AUXFBW32.10 MA_ENB_STAT MA cont enable stat

18

Undefined

19

ZEROSPD ZERO_SPD Zero speed active

20

Undefined

21

Undefined

22

Undefined

23

Undefined

24

(EE.781) AUXFB01 LAN_B01_ADR LAN_B01_ADR

25

(EE.782) AUXFB02 LAN_B02_ADR LAN_B02_ADR

26

(EE.783) AUXFB03 LAN_B03_ADR LAN_B03_ADR

27

(EE.784) AUXFB04 LAN_B04_ADR LAN_B04_ADR

28

(EE.785) AUXFB05 LAN_B05_ADR LAN_B05_ADR

29

(EE.786) AUXFB06 LAN_B06_ADR LAN_B06_ADR

30

(EE.787) AUXFB07 LAN_B07_ADR LAN_B07_ADR

31

(EE.788) AUXFB08 LAN_B08_ADR LAN_B08_ADR

Series

Mnemonic

Innovation

Series

active

active

Notes:

For CFGCMDx reference bits to be active, drive EE.762.8 (LDRVJP.8) must be set.

For AUXFBW32.x feedback bits to be active, drive EE.5626 (AUXFBJP) must be set to 3 (bits .1 & .0 must be set).

6

Auxiliary Drive to ISBus Interface Board IS200ADII GEI-100305

Page 7

••••

Table 5. AcDc2000 References and Feedback Values (1pu)

Variable AcDc2000 Signal (1pu)

Armature Current Refr LOADADJ 5000

Speed Refr MMSETP 20000

Ramp Refr

Droop Gain R

Field Flux Refr

Speed Rate Reg Output

Voltage Fdbk

Field Current Fdbk

Armature Current Fdbk LCPCFB 5000

Speed Fdbk LCPSFB 20000

20000

10000

5000

5000

20000

5000

Drive Parameters

All of the ADII board configuration parameters are stored in the drive and loaded

into the ADII board when the drive is powered up or reset. The parameters can be

modified using the drive’s keypad or the toolbox, either through the ISBus LAN or

through the drive’s RS-232C port.

The following parameters configure the application interface:

• ADII Jumper 1 (ADIIJP1)

ADIIJP1.0 = Enables the ADII interface

When ADII is enabled, all other LAN interfaces must be disabled.

ADIIJP1.14 = Disables the ISBus controller ASIC watchdog.

This is a special diagnostic bit that is normally not set. Setting this bit

disables the ISBus controller watchdog detection.

ADIIJP1.15 = Enables Loop Back Mode

This is a special diagnostic mode that loops the references received back

into the feedbacks. The references do not go to the drive’s regulator

processor but are short circuited to the feedback area of the ISBus

controller.

• ADII Node Number (ADINID)

ADINID = The drive’s ISBus node ID (1−31).

The controller is drop number 0 and the drives may be drops 1−31.

Drive blockware patterns should be set up to accept the references and perform the

required functions. Drive blockware patterns must also be set up to load the feedback

data appropriately.

LAN Validation

The drive has two levels of validation, the LAN watchdog and the LAN heartbeat

functions.

GEI-100305 Auxiliary Drive to ISBus Interface Board IS200ADII

7

Page 8

••••

The LAN watchdog function is made up of three parts:

• First, the LAN Control Processor (LCP) monitors the ISBus controller’s fault

bits and displays an ADII fault, if the ISBus controller is in a fault state.

• Second, the LCP monitors it’s own communication with the ISBus controller

and if for any reason the ISBus controller is not communicating to LCP, then a

drive fault FLT.xxx ADIIRTM displays.

• If the LCP and the Drive Control Processor (DCP, on the LDCC board) fail to

communicate with each other, then a drive fault is triggered and displays.

The LAN heartbeat function can loop back a signal between the drive and any level

in the LAN hierarchy, such that a higher-level controller can validate the entire

connection pathway, including the drive.

A Programmable Logic

Controller (PLC) used as a

master controller can

generate a heartbeat to the

drive by inverting the

heartbeat from the drive and

sending that value back to the

drive.

The first bit in the drive’s feedback map is used as a heartbeat from the drive to the

master controller. The drive LCP always writes the heartbeat feedback to the same

state as the heartbeat reference. Thus, the master controller can monitor the status of

the communication with the drive by continually toggling the heartbeat to the drive

and monitoring the heartbeat from the drive.

