GE HMAA Installation Guide

GE

g

READ THOROUGHLY BEFORE INSTALLING

Lighting Solutions

WARNING

Risk of electric shock

• Turn power off before servicing

– see instructions

GENERAL

This luminaire is designed for outdoor lighting service,

and should not be used in areas of limited ventilation, or in

high ambient temperature enclosures. Best results will be

obtained if installed and maintained according to the

following recommendations.

INSTALLATION

CAUTION

Unit will fall if not installed properly

• Follow installation instructions

GEH-5841

INSTRUCTIONS

High Mast Luminaire

5. Place a level on top edge of ballast housing and snug up

bolts 1 thru 4 (4-5 foot-pounds). Unit may be adjusted up

or down 5 degrees with respect to mounting arm. If more

lift on front of luminaire is required, first loosen bolts 1

and 3 slightly, lift luminaire and re-snug bolts 2 and 4. If

downward tilt is necessary, reverse procedure. Side-to-side

leveling can be accomplished similarly.

6. Once the proper level has been achieved, tighten bolts 1

thru 4 to twenty foot-pounds, alternating front to back

across diagonals of brackets as shown in figure 2.

1. Loosen the bolt on top of the luminaire and remove the

cover.

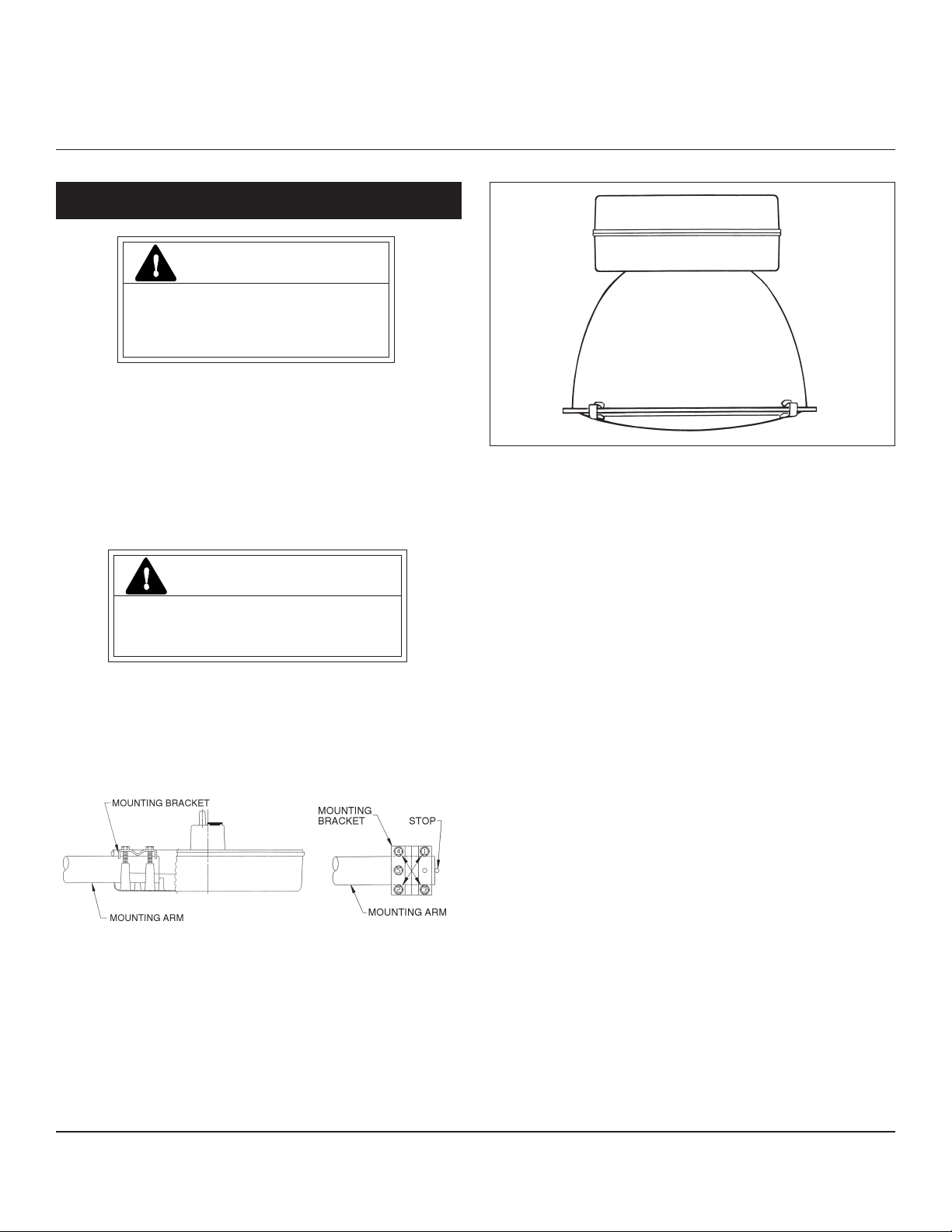

2. Slide ballast assembly onto mounting arm as shown in

Figure 1. If necessary, adjust bolts 1 through 4 (see

Figure 2) such that opening is slightly larger than

mounting arm.

3. Tighten bolts 1 thru 4 (in sequence shown) until

mounting bracket is in contact with mounting arm.

4. Align bolt 5 with hole in top of mounting arm and

tighten until “bottoming” occurs.

NOTE: If mounting arm was not provided by GE or

is an older existing GE arm, omit step 4, and after

