Page 1

INSTRUCTIONS

Supplement

GEK-65572

GEK-45375

to

OVERCURRENT

TIME

TYPE

RELAY

IFC53M

GENERAL

‘1’

ELECTRIC

Page 2

Page 3

GEK-65572

These

form

instructions

These

taneous

right—hand

unit.

The

dropout

a

with

calibrated

The

The

coil

The

of

tion

support

instructions

relays

overcurrent

target

special

values

special

in

high

ratings

high

high

the

structure.

for

provide

and

high

of

80

wave

standard

the

dropout

available

dropout

or

are

the

unit.

seal-in

dropout

percent,

washer

instantaneous

instantaneous

range

low

a

Type

for

The

so

manner

are

supplement

IFC53M

target

a

IEC53M

Type

and

unit

instantaneous

higher,

or

it

that

once

HI-SEISMIC

unit

in

shown

unit

is

accomplished

relay.

seal-in

a

can

the

TIME

to

relay

high

of

be

pole

HIGH

contacts

Table

is

OVERCURRENT

IFCS3M

TYPE

I

NTRODUCT

instruction

for

unit

is

similar

dropout

is

unit

pickup

constructed

current.

rotated

piece

DROPOUT

will

1.

by

for

means

tapped

RELAY

ION

book

GEK-45375.

the

both

the

to

instantaneous

without

The

has

the

been

most

adjusted

to

INSTANTANEOUS

amperes

30

close

operation

range

of

a

overcurrent

time

Type

unit

pole

favorable

either

on

selection

The

IFC53A

mounted

a

piece

for

UNIT

at

combination

target

is

position.

80

voltages

two

of

link

element

the

with

in

the

is

and

constructed

percent

less

ranges

located

of

addition

rear

designed

The

dropout

and

unit

than

(H

on

the

and

of

or

the

two

the

the

secured

may

or

250

L).

top

instan

of

to

higher.

volts.

books

a

relay

yield

be

Selec

of

the

*The

one

higher

the

ever;

farther

the

but

range

drnpere

range,

correct

These

possible

information

ourchaser’s

the

Tc

no

such

approximate

is

overlap

since

position

2nstructloflq

contingency

purposes,

extent

assurance

Unit

2-8

4-16

10-40

20-80

between

has

it

for

desired

be

requirod

is

the

do

given

which

the

the

not

to

the

Tap

Position

means

maximum

higher

range

purport

be

or

matter

the

with

L

H

L

H

L

H

L

H

in

met

should

products

that

setting

L

continuous

which

to

connection

in

particular

should

respect

*Range

2-4

4-8

4-8

8-16

10-20

20-40

20-40

40-80

the

it

cover

be

described

to

TABLE

2—4,

and

rating.

is

all

referred

local

1

Continuous

Rating

(Pjnps)

16.2

12.6

20.0

4-C

the

operate.

to

details

with

problems

herein

codes

1.9

3.0

4.3

6.9

9.0

be

may

minimum

Make

installation,

the

to

meet

and

or

arise

**One

2-5,

setting.

H

sure

variations

General

applicable

ordinances

Rating

(mps)

140

275

275

4-8.

that

which

Second

70

operation

Electric

There

the

in

are

SI,

because

K

4900

19600

75500

75500

will

Whenever

range

equipment

or

not

covered

Company.

IEEE

they

always

possible

selection

nor

maintenance.

and

vary

be

link

provide

to

sufficiently

NEiL21

standards;

greatly.

at

select

Should

least

is

the

in

for

for

3

Page 4

GEK—55572

**Higher

The

to

45375

The

target,

the

of

The

pickup,

the

to

ing

retightened.

attached

thereby

obtain

tlng.

attached

is

shading

The

current.

The

currents

high

determine

high

dropout

and

high

dropout

adjustable

while

the

turn

must

determines

percent

80

Should

must

ring

unit

The

Hi-Seismic

Hi—Seismic

High

Inst.

(Amps)

maybeapplied

dropout

the

dropout

turning

core,

loosening

When

held

be

the

dropout

it

be

always

assembly

pick

will

operating

Dropout

Unit

unit

current

instantaneous

current

unit.

(A)

core

the

the

locknut

preveit

to

quietness

at

necessary

be

from

up

time

dropout

high

Hz

is

coil

limiting

is

approximately

sets

core

tightening

or

the

to

turned

being

the

at

is

shown

Movable

Lead

Position

shorter

for

in

series

element

is

unit

pickup

the

(counterclockwise,

up

must

(B)

turning.

from

it

operation

of

minimum

change

in

loosened.

scale-plate

instantaneous

the

in

setting

the

clockwise

Fig.

lengths

with

similar

80

level.

be

loosened.

the

in

dropout

marking

4.

the

for

90

-

locknut,

Rotation

the

and

direction

Fig.

unit

TABLE

Mm.

Pickup

Amps

time

of

time

overcurrent

continuous

both

standard

the

to

percent

Turning

top

After

the

picked

approximately

setting,

or

plus

shows

S

burdens

2

I

Burdens

R

in

accordance

and

instantaneous

the

core

adjusting

the

position.

sleeve

view).

minus

transient

listed

pickup

down

increases

(C)

shading

percent

90

five

Mm.

at

of

the

view)

sleeve

of

up

the

(top

are

Pickup_(Ohms)

unit

short

the

which

to

The

(C)

This

percent

overreach

in

Table

Z

with

the

coil,

time

current.

(clockwise,

pickup.

the

core,

the

sets

ring

core

dropout

which

to

will

with

2.

Burdens

Times_Pickup

3

formula:

Table

see

ratings.

except

unit

Fig.

3

top

Before

locknut

the

shading

dropout

the

been

has

the

at

shading

the

prevent

gradually

characteristics.

in

Ohms

10

and

I,

it

Is

a

view)

must

ring

factory

maximum

the

(Z)

20

GEK

has

picture

lowers

attempt

(D)

level

ring

sleeve

applied

no

be

is

set

set—

and

to

CD)

and

tion

outline

The

diagram

2-8

2-8

4-16

4-16

10-40

10—40

20-80

20-80

is

and

shown

60

50

60

60

[50

panel

in

50

60

50

drilling

Fig.6of

The

0.52

0.22

0.44

0.19

0.13

0.056

0.12

0.052

0.029

0.017

0.025

0.014

0.021

0.013

0.017

0.011

internal

connec

0.77

2

4

2

4

4

8

4

8

10

20

10

20

20

40

20

40

INSTALLATION

is

shown

0.26

0.68

0.24

0.22

0.079

0.19

0.069

0.045

0.020

0.039

0.017

0.025

0.018

0.021

0.015

instruction

in

0.66

0.16

0.56

0.13

0.18

0.030

0.14

0.030

0.027

0.007

0.024

0.006

0.008

0.001

0.007

0.001

book

diagram

this

2-4

4-8

2-4

4—8

4-8

8-16

4-8

8-16

10-20

20-40

10-20

20-40

20-40

40-80

20-40

40-80

supplement.

L

H

L

H

L

H

L

H

L

H

L

H

L

H

L

H

0.66

1.02

0.23

0.30

0.60

0.88

0.22

0.27

0.18

0.29

0.061

0.084

0.024

0.075

0.053

0.021

0.046

0.018

0.027

O.OU

0.022

O.0l0.O12

GEK-45375.