The LCP sets AUXCMD0 if references are being received from the LAN and clears

AUXCMD0 if references are not being received from the LAN. The drive blockware

may be set up to monitor AUXCMD0 and cause a fault FLT.359 LINKLOSS if

AUXCMD0 is cleared.

LAN Faults

The following signals determine LAN health and declare faults:

• AUXCMD0 (master link presence)

• Heartbeat ref, LAN (Lan_Htbt_Ref)

• Heartbeat fbk, LAN (Lan_Htbt_Fbk)

The following faults are associated with the LAN interface: (See Table 6 for

descriptions.)

• FLT.359 LINKLOSS

• FLT.446 LADIINIT

• FLT.447LADIIWDG

• FLT.448 LADIIRTM

• FLT.449 LADIISEL

8

Auxiliary Drive to ISBus Interface Board IS200ADII GEI-100305

Page 9

••••

Table 6. Fault Codes for ADII Board and ISBus Interface

Fault

No.

359 FLT_LINK_LOS

446 FLT_LADIINIT ADII board failed initialization Check/replace LNPL and 2PL connections

447 FLT_LADIIWDG ISBus controller and/or LCP has failed

448 FLT_LADIIRTM ADII board run time fault

449 FLT_LADIISEL Another drive LAN is enabled besides

Fault Name Description Corrective Action to Take

(May be set up to

monitor

AUXCMD.00 bit.

If AUXCMD.00 =

0, the cause fault

FL359.) *

The ISBus controller is not receiving

data from the ISBus LAN.

(LCP ADII interrupt is not being

triggered)

the watchdog

The ISBus controller has a fault or LCP

has detected a problem with the ADII

board or ISBus controller interface.

ISBus.

Check to make sure there is a master

controller on the ISBus and that it is

communicating.

Check ADII board JP1 for a 1-2

connection.

Check/replace LNPL and 2PL connections

and cables.

Check the ISBus connections (RJ45 – P2

& P3)

Replace ADII board

and cables.

Replace ADII board

Check/replace LNPL and 2PL connections

and cables.

Check the ISBus connections (RJ45 – P2

& P3)

Replace ADII board

Check/replace LNPL and 2PL connections

and cables.

Check the ISBus connections (RJ45 – P2

& P3)

Replace ADII board

Modify the drive’s parameters (EEROM)

to disable the other LANs

DLAN – LCPJP1.0 (EE615.0 ) = 1

DLAN + – ARCJP1.0 (EE706.0) = 0

GENIUS – GENJPR.0 (EE725.0) = 0

ADCI – LCPJP3.0 (EE617.0) = 0

(CPL/CBUS/FBUS)

* = AUXCMD.00 will be set if the LCP is interrupted by the ADII board's interrupt line (the ISBus controller received

data from the master), AUXCMD.00 will be cleared if the interrupt does not happen for 80 ms.

Application Data

The ADII board has no fuses or hardware jumpers. The ADII board has LED

indicators and testpoints for diagnostic and setup purposes. Any ISBus or ADII

board faults will be displayed on the drive’s display. The testpoints on the ADII

board are for manufacturing, diagnostic, and setup purposes. See Figure 2 for the

locations of these devices.

GEI-100305 Auxiliary Drive to ISBus Interface Board IS200ADII

9

Page 10

••••

2PL

BUS ACTIVE 1

CHASSIS

RX/IN RX/TX

TX/OUT

DS1

E2

P3

TP1TP3 TP2

P24 P5 DCOM

ISBus Cable

Strain Reliefs

P2

DS5

DS6

DEBUG G1A

BUS ONLINE 1

DS2

DEBUG G1B

DS3

DS4

XMIT DATA IN RELAYS ENABLED

0BACTIVE1

DBG1A

0ONLN1

TP6

TP7

DBG1B

TP4

TP5

IS200ADIIH1A

U6

U5

U2

U4

E1

LNPL

COM1

Figure 2. ADII Board Layout Diagram

10

Auxiliary Drive to ISBus Interface Board IS200ADII GEI-100305

Page 11

••••

LED Indicators

The LEDs on the ADII board are only intended for diagnostic purposes. See Table 7

for a description of the LED indications. The drive’s display will show any ISBus

faults or ADII board interface faults.

Note Debug LEDs DBG1A (DS3) and DBG1B (DS4) are for manufacturing test

only.

Table 7. ADII Board LED Indicator Descriptions

LED Mnemonic Description

DS1 Bus Active On if LAN pulses are detected and in an active state. If this LED

is not on, then the ISBus Controller has not detected any LAN

pulses and is not in an active state.