completing Installation Instructions, refer to Drilling

instructions.

Drilling Instructions: If mounting arm has no hole to

prevent rotation of luminaire or has hole in different

location, refer to steps A thru C below.

A. After bolts 1 thru 4 have been securely tightened (step 6

of Installation Instructions), remove and retain bolt 5.

NOTE: Hole located between bolts 1 and 3 on

mounting bracket should be ignored in these

instructions.

B. Drill a 21/64” hole into mounting arm by using hole in

mounting bracket as a guide. The threads in the

mounting bracket may become damaged but the selftapping bolt (bolt 5) will cut new threads into the newly

drilled mounting arm, eliminating the need for threads

in the mounting bracket.

C. Reinstall bolt 5 and tighten until “bottoming” occurs.

WIRING

Make all electrical connections in accordance with

the National Electrical Code and any applicable local

code requirements.

Verify that supply voltage is correct by comparing it

to nameplate.

These instructions do not purport to cover all details or variations in equipment nor to provide for every possible contingency to be met in connection with installation, operation or

maintenance. Should further information be desired or should particular problems arise which are not covered sufficiently for the purchaser’s purposes, the matter should be referred

to GE Lighting Solutions.

1. Attach supply leads to terminal board a shown on

nameplate.

2. Replace top housing and tighten bolt.

LAMP INSTALLATION

CAUTION

Risk of burn

• Allow lamp/fixture to cool before

handling

Use only lamps specified on nameplate. Observe

lamp manufacturer’s recommendations and restrictions on lamp operation, particularly ballast type,

burning position, etc.