0.16

0.056

0.037

0.018

0.032

0.015

0.022

0.014

0.018

0.52

0.22

0.48

0.19

0.14

0.056

0.13

0.054

0.032

0.017

0.028

0.014

0.022

0.014

0.018

0.012

4

Page 5

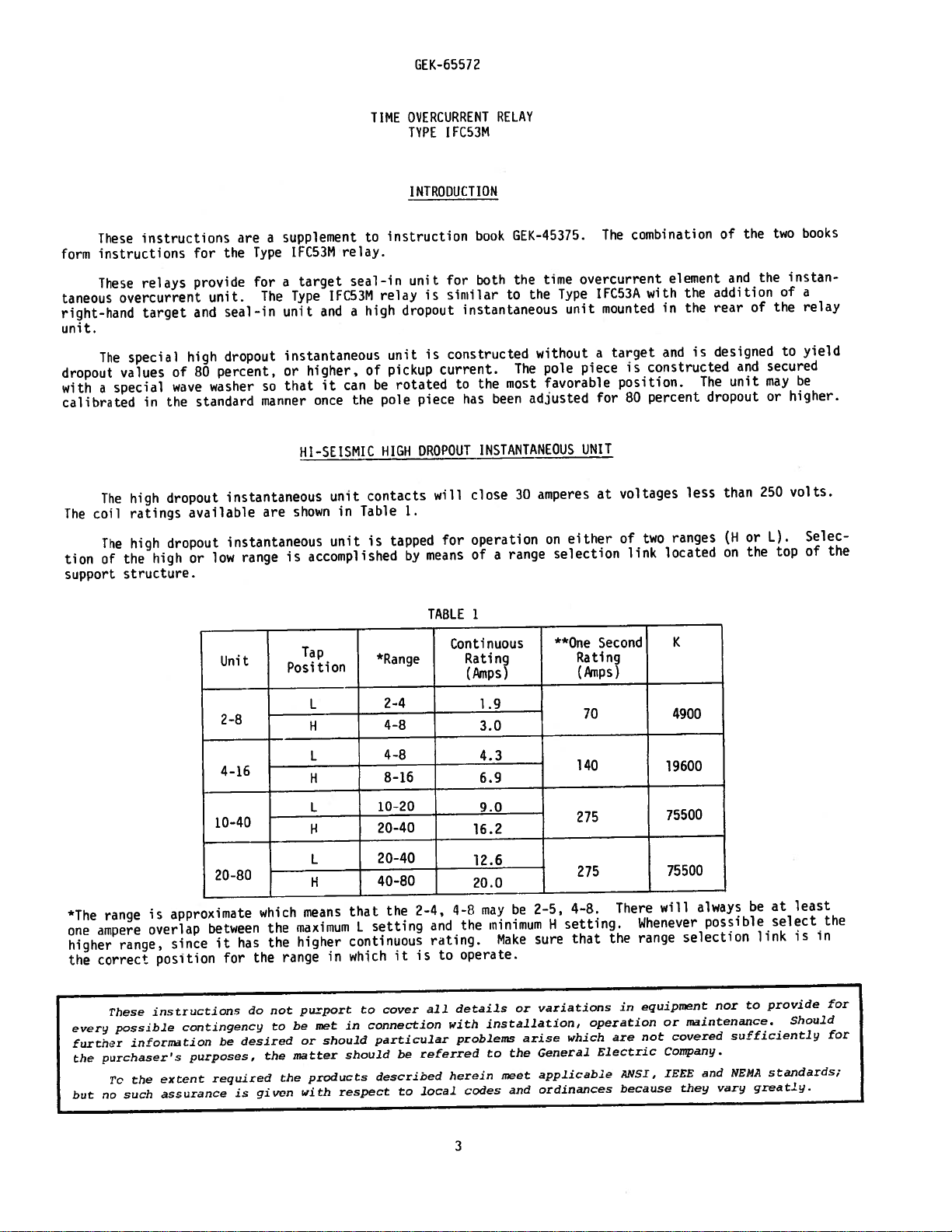

GEK-b5512

TIME

IN

SEALTARGET

TIME

FOR

OVERCURRENT

UNIT

AL-N

E

T

AROFT

TAP

SE[.LCT

DR

DIAL

SELECTION

TAP

N

--

INSTANTANEOUS

RANGE

BLOCK

UNIT

SELECTION

LINK

SEAL-IN

FOR

TARGET

INSTANTANEOUS

OVERCURRENT

UNIT

SEAL-IN

TAP

TARGET

SELECTOR

SCREW

Fig.

(8043607)

1

Type

IFC53M

Relay,

5

Renoved

fro

Cise.

Front

‘[lew

Page 6

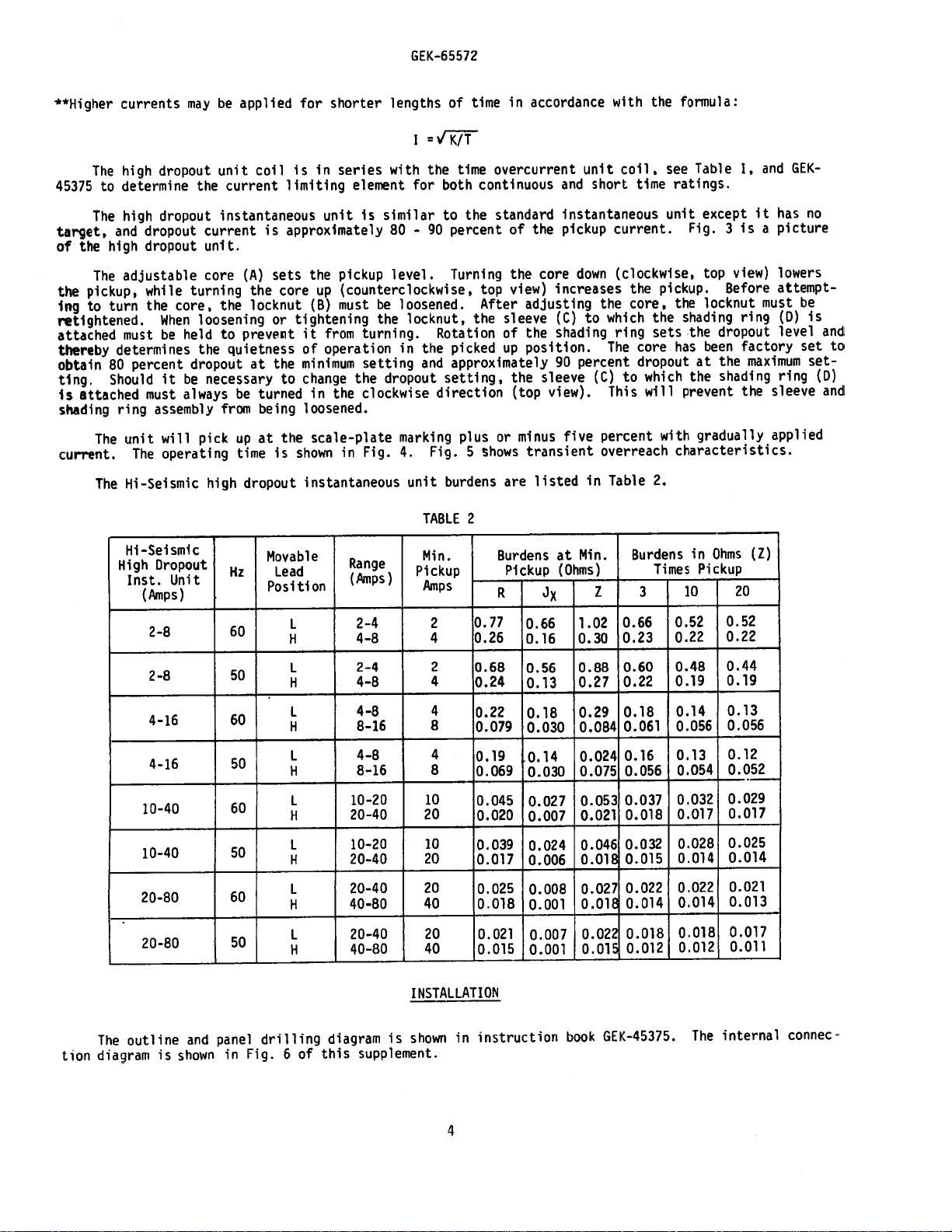

INS

IANTANEOUS

HIGH

DROPOUT

UNIT

WITH

ADJUSTABLL

/

CORE

-MAGN

ASSEMBL’

TIME

OVERCURREN

UNIT

El

FOR

Fig.