DS2 Bus Online On or flashing if modulation on the LAN is detected. If this LED is

not on, then the ISBus Controller is not online. See Table 8 for a

description of flashing indications.

DS3 Debug1A Manufacturing use only

DS4 Debug1B Manufacturing use only

DS5 Bypass Relays

Enabled

DS6 Xmit Data On if there is data being transmitted. If this relay is not lit (dimly),

On if these relays are being driven (meaning the drive’s P5 is

OK). If this LED is not on, then P5 (+5 V) is below 4.6 V or P24

(+24 V) is too low to drive these relays.

then there is no transmitted data.

(because this LED is directly across the differential transmit lines,

it is being pulsed and will appear to be very dim)

Table 8. DS2 LED Indicator Flashing Indications

Modulatio

n Present

No x Off Solid

Yes RESET 1

Yes OFF LINE 2

Yes STANDBY 3

Yes ONLINE On Solid

GEI-100305 Auxiliary Drive to ISBus Interface Board IS200ADII

ISBus

Controller

Core State

DS2

Flashes/Second

11

Page 12

••••

Testpoints

There are seven testpoints on the ADII board as follows:

Table 9. Testpoint Descriptions

Testpoint Nomenclature Description

TP1 P5 Positive 5 V dc

TP2 DCOM Digital common

TP3 P24 Positive 24 V dc

TP4 DBG1A Manufacturing use only

TP5 DBG1B Manufacturing use only

TP6 0BACTIVE1 Manufacturing use only

TP7 0ONLN1 Manufacturing use only

Connectors

There are four plug connectors and two stab-on connectors on the ADII board. Refer

to the following tables for complete descriptions of these connectors:

Table Description

10 Stab-on Connectors

11 2PL Power Connector

12 LNPL Connector to LDCC Board

13 P3 ISBus Connector

14 P2 ISBus Connector

Table 10. Stab-on Connector Descriptions

Connector Nomenclature Description

E1 COM1 Common (to LDCC board)

E2 CHASSIS Chassis ground

Table 11. Connector 2PL, Power Supply to ADII Board

Pin No. Nomenclature Description

1 P24 +24 V dc

2 N24 Not connected

3 DCOM Digital common

4P5 +5 V dc

5P5 +5 V dc

6 DCOM Digital common

12

Auxiliary Drive to ISBus Interface Board IS200ADII GEI-100305

Page 13

••••

Table 12. Connector LNPL, I/O Between the LDCC Board and ADII Board

Pin No. Nomenclature Description

1, 2 DCOM Digital common ground

3 − 10 LND0 − LND7 ADII board data signals (D0 − D7)

11 DCOM Digital common ground

12 LNRST Reset signal going to ADII board

13 LNINT ADII board interrupt

14 DCOM Digital common ground

15 LNRDY Ready/busy signal from ADII board DPRAM

16 DCOM Digital common ground

17 LNALE NC

18 DCOM Digital common ground

19 LNRD ADII board read control signal

20 LNWR ADII board write control signal

21 DCOM Digital common ground

22 − 34 LNA0 − LNA12 ADII board address signals (A0 − A12)

35 P5 +5 V dc

36 LNACS Not connected

37 LNCS1 ADII board DPRAM select

38 LNCS2 ADII board ISBus controller select

39, 40 DCOM Digital common ground

Table 13. P3 Connector, RJ45 ISBus RX/IN RX/TX

Pin No. Nomenclature Description

1, 2 NC Not connected

3 ISBRXP ISBus receive positive

4

5

6 ISBRXN ISBus receive negative

7, 8 NC Not connected

9, 10 Shield Shield connection

GEI-100305 Auxiliary Drive to ISBus Interface Board IS200ADII

4 − 5

4 − 5

Pin 4 is tied to pin 5

Pin 5 is tied to pin 4

13

Page 14

••••

Table 14. P2 Connector, RJ45 ISBus TX/OUT

Pin No. Nomenclature Description

1, 2 NC Not connected

3 ISBTXP ISBus transmit positive

4, 5 NC Not connected

6 ISBTXN ISBus transmit negative

7, 8 NC Not connected

9, 10 Shield Shield connection

Installation and Renewal/Warranty Replacement

How to Order a Board

When ordering a replacement board for a GE drive, you need to know:

• How to accurately identify the part

• If the part is under warranty

• How to place the order

This information helps ensure that GE can process the order accurately and as soon

as possible.

