Page 1

GE

FLOOD LIGHTING

g

Lighting Solutions

GUIDE FORM SPECIFICATIONS

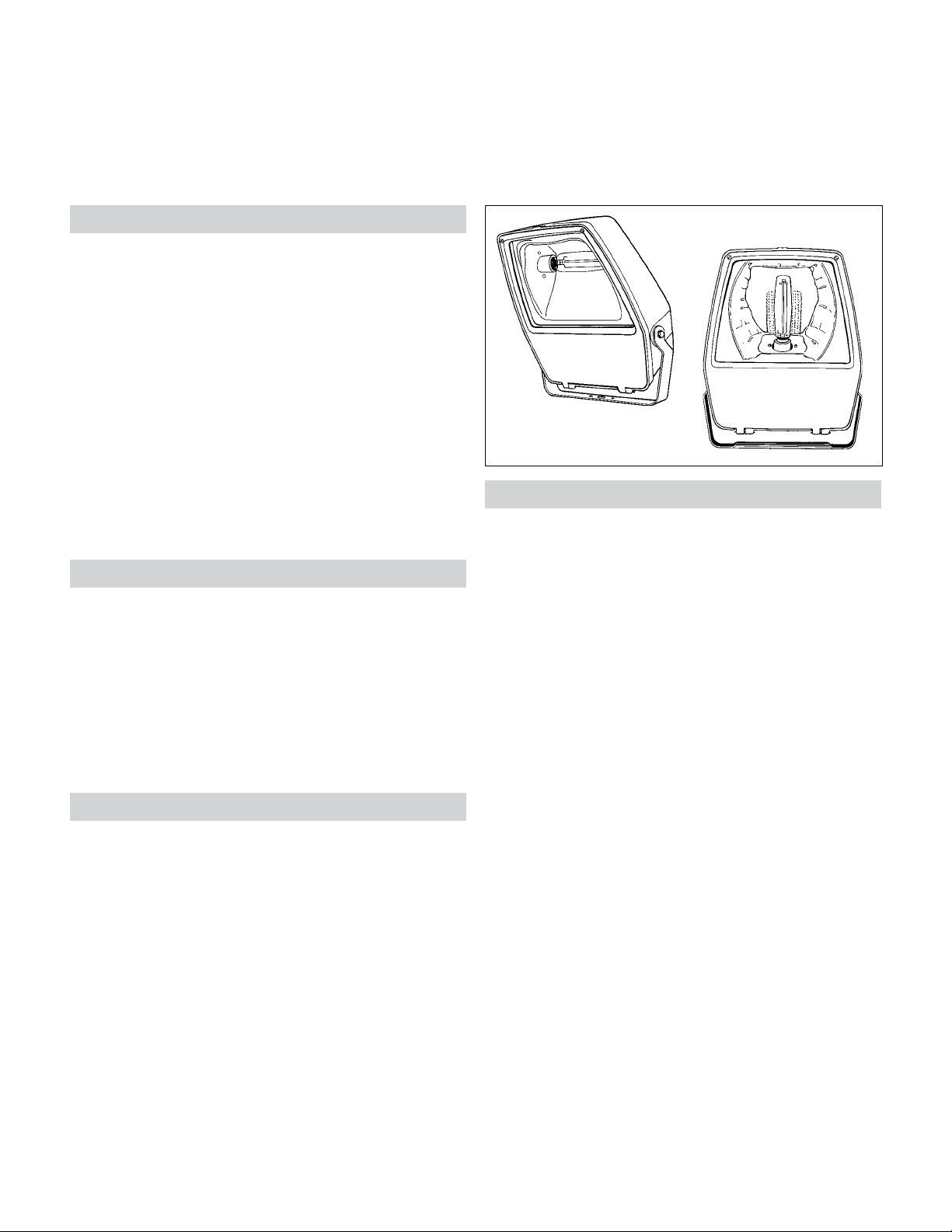

HLU/VLU POWERFLOOD ® FLOODLIGHT

GENERAL DESCRIPTION

The NEMA heavy-duty weather-resistant floodlight designated

_______ (identify) shall be a GE HLU or VLU POWERFLOOD®

FLOODLIGHT, ordering number _______ (specify HLUF or VLUF,

plus ordering number logic from catalog) or approved equal,

for operation of one horizontally-oriented (HLUF) or verticallyoriented (VLUF) _______ (specify [(200, 250 or 400) watt high

pressure sodium (HPS)] or 400 watt metal halide or mercury]

lamp from a nominal _______ (specify 120, 208, 220, 240,

277, 347 or 408 volt, 60 Hz or 200 volt, 50 Hz) power source

and shall be capable of starting and operating the specified

lamp within the limits specified by the lamp manufacturer.