2

(8O436O8

Type

IFC53M

Relay,

6

Removed

from

Case,

Rear

View

Page 7

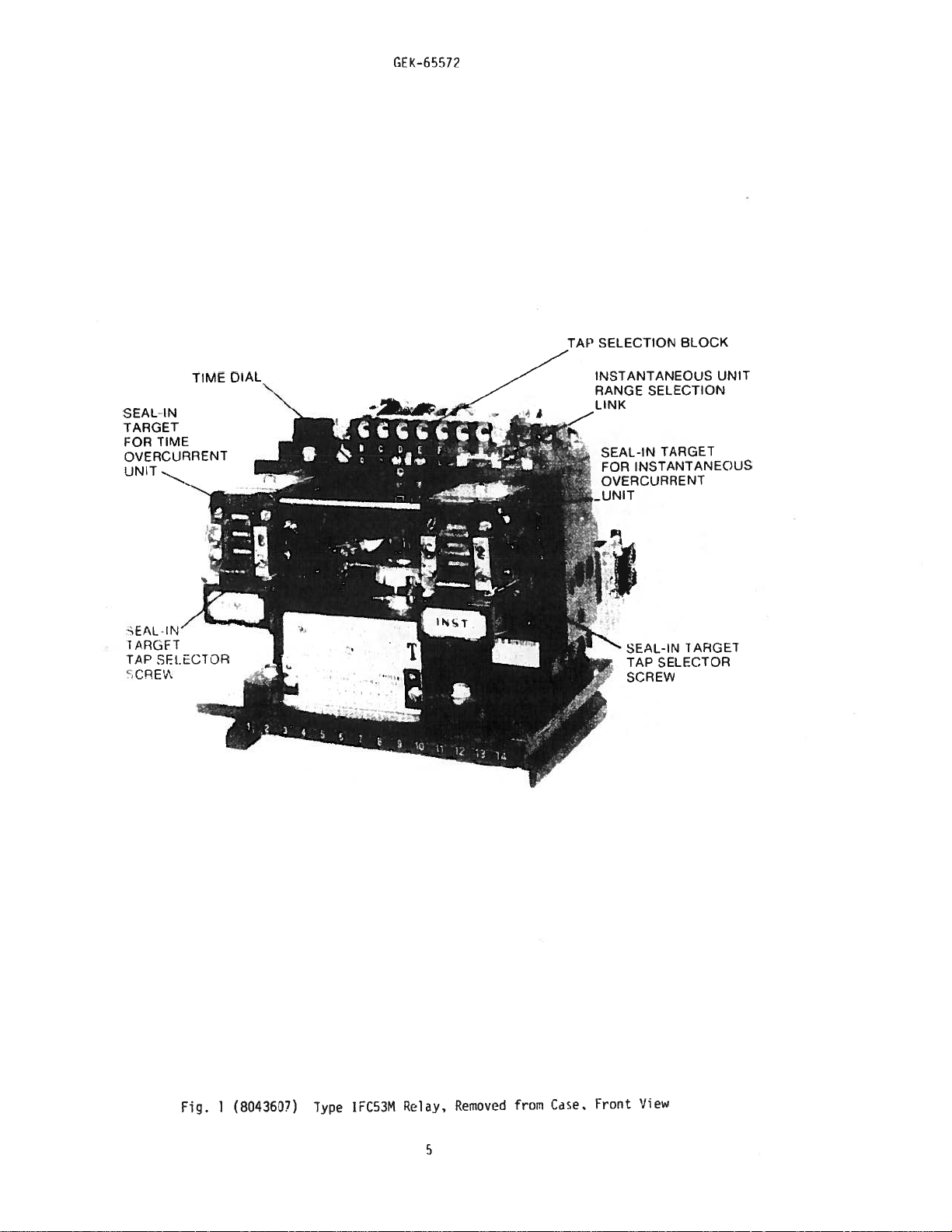

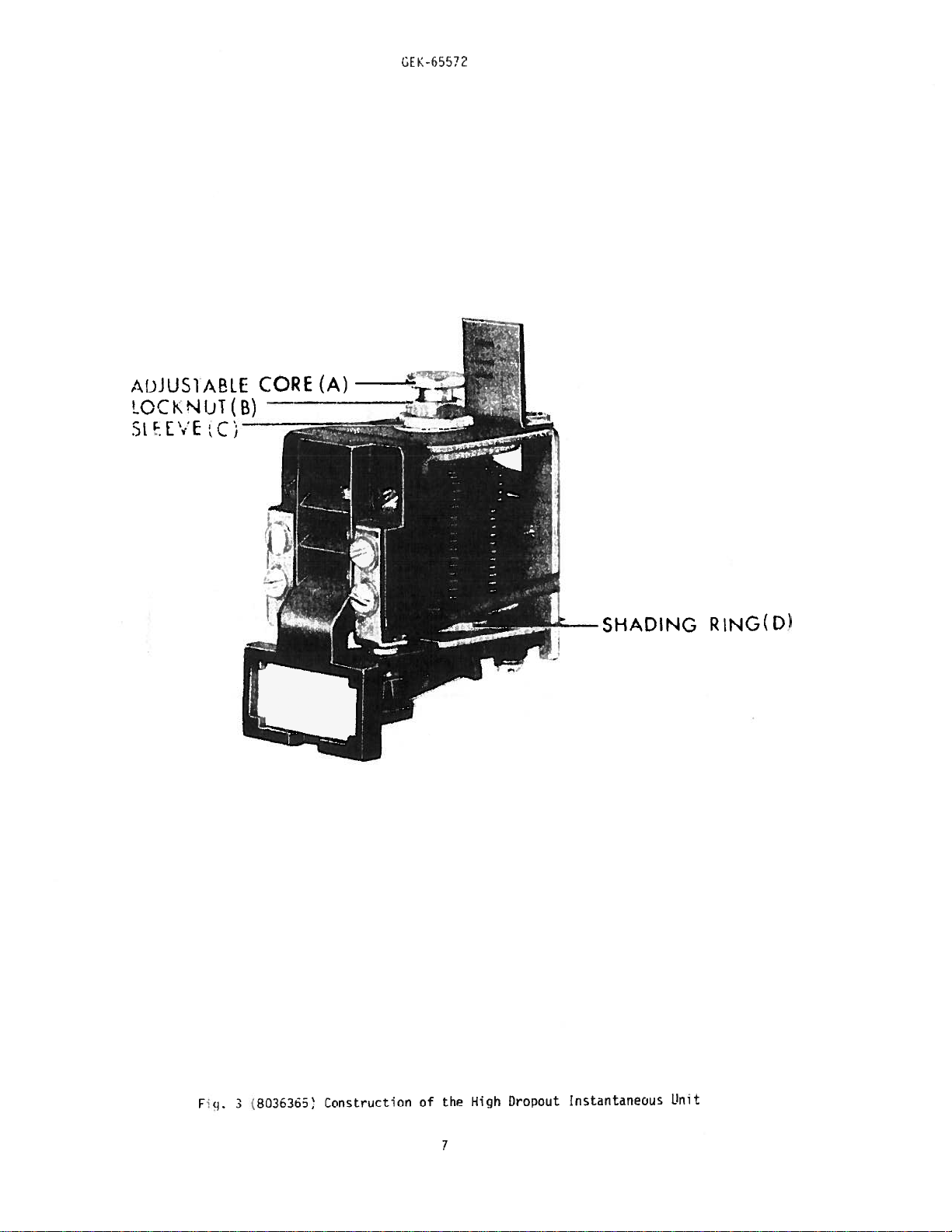

ADiUSABLE

LOCKNUT(B)

)tL

E’

CORE

(A)

..‘--

—

—SHADING

-

RiNG(D

high

the

.3

Fi1.

8O3b363

Construction

of

1

Dropout

Instantaneous

Linit

Page 8

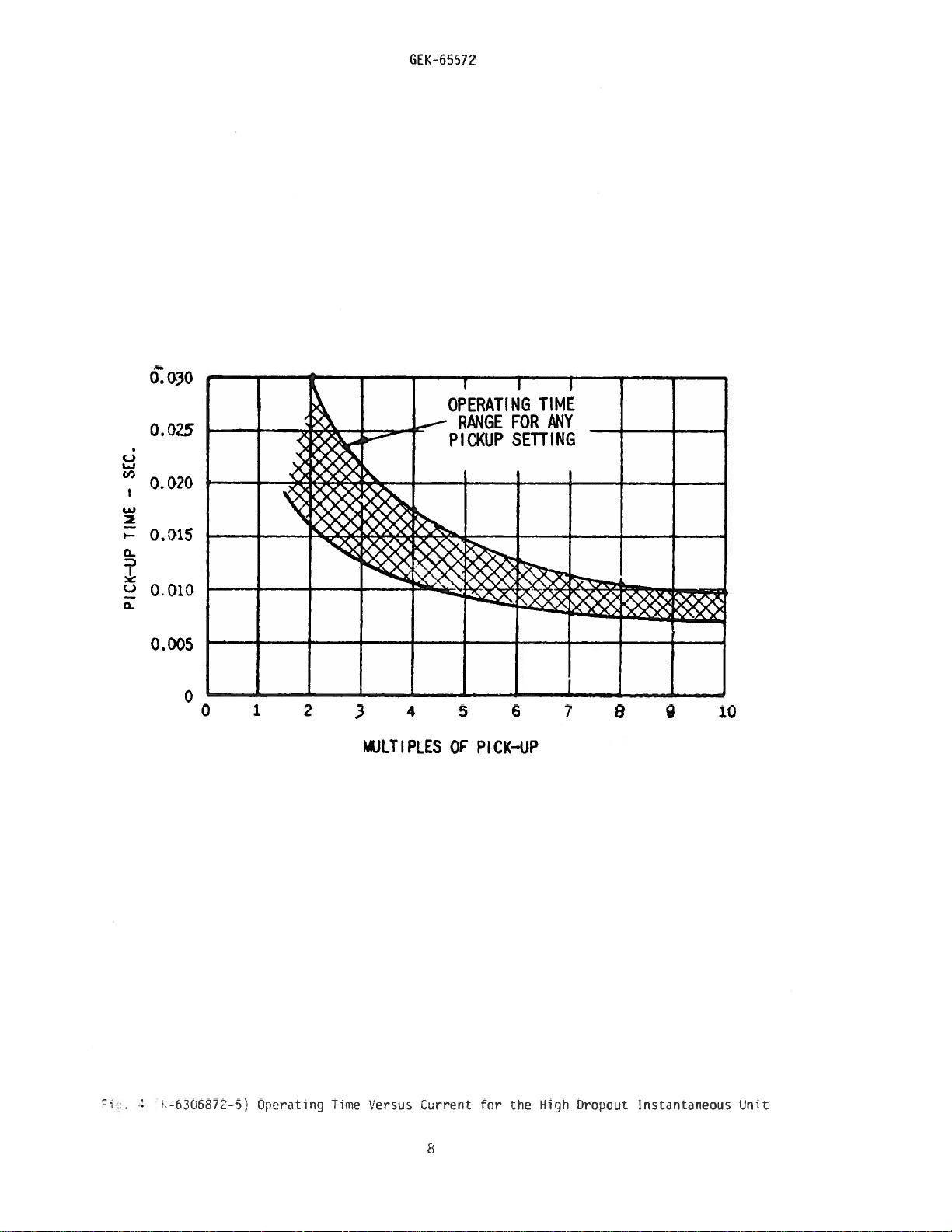

GE

K-6

557?

c

030

.