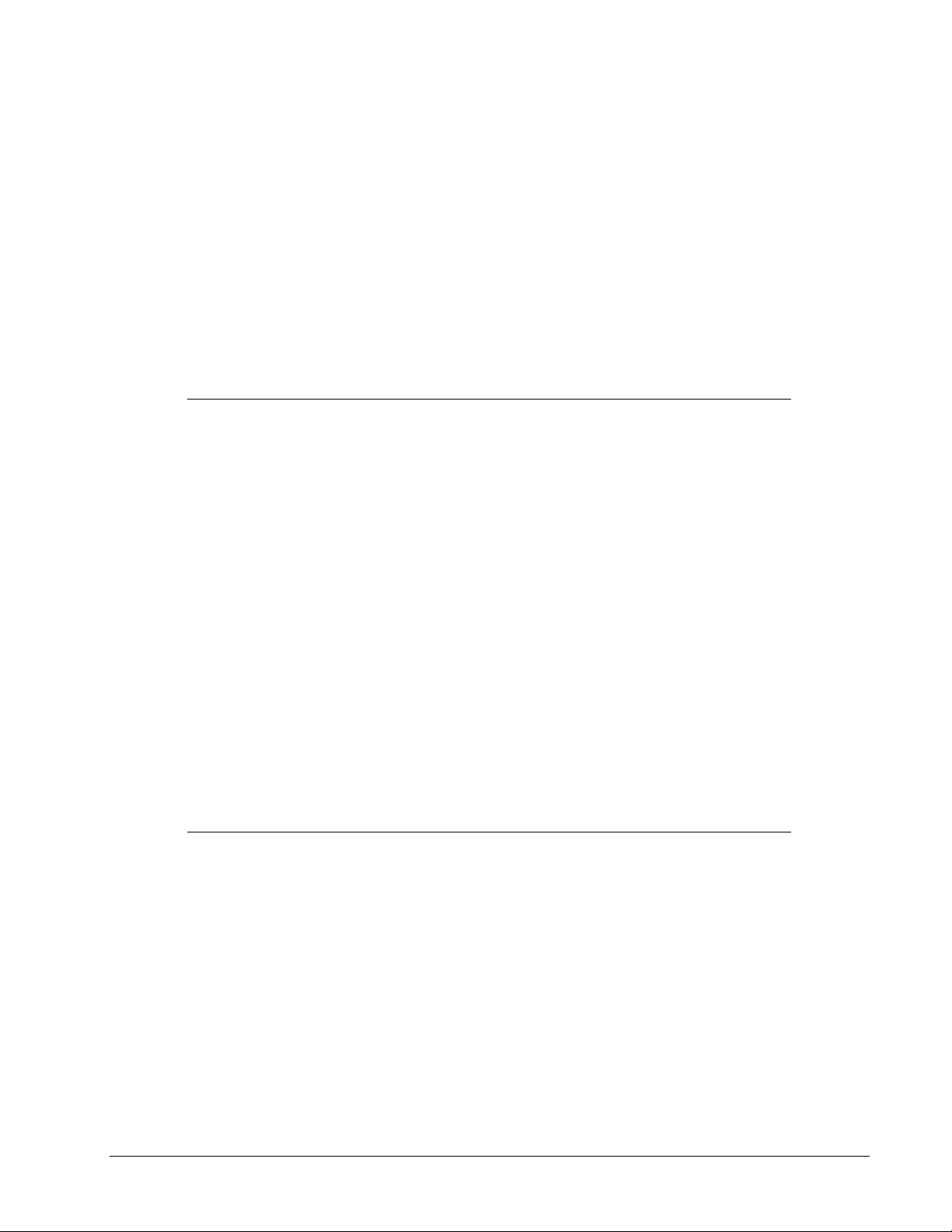

Board Identification

A printed wiring board is identified by an alphanumeric part (catalog) number

located near its edge. Figure 3 explains the structure of the part number.

The board’s functional acronym, shown in Figure 3, is normally based on the board

description, or name. For example, the ADII board is described as the Auxiliary

Drive to ISBus Interface board.

IS 200 ADII H# A A A

Artwork revision

Functional revision

Functional revision

Group (variation, G or H)

Functional acronym

Assembly level

Manufacturer (DS & IS for GE in Salem, VA)

1

Backward compatible

2

Not backward compatible

3

200 indicates a base-level board; 215 indicates a

higher-level assembly or added components (such

as PROM)

3

Figure 3. Board Part Number Conventions

1

1

2

14

Auxiliary Drive to ISBus Interface Board IS200ADII GEI-100305

Page 15

••••

5

(“+” indicates the

international access code

required when calling from

outside of the USA.)