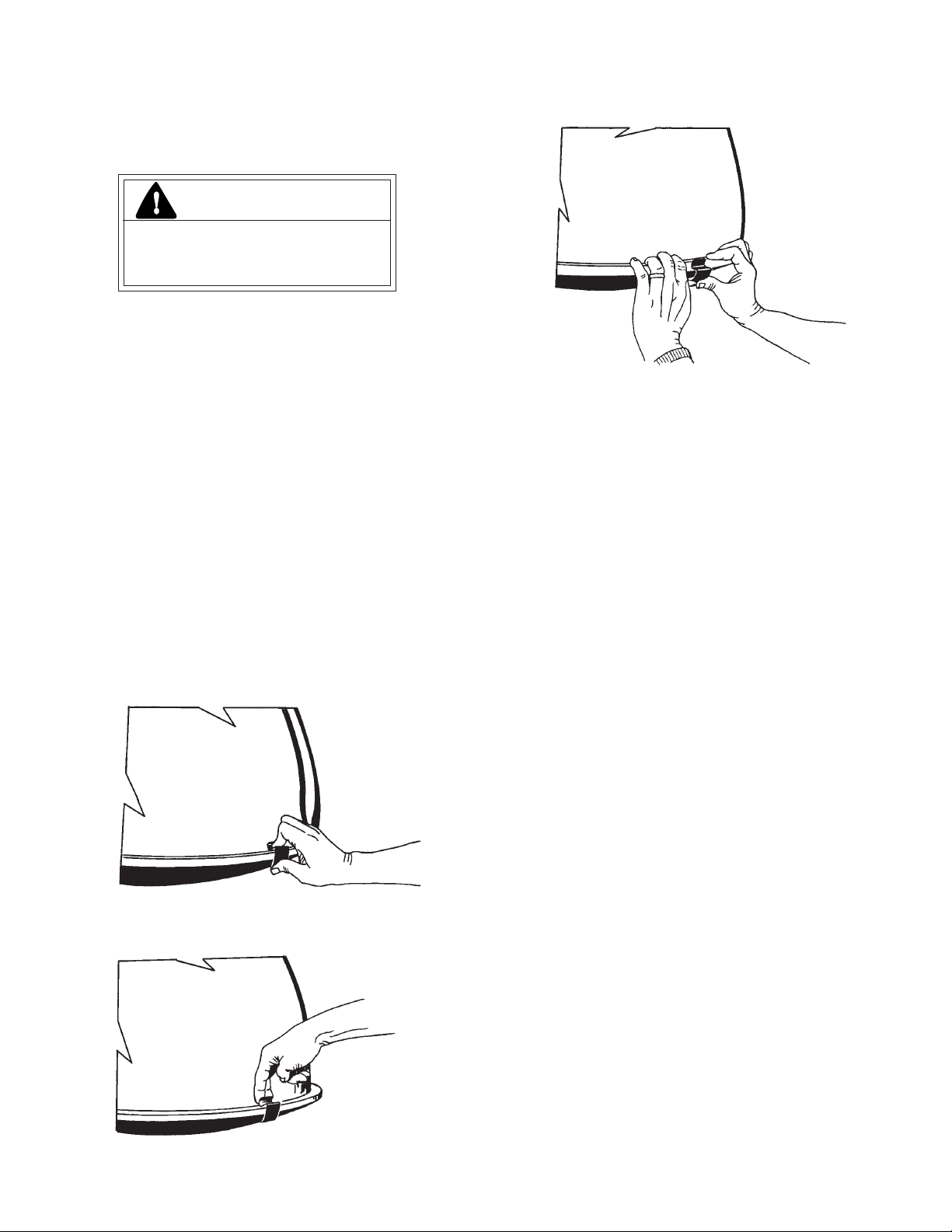

To close latches get them started by pressing against the

pressure point shown in Figure 5, then strike that pressure

point with the heel of your hand.

Figure 5

LAMP TIGHTNESS: The lamp should be securely

inserted to NEMA-EEI specified torque of 35 inchpounds, which is best achieved by very firmly tightening

to insure application of sufficient torque. Tightening

must be sufficient to fully depress and load center contact

of socket.

To install lamp in an enclosed luminaire, open four

spring latches while maintaining a firm grip on the glass

clampband. Latches are easy to open if the two-stage

technique shown in the picture is used. Pull the latch away

from the reflector as shown in Figure 3. Then place fingers

between the latch and reflector (Figure 4) and snap the

latch off of the reflector flange.

DO NOT LET GO OF THE GLASS, SO THAT IT WOULD

SWING FREE.

Optical assemblies designed for 1000 watt lamps are

equipped with a lamp support that grips the base of the

lamp. Be sure the grips are covered with fiberglass sleeving.

If sleeving is missing, replace it before relamping,

WARNING: FOR 1000 WATT HIGH PRESSURE

SODIUM LAMPS, A VOLTAGE PULSE IN EXCESS

OF 4000 VOLTS IS PRESENT AT THE LAMP

SOCKET UNDER OPEN CIRCUIT CONDITIONS.

ADJUSTMENT OF ASYMMETRICAL (UNDER)

REFLECTOR

The inner reflector is clamped to the outer reflector by

means of three screws located 120 degrees apart near the

bottom of the outer reflector. Slightly loosen these screws.

The screws have stop nuts on them to prevent the clamps

from falling off, so if a screw starts to bind, do not force it.

The inner reflector must be supported while it is being

rotated, because if the three notches in its flange line up

with the three support brackets, it will fall out.

The inner reflector is aimed by aligning the indented

degree marks with the indented line on flange of outer

reflector. Indented line on outer reflector is located

opposite hinge. Rotate the inner reflector until the desired

position is reached, then tighten the three clamping screw.

Figure 3

Figure 4

MAINTENANCE AND CLEANING

In order to maintain the high efficiency of General

Electric reflectors and enclosures, a regular cleaning cycle

should be established with frequency dependent on local

conditions.

Use a soap, cleaner, detergent, or a solution of the same

(6-10 ounces per gallon of water or the manufacturers’

recommendation) which is essentially neutral (pH

approximately 6 to 8), nonabrasive, and which contains no

chlorinated or aromatic hydrocarbons. Wash thoroughly in

this solution, using a soft cloth, of brush if necessary. Rinse

in clean, cold water and wipe dry.

Loading...

Loading...