0.025

0

LI

U,

o.c20

LI

—

OPERATING TIME

RANGE

PICKUP

ANY

FOR

SETTING

0.015

D

0

0010

005

o.

0

0

1

2

3

4

MULTIPLES

5

OF

PICK—UP

6

7

8

9

10

F-€UbR7-5)

O;erting

Ti

e

Vrsus

Current

for

the

Hich

Dropout

Instantaneous

(int

Page 9

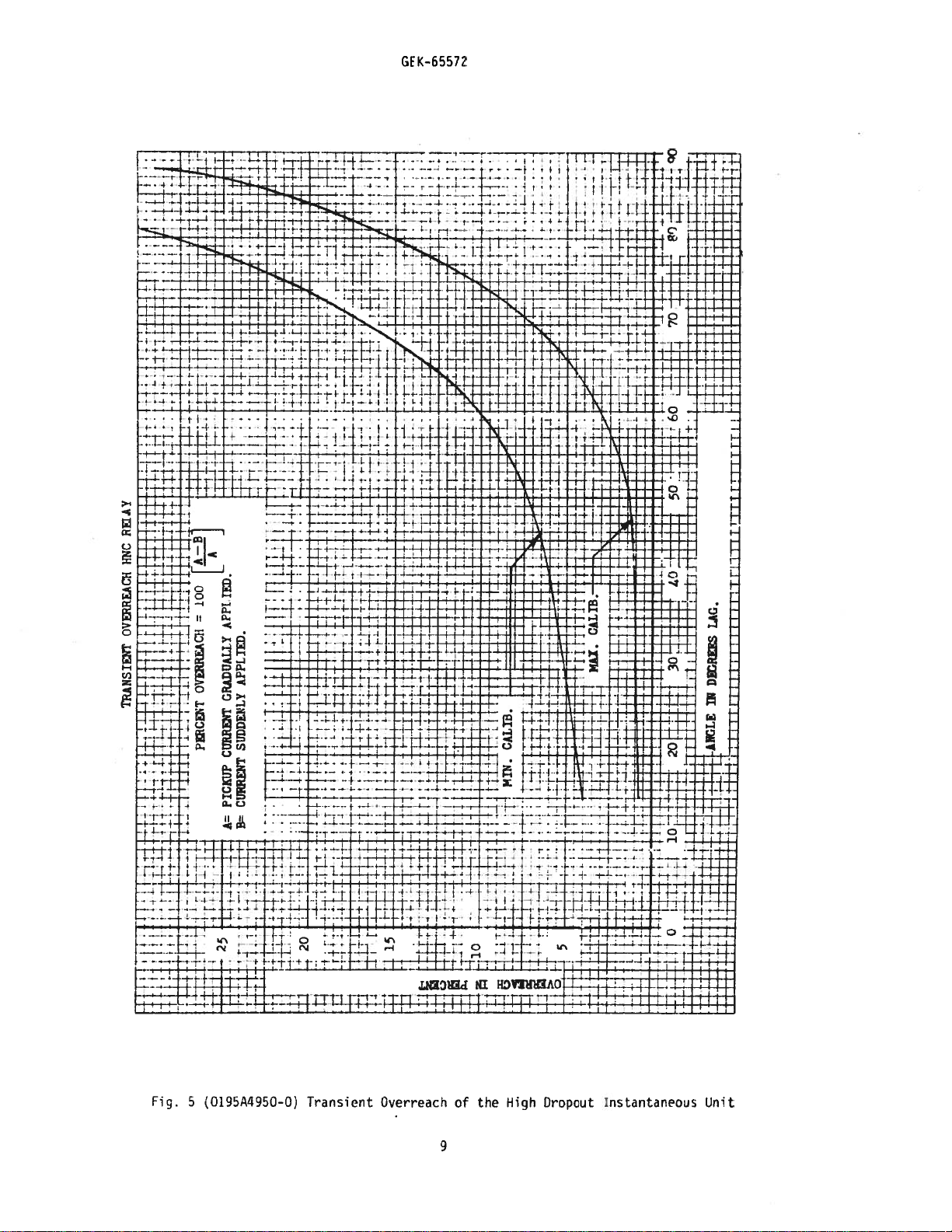

‘-I,

7c

4

TTiJTf

-fL:

HtL

fmHtT.1-.I-n

REAY

HNC

0VEN.REACH

TRANSIENT

L

Lfljff.-}

4

_u:.

TiI

.f1t_H

—

Ti:ii

I

f-

4

t—+

Vt

-I--.

.-.--

ft

-

1.

-H-4-1

ri

100

EAC}1

OV

PCENT

ii

i4E:.

i

-*H

441+-

+

llII

f.1..’

1

-H-f-i-!

tt-f-l

WI

I

1t

Ht

.H-ll-

-

4-z

-1-’

Tf

H

TED.

APPI

APPLIED.

GRADUALI.Y

SUDDENLY

CURR2T

PICKUP

CURRENT

B=

A=

t

4

.-t

1.-f

•

--I

1:

25

4.

—

-‘4--

-

,4.

-

T_i

Ii

JiiT

t--

H-

-f

‘-4

-tY

-:

:tf

±±

-r-t-t

4

j

;4.-44

I

4

-4.

1—

f

I

20

-4

41

4

-1--ftt

-h-H*

T

•—;-t

..4-_.4._._•,

1--

i

it

:;

4H-

—

-4

‘4-.

4

f

.ZE

V

4

f-Vt

f:t

ii

t•!-f..

—

-

4,

-if-.

Tfl1f

4

H

-

4

H-

4

H:

I

•i

15

-f-

-H

E

3..

.-4

-

.

•,

4..

t

t__+

—4-,

-

4-.

H

I

-‘-$A

-

-,-j--i-,-

tfI!II,H.f4-:b

i*t-i.

—s--’

-1-_-1_

4

-tfl-

--f-f’

----4----I---1--4---

I—+-,--j-H-—-

-I

•

L1i

(Ir

h-t-t-r-t-I--t-t

CALm.

ll:Fit:

-.

jiL:j

IT

1::

•

-I-I-’

T

4-1-

±Vt-

t-

-

14

-±tt------f

H-f+

i-H-u

CALTh.—

H

MAX.

--H-f

IT

TEETTr

-

-+

1—

—

-

-—:-

tIT

t---

‘-f-rj--I--

:r

-+

ItT

---H

—ti

fZZl44

;!

-I

‘i:i

‘_11j,4

I’

5-i

—

—

—I-

1--1-+

-

1-4

4-

;4...

.1_I

F

4

ii

It

go

-

J17O

‘:•

fl4$:

rEdil

4

:$1tfl

ztt

111111:11,

11111

ill

---44.--,-.-

L

60

50

4-

-

I--’

140

tttfii

30

:1±1

20

‘

1

oH-

.1-f

+11-

-[f-i

r:lo

1fIiTTtTTTi

I

LAG.

I I

I1fI

DrREES

I

IN

±LLtLHffFJJ

I

j-4NGLE

LI4

:1W:

‘TTT

1

Ii

0.

D

-3

0)

c-

-5

-3

0)

n

C-h(0

‘

=

I-

C

V

C

C

3)

0)

0)

C

V

C

Page 10

GEK-65572

INDUCT

ION

LNSTANTANEOUS

HI

DROPOUT

N

SI

*

Fig.6(o275A4554-a)

*

2

=

SHORT

FINGER

Internal

Connection

10

Diagram

for

Type

(0

IFC53M

Relays

Page 11

Page 12

GE

Power

Management

Anderson

215

Markham,

Canada

Tel:

Fax:

www.ge.comlindsyslpm

L6E

(905)

(905)

Avenue

Ontario

1B3

294-6222

201-2098

Page 13

INSTRUCTIONS

GEK—45375J

OVERCURRENT

TIME

Types

IFC51A

IFC53A

IFCJ7A

and

and

and

RELAYS

51B

53B

778

Protection

GE

Great

205

Malvern,

and

Valley

19355-1337

PA

Control

Parkway

Page 14

GEK-45375

CO

N

TENTS

DESCRIPTION

APPLICATION

CONSTRUCTION

RATINGS

TIME

OVERCURRENT

HIGH-SEISMIC

HIGH-SEISMIC

CONTACTS

BURDENS

CHARACTERISTICS

TIME

OVERCURRENT

HIGH-SEISMIC

HIGH-SEISMIC

RECEIVING,

ACCEPTANCE

VISUAL

HANDLING

TESTS

INSPECTION

MECHANICAL

DRAWOUT

GENERAL

TIME

RELAY

POWER

OVERCURRENT

HIGH-SEISMIC

HIGH-SEISMIC

UNIT

INSTANTANEOUS

TARGET

AND

UNIT

INSTANTANEOUS

TARGET

AND

AND

STORAGE

INSPECTION

TESTING

REQUIREMENTS

UNIT

INSTANTANEOUS

TARGET

AND

UNIT

SEAL-IN

UNIT

SEAL-IN

UNIT

SEAL-IN

UNIT

UNIT

UNIT

3

3

5

6

6

7

8

8

9

10

10

10

10

10

11

11

H

12

12

12

13

14

INSTALLATION

INSTALLATION

PERIODIC

CHECKS

TIME

OVERCURRENT

HIGH-SEISMIC

HIGH-SEISMIC

CONTACT

COVER

SYSTEM

SERVICING

TIME

OVERCURRENT

HIGH-SEISMIC

HIGH-SEISMIC

RENEWAL

LIST

OF

PARTS

FIGURES

TESTS

AND

INSTANTANEOUS

TARGET

CLEANING

CLEANING

TEST

INSTANTANEOUS

TARGET

ROUTINE

UNIT

AND

UNIT

AND

MAINTENANCE

UNIT

SEAL-IN

UNIT

UNIT

SEAL-IN

UNIT

—2-

15

15

16

16

16

16

16

17

17

17

17

19

19

20

40

Page 15

GE

K-

45375

type

The

phase,

available

IFC51B,

The

overcurrent

levels.

relays.

described

are

equipped

When

semi

capability,

overcurrent

Components

the

IFC

time

Both

with

flush

are

538

unit,

The

including

unit

relays

covered

overcurrent

follows:

as

and

which

instantaneous

time

the

detail

in

dual-rated

a

mounted

when

Program

relays.