Warranty Terms

The GE Terms and Conditions brochure details product warranty information,

including warranty period and parts and service coverage. The brochure is

included with customer documentation. It may be obtained separately from the

nearest GE Sales Office or authorized GE Sales Representative.

Placing the Order

Parts still under warranty may be obtained directly from the factory:

GE Industrial Systems

Product Service Engineering

1501 Roanoke Blvd.

Salem, VA 24153-6492 USA

Phone: + 1 800 533 5885 (United States, Canada, Mexico)

+ 1 540 378 3280 (International)

Fax: + 1 540 387 8606 (All)

Renewals (spares or those not under warranty) should be ordered by contacting the

nearest GE Sales or Service Office.

Be sure to include the following when ordering any warranty or renewal parts:

• Complete part number and description

• Drive serial number

• Drive Material List (ML) number

Note All digits are important when ordering or replacing any board. The factory

may substitute later versions of replacement boards based on availability and design

enhancements. However, GE Industrial Systems ensures backward compatibility of

replacement boards.

Handling Precautions

To prevent component damage caused by static electricity,

treat all boards with static sensitive handling techniques.

Wear a wrist grounding strap when handling boards or

components, but only after boards or components have

Printed wiring boards may contain static-sensitive components. Therefore, GE ships

all replacement boards in antistatic bags.

Use the following guidelines when handling boards:

• Store boards in antistatic bags or boxes.

• Use a grounding strap when handling boards or board components (per previous

Caution criteria).

been removed from potentially energized equipment and

are at a normally grounded workstation.

GEI-100305 Auxiliary Drive to ISBus Interface Board IS200ADII

1

Page 16

••••

New Installations

ADII Required Parts

When installing an ADII board in a drive that has not had this board in it previously,

GE kit number 277A8496G01 is required. This kit includes the ADII board, LNPL

cable, DCOM wire, and chassis wire (see Table 15 for individual part numbers).

Note When adding the ADII board in the field, a new 2PL cable assembly will also

be needed. The part number for the 2PL cable assembly differs for different drives.

Refer to Table 16 for the 2PL part number of the applicable drive/frame size.

Table 15. ADII Board New Installation Part Numbers

Part Description Part Number

ADII board Auxiliary drive to ISBus interface board IS200ADIIH_A_ _

2PL Power cable from the power supply board to

the LDCC board and ADII board

LNPL 40-pin ribbon cable to the LDCC board 336A3493AA G01

DCOM wire Common wire from the LDCC board to the

ADII board (runs parallel to the LNPL cable)

CHASSIS wire Ground wire from the ADII board to the

drive's chassis

See Table 16

336A3438AT G15

277A8495G01

Table 16. AcDc2000 Frame Size/Drive 2PL Part Numbers

Frame/Drive Part Number

BM 36B605787ACG06

C 36B605787ACG01

G 36B605787ACG01

M 36B605787ACG06

J 36B605787ACG06

AA 36B605787ACG03

AP 36B605787ACG03

AQ 36B605787ACG06

AT 36B605787ACG06

AS/AW 36B605787ACG08

SilcoMatic 2000 246B235JLG01

IM2000 36B605787ACG03

CV2000 36B605787ACG06

16

Auxiliary Drive to ISBus Interface Board IS200ADII GEI-100305

Page 17

••••

7

Installation Procedures

To prevent electric shock, turn off power to the drive,

then test to verify that no power exists in the drive

before touching it or any connected circuits.

To prevent equipment damage, do not remove, insert, or

adjust board connections while power is applied to the

equipment.

ØØØØ To install a new ADII Board in a drive

1. Make sure that the drive in which the board is to be installed has been

deenergized. (Refer to the appropriate User's Guide for complete de-energizing

procedures and follow all local practices of lock out/tag out.)

2. Open the drive’s cabinet door, and using equipment designed for high voltages,

test any electrical circuits before touching them to ensure that power is off.

3. Install the ADII board in the drive as follows:

a. Release the two board carrier retainers by pulling them forward.

b. Lift up and rotate the front board carrier out and down until it is resting on

its stops.

c. Place the board in position on the four tabs (on left side) of the back of this

board carrier and press it firmly into position on these tabs.

4. Install the LNPL ribbon cable into the LNPL connector on the ADII board and

the LNPL connector on the LDCC board.