The floodlight shall contain a completely prewired integral

ballast and optical assembly with _______ (specify [4X2 or 6X5]

for HLUF or [7X6 or 7X7] for VLUF) according to photometric

selection table in the catalog) NEMA type beam spread

(horizontal X vertical). The floodlight shall have a NEMA lamp

identification decal. The floodlight shall be

UL/cUL1598 Listed SUITABLE FOR WET LOCATIONS. Standard

construction is IP55.

MECHANICAL CONSTRUCTION

The floodlight shall include a heavy-duty corrosion-resistant

fiberglass reinforced polyester (FRP) dark-bronze housing with

hinged and removable front door glass frame; removable ballast tray; anodized, gasketed and charcoal-filtered optical

assembly, _______ (specify heavy--gauge steel trunnion with

wiring through grommeted cable entry [standard] or die-cast

aluminum knuckle slipfitter with integral wiring box); built-in

aiming sight; tempered heat-resistant door glass (and optional

prewired photoelectric control receptacle). The floodlight shall

be sealed and have an activated-charcoal filter to help eliminate particulate matter and gaseous contaminants. All hardware shall be corrosion-resistant .

BALLAST OPERATION

OPTICAL ASSEMBLY

HLU/VLU

The optical assembly shall include a hydroformed aluminum re-

flector and heat/impact-resistant flat door glass with gasketing

around the perimeter of the housing. The reflector shall have a

chemically-bonded lightweight non-breakable glass ALGLAS

finish on all surfaces providing enhanced specular reflectance,

corrosion resistance, durability and ease of cleaning. The optical assembly shall contain an E39 mogul base socket with

superior lamp gripping. The socket shall have added insulation,

giving it the ability to handle the higher pulse ratings of newer

HID systems.

HLU

Horizontally mounted lamp shall provide precise vertical beam

control.

VLU

Vertically mounted lamp shall provide a uniform wide beam

spread.

®

All electrical components except the photoelectric receptacle

shall be mounted on a removable galvanized steel ballast tray

for convenience of installation and maintenance. The ballast

shall be prewired to the lamp socket and terminal board and

the ignitor for high pressure sodium fixtures. The floodlight

shall contain a _______ (specify standard Autoreg or Mag-Reg

[for HPS lamps only]) type ballast* in full compliance with lampballast specifications available to the fixture manufacturer from

the lamp manufacturers at the time of fixture manufacture.

As an option the ballast may have the capability of operating a

250 or 400 watt high pressure sodium or metal halide lamp at

any of four voltages — 120, 208, 240 or 277 volts. When specified, the multiwatt ballast (250/400) shall be connected for 250

watts unless otherwise specified.

The ballast shall reliably start and operate the lamp in ambient temperatures down to -20°F for mercury or metal halide or

-40°F for HPS.

The floodlight and ballast shall be from the same manufacturer.

* REFER TO PRODUCT PAGE FOR OTHER BALLAST SELECTIONS.

FOR MORE DEFINITIVE INFORMATION, REFER TO BALLAST SPECIFICATIONS IN TECHNICAL DATA SECTION.

Guide Form Specifications – 2011

Page 2

g

GE Lighting Solutions • 1-888-MY-GE-LED • www.gelightingsolutions.com

1 6 9 4 3 5 3 3- - -- 8 8 8

GE Lighting Solutions is a subsidiary of the General Electric Company. Evolve and other trademarks belong to GE Lighting Solutions. The GE brand and logo are trademarks of the General Electric Company.

© 2011 GE Lighting Solutions. Information provided is subject to change without notice. All values are design or typical values when measured under laboratory conditions.

Loading...

Loading...