IFC51A,

IFC53A,

IFC77A,

778

relays

overcurrent

on

both

is

it

of

Underwriters

TIE

by

IFC51B

1FC538

IFC77B

provides

unit

the

in

target

suitable

a

the

supplied.

OVERCURRENT

TYPES

IFC51A

IFC43A

IFC77A

DESCRI

these

also

and

and

and

PTION

instructions

various

The

—

Inverse

—

Very

Extremely

-

include

518

53B

778

instantaneous

included

not

is

and

unit

section

and

seal-in

on

panel,

target

seal-in

Also,

Laboratories,

RELAYS

are

time-current

time

inverse

time

inverse

hinged-armature

a

tripping

in

instantaneous

the

CONSTRUCTION.

unit.

these

relays

unit

these

relays

Inc.

extended

time

the

and

at

IFC51A,

have

the

are

range,

characteristics

instantaneous

high

53A

overcurrent

Each

a

relay

high

instantaneous

recognized

single

current

or

unit

seismic

under

77A

is

relay

The

outline

connections

for

the

Time

overcurrent

industrial

protection

Figures

where

they

distribution

allow

which

for

results

devices

Such

of

load

feeder

every

further

the

but

is

mounted

and

panel

are

IFC51B,

power

at

10

and

are

cutouts

cold

as

such

accumulations

full

These

possible

information

purchasers

Do

the

no

such

drilling

shown

53B

relays

distribution

other

22,

of

required

load

in

a

refrigerators,

load

instructions

continqenry

purposes,

required

extent

assurance

in

in

77B.

and

are

locations.

the

and

pickup

heavy

current

do

desired

be

the

given

is

size

a

are

Figure

used

IFC77A

to

reclosers.

such

accumulation

often

for

not

purport

met

to

be

or

should

matter

products

the

with

drawout

Cl

shown

for

4

APPLICATION

extensively

systems

The

and

coordinate

results

as

water

produce

short

a

cover

to

connection

jn

particular

be

described

to

referred

local

should

respect

case

in

Figures

the

IFC51A,

for

and

frequently

EXTREMELY

77B

relays

rather

They

also

from

loads

of

heaters,

inrush

time

codes

or

installation.

arise

the

to

meet

and

details

all

with

problee’

herein

-3—

of

and

23

53A

the

INVERSE

are

closely

provide

an

of

water

currents

after

variations

which

General

applicable

ordinances

molded

24.

77A,

and

protection

for

time

designed

maximum

extended

automatically

pumps,

considerably

feeder

the

equipnt

in

are

ANSI,

because

or

covered

not

CoaflY.

operation

Electric

construction.

relay

The

and

of

overload

charactersistics,

primarily

with

power

tolerance

service

burners,

oil

is

to

flat

wsintananCe

sufficientl

NE

and

IEEE

vary

thei

gr.atly.

internal

Figure

in

utility

for

outage,

controlled

in

energized.

provide

Should

standards,

The

5

and

backup

use

fuses,

to

etc.

excess

for

for

Page 16

The

EXTREMELY

these

The

relays

the

relatively

fault

location

The

and

magnitude

INVERSE

faster

magnitudes

impedance

The

fault

single—phase-to—ground

cation

because

fa

VERY

available

INVERSE

513

usual

u

1

t

s.

loads

INVERSE

are

current

of

relays

devices.

overall

protection,

are

it

INVERSE

and

likely

constant

the

time

of

the

vary

due

to

application

shown

can

at

time

fault

through

fault

tend

protection

significantly

system

in

be

time

the

same

characteristics,

to

provide

current

generating

with

overcurrent

to

fault

one

For

current

this

loading

of

per

faults.

Figure

set

characteristic

time

the

respect

make

in

these

phase,

9.

provide

to

GEK—45375

provides

faster

magnitude

capacity.

relay

to

characteristics,

the

relay

than

reason,

applications

as

a

and

switching.

relays

and

Typical

Use

of

adequate

Figures

overall

remains

is

therefore

the

relay.

operating

in

the

INVERSE

result

requires

separate

a

external

a

separate

more

sensitive

often

protection

The

case

type

where

of

permits

7

and

variation

Figures

time

of

relays

the

frequent

three

relay

connections

ground

fault

21,

fairly

mainly

6

VERY

available

residually

protection

successful

protection.

of

in

constant

in

dependent

and

less

INVERSE

are

changes

relays

relay

the

IFC53A

applications

the

magnitude

20,

of

dependent

and

likely

fault

in

for

connected

for

this

is

advantageous

against

pickup

and

53B

where

due

to

upon

the

upon

EXTREMELY

to

the

multiphase

the

IFC51A

the

provide

current

source

for

appli

ground

of

a

of

In

the

devices,

for

the

position

reset

EXTREMELY

INVERSE

When

time

clearing

estimated.

time,

For

coordination

time

times

relays

setting

of

0.10

example,

is

tested,

downstream

(0.08

times

Figures

+

are

0.10

10,

operating

relay

and

the

in

to

with

the

necessary

appropriate

percent

the

breaker

operating

this

value.

application

the

relay

relay

when

time

set

the

set

are

INVERSE

these

from

of

These

seconds

if

time

for

safety

breaker

+

marginal

11

time

which

of

time

reset

to

go

from

at

the

proportionately

relays

covered

relays

0.25

to

the

breaker

coordination

for

the

breaker

would

the

specific

factor

time

0.07)

could

or

or

12

to

necessary

coordination

time

curve

of

operating

time

to

determine

of

these

time

the

number

is

by

these

to

0.40

relay

be

0.40

may

is

5

be

impossible

refine

to

dial

setting

Figure

time,

and

the

the

relays

should

contacts—fully-closed

10

time

lower.

approximately

instructions

coordinate

seconds

involved

times

overtravel

clearing

seconds

current

be

cycles

allowed

to

the

relay

just

is

match

desired.

10,

and

covert

safety

final

be

is

and

include,

time

level

reduced

(0.08

for

obtain,

to

provide

11

or

factor

relay

with

considered.

dial.

The

with

generally

(0.13

settings.

the

downstream

At

reset

60

seconds.

is

approximately

downstream

how

accurately

in

and

0.17

is

0.13

+

0.10

at

the

to

0.07

seconds),

coordination.

use

the

operating

Determine

this

12

to

determine

this

into

time

operating

This

position

lower

time

allowed,

addition

seconds

seconds

site,

a

relay

First

relay

real

and

automatic

is

time

all

of

The

relays,

the

to

for

+

0.17).

and

seconds.

minimum

If

overtravel

determine

time

the

multiple

operating

the

time.

the

time.

the

to

the

dial

VERY

reset

12

seconds.

a

depending

relay

breaker

safety

(8

if

of

relay

of

the

overtravel

Add

original

Set

reclosing

time

required

fully—open

settings

INVERSE

time

coordination

cycles),

If

it

Then

0.25

time

of

on

can

clearing

factor.

the

has

if

seconds

coordination

curves

the

downstream

pickup

of

time.

this

the

relay

the

and

all

the

be

the

relay

been

the

of

relay

Use

time

time

relay

to

—4-

Page 17

GEK-45375

Once

will

contact

circuit

overreach

device

The

connection.

activated

completes

disk

closing

molded

the

open

wipe.

instantaneous

breaker

cleared.

The

instantaneous

has

the

inception

transient

proportionately

scheme.

14.

structure

show

i-Magnet.

transient

a

result

and

IFC

the

assembly

current.

housing

induction

current

in

approximately

reclosing

of

the

of

a

overreach

should

thereby

The

operating

induction

assembly,

See

by

a

The

the

alarm

on

in

the

relay

This

is

overeach

DC

fault.

so

Cover

current—operating

disk

is

Its

the

permits

reclosed

overcurrent

characteristic

offset

When

must

be

applied

that

the

cause

time

disk

and

Figure

unit

mounted

and

or

trip

restrained

rotation

support

schemes

be

relays

operating

6

cycles

the

without

on

a

unit

is

that

determining

taken

to

instantaneous

loss

a

characteristics

CONSTRUCTION

consist

connection

a

and

to

coil

shaft

circuit

by

a

is

structure.