5. Install the COM1 wire onto the E1 (COM1) stab-on terminal on the ADII board

and the E1 (COM1) terminal on the LDCC board.

6. Install the CHASSIS wire onto the E2 stab-on terminal on the ADII board and

secure the other end to an accessible screw on the drive chassis.

The chassis wire must be securely mounted to the drive’s

chassis to shunt the ISBus shield to ground.

Care must be taken to keep the chassis wire tight to the ADII

board and away from the power supply board at all times. Use

a wire tie down strap connected to the bottom of the board

carrier to keep it away from the power supply board.

7. Plug the 2PL cable connector into the 2PL receptacle on the ADII board.

8. Install an ISBus cable into the RX/IN RJ45 jack (P3) on the ADII board and the

TX/OUT jack (P2) of the previous device on the ISBus.

9. Install an ISBus cable into the TX/OUT RJ45 jack (P2) on the ADII board and

the RX/IN jack (P3) of the next device on the ISBus.

GEI-100305 Auxiliary Drive to ISBus Interface Board IS200ADII

1

Page 18

••••

Care must be taken to keep the ISBus cables away from any

high voltage wires and any electrically noisy wires. Keep the

cables tight to the ADII board carrier and use the tie down strap

holders to hold the cables close to the ADII board and away

from the power supply board.

10. Install cable ties to the ISBus cables on the ADII board strain reliefs and on the

other cables/locations as necessary to keep the cables tight to the board and

board carrier, and away from the power supply board.

11. Raise the board carrier back up into its normal position, slide the board carrier

retainers in to secure it in this position, and close the drive cabinet door.

Replacement Procedures

To prevent electric shock, turn off power to the board,

then test to verify that no power exists in the board

before touching it or any connected circuits.

To prevent equipment damage, do not remove, insert, or

adjust board connections while power is applied to the

equipment.

ØØØØ To remove the ADII Board from the drive

1. Make sure that the drive in which the board is to be removed has been

deenergized. (Refer to the appropriate User's Guide for complete de-energizing

procedures and follow all local practices of lock out/tag out.)

2. Open the drive’s cabinet doors, and using equipment designed for high voltages,

test any electrical circuits before touching them to ensure that power is off.

3. Carefully remove the board from the drive as follows:

a. Release board carrier retainers by pulling them forward.

b. Lift up and rotate the front board carrier out and down until it is resting on

its stops.

c. Disconnect all cables and wires from the ADII board (2PL, TX and RX

ISBus, CHASSIS ground wire, LNPL, and COM1 wire). (The COM1 wire

runs parallel to the LNPL cable.)

d. Pull back on the four locking tabs and lift board up and off of the board

carrier.

18

Auxiliary Drive to ISBus Interface Board IS200ADII GEI-100305

Page 19

••••

ØØØØ To install the new (replacement) board on the board carrier

1. Orient the new board in the same position as the one removed, and seat the

board by firmly pressing the board onto the four tabs (on left side) of the back of

the front board carrier. (LDCC board is on front of this carrier.)

2. Reinstall all cables that were removed from the old ADII board (COM1 wire,

CHASSIS ground wire, LNPL, 2PL, TX and RX ISBus).

The chassis wire must be securely mounted to the drive’s

chassis to shunt the ISBus shield to ground.

Care must be taken to keep the chassis wire tight to the ADII

board and away from the power supply board at all times. Use

a wire tie down strap connected to the bottom of the board

carrier to keep it away from the power supply board.

Care must be taken to keep the ISBus cables away from any

high voltage wires and any electrically noisy wires. Keep the

cables tight to the ADII board carrier and use the tie down

strap holders to hold the cables close to the ADII board and

away from the power supply board.

3. Reinstall cable ties to the ISBus cables on the ADII board strain reliefs and on

the other cables/locations as necessary to keep the cables tight to the board and

board carrier, and away from the power supply board.

Note If the ADII board must be configured in any way, refer to the applicable

User's Guide for the drive/source for procedures.

4. Raise the board carrier back up into its normal position, slide the board carrier

retainers in to secure it in this position, and close the drive cabinet door.

GEI-100305 Auxiliary Drive to ISBus Interface Board IS200ADII

19

Page 20

••••

Notes

A

g

GE Industrial Systems

Issue date: 2000-04-05

1999 by General Electric Company, USA.

ll rights reserved.

20

Auxiliary Drive to ISBus Interface Board IS200ADII GEI-100305

General Electric Company

1501 Roanoke Blvd.

Salem, VA 24153-6492 USA

Loading...

Loading...