(0.1

use

circuit

present

usually

into

increase

of

coordination

Figures

the

mounted

assembly

when

spiral

retarded

coil

second)

the

of

risk

from

in

as

illustrated

present

the

pickup

consideration.

the

unit

of

of

a

plug

1,

2,

molded

it

carries

touches

spring

by

support

on

a

is

cut

relay

of

which

the

setting

calculated

will

this

molded

to

3

either

to

permanent

off,

with

false

a

a

IFC51B,

in

in

the

not

overreach

the

in

unit

case,

make

and

structure.

moving

a

a

stationary

give

normal

in

fault

Figure

line

The

are

up

19.

a

laminated

the

magnet

the

relay

adjustment

conjunction

retrip

has

53B

and

current

for

this

percent

pickup

system

shown

cover,

the

Figures

contact,

contact.

proper

contacts

when

just

77B

13.

unit,

transient

downstream

a

protection

in

electrical

2

This

EE-

mounted

with

been

relays

This

at

setting

Figure

support

and

disk

or

which

contact

in

of

the

is

the

the

3

is

a

The

a

The

drawout

provisions

front.

fingers

opened

fingers

lower

secondary

shorting.

on

the

the

drawout

There

left

of

unit

has

the

time

seal—in

the

raises

by

pressing

As

in

before

on

front

case

is

a

the

its

overcurrent

a

target

connection/test

for

the

the

the

connections.

The

and

element

High-Seismic

shaft

unit

a

14

connection

output

any

case

the

of

connection

finally

coil

picks

into

reset

connection

contact

other

connection

case)

completely.

of

the

in

series

unit,

up

view,

button

circuits

The

plug

those

target

time

and

which

located

system

points,

plug

to

and

such

for

is

withdrawn,

circuits

are

block

short-circuit

window

then

clears

on

the

and

seal-in

overcurrent

its

contacts

that

seals

latches

on

the

and

a

first.

disconnected.

engage

provides

relay

when

in.

up

the

upper

—5—

Cl

visible

the

the

support

unit

unit

the

When

and

case,

it

shorting

external

current

(see

in

parallel

induction

the

remains

left

shown

CT

clears

Thus,

visual

structure,

mounted

Figure

seal—in

side

shorting

the

the

Next,

bar

current

confirmation

circuit

on

with

unit

exposed

of

in

the

1).

unit

the

Figure

bar

shorter

trip

current

(located

contact

to

front

the

contacts

picks

until

cover.

19,

located

contact

circuit

circuit

at

transformer

of

fingers

de-energize

to

The

seal—in

contacts

close,

up,

released

has

up

is

the

CT

the

of

it

Page 18

The

IFC

instantaneous

type

unit

overcurrent

contacts

with

raises

same

target

A

of

the

a

reset

of

magnetic

inverse

eliminate

‘SB”

which

of

time

target

the

shield,

and

the

model

unit

is

unit.

the

time

overcurrent

which

button

instantaneous

very

proximity

relays,

(see

mounted

Its

contacts

overcurrent

latches

that

depicted

inverse

effect

in

Figure

on

unit.

releases

unit.

the

up

in

time

GEK—45375

addition

1).

front

are

unit,

When

and

the

Figure

overcurrent

of

external

to

The

instantaneous

to

normally

remains

target

1,

the

the

and

the

is

magnetic

above,

right

connected

its

coil

instantaneous

exposed

until

seal—in

mounted

IFC

relays

materials.

contain

unit

of

is

unit

to

is

the

shaft

In

parallel

connected

unit

it

also

the

support

(IFC51

a

a

is

and

small

picks

released.

releases

high-seismic

hinged—

of

the

with

in

series

up,

structure

1FC53),

time

the

it

The

the

to

Both

the

instantaneous

distinguish

axial

acceleration

frequency

accordance

May,

1977.

The

relays

-20°C

TIME

Ranges

to

OVERCURRENT

for

Relay

IFC51A

IFC53A

IFC77A

High-Seismic

unit

them

input

with

are

+55°C.

the

time

&

B

B

&

B

&

have

High—Seismic

as

of

motion

the

IEEE

designed

UNIT

overcurrent

Frequency

target

the

lOg’s

to

Proposed

50

and

letters

(4g

produce

for

unit

(Hertz)

60

and

“Hi—G”

units.

ZPA)

a

Guide

RAT

operation

are

TABLE

seal-in

Seismic

when

Required

for

I

NGS

shown

I

molded

Seismic

in

an

Current

unit

tested

in

into

Fragility

using

Response

Testing

ambient

Table

Range

0.5

1.0

and

-

-

their

I.

12.0

the

target

Level

a

Spectrum

of

air

temperature

(Amperes)

4.0

High—Seismic

blocks

exceeds

biaxial

(RRS)

Relays,

to

peak

multi—

in

P501,

from

The

current

labeled

The

of

relay

The

one—second

tap

tap

screw

and

taps

block.

settings

tap

thermal

are

range.

selected

are

ratings

as

with

listed

are

two

listed

-6-

sliding

in

Table

in

tap

II,

Table

screws

on

page

III.

on

an

20,

alphabetically

for

each

model

Page 19

GEK—45375

L

Ratings

The

and

4

1FC51

1FC53

1FC77

Model

IFC51

1FC53

1FC77

less

continuous

V.

Model

TABLE

Time

Overcurrent

Unit

(Amperes)

0.5

-

4.0

-

-

-

-

-

second

where

12.0

4.0

12.0

4.0

12.0

for

may

be

the

time

time

T

is

the

1.0

0.5

1.0

0.5

1.0

one

than

JK/T,

I

ratings

TABLE

4.0

0.5

—

Ampere

III

One

calculated

in

overcurrent

IV

Range

Second

seconds

Rating

(Amperes)

128

260

140

260

84

220

according

that

unit

Ratings

the

are

Any

to

Tap

the

current

shown

16384

67600

19600

67600

7056

48400

formula

flows.

in

K

Tables

IV

Tap

3.0

0.5

1.6

3.8

2.5

0.7

0.6

1.8

2.0

4.0 4.2

2.7

3.0

0.8

2.1

4.4

3.2

1.0

2.3

4.7

3.6

1.2

2.7

5.0

4.0

1.5

3.0

5.3

4.5

2.0

3.5

5.8

5.2

2.5

4.0

6.2

5.9

4.0

5.0

4.5

7.1

6.6

6.5 7.5

Model

IFCS1

1FC53

1FC77

1.0

3.7

6.8

5.8

HIGH-SEISMIC

instantaneous

The

L).

link

Selection

located

or

the

VI).

1.0

1.5

4.6

7.7

7.2

2.0 2.5

5.3

8.3

8.4

1.2

4.1

7.1

6.4

INSTANTANEOUS

coil

on

of

is

the

the

6.0

8.8

9.4

UNIT

tapped

high

top

TABLE

12.0

Ampere

-

V

Range

Ratings

Tap

ranges

and

12.0

13.2

14.41

21.

(H

of

Table

of

3.0

10.4

or

the

6.5

9.4

for

low

4.0

7.6

10.3

12.1

operation

range

support

5.0

8.5

11.0

13.6

is

structure

6.0

9.3

11.6

15.1

either

on

determined

7.0

10.0

12.4

16.4

(see

one

8.0

10.8

12.6

17.6

of

by

Figure

the

10.0

12.1

13.5

19.8

two

position

2

-7-

Page 20

GEK—45375

Since

coil,

for

High—Seismic

Instantaneous

Unit

2

-

6-150

The

8-50.

maximum

sure

rating.

Higher

accordance

the

instantaneous

see

Tables

both

continuous

(Amps)

50

range

to

is

There

L

setting

select

currents

with

III,

Link

Position

L

H

L

H

approximate,

will

always

and

the

higher

may

the

formula:

I

=

v’K/T

unit

IV,

V

and

short—time

be

coil

and

Range

(Amps)

2

10

30

the

TABLE

-

10

-

50

6

30

-

150

which

be

at

minimum

range,

applied

is

VI

to

ratings.

means

least

in

series

determine

VI

Continuous

Rating

(Amps)

2.7

7.5

10.2

19.6

that

one

H

setting.

since

for

it

shorter

with

Second

Rating

(Amps)

130

260

the

2—10,

ampere

Whenever

has

the

the

time

the

current—limiting

One

10-50

overlap

higher

lengths

K

16,900

67,600

may

between

possible,

continuous

of

overcurrent

be

time

element

2-8,

the

be

in

unit

HIGH-SEISMIC

Ratings

for

DC

Mm.

Carry

Carry

Carry

60

If

the

tripping

the

connections

contacts

or

CONTACTS

The

current-closing

exceeding

the

seal—in

250

TARGET

the

target

Resistance

Operating

Continuous

30

Amps

Amps

10

Hz

Impedance

current

being

the

target

volts.

unit.

AND

and

±

for

for

such

and

rating

The

SEAL—IN

UNIT

seal-in

10%

(ohms)

(Amps)

+0

(Amperes)

(sec.)

(sec.)

(ohms)

exceeds

that

30

the

seal-in

of

the

current-carrying

unit

TABLE

-60%

amperes,

tripping

coils

contacts

are

VII

of

shown

an

current

the

is

rating

in

0.2

8.0

0.2

0.3

0.03

0.25

68.6

auxiliary

protective

30

is

Table

Tap

relay

does

amperes

limited

VII.

not

relay.

2

0.24

2.0

3

4

30

0.73

pass

for

by

should

voltages

the

be

through

ratings

used,

the

not

of

-8-

Page 21

GEK—45375

BURDENS

Burdens

Model

Note:

for

the

Hz

IFC51

1FC53

1FC77

IFC51

1FC53

1FC77

The

60

60

60

50

50

50

impedance

Impedance

(approximately)

relay

Hz

60

amp

0.5

0.176

tap.

ohms.

time

Range

0.5—

1.0—12.0

0.5—

1.0—12.0

0.5—

1.0-12.0

0.5-

1.0—12.0

0.5—

1.0—12.0

0.5—

1.0-12.0

for

with

overcurrent

4.0

4.0

4.0

4.0

4.0

4.0

values

as

taps

the

other

0.5

impedance

The

Mm

Tap

Amps

0.5

1.0

0.5

1.0

0.5

1.0

0.5

1.0

0.5

1.0

0.5

1.0

given

square

—

4.0

at

unit

TABLE

Burdens

Pickup

R

5.43

1.47

1.52

0.38

1.55

0.59

4.53

1.22

1.27

0.32

1.29

0.49

are

pickup

of

amp

of

are

(Ohms)

those

the

range

the

given

vrir

at

Mm.

Jx

21.53

5.34

4.23

1.06

2.36

0.43

17.95

4.45

3.52

0.88

1.97

0.36

for

current

tap

has

2.0

In

Mm.

Tap

Z

22.20

5.54

4.50

1.13

2.82

0.73

18.50

4.62

3.75

0.94

2.35

0.61

minimum

(tap

rating.

an

amp

tap

Table

Burdens

(Z)

3

12.55

3.09

4.47

1.11

2.86

0.74

11.45

2.58

3.72

0.93

2.38

0.62

tap

rating)

For

impedance

(0.5/2.0)2

Is

VIII.

Times

of

example,

of

in

10

5.14

1.28

3.10

0.78

2.93

0.75

4.28

1.07

2.58

0.65

2.44

0.63

each

varies

2.82

Ohms

Pickup

20

3.29

0.82

1.93

0.49

2.76

0.70

2.70

0.68

1.61

0.41

2.30

0.58

range;

inversely

an

ohms

2.82

x

the

1FC77

on

=

the

High—Seismic

The

High—

Seismic

Inst.

Unit

(Amps)

2—50

6—150

2

50

6—150

Hz

60

60

50

50

instantaneous

Link

Posi—

Range

(Amps)

tion

L

H

L

H

L

H

L

H

2-10

10—50

6-30

30—150

2—10

10-50

6-30

30-150

unit

Mm.

Pick-

up

Amps

2

10

6

30

2

10

6

30

burdens

TABLE

Burdens

Pickup

R

0.750

0.070

0.110

0.022

0.625

0.058

0.092

0.018

are

IX

at

Mm.

(Ohms)

0.650

0.024

0.078

0.005

0.542

0.020

0.065

0.004

listed

Mm.

Tap

Z

0.982

0.079

0.135

0.023

0.827

0.062

0.112

0.019

in

Table

Burdens

(Z)

3

0.634

0.072

0.095

0.022

0.528

0.060

0.079

0.018

IX.

Times

10

0.480

0.071

0.081

0.022

0.400

0.059

0.068

0.018

in

Ohms

Pickup

20

0.457

0.070

0.079

0.022

0.380

0.058

0.066

0.018

9

Page 22

GEK—45375

TIME

OVERCURRENT

Pickup

Pickup

contacts

of

two

structure

through

A

Example:

Operating

The

IFC

0.10

and

The

the

second,

20-22

setting

contacts

longer

The

contacts

setting

maximum

in

from

movable

(see

N.

The

movable

Time

relays

show

the

operating

occurs

distance

these

the

leads

Figure

See

amp

2

Accuracy

should

whichever

the

of

the

for

are

when

UNIT

relays

0.5

the

tap

lead

a

just

to

time

which

1).

nameplate

in

various

time

given

time.

closed

the

close

is

The

for

position

operate

is

greater,

dial

time

the

CHARACTIERISTI

defined

dial

position.

connect

1

a

tap

to

on

block

the

12

D

to

and

within

of

time-current

determines

current.

when

dial

the

is

contacts.

as

the

relay

1FC77

the

.

the

The

time

set

is

the

to

Cs

the

current

Current

tap

block

marked

for

tap

time

overcurrent

other

7%

or

.

published

characteristics

length

higher

dial

10

is

and

A

in

the

the

set

the

required

settings

at

through

settings.

position

time

time

of

time

time

to

disk

the

are

top

J,

relay

dial

curve.

for

required

dial

0.

has

H.

The

of

A

the

to

to

close

made

the

through

requires

setting

Figures

IFC

setting,

maximum

travel

by

support

relays.

to

the

means

N

one

times

6—8

close

the

time

its

or

Reset

The

unit

proportionate

time

seconds

dial

for

approximately

HIGH-SEISMIC

The

instantaneous

and

low

ranges,

structure.

is

shown

in

HIGH-SEISMIC

The

target

unit.

These

cartons

See

relays,

designed

resets

position

to

the

12

at

the

when

1FC53

seconds

time

INSTANTANEOUS

unit

selected

See

Figure

Figure

TARGET

and

Figure

when

seal-in

1.

to

14.

AND

not

protect

90%

of

dial

the

and

from

UNIT

has

a

by

means

1.

The

SEAL-IN

unit

has

RECEIVING,

included

them

the

settings.

current

77

the

25

to

time-current

UNIT

two

as

minimum

is

relays.

same

number

I

range

of

a

tap

link

selections

HANDLING

part

of

against

closing

The

reduced

The

10

with

located

curve

AND

a

control

damage.

current.

time

to

to

IFC5I

time

dial.

tapped

a

on

for

located

STORAGE

panel,

Immediately

reset

0

relay

coil.

the

the

is

Reset

to

the

approximately

will

There

top

of

instantaneous

on

the

front

will

be

upon

times

number

reset

are

the

shipped

receipt

high

support

unit

of

the

are

10

60

in

in

of

-10-

Page 23

relay,

a

resulting

transportation

Office.

Reasonable

parts

the

of

relays

the

If

their

original

metallic

way

its

relay.

the

of

examine

from

care

are

chips.

inside

it

rough

company

should

injured

not

are

cartons

Foreign

when

for

handling

and

be

to

the

any

exercised

or

be

in

matter

cover

damage

is

promptly

adjustments

the

installed

place

a

is

GEK-45375

sustained

evident,

notify

in

that

collected

removed,

in

a

file

the

unpacking

disturbed.

immediately,

is

the

on

and

transit.

damage

nearest

the

free

outside

cause

claim

General

relay

they

from

trouble

injury

If

at

in

should

moisture,

the

of

in

once

Electric

order

be

case

the

or

damage

with

Sales

that

stored

dust

may

operation

the

none

in

and

find

Immediately

should

that

test

be

the

indicates

relay

SERVICING.

These

tests,

Since

tests

at

most

installation

performed

be

may

VISUAL

Check

INSPECTION

the

calibration

Remove

no

the

broken

MECHANICAL

There

1.

clockwise.

upon

made

to

calibrations

that

be

may

discretion

the

operating

tests,

on

nameplate

range

relay

cracked

or

INSPECTION

should

receipt

insure

performed

the

these

the

of

from

molded

be

disk

The

of

that

have

readjustment

the

of

companies

following

relays.

stamping

relay

case

its

parts

noticeable

no

should

ACCEPTANCE

relay,

the

damage

no

been

not

is

as

part

of

user.

different

use

section

insure

to

received

check

and

other

or

friction

return

TESTS

an

has

disturbed.

necessary,

installation

the

includes

that

agree

by

signs

itself

by

inspection

been

procedures

the

the

with

visual

of

when

to

sustained

If

refer

all

model

requisition.

inspection

physical

disk

the

its

acceptance

and

the

the

to

of

or

for

applicable

number,

damage.

is

position.

rest

shipment

in

examination

section

acceptance

the

acceptance

tests

rating

that

rotated

there

test

and

or

on

and

that

and

are

slowly

convolutions

its

as

move

on

nor

well

the

freely

by

as

when

seal-in

unit

hand

the

armature

operated

and

must

and

the

come

sh®uld

not

1/64”

in

is

deformed,

unit,

should

wipe

instantaneous

the

operated

are

operated.

at

unit

is

seal-in

the

unit,

least

and

armatures

button

control

or

when

the

touching

and

of

there

contacts.

in

and

the

each

contacts

the

should

the

latch

target

Make

2.

sure

tangled

armature

The

3.

contacts

and

hand;

by

instantaneous

targets

The

4.

view

into

unlatch

spring

other.

of

instantaneous

be

seal-in

when

the

release

—11—

Page 24

5.

6.

Make

connections

Check

sure

that

that

diagram.

all

the

screws

brushes

are

tight.

GEK—45

and

shorting

375

bars

agree

with

the

internal

SHOULD

PREVENT

DRAWOUT

The

IFC

12XCA11A1

connections

maximum

is

necessary

using

Figure

GENERAL

All

Since

harmonics

will

test

The

expressed

using

as

waveforms.

recommended.

an

15.

POWER

alternating

non—sinusoidal

be

AC

purity

tuned

time

THERE

STRIPPING.

RELAY

relays

flexibility

affected

relays

overcurrent

TESTING

four-point

to

when

ammeter

REQUIREMENTS

of

the

of

as

a

circuits,

Hence

BE

A

may

be

both

but

testing

instead

current

waveforms

fundamental

by

the

it

is

the

sine

finite

relays)

a

resistance-limited

NEED

tested

test

the

requires

(AC)

applied

essential

wave

number

R-L

TO

probes.

relay

the

of

or

would

TIGHTEN

without

and

reasonable

relay.

the

shorting

operated

can

frequency,

waveform.

to

(i.e.,

for

RC

networks,

CAUTION

ANY

removing

The

the

The

be

analyzed

use

a

its

any

particular

be

essentially

circuit,

SCREWS,

theni

12XCA1JA2

external

care,

CT

circuit

jumper.

devices

as

it

follows

Therefore,

sine

wave

freedom

or

saturating

as

DO

NOT

from

four-point

circuitry,

since

See

are

affected

a

fundamental

that

of

current

from

relay;

affected

shown

OVERTIGHTEN,

the

panel

test

which

a

CT

shorting

may

also

the

test

by

frequency

AC

devices

in

order

and/or

harmonics)

however,

electromagnets

by

non-sinusoidal

in

Figures

by

using

probe

be

tested

circuit

frequency.

to

cannot

any

16—18,

TO

the

makes

provides

jumper

by

in

plus

(relays)

properly

voltage.

be

relay

(such

is

TIME

OVERCURRENT

Rotate

just

The

stationary

With

sufficient

strip

The

tap

CHARACTERISTICS

The

adjusted

the

close

point

the

to

ensure

minimum

setting

pickup

by

time

at

the

at

contact

contacts

gap

current

in

of

means

UNIT

dial

C

time

which

the

brush

just

between

approximately

at

the

tap

section.

the

time

of

a

slowly

the

dial

contacts

in

or

closing

and

setting.

out

stationary

1/32”

which

the

block

overcurrent

spring-adjusting

check

just

by

at

wipe.

contacts

at

the

—12-

close

means

No.

contact

unit

by

top

ring.

will

means

of

0

time

of

for

can

its

just

of

be

adjusting

setting,

brush

close

the

any

See

a

lamp

adjusted

and

support

current

Figure

that

screw.

there

its

is

determined

1.

the

by

running

metal

structure.

tap

setting

The

contacts

should

backing

spring

by

the

be

the

See

is

Page 25

GEK—45375

adjusting

1).

into

By

agreement

disturbed.

between

required,

that

the

characteristics

up

pick

been

has

Setting

Time

setting

The

close

to

contacts

on

set

is

therefore

and

primary

The

the

of

permanent

shaft

and

Pickup

Set

Test

the

connections

tap

of

Hz

50

for

ring

turning

the

it

a

at

changed.

the

are

10,

time

magnet

decreases

relay

value

relays.

either

the

with

This

various

recommended

is

relay

of

value

the

of

contacts

just

the

this

adjustment

dial.

along

at

Figure

in

current

winds

ring,

the

adjustment

tap

will

Figures

other

than

time

when

closed

disk

must

setting

for

However,

its

time,

the

time

0.5

16,

for

or

the

tap

settnqs

that

not

6-8

dial

the

when

gives

the

supporting

dial

the

60

unwinds

operating

setting

also

the

necessarily

and

value,

tap

determines

current

time

the

travel

the

time

further

while

position

main

relays

Hz

the

employed,

permits

be

to

higher

20—22

the

maximum

operation

of

shelf;

moving

unit

and

spiral

current

any

obtained.

tap

agree

the

if

because

length

the

reaches

dial

is

maximum

time

adjustment

moving

away

it

and

should

within

set

the

close

control

the

of

this

if

desired

used.

be

with

relay

torque

the

of

predetermined

a

on

amount

setting.

the

of

is

the

increases

lowest

the

7.5%

±

spring

unit

adjustment

setting

such

If

It

the

has

time

0.

to

unit

obtained

magnet

tap.

contacts

of

been

level

the

When

close

is

the

tap

(see

be

may

intermediate

adjustment

should

time

adjusted

of

unit

value.

the

the

made

by

toward

time.

Using

within

value

Figure

brought

has

be

current

the

requires

time

contacts

by

moving

the

the

current

been

noted

relay

The

dial

means

the

disk

test

±

is

to

3%

Test

Time

relay

the

Set

connections

relay

operating

HIGH-SEISMIC

range

5,

and

sure

in

which

connect

Make

possible,

rating.

No.

at

Figure

in

time

Relay

IFC51

1FC53

1FC77

INSTI\NTANEOUS

that

is

it

instantaneous

the

as

higher

the

use

5

time

16,

close

to

—

operate.

to

indicated

range,

dial

apply

UNIT

its

Hz

50

50

50

in

setting

five

contact

and

and

and

unit

See

the

since

times

TABLE

60

60

60

link

the

test

the

—13-

and

is

X

-

is

Internal

higher

the

tap

listed

circuit

in

lowest

current

the

range

tap.

to

Table

in

(seconds)

Time

Mm.

1.76

1.28

0.89

correct

Connections

Figure

of

has

X.

Max.

1.80

1.34

0.95

a

Using

the

position

Diagram,

17.

higher

the

relay.

continuous

test

The

the

for

Figure

Whenever

Page 26

GEK-45375

Setting

The

as

loosen

the

the

this

pickup

the

instantaneous

shown

in

the

pickup;

current

operation

value

REFER

INSTANTANEOUS

CURRENT

The

range

core

of

position

counterclockwise

the

full

clockwise

HIGH-SEISMIC

The

target

amperes.

higher

The

ampere

stationary

the

left-hand

remove

the

stationary

procedure

getting

same

time.

is

out

High-Seismic

unit

Figure

locknut

turning

slowly

until

is

reached,

TABLE

TO

THE

TO

instantaneous

the

of

from

TARGET

and

seal-in

relay

position.

contact.

stationary

screw

contact

necessary

of

adjustment.

Instantaneous

and

until

1.

the

has

adjust

core

the

adjustable

an

To

set

the

counterclockwise

the

unit

desired

tighten

VI

FOR

THE

UNIT.

DO

INSTANTANEOUS

the

of

full

a

1/8

position.

AND

SEAL-IN

is

To

unit

shippped

change

The

has

tap

contact

from

where

the

to

the

undesired

first

prevent

Screws

Unit

the

instantaneous

core.

picks

pickup

the

locknut.

CAUTION

CONTINUOUS

EXCEED

NOT

UNIT.

unit

turn

(see

from

clockwise

UNIT

an

operating

from

the

screw

the

tap

and

place

tap

screw

the

should

core

Turning

up.

value

AND

THESE

Table

position.

factory

is

the

setting,

and

was

right-hand

never

located

unit

the

core

increases

It

may

is

obtained.

ONE-SECOND

RATINGS

VI)

must

full

clockwise

Do

coil

with

screw

first

it

in

the

place

removed

stationary

left

be

at

the

to

the

be

be

not

tapped

the

holding

remove

desired

it

(see

in

top

a

desired

clockwise

pickup.

necessary

Once

RATINGS

WHEN

obtained

and

leave

at

tap

the

one

the

on

Figure

both

of

the

pickup)

decreases

Bring

to

repeat

the

desired

THE

OF

APPLYING

between

20

the

core

and

0.2

screw

in

right-hand

screw

tap.

left-hand

1).

contact

taps

at

unit

up

a

turns

in

2.0

the

from

Next,

This

from

the

Pickup

1.

2.

3.

4.

5.

and

Dropout

Connect

a

DC

and

load

0.1

to

Turn

Increase

Table

Move

in

unit

Decrease

Table

Test

source

2.0

the

XI.

the

should

XI.

relay

box

time

the

time

the

studs

of

proper

so

amperes.

dial

current

dial

remain

current

that

1

to

away

and

frequency

the

current

the

ZERO

slowly

from

the

in

slowly

-14-

2

(see

TIME

until

the

picked—up

until

the

and

can

ZERO

DIAL

the

the

test

good

be

TIME

position.

seal-in

circuit

waveform)

controlled

position.

seal—in

DIAL

unit

position;

unit

of

using

over

picks

drops

Figure

an

a

range

up.

the

out.

18)

ammeter

See

seal-

See

to

of

Page 27

GEK-45375

Tap

0.2

2.0

relay

The

lighted

well

relay

The

drillings

mounting

methods

internal

The